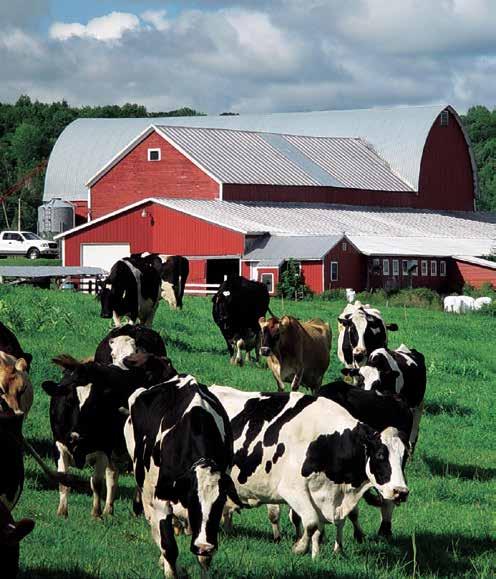

SPENCER, Iowa – A benet of dairy farming is the opportunity to work with family. This has been the case at Jones Dairy for well over a century.

Pat Jones and his wife, Nancy, joined their family’s operation in 1972 and built an 80-cow freestall barn. Two of Pat and Nancy’s eight children – daughter Aaron Titterington and son Nate – have since become integral parts of Jones Dairy. Titterington is the dairy’s herdswoman, while Nate serves as the operations manager.

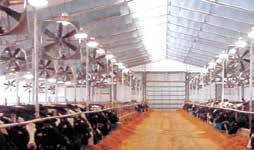

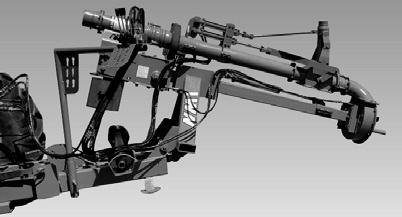

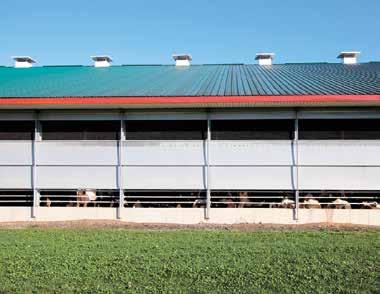

This past spring, the Jones family opened the next chapter of their story. They began milking in their new dairy facility which includes a 500by 235-foot tunnel-ventilated freestall barn and a 64-cow DeLaval rotary parlor.

Jones Dairy will host an open house and breakfast on the farm Saturday, June 17.

“The whole thing started

out as a discussion about a new barn for our dry cows,” Titterington said. “Then we began to ask, ‘Why not do this or why not do that?’ Before long, we were making plans to build an entirely new dairy facility.”

The Joneses had been milking 24 hours a day in their old double-12 parlor. The facilities that they had built more than a quarter of a century ago were showing their age and needed repairs.

“Nate was the general contractor for the new barn build,” Pat Jones said. “He had to manage all of the different contractors and attend to a million different details. Nate did a superb job.”

Jones’ grandfather, Miner, moved to the area from southern Iowa and began renting the farm in 1906. Miner then purchased the farm in 1934.

After serving in World War II, Jones’ father, Dale, returned to the farm.

“Dad decided to concentrate on dairying, so he sold the hogs and expanded the milking herd to 35 cows,” Jones said.

In 1997, Jones Dairy constructed a new facility that featured 350 free stalls and a double-12 parallel milking parlor. Over the years, the Joneses

gradually grew their herd of Jerseys to its current size of 1,300 lactating animals.

The Jones family consulted with a trusted source during the planning phase of their new barn project.

“We have worked with Brad Fischer, who is with Farm Systems at Melrose, Minnesota, for more than 20 years,” Jones said. “Brad has installed numerous rotary parlors and knows the tricks of the trade. We were glad for his assistance with the design and the build of our new facility.”

The Joneses milked in their new rotary parlor for the rst time March 20. It did not take long for their cows to adapt.

“After about ve days, you had better get out of their way because the cows were crowding their way into the new parlor,” Jones said. “Our cows really like the new system.”

Titterington agreed.

“The transition from the old facilities to the new ones

has been seamless,” she said. “At the end of the rst week, all we had to do was stand back and watch the cows load themselves onto the carousel. Some of them were a bit too pushy and had to learn how to wait their turn.”

The Joneses’ new barn features 1,300 exible free stalls that are bedded daily with manure solids. A set of scrapers continuously moves manure from the freestall alleys to a gutter that is located at the end of the alleys. A chain-type gutter cleaner transports the manure to a holding pit.

Liquid manure is pumped from the holding pit to a pair of manure separators. The separated manure solids fall onto a conveyor belt that transports the solids to an adjoining storage room.

“We looked at bedding with sand, but sand can be tough to handle and is hard on equipment,” Jones said. “Using manure solids – which we

like to call dry, soft bers – for bedding ts in with our philosophy of recycling and making the best possible use of our resources.”

The Jones family farms enough land to meet the forage needs of their dairy herd. They do not have sufcient acreage to accommodate all the manure their animals produce, but that is not a problem.

“We have a list of neighboring farmers who are eager to take our manure,” Jones said. “They recognize the value of manure as a source of fertilizer and as a way to increase the soil’s organic matter.”

Jones Dairy has to buy grain to meet the nutritional needs of their herd. The amount of grain they need to purchase changed a few weeks ago.

Their milk is sold to Agropur and made into cheese at the Le Sueur, Minnesota, facility.

“Agropur recently asked us if we would like to receive some of their whey,” Jones said. “We immediately said yes.”

Titterington said they are eager to utilize the whey.

“Including whey in our cows’ TMR has reduced the amount of grain that we need to buy,” she said. “It also ts in with our efforts to recycle as much as possible.”

Jones agreed.

“The whey adds moisture to our ration,” he said. “We have learned that the whey also makes our TMR more consistent and reduces sorting. It’s a win for the cows, and it’s a win for us from an economic standpoint.”

The new rotary parlor has resulted in drastic time management changes at Jones Dairy.

“Instead of milking virtually around the clock, we can now complete our three-times-a-day milkings in four hours,” Titterington said. “This frees up our guys to do other critical jobs on the farm.”

The new dairy facilities at Jones Dairy signify a secure future for the Jones family.

“Nate’s kids and my kids represent the fth generation of our family on this farm,” Titterington said. “Our hope is that the new barn will create opportunities for the next generation.”

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

MURDOCK, Minn. – Carmen

Maus simply could not help herself; a goat was brought up for sale, and she made it hers.

“In hopped this little wether, and he was so stinking cute,” Carmen Maus said. “I bid on him.”

It was a gut reaction to the little guy.

Maus looked over and her best friend, who rst introduced her to the idea of goats, was grinning.

“My husband was not stopping me, so that was my permission,” she said.

That was just the beginning.

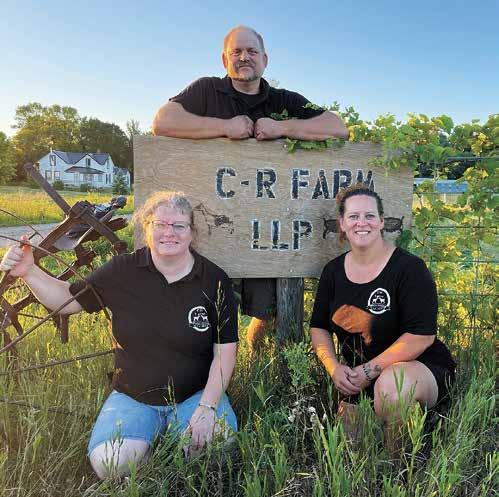

Today Maus, along with her husband, Ryan, and that same best friend, Theresa Smith, run C-R Farm, a goat dairy with over 80 goats being milked twice each day in a straight-16 parlor. The whole herd numbers 200.

The farm’s name is a nod to Carmen and Ryan’s initials but also a welcoming play on words meaning, “See our farm.” The dairy is located on the farm site near Murdock owned by the Mauses where they raised their two children, Faith and Thomas, and reside today.

“We buy the goat,” Maus said. “I hug him and I squeeze him and I kiss him and I call him George. He becomes our

gateway goat.”

Maus said she held back on buying more goats for about a year, but then she bought ve more.

“They’re like potato chips,” Maus said. “You can’t have just one.”

That is when goat space became an issue.

“They couldn’t be in the garage anymore,” Maus said.

Maus had never liked goats. The times she fed and milked Smith’s dozen goats when Smith was on vacation, Maus said she did not enjoy it one bit.

“I said that I was never having goats because they jumped all over you,” Maus said. “Then you had to lead them up to the milk stand, tie them up and milk them by hand. It seemed so inefcient.”

C-R Farm now is home to a variety of goat breeds: Oberhasli, Alpine, Nubian, Nigerian, Saanen, Sable, Lamancha, Angora and crossbreds. Maus calls each individual goat by name.

Around 7% of the dairy’s milk is used on the farm to make soaps and lotions. The rest is picked up twice per week by Stickney Hill Dairy, of Cold Spring, which uses the milk to produce cheese.

“It’s Theresa’s fault we have goats,” Maus said. “I remind her often when they are being naughty.”

Long before she and Ryan bought their farm from her brother, she milked cows for him. He still owns a fth-generation farm across the road. Ryan worked

Dive into the wonders of agriculture at Farm Wisconsin Discovery Center and discover why we’ve been named among Time for Kids’ 50 Coolest Places of 2019 and a Trip Advisor Top Choice. Spend a day as a family or group exploring interactive exhibits, seeing a local farm firsthand through a bus tour, or experiencing the miracle of birth in the birthing barn. Have a meal in the farm-to-table café or book your group outing in the conference center, and be sure to save room for ice cream and other treats in the Farm House Store.

Sunday, June 18 | 10 a.m. - 2 p.m.

Menu for the event includes pork carnitas, mac & cheese, scrambled eggs, sausage, bacon, breakfast potatoes, biscuits & gravy, and French toast sticks.

NOW

Gass Lake Road Manitowoc, WI 54220 920.726.6000 •

Carmen Maus stands among some of her goats Nov. 8, 2022, at C-R Farm near Murdock, Minnesota. Maus partners with her friend, Theresa Smith, and husband, Ryan, to run the goat dairy, which milks about 80 goats and has a herd of 200.

and continues to work, for CNH Industrial in Benson.

Maus had a back injury in 2002 that ended her milking days. She went to school to earn a degree in counseling and spent 14 years working for the state of Minnesota in outpatient programs.

During that time, the Maus children were showing cows, heifers and rabbits for 4-H.

Smith’s children were showing goats. A trip that the Mauses and Smith took in 2017 to the local sales barn to sell some rabbits changed Maus’ goat disdain to goat joy in under a minute when little George appeared.

However, the space problem created by George and the other ve goats that followed needed to be addressed. The problem was solved when Maus’ brother decided to sell the cows and farm site on which the Mauses lived. They bought the land and buildings but not the cows. Instead, they used the space to grow the goat herd. The barn’s existing milking system was converted for goat milking.

Within the herd, the rst kid, Flopsy, was born in 2019. They began to plan for a larger dairy and to eventually create an on-farm creamery. In the meantime, Maus, along with her husband and Smith, learned how to make soaps and lotions and sold the products at farmers markets and craft shows.

Then, the coronavirus pandemic began.

Maus lost her job in outpatient counseling.

“I was devastated,” Maus said. “Here comes this virus, and no one can go anywhere or do anything. We were milking six goats, and we just bought the farm.”

Ryan continued his job with CNH Industrial. Smith had her job with Select Genetics of Willmar. Maus wondered if she could carve out a full-time career with the goat dairy. The pandemic made the reality of building a creamery next to impossible with materials and contractor costs skyrocketing, Maus said.

However, the herd was multiplying.

“In the meantime, our goats were having babies, and their babies were having babies,” Maus said. “Our herd had now increased from 6 to 50, and we had more milk than we could make into soap and lotion or give away.”

Maus contacted Stickney Hill Dairy and received the answer she needed. Stickney Hill Dairy was looking for more milk. With a buyer, Maus was in business.

“Stickney has been great to us,” Maus said. “They have been so easy to work with.”

Today, Stickney Hill Dairy picks up milk from C-R Farm twice a week. Maus milks the goats every morning. Her husband and Smith help milk in the evenings. All three owners use time on weekends and evenings to make soaps and lotions that they sell at farmers markets several days a week during the summer and craft fairs in the fall.

They also have groups visiting the farm by appointment to see the dairy, make soap or shop and make gift baskets that Maus shrink wraps for them.

While C-R Farm has a number of goat breeds, the 12 Angora goats on the farm, with their prized mohair, were given to the farm from an owner who could no longer care for them. Once the Angoras were on the property, Maus acquired a spinning wheel.

“I plan to be spinning Angora ber in the future,” she said.

A friend knows how to knit hats, and the pair is considering making and selling hats.

Through it all, Maus keeps her goats in the forefront.

“I love all my animals,” she said.

That love includes creative ways to make sure they eat well.

“I have three brothers who farm,” she said. “I’ll exchange tractor time or some other labor for things such as feed.”

The Mauses and Smith also bale grass hay and have an alfalfa eld 5 miles from the farm. The milking goats are fed alfalfa, corn, oats and a supplement. The other goats eat grass hay, corn and oats.

Kidding is spread throughout winter, from December to May, to have milk year-round. When other crafters and marketers are talking about winding down for winter, Maus laughs.

“My busiest time is just starting,” she said.

Maus has embraced her new career and cherishes all things goat. She serves as superintendent for the goat barn and is on the livestock board for the Swift County Fair. This past January, the farm hosted a Goat Information Day for Swift County 4-H’ers. Five families are currently prepping C-R Farm goats for upcoming show competitions this year. Other youth have shown the farm’s goats in the past. A C-R Farm Oberhasli goat named Éclair won grand champion the past two years in a row at the Minnesota State Fair.

Learning that llamas are natural protectors of goat herds by fending off coyotes and other predators, Maus set out to buy some of them as well. C-R Farm welcomed three llamas to the farm– plus one alpaca for good measure. This year, a surprise baby animal was born on Memorial Day. Maus named him Maurie as a nod to the holiday. Since alpacas can mate with llamas, Maus will not know who the sire is until the baby’s ears grow a bit more. Bigger ears will mean it is a cria; smaller ears will mean it is a llampaca.

With a goat processing facility recently breaking ground in nearby Willmar, C-R Farm might start raising wethers as well. They currently sell them when they are young.

Whatever happens in the future, it will involve goats.

“I love goats now,” Maus said.

“They’re funny, … and they don’t care who I’m voting for. The stress level is so low here. You can’t have a bad day when you’re around a bunch of goats.”

Happy June Dairy Month consumers, but know that it is not a happy month for dairy farmers.

The U.S. Department of Agriculture announced the May federal order Class III benchmark milk price at $16.11 per hundredweight, down $2.41 from April due to sharply lower cheese and dry whey prices. This is $9.10 below May 2022 and is the lowest Class III price since August 2021.

The ve-month Class III average stands at $17.99, down from $22.67 at this time a year ago, but it compares to $16.94 in 2021. The bottom line is, very few, if any, dairy farmers can make milk at current prices.

Late Friday morning Class III futures portend a June price at $15.33, July at $16.17 and August at $17.02, with a peak at $18.68 in November.

The May Class IV milk price is $18.10, up 15 cents from April but $6.89 below a year ago. Its vemonth average is at $18.66, down from $24.44 a year ago but comparable to $14.54 in 2021.

StoneX dairy broker Dave Kurzawski called the situation “ugly” in the June 5 “Dairy Radio Now” broadcast. Farmers have told him that it feels like 2009, when milk prices plummeted, and he admitted, “I don’t have a great response to this.”

Typically, lows are put in, in May or June, he explained, so it’s a seasonal norm.

“The good news is that we are seeing a number of buyers step in to buy loads of cheese at the (Chicago Mercantile Exchange), and they are getting a fantastic deal,” he said.

That’s good for them, but the lower prices are attracting more export interest in third quarter, he said. The USDA also solicited bids to purchase 47 million pounds of cheese through June 5 and will award them June 14. He believes that purchase will all be made before Christmas and result in more price stabilization.

Corn and alfalfa hay prices climbed higher in April, according to the USDA’s latest Ag Prices report, and the all-milk price dropped some more. The milk feed ratio fell to 1.48, down from 1.56 in February, the lowest since July 2012’s 1.33 and com-

parable to 1.95 in April 2022. The all-time low was 1.02 in August 1974.

The all-milk price average fell for the sixth consecutive month, falling to $20.70 per hundredweight, down 40 cents from March and $6.30 below April 2022.

California’s all-milk price averaged $20.70, down 50 cents from March and $5.60 below a year ago. Wisconsin’s, at $20.40, was up a dime from March and $6.70 below a year ago.

The national corn price averaged $6.70 per bushel, up 3 cents from March, after dropping 13 cents the month before, but it is 37 cents per bushel below April 2022.

Soybeans were unchanged from March at $14.90 per bushel after dropping 20 cents the previous month, but they are 90 cents per bushel above a year ago.

Alfalfa hay soared to an average $287 per ton, up $20 per ton from March and $30 per ton above a year ago.

The April cull price for beef and dairy combined continued climbing, averaging $99.30 per cwt, up $3.60 from March after gaining $6.20 the month before, which also makes it $11.20 above April 2022 and $27.70 above the 2011 base average.

Income over feed costs in April were below the $8-per-cwt level needed for steady to increasing milk production for the third month in a row, according to dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri. “Input prices were mixed when compared to all-time record high prices in April, but all three commodities were in the top three for April all time,” he said. “Feed costs were the highest ever for the month of April and the fourth highest all time.”

“For 2023, milk income over feed costs (using May 31 CME settling futures prices for Class III milk, corn and soybeans plus the Stoneheart forecast for alfalfa hay) are expected to be $7.60 per cwt, a loss of 43 cents per cwt versus last month’s estimate,” Brooks said. “2023 income over feed would be below the level needed to maintain or grow milk production and down $4.39 per cwt from 2022’s level.”

“Milk income over feed costs for 2024 are expected to be $9.43 per cwt, a gain of $1.83 per cwt versus the 2023 estimate,” Brooks said. “Income over feed in 2024 would be above the level needed to maintain or grow milk production.”

Meanwhile, the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC said, “Dairy margins continued to erode over the second half of May on a further decline in milk prices that more than offset the impact of lower projected feed costs. In addition to abundant supplies of cheese, whey prices have also pressured Class III milk values as they continue to drop.”

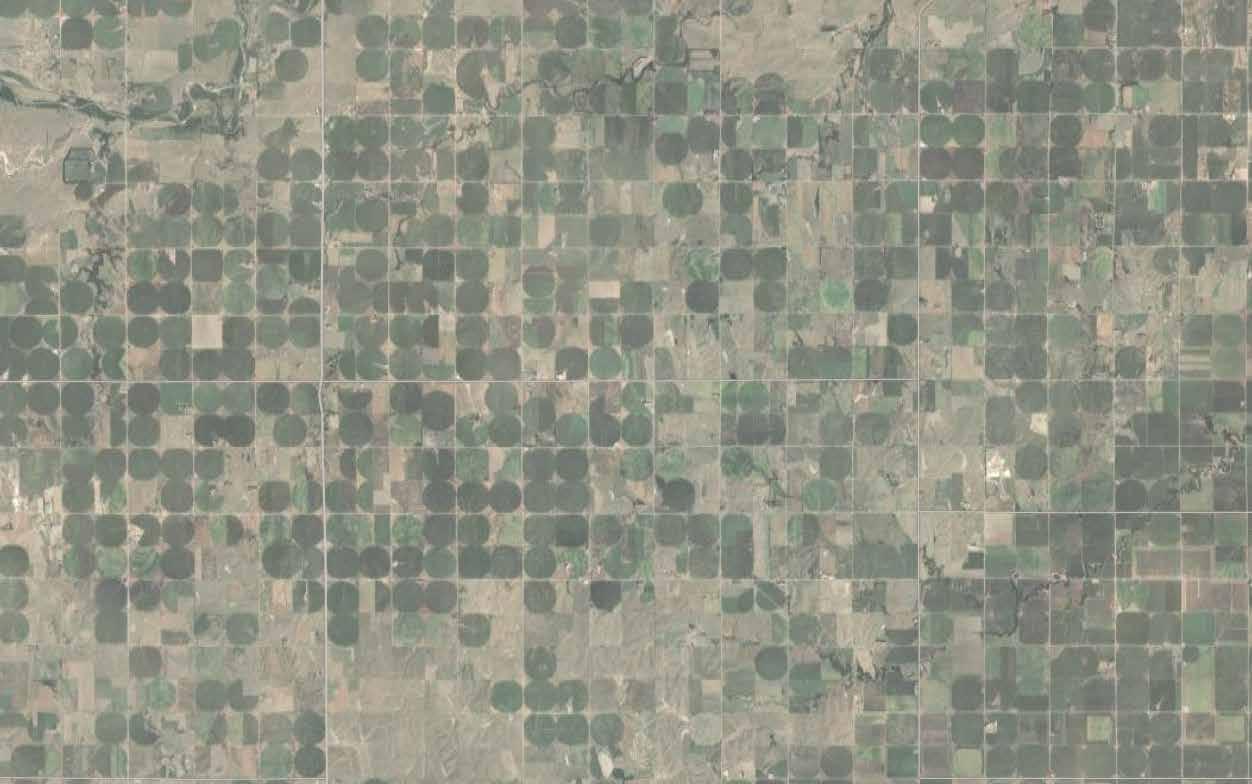

The MW detailed the April Milk Production report, stating it showed “the slowest year-over-year growth since June 2022.” Production gains remained heavy in central and midwestern states with South Dakota, Kansas and Iowa up 7.7%, 5% and 2.9%, respectively.

“U.S. dairy producers are expected to suffer their worst losses this spring since the 2009 campaign that led to massive industry liquidation,” the MW said. “There are already indications of increased cow culling in western states and this will likely expand into Central and Midwest regions soon. In 2009, it took 13 months before there was a signicant recovery in milk prices, so this process may take time.”

Corn planting was at 92% as of the week ending May 28, according to the USDA’s latest Crop Progress report. That’s up from 81% the previous week, 8% ahead of a year ago and 8% ahead of the ve-year average. The corn was 72% emerged, up from 52% the previous week, 14% ahead of the previous year and 9% ahead of the ve-year average. 69% was rated good to excellent, down from 73% a year ago.

Soybeans were 83% planted, up from 66% the week before, 19% ahead of a year ago and 18% ahead of the ve-year average. 56% are emerged, 20% ahead of a year ago and 16% ahead of the veyear average.

HighGround Dairy’s Tuesday “Morning Huddle” said, “Corn futures have picked up steam against dry conditions in the Corn Belt, with no rain on the horizon in the two-week forecast. Farm Journal’s AgWeb reports that 26% of corn acres are presently impacted by drought. The growing season has just begun, with the most critical parts remaining, and soil moisture has been decent to aid emergence, so it is not time to panic yet. Weather will drive crop prices and could help or hurt dairy farmer margins, particularly those who purchase feed.”

The week ending May 20 saw 54,900 dairy cows go to slaughter, down 1,100 from the previous week but 2,000 head, or 3.8%, more than a year ago. Yearto-date, 1.281 million head have been culled, up 55,000, or 4.5%, from a year ago.

Tuesday’s GDT Pulse saw another 2.2 million pounds of Fonterra whole milk powder sold, same as on May 23, but at $3,100 per metric ton, down $50 from the last Pulse and down $95 or 3% from the May 16 GDT. HGD said, “With ample supplies outpacing weak global demand, there is little challenge for buyers to procure product, resulting in further WMP price declines.”

Cooperatives Working Together member cooperatives accepted 20 offers of export assistance this week that helped capture sales contracts for 1.2 million pounds of American-type cheese and 562,000 pounds of cream cheese. The product is going to customers in Asia, Central America, the Caribbean and Oceania, and will be delivered through September.

Block cheddar, in ve successive declines, fell to $1.42 per pound Wednesday, the lowest CME price since May 11, 2020, when it traded at $1.3875. It regained 7.25 cents Thursday but gave some back Friday to close the Memorial Day holiday-shortened week at $1.43, down 4.75 cents and 84 cents below a year ago.

The barrels closed Friday at $1.5125, up 2.25 cents on the week, 73.25 cents below a year ago and an inverted 8.25 cents atop the blocks. Sales at the market of last resort totaled 25 loads of block for the week and 122 for the month of May, the highest monthly total in two years and up from 76 lots in April. Barrel sales totaled 35 for the week and 184 for the month, down from 212 in April.

To give a little dairy month perspective, a load of cheese is approximately 40,000 pounds. If you add May’s CME block and barrel sales, you get 306 loads of cheese or about 12.2 million pounds. That does not include the privately traded cheese. Keep in mind, it takes 10 pounds of milk to produce 1 pound of cheese. A gallon of milk weighs about 8.6 pounds.

Midwest cheesemakers are running full schedules, according to Dairy Market News. A number of plants worked through the holiday weekend, and plants that had been down for updating in recent weeks were back online. Cheese demand is mixed, but more processors are reporting upticks. Cheese inventories are moving somewhat briskly. Milk availability is “readily accessible,” and plants are turning spot milk offers away as they are already full. Midweek spot milk prices ranged $11 to $4 under Class III, compared to $2.75 under to Class a year ago.

Retail and food service cheese demand is steady to lower in the West as some reports of decreased sales activity surfaced. Some cheese makers relay contract obligations are making heavy pulls on their supply. Inventories are available with production keeping moderately ahead overall. Export demand is steadier from Mexico and South America, compared to softer Asian demand, DMN said.

CME butter climbed to $2.4650 per pound Thursday, the highest since Dec. 22, 2022, but it closed Friday at $2.4450, up 1.50 cents on the week while 47 cents below a year ago. Sales totaled six

cars for the week and 29 for May, down from 38 in April. A car of butter is also about 40,000 pounds.

Some butter plants churned cream through the weekend while others scheduled downtime. Contacts say, as Class II processing ticks up, along with temperatures, cream accessibility is not expected to remain as widely available as it is now. Butter demand is steady, but seasonal upticks are expected soon, DMN said.

Cream is widely available in the West, and cream multiples were largely unchanged this week. Butter production has been quieter as some facilities planned downtime for the holiday weekend and some cream shifted from butter making to ice cream in recent weeks. Food service demand is strong to steady, while retail demand is steady. Aside from interest from purchasers supplying butter to Canada, export activity is on the quieter end, according to DMN.

Grade A nonfat dry milk fell to $1.1550 Wednesday, then rallied Thursday and closed Friday at $1.17, unchanged on the week but 69.25 cents below a year ago. Six loads were sold on the week and 45 for the month, up from 18 in April.

Dry whey fell to 25.75 cents per pound Thursday and stayed there Friday, down 1.75 cents on the week and 3 cents below a year ago. Sales amounted to 37 loads on the week and a record 218 for the month of May, up from 142 in April.

In politics, the USDA’s Agricultural Marketing Service issued an invitation for additional proposals and issued an action plan on proposed amendments to pricing provisions of Federal Milk Market Orders.

The USDA said, “The National Milk Producers Federation has requested the USDA begin a rulemaking proceeding to consider proposals to amend pricing provisions in all Federal Milk Marketing Orders. The proposal requests USDA consider amending ve provisions related to increasing manufacturing allowances, returning to the ‘higher of’ as the mover for Class I milk prices, updating the milk composition factors, removing barrel cheese from the Class III price formula, and updating the Class I price surface. … NMPF contends the dairy marketplace has changed substantially since the current market order pricing system was adopted in 2000,

and pricing provisions should be updated to re

current market conditions.”

“The proposal has not yet been approved for inclusion in a Notice of Hearing,” the USDA said. Furthermore, on May 30, the International Dairy Foods Association and the Wisconsin Cheese Makers Association provided additional information seeking to increase manufacturing allowances, as requested by USDA. Those proposals are now considered in conjunction with this request and may be viewed at https://www.ams.usda.gov/rulesregulations/moa/ dairy/petitions.

NMPF responded immediately.

“We’re gratied that USDA recognizes the comprehensive nature of our proposal and are looking forward to it being considered in full because the whole of our plan adds up to more than the sum of its individual parts,” said NMPF President and CEO Jim Mulhern. “We will bring the same level of dedication and preparation to this part of the process that we did in drafting our own plan, which included more than 150 meetings and wide consultation across dairy producers and the entire industry.”

NMPF also voiced opposition to legislation introduced that the federation said would “increase U.S. vulnerability to infant formula supply disruptions by increasing U.S. reliance on imported formula and formula inputs. The legislation would unilaterally and permanently remove tariffs and tariff rate quotas on infant formula and infant formula base powder, resulting in job loss and foreign dependence.” More details are posted at the NMPF website.

Thursday, June 15th

Hay 10:00 a.m. • Cattle 11:00 a.m.

Early Consignments

9 Holstein tie stall cows, all stages of lactation. Several just fresh milking up to 100 lbs! 3 hol hfrs bred 7 months. 5 open Holstein heifers 650 lbs.

PENDING: Complete dispersal 45 Holstein and crossbred Tie stall cows. Grazing program, not pushed for production. Averaging 73 lb with a 100 scc.

ADVANCE NOTICE

Tuesday, July 11th (Loyal yard)

Accepting all classes of farm, construction and recreational items. Anticipating another large auction, get your items consigned early to maximize the exposure of advertisement of your machinery. This will be a live auction with larger items being on HiBid and Equipment facts

Formerly Turenne Livestock

SALE EVERY MONDAY AND WEDNESDAY 5:00 PM Selling Baby Calves, Hogs, Sheep, Goats, Feeder Cattle, Fat Cattle, Market Cows and Bulls

VERY COMPETITIVE MARKET PRICES Call 712-432-5500 for daily market report

JWO NOTES & MARKET REPORT:

Big enough to make a difference, small enough to care!

As long as I can remember June has been called Dairy month. Now I see they also call June pride month. The Bible is clear, God hates Pride. Top dairy cows continue to sell well. $2,700 Urie Yoder, Abbotsford. $2,225 Wilson Brubacker, Stratford. $2,100, $2,100 Michael Martin, Colby. $2,000 Loren Hoover, Owen. Many good cows $1,450-1,850. Springing Holstein heifers $1350-2100 NT. Opens $1.10-1.40 with light weights up to $2.12/ lb. Single birth Holstein heifer calves $25-170/head. Breeding Bulls $800-1500. Market Bulls $105-123.

Choice Holstein steers up to 166 this week with beef cross up to $173.50. Feeder Cattle Market continues strong with holsteins up to $175 and 600 lb cross breds up to $215. Holstein bull calves sold $150-375 with a top of $395/head. Beef cross calves topped at $600 per head early in the week with majority of calves selling $350-575. Good butcher hogs $45-57. Sows $23-27. Boars $10-14. 20% of Market cows sold $107-123. Top $127. 50% of cows sold $87-106. 3x3x8 Alfalfa grass mix $135. Round and squares lower quality grass hay $35-45. As always, thank you for your business!!

Dairy & Hay sale EVERY Thursday starting with hay @ 10:00 followed by Dairy Cows @ 11:00 sharp, then bred heifers, open heifers and feeders followed by calves, market bulls, fat cattle and cull cows. Special feeder sale 2nd & 4th Thursday. WATCH OUR

Sale Location: W1461 State Hwy 98, Loyal, WI 54446

Spencer, WI take Hwy 98 west 5 miles. From Loyal, 5 miles east on 98

SALE CONDUCTED BY: Oberholtzer

Over the past several months there have been worsening situations with milk plant pay prices. Individual circumstances are getting bad enough that producers will not survive the outcomes that they are having to deal with. From our perspective this can be very difficult to watch as some very good dairy producers struggle to overcome substantial pay price discounts that they have no control over.

It is surprising how significant component and plant milk price discounting is becoming relative to FMMO announced prices. It is to the point that there is almost more milk pay price risk from this than from futures falling away. The challenge for producers is there is no way to hedge this price risk. It also makes it difficult to project forward profit margins when you don’t know if a producer will get paid the announced FMMO price or get discounted $1-5/cwt on their pay price from their milk plant.

CME Group spot cash trades continue to see heavy price pressure in the cheese, whey, and nonfat dry milk auctions. Trading volumes remain high compared to historical levels as sellers are being forced to move excess inventories to the spot session to remain current in their plant inventories.

Block cheddar and whey prices seem to be the weakest of the dairy complex at the moment. Dairy Market News reports express that Western regions are seeing demand slow down which has been allowing block inventories to grow some. Cold storage data does not reflect anything overly concerning for inventory builds, but regional challenges will continue to be dumped onto the spot market.

Whey prices remain under heavy pressure with front end futures trading in the low 30 cent range and spot whey auction results in the mid 20’s. Unlike cheese, inventories are high in several high protein whey product categories. It appears that some high protein whey production is shifting to sweet whey so it can be dumped onto the spot market auction. Whey exports remain good, so it is likely that domestic sales are slow or that production is high enough that new markets are needed to absorb growing production.

Butter prices continue to hold up well with spot butter trading in the mid $2.40’s and futures at similar levels through all of 2023. Export sales volumes are slowing due

*Futures and options trading involve significant risk of loss and may not be suitable for everyone. Therefore, carefully consider whether such trading is suitable for you in light of your financial condition. Past performance is not indicative of future results. DVi is an equal opportunity employer.

• 605-692-0955 AGRI-TECH Watertown, SD • 605-882-7015

WISCONSIN ADELL COOPERATIVE Adell, WI • 920-994-4125

CHIPPEWA VALLEY DAIRY SUPPLY Stanley, WI • 715-644-2350

D&D FARM SUPPLY Arcadia, WI • 608-323-7001

DICKEYVILLE FEED Dickeyville, WI • 608-568-7982

FARMERS ELEVATOR COMPANY Waupun, WI • 920-324-3593

Tell

IOWA

GARNAVILLO MILL INC.

Garnavillo, IA • 563-964-2243

DAVE’S FEED STORE

Luxemburg, IA • 563-853-2415

DOON ELEVATOR CO.

Doon, IA • 712-726-3215

MINNESOTA

ALBANY FEED SHED

Albany, MN • 320-845-2303

CHANDLER FEED CO. – CHANDLER

Chandler, MN • 507-227-6450

DOANE’S GRAIN SERVICE

Plainview, MN • 507-534-3165

ELROSA GRAIN AND FEED

Elrosa, MN • 320-697-5515

GLACIAL PLAINS COOP Benson, MN • 320-843-3999

GLACIAL PLAINS COOP DeGraff, MN • 320-843-5634

GLACIAL PLAINS COOP Kerkhoven, MN • 320-264-3831

GLACIAL PLAINS COOP Sunburg, MN • 320-366-3456

GULLY TRI-COOP

Gully, MN • 218-268-4181

HOLDINGFORD MILL Holdingford, MN • 320-746-2281

LEAF RIVER AG SERVICE Bluffton, MN • 218-385-2559

LEWISTON FEED & PRODUCE Lewiston, MN • 507-523-2196

LUXEMBURG FEED SERVICES, INC St. Cloud, MN • 320-252-1513

MILLVILLE FEED INC Millville, MN • 507-798-2391

OAK PARK CREAMERY Oak Park, MN • 320-968-7864

PRAIRIE FARM SUPPLY Belle Plaine, MN • 952-873-4234

SUNRISE AG CO-OP Buckman, MN • 320-468-6433

UNITED FARMERS COOP LeSueur, MN • UFCMN.com 507-665-6421

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

Editor’s note: This series, which highlights families who are the last dairy farms to operate within their respective counties, has been expanded to include farms across the wider United States. Therefore, it will now be published in both zones of Dairy Star. To read past stories in the series, beginning with the Jan. 28 issue of Zone 1, visit www. dairystar.com and search for “And Then There Was One.”

When Scott Plagerman saw a television program in 2008 about vegetable and hobby farming in Alaska, it stuck with him. The dairy farm he ran in Washington state with his wife Connie and their young children – Kyle, Jessica and Cody – was being encroached on by suburbia and regulations, leaving no options to expand. The isolation and freedom of Alaska as it appeared on the television screen was enticing.

“I thought that looked kind of neat,

so I Googled farms for sale in Alaska, and the one we’re currently living on popped up,” Plagerman said. “A few weeks later, I looked at it again online. About a month later, I actually called the guy and got a little more information. I was more curious than anything.”

However, the idea stuck with him.

“Then I said to my wife, ‘Hey, do you want to move to Alaska and live there?’” Plagerman said. “She started packing. She was game to go.”

At the time, Plagerman did custom harvesting on the side. One of his customers was looking for another place

to house his heifers. When Plagerman asked if he would be interested in buying his farm, the customer jumped at the chance.

“(My wife and I) were like, ‘Oh man, this is getting real all of a sudden,’” Plagerman said.

Plagerman asked his friend, a cattle broker, if he would be able to sell the family’s cows and heifers. The friend was able to line up a buyer within a week.

“We thought, the way this was coming together, the Lord was leading us through it all and opening the doors,”

Plagerman said.

Today, Scott and Connie, along with their sons Kyle and Cody, now in their early 20s, milk 45 to 50 cows with a Lely robotic milking system near Delta Junction. Their daughter lives nearby in town. The Plagermans’ farm, Alaska Range Dairy, is the only dairy in Southeast Fairbanks County. In fact, it is the last remaining cow dairy in the entire state. The only other dairy is a goat dairy on Kodiak Island.

Along with milking cows and raising their youngstock, the Plagermans farm 1,500 acres across four sites, raise between 200 to 250 bison, run a hay business for the horse market and board 30 to 50 horses each winter – mostly for tourist companies, outtters and hunting guides.

The dairy is the newest part of their operation.

“Our main production, and what we started with up here, is hay for the horse market,” Plagerman said. “We started (dairy farming) about two years ago. We’re just getting going.”

It was four years ago, after the Plagermans bought a second farm property nearby, that the idea of returning to their dairy roots began to form.

“We bought (the second farm) without dairy intentions, but there was a decent smaller barn on it to start with,” Plagerman said. “We probably owned that site about a year and then kind of got the dairy bug again. We thought, ‘Well, it’s a good place to do it.’”

However, they were in a state that was not set up for agriculture, much less dairy farming.

“In Alaska, there is absolutely no agricultural labor,” Plagerman said. “We didn’t have any more people than just our family, and we still had all the other operations going, so the only way we were going to do it was robotic.”

In 2020, the family bought an already-existing robotic milking system from a farm in Minnesota. The setup included gates, collars, pipelines and all necessary parts.

The Plagermans also needed to acquire a milking herd.

“My two brothers both still have

dairies in northwest Washington,” Plagerman said. “Our plan was to buy heifers from them and haul them up here, calve them in and start, but that’s about when (the pandemic) hit, and we couldn’t transport through Canada. So then, we started looking for every backyard cow we could nd.”

They were not picky.

“We ended up with some odd ducks – some Guernsey, some Jersey, some Brown Swiss and some Holstein – it was a pretty ugly-looking herd at rst,” Plagerman said. “Then, there was another dairy down in the (Matanuska-Susitna Valley) near Anchorage. They quit, and we picked up some of their herd –younger cows and heifers … 30 to 40 milking and 40 youngstock.”

Today the Plagermans’ herd is about 75% Holstein and 25% various breeds.

With a milking facility and herd, the Plagermans had to complete the puzzle by nding a way to process and market the milk in a state that shipped in its dairy from points elsewhere.

“We knew from the beginning that we were going to have to process the milk, bottle it and sell it all on our own,” Plagerman said. “In our constructions, we gured in a bottling plant at one end of the barn. It’s kind of small, but it’s big enough for us to get started, and then we can expand.”

To market their milk, the Plagermans needed to be unique.

“The way freight and costs are for production in Alaska, we knew we could not compete with your typical grocery store milk, like your bigger chain store

Con nued from ALASKA | Page 13

milk where they are bringing it in as a loss leader, so we wanted to go with the more natural, unprocessed type of milk,” Plagerman said.

The Plagermans vat pasteurize at a low temperature and do not homogenize.

“That way, we don’t damage the milk at all and keep it as good as it can be,” Plagerman said. … “It’s old-fashioned cream-top milk. It’s as the cow makes it, pasteurized and put in a bottle.”

Alaska Range Dairy sells whole and chocolate milk in half-gallon returnable glass bottles and both half-gallon and gallon plastic bottles. The creamery also recently began processing and selling plain and vanilla yogurt in quarts.

“We’re doing what we can with the equipment we have right now,” Plagerman said.

The products are sold all over the state. Everything within 150 miles of the farm is delivered by the family. A freight company takes the rest to a distributor.

“Marketing is our biggest issue; trying to get a smaller farm product into a large chain

grocery store is next to impossible – getting through the bureaucratic system, the paperwork, the logistics, getting the right person to sign off on it,” Plagerman said. “We are hopefully going to be starting into Walmart here really soon.”

In all, the dairy gamble has been a success for the Plagermans.

“The dairy itself is going better than expected as far as producing the milk and cow health,” Plagerman said. “The cows put out around 350 gallons a day at 45 cows right now. We’re going to be installing a second (robotic milker) this summer. Our hope is that (the dairy) becomes the main income source and less so the selling of hay.”

Cow management is mostly Plagerman’s job, but he said the whole family pitches in with all areas of the business.

Connie does the bookwork and oversees bottling of milk. A neighbor works part time with her in that.

“Basically, you have to be completely self-sufcient farming here; there is no agricultural support because there is such a

small amount of it,” Plagerman said. “We build our own barns, pour our own concrete, rebuild our own tractor engines – absolutely everything you want to do, you do yourself.”

That includes wiring, plumbing and installing insulation and piping. They did hire one person to set up refrigeration for the bulk tank.

“We have our own semis that run to the lower 48 a few times a year and get supplies,” Plagerman said. “Basically, everything we need comes out of that because there is nothing here. Baling twine to silage wrap to parlor chemicals – we truck in absolutely everything.”

The Plagermans’ barn has a catch-pen area with headlocks near the milking robot where they have a full secondary atbarn style milking system with automatic takeoffs.

“It’s ready to go with the ip of a switch,” Plagerman said. “If the robot fails, we have a secondary way to milk.”

The farm’s fully-enclosed freestall barn is well-insulated with air ow monitored closely and temperatures kept just above freezing. Automatic barn scrapers put manure into an underground pit. About once a week, it is pumped to a lagoon.

“(The system) keeps the oors clean all the time,” Plagerman said. “The less manure around, the less ammonia you have.”

The cows have access to pasture in the summer. The farm is in a delta valley, so it is at with mountains in the distance.

“Everything the cows eat we grow on our own farm,” Plagerman said.

They feed the herd dry grass hay or haylage and brome or Timothy grass that survives in winter there. For grains, they feed barley and eld peas for protein and energy, but Plagerman said protein is a bit of a shortfall in their climate. This spring, they planted canola to

address that issue and are waiting to see how it fares. In the meantime, they ship in mineral supplements to mix in the grain. Grain is fed through a robotic feeding system while haylage is fed in the bunk.

“It’s kind of old school, but it’s simple,” Plagerman said. “Up here at 50 below zero, I can’t imagine getting a mixer box and mixing feed for a (total mixed ration). It’s just not feasible on a small-herd basis.”

Looking back on taking the leap from Washington to Alaska to create a new home and business, Plagerman said he has no regrets.

“The struggles of farming are the same everywhere; you’ve got your bad crop years, your good ones – that part didn’t change – but the challenge of being self-sufcient is what we enjoy,” Plagerman said. “It’s freedom … to do what you want when you want and how you want to do it. If you screw up, it’s your own problem.”

most

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

DORCHESTER, Wis. – Recently, the days have been a bit more atypical than normal at Evan and Taylor Ensign’s Rolling Acres Farm near Dorchester.

The Ensigns started up a used DeLaval robotic milking system May 16 after retrotting the machine into their existing tiestall barn.

“Our goal is not to grow or to max a robot out,” Evan said. “We just want to simplify and allow for exibility in our lives. Our kids are growing quickly, and we know all too well that life is short.”

A week into their new management system, the Ensigns began to breathe a sigh of relief May 23.

“We’re not really seeing all the benets of the robots yet, but with eldwork, we are starting to see some,” Taylor said. “It has been nice that Evan can spend more time in the elds, and I can handle everything here on my own. That has been the biggest benet so far.”

The couple renovated their 50-stall tiestall barn to retain 38 free stalls and create a feeding area and area for the robot without having to add on to the existing structure of the barn.

“Being able to do it without building on kept it within our budget,” Evan said. “We never really truly had a design worked out. Everything was just sketched on pieces of paper, but after a meeting I went to, I felt if I could retrot the barn and keep 38 stalls, we could do this. We can’t say enough about all the help and support we have gotten from Bob’s Dairy Supply (of Dorchester).”

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

The Ensigns broke out the concrete from their center walkway and poured new, grooved concrete in order to remove the gutters and end up with the desired slope.

“A robot was in the future plan, but we just started thinking seriously about it now in December when Evan came across some used robots on Facebook Marketplace,” Taylor said. “By the end of January, we had made the decision to move forward with it.”

The concrete work got underway in March, which Evan said was a little less than ideal.

“It was either plan to do it early or plan to do it late in Novem-

Con nued from ENSIGNS | Page 16 ber,” Evan said. “I gured we might as well get on with it. Of course, the cows were living outside during all the snow we got in March and April, which was challenging, but they handled it well.”

In preparing for the transition, the Ensigns dried off some later-lactation cows and purchased a couple of ad-

ditions to their herd. With the startup, the Ensigns are milking about 40 cows.

As the concrete work was completed and the curing process was taking place, the cows were slowly allowed more access to the barn. Once the concrete was cured, the cows moved back in and began getting used to their new-

ly remodeled home.

“I think our startup has gone pretty well because for the past four or ve months, there have been a lot of smaller transitions,” Taylor said. “They had some time to get used to living in here as a freestall before the robot came.”

Wis.

The Community Wellness Group, along with Farm Well Wisconsin, honored mental health month in May with the annual mental health summit. Resources were shared for individuals recovering from substance abuse or living with mental health challenges.

The summit took place May 23 at Southwest Wisconsin Technical College in Fennimore.

One program that was highlighted, Recovering Pathways, was launched in 2015 and links recovering individuals with a peer support specialist to help bridge the gap between the recovering individual and their recovery team.

Kyle Wicks, a peer support specialist with personal experience in recovering

from addiction and mental health challenges, is working as a mentor in the Recovering Pathways program, which is offered through the Southwest Wisconsin Community Action Program.

“We focus intently on leveling the playing eld between us and the people that we are working with,” Wicks said. “There is always going to be some sort of power dynamic, but we aim to make the people we are working with feel as much or more than us.”

A peer support specialist is not a therapist but rather a person with lived experience. They do not limit the recovering individual to a clinical path to recovery. Instead, they walk alongside the person and offer an empathetic ear and give the option of a social method of recovery.

The core values of the peer support program include the understanding that there

are multiple pathways to recovery and the recovering individual should have the power to choose their own path and dene their own trauma. Peer mentors are not necessarily informed of a person’s specic diagnosis

before working with them because the learning and discovery process builds trust between the survivor and the mentor.

Peer support specialists are care professionals who are trained and hold a state

certication. They commonly spend considerable time with volunteer efforts. It is up to the recovering person to decide how involved they

want the peer mentor to be in their recovery. When involvement does occur, the program is strengthfocused.

“The people we’re working with are oftentimes in a really hard place in their lives and there’s a lot of chaos and disorder in their life,” Wicks said. “We focus on nding the strengths in the people we’re working with and using that to empower them toward healthy decision making.”

Wicks said that through the history of care treatment, the eld of psychology has progressed where the brain was viewed as unchangeable to more recent understandings where the brain continues to learn and prune off old neurons that are really encouraging unhealthy or destructive behaviors.

With peer support, the mentors are building support in people’s lives so that regardless of the outcome of a recovering person’s decision, the decision-making process is benecial to their personal development.

“Sometimes I have to walk with my peer in a decision (where the peer realizes), man, I’ve already done that and it wasn’t the greatest,” Wicks said. “It’s healthy to have a support person walking with you in that decision because then you build trust and they start to model the behavior that they see you walking in. Eventually they see another way. It’s just mutuality in the relationship.”

Wicks said a lot of people make it through probation because they are conforming to the rules rather than forging changes in their thinking, beliefs, their behaviors and their patterns that are causing them to commit crimes or deviate to begin with. The practices of a peer support specialist and the mutual relationship is giving people space to learn that they really do want to have a more functional life and they can achieve one.

“The moral of the story is that peer support is really just a good relationship where people have authentic support and understanding to live their lives,” Wicks said. “Oftentimes people who are needing these services don’t really have many people to navigate their experiences in a proactive, productive way. So, the peer specialist in that space is multifaceted in those outcomes. We’re exemplifying that change.”

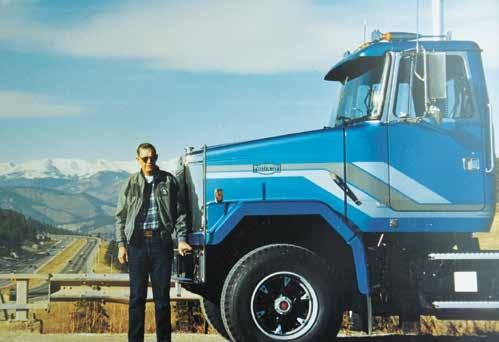

Dinse hauled milk in south central Minnesota for about 67 years, only taking a break during two of them. That was solely because he was drafted by the United States Army and hauled fuel in Germany. After his Army service ended, he returned to hauling milk.

From the age of 20 to the age of 88, Dinse’s profession remained the same.

“I never had to look for a job,” said Dinse, of Meriden. “I had a job. I always wanted to be a farmer, but I just never had enough money to get going on it.”

Instead, Dinse made a career of milk hauling. Dinse said his favorite part was visiting with farmers every time he picked up their milk.

“They were good,” he said. “Very nice people to work for.”

Dinse began hauling milk in 1955 with a can milk route for the Meriden Creamery. In 1957 he was drafted, and by 1959, he was back hauling can milk again. In 1970, he bought a bulk milk truck from a creamery in Owa-

tonna and took on a bulk milk route. Dinse continued hauling milk for the next three decades until 1999 when he sold his business to his son, Darl. Selling the business did not mean Dinse stopped working, however. He kept hauling milk for his son until 2022 when health issues forced the then 88-year-old to quit.

During the peak of his career, Dinse was picking up milk from dozens of farms.

“One year I had 40-some stops,” he said. “They usually always gave me a Christmas gift, and that year I think I got a gift from every farmer.”

most of his years, working 10 hours a day, seven days a week. Very occasionally he and his wife, Darlene, would sneak away on a vacation up north, or he could grab a Sunday off or have his second load taken so he could get done early.

The hardest days were when Minnesota’s weather stepped in.

still going down the road, trying to pick up milk,” Dinse said. Getting out a shovel was part of life. Dinse said he remembers trying to take a load to Associated Milk Producers Inc. when they had a plant in Rochester, and the road havd only a single clear lane, meaning there was

Dinse hauled milk by himself Turn

“You couldn’t see beyond the end of the hood of the truck, and you were

“We like the waterbeds because the water is constantly moving so every cow is comfortable. As the cow moves the water adjusts to her and when she leaves the water moves back for the next cow to lay down.

use a 1/3rd less bedding than we did before because it stays longer.

— Carlie Rademacher, R-Acres, Cottage Grove, WI, Installed in

no space to meet oncoming trafc.

Dinse slowed down in the later years of his career, hauling milk every other day. The last year he hauled milk, he worked in a team with his cousin, Ken Dinse, to get the route completed.

“Between … two old guys, we got it done,” he said.

Dinse said other milk haulers jokingly told Darl he should re his dad because he was making the rest of them look bad by driving for so long.

This spring, Dinse was recognized for his years of contributions to the dairy community, receiving the Milk Pitcher Award from the Waseca County American Dairy Association.

The award was planned to be a surprise. Darl was tasked by the president of the ADA with getting his dad to the banquet. Dinse said Darl got him to go by suggesting he would get to visit with former patrons.

“Next thing I know, I heard my name called and I get the pitcher award,” Dinse said. “That’s quite an honor.”

In his many decades of milk hauling, Dinse drove eight trucks. His favorite was a blue Autocar he bought from his brother-in-law in Colorado in 1991. Dinse and Darlene drove there

and picked up the truck. Darl said the truck was his dad’s baby. Dinse drove it for the next seven years until he bought his rst Peterbilt in 1998.

Though he hauled milk into his late 80s, Dinse said Darl never pressured him to retire.

“Darl said, ‘I’ll never tell you to quit,’” Dinse said. “‘You quit on your own. … You make your own decision when you want to leave it.’”

Darl said the conversation with his dad in 2022 when he decided to retire was the hardest conversation he has ever had as he listened to his dad cry and explain that it was not going to work anymore.

Dinse will occasionally drive a truck to the shop for repairs. Darl is ne with that, simply concerned that his dad stays safe.

Today, Dinse’s life is quieter, but he still gets out and about. Every week he has a breakfast date with his daughter, Dawn, replete with campre mochas he buys as his contribution to breakfast at her home. He celebrated his 89th birthday in late May with a pizza party at his house and family around him.

After a lifetime of hauling milk, it was relaxation well earned.

Having the time of his life

Bryton Miller bought a 50-cow, 160acre dairy farm near Kellogg, Minnesota, from his next- door neighbors, Bill and Bonnie McMillin. Though Miller had grown up on a dairy farm, he learned a lot in his rst year of farming at his own farm. The McMillins rotationally grazed their cows and wanted someone who was willing to incorporate the conservation practices they had started. With Bill McMillin assisting, Miller milked his own cows in his own barn for the rst time in March 2017.

Brothers Ron, Paul, Glen and Jeff Middendorf grew up together on a dairy farm near Melrose, Minnesota. Each of the brothers in turn went on to dairy farm on their own, and by spring of 2018, all had a son, or sons, who had come home to dairy farm. Ron took over the home farm near Melrose, Minnesota, and his son Cory began farming full time with him in 2001 when he graduated high school. Paul’s son Jeremy returned home to their dairy farm near Browerville, Minnesota, in 2015. All three of Glen’s sons wanted to dairy

farm, so in 2000 he bought another farm site down the road from their home farm near Long Prairie, Minnesota. Sons Nathan and Matthew began managing the second farm site while Daniel and Glen ran the home farm. Last but not least, Jeff, who dairy farmed near Sauk Centre, Minnesota, welcomed his son Austin into the family’s farming operation after Austin, who graduated in 2017, decided to become a full-time dairy farmer as well.

Grass Ridge Farm LLC was rst started in 1918 by Charles and Augusta Lippert near Pittsville, Wisconsin. In 2018, Matt Lippert and his sons, Paul and Carl, were still farming at the same farm but had grown to milk 560 cows three times a day. To celebrate the milestone of the farm turning 100 years old, the Lipperts were preparing to host the 35th annual Pittsville FFA Dairy Breakfast on the Farm, which was set for June 16.

In 2018, the Shea, Roth and Wiederholtz families were preparing their farm, Banner Ridge Farm near Platteville, Wisconsin, to host the Grant County Dairy Breakfast. From 1996 to 2016, the Grant County dairy breakfasts were held at the Grant County

Fairgrounds in Lancaster, Wisconsin. John Shea and other farmers worked to get the breakfasts moved to working dairy farms, and in 2017, their efforts paid off. The breakfast was held on another farm in 2017, and in 2018, Banner Ridge Farm took their turn and offered to host the breakfast at their farm.

Four generations of the Tyrrell family worked together on the family dairy farm, Oak Crest Acres, near Browerville, Minnesota. In 2018, Howard and Marlys Tyrrell were farming with their son Dennis and his wife Cheryl, their grandson Jakin and his wife Amanda, their granddaughter Nikki Deyle and her husband Nathan and their children: Lucas, Zach and Sydney. The Tyrrells milked 55 Guerney cows in a tiestall barn and farmed 1,206 acres. Cheryl, Amanda and Nathan worked full time off the farm.

Groetsches host 2,500 for Stearns

Steve and Lisa Groetsch and their three children – Jennifer, Matthew and Katelyn – hosted the sixth annual Stearns County Breakfast on the Farm. The Groetsches, along with the Stearns County Breakfast on the Farm committee, worked together for over a year to plan the event, which included a petting

zoo, visit by Princess Kay of the Milky Way, tours of the farm and breakfast. At the time, the Groetsch family milked 240 cows with four robotic milking systems at their farm near Albany, Minnesota.

The art of grazing

Back in the 1980s, Dan Miller and his dad Glenn, who farmed near the North Deer Creek River, received 15 inches of rain at their site within two weeks. The Millers lost almost their entire crop. Afterward, they cut back on the number of acres planted to corn and soybeans and planted 30 acres of cropland to oodresistant grasses and clovers. Dan got the idea after attending a symposium on grazing. By 2003, Dan had 30 paddocks, each 2 to 3.5 acres for his 90 milk cows to graze on.

Writing the book on flexibility

In 2002, Brian Hazel made the decision to renovate his tiestall barn into a double-8 parlor. Prior to the expansion, Hazel was milking 85 cows. After the parlor was installed, he increased his herd to 180 cows. With the parlor also came a new freestall barn where the cows were housed and fed. Hazel visited several farms in Minnesota, Wisconsin and out west to determine how his new setup would look.

Hay sales start at 12:30 p.m. and are the 1st and 3rd Thursdays of the months of September through May and the rst Thursday in June, July and August. Next sale is July 6, 2023

For more information, contact Kevin Winter 320-352-3803, (c) 320-760-1593 or Al Wessel at 320-547-2206, (c) 320-760-2979

ANDREW INGVALSON

175 cows, 600 acres

All the crops are planted and up. Conditions have been very dry here. We had to turn on our irrigators on both the corn and alfalfa ground. We finished the first crop at the end of last week. We cut, baled and wrapped our hay in round bales. It yielded well, considering how dry we are. Most farmers in the area are done with first crop, but a few are still finishing up.

ALAN VANNURDEN

600 cows, 1,400 acres

We cut hay May 29 and chopped June 1-2. Then we got four-tenths inches of rain on some of our hay, and we finished chopping that yesterday (June 5). We put it all in a bunker.

The hay was lodged and was really good on the heavier ground. North of here toward Pierz, they are working on hay now. We plan to spray for weevils next week.

By the end of the week, some of the corn should be knee high. It looks really healthy. A lot of people are putting on nitrogen, and we plan to start tomorrow. The soybeans are 2-6 inches tall but look like they are standing still because it’s so dry.

ARIANN DOE

250 cows, 5,530 acres

We are done planting everything except 200 acres of corn and our sunflower acres. We are working on corn now. Once we finish the corn, we will do first-cutting hay. The hay looks really good. The durum, barley and oats are up and look pretty good. The crops are starting to look green. Most everyone around here is done planting except for where they had to avoid wet spots. We also plan to continue to work on spraying.

BENJAMIN SEIFERT

350 cows, 450 acres

Everything is looking very good. We still need to plant corn, and some farmers are having to replant because of the wet spring. There continues to be spotty showers popping up in the area, pushing some back even further to plant. If it stays dry, we hope to plant later this week (week of June 5). We finished first crop on Saturday, June 3. We chopped and made a pile. It was a very good crop in quality and quantity. When we chopped, it was 32-36 inches and had not started to bloom.

DENISE KURTH

40 cows, 250 acres

Our first cutting of alfalfa turned out pretty good; we got 108 big round bales from 60 acres. We need more rain, or we won’t get a second crop. The pastures look good, and the corn and the soybeans are about ankle high. The oats are starting to head out even though they are still a bit short. The unseasonably hot weather has had a big effect on everything from the crops to the peonies.

CHARLIE DICKE

200 cows, 850 acres

We put up first crop and harvested rye cover crop in the last two weeks. We plan to haul manure and terminate our cover crops on 150 acres where we will plant sweet corn in the next two weeks. Rain has been very spotty, varying from 0.25 inches to 2 inches within the space of a mile. All of first crop is up in our area. Also, in the area, corn is getting side dressed with fertilizer, soybeans are up, and the crops in general look good.

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

LANE

130 cows, 75 acres

We have been getting small, spotty showers over the past week or so, and the moisture has been most welcome. The crops are looking excellent. The corn is a bit over ankle high, the soybeans are coming along nicely and it looks like the first cutting of alfalfa was above average.

DOUG FAIRBANKS

380 cows, 600 acres

In the last month, we have received 0.3 inches of rain. Corn that was planted on time looks good, but corn that was planted after cover crops is either sickly or is just lying in the dry dirt. People in our area have sprayed their corn three times trying to keep ahead of the weeds because there has not been enough moisture. Alfalfa looks like we will get a decent second crop, but we will need rain to get a third crop. Lawns are going 10-14 days between mowing and are already starting to show brown spots.

RICH HOUZNER

54 cows, 600 acres

We had rain this morning for the first time in a while, probably a tenth or two. The hay crop had areas that were disappointing but some that were quite good. Corn in the knolls is hurting for rain. We got the dairy hay done in the silos, and we have another 100 acres of first crop to get wrapped and round baled. Corn is in the ground, and we hope to not have to replant anything. Rain is in the forecast for the weekend, so hopefully it comes.

MATT REDETZKE

250 cows, 450 acres

We got about a quarter-inch of rain on Friday (June 2), but that is all in the last two weeks. We are working on our hay this week. It doesn’t look too bad, but it is a little lighter than normal this year. We are waiting on some moisture to spray the corn. We are supposed to get some rain on Saturday (June 10), so hopefully we can spray next week. The corn and beans all look really pretty good. They have been able to set roots down into where there is moisture. The new-seeding Italian ryegrass we put in is struggling; it is just kind of sitting on top.

230 cows, 400 acres

Half of our fields, 3 miles away, got a halfinch of rain, including our largest cornfield and largest hayfield. We cut first-crop hay May 28 and chopped everything May 30 and had a good yield. We waited a little longer than last year, but the quality was still just as good. We did 50 acres of grass and 70 acres of hay. Grass will be heifer feed, and haylage will be cow feed. There’s a lot of manure being hauled in the area, even on some growing crops because it’s been so dry.

TIM VOSBERG

140 cows, 380 acres

We have only had a little sprinkle of rain and not enough to measure since last time. There is rain in the forecast, so hopefully it comes. All of my corn has come up but has not had any rain on it yet. It’s all still alive yet, so if we get rain, it will be fine. We are tine weeding the beans, and that takes a lot of adjustment, but I think it’s going well. First crop of hay is done, and that went really well; we had a huge crop. We got all of our big square baling done for the year as well as chopping two-thirds of the crop. We had dry weather, so we figured we’d get some baling done.

100 cows.

1,400 acres

We’ve had no rain in the last two weeks. We are chopping up around Antigo, Wisconsin, right now, and they have had a pivot that is not working; otherwise, a lot of the ground we cover is being irrigated in that area. By the end of the week, we’ll have the haylage finished up and then have some wrapped hay to make. The first crop has been yielding surprisingly well for how dry it is, and the new seeding is all coming along pretty well. I’m surprised by how good things look right now, but everything really needs a good drink of water. We will be starting second crop about June 21. The corn is about popcan height, and the beans are about 3 inches tall. Everything has come up really well in our area.

ALAN AINGER

300 cows, 1,100 acres

We finished planting beans May 18 and finished first-crop hay May 27. It was kind of dry hay but really good quality. Second crop is coming along, but it’s going to be light. There’s not going to be much out there without any moisture. The corn we planted early looks pretty good even though we haven’t had any rain. Most first-crop hay is wrapped up in the area, and people are working on spraying and side-dressing.

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

HARVARD, Ill. – The Harvard Milk Days Dairy Show is a 75-yearold tradition ensconced in the town’s annual celebration of all things milk, which has been held the rst weekend in June each year for the past 82 years.

Kate Olbrich of Harvard took over the duties of organizing the show from her father-in-law, Bill Olbrich, four years ago. Bill managed the show for 20 years before handing the reins to Ka te.

“There is a lot of tradition with the Milk Days show,” Kate said. “It means a lot to a lot of people. It’s the kick-off to summer for our town, and we can get together with our friends and watch our kids enjoy the same things we did growing up.”

This year’s show, held June 4, welcomed 82 head of all breeds from across northern Illinois and southern Wisconsin, all exhibited by youth. Abbi Goldenberg of Frederick, Maryland, served as the judge for the event.

“It was great to see our numbers up again this year,” Kate said. “It is exciting to watch the enthusiasm the next generation has for our industry. The dairy barn was packed full this year,

and because of the increasing numbers, we are hopeful that the Milk Days Board is considering adding on to the barn to accommodate the larger show.”

The Olbrich family has been participating in the annual show for about 45 years, said Kate’s brother-in-law, Brian Olbrich.

“I was about 10 years old the rst time we showed at the Milk Days show,” Brian said. “That was when we had gotten our rst registered Holstein.”

Brian, his brother Mark and their families operate Holbric Holsteins just outside of Harvard, where they milk 170 registered Holsteins and Jerseys.

Grapple buckets, bale spears, rock buckets etc.

Large 8-10 Buckets

Seven members of the fourth generation of the Olbrich family participated in this year’s show.

While the show evolved into a youth-focused show in the late 1970s and early 1980s, Brian and Mark recall the days when it drew prominent herds from the area, such as Curtis Candy, Maytag, Hawthorn Mellody Farm, Elmwood and Skokie Holsteins.

“In the 1940s and 1950s, all the big herds in the area would come to Milk Days,” Brian said. “The show was really a big deal. I have always been told it was considered to be one of the better shows of that time.”

Brian said the show placings were

included in the All-American contests.

“When Skokie Holsteins had their dispersal in the 1980s, you could look through the catalog and nd all of the references to Harvard Milk Days in the show placings in the pedigrees right alongside the placings from shows like Waterloo,” he said. “Over the course of time, there have been a lot of animals that have gone through the Milk Days show that have been either All-Ameri-

can or junior All-American.”

Brian said the original site of the show was only a few blocks from the railroad tracks. Most of the show herds came via rail and were either walked or trucked from the tracks to the show grounds.

“Milk Days was the rst time either of us ever saw those famous show cows, the ones you might read about in the Holstein World,” Mark said. “It was really a great experience for us, and it happened right here. It was like having World Dairy Expo in our backyard.”

The brothers recalled how much they enjoyed attending the shows and said watching their own kids enjoy the same experiences brings a sense of nostalgia.

“It was the kick-off for the summer for us,” Brian said. … “We were done with school and got to spend time with our friends. Just after midnight, we would all walk over to the main street and watch the city crews paint the Milky Way. Every year, they paint the main street white in honor of Milk Days.”

Mark agreed.

“Now we get to watch our kids do some of the same things and make some of the same memories that we were able to make,” Mark said. “It’s a lot of work to get them here with their animals, but it is worth it.”

Becky Wellnitz of Brodhead, Wisconsin, made the hour-long trek east to Harvard to participate in the Milk Days show for the rst time.

Wellnitz milks 46 cows and each year works with several Green County 4-H members, giving them the opportunity to show some of her animals.

She traveled to Milk Days with four kids and six heifers.

“This year, we have a few new kids who have never shown a dairy calf before, and we decided this show was a chance for them and their parents to see what showing a calf is all about,” Wellnitz said. “It worked well with our schedule, and we managed to get our rst crop hay done before the weekend.”

Wellnitz said the biggest show, besides the Green County Fair, that her 4-H’ers will compete in is the upcoming Green County Dairy Day June 17 in Monroe, Wisconsin, where she will have nine junior members exhibiting 17 head from her farm.

“The kids had a great experience (at the Harvard Milk Days show) and really appreciated the help of their fellow exhibitors when it came to knowing which classes were getting ready to go into the show ring, where to line up and who to follow,” Wellnitz said.

“They got some experience and practice in showmanship and things like remembering birth dates, sires and dams, and all the other questions they might get asked – but in a smaller setting than the Green County Dairy Day or Green County Fair.”

For her rst time attending and participating in the show, Wellnitz said she was impressed with the camaraderie of the exhibitors.

“We really appreciated the friendly environment and the helpful dairy community that supports the Harvard Milk Days show,” Wellnitz said. “As we were leaving, one of the kids saw a sign promoting next year’s dates and said, ‘OK guys, mark your calendars; we’re coming back next year.’”

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

HUTCHINSON, Minn. –Laughter echoed through a kitchen as a group of women sat around the table. They have experienced it all together. From their laughter to the excitement and joy of weddings and births to the deep pain of losing a spouse, these women bring support, encouragement and a listening ear to each other’s lives.

They call themselves the Porch Ladies.

Most of the founding members of the group have a connection to dairy, whether they dairy farm or grew up on a farm.

Retired dairy farmer Diane Kaehler said she has built rapport with these farm women like nothing she has ever experienced before.

“I was very isolated,” Kaehler said. “I lived on a dairy farm, and I worked out in the elds. And so, I didn’t nd people that got me until I was invited to this group.”

h co ha

DC - 1125 Series Dump Carts have a durable and time proven box design to keep continuous harvest production. DC-1125 Series carts have high floatation tires that create less damaging impact on your fields and harvesting equipment. DC-1125 Series now also comes standard with the fold down gate and ground level grease banks.

16’

› Self Unloading

› Self Loading (If Tires Are Stacked Properly)

› Haul Up to 80 Sidewalls (Varies Depending Loader) or 110 with wheel loader tire shooter

› Reach over 18’ Cement Walls (Varies Depending Loader)

› Drop Sidewalls 22’ from Edge of Plastic on skid steer or telehandler, and 30’ with wheel loader tire shooter

› Custom Fit Any Skidsteer, Telehandler or wheel loader

› Use with Sidewalls or Full Tires

› Powder Coated

› Typical customers say it saves half the time or half the labor; some say both

One of the founding members, Kim Asche, agreed.

“I don’t think people who have not been in a farming ag background understand how hard it is to be a farmer,” she said.

A dairy background was not something the group sought out, just something that happened.

As a former dairy farmer, Mary Nelson understands the importance of building these relationships.

“When farming, you are out on the farm, and you put so much effort into your daily life,” she said. “Sometimes you just need to walk away from it for an hour.”

Marlene

Benson, a dairy farmer and one of the Porch Ladies, said her now best friend is a neighbor she got to know through their gatherings.

The Porch Ladies’ gatherings began in 2015. That year, Barbara Bumgardner’s husband took a job in Park Rapids, three hours away, and she had to stay behind to get the house sold.

“I got ahold of Mary (Nelson) and said, ‘I need company; I need some women,’” Bumgardner said. “I have this beautiful front porch, and that’s where the name came from.”

Years later, the group is still gathering, and the friendships continue to deepen among the kindred spirits. They gather whenever someone feels like they need to see the group.

Asche said she knows some of the reasons the group has lasted so long.

“We’ve gone through a lot of challenges,” she said. “The important thing is that our group is based on faith and friendship and support and fun and laughter and basically kindness and giving.”

The group shares their lives in the good and the bad.

“It’s not just the weddings and the births and the showers,” Asche said. “It’s also the deaths.”

This support is especially real for Nelson. When her husband Duane passed away from cancer seven years ago, she was left with the pain of the loss and with many life decisions and changes. The Porch Ladies helped her walk in her grief as she sold her dairy farm and moved into town.

“It took me three years before I could breathe,” Nelson said. “I wasn’t functioning, and they kind of pulled me along.”

Asche said most of their gatherings are informal as they meet at someone’s home or out for a lake day.