WANT TO WIN $100 CASH?

See page 23 of the first section for details!

See page 23 of the first section for details!

Two Clark County farms suffer damage in spring snowstorm

By Danielle Nauman danielle.n@dairystar.comTHORP, Wis. – Two Clark County dairy farm families are hoping the old wives’ tale that bad things happen in threes does not hold true. Both have twice faced major structural troubles and tragedy on their farms and do not wish to do so again.

Finals held in Walworth County include visit to Loudenbeck goat farm

By Stacey Smart stacey.s@dairystar.comLAKE GENEVA, Wis. – Before the 76th Alice in Dairyland was crowned May 13, the top six candidates spent time touring farms and businesses as part of the three-day Alice in Dairyland Finals held in Walworth County.

On May 12, nalists Ashley Hagenow, Shannon Lamb, Lydia Luebke, Jackie Rosenbush, Charitee Seebecker and Jodie Weyland, along with the current Alice in Dairyland, Taylor Schaefer, visited Loudenbeck Farm – a dairy goat operation near Lake Geneva that milks about 400 goats.

Siblings Seth and Hannah Loudenbeck, who farm with their dad, Steve, and their uncle, Matt, welcomed the nalists while sharing details of their dairy. The Loudenbecks’ mom, Chris, and younger brother, Ryan, also help on the farm.

A spring snow storm April 1617 dumped over 2 feet of wet, heavy snow across a narrow band of Clark County. Sander and Amy Penterman’s 850-cow Dutch Dairy and Brandon and Meredith Maier’s 200cow Maier’s Acres, located just over 2 miles apart from each other near Thorp, both fell victim to the storm, losing signicant portions of the freestall barns housing their respective milking herds.

Unfortunately for both farm families, this is not the rst time adversity and misfortune have affected their farms. The Pentermans have dealt with a roof collapse before, in the aftermath of a February 2019 snowstorm. In February 2022, the Maiers suffered a re that destroyed their calf barn, claiming the lives of the calves housed inside.

“We were just fortunate and grateful that all our people and all our cattle were safe,” Meredith Maier said. “I truly believe that God works in mysterious ways. In February (2022), we had just started milking three times a day. If we hadn’t made that change, there is a good chance no one would have been in the barn at that time, and things could have ended a lot differently.”

Maier said at approximately 11:30 a.m. on the second day of the snowstorm April 17, an employee was in the freestall barn moving cows toward the parlor for the midday milking shift when he heard the beams in the barn cracking and creaking. The employee immediately called Brandon, and the cows

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

Deadlines

The National Milk Producers Federation has submitted its proposal to update the Federal Milk Marketing Orders. This proposal goes beyond the changes sought by the International Dairy Foods Association, which is only calling for an update in the make allowances used in pricing milk.

“We’re really excited that (this) is a plan that will point a way toward a much brighter future for us (in the) dairy industry,” said Jim Mulhern, president and CEO, NMPF.

AFBF wants USDA to go further

The American Farm Bureau Federation wants the U.S. Department of Agriculture to hold a hearing on milk pricing reforms. Chief economist Roger Cryan said changes that go beyond the current proposals should be considered. “Processors asked USDA to have a hearing just to update make allowances,” Cryan said. AFBF also wants to go beyond the policy issues advanced by the NMPF in its proposal.

Ending misleading labels

Wisconsin Sen. Tammy Baldwin and Idaho Sen. Jim Risch are leading the charge against plant-based products using dairy labels. The two senators wrote a letter to the Food and Drug Administration, saying, “It’s imperative that the FDA enforce existing standards of identity for dairy in both current and future guidance.”

National Council of Farmer Cooperatives President and CEO Chuck Conner is urging lawmakers to take action on ag labor. “Labor has quickly taken over as the No. 1 challenge facing cooperatives and farmers,” Conner said. Two years ago, the House passed legislation expanding the amount of time immigrant workers with H-2A visas could

work in the U.S. However, the Senate version did not pass. “It failed because of the controversy over border issues and the whole immigration space that isn’t particularly targeted at farm labor,” Conner said. Action is needed because Conner believes U.S. dairy farms can’t operate strictly on family labor.

Torres Small faces conrmation hearing

The Senate Agriculture Committee hosted a conrmation hearing for USDA’s deputy agriculture secretary nominee Xochital Torres Small

“My own roots are both rural and urban, and we’re all connected by land, resources and food,” Torres Small said. Torres Small, who is the USDA rural development undersecretary, identied several challenges in the department. “Outdated technology, antiquated loan and grant applications, and the ongoing need to do more with less are all challenges I foresee,” Torres Small said. If conrmed by the Senate, Torres Small would succeed Jewel Bronaugh

Senate Dems take aim at China

Senate Democrats are proposing legislation to reduce China’s inuence worldwide. This proposal would limit the ow of advanced technology and investment to China

year

the

and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Visit your local Wisconsin KUHN livestock dealer today! INVEST IN QUALITY ® www.kuhn.com Farmers' Implement Allenton D & D Farm Supply Arcadia Chili Implement Chili Cherokee Garage Colby Beaver Machine Coleman Kalscheur Implement Cross Plains Komro Sales & Service Durand Hillsboro Equipment Hillsboro W. H. Lien Hixton Eron Equipment Junction City Luxemburg Motor Co. Luxemburg Lulich Implement Mason Persha Equipment Mayville Lindstrom Equipment Mondovi East Side Farm Equipment Monroe Midwest Machinery Osceola New Richmond Turtle Lake Steinhart's Farm Service Platteville Gruett's, Inc. Potter Priebe Sales & Service Ripon Tesch Bros. Implement Seymour Riesterer & Schnell, Inc. Shawano Eis Implement Two Rivers Gibbsville Implement Waldo Carl F. Statz & Sons Waunakee Spiegelberg Implement Weyauwega Triebold Implement Whitewater A.C. McCartney Durand, IL Peabudy's North Pecatonica, IL THE MOST COMPLETE MIXER LINE IN THE INDUSTRY VS: Vertical Single-Auger VXL: Triple-Auger Mixer Botec: 4-Auger Mixer RA: Reel Mixer KUHN is committed to creating innovative mixers that prov ides a quality ration and years of low-maintenance service. A MIXER FOR EVERY OPERATION 147 – 1960 cu. ft. mixing capacities VT: Vertical Twin-Auger

• Reduces temperatures quickly and uniformly with minimal energy use

• Easy to retro t your current ventilation system

• Made from corrosion resistant materials for long life

• Single phase and 3 phase systems available

Con nued from AG INSIDER | Page 2 while boosting similar efforts in the U.S. Senate Majority Leader Chuck Schumer said, “The Xi regime is working every day to catch up and surpass the United States.”

Farm real estate debt is record high

According to the USDA Economic Research Service, farm sector debt tied to real estate is expected to hit a record high of $375.9 billion in 2023. Farm real estate debt has been increasing since 2009. The average value of farm real estate reached a record $3,800 per acre in 2022, up 12.4% from the previous year.

According to USDA, the average net cash income of U.S. farm businesses is expected to decline by 18% in 2023, compared to 2022. Farm businesses across the country are forecast to see higher production expenses and lower cash receipts.

According to the latest USDA supply and demand report, 2023 milk production was estimated to be at 228.6 billion pounds. That’s down 100 million pounds from the most recent forecast. The 2023 all-milk price declined 15 cents to $20.50 per hundredweight.

As temperatures begin to rise, dairy cows become at risk for heat stress. Purina Animal Nutrition technical support dairy nutritionist Stuart Rymph said heat stress can begin when temperatures hit 72 degrees. Humidity and sun exposure will only increase the problem. “From the nutrition side, reduced feed intake is the thing that we worry about as much or more than anything else,” Rymph said. “We can get to the point where we have lethargic cows that really don’t want to do a whole lot and that would be the most extreme case.” There should be plenty of water available for the cow herd. In the area of nutrition, Rymph encouraged dairy farmers to feed more highly digestible feeds. “That doesn’t mean feeding less forage,” Rymph said. “In my book, it means feeding better forage.”

The keynote speaker at the Animal Agriculture Alliance Stakeholders Summit is the author of the book, “Farmers Versus Foodies.” “There seems to be two prevailing sides of the food system,” Ray Starling said. “The aggies and the consumers, there’s this growing chorus of folks that says the food system is broken and has major problems.” Starling said the agriculture industry needs to be watchful of negative inuences on agriculture practices and policy. “I think the food system is doing great, but I’m concerned outside forces will try to ‘x’ the food system,” Starling said. Starling was the chief of staff for former Agriculture Secretary Sonny Perdue and now serves as the general counsel of the North Carolina Chamber of Commerce and president of the North Carolina Chamber Legal Institute.

DATCP appointments announced

Wisconsin Gov. Tony Evers has appointed four people to the Wisconsin Department of Agriculture, Trade and Consumer Protection Board. Miranda Leis of Cashton and Paul Bauer of Ellsworth were reappointed. Leis is the senior director of dairy handling and supply for Organic Valley/CROPP Cooperative, and Bauer is the chief executive ofcer of Ellsworth Cooperative Creamery. The new appointees are Tina Hinchley of Hinchley’s Dairy Farm at Cambridge and Chippewa Valley Bean President Cindy Brown of Menomonie.

Trivia challenge

Pending conrmation, Xochital Torres Small is the incoming deputy secretary of agriculture. That answers our last trivia question. For this week’s trivia, when did June ofcially become dairy month? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Finalists had the opportunity to milk a goat in the parlor, interact with kids and see where the goats are housed while asking Seth questions about the operation. Other stops on the two-day tour included Pinn-Oak Ridge Farms, DeBuck’s Sod Farm of Wisconsin and Staller Estate Winery – all located in Delavan; Sunshine Genetics in Whitewater, Complete Feed Service in Sharon and Hill Valley Cheese in Lake Geneva.

Although six ladies had their hearts set on the crown, it was Ashley Hagenow who was selected as the next Alice in Dairyland at the Grand Geneva Resort in Lake Geneva. Alice in Dairyland is a one-year, fulltime communications professional for the Wisconsin Department of Agriculture, Trade and Consumer Protection, who educates the public about the importance of agriculture in Wisconsin. Hagenow will begin her term July 5.

“I am excited and humbled to be able to serve in this role for the next year as the 76th Alice in Dairyland,” Hagenow said. “There is a lot of tradition with this program, and it brings people together, which I think is so cool. I am eager to continue that tradition while putting my own spin on the position as well.”

Hagenow is the daughter of Bob and Lisa Hagenow of Poynette. Although she did not grow up on a farm, Hagenow’s connection to the dairy in-

dustry started early in life. Her father grew up on a dairy farm in northeast Wisconsin where his family milked 60 cows in a tiestall barn. He would later become a nutritionist and sales manager for Vita Plus while ensuring Hagenow and her sister, Sarah, remained close to the dairy industry.

“My dad has such passion for the industry and made sure our family understood the hard work and long hours that go into making high-quality dairy products,” Hagenow said. “My sister and I received a well-rounded experience in dairy and agriculture that has set us up for success.”

As a youth, Hagenow was active in 4-H and FFA. She leased dairy heifers to show, starting with Holsteins and later adding Milking Shorthorns to her string that were provided by a family friend. Her sister has started a small herd after purchasing some of the animals she has shown.

“Showing cattle was always a fun family affair,” Hagenow said. From attending June dairy breakfasts to the Cows on the Concourse event, outreach advocacy promotion on behalf of dairy farmers has always been important to Hagenow.

“I have a huge appreciation for what dairy farmers do and the great products they produce,” she said. “There is a lot of tradition, pride and heritage that goes into dairy farming, Turn to ALICE | Page 7

Con nued from ALICE | Page 6

and that’s an exciting and important message to share with consumers who enjoy dairy products.”

Hagenow recently graduated from the University of Minnesota with a bachelor’s degree in agricultural communication and marketing and minors in animal science and agricultural and food business management. During college, Hagenow was involved in Agriculture Future of America, the National Agri-Marketing Association, the Gopher Dairy Club and the University of Minnesota dairy challenge and dairy judging teams.

Four of this year’s nalists hailed from dairy farms. Lamb grew up on her family’s farm near Waunakee, where she continues to feed calves each night in addition to working as an analytical development scientist at MilliporeSigma, a pharmaceutical company.

Luebke grew up on her parents’ and grandparents’ 150-cow dairy farm, Kissinger’s Family Farms, near Kiel and is employed at Sargento Foods Inc. as a microbiology specialist.

Seebecker grew up on a familyowned dairy farm near Mauston and works as a farm broadcaster at the Mid-West Farm Report.

Weyland grew up on her family’s dairy farm near Neenah and is an associate consultant at Tilth Agronomy Group LLC. When Weyland is not scouting elds, she spends time working on her sister’s dairy farm.

As the end of Schaefer’s reign as Alice in Dairyland draws near, she said it is bittersweet to see it come to a close but is excited for the opportunities that await the next Alice.

“This job is a great opportunity to

meet many people, and the more times you say yes, the more that you’re able to do and the more that you’re able to learn,” Schaefer said. “I love everything I’ve done during my term –from visiting schools to visiting farms and talking to people from all walks of life.”

Schaefer said she has many favorite memories from the past year, but her favorite events were Green Coun-

Alfalfa Dealer. Brunner Seed, Corn & Soybeans, PWI Seed Corn

ty Cheese Days in Monroe and Warrens Cranberry Festival in Warrens.

“I ate so much cheese at Cheese Days,” Schaefer said. “It was a lot of fun.”

Like Schaefer, Hagenow is also looking forward to the many opportunities that lie ahead when she assumes the role of Alice in Dairyland.

“I am so excited to travel the

state in the upcoming year and meet the many people related to different types of agriculture and connect with folks who don’t have direct ties with the industry,” Hagenow said. “I look forward to building connections and cultivating relationships with consumers, farmers, processors and agribusinesses that drive our ag industry forward.”

•

•

were moved from the pen quickly and safely. Twentyve minutes after the initial phone call, the roof collapsed.

“By the time the construction crew removed the damaged parts of the roof, about half of the roof over the freestall barn where the milking cows are housed was gone,” Maier said.

Earlier that morning, just up the road, the Pentermans were hoping they would wake up and realize they had just suffered a bad dream, Amy Penterman said. Three sections of the roof on their freestall barn had collapsed and two additional damaged sections needed to be removed.

“I’m not sure how much snow we had; it was so hard to measure with all the blowing and drifting,” Penterman said. “There were spots on top of some of the roof with 7-foot drifts. I have never seen drifts the way this storm drifted, all over the farm, and it just kept snowing. … You kept thinking you’d get a break and it just kept going.”

However, this time around, Penterman said things could have been worse than they ended up being.

“We almost lost the holding area too,” Penterman said. “I don’t know how the guys from RZ Builders in

Loyal got here through the storm, but they did right as the freestall roof was collapsing. They took one look at the holding area and got up there with my husband to try and get that snow off as quickly as possible.”

In the hours following the collapses, the Pentermans relocated 180 cows to another farm that was able to accommodate them. The

Sander and Amy

once in February 2019 and most recently in April.

Maiers were able to keep their cows at home by relocating some cows to another barn on their farm and overcrowding another pen. Neither situation has been ideal, and the pressures – both nancial and emotional – have been wearing on the winterweary dairy farmers.

Both families thought they had done everything right in terms of building their barns to withstand everything an angry Mother Nature could throw their way. The Maiers’ barn was constructed largely of steel with limited numbers of wooden crossbeams, while the Pentermans double-reinforced everything throughout their entire barn when the damage was xed from the rst roof collapse.

“It is so frustrating; you think you do everything right to correct the problem the rst time,” Penterman said. “I guess steel is our next option, but then I look at how Brandon and Meredith’s barn was built, with steel, and watch as they are going through the same thing. It is just disheartening to not know what more you can do to prevent this sort of thing from happening.” Maier agreed.

“I guess all we can do is have the steel rafters remade,” Maier said.

The Pentermans are becoming concerned about the timeline with repairing their roof.

“Our builder is so short-staffed and backlogged right now,” Penterman said. “They aren’t sure when they might be able to get to our job, so we are looking at other companies to work with. I am starting to worry we might not be able to get it taken care of before winter comes again.”

The Maiers are faring better with their reconstruction efforts and said the process is nearly halfway complete.

“We are hoping to be able to move the cows back in by the end of May,” Maier said. “They are really showing the signs of stress from everything they have been through and the less-than-ideal conditions they have been dealing with for the last few weeks.”

Maier said besides a decrease in milk production, they are seeing more foot-health issues and some pregnancy loss in their cows as well as having a harder time detecting heats among the herd.

“The insurance company has been good with dealing with the replacement of the barn roof, but there is nothing to compensate for lost production or the other issues the cows are suffering,” Maier said. “We know we will feel those effects for a long time.”

Those effects weigh heavily on the minds of both farm families as the dairy industry enters another time of turbulent milk prices, increasing input costs and supply chain issues.

“This has been so hard, so draining,” Maier said. “I hate that the Pentermans are dealing with this for a second time, but I am so grateful to have friends like them who understand the frustration, the nancial issues and know how emotionally draining this is.”

1/2” thick x 16” wide

12’ long $35 • 16’ long $47

White Corrugated PVC liner panels

40” wide x 16’4” long $1950

White smooth PVC sheeting

4’ x 8’ x 1/2” thick $5750

ATTENTION FARMERS...

Are rocks, re-rod or holes showing in your bunker silo?

WE CAN RESTORE YOUR BUNKER TO LIKE NEW CONDITION!

BUNKER SILO RESTORATION/ REPAIR WITH JETCRETE

Approximately 1” of steel reinforced material added to bunker walls.

• High pressure water blasting of walls for excellent bonding.

• 6 gage heavy duty wire mesh installed

• Jetcrete -phnuematically applied concrete. GUARENTEED

SILO RELINING WITH “JETCRETE”

BARN WALL & BASEMENT RESTORATION WITH “JETCRETE” (Limestone, rock, block & concrete wall)

SERVING IA, MN, WI, IL AND SD

CONTACT: 800-866-7327

PTO

WASECA, Minn. – An energy of happiness and excitement mixes in the air with woodsmoke, pizza, garlic and folk Americana music on a Sunday afternoon at Pleasant Grove Pizza Farm.

Out in the grassy yard, guests relax with a beer or wine they brought with themselves, or a favorite snack, as they wait in anticipation of a woodred pizza made on-site.

A customer bites into the featured pizza of the week, Peary Spring. Instantly, taste buds are met with the sweet avors of pear blending with the richness of caramelized onions, a tart note of Gorgonzola cheese, smokey bacon and the fresh spring avor of dill.

On the perimeter, children play games, making instant new friends with kids who were strangers just hours ago, and a football ies through the air among friends.

Established in 2015, Pleasant Grove Pizza Farm is owned by husband and wife Bill Bartz and Emily Knudsen. Their business is open May through October on-site, and their winter menu pizzas are available for takeout and delivery at Half Pint Brewing Company during the offseason.

Approaching the site in rural Waseca County, the entry road to Pleasant Grove Pizza Farm looks like just another gravel driveway, but what happens at the end of that driveway is special. There, families and friends connect, and somehow the busier it gets, the better the energy.

• 5 sizes from 45 to 100 cu. ft.

• Stainless steel mixing chamber

• Stainless steel auger ight

• 14” carbide tipped hay knives

“You don’t spend an hour here; you spend an afternoon here,” Knudsen said.

She said agritourism is important to her because it is a new way to use their land.

“My goal is to teach kids and adults alike that there’s just more to do on a property than traditional farming,” she said.

Their pizza farm focuses on high-quality ingredients, locally sourced when possible. Some ingredients come from their own gardens where they raise herbs, vegetables and owers. They

also do collaborations with local farms to highlight an ingredient from an area farm on the pizza special of the week.

“When I create a pizza, I kind of pick one main ingredient and then build the avor proles from that,” Knudsen said.

She crafted the menu herself with tasting input from employees, family and friends. Her creations focus on synergistic blendings of ingredients.

“I love to build pizzas off of avor combinations because it leaves everybody excited for the next bite,” Knudsen said. “Food just tastes better when it’s paired … with other foods that intensify the avors.”

A pizza special must be totally perfected before it is served. An hour before they open, staff will share the special of the week together. If everyone cannot agree that it is ready, it will not be served.

“If one of us is like, ‘Oh no, there’s something off,’ we are changing that,” Knudsen said. “We are coming up (with changes) within minutes.”

The farm has also been known to collaborate with chefs from the Twin Cities to create the special of the week.

Customers bring their own chairs, plates, utensils, drinks and any other food they want to go with the pizza. Many also bring games. Guests are asked to pick up after themselves and leave their dogs at home.

While event-goers are most often focused on food for themselves, some bring snacks for the kids to feed to the two pet goats on the farm. The llama and alpaca who also live there forego snacks as they like to keep to themselves.

During the busiest part of the summer, the farm will make 200 pizzas in a night and use 500 pounds of cheese in a week.

Having a pizza farm has been a dream for Knudsen ever since she visited her rst one at 21 years old.

“It was just a concept that blew my mind,” Knudsen said. “I just remember thinking in my head, ‘I would love to own one of these one day.’ So, every time I went to that pizza farm, I couldn’t shake it.”

Fast forward eight years, and Knudsen began dating her now husband who owned a 50acre property with a horse stable on it. When she suggested they start a pizza farm, he was initially

Free brochure! 1-800-436-5623

unimpressed by the idea, but after a date to a pizza farm together in eastern Wisconsin, Bartz was interested too.

“Part of me got a little worried because I was like, ‘Oh my gosh, I just gave my dream to some guy I’m dating,’” Knudsen said.

Two years later in August 2015, their pizza farm opened.

“Everything just naturally owed,” Knudsen said. “We were very excited and very inspired to do this, and it just really felt right for both of us.”

Their business has grown over the years. In 2020, Knudsen quit her job and started working at their pizza farm full time. Knudsen said that year they saw a lot of growth,

as people were gravitating toward outdoor experiences.

Also in 2020, they were featured in the New York Times food section in June and were part of an episode of a show on the Magnolia Network in the fall. Knudsen said they had a couple y from Florida to visit their farm after seeing the episode.

Knudsen enjoys her guests, whether they have own from Florida; driven from the Twin Cities suburbs, Mankato, Rochester or Owatonna; or stopped during a camping trip.

“I love being able to come out and talk to our customers,” Knudsen said. “I love watching families and friends hanging out … and I love watching kids play.”

We are grateful to dairy farmer Directors who share their time, their ideas, and their common sense to help keep DHIA services relevant. From time to time we will use this space to recognize these leaders and to say thank you. This time we will feature Peter Seitzer. Peter has been a DHIA director for 13 years.

What are some of your duties as director?

Peter Seitzer

Saint Peter, MN DHIA Director for 13 years

Saint Peter, MN DHIA Director for 13 years

My duties include attending state and national meetings, along with helping nd new tests from the milk sample to improve the ef ciency of the dairy farmer. I also want to keep DHIA moving forward for long into the future.

What do you like about this role? I like being involved in helping to keep the dairy industry strong, and I like to help give dairy farmers new tools to help them in managing their farms, so they can be as productive as possible.

Why is DHIA important to you? DHIA is important to me because it helps me make good production and management decisions for my own herd.

Tell us about your farm. I am the fourth generation on the farm, which is located in Saint Peter, MN. We milk 65 registered Holsteins. We also farm 630 acres of corn, soybeans and alfalfa.

“I like to help give dairy farmers new tools to help them in managing their farms.”

NEWTON, Wis. – When faced with updating their 25-year-old milking parlor or going in a new direction, the Brunmeier family chose the latter. They left the parlor behind in favor of a fully automated system.

“Rather than sticking money into our parlor and holding area, we decided to invest in robots,” Jeff Brunmeier said. “We were also crunched for time between milkings and were dealing with employee turnover. One shift was a constant rotating door.”

The farm’s future would ourish in robots, which were retrot into the existing freestall barn in 2021.

Following in the path of their parents, Jim and Karlene, three Brunmeier siblings operate Brunmeier Dairy Farm.

Brunmeier farms with his brother, Mike, and his sister,

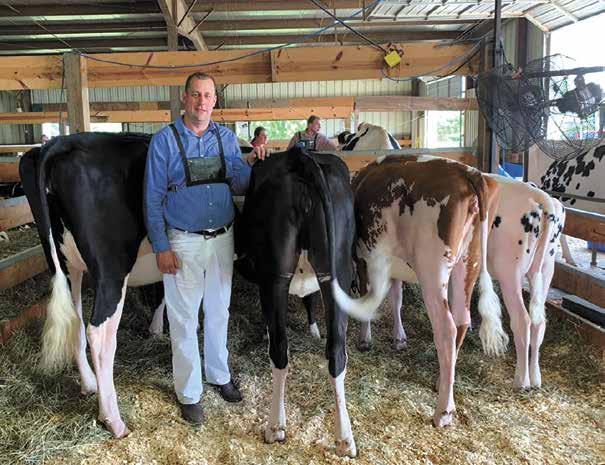

The Brunmeier family – Mike (from le�), Kim Pahl, Jeff and Lindsey – take a break in their freestall barn April 27 on their farm near Newton, Wisconsin. The barn was retrot with eight Lely A5 robo�c milking systems in 2021 in which the Brunmeiers milk 430 cows.

Kim Pahl, as well as his daughter, Lindsey, who represents the fourth generation. The Brunmeiers milk 430 cows with eight Lely A5 robotic milking systems and farm about 900 acres near Newton.

Kim is in charge of calves and bookwork, Mike manages feeding and crops, while Brunmeier oversees the barns. Lind-

sey is one of the herdspersons and serves as backup for calves while also managing data from the robots.

The Brunmeiers did two startups of robots about six weeks apart – ring up the rst four at the end of October 2021 and the second four the last week of November 2021.

“Since it was a retrot, we

were able to train cows before we started milking with robots,” Brunmeier said. “Cows started getting pellets manually by top-dressing them on the TMR 10 days prior to startup to get them to recognize the pellets and want them.”

A few days before startup, the Brunmeiers pushed every cow into the robot where pel-

lets were then delivered in the feed bowl, enticing cows to go through on their own. The arm would also start moving to get cows familiar with the process.

“After the rst time through, about one-third of the rst-lactation cows revisited on their own,” Brunmeier said.

After the second startup, the Brunmeiers shut down their double-8 parallel parlor and have not milked in it since.

“We pulled out the old bulk tank, and everyone goes through the robots, including fresh cows and hospital cows,” Brunmeier said.

Robots t well into the Brunmeiers’ setup, eliminating the need to build new facilities. Their freestall barn was built in 2010 and added onto in 2017. Robots were already on the family’s radar during the 2017 expansion. In anticipation of installing a robotic milking system one day, provisions were put in place under the concrete to create the infrastructure that would ensure the barn was robot-ready when the time came.

“Our vision changed a little, but we were still able to utilize some of those features,”

This pen of 180 cows features three robo c milking systems arranged in a L shape, with the same arrangement mirrored in the pen across the feed alley, at Brunmeier Dairy Farm near Newton, Wisconsin. Cows average 95-96 pounds per day on 2.8 to 2.9 milkings.

Brunmeier said. “At rst, we thought we could get by with six robots, but then cow numbers went up. We also envisioned putting them on the outside wall of the barn.”

Instead, robots are positioned in a L shape within the barn’s two largest pens, creating a central milking area. Each pen houses up to 180 cows that are milked by three robots. Cows are grouped by lactation, and one pen is designated for rst-lactation and smaller second-lactation cows while the second pen is for mature cows in their second through fourth lactations. Fetch areas in each pen contain 17 stalls and are also used to sort cows for breeding and hoof trimming.

A pen for cows in their fourth lactation and higher contains one robot, while a special needs robot serves a hospital pen of 40 cows. The Brunmeiers said the hospital robot is a feature unique from what they saw when touring other farms. Heifers are also trained on this robot. Cows move directly from the fresh pen to the hospital pen through a breezeway that connects the main barn to the dry cow/heifer barn for easy transfer of cattle.

“Our hospital group is purposely undercrowded for extra attention,” Pahl said. “We only collect rst colostrum from fresh cows, and after that, they are allowed to go through the robot at free will.”

Cows were milked three times a day in the parlor and now average 2.8 to 2.9 milkings daily in the robot. The milking herd grew up with automation, drinking from automatic feeders as calves, and therefore trained faster on the robots.

“They know when they go through the robot, they will get something in return,” Brunmeier said. “They retained that memory, and heifers train really quick. The fact it was a retrot also helps.”

During the retrot, there were ve construction projects going on in the barn at once, which Pahl said was a stressor for the cows. The barn lost 59 stalls when adding robots to four pens which prompted a 120-foot addition to the barn as well in 2021.

It took a few months for milk production levels to match those from the parlor, but by six months in, cows were averaging 95-96 pounds per day. Components also crept up and are now around 4.3% for butterfat and 3.3% for protein.

Waste milk is collected from the robots and pumped 608 feet to the calf barn where it is pasteurized and fed to calves.

“That’s been a big plus,” Pahl said. “There’s a cost benet to it as we were

feeding milk replacer before, but we also see benets in calf frame, hair coat and overall health. We’re growing a bigger, stronger calf on whole milk.”

The calf barn was built in 2004 and retrot with an automatic feeding system in 2014. The system contains one feeder and two drinking stations – one in each pen. Calves drink an average of 8.5 liters per day per calf but are allowed up to 14 liters. Average daily gain is 2.25 pounds.

A reduction in labor was a key benet the Brunmeiers realized when switching to robots as they were able to eliminate ve people from the payroll. The family now employs six full-time people as well as three part-time helpers. The robots eliminated issues with labor, and Pahl said employees seem happier.

“There is more variety in their work, and they’ve adapted fairly well to the robotic technology,” she said.

In the past, someone was in the barn for 18 or 19 hours every day. Now, from 7 p.m. to 5 a.m., the barn is on its own, and the family gets the work done with less people. The Brunmeiers appreciate the time saved by milking with robots compared to milking in the parlor. They also like the ease at which cows can be automatically sorted and routed for breeding, moving or treatment.

“We have a lot less lockup time now, and that’s important,” Pahl said. “We want to spend the least amount of time disturbing the cows. The more you stay out of the pens, the better they do.”

The amount of data produced by the robots astounded the Brunmeiers, who altered their management style as a result.

“We have tons of data we didn’t have before when testing milk only once a month,” Pahl said. “We have more information and better information for managing, and we’re catching things a lot quicker, such as mastitis. The robot senses a change in milk and calls it out before there’s anything to see.”

Brunmeier said the data is also helping the family make better breeding and culling decisions. The Brunmeiers breed 80% of the milking herd to beef while the top 20% and all heifers are bred to sexed semen. That philosophy is starting to change as they utilize more data and take advantage of genomic testing which they started in November 2022.

Grateful for the benets robots provide, the Brunmeier family is happy they chose the path of automation.

“We put our money in the right place when we went with robots,” Brunmeier said.

High school graduates: How has farm life prepared you for what’s next?

Brianna

Brianna

Tell us about your greatest high school accomplishment. My greatest high school accomplishment is graduating as valedictorian of my class. I have worked hard over the past four years to prioritize my academics, and I am very proud to be graduating No. 1 in my class.

What do you plan to do after high school? After high school, I will be attending the University of Wisconsin-Madison to study dairy science with aspirations of attending vet school and pursuing a career in largeanimal medicine.

What are some benets of being raised on a farm? Being raised on a farm has been the greatest blessing of my life, as the everlasting importance of responsibility, strength and a strong work ethic were fostered early in my childhood. This helped me take on a multitude of activities and projects and get involved in many organizations as I was taught how to work hard and work efciently to accomplish what needed to be done.

How has farm life prepared you for what’s next? Farm life helped prepare me for what’s next as it helped me to nd my place in the world. I was able to nd my passion for dairy and agriculture from a young age, and I knew serving my agriculture community in the role of a large-animal veterinarian was right for me. Farm life also helped me to build connections and relationships in my life that have been instrumental in my journey thus far and will continue to help me as I continue into college. Further, being involved with my family’s farm and other outlets and organizations within the agriculture industry has shaped me into the person I am today, helping me to grow my condence in myself and dene my personality.

Where do you see yourself in ve years? In ve years, I hope to be completing my rst year in vet school and continuing my path to becoming a large-animal veterinarian.

Tell us about your farm. My family’s farm is Jenlar Holsteins and Brown Swiss, located in Chilton, Wisconsin. We milk about 100 Holsteins and 25 Brown Swiss with two robotic milking systems, and our milk is shipped to Baker Cheese. My parents, Larry and Jennifer Meyer, own the farm, and my grandparents, Andy and Joan Meyer, as well as my siblings and I all help manage and operate the farm. We raise all our own heifers, and we farm 450 acres. We also enjoy traveling throughout the state with our show string.

Allison Ahrensmeyer Parents: Larry and Laurie Ahrensmeyer Baraboo, Wisconsin Baraboo High SchoolTell us your greatest high school accomplishment. My greatest high school accomplishment was making the high honor roll every semester while taking challenging classes and earning lots of scholarships. My GPA is 3.8 on a 4.0 scale. I have earned scholarships from Foremost Farms, Compeer Financial, Baraboo FFA, HCE, Farm Bureau, United Cooperative and more. As a senior, I received the Wisconsin State FFA Degree.

What do you plan to do after high school? After high school, I plan to go to the University of WisconsinPlatteville for dairy science. I plan to work on their dairy farm. My nal plan is to be a manager on a big dairy farm.

What are some benets of being raised on a farm? Some benets of being raised on a farm are you know how to work, you’re not afraid to get dirty, and it teaches responsibility while enjoying what you do. I know and can explain how food gets to the store because I am making that happen. Another benet is you are outside getting fresh air and exercise daily.

How has farm life prepared you for what’s next? By working on the farm, I know I am interested in pursuing a dairy science career. I have known this for quite some time. Most seniors don't really know what they want to do after high school, so they begin college undecided.

Where do you see yourself in ve years? In ve years, I plan to be graduated from UW-Platteville. I hope to have found a guy who wants to farm with me. I would like to come back to my home farm and continue our operation or work at a big farm somewhere in the state of Wisconsin since Wisconsin is the dairy state.

Tell us about your farm. My family farm is located just outside of Baraboo, Wisconsin. We milk 170 Holstein cows twice a day in a double-8 parallel parlor. My father and I milk the cows. My father, grandma and uncle are full-time workers while I do the milking at night through the Youth Apprenticeship Program. My mother helps after work and on the weekends wherever she is needed. We ship our milk to Foremost Farms. I am the fourth generation of our farm. Besides milking the cows, I also assist the veterinarian, hoof trimmers and A.I. technician. In 2020, our farm was presented the Century Farm Ownership Award. I enjoy being on the farm and am glad I was raised this way.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years.

Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed,

Brooklyn Schwoerer

Parents: Rick Schwoerer and Mina Gumieny Edgar, Wisconsin Edgar High School

Tell us your greatest high school accomplishment. One of my greatest high school achievements was being selected to go on an international dairy judging tour trip through FFA, which will be this June.

What do you plan to do after high school? After high School, I plan to attend the University of Wisconsin-Madison to pursue a degree in dairy science.

What are some benets of being raised on a farm? From a young age, I always enjoyed being around animals, especially my dairy cows. This has truly shaped me into the person I am today. Working on a farm has taught me the value of hard work and determination. It has given me the opportunity to meet and get to know locals who are involved in the dairy industry, allowing me to expand my knowledge and prepare me for the future.

How has farm life prepared you for what’s next? Farm life has prepared me for what’s next by giving me a passion for working with dairy cattle. This has further allowed me to expand my knowledge of what the dairy industry has to offer, which will help me work toward a career in the same eld.

Where do you see yourself in ve years? In the next ve years, I see myself graduating from college. From there, I hope to have a job working with dairy cattle genetics and improving the outcome for future generations of dairy cattle. I am not sure if this will entail working for a larger farm in a herd manager position or running my own dairy farm, but either way, I want to work with dairy cattle.

Tell us about your farm. In 1995, my parents established Red Rock Dairy Farm. Today, the farm is run by my mom and dad along with my two brothers and me. We milk 62 cows in our tiestall barn. Our milk is shipped to Nasonville Dairy, where it is made into cheese products. Our herd consists of registered Ayrshires, a few Brown Swiss, purebred Holsteins and Dutch Belted. We raise our youngstock and do most of our eldwork. We own 250 acres and farm roughly 170.

in balancing diets, or work with your private nutritionist or dairy consultant.

Carol Traynor

Parent: Brenda Traynor

Milton, Wisconsin

Milton High School

Tell us about your greatest high school accomplishment. My greatest accomplishment throughout my high school career, besides being a part of the Milton FFA Chapter, is probably being awarded the Rock County Dairy Promotions Scholarship at our high school’s scholarship night.

What do you plan to do after high school?

After I graduate high school, I plan to attend the University of Wisconsin-Platteville to major in agricultural business with an emphasis in communications and marketing. After college, I plan to use my degree to become an advocate for agriculture also known as an agvocate. Besides becoming an agvocate, I plan to return to my family’s dairy farm and continue working alongside my family in production agriculture.

Bo Afdahl

Parents: Brad and Kristin Afdahl

Arkansaw, Wisconsin

Durand-Arkansaw High School

Tell us your greatest high school accomplishment. I am proud of how far I have come in band throughout the years. I play the baritone saxophone.

What do you plan to do after high school? I plan to continue dairy farming on my family's farm.

What are some benets of being raised on a farm? It builds a strong work ethic from a young age.

How has farm life prepared you for what’s next? Farming is a very diverse industry, so you have to be prepared for anything. You might have a rough idea of what is going on in the morning, but there are always some curveballs.

Where do you see yourself in ve years? I hope to still be farming with my parents and having a larger role in the operation of the farm.

Tell us about your farm. We milk around 40 Holsteins and own about 170 acres. We ship our milk to Ellsworth Cooperative Creamery.

What are some benets of being raised on a farm? Some of my favorite benets of being raised on the farm include being taught the value of hard work and learning how to adapt to situations that are constantly changing.

How has farm life prepared you for what’s next? Farm life has prepared me for my future by teaching me the value of hard work, which has shown me I can achieve anything I put my mind to.

Where do you see yourself in ve years? In ve years, I see myself working for an agricultural company where I can be an agricultural communicator/marketer promoting production agriculture. In addition to promoting production agriculture, I also plan to work on my family farm with the dairy cattle.

Tell us about your farm. On my family farm, we are milking around 50 cows and shipping all of our milk to Foremost Farms. There are three generations working on the farm – stemming from my grandfather down to my mother and uncles, all the way down to my brothers, cousins and me. Since our farm is seven generations old, we have gone through many setup changes, but currently, we milk in a tiestall parlor and rotate in ve groups of cows.

Mason Sobeck

Parents: Tim and Michele Sobeck

Lena, Wisconsin Lena High School

Tell us your greatest high school accomplishment. Receiving Marinette & Oconto All-Conference academic honors.

What do you plan to do after high school? I plan to attend St. Norbert College in the fall to study business.

What are some benets of being raised on a farm? The biggest benet of being raised on a farm is denitely the work ethic you develop from a young age. I was so fortunate to grow up around such great, hardworking men. My dad and grandpa taught me about working hard in order for your dreams to come true.

How has farm life prepared you for what’s next? Farm life has prepared me for the next chapter in my life by giving me a really good foundation of skills that I will use in my next endeavors of life.

Where do you see yourself in ve years? In ve years, I see myself as a college graduate chasing my dreams as an entrepreneur and hopefully working on products I want to develop in the future.

Tell us about your farm. Our family farm was established in 1899 by my great-grandpa. It was then passed down to my grandpa and then my father. The future is looking bright as my brother has already returned to the farm after college. We milk around 400 cows and ship to BelGioioso Cheese. Being able to work with family all through school has truly been amazing. It is so special to work with the people you love. I especially am grateful for being able to work with my grandma and grandpa in our calf barn every day. Working with them is something I will forever cherish and wouldn't have traded for anything. We take pride in making our operation a family affair and not hiring out so much help. Almost everything on our farm is done by someone in the family, and that's awesome because it shows the hard-working spirit of our family.

Describe your farm and facilities. We are a family farm founded in 1857. I farm with my brother, Bill, and my father, Allen. We milk 4,300 cows. The cows are housed in tunnel-ventilated freestall barns and milked three times a day on an 80-stall GEA carousel parlor. Our heifers are raised in western Nebraska at Oshkosh Heifer Development.

What forages do you harvest? We harvest mostly HarvXtra alfalfa and mostly brown midrib corn silage as well as some oatlage from new seeding for dry cows.

How many acres of crops do you raise? We raise 1,800 acres of corn silage and buy another 1,700 acres from local growers. We also raise about 1,200 acres of alfalfa and buy another 300 acres from local growers.

What quality and quantity do you harvest of each crop? We typically harvest about 6,000 ton/dry matter of haylage that tests between 165180 RFQ. We harvest about 75,000 tons of BMR corn silage that test about 33%-37% starch.

Describe the rations for your livestock. We feed milk cows and dry cows at our dairy, and we try to feed rations that are relatively high in high-quality forages, containing 60% to 65% forages. The ration is mostly comprised of corn silage, alfalfa haylage, wheat straw, ne ground corn, soybean meal, corn gluten feed and cottonseed. Dry cows are fed oatlage, corn silage and wheat straw.

Describe your harvesting techniques for alfalfa and corn silage. We have our own equipment but also have a local custom harvester help us with harvesting both haylage and corn silage. We run a New Holland chopper while he runs a John Deere. Haylage is cut on approximately 28-day intervals with triple mowers with ail conditioners. Once it is dry enough (40% dry matter), it is merged and chopped into trucks. Corn silage is chopped at about 35% dry matter and processed. High-quality inoculants are a must.

“We use Udder Comfort™ on fresh cows, works tremendously on fresh 2-yr-olds. It softens udders quickly, reducing pressure and increasing comfort for better performance. We have used Udder Comfort for 10 years, blue spray in the parlor, white lotion at shows. There’s a real benefit from the start of bagging to milking out after,” says Jeff King, Kings-Ransom Farm, Schuylerville, New York, milking 1000 reg. Holsteins producing over 30,000M at 90,000 SCC.

Award-winning King Brothers Dairy products start with quality udders making quality milk. They credit good staff, milking routines, genetics, sand bedding, cow comfort, including Udder Comfort for fresh 2-yr-olds. With over 120 EX in this large freestall herd, they produce A.I. sires like Dynasty, Cadillac and Dropbox from homebred cow families like Cleavage, Cleo, Dextra.

“It’s easy to love the great ones but when you have cows walk in the freestall barn with good feet and legs and udders full of milk, cows the kids enjoy showing and do well with and learn from, that’s what it’s about,” adds Jan King.

Con nued from FORAGE | Page 18

What techniques do you use to store, manage and feed your forages? Our corn silage is stored on one large drive-over pile using a Lactobacillus buchneri inoculant. We emphasize packing density and covering quickly. Haylage is stored in large bunker silos with an inoculant. The walls are wrapped, and it is covered immediately after lling. The plastic is cut daily, and the forage is faced with a silage rake.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We have changed from conventional silage to BMR corn silage. Haylage has all been transitioned to HarvXtra. This has allowed us more exibility in our harvest window while increasing RFQ. We used to plant and feed some winter rye, but we were not able to consistently make highquality dairy forage from it.

Corn silage is stored on one large drive-over pile Corn is stored on one drive-over pile and faced with a silage rake at Abel Dairy Farms and faced with a silage rake at Abel Farms near Eden, Wisconsin. During harvest, the Abels near Eden, Wisconsin. harvest, the Abels emphasize packing density and covering quickly. and

Describe a challenge you overcame in reaching your forage quality goals. It was taking too long to harvest our haylage with our conventional sickle mowers, and we had too much variability in our moistures. We invested in a triple mower and shortened up the time our hay laid on the ground. This improved consistency and helped us eliminate any butyric acid in our bunkers.

How do quality forages play a part in the production goals for your herd?

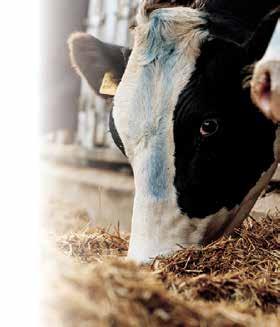

Cows at Abel Dairy Farms eat their ra on May 18 near Eden, Wisconsin. The Abels focus on feeding their cows high-quality forages, which make up 60% to 65% of the ra on.

You can’t get high production out of low-quality forages. Every forage we feed needs to be very high quality. We will not sacrice on quality during harvesting our forages or feeding it to our cows.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? We needed to make the conscious decision that we would only harvest the best quality forages. If the quality is not perfect, we will not put it in the bunker. We purchased a large hay tedder so we could better control the moisture of the haylage we were chopping. We also put an emphasis on kernel processing of our corn si-

lage. We pull samples for kernel process scoring daily during harvest to ensure we are doing a good job.

6000 BC, #544396 .......................... $13,500

NH BR780 2005, 1000 PTO, 5 ft. bales, 7700 BC, #557075 ........................ $13,500

JD 568 2008, 540 PTO, 5 ft. bales, 17,649 BC, #550655 ............................. $14,500

NH BR780A 2007, 540 PTO, 5 ft. bales, 7350 BC, #542859 ....................... $14,750

JD 582 Silage Special 2009, 540 PTO, 4 ft. bales, 22,825 BC, #542349 ....

JD 569 2014, 1000 PTO, 5 ft. bales, 10,100 BC, #553387 ...........................

569 2016, 1000 PTO, 5 ft. bales, 13,560 BC, #554379 ...........................

460R 2018, 1000 PTO, 4 ft. bales, 15,600 BC, #550251 ........................ $33,000 Case IH RB455 2018, 540 PTO, 4 ft. bales, 2091 BC, #543641 .................. $33,500 JD 569 2015, 1000 PTO, 5 ft. bales, 9200 BC, #545913 .............................. $33,900 Krone Comprima V 180XC 2019, 1000 PTO, 4 ft. bales, 13,573 BC, #550353 ....................................................................................................

Case IH RB565 2020, 1000 PTO, 5 ft. bales, 10,094 BC, #556680 ............. $34,900

JD 569 2014, 1000 PTO, 5 ft. bales, 6500 BC, #554698 .............................. $36,900

NH Rollbelt 460 2021, 540 PTO, 4 ft. bales, 687 BC, #553694 .................. $42,500

JD 560R 2018, 1000 PTO, 5 ft. bales, 8654 BC, #556060 ........................... $43,000

JD 560M 2019, 1000 PTO, 5 ft. bales, 7000 BC, #550210 .......................... $43,900

JD 560M 2019, 1000 PTO, 7300 BC, #555035............................................ $44,900

Vermeer 605N Cornstalk 2017, 1000 PTO, 5 ft. bales, 6768 BC, #548033 .................................................................................................... $46,500

JD 560M 2020, 1000 PTO, 5 ft. bales, 5491 BC, #552770 .......................... $46,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 3576 BC, #531213 .......................... $46,900

JD 560M 2020, 1000 PTO, 5 ft. bales, 5500 BC, #544100 .......................... $47,900

JD 450M 2019, 1000 PTO, 4 ft. bales, 1918 BC, #531693 .......................... $48,500

JD 560M 2021, 1000 PTO, 5 ft. bales, 8233 BC, #557166 .......................... $51,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 6000 BC, #554127 .......................... $51,900 JD 460M 2019, 1000 PTO, 4 ft. bales, 5898 BC, #557634 .......................... $53,500

JD 460M 2022, 1000 PTO, 4 ft. bales, 2600 BC, #557280 .......................... $57,900

540 PTO, 5 ft. bales, 1516 BC, #547391 ............................ $61,500

#555841 $289,000

Claas 970 2018, PRWD, 2257 hrs., 1639 CH hrs., #533174 ..................... $299,000

JD 8500 2017, PRWD, 1460 hrs., 1070 CH hrs., #553938 ........................ $299,000

JD 8700 2017, PRWD, 2544 hrs., 1835 CH hrs., #546919 ........................ $308,000

JD 8700 2016, PRWD, 1840 hrs., 1103 CH hrs., #525709 ........................ $324,000

JD 8700 2016, PRWD, 1469 hrs., 933 CH hrs., #532572 .......................... $339,000

JD 8800 2017, PRWD, 1728 hrs., 904 CH hrs., #544616 .......................... $339,900

JD 8600 2018, PRWD, 1652 hrs., 778 CH hrs., #188792 .......................... $342,000

JD 8700 2018, PRWD, 1702 hrs., 1069 CH hrs., #541389 ........................ $348,500

JD 9600 2019, PRWD, 1726 hrs., 1130 CH hrs., #553763 ........................ $349,900

JD 8800 2017, PRWD, 1558 hrs., 862 CH hrs., #524820 .......................... $355,000

JD 9800 2019, PRWD, 1893 hrs., 1368 CH hrs., #543355 ........................ $390,000

Claas 940 2020, PRWD, 650 hrs., 480 CH hrs., #532728 ......................... $399,900

JD 9600 2019, PRWD, 1224 hrs., 811 CH hrs., #532049 .......................... $409,900

JD 8300 2022, PRWD, 33 hrs., 9 CH hrs., #537501 .................................. $459,000

JD 9800 2020, PRWD, 1415 hrs., 942 CH hrs., #554135 .......................... $459,900

JD 9900 2019, PRWD, 1224 hrs., 884 CH hrs., #550177 .......................... $493,000

JD 9800 2020, PRWD, 1288 hrs., 833 CH hrs., #536344 .......................... $497,000

JD 9700 2020, PRWD, 1166 hrs., 835 CH hrs., #543646 .......................... $503,000

JD 9800 2019, PRWD, 899 hrs., 660 CH hrs., #550175 ............................ $503,000

JD 9900 2020, PRWD, 844 hrs., 661 CH hrs., #553436 ............................ $508,000

JD 9800 2021 PRWD, 416 hrs., 302 CH hrs., #550106 ............................. $518,000

JD 9900 2020 PRWD, 784 hrs., 455 CH hrs., #561177 ............................. $523,000

JD 9700 2020, PRWD, 961 hrs., 500 CH hrs., #552460 ............................ $524,900

JD 9800 2021, PRWD, 569 hrs., 369 CH hrs., #552624 ............................ $553,000

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Editor’s note: This story is a continuation of Pauly Paul’s cashow workshop held April 25 in Malone, Wisconsin. The rst story, “Boosting their bottom line: Milking 4 times a day, cutting feed costs helps Laveys cash ow” appeared in the May 13 issue of Dairy Star.

MALONE, Wis. – In a time of ination and rising inputs, many dairy farmers are looking for ways to cut expenses and raise income to ensure profitability.

Pauly Paul, dairy management consultant with Complete Management Consulting, helps farms do exactly that. Taking farms out of the red and into the black on their nancial statement is Paul’s specialty.

“We look at everything on an operation inside and out,” Paul said. “I’m able to see things that are out of place on a farm.”

Paul led a workshop, “What you need to know to cash ow,” in partnership with Peggy Coffeen – Uplevel Dairy founder and podcast host – April 25 near Malone. The workshop began with a tour of a local dairy farm that Paul works with and continued at LaClare Creamery with lunch and additional conversation.

Putting together a projected cash

ow statement for a dairy farm is one of the rst things Paul does when working with a client. This two-page report notes all avenues of income and every expense line by line and month by month for the entire year on page one. Page two of the report lists personal loans or draws, loan payments to the bank or Farm Service Agency, money borrowed and assets purchased.

“This piece of paper is key,” Paul said. “We can show you where you’re at today and where you’re going to be in the future. We try to keep it as simple as possible.”

Page two of the report also includes the gure Paul is most interested in –the net margin. This is the amount of income left over after debt payments have been factored in.

“This is the number that tells me if a dairy is actually making money, and it’s the number I’m always looking at,” Paul said.

During the workshop, Paul shared the report of a dairy farm he helped bring out of debt. When the farm owners began working with Paul, their net margin number was red and had been for years. The farm was losing hundreds of thousands of dollars annually.

“They had a lot of loans and a lot of debt services to make, and we had to determine on the expense side how to work that out,” Paul said. “I wanted to gure out how to generate more income to get this dairy out of a nancial rut.”

At Paul’s advisement, the farm began milking four times a day.

“We don’t do that on every farm, but this farm was at the end of their rope and needed to make money instantly,” Paul said.

Milk ultimately increased by 15 pounds per cow – a jump Paul said was due not only to the additional milking but also to resolving management issues on the farm.

“They generated more income, but milk prices were not stellar at the time, so it was hard to make income for them,” Paul said.

However, more milk is only one piece of the puzzle and does not tell the whole story about a farm’s nancial position, Paul said.

“Some dairies getting 100 pounds are struggling because they’re paying

for their milk,” Paul said. “You can have an 80- or 75-pound herd making more money than someone getting 100 pounds.”

Paul then focused on trimming the farm’s expenses and tried to chop even just $50 a month off anything he could. He drove breeding costs down by more than half from what the farm was previously spending.

“Every little thing kept adding up as we kept going down the line,” Paul said. “If you can save $50 or $100 somewhere when you’re in dire straits, you have to do it.”

Paul worked especially hard on the feed side and was able to lower the cost of the ration, nding many things in the ration the farm did not need. He was able to take $20,000 off their feed bill – dropping it from $55,000 to $35,000.

“They had a lot of band-aids in there, and as desperate as this farm was, we pulled all of those things out,” Paul said. “You need to constantly go through and look at what’s in your ration. Whether or not you can or can’t pay your feed bill month to month, there’s always room for improvement.”

Hoof care also got an overhaul.

“This farm had state-of-the-art everything, including an automated footbath, but they couldn’t afford it,” Paul said.

They reduced the amount of copper sulfate being used to a lower yet effective amount and trained employees to do some of the treatments.

byHighlineManufacturing-ADivisionofBourgaultIndustriesLtd.

BP660BALEPRO®-Withmanynewenhancements thisisagreatoptionforcattleoperationslookingforadurable, well-engineeredbaleprocessor.TheBP660

BalePro®hasadualfeedrollerprocessingchamberwithacentrally drivenflaildrumprocessor(picturedleft).ExpandyourBP660by addingaFeedChopper™and GrainTank.

BP661BALEPRO®-Manynewenhancementshavebeenaddedto thismodelbutunliketheBP660Bale Pro®,the661BalePro®hasaslatandchainprocessingchamber withanoffsetflaildrum.ExpandyourBP661byaddingaFeed Chopper™andGrainTank.

FEEDCHOPPER™ TheFeedChopper™,exclusivelyfrom Highline®,isasecondaryprocessingoptiontocreate shortercutlengths.Ratherthanstationaryknivesthat pulverizeordragleavesoffofstems,theHighline® FeedChopper™trulyslicesthroughthehaycreatingan optimalconsistency.TheFeedChopper™isagreat alternativetotubgrinders.

When it comes to repairs, Paul recommends a farm employee handle as many repairs as possible to reduce expenses incurred from outside services.

“Milking equipment repairs on farms tend to be high as well as repairs in general,” Paul said. “Find somebody on-site to take care of a lot of the basic stuff if possible.”

For this farm, that included changing inations and rebuilding pulsators.

Furthermore, Paul said an overowing inventory of supplies is not cost effective.

“I’ve gone into foreclosed farms that have enough semen to breed for years and milking gloves to last for months,” Paul said. “Those sorts of things cost you a lot of money.”

Paul also looks at which expenses are directly tied to increasing cash ow versus which are just nice to have. For example, paying for a milk testing service may be something the farm has always done, but if the data being collected is not used to drive income, then it may simply be an unnecessary cost when times are tight.

“It’s nice to test and get that information, but what are you going to do with it?” Paul said. “If I’m in dire straits, these types of services are something I would cut.”

Paul said the example farm also used vaccines heavily, but with better

management, they were able to eliminate some and cut costs in this area down to $1,800 a month.

In the end, Paul helped the farm achieve a $300,000 ip from the red into the black.

“Every farm should sit down with their nancial advisors and key people on their operation to look at what’s being shelled out in expenses in every area,” Paul said. “You might be surprised to learn your neighbor is paying half the price for seed corn and you’re buying the same type of seed.”

Paul encourages farmers to spend cautiously and not be afraid to make serious cuts when situations call for drastic intervention.

“If things are desperate, you do what you have to do and learn to live within your means,” he said.

By determining where more income can be squeezed out and where spending can be curbed, Paul is helping farms increase prot.

“No matter what situation you’re dealing with on your farm or what issues you see, there is always a way to get things running smoothly,” Paul said. “No matter how much debt you have, you can make a go of it, and then no one has to stay awake at night wondering what’s going to happen the next day.”

“Every farm

sit down with their nancial advisors and key people on their operation to look at what’s being shelled out in expenses in every area.”

PAULY PAUL, COMPLETE MANAGEMENT CONSULTING

NEWTON, Wis. – A manure digester can be seen as an investment in alternative revenue as well as an investment in sustainability. For the Grotegut family, their digesters are serving both purposes.

The Dairy Business Association and Edge Dairy Farmer Cooperative held a Farmer-to-Farmer Policy Picnic May 3 that began with a visit to Grotegut Dairy near Newton. The operation is home to two methane anaerobic digesters built in 2008 and 2010, which were the focus of the tour hosted by Eric Grotegut.

Grotegut farms with his wife, Rosario, and his uncle, Doug, and Doug’s son, Kip. The family milks 3,100 cows and farms about 3,300 acres. Cows are milked in an 80-stall rotary parlor built in 2011, and the majority of the herd is housed in a cross-ventilated freestall barn built in 2010 that was added onto in 2014 and 2019. The stalls are deep bedded with separated-manure solids that come from the digester.

“We like that we’re able to use a recycled product to bed our cows, and it’s comfortable for them to lay on,” Grotegut said. “Also, the separation process takes nutrients out of the liquid manure, which gives us more exibility with manure application and reduces the odor of the manure.”

The Groteguts started out selling

electricity from their digesters, which they did for about seven years until it was no longer protable. In 2019, they switched to making and selling renewable natural gas. The dirty gas from the digesters is taken off the line and run a half mile up the road to a cleaning site where it gets scrubbed, cleaned, compressed and injected into the main line.

The Groteguts own and operate the digesters while partnering with DTE Biomass Energy – a Detroit, Michigan-based energy company that purchases the gas from the Groteguts and also handles the carbon credits the digesters generate. By rst selling electricity and now natural gas, the Groteguts are proting from the renewable energy their digesters produce. Each 1.8-million-gallon digester is built for 2,400 cows.

The Groteguts have bedded with manure solids since 2005, having purchased the material for several years before installing their rst digester. Cows are bedded three to four days a week, and stalls are groomed every night.

Manure in the digester is heated to 102 degrees for 21 days to kill pathogens. It is then run through a screw-press, which removes the water. This takes the solids down to 70% moisture, which is what the Groteguts use for bedding. The solids separator provides bedding daily, running about 15 hours per day.

According to Grotegut, the recycled bedding makes for a comfortable bed but does stir up mastitis in the herd from time to time due to pathogens that remain in the solids. However, the Groteguts have learned to manage challenges of the bedding, and for the last two years, the farm has maintained an average somatic cell count of 130,000. The barn’s ventilation system helps dry the bedding, which makes for a cleaner product.

“The bafes force the air down and

STACEY SMART/DAIRY STAR

Eric Grotegut speaks about the solids separator, which is used to make bedding from the manure that is sent to the farm’s two digesters, May 3 at Grotegut Dairy near Newton, Wisconsin. The Grotegut family milks 3,100 cows and farms about 3,300 acres.

keep it lower to the ground, which dries the bedding,” Grotegut said. “But in the winter, the bedding doesn’t dry as well, which can cause more problems with mastitis.”

After the tour, the picnic continued with dinner and other speakers at Farm Wisconsin Discovery Center – an interactive educational destination near Manitowoc. Grotegut Dairy has a partnership with the center, supplying cows for calving demonstrations and also offering tours of their farm to those who visit the center.

“We like being able to help educate the community in this way,” Grotegut said.

During the picnic, Kyle Lange, who owns an American Family Insurance agency near Menasha, discussed insurance for digesters. A large portion of Lange’s work is farm insurance, and a couple of his customers have digesters. “Every project is a little different,” Lange said. “Some digesters are on-site, some are off-site. Some are owned by the farmer, and some are owned by the digester company.”

Turn to GROTEGUTS | Page 27

This past weekend at church, a friend started talking about the cozy morning they had had next to the replace. Usually, I would think nothing of it, but this time, with only a major twinge of jealousy, I mentally compared said cozy morning to my reality of being jolted awake by a call up the stairs about the beef cows being out and then spending the next 40 minutes out in the damp, cold rain putting the cows back in and getting the fence xed.

Life is just different on the farm.

calf management. I remember an older sibling coming home from college, brimming with new ideas of how we could do things better, and like politicians working together across the aisle, I stonewalled most of them whenever I could.

By Amy Kyllo Staff Writer

By Amy Kyllo Staff Writer

I spent all my growing up years helping with calves. I reigned champion over myriads of buckets, bottles, pails of warming water, electrolytes and colostrum, perfecting my tummy rubbing skills and every trick my sisters and I could concoct to coax calves to drink their bottle.

The problem with having 10+ years of calf-feeding experience by the time you nish high school is that it means you started feeding calves when you were young and clueless. I still giggle as I remember my sister reacting in abject horror to the fact I had decided to stir up the milk replacer with the bottle scrubbing brush the night before because I could not nd the usual (clean) whisk. I remember thinking she was way overreacting, but now I realize how ridiculous and completely undermining to our sanitation and disease prevention my young choice was.

Calves teach humbleness. I remember sitting at the kitchen table one Sunday evening in 2020, crying because calf feeding was so overwhelming. We had a new disease in our calves that year, and no matter what we did, it felt like it was not enough. It is those days that make you strong somehow.

On a much lighter note, I honed my negotiation skills in the barn, especially since I was the youngest. I get along really well with my siblings, but the debates always started when it came to

Con nued from GROTEGUTS | Page 26

Lange recommends meeting with the contracting team and thinking about who is responsible for which items within the project.

“It can be tricky when you assume who is responsible for maintaining a certain piece of equipment, such as a sand separator,” he said. “If there is a re or explosion, who is responsible for covering it? You certainly don’t want to nd that out after the fact.”

Lange said digesters are covered under two major forms of insurance – property and liability. The property side includes coverage for things like collapse, explosion and re. Lange recommends an added equipment breakdown endorsement that covers pressure, mechanical or electrical failures.

“Our policy can also cover the income component of that part,” he said. “If you’re responsible for some of the major components, you’re going to want that endorsement.”

The liability portion differs upon the type of setup at each farm. If a farm has a pipeline running straight from its manure pit to the digester, there needs to be an understanding of where the farm’s li-

My problem with the new ideas was they generally always seemed like more work than the old ones, which in my mind worked well enough. With this open and supportive attitude, I did my best to play devil’s advocate and cling to the status quo. Between my sometimes-overzealous sibling and my often-lazy self, we worked out enough of a balance to usually have pretty nice calves.

My secret weapon was to convince Mom that my way was right and then get her to tell my older sibling we were going to do it the way I wanted it done. There is an evil satisfaction in watching your older sibling bend to your will by proxy.

Parents taking vacations creates an infamous experience when you stay behind on the farm whether you feed calves or otherwise. I remember my sister and I and a local high schooler watching the farm for one simple weekend. Our dairy calved seasonally, and that weekend we got one-third of the calves we were expecting the entire fall in three days. We never got that many calves in one weekend before or after.

Yet, dairy farming was not just hard days or life lessons learned. I think of belting gospel songs together with my sisters in the milkhouse, braiding dandelions while I guarded a pasture gate and a lifestyle that could include catching interesting bugs in the farmyard and putting them in the freezer in old salsa jars to be identied later – or more likely forgotten about. Today, I don’t do the hard work of dairy farming, I just write about it. But, who I am is forever changed because I grew up in one of the hardest, and best, places in the world.

ability ends and where the digester company’s liability begins.

“If manure is going down that pipeline and the life expectancy is 25 years, but 17 years go by and all of a sudden there’s a seepage that occurs, whose liability does that go under?” Lange said.

Any shared ownership of the sale of gas or a fertilizer component should be discussed with the farm’s attorney and insurance agent as well, Lange said. If a farm is opening itself up to exposure for this aspect, separating the liability across several entities is recommended.

“There are many different areas of assets on a farm – from equipment to buildings to land – that you can use different LLCs to separate to some of the liability exposure,” Lange said. “You wouldn’t want the dairy farm LLC to own it all since liability is usually where the biggest claims come from.”

From a coverage perspective, Lange said it is better to do due diligence beforehand than to assume and nd out after a catastrophe that the digester was not adequately covered. Taking steps to properly insure a digester project will safeguard a farm from potential issues.

Zumbrota,

Krista Klinkner Genoa, Wisconsin Vernon County 60 cows

Krista Klinkner Genoa, Wisconsin Vernon County 60 cows