Read our Past, Present, Future feature starting on page 13 of the 2nd section!

DAIRY ST R25

“All dairy, all the time”™

Dry days of spring carry into summer

Flash drought causing problems for area farmers

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

SPRING GROVE, Minn.

– Darin Bratland was 6 years old when the drought of 1976 hit his family’s farm. He was a teenager when an even bigger one made its mark in 1988.

“I do remember the talk about the centennial year being really dry, but the summer of 1988 between my junior and senior years of high school, I can remember how bad it was,” Bratland said. “Then we just baled hay; we didn’t make any

MARK KLAPHAKE/DAIRY STAR

baleage. Basically, we got a rst crop of hay and that was about it.”

However, Bratland said he does not remember ever experiencing such a fast and early drought like the one that arrived this May.

“For this time of the year, nothing (in the past) has been even close,” Bratland said June 13. “This is by far the driest.”

Bratland and his brother Duron milk 110 cows near Spring Grove in southeastern Minnesota. They also farm 525 acres of corn, 320 acres of soybeans, 111 established hay ground acres and

60 acres of new direct-seeding alfalfa. They pasture milk cows, heifers and most youngstock.

“Pastures have really changed this week; they had been pretty good until the last week whereas they are not recovering now and turning around,” Bratland said. “As far as the crops, no-till soybeans, if we even have a 60% stand, that would be it. I don’t think the soybeans that aren’t coming are dead; they just haven’t germinated yet. I think if we’d get rain, they’d still come out of the ground.”

Minnesota assistant state climatologist Pete Boulay calls this spring’s sudden drought a ash drought.

“We’re getting used to these ash droughts now,” Boulay said. “We had a really sharp drought, a deep drought, in 2021 in the north (Minnesota). Then

DJ Hemmesch checks his soybean eld June 17 at his dairy farm near Albany, Minnesota. Dry condi ons have made for patchy germina on in parts of his elds. Turn to DROUGHT | Page 7

Expanding the dairy market in Southeast Asia Krause visits Singapore through USDEC

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

BUFFALO, Minn. – Until this spring, Charles Krause had never left his dairy farm near Buffalo for more than six days in a row. However, June 1 he traveled for two days to reach Southeast Asia with seven dairy farmers from across the U.S.

The group was on a weeklong learning mission to see what the Center for Dairy Excellence in Singapore was doing to promote U.S. dairy exports. The center is part of the U.S. Dairy Export Council, funded primarily through checkoff dollars through Dairy Management Inc.

Krause, who milks 350 cows and farms 500 acres near Buffalo, said the trip had been in the making ever since the center rst opened its doors.

“The center actually opened up through (the coronavirus pandemic), and we’ve tried for three years to arrange this,” Krause

said. “We nally were able to get some farmers over there to see it in person. The center had been running for those three years –about a dozen people work out of the ofce there or call it their homebase.”

Krause, chair of Midwest Dairy’s corporate board, serves as secretary on the national board of dairy farmers through United Dairy Industries Association of which Midwest Dairy has six seats. The board makes up part of the larger national board for DMI.

Having an exports promotion center in Singapore offers several benets for promoting dairy.

“Sixty-ve percent of the world’s population is in the Pacic rim – going from China, India and Southeast Asia – so we thought that would be a good place to start to have a presence on the ground,” Krause said.

“Four of our top 10 export markets are in Southeast Asia for U.S. dairy.”

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com Consultant

Jerry Jennissen 320-346-2292

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

DeadlinesSubscriptions

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Advertising

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters

Class III milk prices have slipped into the high $15 level, causing problems for the entire dairy industry. AgResource Company president Dan Basse said it is a demand issue: “It’s really a problem in the whey market; China has not shown up for whey and that’s been leaning on price.” European butter imports into the United States have also surged. The combination has brought milk prices to their lowest level in a year and a half. Basse said the dairy industry is not in a good place. “The big problem would be if feed prices rocket to the upside due to a weather problem,” Basse said. “The only helpful aspect is that the price of beef is at a record high. That’s giving the cull cow market some opportunity.”

USDA drops milk production forecast

According to the June U.S. Department of Agriculture supply demand report, the 2023 milk production forecast is down from the previous month due to slower than previously expected growth in the amount of milk per cow. The annual production estimate is 228.4 billion pounds, down 200 million pounds from the May report. The forecast for 2024 milk production was left unchanged.

Dairy industry quanties its economic impact

The International Dairy Food Association has released its latest economic impact study. The report said the U.S. dairy industry’s economic impact totaled nearly $794 billion and is responsible for 3.2 million jobs. An additional 60,000 new jobs were created in the past two years.

Changes proposed for DMC update

Improvements are being recommended for the Dairy Margin Coverage program in a bill titled the Dairy Farm Resiliency Act. This bill would require the USDA to update the production history calculation every ve years and be based on the higher production year out of the last three years. The proposal also increases the Tier 1 threshold from 5 million pounds to 6 million pounds to reect how the average herd size has risen since the 2018 farm bill. New York Republican Marc Molinaro introduced this bill.

Smith seeks to maintain milk options

Minnesota Sen. Tina Smith and Iowa Sen. Joni Ernst have sent a letter to Agriculture Secretary Tom Vilsack, urging USDA to continue to allow non-fat and low-fat avored milk in schools. The letter said a decision to remove avored milk could “have devastating effects on student’s consumption of essential nutrients and their ability to learn in the classroom.”

Wolf delisting bill introduced

The Dairy

Star

is

flexible

conveyor

VS 100 SERIES VERTICAL MAXX® Single-Auger Mixers 270 - 480 cu. ft. mixing capacities trailer and stationary models SIMPLE. DEPENDABLE. AFFORDABLE . Visit your local KUHN livestock dealer today! INVEST IN QUALITY ® www.kuhn.com Lindell Sales & Service Cannon Falls, MN HammellEquipment Chatfield, MN Eitzen, MN Adkins Equipment Detroit Lakes, MN Isaacson Sales & Service Lafayette, MN Blue Hilltop Lake Wilson, MN Schlauderaff Implement Litchfield, MN Fluegge’sAg Mora, MN Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Minnesota Ag Group Plainview, MN Dairyland Supply Sauk Centre, MN Woller Equipment Swanville, MN WernerImplement Vermillion, MN Anderson Bros. Edgeley, ND Duppong's, Inc. Glen Ullin, ND Enerbase Cooperative Minot, ND Roeder Brothers Inc. Bellevue, IA Maquoketa, IA Kunau Implement DeWitt, IA Preston, IA Bodensteiner Implement Elkader, IA Rexco Equipment Farley, IA Burco Sales Independence, IA Engel Agri-Sales Sac City, IA DeeImplement of Waukon Waukon, IA Fast, consistent

Con nued from AG INSIDER | Page 2

Dairy leaders travel to Singapore

A delegation of U.S. dairy leaders traveled to Southeast Asia to visit the U.S. Center for Dairy Excellence. This Singapore-based education hub opened in 2020, but the in-person visit was delayed for three years due to the pandemic. Southeast Asia is the second largest market for U.S. dairy exports on a volume and value basis. The center is used to educate potential buyers about U.S. dairy ingredients through training and customer engagement. There were a dozen dairy leaders on the trip, including Charles Krause of Buffalo, Minnesota.

Dairy innovation grants available

USDA is making $23 million in grant funds available for the Dairy Business Innovation program. This program supports the expansion of processing capacity, on-farm improvements and technical assistance for dairy farmers. The application process continues until Aug. 10.

Dealing with difcult times

Doud to succeed Mulhern at NMPF

The National Milk Producers Federation board of directors has unanimously voted to name Gregg Doud as its next president and CEO. Doud will succeed Jim Mulhern, who is retiring at the end of the year. Doud was the chief agricultural trade negotiator during the Trump administration. Doud is now with Aimpoint Research. Previously, the Kansas native was president of the Commodity Markets Council, chief economist for the National Cattlemen’s Beef Association and a member of the Senate Agriculture Committee professional staff.

Wagner moves to IDFA

The International Dairy Foods Association has named Roberta Wagner as its senior vice president of regulatory and scientic affairs. Wagner succeeds Joseph Scimeca, who announced his retirement earlier this year. Wagner comes to IDFA from Consumer Brands Association, formerly known as the Grocery Manufacturers Association.

Anti-BST activist passes

Longtime activist, Ronnie Cummins, 76, has died. Cummins and his wife, Rose Welch, founded the Organic Consumers Association in Finland, Minnesota, in 1998. Before that, Cummins worked with environmental activist Jeremy Rifkin to oppose recombinant bovine somatotropin. He continued his battle against BST after establishing the Organic Consumers Association. In 2008, Cummins was quoted as saying BST “is bad for dairy cows, literally burning them out in three or four years.” Biotechnology was another frequent target for Cummins.

Trivia challenge

It takes 10 pounds of milk to make 1 pound of cheese. That answers our last trivia question. For this week’s trivia, how many pounds of whole milk are needed to produce 1 pound of ice cream? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

The

create

The KUHN Knight PS 250 & 260 ProSpread® apron box manure spreaders are high-capacity, non-commercial spreaders designed for feeder, cow/calf, and dairy operations that process a wide array of semi-solid and solid materials.

The KUHN Knight PS 250 & 260 ProSpread® apron box manure spreaders are high-capacity, non-commercial spreader designed for feeder, cow/ calf, and dairy operations that process a wide array of semi-solid and solid materials. A 10-degree sidewall flare provides greater capacity while still maintaining ease of loading and unit maneuverability. A heavy-duty guillotine gate delivers greater metering capability and material flow management. Improved beater location provides an enhanced spreading pattern by streamlining material flow from the apron to the beaters.

Con nued from USDEC | Page 1

site. In that market, Krause said, the Philippines accounts for the biggest share of U.S. dairy exports at 31%, followed by Indonesia at 27%, Vietnam at 17% and Malaysia at 12%.

“With a large population base there and a growing economy, people have money, and they want to buy good protein and dairy products,” Krause said. “In Southeast Asia alone, there are 600 million people – consumers – very much a growing demographic that we want to reach with U.S. dairy.”

A goal for U.S. dairy exporters is to compete with New Zealand and Australia, which have historically garnered the lion’s share of dairy export business in that area.

“The U.S. has always played second ddle to Australia and New Zealand,” Krause said. “One-third of the population in Southeast Asia is 14 years old and younger. If we can get (U.S. dairy) in their lives when they are younger, hopefully it will follow them through their lives. We want them to not buy from Australia, New Zealand or even the European Union.”

The USDEC was formed around 26 years ago and has since found gradual success in increasing exports.

“At that point, we were basically exporting nothing – 3% – and now last year we were at 18%,” Krause said. “Nearly one out of every ve days of milk is exported out of this country.”

The Center for Dairy Excellence was built in Singapore for a reason. It is the biggest shipping-container port in the world, largely because of its location and its free-trade status.

“We spent a whole day touring (Port Singapore Authority), and it’s amazing the number of ships and amount of cargo that comes in and out of that country every day,” Krause said. “Thirty-seven million containers a year go through that port. It’s a free-trade zone, so it’s very attractive for businesses to avoid paying tariffs on some things and to move their product in and out. The port is very business-friendly.”

Krause compared the large ship trafc there to the few 1,000-foot cargo ships he has seen at Lake Superior in Duluth on a given day.

“As far as you can see (in the port of Singapore), you can’t see the end of the ships coming,” Krause said. “It’s hundreds and hundreds of ships all along the whole coast, coming and going all day long.”

Center for Dairy Excellence staff hope to increase the amount of U.S. dairy coming to port on those ships. The building offers three prongs for achieving this.

The rst is a test kitchen where products are developed, tailored to taste preferences of Southeast Asian consumers.

“We got to sample some of those,” Krause said. “A lot of the things we are exporting are powder products – whole milk, skim milk powder, whey protein isolates. One of the things they are exploring is using milk permeate, which we never really knew existed 15 years ago. They’re using this as a replacement for salt in a lot of the foods.”

Krause said Southeast Asian government entities and consumers, especially in Singapore where the population is older, are salt-conscious with their diets.

“They are able to use permeate and eliminate a lot of the salt but still maintain that same taste prole,” Krause said.

As products are developed, the second prong of the center, a product-feedback lab, is utilized. There consumers are brought in to try the products, recording their assessments of taste, appearance, texture and other aspects of each product.

Some of the products receiving good feedback are three-in-one foods and beverages that are popular now in Asia. Consumers seem to favor a balance of taste and health, especially valuing added protein, so the center is trying to add more of that to products.

Two such products Krause and his group sampled were a honey-ginger-milky beverage and a protein-malty-hot chocolate. Krause said, although they were not

necessarily to his taste, he still liked them.

The third prong of the center is its offering of meeting spaces for bringing in buyers and other groups to experience the center’s product developments and make connections with the center’s team.

“You can’t just have a great dairy product and expect people to buy it unless there is human interaction and you have a relationship,” Krause said. “That’s why we found importance in getting the Center for Dairy Excellence open and having people work on our behalf, being a voice for the American dairy farmers.”

The center even brings in members of the Southeast Asian culinary communities and demonstrates to them how to use U.S. dairy products in various dishes and cuisine.

“Having the Center for Dairy Excellence over there gives the ability to bring in all kinds of different customers,” Krause said. “It could be restaurants, hotels, suppliers to grocery stores and others. We want to reach them and show them the capabilities that U.S. dairy has and show them how we can be an assistance to them, giving them the technical backing that they need and answering their questions.”

Krause and his group also visited a few grocery stores there and saw U.S. cheese on the shelves, primarily from California and the West Coast.

The center’s team has been working to change the old image of U.S. dairy as being too inconsistent in product ow, making it risky for overseas buyers to contract with.

“It used to be 10 to 15 years ago, whenever we had too much milk, we’d dump all this powder on the world,” Krause said. “We were known as an unreliable source as to consistent export markets, and some people were leery about teaming with us because we would only sell stuff if we had too much. That is not who we are anymore; now we are a consistent supplier of sustainably produced dairy products.”

Even if dairy is exported from areas not in the Midwest, Krause said it is a benet for all U.S. dairy farmers.

“If California doesn’t export the majority of their product, it gets put on the domestic market, and we can’t consume all that,” Krause said. “It clears the way for our (Midwest) products to go to other parts of the country.”

Krause said the overall goal is for steady, continuous growth in the export market.

“Ninety-six percent of the world’s population is not in the United States, so we have to go beyond and access the people around the world,” Krause said. “Dairy farmers are very good at what we do. We produce a sustainable, nutritious product, and every year we produce a little bit more. It’s almost a linear line, 1% to 2% more every year, and we need to nd value-added markets and to move that.”

in 2022, we had a drought in southwestern Minnesota through the Twin Cities, so it shifted a bit, but it was still a pretty severe drought in both situations. The plus side of it is that, in both, we got completely bailed out.”

Boulay said it was like starting from scratch again in 2023 with the winter snow and early rains, but, in a ash, that changed.

“Now we’re getting dry again, and there’s no way to predict way out in advance what is going to happen,” Boulay said. “Who will get the rain? That’s the key, but it’s really hard to predict where it will fall.”

Near Albany, in the central part of Minnesota, DJ Hemmesch is seeing dry elds and pastures on his farm where he milks 68 cows and raises 38 head of beef cows.

“There’s a lot of mouths that have to get fed; we’re going to have to come up with all the silage,” Hemmesch said. “With the snowfall we had, the rain this early spring and not much frost in the ground, the moisture went down into the ground. The early corn that was planted looks really nice because the roots went down and are getting moisture, but the later corn was planted in dry ground and just didn’t germinate. I have not seen it this dry this early.”

Soybeans are struggling as well.

“We’ve got a lot of beans lying in dry ground yet not germinating,” Hemmesch said. “We had three- to four-tenths inches of rain May 9; after that, we’ve had just a few traces of rain, not much.”

Hemmesch said pastures are dry and meadows are short. He has begun adjusting feed.

“I just had to start feeding the beef cows; I take a bale of hay a day for them,” Hemmesch said. “With the earlier rain we got, (the pasture land) took off fairly good, but now it’s getting pretty skimpy, but the thistles still like to grow in the dry.”

The alfalfa, he said, is coming back, but he does not expect decent tonnage with the second cutting. Where he has newly seeded alfalfa, a lot of seed has not germinated yet.

“If it rains, it could still help a lot,” Hemmesch said.

Some areas of Minnesota have avoided the drought altogether.

“It’s a big state, and it varies quite a bit,” Boulay said. “There are still a few people in Brown County who say we’ve had enough or please turn it off because they had their elds ooded with the heavy rains last month. The people who are in the best shape are on either side of the Minnesota River, one or two counties

on either side, because they had decent moisture this spring.”

Most of Minnesota, however, is far below normal for moisture.

“Once you get north of the Twin Cities, they didn’t get as much rain this spring, so they are farther behind,” Boulay said. “From basically far southeastern Minnesota, coming up through the Twin Cities and east central and much of central Minnesota, very little rain has fallen over the past month – less than an inch – so those are the areas that we’re most concerned about right now.”

Far southwestern Minnesota is part of a dry swath that goes up through the I-29 corridor of South Dakota, known for its higher concentration of dairy farms. Laura Edwards, state climatologist through the South Dakota State University Extension ofce, has been watching that area.

“Down in our southeastern area, we’ve seen expansion and increase in severity of drought,” Edwards said. “We’re keeping an eye on a lot of eastern South Dakota where we are approaching what I might call a tipping point toward more severe drought.”

Edwards said she has not heard of any stress on dairy herds since most farmers today have cooling protocols and systems in barns for such weather, but feed for dairy cattle is a concern.

“The hot temperatures have really accelerated (crop) impacts, and that mostly applies to the forage and feed situation,” Edwards said. “In that part of the state, we don’t see drought a lot. In 2021 and 2022, we saw some, but that was more of a slow, progressing, lingering drought. This one is progressing more rapidly.” Predictions for forage yields are looking less promising than most years.

“We’ve had rst-cutting alfalfa already, and it was decent, but looking in the southeastern area (of South Dakota) in particular, signs are already pointing toward lower yields for the year in general because rainfall in May and June really count a lot toward our forage production,” Edwards said. “May and June are our wettest months of the year, and we are falling far behind normal pretty quickly here.”

Near Spring Grove, Bratland said he has seen some bright spots.

“We’ve had a few teasers over the last week where we got a 10-minute sprinkle or just barely a dust settler – .2 inches at the most – but it seems like the corn has reacted to that,” Bratland said. “That has actually perked up the corn a little this week. Surprisingly, for the most part, it looks pretty good, not quite knee high.”

Another bit of hope came June 15

when the National Weather Service’s Climate Prediction Center updated its predictions for the period of June 23-29. North Dakota and South Dakota and most of Minnesota were given a 33% to 40% chance of having above-normal precipitation. Most of Iowa, northeastern and southeastern Minnesota and all of Wisconsin were predicted to be receiving near normal precipitation in that same timeframe. However, the whole Upper Midwest is predicted to receive above normal temperatures, so evaporation

could be higher.

Meanwhile, Leo Schlangen, who has been dairy farming for 55 years near Richmond in central Minnesota, is taking a practical view.

“It’s very dry right now, but my dad always said, ‘If crops grow up dry, they get a good root system,’” Schlangen said. “Our crops came up so nice and aren’t hurting a whole lot yet. Our alfalfa is not so good, but I’m a person who’s always thankful for what I get. I don’t worry about what I don’t get.”

Malechas utilize family members’ talents

A place for everyone

chas also farm about 2,400 acres of alfalfa, soybeans and corn and raise their beef calves to sell when they are 6 months old.

VILLARD, Minn.

– June 15 found Todd and Louise Malecha traveling to Oklahoma from their dairy farm near Villard to look at a trailer.

The couple did not need to worry about the day’s operations on the farm struggling without them. With ve of their seven adult children and several of their children’s spouses running things at Malecha Enterprises, things were in good hands.

Louise said watching her children step into roles and grow the farm in recent years has been a highlight for her.

“I’m proudest of what my kids have become and what we have all done together,” Louise said.

June 15 was also the 25th anniversary to the day of when the Malechas rst began milking cows in their then newly built, double-16 parlor where they still milk today. Their herd now consists of 1,200 cows, mostly Holsteins, and the milk goes to First District Association in Litcheld. The Male-

Malecha Enterprises consists of other businesses outside the dairy farm as well. The family has custom chopping, custom baling and custom manure-pumping businesses. They also own a gravel pit and sell sand and other rock materials from it.

The farm’s evolution and expansion has made room for everyone’s strengths and talents.

“Todd and I were wearing a lot of ‘the hats,’” Louise said. “We had to bring the next generation in and let them take over leading and managing areas. How do you do that? People will gravitate to what they’re good at and to where their expertise is, and that’s what we’ve accomplished with our kids who are involved in the farm.”

Today, their sons, William and Jonathan Malecha, are operation managers. William serves as integrator and oversees the dairy as well as the cropping and custom chopping crew. Jonathan manages the shop, the custom baling and manure-pumping crews.

“They help each other,” Louise said.

Their daughter, Rebecca

Orr, manages calf care, and her sister, Katelynn Roelike, runs social media for the farm, including the Malechas’ YouTube channel. The youngest sibling, Robert Malecha, will enter his last year of college this fall where he is in the machine and tool program. On the farm, his skillset is already helping in that area.

“He is under William and Jonathan’s management,” Louise said. “He works in the eld and shop.”

The Malechas have large equipment and like to do their own manufacturing in their shop.

“We have built seven super hutches for our calves,” Louise said. “We also have manufac-

tured gears, sprockets and all kinds of stuff.”

The spouses of the Malechas’ children also play important roles. William’s wife, Emily, is Malecha Enterprises’ ofce manager, and Jonathan’s wife, Naomi, is nanny for Emily and Rebecca’s children. All

Turn

three women are expecting a child, which will bring the number of Todd and Louise’s grandchildren to 19.

Louise said the way the family business grew throughout the years was more organic than calculated. She said most ideas came from Todd, who is the head of nance for Malecha Enterprises. He also holds the title of “the visionary,” Louise said.

“He’d think of these ideas and create new things, get new things happening,” Louise said. “For instance, we had the gravel pit on the farm. Now we sell sand from there and assorted products. He comes up with ideas like that. At the end of the day, that is how you become what you are.”

Todd continues to come up with ideas. His latest is premium ice cream using cream, sugar, vanilla extract and no high fructose corn syrup or food coloring.

“We are looking into it,” Todd said. “We made around 170 containers of it, and it has been a lot of fun. We are just researching it at this point. Right now, it might be just a hobby that will turn into a business.”

The Malechas have embraced the idea of trying new things without fearing failure.

“We have always had a commitment to … constant and never-ending improvement,” Todd said. “We are far from perfect; for every success, there is a lot of failure right alongside it. We surely have not succeeded at everything we have done, but we just try to remain true to our values.”

When their oldest child was about 8 years old, the couple hit a crossroads, Louise said. They decided they were going to grow the dairy or stop milking cows altogether because milking in a tiestall barn was too labor intensive for their bodies. They considered different avenues, such as creating a at parlor or guring out how to rely on other income from the farm instead of dairy, but when they would start to make plans, something always came up to change their minds.

“It was like a telltale sign that that’s not the way we were supposed to go,” Louise said. “We then just started working toward building a bigger dairy.”

Once the parlor was built in 1998, other aspects of the farm grew fast.

“When we built the bigger dairy, we needed bigger equipment, so how were we going to pay for it?” Louise said. “Well, we did more custom work.”

Todd and his dad were already doing custom work, but now that part of their operation grew and continues to grow. They also bought a drag hose for pumping manure and expanded their pumping business. They added crews of workers on the road. The farm also needed more straw to bed the increased herd, so the Malechas looked for straw to buy and bale. When they baled straw in wheatelds in the western and northern parts of the state, they ended up buying extra to sell to other farmers.

“All these different things were a need for ourselves, and then we just created another line of income,” Louise said.

The couple rst met and married in 1989. Todd’s family had moved to the farm site when he was 9 years old, so he is the second generation there. Louise grew up on her family’s dairy farm to the north, just across the highway.

The pair did not know each other while growing up. Todd went to school in Villard, and Louise attended a private school started by a group of homeschooling parents.

Turn to MALECHAS | Page 12

Buying? Selling? Check the classieds!

Adding unique value to cheese byproduct

Eight bolts later, it will look like it was born there. Legendary kernel processors for pull-type forage harvesters. Legendary dairy nutrition and profits. Turn a wrench and turn it loose.

Copper Crow Distillery creates whey-based spirits in Wisconsin

By Danielle Nauman danielle.n@dairystar.com

BAYFIELD, Wis. – When an injury brought forth the time for Curtis Basina to retire from his law enforcement career with the Wisconsin State Patrol, he was ready to look for a new place to direct his energy and interest. He found that in what would become the Copper Crow Distillery LLC near Bayeld.

“I have always enjoyed math and science,” Basina said of how he became interested in distilling. “Looking at it from a business standpoint, no one in the immediate area was doing any distillation. The Greater Bayeld Area is very highly visited with the national park.”

For several years, Basina and his wife, Linda, attended conferences on the topic of distilling and toured distilleries, wineries and breweries as they traveled.

“After a while, I told Linda no one was doing distillation here, and we saw it as an opportunity,” Basina said. “So, we made the investment, and six years later, here we are.”

For Basina, uniqueness is part of the intrigue in operating the distillery.

At a conference Basina attended in Seattle, Washington, Basina connected with course leader Rusty Figgins, who encouraged him to try something new and different in his distillations: creating spirits distilled from whey.

“Rusty grabbed me and took me off to the side and said, ‘You’re from Wisconsin, the dairy state; you need to look at doing something from dairy,’” Basina said. “He told me I needed to look at working specically with whey. He told me it wasn’t easy, and that it involved a lot of math and science, but he offered to get me going in a general direction. It wasn’t necessarily my rst choice, but I decided to give it a whirl.”

Distilling with whey is a complicated process, Basina said, because lactose sugar does not ferment well.

According to Basina, there are two ways to make lactose sugar ferment.

“There is a really expensive yeast that should be able to ferment all the available sugars; lactose

is composed of glucose and galactose,” Basina said. “The way we chose to do it is to hit that lactose sugar real hard with an enzyme and bust those sugars apart.”

Through a series of small-scale experiments, Basina determined what enzyme would most efciently accomplish the result he wished to achieve.

“We soon determined we could readily ferment the glucose, but the galactose did not want to ferment very well,” Basina said. “We accepted that and started up the experimentation to the point where we’re at now.”

To create the whey spirits, Basina procures his whey from Burnett Dairy in Grantsburg. He travels to the plant at least once a month and picks up three totes of whey on a trailer. The whey is pasteurized again by Burnett Dairy, eliminating a step for Basina.

Once the whey arrives at the distillery, Basina processes it, preparing it for fermentation.

“We cut it down slightly with water and heat it just to a temperature that the yeast likes,” Basina said. “The whey comes out of Burnett Dairy at about 48 degrees Fahrenheit, and the yeast doesn’t like to grow at that temperature. We heat it up to between 80 to 85 degrees, adjust the pH, add the enzymes. We separate three totes into four totes to allow for expansion from the fermentation. Then, we add the yeast.”

Once the whey goes through the rst segment of the distillation process, Basina said about 50 gallons will remain.

“Once we save enough from the stripping runs to charge the big still, then we will do the nish run and make very big cuts, keeping only the very best,” Basina said.

Currently, Basina is producing a whey gin and a whey vodka.

“By denition, vodka is supposed to be neutral –no smell, no taste – and it needs to come out of that still at 190-proof,” Basina said. “Gin is essentially the original avored vodka. We do a little bit different process to make gin than others do, but essentially, you are adding a bunch of botanicals and juniper because gin is supposed to have a juniper forward.”

Basina received a Dairy Business Builder Grant from the Dairy Business Innovation Alliance to help increase his whey-based distillation efforts into new products.

“The grant doesn’t cover our existing whey-based products, but we can use it to develop new products,” Basina said. “That is where we came up with the idea of aging some of the vodka and gin. We are producing an amaretto that uses whey and an aquavit. We are maybe going to try and do an absinthe and a coffee liqueur. One of the things we’re really excited about is using whey as a base spirit to make bitters.”

The Copper Crow Distillery is the rst Native American-owned distillery in the U.S., and the rst distillery to be located on tribal land, Basina said.

Basina grew up in nearby Washburn where his father was a teacher. Basina’s father, a tribal member, grew up on the Red Cliff Indian Reservation near Bayeld and was one of the rst tribal members to attend college. His wife is also an enrolled tribal member from Red Cliff and grew up in nearby Bayeld proper.

“We were living in Superior, and when I retired, we bought a house in Bayeld and some property in Red Cliff,” Basina said of how the distillery came to be located on tribal land. “We sold the house in town and built one in Red Cliff.”

When naming the newly launched distillery, Basina said he chose the name Copper Crow for a variety of reasons.

“Copper is a very useful metal

Val Schumann35 years with DHIA

in the distilling process,” he said. … “It is also somewhat native to this area. Finally, it’s a little bit of a play on words, being I used to be a cop. If you know about crows and watch them for a while, they are extremely smart and very family-oriented. In our culture, they help us nd our way. The building was designed to somewhat resemble a crow, if you get back away from it. There is some really great lore that goes along with native culture and crows.”

DHIA PROFILE

What has been key to your longevity with DHIA? An appreciation for the members that we serve at Minnesota DHIA. I love working with them and the cows.

What is your current title and some of the jobs you do? I am the data ow manager. During my time with DHIA, I have done just about everything to do with the service to our members. Quality control, software support, putting data together for our annual summary, day-to-day processing of records, working with DairyComp 305 programmers to implement improvements and upgrades, relief testing and training. Currently, I am the main trainer for new eld techs.

What do you like about your role for DHIA? Getting on your farms and having that one-on-one interaction. When I have helped one of our members, and they tell me, “You’ve just made my day or my job easier.” Sharing what we offer to eld techs and members so they can implement changes or improvements.

What message would you like to send to the dairy farmers you work with? Thank you for allowing me to serve you. It’s been a fun, challenging, sometimes frustrating but always interesting job.

What do you enjoy doing in your spare time? We enjoy getting away to property up north to relax. I enjoy deer hunting, gardening, reading, spending time with my grandkids, kids and other family members and napping; naps are good.

DHIA: Now MORE than ever

“Thank you for allowing me to serve you.”DANIELLE NAUMAN/DAIRY STAR Cur s Basina explains the rst-run dis lla on process May 10 at Copper Crow Dis llery in Bayeld, Wisconsin. Basina has been producing a whey gin and a whey vodka.

“We didn’t know each other until nine months before we got married,” Louise said.

However, Louise was ready to step in as a full dairy partner. She even milked the cows on her own when Todd and his dad were custom baling.

“I liked dairy,” Louise said. “I was all in. The vision was for us to do the milking and for Todd’s dad to do the eldwork.”

They milked about 120 cows in the farm’s tiestall barn, a big herd compared to the 13 cows milked there when Todd’s family rst started dairy farming.

Malecha Enterprises has grown since then to have different entities and cover more acreage. They employ around 27 full-time employees and bring in an additional 20 H-2A workers from South Africa for seasonal work.

Louise said the business benets from these workers bringing skills with them.

Seven years ago, Todd and Lou-

ise formally started their transition to the next generation. The family began working with a transition-planning consultant. Since then, the strategy has been mapped out as to how the farm’s legacy will continue.

“Our vision of our kids taking over was not a conscious thought planned out until we started transition planning, but we always looked at building for the future,” Louise said. “Many people wait until their kids are 50 years old and then just sell them the farm. We did not want to do that. Our youngest was 12 years old when we started transition planning. Now he is going to be 20.”

Louise said the plan has brought peace of mind.

“We can hand over the torch to our kids and see where they can go with it,” Louise said. “It’s hard to step back sometimes, but you must for the next generation to take over. It also gives me more time to enjoy my grandkids.”

Part of that enjoyment for Louise came in the form of writing. In 2020,

she wrote and published her rst children’s book, “Going to Papa and Nana’s Farm.” On June 21, her second book came out, “Ginger’s Big Day.” Both are illustrated by Katelynn and available online. Louise plans to continue writing more books.

“I wanted to write our story for our kids to see where we come from, and I’m still in the process of writing this story,” Louise said. “With these children’s books, I want to teach kids around the world what happens on a farm and where our food comes from.”

As a sign of how far the family’s farm has come, the Malechas became 2022 Farm Journal’s Top Producer of

North America. The couple traveled to the awards ceremony in Nashville last February, where they were announced as the winner among three nalists.

More than receiving awards though, Louise said dairy farming brings the biggest rewards.

“I like the outdoors, and no one day is the same as the next day,” Louise said. “There’s always a challenge, whether it is the weather or an animal. There is always something that’s making you a better person or testing your limits. It is an enjoyable life.”

Dairy Star intern Alex Christen contributed to this article.

New application made easier up front

MDA’s grant helps dairy farms evolve

By Jan Lefebvre jan.l@star-pub.com

By Jan Lefebvre jan.l@star-pub.com

Although the Minnesota Department of Agriculture’s dairy business planning grants have been around since 2002, the application process is now less complicated.

“We revamped the application,” said Kami Schoenfeld, farm nancial assistance administrator at MDA. “Before, it used to ask for a lot of information up front. Now, we want people to submit projects that are going to change and advance the dairy farm, and then we want more information at the end as to those projects and how well they impacted farms long term.”

The new application form rolled out June 7.

The grant money available each year, $80,000, resets every July 1. Schoenfeld said some of the money has been left over the past few years due to fewer farmers applying. The new application may help address that.

“Sometimes it’s hard (to ll out an application); you want to do a project and you’re asked questions that you don’t necessarily have a solid answer for, such as why you were looking at building a new barn or adding robots or how you are going to do farm transition,” Schoenfeld said. “Sometimes you don’t know that until you get into the project. Now, the application is easier up front, and then we want more information at the end.”

The application is now only three pages in length.

MDA has also expanded the definition as to what the grant can be used for.

“It’s meant to help dairy farms expand, grow, change with a thirdparty consultant,” Schoenfeld said. “Dairy farmers are really good at farming but may not be good at other parts of the business, so this helps them hire somebody who can help them grow their business and research what they are looking into.”

The denition has been expanded to include feasibility studies and business development for valueadded projects.

“We’re trying to support dairy farms as they expand and change in today’s world,” Schoenfeld said.

“If farms are looking at how to do a small farm processing, this grant might be a way to help a farmer hire a consultant to help write that plan or help do research on markets. We tried to expand it to include more things than just a robotic system or farm transfer.”

Both existing and beginning Minnesota dairy farmers are eligible to apply. The grant pays 50% of the cost to develop a business plan – up to $5,000 – with the farmer covering the other 50%.

MDA’s website has posted the new parameters of the grant.

“This grant can be used to help cover the costs of hiring a qualied, independent third party to create a business plan for dairy operations,” MDA said. “Dairy producers have used grant funds to evaluate the feasibility of expanding an operation, plan environmental upgrades, create strategies to transfer the operation to a family member or other new owner, and other business activities.”

The application states that grant money can also be used to help pay for stray voltage testing.

Grants cannot be used for capital purchases, nutrition consulting, retirement and investment planning, tax planning and tax return preparation, intergenerational transfer planning that discontinues the dairy enterprise, loan origination or documentation fees, chattel real estate appraisal, crop consulting, nutrient management planning (except as required in the business plan), veterinary/herd health consulting or the cost to complete a dairy business planning grant application.

A benet for both MDA and farmers in gathering more information at the tail end of the grant process as opposed to the front end is in seeing the good the grants do in helping farms achieve goals.

“We really want to see the impact as to how the grant is helping the farm,” Schoenfeld said. “It allows us to tell the story about how the grants are working for dairy farmers.”

Having legislators see the value of dairy business planning grants helps secure continuation of the grants.

“Dairy farmers today need all the help we can nd for them,” Schoenfeld said. “Dairy farms need to evolve. We want this grant to help them evolve, and that’s looking very different now and in the future.”

To view the full eligibility requirements as well as access the application, visit www.mda.state.mn.us/dairy-business-planning-grants. Kami Schoenfeld is available to answer questions at kami.schoenfeld@state.mn.us or 651-201-6643.

How does this year’s first-crop hay harvest compare to previous years?

Joe Nickelotti La Crescent, Minnesota Winona County80 cows

Tell us about your rst-crop hay harvest. I’m by myself, so harvesting is slow. I started May 24 and nished June 15. I’m harvesting 150 acres for haylage.

What was the yield? The yield was good because most of my hay was new seeding from the past two years, but is there going to be a second crop because of the drought? It will all be fed to the dairy cows.

How does this year’s rst crop compare to previous years? The rst crop is comparable to other years, but how do we know if we will get a second crop with as dry as it is out here on the farm? The acres are the same as other years.

What challenges have you had and how did you manage to work through them?

My problem is nding help. I have three wagons, so I chop three loads, unload three loads, then chop three loads. When you are milking cows morning and night too, you don’t get much done in a day.

How are you planning to manage your hayelds through the rest of the season? I was hoping to get four cuttings on the early stuff, but with the drought, I’m thinking I might just get three cuttings. I might have to wait longer on cutting second crop, hope for a rain and hopefully get a third crop. The interval will depend on what is there in the eld.

Tell us about your farm. I have a stall barn that holds 68 and a freestall barn that holds 40, so I have to switch cows for milking. I sell to Elba Creamery. It’s a threehour process for chores morning and night between switching and feeding cows. I used to have 100 cows, but I went to the hospital in February with several herniated discs, so I cut back my cows to 80. I breed all my cows to beef, sell the calves and purchase my replacements.

Allen Blommel

Clarissa, Minnesota Todd County

Allen Blommel

Clarissa, Minnesota Todd County

50 cows

Tell us about your rst-crop hay harvest. We put up 70 acres of alfalfa. We chopped the rst half June 10 and put it in our Harvestore silo. The second half, which was 25 acres, was cut June 2 and baled and net wrapped June 10, which will be stored in our shed. We also cut some meadow hay.

What was the yield? I am very pleased with the yield. It was a nice, heavy stand; one of the better yields I’ve had in years. When we cut, it was 24-28 inches tall.

How does this year’s rst crop compare to previous years? It was much better than in previous years. It was good drying hay weather. Now if we could get some rain so that we can get a good second crop. The regrowth is very slow at coming back.

What challenges have you had and how did you manage to work through them? The hay we chopped got half an inch of rain on it. That pushed us back a day on chopping.

How are you planning to manage your hayelds through the rest of the season? I will put potash down as fertilizer on all 70 acres, as I do every year.

Tell us about your farm. My wife, Charlet, helps me with every aspect of the farm. We farm about 400 acres total of corn, soybeans and hay ground along with milking our 50 cows. I am the second generation on this farm, and I started in 1981. We sell our milk to First District Association. We also have goats and donkeys running around just for fun. We nished out our steers on our other farm site that is a mile down the road. We have 10 children and 25 grandchildren.

Tell us about your rst-crop hay harvest. We cut 40 acres of alfalfa May 30 and baled and wrapped it two days later as baleage.

What was the yield? The yield was really good. This crop was running 1.5 ton to the acre. This crop will all be fed to the milk cows.

How does this year’s rst crop compare to previous years? This is the best rst crop I've ever had. This eld is irrigated but has dry corners. Usually by mid-June, it does not grow anymore.

What challenges have you had and how did you manage to work through them? It was a good cutting. The neighbor’s wrapper was having issues, so we had to call a different neighbor to wrap hay, which sure is nice having neighbors to call on for help.

How are you planning to manage your hayelds through the rest of the season? Right now, we will just keep turning the irrigators on to keep the hay growing. I seeded down another 40 acres of alfalfa and am trying to get that to establish as well. Each year, we hope to get four cuttings.

Tell us about your farm. We are just a simple dairy with an old red barn with a retrotted parlor and freestall barn on the side. I take care of all the day-to-day chores. My ancée works full time as a calf and heifer nutritionist and helps as much as possible on the farm. The majority of our herd is Holstein with some registered Jerseys. My ancée shows the registered Jerseys. I'm the third generation on this farm. My dad helps with eldwork and random things in between, and my brother helps haul hay and will milk if we want to get away for a night, which is really nice.

Roger Mohr New Ulm, Minnesota Brown County

100 cows

Tell us about your rst-crop hay harvest. We have 70 acres of alfalfa. We chopped 60 acres of it and round baled the last 10 acres. The stuff we chopped we put in 200-foot bags. The chopped hay will go for the milk cows, and the bales will be for the heifers.

What was the yield? We got 3 tons to the acre. The relative feed value was about 170.

How does this year’s rst crop compare to previous years? This is by far better than what we’ve had in the past.

What challenges have you had and how did you manage to work through them? We’ve had a lot of rain this spring, so we were worried about nding enough days to make hay, but when the time came, the land and the hay making went really good. How are you planning to manage your hayelds through the rest of the season? I foliar sprayed them and used an insecticide with the foliar feed. We are having some bugs in the hay. We hope to get four cuttings of hay this year. We usually bale and chop each time, depending on weather.

Tell us about your farm. Our farm is run by my wife, Anita, our son, Scott, and me. Together, we farm 350 acres of corn, soybeans, alfalfa, peas and kale. We use the peas and kale as a forage. I am the fourth generation on this farm. We milk 100 cows in a double-11 parlor. We ship our milk to Associated Milk Producers Inc.

Michael Rose and Kayti Lyseth Kimball, Minnesota Stearns County 50 cows

Michael Rose and Kayti Lyseth Kimball, Minnesota Stearns County 50 cows

75 cows

Tell us about your rst-crop hay harvest. We chopped and bagged our 25 acres of old crop alfalfa May 25. We chopped and bagged 25 acres of new crop alfalfa/oats June 14 and big square baled 20 acres of grass hay June 12.

What was the yield? The old crop alfalfa, which we mowed and chopped, yielded about 80 feet of a 10-foot diameter bag. That will be fed to the cows. Our new crop oats/alfalfa was mowed and chopped and yielded about 60 feet of a 10-foot diameter bag. This will be fed to the cows and the heifers. The pasture yielded 44 big square bales, which will be fed to youngstock calves.

How does this year’s rst crop compare to previous years? The yield of the rst crop of haylage was on par with last year’s. We seeded more acres to account for our aging old seeding and the lack of a winter rye crop. We increased our dry grass hay by about 33% over last spring. That yield bump was due to rainfall.

Dennis Reuter Hastings, Minnesota Dakota County140 cows

Tell us about your rst-crop hay harvest. We chopped hay May 25. We put up 70 acres as haylage. We did it all in one day. We even had a three-hour breakdown in the middle. We have what the experts would say is oversized equipment, but we like it. We have a selfpropelled chopper and a large merger.

What was the yield? We got about 1.75 tons of dry matter per acre. Our hay got dry; it was dry when we started and then the breakdown made it even dryer. We will be feeding it mostly to the milk cows and a few pounds to the dry cows because we only have the calves and the cows on our farm.

How does this year’s rst crop compare to previous years? The yield was a little less. Our timing of harvest is similar each year. Even on years when we have a late or early spring, we cut at about the same time. Field conditions were dry. We have irrigation, though, so we began wetting the eld once we were

What challenges have you had and how did you manage to work through them? The lack of rainfall has been the biggest challenge. We planted 30 acres of cereal rye on our chopped corn silage ground last October. It was too dry last fall, and the rye didn't germinate. The rye didn't germinate until later this spring and was very spotty. We ended up terminating the rye to grow a better soybean crop. The lack of rye prevented us from terminating a few older alfalfa elds that we were scheduled to rotate. We also decided to add an oat nurse crop to the new alfalfa seeding to add some feed sooner in the summer.

How are you planning to manage your hayelds through the rest of the season? We typically have 28 days between alfalfa cuttings for silage and fertilize between each cutting. We recently received an inch of rain, the rst substantial rain in about six weeks, on the second cutting of alfalfa. That will cause us to push back the second-cut harvest date in order to maximize our tonnage potential. We hope to get four cuttings of old crop alfalfa for chopping and three cuttings of new crop alfalfa.

Tell us about your farm. Our farm, which is located south of Cleghorn, Iowa, has been in our family since 1876. We milk 75 Holsteins and farm about 800 acres of row crops. I operate the farm with my parents, Mark and Sara, and my wife, Jill. Jill and I have a son, George.

done. We harvested similar acres compared to other years. It will be similar feed value compared to other years as well.

What challenges have you had and how did you manage to work through them? We did not have any winter kill. Because there was no rain, we just went with the size of the plant for cutting time. With our equipment size, chopping went quickly. Our bagger did break, but a guy brought a bearing for it while we tore it apart. Within three hours, we were back to bagging.

How are you planning to manage your hayelds through the rest of the season? Someone from the co-op regularly walks through with a sweep net, and that determines spraying from the pest thresholds. We plan on every 24-28 days on cutting depending on the plant development. We only ever take four cuttings. Whenever we take a fth cutting, it leads to too much winter kill, so we do not do it unless we plan on plowing it up.

Tell us about your farm. Reuter Farms is my brother, Carl, and I and my son, Phil, who works for us as our herdsman. My son, Jake, works part time for us when we need help. We farm about 600 acres, with alfalfa, corn, soybeans and grass for the dry cows. Heifers are all custom raised. They all leave at 4 months old and return a month before they are due. Any feed I put up has to be dairy quality. We sell our milk to First District Association. We milk with two robotic milking systems.

DAIRYSTAR.COM COM

Information at your ngertips- Easy, clean, fast. When you are looking for resources you’ll nd them on our site. Our clean, easyto-navigate site makes it simple to locate the information you’re searching for.

Describe your farm and facilities. We milk in a newly renovated tiestall barn.

What forages do you harvest? The cows’ main forage source May through October is typically fresh pasture using intensive rotational grazing. Over winter, we usually feed corn silage and dry hay in round bales.

How many acres of crops do you raise? We have over 100 acres of alfalfa-grass mix hay, over 50 acres corn for both grain and silage, and nearly 50 acres of pasture.

What quality and quantity do you harvest of each crop? We cut hay and rotate pastures to maximize quality of the grasses. It took several years to realize the grass was ready long before the alfalfa. Rest on the pastures is key to maximize regrowth, and leaving a 5- to 8-inch grass stubble greatly increases how fast it regrows. Corn silage is harvested when moisture is below 65% for our upright silos.

Describe the rations for your livestock. Our summer ration is typically pasture plus a grain mix fed at milking time. Winter ration is corn silage and dry hay plus grain. We hope to add another silo and have corn silage year-round in the future. We also plan to make haylage again like we did in the past.

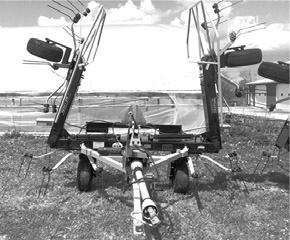

Describe your harvesting techniques for alfalfa and corn silage. Hay is cut based on the maturity of the grasses to maximize quality. We cut with a pull-type Discbine with steel roller conditioners. The interval is usually under 28 days. We usually either chop it for the silo or make dry round bales. Chopping of hay and corn is done ourselves with a New Holland 900. We hope to add a kernel processor in the future for corn silage. We do our own round baling with a Vermeer 604K.

What techniques do you use to store, manage and feed your forages? We use upright stave silos for corn silage and haylage. Dry hay is usually made as round

Dairy FarmersSaluting LOCAL

The Bongards Cooperative is made up of hundreds of familyowned farms – many run by farmers carrying on a legacy that reaches back multiple generations. These farms supply the milk used to craft Bongards’ distinctive brand of cheese using old-world craftsmanship paired with cutting-edge technology. The result is cheese that delivers unforgettable taste and unparalleled quality. Learn more about our co-op, products, and current job openings at www.bongards.com.

bales and occasionally small square bales. We component feed everything. Corn silage is fed via an electric feed cart or bunk feeder. Round bales are unrolled by hand in the manger or fed outdoors in a feeder. When baleage is made, it is usually fed outside in feeders.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We needed to maximize yield on our home acres after some rented ground was sold. This rst led to intensive rotational grazing of our existing pastures, which simultaneously increased quality and yield compared to what we came to expect from pasture. Pasture is just a hayeld harvested with cows. Corn that would typically have been harvested as high-moisture shell corn was also being chopped to increase tonnage. The milk and milk solids yield seems

TridentPulsation™

Manage the liner, protect the teats:

TridentPulsation™ optimizes the machine to animal interface by properly controlling the liner action on the teat. It starts by holding the liner fully open to ensure a consistent full attach followed by a brief stimulation. The positive pressure fresh air system then ensures a consistent gentle full teat massage to completely rest the teat preventing swelling/damage. It then holds the liner fully open for a gentle detach. Consistent gentle milking action prevents teat harm ensuring healthy teats with quality milk allowing more cows to remain in your herd. Consider our customers who reduce cull rates by 1/3 keeping high producing cows in the herd while reducing heifer raising cost by 30%.

Why not start saving $400/cow/year now?

www.TridentPulsation.com

Trident@TridentPulsation.com

TridentPulsation™ System

607-849-3880 • 607-759-1037

No matter how you milk your cows

Udder Comfort is...

Softer udders More comfort Better letdown Faster, more complete milking Better quality More milk

“ This is the one that does what it’s supposed to do. Using Udder ComfortTM on all fresh cows for 7 days after calving, we saw our quality keep getting better, and now we rarely have to treat for mastitis.”

- Parlor manager, PA, 500 cows

“ When we spray Udder Comfort 1x/day for a week before calving, our cows, especially 2-year-olds, come in with a little more milk and a lot more comfort. They milk faster and adapt faster. Unit attachments are quicker because edema is gone, or it’s very minimal. This reduces our fetch

Robotic dairy owner, MN, 340 cows

“ Udder Comfort makes sense, and the investment per fresh cow is minimal. It wasthe missing piece, helping us get the most from all we do for comfort and quality. When we adopted the fresh cow routine with Udder Comfort, SCC dropped like a rock, we were down to just 4 hospital cows, and our production average moved higher.”

“ It is the best tool to get cows through transition and into milk faster with healthier udders. In 3 months of getting our fresh cows sprayed more consistently with the Udder Comfort Battery-Operated Backpack Sprayer, our SCC came down from 165 to 137,000, and if we do get clinicals, they clear faster and don’t become repeat offenders.”

- Herd health manager, IA, 750 cows

to be better when we are able to feed corn silage. We started planting grasses, primarily festulolium, with our alfalfa. The goal is to increase stand longevity, increase digestibility, and allow for better and faster dry down to make dry hay.

Describe a challenge you overcame in reaching your forage quality goals. I quit watching the weather when deciding to start cutting hay. If it’s ready, get it cut. Having to make baleage out of highquality hay that got rained on once is preferable to having tons and tons of stemmy, full-bloom alfalfa bales.

How do quality forages play a part in the production goals for your herd? Excellent quality pasture has cut protein costs signicantly over the summer months.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? Adding grasses to our alfalfa stands allows for faster dry down and earlier harvesting, which greatly improves quality. Treating the pastures as another hayeld quickly improved forage yield and quality. We have learned to keep the cows off them for 28 to 35 days between cuts and don’t let pastures turn into golf course greens.

ROUND BALERS

1000 PTO, 5 ft. bales, 13500 BC, #543058 ............................ $28,500

Kuhn VB2190 2012, 1000 PTO, 4 ft. bales, 16000 BC, #543785................ $26,000

JD 560M 2020, 1000 PTO, 5 ft. bales, 5500 BC, #544100 .......................... $47,900

NH BR750 2005, 540 PTO, 4 ft. bales, 6000 BC, #544396 .......................... $13,500

JD 569 2015, 1000 PTO, 5 ft. bales, 9200 BC, #545913 .............................. $33,900

JD 560M 2022, 540 PTO, 5 ft. bales, 1516 BC, #547391 ............................ $61,500

Vermeer 605N Cornstalk 2017, 1000 PTO, 5 ft. bales, 6768 BC, #548033$46,500

JD 582 Silage Special 2006, 540 PTO, 4 ft. bales, 7685 BC, #550012 ....... $26,500

JD 560M 2019, 1000 PTO, 5 ft. bales, 7000 BC, #550210 ..........................

1000 PTO, 5 ft. bales, 10094 BC, #556680 .............. $34,900

NH BR780 2005, 1000 PTO, 5 ft. bales, 7700 BC, #557075 ........................ $13,500

JD 560M 2021, 1000 PTO, 5 ft. bales, 8233 BC, #557166 .......................... $51,500

JD 460M 2022, 1000 PTO, 4 ft. bales, 2600 BC, #557280 .......................... $57,900

JD 459 Silage Special 2015, 540 PTO, 4 ft. bales, 19000 BC, #557420 ..... $19,500

JD 460M 2019, 1000 PTO, 4 ft. bales, 5898 BC, #557634 .......................... $53,500

JD 568 2010, 1000 PTO, 5 ft. bales, 14683 BC, #559585 ............................ $30,000

JD 567 2003, 540 PTO, 5 ft. bales, 13500 BC, #561591 .............................. $17,900

JD 560M 2022, 1000 PTO, 5 ft. bales, 900 BC, #563551 ............................ $57,900

NH Rollbelt 460 2021, 1000 PTO, 4 ft. bales, 6846 BC, #563911 .............. $41,900

ROW CROP TRACTORS

JD 8R 370 2021, Cab, 1000 Rear PTO, Duals, 956 hrs., #535131 .............. $392,500

JD 8R 370 2021, Cab, 1000 Rear PTO, Duals, 608 hrs., #535161 .............. $431,600

JD 8R 410 2021, Cab, 1000 Rear PTO, Duals, 468 hrs., #541906 .............. $466,700

#550330 ............ $437,500

JD 8R 310 2022, Cab, 1000 Rear PTO, Duals, 525 hrs., #553951 .............. $410,000

JD 8R 340 2020, Cab, 1000 Rear PTO, Duals, 1341 hrs., #554058 ............ $382,500

JD 8R 340 2020, Cab, 1000 Rear PTO, Duals, 1396 hrs., #554059 ............ $375,500

JD 8R 310 2020, Cab, 1000 Rear PTO, Duals, 1416 hrs., #554060 ............ $362,500

JD 8R 340 2022, Cab, 1000 Rear PTO, Duals, 677 hrs., #554166 .............. $419,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 159 hrs., #557151 .............. $504,900

JD 8R 410 2022, Cab, 1000 Rear PTO, Duals, 234 hrs., #557154 .............. $514,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 605 hrs., #558224 .............. $374,400

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 311 hrs., #559372 .............. $477,900

JD 8R 310 2021, Cab, 1000 Rear PTO, Duals, 938 hrs., #559593 .............. $349,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 323 hrs., #559674 .............. $499,800

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 400 hrs., #559680 .............. $475,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 269 hrs., #559753 ............. $479,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 603 hrs., #559754 .............. $364,900

JD 8R 250 2022, Cab, 1000 Rear PTO, Duals, 307 hrs., #559757 .............. $379,900

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 395 hrs., #560057 .............. $468,000

NH T8.300 2012, Cab, 1000 Rear PTO, Duals, 2057 hrs., #561011 ........... $159,900

International 966 1971, 2WD, 540/1000 Rear PTO, Singles, 6534 hrs., #562559 .................................................................................................... $15,500

JD 8R 370 2022, Cab, 1000 Rear PTO, Duals, 569 hrs., #562744 .............. $459,900

Case IH Puma 240 2021, Cab, 540/1000 Rear PTO, Singles, 312 hrs., #563034 ..................................................................................$229,900

JD 8R 340 2022, Cab, 1000 Rear PTO, Duals, 402 hrs., #563581 .............. $424,500

JD 8R 340 2022, Cab, 1000 Rear PTO,

Lending a hand during times of sorrow

There are many qualities of a dairy farmer I truly admire: hard-working, dedicated and tough are just a few I can mention within these lines.

Perhaps a trait I admire most is their willingness to help even though they really don’t have the extra time to do so. Think about it. Many farmers consider a 10-hour day an easy day. But if the neighbor’s cattle are out or someone has a at tire near the farm, they will halt what they are doing to help.

It’s the fabric that most farmers are. They are good neighbors willing to adjust their day to help anyone in need.

Just last week, this quality came to forefront on a modest 100-cow dairy near Norwood Young America, Minnesota.

The younger of two brothers, who had been dairying together for more than two decades, suddenly passed.

Dealing with the emotion of losing perhaps his best friend and operating a business as diverse as dairy farming would not be comprehendible.

By Mark Klaphake Editor

The farm couldn’t stop because of the vast amount of daily activities that occur on a farm. The animals needed to be fed, the cows needed to be milked, and the constant challenges that each day brings needed to be dealt with.

But the surviving brother needed to halt to process the grief of suddenly losing the other half who was equally committed to doing his best to make their dairy farm journey a success.

They saw each other many times every day. The duo probably had thousands of conversations in the barn, farmyard or elds about the plans for the dairy and the next hurdle to overcome.

But now, that was gone forever.

So, on a warm week in Carver County, while the dairy farmer and his family were accepting condolences for the loss of their brother and a son, uncle and neighbor, the farm was bustling with activity.

First-crop hay was being laid down in the eld, rakes were combining the rows, and, later, big square balers were rolling through the elds, stringing together bales for the animals on the farm.

A nearby dairy farm neighbor was the ringleader to the event. Upon realizing that part of the rst-crop hay wasn’t complete at the time of the passing, he sprang into action.

He connected with local farmers, some up to 20 miles away, to bring their equipment to conquer the job. He synchronized the farmers for different roles, whether they would be cutting, raking or baling hay for the dairy farmer in need.

The volunteerism started on a Monday, and by Saturday, around 70 acres of hay were put up to yield 215 big square bales as well as round bales.

This all occurred while operating their own individual farms and dealing with their vast daily challenges and problems that arose from those farms.

The price tag for the good deed was $0. The display of farm equipment on procession for the farmer’s funeral signaled the truth: That’s just what dairy farmers, and farmers in general, do – help when needed.

Alberts advocates for women in agriculture

By Alex Christen Staff InternPINE ISLAND, Minn. – Growing up in the world of dairy has led Mackenzie Alberts to recognize the importance of women in the agriculture industry.

“My dad has really installed in me the importance of having women in agriculture,” Alberts said. “I have looked up to many women working in the dairy industry both on and off the farm, and now I have the opportunity to follow in their footsteps.”

Alberts, the daughter of Eric and Angie Alberts, now has the opportunity to represent the dairy industry as a woman in agriculture as she serves as one of the 10 nalists vying for the title of Princess Kay of the Milky Way. The Alberts milk 500 registered Holsteins near Pine Island.

As a dairy farmer herself, Alberts sees the time and dedication farmers put into their passion for their career. She wants to be able to apply that passion to her role as a dairy princess.

“Being a dairy princess and being out in the public is a great way to represent the farmers who are at home working 365 days a year,” Alberts said. “It truly is a blessing to be able to pass on the legacy my family has had over the last seven generations.”

On the farm, Alberts is known as

Sharing her legacy

a jack of all trades. She plays multiple key roles on the farm but spends most of her time with the calves.

“I love to feed the calves, and I developed a passion for calf care,” Alberts said. “I ll in as a substitute milker as well if needed.”

In 2020, Alberts had her rst experiences with the machinery side of the farm when her dad put her in a tractor.

“He hasn’t been able to get me out since,” she said. “I love helping haul hay or corn during harvest or manure and anything in between. Now, I am learning more of the mechanical side of the tractors and farm equipment.”

Outside of growing up on her family’s dairy, Alberts also found a passion for the industry through her involvement in 4-H and FFA. As the retiring Minnesota FFA state secretary, she has had the opportunity to connect with others all over the state and build lifelong friends. She hopes to continue building those connections and friendships within the Princess Kay program.

“I love to make connections with others,” Alberts said. “Being Princess Kay, you are given the opportunity to talk to a wide variety of people, so being able to make those connections will be important.”

Alberts is attending South Dakota State University, majoring in agricultural communications and leadership. She is planning to use her degree to nd a career in connection with what she loves most – the dairy

industry. In the future, she also has a goal of writing a book about her experiences growing up on a farm and hopefully raising a family on a farm.

When the nalists were announced

in May, Alberts and her family had plans to watch it on the television in her house; however, as often happens in the

Like mother, like daughter

Ratka contends for Princess Kay title

By Alex Christen Staff Intern

By Alex Christen Staff Intern

COLD SPRING, Minn. – As someone who has attended the Minnesota State Fair every single year of her life, Megan Ratka is no stranger to the world of agriculture, show rings and the Princess Kay of the Milky Way butterhead tradition.

Ratka was named as a 2023 nalist for Princess Kay of the Milky Way exactly 30 years after her mother, Kathy (Kuechle) Ratka, was named as a nalist in 1993.

Ratka, the 20-year-old daughter of Kevin and Kathy Ratka from Cold Spring, did not grow up on a dairy farm but instead found her passion for dairy in the show ring.

Her journey to the butter booth began in rst grade.

“I was watching the 4-H show at the state fair with my parents, and I told them that I wanted to do that,” Ratka said.

From there, Ratka’s parents connected her with Jerry and Linda Jennissen, owners of Jer-Lindy Farms near Brooten. They agreed to lease Ratka a calf named Cocoa, and Ratka continued to lease from them through the years.

When Ratka reached ninth grade, she also began purchasing her own cattle to show. Together, Ratka and her brother and sister, Tyler and Allison,

Megan Ratka walks Mara, a Brown Swiss winter calf, at her family’s home May 20 near Cold Spring, Minnesota. Ratka and her siblings, Tyler and Allison, own a total of nine dairy ca le.

now own nine dairy show cattle. They raise the heifers at home, and once the cattle reach milking age, they are moved to Jer-Lindy Farms.

While Ratka loves her show cattle,

the show ring is not her only connection to the dairy industry. Both of her parents grew up on dairy farms and now work within the dairy industry. Ratka has also participated in dairy judging

and knowledge bowl through her involvement in 4-H and FFA programs.

As one of the newly named nalists, Ratka spoke of the importance behind having dairy representation available to the consumer.

“I want them to remember the dairy princesses as the friendly face of the dairy industry that they can trust,” she said. “It gives them a personal connection to our industry.”

Ratka said she would be honored to represent Minnesota dairy farmers.

“Princess Kay has the opportunity to connect with such a broad scope of people, both within and outside of the dairy industry,” Ratka said.

As a sophomore at the University of Minnesota-Twin Cities, Ratka is majoring in animal science with an emphasis in dairy production. She said she wants to use her passion for dairy to work in a lab doing research on dairy cattle reproductive technologies.

In addition to her mother, Ratka has other family members who have been crowned within the dairy princess program, including her aunts Karen (Kuechle) Johnson and Janelle (Kuechle) Daberkow.