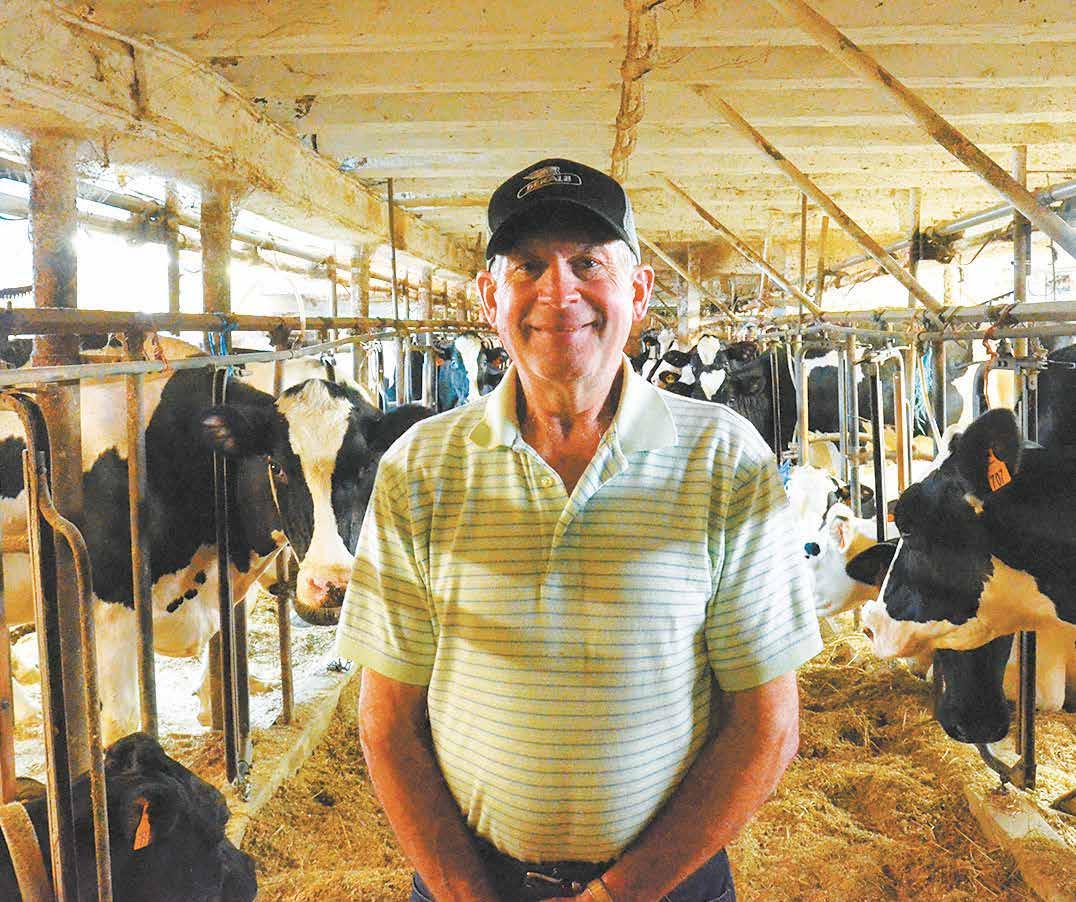

LUANA, Iowa — The only thing the Martins family would change about their robotic milking system is to have done it ve years earlier.

“I have yet to nd a negative,” Dan Martins said.

Dan and his sons, Drew and Adam, recently put in Lely robotic milking units as part of a greater project that helps nancially equip Drew and Adam to take over the farm. The family milks 160 cows. They farm 925 acres for feed and cash crops and rent additional acres for pasture.

The Martins started milking in their new facility Oct. 31, 2023. Their project included the addition of 117 free stalls, the robotic milking units and new manure storage that almost triples their manure capacity.

Drew said the project came as part of their transition plan.

“We knew that to buy Mom and Dad out, we’d have to produce more to pay for (equipment),” Drew said. “The parlor was ... small and old and falling apart.”

Their old facility was a double-6 parlor built in the early 1990s. Milking took three or more hours, morning and night.

The Martins felt an increase from twice-a-day milking to three times a day was necessary to stay economical-

ly viable. When considering labor costs on top of the costs for a new parlor, they said it made sense to spend more to get robotic milking units.

“We were denitely more biased towards robots,” Drew said. “We did price a parlor, but ... we looked at it for like 10 minutes.”

The Martins family said they have noticed the change in their schedules.

“The biggest, greatest thing for me, is I get to see my wife and kids more,” Drew said.

“This is our third vertical mixer and the Cloverdale is much heavier. We love the 3 speed and are very happy with the ration. Even though we had dried up cows, production was great.”

- Andy and Duke Ernste, Faribault, MN

Made of high carbon steel and heat treated, they offer high resistance to abrasion and shocks.

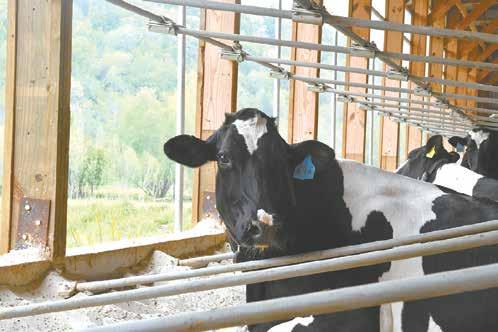

A cow relaxes in a new, sand-bedded free stall May 13 on the Mar ns family farm near Luana, Iowa. The Mar ns family began using ac vity monitors with their new robo c milking units, which has helped them track heats and monitor health.

Adam said he is able to get to his children’s sporting events easier with the new setup. Adam has four children: Brooklynn, Peyton, Maryn and Porter.

“I was married to the parlor, versus now I get to enjoy a little more exibility with them,” Adam said.

Dan’s wife, Coleen, works off the farm at a daycare in Monona.

The Martins said during planting they were able to keep going versus stopping for chores. They do 80% of their chores in the morning.

ground on the manure pit in September 2022. Their previous pit’s capacity was 600,000 gallons. Their new manure storage is 1.6 million gallons. While it was being built, they had to haul manure daily from a small, temporary pit.

Before they were able to build new manure storage, the Martins family worked on permits. This was a challenge because there is a stocked trout stream running down the bluff nearby and their manure storage borders a ood plain. However, the Martins said everyone was good to work with.

“One guy can handle chores easily in a fraction of the time it took both of us to do everything before,” Drew said.

In the robotic setup, they are averaging 3.1 milkings.

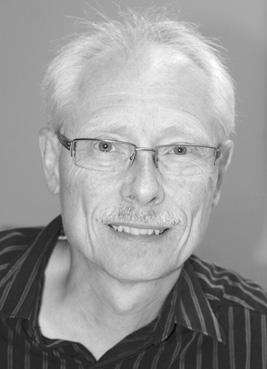

“I always say ... it’s good to learn from your own mistakes, but it’s better to learn from somebody else’s.”

“They (were) all worried about our best interests,” Drew said.

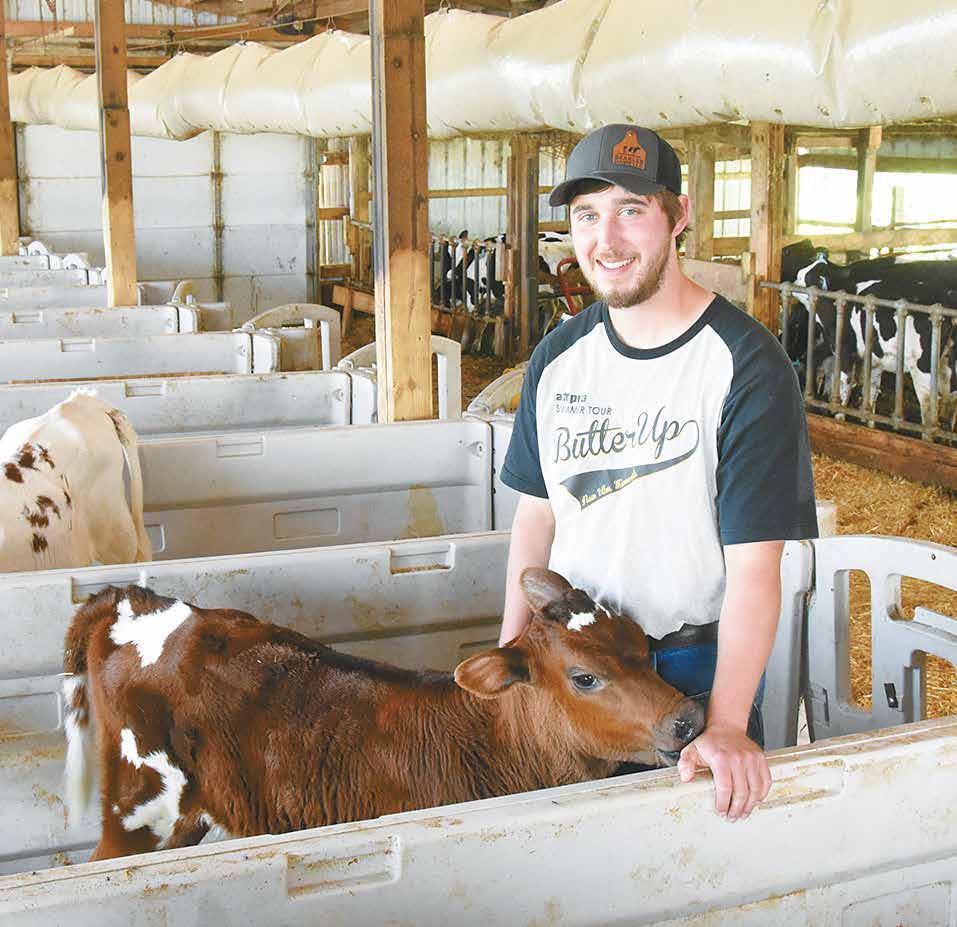

DREW MARTIN, DAIRY FARMER

“With the shrinking prot margins, you have to make it up in volume, unfortunately,” Drew said.

Adam agreed.

“Efciency is the name of the game,” he said.

The Martins family also added activity monitors. Before, they used a breeding wheel and their records were hand recorded.

Construction began on the freestall barn in April 2023. The Martins family moved their dry cows to pasture and housed their milk cows in their dry cow facility. They continued milking in the parlor which was in a separate building from the one in which the robotic milking units were being installed.

“Looking back, I don’t know how we did everything and still managed the cows amongst the chaos,” Drew said.

“With all the data, now we can really single out cows that aren’t producing,” Adam said. “We can do a better job of managing.”

He said it is also easier to spot cases of mastitis.

Drew agreed.

Before building, the family toured about seven dairy farms.

“I always say ... it’s good to learn from your own mistakes, but it’s better to learn from somebody else’s,” Drew said.

“You know that they’re going to be sick before they know,” he said. “You can really start to set the bar high and sharpen your pencil.”

The Martins family said their operation is past the transition phase. They have been able to reduce their pellets in the robotic milking units from 12 pounds to 10 pounds per day.

With their new setup, they separate their two-year-old heifers from the rest of the herd and feed them a different ration.

Drew said the older cows are more stubborn about learning the robotic setup.

“(They are) set in their ways,” Drew said. “They don’t want to change, but they do eventually give in and adapt.”

Their project began by breaking

During the building process and the farm transition, the Martins family used a farm management professional to facilitate conversations. Adam said for those going through transition, the group needs to sit down and have good communication.

“Problems have to be on the table before you start,” Adam said. “You have to work out the issues. Everybody’s going to (need to) be on the same page.”

Drew agreed.

“I’d be lying if I said it was a walk in the park,” he said. “At the end of the day there’s a job to be done and you

Con nued from MARTINS | Page 4

have to put problems aside. ... We all have the same goal, so we’re all working for the same thing.”

Looking to the future, the Martins family said they may expand again. Their mono-slope freestall barn could be doubled. They also want to update their dry cow facility.

“Right now, paying down the debt (is our big concern), and we are trying to put this one in our rearview mirror,” Drew said.

AMY KYLLO/DAIRY STAR

The Mar ns family farm sits nestled among the hills May 13 near Luana, Iowa. The Mar ns family milks 160 cows, farms 925 acres and rents land for pasture.

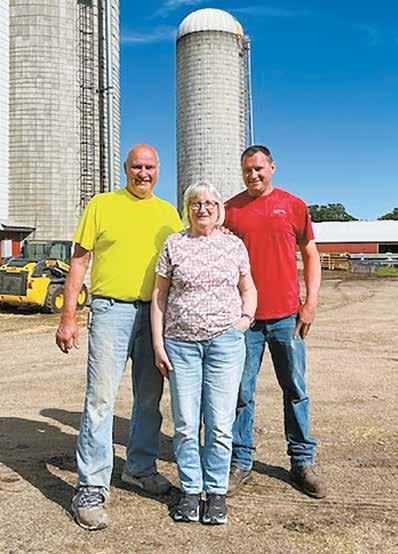

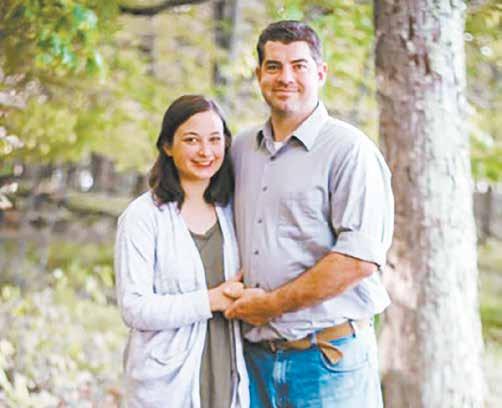

CASHTON, Wis. — Ben Klinkner was sure he would never milk another cow when he left home for college at 18 years old. While he was earning his master’s degree, however, his dad asked him if he wanted to come back. Ben’s girlfriend at the time, Erin, thought dairy farming with his parents sounded OK.

Ten years and six kids later, Ben and Erin Klinkner are amid a good farm transition.

“We had the opportunity from Mom and Dad and Erin made it an option as well,” Ben said. “Being able to spend time with your family every day versus me being on the road or doing business type stuff instead, the money is not worth that. So here we are.”

Ben and Erin milk 55 organic cows near Cashton with Ben’s parents, Paul and Geralyn. The land has been in the Klinkner family for over a century.

Paul and his brother, Gerald, have farmed side by side since their own father got them started when they were young. Paul said it is important for him to pass on what his father helped him do.

“My dad helped my brother and I get started and I just wanted to help out somebody too,” Paul said. “Geralyn and I worked for a long time to get it where it’s at, so we’d like to see it go on.”

Paul and Gerald have always had their own separate herds but collaborated efforts on everything else. Now that Ben is taking over from Paul, and Gerald’s son, Dillan, is taking over from Gerald, the collaboration continues to be helpful.

That communal mindset is what led to the Klinkners becoming organic 24 years ago. Gerald decided to try it, so Paul did too. It was an adjustment at the time, to farm differently than all the neighbors and differently than his father had farmed, Paul said. They were shipping milk to Westby Cooperative Creamery, which did not have an organic market at the time. They got on the waiting list for Organic Valley and did the three-year transition to achieve organic certication. Eventually, Westby Creamery opened an organic market and the Klinkners were able to ship milk to the processor again in 2007.

ABBY WIEDMEYER/DAIRY STAR

ABBY WIEDMEYER/DAIRY STAR

for milking June 13

Klinkner family has been organic for 24 years on their Monroe County dairy.

Today, Paul and Ben farm 300 acres. Ben and Erin moved into the farmhouse two years ago, while Paul and Geralyn moved to a nearby home off the farm. Paul still comes to help with both milkings when he is not in the elds. Erin manages calf chores as well as a large garden and cares for their six children. They also have horses, chickens and pigs.

Ben and Erin have been able to slowly take ownership of the business. They began by working for a wage, and they progressed to purchasing some of the cattle and receiving a percentage of the milk check. As they purchased more cattle, their percentage grew. At the end of this year, they will own all the cattle. They have also purchased the farm they live on through a land contract and started to help buy machinery.

Ben said he is grateful for the opportunity to join the operation in phases.

“We wouldn’t be able to do this without Mom and Dad,” Ben said. “For young people to start in the industry is a huge challenge nancially but then you add in the labor factor, I feel it’s almost impossible to do.”

In 24 years of farming organically, the family said the drought last year

was the most interesting year they have seen. Ben said he noticed the healthier soil handled the dry weather well. They normally control weed pressure with a amer. They skipped that last year because their corn had not seen rain since planting, but they ended up regretting it since weed pressure was higher than ever.

“Last year we didn’t ame because it was too dry and this year I nished aming when it was raining,” Ben said.

Even with more weeds, however, Ben said last year was the rst time he ever thought their organic corn looked better than some conventional corn in the area.

They all agree that the organic practices have positive effects on the cattle as well.

“I believe the animals benet from being organic,” Ben said. “We’re not stressing them out too much; we need them to last.”

While the land and health benets are appreciated, Paul said the community makes it even more worthwhile.

“You’re in a nice group of likeminded people,” Paul said. “And then there’s the premium on the milk which has got to be a plus.”

AMY KYLLO/DAIRY STAR

Alex Schroeder (le ) and Jacob Schimek t their heifers June 6 at the Quadricentennial Party ‘ l the Cows Come Home dairy show in Kasson, Minnesota. The show featured both a junior and senior ng contest.

AMY KYLLO/DAIRY STAR

Kamrie Mauer leads her heifer during junior showmanship June 6 at the Quadricentennial Party ‘ l the Cows Come Home dairy show in Kasson, Minnesota. The event featured a showmanship contest, a ng contest and shows for colored breeds and Holsteins.

AMY

Diego Espinoza clips a heifer during the senior

tng contest June 6 at the Quadricentennial Party ‘ l the Cows Come Home dairy show in Kasson, Minnesota. The show spanned two days and included 25 exhibitors and 57 animals.

Gracie Pearson holds a cow in the barn June 6 at the Quadricentennial Party ‘ l the Cows Come Home dairy show in Kasson, Minnesota. Pearson’s family dairy farms near Red Wing.

Fort Atkinson Hay

Ft. Atkinson, Iowa • 563-534-7513

June 12, 43 loads

Small Squares

Grass

New seeding

Straw

Grass

New seeding

2nd crop

3rd crop

New seeding

$115-135/ton 3 loads

$70-145/ton 3 loads

$145/ton 1 load

Large Squares

$95/ton 1 load

$85-100/ton 2 loads

Rounds

$20-70/ton 2 loads

$100/ton 1 load

$65-130/ton 30 loads

Rock Valley Hay Auction Co.

Rock Valley, Iowa • 712-476-5541

June 13, 54 loads

Large Squares

1st crop

2nd crop

Grass

Straw

1st crop

2nd crop

3rd crop

Grass

Mixed

Straw

Corn stalks

$70-170/ton

$142.50-160/ton

$125/ton

$72.50-170/ton

Large Rounds

$55-167.50/ton

$85-160/ton

$135-150/ton

$50-165/ton

$130-137.50/ton

$72.50-170/ton

$40-45/ton

There’s a New Holland Roll-Belt™ round baler that’s right for your hay operation. Whether 4’x5’, 4’x6’ or 5’x6’, all models feature wide, durable pickups and smooth feeding systems with the capacity for faster baling. Innovative Precision Land Management (PLM™) solutions like IntelliBale™ automation, in-cab density control and factory-installed moisture sensing help you make smart decisions on the go. You’ll get the high bale density you expect for savings you can take to the bank.

Increase your haymaking productivity with a Roll-Belt round baler. Stop in today or visit newholland.com to learn more.

The U.S. Department of Agriculture left its 2024 and 2025 milk production forecasts in its latest World Agriculture Supply and Demand Estimates report unchanged, with slight adjustments to cow inventories offset by slower growth in milk per cow.

2024 production and marketings were projected at 227.3 and 226.3 billion pounds, respectively, unchanged on both counts from last month’s estimate.

2025 production and marketings were projected at 229.3 and 228.3 billion pounds, respectively. If realized, both would be up 2 billion pounds or 0.9% from 2024.

Commercial exports for 2024 were raised on a fat basis, largely due to higher expected shipments of cheese. Skim-solids basis exports were unchanged. Exports were raised for 2025 on a fat basis and a skim-solids basis based on expectations of continued strong international demand.

Imports for 2024 were raised on both a fat- and skim-solids-basis, supported by higher expected butter and milk protein-containing products, respectively. Import forecasts for 2025 were raised as well.

Butter, cheese, whey and nonfat dry milk price forecasts for 2023 were raised from the previous month on recent price strength. Cheese is expected to average $1.79 per pound in 2024, up 9.50 cents from last month’s projection, and compares to $1.7593 in 2023 and $2.1122 in 2022. The 2025 average was projected at $1.7950, up 13 cents from last month’s estimate.

Butter was projected to average $2.97 per pound for 2024, up 3.50 cents from last month’s estimate, and compares to $2.6170 in 2023 and $2.8665 in 2022. The 2025 average was projected at $2.9450, up 3 cents from last month.

The 2023 nonfat dry milk average was estimated at $1.1750 per pound, up from $1.16 last month, and compares to the 2023 average of $1.1856 and $1.6851 in 2022. The 2025 average forecast was kept at $1.14 per pound.

Dry whey is expected to average 43.50 cents per pound in 2024, up 3.50 cents from last month’s estimate, and compares to 36.18 in 2023 and 60.57 in 2022. The 2025 forecast is 40 cents per pound, up 2.50 cents from last month.

With the changes in product prices, Class III and Class IV milk prices were raised. The 2024 Class III is expected to average $17.90 per hundredweight, up $1.15 from last month’s estimate, and compares to the 2023 average of $17.02 and $21.96 in 2022. The 2025 average was estimated at $17.70, up $1.40 from a month ago.

The Class IV is projected to average $20.50 per cwt in 2024, up 25 cents from a month ago, and compares to $19.12 in 2023 and $24.47 in 2022. The 2025

projection at $20.10 is up 15 cents from what was expected a month ago. Strong demand for dairy products is expected to carry into 2025, according to the USDA.

The U.S. corn outlook was unchanged from last month at 14.86 billion bushels, with the yield forecast at 181 bushels per acre. The season average price remained at $4.40 per bushel. The USDA will release its acreage report June 28, which will provide surveybased indications of planted and harvested area.

The outlook for U.S. soybeans includes higher beginning and ending stocks. Higher beginning stocks reect reduced crush, down 10 million bushels on lower soybean meal domestic use, partly offset by higher exports. Production was projected at 4.4 billion bushels, with a yield of 52 bushels per acre. Ending stocks were projected at 455 million bushels, up 10 million. The soybean price forecast was unchanged at $11.20 per bushel. Soybean meal and oil prices were also unchanged, at $330 per short ton and 42 cents per pound, respectively.

The latest crop production report shows 95% of the U.S. corn crop was in the ground as of the week ending June 9, 3% behind a year ago and dead even with the ve-year average. Emerged was 85%, 6% behind a year ago but 1% ahead of the average. Seventy-four percent was rated good to excellent, up from 61% a year ago.

Soybean plantings were at 87%, 8% behind a year ago but 3% ahead of the ve-year average. Seventy percent has emerged, 13% behind a year ago but 4% ahead of the average. Seventy-two percent were rated good to excellent, up from 59% a year ago.

Dairy prices were mostly higher in mid-June except for butter. Cheddar blocks climbed to $1.9825 per pound Thursday, the highest since Aug. 31, 2023, but closed Friday at $1.97, up 12.50 cents on the week and 59.50 cents above a year ago.

Barrels nished at $2.02, 6.50 cents higher but 10.50 cents below its May 17 high for 2024, 49.50 cents above a year ago, and 5 cents above the blocks. Sales to the market of last resort totaled 17 cars of blocks and 13 barrels.

“Cheese market tones continue to garner bullish tailwinds,” says Dairy Market News. Midwest barrel processors “expect more bulls to come.” When spot barrel loads are available, they are not available for long. Mid-week spot milk prices were in line with the previous week, ranging from $2 to $1 under Class III. More cheesemakers are opting for extra milk in recent weeks as they expect further tightening and continued hearty demand, so production is very busy.

Cheese production is steady to lighter in the West. Milk volumes are tighter throughout much of the region as seasonal output ratchets lower. Some manufacturers cited unplanned downtime of other processors contributed to their ability to run at or near capacities.

Cheese demand is steady domestically. International buying is steady to moderate. Some sentiment is that export sales may be more challenging in the second half of 2024, according to DMN.

Cash butter started the week falling to $3.08 per pound but recovered Tuesday, climbing back to $3.1050, but closed Friday at $3.09, down a quartercent on the week and 72.50 cents above a year ago. There were 10 sales for the week.

Central butter plant contacts tell DMN that cream availability has begun its seasonal shift lower and reported multiples are further evidence. Cream markets have been noticeably consistent throughout early and mid-spring, but as summerlike temperatures rise, so go multiples. Regularly reported multiples have shifted from the 1.15 range to the 1.20 range. Some butter plants report receiving as many as a dozen cream loads fewer than in previous weeks. Churning is still ongoing but is expected to quiet further near term. Butter demand is seasonally holding steady. Bulk butter, particularly salted loads, is available, but 82% of unsalted loads are relayed as being tight. “Butter market tones are achieving what other domestic dairy commodities are struggling to gain: an enduring and unambiguous bullishness,” DMN said.

Butter production is mostly steady in the West. A few manufacturers said churning schedules are as full as possible due to upcoming equipment maintenance. Unsalted bulk butter continues to be somewhat tight. Cream availability is tighter, but butter producers indicate it is ample. Domestic demand is steady for salted and unsalted butter. Export demand is steady from Canadian buyers, but moderate elsewhere, DMN said. Believe it or not, StoneX points out that there are some in the butter world that believe $4 butter is possible.

Grade A nonfat dry milk closed Friday at $1.1925 per pound, down a quarter-cent on the week and 3.50 cents above a year ago, with 26 sales on the week.

StoneX said that, in the 23-day month of May, 85 spot loads were traded. So far in just 10 trading days in June, 57 spot loads have changed hands.

Dry whey climbed to 48 cents per pound Wednesday, the highest since Feb. 26, 2024, but saw its Friday nish at 47 cents per pound, unchanged on the week, but 19.50 cents above a year ago, with only three Chicago Mercantile Exchange sales reported on the week.

Speaking in the June 17 “Dairy Radio Now” broadcast, broker Dave Kurzawski said, while U.S. milk production is not terrible, “it is under some bit of duress.”

We have come out of a two-year bear market cycle that put a lot of dairy farmers on the ropes as the costs of everything has gone up, he said. Now we have the avian inuenza knocking down milk output.

When asked if we have an accurate measurement of the inuenza yet, Kurzawski said no. He cited the USDA number of 90 dairies conrmed with it but believes it is closer to a thousand or more. The impact seemed to be worse in February and March than today, so maybe things are changing, but he said, “It’s a big deal and it’s going to be with us for the balance of the year.”

The June 14 “Early Morning Update” stated that we have several problems on the farm: “Slaughter is off yet the herd isn’t growing (it’s attening out) and headline milk production is still expected to be lower. Next week we’ll get May’s milk production and we’re expecting down 0.5%. Granted, milk production per cow rebounded to positive in March and April and feed costs are dramatically lower. Still, we could suggest that lower slaughter numbers are normal as milk prices rise. But that may be missing the big picture.”

“There are few replacement animals out there,” the Update states, “And the ones you can get your hands on will cost you dearly (reports are now over $3,000 per animal).” Add to that, avian u where the worst cases are the older animals.

“The issues with milk production are not a July or August problem, the Update concludes. “They’re more likely a 2024/2025 problem. Maybe longer. Demand has a say and prices can still fall in this environment, but underpinning the whole deal will be this perpetual issue on the dairy farm.”

Speaking of slaughter, dairy cow numbers for the week ending June 1 totaled 42,900 head, down 4,700 from the previous week and 8,900 or 17.2% below a year ago. Year to date, 1,390,800 have been culled, down 187,600 or 13.5% from 2023.

Checking demand, the USDA’s latest dairy supply and utilization data shows April cheese consumption hit 1.2 billion pounds, up 2.1% from April 2023. Domestic use was only up 0.3%, but exports were up 26.7%.

HighGround Dairy reported, “Other cheese domestic use saw the highest April on record with data back to 2011 but was almost entirely offset by plummeting demand for American cheese, which fell to the lowest April volume since 2020.”

Butter usage was down 5.6%, with domestic use down 6.3%, which accounts for 96% of total use, according to HGD. Exports surprisingly were up 21.7% and topped those of a year ago for the rst time since January 2023.

Nonfat/skim milk powder utilization plunged 32.2% from a year ago, the lowest level since November 2018, said HGD, with YTD domestic consumption down 48.3%, the lowest level on record. April exports were down 2.4%.

Dry whey consumption jumped 34.0%, thanks to a 68.4% rise in domestic use, an all-time high for April, according to HGD, while exports were only up 1.4%.

Meanwhile, April uid milk sales came in at 3.6 billion pounds, up 5.9% from April 2023. Fluid sales YTD were up 1.5%. I will have more details next week.

Tuesday’s Global Dairy Trade Pulse auction saw 3.79 million pounds of product sold, up from 3.6 million on May 28. Of the total offered, 98.3% sold.

HGD reported there were 187,391 pounds less instant whey milk powder and 339,508 pounds more regular WMP sold versus the last Pulse. One hundred percent of the 1.1 million pounds of skim milk powder on offer was sold. Of the 551,150 pounds of instant WMP max on offer this week, 66% was sold. Instant WMP also declined versus the prior Pulse and was down $60 per metric ton or 1.7%.

On a brighter note, one of the highlights of the dairy industry that I touched on in my June Dairy Month column this year was sustainability. The dairy industry may be on the verge of taking another step in its environmental efforts.

The U.S. Food and Drug Administration has approved the feed ingredient Bovaer for use in lactating

dairy cattle. The June 3 “Daily Dairy Report” said, “Bovaer is a feed additive that suppresses the enzyme that forms methane, thus reducing emissions. It was developed by DSM-Firmenich and is being commercialized in North America through a strategic collaboration with Elanco Animal Health.”

“Methane is a greenhouse gas that contributes to global warming by trapping heat in the atmosphere,” said the DDR. “The average cow produces 220 pounds of methane per year, mostly through enteric fermentation. According to Elanco, using one tablespoon of the ingredient per cow per day can reduce methane emissions by 30%. This is the equivalent of reducing carbon dioxide emissions by 1.2 metric tons annually. If 1 million cows were on Bovaer, it would be the equivalent of pulling 285,000 cars off the road for one year,” DDR said.

Last but not least, the International Dairy Foods Association held its 40th annual Capitol Hill Ice Cream Party this week, and more than 1,000 members of Congress and their staff attended, according to an IDFA press release.

IDFA staff and leaders from U.S. ice cream makers served more than 950 gallons of ice cream, 1,200 ice cream novelties and 32 ice cream cakes during the event, which was held in Union Square Park in front of the U.S. Capitol.

“IDFA’s Capitol Hill Ice Cream Party is our way of showing appreciation to the public servants, members of Congress and all the individuals working in Congress and within our federal agencies,” said Michael Dykes, IDFA president and CEO. “We are so

pleased to have welcomed our largest crowd for this event in recent years. Ice cream is as bipartisan as you can get. And the ice cream party is an opportunity for us to all come together, share a few laughs, and enjoy America’s most popular frozen treat, ice cream.”

forage box. 16ft, on tandem gear; Attachments Brush Hog mower. 7ft.; Land Pride 7ft 3 point blade.; (2) Double M 3 prong bale spears. New!; Sandman sand leveler; Cattle Handling Semi load of free-standing cattle panels. Vehicles

2019 Chevy Express van. 15 passenger. 200k miles, silver. Good cond.; 2016 Chevy Express van. 15 passenger. 200k miles, black. Good cond.; 2016 Chevy High Country truck. 151k miles. Dually, Duramax, Allison trans. Emissions deleted, gooseneck ball hitch, good tires. Nice!!; Trailers 2008 Merritt gold line cattle pot, 53’ spread axle 4 tires 90% with new rims 2 tires 40% 2 tires 10%, all new break pads, drums, and slack adjusters 4 months ago; 16 ft

MELROSE, Minn. — Marv Thielen has a vague memory from the late 1950s when he was about 3 years old and the last of the horses left his family’s farm near Melrose. At the time, the farm had already been in his family for 90 years, ever since his great-grandfather, John Thielen, homesteaded the site in 1869. Through the years, tractors had replaced horses as the heavy lifters, and the animals were no longer needed.

“When they loaded up the last horses by the barn, I hid behind stacked wood they had there and watched,” Marv said. “I can just remember it.”

Long before Marv was born, the farm had sported a metal-wheeled tractor of some unknown make and model that is evident now only through old, grainy photos. By the time Marv hid behind the wood pile to watch the horses leave, the farm had upgraded to a 1949 8N

Ford — now the oldest tractor on the farm — and also had recently added an even newer tractor that still has special meaning for Marv.

“I have a 1956 800 Ford at my lake home right now,” Marv said. “Dad bought that when I was born that year, so it’s a little keepsake for me.”

Stories, memories and old relics take on rich meaning when they come from a farm that has been in the same family for over a century and a half. Although Marv and his wife, Judy, now live off the farm and are retired, they still come to the farm every day to help their son, Chad, who owns and operates the farm as the fth generation.

Chad and his wife, Jacki, purchased the farm in 2020 and live in the house there with their 6-year-old twins, Ray and Addy. It is the same house in which each generation of Thielens has lived since it was built in 1889 — although it has been remodeled and upgraded numerous times.

Today, Chad carries on the family farming tradition, milking 68 Holsteins in a tiestall stanchion barn and growing crops on 340 acres. He also raises all his own youngstock and nishes his steers. However, there was a time when the continuance of the

farm was uncertain.

When Marv and Judy were considering retirement, none of their four children — Chad, Kelly, Stacy and Brian — seemed interested in taking over.

“I had told the kids that before I would let any of them come back to the farm, they would have to get a job off the farm and see what it was like working for somebody else,” Marv said. “If that ended up being the route they wanted to go, then they could go that route. I wasn’t going to force anyone to take over.”

Marv and Judy kept on farming while Judy also worked off the farm doing transcription at a nearby hospital and later a clinic. Their children grew up and went into other professions. It was looking like the family farm might be heading toward its end.

Then Chad and Jacki became the parents of twins, and Chad began to reconsider options for his young family.

“I had been working in St. Martin for 16 years at Rotochopper,” Chad said. “When (my parents) were talking about retiring, I just didn’t want to see the farm go away.”

It was in 2017 while Chad and Marv were driving home from the Central Plains Dairy Expo in Sioux Falls, South Dakota, that Chad told his dad he was interested in purchasing the farm.

“Chad wanted to come back,” Marv said. “I was hoping it was going to be that way. I still get emotional when I think about it because I wanted the legacy to keep going.”

Marv and Judy began to build their retirement home on lake property they owned, knowing the farm begun by John Thielen so long ago would continue in Chad’s capable hands.

When John Thielen came from Germany to the U.S. in 1867, he went through Ellis Island and spent time in Wisconsin before choosing Minnesota to pursue his dream of starting a farm. He homesteaded the rst 160 acres of the current farm site near Melrose. There he dairy farmed and raised a family with his wife, Gertrude.

The couple’s son, Henry, and his wife, Katherine, eventually took ownership of the farm. Katherine outlived Henry and died in 1936. The farm then passed to their four sons: Raymond, Linus, Paul and Ben. When Paul died a month after his mother, the remaining three brothers farmed together. By the early 1970s, Raymond, who was Marv’s father, had bought out his brothers and was the sole owner with his wife, Verena.

Marv grew up milking cows and working on the farm with his parents and siblings. Then, his dad sold the milking herd in 1968 when Marv’s older brother enlisted in the military. At that time, they had been milking in an old domed-roof barn that had been damaged by several tornadoes through the years, and they nally

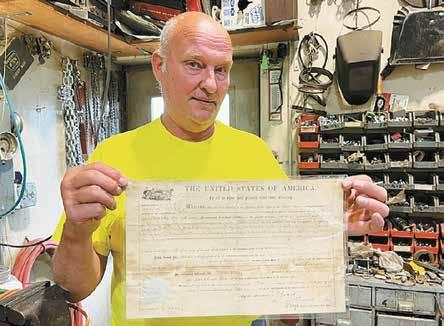

Marv Thielen holds his great-grandfather John’s o

cial homesteading document June 13 at the Thielen dairy farm near Melrose, Minnesota. The document, awarded in 1869 and signed by President Ulysses S. Grant, guaranteed ownership of the land where John’s descendants s�ll farm today.

gave up on xing it. Raymond built the current barn in 1972 and t it for raising hogs and beef cattle.

“The barn was 40-by-80 feet with hogs on one side of it and some pens with beef cattle on the other side,” Marv said. “It had all dirt oors and just some feed alleys.”

Marv graduated in 1975 without having any intention of taking over the farm. Instead, he took a job with Kraft Foods Group Inc. and later worked on a neighbor’s farm, but he grew dissatised. He missed the freedom of working on his own family farm, he said, and being his own boss.

“I thought, ‘This isn’t going to work,’” Marv said. “I was getting

married, so I started back home in 1981.”

He also reintroduced dairy cows to the farm after a 13-year hiatus.

“In 1981, we started redoing the barn,” Marv said. “I gutted that out, put in 16 stalls and bought 22 cows.”

Marv did the remodeling of the barn himself, even mixing the cement. He and Judy began milking cows in the new setup that fall.

“We switched cows and cleaned the barn by hand for the rst year,” Marv said. “The next year, I put in another 16 stalls, and then we put in a barn cleaner. We milked that way for quite a while.”

Turn to THIELENS | Page 15

Judy, who did not grow up on a farm, faced a bit of a learning curve in the beginning.

“I didn’t know the back end of a cow from the front end,” Judy said. “We had horses when I was growing up. My dad was a big horse guy.”

However, it did not take long for Judy to adapt to farm life.

“I liked animals, so that was plus, and I just took to it,” Judy said. “When people I knew from high school would see me a few years later, they would say, ‘You milk cows? I never thought you’d do that.’”

She continued her job off the farm as well, so life was busy as they raised their family, and they needed to work as a team. One day, a few weeks after Chad was born, Judy came home from work and headed to the barn to help Marv with chores. When she arrived, she did not see Chad anywhere and asked Marv where he was.

“I told her that he was in a warm, safe place,” Marv said. “Those vat sinks in the milk house are a perfect little crib. I had moved the faucets to the side and laid him in there. He couldn’t go anywhere, but it was nice and warm.”

By 1987, the couple purchased the farm from Verena since Raymond had passed away. They continued to tear down old buildings, add new facilities and upgrade.

“We did a lot of building,” Marv said. “The only thing that’s still here that is original is the house.”

They also put in a manure pit and began renting a neighboring farm, which made room for raising more cattle.

Looking back, Marv and Judy said many things have changed on the farm during their time there, yet the important things have remained the same.

PHOTO SUBMITTED

A barn stands in 1951 on the Thielen family dairy farm near Melrose, Minnesota. Other than a hiatus from 1968 to 1981, cows have been milked on the farm by genera ons of Thielens since a few years before it was homesteaded in 1869 to the present day.

Marv Thielen (le ) and his son, Chad, visit June 13 at their dairy farm near Melrose, Minnesota. Marv and his wife, Judy, purchased the farm from his parents in 1987, and Chad and his wife, Jacki, purchased the farm in 2020.

“It’s still a family farm,” Judy said. “It was a good place to raise kids. We were together a lot.”

Marv agreed.

“It’s still owned and operated by the family,” he said. “I always told the kids, ‘Since it’s a family farm, everybody works together; everyone gets to do something.’”

Marv noted that if one or both of Chad’s children choose to take over the operation someday, they would most likely see the farm reach the 200-year milestone — but that remains to be seen.

“They are only 6 years old,” Chad said. “They like being out here, and I get them to help in the barn, but we have a lot of time yet.”

For now, he said, he is enjoying his choice to come back.

“I like the freedom — you can do what you want to do as long as you get your stuff done,” Chad said. “I’m glad that (my coming back) keeps the family farm going.”

August Heeg

91 years old Unity, Wisconsin Marathon County

Tell us about your farm then and now. In 1958, my wife, Joanne, and I bought a farm in the town of Richeld in Wood County, Wisconsin. Joanne milked our 35 cows and I worked for the Wood County Highway Department. We were there until 1970, when we bought the farm in Unity. We bought another herd of cows at the same time and milked 66 cows the rst night up there. We built on the herd twice, expanding rst to 85 cows and then to 123 cows. In 1999, we combined our herd with the herd owned by our son, Mark, at the Colby site where he was farming. Since then, the farm has grown to its present size of 1,725 cows and 3,300 acres. We milk 1,060 cows in the double-14 parallel parlor and 450 cows in our recently built robotic barn. The farm is run by our sons, Mark, Gary and Jay, and our two grandsons, Nathan and Cory.

What is your favorite memory on the farm? It’s hard to pick out one favorite memory, but I would say raising our family on the farm is the highlight. Both Joanne and I came from good farming families and knew that was what we wanted to do — we just loved farming. We were both involved in 4-H and enjoyed showing cattle. When you breed good, registered cattle, you can’t wait for the next heifer calf to come — to see what she will become. We were brought up in this life and are happy to raise our family in the same way.

What do you love most about dairy farming? I love the idea of being my own boss, of rising to meet challenges and working hard. It’s a 24/7 challenge with the weather. We still worry about

the weather because our boys are farming. The pride of ownership means a lot. Joanne has always kept the place perfect.

What three characteristics do you possess that helped you maintain a lengthy dairy career? You have to have a will to win. When things don’t go the way you want, you can’t just lie down and give up. You have to keep working at it, keep setting goals and always be willing to learn something new and change how you do things. Always work to be better. I have had a love of dairy farming since I was young; it has always been in my blood. I have always loved what I am doing, and it has always made me happy.

What is the greatest success of your career? The greatest success is seeing where our family is and where the farm is today. A lot of hard work and dedication has gone into this farm.

What has been the biggest challenge, and how did you overcome it? There have been many, but the biggest would have to be dealing with stray voltage at our farm in Unity. That makes you feel helpless, and it was hard on both the animals and our own health. That was a terrible time for our family and our farm.

What piece of equipment being used now do you wish you had for the entirety of your dairy career? A stone

picker comes to the top of the list. In all the years we spent picking rocks, a stone picker would have saved a lot of time and labor! Robotic milkers would be another.

Tell us a lesson you learned that you stand by today. A farm has never got a lot of money, but you build up equity. You have to remember that all of your money is sitting out there.

What advice would you like to offer future generations? You have to love what you’re doing, and dairy farming has to be your own decision. You can’t do it because someone else thinks you should. It’s something that has to be a part of you, deep down, in your blood.

a nice eld of corn or the

out there are other things I love too.

Tell us about your farm then and now. I grew up on a dairy farm in Waukesha. I started milking cows when I was 9 years old, and I’ve wanted to farm ever since. We were only two miles from downtown, and with the city moving out, there was no future there for me. After graduating from the University of Wisconsin-River Falls, I became an ag teacher in La Crosse. My wife, Mary, and I purchased this farm in 1969 with $3,000 and a loan from her parents. We also received help from my aunt and uncle, who helped us buy our machinery and milking equipment. Our realtor, who was good friends with her parents, helped us buy the cows. We looked at a lot of farms, but this place had a halfway decent house, which is why we picked it. We started out milking 40 cows with Surge buckets. In the early 1970s, we put in a pipeline. In the late 1970s, we added more stalls, going from 40 to 60, and built Harvestore silos. We were milking 120 cows in the 60-stall barn when we built a new setup in 20152016 to incorporate the newest milking technology. It was the worst mistake we ever made. We then built a swing-12 milking parlor four years ago and added more stalls in the freestall barn. We farm with our son, Kevin, and our grandson, Austin, and our herd today includes 240-250 cows. We’ve grown from 117 acres to 540 acres, which includes 100 acres of deer habitat. We’re small and want to stay small.

What is your favorite memory on the farm? Watching our kids grow up and help on the farm. God and family are very important to us, and we enjoy being here together every day. Other fond memories include building our machine shed, remodeling the house and putting up the silo. It was exciting to see that happen.

What do you love most about dairy farming? I love that every day is different, and I love being my own boss. Seeing that fresh cow with a beautiful udder,

What three characteristics do you possess that helped you maintain a lengthy dairy career? Lots of patience, I make the best of everything, I like cows, and I try to get along with everybody. Support people have become our friends.

What is the greatest success of your career? Being here for 55 years is my greatest success. A lot of people I know who started farming didn’t make it this long.

What has been the biggest challenge, and how did you overcome it? Putting the latest milking technology into our new setup is the biggest challenge we have faced. We could not keep it running and never got what we actually paid for. We took out the technology and built a milking parlor instead, which got us back on track.

What piece of equipment being used now do you wish you had for the entirety of your dairy career? A skid loader. Many years ago, we had three; now we have two. We use it for everything and have forks and diggers for it. I also love the telehandler. We just bought that and use it for loading the mixer — it’s three times as quick as the skid loader.

Tell us a lesson you learned that you stand by today. No matter how bad things get — weatherwise or nancially — it all works out in the end. God guides you. Every day is a gift. We plan to farm until the end but also keep traveling. Don’t wait until you’re old to travel.

What advice would you like to offer future generations? If you want to farm, follow your dreams. Try to keep a family farm running and keep it in the family because once you sell that land, you’ll never get it back. If you don’t have a family farm, try to work with an established farmer. You can work your way in and maybe take over for them someday.

70 years old Grove City, Minnesota Meeker County

Tell us about your farm then and now. We moved from Fulda, Minnesota, to the farm that we are on now in 1959. My Dad came with eight cows. He milked 30 cows in the traditional barn until 1970 and then built a new 40-cow, one-story barn in 1974. We added on to that and then milked 76 cows. At that time, I bought my rst 20 cows and was also farrowing pigs. In 1995, I built my rst 200-cow freestall barn with a double-6 parlor. We have since added on three more times to get to where we are now, using a double-18 to milk 1,050 cows.

What is your favorite memory on the farm? I have so many, but one would be having hog roasts. We have done one for the neighbors, family and many friends over the years. Every time we have added on to the barn and before bringing cows in, we have a hoedown and celebrate with a hog roast. This year, Liberty, our granddaughter, wanted to do a “Moo Feast” with food trucks and a band. We would have had it in the shop, but due to the bird u, we have held off on this idea.

What do you love most about dairy farming? The every-day challenge. I try to make things better and easier to get the job done. I love making plans for the next year, the next ve years, the next 10 years, and maybe at my age I don’t have to plan beyond that anymore.

What three characteristics do you possess that helped you maintain a lengthy dairy career? Being able to adapt to change. Being able to look into the future and the ability to go with the ow. I also love to be with people and know what makes them tick!

What is the greatest success of your career? Having my son, Joe, farming with me and having our grandsons, Tylor and Eric, and our granddaughters, Liberty and Pyper, being here. We have also been blessed to have our nephew, Seth, and his wife, Ana, in the crew with us along with their kids, Edwyn, Isabella and Makayla. Our almost daughter, Jennessa, has been here with us since she was out of school. Nickie, my wife, had the great pleasure of doing daycare for her kiddos during the time she worked.

What has been the biggest challenge, and how did you overcome it? The biggest challenge was when we went from the 80-cow tiestall barn to the rst freestall barn. My wife even asked the doctor what to do because I was sleeping maybe an hour or two. The doctor said, “When he drops, he will know to stop.” Well, I didn’t drop, and I moved on, thanks to a young couple who came just at the right time with their cows and helped take great care of ours.

What piece of equipment being used now do you wish you had for the entirety of your dairy career? There are so many, but like everyone else, it has to be a skid steer. We have ve of them and two payloaders. The one piece that we do appreciate is our cherry picker. We got one a couple of years ago, and we use it all the time.

Tell us a lesson you learned that you stand by today. Don’t worry what the neighbors are doing and just take care of what you are doing. When it is time to get things done, just get it done.

What advice would you like to offer future generations? Get off of the farm. I am a morning person, so I spend a lot of my time checking out the markets and seeing what is going on in the industry. Now it is time to turn the management over to the next generation and take time to leave the farm for some relaxation.

65 years old

Brillion, Wisconsin Calumet County

Tell us about your farm then and now. I am the fourth generation on my family’s farm, which is 150 years old. I got my rst calf when I was a freshman in high school when I won the Brillion Jaycees calf chain award. The prize was a registered Holstein calf. The calf I won only had one heifer calf, but that heifer had a bunch of heifers. That’s when my herd took off. I did all the milking on our farm since I was 16 years old and was also a relief milker at other places. I like cows and have milked a lot of them in my day. I also took over the breeding on our farm in high school. When I graduated in 1976, I had four job offers, but I wanted to milk cows. I also worked at a feed mill for 20 years. I’ve been making improvements to the farm all along. I installed a pipeline in 1977, and it was the best investment I ever made. I have also built two silos, a heifer barn and manure storage and added onto the machine shed. I bought the farm from my parents in 1996. I milk 46 cows twice a day in a stanchion barn. I’m milking about 20 cows more than my dad on the same number of acres. We had to make the best use of our land. I farm 220 acres and grow alfalfa, corn, oats, soybeans and wheat. High school kids help me do 6,000 small square bales in the summer. I am also a Dekalb seed dealer and have been selling seed since 1991. I’m proud of what I’m trying to do with that.

What is your favorite memory on the farm? I can still remember going to the cheese factory with my dad to take our cans of milk in every day. I enjoyed going into the plant and grabbing some curds out of the back. A new tractor being delivered and calves being born are other favorite memories.

What do you love most about dairy farming? I love the challenge of raising a calf, seeing her mature and being able to milk her. I especially enjoyed raising my rst calf, which I got when she was one week old.

What three characteristics do you possess that helped you maintain a lengthy dairy career? Determina-

tion, patience and resourcefulness. As a dairy farmer, you have to be patient — just look at all the rain we’ve had this year. I wasn’t able to plant anything for three weeks, and that’s a long time. From weather to milk prices, there are things that are out of your control, so you have to do the best you can with what you got.

What is the greatest success of your career? All I ever wanted to do was be a dairy farmer and portray my occupation in a positive way. To be farming for 65 years — all of my life — is what I consider to be my greatest success as well as being interviewed by Dairy Star.

What has been the biggest challenge, and how did you overcome it? Dealing with neighbors who do not understand dairy farming has been my biggest challenge. I have neighbors who live very close to my farm, and they have purposely caused trouble for me over the years. Some of their actions have even led to me losing cows. It is an ongoing struggle. I have a nutrient management plan and a crop consultant, so in case something happens, someone has my back.

What piece of equipment being used now do you wish you had for the entirety of your dairy career? An electric feed cart because I don’t have to fork silage all the time and carry it. My

dad had a big box on a rail for feeding cows. When the pipeline went in, I had to carry feed for a lot of cows. I bought the electric feed cart 25 years ago, and I use it all the time.

Tell us a lesson you learned that you stand by today. Always have enough hay in the barn. I lived through the drought of 1988 when there was no hay. We had one bale left in the barn and were cutting the ditches so that the cows had something to eat. Now I have supply, and there’s a reason for it.

What advice would you like to offer future generations? Keep the passion even when times get tough. God will take care of you.

Brian Schmitz

Brian Schmitz

56 years old

Norwalk, Wisconsin Monroe County

Tell us about your farm then and now. My dad bought the farm in 1956 when he got out of the service. I graduated in 1986. At that time, 55 cows were milked in the stanchion barn. There were about 160200 acres with the original farm and all feed was stored in the silos. Now, I am in partnership with my brother, Steve, and my son, Jaden, is employed here as well. We milk 180 cows with three robots. Cows are housed in a freestall barn. We grow crops on about 1,000 acres and still use silos, as well as bags and bunkers.

What is your favorite memory on the farm? Deer hunting. I began hunting when I was about 10 years old, and I still enjoy it. My boys hunt now. I primarily go gun hunting because there never seems to be enough time to get out during bow season, but my boys do enjoy bow hunting when they can.

What do you love most about dairy farming? I really enjoy cows. The challenges are always there, but I enjoy that too. The robots are a whole different set of challenges but are more family friendly as far as exibility with our time.

What three characteristics do you possess that helped you maintain a lengthy dairy career? I have family support, which is the only way we have been able to maintain a lengthy career here. I am analytical and enjoy solving problems and facing challeng-

McGinn

es. And we have always been progressive to keep the lifestyle going.

What is the greatest success of your career? Building the robot barn. We added that eight years ago. It was a big investment and a huge change, but it has worked well for us. It was the rst GEA robot to be set up in the United States and was approved by the U.S. Food and Drug Administration on this farm.

What has been the biggest challenge, and how did you overcome it? Developing a partnership. We get along great now, but we had to learn how to accept each other’s individual responsibilities and trust that each was doing their best.

What piece of equipment being used now do you wish you had for the entirety of your dairy career? The forage equipment that we use now is so much more efcient. Our triple mower makes it so simple to cut hay, and our 12-row planter and self-propelled chopper allow us to get more done. When we are cropping 1,000 acres, we can’t really afford not to upgrade equipment.

Tell us a lesson you learned that you stand by today. I know a lot of farmers put in a lot of hours, and you have to put the time in and stick to your beliefs about what needs to be done. You can’t let things slide. We strive to do our best, and it pays off. We are careful about what we purchase and make sure we do not purchase it if we cannot afford it.

What advice would you like to offer future generations? Watch your spending and don’t overdo it. You don’t want to get in so deep that you can’t get out.

42 years old Sauk Centre, Minnesota Stearns County

Tell us about your farm and family. My wife Ashley and the kids — Ryland, Elliot, Hailey, Hank and Emily — help with chores and eldwork. We milk in a tiestall barn and ship our milk to First District Association. I bought the cows from my parents, Dan and Ilene, in the mid-2000s. We also do custom baling and chopping.

Why did you choose a career in dairy? It’s something I always wanted to do. I enjoy being my own boss and the variety of work. You never really know what you are going to end up doing some days. I like that milking is the time of day no one is bugging you. It’s my quiet time and gives me time to plan my day.

What is your favorite memory on the farm? Helping my dad and my grandpa, Robert, put up feed and now watching as the kids are getting older and starting to help with more of that stuff and watching them do the same things I used to do. My dad would always drive the chopper while my grandpa hauled loads and he and I unloaded. Now I am running the chopper, Dad is hauling loads, and the kids are running merger and helping unload loads. This is my favorite because everybody is working together.

What is your greatest accomplishment since you began dairy farming? When Ashley and I bought the last piece of land from my parents. We bought it in 2019 and now run around 300 acres between corn and alfalfa.

What will be the biggest challenge you will face in your career? Making sure I am keeping an eye on numbers and am able to cash ow everything and still being able to make money at the end of the day. When I rst bought the cows, I was buying feed from my parents and still making money off of $10 milk.

& LOCKER Aaron Wiener

State Hwy 238

What is the most important lesson you have learned since you began dairy farming? Learn to expect the unexpected and learn to roll with it. If something goes wrong or breaks, you have to change plans and just keep moving and have a positive attitude when it does happen. If you have a negative one, it rubs off on everyone.

Is there a form of technology you have implemented or plan to implement? We have been doing grid sampling, variable rate fertilizing and

liming for many years. It’s nice to see more even stands of alfalfa across the eld. We are also just starting this year with tonnage to the acre on the chopper. It will give us more information to work with and tell us what we could do differently.

What is the best advice you have received? If you take care of the cows, the cows will take care of you. I try to catch things before they get too far. If

they are getting sick, I get them xed up right away. I keep an eye on my cows by milking every morning so that I know what is going on and can pay close attention to details. Making sure I am covering the basics is one of the biggest things to having good cows. This includes making sure they are dry and have good feed in front of them and having the right balance of feed mixed together.

Cody Miner

(pictured with his wife, Ashley, and son, Conway) 33 years old Arpin, Wisconsin Wood County

Tell us about your farm and family. The farm and cows are owned by my in-laws. My wife, Ashley, and I are working into a transition plan with them. We milk the cows along with my father-in-law, Dennis. The cows are housed in a tiestall barn. Our milk is shipped to Dairy State Cheese Company in Rudolph, Wisconsin.

Why did you choose a career in dairy? Dairy farming has always interested me. Everyone in my family was a dairy farmer, except for my dad. I grew up helping on my cousin’s dairy farm.

What is your favorite memory on the farm? I would say my favorite memory of my career thus far has been putting up our new 14- by-70-foot silo for storing high-moisture corn. Watching that go up has been a highlight. Before we put that up, we were storing our corn at a neighbor’s site and had to haul it home throughout the year. Now we are able to store everything here.

What is your greatest accomplishment since you

began dairy farming? We were able to purchase 74 acres of farmland that adjoins this farm from a friend.

What will be the biggest challenge you’ll face in your career? I think the biggest challenges we will face throughout the years will be competing with larger dairy farms for land and foreign companies buying farmland.

What is the most important lesson you’ve learned since you began dairy farming? I do not always follow it successfully, but I have learned that having patience is important. You can get in a rush trying to do something and it seems like nothing goes right. If you slow down, breathe and take your time, things typically go more smoothly. That is easier said than done, though.

Is there a form of technology you have implemented or plan to implement? We put in a stationary total mixed ration mixer and now feed the cows TMR. When we complete our transition, putting up a freestall barn is something we would like to do, and then we will have to see what the industry looks like. Robots are something that might be of interest to us in the future as the technology continues to grow.

What is the best advice you have received? The best advice came from my great-granddad. He told me that farming is an honest way of living and one I would not regret going into. I try to remember that every day.

Isaac Griebel

26 years old

Parents: Mike and Jenna Griebel

New Ulm, Minnesota Brown County

Tell us about your farm and family. Searles Dairy is a partnership between my dad and me. We have two part-time employees, and my grandfather, Jullian, and my two sisters help when they can. Our milk is shipped to Associated Milk Producers Inc. We milk 215 cows in a double-8 herringbone parlor.

Why did you choose a career in dairy? I have wanted to be a dairy farmer since I was a little kid. I love working with cows and being out on the land every day.

What is your favorite memory on the farm? Running around the farm as a little kid with my cousins or neighbor kids climbing on bales and tearing up the yard on the all-terrain vehicle.

What is your greatest accomplishment since you began dairy farming? Probably the increase in

components we have seen in the last few years and being able to maintain our milk in that same period. When I came back to the farm full time, I wanted to breed and feed for better components, and so far, we are up 8% in butterfat and 2% in protein.

What will be the biggest challenge you will face in your career? The increase in regulation coming out of St. Paul and Washington D.C. It will be more and more important for my generation to share our story with consumers and politicians so that we do not get taxed and regulated out of business.

What is the most important lesson you have learned since you began dairy farming? Patience. Some of our biggest accomplishments have come after several years of challenges.

Is there a form of technology you have implemented or plan to implement? I would like to add robotic milkers in a few years. The oldest section of our parlor is over 50 years old and robots seem like a good t for our farm.

What is the best advice you have received? Always be willing to help those around you even when it is hard or inconvenient. When times get tough, good relationships are worth their price in gold.

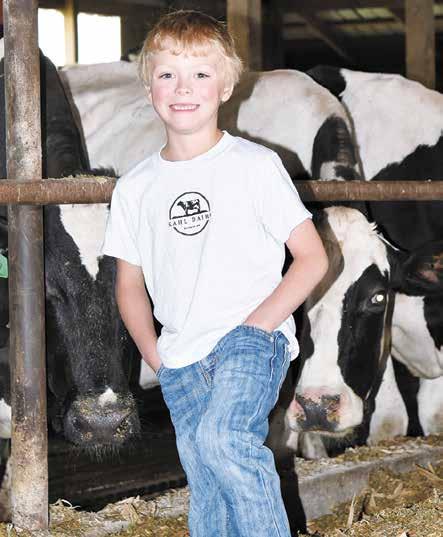

18 years old

Parents: Brent and Tricia Stelling Millville, Minnesota Wabasha County

Tell us about your farm and family. Our farm has been in the Stelling family for 104 years. My dad, Brent, and dad’s cousin, Jake, are the fourth generation that have been farming together for over 25 years. We have ve additional full-time employees, and we milk 275 registered Holsteins three times a day. Our parlor setup is a double-8 parallel. We ship our milk to Ellsworth Cooperative Creamery in Ellsworth, Wisconsin, where many cheese curds are processed and purchased.

What are your duties on the farm? I have many duties on our farm, which makes every day different. This is why farming is so cool; you never get bored. I maintain DairyComp 305 and CowManager, along with selecting sires for our cows and heifers. The chores that I perform are feeding calves, milking cows, mixing feed, scraping the barn and assisting with most of the eldwork. My favorite chores are feeding calves and helping my grandpa register our calves.

What do you enjoy about being raised on a dairy farm? The best part about being raised on a farm is learning how to manage money. I had the opportunity to raise my own bull calves for several years and gained a signicant amount of knowledge on managing money. It is important to know there will always be ups and downs, but the main goal is to stay positive. I also am extremely fortunate that my parents provided me with the work ethic it takes to manage and run our farm.

What is a fond memory from living on a dairy farm? In 2019 we hosted Wabasha County Family Night on the Farm. It was estimated that 1,000 people attended. This was one of my favorite memories because I was able to share the dairy farm with the public for a night and show them the meaning and importance of farming.

What characteristics of your dairyfarming parents do you admire? I admire that they are both friendly people who are willing to help out whenever

and whomever. I also appreciate their ambitious and hardworking personalities but that they still nd time for family, friends and fun.

What do you hope your farm will look like in the future? In the near future, I hope to farm with my dad. We have a plan to add on to our parlor and make it a double-12. In addition, we would like to build another barn for 100 cows.

What will be the biggest challenge you’ll face in your career? Money always seems to be the biggest challenge

in farming even if you think you have it gured out. Prices go up and down, but thankfully we have a high production herd, making that a steady factor on our farm.

What is your favorite way to enjoy dairy products? Cheese curds are denitely my favorite way to enjoy dairy products. There are so many different avors that it can be hard to choose a favorite. At my high school graduation party, we had a cheese curd bar for our guests to try different avors; we’ll just say this went over quite well.

6 years

Parents: Travis and Sarah Kahl Buckman, Minnesota Morrison County

Tell us about your farm and your family. Grandpa started the farm rst, and then when my dad got big enough to reach the milkers when standing on a bucket, he started milking. Dad thinks he was about 9 years old. My grandma helped with chores until Dad was old enough to start milking. Now, my dad milks the cows and Grandpa mixes feed and takes care of the calves. A lot of our equipment has computers in it now, so Grandpa can’t plant corn anymore or chop hay because he doesn’t know how. My dad does all of that. I was born on May 15. My Dad was planting corn but had to stop to go to the hospital with my mom. He had to leave the hospital the next day to plant corn because nobody else knew how. Our parlor is a double-8, so 16 cows can be on milking units at a time. It takes two people and around 3.5 hours each milking. Sometimes it takes three people when I help milk. My great-uncle Ronnie Kahl is our milk truck driver and picks up our milk. He works for the creamery, Sunrise Ag Cooperative. The milk goes to First District Association or Kemps.

What are your duties on the farm? I help milk cows. My grandpa taught me how to drive the Bobcat. I use my Power Wheels and the wagon and haul out the milk replacer bags in the calf barn to clean it out. I help Dad swing gates in the calf barn when he’s cleaning it out. I help feed calves sometimes too, but that’s not my favorite job. I’d rather milk cows. My all-time favorite job is spraying down the parlor after milking with the big hose.

What do you enjoy about being raised on a dairy farm? I like the cows. I like living on the same

farm as my grandma and grandpa. I like having a big yard so that I can have my baseball eld, drive my Power Wheels and play outside all the time. I really like all our tractors. We have all blue tractors except for one huge red one. That one is my favorite. It’s my favorite because it’s the biggest.

What is a fond memory from living on a dairy farm? Crushing my mom in baseball in our big farmyard and the baseball eld that my dad made for me — and learning how to drive our blue tractors. My grandpa is teaching me. He told me it was our secret, but I like to tell the truth, so I told my mom.

What characteristics of your dairy-farming parents do you admire? My favorite drink is chocolate milk. I really like that my dad milks so many cows and gets so much milk so that I can have as

County Rd. G • Darlington, WI 53530 608-776-4048 RUF’S FARM

rufsfarm@gmail.com

much chocolate milk as I want. I like that my mom learns how to run a new piece of farm equipment every year. My dad teaches her. That way, Mom gets to help more, and my sisters and I get to ride along.

What do you hope your farm will look like in the future? I want a track Bobcat. We don’t have one of those, and I really want one.

What will be the biggest challenge you will face in your career? Which kid is going to take over the farm. My mom and dad are having another baby. There’s going to be four of us. I think it’s going to be hard to decide which one of us is going to take over the farm.

What is your favorite way to enjoy dairy products? Chocolate milk.

get first crop grass done in a week. Ours is grass, brome and clover. We’ve baled over 2,000 bales. The corn is over 8 feet high and is getting ready to tassel. The wheat is waist high and variable. It was slow maturing because it was wet. It is turning color and soon people will be combining then they will plant soybeans in those fields. The dairy farmers near here are getting close to third crop alfalfa.

The temperature is starting to warm up for summer, things have been running pretty descent. We finished first crop alfalfa June 10 and it’s coming back really good. Everything got chopped and stored in our inground bunker because the forecast sounded like it would be hard for baling. I finished planting corn by June 13 and the small grains are just starting to poke out heads now. My tallest corn is about 8 inches tall and the neighbor’s soybeans are around 3 to 4 inches tall. I started grazing the second time through my paddocks on June 19.

We got first crop hay off. We chopped it June 9-10 and put it on a pile. We had a lot of tons of hay. Most people chopped when we did. We sprayed for weevils right after we finished first crop. The second crop alfalfa is 4-6 inches tall. We finished planting corn June 15. A lot of corn in the area got planted last week. Some of the earlier planted corn is 1 foot tall. Next on the agenda is spraying, but it will be a while because we have a lot of standing water. A lot of low spots are drowned out.

We have gotten a fair amount of rain and also had some cooler days within the last couple weeks. Everything is pretty saturated right now. The alfalfa is still coming back nice and I am hoping to be in the field for second cutting soon. We finished planting our corn the second week of June. We have had good emergence on corn and the neighbors that were in the fields earlier have some corn that is getting close to waist high. My corn is about knee-high. The soybeans in the area all seem to be coming up good.

We had some nasty weather come through Saturday night (June 15). Areas around here had 5-8 inches of rain. Some areas had 7 inches in seven hours. There are a lot of roads blocked because they have been gullied or water is running over the road. There is standing water in all the fields, the cricks are backed up and the tile lines are full. We helped a neighbor plant soybeans Friday night (June 14). We had to replant 8 acres of corn. The early corn is almost canopied. The later planted corn is 6 inches tall. The soybeans are coming along. The second crop hay and wheat look really nice. There are fields in the area where the water is deeper than the wheat.

We had a good period of dryness with a couple of storms. Most rain was from June 15 and 17. Our alfalfa is starting to come back good now, after being stunted from the alfalfa weevils. The emergence of all the crops have been really good so far. Some of the neighbors have past knee-high corn and the soybeans are 5 to 6 inches tall and looking good. We have a bit of rye that has hit around 6 feet tall. It has been a tremendous year for growing rye.

Earlville, IA

I got the rest of the soybeans planted June 11 and have all the pre-emerge spray on. We cut half the second crop hay (40 acres) yesterday (June 17) and are chopping it today. We plan to put it in a bag. The stand of alfalfa was off because the leaf hoppers moved in and it was too wet. The alfalfa that is two weeks behind, we sprayed for weevils. We replanted 13 acres of corn in low spots that drowned out. I would say half the guys around here did some replanting. When we get a good window, we will do oat and peas. The early planted corn is getting a good color. The yellow spots are less and less.

We are down to the last 60 acres on first crop. We baled about 450 big squares of dry hay within the second week of June. The first stuff we cut took a little while to come back and we were worried, however, now that crop is 26 inches tall on those very first fields and is ready to go again. All our planting is done. We have been hoping to do spraying, but it has been so wet and windy. Our oats are just shy of 3 feet tall. We usually chop some to feed to the heifers and then combine about 100 acres. The fields are definitely on the mushy side.

Ellsworth, WI

Not much for crops because every other day it rains. A little bit of second crop hay has been snuck in but there’s still some first crop hay standing and some laying as well. There is getting to be a weed issue with corn and beans because they can’t get it sprayed. There are ruts in fields because of equipment going through. I have heard of some people replanting and some also have dead spots from standing water. Nothing huge, an acre here and there, but it’s a mess. I probably have 4 acres total that’s dead which out of 300 acres is not the end of the world.

We had 2.5 inches of rain on June 18 and another 1.5 inches that night for a total of about 10 inches in the last two weeks. It’s getting bad. We sprayed some heavy ground, but now even the light ground you can’t walk on without sinking in. We do have all our corn in, some is almost knee-high, but some is also yellow. We did get some dry hay made the second week in June. It was almost questionable to bale, but we need something for the beef cows. Second crop hay will be ready probably next week but we won’t be able to get to it.

Rosendale,

We have had about 1.9 inches of rain in the last two weeks. The corn around here looks really good, other than in the low spots. It is almost knee-high. We finished our first crop hay, we for the cows, last week. We have grass hay to bale and our peas and oats to get off yet, then we will start a new seeding alfalfa. The second crop hay will probably be ready to go at the end of the month too.

JULKA

380 cows, 1,800 acres

All of our side dressing done. Applying nitrogen on the corn was a major project hopefully it will perk up the corn that is a little yellow. The corn we planted first looks really nice, while the stuff planted later is looking OK. June 17-18, we cut and chopped 110 acres of peas, triticale and alfalfa mix that is used for heifer feed. We would like to start second crop hay on June 24, but it’s supposed to rain for five days preceding that. There are some weeds coming up in the soybean fields, so we need to do a post-emerge weed pass hopefully the week of the June 24. Soybeans look really good, and our wheat looks fantastic. We sprayed fungicide on the wheat two weeks earlier than normal.

RIB LAKE, Wis. — Owning a pizza place has been a long-time dream for Cody Baldwin. He was able to embark on this journey in January 2023 when he purchased Man Made Pizza and Ice Cream in Rib Lake with his partner, Chelsea Shook.

“I have been in the restaurant industry pretty much my whole life,” Baldwin said. “When the previous owners were wanting to retire, this seemed like a great opportunity to get started in the pizza business.”

Baldwin and Shook purchased the business from Jim and Chris Mann. At the time the restaurant was called Mann Made, in reference to their last name. Baldwin admits that the name conicted with him at rst.

“I didn’t think it was right to keep the name Mann Made, but everyone knew and loved the business by that name,” Baldwin said. “Small towns don’t always like change, so I was worried about switching it. We compromised by dropping an ‘n,’ so now we have Man Made Pizza and Ice Cream.”

The local community welcomed Baldwin and Shook as the new owners of the establishment, continuing to support a newer version of the establishment that it had come to know and love.

“We are very thankful for how the local community has supported us from the start,” Baldwin said. “They keep us going during the winter and they really get out a lot in the warm months.”

The business is open year-round, but Baldwin said sales are four times higher in the summer.

“The weather denitely plays a huge role in our business,” Baldwin said. “Summer is when we can make forward gains in growing the business, especially in a very small community like this. We see a lot of tourism-driven trafc in the summer — people camping and visiting the Ice Age Trail. ... There

are people that visit and this is their destination. They go on vacation and there is one place they really want to stop at. We are that place.”

Building a family atmosphere is important to Baldwin and Shook.

“We all have to eat, but I think going out to eat is sort of becoming a lost thing, mainly due to the economy,” Baldwin said. “I’d like to see what I can do to change that.”

Although the Man Made menu includes a variety of sandwiches, Baldwin and Shook call pizza and ice cream the staples of their business.

“I was drawn to the idea of running a pizza place because, for a lot of restaurants, it is actually quite difcult for them to pull it off successfully,” Baldwin said. “It is challenging — the amount of ingredients you need to keep on hand, the set-up to do it correctly, the oven space, the amount of room for prepping the pizzas — but if you design it just for pizzas, it is relatively easy.”

Eventually, Baldwin wants to expand his menu to add to the variety of creative specialty pizzas offered. But for now, he is sticking with a more traditional menu with just a few specialties and a build-your-own-pizza option.

Baldwin estimates that during the summer, the restaurant uses somewhere between 120-160 pounds of cheese each week.

“People say they love the cheese on our pizzas,” Baldwin said. “They don’t realize that is because we use more than just mozzarella on our pizzas. I really like using a ve-cheese blend, and then I can use more of a certain kind of cheese, depending on the recipe.”

Another reason Baldwin aspired to own a pizza place was the nature of the ingredients.

“Everything on a pizza can be grown and made right here in Wisconsin. That is a big emphasis for us, one we want to continue to build on in the future,” Baldwin said.

To complement the pizza, ice cream has long been a part of the restaurant’s repertoire, serving both Kemp’s ice cream and more recently, Cedar Crest ice cream.

“Kemp’s isn’t made here in Wisconsin, but they do source local milk,” Baldwin said. “We have been switching to Cedar Crest. It is made in Wisconsin with Wisconsin milk, so we have been leaning towards that product.”

On a good day in the summer, Baldwin says Man Made serves between 1518 gallons of ice cream to their customers.

“We really push dairy,” Baldwin said. “That is the staple of everything we do here.”

Baldwin looks forward to working with local dairy farmers to develop relationships.

“My goal is to keep local businesses together, to keep money here in our Wisconsin communities,” Baldwin said. “It is sad to realize how much dairy we have around us, and how much of our own dairy we use. It’s problematic for everyone, for our economy. I’d like to play a role in changing that.”

Baldwin and Shook saved for several years in preparation to follow their dream.

“We budgeted, saved every dollar,” Baldwin said. “We didn’t use the dryer to save that $1.25 it cost to run it. It takes a lot of sacrice to get something you dream of.”