By Abby Wiedmeyer abby.w@dairystar.com

BLANCHARDVILLE, Wis. —

In 2016, Farron and Jessica Gruenenfelder were considering an upgrade from milking 70 cows in a tiestall barn to milking with robotic milking units.

“We were almost going to sign the papers to do robots and I got cold feet,” Farron said. “It’s a lot of money.”

Instead, the couple built a freestall barn and double-10 step-up parlor. They expanded to 180 cows and hired employees to help with milking. When their hired help decided to move, the Gruenenfelders revisited the idea of robotic milking units.

This time, they leaped. Jessica said they have not looked back.

“We ask ourselves now why we didn’t do this sooner,” Jessica said. “But nobody gets to start out on top. You’ve got to work your way up.”

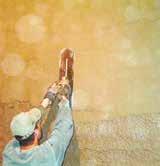

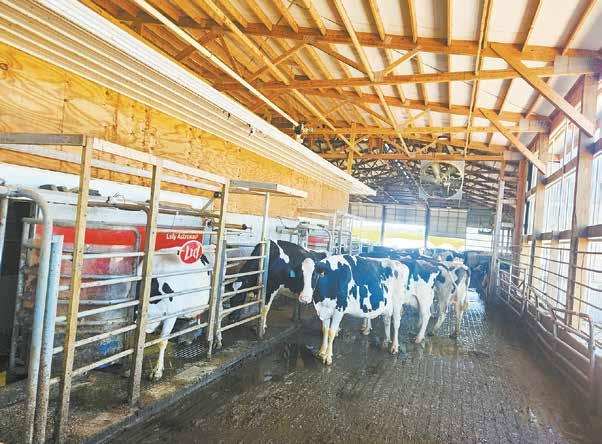

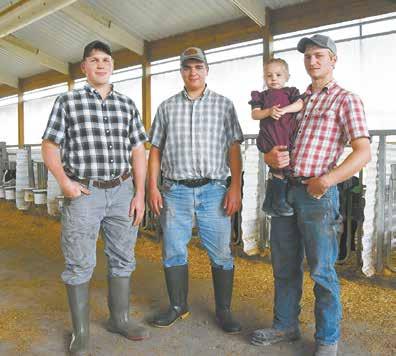

Farron and Jessica are secondgeneration farmers who purchased the dairy in 2009. They have four children — Trinity, Aidan, Layton and Atley. They installed two Lely A5 robots and one Lely Juno in July 2023. The upgrade in equipment required a downsize in cow numbers, and they now milk 120 Holsteins.

Their sand bedded freestall barn has four rows with the robotic milking

units on one end.

Since the switch, their cows have increased milk production by 12 pounds per cow per day. Farron said there seems to be less mastitis with

more milkings per day. The herd is averaging close to three-times-a-day milking.

Besides cow health, the couple said the biggest impact has been on

their lifestyle. Jessica said the exibility of chores has made the change worth it.

Turn to GRUENENFELDERS | Page 4

“This

- Andy and Duke Ernste, Faribault,

“I feel like our cows are calmer and just more relaxed,” Jessica said. “There’s certain things we have to maintain, but it’s a way better quality of life.”

Farron and Jessica operate the farm together and their kids help out when they can. The robots have eliminated the need for hired employees. Each day, the couple gets to the farm around 4 a.m. They begin by scraping the barns, feeding calves and mixing feed.

The cows have developed habits in the year since tran-

Right now, the barn is at capacity with 116 stalls. The Gruenenfelders said there does not seem to be an issue with overcrowding since not all cows are on the same schedule. At any given time, there is a group milking, a group eating and a group lying down.

The biggest disruption that has occurred so far was the result of bad weather. In a storm that was severe enough to pull the roof off a shed, the robots lost power overnight. Before retiring for the night, Farron had hooked up the generator

“I feel like our cows are calmer and just more relaxed. There’s certain things we have to maintain, but it’s a way better quality of life.”

JESSICA GRUENENFELDER, DAIRY FARMER

sitioning. Jessica said the robots are busy around 11 p.m. and the cows tend to visit throughout the night. When the morning chores start, cows usually start going through again, and by the time the robots shut down for washing at 8 a.m., Farron has fresh feed at the bunks and most are done milking.

A footbath is positioned on the same end as the robots. Farron said it gets good use and does not seem to slow down the milking ow. They periodically run the herd through the footbath, so they know every cow is being treated.

When designing the upgrade, the Gruenenfelders originally planned to install three robots. At the last minute, they changed their minds and went with two. When this change occurred, they lost the opportunity to include a calving pen in the design. Farron said that is one thing he would go back to change. However, it is designed so two additional robots could be installed if a future expansion were to happen.

as a precaution. They watched a few cows go through the robot and everything seemed to be working so they went in for the night.

They received no calls overnight and assumed everything was OK until they got to the barn and heard the cows bellering. Evidently, the modem for the internet had been struck and when the cows went through the robot, their identication collars were not recognized and it pushed them through without milking them.

Jessica said they were grateful for the support of their Lely dealers to get them through.

“By the time we realized what had happened, Lely was on it,” Jessica said. “They were here helping us out and the problem was solved.”

The local internet provider and power company provided support as well.

Overall, Farron said the upgrade has proved worthwhile.

“I’ve been happy with it,” Farron said. “It’s a big investment, but if you look at it over time, 12 pounds a cow goes a long way.”

By Lee Mielke

The June Federal Milk Marketing Order Class III benchmark milk price was announced at $19.87 per hundredweight, up $1.32 from May, $4.96 above June 2023, and the highest Class III price since December 2022. The sixmonth Class III average stands at $16.92, down from $17.48 a year ago, and compares to $22.95 in 2022.

Friday morning futures portended July at $19.65; August, $20.11; September, $20.49; October, $20.33; November, $19.97; and December, $19.40.

lion pounds, down 8.6% from April, but 8.9% above a year ago. New Mexico, with 81 million pounds, was up 3.9% from April, but down 13.5% from a year ago.

Italian cheese totaled 505.1 million pounds, up slightly from April and 4.4% above a year ago. Year to date output, at 2.5 billion pounds, is up 4.1% from a year ago

American output climbed to 488.1 million pounds, up 4.5% from April but 5.7% below a year ago. Year to date, at 2.4 billion pounds, was down 4.7% from a year ago.

The Class IV price is $21.08, up 58 cents from May, $2.82 above a year ago, and the highest Class IV since October 2023. Its six-month average is at $20.17, up from $18.59 a year ago, and compares to $24.67 in 2022.

The U.S. Department of Agriculture issued its long awaited recommend decision on amendments to the FMMO pricing formulas. The decision stipulates milk composition factors be adjusted to 3.3% true protein, 6.0% other solids and 9.3% nonfat solids.

Mozzarella cheese, at 405.1 million pounds, was up 7.1% from a year ago, with year-to-date output hitting 1.99 billion pounds, up 4.9%.

Cheddar output totaled 329 million pounds, up 11.8 million pounds or 3.7% from April’s level, which was revised down 5.1 million pounds, but was down 35.3 million pounds or 9.7%, from a year ago. Year to date Cheddar hit 1.6 billion pounds, down 7.6% from a year ago.

•

•

•

It would eliminate 500-pound barrel cheddar cheese prices from the Dairy Mandatory Market Reporting survey and use only the 40-pound block Cheddar price to determine the monthly average cheese price in the formulas. Make allowances would also be revised and the butterfat recovery factor would be updated to 91% from the current 90%.

The decision returns to the “higher of” the advanced Class III and IV skim milk pricing factors in the base Class I skim milk price and implements a rolling monthly Class I extended shelf life (ESL) adjustment to “ensure better price equity for ESL products.” Class I differential values would also be updated to reect the increased cost of servicing the Class I market.

After the nal decision is published in the Federal Register, the dairy industry has 60 days to submit comments. After that, USDA has 60 days to release the nal decision for a vote by producers.

National Milk Producers Federation President and CEO Gregg Doud said, “Based on our initial reading, NMPF is heartened that much of what we proposed after more than two years of policy development, and another year of testimony and explanation, is reected in USDA’s recommended Federal Milk Marketing Order modernization plan.”

Meanwhile, you’ll recall that May milk production was down 0.9% from a year ago but that didn’t have a lot of impact on the May dairy products report, according to StoneX broker Dave Kurzawski in the July 8 “Dairy Radio Now” broadcast.

May cheese production climbed to 1.213 billion pounds, up 2.1% from April’s count which was revised up 1 million pounds and was 0.7% above May 2023. Output for the rst ve months of 2024 totaled 5.97 billion, up 0.6% from 2023.

Wisconsin cheese totaled 305.6 million pounds, up 3.6% from April and up 3.2% from a year ago. California produced 214.5 million pounds, up 3.9% from April, but 0.5% below a year ago. Idaho contributed 81.6 mil-

Kurzawski says Cheddar has been underwhelming all year but pointed to the increase in Mozzarella. He said, “Demand has been really hot.” He suspects that consumers using home delivery services like Door-Dash and Uber-Eats, are reverting to pizza rather than individual meals because they are cheaper, and that has increased the draw on Mozzarella cheese.

Butter production slipped to 204.3 million pounds, down 3.3 million pounds or 1.6% from April but was up 7.9 million pounds or 4% from a year ago. Year to date butter was at 1.04 billion pounds, up 4.7% from 2023. This was the rst time ever to top 1 billion pounds before the month of June, according to HighGrounds Dairy.

Yogurt production totaled 403.2 million pounds, up 5.5% from a year ago. Hard ice cream, at 65 million pounds, was up 2.3%.

Dry whey output fell to 76.6 million pounds, down 4.6 million pounds or 5.7% from April, and down 5.2 million pounds or 6.4% from a year ago. Year to date whey is at 387.7 million pounds, up 1.5%. Stocks fell to 64.5 million pounds, down 8.1 million or 11.2% from April, and down 13.6 million pounds or 17.5% from a year ago.

Nonfat dry milk output slipped to 171 million pounds, down 3.2 million pounds or 1.8% from April, and down 35.5 million pounds or 17.2% from a year ago. Year to date powder was at 814.6 million pounds, down 14.9%. Stocks continued to slowly grow, climbing to 283.6 million pounds, up 2 million pounds, or 0.7% from April, but were down 16.7 million pounds or 5.6% from 2023.

Skim milk powder production jumped to 41.9 million pounds, up 6.1 million pounds or 16.8% from April but was down 4.7 million pounds or 10.1% from a year ago. Year to date SMP was at 199.2 million pounds, down 18.5% from 2023.

Cash dairy prices start July strong. The Cheddar blocks closed the holiday shortened week at $1.90 per pound, down a penny but 50.75 cents above a year ago. The barrels nished at $1.9025, 2.25 cents higher on the week, and 52.25 cents above a year ago. Sales totaled ve cars of block and 14 of barrel.

The holiday threw less of a wrench in Midwest cheesemakers’ plans than is typical, said Dairy Market News. Multiple plants were running a normal veday workweek while milk availability holds up. Cheesemakers are trying to get ahead of a tightening milkshed in the region which faced hot temperatures and/ or heavy rains. Even before the weather conditions, cheesemakers were noting lighter component levels. Cheese demand ranges from steady to strong, says DMN.

Cheese production is steady in the West. Milk demand from cheesemakers is stronger, however farm level milk output is generally declining in the region. Retail cheese demand is steady to stronger while food service is steady. Exports are steady to lighter as price competitiveness impacts the situation.

Almost defying gravity, Chicago Mercantile Exchange butter closed Friday at $3.1325 per pound, up 0.75 cents on the week and 65.25 cents above a year ago, with three sales on the week.

Butter churns ran lighter schedules this week. Cream availability was below typical holiday levels and some multiples inched higher, somewhat abnormal in a weekday holiday. Retail butter demand remains ahead of expectations. Some say prices around $3.10 per pound will keep orders in check but “seasonal butter demand is only expected to push higher moving forward,” said DMN.

Butter production ranges steady to lighter in the West as churn maintenance takes place. The mid-week holiday was expected to loosen cream availability, as availability has generally been tighter in the region. Domestic butter demand is steady to lighter for retail and lighter for food service.

Grade A nonfat dry milk nished the week a quarter-cent lower, at $1.18 per pound, 9.25 cents above a year ago, with six sales logged in for the short week.

Dry whey ended the week at 49.25 cents per pound, up a quarter-cent, highest since Feb. 26, and 26.50 cents above a year ago, with two CME sales on the week.

Dairy margins improved the last half of June as milk prices were mixed while feed costs plummeted with corn trading to three-year lows, according to the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC.

“USDA’s updated June Acreage Report and Quarterly Grain Stocks were both considered bearish for corn,” MW said. “USDA pegged corn acreage at 91.5 million, up 1.5 million from the March Prospective Plantings estimate and outside the range of pre-report estimates. June 1 corn stocks at 4.99 billion bushels were up 22% from last year and higher than the average pre-report estimate of 4.867 billion but within the range of estimates. On farm stocks were particularly burdensome, up 37% from a year ago and the highest in 25 years.”

Soybeans stocks were reported at 970 million bushels, up 22% from June 1, 2023. Soybean acreage was estimated at 86.1 million acres, up 3%. Planted acreage is up or unchanged in 24 of the 29 estimating states, said USDA.

The latest crop production report showed 11% of the U.S. corn crop was silking, as of the week ending June 30, up from 4% the previous week, 4% ahead of a year ago, and 5% ahead of the ve-year average. Sixty-seven percent was rated good to excellent, down 2% from the previous week, but up from 51% a year ago.

The beans are 95% emerged, 2% behind a year ago but 2% ahead of the average. Sixty-seven percent were rated good to excellent, unchanged from the previous week, but up from 50% a year ago.

Meanwhile, a higher all-milk price offset higher corn, soybean and hay prices to lift the May milk feed price ratio. The USDA’s latest ag prices report shows the ratio at 2.24, up from 2.14 in April, and compared to 1.40 in May 2023.

The all-milk price averaged $22 per hundredweight, with a 4.17% butterfat test, up $1.50 from April, and $2.90 above May 2023, which had a 4.06% test.

The national corn price averaged $4.51 per bushel, up 12 cents from April, but $2.03 below a year ago. Soybeans averaged $11.90 per bushel, up a dime from April, but $2.50 per bushel below a year ago. Alfalfa hay averaged $202 per ton, up $7 from April but $77 below a year ago.

The May average cull price for beef and dairy combined climbed to $132 per cwt, up $2 from April, $29 above May 2023, and $60.40 above the 2011 base.

Milk production margins moved to the highest level since June 2022 at $12.17 per cwt and were $1.24 per cwt above April, according to dairy economist Bill Brooks, of Stoneheart Consulting in Dearborn, Missouri. Brooks said May income over feed costs were above the $8 per cwt level needed for steady to higher milk production for the ninth month in a row. Input prices were higher in May with all three input commodities remaining in the top nine for May all time.

“Milk income over feed costs for 2024 (using June 28 CME settling futures prices for Class III milk, corn, and soybeans plus the Stoneheart forecast for alfalfa hay) are expected to be $13.02 per cwt, a loss of 28 cents per cwt versus last month’s estimate. Income over feed cost in 2024 would be above the level needed to maintain or grow milk production, and up $5.01 per cwt from 2023’s level.”

May U.S. milk equivalent dairy exports were down 4.1% from last year. The good news was that low cheese prices in February and March spurred strong sailings in May, up 46.6% from May 2023, with Cheddar exports up 54.9%. HGD says cheese exports were at a second alltime high, with shipments to Mexico, a record 40.4 million pounds, 38% of the total market share.

Unfortunately, nonfat and skim milk powder exports, at 133.6 million pounds, were down 24.2%,the lowest May total since 2017, according to HGD, and down 11.7% year to date. Sales to Mexico dropped 12%.

Dry whey exports were down 1.6%, after a small gain in April. Demand from China picked up in May, reports HGD, but exports to Southeast Asia were down 30%. Butter exports were also down, dropping 19.4% from a year ago.

StoneX’s Kurzawski said we’ve been exporting around 100 million pounds of cheese per month versus about 70 million a year ago, and that’s part of the reason CME prices are at $1.90. He warned, however, that those exports will likely fall in the next couple months as U.S. prices become uncompetitive.

The Global Dairy Trade auction saw its weighted average plunge 6.9% July 2, following a 0.5% slip June 18, and the steepest drop since Aug. 15, 2023. Volume mushroomed to 53.2 million pounds, up from 37 million pounds June 18, and the largest offering since Feb. 20. The average metric ton price fell to $3,782 U.S., down from $3,893.

Anhydrous milkfat led the declines, dropping 10.7%, after slipping 1.2% June 18. Butter was down 10.2% after gaining 6.2% June 18. GDT Cheddar was down 6.9%, after dropping 1%. Skim milk powder was down 6.1%, after inching up 0.7%, and whole milk powder was down 4.3%, following a 2.5% decline. Buttermilk powder was down 5.1%. Lactose showed the only positive move, up 0.6%, which followed a 1.9% gain June 18.

StoneX said the GDT 80% butterfat butter price equates to $2.8970 per pound U.S., down

cents from June 18 and compares to CME butter which closed

Friday at $3.1325. GDT Cheddar, at $1.8053, was down 10.2 cents, and compares to Friday’s CME block Cheddar at $1.90. GDT skim milk powder averaged $1.1731 per pound, down from $1.2544, and whole milk powder averaged $1.4598 per pound, down from $1.5397. CME Grade A nonfat dry milk closed Friday at $1.18 per pound.

Complete Herd Dispersal

(20) tie stall cows including Holsteins, Jerseys, & Norwegian Red crosses. Milked in tie stalls and let outside to the bunk and pasture everyday. Herd is averaging 60 lbs 4.1F, 3.2P, 160scc with only homegrown feed. Several fresh cows milking over 80 lbs!! Ai sired and bred. 3 dry cows. A nice clean set of cows! Klark Dairy, Bloomer, WI Holstein tie stall cow. 3 year old Appaloosa x VG85 Braxton. Fr 6-17-24. 1st test 94 lbs. 4.2F, 3.2P 108scc on 2x milking. Free stall and tie stall adapted. Dam last lac made 46,060M, 1578F, 1482P. Keith & Stephanie Abts, Dykesville Breeding Bulls

(Expecting 35 to 45 Hd. of Bulls) Wisconsin’s Best Bull Auction!!

# 61 L&N Dairy, Radio x Dezi star x Epic x Palermo DOB 7/14/23 33790M 1061F, 1086P 3rd Lac. 349 Days #57 L&N Dairy, Canyon Breeze Allen x Cheers x Undenied x Mccutchen x Guthrie x Laurin x MacLand x 93pt Charles DOB 6/21/23 29820M 1247F x 965P 339 Day 3rd Lac.

# 63 L&N Dairy, Millington x Frazzled x Pety x Deman x Morty DOB 7/18/23 (Milk Records Pending) # 67 L&N Dairy, Brigham x Big Malki x Distiller x Fever x Atlantic DOB 8/7/23 37590M 1491F x 1184P

Photos on all of the above bulls will be posted on website . To consign bulls call or text Irvin @ 715-626-0002

Registered Guernsey bull. Born 6-10-23. Sire; Landon. Dam is GP82 as a 2 yr old then VG85 Legion, and VG86 Atom. Dam in 305 had 18,003M, 758F, 538P. Bull is fully vaccinated, genomic tested and will have A2/A2 results by sale day!! Keith & Stephanie Abts, Dykesville

Auction will be held at Central WI Produce Auction. (See full ad for all details)

Tuesday, July 23rd • 10:30 am

John & Levina Beiler • 19993 West Mound Rd • Platteville WI 53818 52 Fancy Holstein and R&W Holstein cows, 29 heifers (See separate ad for all details)

Alan Ledvina, Luxemburg. $2,700 Dennis Borntrager, Curtiss.

Good springing heifers sold strong. 35 out of 42 sold $2,300-2,950. Open heifers mostly $2.00-2.25cwt. Single birth Holstein heifer calves $330 -450. Light run of feeders.

5 Angus cross bulls 413 @ $2.85. 5 Hol strs 560 @ $2.52. 6 Jersey strs 577 @ $182.50. Assortment of single feeders sold cheaper than groups. Fed cattle still strong.3 Hol strs 1665@ $1,82.75. 1 Hol hfr 1330 @ $1.83. 3 Hol strs 1872 @ $1.79. Beef cross calves $760-920,Top $970. Holstein bull calves $535-690. High yielding cows $121-138.50. Plainer cows $1.03-1.20. Poor cows $70-93. Decent selection of hay on offer. New crop grass baled dry and stored 2 weeks $85-105. 3x4 western grass $175. 3x4

June

Large

2nd

$55-75/ton

$10-150/ton

$62.50-90/ton

$47.50-52.50/ton

By Emily Breth emily.b@star-pub.com

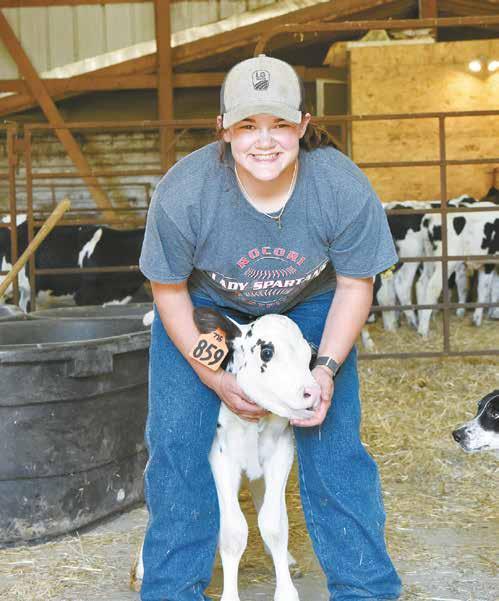

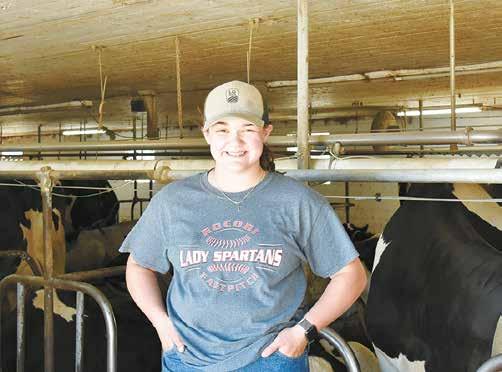

RICHMOND, Minn. — Bella Klocker’s journey of what she wanted to do with her future took a major change when she found a passion for dairy.

“I grew up in St. Cloud, so I (had) never been around cattle,” Klocker said. “Then I started working here and it evolved to me working a little more every week, and now I’m pretty much full time.”

Klocker started working for Linn Dairy in 2020 but said she never thought it would last this long. Linn Dairy is owned and operated by Pat and Nancy Tanner where they milk 145 cows in a tiestall barn near Richmond.

Enjoying the positive environment, learning about cattle and what goes into running a successful farm are some of the things that keep Klocker coming back.

“The more I learned, the more intrigued I got about it,” Klocker said. “Especially with the calves, there is so much science behind calves and how you take care of their moms and the more you take care of their moms, the better the calf is going to turn out.”

Taking care of cattle is not the only thing Klocker has actively been caring for on the farm. She is caring for herself as well.

“If I would have gotten a different

job, I wouldn’t be as healthy as I am now because of how active I am every single day,” Klocker said. “Even if it is my day off, I will be here feeding calves because I love being here, especially with the Linn family.”

The Linns have been a huge inuence for Klocker and are part of her reason for sticking around.

“I plan on staying here to help out the farm,” Klocker said. “I want to be that extra hand so people feel relieved when they want time off to spend with their family.”

Klocker also likes being able to see her family, which is a reason she does not plan on going to a different farm.

“Being (only a couple of miles from) home and my parents is a really big thing to me,” Klocker said. “I feel like it wouldn’t be the same if I went to a different farm to branch out.”

Klocker said she has made many memories on the farm. Among them is the rst time she learned how to drive a tractor.

“It’s kind of like when your dad sits you down to learn how to drive the rst time,” Klocker said. “I would say that, feeding calves for the rst time and chopping and hauling boxes are my best memories.”

Starting from scratch Klocker put in the extra hours to learn as much as she could about the farm and everything it entailed.

“The biggest thing that helped me was sticking around all the time, even if they didn’t necessarily need my help,” Klocker said. “I’d stick around, watch and ask questions and now I am doing a lot of that stuff on my own.”

Turn to KLOCKER | Page 11

Bella Klocker stands in the barn June 13 at Linn Dairy Farm near Richmond, Minnesota. When Klocker started at the farm, her only ca le experience came from seeing them at her grandpa’s farm as a child.

Coming from town, Klocker said she did not realize how much work went into running a farm.

“There is so much I just never thought of,” Klocker said. “It is also emotionally exhausting because it can be stressful. I think that is not advocated enough.”

When it came to holiday seasons, working at the farm was an eye opener for Klocker.

“I never really thought about the cows still needing to be milked on Christmas,” Klocker said. “Farmers can’t just leave and have the cows milk themselves. Things still have to get done, even if it is a holiday.”

She said thinking about the role dairy farmers play in making holidays enjoyable drives her.

“The most rewarding feeling while I’m milking is when I think about the holidays and how much dairy products go into them,” Klocker said. “I am helping provide people with that food.”

Pulling calves is another part of farming Klocker nds rewarding.

“When there is a calf you don’t think is going to make it, but you work really hard and with a miracle it pulls through, that is amazing,” Klocker said. “Everything combined made me want

to go into farming for my life.”

Moving forward Klocker will be attending Ridgewater College majoring in dairy management. Her hope is to take what she learned from the Linns and build off it and bring back new knowledge to the farm.

Klocker’s chores consist of mixing feed, feeding cattle and calves, milking and helping with eld work. As she gained responsibility, her parents became more open to the idea of Klocker working at the farm.

“At rst, they were a little hesitant because they know it can be dangerous,” Klocker said. “Now they know I am going to college for this, and this is what I want to do I feel like they are a lot more open to it and they just want to make sure I’m happy. As long as I’m healthy and happy and doing what I love, I think that is their biggest thing.”

It is the same advice Klocker would give to others.

“Don’t let people decide what you should be doing,” Klocker said. “If you think about getting a job and you’re not sure if you are going to like it, just jump into it because you never know how it is going to end. I never thought I was going to like farming but look at me now.”

Family comes together to harvest 140 acres of hay

By Mark Klaphake mark.k@dairystar.com

BROOTEN, Minn. — Brothers Kenny, Arnie and Jeremy Martin enjoy working together on their 150-cow dairy near Brooten.

They also relish the opportunity to work with their brothers, Wesley and Wendell, and cousins, Jason and Dwight Zimmerman, when they custom chop for area farmers. That scenario came together June 26 when the group went to work for neighboring dairy farmer, Steve Middendorf, to help him put up second-crop hay on his 210-cow dairy 11 miles away.

MIDDENDORF/DAIRY STAR

Jason Zimmerman merges hay June 26 at Steve Middendorf’s dairy farm near Sauk Centre, Minnesota. Zimmerman started merging hay at 8:30 a.m.

“I have a chance to interact with my brothers,” Kenny said. “We enjoy it. We have our own separate farms but work together with eldwork. The families have been doing custom work for 10 years.”

Kenny and Arnie own the chopper and cutter and their cousins own the merger. Both dairies own a forage box.

The sun wasn’t quite out at 5:15 a.m. when Kenny walked south across the yard to the barn to check on the cows and start the day. He then brought the cows to the holding area and Arnie and Jeremy showed up to milk. Ernest, their dad, arrived around the same time and he and Kenny fed calves and scraped the barn. Shortly after 7 a.m., morning chores were complete.

After breakfast, Arnie went to the eld to side dress fertilizer on the corn. Jason started merging rows together at 8:30 a.m. while the rest n-

ished chores around the farm and got their haying equipment ready.

Shortly before noon, they were perched in their seats hoping for a productive harvest day. Kenny was manning the chopper, Jeremy and Dwight were each pulling wagons, Wesley was driving the push tractor and Wendell was mowing elds at John Zimmerman’s.

“I enjoy running the chopper,” Kenny said. “Getting feed made the way you like is a good feeling.”

Turn to MARTINS | Page 14

For the next ve hours the group worked to chop ve different elds totaling 140 acres for the Middendorfs. By 4:30 p.m. the custom work was done, and they had harvested around 360 tons of haylage.

“We enjoy chopping together,” Kenny said. “There is enough of us brothers and cousins.”

Wendell had spent the day cutting the second crop for the Zimmermans.

Once they nished harvesting, Kenny and Arnie turned their attention to their afternoon chores and milking.

Kenny and his wife, Joy, started milking in their double-14 parallel parlor while Jeremy brought the cows to the holding area and scraped

the stalls.

“I always did like the cows,” Joy said.

Once the stalls were clean, Jeremy relieved Joy from milking and she started feeding calves with a milk shuttle.

The Martins — Ernest, Kenny, Jeremy, Arnie and Joy — usually rotate parlor duties.

“We do a lot of shufing around. Nobody gets tired of anything then,” Kenny said.

“You know what’s going on.”

Arnie, with the help of his daughter, Jasmin, spent several hours mixing feed for the different groups of cattle on the farm. The Martins mix and feed once a day.

Arnie’s wife, Kendra, was at home caring for their

6-week-old twins.

There have been changes on the Martin’s farm in 2024.

In January, Arnie and Kenny took over the farm from Ernest and Jolene.

“I always enjoyed farming,” Ernest said. “It’s good seeing crops grow and the cows milking. The boys are keeping everything going.”

Kenny said the transition does not mean a lot of change, although he and Arnie do the bookwork now.

Joy and Kenny moved to the farm in April. However, Ernest said he and Jolene are still going to the farm twice a day.

“We are just slowing down a little bit,” he said. “I enjoy this.”

Turn to MARTINS | Page 15

“We

a bedded pack.

Their cows are currently milking around 85 pounds of milk a day and their breeding is focused on components.

“We enjoy milking cows,” Kenny said. “I like driving the machinery too. I like that we can work together on the farm as a family.”

MARK KLAPHAKE/DAIRY STAR

Joy Mar n feeds calves with a milk shu le during evening chores June 26 on Mar n Dairy near Brooten, Minnesota. Most of the calves are housed in a calf barn or huts.

MARK KLAPHAKE/DAIRY STAR

(Le ) Ernest Mar n scrapes the free stall barn during milking June 26 on the dairy his sons, Arnie and Kenny, operate near Brooten, Minnesota. Earlier this year, Kenny and Arnie took over the farm from Ernest and his wife, Joy Mar n.

MARK KLAPHAKE/DAIRY STAR

Jeremy Mar n walks cows down to the holding area for evening milking June 26 near Brooten, Minnesota. Jeremy helps his brothers, Kenny and Arnie, on their 150-cow dairy.

By Stacey Smart stacey.s@dairystar.com

JEFFERSON, Wis. — Brody Jacobson was 5 years old when he got his rst two goats — Pinky and Blue.

“I like goats because they are calm and lovable,” Brody said. “I also like how they’re a smaller animal. Cows are a big animal, and you could easily get hurt.”

Now, 12-year-old Brody is milking 28 goats with help from his family on their farm near Jefferson. The young entrepreneur has big plans for his growing business, with hopes of milking 150 head.

“I think this is going to be my career someday,” Brody said.

Brody’s father, Willie Jacobson, is helping his son understand the business side of the operation.

“I explain everything to him

about dollars and cents so he can learn how to manage money,” Willie said. “Anybody could do this; you just need some land. It’s not a big investment, and there’s not a lot of overhead. We’re making a prot.”

Willie and his wife, Laura, purchased the farm in 2013. They updated the barn with new wood siding and a new roof and replaced the old house with a new one. Chickens were the rst animals to call the Jacobson farm home. Show pigs followed, and then came the goats.

“We started with Nubians because our kids loved their long, beautiful ears,” Willie said.

The Jacobsons milk with buckets and a portable milker. Starting with one goat stand and one unit, the family slowly expanded and now has a stand that holds eight goats that are milked with four units.

“Everything here is portable, so we can expand at any point,” Willie said. “It’s a work in progress. Our goal is to milk 16 at a time, so we will eventually have two milking stands. We’re also going to install a pipeline and replace our 100-gallon bulk tank with something bigger.”

Goats are milked twice a day — at 3:30 a.m. and when Brody gets home from school. Each milking takes about one

hour. Willie and Laura are usually on the morning shift, but in the summer, Brody does most of the morning and night milkings. He also receives help from his brother, Hunter, and his sister, Autumn. The Jacobsons adjust their milking schedule to accommodate Brody’s sports schedule, which includes baseball and cross country.

Their goats are averaging 7.5-8 pounds of milk per goat per day.

“That’s kind of high for Nubians, but I’m not overly pushing them,” Willie said. “Nubians don’t produce a lot of milk, so we’re slowly transitioning away from that breed and getting more into Alpine. We also have a few Lamanchas. Nubians give us the

butterfat; Alpines give us the milk. We have really good milk that’s high in butterfat.”

The Jacobsons are also experimenting with crossbreeding Lamanchas and Nubians to increase butterfat.

Turn to JACOBSONS | Page 17

The Jacobsons started shipping their milk to Saputo Inc. last year. Before that, extra milk was either dumped or given to people who make soaps and lotions.

“It was so hard for us to get on a milk truck,” Willie said. “Saputo has been awesome. They’re an amazing company.”

The Jacobson’s milk is picked up twice a week — on Tuesday and Friday.

“When we rst started shipping milk, we were just making the minimum 100 pounds per day,” Willie said. “Now, we do about 200 pounds a day.”

Goats are housed on an open bedded pack steps from the milk stand. They consume a diet of pellets and hay.

“We’re making money, but we don’t buy a lot in bulk, so we pay a premium for feed and other supplies,” Willie said.

The family grows 13 acres of alfalfa on their 75-acre farm and rents out the rest of their land.

“Our nutritionist got us going on the right track as far as milk production,” Willie said. “Goats are nicky, messy eaters. They waste a lot of hay and pick around what they don’t want. Working with our nutritionist helps a lot.”

Although he was not raised on a dairy farm, Willie’s connection to the industry is lifelong as his family was in the milk hauling business for 40 years. This is how he met his wife when he was 5 years old.

“Laura was two, and I remember her sitting in a plastic baby carrier in the milkhouse when we came to pick up milk at her parents’ farm,” Willie said. “Then I eventually became their milkman. We’ve been together a long time.”

Willie also helps run his family’s crane business — Jacobson Crane Inspection — and is involved in several other family businesses.

The Jacobsons like to show their goats and took 24 to the Jefferson County Fair this year. The family buys goats wherever they can, including from people they know at county fairs.

“We add whatever we can nd,” Willie said. “One goat we purchased is a vetime grand champion at our county fair. We got her from the neighbors. She was a gift to Brody, and the goat had been a gift to their son. We keep adding, and we’ll see what happens.”

Brody uses most of the money he earns showing pigs to buy supplies for his goats.

“We’re raising kids with animals, and everyone has their thing,” Willie said. “We want these guys to experience it. They have to get up and work even on their birthday and holidays too. This is bigger than them. We’ve seen true changes in our kids and in their work ethic.”

Willie’s mom also helps take care of the goats, feeding kids in the morning.

A growth spurt is on the horizon for the Jacobsons who hope to be milking around 90 goats next year. The family has also considered building a new facility.

“I’ve seen so many guys do expansions in the dairy industry, but I want to see where we’re going to get to rst,” Willie said. “We’ll expand when we have money to do it. We’re taking it step by step and have no debt with this little business.”

can count the rows on the ears. My neighbor will be cutting fourth-crop alfalfa in a week or two. We have been cutting fescue hay for other farmers. Our hybrid forage sorghum is waist to 6 feet high. Most of the wheat got done over the fourth and many farmers are planting soybeans into the wheat stubble. They are spraying fungicide on the corn to stop the Japanese beetles. We plan to do second-crop grass next.

A lot of people are working on hay or have theirs put away already. I started cutting July 8 with hopes of finishing July 9-10. I have all of my corn cultivated besides one field that got planted later. The corn in the area is in all stages, some is maybe knee high and other fields look like it will be tasseling in the next couple weeks. I planted millet around July 4 in an oat field I chopped off, with the warm weather expected it should be growing fast in the next week.

The crop hay is ready to be cut, but we are swamped here with water. There is water standing in a lot of the fields. There is a few guys in the area that have started on second-crop hay. The fields have to dry before we can. Our second-crop is starting to get purple. A lot of people are doing grass or meadows. I don’t think we can get at ours. The corn is chest high on the hills and 6-8 inches tall on the bottom of the hill. We have been working on spraying and have 100 acres left. Some of our neighbors are spraying corn. The soybeans are coming but are slow.

We had a little hail the last couple weeks, but nothing damaging. We got our second-crop alfalfa chopped and put away. It went really well and looks to be coming back really nice. It’s around six inches tall again. In some of the low spots, the corn is looking a bit yellow. There is corn in the area that is starting to tassel. Overall, the crops are looking green and the soybeans should be canopied within the next week or two.

We finished second-crop hay before the fourth of July. We chopped it all and put it in bunkers. We did most of the new seeding before the fourth as well. We have 25 acres left. We had some damage after we took first-crop alfalfa because it was too wet. There was some bug pressure in second-crop, but it was too close to being cut. The early corn is shoulder high. The local coops haven’t been able to travel in the fields. We have some corn that hasn’t been sprayed. There is a neighbor of ours that has a tractor with tracks and a sprayer that’s been doing it for farmers, including us. The wheat is not ready but it could be in a week or two.

We have been lucky with the rain, about 10 minutes south was reported to have 20 inches of rain. We were also lucky with first-crop alfalfa because some people are just getting first-crop now. We are ready to make second cutting as soon as we can drive on it. There are a lot of wet spots in the fields and is seen in the corn with yellowing and the height differences. Some spots are chest high and others are only waist high. We are looking to replant 10-15 acres of soybeans that didn’t germinate in the next couple of days.

We did second crop hay in three stages. One field each in the last three weeks. The third-crop hay is 10 days away. We plan to spray for bugs today (July 9). We finished side dressing the corn fields that we harvested rye off of. The late planted corn is waist high and the corn planted the end of April is starting to tassel. We got the second pass of herbicide on the corn as well. Our chemical guy said they are getting ready for fungicide application. My soybeans are 10 inches tall and some of the neighbors is canopied. We did our oats and peas three weeks ago and the alfalfa underseeded looks really nice. We bagged the peas and oats and plan to use it as dry cow feed.

We have had three days in a row without rain, so I cut my triticale July 7. It appears to be a really good crop. I put italian ryegrass with it, which also likes cool wet weather. The weather forecast looks like it will be good for making the crop. We will be silage baling it for cow feed. Some first-crop is getting finished up and second-crop is started. Discbines and sprayers are running like crazy in the area. People are side dressing their corn. The corn immediately looked better after getting sunshine and side dressed. It gives us a good feeling to see that it’s starting to look like corn again. The beans are finally starting to nodulate, which will help them take off as well.

We finished second-crop hay July 1. It was a lot lower quality than I was hoping for due to stress from the rain and traffic on the fields. We started cutting June 25 but got rained out a few times. Usually, hay takes us three days, but this year it’s taking longer. Our first-crop was so good that most of our bunkers are full, and we are almost out of storage space. We’re spraying soybeans and putting fungicide treatments on with a second herbicide pass. Our beans are looking good except for the low areas, which are starting to turn yellow due to all the moisture. We’ll start harvesting wheat around July 15. It’s looking close – the heads are tipping down and the green is all out of the stem.

Since the first part of April, we have had 25 inches of rain. In the last several weeks we finished our last field of first-crop. We have started on second-crop. We should have started on the first fields a few weeks ago, but the weather did not allow. We have been cutting oats for silage and have finished spraying. With spraying, there are spots with standing water we had to go around. There were a few places during spraying where the ground suddenly got soft and I was afraid of getting stuck, but I was able to get out. It did leave some pretty good ruts though. We are definitely still way behind on fieldwork.

We have only had 0.3 inches of rain in the past two weeks, so we are starting to dry out. We have all of our spraying done and finished our second-crop off about two weeks ago. We were actually able to make some dry hay too. There was a lot out there. The heavy ground was really hurting, so I’m cultivating some of it because the ground is so hard. I haven’t done that in like nine years. The corn on the sandy ground is doing pretty good, it is shoulder-high.

We have had 5.5 inches of rain with some having pretty heavy downpours. We should be able to get our second-crop wrapped up today (July 10). I think we should finally be able to make some dry grass hay coming up. The yields have been really good. There were some low spots where the alfalfa looked a little sick from too much water. The corn looks really good and is about shoulder-high.

We got our last 18 acres of corn planted June 10. We have corn that’s a foot high, we also have corn that’s tasseling. We had 70 acres of first-crop hay that was rained on three times, so we baled that in big squares for heifer hay. We did our peas and oats cover crop in the silo because it was too wet to make baleage. The last of it was so wet that it kind of turned into rotted straw. When it dried down, we made it into round bales for bedding. The rest of first-crop turned out very good. I’m still trying to finish up first-crop on my farm. Daryl is cutting all the secondcrop hay at the main farm and had 82 acres cut by July 8.

By Abby Wiedmeyer abby.w@dairystar.com

SPARTA, Wis. — Raising calves on a dairy farm means investing in the future of the operation. One of the most important aspects of raising calves is nutrition.

“We’re not really feeding an animal, we’re feeding bugs in the rumen,” David Lindevig said. “We have to feed the microorganisms in the rumen to develop the rumen.”

Lindevig shared his knowledge of calf management June 11 at a workshop hosted by Star Blends in Sparta. Lindevig, who has been a dairy nutritionist for over 30 years, said when it comes to feeding calves, the focus should be on rumen development.

When a calf is in its rst two weeks of life, its rumen is only 25% developed. To encourage development in the rumen and the forestomach, milk replacer is generally the main nutrition source, Lindevig said. While milk replacer includes a lot of water, Lindevig said it is important to feed water separately as well.

There is a groove in the esophageal tube that directs milk to the abomasum and water to the rumen. The microorganisms need water to propagate, so relying on the water in the milk replacer is ineffective, as it will end up in the abomasum and not the rumen.

Water is also the best way to boost calf starter consumption, Lindevig said.

“Water provided at all times enhances starter intake and weight gain,” Lindevig said. “This, in turn, is positively associated with milk yield during the rst lactation.”

The water needs of calves under 1 month of age are about 1.3-2 gallons per day. This gradually increases with age and at 4 months of age, calves should have access to up to 3.5 gallons of water per day. There is a direct correlation between water intake and dry matter intake as grain starter is introduced to young calves.

“If water intake is limited, dry matter intake will be limited as well,” Lindevig said. “For this reason, calves need four times more water than dry matter intake.”

Because ruminants use water to transport nutrients throughout the body, water is involved in about every aspect of a calf’s metabolism Lindevig said. It is also necessary for regulating the body temperature and eliminating waste. In a research study from the University of Wisconsin-Madison regarding the performance of calves and nutrition intake when fed water without restriction, there was a 37% difference between limited water and weight gain versus unlimited water offered.

This resulted in a feed efciency increase of almost 10% by offering adequate water.

“Think about how much water costs,” Lindevig said. “The return on investment is pretty huge.”

Water temperature also plays a role in consumption. Ideally, the fed water temperature is between 90-99 degrees. This is true in warm or cold weather. If a calf is fed cold water, the rumen’s temperature decreases. As this happens, the calf has to use energy to get the rumen back up to its normal temperature. In warm weather, this is pulling energy from the calf’s ability to regulate

its overall body temperature. In cold weather, providing warm water aids in keeping the calf warm.

When choosing a calf starter, Lindevig recommends one with 18% crude protein and 30% starch. Additionally, whole corn is recommended for starter feeds.

“I was surprised when I rst started doing research to nd that calves really grow better on whole corn,” Lindevig said. “It’s kind of interesting because as the animals get bigger, we’re grinding this corn to increase digestion.”

Time is important when it comes to introducing starter as well Lindevig said. Calves may only nibble on starter for the rst two weeks, but Lindevig said it is important to get it in front of them so they get used to it. The feed availability can be gradually increased from a handful to about 6 ounces a day the next week. The third week should reveal a noticeable difference in the interest in the feed. Calves should consume a little less than half a pound per day in the third week. This should double in the fourth week and by the fth and sixth week, calves should reach a daily goal of about 2-2.5 pounds of starter per day.

Lindevig said the adequate, early intake of dry feed is important because it stimulates rumen development.

“We need that dry feed to encourage those bugs to grow, just like we needed the water earlier for them to grow,” Lindevig said. “We’re just trying to develop that rumen and get that forestomach and that rumen up to that 70% range for volume. It’s very important.”

There are some things that are just perfect summer combinations, like a dash of salt on watermelon to bring out the juicy sweetness. I replace the seeds of a cantaloupe half with a scoop of cottage cheese topped with salt and pepper for a light lunch. And, of course, there are summer salads combining fresh greens and veggies to wake up standard canned goods.

A cardiologist friend recommended I pick up a summer read called “Undo It, How Simple Lifestyle Changes Can Reverse Chronic Diseases” by Dean and Anne Ornish. It’s a good read with interesting recipes. The gist of the book is how making simple changes in our diets and activities can impact our long-term health. Much of it is common sense. Acting with common sense is a completely different story. I know I should cut back on the sweets and swap out different ingredients for better health results. I’ve been trying some of the recipes in the book with above-average success...that is the guys will eat it. These three salad recipes are in the book as well. I’m looking forward to putting these summer salads together with a good summer book. Enjoy.

Wild Rice and Quinoa Waldorf Salad

Anne Ornish “Undo It”

1/2 cup wild rice

3/4 teaspoon ne sea salt, divided 1/2 cup white quinoa

2 tablespoons apple cider vinegar

2 tablespoons fresh lemon juice

1 1/2 teaspoons maple syrup

1 teaspoon whole-grain mustard

1/3 teaspoon ground pepper

2 cups thinly sliced apple

2/3 cup diced celery

1/4 cup dried currants

1/4 cup thinly sliced scallions

2 cups baby spinach, baby kale or baby arugula

In a small heavy-bottomed saucepan, cook wild rice according to package directions adding 1/4 teaspoon salt.

In a separate small heavy-bottomed saucepan, cook quinoa according to package directions, adding 1/4 teaspoon salt.

In a small bowl, whisk together vinegar, lemon juice, maple syrup, mustard, the remaining 1/4 teaspoon salt and pepper. Set aside.

When the wild rice and quinoa are cooked, combine the grains in a large bowl and let cool to room temperature. Spread the grains out along the sides of the bowl; they will cool faster when spread out rather than heaped in a central pile. When grains are cool, add apples, celery, currants, scallions and greens. Add dressing and toss to coat.

Arugula Salad with Beets and Oranges

Anne Ornish “Undo It”

12 ounces beets (about 1 1/2 medium beets, greens removed)

1 tablespoon sherry vinegar

1 tablespoon frozen orange juice concentrate, thawed

1/2 teaspoon Dijon mustard

pinch ne sea salt

pinch black pepper

3 tablespoons thinly sliced red onion

4 cups baby arugula

2/3 cup navel orange segments (about 2 oranges or one can (15 ounces) mandarin oranges, drained)

Preheat oven to 400 degrees. Wash beets and wrap individually with aluminum foil. Cook until beets are tender when pierced with a fork, 50-60 minutes. Remove from oven, unwrap and allow beets to cool.

While beets are roasting, make the vinaigrette. In a small bowl, whisk together vinegar, orange juice concentrate, 1 tablespoon water, mustard, salt and pepper. Add red onions and let marinate for 10 minutes.

Once beets are cool enough to handle, peel and roughly chop. Place arugula in a large bowl. Add the beets and the orange segments. Lift red onions from vinaigrette and sprinkle them on the salad. Toss with half of the vinaigrette. Taste for seasoning and add remaining vinaigrette.

Serves 4.

Mediterranean Salad with Pita Crisps

Anne Ornish “Undo It”

1 whole wheat pita bread, split horizontally

2 teaspoons ground sumac

2 tablespoons fresh lemon juice

2 tablespoons pomegranate molasses

1/8 teaspoon ne sea salt

1/2 teaspoon ground pepper

1/4 cup thinly sliced red onion

1/2 teaspoon minced garlic

5 cups roughly chopped or torn baby romaine, hearts of romaine or little gem lettuce

2 cups cherry tomatoes, halved 1 cucumber, peeled, seeded and diced (1 1/2 cups)

1 cup at-leaf parsley leaves 1/2 cup fresh mint leaves

Preheat oven to 325 degrees. Line a small baking pan with parchment paper. Place split pita rounds on pan. Bake until dry and crisp, about 15 minutes. Remove from oven and let cool. Break pita into bite-sized pieces.

In a small bowl, cover sumac with 1 tablespoon hot water. Let steep for 5 minutes. Whisk lemon juice, pomegranate molasses, salt and pepper. Add onions and garlic. Set aside for 5 minutes to let onion soften and mellow.

In a large bowl, toss together lettuce, cherry tomatoes, cucumber, parsley and mint. Add pita pieces, soaked onions and half the dressing. Toss and taste for seasoning as needed.

***To make homemade pomegranate molasses, simmer 1/2 cup unsweetened pomegranate juice in a small saucepan over medium heat until reduced to 1 1/2 tablespoons, 10 -15 minutes. Watch carefully so it doesn’t burn. Remove from heat and stir in 1 1/2 teaspoons pure maple syrup.

Sumac, made from the dried berries of the sumac bush, is a crumbly reddishpurple powder with a bright, lemony taste. Look for it in shops specializing in Middle Eastern foods. If you can’t nd it, substitute 1 teaspoon each of ground cumin and coriander and omit the hot water.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

For decades, Calf-Tel® has set the standard for superior durability and

calves, Calf-Tel promises – and delivers – a wise investment.

Caramel Sauce:

32 individually wrapped caramels, unwrapped

5 tablespoons heavy cream

Bars:

1 cup all-purpose our

1 cup rolled oats

¾ cup brown sugar

½ teaspoon baking soda

¼ teaspoon salt

¾ cup butter, melted

½ cup semisweet chocolate chips

½ cup chopped walnuts

Preheat the oven to 350 degrees F (175 degrees C).

Make sauce: Melt together caramels and heavy cream in a medium saucepan over low heat; stir occasionally until smooth. Set sauce aside. Make bars: Mix together our, oats, brown sugar, baking soda and salt in a medium bowl. Stir in melted butter until well blended. Press 1/2 of the oat mixture into the bottom of a 9x13-inch baking dish. Bake crust in the preheated oven for 8 minutes. Remove from the oven. Sprinkle crust with chocolate chips and walnuts. Drizzle with sauce and crumble remaining oat mixture on top. Continue baking until the top is lightly toasted, about 12 more minutes. Cut into squares while still warm.

1 pound lean ground beef

Salt and freshly ground black pepper, to taste

1 yellow onion, chopped

4 celery stalks, chopped

1 tablespoon olive oil

3 cloves garlic, minced

2 tablespoons tomato paste

24-ounce jar of marinara sauce

1 tablespoon fresh parsley, chopped (or 2 teaspoons dried)

1/2 teaspoon dried oregano leaves

1 teaspoon dried basil

6 cups beef broth

9 lasagna noodles, broken into pieces

1 cup heavy whipping cream

1 cup shredded mozzarella cheese

1/2 cup freshly grated parmesan cheese

In a large pot over medium-high heat, cook ground beef until browned. Season with salt and pepper as you cook. Drain grease and remove meat from the pot. In a large pot heat olive oil over medium heat. Toss in diced onion and celery and sauté for about 5 minutes, stirring occasionally. Add in minced garlic and cook for another minute or two. Stir in tomato paste, marinara sauce, spices and broth. Return meat to pot. Bring to boil then add lasagna noodles (broken into small pieces) to pot and reduce heat to medium-low and cook, stirring occasionally, until noodles are tender. Once done cooking, add heavy whipping cream. In a small bowl, stir together mozzarella and Parmesan. Ladle the hot soup into bowls and dollop a scoop of the cheese mixture on top.

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation