HAWTHORNE, Fla. – Florida is most often associated with orange juice and tropical drinks on the beach, but for the Lussier family near Hawthorne, the Sunshine State is better matched with milk.

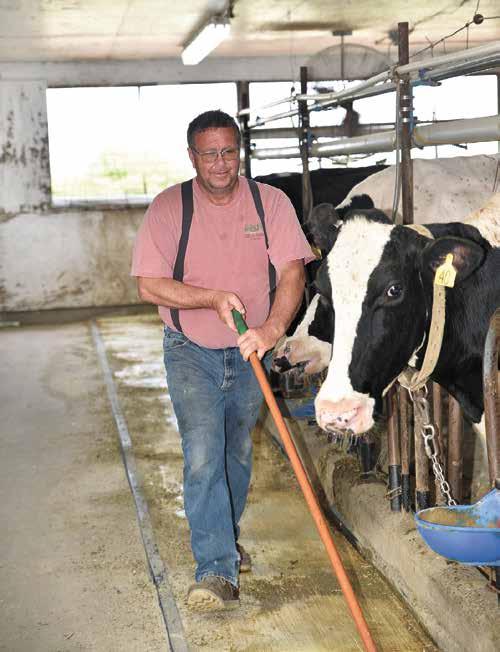

Kevin and Shelby Lussier are the second generation to operate Lussier Dairy near Hawthorne, taking over for Kevin’s parents, Matt and Linda, who continue to help in numerous ways. Their site is the last privately owned, family dairy farm in Alachua County. The only other dairy herd in the county is owned by the University of Florida in Gainsville.

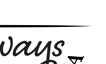

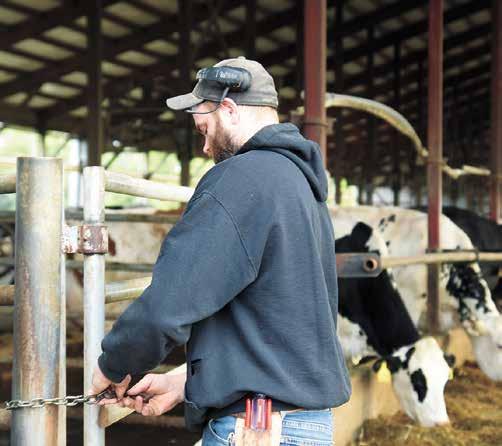

Today the Lussiers have a beef herd of 75 head and sell hay grown on 450 acres. They also milk 200 Jerseys twice a day in a double-6 herringbone parlor. Kevin Lussier said the milking setup is the one the farm had when his parents bought it over 30 years ago.

“It’s old 1950s technology that’s still rocking along today,” Lussier said.

The cows are housed in a freestall barn during the warmest months.

“In the summertime, the cows are primarily in the barn because it’s so hot, so they have fans and can be kept cooler,” Lussier said. “In the wintertime, we like to turn them out (for grazing).”

The Lussiers also own and operate Hawthorne Creek Creamery where they make artisan cheese.

“We are using about 10% to 15% of our milk to make cheese,” Lussier said. “The goal is to get to 100%.”

The rest of the milk goes to Southeast Milk Inc., a farmer-owned dairy cooperative headquartered about 56 miles away in Belleview. The Lussiers employ three people full time at the farm plus two cheesemakers at the creamery. Lussier said their employees make things run smoothly.

“The three employees on the farm have been with our family for over 20 years,” Lussier said. “We have been blessed with them on so many different fronts.”

Although the Lussiers have dairy farmers going back in their ancestry for many generations, Matt and Linda fell into the business in a more accidental way. They are originally from Vermont.

“My grandfather had an auction business there, and he bought and sold dairy cattle and farms all over,” Lussier said. “He did dairy farm for a while,

but he was kind of in and out.”

Matt went to college to become a certied public accountant. There he met Linda, who had grown up spending time on her grandpa’s dairy farm. Although both had exposure to dairy farming, it did not gure into their own career plans.

In 1991, things changed.

“My grandfather had a dairy farm that was being leased in Florida, and he had sort of a falling out with the lessee,” Lussier said.

Matt and Linda had graduated from college, married and become parents of a baby daughter when Matt was asked to help that year. The idea was for him to go to Florida and take over the farm long enough to get it back up to being operational again. Then, it could be sold.

“My dad told my mom, ‘Three years tops,’” Lussier said. “But, they fell in love with it and stayed. The rest is history. They’ve now been down here 32 years.”

Lussier was born in Florida in 1994. His sister Samantha eventually followed her father in his rst career and now works as a certied public accountant. She also helps with bookwork on the farm.

When Lussier’s parents decided to stay in the early 1990s, the dairy industry in Florida looked quite different from today.

“Florida has a rich dairy history; at one point, we were third or fourth in the country in terms of pounds of production,” Lussier said. “When my father got down here in 1991, there were over 300 dairies in the state. As of last month, we’re down to 52. We have shrunk signicantly in those 32 years.”

Some of the loss in number of farms has been due to consolidation.

“If you look at number of cows versus number of farms, the number hasn’t changed as much,” Lussier said.

Today, Florida is 12th in the U.S. for dairy production.

When Lussier returned to farm after graduating from college in 2016, the family needed to adapt for the future.

“We had to make the decision whether we were going to try to grow exponentially to meet the average size of dairies in the state of Florida, which

is about 1,500 head, or we were going to have to diversify,” Lussier said.

They were milking 700 cows at the time.

“As dairy farmers, we have to be creative,” Lussier said. “We needed to nd something where we weren’t so reliant on our milk check.”

Then, a new opportunity arose.

Their neighbors on a nearby farm, Nancy and John Mims, had started a

cheese plant in 2009. A decade later and in their 70s, they were looking for a way to retire. Since the Lussiers were considering diversifying, the Mimses saw them as a good t.

“When they approached us, I told them no because I didn’t know anything about cheesemaking and I didn’t think that was something we wanted

FARM-RITE EQUIPMENT, INC.

INTEREST AS LOW AS 0%

Please

Visit our website: www.farmriteequip.com West Hwy.

SALES - SERVICERENTAL

One Of The LargestLoaderSkid-Steer Dealers In The State Minnesota!Of

Call

to take on,” Lussier said. “Eventually, we looked at it and decided we’d be interested. Part of that contract was that (Nancy Mims) would stay on with us for one year to teach us how to make cheese. She’s been with us now three years, and she is still our head cheesemaker.”

With the creamery up and running under its new name, Hawthorne Creek Creamery, the family decided to downsize the dairy herd.

“We started ofcially making cheese in January of 2020,” Lussier said. “Since then, we’ve gone down to 200 Jerseys just for the cheese.”

The business is one of the only locally crafted creameries of its type in Florida.

“In the state of Florida, there’s not another option for local cheese,” Lussier said.

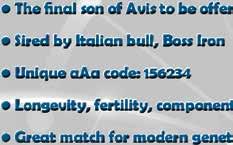

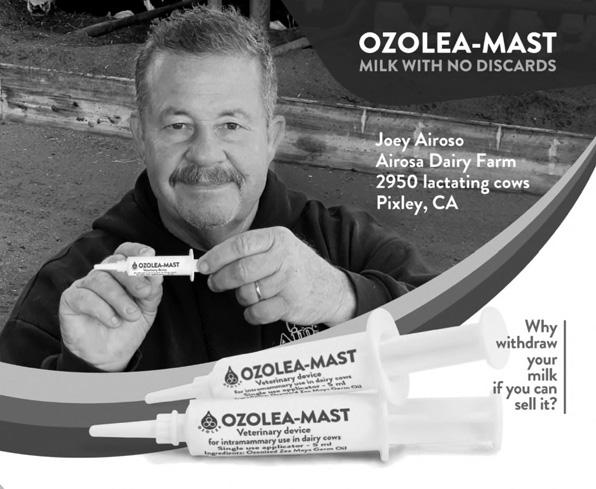

IBA carries an extensive line of nutritional supplements as well as the most complete line of hoof health products available in the industry today. Additionally, we offer syringes, needles, balling guns, magnets and many other animal health items.

• Hoof Health Products

• Boluses

• Pharmaceuticals

• Injectables

• Intramammary Infusions

• Dewormers

• Scours, Diarrhea Products

• Nutritional Products

CONTACT YOUR LOCAL DEALER:

Elsbernd IBA, Inc.

Calmar, IA • 563-419-6757

River Divide IBA

Epworth, IA • 563-543-7710

IBA Fahrney, Inc

Monroe, WI • 608-325-4248

Dairyland Equipment

Menahga, MN • 218-564-4958

Miller IBA Dairy Supply

Goodhue, MN • 507-273-1026

Zumbro Ag Solutions

Zumbrota, MN • 651-380-2856

Pettit IBA Farm Supply

Lewiston, MN • 507-269-5714

Valley Dairy Supply Corona, SD • 608-432-5224

Central Valley Dairy Brandon, SD • 605-467-0812

Elsbernd IBA, Inc.

Calmar, IA • 563-419-6757

Manitowoc IBA

Whitelaw, WI • 920-732-4680

LakeView IBA

Malone, WI • 920-378-2924

Innovative IBA Oconomowoc, WI • 608-347-4948

Balzer IBA

Owatonna, MN • 507-456-1617

“There are a few making cheddar blocks or pepper jack but not the artisan, handcrafted gouda and Havarti style. When we approached distributors, the big selling point was local.”

Hawthorne Creek Creamery also crafts Swiss and Tomme cheese.

“Making cheese is an artform, and Nancy is certainly an artist,” Lussier said. “It’s been a lot of fun to watch.”

Through Nancy’s guidance, Lussier said he and his wife have become condent in their own cheesemaking skills.

“Since then, after the rst diversication with the cheese, we’ve gotten into beef cattle and selling hay, trying to mitigate that risk by having different income lines,” Lussier said.

Today, Lussier and his wife have taken over the day-to-day operations on the farm and creamery.

“My wife has helped me get off the ground,” Lussier said. “She came from the south side of Atlanta, and she had never seen a cow up front and personal when she moved down here.”

Shelby handles the farm’s marketing, websites and ordering and works off the farm as well as vice president in a conference management rm.

“I’m so proud of her,” Lussier said. “She has been so supportive of us. She supported me in living my dream.”

When downsizing the milking herd, Lussier’s parents sold their part of the herd, but his dad still helps. For his full-time job, he buys and sells cows. For many years, Lussier’s mom had been the farm’s herd manager, including health maintenance, but as her asthma became worse, she needed

to stop and instead began working at a local winery. That opened a business connection for Hawthorne Creek Creamery.

“It’s been a great combination for us with having the cheese,” Lussier said. “We’ve been able to do a lot with the business she works for.”

Florida, Lussier said, remains a good place to dairy farm. Both Lussier and his dad have been involved in Florida’s agricultural groups, with Lussier on the state Farm Bureau board. He said infrastructure has become more spread out in the state, but it still exists, and government there is supportive of agriculture.

“We have a very good relationship with our state agriculture commissioner, Wilton Simpson,” Lussier said. “He understands agriculture and wants to help farmers. That has been extremely helpful.”

The agricultural industry brings big money to the state.

“Not just dairy farming, but agriculture as a whole, is the second leading industry in Florida,” Lussier said. “When Mickey Mouse has the u, like in 2020, agriculture rights the ship.” Lussier’s pride in and love for agriculture, he said, runs deep, especially when it comes to dairy farming.

“I’m very proud to be the last Lussier who is milking cows,” he said. “It’s an honor to me, but what’s bigger than that is I just love being out there. I love being around God’s creation and being able to handle these animals every day. Not a lot of people get to say that they are doing what they love every day, and I get to say that.”

He also said he remains optimistic about his profession.

“I know that these last four or ve years have been really tough on dairy farmers across this country, but we have a really bright future,” Lussier said. “I’m excited for the new technologies that farms have been implementing. I see a lot of farms in Florida that are starting to take advantage of renewable resources and bringing in new lines of income like that.”

Lussier said he sees these advancements as the path forward.

“Dairy is here to stay, and I’m excited about that,” Lussier said. “We just have to keep grinding it out and guring it out. There’s nobody more resilient than farmers. We can continue to move forward for that next generation.”

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

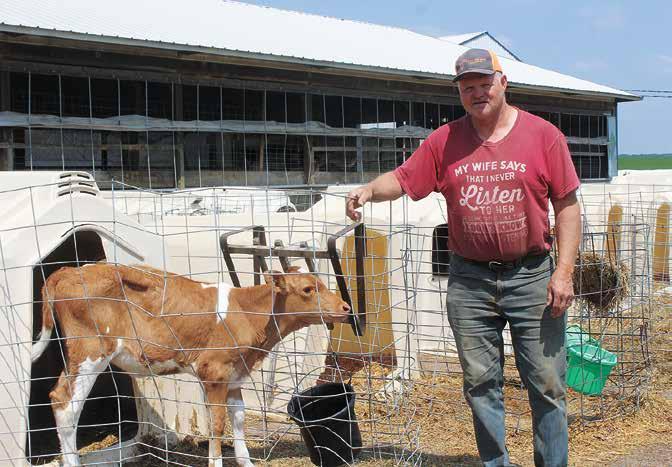

CASHTON, Wis. – The lack of rain this year may be causing worrisome conditions for many farmers, but for the Canter family at Highland Farm, it has been business as usual.

Cows graze every day, and milk production is holding steady.

Matthew Canter’s herd is exclusively grass fed, and he has taken measures to make sure they can thrive in dry weather.

“Our elds, once row crops, are now entirely comprised of pastures that aid not only in our grass-fed system but also in conserving water, soil and nutrients,” Canter said. “(This aligns) to the ethos of our watershed group, which is to make running water walk.”

Canter began milking cows six years ago with his wife, Ashley, and their ve children. They made the transition to grass fed within a couple years of starting their farm, and they were grateful to nd a market for their product with Organic Valley in 2022. Since then, they have also joined the Coon Creek Watershed Council.

The family milks 50 cows that are grazed on 95 acres of pasture near Cashton. The land is planted to pasture mixes of clover and perennial plants. Dry cows and heifers are grazed on a separate site, and 60-75 acres of hay are dedicated to a hay contract to provide winter forage.

“It was very intentional to have too

much pasture rather than not enough,” Canter said. “What I have really hated in the past few years is (when) you get to about July and nothing is growing back very well at all, and now you have to start feeding baleage.”

Canter said the surplus of pasture has allowed him to tweak the grazing schedule so the paddocks are not stressed. When the cows rst went on pasture for the year May 11, he was

rushing them through the paddocks in an effort to keep the orchard grass from heading out. When it became clear the rain was not coming, however, he made

an adjustment.

Instead of grazing on 2 acres per day, the cows now take 3 acres over the course of four days. This gives the paddocks 45 days of rest in between grazing versus the 30-day rest that a sufcient rainfall would allow. Even though some grasses have headed out with the slower grazing, the ground has retained moisture because of the residue on the land.

“It’s that delicate balance of do you keep it in ideal conditions or do you keep it in practical conditions,” Canter said. “I’m afraid that in a drought year, I’m willing to be more practical.”

Since the cows seem to avoid the headed-out orchard grass, Canter experimented with clipping the pastures with a haybine set at 7.5 inches high. This allowed the orchard grass to get clipped while not disturbing the white clover that was about 6.5 inches high.

The pastures have been upgraded this year as well so that every paddock has a water line feeding it. Previously, Canter would haul full totes of water to each paddock whereas now he can take an empty water tank to the paddock and hook it up to a valve.

Canter has utilized looseform fencing to avoid the chore of maintaining fence lines and to allow exibility when hauling manure and hiring custom harvesters. A single electric wire runs the perimeter of the

paddocks, and temporary fencing on spools is used to determine the size of the paddock each day.

The original herd of cows was purchased from ve farms to get the family started. They have a mixed herd of Jersey, Ayrshire and HolsteinAyrshire crossbred cows. Every cow has been bred with a Normande bull, and Canter is excited to see those calves enter the milking herd next year.

“The hope is to have cows that are adapted to grazing, a little beeer and calm,” Canter said. “I wanted temperament.”

Canter hopes to grow his herd to approximately 75 milking cows. He would also like to get to the point where he is not purchasing winter forages, even though he said he will always have it custom harvested.

While he entered the dairy industry without any practical experience, Canter and his family have worked together to learn the lifestyle and what works for their farm. So far, nding a lucrative grass-fed market, growing healthy pastures and maintaining milk production in a drought year have all landed in the success category.

“I’ve been enjoying it,” Canter said. “It’s a pretty good way to live if you don’t mind hanging around your cows and putting up a bunch of fence. And, I absolutely love grass milk.”

Forward looking dairy margins took a beating again as increasing drought concerns are beginning to rally feed and grain prices, while milk remains pressured by adequate supply and softer dairy product demand. A continuation of deteriorating crop conditions could play into an extremely ugly situation for the dairy industry.

In our business we are given a unique perspective on the financial health of the industry as all of our clients provide us with their cost of production info to load into our DVMargin software. This allows DVi to monitor their projected profitability for making decisions in the market. It is an awesome decision-making tool but at times can reveal the ugly reality of some tough situations coming to sectors of dairy producers.

In this price cycle it will likely not be the smaller producers that get pinched financially and decide to quit milking as they are protected fairly well with the tier 1 DMC $9.50 level of margin protection. The herds that will likely pay the price of the upcoming financial pain will be the 300-1200 cow dairies. These herds can’t compete with the labor efficiencies of the larger operations and have minimal DMC price protection relative to production volumes.

It is almost unbelievable that U.S. cheese is trading in

the $1.30’s. Especially with cold storage levels not being overly concerning and international prices significantly higher. Plants remain aggressive in making sure that they do not let their inventories get out of hand as prices collapse. Keep in mind that when cheese markets are declining milk plants are making cheese with higher priced milk and selling it into a softening market. Although this motivates plants to keep current, it can destroy cash markets.

A cheese inventory that is current can quickly support cheese markets if demand starts to respond positively to cheap prices. That is why there are dairy analysts anticipating a turn around this fall. From my perspective, this price cycle has a lot more complexities that make a supportive market forecast much more uncertain. Let’s all hope that inflation hasn’t become so entrenched into food service that is permanently chasing away price sensitive consumers. All you have to do is stop at a fast food or sit down restaurant and you quickly find out that it is no longer an affordable option to dine out for cash strapped consumers.

The U.S Department of Agriculture lowered its 2023 milk production estimate in the latest World Agricultural Supply and Demand Estimate report, citing slower growth in milk-per-cow than previously expected. Milk output for 2024 was unchanged.

2023 production and marketings were estimated at 228.4 and 227.4 billion pounds, respectively, down 200 million pounds on both from a month ago. If realized, both would be up 1.9 billion pounds, or 0.8%, from 2022.

2024 production and marketings remained at 230.8 and 229.8 billion pounds, respectively. If realized, 2024 production and marketings would be up 2.4 billion pounds, or 1.1%, from 2023.

The 2023 cheese price is expected to average $1.73 per pound, down 9.50 cents from last month’s estimate, and compares to the 2022 average of $2.1122 and $1.6755 in 2021. The 2024 average is estimated at $1.7750, 4.5 cents lower than last month’s projection.

Butter is expected to average $2.4350 per pound in 2023, up 50 cents from a month ago, and compares to $2.8665 in 2022 and $1.7325 in 2021. The 2024 average was estimated at $2.3350.

Nonfat dry milk is projected to average $1.19 per pound, up 50 cents from last month’s estimate, and compares to $1.6851 in 2022 and $1.2693 in 2021. The 2024 average was projected at $1.13, up a penny from a month ago.

The dry whey average was projected at 37 cents per pound, down 2.50 cents from last month’s estimate, and compares to 60.57 cents in 2022 and 57.44 cents in 2021. The 2024 average was put at 36 cents per pound.

The 2023 Class III milk price average estimate was lowered to $16.70 per hundredweight, down $1.05 from last month’s projection and compares to $21.96 in 2022 and $17.08 in 2021. The 2023 average was projected at $17, down 50 cents from a month ago.

The 2023 Class IV average was $18.35, up a nickel from last month’s estimate, and compares to $24.47 in 2022 and $16.09 in 2021. The 2024 Class IV average was projected at $17.45, up a dime from last month’s estimate.

The U.S. corn outlook is little changed from last month with increases to both beginning and ending stocks. Corn area and yield forecasts were

unchanged. Beginning stocks were up 35 million bushels, reecting a forecast decline in exports that is partly offset by lower imports. Exports were lowered 50 million bushels and ending stocks were raised 35 million bushels. The season-average farm price was unchanged at $4.80 per bushel.

Soybean supply and use projections included higher beginning and ending stocks. Higher beginning stocks reect reduced exports, down 15 million bushels to 2 billion. With increased supplies and no use changes, soybean ending stocks were projected at 350 million bushels, up 15 million. The soybean price was forecast at $12.10 per bushel, unchanged from last month.

The latest Crop Progress report shows 93% of U.S. corn has emerged as of the week ending June 11, up from 85% the previous week, 6% ahead of a year ago as well as the ve-year average. 61% was rated good to excellent, down from 72% a year ago, as dry conditions prevail over a large section of the crop.

Soybeans were 96% planted, up from 91% the week before, 9% ahead of a year ago and 10% ahead of the ve-year average. 86% are emerged, up from 74% the previous week, 18% ahead of a year ago and 16% ahead of the ve-year average. 59% of the crop was rated good to excellent, up from 62% the previous week but 11% behind a year ago.

The week ending June 3 saw 51,800 dairy cows go to slaughter, down 5,200 head from the previous week but 3,000 head, or 6.1%, more than a year ago. Year to date, 1.325 million have been culled, up 65,100 head, or 4.9%, from a year ago.

The June 15 Daily Dairy Report said lofty cattle prices have “boosted dairy cull cow checks to multiyear highs. The combination of low milk prices and high beef prices may help to accelerate contraction in the dairy herd, speeding the transition to lower milk production and higher dairy product prices.”

StoneX wrote in its June 16 Early Morning Update that if slaughter numbers continue like they are, they could nish the year at near record levels: “Data available from the USDA goes back to 2017 and since then the record for slaughter was in 2019 with an average weekly slaughter of 61,760 head. Our current average weekly slaughter is 60,913 with an expectation that volume should increase on a week-to-week basis moving forward.”

Checking dairy demand, April total cheese usage

came in at 1.19 billion pounds, up 0.6%, thanks to a 1.6% increase domestically outweighing an 11.7% drop in exports. Those exports were likely booked in late 2022 or early 2023, explained HighGround Dairy, “when U.S. prices carried a premium to the rest of the world.”

Butter utilization hit 187.5 million pounds, up 7.9% and up 4.1% year-to-date. It topped prior-year levels for the third consecutive month, said dairy economist Betty Berning in the June 19 Dairy Radio Now broadcast. She said the gain was driven by higher domestic consumption, up 11.6%. Exports, however, were down 53.1%, the lowest volume since November 2020.

Berning blamed high U.S. butter prices at the end of 2022 for the drop in exports. She also pointed to higher output of American cheese, particularly cheddar, for putting the produce mix “off kilter,” adding to inventory without the export demand for it.

Nonfat and skim milk powder demand, at 238.1 million pounds, was up 3.6%. Domestic usage was up 34.1% while exports were down 9.2% from a year ago. HGD said domestic consumption was the highest since September 2020.

Admittedly, uid milk sales continue to struggle, but overall demand for dairy continues to grow in the U.S., contrary to what plant-based producers would like consumers to believe. The International Dairy Foods Association said that in September 2022, the USDA reported U.S. per capita dairy consumption

jumped 12.4 pounds per person in 2021, continuing a 50-year growth trend that started in 1975 when USDA began tracking annual consumption.

Domestic consumption and exports also generated signicant growth in the dairy industry, adding nearly 60,000 new jobs in the past two years, increasing average wages by 11% and increasing its total impact on the U.S. economy by $41 billion, according to IDFA’s latest economic impact report.

IDFA’s 2023 Economic Impact Study showed the U.S. dairy industry’s economic impact totaled $793.75 billion. The report, released at the beginning of National Dairy Month, is conducted every two years.

Newly released gures indicate the U.S. dairy industry supports 3.2 million total jobs, including 1.078 million in dairy product manufacturing, up from 1.018 million in 2021, plus $49 billion in direct wages for workers, up from $42 billion in 2021. The report shows

$72 billion in federal, state and local taxes (not including sales taxes paid by consumers), up from $67.1 million in 2021, 3% of U.S. GDP.

“The dairy industry is growing to keep pace with intense global demand, and that means more jobs, higher wages, more tax benets and more economic growth for communities across the U.S.,” said Michael Dykes, IDFA president and CEO.

Unfortunately, that good news hasn’t been so good for farmers. The June 12 Daily Dairy Report said dairies “continue to struggle as margins remain tight. In 2021, 6% or 1,794 farms called it quits, and last year, another 7% or 1,910 operations sold out, leaving just 27,932 farms to meet growing demand, according to USDA.”

Dairy futures offer little hope for a turnaround any time soon.

CME block cheddar fell to a $1.3750 per pound Friday nish, the lowest CME price since May 8, 2020,

down 4.75 cents on the week and 77 cents below a year ago. With the exception of a half-cent increase the week of May 15, the blocks dropped 11 weeks in a row, losing 72.50 cents in that timeframe.

The barrels closed at $1.5250, 4.50 cents lower, 63.25 cents below a year ago and 15 cents above the blocks. Thirty cars of block sold on the week and three of barrel.

Midwest weather is prolonging the ush, and milk is being dumped though Dairy Market News reports that some cheese plants say spot milk offers were not as numerous this week. There are continued expectations that milk availability will slacken as late spring weather begins, but spot prices got as low as $12 under Class this week, compared to $5 to $1 under a year ago. Cheese processing is busy. Cheese demand is active, according to a number of Upper Midwestern processors, and “customers are clearly less hesitant to purchase for near-to mid-term needs when prices are at current levels,” said DMN.

Cheese demand remains steady for Western retail and food service channels. Export demand is mixed for the remainder of second quarter, ranging from steady obligations to softened while third quarter interest is reportedly quieter. Cheese vats are running strong production with plenty of milk, said DMN.

Cash butter fell to $2.3525 per pound Tuesday, the lowest since April 14. It rallied Wednesday, slipped some Thursday and closed Friday at $2.3650, up 0.25 cents on the week but 57.50 cents below a year ago with 10 sales on the week.

Central butter makers reported similar demand interest as the past two weeks. Retail sales are increasing but nothing out of the norm for late spring. Cream availability remains somewhat steady. Multiples are holding rm in the low to mid 1.20s from cream sources regionally although some Midwestern plants are still taking cream from Western states, said DMN.

Western cream multiples stayed rm, and plenty of volume is available. A few butter manufacturers reported that scheduled equipment maintenance is set to start, but butter making is strong to steady. In some parts of the region, more cream is shifting to ice cream production. Butter demand is moderate to lighter from commercial bulk buyers while food service and retail demand is strong to steady. A few reports indicate inventories are slightly on the heavy side. Export activity is moderate to lighter, said DMN.

Grade A nonfat dry milk slipped to $1.1550 per pound Thursday but closed

Friday at $1.1575, down 0.25 cents on the week and 64.25 cents below a year ago with four sales reported for the week.

Dry whey gained a half-cent Monday, then gave back 0.75 cents Wednesday and closed Friday at 27.50 cents per pound, unchanged on the week but 23.25 cents below a year ago with 31 sales reported on the week at the CME.

Tuesday’s GDT Pulse saw 2 million pounds of Fonterra whole milk powder sold out of 2.2 million pounds offered and at $3,080 per metric ton, down $20 from the last Pulse and down $70 from the June 6 GDT.

HighGround Dairy said, “After trending above $3,100 per metric ton for the last seven weeks, C2 Regular WMP dropped to the lowest price since April 18 due to persistent weak global demand. Lasting only ve bidding rounds, this matched the shortest Pulse Auction on record, which occurred Feb. 14.” DMN said milk production varies across the country as seasonally warmer temperatures come into play. The Northeast is seeing steady milk output. Midwest production tightened in the southern portion of the region while warmer temperatures moving toward the Upper Midwest are expected to impact cow comfort levels there as well. Farm level milk production in the west is mostly steady. Cooler temperatures in portions of the mountainous states have led to stronger milk output.

Looking globally, a number of observers believe the European milk production peak has passed, said DMN, while others suggest it may linger and be slow to decline. In either case, milk volumes are signicant. Manufacturing of most dairy commodities is heavy, and inventories are signicant. Industry contacts report demand is lukewarm for most commodities with the exception of cheese.

Less favorable weather may slow milk production from northeast Germany into Poland and the Baltic States. The European Union Commission extended the trade measures that allow Ukrainian agricultural products to enter the EU without tariffs. The waiver was extended for one year. The governing body also extended the ability of ve neighbors to Ukraine (Bulgaria, Hungary, Poland, Romania and Slovakia) to restrict the domestic sales of selected crops while allowing those crops to enter the country for export into other countries.

Looking down under, May is typically dened as one of the most active months for New Zealand exports; however, the pace of China’s recovery has disrupted those volumes, said DMN, as well as the global economies. Dairy commodity processors point to China’s lack of demand with impacting short-term price movement, relative to the New Zealand farm gate milk price.

Australian milk-production trends remain below levels from a year ago in most regions. However, due to weak dairy product demand, dairy farmers stand to lose as processors released their farm gate milk price offerings for the upcoming season. DMN said farm gate price offerings are set to decline as much as 10% from last season.

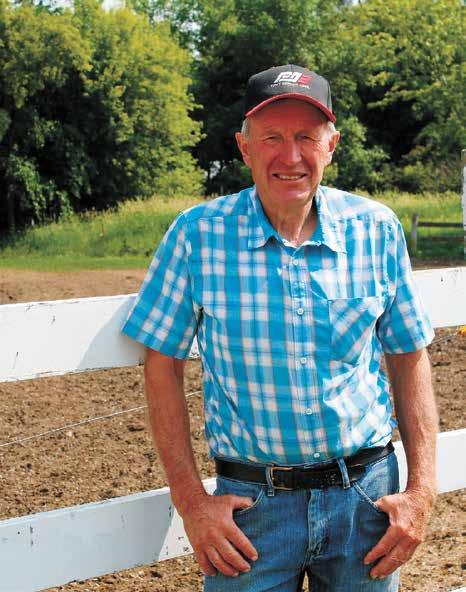

GREENWALD, Minn. – Four generations of the Lieser family work together on a daily basis at their farm near Greenwald.

When it comes time to put up hay, Gerald Lieser, 86, climbs into the tractor to pull the chopper and will gladly remain there until the job is done.

His son, Don Lieser, hauls wagons as Don’s wife, Irene, runs the merger and also makes sure every family member is fed.

Their daughter, Sara Ranta, helps on the farm, and her husband, Jason, runs the bagger. The couple also handles milking 80 cows twice each day in a tiestall barn.

Sara and Jason’s children also pitch in.

Eleven-year-old Logan eagerly rides along and counts down the days when he can farm alongside Jason and also his grandpa and great-grandpa.

“It feels good to see family helping out like that,” Jason said. “I’m really grateful for everybody here and that we can all work together.”

Sara agreed.

“It’s pretty cool to know that we have four generations working together on our farm,” she said. Gerald drives tractor and does

ARNZEN

eldwork, and Don stays busy doing the various other odd jobs around the farm.

said. “He loves helping out and is always doing something.”

“Farming is (my dad’s) life,” Don Turn to LIESERS | Page 14

Besides milking cows, Jason and Sara feed calves with help from four of their seven children who are at home – Gabe, LeAnna, Logan and Addilyn. The children help according to what their ages allow. There is one more child on the way, due this November.

At the beginning of this year, Jason and Sara took ownership of the cows and are now working together with Sara’s parents to transition into full ownership of the farm.

“I don’t come to the barn unless they ask me to come out,” Don said. “Then I will gladly come out and help them, but it’s their animals now. We have a decent herd, and if they take care of the them as I did, (the cows) will take care of them.”

Working together is a natural t for the Lieser and Ranta families. Don knows the land and has over 40 years of experience to share with Jason and Sara as they move their farm forward.

“It is nice to have someone there to go to for advice,” Jason said.

Don said they all contribute in that respect.

“We bounce ideas off each other every day,” he said.

Prior to taking over the dairy, Jason was working for a trucking company, and Sara was teaching and managed a day care.

It had long been Jason’s dream to dairy farm even though he did not grow up on a dairy farm.

“Once I was old enough, I just started working on farms every chance

I could,” Jason said. “I worked for all kinds of farmers, but I really liked the dairy farming. That was my favorite.”

Over the years, Jason worked for various farmers, took construction jobs and did trucking, but he never gave up on his dream to dairy farm. He reached a point in his trucking career where he either needed to stop or create his own trucking company. It also just so happened that Sara’s parents wanted to retire.

“I’m happy every day now,” Jason said. “I like waking up in the morning now. I missed being around animals.”

Once Jason and Sara decided they wanted to take over the farm, they

waited one year before they came to an agreement with Don and Irene on buying the farm.

“I wanted to make sure they knew it was a 365-day commitment and that there are good days and there are bad days,” Don said.

Everyone agreed on the transition plan, and Jason and Sara had time to get to know the nutritionist, veterinarian, agronomist and seed salesmen Don had worked with.

“Once I was old enough, I just started working on farms every chance I could. I worked for all kinds of farmers, but I really liked the dairy farming. That was my favorite.”

JASON RANTA, DAIRY FARMER

The families attended farm transition workshops and have incorporated ideas they learned.

Even though Don and Gerald consider themselves retired, they are outside every day, helping with the various tasks of dairy farming.

“I have to stay busy,” Don said. “If somebody needs help, I will help them out. It’s in my blood and how I was raised.”

Gerald is the same way and is thinking about visiting his daughter in Montana to help her family cut hay.

“I like doing eldwork and keeping up with the maintenance,” Gerald said.

One thing to which everyone on the farm agreed is the importance of family.

Jason and Sara will be raising their family on a dairy farm, just how Sara was raised and how the many generations of the Lieser family were raised.

“It’s a good way to teach responsibility, how to work together and work ethic,” Sara said.

Jason and Sara are already seeing their children’s interest in farming grow as they work side by side.

“I want to be a farmer when I grow up and take over this farm,” Logan said.

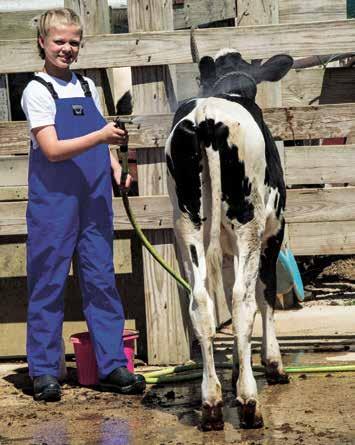

Sara and Jason Ranta’s son, Logan, feeds cows June 15 at the Rantas’ farm near Greenwald, Minnesota. The Rantas’ children have du es on the farm, including feeding cows and calves.

1. Open the Camera app from the Home Screen or Lock Screen.

2. Select the rear facing camera. Hold your device so that the QR code appears in the viewfinder in the Camera app. Your device recognizes the QR code and shows a notification.

3. Tap the notification to open the link associated with the QR code.

9 Year s

OUR MISSION: Champion healthier and responsible food for all.

By Jerry Nelson jerry.n@dairystar.com

By Jerry Nelson jerry.n@dairystar.com

WABASSO, Minn. – The constant rush to get things done can push family connections to the back burner. Maintaining those family connections is the top priority at Goblirsch Dairy.

The Goblirsch family milks about 200 cows in the robotic dairy facility they built in 2005. The Goblirsches have deep roots in Redwood County.

“Our grandparents, Joseph and Rose Frank Goblirsch, homesteaded this farm,” Nels Goblirsch said. “They had nine children, one of which was my father, Bernard.”

Bernard was born on the Goblirsch farm in 1939. He passed away in November 2020 at age 81.

“I met Bernard when I was working as a nurse at Rochester, Minnesota,” Mary Clare Goblirsch said. “We learned that we had the same values and clicked right away. We were married for 55 years and raised nine children together on our dairy farm.”

Mary Clare and Bernard’s sons, Nels and Matt, operate Goblirsch Dairy. Nels and Matt’s sister Kate also works on the farm full time.

Nels is the herdsman at Goblirsch Dairy. Nels and his wife, Shannon, have two children, Cadence and Mikale.

Matt does the feeding and is the farm’s chief mechanic. Matt and his wife, Stephanie, have three children: Mason, Raeya and Scarlette.

Kate and Mary Clare are in charge of caring for the farm’s calves. Mary Clare also handles many of the farm’s bookkeeping duties.

Even though they are teenagers, Cadence and Mikale are well versed in the operation of their family’s dairy.

“Everyone has their own specialty on the farm, but we also know each other’s jobs,” Cadence said.

Cadence is studying animal science at South Dakota State University and has served as a Red-wood County dairy princess for the past two years. She hopes to be admitted to the veterinary medicine program that is offered in conjunction with the University of Minnesota. Cadence wants to become

40 Year s

a veterinarian in a mixed large and small animal practice.

There are times when family dynamics can create stress. But, the Goblirshes have found that the pros of working with family far outweigh the cons.

“Working with family is the best,” Nels said. “There will always be good days and bad days, but you have to learn to be exible and respect one another’s opinions.”

Matt and Stephanie’s children are already learning the rewards of hard work and working with family.

“My kids are starting to help with feeding the baby calves and scooping out the feed bunks,” Matt said. “Because we all can do any job on the farm, we can easily step into each other’s roles if someone wants to take a vacation.”

Kate decided to rejoin the family operation after a years-long interval of working off the farm.

“The day that I was going to start a new job, Dad told me that I was needed on the farm because he was about to retire,” Kate said. “I had worked at a print shop for 13 years and decided to take Dad up on his offer and stay on the farm. I love working with my family and helping with the raising of my nieces and nephews, and it feels good to be your own boss.”

The sense of family on Goblirsch Dairy does not stop at the fence line.

Nels and Matt have partnered with their uncle and aunt, Robert and Lorine Goblirsch, who live on a neighboring farm. Robert and Lorine, along with their son, Joe, and his wife, Sarah, raise all of the bull calves that are born on Goblirsch Dairy. Robert and Lorine also share farm equipment with Nels and Matt.

“We also work with our neighbors when we tackle big jobs such as chopping silage and grain harvest,” Nels said.

The Goblirshes make a point of staying connected with their large extended family.

“We are all very family-oriented,” Cadence said. “Our family celebrates holidays and anniversaries together. Since there are so many of us, it can be difcult to nd a space that’s big enough. We might rent a tent or hold the gathering in a garage.”

Despite her advancing years, Mary Clare continues to be an integral part of Goblirsch Dairy.

“Mom likes to scoot around the farm on her golf cart,” Nels said. “She will go down to the barn the rst thing every morning and check on the cows. She has taken over some of the things that Dad had done.”

Mary Clare smiles broadly as she talks about her rich, full life on the farm.

Turn to GOBLIRSCH | Page 18

“I like to drive through the barn and look things over to see if anyone is calving or is in heat,” Mary Clare said.

“I enjoy gardening, so I will drive my cart down to the garden. It’s wonderful to be able to work with my family and watch my grandkids grow up. The grandkids love it on the farm. They raise chickens and play ball.”

Cadence has been working hard toward her goal of becoming a veterinarian. She already had 40 college credits under her belt when she graduated from high school in 2022.

“I have been shadowing

a veterinarian this summer,”

Cadence said. “This has given me several opportunities to visit other dairy farms and observe how they work.

I have learned that every dairy operation is different and that our family is incredibly blessed to have what we have.”

Even though he is gone, Bernard continues to be an inspiration for the Goblirsch family.

“As I’ve grown older, I’ve gotten a better understanding of how difcult it was for Dad to let go of some of his responsibilities in his later years,” Nels said. “But,

he gradually let his kids take over the decision making. He may not have agreed with all of our choices, but he let us make them on our own.”

Matt, who has worked on the family farm his entire life, has many fond memories of his father.

“Music was always a big part of Dad’s life,” Matt said.

“He made sure that each of us was given the opportunity to learn how to play an instrument.”

In the end, it all boils down to one word at Goblirsch Dairy, and that word is family.

“Raising nine children on this farm was often

challenging” Mary Clare said. “But now that our kids are grown, they thank me for teaching them how to work and the value of teamwork … The best lesson that Bernard and I passed along to our children was that family should always be your number one priority.”

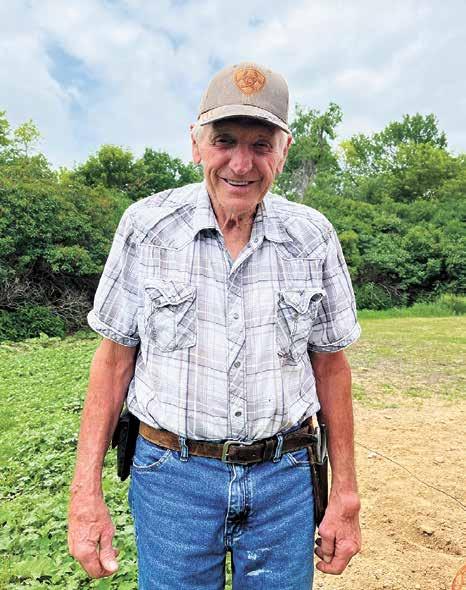

Tell us about your farm then and now. In 1955, when I moved onto the farm, it was in tough shape because the land had been rented out prior to that. I rented to own the farm for about two years. I had a barter system with the previous farmer. He had chickens. I had cows, and we traded so we could get by. We did everything by hand. I started off with only two cows and expanded by xing things up slowly over the next few years. I grew the operation with the help of my brother to install some milking equipment, and I was able to grow my herd from two cows to 14 cows. After adding a gutter cleaner, I increased to 21 cows. In the 1970s, one of my bankers encouraged me to undergo a large expansion, bringing the number of cows to what it is today with 64 milking cows on the property.

What is your favorite memory on the farm? No particular memory pops up, but I always loved working alongside my family. That truly started when I was growing up. My younger siblings and I worked together to keep my dad’s farm going after the Depression in Orange City, Iowa. Then when I started my own farm in 1955, I loved working alongside my kids and then grandkids.

What do you love most about dairy farming? Working with the animals. There is just always something quite special about being able to care for something that is dependent on you. They will love you back, unlike steel or equipment, and that is something that is really special.

What traits do you possess that have allowed you to be a long-standing dairy farmer? Being a hard worker and having the ability to take it day by day. Thinking short term rather than being overwhelmed by all of the uncertainties.

What do you consider to be the greatest success of your career? That I’m still in the dairy farming business at 91. I’ve witnessed neighbors and friends not be able to continue, and that empowered and motivated me to keep pushing forward. I’m thankful to the many friends and family for the help and sacrice they’ve given all these years to keep me going.

What has been the biggest challenge and how did you overcome it? The biggest challenge for me was starting out. Back then, it was really hard to get credit to get started. The bankers were all really supportive of me, and that support continued throughout multiple recessions. I worked harder and took it day by day.

Describe what industry change impacted your career the most. The introduction of the Bobcat. It took away a lot of work that previously had to be done by hand.

Tell us a lesson you learned that you still stand by today. First of all, hard work. Secondly, if you take good care of your cows, your cows will take good care of you.

What piece of advice would you like to offer future generations? Always be willing to work really hard and take advice from farmers who have been successful.

50 cows

Tell us about your farm then and now. I was born on our family farm at Sioux Center, Iowa. When I was 9, Dad sold a quarter-section in Sioux Center and used the money to buy 240 acres here. When I was a kid, we milked 30 cows, three at a time, with belly buckets in a 6-cow stanchion barn. We have a pipeline now and milk 50 cows in a 26-stall stanchion barn. Our operation has grown to 1,000 acres that are located on Buffalo Ridge.

What is your favorite memory on the farm? My grandpa, Edward Hulstein, homesteaded at Sioux Center, Iowa, and made money by buying wild mustangs that came in on the train and breaking them to the harness. My whole family has always loved horses. Dad could control his team of workhorses using just voice commands. I was given a horse when Jean and I got married, and it lived until it was 40 years old. My mom’s family were dog people. Mom had a collie that she had trained to bring lunch out to the eld. She would tie the lunch to his collar, and off he would go.

What do you love most about dairy farming? I love milking. I have milked cows my whole life and have never felt, “Gee, I wish I didn’t have to milk today.”

My wife, Jean, and I have been married for 60 years. We get up to milk the cows at 5 a.m. every morning. Our dog brings the cows in for us. If you have a good dog and good cows, you have it made.

What traits do you possess that have allowed you to be a long-standing dairy farmer? I’ve always had good health. I have had a few setbacks, such as when a Shetland pony stallion attacked me and mangled my hand. That put me in the hospital for ve days. I have learned that, at my age, you have to keep going and stay busy. Jean and I get along really well with our family, and that has been very rewarding.

What do you consider to be the greatest success of your career? We bought land when it was reasonably priced. We purchased our rst 180 acres for $200 per acre and a neighbor said to me, “You’ll never be able to get it paid for!” Milking has always helped

35 Year s

pay the bills. We have two sons and a grandson who farm with us. God has been tremendously good to me and my family.

What has been the biggest challenge and how did you overcome it? Making through the mid-1980s. Prices were low and interest rates soared to 22%. We had just bought a farm and more machinery to farm it. The banker told us to cut back, but we increased instead. That whole experience was a real battle.

Describe what industry change impacted your career the most. We went to using a mixer wagon to blend the total mixed ration for our cows, and that has made a big difference. Advances in nutrition has enabled us to push the cows a lot harder than we used to. Milk was $3 per hundredweight when we started out, and we were able to turn a prot at that price.

Tell us a lesson you learned that you still stand by today. You will never be happy unless you nd contentment in what you do. I nd deep contentment in milking our cows twice a day, every day.

What piece of advice would you like to offer future generations? Believe in what you do and walk with God.

Year s

Tell us about your farm then and now. When we started milking in 1978, I was commuting to the farm from town, and we were milking 38 cows. Since then, we have increased the herd size to about 60. We also have added on to the barn, added new buildings to the farm site and expanded our acreage to about 300 acres, including the rented land.

What is your favorite memory on the farm? I don’t know if I have a favorite memory. I have just enjoyed being with family, both when I grew up on my family’s farm and raising my own family on this farm. There’s a lot of good memories there. I have a lot of fond memories on the farm back when my kids were involved with showing our animals.

What do you love most about dairy farming? Having the family right on the farm with me as the kids grew up. I also appreciate the dairy animal and that it can convert eld crops and byproduct feeds into a nutritious food for humans. It’s nice to know that, and we get to see all of our hard work pay off.

What traits do you possess that have allowed you to be a long-standing dairy farmer? I am committed to the farm, and I’ve stayed healthy, which has always been helpful to myself and the farm. Sticking with it, even when things are tough, just like any other job. Patience with the animals on a daily basis is also important.

What do you consider to be the greatest success of your career? That I was able to raise a family on the farm.

What has been the biggest challenge and how did you overcome it? Working on a dairy farm, there are challenges every day. I’m not necessarily sure what would be classied as the biggest. We did have a re where we lost a pole barn, but the neighbors were able to help us with that. With the stress that comes along with a lot of that, patience helps to stick with it.

Describe what industry change impacted your career the most. There have been a lot of changes in the industry that have been implemented incrementally, and we almost automatically adjust to them. The new machinery technologies such as the skid loader were also helpful in decreasing labor time and allowing us to do less by hand. I would not still be milking if automatic takeoffs had not been invented.

Tell us a lesson you learned that you still stand by today. Always be aware of others’ perspectives. There are a lot of people who do their jobs in order to help you farm. Veterinarians, equipment repair, etc. We make mistakes in our jobs, they make mistakes in theirs, and we all need to understand that those mistakes will happen. I’ve always appreciated the different people you talk to in farming and the service they are providing.

What piece of advice would you like to offer future generations? Educate yourself, especially with the changing technologies. Stick to the basics. Treat the cows properly so they can produce what they are capable of. Even when there is something you would rather be doing, stick with it because it will benet you in the future.

Tell us about your farm then and now. Today, we milk about 170 to 180 cows in northwestern Wisconsin: about 100 Guernseys, 50 Jerseys and 30 Holsteins. We moved here in 1994 from Washington. Our farm was about 50 miles north of Seattle. We were milking about 100 head there, and we moved 190 head total from Washington to Wisconsin.

What is your favorite memory on the farm? It is a toss-up between a couple of things. One would be farming with my family and doing most all of the work ourselves. A second would be watching our cow, Malt, walk out under the spotlights for supreme champion at World Dairy Expo.

What do you love most about dairy farming? That has changed over time too. Back 30 or 40 years ago, it was a good challenge. Way back when, it was fun. Now, it seems to be more work between the aches and pains and all the regulations we have to deal with.

What traits do you possess that have allowed you to be a long-standing dairy farmer? A strong mind and a strong back. You need the strong back to do the work. If you don’t have a strong mind, this profession could drive a not real sane person insane pretty quickly.

What do you consider to be the greatest success of your career? I would say the fact that we’re still here is a great success. We just keep surviving and gure out ways to keep going. Another great success would be Malt, being homebred and doing so well. She was the grand champion Guernsey at World Dairy Expo three times and has been supreme champion at the North American International Livestock Exposition twice. She is the only Guernsey to have been supreme champion there. Both WDE and NAILE are national shows for the Guernsey breed.

What has been the biggest challenge and how did you overcome it? I would say the biggest challenge of my career has been moving everything 1,800 miles. It took nine semi loads of cattle and equipment to get everything here. You don’t realize how little control you have over things until you have your entire life scattered across 1,800 miles.

Describe what industry change impacted your career the most. I would say both markets and the size and scale of what we need to do to keep going has impacted us. At one point, we were able to farm on 140 acres and buy cheap hay. Now, you can’t buy cheap hay, and you need to run more ground to produce

what you need. You have no control over the markets, and the markets don’t care what your cost of production is.

Tell us a lesson you learned that you still stand by today. If “they” tell you to do something, and you’ll get 5 more pounds of milk per cow, don’t believe them. Just because something works for your neighbor, that doesn’t mean it will work for you.

What piece of advice would you like to offer future generations? Don’t overspend; keep your debt as low as possible. Don’t let the bank run you; make sure that you run the bank.

52 years old

Columbus, Wisconsin Columbia County

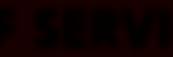

Tell us about your farm then and now. Our farm used to be a much smaller, standard dairy operation similar to thousands of others. As time went by and the spectrums of dairies grew wider, our farm ended up becoming more multi-layered and diversied. In the early 1990s, we were milking 100 cows and farming 500 acres. Today, we milk 800 cows in a 40-stall rotary parlor and farm about 2,000 acres. My brother, Robert, and I farm together with our families, and we are the third generation on this farm. We are more urban than when we started, and we feel the proximity to Madison more so today. In 2008, we opened Sassy Cow Creamery where we bottle milk and make ice cream. We now have a customer base that we have to directly nurture and give attention to because it’s part of our livelihood.

What is your favorite memory on the farm? I always enjoyed going on parts runs with my dad or running other errands together.

What do you love most about dairy farming? My connection with dairy cattle is what I love most. Things are always changing, but the cow hasn’t changed that much. Having cattle around my entire life has been a constant; it’s something I’m comfortable with. It gets to a point where you can’t imagine life without cattle, and you start appreciating them more than when you were younger.

What traits do you possess that have allowed you to be a long-standing dairy farmer? I’m committed to staying close to home. I don’t get very far away for a long period of time, and that’s OK with me. If you have a desire to travel and see the world, you’re probably not going to be a longstanding farmer. My patience or ability to roll with the challenges that each year can present is another trait that has helped me get this far. I try not to get caught up in one particular summer or bad year.

What do you consider to be the greatest success of your career? Having a farm operation that allowed my children to experience farm life and have the opportunity to pursue that lifestyle going forward is what I would consider my greatest success. I’m proud of the longevity of this farm. As my kids get older, they have the ability to be involved with the farm. If there’s anything they are interested in, there is a place for them here.

What has been the biggest challenge and how did you overcome it? The biggest challenge has been keeping up with the cost of what it takes to operate a farm. It’s continuous. No matter who you are or what decade it is, there is always the challenge of being able to continue farming. Some farms do it through growth, while some do it through diversication.

Describe what industry change impacted your career the most. Continual advancements in technology have affected day-to-day life the most. We’re not climbing silos anymore, for example. A lot of dairy farmers’ daily activities are fairly different today from when I started farming due to technology and advancements in agriculture.

Tell us a lesson you learned that you still stand by today. A lesson I learned is to not get too caught up in what everybody else is doing. Sometimes, there is pressure to feel like you have to be farming a certain way. You read magazines about all this great stuff you should be doing. It can feel like if you’re not doing that, you’re doing something wrong. But that’s not always the case. Don’t feel like you have to do everything people are telling you to do.

What piece of advice would you like to offer future generations? Take advantage of as many educational opportunities presented or available to you because in some way, shape or form, there is always something you learn that’s of value to help with your farming operation. Today, there are more opportunities than when I got out of school. Back then, it was a lot more limited.

42 years old

Norwalk, Wisconsin Monroe County

85 cows

Tell us about your farm and family. I farm with my wife Samantha and three kids. We milk 85 cows in a 75cow tiestall barn. We crop 140 acres and pasture our cows in the summer. I grew up on this farm and took over in 2008.

Why is dairy farming the correct career choice for you? I don’t think of it as a career choice, rather as more of a lifestyle that I grew up with. I love animals, and I enjoy watching my 6-year-old love animals. This allows me to have the freedom of being my own boss and do what I want each day.

What is your favorite memory on the farm? Getting married in the barn. Samantha and I got married on a Sunday afternoon among the cows with just our parents and children attending.

What has been your greatest accomplishment since you started dairying? Surviving through the bad times and raising good humans with my wife.

What do you think will be the biggest challenge you’ll face in your career? Getting to the right size where it is protable and manageable without hiring a lot of outside help. I think about 120 cows would be the sweet spot if we could upgrade facilities.

95 Year s

Tell us about a skill you have that has beneted your farming operation. I am not afraid to learn or try anything. I have learned how to do pretty much anything that needs to be done from mechanical work, plumbing and vet work without hiring it out. I have learned to be versatile and use common sense to save money.

Is there a form of technology you have implemented or plan to implement? We plan to build a freestall barn and parlor sooner than later. We are farming 1980s style right now, and we’d like to get more efcient.

What is the best piece of advice you have received? Treat others how you want to be treated.

Donny Oldenburgtold me that. He owned this farm while I was growing up, and my dad was an over-the-road trucker, so Donny was like a second father to me. My dad worked for him since he was in high school, and then we lived in a house on the farm. Donny always said my brother and I were the reason he kept farming, and when he died of cancer, we inherited the farm from him.

7,890 years of combined service!

The advertisers in this feature have over

38 years old Jefferson, Wisconsin Jefferson County

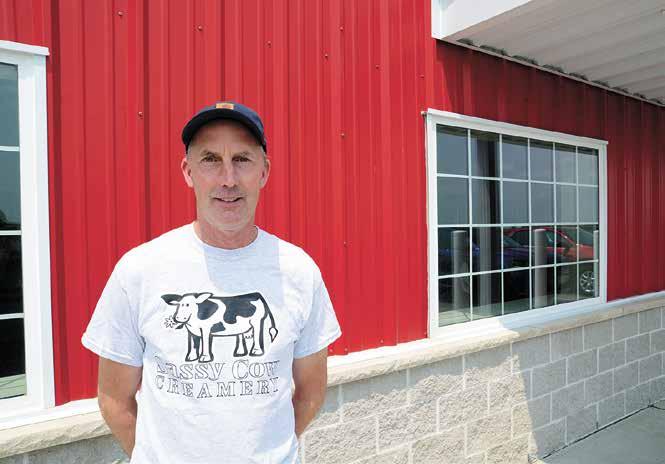

Tell us about your farm and family. I farm with my parents, Scott and Deb Lundy, and my brother, Mark. We milk about 60 cows and farm 180 acres. We have a total of 200 head of registered cattle on the farm, most of which are Red and White Holstein. I have a bunch of other animals as well, including horses, chickens, goats, ducks and geese. My parents moved to our farm in 1987 after farming in Illinois. I come from a long line of farmers and would be at least the fth generation in my family to farm.

Why is dairy farming the correct career choice for you? I am an animal lover, and farming is the only thing I know. It’s what I learned to do while growing up. Dairy farming is a way of life, and I can’t picture doing anything else.

What is your favorite memory on the farm? My favorite memory is winning grand champion of the junior show at World Dairy Expo in 1999 with Deb’s Jack Cinnamon. I was in high school at the time, and it is a moment I will never forget. I have been showing cattle since I was 3 years old, starting with one of our old Ayrshire cows, and I have many great memories that revolve around showing.

What has been your greatest accomplishment since you started dairying? My greatest accomplishment is hosting a national Milking Shorthorn convention in 2021. This was always on my bucket list. I hosted an on-farm tour at Stade Auction Center where I work just down the road from our farm. I also house some of my cows there. People came from all over for the convention. They viewed our

cows as we discussed their pedigrees and genetics. We also had a big lunch on the farm that included homemade ice cream. Last year, we also hosted a World Dairy Expo judging practice for college and 4-H kids at Stade’s. About 100 kids came to judge three classes. One group was from the Netherlands, and they had never been in a stanchion barn before. Afterward, we received thank you notes from the kids, and it was neat to see where everybody was from.

What do you think will be the biggest challenge you’ll face in your career? Trying to stay a small, family-owned farm is the biggest challenge I will face. Many people are putting in robots and rotary parlors and milking lots of cows. How do I stay at 60 cows and be able to compete and pay my bills?

Tell us about a skill you have that has beneted your farming operation. My ability to do veterinary work is a benecial skill on the farm. I handle herd health from IV to A.I., and I also went to hoof trimming school. I like treating the sickly, and I’m good at raising calves.

Is there a form of technology you have implemented or plan to implement? We are starting to do more embryo transfer work, and I would also like to start doing in vitro fertilization as it will work better on our older cows. We would like to use these technologies to improve our herd and genetics and to do so at a faster rate.

What is the best piece of advice you have received? If you work hard, you will succeed. When my brother and I were little, my mom used to make us lead our calves around in a circle 10 times each time we took them out. She told us, “You have to work for it if you want to do well.” Another piece of advice I have held onto is to always do a little more than what is expected – go the extra mile.

Tell us about your farm and family. I’m the third generation to be on our current farm. My parents are Tom and Cherrie Engelken, and I have two younger sisters, Amanda and Amber. We reside outside of Earlville, Iowa, and milk around 200 cows, predominantly Holstein with some colored breeds as well. We raise the majority of our own crops and raise all of our youngstock.

Why is dairy farming the correct career for you? Dairy farming is the correct career for me because I couldn’t see myself doing anything different. If you would have asked me in high school if I’d be back on the farm, I would have laughed and said no way. But once I left, I missed the cows. I love being able to see how the different cow families have developed. Some days may be more challenging than others, but I really don’t know what else I would be doing.

What is your favorite memory on the farm? My favorite memory would be from when I was younger when my red cow had a red heifer on Christmas Eve, who was appropriately named Christmas.

What has been your greatest accomplishment since you started dairying? Honestly, this is a tough one for me. I’m not sure there is one accomplishment that surpasses another one. I feel like each day we go out and try to make it better than the last. In order to do that, you have to keep up with the changes and know what will t your operation best.

What do you think will be the biggest challenge you’ll face in your career?

One of the biggest challenges that we face is labor. We have been fortunate to be able to have a full-time employee for over 16 years along with high schoolers, but labor is always an issue. This isn’t a job that can be done alone.

Tell us about a skill you have that has beneted your farming operation. Since coming back home to the farm, I have taken on a variety of responsibilities. Growing up, I always wanted to be a vet, and while I didn’t go down that path, I focus a lot on the health side of things. In addition to that, calf health and the maternity area has also been a huge focus for me since that is the future of the farm. Furthermore, after traveling overseas several times while in college as well as working on a dairy farm during their calving season in New Zealand, I was able to bring back a variety of perspectives and management styles to our operation.

Is there a form of technology you have implemented or plan to implement? Since we put up our new parlor and freestall barn over seven years ago, we have implemented a variety of technologies including a feed pusher, milk weights and automatic scrapers, but the one that has been the most benecial has been CowManager. While it has been huge in detecting heats, when it comes to transition cows and sick cows, we have been able to detect them much sooner than by visually looking at them. I honestly can’t say enough about this program and how it has helped us to progress our operation.

What is the best piece of advice you have received? If it makes you uncomfortable, do it. You don’t grow in your comfort zone.

(Pictured with his parents, Rick and Peggy)

17 years old Stratford, Wisconsin Marathon County

130 cows

Tell us about your farm. We milk 130 cows. They are housed in a sandbedded freestall barn and are milked by two DeLaval robotic milking systems. We crop 625 acres of corn, soybeans and alfalfa.

What are your current duties on the farm? My duties include cleaning calf pens, helping with robot chores which include getting fetch cows, cleaning stalls and cleaning robots, doing eldwork and feeding heifers.

What do you enjoy about being raised on a dairy farm? I enjoy the opportunity to work alongside my family, which includes my parents, sisters and grandparents.

Tell us about a fond experience you’ve had growing up on a dairy farm. Hosting our local FFA dairy breakfast on our farm last year was a great experience.

What characteristics of dairy farmers do you admire? I admire the hard work ethic and determination of a dairy farmer because they are the type of people who do not quit until the job is done.

What do you hope your farm will look like in the future? I would hope not much different than it is now. We have already implemented improvements over the last decade with the robotic milkers and a new shop, and we have plans on updating the heifer and dry cow barns.

What do you think will be the biggest challenge you’ll face in your career? The rising cost of keeping a farm running smoothly, from the equipment to supplies. Farm labor and labor hired off the farm for services that we are not equipped for will be challenges I will face in my career.

What is your favorite way to enjoy dairy products? From a Culver’s ice cream cone to a home-grilled cheeseburger, I enjoy all dairy products.

5 years old and 7 years old

Parents: Tony and Betsy Kasper

Tell us about your farm. We milk cows, about 400 cows, and have calves and skid loaders. We have a freestall barn bedded with turkey shavings.

What are your current duties on the farm? We help with milking cows and trying to shove the calves’ noses to the bottles to help calves get started on their bottle. We feed the corn to the calves, and we also help breed the cows. We snap cows. We clean and bed the red barn where the calves are. We help in the elds. We ride in the skid loader sometimes.

What do you enjoy about being raised on a dairy farm? It’s more space than living in town because we just had our house in town. We like being able to go out and nd Dad and be with him. We like riding our bikes with more room. Milo enjoys playing in the ground corn and creating a farm setup in it. We like being dairy duke and duchess for the Steele County American Dairy Association.

Tell us about a fond experience you’ve had growing up on a dairy farm.Lucy: I like the fair, showing calves there. My favorite show animals are Gingerbread, Brownie, Lacey and Raya. Milo: Oh, I know, driving the pickup truck. Also, making my own bunker of silage.

What characteristics of your dairy-farming parents do you admire? Dedicated. Dad is incredible. Our parents are genius. Genius, genius, genius, genius!

What do you hope your farm will look like in the future?Milo: I don’t know. It will have cows, lots of tractors and be clean and organized, not like Daddy’s. He doesn’t organize once he’s done. He doesn’t even wash the skid loaders. Lucy: I don’t know. Brown Swisses and that is it for animals. The cows would live in a barn with robots.

What do you think will be the biggest challenge you’ll face in your career? Fixing stuff and backing up. That’s really hard, but that’s kind of easy with toys. Fixing skid loaders and tractors and everything will be the hardest.

172 Year s

SKIP

What is your favorite way to enjoy dairy products?Milo: My favorite dairy products are ice cream and cheese. I like to eat my ice cream out of the cone. I like to eat my cheese fast because it’s so good. The cheese can only be yellow. Milo likes the American cheese slices from Associated Milk

Producers Inc. and can tell the difference between them and other brands of American cheese slices. Lucy: My favorite dairy products are strawberry milk and yogurt. I drink it at bedtime and at breakfast time. I eat yogurt with granola.

ANDREW INGVALSON

175 cows, 600 acres

We cut half of second crop hay June 19, and then we round baled and wrapped it. The other half I will let grow and plan to cut it next week. We had to spray for bugs after first cutting. The hay was a little above knee high. The corn looks nice and is above knee high and starting to canopy but needs rain pretty quickly. There isn’t a lot of soybeans in the area. We missed on the rains that came through the area on Sunday. It’s pretty quiet in the field right now.

ARIANN DOE

250 cows, 5,530 acres

We finished planting corn June 8. We started first-crop grass last week and plan to start cutting alfalfa this week. We planted 25 acres of new seeding last week. We plan to round bale our alfalfa and small square bale the grass hay for the calves. We have a lot of grass hoppers around, and guys are spraying for them. The oats, barley and durum are up, and some of them are near knee high and thick. The corn has all emerged and hopefully will be knee high by July 4. Everyone is starting hay and spraying for weeds around here.

ALAN VANNURDEN

600 cows, 1,400 acres

The hay cut on May 26 is coming back, and the others are standing dormant. The secondcrop hay is a week behind normal. I would say a quarter of the hay looks alright, and for the rest, there is not much coming back. We had to reseed hay five days ago that was under the irrigation. We sprayed existing hayfields around June 10. We have one-third of our corn under a center pivot that is close to waist high. All the corn is green but needs water. The soybeans are spotty, and on the hills, there are spots where the soybeans didn’t germinate. The next 10 days will tell the story about a lot of our crops.

BENJAMIN SEIFERT

350 cows, 450 acres

By the end of the week, we will be cutting second-crop hay. It looks good. We plan to chop it all and put it on a pile. We haven’t had to spray for bugs. We started planting corn June 16 and will be finishing up today (June 20). We do 300 acres. We hauled solid manure on the fields before we started planting. Everything looks good around here. The soybeans are a couple inches tall, and the earlier planted corn is knee high. Near the towns of Franklin and Fairfax, they got 8-10 inches of rain in one rainfall. It’s been so spotty around here.

DENISE KURTH

40 cows, 250 acres

We received only a few small, spotty showers over the past two weeks. The corn and the beans are still looking good despite the dryness. The second cutting of alfalfa is coming along, but it won’t be anywhere near as good as the first crop. I just put my dairy heifers and beef cows out on the pasture, and they are waddling in belly deep grass.

CHARLIE DICKE

200 cows, 850 acres

We sprayed for weevils. We hope to put in sweet corn in the next week. We are still a week out from second-crop hay. In the community, side dressing is complete, and lots of ditches and waterways are getting baled. Drought is having some effect. The pastures are burning out. Overall, the corn looks pretty good, but leaves are curling slightly. We have some corn that does not look the best, but we are blaming that on not taking off the cover crop rye quickly enough.

LANE HETTINGA

130 cows, 75 acres

It has been mostly sunny and dry with only small showers. We received 1.5 inches of rain last Saturday, which was great for the corn and a true blessing. All of the crops are looking really nice. The corn is well over knee high, the soybeans are doing well and it looks like the second crop of alfalfa is coming right along.

DOUG FAIRBANKS

380 cows, 600 acres

We just finished second-crop hay. The bugs were going to get it, so we decided to take it. We got some beautiful feed. There just was not much of it. Once the hay greens up, we will have to spray for bugs. The drought is really bad. Earlyplanted corn looks better than it should, but late-planted corn is white and drying up. If we don’t get substantial rain in the next week, the damage to the late-planted corn will probably be irreversible. People are starting to give hay to their pastured cattle.

RICH HOUZNER

54 cows, 600 acres

Things are pretty dire right now. Corn that was no-till planted in the heavy sod is getting hit with the army worms now. It got sprayed a little late and then did not get rained on. Between that and the deer and the racoons, there’s all sorts of things working against us. Some corn is 3-4 inches tall and some is knee high. The corn that was no-till planted into cornstalks looks pretty good. We got done with the first crop, and that yield was very decent considering everything involved. Second crop is not going to be good unless we get some relief.

MATT REDETZKE

250 cows, 450 acres

Everything is actually growing pretty well for how dry it is. We have gotten all our spraying done and will be side dressing some urea on the corn before this weekend. We finished up our first crop and were really pleased with how it turned out. The wet ton yield was about 4 tons to the acre. The second crop is coming along pretty well. It caught both shots of rain we got. The soybeans are looking pretty good too.

MITCHELL SCHAEFER

230 cows, 400 acres

We’re still dry, but everything greened up a bit and got a jump with the rain we received. Corn is off to a slow start but starting to look a little better. There are some no-tilled fields that are still kind of behind. We’ll probably be doing second crop hay the week of June 26. Hay doesn’t look bad, but it doesn’t look great. Our pastures are less than normal yield. They are not keeping up quite as much because of the drought.

TIM VOSBERG

140 cows, 380 acres

Most of our corn still looks okay except about 15 acres. That was the first corn I planted, and I did not have the planter set as deep. We dug in some of our fields, and the seed is there and it didn’t rot, but it hasn’t had enough moisture to grow. I’m actually shocked by how good the crops look despite the lack of rain. I’ll be cutting the second crop tomorrow, and it looks okay. It’s just a touch higher than my knee, and some closer to home is taller yet. Now we are cultivating the beans, and they look really good. They had an inch of rain the night after I put them in, so they got a good start.

WUSSOW

100 cows.

1,400 acres

We have had about 1.5 inches of rain in the last two weeks, but just north of us, they only got about 0.4, so I guess we lucked out. We finished baling first crop and started second crop June 20. The first crop we baled yielded about an average of three 3- by 4- by 7.5-foot bales per acre, so about 1.5 tons of dry matter per acre. The first crop in general yielded more than I anticipated, but it was not where it should be. The soybeans are looking pretty good; they are about shin-high. The BMR corn we have around us, if we get a shot of rain this weekend, should canopy. It really responded to what we did get. We finished a second pass of herbicide this last week too.

ALAN AINGER

300 cows, 1,100 acres

We could use a lot more rain as things are starting to look kind of tough. We started second crop hay June 14 and finished up June 16. Some fields were decent, and some were not. Corn still looks OK but is starting to deteriorate a little bit. Soybeans are at a standstill almost. They don’t look dead; they are still green but not doing a lot. Many people in the area are working on second-crop hay right now.

HAYFIELD, Minn. – One of the things Kyle and Keith Behounek enjoy about dairying is the variety.

“I like the change,” Keith said. “You’re never doing the same thing every day.”

The brothers dairy with their parents, Ron and Rhonda, Keith’s wife, Heather, and eight part-time and fulltime employees.