WANT TO WIN $100 CASH?

See page 5 of the second section for details!

See page 5 of the second section for details!

Volume 25, No. 6

By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

cows and farm 900 acres.

“Milk production was not enough to sustain expenses, and we needed to nd a way to get more milk out of here quick,” Paul said.

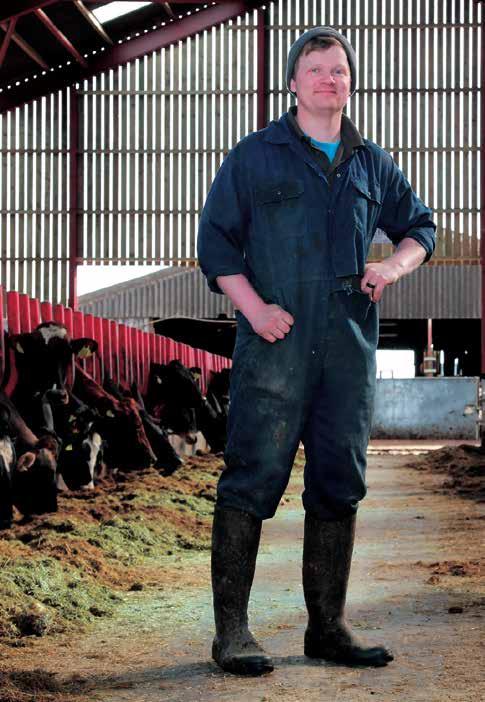

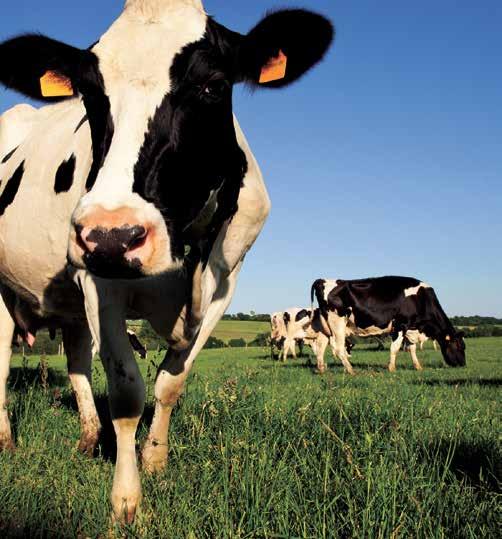

MALONE, Wis. – Six years ago, the Lavey family went from milking twice a day to milking four times a day. Doubling the number of milkings required no additional labor and ironically reduced the amount of time cows spent in the parlor. Increased efciency resulted in higher milk production, earning a bigger return for a dairy that had been struggling.

“I was borrowing $10,000 to $20,000 almost every month to make payments,” said Matt Lavey, who farms with his sons, John, Tom and Joe.

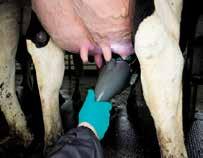

The Lavey family – Joe (from le ), Ma and John – gather in their double-12 milking parlor April 25 on their farm near Malone, Wisconsin. The Laveys milk 600 cows four mes a day and gained 20 pounds of milk per cow since increasing from twice-a-day milking six years ago.

To gure out where they could obtain more income and cut costs, the Laveys worked with Pauly Paul – a

dairy management consultant with Complete Management Consulting. The Laveys leaned on Paul’s expertise to

guide them to money-saving and money-making opportunities on their farm near Malone where they milk 600

On April 25, Paul led a workshop, “What you need to know to cash ow,” which began with a tour of the Lavey Dairy Farm. The workshop was presented in partnership with Peggy Coffeen – Uplevel Dairy founder and podcast host.

“When we look at where we can make more money on the farm, it’s usually the parlor,” Paul said. “The parlor was the key to making more money at this farm. When you get more cows through the parlor and create more milk income, you’re able to do other things.”

Initially, the Laveys gained 10 pounds of milk per cow. Now, cows are milking 20 pounds more than when

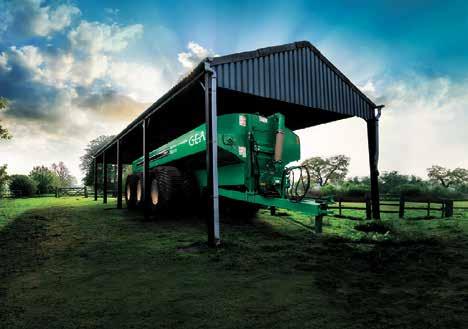

Every morning at 6, the manufacturing crew at GEA Farm Technologies in Galesville gathers on the shop oor for a discussion about the agenda and any challenges or ideas.

The discussion will now include the manufacturing of two types of rotary parlors, which are starting to be made in the Galesville plant.

The GEA T8800 and T8900 rotary parlors were previously man-

ufactured in New Zealand and shipped to the United States and Canada. The change is in response to the growing demand for rotary milking systems and logistics in shipping.

Matt Daley, the North American president of GEA Farm Technologies, said it solidies the future of rotary manufacturing in North America for the global company.

“It makes a lot of sense for us to make this move at this time,” Daley said. “It shows our customers that we’re committed to the U.S. and Canadian dairy

industry.”

The rst stage of this manufacturing change includes building parlors for North American dairy farms.

“Our production volume depends on the year and the milk price,” Daley said. “But the general idea is to get up to speed here in the next 12

months and then manufacture for other markets that are in close proximity to the U.S. in

“All dairy, all the time”™

Published by Star Publications LLC

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Hans Lammeman - Staff Writer hans.l@star-pub.com

Consultant: Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Russell Group President Randy Russell does not expect the new farm bill passed before the current bill expires at the end of September. “There’s not a snowball’s chance that is going to happen,” Russell said. It is more likely action will be taken by the end of the calendar year. Russell said it’s important to consider that when lawmakers negotiate. “The nutrition and climate money that was included in the Ination Reduction Act was a one-time $20 billion that goes to (the U.S. Department of Agriculture),” he said. “If Congress takes no action, nutrition funding, including SNAP, continues as it currently is. So, if you’re in a negotiation, you need to know what the motivation is behind those you’re negotiating with and who’s holding the cards and who isn’t.”

Animal rights group lobbies Congress

Education needed

NMPF submits federal order proposal

Market lows seen in cheese, butter

Ag InsiderWFBF weighs in on labeling issue

Cashton,

Avoca, WI

Technology helps

Viroqua,

For additional stories from our other zone, log on to www.dairystar.com

Con nued from AG INSIDER | Page 2

Dairy Day at the Capitol

A Dairy Business Association delegation of 23 farmers and dairy professionals participated in its annual Dairy Day at the Capitol. “It’s so critical for our state’s leaders to hear from farmers on what helps drive success not only for our farms but for the rural communities they support,” said Chad Zuleger, DBA director of government affairs. DBA legislative priorities include funding for road improvements, the farmland preservation program and Wisconsin Initiative for Agricultural Exports.

Lawmakers hope to overturn new H-2A rule

A group of Republican senators has introduced a resolution of disapproval to overturn a U.S. Department of Labor rule dealing with H-2A workers. This rule increases the minimum wages for those working on an H-2A visa.

Workforce issue is ‘a real mess’

Finding labor is one of the biggest headaches for farmers and agribusinesses. National Council of Farmer Cooperatives President and CEO Chuck Conner said efforts are underway to ease the labor shortage by making the foreign guestworker program more assessable. “In the meantime, there’s been new rules put out by the Biden administration that would not be helpful but actually take us backward quite a bit,” Conner said. “This rule was put into effect April 1 and is taking us backward in terms of higher cost and fewer farmers being able to use the H-2A program; labor is a real mess right now.” Lawsuits have been led in an attempt to shut down the Biden rule.

The U.S. Dairy Export Council and NMPF are partnering with similar organizations from Argentina, Brazil, Paraguay, Uruguay, Chile, Bolivia and Colombia on climate issues. The collaboration will work with governments and international organizations to promote policies that consider the unique needs of the livestock industry.

An annual report from the U.S. Trade Representative’s Ofce outlines trade barriers from the European Union. In particular, the EU uses geographic indicators to control the use of common terms, such as Parmesan or mozzarella

cheese. The U.S. Dairy Export Council and NMPF are asking the trade ofce to preserve export access for food with these common names.

APHIS outlines its strategic plan

USDA’s Animal and Plant Health Inspection Service has unveiled its new ve-year strategic plan. It includes six goals, including the protection of agriculture from plant and animal disease, expanding safe trade, promoting animal welfare and addressing the agency’s workforce challenges. APHIS also focused on trends. That list ranges from threats to security, climate change and advances in science and technology.

Farm numbers decline

According to data from USDA Economic Research Service, the number of U.S. farms has continued to decline since 1982. In 2022, there were 2 million farms, down from 2.2 million in 2007. Farmland acreage also continues to decline with 893 million acres accounted for in 2022, down from 915 million just 10 years earlier.

Bryan returning to Wisconsin

Country singer Luke Bryan is planning another farm tour. The ve tour stops are designed to honor the American farmer. The Klondike farm at Brooklyn, Wisconsin, will host the concert Sept. 22. Four other Midwest locations are part of the tour.

Fencl joins DBA/Edge Co-op staff

Andrea Fencl is the new communications specialist for the DBA and Edge Dairy Farmer Cooperative. Most recently, Fencl held a similar role for Faith Technologies. Before that, Fencl worked for a Waukesha newspaper.

Trivia challenge

The nutrition title accounts for 76% of mandatory spending in the farm bill. That answers our last trivia question. For this week’s trivia, who serves as USDA’s deputy agriculture secretary? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

milked twice a day, jumping from 70 pounds per day to 90 pounds with a 4.5% butterfat and 3.1% protein. All groups go through the parlor four times a day.

“This is a young herd with a lot of rst-lactation animals,” Paul said. “We’ll see production go up as animals get older.”

When the Laveys began working with Paul, labor issues and a high somatic cell count were primary problems that needed to be addressed.

“Employees were taking their time and dragged out the milking process a lot longer than they needed to,” Paul said. “They were holding up cows all day, and the parlor had a lot of idle time.”

Paul and the Laveys keyed in on good employees who bought into the changes. They provided additional training in the parlor that led to more consistent milking procedures. Employees picked up the pace and tightened up routines to get cows through the parlor two more times.

“We doubled animals through the parlor when going from twice-a-day milking to four times a day and didn’t hire any employees to do that,” John said. “We also added a couple hundred cows.”

Paul said this was a major advantage to the farm.

“That’s where you really reap the benets – when you add more cows with the same amount of labor,” he said. “When looking at how to generate more income, the best thing to do was ll the parlor and keep it running around the clock.”

The Laveys are utilizing resources to the fullest, doing just over six

turns per hour in their double-12 parlor that runs 20-21 hours per day. People in the parlor work a 10-hour day. They milk for ve hours, take a break and then milk for another ve hours. They spend 11 hours on the farm but are paid for a 12-hour shift. With the switch, the Laveys reduced the number of shifts from three to two.

Two employees milk while another employee pushes cows and beds. Several employees were moved from the milking crew and put into other areas, such as calf feeding. The Laveys’ herdsperson, who used to work in the parlor, is an instrumental part of the operation.

“He’s one of the gems,” Paul said. “We trained him in herd work, breeding, etc., as well as employee issues, and he ourished. He can do everything on the farm; he’s that good. He is really turning the dairy around.”

Reproduction numbers are solid with a pregnancy rate of 30%, and services per conception are around 2.1. Cow health is also thriving, with mastitis and fresh cow ailments at a minimum or non-existent. Milk quality improved as somatic cell count dropped to under 100,000. The cull rate also fell from nearly 40% to less than 25%.

“The lower cull rate has allowed the Laveys to decrease heifer numbers, which is a huge deal to help with cash ow,” Paul said.

Adding two more milkings did not add to the amount of time cows spend on their feet. Paul said cows are spending less time in the parlor and getting back to the pen quicker to

Con nued from LAVEYS | Page 6 eat, drink and lay down. Foot and leg health has not been compromised with additional trips to the parlor.

With the right people in the right positions, the farm is streamlined for success.

“The Laveys have really good employees, and they are treated well,” Paul said. “Turnover is low.”

Matt agreed.

“Employee attitude is excellent,” he said. “Our workers are neat, polite and friendly.”

Matt also stressed the importance of rewarding good employees.

“If you have someone who is good, pay them, even if it’s more than you think you should,” Matt said. “We never cap an employee’s wages; they can keep going up.”

Paul said milking four times a day is not for everyone. He and his team spend ample time in the parlor to determine the best individual t for each farm – carefully examining cow numbers, stall numbers and labor dynamics. If a farm has a quota, Paul places more emphasis on expenses – looking at other areas of the farm where money can be saved.

Analyzing every expense on a dairy, the Laveys’ feed center was targeted by Paul as an area where expenses could be cut.

“The Laveys were buying a lot of purchased feed, com-

modities and supplements, and there were binders and additives in the feed that we were able to pull out,” Paul said.

They dropped the llers and other unnecessary ingredients from the recipe. The result was a more precise ration void of expensive uff. Switching to a feed software program also helped ensure accuracy in mixing feed and feeding cows. Cows are fed once a day – in the morning – and feed is pushed up three

times during every milking. The Laveys also changed nutritionists – another move that proved benecial.

“Joe is the feeder, and he’s doing an awesome job making sure all ingredients are put in the ration accurately,” Paul said. “Cows are also getting fed on time. All of those things added up, and we were able to start reducing extra things added to the feed. They removed the band-aids, and as a result, reduced feed expenses considerably.”

Paul said the Laveys also needed to look at how they were putting forages in the bunkers. They started lining bunkers, making sure minimal air entered the feed – a crucial move according to Paul.

“They line the back walls and side walls and do a good job of getting tires on,” Paul said. “The Laveys pack feed a lot better and have really good forage quality now.”

Making intelligent purchasing decisions also helps

the Laveys do right by their farm, and Matt considers himself a conservative spender.

“I’m not a person who buys new things unless it’s something that doesn’t cost a lot,” he said. “For example, I wouldn’t buy a new tractor. A used tractor can have a lot of hours left in it.

I try to keep expenses down and be smart about what I buy.”

Matt is happy to be free from the anxiety caused by regular money borrowing.

“Today, I don’t have to borrow money, and I’m not stressed all the time,” he said.

Through strategic moves that bumped up income and pushed down expenses, Paul helped the Laveys reboot their operation, putting the farm on a protable path. Instead of borrowing money, Lavey Dairy Farm is now able to sustain its cash ow.

The dairy is a long-term client of Complete Management Consulting and continues to use their operational management services, with one team member coming to the dairy weekly to do employee follow-ups and check on herd health, etc. They also provide monthly bookkeeping services.

“This is one of the dreams people think of when you’re running a farm,” Paul said. “Things run really smoothly here, and it can happen on every single dairy.”

By Sherry Newell

Contributing writer

By Sherry Newell

Contributing writer

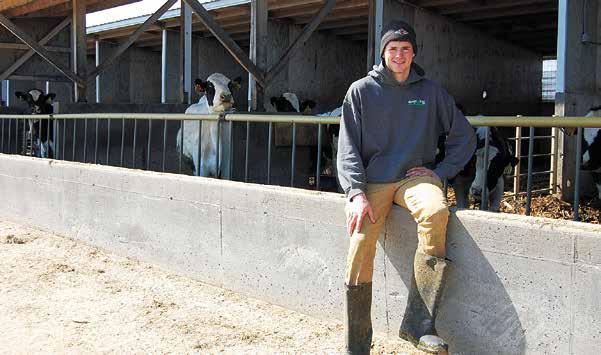

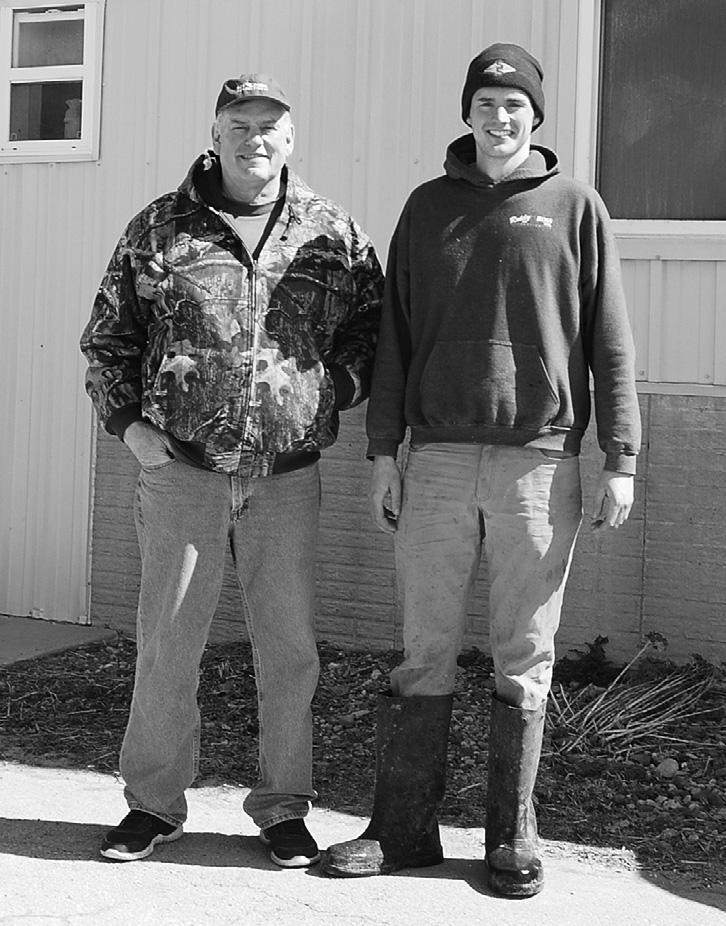

FARLEY, Iowa – The dairy where Virgil and Alvina Murphy, and later their son, Dan, and his wife, Christine, have farmed since 19XX operates a little differently since the third generation came home from college. Gone are the herd bulls, hot iron dehorning and the old calf barn. Now, 25-year-old Owen Murphy, Dan and Christine’s son, is in charge of the cows, calves and breeding.

Owen’s return also relieves a good deal of the stress Dan had as the manager on the 200-cow farm with 400 owned and 80 rented acres near Farley.

While Owen handles the animals, Dan manages the eldwork and does the feeding. But, it remains a joint effort in many ways.

“I don’t bother with the stuff he’s in charge of, but we meet with the nutritionist together because that way we both hear the same thing,” Dan said.

The two men said they get along ne despite the new approaches Owen brought home with him after graduation from the University of Wisconsin-Platteville in 2019.

Owen takes care of morning

milking in the farm’s parabone double-8 parlor. Cows are milked and housed in free stalls with rubber mats and chopped straw.

One of the rst changes Owen made as he stepped in was a switch to A.I. The Murphys usually kept ve or six bulls on hand for breeding. That was not Owen’s preference.

“Two of those were breeding and three of them were usually hurt,” Owen said.

Plus, upon returning home a month before graduation, Owen was chased by a bull with its head down and in an aggressive manner.

“That freaked me out,” he said.

So last winter, Owen switched to A.I. but not without discomfort.

“It was denitely scary, going to preg check and not having any idea how things would turn out,” Owen said. “Dad had a few sleepless nights.”

Along with the disappearance of the bulls, Owen began breeding heifers twice to sexed semen then to beef if not settled. The same protocol is applied to the top 20% of the herd. Everything else is bred to beef, reducing

the number of replacements on the farm.

“We have half the number (of heifers) that we used to have,” Owen said.

His father was quick to agree.

“It’s a great thing,” Dan said.

The Murphys added CowManager tags to support heat detection under the new protocols. Owen averages two services per conception now.

“I give minimal shots, … maybe one or two a week,” Owen said. “I don’t think we’re going to be giving

shots forever. I think it can give dairy a black eye; the consumer doesn’t really want us to be doing that.”

With no headlocks on the farm, breeding is done in stalls. Owen said he thinks that contributes to calmer cows, although he hopes installing heifer headlocks will be the next investment.

Calf care has also undergone changes at the Murphys’. Last October, they installed a pasteurizer and

Turn to MURPHYS | Page 10

Tim

this facility as well.”

The rotary parlor designs were originally made for New Zealand and German production lines with metric materials. The engineering team in Galesville reviewed every aspect of the parlors between engineering and manufacturing and then evaluated how they could keep the form, t and function of the parlors using nonmetric materials.

Engineer Keith Nedegaard said it is part of the company’s design anywhere, build anywhere initiative.

“As we move manufacturing over here, we don’t have access to metric materials at least not without some signicant cost,” Nedegaard said. “It will be the same product with the same parts, but they come from different raw material sources.”

Collaboration between the New Zealand, Germany and Galesville teams has made the planning process smoother, Nedegaard said.

Disruptions in overseas shipping and rising freight costs had GEA looking for a more viable way to meet the needs of American dairy farmers. Daley said the goods can take months to get from New Zealand to the United States.

“Manufacturing in China or New Zealand and shipping it to the U.S. doesn’t make sense economically,” Daley said. “Then, of course, the freight to ship things in a container from New Zealand to the U.S. is substantial; we’ve got $20-$50 million worth of product en route from one place to the next. We knew we could make smart changes that would deliver a high-quality product to our

customers much faster.”

Preparations at the Galesville site included making space available for equipment that will be used in the manufacturing of the rotary parlors. Daley said it is a project worth investing in.

“Rotaries are our future, along with the robotic business, so we have to make a signicant investment like we have with the robots for the rotary parlor manufacturing,” Daley said. “We really feel strongly not only in the work ethic of the people employed here but also in the technology that we are investing in this facility so that we will be ready for the future.”

The Galesville site has been manufacturing GEA products for over ve decades. The average employee has 14 years of experience. The site hosts training for dealers, service technicians and milk quality staff with their in-house parlor and robotic training facilities and test lab.

When building parlors, raw materials are brought into the facility on a conveyor and cut to length. Then, they are sent to be notched, welded and galvanized. A bigger machine will be used to bend the pipeline that creates the rotary parlors. The team is also discussing the possibility of preassembly on new parlors to make sure everything ts together properly before installation on a farm.

“We’re clearing out space and optimizing our processes in order to accomplish something that we haven’t done here before,” Daley said. “The rst rotary that is fully nished in this facility will come off the line Sept. 1.”

2650 bale grinder

‘14 NDE 2906 twin screw TMR

Tubeline 5500 inline wrapper

JD 146 Loader w/bucket

‘98 Agco Allis 8875, 2WD, CAH w/ Westendorf loader

‘20

JD 5045E, 2WD, only 200 hrs.

‘21 MF 1725, ldr., snowblower, Curtis Hard Cab, only 127 hrs.!

‘21 MF GC1723, ldr., mower, 180 hrs.

MF GC1705 w/60” deck

‘18 MF 1705, 60” deck, 200 hrs.

‘18 MF 1705, 60” deck, 300 hrs.

‘16 MF GC1705, 60” deck, 500 hrs.

‘97 Kinze 2600, 31R15”

Sunflower 4211-9, disc chisel w/ buster bar

DMI 530B Disc Ripper

JD 712 9 shank disc chisel

CIH MRX690, 5 shank disc ripper disc.

JD 980 Field Cult., 44’ w/harrow

CIH 4800 30’ Field Cult, w/3 bar coil tine harrow

Loftness 20’ Stalk Shredder, NICE!! ‘08 Agco 3000 Corn Head, 8R30, poly

Gehl 100 Feed Mill

SKID LOADERS

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, 215 hrs.

‘20 Bobcat T770, SJC, 300 hrs. ‘20 Bobcat T770, high flow, 1,000 hrs.

‘12 Brent 782 Cart, w/tarp & scale

Wis. –

As a native Spanish speaker, Tania Groen recognized a need in the dairy community and has taken it upon herself to become a resource for those needing assistance in overcoming communication barriers that might exist on Wisconsin dairy farms.

Earlier this year, Groen launched Breaking Barriers where she works as a translator to help bridge the language gap that might exist between dairy farmers and their Spanish-speaking employees.

Groen and her husband, Corby, milk 100 cows on their Ev-

ergreen Acres Organics dairy farm near Amherst Junction in Portage County. The Groens ship their milk to Organic Valley.

Groen grew up in a household with Spanish-speaking parents, giving her a command of both Spanish and English. She also grew up around the dairy industry, giving

her the background knowledge and experience to understand and be empathetic to problems and concerns that might arise on a farm.

“My father worked on dairies while I was growing up, so I can see the employee side of things from that experience, and dairy farming with my husband, I have had the

experience of being on the employer side of things,” Groen said.

“That gives me the unique perspective of being able to see both sides of the coin when it comes to helping resolve issues that become even more complicated with the lan-

Turn

bottle washer, saving money on milk replacer and improving calf health.

Con nued from MURPHYS | Page 8 which father and son agreed is the upright storage of silage, a feedstuff they are using more of now and utilizing a vertical mixer.

“The calves are doing so much better,” Owen said. “Getting milk at the same temperature every day with no bacteria makes a difference.”

Under Owen’s management, calf care also includes paste dehorning rather than the hot irons used previously.

Owen said the farm has been using 70% fewer drugs since the change in breeding and calf feeding.

Weaned calves have been moved from an older calf barn where manure had to be pitched manually. A year ago, the Murphys installed a pad with super hutches for post weaning. The calves stay in the super hutches for two months, then move to groups of eight in an open-front heifer barn, continuing to move through the system until 21 days before calving.

“Pitchforks are a thing of the past,” Dan said.

Another thing on

“When you’re doing bags by yourself, you have to get on and off the tractor, make sure it’s packed right, and then if you leave for chores, everything stops,” Owen said.

Dan agreed.

“You’ll get people to disagree when you say uprights are best,” he said. “But if it’s just us when we’re chopping, it’s easier, and we think the quality of the feed is better.”

Owen’s near-term goals include getting the rolling herd average higher, and by breeding for components, structure and longevity, he hopes to create a betterlooking herd.

To Dan, Owen’s ideas have made sense, even if they are different from his previous practices.

“We just did things the way we always did,” Dan said. “It was kind of impressive what (Owen) said he had learned ev-

ery time he came home (from college).”

Owen said some of what he learned was in class, but he also took many of his ideas from what other people were doing. And, he is

pleased to be using his knowledge at home.

“A lot of people I graduated with didn’t come back to the farm,” Owen said. “I can’t even imagine that.”

guage barriers that might exist.”

Groen’s new undertaking began when the Groens moved their dairy farm to Wisconsin from Washington in 2021, and Groen said she noticed a difference in the community of dairy farm workers in the region.

“Back in Washington, there were not many rst-generation Hispanic farm workers,” Groen said. “Mostly you saw second- and thirdgeneration workers, and most all were bilingual. Here, I see a large population of rst-generation workers from countries like El Salvador and Nicaragua. These people do not have the experience with the English language and are not bilingual.”

That lack of experience can create issues on a dairy farm that Groen said could easily be avoided if proactive measures are taken to ensure clear and effective communication.

“If there is a language barrier in the workplace, it can be hard for both employees and the employer,” Groen said. “It is sometimes hard to know if you are really being understood or not.”

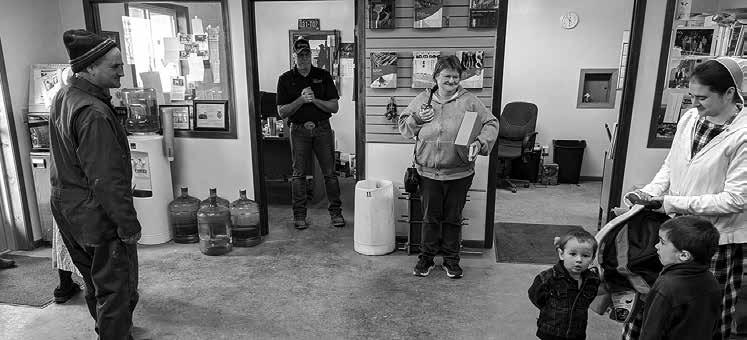

That is where Groen comes in. She offers her services as an outside observer, which can be particularly helpful when it comes to things like employee evaluations.

Groen said she has often heard of situations where a dairy farmer with Hispanic employees might rely on one of the employees who does speak English to facilitate communication with those who do not speak or understand much English.

“That might potentially lead to some issues,” Groen said. “Employees might not be comfortable dis-

cussing employment matters in the presence of other employees. Then, there is also the question of exactly how well the employee you are counting on to translate speaks and understands English themselves.”

Groen said she can tailor her services to each farm depending on their needs. She is able to translate complete documents for training manuals, protocols and standard operating procedures; assist in employee training and continuing education; help facilitate employee evaluations as well as provide translation services for any instance where language clarication might be needed.

“I spent a day assisting a dairy farmer with doing employee evaluations, and it was a very productive day,” Groen said. “We solved a lot of issues that the dairy farmer didn’t even really know existed because of the language barrier.”

Groen said language barrier issues can affect an employee’s life outside of work and that can ultimately impact job performance.

“When a language barrier exists, it can be difcult for someone to nd the resources to help them become a part of a community,” Groen said.

In addition to helping dairy farmers communicate with Spanish-speaking employees, Groen has been assisting in her community by working as a substitute translator in the local school district.

“I really enjoy translating,” Groen said. “I want to help people in my community with language barriers they might experience. Translating also allows me to keep my language fresh.”

We are grateful to dairy farmer Directors who share their time, their ideas, and their common sense to help keep DHIA services relevant. From time to time we will use this space to recognize these leaders and to say thank you. We will start with our current president, Dave Scapanski. He started as a local DHIA leader in Benton County, serving on the Board and as President.In 2002 Dave was elected to the Minnesota Board, and has been our President for the past 10 years. He was elected to the National DHIA Board 10 years ago as well, and currently serves as Treasurer there.

What are some of your duties as director? Making sure that we are nancially sound, competitive and ef cient. We work to keep DHIA affordable, accurate, and timely for management decisions for your farm.

What do you like about this role? As president of the board, I enjoy working with good board members who all give a lot of insight into the future of DHIA. Also working with Bruce and the staff make my role as president an easier job.

Why is DHIA important to you? DHIA is a very important management tool to us and our consultants for making good decisions. We use PCDART software to keep track of herd information on our farm. Nutritionists look at it monthly or more depending on ration changes. PCDART also works with our activity monitoring system. We are a big user of the milk pregnancy test. Preg tests are taken every test day and in between tests. It is a big labor saver. The somatic cell count list is watched closely. We either cull or treat high cows. The treated waste milk is pasteurized for calves.

Tell us a about your farm. The farm – Scapanski Farms LLC – is a partnership with my two sons, Chad and Brad. We are a diversi ed farm. In addition to the dairy herd, we raise all of our heifers, feed our steers and farm 1,100 acres for feed and to sell. We also do custom chopping, planting and combining. Sauk Centre, MN Buffalo, MN 763.682.1091

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

PITTSVILLE, Wis. – A few family road trips led to a question that began to churn in the minds of Mike Hobbs and Kim Baas: Could an ice cream shop be protable in a town like Pittsville?

After extensive market research, the couple felt the small town, located at the center of the state of Wisconsin with a population just under 900 people, might indeed be a good place to open a specialty ice cream shop.

“We really felt that if it was done right, an ice cream shop could be a good t for the community,” Hobbs said. “This feels like what an ice cream shop is supposed to be.”

Hobbs and Baas share an entrepreneurial streak and own another small business called Event City Designs, which shares building space with the ice cream shop. They relished the idea of creating a new business from scratch despite nei-

ther having a background in either food service or the dairy industry.

“We began researching the idea of stocking a premium ice cream brand, but that meant dealing with minimum orders and needing a crazy amount of freezer space,” Baas said. “Then, I came across a company that makes batch freezers, and I started playing around with the idea of making our own ice cream.”

For about four months after the arrival of the batch freezer, Hobbs taught himself to make ice cream, largely using tutorial videos put out by the freezer manufacturer.

“It really came pretty easily,” Hobbs said. “I just felt like I knew what I was doing.”

After all the planning, The Cranberry Creamery opened its doors to the public for the rst time over Memorial Day weekend last year and was

open through September. The success of the shop exceeded Hobbs’ and Baas’ expectations.

“We really thought we could staff this with just our own family,” Baas said. “We were blown away by the response, and we quickly learned that we needed more staff than just our own family. We were both working 80-hour weeks most of the summer.”

Hobbs and Baas turned to

the young people of Pittsville to staff their ice cream venture.

“We have been lucky to have such a great group of kids want to come work for us,” Baas said. “They are so happy and work together well; there is no drama. All of the kids who worked for us last season are coming back to join us again this year.”

The top two sale days last summer both came in July –National Ice Cream Day July 17 and the Fourth of July.

“We didn’t even know National Ice Cream Day was a thing, but it was great,” Hobbs said. “One of the local radio stations kept talking about it, and people came in steady all day.”

Baas said more than 20,000 customers were served during their inaugural year, and sales exceeded their expectations by over 50%

The Cranberry Creamery opened for business this season in early April, and the ice cream season in Pittsville runs through the later part of September.

What sets The Cranberry Creamery apart from other central Wisconsin locales is the ice cream itself. Hobbs makes all of the store’s ice cream in

A ight of four ar�san ice cream avors – Co�on Candy, White Chocolate Raspberry, Cookies and Cream, and All The Chocolate – is served with a piece of homemade waffle cone May 4 at The Cranberry Creamery in Pi�sville, Wisconsin. The shop is open from April to September.

small artisan batches of 5-6 quarts.

“We wanted this to become a destination and an experience,” Hobbs said. “We want the ice cream to be the main focus not just dessert after a meal. We purposely avoid having food on the menu. We don’t even have sundaes or any toppings; it is just about the ice cream.”

Hobbs and Baas have developed more than 130 recipes, and they typically have 15 on their avor board each day and up to 24 avors in their ice cream case.

“Some are rather basic standards, and some are pretty unique,” Hobbs said. “Some we make frequently, and there are others we have made once and might not make again.”

One of the most popular avors is Apple Pie. Contrary to what people might think, cranberry being in the name is not necessarily related to the ice cream itself.

“Cranberry is actually a really hard fruit to make ice cream with, because the dairy hides the tartness of the berry,” Hobbs said. “We do have several recipes that include cranberries, but we chose the name because the cranberry is the Wisconsin state fruit. We are in the heart of cranberry country in Wood County.”

Hobbs and Baas purchase the base mix for their ice cream from the Galloway Company Classic Mix Partners in Neenah.

“We tried nding a way to have it

made locally, but it wasn’t feasible,” Hobbs said. “We even considered making our own, but that meant more equipment, required more space and more things we had to learn to do. We decided to focus on doing one thing, rst, and doing it well.”

Keeping with the idea of making their shop a unique experience, Hobbs and Baas make the wafe cones for their ice cream on-site.

“We had planned to make the wafe cones in the back room, but we didn’t have enough counter space,” Baas said. “So, we were making them out here behind the ice cream case. People, especially kids, loved to watch them being made.”

That realization led them to rearrange their seating area to make room for a wafe-making station where customers could have a vantage point to watch the cones being made.

“It makes the place smell amazing, and it wafts down the street,” Baas said. “People will come in and say, ‘We knew you were making cones today.’”

For Hobbs and Baas, supporting the community that has supported them played a role in their desire to bring another small business to the downtown area of Pittsville.

“We hope others will see that small businesses can thrive in a small town like this,” Hobbs said. “People want a memorable experience, and providing that is our goal.”

70 cows

Tell us about your family and farm. My husband and I have been blessed with four children. Together, we raise 300 head of feeder steers a year, crop farm, run a seed and chemical supply company, and raise a beef herd. We live across the eld from my parents’ dairy farm where the children and I also assist daily with milking, herd health, record keeping and the show string.

What are some of the best aspects of being a mother and dairy farmer? Doing everyday life with our family is a highlight for me. We also homeschool, so we get to do all aspects of day-to-day farming together. Like anything, it's not without its struggles, but I am so blessed to be able to do life with them.

What are the biggest challenges with your dual role? Mom, teacher, farmer; they are all full-time jobs. There is always more that can be done, and I am a doer. The hardest part for me is learning to prioritize relationships over getting my to-do list done.

What are three traits you want to pass on to your children? To live wholehearted and to give it your best. Jesus said, "Love the Lord your God with all your heart and with all your soul and with all your mind." And, "Whatever you do, work with all your heart as working for the Lord not for man." To choose to be joyful and full of thanksgiving. We can't control what hand we are dealt in life, but we can choose our response to it. There is always something to thank God for. To be a good and respectful steward of what God has given them. Whether that's the land and animals, our minds and body or the relationships God has given us. I desire for them to take their responsibilities seriously and as God assigned.

What has been a highlight of your dairy career as a mother? It's always a delight for me when the kids tell me how much they love farm life or ask to be involved in something I'm doing.

If you had an afternoon all to yourself, what would you do? I'd be outside in my garden probably with more than a little dirt on me.

Who do you admire? My husband, Mike. He is my best friend and hero. He was diagnosed last year with an aggressive brain cancer, and instead of becoming bitter or depressed at the diagnosis, he has embraced the challenges and has used his struggles to become stronger.

Erin Grawe (pictured with daughter, Gwen) Janesville, Wisconsin Rock County 140 cows

Tell us about your family and farm. I am married to Tristan Grawe, and we have a 4-year-old daughter, Gwen. We farm with my sister, Megan Daluge, and my dad, Peter Daluge. We milk 140 registered Holsteins.

What are some of the best aspects of being a mother and dairy farmer? The best aspects about dairy farming with my daughter is showing her how to thrive in a male- dominated career. I love that I get to show her what women are capable of. Raising a child on a farm is very unique, and I can teach her skills that are rare nowadays.

What are the biggest challenges with your dual role? The biggest challenge of being a dairy farmer is not having much time off the farm for vacations and getaways. I want Gwen to see the world and give herself options, and that can be challenging as a dairy farmer.

What are three traits you want to pass on to your children? Three traits I want to pass on to my daughter are work ethic, trail blazing paths for women and breaking stereotypes. I also want to pass on my perseverance. I want her to continue not to limit herself and her options in life.

What has been a highlight of your dairy career as a mother? The highlight of my dairy career as a mother is the perspective it gave me about the farm. I used to put the farm before all things, and now it’s my family before the farm every time. Nothing comes before my daughter.

If you had an afternoon all to yourself, what would you do? It’s not if I get an afternoon to myself, it is when. I make sure I carve out time for me. To get that time helps me be the best, most present mom I can be. So, when I get an afternoon to myself, you can nd me working out, dressing up or treating myself to a mini spa at home and a glass of wine or an ice-cold beer.

Who do you admire? I admire my good friend, Becky Hurley. She recently got back into agriculture herself, and she is also a mama of two. I admire her because she is an entrepreneur as well, who is showing her kids how to go for opportunities and to do it even if you’re not ready and not to be afraid to learn along the way. That is the example I follow and want to be like as a mother.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant.

Kati Rasmussen (pictured with her husband Levi) Norwalk, Wisconsin Monroe County 68 cows

Tell us about your family and farm. My husband, Levi, and I have been farming for 15 years. We milk 68 cows in a tiestall barn and crop approximately 400 acres. We breed our heifers to dairy and our cows to beef and have developed quite a beef operation. Our four kids farm with us: Madi, Annie, Lee and Charlotte.

What are some of the best aspects of being a mother and dairy farmer? Being home, being able to participate in the kids’ activities and, for the most part, making my own schedule.

What are the biggest challenges with your dual role? Finding a balance between instilling a good work ethic in the kids and also allowing them to do fun kid things.

What are three traits you want to pass on to your children? A good work ethic, animal husbandry and compassion. Just learning not to put themselves rst.

What has been a highlight of your dairy career as a mother? Seeing the kids accomplish things on their own. Also, watching Annie work cattle is amazing.

If you had an afternoon all to yourself, what would you do? Sleep and catch up on housework.

Who do you admire? Levi, denitely. I admire his steadfast work ethic and willingness to provide for his family and help others.

185 cows

Tell us about your family and farm. I farm with my husband, John, and our ve children. Our oldest is Faith who is graduating from Iowa State University with a degree in dairy science this month. She and her husband are expecting our rst grandchild very soon. At home are Ethan, Norah, Naomi and Roslyn. All the kids have always been active in the day-to-day operations, and the oldest kids help with eldwork. My husband and I grew up only a couple of miles from each other, and we are fortunate to have each of our family farms close and a part of our daily lives and farming operation. We own and milk cows on the farm I grew up on, and it means a lot to me to be able to raise my children here. We grow all our feed and raise our youngstock. We started a small cow-calf herd, and so far that has been a fun experience.

What are some of the best aspects of being a mother and dairy farmer? I can’t think of another profession that enables the entire family to work together for a common goal while sharing in each other’s trials and successes. I appreciate seeing my kids grow up with the values I think are important to leading a successful life. I am fortunate I am able to be home to get the kids to school and am here when they get off the bus. I am also a registered nurse. I have been able to cut back to the level that I only pick up hours when I want to a couple times a month. The days I do work off the farm make me appreciate being able to be home on the farm that much more.

What are the biggest challenges with your dual role? Balance is always something we have to try hard to nd. Even though we work at home, that also means we are always at work. Planning time away from the farm can be a challenge, and there is always worry when you are away. I encourage my kids to be involved in school sports, 4-H, FFA and Holstein association activities, but it’s denitely hard to attend games, shows, contests, etc. Thankfully, the kids understand.

What are three traits you want to pass on to your children? In my living room, I have a sign that reads, “In a world where you can be anything, be kind.” That is something I hope my kids read and remember each day as they go about their lives. Otherwise, I want them to be curious and strive to never stop learning. The farm is the perfect place to teach hard work and resiliency.

What has been a highlight of your dairy career as a mother? Watching the kids enjoy life on the farm is what I enjoy most and a necessary reminder of why we do what we do on the harder days. I love watching them work together to get a job done and interact with the cows, calves and kitties.

If you had an afternoon all to yourself, what would you do? In the warm months, I would work in the ower garden and go on a long walk or go do a bike trail. In the winter, I would work on a quilt or just sit down and read a good book.

Who do you admire? I admire my mom and grandmothers. They were all farm wives. While my mom always worked full time off the farm, she was always supportive of my dad and proud of raising me and my siblings on the farm. My grandmothers and great-grandmother were integral parts of their farming operations while raising their families. They probably never got enough credit for that. I am fortunate that women are receiving recognition and respect as partners in their farming operations.

Moriah Brey Sturgeon Bay, Wisconsin Door County1,000 cows

Tell us about your family and farm. My husband, Tony, and I have two children – Evan and Alexa. We farm with Tony’s brother, Jacob, and his wife, Lauren, who also have two kids – Rosella and Willem. We milk about 1,000 registered Holsteins, raise our own youngstock and crop 1,500 acres of land. Additionally, we have an on-farm beef store, Brey Family Beef. We focus on sustainability, employee culture and community relations.

What are some of the best aspects of being a mother and dairy farmer? For me, the exibility of my role on our farm allows me to show my kids responsibility, hard work, and dedication while also being available to be their biggest cheerleader and support person. Being their “person” is my No. 1 role. Additionally, I’m able to model what a supportive family, friend-family or work-family looks like. By raising our kids around our family, employees, vendors, friends and trusted advisors, we’ve had ample opportunities to model how to have a conversation, shake hands, be caring and understanding, chip in where needed, etc.

What are the biggest challenges with your dual role? As most moms would say – separating our roles is difcult. Feeling guilty on one side of the equation

or the other is almost a given. Additionally, sometimes as a mother, friend and employer, the impact you’re having in the world doesn’t necessarily garner an immediate accolade. In a world focused on immediate gratication, our work can be overlooked in the present, but building up great people is really one of the most important things we can do even if it takes patience and time, and that course isn’t a shiny and ashy one.

What are three traits you want to pass on to your children? Adaptability, empathy and self-condence.

What has been a highlight of your dairy career as a mother? I’ve been lucky to have a dairy career that has been well-rounded enough to allow me to contribute in different ways. There’s not one highlight – just a journey that includes different focuses during different times. Being able to draw on the various things I’ve learned while focusing on my family rst and foremost is, in a way, a highlight of this current chapter.

If you had an afternoon all to yourself, what would you do? I would gather with my friends. I’ve been blessed with some beautiful friends from each era of my life. We’ve worked hard to cultivate and grow these friendships over time. My friends are my lifelines – my condants, my people.

Who do you admire? I admire our farm family. We continue to grow our farm in part to be able to involve more people. Many of our employees have immigrated to a new country to work with us. We’ve learned so much from every new person who joins our team. Overall, their grit, positive attitudes and adaptability are admirable. They are why we do what we do.

Describe your farm and facilities. We have a 64-cow organic dairy with 64 head of replacements. This is a small family farm passed down from Pam’s parents. We purchased it in 1993, and now our son and his wife are working their way into ownership. They will be the fth generation. The milking barn is a converted stanchion barn to a at-barn parlor with free stalls and a manure pit. We have a small barn for the young babies and an open-sided shed for heifers with headlocks and drive-along feeding. For feed storage, we have a grain bin, two silage bunkers, an upright silo and a feed bin. What forages do you harvest? Forages consist of grain corn, silage corn and alfalfa, grain barley and/or wheat and alfalfa hay. We use a crop rotation of corn, corn, barley or wheat with a new seeding of alfalfa and three years of alfalfa hay.

How many acres of crops do you raise? We own and rent 300 tillable acres and have 130 acres of pasture land.

What quality and quantity do you harvest of each crop? We chop the rst cutting of alfalfa for optimum quality and bale the

remainder for dry hay. Then, we bale second and third cutting with high-moisture round bales with approximately 2,000 dry small

squares for calves. We chop about 40 acres of corn for silage; the remaining 40 acres are shelled for grain with an average of 120 bushels per acre of corn. We usually have surplus of hay which is sold to other farmers.

Describe the rations for your livestock. The cows get corn silage, haylage, baleage, ground corn, mineral, and soybean meal or roasted soybeans. Pasture is accounted for in the summer months into the ration. The dry cows get corn silage, baleage, ground corn, mineral, soybean meal or roasted soybeans, and pasture in the summer. The heifers get corn silage, haylage, baleage, ground corn, mineral and some soy if called for by a nutritionist. The summer ration for heifers is ground corn and mineral with most dry matter intake coming from pasture.

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51

Bongards, MN 55368

(952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE

Perham, MN 56573

(218) 346-4680

Fax (218) 346-4684

“Using the Udder ComfortTM Battery-Operated Backpack Sprayer every day has made us more compliant with our fresh cow protocol for better udder health. We’re getting our fresh cows sprayed more consistently with Udder Comfort 3x/day for a week after calving. In 3 months of getting fresh cows sprayed consistently, our SCC came down from 165 to 137,000. We run a really full freestall, and if we do get clinicals, they clear faster and don’t become repeat offenders,” says Scott family’s 750-cow Registered Holstein dairy near Maynard, Iowa.

“We notice a lot more udder texture and veination at 2 weeks in milk when sprayed consistently and right away after calving, compared with 3 to 4 weeks in, if they are not.

“The Udder Comfort Battery-Operated Backpack Sprayer is smooth. It puts a nice, even, effective coat of Udder Comfort on the udders. It gets under the udder, broadcasting over the ligament and around the teats, where you want it,” Scott explains.

“We have relied on Udder Comfort over 10 years as the best tool to get cows through transition and into milk faster with healthier udders,” he adds.

“We always talked about getting milkers to stick to the protocol. The Sprayer does that. It’s more convenient and user-friendly than I thought it would be. It holds a lot of product, charges fast, holds the charge well, so it’s always ready and easy to grab, turn on, and go,” Scott reports.

Describe your harvesting techniques for alfalfa and corn silage. We chop our own hay and corn with a pull-type chopper and custom hire a combine for corn, barley and wheat. We harvest hay three times a year, preferably every 30 to 40 days. Of course, corn is chopped in the fall.

What techniques do you use to store, manage and feed your forages? Haylage is stored in a bunker and covered with plastic and tires. Corn silage is stored in a bunker and covered the same as the haylage. The rest of the corn silage is in an upright silo for summer use. The animals are fed with a vertical mixer.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? When we rst purchased the farm, there was cropland around the barn. We seeded in the corn ground with a pasture seed mix and left the hay, turning it into 50 acres of pasture on the farm utilizing rotational grazing with permanently fenced paddocks. Pasturing our cows made the switch from conventional to organic certication an easier transition. We also went from using oats to barley or wheat for nurse crops for alfalfa. The barley and wheat have less lodging, and the grain is used as a partial corn replacement in our cattle ration. We are experimenting with soybeans no tilled into crimped winter rye.

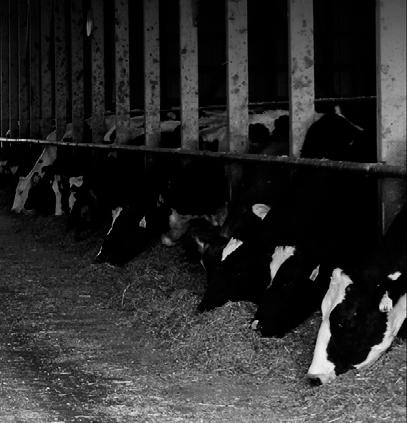

Cows eat a ra on May 3 at the Seelow family’s farm near Chaseburg, Wisconsin. Corn silage, haylage, baleage, ground corn, mineral, and soybean meal or roasted soybeans make up the total mixed ra on.

Describe a challenge you overcame in reaching your forage quality goals. Using our nutrient management plan as a guide in reaching optimum soil health which in turn gives a better long-term alfalfa stand. Soil testing tells us when we need to spread potash and lime.

How do quality forages play a part in the production goals for your herd? Quality hay reduced the need for added protein sources which lowers our cost of production.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? We have gone from hiring custom choppers to purchasing our own equipment which can make a difference in harvesting when the crop is ready.

6000 BC, #544396 .......................... $13,500

NH BR780 2005, 1000 PTO, 5 ft. bales, 7700 BC, #557075 ........................ $13,500

JD 568 2008, 540 PTO, 5 ft. bales, 17,649 BC, #550655 ............................. $14,500

NH BR780A 2007, 540 PTO, 5 ft. bales, 7350 BC, #542859 ....................... $14,750

JD 582 Silage Special 2009, 540 PTO, 4 ft. bales, 22,825 BC, #542349 ....

569 2014, 1000 PTO, 5 ft. bales, 10,100 BC, #553387 ...........................

569 2016, 1000 PTO, 5 ft. bales, 13,560 BC, #554379 ...........................

460R 2018, 1000 PTO, 4 ft. bales, 15,600 BC, #550251 ........................ $33,000 Case IH RB455 2018, 540 PTO, 4 ft. bales, 2091 BC, #543641 .................. $33,500 JD 569 2015, 1000 PTO, 5 ft. bales, 9200 BC, #545913 .............................. $33,900 Krone Comprima V 180XC 2019, 1000 PTO, 4 ft. bales, 13,573 BC, #550353 ....................................................................................................

Case IH RB565 2020, 1000 PTO, 5 ft. bales, 10,094 BC, #556680 ............. $34,900

JD 569 2014, 1000 PTO, 5 ft. bales, 6500 BC, #554698 .............................. $36,900

NH Rollbelt 460 2021, 540 PTO, 4 ft. bales, 687 BC, #553694 .................. $42,500

JD 560R 2018, 1000 PTO, 5 ft. bales, 8654 BC, #556060 ........................... $43,000

JD 560M 2019, 1000 PTO, 5 ft. bales, 7000 BC, #550210 .......................... $43,900

JD 560M 2019, 1000 PTO, 7300 BC, #555035............................................ $44,900

Vermeer 605N Cornstalk 2017, 1000 PTO, 5 ft. bales, 6768 BC, #548033 .................................................................................................... $46,500

JD 560M 2020, 1000 PTO, 5 ft. bales, 5491 BC, #552770 .......................... $46,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 3576 BC, #531213 .......................... $46,900

JD 560M 2020, 1000 PTO, 5 ft. bales, 5500 BC, #544100 .......................... $47,900

JD 450M 2019, 1000 PTO, 4 ft. bales, 1918 BC, #531693 .......................... $48,500

JD 560M 2021, 1000 PTO, 5 ft. bales, 8233 BC, #557166 .......................... $51,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 6000 BC, #554127 .......................... $51,900 JD 460M 2019, 1000 PTO, 4 ft. bales, 5898 BC, #557634 .......................... $53,500

JD 460M 2022, 1000 PTO, 4 ft. bales, 2600 BC, #557280 .......................... $57,900

540 PTO, 5 ft. bales, 1516 BC, #547391 ............................ $61,500

#555841 $289,000

Claas 970 2018, PRWD, 2257 hrs., 1639 CH hrs., #533174 ..................... $299,000

JD 8500 2017, PRWD, 1460 hrs., 1070 CH hrs., #553938 ........................ $299,000

JD 8700 2017, PRWD, 2544 hrs., 1835 CH hrs., #546919 ........................ $308,000

JD 8700 2016, PRWD, 1840 hrs., 1103 CH hrs., #525709 ........................ $324,000

JD 8700 2016, PRWD, 1469 hrs., 933 CH hrs., #532572 .......................... $339,000

JD 8800 2017, PRWD, 1728 hrs., 904 CH hrs., #544616 .......................... $339,900

JD 8600 2018, PRWD, 1652 hrs., 778 CH hrs., #188792 .......................... $342,000

JD 8700 2018, PRWD, 1702 hrs., 1069 CH hrs., #541389 ........................ $348,500

JD 9600 2019, PRWD, 1726 hrs., 1130 CH hrs., #553763 ........................ $349,900

JD 8800 2017, PRWD, 1558 hrs., 862 CH hrs., #524820 .......................... $355,000

JD 9800 2019, PRWD, 1893 hrs., 1368 CH hrs., #543355 ........................ $390,000

Claas 940 2020, PRWD, 650 hrs., 480 CH hrs., #532728 ......................... $399,900

JD 9600 2019, PRWD, 1224 hrs., 811 CH hrs., #532049 .......................... $409,900

JD 8300 2022, PRWD, 33 hrs., 9 CH hrs., #537501 .................................. $459,000

JD 9800 2020, PRWD, 1415 hrs., 942 CH hrs., #554135 .......................... $459,900

JD 9900 2019, PRWD, 1224 hrs., 884 CH hrs., #550177 .......................... $493,000

JD 9800 2020, PRWD, 1288 hrs., 833 CH hrs., #536344 .......................... $497,000

JD 9700 2020, PRWD, 1166 hrs., 835 CH hrs., #543646 .......................... $503,000

JD 9800 2019, PRWD, 899 hrs., 660 CH hrs., #550175 ............................ $503,000

JD 9900 2020, PRWD, 844 hrs., 661 CH hrs., #553436 ............................ $508,000

JD 9800 2021 PRWD, 416 hrs., 302 CH hrs., #550106 ............................. $518,000

JD 9900 2020 PRWD, 784 hrs., 455 CH hrs., #561177 ............................. $523,000

JD 9700 2020, PRWD, 961 hrs., 500 CH hrs., #552460 ............................ $524,900

JD 9800 2021, PRWD, 569 hrs., 369 CH hrs., #552624 ............................ $553,000

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029

Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

CASHTON, Wis. –

When record rain falls caused a 45-foot high dam to fail and ood the valley below his dairy farm in 2018, Tucker Gretebeck had to watch a dream wash away.

The valley was home to a pumpkin patch and agritourism business that drew 4,000 people a year and also helped cash ow the dairy farm.

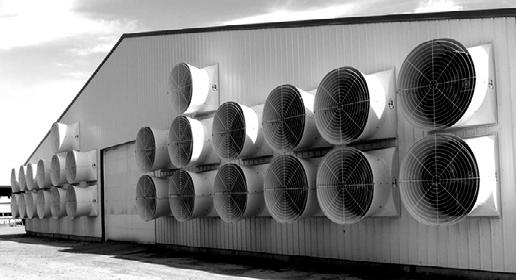

Gretebeck also lost his hot weather pasture and source of shade for the cows. He began to research ways to make his farm less susceptible to ooding and also provide shade for his animals.

Through the collaboration of the Organic Valley insetting program, Wisconsin Land and Water Conservation Association, the Savanna Institute and Monroe County Climate Change Task Force, 1,2000 trees

Snow Buckets

were planted on Gretebeck’s ridgetop pastures. The move was an effort to aid in sequestration and eventually provide shade for cows and economic value to the land.

Since planting the trees, Gretebeck has revived the Coon Creek Community Watershed Council Inc. as part of an effort to educate people about sustainable farming practices and be a resource to each other.

“I almost feel like we’re running out of time,” Gretebeck said. “If we’re going to do something different, we just have to help people do it. That’s what we’re trying to do with the watershed group.”

Gretebeck milks 50 organic cows on his farm near Cashton with his wife, Becky, and children, Trent and Lana.

The idea for the tree planting came when Organic Valley was looking for a project for their climate change task force and Gretebeck was wanting to make changes toward sustainabil-

Grapple buckets, bale spears, rock buckets etc.

ity. Matt Wilson from the Savanna Institute designed the layout of the trees based off of how the land had been row cropped years before.

They planned for 1,200 trees of crab apple, black walnut, honey locust and a

hybrid poplar tree variety. The trees line the fences between each paddock of 50 acres of pasture. It took a couple of months of planning and ordering trees, but once it all came together, it took 12 people 12 hours to

plant 1,200 trees.

“This is an awesome project that I never thought we could get done, and we got it done in two days,” Gretebeck said. “I would’ve thought it would take three years to do all of this.”

Neighbors and members of the watershed group volunteered their time to help complete the project.

The trees were planted and canopies were attached to protect them. In only one year, they have outgrown the canopies, and Gretebeck said they will provide shade within three years.

“My goal is to put more milk in the tank by providing shade,” Gretebeck said. “I hope to take their stress level down.”

The land where Gretebeck’s farm is located consists of steep hills and valleys. His research indicates there is a 700-foot drop in elevation from his farm to the Mississippi River.

“We are in a steep slant really fast and then the rest of the country is at to the Gulf of Mexico,” Gretebeck

said. “When it rains around here, we all tense up a little, especially people in the valley.”

Gretebeck’s herd is exclusively grass fed. He plants a mixture of warm and cool season grasses, so they bloom at different times. He also replaces corn silage with sorghum-sudangrass which he said is an economical sugar source for the cows.

Gretebeck said by planting trees and perennial grasses, the land will have an easier time soaking in water and reducing oods. His hope is everyone in the area, not only farmers, will benet from the practice.

He already has the support of his agritourism participants, who have

been helping him slowly rebuild that business as well.

“People in town are enthused about this,” Gretebeck said. “This is what makes farming fun for me. It’s going to benet a lot of people with the sequestration. I don’t know if it’ll ever come back to me, but I feel good about it.”

Gretebeck said the trees will also provide a future for either dairy, beef or further agritourism opportunities if his children end up joining the operation once they are grown.

“I don’t know if they’re going to farm like me because I don’t farm like my dad did, but at least they’ll have opportunities,” Gretebeck said.

COLBY, Wis. – When the opportunity to buy a neighboring dairy farm presented itself, Jim and Jenny Briggs jumped at the idea.

The farm, which the Briggses closed on in February, has been on their radar for a couple of years as a potential avenue of growth for their own dairy farming enterprise as it was previously owned by the grandparents of a girl who milked for the Briggses a few years ago.

“You don’t get an opportunity like this every day so close to home,” Jim said. “A few years ago, we let the previous owner know our interest in purchasing the farm when they decided to retire. They nally came to us this past fall, and we started discussing things. I think he is glad to see it remain as a small dairy farm.”

The Briggses were grateful for the opportunity that was born of their personal connection. Jenny said they

farm in an area where competition for farm land is erce.

“Before this, there was nothing that we could nd, especially this close, that we could afford,” Jenny said. “This turned out to be a great opportunity for us.”

The Briggses milk 56 Jerseys on their home farm just up the road from the recently purchased farm. The new farm doubles the size of the milking herd to 102 and provides additional acreage, bringing the total of the two farms to 240 acres. The milk from both farms is shipped to Mullins Cheese.

“The additional acreage was really a driver behind wanting to purchase this farm,” Jenny said. “We didn’t have enough acreage on our home farm to grow all of our feed.”

In addition to the acreage, the infrastructure available on the second farm – particularly a large machine shed and a shop – was enticing.

The mixed breed herd was included in the sale of the farm, and the Briggses plan to

utilize their own replacement Jerseys to continue to populate the second farm.

“It was really helpful to have the cows come with the farm,” Jenny said. “That made the transition go that much easier, not having to buy and

acclimate cows to a new barn and new routine themselves. It was just us coming into their world. Getting the new routine down was just a bit of a challenge for us.”

Adding a second farm doubled the work load for the

Briggses, and they admit the rst few weeks following the purchase were harried.

For the last 100 years, Ritchie has been manufacturing a complete line of livestock watering products with thehighest specifications in the industry.

From a single horse Stall Fount to a fountain that waters up to 500 head, Ritchie fountains are top quality. Plus,every Ritchie fountain is backed by our 10 year limited warranty.

The Briggses made the move to central Wisconsin and established their farm in 2014. The couple said that while this transition has been challenging, taking over a routine and herd that are already established has been much easier than starting a dairy farm from scratch.

“It would have been better starting here rst, because everything was running and operating,” Jim said. “We just took over. When we started at the other farm, we had to buy the cows and the feed and all the equipment and create the routine out of nothing. That was kind of stressful for both us and the cows.”

For the rst two weeks, the Briggses were handling both farms mostly on their own, with only two people helping to milk in the mornings while Jim fed cows. In addition to helping with the farm work, Jenny works full time off the farm.

“It’s been a challenging spring, especially with the weather,” Jenny said. “But it’s coming. We’re doing way better now than we were two months ago.”

One of the Briggses’ part-time helpers, Megan Steines, recently made the decision to leave her job in town and join the team full time, working primarily as a herdsperson at the rst farm.

“Megan didn’t grow up on a dairy farm, but after showing when she was younger, she went on to school for

dairy herd management,” Jim said. “When we knew this place was going to be a go, I convinced her that she should consider coming to work for us full time. She started here full time March 6, and that has been great.”

At the urging of the Briggs family, Steines joined the Dairy Grazing Apprenticeship program. The Briggses are believers in the premise behind the DGA and were happy to facilitate that connection for Steines.

“We have been signed up as a mentor and looking for someone to work with for the past four years or so,” Jim said. “This farm will hopefully become helpful to facilitating future connections with the DGA as we will be able to provide the option for on-farm housing for someone.”

The desire to be a mentor through programs such as the DGA and help teach people to become dairy farmers is rooted in the Briggses’ philosophy about the importance small family-operated dairy farms play in rural America’s economy and landscape.

It is really important to keep as many of these small farms operating as possible for the local economy,” Jim said. “The more farms on the land, the better for the economy. If I had the money, I’d buy every one of these farms and match them up with people that wanted to get started farming.”

Tell us about your family and farm. I work alongside my sisters, Maddy and Grace, to develop our small herd of registered Red and White Holsteins at Red Blossom Farm. We board our animals at Dorsland Farms in Rudolph, Wisconsin, and with the Hughes family at Sunsett Dairy in Pittsville, Wisconsin. I have been the full-time herdsman at Dorsland Farms since September 2022. We milk 45 registered Holstein cows in a tiestall barn and manage about 100 head of youngstock. During the summer months, the herd spends most of its time on pasture. We appreciate cows that excel in dairy strength and functional mobility that have the potential to live a long and productive lifetime.

What is a typical day like for you on the dairy? My morning starts with feeding our component-fed herd and milking. After milking, I feed calves and do heifer chores. Throughout the day, I like to focus on heat detection, facility cleanliness and other tasks around the farm. Afternoon and evening chores are similar to morning tasks.

What decision have you made in the last year that has beneted your farm? In my small herd, we have become more focused on breeding polled and red animals as those traits have come to be in higher demand in the industry. Currently, over 40% of the Red Blossom herd is polled, with all of our animals being red. We value bigframed, strong cows that work hard with well-balanced udders. I appreciate quality over quantity. My sisters and I are grateful to our mentors who have helped us learn and grow in the dairy industry.

Tell us about your most memorable experience working on the farm. My most memorable experience has been preparing the animals for classication at Dorsland Farms this past March. It was rewarding to see Excellent cows gaining additonal points and so many young cows going Very Good. I have learned many new things and have strengthened my skills as a herdsperson

Hannah Hensel Rudolph, Wisconsin Wood County

at Dorsland Farms and look forward to making more memories in the future.

What have you enjoyed most about dairy farming or your tie to the dairy industry? I have truly enjoyed developing my herd and creating connections throughout the dairy industry. I value showing bred and owned animals as it is fullling watching your own breeding successes do well both in the barn and in the show ring. I am fond of my time involved with the Wisconsin Holstein Association and as a graduate of the last farm and industry short course class held at the University of Wisconsin-Madison.

What is your biggest accomplishment in your dairy career? From being a young 4-H’er not having grown up on a dairy farm to becoming a herdsman of an impressive herd of Holsteins is my biggest accomplishment. In just 10 short years, I have learned and grown and took chances on new experiences that have led me to the place I am now. I am thankful for my family and friends who have helped me and supported me. I am proud of myself and my sisters for being dedicated to our herd and working together. The learning never stops, and I can’t wait to see what the future holds as I know it is bright.

What are things you do to promote your farm or the dairy industry? To promote the dairy industry, I support young showmen by answering questions and encouraging their involvement. Social media is an important platform to share promotion events and information. As a past and current member of youth organizations such as 4-H, FFA and junior Holstein, it is important for youth to become involved in these programs because it helped me become the person I am today.

What advice would you give to other women in the dairy industry? Do not let one bad day or experience ruin your future in the industry. You are strong and resilient.

What is a challenge in the dairy industry you have faced and how did you overcome it? When I was in high school, I received comments surrounding the idea of why I chose to pursue an education for my career choice of becoming a herdsman. My mentors supported and encouraged me on my choice of going to UW-Madison’s Farm and Industry Short Course, and I absolutely do not regret my decision. I made lifelong friendships, learned more about myself and this industry, and it helped me make a seamless transition

into post-secondary life. Education is important for every career path. Whether it is through a certication course, technical school program or a four-year university, it is worth the investment of your time. Every day is a new opportunity to learn something.

When you get a spare moment, what do you do? I like to visit my family and friends, spend time with my cat, Tootsie, and go shopping at local small businesses.

AVOCA, Wis. – When Jody and Dan Miller updated their farm from a stall barn to a parlor and freestall setup in 2015, it was the rst step in their expansion plan. After hiring employees and adding cows, they are nally utilizing technology they have planned for since the beginning.

Herd health is managed with SCR ear tags and DelPro parlor software. The ear tags monitor the cows’ activity while the parlor software is an identication system with a separate RFID tag that tracks events in the parlor, including pounds of milk. All of the data is sent to the ofce computer which is close to the parlor.

Jody said the technology has helped them achieve their herd goals and made adapting to a parlor easier.

“I love the ID in the parlor because when we were in the stall barn, you knew every single cow,” Jody said. “Now, you only see the udders, and we have a lot of new heifers. It tells us who they are and

helps everyone identify a little better.”

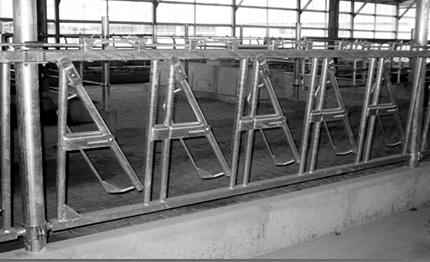

The Millers milk 250 cows three times a day in a double-12 DeLaval Champion parlor and GEA inations.

Jody milks the rst shift with an employee and serves as parlor manager for the farm near Avoca, while Dan is in charge of breeding and herd health. Dan’s son, Derek, and

DC - 1125 Series Dump Carts have a durable and time proven box design to keep continuous harvest production. DC-1125 Series carts have high floatation tires that create less damaging impact on your fields and harvesting equipment. DC-1125 Series now also comes standard with the fold down gate and ground level grease banks.

16’ Skid Steer/Telehandler Tire Shooter Wheel Loader Tire Shooter

Dan’s brother, Scott, are in charge of calf chores, mixing feed and taking care of the youngstock. Derek also runs the equipment for the farm’s custom farming operation in the summer.