Miller Broz. Dairy invites WabashaKellogg fourth graders for a tour

By Amy Kyllo amy.k@star-pub.com

KELLOGG, Minn. —

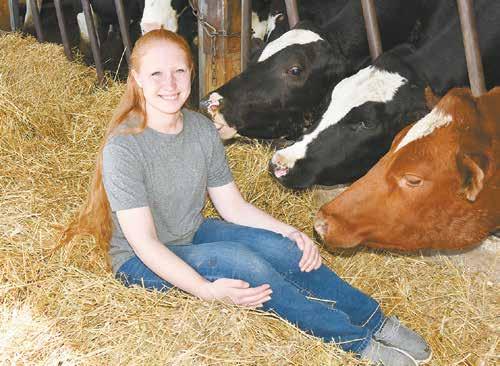

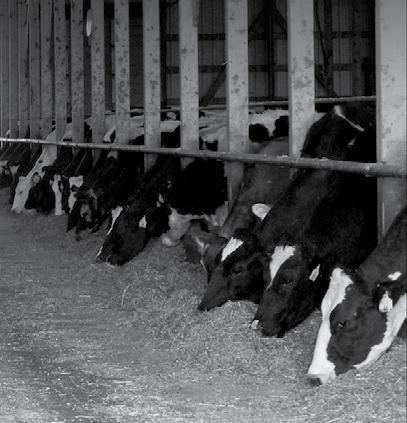

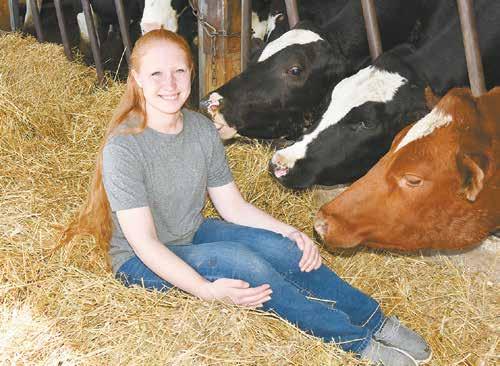

On a sunshiny May afternoon, Miller Broz. Dairy is buzzing with activity. Kids sit in the wheel well of a parked tractor, a young girl wraps her arms around a big, patient Red and White Holstein cow and other youngsters make friends with the calves.

The children are fourthgrade students at WabashaKellogg School District where Brianna (Miller) Baab is a teacher. Baab brought her students and the rest of the fourth grade on a eld trip to visit her home dairy farm.

Miller Broz. Dairy consists of Baab’s parents, Tom and Kay Miller, as well as her twin brother, Bryton Miller, and his wife, Morgan Miller, who farm alongside but separately from their parents. Together, the Millers milk 240 cows on the same property near Kellogg with four Lely robotic milking units, which they began using in January.

Other members of the family — including Austin Baab, Dalon Miller, Carley Miller, Talia Miller and Terrik Miller — are involved on the

Turn to MILLER BROZ. | Page 2

Gone in 60 seconds

An immersive farm experience Blowing

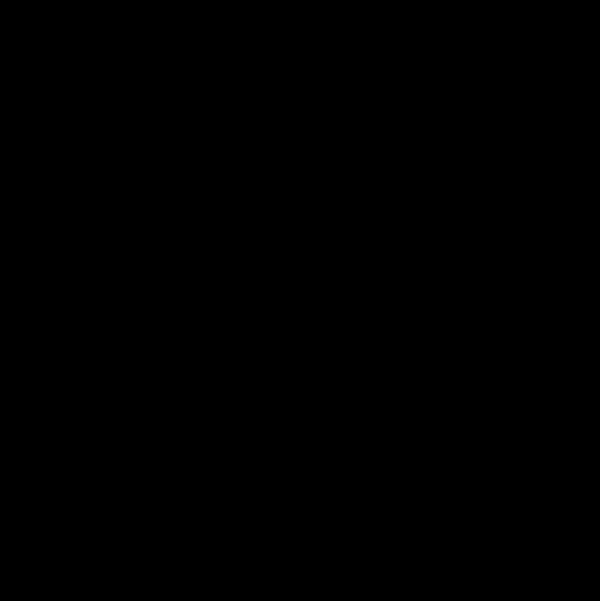

DANIELLE NAUMAN/DAIRY STAR

The remains of the dairy barn lies in Jeff Gajewski’s yard May 25, a�er an EF1 tornado destroyed his farmsite located near Edgar, Wisconsin. A�er the May 21 storm, Gajewski worked with family, friends and neighbors through the night to free his herd of dairy cows.

Gajewski’s dairy farm destroyed in tornado

By Danielle Nauman danielle.n@dairystar.com

EDGAR, Wis. — Jeff Gajewski spent his life building his dairy farm, but in a matter of seconds, it was all destroyed when a tornado ripped through the Marathon County farm May 21.

“Forty-six years, gone,” Gajewski said. “All the years spent building this place, making it what it was, all gone. At least I have pictures of the place.”

The National Weather Service conrmed that an EF1 tornado with maximum wind speeds of 90 mph traveled 3.57 miles. In its path was the Gajewski dairy farm near Edgar.

Turn to STORM DAMAGE | Page 6

June 8, 2024 Volume 26, No. 8 “All dairy, all the time”™ J

through rst crop alfalfa

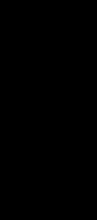

AMY KYLLO/DAIRY STAR

Wabasha-Kellogg School District fourth-grade students listen to nutri�on consultant Barloe Brisson Kanz share about total mixed ra�ons May 14 at Miller Broz. Dairy near Kellogg, Minnesota. The nutri�on sta�on was one of four stops the students made on their farm tour.

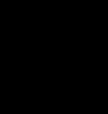

MARK KLAPHAKE/DAIRY STAR

John Fuchs chops rst crop alfalfa for his son, Mike, near his dairy by Lake Henry, Minnesota. Mike Fuchs milks 74 cows in Stearns County.

Sign up for our Newsletter up for our Dairy St r Milk Break Visit dairystar.com to sign up!

DAIRY ST R

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) (Western Wisconsin) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

dairy as well during high labor times such as forage harvest. Tagen Miller has assisted full time in the past but is stepping back now that the farm is adjusting to the robotic milking units.

This was the rst time the Millers hosted a school visit.

“We wanted them to go home and talk to their families about how exciting it was to see the calves and pet the cow,” Kay said. “(We want them to) spread the word and let ... other people enjoy it through them.”

This year, Bryton said their new barn was something different and exciting for the kids to see.

“(We wanted) to get kids out on the farm and show them what it’s all about and where their milk is coming from,” Bryton said.

The Miller farm was the second stop of the day for the school group.

In the morning, they visited Jeremy Holst’s dairy farm near Lake City. Holst milks in a parlor, which gave the students an opportunity to see two different milking systems.

Tom talked about how far removed this generation is from dairy farming.

“When we grew up, everybody grew up on a farm or their grandma and grandpa had a farm,” Tom said. “Most of these (kids) have never been on a farm.”

The kids were split up into four groups to explore four immersive stations.

Wabasha-Kellogg School District fourth-grade students try

14 at Miller Broz. Dairy near Kellogg, Minnesota. The calf area was

calf

of the stops on the tour.

The rst station had a New Holland TG275 tractor where students could take turns sitting in the driver’s seat. The next area held the calves, where students could try bottle feeding. Near the barn, a nutrition consultant, Barloe

Brisson Kanz, showed the students the total mixed ration and talked about other aspects of the diet.

GF 102 & 1002 SERIES | Rotary Tedders 8'6" – 25’7" working widths • mounted & trailed models

DRY WITH THE SPEED OF LIGHT

Woller Equipment Swanville, MN

Miller Sellner Slayton Slayton, MN

Page 2 • Dairy Star • Saturday, June 8, 2024

views

opinions expressed

Dairy Star columnists

writers are not necessarily those

the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. © 2023 Star Publications LLC

and

by

and

of

Con nued from MILLER BROZ. | Page 1 Invest in Quality ® www.kuhn.com Visit your local KUHN Hay & Forage dealer today! Isaacson Sales & Service Lafayette, MN Dave's Repair Farm Equipment Hills, MN Northland Farm Systems Owatonna, MN Bodsensteiner Implement Company Elkader, IA Fluegge's Ag Mora, MN Burco

Dee

Kunau

Sales Independence, IA

Implement Of Waukon Waukon, IA

Implement Company Dewitt, IA Rexco Equipment Farley, IA Greiner Implement Company Ottumwa, IA Helmuth Repair Kalona, IA Beck Implement Elgin, MN

Exclusive DigiDrive ® couplers provide low maintenance and long life Multiple options and adjustments for tedding in various crop conditions Hydraulic folding provides easy Reduce drying time with steep pitch angles and asymmetrical tines

AMY KYLLO/DAIRY STAR

feeding a

May

one

Turn

MILLER BROZ. | Page 5

to

St. Joseph MN

Lansing, IA

For additional

Dairy Star • Saturday, June 8, 2024 • Page 3 Kids Corner: The Lehnertz family Third Section: Pages 10 - 11 Plainview,

Kerndt milks cows from age 10 to 85 Second Section: Pages 22 - 23

stories from our other zone, log on to www.dairystar.com

MN

A day in the life of the Meyer family Second Section: Pages 15 - 17 Grove

Dairy background inuences Hageman’s agriscience research Second Section: Pages 18, 19 New Vienna, IA Columnists Ag Insider Page 10 First Section F Dear County Agent Guy Page 36 First Section Dea Ag P Firs The “Mielke” Market Weekly Pages 8 - 9 Second Section Veterinary Wisdom Page 37 First Section Vet V W Pa P Fir F s From the Zweber Farm Page 38 First Section F Zwe P Firs Country Cooking Page 30 Second Section Co S Corona named nalist for Princess Kay First Section: Pages 23, 25

City, MN

Woitalla looks towards future as a Princess Kay contender First Section: Page 26

Dairy Fest continues to grow First Section: Pages 27, 29 Brookings, SD Avon, MN Walking sustains retired dairy farmer First Section: Pages 32 - 33 Forage Prole: Steve Hoen First Section: Pages 18, 20 Norwood, MN Zone 2 2 Zone 1 What dairy products does your family consume? First Section: Pages 15 -16 FROM OUR SIDE OF THE FENCE:

Holdingford, MN

Page 4 • Dairy Star • Saturday, June 8, 2024 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 Is your IODINE Teat Dip COSTING You More? • Express has 2 germicides • Highly effective under organic load • Great marking • 6 log 15 second kill • Concentrate / Economical Pricing Available in Yellow, Blue and Green! Chlorine dioxide teat dips have a better, faster kill and are more economical! Get ready to start counting additional profits... FAST KILL RESIDUAL KILL DUAL GERMICIDE BARRIER BARRIER 112 has a greater than 99.999% Reduction of Staphylococcus Aureus & E-coli organisms! TONEOFTHESE DEALERS GERM HIGHER ROI! DIP more Cows/gal. 12% Skin Conditioners

Enjoy One Free Single Scoop Udder Brothers’ Ice Cream LANCASTER DATE: Thursday, June 20th • 12pm-2pm RICHLAND CENTER DATE: Tuesday, June 25th • 12pm-2pm If you can not make it to either event, you may redeem your coupon at Udder Brothers’ Restaurant, Boscobel through 6/30/24 Expires 6/30/24. Coupon must be given to vendor in exchange for scoop.

Thank You Dairy Farmers!

The fourth location focused on equipment. Students toured the farm ofce to look at data on the computer, watched cows being milked from the robot room, and then had a chance to climb up on the bulk tank and look inside.

Students nished the day with a snack and a glass of milk.

The robotic dairy barn the students toured is a recent addition for the Millers. Their rst day milking cows in the facility was Jan. 2. The transition to the new robotic setup has been quick.

“Never in my wildest imagination did I think it was going to turn out this nice and be running like this at this point,” Tom said.

Bryton agreed.

“We thought it’d take like two to three years to get to where we’re at,” Bryton said.

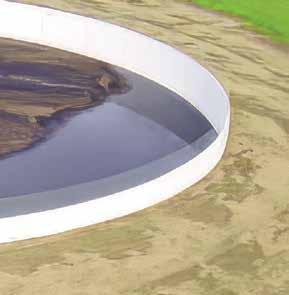

The update included a new freestall barn with the robotic milking units and a lagoon with a storage capacity of nine months.

The project was not an expansion. The barn has two sides, one for Tom and Kay’s cows and one for Bryton and Morgan’s.

“It’s not about getting bigger; it was just (about) maintaining it as a family dairy,” Kay said.

The family broke ground for the project in June 2023, the day Bryton and Morgan were married.

“It was hard to leave here to go to my wedding, knowing that this project was starting,” Bryton said.

The Millers poured the cement for the barn themselves. This was the rst time the Millers had done a cement project of this magnitude, Tom said. In

all, they poured about 863 yards of cement. They even had to form cement by the headlight of their utility terrain vehicle to get the project done.

The decision to update came because their freestall barns were worn out and it was difcult to nd help to milk in the parlor. With the new facility, the Millers have eliminated outside labor.

“We still work ... just as hard as we did before,” Tom said. “The times are more exible (now), and we’re not as tied down.”

Tom said when they had employees in the past, they dealt with employees only showing up when they felt like it.

During the transition, the Millers said, they appreciated the help of friends and neighbors pushing cows through the robotic milking units.

The cows average 2.9 visits to the robots per day and give 82 pounds of milk. Before switching to the robotic milking units, the Millers milked their cows twice a day. With the additional milking, the Millers increased production by about 8-10 pounds of milk per cow.

The Millers said they have seen a change in the demeanor of their cows, which have become friendlier.

“They sleep when they want, they eat when they want and they get milked when they want,” Tom said.

The Millers are content with the project Kay said.

“(We are) 100% happy,” she said. “There are challenges and there’s still a lot of work involved in it, but it is absolutely the right thing for us.”

Dairy Star • Saturday, June 8, 2024 • Page 5 320-836-2145 or 800-450-2145 www.famofeeds.com Check out our newly redesigned website to nd a Famo Feeds dealer near you! At Famo Feeds, we strive to provide the best support for your operation and work to accommodate your specific needs. From calf to cow and everything in between! TRUST THE EXPERTS • Milk Replacers • Starter Feeds • Protein Concentrates • Premixes • Minerals • Animal Health Products • Lick Tubs FEED THEM FAMO!

Con nued from MILLER BROZ. | Page 2

Prior to the storm, Gajewski milked 32 cows in the barn he rebuilt after he purchased the farm in the late 1970s.

“I had planned to sell the cows here in a couple of months, but I didn’t want to go this way,” Gajewski said. “My sons had planned to use the buildings for their beef cattle.”

Gajewski’s barn and two silos took a direct hit from the tornado. Gajewski was emotional talking about it.

“The cows were trapped in the barn, the beams were on top of them,” Gajewski said.

Two cows were killed when the barn collapsed and four additional cows were put down that night, due to the severity of their injuries. The remaining cows were sent to Premier Livestock & Auctions LLC the next morning.

•

•

•

•

“I yelled, ‘Tornado!’ and we took off for the basement,” he said. “We didn’t even get to the basement door and it was over. It was gone so fast.”

The storm left the house largely untouched. Gajewski made his way back outside, dazed, to survey the damage wreaked upon his farm in sheer seconds, only to see his barn lying in a heap.

“The guys that hauled them said they looked great when they got to Premier,” Gajewski said. “They didn’t limp or stumble or anything getting off the trailers. That is really quite remarkable.”

Fifteen youngstock will remain on the farm until he can sell them as springing heifers, Gajewski said.

Gajewski evaded injury himself, having started chores early due to the forecast for severe weather.

“I started early that day because I didn’t want to chance losing power before I got done milking,” Gajewski said. “If I would have been in the barn like I usually would have at that time, I wouldn’t be here today.”

Gajewski said the weather reports made it sound like the brunt of the storm was going to stay south of Highway 29, leaving his farm out of the path of the worst damage.

“I could hear the cows bellering in fear and pain,” Gajewski said.

In short order family, friends and neighbors descended upon the farm, helping Gajewski begin the task of saving his cows.

“News travels so fast,” Gajewski said. “I don’t know where everyone came from, but I am grateful to each person who showed up to help. We worked until about 1:30 a.m., getting the cows out of the barn.”

Gajewski said that the rst night was a sleepless one for him, after extricating the cows from the barn, and the succeeding days have been long.

“The next day I was so dang tired from picking things up, my back and legs were aching,” Gajewski said. “If you think about it, it can really get to you.”

“I started early that day because I didn’t want to chance losing power before I got done milking. If I would have been

I

JEFF GAJEWSKI,

“It was getting dark out to the west, but there was really no lightning or thunder,” Gajewski said. “I went to the house and changed clothes. I came out of the laundry room, and it had started lightning. I told my son to get out of the shower because of the lightning. I went into the kitchen and all of the sudden everything outside was ying — it was like it dropped right on top of us.”

Through the chaos outside, Gajewski yelled for his son again.

I

As the clean-up process continues, Gajewski has thought about how he will proceed. He said he wants to x up the lean-tos for shelter for the animals during the summer months. The roof on the north side of the barn is laying nice and straight, so they are going to save that to x the leantos so they only have to buy twoby-fours. He said depending on how much everything costs, he would like to build a heated room where the milkhouse was, to keep water running during the winter. He would also like to build housing approximately the width of the barn for the youngstock for winter.

“It just bothers me,” he said. “I had everything xed up so nice, and I was so close to selling the cows on my own terms. After all these years, you become attached to it — the farm, the machinery, the land. It’s just the way life goes. All the years I farmed, I had certain setbacks with things. You just pick yourself up and keep going.”

Page 6 • Dairy Star • Saturday, June 8, 2024 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! Keep an eye out for our other June is Dairy Month promotions Dairy Farmers Thank you CAJune1-1B-MT Electronic Dairy Board Repair Service Specializing in: WestfaliaSurge, BouMatic, & DeLaval pulsators & Takeoffs, circuit boards, Mueller milk tank circuit boards. Call: (c) 406-590-7764 www.circuit xer.wixsite.com/ boumaticboardrepair Repair vs. Replace www.dhfieldservices.com D&HFIELD SERVICES, INC . Darrin Herickhoff 320-760-0848

Liquid Manure Handling

Solid Manure Handling

Trucking

Pushing & Packing

Con nued from STORM DAMAGE | Page

1

Martin Ag Supply LLC 3128 Mitchell Line St. Orchard, IA 50460 641-982-4845 2021 JCB 270T Skid Steer 1800 Hours, Cab Heat Air, 2 Speed, Power Detach, New Tracks and Sprockets, Selectable Controls, Air Ride Seat, Radio, Good Bucket, Runs and Drives Great $45,500 Esch hay equipment 4222 22’ working width, 10’11” transport, 540 PTO, hyd tilt / lift, lifetime warranty on arms, Heavy Duty tedder, 22’ works very good w/ 12-14’ windrowers, In Stock $11,200 Esch hay equipment 4218 18’6 working width, 540 PTO, HD drive line for HD use, hyd. fold, hyd. tilt, high tensile arms that have lifetime warranty against bending and breaking. In Stock! $8,900 Montana post driver 750R Working Weight 1380lbs, Flat Tool, 11-18 gal per min, Charge Kit, Nitrogen Bottle, Chain, 2.7” Shaft, A Fence Builders Dream, In Stock $6,800

Jeff Gajewski

at

in the barn like

usually would have

that time,

wouldn’t be here today.”

DAIRY FARMER

Revolutionizing the way dairy

Friendshuh launches FODD 3.0 to market

By Danielle Nauman danielle.n@dairystar.com

AMERY, Wis. — Feeding dairy cattle is possibly the most important, and potentially the most expensive, act on a dairy farm, with little room for error.

Greg Friendshuh has developed a system that he believes could revolutionize feeding dairy cattle.

“This machine is going to have an impact on the lives of many people, on many dair-

ies,” he said. “It will have an impact on the feed industry overall. How honored am I (to be ) the one to steward it forward.”

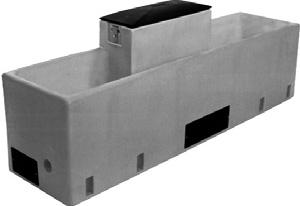

The FODD 3.0 is the newest version of the original prototype that Friendshuh has been developing on his farm for four years.

“This system allows us to separate corn silage into high-starch nes and lowstarch fodder,” Friendshuh said. “That allows us to feed more corn silage, which lowers feed costs and creates

16 at Friendshuh Farms near Amery, Wisconsin. The FODD 3.0 consists of a hopper and a rolling trommel, which can separate 60 tons of silage in ve hours.

more milk, all with less work. The cows don’t have to eat more to make more milk. The FODD helps them be more efcient at making milk.”

Friendshuh milks 1,250 cows near Amery.

The FODD 3.0 has been in use since February. His herd is averaging 107 energycorrected pounds of milk per day, and he is shipping 7.42

pounds of combined fat and protein.

Using the FODD 3.0, the Friendshuhs separate 60 tons of corn silage into nes and fodder daily, a process that takes approximately ve hours.

The nes are used to make the lactating cow ration. Half the fodder produced is fed to the dry cows, and the other

half is fed to the heifers.

“If I had a dairy without youngstock, I would probably sort enough fodder to feed the dry cows and the nes would go to my earlier lactation cows, trying to get their peaks up,” Friendshuh

Dairy Star • Saturday, June 8, 2024 • Page 7 Jct. Hwys. 55 & 23 • Paynesville • 320-243-3736 • 320-243-7544 www.acfarmservice.com Customer Appreciation! Lunch from 11:30 - 1:30Hot Dogs, Brats & Ice Cream A&C Farm Service, Inc. LUNCH ON US! 11:30 am - 1:30 pm Everyone’s Welcome Friday, June 24, 2022 FACTORY REPS WILL BE ON SITE $100 Gift Card Drawing Thursday, June 13, 2024

cows are fed

DANIELLE NAUMAN/DAIRY STAR

Greg Friendshuh shares the story that lead to the crea on of the FODD 3.0 May 16 at Friendshuh Farms near Amery, Wisconsin. The FODD 3.0 separates silage par cles allowing producers to be er u lize the starch in corn silage.

DANIELLE NAUMAN/DAIRY STAR

A pile of silage lies in front of the FODD 3.0 May

Turn to FODD | Page 8

said. “Once they get past about 150 days, you can put them on a corn silage diet, and they would have the capacity to eat enough.”

By feeding fodder to dry cows, Friendshuh has noticed an increase in dry matter intake of over 2 pounds per cow, pre- and post-fresh. That increase benets the cows through the transition period, with less susceptibility to metabolic issues.

“Corn silage is the most consistent feed on the dairy, but it’s really very inconsistent,” Friendshuh said. “With the FODD, you take that corn silage and run it through a process, and pretty soon, you have homogenized corn silage. Cows love that consistency. Eliminating the variables at the bunk has a big impact. They can’t sort anymore. … Our milk has climbed, and our metabolics are nearly perfect.

Friendshuh said he feeds dualpurpose and hybrid varieties of silage rather than brown mid-rib.

Jim Smith, dairy strategic accounts manager for Pioneer, said the end result of a silage harvest can only be as good as the growing season allows it to be.

“Corn silage is great, but once that pile is there, you’ve got to feed

Silage is separated into nes, le , and fodder, right, May 16 by the FODD 3.0’s rolling trommel at Friendshuh Farms near Amery, Wisconsin. Greg Friendshuh feeds the lower starch fodder to dry cows and heifers, reserving the higher starch nes for his lacta ng cows.

it,” Smith said. “If it’s not good corn silage, you’re going to be ghting it all year, and it’s going to get expensive from a cow health standpoint, milk production, feed costs — every-

thing.”

Smith said FODD 3.0 is a tool that can help dairy farmers manage the variability that arises from environmental conditions affecting their

corn silage each year in a way that was not previously available.

The idea for the system was born during a conversation Friendshuh had with his nutritionist, Keith Sather, in 2019.

“Feeding straw was a pain point,” Friendshuh said. “Straw was expensive, hard to nd and when you did nd it, the quality was poor. We started looking for an alternative. How many times do we have bad bales of straw that get chopped up and we don’t even know about it? This eliminates that factor.”

The idea was to separate the particle sizes of corn silage, eliminating the need for straw in the dry cow and heifer diets.

“The FODD today makes my life easy; everything is consistent now,” Sather said. “We are feeding the dry cows and heifers predominantly with the fodder. That was the focus: to get to the point where we didn’t have to feed straw. We’re there now. We accomplished that goal.”

Page 8 • Dairy Star • Saturday, June 8, 2024 320-200-1221 Visit us at www.justinaddy.com Avon, MN Covering MN, SD, IA, & WI Drink Milk Graduate of the Dairyland Hoof Care Institute Proud member of We do wide grooving and mini grooving Help keep your cows safe. Hoof trimming since 2003 WE OFFER COMPLIMENTARY: UDDER SINGEING TAIL TRIMMING Keep your cows cleaner, healthier & save time! CALL FOR ALL YOUR CONCRETE GROOVING NEEDS June is Dairy Month! Thank you farmers Blue Hilltop, Inc. Dana Berreau 507-879-3593 / 800-821-7092 Box 116, Lake Wilson, MN 56151 Your Mixer, Spreader, Hay Processor Headquarters We carry:

Con nued from FODD | Page 7

DANIELLE NAUMAN/DAIRY STAR

Got something to sell? Try the Classieds.

Turn

to FODD | Page 9

By being able to manipulate the amount of starch available through the nes and the fodder, Sather said the result is a healthier diet for all animals on the farm.

“We have taken corn silage that was 32% starch and we’re feeding the cows with nes that are 37%-38% starch, so we can have more forage and less concentrate going into the diet,” Sather said. “The nes make an awesome lactating feed, and we’re seeing a fast track to peak milk.”

The FODD allows dairy farmers to improve upon their corn silage crop, no matter how good or bad it might be.

“Where I would love to have a FODD machine to work with is a year like last year when we had really tough weather in the area and I am feeding a silage that is 28% starch,” Sather said. “If I had a FODD machine, I could boost the starch content of that corn silage, and it would make feeding those cows much easier.”

Between decreased feed costs and increased production, the FODD 3.0 could help the bottom line of a dairy farm, said Tim Swenson, of Swenson Management Service LLC.

“This could be a real game-changer,” Swenson said. “The average net income per cow in Wisconsin

and Minnesota is about $350 per cow. If we can add another $200 per cow, we’ve changed that prot level substantially.”

Friendshuh estimates feed savings on-farm to be $175 per cow, based on how his ration using the FODD compares to prior rations. On the conservative side, he estimates production to be up over 2 pounds per cow per day. He estimates the payback

DANIELLE

The hopper of the FODD 3.0 is loaded with corn silage May 16 at Friendshuh Farms near Amery, Wisconsin. Greg Friendshuh began working to create a system to be er ulize his corn silage in 2019.

on the installation of a FODD 3.0 to be under two years, depending on herd size.

“I get excited about this system; it has simplied our dairy, streamlined our operations and made it a more robust system,” Friendshuh said. “This has the potential to change our industry by how we feed our cattle. … It is going to have an impact on good and average corn silage, but the greatest impact will be

Dairy Star • Saturday, June 8, 2024 • Page 9 THE NATION’S LEADER IN AGRICULTURAL CONCRETE (920) 948-9661 | www.pippingconcrete.com dennis@pippingconcrete.com 37+ years in business | U.S. Navy Veteran owned dennis@pippingconcrete.com

Con nued from FODD | Page 8

NAUMAN/DAIRY STAR

(Below) A pile of nes collects beneath the rolling trommel of the FODD 3.0 May 16 at Friendshuh Farms near Amery, Wisconsin. The ne par cles provide lacta ng cows with more energy.

TOOTHSOME

Feed quality fit for a king! Discover KP Rolls that crank out the goods. Good feed. Good money.

Another dairy farmworker contracts H5N1

H5N1 has been conrmed in a third farmworker. This is the second human case in Michigan and is part of the multistate outbreak in dairy cattle. This individual had minor respiratory issues and was treated with antiviral medication. The Centers for Disease Control and Prevention advises dairy farmworkers to use personal protective equipment as a biosecurity precaution. The virus has been identied in 66 dairy herds in nine states.

Testing identies H5N1 in one meat sample

The U.S. Department of Agriculture’s Food Safety and Inspection Service reports H5N1 has been conrmed in meat tissue from one dairy cow. Tests were conducted on 96 dairy cull cows; 95 cows tested negative. USDA emphasized none of the meat from any of these dairy cattle entered the food supply. Consumers are reminded to cook meat to the proper temperature.

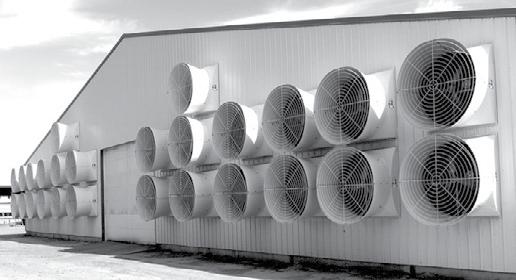

55” Panel Fans

to start to build a bipartisan coalition that can get this bill through the oor of the House. There are a lot of Republicans that are going to vote against this on the oor, so we’re going to need 20, 30 Democrats at least to get this bill passed.”

By Don Wick Columnist Ag Insider

Working out the funding gap

USDA launches pilot program to protect animal ag sector

Agriculture Secretary Tom Vilsack has approved an additional $824 million in emergency funding to respond to H5N1 in the U.S. dairy herd. The money will launch a new voluntary pilot program to give dairy farmers more options to monitor the health of their herds. The money will be used to support additional surveillance and testing. Farmers who enroll in this program and demonstrate their herd is free of the virus will be able to ship their cows without testing individual animals. USDA is now identifying states that will be part of this pilot program.

Stockpiling vaccine

The House Committee on Agriculture bill suspends Section 5 of the Commodity Credit Corporation Act, limiting the agriculture secretary’s authority to use CCC funds. Chairman Glenn “GT” Thompson plans to use those savings to increase reference prices. The Congressional Budget Ofce has disagreed with the Grand Old Party staff about those budget savings. Minnesota Representative Michelle Fischbach is a member of the Budget Committee, working to ensure the CBO scores are accurate. “There are issues with some of the CBO scores because we need to make sure that we’re paying for everything great that we’ve done in the farm bill, and so we’re working with CBO to make sure that they understand how things need to be scored so we can pay for that bill.”

SD continues to add to its dairy herd

April milk production totaled 19 billion pounds nationwide. That’s down 0.4% from one year ago. In South Dakota, milk production rose 12.3% with the addition of 23,000 cows. Minnesota milk output was down a fraction of 1% with cow numbers dropping 8,000 head.

Increased protability for water quality-certied farms

The U.S. is taking steps to acquire vaccines to protect at-risk poultry and dairy workers. Veterinarians and lab technicians could be eligible for H5N1 vaccines. The move is seen as a way to limit the threat of a pandemic. The CDC said the decision to use vaccines will depend on reports of more cases or the severity or mutations of the virus. Other governments are also considering plans to stockpile vaccines.

House Ag Committee passes farm bill

Farmers in the Minnesota Agricultural Water Quality Certication Program have higher prots than non-certied farms. AgCentric Executive Director Keith Olander attributed the protability to their management characteristics. “We have over 100 producers that are agricultural water quality-certied that span the state of Minnesota, and they are also part of farm business development,” he said. “We have developed a ve-year run of the economics of those producers. They are outperforming their peers on a regular basis.”

Certied farms had an average net cash income of nearly $214,000 compared to $163,000 for noncertied farms. Certied farms also had better debtto-asset and operating expense ratios.

BWSR grant funds available

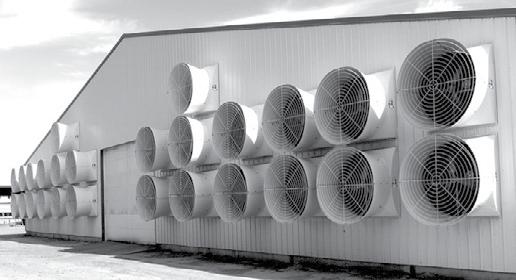

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

In a marathon hearing that started at 11 a.m. and wrapped up after midnight, the House Agriculture Committee passed the farm bill on a 33-21 vote. All 29 Republican members of the committee and four Democrats voted for the farm bill. There was a fair amount of partisanship during the debate over spending priorities and the nutrition title. House Committee on Agriculture Chair Glenn “GT” Thompson defended his work. “I’ve had no alternative solutions for funding submitted from the Democratic side of the aisle other than the $5 billion on the Senate side, so my door is open and I am more than happy to work,” Thompson said. “The only reason the pay-fors have not been bipartisan is because, quite frankly, the Democratic Party hasn’t been at the table. Please come to the table, or we’re not going to see all these great new innovations.”

“Pay-fors” are items that would be used to offset the cost of other farm priorities. In a statement after the vote, Ranking Member David Scott said the bill may have advanced out of the committee, but it will not have the votes needed when it comes to the House oor.

Collin Peterson, farm bill optimism

Former House Committee on Agriculture Chair Collin Peterson sees a path forward for the farm provisions of the bill. “The way the debate happened did not put anybody into any corners that they couldn’t get out of,” Peterson said. “Most of the divisiveness was over how to pay for this. It was over food stamps. It was over the sideboards on conservation. It was over the Commodity Credit Corporation. Those are things I think can be worked out.”

It will likely be September before this bill advances to the House oor. Peterson, who now leads the Midwest Council on Agriculture, said more work will happen ahead of that vote. “The fact that we got four Democrats that voted for the bill gives us a place

The Minnesota Board of Water and Soil Resources is providing $6.4 million to soil and water conservation districts to support soil health projects. The Soil and Water Conservation Districts can request funding through July 2. The money can be used to help landowners implement conservation practices or for outreach and education projects.

First-in-class methane reducing feed Ingredient gets FDA approval

For the rst time, the Food and Drug Administration has approved a feed ingredient for dairy cattle that will reduce methane emissions. Elanco Animal Health already has approval for Bovaer in Canada and Mexico. This product suppresses the enzyme in the cow’s rumen that forms methane. One tablespoon of Bovaer per lactating dairy cow per day can reduce methane emissions by 30% per year.

Trivia challenge

National Milk Month, which was the precursor for June Dairy Month, began in 1937. That answers our last trivia question. For this week’s trivia, when is National Ice Cream Day? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Page 10 • Dairy Star • Saturday, June 8, 2024

717.844.9069 | New Holland, PA

133 Atlantic Ave. NE • Pennock, MN 320-599-4466 NEW High Pressure Fog Ring Now Available

Minnesota dairy herds with low SCC

Minnesota Agriculture Commissioner

Thom Petersen released the annual list of top Minnesota dairy herds with low somatic cell counts. Somatic cell count is a key indicator of milk quality – a lower SCC count is better for cheese production and a longer shelf life for bottled milk.

In honor of National Dairy Month, 93 Minnesota dairy farms are being recognized for their superior herd management skills by achieving an average SCC of under 100,000.

“I’m honored to recognize these dairies for their dedication to quality and excellence,” Petersen said. “Minnesota’s dairy farmers provide the state and the world with high quality, wholesome dairy products for us all to enjoy.”

Although somatic cells occur

naturally and are not a food safety concern, dairy farmers monitor them because they can be used as a measure of the health of their cows. Processors also pay a premium for milk with low counts. A farmer whose herd has a very low count can receive a higher price per hundredweight compared to a farmer whose herd average is high.

Minnesota Department of Agriculture and University of Minnesota dairy experts have worked with the state’s dairy farmers for 20 years to lower somatic cell counts. When the initiative began in 2003, the herds honored that year included those with SCC averages as high as 144,000, compared to the current goal of obtaining a SCC under 100,000.

Producer County

Harmony Hills Dairy, LLC

Kent Happke

Dennis and Wayne Wolters

Joe and Kim Engelmeyer

Hendel Farms

Kimm’s Dairy (Brian)

Carver

Benton

Morrison

Stearns

Houston

Ottertail Hoefs’ Dairy LLC

Alan and Jessica Klimek

LeSueur

Douglas Selke Farms

Robert, Terri, & Mike Ketchum

Tim & Julie Bruder

Magedanz-Foreview Dairy LLC

Maynard & Jeremiah Schumacher

Lax-Pietig Dairy LLC

Houdek Dairy LLC

Winona

Winona

Todd

Stearns

Wabasha

Renville

Houston

Dairy Star • Saturday, June 8, 2024 • Page 11 320-808-3936 300 E Main St. Osakis, MN 320-859-5340 Visit us online at www.osakissilo.com 24 Hours 7 Days A Week Call Anytime The Best Service Crews, The Best Replacement Parts, The Best Service... That’s The Osakis Silo Advantage To You!!! EVERYTHING SILO CALL TO SCHEDULE YOUR PROJECTS TODAY!

Turn to SCC | Page 12 Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org DHIA: Now MORE than ever Minnesota DHIA would like to salute dairy producers for producing a quality product and thank the industry professionals that provide support and encouragement to our customers! Dairy Producers! Thank you Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere Guess where your feed dollars are going? Our soybeans have the energy, protein, amino acids and bypass protein for your cows! Incorrectly roasted soybeans?

Producer County

Mark and Marcus Klehr

D & D Dairy LLP

Hammell Dairy Inc.

Pine-Vue Farms

Matt & Tony Berktold

Scott

Winona

Houston

Winona

Wabasha

Dean and Elizabeth Johnson Cottonwood

Edward and Mary Warmkagathje Olmsted

Kevin Hanson

Mark Flicker Morrison

Youngren Dairy Farms Inc.

Colleen Berscheit

Schulte Farms of Caledonia LLC

Eugene and JoAnn Hartung

Scott & Michelle Herber

Kandiyohi

Brown

Houston

Stearns

Winona

Randy H. and Kathleen J. Bauer Rice

Wirtland Holsteins

Producer County

Overdale Dairy Inc.

Nietfeld Family Farms LLC -

Stearns

Ashley & Cory Nietfeld Stearns

Tatge Dairy LLC Rice

Fussy Farm LLC

Morrison

Naatz Dairy Farm Dodge

Michael Menze Ottertail

Jeff Beckman Goodhue

Roger Aldinger Winona

Sandra Erickson Sherburne

Dev-Lin Holsteins LLC

Robin Winscher

Bob & Kaylie Gruber

Schefers Bros. LLC

Winona

Lloyd Blommel Todd

Reuter Farms

Bill Miller Wabasha

Paul and Bonnie Middendorf Todd

Barkeim Farms LLC

Duane Burke

James & Mary Evans

Sunny Side Dairy

Knisley Dairy Inc.

Robert Hinsch

Chad Waltman

Funks Midway Dairy

North Creek Dairy LLC

Cory & Jenna Middendorf

Trailside Holsteins LLC

Kraig and Rachelle Krienke

DNA Farms Inc.

Houston

Morrison

Morrison

Stearns

Ladies First Dairy Stearns

D & L Johnson Dairy Farm LLC

Shawn & Sarah Winscher

Winona

Otter Tail

Pipestone

Hennepin

Stearns

Goodhue

Morrison

Stearns

Olmsted

Stearns

Fillmore

McLeod

Chisago

Darin & Brierly Grimsgard Meeker

Steve and Lori Dockendorf

Winona

Morrison

Dollymount Traverse

Kelly Felling

Scott & Denise Gathje

Walter Bros Dairy Inc

Zweber Farms, LLC

Stearns

Stearns

Red Lake

Scott

Bechtold Brothers LLC Stearns

Francis Rynda LeSueur

Christoper & Jessie Lee

Peter Mark Hendrickson

Meeker

Todd

Riverview LLP - West Dublin Swift

Jeff & Austin Middendorf Stearns

Rolling Ridge Acres Inc.

R and R Farms

Randal and LouAnn Wagner

Sorg Dairy LLC

Stearns

Valley Acres Dairy LLC Winona

Keith & Jennifer Middendorf Todd

Marshall and Melanie Korn

Kandiyohi

Winona

Scott

Rice

Dakota

Barfnecht Farm LLC Carver

Suzanne & Tim Jacobs Otter Tail

Kevin Virchow

New Heights Dairy LLC

Waukon Dairy

D & D Dairy LLP

Freeborn

Morrison

Norman

Winona

Page 12 • Dairy Star • Saturday, June 8, 2024

Polk

Dakota

Con nued from SCC | Page 11

Questions answered lead to more questions

Researchers continue to dig for answers to stop spread of HPAI

By Danielle Nauman danielle.n@dairystar.com

As the number of dairy farms with conrmed cases of Highly Pathogenic Avian Inuenze H5N1 continues to climb, so do the questions about how the disease is the spreading. Vigilant biosecurity continues to be the best answer for its prevention.

As of June 5, there were 82 herds in nine states — Colorado, Idaho, Kansas, Michigan, New Mexico, North Carolina, Ohio, South Dakota and Texas — with conrmed positive cases of H5N1. Three dairy farm workers — two in Michigan and one in Texas — have tested positive for the virus following exposure to infected cows. The third individual is the rst human to report more typical symptoms of acute respiratory illness associated with inuenza, according to the Centers for Disease Control and Prevention.

Dr. Kammy Johnson, a eld epidemiologist with U.S. Department of Agriculture’s Animal and Plant Health Inspection Service, shared in a May 23 webinar hosted by the National Milk Producers Federation.

“We have seen the spread of H5N1 between states that was potentiated by cattle movement and now we have evidence of local spread between dairy farms in some states,” Johnson said. “Spread between dairy farms is likely multi-factorial. There is nothing really conclusive, so biosecurity becomes the key to mitigating the risk of spread between farms.”

As a response to risk mitigation, May 10, the USDA announced funding to help farmers dealing with conrmed cases of H5N1 to increase biosecurity measures, provide personal protective equipment for themselves and workers, properly dispose of discarded milk and help with covering veterinarian and testing costs associated with the virus.

On May 23, the USDA announced expansion of some programs to include all dairy farmers. Unaffected producers may receive up to $1,500 per premise to develop and implement biosecurity plans based on existing secure milk supply plans. This includes enhanced biosecurity protocols for industry workers frequenting multiple dairy farms. A $100 payment will be provided to dairy farmers who purchase and use an inline sampler for their milking system.

Up to $2,000 per premise will be reimbursed for costs associated with collecting samples for testing performed beginning April 29, in accordance with the Federal Order. The cost to ship samples will be reimbursed as well up to $50 per shipment for two shipments per month.

Information will be forthcoming about compensation available to dairy farmers to offset lost milk production due to the virus.

Dr. Tavis Anderson, a member of the virus and prion research unit with the USDA’s National Animal Disease Center in Ames, Iowa, shared in the NMPF webinar about how the virus initially infected dairy cattle and how it is spreading among dairy cattle and into other species.

“Inuenza A virus is relatively short, with just eight gene segments,” Anderson said. “It’s an RNA virus and doesn’t have any proofreading when it replicates, so it can accrue mutations in the genome rapidly. Within an individual animal you can get co-infection, and those two viruses can exchange genetic components. What emerges is a Frankenstein virus in a process known as reassortment and we call that antigenic

shift.”

Anderson explained that a surveillance structure exists for monitoring H5 viruses in other species, and that infrastructure was easily deployed as researchers began trying to unravel how H5N1 found its way into dairy cattle. He said their rst question was whether it was a single spillover.

“Did it come from a person, a pig?” Anderson said. “Was it out there in wild bird origins? Once into dairy cattle, was it multiple times? This is the unknown right now. There is a lot of active research trying to understand if dairy cattle are going to be plugged into the general inuenza ecology or remain an unusual host event.”

Anderson said that all data of anything infected with H5 inuenza over the past four years is being compared to over 220 inuenza viruses isolated in dairy cattle from March through the end of April.

“One of the silver linings here is that it was a single spillover rather than multiple wild bird viruses getting into dairy cattle,” Anderson said. “We were able to date when that happened – approximately the end of December, give or take a couple weeks. That means there was essentially relatively limited local transmission, and (it) sort of bubbled away in dairy cattle for a couple of months, to that time and place where it spread relatively rapidly and was able to be noticed by producers and veterinarians in 2024.”

Anderson said he and his fellow researchers wondered whether there was anything unique about this virus that may have facilitated the interspecies transmission.

“All of the mammalian detections of H5 over the last four years have reected what was circulating in wild birds, with viruses spilling over into mammals, then dead-ending,” Anderson said.

He said this process has happened over 100 times in the last four years, across 20 mammalian species. What was unique in this case he said was that there was a rarely detected virus out there in wild birds that had reassorted and accrued two different gene segments.

“That really rare virus is the one that got into dairy cattle,” Anderson said. “It truly was a very rare event, and it was that reassortment just prior to spillover at the end of 2023 that seems to have changed the phenotype of the virus, prior to it getting into dairy cattle.”

Anderson shared how it went from a single, conrmed case to hundreds.

“Animals are moved in modern agriculture, and unfortunately if they are infected with a virus, that virus is moved as well,” Anderson said. “Animals without any overt clinical symptoms were moved from Texas. That initial movement seeded three distinct epidemiological clusters; within those distinct clusters you can see movement across state boundaries and within locations as well.”

Anderson said concern remains that the virus found in dairy cattle may be evolving into something slightly different from that initial spillover from wild birds. More than 10 transmissions from cattle to other species such as poultry, cats, birds and other peridomestic animals such as raccoons have occurred.

“Additional experimentation is required to understand what is driving that transmission, whether it is people, shared water, food or contaminated surfaces,” Anderson said. “The more virus that is out there, the more probable you are to detect these interspecies transmission events.”

Anderson said that while the virus is moving from cattle to other species, there does not appear to be major changes going on in the virus at this time.

“The longer this persists in dairy cattle, the more potential there is for these types of mutations to emerge, and then sweep through that population,” Anderson said.

Sparta,WIJune11,2024 11:00AM-2:00PM

AlmaCenter,WIJune12,2024 11:00AM-2:00PM

LunchProvided TransportationAvailable

Registration 10:30 am -11:00 am

Managing Grain Intake in Pre-weaned Calves

- Dave Lindevig , Dairy Nutritionist Vaccines and Antibiotic Usage in Calves

- Dr. Luke Trapp & Dr. John Borzillo

Profitability in Calf Raising

- Jake Rupert

Dairy Star • Saturday, June 8, 2024 • Page 13 THAT'S THE HIXWOOD DIFFERENCE Quality craftsmanship. Outstanding service. Find the right post-frame solution for your business or operation from Hixwood. Give us a call or visit us online today. 715-644-0765 | HIXWOOD.COM June2024Calf Workshop

Hosted by:

RegisterbyQRCodeorby Phone(608)-269-1515 Hosted by: RegisterbyQRCodeorby Phone(608)-269-1515

LunchProvided TransportationAvailable

Page 14 • Dairy Star • Saturday, June 8, 2024 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH Happy June Dairy Month! Thank you Dairy Farmers! In Stock SPREADERS Call for availability Parts In Stock Penta 6730 6730 Parts in Stock! Many Different Sizes In Stock Parts In Stock HYDRA-SPREAD In Stock WE ARE YOUR TRIOLIET DEALER! In Stock Steerable Series Spreaders Steerable Series Spreade LIQUID MANURE TANKS NEW SUSPENSION OPTION ONTACT DAN OR RANDY FOR MORE INFO! Parts In Stock In Stock SAVE TIME & MONEY! AGRI-CHOPPER Parts In Stock SUPERCART ANY BALE, ANY CONDITION! 7800 Series Bale Processors Parts In Stock Flat, Frozen, Wet, Hard or Soft, no problem, no matter what condition ECORN ers e n ck ART AN CON M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com

from our side our side OF THE FENCE THE

What dairy products does your family consume?

Amelia (front, from left) and Mallory; (back, from left) Kim, Gavin and Andy Olson

Lewiston, Minnesota

Winona County

150 cows

What dairy products does your family consume within a week? We go through approximately 4-5 gallons of milk per week, along with 2-3 large tubs of yogurt, 4-5 pounds of shredded cheese, and a variety of cheese sticks, Go-Gurts and ice cream.

What is your favorite meal to make that incorporates dairy products? Lasagna with cheesy garlic bread is always a great comfort food, and the kids love anything with cheese!

What is your favorite dairy product to splurge on? Ice Cream — the kids love to make special ice cream sundaes with sprinkles, chocolate and caramel.

What is one way you help promote dairy products? By using dairy in our everyday life. Whenever we have a family or friend gathering, we always bring dishes made with cheese and make sure we always have white and chocolate milk to share at our parties.

What is a memory you have of enjoying dairy products as a family or from your childhood? One of Jeremy’s favorite memories growing up was the promise of ice cream or Dairy Queen after a long day of picking rocks or making hay. It is something we have tried to carry on with our kids as well. The reward is always that much sweeter when you have really worked for it.

If you had to put together a dairy promotion, what would it be and how would you implement it? We would advertise that dairy comes from loving, caring farms just like ours. We care about our farm and our animals, and we take pride in what we produce. Milk from the stores comes from families just like ours, and we are proud to feed the world.

Tell us about your farm. We are partnered with Jeremy’s parents, Paul and Bonnie Middendorf. The farm has been in the family since 1974. Paul and Bonnie started milking there in 1982 and raised their family along with growing the farm. Jeremy and I moved to the farm in the fall of 2016. We are lucky to be farming alongside Paul and Bonnie and learning from their wisdom and experience. It has been a blessing to be able to raise our children the same way that Jeremy grew up. I love that our children will have the memories and experiences growing up on the farm that will stick with them for their whole lives.

What dairy products does your family consume within a week? We drink a lot of milk. How much we drink in a week depends on if we have cookies in the house to dunk in milk. If we do, then we go through a lot more. We also eat quite a bit of cheese. Andy and Gavin like ice cream, Kim and Mallory like sour cream and Amelia likes yogurt and ker.

What is your favorite meal to make that incorporates dairy products? A favorite meal in our house is a taco skillet made with ground beef, cut-up tortillas, tomato soup, salsa, black beans and a layer of melted cheese on the top. It is best served with shredded lettuce and a big dollop of sour cream on top.

What is your favorite dairy product to splurge on? For a treat, we like to go out for ice cream as a family. We also enjoy ordering cheese curds if we go out to eat.

What is one way you help promote dairy products? We try to talk to consumers when we can and have done the “adopt a classroom” program where we talk with kids about the importance of dairy in their diet.

What is a memory you have of enjoying dairy products as a family or from your childhood? When our kids were younger, we would visit a family in Wisconsin every Fourth of July, and we would stop in Nelson, Wisconsin, and get ice cream cones for breakfast.

If you had to put together a dairy promotion, what would it be and how would you implement it? We used to sell milk to a place that would give the dairy farmers coupons for products from the co-op to hand out to others. I loved this idea and would hand them out in the dairy section at the grocery store. This was a way to connect with the consumers and promote our dairy products. The consumer was able to see exactly who they were supporting by buying that product.

Tell us about your farm. We own and operate Prime Pastures Organic Dairy along with Kim’s parents, Dale and Carmene Pangrac, near Lewiston, Minnesota. Our three children help out too. We use two Lely robotic milking units to milk around 150 cows and Lely Grazeway sort gates to rotationally graze them. We ship our milk to Westby Cooperative Creamery in Westby, Wisconsin.

What dairy products does your family consume within a week? We eat cheese, cottage cheese, milk, yogurt, sour cream, ice cream, butter and more cheese!

What is your favorite meal to make that incorporates dairy products? We eat dairy products at every meal and on everything. This includes lots of hamburgers, tacos, haystacks and loaded baked potatoes.

What is your favorite dairy product to splurge on? I like ice cream, and Kevin loves blue cheese.

What is one way you help promote dairy products? We run the Lyon County dairy booth at the Lyon County Fair. We also give out cheese to off-the-farm friends and encourage people to enjoy it.

What is a memory you have of enjoying dairy products as a family or from your childhood? Going out for ice cream whenever possible is an enjoyable memory for the whole family. We all enjoy serving ice cream at the Lyon County Fair.

If you had to put together a dairy promotion, what would it be and how would you implement it? I would like to promote uid milk and the benets thereof. I would go into schools and change cartons to plastic and get whole milk versus fat-free so that everyone can enjoy the great taste and benets of full-fat milk. I would do this along with educating the consumer on the care that American dairy farmers have for their cows.

Tell us about your farm. We milk 150 registered Jersey cows (and a few registered Holsteins) in a 95-cow tiestall barn. We, Kevin and Cari, along with our children, Nathan, 21, who recently graduated as a diesel mechanic from Southeast Technical College, but works as an auto mechanic; Tara, 19, who is studying sonography at Southeast Technical College and works as a transport tech at Avera hospital; Angie, 18, who works as a nanny; along with Erica, 15, and Logan, 13, work on the farm alongside their other professions and are the majority of the workforce. We also have a few part-time employees. We raise all of our replacement heifers and sell our beef crossbred and bull calves at birth. We grow our silage and purchase most of our hay. Our milk goes to Associated Milk Producers Inc.

Ryder (front, from left) and Tate; (back, from left) Hope, Emma, Harper and Jeremy Middendorf Browerville, Minnesota Todd County 70 cows

Ryder (front, from left) and Tate; (back, from left) Hope, Emma, Harper and Jeremy Middendorf Browerville, Minnesota Todd County 70 cows

Dairy Star • Saturday, June 8, 2024 • Page 15 Turn to OUR SIDE | Page 16

www.norbco.com 67962 State Hwy 55, Watkins, MN 55389 • 320-764-5000 MA KING COW COMFORT OUR PRIORITY Curtain SystemsVentilation SystemsFreestall SystemsHeadlocks

Kevin and Cari Knapp Larchwood, Iowa Lyon County 150 cows

Jacob (front, from left) and Olivia; (back, from left) Monica, Bradley and Brian Postville, Iowa

Allamakee County

130 cows

What dairy products does your family consume within a week? We consume a lot of dairy products: 8 gallons of milk, 12 1-serving containers of yogurt, 2 pounds of cheese, 8 ounces of sour cream, 48 ounces of cottage cheese, 1 gallon of ice cream and miscellaneous other dairy products.

What is your favorite meal to make that incorporates dairy products? Homemade macaroni and cheese. We basically top all of our meals with cheese. We also love lasagna.

What is your favorite dairy product to splurge on? Ice cream. We love to have ice cream at home, and we like to treat ourselves to ice cream from WW Homestead Dairy in Waukon, Iowa.

What is one way you help promote dairy products? I love sharing our story online. I recently started a Facebook page and have been sharing our farm on there and on my personal page. It is important to share our story with others to show others how we care for the land and the animals. I also share our favorite dairy products and recipes as well as tips and facts about farming. It is my hope to connect others a little better

Anna

Stearns County 70 Cows

What dairy products does your family consume within a week? We consume approximately 10 gallons of milk per week for cooking and drinking, 2-3 pounds of butter for baking and eating, 1 pound of cheese and a 1/2-gallon of ice cream or yogurt.

What is your favorite meal to make that incorporates dairy products? Homemade mufns and milk for breakfast.

What is your favorite dairy product to splurge on? Ice cream.

What is one way you help promote dairy products? We serve milk at every family meal gathering.

What is a memory you have of enjoying dairy products as a family or from your childhood? Going to Hemker Zoo and getting ice cream afterwards at Oak Station in Freeport, Minnesota.

If you had to put together a dairy promotion, what would it be and how would you implement it? A newspaper ad with Holstein, Jersey, Brown Swiss, Guernsey and Ayrshire cows drinking milk.

Tell us about your farm. We’re a third-generation family farm. Everyone is involved in some way or another. We milk 70 cows in a tiestall barn and raise all our replacement heifers. We graze and grow all our feed on 300 acres. Our milk is shipped through Green Acres Organic Coop. We also have a variety of other animals for the kids.

with their food and give people a place to ask questions and learn more about where their food comes from.

What is a memory you have of enjoying dairy products as a family or from your childhood? Monica: I will forever remember the days of promoting the dairy industry as a patron of Wisconsin Dairies. My family and a few others spent many summer parades promoting the dairy industry, handing out cheese sticks. We got to have the rst of the cheese sticks and had a ton of fun doing it. Many times, after parades, we got to enjoy an ice cream treat for our hard work. As a family, we like to support the dairy stands at fairs and the state fair. We like to see what products they are offering and what kind of ice cream they sell.

If you had to put together a dairy promotion, what would it be and how would you implement it? One thing we are working on in our county this year is sharing more about the dairy farmers in our county. On Facebook, you can nd Allamakee County Dairy Royalty and Dairy Promotion. Our princess will be sharing stories from dairy farmers to introduce dairy farmers to others in our area. It is our hope that these stories will not only reach our county but far beyond to show anyone who sees it the hard work dairy farmers are doing to get them a good, quality product.

Tell us about your farm. Enyart Dairy is a fourth-generation farm owned and operated by Brian and Monica Enyart of Postville, Iowa. We have been farming together for the past 18 years and were both raised on dairy farms in Allamakee County. We have three children, Olivia, Bradley and Jacob, who are active and help regularly on the farm. We milk 130 cows and raise all replacement heifers on the farm. We also farm approximately 750 acres of corn, soybeans and alfalfa, allowing us to raise all our feed. We have a double-8 parallel parlor with a 130-cow freestall barn. We ship our milk to Wapsie Valley Creamery Inc. where it is made into cheese and sold privately to companies.

Krysten (front, from left), Maija, Claire and Lauren; (back, from left) Avery, Jamin, Callie and Gina Aho Frazee, Minnesota Becker County 500 cows

What dairy products does your family consume within a week? We usually drink around 6-7 gallons of milk along with homemade yogurt — a gallon a week if I had it. We also eat lots of cheese and butter.

What is your favorite meal to make that incorporates dairy products? Breakfast. I make a big breakfast every morning that usually includes milk and cheese. We eat cereal with milk or yogurt every morning. I make pancakes or wafes or pannukakku (Finnish pancake) every Saturday morning.

What is your favorite dairy product to splurge on? We love to go out for ice cream.

What is one way you help promote dairy products? I use them to make goodies and food for myself and others. I always recommend Bongards cheese to others in the area.

What is a memory you have of enjoying dairy products as a family or from your childhood? While growing up, we used to go out and get hard ice cream as a family. Good memories.

If you had to put together a dairy promotion, what would it be and how would you implement it? It would include something about how food and people create memories that last a lifetime.

Tell us about your farm. We are in a partnership on a 500-cow dairy. We have around nine employees along with our own children who milk on the farm. We milk twice a day in a double-12 parlor. We sell our milk to Lakes Area Cooperative who then sells it to Bongards to be made into cheese. We also raise our own feed for the cows. We are the fourth generation on this farm.

(front); (middle, from left) Irene, Henry, Marie, John; (back, from left) Irvin, Becky and Josh Wolbeck Sauk Centre, Minnesota

(front); (middle, from left) Irene, Henry, Marie, John; (back, from left) Irvin, Becky and Josh Wolbeck Sauk Centre, Minnesota

Page 16 • Dairy Star • Saturday, June 8, 2024 Con nued from OUR SIDE | Page 15 Your Leading Supplier of Manure Handling Equipment in Southern Minnesota Your Yo FEATURING OUR CUSTOM DESIGNED, QUALITY BUILT, AND FASTEST OFFLOADING TANKER TRAILERS IN THE INDUSTRY. We are also a proud dealer of: Give Joey Burns a call: 507-461-0038 Email: parts@bosssupplyinc.com 414 South Main St. Janesville, MN 56048 We are also Give Joe Email: part s 414 South Now Introducing our new line of replacement parts compatible with Houle & GEA Liquid Manure Equipment! *Parts are not OEM, manufactured, or aff iliated with Houle/GEA* WWW.BOSS- S UPPLY.COM SEEOUR INVENTORY

Dairy Star • Saturday, June 8, 2024 • Page 17 JOIN OUR TEAM Now Hiring Service Technician Intern Apply Now! SCAN ME bit.ly/3fwYBl6 Paid Internship +1-800-636-5581 | Proudly serving you from Brookings, SD; St. Peter, MN; and Melrose, MN! DEALER Cutting-Edge Milking Equipment | Supply Delivery | Preventive Maintenance Herd Advisory & Software Support | Manure Management Services | Feed Management farm-systems.com © 2022 Farm Syststeems. All rig ts hts rese e rved. A-3386648395 Need Service? Keep your operation up and running with Farm Systems Your Local Milking, Manure and Feed Management Solutions & Service Provider

Describe your farm and facilities. We have a double-4 step-up parlor. Our farm is run by me and my wife, Michelle; our three kids, Jacob, Libby and Zander; my parents, Leonard and Rose Hoen; and a hired hand.

What forages do you harvest? We harvest haylage, corn silage and oatlage.

How many acres of crops do you raise? We have about 600 acres of cropland — about 55 acres of alfalfa, 30-35 acres of silage corn, 10 acres of oats, and the rest is planted to soybeans or grain corn.

Describe the rations for your livestock. We have a total mixed ration and do about 50-50 corn silage and haylage. We add a custom blend from the local feed mill and an on-farm blend that includes corn, cottonseed, soybean meal, extruded meal, whole soybeans and fat. We also have oatlage that I will feed as a ller with either third- or fourth-crop haylage. It seems to work well.

FORAGE PROFILE

What quality and quantity do you harvest of each crop? We try to cut our alfalfa at 28 days for each crop. Sometimes it differs, depending on the weather we are having during that time. We watch the elds for buds, and by the time I am cutting, about half the eld is at budding stage. We try to harvest our haylage at 60% moisture since we have a dryer silage. For our silage, we chop it at about 58% moisture. Since it is going in a silo, we don’t want it to be too wet.

Describe your harvesting techniques for alfalfa and corn silage. All of the alfalfa gets cut with a disk mower, and the following day it will get chopped. I start out by laying the rows at 13-feet wide and slowly lay them tighter as I am cutting to help hold some of the moisture in. I try to emphasis the moisture because it helps so much in the TMR mixer and the feed bunk. We harvest our haylage with a New Holland 230 pull-type chopper, and we usually use three chopper boxes. Everything will get cut at a 3/4-inch length. The

silage will also go through a processor that we added about 15 years ago. We were able to nish our rst-crop haylage on May 30.

What techniques do you use to store, manage and feed your forages. All of our haylage and oatlage goes in a bag. We end up lling four 9by 250-foot bags. We lay our bags north and south, which lets us open the bags on the north side during the summer to limit sun exposure. I try to only have one bag open at a time, especially during the summertime, while managing the length of it so that the wind doesn’t get underneath it, and I will have tires with strings on them to hold the seams down to prevent air from getting underneath. Our silage goes into two 18- by 65-foot silos, which can hold around 300 to 320 tons each.

Page 18 • Dairy Star • Saturday, June 8, 2024

DECORAH LOCATION 2337 Millennium Rd Decorah, IA 52101 563.382.8722 LANGSDAIRY.COM LEWISTON LOCATION 295 East Main Street Lewiston, MN 55952 507.452.5532 COME JOIN US FOR AN OPEN HOUSE June 20th • 11 am - 3 pm at our Decorah location Food & Door Prizes! Lang’s Dairy is proud to have been serving the dairy industry for 75 years!

Steve Hoen, Norwood, Minnesota | Carver County | 80 cows

GRACE JEURISSEN/DAIRY STAR

Turn to FORAGE | Page 20

Steve Hoen stands in front of the tractor he uses for chopping forages June 4 near Cologne, Minnesota. Hoen milks 80 cows on his farm

W4 W 4 92 9 2 7 Cl C ea e a rv r v ie i e w Rd d R ., , Waal l do d o , WI W 5 30 3 0 93 3 9 9 2 0 - 52 8 - 1 4 3 6 WW W W W. W GI G BB SV S V IL L I LE L E IM M I PL EM M EN N E T T.CO C O M

Bongards’ Creameries

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51

Bongards, MN 55368 (952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE Perham, MN 56573 (218) 346-4680

Fax (218) 346-4684

Chambersburg, PA Doug and Julie Martin, son Grant and wife Kim, daughter Jill and husband Josh Wiser 300 Registered Jerseys, grazing herd 12,000M

“We love Udder Comfort™ for fresh cows. We’ve been using it for 15 years. It’s the only one that works to get swelling down fast and make cows comfortable so they do better,” says Jill Wiser, dairy manager and partner in her family’s Pleasant Valley Jerseys, Chambersburg, Pa., a grazing dairy milking 300 reg. Jerseys.

“We spray fresh udders 2x/day for 5 days with Udder Comfort. We don’t do intramammary treatments while in the milking period but dry treat a few. If we get flareups, we use this, and in most cases, they clear within a week,” she explains, noting they “very much enjoyed the convenience, ease and coverage” having the Udder Comfort Battery-Operated Backpack Sprayer to do large groups of fresh cows this spring.

“Fresh group applications went so much quicker. We can have 30 cows done in under 5 minutes! It really shortened the application process for us.”

Dairy Star • Saturday, June 8, 2024 • Page 19

With the backpack sprayer... “We can have 30 cows done in less than 5 minutes!” Quality Udders Make Quality Milk PLEASANT

For external application to the udder only, after milking, as an essential component of udder management. Always wash and dry teats thoroughly before milking. Her Comfort is Our Passion! Softer udders [ Faster milking Better quality [ MORE MILK 1.888.773.7153 uddercomfort.com Helping reach their potential since 1998! •Both Straight and Interlocking Sides Available • Hammer Blow Top • Grooved on Bottom • 100% Virgin Rubber • 5 Year Manufacturers Warranty • Quantity Discounts • Delivery Available RUBBER MATS Chippewa Valley Dairy Supply YOUR MAT DEALER 6053 CTY. HWY. G • STANLEY, WI 54768 | 715-644-2350 47" X 70" COVERAGE • 3/4" THICK

— Jill Wiser

VALLEY JERSEYS,

5.8F 4.2P, 200,000 SCC

How does quality forages play in the production goals for your herd? Milk production is probably our biggest goal. Having quality forages is denitely one of our top three goals. We have noticed a difference as we have been making changes to our forages.

What are management or harvesting techniques you have changed that has made a notable difference in forage quality? We added a kernel processor about 15 years ago and switched to a TMR about 18 years ago, which has certainly helped with labor and cow health. We stopped feeding dry hay in our rations and created a tighter cutting window within the last ve years. This has made a difference across the board. It helps in the bunk with more moisture, so they don’t sort it. Milk production has gone up, and feed costs are more manageable. We have also noticed that it mixes faster since we don’t have to process the dry hay and mix it in. We also put on a granular inoculant at the bagger and the blower. I have found it helps to put extension hoses on the applicator so that the wind doesn’t blow the inoculant everywhere.

JEURISSEN/DAIRY STAR

A freshly lled bag rests June 4 at Steve Hoen’s farm near Cologne, Minnesota. Hoen stores his forages in silos and bags.

Describe a challenge you overcame in reaching your forage quality goals. Having a different cutting schedule and not baling any of it. We weren’t getting timely cuts. Now we have put more of an emphasis on it, and we can see the difference it is making.

Page 20 • Dairy Star • Saturday, June 8, 2024 DECORAH, IA Lang’s Dairy Equip. 563-382-8722 MONTICELLO, IA United Dairy Syst. 319-465-5931 WEST UNION, IA United Dairy Syst. 563-422-5355 FREEPORT, MN Arnzen Construction 320-836-2284 Hartung Sales & Serv. 320-836-2697 LEWISTON, MN Lang’s Dairy Equip. 507-452-5532 MELROSE, MN Farm Systems 320-256-3276 MENAHGA, MN Dairyland Equip. 218-564-4958 PENNOCK, MN D&D Ag Supply & Construction 320-599-4466 SAUK CENTRE, MN Dairyland Supply 320-352-3987 800-338-6455 JANESVILLE, WI Tri-County Dairy Sup. 608-757-2697 LANCASTER, WI Fuller’s Milker Center 800-887-4634 MARSHFIELD, WI Podevels Farm Serv. 715-384-6193 800-742-5748 MT. HOREB, WI The Scharine Group 800-872-3470 RICHLAND CENTER, WI Fuller’s Milker Center 800-887-4634 SPARTA, WI Preston Dairy Equip. 608-269-3830 WHITEWATER, WI The Scharine Group 608-883-2880 WITHEE, WI Hoover Silo Repair 715-229-2527 www.jdmfg.com www.jdmfg . com Family Owned & Operated in Eau Claire, Wisconsin Where you can buy : : #RequestTheTest RequestTheTest We are your Ventilation Experts IOWA MINNESOTA WISCONSIN FAN SELECTION & LAYOUT THANK YOU FARMERS #JuneDairyMonth WE DESIGN VENTILATION SYSTEMS. • Fan placement • Simulations • Tested data

Con nued from FORAGE | Page 18

GRACE JEURISSEN/DAIRY STAR

Steve Hoen holds haylage June 4 near Cologne, Minnesota. Hoen feeds haylage in his dairy’s ra on.

GRACE