Pr esent, Past, Future. Present,

Read our Past, Present, Future feature starting on page 13 of the 2nd section!

Read our Past, Present, Future feature starting on page 13 of the 2nd section!

Nearly three months ago, the rst cases of Highly Pathogenic Avian Inuenza H5N1 in dairy cattle was conrmed by the U.S. Department of Agriculture’s Animal and Plant Health Inspection Service. Since then, the virus has continued to spread, affecting dairy cattle across the country.

This month, documented conrmed cases in Iowa, Minnesota and Wyoming bring the total number of conrmed cases to 102 herds in 12 states as of June 18. Illness among three dairy farm workers — one from Texas and two from Michigan — have been conrmed after exposure to infected dairy cattle.

The spread of H5N1 between states has been linked to the movement of lactating dairy cattle. This prompted the Federal Order that went into effect April 29 requiring lactating dairy cattle to have a negative test within seven days of crossing state lines. Epidemiological evidence suggests that further local spread is likely multi-factorial, through both direct and indirect transmission routes.

A national epidemiological brief posted June 13 on the APHIS website, which detailed information collected from 54% of affected premises as of June 8, said that more than 20% of affected farms brought animals into the herd within 30 days of the initial observation of clinical symptoms. More than 60% of farms continued to move animals off the farm after the onset of those clinical signs.

The level of impact the disease has had on affected farms varies greatly. The most prevalent clinical signs observed in dairy cattle include milk that appears abnormal and a decrease in production, feed consumption and rumination. Cows frequently exhibit fevers and dehydration.

Other clinical symptoms reported include respiratory issues such as increased respiratory rates, labored breathing, nasal discharge and pneumonia.

Count the logos Count the for your chance to win for your chance to win butter and cheese!

See page 24 of the this section for details.

“All

WALDO, Wis. — Farming is hard work. But when that work is recognized by others, it can make a big difference.

On May 30, six farmers in Sheboygan County were shown appreciation when they received a visit from Wisconsin Secretary of Agriculture Randy Romanski. He came bearing gifts and lent an ear to learn about their farms and issues they might be facing.

“I was glad to be part of this event,” Romanski said. “It highlighted how important it is for us to be connected with our neighbors, and how those relationships can create a support network within our community. I always enjoy hearing

from farmers about their operations, what they’re most proud of, and how we at the Department of Agriculture, Trade, and Consumer Protection can help connect the dots to resources that may support their farm goals.”

May was Mental Health Awareness Month, and as part of awareness efforts, the Sheboygan County Farm Bureau hosted Romanski in conjunction with the Farm Neighbors Care campaign. This campaign was started by the Wisconsin Farm Bureau Federation to bring awareness about farmers’ mental health and the struggles farmers face.

ALMA CENTER, Wis. — Richard and Sara Larson’s 42-year dairy career had its share of challenges, but also included many highlights.

“It’s been good to us,” Richard Larson said. “It’s been tougher at times, but it’s been alright.”

Richard and Sara sold their 26-cow dairy herd in April to retire from milking on their farm near Alma Center.

Richard purchased the

farm on a land contract July 8, 1981. The 16-year-old had just nished his sophomore year of high school. He had been renting the land since he was 14 years old, with his father co-signing a crop loan. When the owner was ready to retire, they made a deal with Richard to purchase the farm. The interest rate on the land contract was 12.75% and personal property was charged at 19% interest. Richard purchased 24 calves in the fall of 1981, raised them, bred them and then sold all but seven as springing heifers in 1983. He bought another 30 milking cows when he was 18.

www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) (Western Wisconsin) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and opinions expressed by

columnists and

are not necessarily those of the

The

Con nued from H5N1 | Page 1

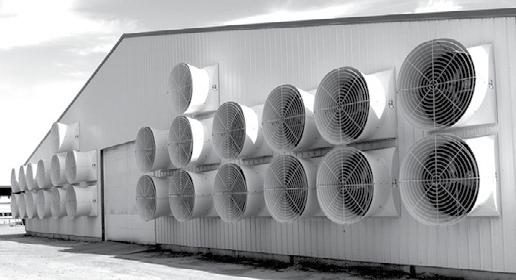

Due to that evidence, researchers recommend dairy farms develop and enforce strict biosecurity protocols as a measure to help mitigate the risk of the virus reaching their herds. While enhanced biosecurity is a measure to prevent the spread of disease, the summer fair and show season adds another layer to the issue.

On June 11, during a press call, Wisconsin Secretary of Agriculture Randy Romanski announced a new testing order put in place by the Wisconsin Department of Agriculture, Trade and Consumer Protection. He said it continues to be an evolving situation.

“With an increasing number of affected states and a busy fair season ahead of us, DATCP is acting within our regulatory authority to try and minimize the risk of commingling potentially sick animals,” Romanski said.

The order, which went into effect June 19, requires all lactating dairy cattle moving within the state for purposes of show or exhibition to have a negative H5N1 test within seven days before movement.

“We have been monitoring the increase in cases, especially in the upper Midwest,” said Wisconsin State Veterinarian Dr. Darlene Konkle. “With the increasing number of cases in our region, it made sense to minimize the opportunities for the virus to be introduced or spread in Wisconsin, particularly if animals are moving to fairs and exhibitions.”

Konkle said the purpose of the order is to protect not only the dairy industry in Wisconsin, but poultry and other live-

stock industries as well.

“We know the virus can spread cow to cow and also from cattle to poultry and poultry to cattle,” Konkle said. “We know that lactating dairy cattle are potentially the highest risk of spreading large amounts of the virus, but we also know that lactating dairy cattle and other classes of cattle could be affected without showing clinical signs.”

On June 13, the Minnesota Board of Animal Health issued an order effective June 18 that requires a negative test and a certicate of veterinary inspection for all lactating animals before in-state movement for all exhibitions.

Both the Wisconsin and Minnesota orders require testing at National Animal Health Laboratory Network facilities, with samples being collected within seven days of movement. While the testing is run at no charge to producers, funds are available through the USDA to help cover veterinarian and shipping costs associated with testing.

Konkle said that the Wisconsin Veterinary Diagnostic Laboratory is running tests Mondays, Wednesdays and Fridays. Samples that arrive at the laboratory on those days before 1:00 p.m. will be tested the same day. Samples arriving after 1 p.m. or on Tuesdays and Thursdays will be tested the next day tests are run.

The Minnesota order is in effect until the end of 2024, unless rescinded earlier. The Wisconsin order will remain in effect until 60 days after the last detection of H5N1 in cattle herds in the U.S.

Konkle and Romanski encourage

exhibitors to follow the USDA’s recommendations for minimizing transmission at exhibitions which was published last month.

Exhibitors are encouraged to become familiar with signs of H5N1 in dairy cattle and to discuss the potential risks of exhibiting animals with their herd veterinarians.

To the greatest extent possible, an attempt should be made to limit the commingling of animals from different herds to reduce nose-to-nose contact.

Exhibitors should not share husbandry tools, feed and water, portable milking equipment or grooming supplies with other exhibitors. All equipment, including trailers, should be thoroughly cleaned and disinfected before leaving the farm and before returning to the farm. This protocol should also be frequently conducted during the show. Exhibitors should avoid transporting animals from different farms in the same trailer.

Animals returning to the farm from an exhibition should be isolated and observed before they come into contact with animals that did not leave the farm. It is also recommended that equipment not be shared between show animals and other animals at home.

“We wanted to get ahead of a busy show and fair season this summer,” Romanski said. “We have lots of dairy kids wanting to show. The way Dr. Konkle has structured this order, those kids will still have the opportunity to exhibit a cow at the fair — the only extra step is testing.”

ABBY

ABBY

“At the beginning, I was considered high risk so in my rst year of milking cows they took 45% of my milk check,” Richard said. “The land contract payment was $13,400 and some odd dollars and in the rst year, the principal was 21 bucks. That’s the honest-to-goodness truth.”

Richard milked his 37 cows with bucket milkers and a step saver at rst and did not have a barn cleaner or silo unloader. He did have support from his brother, Jon, eight years his elder, who was established with a dairy on the farm next door. He and Richard shared his equipment.

In Richard’s rst year shipping milk in 1983, he received a base pay of $14.50 per hundredweight. With the fat differential, Richard gures he received close to $16 cwt.

“That was 42 years ago,” Richard said. “When we sold our cows, our last milk check was $16.87(cwt).”

Richard and Sara were married in 1995 and had their only child, Bailey, in 1997. The milking herd had grown to about 50 cows. They were milking at Jon’s farm and using Richard’s facilities for youngstock. Jon also milked his own herd so altogether they were milking close to 100 cows.

Jon was diagnosed with cancer and passed away in 2011. At his passing, he and Richard had farmed together for 29 years.

In 2000, when Jon began traveling for treatments, Richard and Sara sold their cows so they could take care of Jon’s herd. When his treatments ended and Jon returned, he resumed milking and Richard and Sara decided to remodel the barn at their farm and milk cows again, but on a smaller scale.

They calved in heifers and purchased a few more cows. Their barn held 26 milk cows and from then on, the milking string never exceeded that number. They kept all their youngstock and raised heifers for replacements and steers for a cash crop. They also sold hay and corn as cash crops.

Sara said diversity kept them protable.

“That’s how we made it over the years,” Sara said. “We had multiple things, and something was usually high, whether it was hay or corn or beans or steers or cull cows.”

The couple also credits their dairy herd for their success. In 1985, Richard was one of the rst herds in Jackson County to implement a mating program through what is now ABS Global Inc. They averaged between 75-85 pounds of milk per cow per day throughout their career. Their feeding program consisted of a silo of haylage and another of corn silage. In later years Richard added steamaked corn to the ration, which he said yielded good results.

The Larsons shipped their milk to Associated Milk Producers Inc. throughout their career and received many quality awards. Their best tank somatic cell count was 20,000.

“I’ll never forget that,” Richard said. “The one year we averaged just over 100 (SCC).”

The couple had one hired man to help with crops but did all the milking themselves. They were also diligent about managing the time the cows spent in the barn or on pasture.

“If it was too hot they were in the barn; if it was too wet they were in the barn,” Sara said. “We spent a lot of time just coordinating them. Everything (revolved) around the cows.”

Richard agreed.

“You don’t realize how much you think about them until they’re gone,” Richard said.

Richard and Sara watched the industry change in 42 years of dairying. Richard said the biggest change is how farming has evolved to require a business mind.

“It was always work but it’s just as much thinking now,” Richard said. “You’ve got to be so careful. One mistake, whether you can prevent it or not, can cost you thousands.”

The couple plans to enjoy their retirement from milking by raising some youngstock and continuing to crop. Sara also purchased a couple of goats to keep her company.

Through an anonymous online nomination form, community members nominated local farmers to receive a care package which included a lunch bag, snacks and a Culver’s gift card.

Nicole Laack is the chair of the Sheboygan County Farm Bureau Young Farmer and Agriculturist program.

“The packages are a way to say thank you for what you’re doing, we recognize your hard work, we are here as a resource and appreciate that you’re a part of our ag community,” Laack said. “It was a very good day.”

Thirty-ve individuals or couples were nominated to receive packages.

“That’s an outstanding number,” Laack said. “Last year was our rst year doing this, and we only had 12 nominations. We were very excited to have 35 in our second year.”

Laack said over 90% of the farmers nominated were dairy farmers.

Laack gives credit to the county’s district coordinator, Becky Salm, and the promotion education committee chair, Kathy Salm, for encouraging the county to get started on this program.

“It’s not something every county has to do, but we saw it as a good opportunity to get out in our community and connect with our farmers,” Laack said.

Five of the six farms Romanski and Farm Bureau committee members visited May 30 were dairy farms.

“The visits highlighted a good snapshot of the diversity of agriculture in Sheboygan County,” Romanski said. “It’s an example of how all types and sizes of agriculture have an opportunity to be successful in Wisconsin.”

Dan Mullikin and his family milk 500 cows and farm 1,200 acres near Waldo.

“We were a little surprised or humbled when we found out we had been nominated to receive a care package,” Mullikin said. “We weren’t planning on it, and all the sudden, there it was. It was neat to meet with Secretary Romanski and have him tour our facilities. He’s very down to earth and is a super nice guy.”

Mullikin farms with his wife, Shelly, and their three adult children, Cody, Jessica and Brett.

“Everybody needs to eat and realize their food doesn’t come from the grocery store — that somebody is actually working hard to produce safe and enjoyable products for them to consume,” Mullikin said.

Recognizing that farming can be an isolating career, the Farm Neighbors Care campaign stresses the importance of checking in on friends, neighbors and family members to gauge how they are doing and offer support and a listening ear.

“I think now more than ever, we hear a lot on social media and in the media in general about mental health awareness,” Laack said. “We all know the number of farmers is declining each year. If we can get out there and recognize the people who are still dedicated to doing this hard work of feeding the world, it goes a long way.”

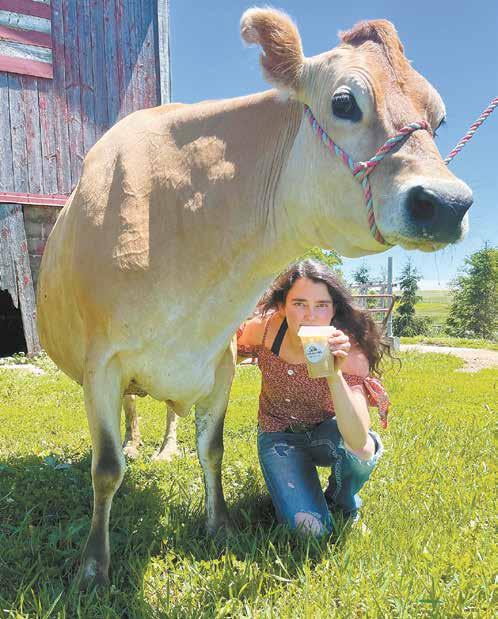

CUBA CITY, Wis. — Tabitha Vosberg has always been slightly enamored with coffee. She even named one of her cow families with coffee names. Now, she has combined her love of coffee and cows in her new business, Farm Girl Coffee Shoppe LLC.

“I wanted to start a business of some sort and have an income off the farm just because farming is not easy or lucrative,” Vosberg said. “This is a way to support myself a little more.”

Vosberg works with her family on their 145-cow dairy farm near Cuba City. She is in charge of managing the evening milking and is a co-herdsman. She also does all the breeding on the farm, and, during crop time, she is out in the elds with her father, Tim, and her siblings.

The idea for a mobile coffee shop started a little over a year ago. Vosberg and her family were discussing the growth of the nearby town Kieler and said it could really use a good coffee shop. Vosberg started pursuing the idea while nishing her studies at Southwest Wisconsin Technical College. She graduated in May with a degree in farm operations and management with an emphasis on dairy.

Vosberg purchased a atbed trailer and built the coffee trailer

from scratch. The outer boards on the trailer came from the barn decorated with a ag on the Vosberg farm. The original part of the barn is constructed from wood from the 1800s, preserved perfectly for use on the coffee trailer.

“The barn boards haven’t seen weather for over 100 years,” Vosberg said. “It was the original horse barn. They added onto it but left the exterior boards in the middle inside. We ended up just taking those boards back.”

The rest of the trailer was built with help from her dad and former farm employees who have a construction businesses of their own. The inspection process was challenging because it is so different from farm inspections, Vosberg said. She had to have every piece of equipment documented, including the wattage of everything in the trailer and the entire plan on paper.

Vosberg learned about the coffee business by shadowing other baristas, interviewing coffee shop owners and watching YouTube videos. She said it is a craft she is still perfecting.

“I know how to dairy farm; I did not know how to make coffee,” Vosberg said. “I’ve learned a lot of people do things differently, so you have to have your own way of doing things.”

Vosberg offers lattes, Americano, caramel macchiato, chai tea, drip coffee and Lotus Energy drinks. She also has a vast selection of avored syrups.

She has learned the difference between making traditional coffee from Europe, where a lot of the drinks were

Turn to VOSBERG | Page 9

originally invented, and modern, more American coffee. The biggest difference is the size of the drinks Vosberg said. Vosberg offers 12- and 16-ounce drinks, because she feels they appeal to her customer base.

In the process of learning how to make coffee, Vosberg said she learned more about milk as well, along with the science behind the steaming process.

“It’s interesting to learn more about milk from the aspect of the end product rather than at the beginning,” Vosberg said.

The coffee trailer was rst opened in April one day a week because Vosberg was still in school. Now that she has graduated, she is open Monday through Saturday from 6 a.m. to 11 a.m. She rents a spot in Kieler next to the Casey’s gas station near U.S. Highway 151. Here she has access to electricity, though she now has a generator as well which will offer exibility for events.

A typical day for Vosberg begins around 5 a.m. when she wakes up to get the coffee machines started. She drives one mile to her designated spot and gets ready for customers. So far, her highest number of customers in a day was 42. Vosberg said her peak time is around 8 a.m. to 10 a.m. during the weekdays.

On Saturdays, customers tend to arrive later.

Vosberg has kept her advertising to a minimum, just posting on social media. She said she would like to get more comfortable with making coffee and handling customers before she tries to draw too big of a crowd.

“My sisters jump in and help when they want to just for funsies, so that’s really helpful,” Vosberg said. “I’ll try to handle it mostly by myself but if it picks up enough then I’ll have to hire somebody.”

Vosberg said that dairy farming has helped her handle becoming an entrepreneur.

“In farming, nothing ever goes perfectly as planned and you have to be able to make quick decisions and go with the ow,” Vosberg said. “That really has helped me because it’s problem solving. That’s denitely a skill that you need with any business.”

ABBY WIEDMEYER/DAIRY STAR

Tabitha Vosberg steams milk May 29 on her farm where her coffee business is based near Cuba City, Wisconsin. Vosberg serves coffee six days a week in Kieler and is now set up with a generator to do events.

The Fleckvieh breed is renowned as a dual-purpose breed, excelling in both strength and fitness while maintaining consistent lifetime milk production. Known for its adaptability, Fleckvieh thrives in various management and breeding systems. It offers an excellent choice for heterosis, making it an ideal candidate for crossbreeding with other dairy breeds. This breed strikes a perfect balance between cow health and efficiency, making it a valuable asset for dairy farmers seeking robust and productive cattle.

⊲ Robust, long-lasting, easy keeping cows

⊲ Persistaint production, increasing each lactation

⊲ Excellent fertility with shorter calving intervals

⊲ Moderate sized, low maintaince cows for reduced cost

BY SMITH’S OF WI LLC

BY SMITH’S OF WI LLC

According to Agriculture Secretary Tom Vilsack, the U.S. Department of Agriculture has a good sense of the way the H5N1 virus is spreading. “Thousands of tests have been conducted and reviewed,” Vilsack said. “Not only of cattle but of milk taken directly from cows and bulk tanks on the farm, I’m condent that we have a good understanding of the nature of this virus and how it’s being transferred between various farms.”

A plan is in the works that would reimburse dairy farmers for loss of production related to the virus. “Hopefully, in the very near future, we’ll be outlining the indemnication process and how that might operate in order to indemnify or reimburse the farmer for their losses,” Vilsack said.

New testing requirements

The Wisconsin Department of Agriculture, Trade and Consumer Protection, has announced new testing requirements for lactating dairy cows. These animals must test negative for H5N1 and get a Certicate of Veterinary Inspection before attending events, like a show or fair. If samples test positive, the state will begin a disease investigation and quarantine the cows. All results will remain condential.

Farm bill framework released

Stabenow rallies anti-hunger advocates

Senate Agriculture Committee Chair Debbie Stabenow criticized the House Committee on Agriculture farm bill during an appearance at the National Anti-Hunger Policy Conference. Stabenow said the House bill took nearly $30 billion from federal nutrition assistance and “gave a 70% increase to the biggest farmers.” The Michigan senator went on to say she supports risk management for all farmers, but it shouldn’t come at the expense of the most vulnerable.

By Don Wick Columnist Ag Insider

By Don Wick Columnist Ag Insider

Senate Agriculture Committee Ranking Member John Boozman has released his farm bill proposal. It includes language similar to the farm bill passed out of the House Agriculture Committee. Ag Committee Chair Debbie Stabenow welcomed Boozman’s farm bill framework but quickly criticized it. Stabenow said the Republican proposal follows what she called the “awed approach” taken in the House Committee on Agriculture farm bill and splits the broad farm and food coalition.

Fighting the same farm bill funding issues

North Central Extension Risk Management Education Center Director Brad Lubben describes himself as a “cynical optimist.” Lubben was part of a farm policy discussion at the Midwest Council Ag Forum and said lawmakers have been ghting over the same farm bill funding issues for many years. One issue is the use of the one-time Ination Reduction Act to fund conservation programs. Secondly, Congress is bogged down with the agriculture secretary’s authority to use Commodity Credit Corporation funds. “We have a history of almost 15 years battling over that discretionary authority, and neither party generally seems to be willing to trust a (agriculture) secretary of the other party with how to spend that money, so we’re ghting over the same issue,” Lubben said. Lubben, who is at the University of Nebraska-Lincoln, said the third funding issue is with federal nutrition programs.

Policy highlighted at NMPF board meeting

The National Milk Producers Federation leadership has wrapped up its summer board meeting. The modernization of Federal Milk Marketing Orders and the H5N1 response were high on the agenda. The board also considered improvements to its Cooperatives Working Together self-help initiative, which promotes dairy exports.

According to American Farm Bureau Federation Government Affairs Director Joe Gilson, House Republicans want to nish the work on the scal year 2025 spending bills before focusing on the farm bill. That puts the appropriation bills and the farm bill on a collision course with the same September 30 deadline. Without a path to passage of a ve-year farm bill, another extension will be necessary. “We’re starting to hear some extension talk, but remember with a lot of the farm bill programs, while the expiration is September 30, they run ‘til the end of the year, so really we need a (farm bill) extension by the end of the year,” Gilson said.

Court rules on Emergency Relief Program for “socially disadvantaged” farmers

A federal court in Texas has granted part of a motion to prevent USDA from providing additional assistance to socially disadvantaged farmers. The case centers on payments for the ERP which based the assistance on a farmer’s gender and race. The court said a progressive payment system can be used in future assistance programs if it is not based on race or sex.

Dairy demand boosts milk price outlook

The latest USDA supply and demand report left the milk production forecast for this year and next year unchanged from last month. For 2024, commercial exports were raised on a fat basis due to higher-than-expected cheese shipments. Strong international demand remains in place for 2025. The all-milk price forecast was raised to $21.50 per hundredweight, and the Class III milk price outlook also rose. The Class III milk price is inuenced by the strong demand for butter, cheese and whey.

New dairy forage research facility

Ground has been broken for a new state-of-theart dairy forage research facility at Prairie De Sac, Wisconsin. The facility is scheduled for completion in 2027. It is a joint effort of USDA’s Agricultural Research Service and the University of WisconsinMadison. It will include robotic milking systems, an advanced animal nutrition center and agronomy and dairy science laboratories.

Crowder passes May 30

Richard Crowder served as the chief agricultural trade negotiator in the U.S. Trade Representative’s Ofce during the George W. Bush Administration and was the USDA undersecretary for international affairs and commodity programs during the George H.W. Bush years. Crowder’s career also included time as a senior vice president for Dekalb Genetics and as the head of the American Seed Trade Association.

AMPI chair elected to NMPF board

The National Milk Producers Federation board has elected three new members, including Associated Milk Producers Inc. Chairman Dave Peterson Peterson farms at Boyd, Wisconsin.

Stars recognized

The Wisconsin FFA honored its Stars during the state convention. Taylor Maroszek of Pulaski is the Star Farmer. The Star in Agricultural Placement is Kaydence Hodorff of Eden. The Star in Agribusiness recognition went to Allison Loosen of Slinger, and The Star in Agriscience is Andrew Gotham of New Auburn.

Trivia challenge

The third Sunday of July is National Cream Day. That answers our last trivia question. For this week’s trivia, what is the most popular ice cream topping? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Cheese vats shine June 12 in the new facility at the Center for Dairy Research on the University of Wisconsin-Madison campus in Madison, Wisconsin. This room is part of the recent 57,000-square-foot expansion at the CDR which includes 30,000 square feet of manufacturing space on two oors.

Center for Dairy Research grows the product category

By Stacey Smart stacey.s@dairystar.comMADISON, Wis — From developing new specialty cheese recipes to nding alternative uses for whey to training the next Wisconsin

Master Cheesemaker, the Center for Dairy Research continuously works to grow demand for dairy products.

“Our mission is to advance the dairy industry through innovation, education and entrepreneurship,” said Dr. John Lucey, CDR director and professor of food science at the University of Wisconsin-Madison. “If a company is looking to make a new cheese, a new beverage, or a new bar, we help them do that. More dairy sales are good for us, and it’s good for farmers.”

Turn to CLOSER LOOK | Page 12

“We use these tests as an overall guide of how our herd is doing...”

How long have you been testing with DHIA?

Since we started milking in 2010.

What tests do you use and what do you like about those tests? So far we have only had the milk tested for somatic cell count, butterfat, and protein. We use these tests as an overall guide of how our herd is doing, and it helps us to see if our nutrition is in check. It helps us to decide if we need to make changes on our farm and assists us when making culling decisions. We have not utilized the pregnancy test yet but are considering it in the future.

Which is your favorite and why? We like all the tests we’ve used so far, but the somatic cell test helps to pinpoint the cows that are high in somatic cell.

How does testing with DHIA bene t your dairy operation? Overall, DHIA is a good tool to help manage our dairy.

Tell us about your farm. We have a registered dairy herd near Sebeka, Minnesota. We milk 170 cows. We raise our own replacements and grow our own alfalfa and corn for feed for our animals.

CIH 9330, FWD, PTO, 3 pt., 2,800 hrs. .$125,000

CIH 8940, FWA, 1,800 hrs. ..................Coming In

CIH 8920, 2WD, 3,500 hrs ......................$84,000

CIH 8920, 2WD, 6,700 hrs. .....................$65,000

CIH 8920, 2WD, 7,900 hrs. .....................$59,000

CIH 8920, 2WD, 4,100 hrs ......................$72,000

CIH 8920, FWA, 2,600 hrs ....................$110,000

CIH MX240, 4,700 hrs .............................$85,000

CIH MX220, FWA, 3,600 hrs. ..................$88,000

CIH MX120, 2WD, 3,800 hrs. ..................$72,000

CIH MX120 w/loader ...............................$75,000

IH 1456, cab ............................................$22,000

IH 1086, 9,700 hrs. w/ldr. ........................$23,000

IH 1066, no cab .......................................$13,500

IH 686 ......................................................$14,000

TILLAGE

CIH Tigermate II, 26’ ...............................$28,000

CIH Tigermate II 26’ w/rolling basket.......$32,000

CIH Tigermate 200 w/basket, 34’ ............$42,500

CIH Tigermate 200, 28’ w/rolling basket..$40,000

CIH Tigermate 200 28’ w/basket .............$37,000

CIH RMX 340 28’ w/mulcher

Since opening in 1986 on the UW-Madison campus, the CDR has pushed the industry into offering more diversied, value-added products that can garner a higher return. A recent expansion and renovation of the CDR has helped it reach a new level of capabilities in dairy innovation.

The 57,000-square-foot expansion includes 30,000 square feet of manufacturing space spread over two oors. Featuring state-of-the-art technology, the facility opened last year and also includes a training center and test kitchen. In addition, the $72 million project involved a renovation of the Babcock Dairy Plant.

Ten cheese ripening rooms were added to the center — an offering not previously found at the CDR.

“When making specialty cheese, much of the magic happens when you put it into a ripening room or cave,” Lucey said. “Our rooms cover every type of cheese you can imagine. The specialty cheese rooms are our jewel in the crown.”

Also newly installed in the CDR is a shelf-stable, aseptic beverage line which will open later this year, allowing the CDR to create fully sterile shelf-stable dairy beverages from start to nish.

“This was a big step for us as we’ll be able to make lots of new and exciting beverages,” Lucey said. “This will

expand the reach of dairy beverages, allowing us to export these products and get them into vending machines. By extending shelf life, we can also limit the amount of dairy that is wasted. There are many opportunities.”

Lucey said many cultured products are made in Wisconsin, and to better serve the companies making these products, the CDR installed yogurt fermenters. The center has four 40-gallon and four 150-gallon fermenters to make products like Greek yogurt and cream cheese.

“We’re in great shape now to make cultured products and help innovate in that space,” Lucey said.

The CDR also added a second spray dryer for producing dried dairy proteins and ingredients.

“We know a lot of dairy proteins and ingredients are dried, and we want to help those companies as well,” Lucey said. “We put in a second dryer because we wanted to be able to make unusual products like infant formula, nutritional powders, powders that go into bars, etc.”

Product development is at the heart of the work done at the CDR, which is often consulted for its cheesemaking expertise. The center’s involvement can range from developing recipes from scratch, to tweaking recipes, to training a cheesemaker how to make specialty cheese

through one of the CDR’s short courses.

“The numbers for specialty cheese are very exciting,” Luc-

ey said. “We are almost reaching 1 billion pounds of specialty cheese made in the state of Wisconsin. Almost 30% of our

milk goes into this.” Lucey said there are close to 120 cheese plants in Wisconsin making different varieties and styles of cheeses, and around 90% of Wisconsin milk processing plants make at least one specialty cheese.

“Feta was a cheese unknown in our state not that long ago,” Lucey said. “(It is the) same with blue cheese. Now, there are major producers of feta and blue cheese in Wisconsin. We help these cheesemakers with recipes, troubleshooting, training and equipment selection.”

Every year, the CDR brings in close to 1,000 people from the dairy industry, including cheesemakers, butter makers, plant operators, buyers and more to be trained on the core technical aspects of making cheese or processing milk.

“It’s important to keep a well-trained workforce in order to make high-quality, safe products,” Lucey said.

The CDR runs the Wisconsin Master Cheesemaker program — an advanced training course backed by a 30-year history. Experienced cheesemakers licensed for at least 10 years can apply for the rigorous program that takes about three years to complete.

“This program elevates the cream of the crop in cheesemakers,” Lucey said.

The efforts of the CDR have helped keep cheese plants open while also providing dairy farmers with more opportunities for selling their milk, Lucey said. In some cases, the plants are located closer to farmers, which decreases transportation costs.

With ve licensed butter makers on staff, the CDR also offers advanced courses in how to make different kinds of butter.

On the beverage side, GoodSport and Slate milk are two major product successes to come out of the CDR in recent years. Made from milk permeate, the CDR helped develop the original recipe for GoodSport.

“Permeate is something the average customer doesn’t know about,” Lucey said. “It’s an underused product that comes out when we lter milk. Permeate contains electrolytes, minerals and salts, which was perfect for this type of drink focused on hydration.”

The CDR helped reformulate Slate — an ultra-ltered milk beverage that is packed with protein and comes in a can.

“The company turned to us for help, and we came in and gave them the piece they needed,” Lucey said. “Now, they’re doing phenomenal. The beverage launched into 1,000 stores in the past year.”

People come from all over asking for the CDR’s help, but Wisconsin companies take priority.

Another focus for the CDR is developing creative ways to add value to whey and the fractions that come out of it. Lucey said this is essential because the value of whey can negatively impact the Class III milk price.

“Everything is important in our milk — not just the fat and protein,” Lucey said. “Part of the Class III price calculation is based on the value of the fat, protein and whey that it contains. The calculation looks at parts of milk and what they are selling for as separate ingredients on marketplaces across the U.S. The whey part could be as low as 8% but may be as high as 20% of the Class III price.”

Whether making a protein powder or putting whey into a beverage or making green chemicals out of it, this will help farmers directly, Lucey said.

“When whey is cheap, it brings down the milk price, but if we could make the whey part more valuable, it will bump up the Class III price,” he

said. “Getting the most value for everything in our milk is important for the long-term price. We spend a lot of time trying to gure out what we’re going to do with this whey.”

A large amount of whey is generated in Wisconsin every year, Lucey said.

“We lter out proteins to sell as whey protein products, but less than 1% of solids in that whey is whey proteins,” he said. “Five percent is lactose and sugars. We’re still left with what to do with all those sugars. That’s a signicant challenge for our industry right now.”

The CDR is also investigating options to use whey for making bioplastics.

“It’s a way to take these massive amounts of whey and make what we call green chemicals,” Lucey said. “This is a smart way of using every drop of milk. We just installed our own bioreactor and plan to help researchers make plastics from dairy waste. We need to see if the process really works, how efcient it is, and if it will it be protable.”

Supporting exports is another role of the CDR.

“Exports have been a critical part of our markets and customers over the last 20 years,” Lucey said. “If we didn’t have exports, farm milk prices would go down signicantly because that’s a huge market for our cheeses and powdered ingredients.”

Lucey said he and his team are constantly thinking about tweaks they can make to cheeses to t the needs of other countries. The opportunities for growth abroad are signicant, he said.

When looking at shipping to places such as Asia, a longer shelf life is critical.

“We’ve done a lot of research on extending shelf life of our cheeses so they can be sold into distant markets but still be of the expected quality,” he said. “Achieving a longer shelf life is an important tool for the U.S. industry in reaching those markets. It will result in higher milk prices for farmers.”

Lucey is excited about the future and the new possibilities provided by the CDR expansion.

“At the CDR, we look at all dairy spaces,” Lucey said. “We want to cover everything – from cheese to yogurt to milk beverages to dried ingredients. There really isn’t a sector of products we can’t make with our technology.”

Dairy processors: How has your business continued to adapt in recent years?

John Schram Chief OperatingOf

cer

Harmony Cheese

60 years of cheesemaking experience between four cheese makers Al Graveen, who heads up our cheesemakers at the Edgar, Wisconsin, plant has 42 years of experience.

Tell us about your processing plant. Our main plant is located in Edgar, Wisconsin. We have three cheese vats and are working to expand. We process between 50,000-100,000 pounds of milk a day.

What is the capacity of your plant? The total capacity for milk is 1,050,000 pounds of milk per week, or 105,000 pounds of milk per day.

What products does your company make? We produce artisan cheeses, old Welsh-style cheeses and cheese curds. We are best known for our Golden Age Cheese label, particularly our Kosher Gouda and cheese curds.

What promotions does your business do during June Dairy Month? We offer vouchers for people to stop by our Athens plant on Thursdays and get fresh cheese curds produced that morning.

How close is your plant to full capacity? We are currently operating at 40%-full capacity. Several factors limit our capacity, such as the kosherizing process. We set aside specic days to produce only kosher products. By grouping our kosher customers together, we have been able to increase our capacity to produce more kosher products.

How has your business continued to adapt in recent years? As competition has grown, Harmony Cheese has adapted by focusing on our strengths: making small batches of crafted artisan cheeses, working with small customers who want to private label their products and growing our presence on social media.

Why is the dairy industry important to you? Having grown up on a small dairy farm, I deeply appreciate the often-overlooked nutritional value of dairy as a great source of protein. The industry is currently experiencing a wave of advancements, from the introduction of robotics and automation to the increasing use of data by farmers and dairy producers. I'm excited to see where these innovations will take us in the next decade. Personally, as someone with lactose intolerance, I've been amazed by the innovative progress made by small farms to reduce the amount of lactose. Our partnership with Two Guernsey Girls Creamery, for instance, has allowed me to enjoy their milk without any issues. I look forward to seeing this kind of scientic progress become more mainstream within the dairy industry.

Will Faucett Plant manager/cheesemakerScray

Cheese7 years of experience

Tell us about your processing plant. Scray Cheese is a family-owned, fourth-generation artisan cheese factory that was established in 1924. We are located in De Pere, Wisconsin, and have 11 farmers that we work with for our milk. We process approximately 90,000 pounds of milk per day, making roughly 9,000 pounds of cheese.

What is the capacity of your plant? The capacity of our plant is up to 63,000 pounds of cheese per week in our current facility.

What products does your company make? Scray Cheese specializes in handcrafting cheddar, Gouda, Fontina and Edam cheeses.

What promotions does your business do during June Dairy Month? This year, we are having a 100year customer appreciation party June 22, but we also have different specials going on in the store every week of June Dairy Month.

How close is your plant to full capacity? Our plant production increases by 20%-30% each year. We are continuously expanding our building and equipment. For example, we recently added employee parking to accommodate for the increase in private label work which made it necessary to add to our production and packaging teams. We have purchased a few new pieces of equipment with efciency in mind and plan to expand our building again in two to ve years.

How has your business continued to adapt in recent years? We have adapted by continuing to focus on our company culture and making the changes necessary within the factory to create longevity. That is visible in our expansions, our equipment purchases and getting our name out to the community more than ever.

Why is the dairy industry important to you? The dairy industry was born out of necessity and has become a lifeline for many over the years. Scray Cheese ts right into that sentiment. We are a 100-year-old factory, and there is so much family tradition embedded in every product we make. For us, the dairy industry is crucial to our community so that we may continue to uphold the traditions of the families before us who pioneered and persevered in cheese production. The farmers we buy our milk from are dedicated to providing a quality product, and that has been key to our success and continued growth.

Paul Bauer CEOEllsworth Cooperative Creamery

16 years of experience at Ellsworth Cooperative Creamery

37 years of experience in the dairy industry

Tell us about your processing plant. The Ellsworth Cooperative Creamery has two natural cheese processing plants in Ellsworth and Menomonie and a processed cheese plant in New London — all in Wisconsin. We have approximately 200 patrons.

What is the capacity of your plant? The total capacity is about 2.4 million pounds per day.

What products does your company make? We produce retail cheese curds, curds for business-to-business and curds for breading. We also produce barrel cheese, block cheese, Muenster, cheese infused with avor and processed cheese in 5-pound loaves and 40-pound blocks.

What promotions does your business do during June Dairy Month? We participate in ve dairy breakfasts at local farms for June Dairy Month. We also sponsor and volunteer at the Cheese Curd Festival, which will be held June 21-22 this year. Our retail stores also have multiple promotions running during the month of June, including pizza sales, ice cream sales, cheese sales, and, as always, sampling at both stores. We also support 10 different food banks within our patron base area throughout the year.

How close is your plant to full capacity? Capacity is variable depending on the product types we make. We run nearly at 100% capacity and can add more in the future.

How has your business continued to adapt in recent years? For the last 15 years, we have set a road map to add as much value to our members' milk as possible, allowing us to move away from the commodity markets to stay competitive on milk prices. It has been hard to make full-fat cheese whereas butterfat has been worth much more than cheese in the past 18 months. We are also working to adapt to the ever-changing social challenges and requirements for reporting environmental, social and economic issues to consumers and customers alike.

Why is the dairy industry important to you? I grew up on a farm and in the dairy industry. It has been very rewarding to work in this industry, where we can be competitors and supporters of one another for the benet of the entire industry. We are so interconnected, from how well the soil is taken care of to how the cows are being fed and treated to the farmers’ economic viability, the social well-being of the farmers, the workers in the plants, and our end-customers. We are all adapting and are closely tied to one another.

Sheryl Meshke

President and CEOAssociated Milk Producers Inc.

30 plus years of experience

Tell us about your processing plants. The dairy farmer-owners of Associated Milk Producers Inc. own seven manufacturing plants located in Paynesville and New Ulm, Minnesota; Blair, Jim Falls and Portage, Wisconsin; Sanborn, Iowa; and Freeman, South Dakota. AMPI is the largest cooperatively owned cheese company based in the U.S., annually producing more than 500 million pounds of cheese.

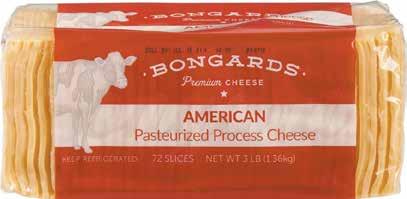

What is the capacity of your plant? AMPI’s network of manufacturing plants annually produces about 8%-10% of the country’s American-type cheese and about 85% of packaged butter. What products does your company make? AMPI cheesemakers specialize in the production of cheddar, Colby, Colby Jack, Monterey Jack, pepper Jack and gouda, and shredded natural cheese, American slices and loaves. Whey is sold in dried and liquid form. Salted and unsalted butter is packaged for retail and food service customers. Nonfat dry milk is sold to bakery and ingredient customers.

What promotions does your business do during June Dairy Month? We celebrate June Dairy Month in a wide variety of ways, from supporting members’ on-farm education events to serving cheesy nachos to employees. We recently hosted the AMPI Young Cooperator Summer Tour in the Chippewa Falls, Wisconsin, area. Attendees learned more about their Jim Falls plant and area member farms.

Throughout the month, AMPI members and employees can purchase Dinner Bell Creamery’s popular 1-pound salted butter quarters and award-winning Mild Cheddar cheese at a reduced price. Each Friday we feature a member family on Dinner Bell Creamery’s Facebook and Instagram.

Though June is dairy month, the dairy farmer-owners and employees of AMPI have an opportunity to tell our farmer-owned, Co-op Crafted story every month. The co-op developed the

Luke Buholzer Vice President of SalesKlondike Cheese Co.

23 years of experience

Tell us about your processing plant. We are located in Monroe, Wisconsin, in the rolling hills of Green County. Klondike Cheese has been producing award-winning cheese at the same location since the late 1800s, and, today, our staff includes ve Wisconsin Master Cheesemakers. We have 56 patrons which account for 80% of our milk needs.

What is the capacity of your plant? We process 1,500,000 pounds of milk per day.

What products does your company make? We make feta, brick, muenster, havarti and gouda cheeses and various cultured products.

What promotions does your business do during June Dairy Month? We don’t do any specic promotions related to June Dairy Month, but we do have promotions that run during June.

How close is your plant to full capacity? Our feta plant is almost at capacity. We are in the design stage to be able to bring on additional capacity to meet future demand. Our Greek yogurt plant is getting close to capacity, and we are currently looking to add more capacity to that operation.

How has your business continued to adapt in recent years? We continue to add new equipment and automation. We have done this to increase throughput to keep up with growing customer demand. Over the last few years, we have also added automation to improve ergonomics in the plant and to open jobs up to a wider pool of workers.

Why is the dairy industry important to you? As a fourth-generation cheesemaker, the dairy industry has been my entire life. It’s been very interesting and fascinating watching how the industry has changed over the years. It’s been a great adventure.

mark and promise in 2019, highlighting more than 50 years of dairy farm families partnering with skilled butter makers and cheesemakers. Co-op Crafted represents many families with one purpose: to produce good food with a promise. Together, we promise to provide exceptional care for our animals, land, co-op and communities.

How close are your plants to full capacity? AMPI manufacturing plants are at capacity. We are overcoming challenges posed by an early 2023 re at our cheese packaging plant in Portage, Wisconsin. Employees were safe, but operations slowed for several months. Packaging of natural cheese resumed shortly after the re. Processed American cheese slice and loaf production remains limited until rebuilding the area impacted by the re is complete. That process is currently underway.

In that same timeframe, an automated, state-of-the-art, high-speed shred line for natural cheese became fully operational in Portage. The new line increases production efciency and reduces the need for operators. Automation projects are regular line items in the co-op’s budget.

How has your business continued to adapt in recent years? The co-op’s dairy farmer-owners and employee team are building more exibility, capacity and value within our Upper Midwest blueprint. Doing so is helping position the co-op as a reliable supplier for domestic and global customers.

Cheese offerings continue to evolve with new avors and varieties while building on the co-op’s reputation for award-winning cheeses. We remain committed to doing what we do best: making really good cheese that delivers great avor, every time.

Our Co-op Crafted mark and Dinner Bell Creamery brand represent dairy farmers coming together to market their milk and work with a team of skilled butter makers and cheesemakers. It reects a dedication to caring for their animals, land, cooperative and communities while producing nutritious, wholesome dairy products.

By aligning time-honored values with innovation and engagement, we’re creating a sustainable business for the next generation of dairy farmers and the world they feed.

Why is the dairy industry important to you? Farming and food production is an incredibly noble profession. Working for dairy farm families and making good food is a source of daily inspiration. Our farmer-owners and employees share rural values and commitments encapsulated in our Co-op Crafted promise.

John R. Wiskerchen President WiskerchenCheese, LLC 33 years of experience

Tell us about your processing plant. Wiskerchen Cheese was founded in 1936 and is a fourth-generation cheese manufacturer located in Auburndale, Wisconsin. We process 250,000 pounds of milk daily, ve days per week, with 90% of our milk being sourced in central Wisconsin.

What is the capacity of your plant? Our plant has the capacity to produce 10 million pounds of cheese annually.

What products does your company make? We produce specialty cheeses, whey and cream.

What promotions does your business do during June Dairy Month? We support the local dairy breakfasts in our area, participate in parades and have employee celebrations.

How close is your plant to full capacity? We are anticipating expansions in both manufacturing and packaging in the fourth quarter of 2024 and 2025.

How has your business continued to adapt in recent years? We have grown with quality partners — both suppliers and customers. We work to reinvent the organization every decade.

Why is the dairy industry important to you? The dairy industry is our heritage, and it is a critical industry for the state of Wisconsin. We are “bullish” on cheese and dairy in the U.S. and for exports in the years to come.

Describe your farm and facilities. This is the family farm that I grew up on, and I farm with help from my dad and two full-time employees. We milk twice a day in a double-8 parallel parlor, and cows are housed in a freestall barn. We built new facilities 10 years ago. We raise our youngstock, with calves starting out in hutches. They are then moved into super hutches before moving to our other farm where heifers stay until breeding age. We have 225 head of youngstock. Our farm is one of three farms that ships its milk to Widmer’s Cheese Cellars in Theresa.

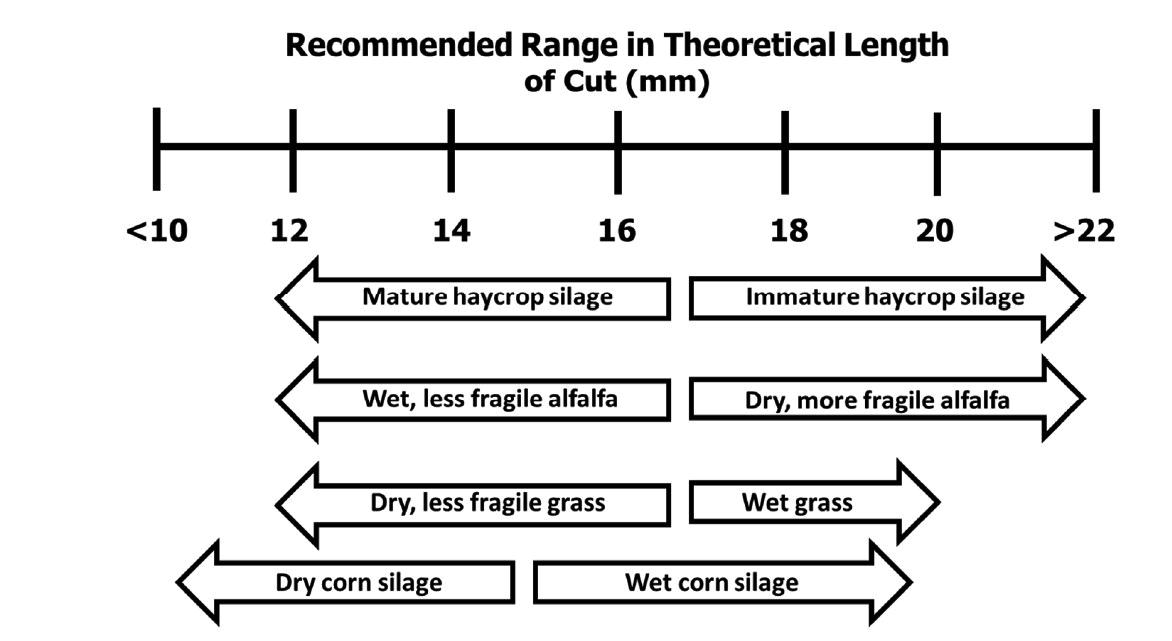

What forages do you harvest? We harvest corn silage and haylage.

How many acres of crops do you raise? We farm about 575 acres.

What quality and quantity do you harvest of each crop? We harvest 250 acres of corn, 180 acres of alfalfa,

100 acres of soybeans and 40-50 acres of grass. I shoot for a relative forage quality of 170-180 for haylage. I have 120 acres of corn silage and always try to get the best quality I can within reason. The growing year dictates the starch content, but my ideal starch level would be 40%. I shoot for 68%-70% moisture. I don’t feed brown midrib corn. It’s a nicky crop that requires a lot of babysitting.

Describe the rations for your livestock. Milk cows receive a total mixed ration consisting of 50% corn silage and 50% haylage, soybeans and high-moisture corn. I only feed one ration to both pens of cows — there is no high group or low group. Instead, I separate cows by age, with younger cows in one pen and older cows in the other. Dry cows get mature grass, corn silage, a little haylage and minerals. Our dry cow ration is low in potassium and it’s worked well for us. When cows freshen, they go straight

from the dry cow ration to the milking ration. I don’t have a transition group, but I’ve had pretty good luck doing that.

Feeding the right minerals and the right feed to dry cows is key. For youngstock, I’d rather have them on a grass

During Dairy Month, we’d like to thank the men and women of our dairy industry for their hard work and commitment to quality and sustainability. We appreciate all that you bring to the table!

mix versus pure alfalfa from the time they are weaned until 6 months of age.

Custom harvesters and nutritionists demand Scherer Inc.’s Kernel Processor. Improve your KP score with exceptional processing of kernels and cobs.

•Designed for higher outputs

•Handle all crop lengths

•Hinge open frames

•Easy servicing

The amazing dairy cow connects us in this industry that we are blessed to be part of. Since 1998, her comfort is our passion! We know it’s yours too. We’ve watched generations of farm families and cow families grow and excel in this business. We’re here, celebrating those victories and providing the tools to take on those comfort challenges, so your cows are free to reach their potential. Thank you for your trust, patronage and friendship over these 25 years. Here’s to the next 25... and our shared commitment to excellence.

When quality counts, count on Udder ComfortTM to deliver comfort that matters and results that inspire. We have the innovative spray delivery systems for any dairy management environment. Whenever we can improve comfort and softer udders, calmer cows, faster attachments, faster and more complete milking, more milk, and better

Describe your harvesting techniques for alfalfa and corn silage. I hire a custom operator to harvest our haylage and silage. All the hay is cut in one day, and by the next day, they are done chopping. Hay is cut with a triple mower, and then it lies for 2024 hours before it is merged and chopped. I don’t do the hay-in-a-day thing. I like to go for tonnage with rst-crop hay to give me the quantity I need and the ability to blend. I nd that 28-day cutting intervals make good feed for second- through fourth-crop hay. When making corn silage, the chopper has a kernel processor, and we pile, pack and cover as soon as possible. What techniques do you use to store, manage and feed your forages? Our forages are stored in drive-over piles. The biggest improvement we made was going from bags to drive-over piles for storing feed. It’s not because I didn’t like the quality with bags; it’s that I get a more consistent feed with the piles because everything is blended. You can also make the pile as big or as small as you need to. The exibility and ability to size properly are what I like about piles. Piles make nice, easy feeding. I cover the piles with a 6-millimeter vapor barrier and sprinkle gravel around it to create a good seal. I don’t

Haylage is stored in a drive-over pile June 11 near Theresa, Wisconsin. Rick Chrisan covers his forage piles with a 6-millimeter vapor barrier and sprinkles gravel around it to create a good seal.

have much waste at all.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We tend to plant the same forages but always shoot for something with a softer kernel. We’ve had success doing it this way and haven’t seen the need to change forages.

Describe a challenge you overcame in reaching your forage quality goals. Weather is the biggest challenge. We have a lot of lower ground, and in a wet year, we suffer. Last year, we had awesome crops because it was dry. We can get away with an inch of rain per month. But when you get six inches of rain in three weeks like we did this year,

that’s way too much. We’re going to be late with chopping hay, but it will all even out.

How do quality forages play a part in the production goals for your herd? Consistent feed is important for maintaining production goals. I don’t push for superhigh production. We run in the low to mid 80s for pounds of milk per cow per day and a little above 4% for butterfat. Good feed is what it comes down to. The better haylage you have, the less protein you have to feed. And the higher the starch in your corn, the less corn you have to feed. Moving into the new barn also made a big difference in production.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? Many years ago, we didn’t have a kernel processor on the chopper. Adding that was a huge benet. Before we started

feeding a total mixed ration in 2011, we just slug-fed corn, so it didn’t have to be as ne. Now, the ner the corn we can get, the better off we are. It blends better in a wet mix and improves intake and digestibility for the cow.

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc.

West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Editor’s Note: The following climate summary was provided by the Wisconsin State Climatology Ofce. The SCO is a combined effort between the University of Wisconsin–Madison’s Nelson Institute, Division of Extension, and Department of Atmospheric and Oceanic Sciences to help Wisconsinites use weather and climate data effectively. As part of UW’s Rural Partnerships Institute, the SCO focuses a large portion of its efforts on Wisconsin’s agricultural communities, offering tailored tools like drought monitoring for crop management, divisional climate data and monthly climate summaries.

May continued Wisconsin’s monthly warmer-than-normal temperatures. Last month’s statewide temperatures averaged 57.7 degrees Fahrenheit, which ranked 28th warmest among all Mays since records began in 1895. Northern Wisconsin averaged a mild 50-55 degrees or 1- 2 degrees above the 1991–2020 normal. But in the south, temperatures were a considerably warmer 60-65

degrees, or 3-4 degrees above normal.

Daytime highs averaged 65-75 degrees from north to south, while overnight lows sat around 40 degrees in the north to 50 degrees in the south. Extreme temperatures ranged from 91 degrees at the Boscobel Airport May 18 to 24 degrees in Hurley May 5.

Despite the ups and downs in temperatures, the entire spring (March through May) ended an impressive 3.1 degrees warmer than normal with an average of 46.1 degrees. Compared to all other springs on record in Wisconsin, this spring ranked in a tie for seventh warmest.

May started wet and became even wetter as the month went along, culminating in heavy rainfall during the nal 10 days. The statewide average precipitation during May was a hefty 5.52 inches, which exceeded the 1991–2020 normal by 1.59 inches and by a remarkable 40%. The month ranks as Wisconsin’s tenth10th wettest May on record.

The central portion of the

state was soggiest, especially the Central Sands region encompassing Wood, Portage, Juneau and Adams counties, where the monthly rainfall total exceeded normal by more than 4 inches. This area and east-central Wisconsin (from Fond du Lac County northeast to Door County) received more than double the normal amount of May precipitation.

The wet, nal month of spring capped an exceptionally soggy season with 11.74 inches of precipitation, ranking fourth among Wisconsin’s highest totals from March to May. Throughout the spring, every month was wetter than normal, starting with a statewide surplus of 0.73 inches in March (40% above normal) followed by an additional excess of 0.48 inches (15% above normal) in April.

Although most of this glut came in liquid form, snow also contributed. Spring snowfall was heaviest in northern Wisconsin, where more than 15 inches fell in many places.

Wet springs are nothing new for Wisconsin. Three of the four wettest on record have occurred this century (2004, 2013, 2024), and the state’s seasonal precipitation has increased over the long term by 1.5 inches (20% increase) since records began in 1895. Surprisingly, the resulting moist soils did not delay spring planting on

the whole. By the end of May, crops statewide were ahead of their ve-year average planting dates by up to one week, according to the U.S. Department of Agriculture’s Crop Progress and Condition Report.

Our wet spring has led to a dramatic alleviation of drought conditions in Wisconsin that emerged last June and persisted ever since. The U.S. Drought Monitor depicted maximum drought conditions last September, followed by improvement during autumn, but then a secondary peak in the middle of March due to the dry late-winter season.

Most of Wisconsin was experiencing moderate or severe drought as of mid-March, leading to worries that the dry pattern might create another difcult growing season and an early and volatile wildre season. The number and extent of wildres in the state as of the middle of March was more than 10 times higher than normal. But Wisconsin’s drought virtually disappeared by late May, with only a small residual patch remaining in Iron and Ashland counties covering less than 1% of the state. With that, the rapid emergence that characterized last year’s “ash drought” has been bookended by almost as abrupt an ending across nearly the entire state.

Severe weather was un-

common throughout March and April; however, as May rolled around, so did the storms. On May 7, an EF-0 tornado and a short-lived EF-1 tornado occurred in Walworth County. The EF, or Enhanced Fujita, ratings were assigned based on the highest wind speed that occurred within the damage path, where EF-0 and EF-1 tornadoes have three-second wind gusts of 65-85 and 86-110 mph, respectively.

The atmosphere destabilized the afternoon and evening of May 21, creating widespread strong winds, localized areas of hail and 16 tornadoes. Of those 16 tornadoes, one was the rst tornado to ever occur on Washington Island since ofcial records began in 1950. Another tornado leveled a roughly 100-year-old barn near Cochrane. Near Hollandale in Iowa County, 80-mph, straightline wind gusts crumpled several large grain bins. There were 22 conrmed tornadoes in May, which is the second most during any May since 1950. The No. 1 May remains May 1988 with 24 tornadoes, all of which occurred on Mother’s Day. Wisconsin’s 2024 tornado count is up to 24, including the rst two February twisters on record, already more than Wisconsin’s annual average tornado count of 23.

Find the Bongards logos and enter for your chance to WIN 10 pounds of Bongards® Premium Cheese and Butter.

Here’s how it works:

1. Count the Bongards logos throughout this issue (excluding this page).

2. Complete the entry form.

3. Send entries to: Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378, Attn: CA Contest

4. Entries must be received by July 22.

5. Winners will be drawn at random from the correct entry blanks received. Five winners will each receive eight pounds of cheese and 2 pounds of butter.

|

WAUZEKA, Wis. —

When the Mullikin family renewed their dream of dairy farming four years ago, they were patient with bringing their vision to new life. They had rented out their farm for 20 years before returning to the industry with 40 Jersey cows and 44 acres of grazing paddocks. Now they have implemented the next step in their vision, which is an upgrade from milking in the stanchion barn to a retrotted parlor.

Andrew Mullikin said it has allowed them to keep the dream alive.

“In order for me to keep doing what I’m doing and keep us in business, this is what had to happen,” Andrew said. “It’s been great.”

Andrew farms with his girlfriend, Crystal Anderson, sister, Heather Keane, and parents, Mike and Julie Mullikin, near Wauzeka. Andrew

June 7 at their farm

ed swing-9 parlor.

and Crystal (who also works full time from home) manage the daily operations, while Heather manages the business aspect with her family and is on site whenever possible. Mike helps with cropping and is around to help when needed.

Crystal and me, they’re used to us, and they follow us. It was easier to get them to train to the parlor than it was to get them to use the stanchion barn.”

The family opted for a swing parlor for various reasons but mostly because it allowed them to stay within their budget. The parlor itself was gently used and the machines were a signicant cost of the project, so avoiding a double parlor helped save money as well.

The pit is ve feet wide, which Andrew admits is slightly tighter than he wanted. However, it allowed them to retain 75% capacity of the upstairs of the barn by not moving a king beam and also minimized the construction process.

“Absolutely everything we did was on purpose and with a purpose,” Andrew said. “I wanted to maintain as much structural integrity of the barn, which we did.”

The holding area is within the original stanchion barn. Nine stanchions were left in to use for herd work and are gated off while not

The swing-9 parlor was retrotted into the original stanchion barn. Cows were already utilizing a freestall addition to the barn, which they still use when not on pasture. Construction on the project began last summer and took 15 weeks to complete. Transitioning the cows went better than expected, Andrew said.

“It didn’t take us long at all,” Andrew said. “The girls (cows) trust me. Between

Turn to MULLIKINS | Page 26

in use. All the cows t in the holding area, but Andrew prefers they remain outside until he brings them in. This keeps the area cleaner, he said.

“I’d rather take a few extra minutes to milk than take twice the time to clean the holding area,” Andrew said. “The other night it took me an hour and seven minutes to milk 37 cows.”

While the time savings are a huge benet of the new system, the labor efciency was the real goal and one they denitely achieved. When the family resumed milking in the stanchion in 2020, it did not take long for Andrew and Mike to feel the effects on their knees. The pair resorted to wearing knee pads, but the physical demands of incessantly bending and kneeling still took their toll.

Heather said she notices a difference in energy in her brother and father already.

“Farming is already hard on your body,” Heather said. “Any little thing that is going to take away just a fraction of the stress opens up opportunities to enjoy it.”

Andrew agreed.

“I had aged my knees 15 years by kneeling on the concrete,” he said. “The physical difference is absolutely remarkable.”

Milk production and

quality have remained steady throughout the transition. Because the milking procedure is so consistent, the cows have barely noticed the change.

The height of the parlor is something Andrew feels they got right. The used parlor came without manure pans, but since Andrew is conscientious during milking, it has

not posed a big problem. The family is exploring options for where to take the vision next. While they are primarily a grass-fed herd, the cows do get supplemental grain. The goal is to become 100% grass fed, and Heather is researching organic options as well.

VT 200 Series features multiple improvements that will provide enhanced performance and longer, more reliable service. These improvements include updated front conveyors, better door-to-floor sealing, heavier high-wear auger flighting and EZ-mate scale system. The VT 200 Series mixers range in capacity from 320 – 760 ft3, and are available in trailer and truck configurations. Multiple configurations, single- or 2-speed drive options, along with multiple discharge options, allow machines to be tailored to every feeding operation’s needs.

DANIELLE NAUMAN/DAIRY STAR

Abigail Mathis plays guitar June 5 for a performance in Schuster Park in Neillsville, Wisconsin. Mathis serves as the herdsperson on her family’s 240-cow dairy farm.

Mathis embraces vocal performances

By Danielle Nauman danielle.n@dairystar.comNEILLSVILLE, Wis. — Abigail Mathis has always had a love

Mathis works as the herdsperson on her family’s dairy farm near Neillsville alongside her family — parents, Sam and Stacey, brother, Gabe, and sisters, Alaina and Anita — where they milk 240 cows with four robotic milking units.

Performing in front of an audience is relatively new for Mathis, whose rst on-stage appearance was just last summer when, at the urging of friends, she joined a band on stage at a rodeo in Amherst. She joined the band for a rendition of country artist Lainey Wilson’s song, “Watermelon Moonshine.”

“I got up the courage to go up there and sing with the band,” Mathis said. “I had never really sung in front of anyone before.”

Mathis said that night a seed was planted, and she believes she found her calling.

“I was in choir in high school and had one solo, but I was always super shy and never stepped out of my box,” Mathis said. “This experience was different. Singing

Turn to MATHIS | Page 29

with that band kind of kickstarted everything.”

Perhaps by coincidence, her grandparents had given Mathis a guitar as a graduation gift earlier that summer. She took on the challenge of teaching herself to play the instrument.

“I just picked up the guitar and taught myself,” Mathis said. “I had piano lessons since I was in third grade, so I knew general music. I feel like the piano is the base instrument for everything.”

As Mathis began to undertake her musical journey in earnest, she went through a relationship breakup. Mathis chose to channel her feelings into the task of writing some original material while continuing to hone her newfound skills playing guitar.

Abigail

farm near Neillsville, Wisconsin. The Mathis family milks 240 cows with four robo c milking units.

With her condence building, Mathis began sharing her music in the world of social media, posting videos featuring her talents on platforms such as Facebook, Instagram and TikTok throughout the winter.

She said the response she received came as a surprise.

“I got a lot of feedback from people in my community and also from people outside the community, from family and friends,” Mathis said. “They all were so supportive and encouraging.”

As winter faded to spring, people began inquiring with Mathis about booking her for performances.

“The outreach from people asking me to sing at events has been amazing,” Mathis said. “I never really had to reach out to people to ask for the opportunity. It’s astonishing how many people have reached out to me.”

Mathis had her rst solo public performance in April and has been performing regularly in the community since. She has performed at area bars, restaurants, parks, festivals and even a wedding. She has bookings coming up throughout the summer, with only a few open dates remaining.

“Recently I was in Eleva for their Broiler Festival, taking photos for a friend who is a photographer” Mathis said. “We were in the beer tent, taking photos and my friend mentioned that I sang, and these people started saying I should sing for them that night. I just happened to have all my stuff in my car, so really impromptu, I ended up performing that night.”

The repertoire of songs Mathis brings to her performance is varied.

“I lean heavily towards country, especially older country,” Mathis said. “But I really like classic rock, and I have picked

up a knack for that. I really enjoy it. It is fun to sing.”