Family’s venture allows for expansion

Lax-Pietig farm triples in size with purchase

By Hans Lammeman hans.l@star-pub.comFAIRFAX, Minn. – Forty-ve years after Steve and Jeanette Lax purchased their family farm near Sleepy Eye through a farm security loan, the family made a move to triple the size of their operation and position for a successful future in agriculture.

Steve expanded the operation with the acquisition of Nosbush Dairy near Fairfax along with his children, Mike Lax and Melissa Pietig, and his son-in-law, Jamie Pietig. The farm sale included about 1,300 acres and 900 cows, along with existing facilities, feed inventory and growing crops. Now, the family milks 920 cows in a double-16 parallel parlor. The

herd is housed in a sand-bedded freestall barn.

Mike said each family member is vital in managing

their diverse farming portfolio, Lax-Pietig Dairy LLC and Lax-Pietig Family Farms LLC. While they all help with addi-

tional duties, Jamie operates as the chief executive ofcer with a focus on crops, Mike serves as the chief operating ofcer

Inspired to promote

McNamara hosts Goodhue County Breakfast on the Farm

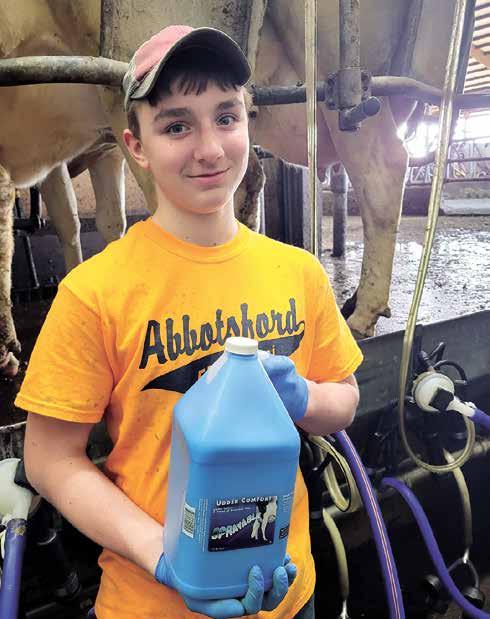

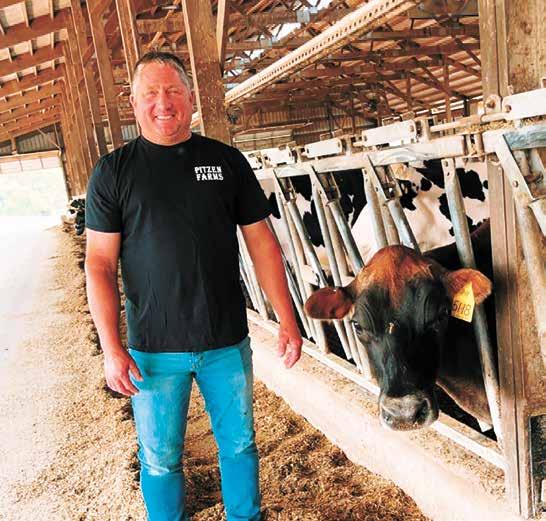

By Amy Kyllo amy.k@star-pub.comGOODHUE, Minn. –Rich McNamara is promoting dairy from the acres of his farm and into his community. For the very rst time, he will be hosting the Goodhue County Breakfast on the Farm June 16.

McNamara said he looks forward to the event, especially since the urban-rural gap is widening quickly.

“This is a way to try to connect the people, to realize we take a lot of pride in the product that goes in the store,” McNamara said.

More than just dairy promotion is inspiring Mc-

Namara to open his farm to 1,500 to 1,700 guests. Nine years ago, his son Derek was killed in an all-terrain vehicle accident the same day

McNamara welcomed his rst grandchild. McNamara said his son would want him to host the event and is driven by his memory.

McNamara began dairying on his farm in 1987 and now milks 305 Holsteins on his farm near Goodhue. He is assisted by his nephew, Michael McNamara, and hired help.

When he was approached by fellow dairy farmer Lyle Dicke a year ago, asking him to host, his immediate response was yes. McNamara said many surrounding

dairy farms have hosted, and he had been thinking about it for several years before he was asked. He said he

understands the importance of this type of event for the community.

“It was a good way to

with oversight of cattle movement and other cattle-related duties, Steve manages crops on about 1,200 acres near Sleepy Eye and Melissa operates as the chief human resources ofcer and research manager over two hog research barns.

Steve said he was glad to see the operation grow so signicantly at a time when many family farms face the risk of closing. He and Mike previously managed about 350 cows at their dairy near Sleepy Eye.

“This was a way to (expand) without having to look at the building and the permitting process – so many things were already in place,” Steve said. “This was an excellent way to basically triple the size of our business in a short time. The Nosbush group has been excellent to work with through this whole process.”

Turn

showcase the strength of

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

DeadlinesOne year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Advertising

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order. Letters

The

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre,

MN

Combest Sell and Associates managing partner Tom Sell hopes the agreement on the debt ceiling will spark momentum for the farm bill. “The farm bill tends to be an area where Congress can show how it can work together at its best. It doesn’t make it easy, but we have great leadership,” Sell said. Sell expects forward momentum in June and July with the farm safety net at the heart of those discussions.

Former House Agriculture Committee Chair Collin Peterson addressed the U.S. Meat Export Federation Spring Conference. Peterson said he would be surprised if a farm bill is passed before the current law expires at the end of September. “I think they probably have until the end of the year to get something done,” Peterson said. “If it doesn’t get done by the end of the year, I think it will probably get extended, and with it being an election year, I wouldn’t be surprised if you do a one-year extension, you’ll end up with a two-year extension.” Farm groups are seeking additional farm bill funding to increase reference prices and boost international market development. “I just don’t know where it will come from,” Peterson said.

Supreme Court delivers victory for landowners

In a long-awaited decision regarding the Waters of the United States rule, the high court found the Environmental Protection Agency and Army Corps of Engineers wrongfully claimed authority over wetlands. In a 9-0 holding, the Supreme Court ruled in favor of the Sackett family and killed the signicant nexus test which has caused headaches for landowners around the country. Rinke Noonan Law Firm attorney Kale Van Bruggen said the nexus analysis was very unclear. “It was almost impossible for a landowner or a farmer to quickly and efciently decide which wetlands are regulated,” he said. Van Bruggen expects changes to be

made to EPA’s WOTUS rules that were released earlier this year.

White House: WOTUS ruling is

a step ‘backward’

EPA Administrator Michael Regan said the agency is still evaluating the Supreme Court decision on Waters of the United States. “I am deeply disappointed that the Court is taking away EPA’s ability that has been standing for 50 years,” Regan said. Meanwhile, the White House said the court ruling “will take our country backward.” In a statement, President Joe Biden said it puts our nation’s wetlands at risk of pollution and destruction, jeopardizing the clean water that American families and farmers depend on.

Dairy farmers receiving pandemic funds

The U.S. Department of Agriculture is preparing to distribute funds for the second round of Pandemic Market Volatility Assistance Program payments to dairy farmers within a matter of weeks. The rst round of payments reimbursed dairy farmers for 80% of the calculated revenue difference per month during the July-December 2020 time period. The rst payment was on the rst 5 million pounds of product, and the second round pays dairy farmers for 5-9 million pounds of milk production during that same window of time. Payments should be made by June 20.

MOST COMPLETE HAY LINE Cut • Dry • Harvest Save time, money and improve hay quality with KUHN.

Mower Conditioners

THE HAY AND FORAGE TOOL SPECIALISTS

hay and forage is the focus of KUHN's hay tool innovation. Our commitment is to help you gain a maximum return on investment by providing products known for performance, reliability, and longevity.

IA

Indianola,

Fluegge’s Ag Mora, MN

Northland Farm Systems Owatonna, MN

Lake Henry Implement Paynesville, MN

Miller-Sellner-Slayton Slayton, MN

KuhnNorthAmerica.com rthAm Visit your local KUHN Hay and Forage Dealer today! INVEST IN QUALITY ® www.kuhn.com Van-Wall Equipment

Woller Equipment Swanville, MN A & P Service Wells, MN

Pfeifer Implement Sioux Falls, SD

Grossenburg Implement Winner, SD

Mark's Machinery Yankton, SD

America’s Dairyland celebrates June Dairy Month

In the words of Wisconsin Gov. Tony Evers, “No one does dairy like us.” In a video message to commemorate June Dairy Month, Evers emphasized Wisconsin supplies over 25% of the cheese to the nation. Evers cited the state’s support for the industry with its Dairy Processor Grant Program and Wisconsin Farm Support Program. The dairy industry contributes nearly $46 billion to the state’s economy.

Added sugars debate includes avored milk

USDA is looking for ways to reduce the amount of added sugars in food and is considering a ban on chocolate milk from schools. Milk consumption declines signicantly in schools when avored milk isn’t an option. Nearly 40 major school milk processors have pledged to offer school milk options with no more than 10 grams of added sugar per 8-ounce serving by the 2025-26 school year. The Healthy School Milk Commitment has been made to get ahead of USDA’s update of its dietary guidelines.

Heroes of Hope

The Wisconsin Farm Bureau Federation has honored Bob Nash of Ozaukee County as this year’s Heroes of Hope award recipient. Nash served this past year as the agriculturalist representative on the WFBF Young Farmers and Agriculturalist Committee. After a re destroyed a local farmer’s barn, Nash found a new location for the cattle and coordinated the cleanup. This recognition is part of the #FarmNeighborsCare campaign.

New headquarters for WFU

The Wisconsin Farmers Union has announced plans for its new headquarters in downtown Chippewa Falls, Wisconsin. Construction will begin this summer with plans to be completed by July 2024. In addition to the state WFU headquarters, the facility will include a food hall, which will house up to 14 independent small food businesses.

A victory for AM radio

Ford Motor Company has reversed its previous decision and will keep AM radio in its new vehicles. Ford is also offering a software update to provide AM broadcast capabilities in its electric vehicles. National Association of Farm Broadcasting Executive Director Tom Brand credits the rural community and their lawmakers “Listeners responded and reached out to lawmakers and automobile manufacturers,” Brand said. “There was also a letter sent by 102 mem-

bers of the House of Representatives in recent weeks to several automakers; it not only reminded them about the importance of AM radio, but also asked some pointed questions, including the amount of federal subsidies they’ve received in the last 15 years.” Bills have also been introduced in the U.S. House and Senate to preserve AM radio in cars and trucks. Local radio has a role in providing information during weather emergencies, and these proposals would consider radio as a safety feature in cars and trucks.

Stenholm passes

Former Texas Congressman Charlie Stenholm, 84, has died. Stenholm was the ranking member of the House Agriculture Committee from 1997 to 2005. Stenholm also chaired the Blue Dog Coalition. Once his time in ofce ended, Stenholm was a lobbyist on agricultural interests and taught farm policy at Tarleton State University.

Cheese champions

The Wisconsin Cheese Makers Association has presented its annual Cheese Champion awards to six lawmakers. Wisconsin Sen. Tammy Baldwin was honored for her work on the Dairy Business Innovation Alliance and the dairy labeling issue. WCMA recognized Gov. Evers for expanding Wisconsin dairy exports and supporting rural broadband. Four state Republican lawmakers were also honored for their support of the dairy processing industry. The honorees include Sen. Joan Ballweg of Markesan, Rep. Tony Kurtz of Wonewoc, Sen. Howard Marklein of Spring Green and Rep. Travis Tranel of Cuba City.

WDE hires sponsorship manager

Jennifer Dobbs is the new sponsorship manager for World Dairy Expo. For the past 12 years, Dobbs was the director of festivals and events for the Wisconsin Dells Visitors and Convention Bureau.

Trivia challenge

June Dairy Month began as National Milk Month in 1937. That answers our last trivia question. For this week’s trivia, how many pounds of milk are needed to produce 1 pound of cheese? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

The family’s primary connection to the Nosbushes before the deal was Melissa’s ve years of employment at their Fairfax dairy from 2012 until 2017, overseeing the embryo transfer and in vitro fertilization programs.

“My husband and I have always talked about how we could grow our farm, be relevant and be a place where people want to be,” Melissa said. “This was just kind of another piece in that puzzle, and we were really grateful that it was able to go through.”

As an employee, Melissa valued the attention to detail and high standards with which the Nosbush brothers – Brad, Leroy and Dave – ran the dairy. She said she did not expect her family to be considered to take on the operation when they were looking for an exit strategy.

“I was very surprised and pretty humbled that Brad thought well enough of me and my family that he was interested in us being the ones to take over,”

Melissa said. “I was oored when it rst got brought up.”

After approximately a year and a half of ironing out the details, the LaxPietig operation took on the Nosbush Dairy farm Sept. 1, 2022. During their rst nine months of operation, described by Jamie as “challenging but enjoyable,” the family remodeled some of the pens to optimize space for the cattle and built a breezeway behind the holding pen.

The Nosbushes continue to work closely with the dairy’s new owners, occasionally providing tips and advice to aid the operation. Melissa also credited long-time staff members with aiding in the transition process and ensuring minimal hiccups along the way. “Paul Rettmann, Kari Schumacher, Sarah Dalgleish, and newcomer John Helget have really been a big part of making things run smoothly,” she said. “Everyone has been really

“Everyone has been really great to work with through the transition. Our team makes everything work and we are so grateful, we can’t say that enough.”

MELISSA PIETIG

great to work with through the transition. Our team makes everything work, and we are so grateful. We can’t say that enough.

The acquisition allowed Jamie to focus entirely on farming and business management instead of on his previous position with Hubbard Feeds as a nutritionist working primarily with swine.

“I truly enjoy farming; that is my No. 1 passion,” Jamie said. “Every day I get to farm, take care of livestock and do eldwork, that’s a good day. It doesn’t feel like you’re working.”

In addition to sharing a passion for farming, the Pietigs and Laxes said they enjoy working so closely with family. Their 18 full-time staff members consist

of several cousins and people they praised for their reliability.

A third generation of Laxes and Pietigs already expressed interest in the family tradition of farming. Melissa and Jamie’s son Henry requests to tag along on tractor rides, and their daughter Rosie repeatedly expresses interest in veterinary science. Mike’s daughter Millie is known to lend a hand with the calves and pigs.

“It’s always been a goal to work with family,” Mike said. “Anytime you work with family, you always want to make sure you listen to everybody and everyone’s concerns get heard to move forward with a common vision. We try to make sure everybody is rowing the boat in the same direction at the same time.”

The expansion doubled down on the family’s commitment to the agriculture industry as a move to position them for future success.

“We understand that we have to stay progressive in farming, and that means looking for the next opportunity because we always need to keep moving forward,” Jamie said. “I’d say what has categorized us as a business

so far is that we have looked for opportunities, and when we nd a good one, we’ll jump on it. The research barns were a good example of that.”

Melissa leads research in the hog barns that house approximately 7,500 pigs between both locations. The family works with Hubbard Feeds to determine the effects of feed

variation and other factors on the pigs’ weight, health and growth.

The Pietigs’ and Laxes’ diverse agricultural portfolio demonstrates their desire to continue their family tradition within the industry for decades.

Melissa said they hope to continue seeking opportunities and creative solutions to grow the

operation for future generations.

“The goal is to keep moving forward and playing a role in agriculture,” Melissa said. “The percentage of people who grow and produce food keeps getting smaller, and we all have to eat. We want to be able to stay part of the community and part of producing food as well.”

dairy in Goodhue County and Goodhue in particular, how important an industry it is to the local economy and school,” McNamara said.

As the farm host, he has been part of the planning process alongside other members of the dairy community.

“I didn’t realize how much planning this takes,” he said. “I feel very fortunate that I just kind of have to keep getting my place ready.”

Preparations on his farm have included replacing a retaining wall and ower bed. He also expects to do basic cleaning along with planting some owers and painting his white wood fences before the day.

He was able to put up his rstcrop hay early enough that it will be done by the event; his second crop will not be ready until after the event.

McNamara houses his cows in three sand-bedded, freestall barns and milks in a double-8 herringbone parlor. He raises his calves to 400 pounds and then sends them to a heifer raiser.

Michael works with the calves and is in charge of the farm’s custom cornstalk round baling operation. Michael also has his own dairy steer calf operation with around 100 calves that he raises to 400 pounds before selling to a network of buyers.

On the day of the event, McNamara expects to get up at 3 a.m. to do some chores and work in order to be ready to host by 7 a.m. when

Hay dries May 25

there.

front

the breakfast begins. His milking will continue on its normal schedule from 5-10 a.m. He has hired additional help for the day so he will not need to do milking that morning.

Since McNamara lives on a

LIGHT WEIGHT, FAST AND BUILT TO LAST

AirFLEX SDX is the clear-cut choice for soybean growers. It offers streamlined flex cutting for your soybeans, providing optimal ciency with fewer components, making it simpler to maintain.

The harvest window is short for soybeans. You want to get them off the ground fast and into your bins where they’ll be warm, dry and safe.

You’ll get all the speed you need with the next generation of draper header innovation. The AirFLEX SDX features sensors and air suspension that allow the flex header to shave the ground, picking up more of the crop. It’s lightweight yet durable, sophisticated yet easy to use, all while integrating cutting-edge innovation. Crafted on the farm, you’ll appreciate the combination of thoughtful design, high performance and simplicity – and the extra money it will generate.

“Overall, I’m going to say that the header is above anything that I have run personally. It’s simple yet it does exactly what you want it to do. It’s not a complicated head; it’s not complicated electronically or mechanically. They’ve done a good job of keeping it simple so its maintenance over time is going to be easy. I don’t think that’s going to be an expensive header to keep operating.” - Bruce Baldwin, Kalvesta, Kansas

gravel township road and does not have much space for additional parking, guests will be shuttled to and from the event from Goodhue and Red Wing high schools. A free breakfast will be served

in his shop building that includes Ellsworth cheese curds, made by Ellsworth Cooperative Creamery, where McNamara sells his milk.

“I’m kind of doing this … to showcase Ellsworth Creamery

Turn to MCNAMARA | Page 9

… that top quality milk goes into their cheese curds,” he said.

McNamara wants guests to feel welcome as they walk onto his farm and be surprised by the excellent care the cows receive on the dairy.

Bluff Country KCUE 1250-AM and 98.9-FM will be broadcasting live during the entirety of the event from 7-11 a.m.

Guests will be able to go on farm tours, meet Princess Kay of the Milky Way Rachel Rynda and the Goodhue County dairy royalty, play McNamara bingo, enjoy a petting zoo, milk Annabelle the cow, play games, see a farm equipment display, try out the Ag Cab Lab, participate in a name a calf contest and ride on a kids tub train.

McNamara plans to put bales down the center of his wide alleyway in the calf barn for parents to take photos of their kids sitting on them or for just sitting. He expects the calves to be popular.

Though McNamara has never hosted the Goodhue County Breakfast on the Farm before, it is not his rst large event on the farm. Two years ago, he hosted a quinceañera for the niece of one of his employees. The celebration included a 12-piece band, lights and 400 guests.

McNamara has dairy farmed his entire life and never considered doing anything else. He is proud of his two daughters who have both married farmers and are teachers in their communities.

“It’s been in my blood because there’s been cows in our family for 75 years,” McNamara said.

BUILT TO KEEP GOING.

BECAUSE

Sudden arrival of change

Agco Allis 8875, 2WD, CAH w/

loader

GC1723, ldr., mower, 180 hrs.

1705, 60”

1705, 60”

Hebigs continue legacy of late uncle’s farm

By Jan Lefebvre jan.l@star-pub.comLITTLE FALLS, Minn. – When Adam and Hanna Hebig moved their young family to the farm near Little Falls they had been operating with Adam’s uncle, Peter Fussy, it was with unexpected heavy hearts. Instead of moving into a manufactured home they had ordered but had not yet been delivered to the farm site, the couple and their children moved into the farm’s existing house.

“The (manufactured) house was supposed to have been here already, but the company was late making it,” Hanna said. “Now (the timing delay) seems strange.”

Together, the Hebigs and Fussy were milking 150 cows in a tiestall barn with the milk going to Land O’ Lakes in Melrose.

“Peter was always saying, ‘If you take care of the cows, they’ll take care of you,’” Hanna said. “We’re even teaching that saying to our kids.”

That motto, Adam said, is one reason that Fussy and the Hebigs had set the goal to focus on their herd’s health and performance, and they have been seeing steady improvement.

“In 2019, we got away from the bed packing and went to free stalls with just the rubber mat and chopped straw over the top,” Adam said. “The cows are a lot cleaner now than when we had the bed pack. Cow comfort is key, so we really push to make sure everything is clean and dry all the time.”

The Hebigs divide the herd in half, switching them between the freestall area and the tiestall barn.

“The one group that’s outside during the day is in the barn at night,” Hanna said. “They kind of get the best of both worlds. They get to wander in the free stall for half their day and then be in the tie stall the other half.”

Individual cow care is enhanced by the use of cow monitoring.

200 hrs.

300 hrs.

The Hebigs had been living in nearby Sobieski and driving each day to the farm. The morning of Oct. 4, 2022, they arrived to nd that Fussy was not out doing chores already as was his typical routine, so they went to check on him. They found Fussy in his house, collapsed from a fatal heart attack.

“He was getting ready to come outside,” Adam said.

“We installed some cow manager ear tags, and it helps us detect if we are going to have a somatic cell count issue with a cow almost before it happens,” Hanna said. “Then we take her out right away to see if she just got bumped and got mastitis or what it is. If we catch it sooner, the cow’s not down for as long a time.”

Careful attention to genetics has also improved the herd.

JD 146 Loader w/bucket

Loftness 20’ Stalk Shredder, NICE!!

Gehl 100 Feed Mill

‘21 Bobcat T870, SJC, High flow, 500 hrs.

‘21 Bobcat S76, SJC, 2,300 hrs.

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘14

Disc Ripper

JD 712 9 shank disc chisel

CIH MRX690, 5 shank disc ripper disc. JD 980 Field Cult., 44’ w/harrow

CIH 4800 30’ Field Cult, w/3 bar coil

harrow

‘08 Agco 3000 Corn Head, 8R30, poly

SKID LOADERS

Fussy was 55 years old and the third generation on the farm. Without a family of his own, he had welcomed his nephew and his family as the fourth and fth generations to farm there. The Hebigs have three young children – Adeline, Henry and Hudson.

Adam remembers working with his uncle at a young age.

“When I was 13, Dairy Star came out and did an article on me for a (Working Youth) story,” Adam said. “At that time already, I knew that dairy farming is what I wanted to do. When I got my license, I began milking with Peter mornings before school and after school. He was always supportive of me being here.”

Far too soon, the Hebigs have had to keep their farm going without Fussy.

“The rst month was a real shock,” Adam said. “At rst, there were so many people around helping, but once Christmas and the rst of the year came around, then it was just us and the kids and the crew. They all stepped up and did what they could, and if they didn’t know something, they would ask me.”

Today the Hebigs are in the process of buying the farm from the family estate. Hanna said Peter taught them so much to prepare them for the suddenness of owning the farm, and they hear themselves saying his mottos.

“Because I do all the breeding and am milking, I can see what that cow produced as far as a calf and then see what that offspring does when she comes into the barn,” Adam said. “I like the genetic side of things, to see if the genetics made an improvement or not.”

Hanna agreed that it is exciting to watch the herd’s progress.

“Now I’ve been raising calves long enough that those calves that I started raising are in the herd,” Hanna said. “It’s nice because I get to see with genetics how things change.”

Adam also credits his uncle with teaching him a good philosophy for growing crops as a dairy farmer. The Hebigs farm 400 acres of alfalfa and corn.

“(Peter) always said that, even if you don’t have the money, you still need to put in the crop to feed the cows,” Adam said. “He was always one who wanted to make sure you had feed for the cows before you decided to prevent plant, and he would plant right up to when it became basically too late to plant to get anything back. I still follow that. He’d say, ‘A paper check won’t feed the cows.’”

Solid and sensible farming is what Fussy promoted, Hanna said, and that continues with the next

generation.

“Peter always said, ‘If it’s working good, don’t change it,’ Hanna said.

The Hebigs are still adjusting to farming without Fussy, but they found support through their young employees. The loss of Fussy has made the team band together.

“It’s still weird that Peter’s not here,” Hanna said. “But, we are really blessed with how everyone stepped up to the plate.”

One current employee, Dillon Krebs, started working part time in 2019 when he was 14 and his parents had to drive him to the farm. Logan Leyendecker started part time in 2021. He just graduated and switched to full time. Another employee, Colton Waltman, 14, started bringing his 12-yearold brother Alex with him for extra help when Fussy died. Alex has been working there ever since. Adam’s sister Alice helps part time as well.

That crew, the Hebigs said, has more than earned their trust and given them peace of mind to dedicate even

Peter Fussy holds his greatnephew, Henry Hebig, in 2020 on his farm near Li le Falls, Minnesota. Henry’s parents, Adam and Hanna, said they learned their farming philosophy from Fussy, who passed away Oct. 4, 2022

more time to cow health management, further helping them succeed with the goals they had set with Fussy.

“Everything improves and the cows do well because we have the help that lets us take care of cows while not exhausting ourselves,” Hanna said.

Adam agreed.

“If it hadn’t been for our help, we couldn’t have made this go as well as it did,” he said.

As the Hebigs raise their children on the farm, living in what was Fussy’s home but is now theirs, they plan to keep his legacy going.

“To be fourth generation is pretty good, and to have the fth generation following beside you makes you push through some of those rough days,” Adam said. “We’ll expand a little bit, but it will still stay a family farm. We’re going to make it so that, if (our children) want to, they can survive off the farm that we and they have helped build.”

That goal is important to Hanna as well.

“Peter has pushed for so many years to keep it a family farm and to keep it in the family,” Hanna said. “There were years that were tough for him, and he pushed through just so Adam would be able to farm one day. Now, we are going to do the same for our kids.”

it s hot out. I have a hard time keeping my dry matter intake up.”

A Milwaukee tradition

Wisconsin’s oldest custard stand celebrates 85 years

By Stacey Smart stacey.s@dairystar.com

MILWAUKEE, Wis. –

When craving custard, people in the Milwaukee area can satisfy their longing with a trip to Gilles Frozen Custard. A local favorite of custard connoisseurs, Gilles Frozen Custard has been serving customers since 1938, making it the oldest custard stand in Wisconsin. Father and son duo Tom and Willy Linscott – the establishment’s present owners – have created nearly 200 avors of custard that keep customers coming back for more.

“We’ve been here a long time, and this place is very nostalgic to people,” Willy said. “Gilles Frozen Custard is the rst stop some people make after coming back from the airport and their rst stop before going to the airport.”

Tom echoed Willy’s sentiments.

“Some people come here more than once a day,” Tom said. “It’s very humbling.”

Gilles Frozen Custard was started by Paul Gilles, who in the beginning served vanilla custard, hot dogs and root beer from a walk-up window from March through November. Gilles Frozen Custard was not the rst custard stand in the state, but it is the longest running. While other custard

stands have come and gone, Gilles Frozen Custard remains a xture in the community, celebrating 85 years in business.

Tom began working at Gilles Frozen Custard in 1975. His dad, Robert, who worked at the custard stand since 1942, purchased the business from Paul in 1976. In 1978, a lobby

was added to the building, and Gilles Frozen Custard became a year-round destination.

Tom and his brother, Patrick, bought the restaurant from their parents in 1992. When Patrick passed away, Tom bought his brother’s portion of the business. Tom’s brother, Bob, also works at the

business. Willy came on board in 2013 and is the third generation in his family to own and operate Gilles Frozen Custard. The business is known for its classics – frozen custard in cones, dishes, pints, quarts and party tubs as well as sundaes, shakes, malts, oats, specialty custard pies and novelty treats. Gilles Frozen Custard also sells hamburgers, cheeseburgers, hot dogs, homemade sloppy joes, French fries, cheese curds, sh fries, grilled cheese and more.

The frozen custard recipe begins with Gilles Frozen Custard’s patented mix, an original recipe of Willy’s grandfather, which contains a high level of butterfat. The custard is then made fresh on-site into thick and creamy avors.

In addition to favorites like vanilla and chocolate, Gilles Frozen Custard offers a variety of tempting avors from Monkey Madness and Mocha Tiramisu to avors modeled after liquor, such as their Jameson Whiskey and Bailey’s Irish Cream avors. The Linscotts also created a tequila custard once for a wedding.

“The sky’s the limit for avors of the day,” Tom said.

The stand’s most popular avors are butter pecan and turtle.

Group of Companies

“Those are classics in our communities,” said Willy, who also has avors named after his four children.

London’s Lemondrop, named for his daughter, is a lemon custard blended with lemon meringue. Chocolate lovers will nd happiness at Gilles Frozen Custard with avors like chocolate candy bar crunch, chocolate decadence and heavenly chocolate.

“Add chocolate to anything, and it moves,” Tom said.

The stand is known for its fancy sundaes, like the Zombie, which Willy describes as “a banana split and then some.” On top of a heap of custard are bananas, marshmallows, strawberries, pineapples, jimmies, chopped nuts, hot fudge and pecans.

From its owners to their loyal employees and customers, Gilles Frozen Custard brings families together.

“Working here is a family tradition,” Tom said. “There are grandkids of people I used to work with who work here now.”

Gilles Frozen Custard has 40 employees, including many long-term people. Husbands and wives, siblings, and mothers and their children work together where a busy summer day can draw a couple thousand people. Located 1.8 miles from American Family Field where the Milwaukee Brewers play baseball, Gilles Frozen Custard attracts many fans after games as well as other events.

The Linscotts encourage input from their employees, and Tom said their workers come up with many good ideas.

“We’ve built an environment where people feel comfortable bringing ideas to the table,” Tom said. “They might say, ‘What if we did this?’ And Willy and I will say, ‘Let’s try it.’ Our people are important.”

Working at the custard stand was not the job either Linscott originally envisioned for himself.

“I was going to go in the trades after high school and get a real job,” Tom said. “But, my dad had remodeled the place, and he told me three things he could guarantee about working here: There will always be work, you’ll never go hungry, and you’ll never be rich. That sounded good to me, so I decided to stay.”

Growing up, Willy also had dreams of working elsewhere.

“Watching my dad do it, I was very adamant (I was) not going to do this,” Willy said. “I went to college and had

another job for a while, but I came back because my heart was still in it. ‘What’s going to happen to the business if it’s outside of the family?’ I wondered. There is untapped potential here – a lot of people don’t know the story or our legacy.”

Willy has dressed the walls with details of the company’s history that illustrate the progression of Gilles Frozen Custard from the day it started up to today.

The quaint custard stand offers both indoor and outdoor seating. Not long before the coronavirus pandemic started, the Linscotts also put in a phone-in pickup window.

“That window saved us,” Tom said. “The business that went through the window was unbelievable.”

The Linscotts also cater for weddings, parties, funerals and company events. In total, Gilles Frozen Custard sells about 15,000 gallons of custard each year.

“The dairy industry is vital to our business,” Willy said. “We’re so dependent on it. Dairy makes up 50% of our business.”

In addition to all the custard rolling out its doors, the restaurant also uses a lot of cheese, the Linscotts said.

“Through all of the supply issues we’ve faced the last few years, the dairy side has kept up with it,” Willy said. “Dairy is in our name. It would just be Gilles Frozen without it.”

The Linscotts are quick to point out that custard is not the same as ice cream, and they never use the terms interchangeably.

“The egg yolk solids in custard are slow melting,” Tom said. “Also, there is way less air whipped into custard. When you compare a pint of custard to a pint of ice cream – ours will drop the scale. It’s solid.”

To celebrate their 85th anniversary, Gilles Frozen Custard is having a customer appreciation party June 27 and July 4, providing food, games and other family-friendly activities.

“We’re doing a lot of specials and throwbacks this summer,” Willy said.

The iconic little stand on West Bluemound Road has grown over time while staying true to its roots.

“Gilles Frozen Custard has built a community identity as a taste of the neighborhood,” Willy said. “This is a good thing going for a long time, and thanks to the customers, we’re still here.”

from our side our side OF THE FENCE THE

Dairy farmers: If you were organizing a June Dairy Month activity, what would you do?

Rosanne Caughey Ft. Ripley, Minnesota Crow Wing County110 cows

What does being a dairy farmer mean to you? Dairy products are a basic need of the human body, and I am honored to be someone who helps supply that need. Being a dairy farmer has been my life.

I have been referred to as the "Cow Lady" several times, and I am proud of it. Dairy farming means getting up early to care for the animals that make milk for my refrigerator and ice cream for the freezer. It is an occupation that requires dedication and commitment. At the end of the day when it seems I haven't accomplished much, if the cattle got cared for, it was a good day. Working with my husband and children is rewarding as we watch the growth of the animals, the farm and the family. It is amazing.

How do you personally promote the dairy industry? I have personally promoted the dairy industry in many ways by doing a lot with the dairy princesses and ambassadors over the last 40 years. Specically, there have been dairy princess banquets; milkshakes served at the fair; radio interviews; farm tours; classroom, library and nursing home visits; milk-drinking relays; cow milking contests; dairy days at the bank; and dairy products at meetings, festivals and fundraisers.

If you were organizing a June Dairy Month activity, what would you do? If I were organizing a June Dairy Month activity, it would have to be simple because everyone is so busy. I am not very wise about posting on social media, so I would encourage our dairy princesses and ambassadors to post dairyrelated facts and recipes on their sites. And, I will be bringing dairy refreshments to the meetings I go to this month.

What are the most effective dairy-related campaigns of all time? The most effective dairy-related campaign has been the REAL seal. When it rst came out, we encouraged people to look for it because there was imitation cheese in the dairy case. Now, the other beverages are encroaching on us, so we need to make the seal bigger and bolder on dairy products.

What is the biggest misconception in the dairy industry?

The biggest misconception in the dairy industry is that we don't need the 100 or fewer cow dairy farms. Efciency is good, but being bigger isn't always better. Consumers think dairy farmers are getting rich by the prices they see at the stores for dairy products.

What is your favorite dairy product and meal with dairy in it? My favorite dairy product is an ice-cold glass of milk. Add a hotdish with cheese and a bowl of ice cream, and I'm happy.

Tell us about your farm and family. My husband and I farm with our two sons, being a minor partner in both of their family farms. One has beef and the other dairy. Our dairy, Cornerstone Dairy, consists of about 110 dairy cows and all the youngstock. We milk in a tiestall barn that has the capacity of 56, and we sell our milk to Associated Milk Producers Inc. Our crops consist of corn, alfalfa, oats and rye, and I help raise our seven grandchildren, who live next door.

Nicolien Hammink Bruce, South Dakota Brookings County4,500

cows

cows

What does being a dairy farmer mean to you? It feels good to know we are producing the milk that will be made into products that will help feed the world. How do you personally promote the dairy industry? We do volunteer work every year for each new dairy fest and share information about our farm by posting frequently on Facebook. We hosted dairy fest this year at our farm June 3 and had a really good turnout. We received a lot of nice comments from people who visited our farm.

If you were organizing a June Dairy Month activity, what would you do? It would be an open house with lunch on the farm so that people could see where their milk comes from and what is needed to run a dairy farm. Visitors could ask all the questions that they have in a friendly atmosphere.

What are the most effective dairy-related campaigns of all time? The “Got Milk?” slogan and the milk moustache were both very effective. They were easy to remember and fun to work with.

What is the biggest misconception in the dairy industry? Many feel that it’s better for cows to be outdoors. During our recent dairy fest open house, we got many comments from people who were surprised at how relaxed and comfortable our cows are. Our cows never get cold in the winter and are kept out of the hot sun in the summer. People could see for themselves that it’s actually better for the cows to be inside.

What is your favorite dairy product and meal with dairy in it? My favorite dairy product and meal is cheese enchiladas.

Tell us about your farm and family. My husband, Wim, and I came to South Dakota from the Netherlands in 1995 with three boys under the age of 7. We started milking in a barn with 300 cows. Now we have two locations with a total of 4,500 cows. The original location is currently being used for maternity cows, fresh cows and sick cows. We keep our calves there for ve months before they go to a grower in Minnesota. The south location has a carousel milking parlor where we milk about 3,200 cows. We ship our milk to Valley Queen Cheese Factory in Milbank, South Dakota. We grow corn and rye grass and buy additional corn and alfalfa from our neighbors.

Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant.

Feeding your animals like they’re our own

Contact Star Blends at: 800-462-4125 or StarBlends.com

Kathi Molitor Belgrade, Minnesota Stearns County

80 cows

What does being a dairy farmer mean to you? It’s a huge commitment. It’s every day. Dairy farmers don’t get holiday off or paid vacation. I didn’t come from a farm myself and was amazed by the dedication my husband and all dairy farmers have.

How do you personally promote the dairy industry? I faithfully purchase a lot of dairy products, milk, creamer and butter. They are staples in our house. I personally thank the cashier every time I get my coffee at a gas station and they have real dairy creamer.

If you were organizing a June Dairy Month activity, what would you do? I would focus in on preschool children and kindergartners and teach them where their dairy products come from. I would have them make butter in baby food jars. We would put cream and salt in the jars and have the kids shake it. This has the same effect as churning. Then the kids could taste it by putting it on crackers. I would teach the kids about how nutritious dairy products are.

What are the most effective dairy-related campaigns of all time? The 3x3 program from in the 1980s when my kids were little. That focused on getting three servings of dairy three times a day. The “Got Milk?” campaign was also a popular one.

What is the biggest misconception in the dairy industry? There are dairy products out there for people who are lactose intolerant. Most people who are lactose intolerant just assume they cannot eat real dairy products anymore. There are real milk options available for those who are lactose intolerant.

What is your favorite dairy product and meal with dairy in it? I love lasagna and pizza. I always get the tater toper sour cream with chives in it for baked potatoes. My favorite dairy product of all time is the sliced baby swiss cheese.

Tell us about your farm and family. My husband, Al, and our son, Tyson, who has been farming with us for 11 years. Together, they milk 80 cows in a tiestall barn and farm 325 acres. We have three grown children and four grandchildren. We ship our milk to First District Association in Litcheld, Minnesota. I love to garden and spend time with my grandchildren.

220 cows

What does being a dairy farmer mean to you? Being a dairy farmer to me means commitment, dedication, passion and hard work. Dairy farming is by no means an easy task; however, these farmers are committed to their business, ensuring consumers get nutritious high-quality milk. They are dedicated to their herd’s health, safety and well-being. They are passionate not only about their career but their lifestyle and are some of the most hardworking individuals who put in countless hours before sunrise to after sunset.

How do you personally promote the dairy industry? I personally promote the dairy industry by being a dairy princess for Brown County, Minnesota, and a dairy ambassador for Brookings County, South Dakota, both through Undeniably Dairy. These programs have given me countless opportunities to learn and grow within the industry. By doing so, I am able to effectively communicate with consumers one-on-one and give insightful answers to their questions, give knowledgeable tours of dairy farms and encourage children to be excited about their favorite dairy product.

If you were organizing a June Dairy Month activity, what would you do? If I were organizing a June Dairy Month activity, I would create a dairy trivia night suitable for all ages. While I was growing up, I attended trivia nights hosted at my town’s local coffee and brewery shop. A dairy trivia night would be a fun and educational event that would consist of teams competing against one another. Each team could choose their own dairy-related name, and they would have to compete in a few rounds of questions ranging from easy to difcult. This family friendly event could offer a dairy-related prize for the top three teams which would hopefully not only draw in dairy farmers and their families but locals as well.

Larry Clayton

Waseca, Minnesota

Waseca County

37 cows

What does being a dairy farmer mean to you? Being able to be your own boss and seeing the rewards of your hard work. There is nothing like helping an animal in need, caring for each cow and watching the crops grow in straight lines in your elds. Teaching my children the importance of hard work and caring for the animals has been an integral part of being a farm family.

How do you personally promote the dairy industry? I have been on the Waseca County American Dairy Association board for over 30 years. In that time, I have been in the public eye at our county fair in the malt wagon and at the June ADA events. I have driven in parades and helped educate our youth at Ag in the Classroom. I have also been involved with our county fair’s open class dairy show for over 20 years.

If you were organizing a June Dairy Month activity, what would you do? It is important to educate people, starting with the younger generation and the urban population. People enjoy hands-on experiences, so I would make sure to have different learning areas that would be interactive and educational. I would want to

What are the most effective dairy-related campaigns of all time? The “Got Milk?” campaign. In the 1980s, the ads for sugary drinks were outweighing the milk campaign which led to the creation of “Got milk?” This campaign took an entirely different route in order to draw consumers back in. Instead of focusing on the health benets of milk, they focused on creating an ad based on when people noticed milk the most, which happened to be when they were out. The central point of the rst commercial was to focus on the frustration of not having milk. This campaign would not have been as successful as it was if they had not used deprivation marketing. On top of that, “Got milk?” is a short and catchy phrase I still remember learning about as a kid.

What is the biggest misconception in the dairy industry? The biggest misconception in the dairy industry is that it is cruel to separate calves from their mothers. When individuals go on tours of dairy farms, they often draw a concern to the calf pens when they realize the calves are away from their mothers. What people often don’t know is that claves and cows are separated because it is best for both their health and safety. This allows the cow to return to her herd where she is most comfortable and happy. The calf is then carefully brought to a clean, freshly bedded pen. Calves are given care and are made sure they are getting the colostrum saved from their mothers within the rst 12 hours of life. Cows can also reject their calf, neglecting care or milk for its offspring. Dairy farmers want the absolute best for their animals, so they ensure their health and well-being by keeping a close eye on the calves as well as making sure they are all receiving clean and nutritious milk.

What is your favorite dairy product and meal with dairy in it? Most denitely ice cream. There is something about the sweet, creamy frozen desert that I cannot go a day without. My favorite meal containing dairy is my parmesan chicken and shrimp hotdish containing whole milk, cream cheese and parmesan cheese.

Tell us about your farm and family. I live on a retired dairy farm; however, I have been employed at my neighbor’s 220-cow dairy for the past four years. This summer, I am interning for them, Roseview Dairy, where I milk twice a day in their double-12 parallel parlor, feed calves, clean and bed pens, sort livestock, IV cows, update information in their dairy programs and many other jobs. During the summer months, they are busy planting and harvesting corn and soybeans, cutting hay and making silage. Roseview Dairy exists to raise and maintain high-quality performance dairy cattle and produce the best quality milk to nourish the community while maintaining the family business.

have them explore how the milk gets from the cow, to the milker, to the bulk tank, to the truck and the processing plant, and nally to the grocery store.

What are the most effective dairy-related campaigns of all time? “Got Milk?” Everyone knows what that is, and many people still use the phrase. It is something that sticks in your head. Another one is “3-A-Day” because it reminds people about the importance of having three servings of dairy products a day.

What is the biggest misconception in the dairy industry? That even though eggs and orange juice are near the dairy section in a grocery store, they are not dairy products. Plus, chocolate milk doesn’t come from brown cows. On a more serious note, dairy cows are well taken care of on most farms. When a farmer doesn’t take care of their cows, the cows stop producing milk. So, we want to make sure the cows are comfortable and well cared for.

What is your favorite dairy product and meal with dairy in it? Chocolate milk and ice cream are my favorite dairy products. My favorite recipe is my wife’s homemade pizza with just the right amount of cheese.

Tell us about your farm and family. We have 210 acres of farm land and grow corn, beans and alfalfa. We milk 37 cows in a tiestall barn. We raise our own replacement heifers and have about 75 head. Our milk is shipped to Associated Milk Producers Inc. in Le Sueur, Minnesota. I operate the farm with my brother, Bill. My wife, Cindy, and Bill’s wife, Sofy, occasionally help; otherwise, they both work full time off the farm.

Using baleage for better butterfat, protein components

Describe your farm and facilities. We have a 103-stall freestall barn with a problem pen. We milk in a double-8 swing parlor with automatic takeoffs.

What forages do you harvest? We have 55 acres of hay to make baleage and 125 acres of corn to make corn silage. If we have corn after making the corn silage, we make snaplage.

How many acres of crops do you raise? We farm 180 acres, 60 of which are rented. This year, there are 55 acres of hay ground and 125 of corn.

What quality and quantity do you harvest of each crop? We try to get hay made at 160 relative feed value for the cows.

Describe the rations for your livestock. Per cow, we feed 71.7 pounds of corn silage, 24 pounds of baleage and 14 pounds of a complete grain protein mix.

Describe your harvesting techniques for alfalfa and corn silage. Our hay is baled. We hire someone to bale and cut it. We hire

a custom chopper for doing our pile.

What techniques do you use to store, manage and

feed your forages? Our farm does alfalfa baleage at around 40% moisture, and we hire a guy to wrap it. We have round bales and wrap

them in a tube. We like to catch the alfalfa at 160-165 RFV, and we use a chart from the University of Minnesota that tells us we should cut when it is 27 inches tall, just as the buds emerge. We have a tar pad and do a pile for silage.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We now do baleage for better butterfat and protein components. We used to do haylage, and we were at 3.9% butterfat. Now it is at 4.3%. Protein used to be at 2.9% and now is at 3.19%.

Describe a challenge you overcame in reaching your forage quality goals and you overcame it. We used to do all hay and silage in ag bags. We wasted too much

Turn

Happy June Dairy Month!

USED TRACTORS

2200 hrs .........IN SOON

Magnum 280, ’19, 4k hrs .........IN SOON

Maxxum 150, ’21, 1200 hrs ......IN SOON

(3) Magnum 320, ’22, 500 hrs .$330,000

Magnum 7220, MFD..................$48,500

Farmall 55C, MFD, loader .........$34,000

IH 656, gas, NF .............................$7,000

USED COMBINES

9240, ’17, 2300/1700 hrs..........$269,000

8250, ’22, 385/300 hrs..............$485,000

8230, ’14, 3000/2200 hrs..........$135,000

7240, ’16, 1800/1400 hrs...........IN SOON

7230, ’13, 3000/2450 hrs..........$125,000

7150, ’19, 1400/1100 hrs......... $229,000

7010, ’08, 3300 hrs....................$ 68,500

5088, ’12, 2000/1500 hrs..........$125,000

2577, 2400/2000 hrs................. IN SOON

2388, ’99, 4000/2900 hrs............$42,500

1680, ’86, 5300 hrs.....................$17,500

JD 569 2014, 1000 PTO, 5 ft. bales, 13500 BC, #543058 ............................ $28,500

Kuhn VB2190 2012, 1000 PTO, 4 ft. bales, 16000 BC, #543785................ $26,000

JD 560M 2020, 1000 PTO, 5 ft. bales, 5500 BC, #544100 .......................... $47,900

NH BR750 2005, 540 PTO, 4 ft. bales, 6000 BC, #544396 .......................... $13,500

JD 569 2015, 1000 PTO, 5 ft. bales, 9200 BC, #545913 .............................. $33,900

JD 560M 2022, 540 PTO, 5 ft. bales, 1516 BC, #547391 ............................ $61,500

Vermeer 605N Cornstalk 2017, 1000 PTO, 5 ft. bales, 6768 BC, #548033$46,500

JD 582 Silage Special 2006, 540 PTO, 4 ft. bales, 7685 BC, #550012 ....... $26,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 7000 BC, #550210 .......................... $43,900 JD

1000 PTO, 4 ft. bales, 15600 BC, #550251 .........................

Comprima V 180XC 2019, 1000 PTO, 4 ft. bales, 13573 BC, #550353 ....................................................................................................

4 ft. bales, 19000 BC, #557420 ..... $19,500

JD 460M 2019, 1000 PTO, 4 ft. bales, 5898 BC, #557634 .......................... $53,500

JD 568 2010, 1000 PTO, 5 ft. bales, 14683 BC, #559585 ............................ $30,000

JD 567 2003, 540 PTO, 5 ft. bales, 13500 BC, #561591 .............................. $17,900

JD 560M 2022, 1000 PTO, 5 ft. bales, 900 BC, #563551 ............................ $57,900

NH Rollbelt 460 2021, 1000 PTO, 4 ft. bales, 6846 BC, #563911 .............. $41,900

ROW CROP TRACTORS

JD 8R 370 2021, Cab, 1000 Rear PTO, Duals, 956 hrs., #535131 .............. $392,500

JD 8R 370 2021, Cab, 1000 Rear PTO, Duals, 608 hrs., #535161 .............. $431,600

JD 8R 410 2021, Cab, 1000 Rear PTO, Duals, 468 hrs., #541906

1150 hrs., #550330 ............ $437,500

JD 8R 310 2022, Cab, 1000 Rear PTO, Duals, 525 hrs., #553951 .............. $410,000

JD 8R 340 2020, Cab, 1000 Rear PTO, Duals, 1341 hrs., #554058 ............ $382,500

JD 8R 340 2020, Cab, 1000 Rear PTO, Duals, 1396 hrs., #554059 ............ $375,500

JD 8R 310 2020, Cab, 1000 Rear PTO, Duals, 1416 hrs., #554060 ............ $362,500

JD 8R 340 2022, Cab, 1000 Rear PTO, Duals, 677 hrs., #554166 .............. $419,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 159 hrs., #557151 .............. $504,900

JD 8R 410 2022, Cab, 1000 Rear PTO, Duals, 234 hrs., #557154 .............. $514,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 605 hrs., #558224 .............. $374,400

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 311 hrs., #559372 .............. $477,900

JD 8R 310 2021, Cab, 1000 Rear PTO, Duals, 938 hrs., #559593 .............. $349,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 323 hrs., #559674 .............. $499,800

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 400 hrs., #559680 .............. $475,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 269 hrs., #559753 ............. $479,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 603 hrs., #559754 .............. $364,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 307 hrs., #559757 .............. $379,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 395 hrs., #560057 .............. $468,000

NH T8.300 2012, Cab, 1000 Rear PTO, Duals, 2057 hrs., #561011 ........... $159,900

International 966 1971, 2WD, 540/1000 Rear PTO, Singles, 6534 hrs., #562559 .................................................................................................... $15,500

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 569 hrs., #562744 .............. $459,900

Case IH Puma 240 2021, Cab, 540/1000 Rear PTO, Singles, 312 hrs., #563034 ..................................................................................$229,900

JD 8R 340 2022, Cab, 1000 Rear PTO, Duals, 402 hrs., #563581 .............. $424,500

JD 8R 340 2022, Cab,

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470 MINNESOTA

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029

Pierz, MN

320-468-2494 St. Charles, MN 507-932-4288 Wadena,

Blue and gold honoree

Newell inducted into the MN FFA Hall of Fame

By Alex Christen Staff InternAVON, Minn. – After graduating from high school with one year of FFA experience under her belt, Sherry Newell had no idea how much of an impact she would leave on the organization throughout the rest of her life.

Newell was one of nine 2023 inductees to the Minnesota FFA Hall of Fame. The inductees were recognized at the organization’s alumni meeting March 4 and were formally inducted at the Minnesota State FFA Convention April 23 in Minneapolis.

As a mentor, coach and judge for FFA members for many years, Newell, of Avon, is well known for her work and dedication to the FFA organization.

“Even once my daughter had graduated, I continued coaching,” Newell said. “I have coached dairy judging, public speaking and even an ag communications team.”

In the late winter of 2023, Newell received a phone call from Natalie Utsch, FFA advisor in Paynesville. As the advisor for the chapter where Newell coached, Utsch was the one to notify Newell of her induction.

“I was somewhat sur-

prised,” Newell said. “I did not know that my name had been submitted this year.”

Newell’s involvement with local FFA chapters stretches back to the rst 12 years of her working career, where she was a farm broadcaster in St. Cloud. Right away, she connected with FFA chapters through a program called FFA Radio Days, where FFA members read the markets, news and ads on the radio.

“I also did a number of stories that involved FFA members,” Newell said. “I went to the National FFA Convention in Kansas City and to the Minnesota State Convention where I did lots of FFA interviews.”

In those rst 12 years of her career, Newell had a lot of FFA contact. She saw many of the changes the organization experienced through the years from the time she was a member during her senior year of high school.

When Newell was a member, the organization had just recently opened its membership to women.

“I was among the rst ve women in my chapter,” Newell said.

In addition to this change, Newell has seen the organization grow in the number of options offered for Supervised Agricultural Experiences and for prociency areas. She said the

Sherry Newell is one of nine 2023 inductees to the Minnesota FFA Hall of Fame. The inductees were recognized at the organiza on’s alumni mee ng March 4 and were inducted at the Minnesota State FFA Conven on April 23 in Minneapolis.

organization has more variety compared to what there was at one time.

Once Newell left the world of radio broadcasting, she went on to work for Midwest Dairy. This career change only furthered her connection to the FFA organization. Newell represented Midwest Dairy in multiple FFA events, such as judging at the state level and offering ways

that Midwest Dairy could support FFA, primarily at the state level.

Not even retirement from Midwest Dairy could stop Newell’s dedication to the FFA organization. She continued to be involved, this time through mentoring college communication students. She is a partner in leading these students to manage the communications surround-

ing the state FFA convention. Newell said she loves being involved in this organization, no matter in what way.

“The coolest thing is just to be able to stay connected to this organization,” Newell said. “Time, talents and mentoring are a huge help to the organization, and I’m just proud to have had the opportunity to do that.”

Newell had the opportunity just last year to be a judge at the national level, judging dozens of scripts for the Prepared Public Speaking Leadership Development Event.

The many ways Newell volunteered her time and efforts to FFA led to her receiving honorary Minnesota and American FFA degrees. These are both accomplishments that she said she is proud of. Her continued dedication now brings the new honor of being inducted into the Minnesota FFA Hall of Fame.

After reaching this high level of honor within FFA, Newell hopes to continue leading students and being involved in the FFA organization. She has attended the Minnesota State FFA Convention at least 30 times throughout her life, and she is not planning on stopping now.

“I might not be as young and energetic as I once was, but I hope I can continue to contribute to the organization,” Newell said. “I hope that there are people who can see that you can be a supporter by the ways that I have been and that they can step up into those places.”

IT’S CONTEST TIME!

Find the AMPI logo and enter for your chance to WIN 10 pounds of AMPI’s Dinner Bell Creamery cheese and butter.

Here’s how it works:

Count the AMPI logos throughout this issue (excluding this page).

Complete the entry form.

Send entries to: Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378, Attn: Dairy Contest

Entries must be received by July

5.Winners will be drawn at random from the correct entry blanks received. Five winners will each receive five pounds of butter and five pounds of cheese.

Minnesota dairy herds with low SCC

Minnesota Agriculture Commissioner

Thom Petersen released the annual list of top Minnesota dairy herds with low somatic cell counts. Somatic cell count is a key indicator of milk quality – a lower SCC count is better for cheese production and a longer shelf life for bottled milk.

In honor of National Dairy Month, 93 Minnesota dairy farms are being recognized for their superior herd management skills by achieving an average SCC of under 100,000.

“I’m honored to recognize these dairies for their dedication to quality and excellence,” Petersen said. “Minnesota’s dairy farmers provide the state and the world with high quality, wholesome dairy products for us all to enjoy.”

Although somatic cells occur naturally and are not a food safety concern, dairy farmers monitor them because they can be used as a measure of the health of their cows. Processors also pay a premium for milk with low counts. A farmer whose herd has a very low count can receive a higher price per hundredweight compared to a farmer whose herd average is high.

Minnesota Department of Agriculture and University of Minnesota dairy experts have worked with the state’s dairy farmers for 20 years to lower somatic cell counts. When the initiative began in 2003, the herds honored that year included those with SCC averages as high as 144,000, compared to the current goal of obtaining a SCC under 100,000.

Producer County

Kent Happke

Dennis and Wayne Wolters

Edward and Mary Warmkagathje

Keith and Jennifer Middendorf

Tony and Matt Berktold

Selke Farms

Hendel Farms

D and D Dairy

Harmony Hills Dairy

Hoefs’ Dairy LLC

Kevin Braulick

Scott and Denise Gathje

Reuter Farms

Morrison

Morrison

Olmsted

Todd

Wabasha

Winona

Houston

Winona

Carver

LeSueur

Brown

Stearns

Dakota

Kevin Hanson Polk

Colleen Berscheit

Brown

Chad Waltman Morrison

Fussy Farm LLC Morrison

Randy H. and Kathleen J. Bauer

Robert, Terri, and Mike Ketchum

Rice

Winona

Twine, Wrap & Net Wrap IN

Producer

Robin Winscher

Lax-Pietig Dairy LLC

Dev-Lin Holsteins LLC

Joe and Kim Engelmeyer

Kraig and Rochelle Kreinkie

Brian and Julia Libbesmeier

Brandon and Jill Marshik

Barkeim Farms LLC

Scott and Michelle Herber

Youngren Dairy Farms Inc.

Morrison

Renville

Houston

Stearns

McLeod

Meeker

Benton

Winona

Marshall and Melanie Korn Kandiyohi

Harlan and Jenny Poppler

Houdek Dairy LLC

Jerome, Beverly, and Aaron Pohlmann Todd

Zweber Farms LLC

USED TRACTORS

CIH 215 Magnum, 2,500 hrs., FWA .....$138,000

CIH 8950 1,600 hours ..............................$165,000

CIH 8920, 2WD, 1000 hrs. .........................$13,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 7240, 2,500 hours, coming in ...........$110,000

CIH MX120 ............................................Coming In

CIH MX110, FWA, 1600 hrs. ......................$65,000

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 1086, nice..............................................$21,000

IH 806 ....................................................$11,000

TILLAGE

CIH 527B ripper .....................................$13,500

CIH 530B................................................$18,000

CIH 870 7-shank ....................................$38,000

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate II 26’, w/28’ pull crumbler $31,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

JD 714 11 shank chisel plow .................$14,000

CIH 5700 chisel plow, 23’ ...................Coming In

CIH 4300, 32’ ...........................................$7,500

CIH 4800, 24’ ...........................................$6,500

CIH

w/mulcher ..........$42,000 DMI 530 Ecolo-Tiger w/basket ...............$12,000 DMI 530 ripper w/leads..........................$14,000

DMI 530B w/lead ...................................$16,500

HAYING & FORAGE EQUIP.

Sitrex QR12, QR10, QRS rakes ....................New Sitrex MKE 12-wheel rake ......................$11,000

Many sizes of rakes available

All Sizes of Sitrex Rakes.........................On Hand

GRAVITY BOXES & GRAIN CARTS

(2) Demco 365 ..........................$7,800 & $5,000

Many Sizes of Gravity Boxes ..................on Hand

Brent 657 gravity box, green & black, fenders ................................................$23,000

(2) Brent 644 box .......................................$18,000

Brent 644 ...................................................$16,500

J&M 385 ......................................................$6,500

J&M 540 box .............................................$13,500

Parker 4800 box...........................................$8,500

Unverferth 7250 grain cart .........................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

GREENWALD FARM CENTER CENTER

Tell us about your farm and family. My husband, Brooks, and I dairy farm with my in-laws, Jeff and Kate Hendrickson. Brooks and I have two children, Adlee and Callum. Jeffrey-Way Holsteins is home to 120 registered Holsteins and 150 youngstock. The cows are milked in a tiestall barn with a handful of box stalls for fresh cows and hospital cows. Half of the herd is kept in the tiestall barn, and the other half is housed in a freestall barn. There are three heifer sheds on-site – a calf barn, wean shed and open-front shed for breeding-age heifers. Bred heifers are moved to an off-site location until they are close to calving. We farm 320 acres of hay, corn and beans. Our registered herd currently has a BAA of 113 with 66 Excellent cows (one 95-point and several 94-point) and 44 Very Good cows. Genetics is a main focus of ours as we try to breed for longevity, functionality and production. We enjoy showing at local, state and national shows. In 2021, our heifer Jeffrey-Way Doorman Tavor was the junior champion of the International Junior Holstein Show at World Dairy Expo.

What is a typical day like for you on the dairy? My day on the dairy begins when my full-time job ends. In addition to the farm, I work as a eld representative with Rolling Hills Dairy Producers Cooperative in Monroe, Wisconsin. After work, I head to the farm to help with milking and nishing chores. I also manage the animal information using the herd management software, PCDART. Depending on the day, I will generate reports for testing milk or pregnancy checks, which we do every two weeks.

What decision have you made in the last year that has beneted your farm? Our recent focus has been improving foot health and overall efciency. Last year, we began using sand as bedding in the tie stalls. Prior to that, the stalls were tted with pasture mats and topped with lime and straw. The pasture mats were worn, and we were noticing an increasing number of sore

Riley Hendrickson Belleville, Wisconsin Green County 120 cowsfeet. Bedding the barn with straw was also a time-consuming chore done every morning. Now the stalls are rebedded with sand every few days using a skid loader and sand shooter attachment. We also upgraded our foot bath at the end of the barn to make it more efcient and effective. It is longer now, allowing cows to get in more strides. Since making these changes, we have had fewer lame cows and our cows are overall more comfortable. We also began using a herd management software program, which has been benecial for recording animal information and generating necessary reports.

Tell us about your most memorable experience working on the farm. I have had many through the years, but raising our kids on the farm has handsdown been the most rewarding. Our daughter, Adlee, loves being in the barn helping with chores – whether it’s carrying buckets or chasing cats. It isn’t easy, since little ones seem to get into everything, but seeing the excitement on their faces is priceless.

What have you enjoyed most about dairy farming or your tie to the dairy industry? Denitely the people. From growing up on my family’s dairy farm to showing cattle at various shows to graduating from the University of Wisconsin-Madison with a dairy science degree and entering the real world – the connections within the agriculture industry are endless.

What is your biggest accomplishment in your dairy career? There are a handful of things in my dairy career that I am proud of, including success showing cattle in 4-H and as a junior Holstein member, representing UWMadison at the National Dairy Challenge contest and nding a job I enjoy that still allows me to be present on our family farm. I’m looking forward to what is to come within my career.

What are things you do to promote your farm or the dairy industry? Our farm hosts many groups throughout the

year. We welcome farm tours to showcase our genetics during WDE as well as offer a location for dairy judging practices.

What advice would you give another woman in the dairy industry? Communication is key. Farming is always changing, but being able to communi-

cate, listen and gure out a game plan will help navigate through the chaos.

When you get a spare moment, what do you do? The majority of my vacation days are spent at cow shows, which serve as a great time to connect with friends and family. I also enjoy baking, cooking and reading.

www.extension.umn.edu/dairy

Tips for feeding in robotic milking systems

The number of robotic milking systems has been growing rapidly in the Upper Midwest for about the last 15 years. Since then, we have been learning about successful feeding strategies for farmers who use robots.

Feeding cows milked with robots is more complicated than feeding cows that are simply fed a total mixed ration. Even though offering palatable feed in the robot box is important, there are other factors that greatly contribute to high production and optimal visits. In addition to robot feed, it’s important to consider the partial mixed ration that is delivered in the feed bunk, feed table settings and milking permission settings. This balance can be challenging.

These cows will visit the robots more often, promoting high early lactation milk production. This in turn drives PMR intake and more frequent robot visits. This pattern results in the goal of high-producing, healthy cows. (See Figure 1.)

Second and later lactation cows typically ramp up in visits and milk production rapidly. Take this into account as you set up feed tables. Canadian research showed that older cows on robot dairies had a 1.45 times higher risk of ketosis than cows on non-robot farms.

from Germany showed a similar trend with increased milking frequency and a decrease in the number of fresh heifers that needed to be fetched when they were pre-trained.

By Jim Salfer U of M

Below are some feeding-related factors that research shows, along with what we have learned while working with robotic farmers throughout the Upper Midwest, that can help achieve consistently good results on robotic farms.

– Set your cows up for success. It is important to have an excellent pre-fresh program if cows are milked on robots. Excellent pre-calving management results in cows with minimal metabolic diseases. Healthy cows have good appetites and are more active in the barn.