WANT TO WIN $100 CASH?

See page 12 of second section for details!

See page 12 of second section for details!

25,

BRILLION, Wis. – Dan Dallmann and his family prefer to grow with the environment rather than against it. As a result, the Dallmanns have implemented practices that are better for the earth as well as their bottom line. They have become ultimate recyclers, repurposing manure for bedding, collecting

runoff water and putting it back on their elds, and capturing energy from the sun to run their digester.

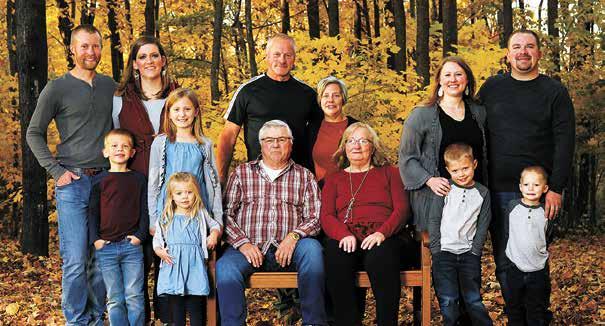

Dan and his wife, Shirley, farm in partnership at Dallmann East River Dairy near Brillion with their son, Nick, and daughter, Lindsay Hansen. Dan’s parents, Terrell and Darlene, started the farm in 1964 with 80 acres of land and 15 cows and remain active on the farm.

“My grandpa comes to the

STACEY SMART/DAIRY STAR

The Dallmanns’ Rain 360 unit sits in a eld June 27 where corn was no-�lled into rye on their dairy near Brillion, Wisconsin. The Dallmanns are using the unit to apply manure and runoff water to growing corn.

farm every day and hauls cattle, etc.,” Lindsay said.

The Dallmanns milk around 2,600 cows in a double-25 parallel parlor and farm 3,300 acres with 5,000 animals on-site.

Nick heads up eldwork and the farm’s digester, while Lindsay manages the books. Both Nick and Lindsay can also be found in the barn working with the cattle. The farm has 37 employ-

ees, including family members. Efciency in the parlor is a priority for the Dallmanns, who have created a unique milking schedule. Cows are milked 2.6

shortages, Volk said.

A portion of the roof of the previous show ring facility, known as the Big Red Barn, had collapsed in 2019, Volk said, rendering the building unsafe. That building was 130 years old.

CHIPPEWA FALLS, Wis.

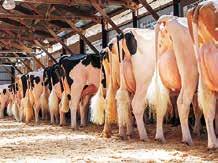

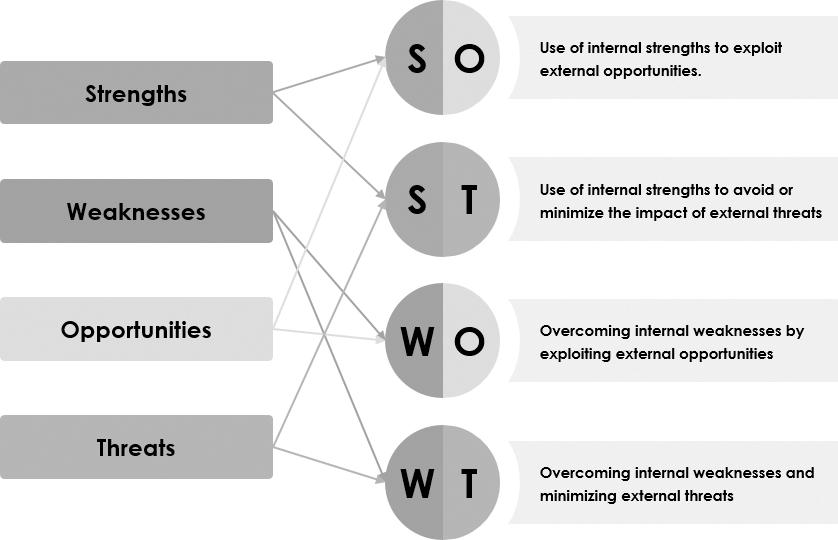

– When trucks and trailers lled with exhibitors and their animals rolled into the 125th edition of the Northern Wisconsin State Fair, they were greeted by the sight of two new cattle buildings and a new show ring facility.

“The old barns these new buildings replaced were all over 100 years old,” said Rusty Volk, executive director of the NWSF.

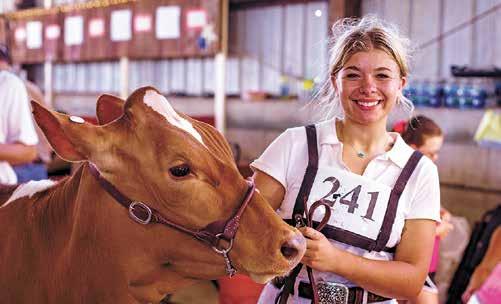

Exhibitors at the Northern Wisconsin State Fair showcase their animals July 16 in one of the new ca�le buildings in Chippewa Falls, Wisconsin. The buildings replaced deteriora�ng 100-year-old buildings.

“We did numerous studies and lots of strategic planning and determined that the best course of action was to replace the barns,

which we determined to be beyond repair.”

The coronavirus pandemic delayed the onset of the envi-

sioned building project and increased the eventual cost due to the availability of necessary building materials and labor

“We had been looking at a building project for several years, but that really became the catalyst,” Volk said. “We had to do something at that point. It was sad to let the history go, but we needed to move forward.”

Included in the nearly $7 million dollar building project were two new livestock buildings; a small animal building; a year-round, multipurpose building which can serve as a show ring venue; and a restroom and shower facility that will serve as a safety shelter in the event of severe weather.

At the conclusion of the 2022 NWSF, crews began the

125th edition of Northern Wisconsin State Fair features new livestock buildingsDANIELLE NAUMAN/DAIRY STAR

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

In the new U.S. Department of Agriculture supply and demand report, the milk production forecast for 2023 was left unchanged from last month. The outlook for 2024 declined due to lower dairy cow inventories and slower growth in milk per cow. Dairy exports were cut for this year, reecting lower butter, cheese and whey shipments. The weakness in butter exports is expected to carry over into next year. For 2023, prices for cheese, nonfat dry milk and whey are lower than the previous month’s forecast based on large supplies of cheese and competition in the NDM and whey markets. The Class III price forecast is reduced for this year and 2024.

Summertime blues

Even the most efcient dairy farmers are struggling with the current price situation. A quarterly report from the CoBank Knowledge Exchange said USDA’s estimated milk price to feed-cost ratio is at its lowest level since 2012. Protability is expected to bottom out in July and August before improving considerably this fall when Class III prices are forecast to increase about $3 per hundredweight. This downturn in milk prices is due, in part, to poor exports. South Korea is the second largest U.S. cheese customer, and sales are down 20% for the rst four months of the year. Mexico is the No. 1 buyer of U.S. cheese, and they are trying to make up the difference with a 14% increase in export volumes this year.

Farm loan numbers decline from 2022

As interest rates pushed higher, farm lending activity at commercial banks slowed during the rst half of the year. The quarterly report from the Federal Reserve Bank of Kansas City said the drop was due to a lower

average loan size and fewer farm loans compared to one year ago. As interest rates moved up rapidly over the past year, variable rates have become more common.

Wisconsin Sen. Tammy Baldwin and Tennessee Sen. Marsha Blackburn have introduced the Dairy Business Innovation Act of 2023. This bipartisan proposal will reauthorize and strengthen the Dairy Business Innovation initiatives that passed as part of 2018 farm bill. “I’ve heard directly from dozens of Wisconsin dairies that have expanded their businesses thanks to the Dairy Business Innovation Initiatives, and I’m proud to lead the charge to ensure this program has the resources it needs to help more businesses innovate and grow for the future,” Baldwin said. Since the program was created in 2019, DBI Initiatives have supported over $150 million in awards through regional centers nationwide. The new proposal will increase funding for these initiatives from $20 million to $36 million per year.

Competition, not consolidation

The White House and USDA met with representatives of 16 food and agriculture organizations July 13 to discuss the need for more competition in agricultural markets. According to a White House summary, the administration said consolidation can reduce the options for seed, fertilizer and farm equipment. The groups participating in the listening session included American Farm Bureau Federation and the Campaign for Family Farmers and the Environment.

US-China trade opportunities

U.S. Secretary of the Treasury Janet Yellen spent four days in Beijing, meeting with Chinese leaders. During the trip, Yellen said there is “ample room” for the United States and China to enhance their trade relationship. Despite recent tension between the two superpowers, 2022 was a record year for bilateral trade. Yellen’s visit is the second trip to Beijing by a Biden administration cabinet member in less than a month.

Budget signed into law

Wisconsin Gov. Tony Evers has signed the 2023-25 budget. For agriculture, the bill includes support for the Dairy Processor Grant Program and the Producer-Led Watershed Protection Grant Program. The budget features $150 million for the new Agricultural Road Improvement Program. A total of $6.5 million is devoted to nonpoint source pollution abatement.

meets

The Wisconsin Farmers Union summer conference was held at Lake Wissota. A new WFU building project in Chippewa Falls was discussed. WFU purchased the building for its ofces. In addition, a restaurant and retail locations are planned.

WDE to remain in Madison Madison, Wisconsin, will continue to host World Dairy Expo through 2028. A new ve-year contract was signed for the massive dairy event. Madison has hosted every World Dairy Expo since its inception since 1967.

Torres Small conrmed as No. 2 at USDA

Xochitl Torres Small has been conrmed by the Senate as the next deputy secretary of agriculture. Torres Small has served as an undersecretary

at USDA since 2021 and was a member of Congress from New Mexico for one term. Torres Small was conrmed by the Senate on a vote of 79-8.

DFW elects ofcer team

Janet Clark, who is a dairy farmer from Rosendale, Wisconsin, was unanimously reelected as president of the Dairy Farmers of Wisconsin. Gail Klinkner of Viroqua, Wisconsin, was elected vice-chair. The DFW secretary is Sandy Madland of Lyndon Station, Wisconsin, and Mark Crave of Watertown, Wisconsin, is treasurer.

Hero of hope

Bob Nash has been honored as the Wisconsin Farm Bureau Hero of Hope award winner. Nash works at Golden E Dairy Farm at West Bend, Wisconsin. When a re occurred at a nearby dairy farm, Nash relocated the cattle that survived the re and organized the debris cleanup.

The union for employees at the New Dairy Select Milk at De Pere, Wisconsin, is on strike. The company’s health care plan is the sticking point for the labor dispute. Borden Dairy is the parent company for the De Pere sour cream facility.

‘Top Chef’ coming to Wisconsin

The 21st season of the “Top Chef” television show will take place in Milwaukee and Madison. Evers welcomed the news. “We’re proud to be known here for our rich food culture, talented chefs and exceptional local ingredients,” Evers said. As America’s Dairyland, dairy products will likely garner a lot of attention during the Wisconsinbased broadcast.

Trivia challenge

Dippin’ Dots is the ice cream company that bills itself as “the ice cream of the future.” That answers our last trivia question. For this week’s trivia, when is National Ice Cream Day? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

work of demolishing the existing agricultural exhibition buildings at the fairgrounds. While some work on the various pieces of the project remains to be nished, all of the buildings with the exception of the severe weather shelter were operational prior to the rst day of this year’s fair, which took place July 12-16.

“It has taken a lot of community support to bring this project together,” Volk said. “The fairgrounds is a private, non-prot facility. We had many donors and were able to apply for and receive a FEMA grant.”

The two new cattle buildings, one which is named the Rooney Grain Building, are naturally ventilated and include side curtains that can be raised for increased airow. Between the two buildings is a concrete wash rack, which drains appropriately into the sewer system, eliminating any concern of runoff affecting nearby waterways.

“We really wanted to make these buildings so that the exhibitors would enjoy coming to our fair,” Volk said. “There is 10 times the electric power available in the new buildings as there was in the old barns.”

The oors of the cattle buildings are cemented, allowing for the buildings to have multipurpose functions outside of housing cattle, similar to the other new facilities. Volk said that during the planning phase, emphasis was placed on allowing for ease of movement of cattle throughout the campus.

The L.E. Phillips building is designed for housing smaller species of livestock, while the Custer Coliseum is a year-round, multipurpose facility which will have both heat and air conditioning systems. That facility will serve as the livestock show ring during the fair.

“We want the Custer Coliseum to be a well-utilized building throughout the year,” Volk said. “We want it to serve the community as an educational venue.”

A unique aspect of the Custer Coliseum, Volk said, is that the interior is nished with pine boards milled from 28 large pine trees that were taken down as part of the demolition of the previous agricultural exhibition campus.

While Volk was sad to see those old

pine trees go, he said that more than twice as many trees were planted to replace those cut down, including 20 larger trees that are already over 5 inches in diameter. For many exhibitors, the NWSF ranks as one of their favorite activities of the summer, and the new facilities enhanced that experience this year.

Stephanie Hughes and her family milk 55 cows on their Pittsville dairy farm. Hughes has been exhibiting at the fair for over 30 years. This year, with her sons Bryce and Gavin, Hughes took ve head to compete this year.

“This is one of our favorite fairs that our family loves to show at,” Hughes said. “We have so many fun memories from the old barns, but we started making more memories in the new barns this year.”

Melissa Boehlke, a dairy farmer from Thorp, milks 50 cows with her family. Boehlke rst came to the NWSF as an exhibitor nine years ago with her daughter and a March calf. This year, her family exhibited three head and was honored by the show staff with the Tom Hinke Recognition Award for her positive and courteous approach towards exhibiting at the fair.

“I loved the nostalgia of the old barns, but the new barns are very nice,” Boehlke said. “It is a good feeling to see the investment in agriculture that the fair has made, especially during a time when ag seems to be an afterthought or left behind all together.”

Hughes agreed.

“There was a bit of a learning curve with the new facilities, but they are so beautiful,” Hughes said. “We appreciate everyone that made them possible.”

Volk said the exhibitors and the wellbeing of their animals, along with a dedication to agriculture, were primary considerations during the planning phase.

“We really wanted to make sure we were looking ahead to the future with this project,” Volk said. “We plan for it to serve our fair for our next 100 years. Our goal was a beautiful facility for our exhibitors to showcase their animals. We think we achieved that goal. Our new campus is one of the nicest in Wisconsin.”

Con nued from DALLMANS | Page 1 times per day, or every 9 hours and 20 minutes, around the clock.

“This made us more efcient, and we didn’t see a loss in milk production,” Lindsay said. “It works well, and employees still have an eight-hour shift.”

The Dallmanns previously milked three times daily before implementing this new strategy in February 2022.

How they manage the farm’s manure has also changed over the past decade. In 2012, the Dallmanns installed a digester and use all solids for bedding while selling excess bedding to several farms.

“We sell ve to six semi loads of solids per week,” Dan said. “There is good demand for it.”

Prior to bedding with manure solids, the Dallmanns used wheat straw. They had mattresses when switching over to solids but eventually converted to deep beds. The solids proved to be a cost savings for the Dallmanns while also providing a protable side business.

At rst, the digester used a 600-kilowatt engine to produce electricity. In 2020, the digester was converted to produce renewable natural gas that is injected into a pipeline for transportation fuel. The digester produces between 1,500 and 1,800 diesel equivalents per day.

U.S. Gain owns the 1.5-million-gallon digester while the Dallmanns supply the manure and maintain the pumps. Last year, the Dallmanns installed a 3-acre solar eld to power the

The Dallmann family installed this 3-acre solar eld last year to power their 1.5-million-gallon digester, which has helped lower their carbon intensity score. The digester consumes 97% of the solar energy while excess energy feeds the grid.

digester, which has helped lower their carbon intensity score.

“The more carbon you create, the less incentives you receive,” Nick said. “The lower this score is, the better off you are.”

The digester consumes 97% of the solar energy. Excess energy charges the battery, and any excess beyond that feeds the grid.

Seven years ago, the Dallmanns nearly eliminated the need to truck manure when they installed 3 miles of underground manure pipeline.

“We have 600 acres on either side of the Manitowoc River,” Dan said. “That’s 1,500 truckloads of manure we don’t have to take over there now.”

There are 10 locations the manure can travel to, and from there, the Dallmanns can hook up a hose and do their applications. Cover crops and no till practices at Dallmann East River Dairy are having a profound

impact on soil health and quality while also saving the farm money.

“We’ve been pretty heavy into cover crops the last three to four years,” Dan said.

The Dallmanns’ corn was 100% no till this year, and 50% of their land is in cover crops.

They typically plant rye which they terminate in the spring and no till corn into. The Dallmanns harvest about half of the rye as feed for heifers, which are housed on-site starting at 5 months old.

The Dallmanns’ crop practices have improved soil structure, retaining more moisture during dry periods and reducing erosion in wet periods.

“No erosion in the elds is a huge benet we have seen by no tilling and planting cover crops,” Dan said.

The crop practices also require fewer passes per eld and less fuel use per acre, Nick said.

“That’s important with the cost of fuel, machinery and la-

bor,” Dan said. “We get 1,300 to 1,400 acres planted quicker.”

In 2014, the Dallmann family took a new approach to managing bunker leachate when they created a separate 8-million-gallon pit devoted to collecting runoff from the bunker as well as runoff from barnyards.

“We used to collect the rst ush, and the rest was runoff,” Nick said. “We pumped it into the manure pit, but dirty manure is not as nutrient-dense, so we wanted to separate it out. Now, we collect 100%. The nutrient value is minimal; therefore, it works well as irrigation when it’s dry.”

The dairy has two center pivots that draw from this holding area to irrigate crops. This year, 1.2 inches of water was applied on growing hay between rst and second crop.

“That’s the biggest benet, and it’s nice to see us properly using this pit how we intended,” Dan said.

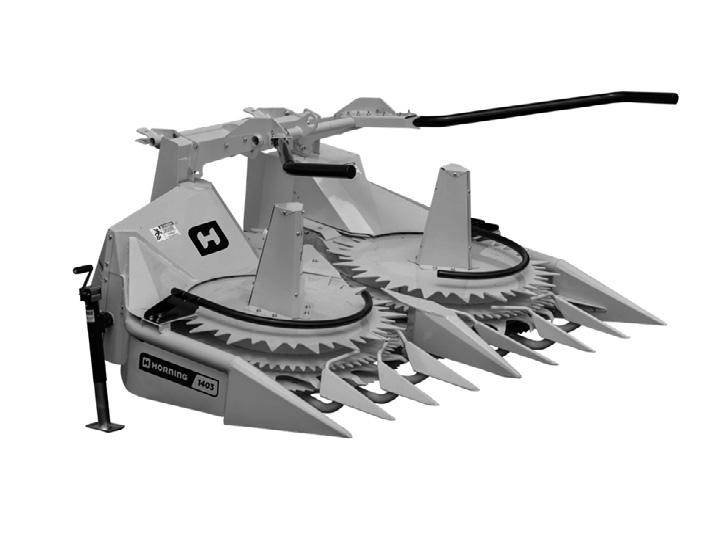

The Dallmanns recently began using a Rain 360 unit to apply manure and runoff water to corn in season. Rain 360 is a three-wheeled electric vehicle that uses a small diesel engine and follows paths created by the planter to provide total eld coverage. The automated system applies water at a rate of 250 gallons per minute, requiring lower volumes than traditional pivot systems.

“It caught our eye when we saw a way to get manure on the corn while it’s growing,” Dan said. “It can apply when the corn is 6 to 8 feet tall even.”

Nick said the new technology will cut down on eld applications and allow them to concentrate on putting all nutrients on in season instead of in the fall.

“When corn is knee high and starting to tassel, we can put half manure and half water on it,” Nick said. “When it’s dry, we can add more water and then add more manure when it needs the nutrients. You can dial in based on current weather conditions.”

From land to cattle, creating efciencies and cost savings go hand in hand at Dallmann East River Dairy. The Dallmanns demonstrate an ongoing commitment to sustainability – a commitment that has grown as their farm grows.

“There are so many practices that can benet both a farm’s bottom line and the environment,” Nick said. “We have to be efcient, so we try to implement as many of those kinds of practices as we can.”

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

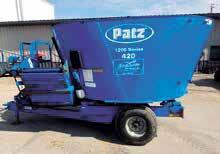

CASHTON, Wis. – Caring for the 2,500 milk cows at MDS Dairy in Cashton is made easier with the use of technology in many forms.

Participants of the National Jersey Convention were able to tour the farm June 23 and see some of the equipment in action. Even though the farm is home to Holsteins, tour goers were able to receive an education on the benets of progressive tools.

MDS Dairy is owned by Phil Mlsna, who is also the owner of the DeLaval dealership in Cashton. The farm has been managed by Jered Hemmersbach for the last 23 years. Hemmersbach lives on the farm and is in close communication with the team of employees throughout the day.

The mixer holds 26,000 pounds of feed and is equipped with a cab and a conveyor to load the feed. A second person mixes the dry ingredients that are stored in a commodity bay three times a week.

Hemmersbach said the machine saves labor and maintenance costs.

“You don’t have a tractor, TMR and a loader and the wear on all of that,” Hemmersbach said. “Otherwise, you’d have to have three guys, or (the employee) would be walking all the time. In that sense, it saves a huge amount of time.”

Once feed is made available to the cows, it is pushed up every hour by the most recent advancement on the farm: two robotic feed pushers. In just 11 minutes, the robot can push up feed to all 1,200 cows in the freestall barn.

Manure is scraped three times a day using a Mensch manure vacuum. The vacuum is also used in the youngstock facilities. The machine handles bedding from all of their facilities, which includes sand in the cows’ free stalls, sawdust in the heifer barn and straw in the calf barn.

The mornings start early at MDS Dairy, with the feeder arriving by 4 a.m. One person mixes feed for all the cows, heifers and dry cows, using a self-feeding total mixed ration.

Cows are milked three times a day in a double-30 parlor. Four employees are on each shift, with three in the parlor and one moving cows and cleaning barns.

In order to achieve healthy and productive cows, calves are raised onsite with a strict protocol. For the rst week of a calf’s life, it stays in the nursery. MDS Dairy averages about eight new calves per day. Fresh colostrum is pasteurized and then stored in a refrigerator and heated up in a colostrum warmer when calves are born. They are tube fed the rst feeding, and their navel is dipped within a half an hour of birth.

Every Monday, the calves that are thrifty and aggressive and at least 1 week old get moved to the calf barn with automatic feeders. In their rst week in the barn, the calves are hand fed three times a day. In their second week, they are hand fed twice a day and pushed to the feeder once a day at noon. In the third week, they are

“Since installing the Westwaard 150-bottle washer and stand alone pasteurizer, we have found a huge benefit in labor savings and consistency. Prior we were only able to pasteurize enough milk for the younger calves and had to hand wash each bottle. The service from Fuller’s has been excellent.”

Feed is mixed June 23 at MDS Dairy near Cashton, Wisconsin. The self-feeding total mixed ra�on has increased efficiency by saving �me and maintenance.

pushed to the feeder twice and hand fed once. Hemmersbach said by that third week, the calves are usually utilizing the automatic feeder on their own.

“We found that they don’t go backward as fast as when we were relying on the machine exclusively,” Hemmersbach said. “By the time they’re 30 days old, you just make sure there’s powder in the machine.”

The calf barn has ve automatic feeders in separate pens. Each pen is all in and all out, meaning the calves move as a group. It is cleaned every week, and calves are weaned at 56 days.

Two weeks after calves are weaned, they move to the heifer barn, which holds about 700 heifers, and stay there until they are pre-breeding

age. The barn has free stalls with sawdust bedding even in the youngest pen.

“They go from the calf barn right here to the free stalls,” Hemmersbach said. “We had no idea how it was going to work, and I’ve been really happy and impressed with it.”

With all of the advances in technology, Hemmersbach appreciates being able to utilize the data that the automation presents.

Future plans are being made to add a manure digester to the farm.

“You can look at what feedback the technology is giving you and decide how to use that data,” Hemmersbach said. “You can make educated decisions and nancial decisions that will better your dairy and your employees.”

NEW MF ROUND BALERS, 4160V and 4180V ON HAND, RotoCut, Auto Oiler - CALL NOW (WATERTOWN)

2022 KWIK TILL AVAILABLE HIGH

2016 MASSEY 8732, 1900 Hrs., CVT, Front 3 Pt./PTO, Luxury Package, EX Condition $215,000 (Watertown)

Seeds, IN STOCK READY TO GO

2017 SUNFLOWER 9435, 40 Ft. Drill, Small Seeds, Bin Level Sensors, Blade Scrapers, VG Cond $88,900 (Potter)

EDGAR, Wis. – Tucked away in the rear of her family’s oral shop is a hidden gem operated by Krystle Guerrero-Schmitt, which features an old-fashioned soda fountain and lots of local history.

The Back Room Ice Cream Shoppe, located in Edgar, was originally established in 1995 by Guerrero-Schmitt’s mother, Karen Schmitt.

“I grew up helping in my family’s businesses and have always loved the service industry, and I love making people happy,” Guerrero-Schmitt said. “Ice cream makes people happy. Taking the reins and running with this was a natural t for me.”

Guerrero-Schmitt began working in the ice cream shop when it opened and took over the business in 2005, while she was still in college.

“Mom had so much going on with her other businesses that I took this over to help her out,” GuerreroSchmitt said. “It’s been my baby ever since.”

The space had previously housed a video rental store and was sitting empty, waiting for its new purpose. That purpose came when the Edgar Drug Store closed. The old-fashioned soda fountain that had been operating there was looking for a new home. The two seemed a great t.

While the idea seemed great, it was not without obstacles. Moving a 12-foot long, 1-ton soda fountain was not an easy proposition, Guerrero-Schmitt said.

“It took eight men to move it,” she said. “They got it up onto pipes and rolled it down the main street of town. They kept moving pipes from the front to the back as they went down the street. They got it through the door and parked it there. It sat in that spot for the next 25 years until we took advantage of the pandemic and did some remodeling.”

In addition to the soda fountain, the service counter, stools and malt machine were purchased from the drug store, keeping the aesthetic of the ice cream shop whole. Continuing with that theme, The Back Room Ice Cream Shoppe is lled with nostalgic decor that celebrates the heyday of the traditional soda fountain and ice cream parlor.

Guerrero-Schmitt and her staff, which consists of three or four employees throughout the summer, serve up Cedar Crest ice cream. The store’s ice cream case holds 19 tubs for serving, so Guerrero-Schmitt rotates the avors offered between the tried-and-true customer favorites and the company’s seasonal specialty avors.

On a weekly basis, Guerrero-Schmitt said she orders between 15 and 25 3-gallon tubs of ice cream varieties. Her largest weekly order has been for 30 tubs.

“Some of our best sellers are Superman, Pirate’s Bounty and Caramel Collision,” Guerrero-Schmitt said. “This year, anything with mint in it seems to be selling really well too.”

As far as volume of a avor, Guerrero-Schmitt said she orders more vanilla ice cream than any other avor – typically four tubs per week – because it is the base in so many offerings.

Besides the ice cream, Guerrero-Schmitt offers various avors of a version of old-time phosphate sodas and a variety of other vintage-like ice creambased novelties including banana splits, oats and malts, all made the old-fashioned way.

“Our malts are traditional; they are made in our malt machine,” Guerrero-Schmitt said. “We get so many compliments on the malts, people telling us they are just like they remember from their childhood.”

That link to the past has helped solidify GuerreroSchmitt’s customer base of residents.

“People really like the nostalgia; they like that feeling they get when they come in and things are like they were when they were young,” Guerrero-Schmitt

This 1-ton soda fountain, which has called The Back Room Ice Cream Shoppe home for 28 years, has been a familiar sight in the community for decades as a part of the Edgar Drug Store in Edgar, Wisconsin.

said. “Many of our customers grew up visiting or working in the Edgar Drug Store’s ice cream parlor.”

As her business has grown, Guerrero-Schmitt has added new items to her menu to help keep pace with the palate of a growing customer base, including other beverages that utilize the sparkling water needed to make the phosphate-type sodas and fruit-based smoothies. Guerrero-Schmitt and her sisters have a coffee roasting business, and she has integrated coffee-based treats into the menu

Guerrero-Schmitt opens The Back Room Ice Cream Shoppe from early May through mid-to-late September, depending on inventory. During the remainder of the year, she focuses on other business ventures.

Business is booming for GuerreroSchmitt throughout those months, she said, and she credits the small-town community atmosphere for that.

“We don’t do a lot of advertising, just in our local paper and shopper,” she

said. “We put signs around town. We just recently entered the world of social media. We rely a lot on word-of-mouth advertising and repeat customers.”

The local schools, day cares, churches and other organizations make The Back Room Ice Cream Shoppe a destination for their groups.

In her social media marketing, Guerrero-Schmitt tries to focus on interactive marketing to draw customers to the ice cream parlor, with giveaways and contests for followers.

For Guerrero-Schmitt, everything goes back to that 1-ton soda fountain that was rolled down the street 28 years ago.

“The fountain, and now The Back Room, have been a part of Edgar’s history for such a long time now,” she said. “It’s been a part of my whole life. I remember going to the drug store as a kid, and now I can provide that same experience for someone else. It’s a cool thing that they are both still here.”

What has been key to your longevity with DHIA? I was born and raised on a dairy farm and this was the rst position I was offered after leaving the farm. I guess you could say it has kept me close to the farming community. I may not be milking cows but am not too far away from the farm with this position. There are also very few dull days.

Every day you seem to learn something new.

What is your current title and some of the jobs you do? Manager of DHIA Laboratories in Sauk Centre. I manage the day to day operations of the lab and repair instruments to keep samples owing through the lab.

What do you like about your role for DHIA? Giving the DHIA members the accurate analysis they deserve. We know many decisions are based off of the different testing options we offer so we must give accurate results to all of the members and nonmembers that use our services.

How has DHIA continued to adapt to help dairy farmers?

We have added additional types of testing. When I started it was just fat, protein and SCC. You now have the option to have MUN, other solids, pregnancy, Johne’s, leukosis or fatty acids tested from the same DHIA sample. We have also added other testing like manure analysis. From test day to members having results in their hands has also drastically improved. We know everyone needs the info in their hands as soon as possible, so the DHIA staff does what can be done to make that happen. It doesn’t take 10 days for this to happen like it used to. DHIA eld techs also continue to adapt to all the different farm types and sizes including robots. DHIA continues to add additional reports for the members.

What message would you like to send to the dairy farmers you work with? Thank you for your continued support of Minnesota DHIA. Without you this organization, lab and eld staff wouldn’t exist. We also hope that milk prices improve for all of you.

What do you enjoy doing in your spare time? I enjoy spending time with family and friends. I used to enjoy playing sports, but I am now too old for that. I have switched from sports to starting owers and vegetables from seed in the spring, and then plant them and take care of them the rest of the summer. I also like having a nice green lawn. In the fall I like to cut and split wood. Starting in November I start putting up the Christmas light display for the community to enjoy during the Christmas season.

“...giving

s hot

I have

hard time keeping my dry matter intake up.”

WAUKESHA, Wis. – Before there were light bulbs or telephones, there were county fairs in Wisconsin. Held in the city of Waukesha, the rst fair took place in 1842 – six years before Wisconsin became a state. The fair featured reworks and a festive dinner as well as a plowing match between farmers.

Celebrating its 181st anniversary July 19-23, the Waukesha County Fair is Wisconsin’s oldest fair. Although much has changed since that rst fair held in a poplar grove on the Fourth of July, the concept of competition remains the same.

A highlight of the county fair from nearly the beginning was the dairy show. Brittany Renn Gerrits, a member of the Waukesha County Fair’s dairy superintendents’ committee, said the fair started as a dairy summer exposition show and evolved into the county fair.

“For many years, we had lots of dairy cows in our area,” Gerrits said. “During the 1980s, there were over 300 herds in Waukesha County. Now, it’s down to less than 10. Back then, the show barn used to have no tack space; it was full all the way through.”

The show shrunk as time went on, and last year, 40 head of dairy cattle were exhibited. This year, about 50 head were entered.

“We saw some growth from last year, which is great,” Gerrits said. “It’s a smaller

show, and each kid usually has one animal they really focus on. Most of the animals are heifers with just a handful of cows.”

Animals are shown by 30 to 35 4-H youth exhibitors, many of whom come from the city.

“With lots of urbanization and change through the generations, we went from being called Cow County USA down to what is now a pretty unique show,” Gerrits said. “Almost none of the kids showing come from dairy farms.”

When Cozy Nook Farm opened up its dairy project in March, many kids had never stepped foot on a farm before, let alone walked into a pen and put a halter on a calf, Gerrits said. A lot of development takes place in a short time as youth go from timid to condent in working with cattle.

“We’re building a herdsman from the ground up, and there’s a lot of work that goes into that,” Gerrits said. “The parents don’t have experience either, so both are learning at the same time.”

Because these youth do not do the dayto-day work on a dairy farm, Gerrits said the atmosphere is different from a county fair where a kid might have delivered their show animal as a calf and showed her until she was a 5-year-old cow.

“A lot of times, we don’t have that story here,” she said. “When my parents showed, everyone came from a farm.”

Waukesha County offers classes for all seven dairy breeds, but typically the Brown Swiss, Guernsey, Holstein and Milking Shorthorn breeds are shown. Classes range from a spring calf up through a 5-year-old

cow within each breed. Last year, the show was moved into the dairy barn, and now, half of the barn is devoted to housing animals while the other half is re-served for show space.

“The winter calf classes are pretty big because that animal is the right size and age range for kids to handle comfortably,” Gerrits said. “We’re still in the white shirt and white jeans era, and kids who never had to buy a white pair of jeans before in their life are having to buy them for the show.”

Three showmanship classes are offered – junior, intermediate and senior. Showmanship also recognizes rst-year showmen, who receive a medallion welcoming them to the dairy project. Grand champions of each breed are named along with a junior and senior supreme champion and overall supreme champion.

“There is an open show in the book, but rarely does anyone show in that,” Gerrits said.

The Waukesha County Fair also holds a milk quality contest based on a cow’s DHI test. The exhibitor with the top milk quality cow in each lactation gets to sell a Golden Gallon in the livestock auction. The purchaser of that gallon receives an engraved glass pitcher lled with owers, and the exhibitor is given the proceeds.

Gerrits handles all the awards for the show – from nding sponsors to ordering awards – and said prizes have changed quite a bit in recent years. Historically, each class winner received a plastic trophy, while a bigger trophy was given to the grand champion. But prizes have since transformed into items kids can use, Gerrits said. For example, class winners now receive supplies to use in the barn or in the future, such as folding tables, chairs, coolers and back-packs.

“These are things they can take out into their everyday lives and use as they go for-ward,” Gerrits said. “It’s fun to think outside the box a little bit.”

The fair continues to provide ribbons to each exhibitor as well as trophies for grand champions. They also offer a premier exhibitor award which is based on a point system. The top ve exhibitors receive prots from baskets sold at a silent auction that takes place during the show.

“This provides motivation to come back with a vengeance next year with more animals and do better in showmanship,” Gerrits said.

When it comes to sponsors, Gerrits said a great group of farm families in the county step up every year. Families that have started showing or grandparents of 4-H kids will donate money toward a class or junior champion. Breed associations also donate.

Five volunteers at the Waukesha County Fair specialize in the dairy side of things. They receive help from an overall livestock superintendent, board of directors and fair president.

“Many hands make light work,” Gerrits said. “Whether we’re moving gates or taking down the show ring, we call on a lot of the kids – especially the older ones – to

be leaders and rely on them to help us get things where they need to be.”

Held in Plymouth every Labor Day weekend, the Sheboygan County Fair is not far behind Waukesha County in longevity and will celebrate its 172nd year in 2023.

Dairy superintendent Trevor Mentink is one of three superintendents for the fair’s dairy show. Mentink, who grew up showing at the Sheboygan County Fair, said showmanship records for the show date back to 1948 when an overall champion showman was selected.

“When I was a kid, there were quite a few animals in the show,” he said. “Our barn was always very full, and there was not enough space. We used to have lofts in an old barn where we kept supplies, but it got to the point where there was nothing but animals in there. Now, we have plenty of space for animals, tack and supplies.”

The one dairy barn on the grounds has been a part of the fair since it started and is listed on the National Register of Historic Places. Last year’s show welcomed 177 dairy animals to the fairgrounds, with 95 entries shown by 43 youth exhibitors in the junior show and 82 entries in the open show. Mentink said those numbers are small compared to past years, but numbers are holding steady for the time being.

“Our dairy show has gotten considerably smaller in the last 25 to 30 years,” he said.

Unlike Waukesha’s fair, youth exhibitors at the Sheboygan fair are a mix of dairy farm kids and kids adjacent to a farm, Mentink said, such as someone who helps on a farm or has grandparents who farm.

The youth show is a day-long event that takes place on Friday starting at 9 a.m. Cows are shown rst followed by heifers in the afternoon. Showmanship classes are held Saturday morning followed by the open show which begins around noon. The futurity is held on Sunday.

“We have a very popular futurity contest with close to 30 entries,” Mentink said. The Sheboygan County Fair is home to the largest Holstein futurity in the state.

According to Mentink, competition in the dairy show is fairly stiff.

“Last year’s Holstein spring calf class contained three animals that were nominated All-American,” Mentink said.

Holsteins are shown alongside Red and Whites in the registered and grade Holstein classes, which make up the majority of the show’s animals. There are also “any other breed” classes in which Jersey, Ayrshire, Brown Swiss and Guernsey cattle can compete in a class together by age group.

“These classes are primarily Jerseys, but we also have some Brown Swiss that show up,” Mentink said.

All exhibitors receive a ribbon, while the rst-place animal in each class is awarded a larger rosette ribbon, Mentink said. The fair also holds four showmanship classes divided according to an exhibitor’s school grade.

“There are special prizes throughout the show as we get further into it,” he said.

Junior and senior champions and overall best of show receive banners and chairs. The champion rst-year showman or highest placed in the youngest showmanship class receives a traveling trophy. Special recognition is also given to an individual selected from the entire dairy project, and an overall champion from all breeds is selected as well.

When showing, exhibitors wear white pants and a solid-colored top.

“When I showed as a kid, we also wore hats,” Mentink said.

Kids have an opportunity to win money in a competition known as the Showcase of Champions. The top two winners from each showmanship and the champions of the junior and senior show are placed into an auction setting with their animals while gift baskets are bid on to generate revenue for the top exhibitors.

“This is a way for the community to help support the dairy project in Sheboygan County,” Mentink said.

In addition, a special class known as Farmer Bud creates such a buzz that it lls stands to capacity. In this class, kids too young for 4-H have the opportunity to show a calf. These future showmen get their moment in the spotlight on Saturday when they bring a small calf and walk it around the ring a couple of times. At the end, they receive free ice cream.

“The stands ll up quite fast because parents and grandparents want to see the little kids showing,” Mentink said. “It’s usually standing room only.”

There is also a herdsmanship compe-

tition in the barn between 4-H clubs and FFA chapters to promote keeping exhibits in good condition.

“This is sort of like an MVP sportsmanship-type award,” Mentink said. “Last year, this award was given to an entire club for their efforts to help support one of their members who is in a wheelchair.”

Mentink said most show sponsors are dairy folks – farmers and industry persons wanting to encourage showing in the next generation. Grocery stores, car dealerships and other businesses also help sponsor the show.

“These sponsors are typically people who had experiences at the fair themselves and want to give kids the opportunity to have similar experiences,” Mentink said.

Volunteer involvement before and during the show are critical to its success. Mentink and his committee collect entries, decide the layout of the barn, create a show schedule and do many other tasks to get the show up and running.

“Keeping the barn clean and tidy and presenting ourselves the best we can to the public is always our goal during the fair,” Mentink said. “My family does a lot of showing throughout the year, and at the county fair, we’re trying to promote dairy and make it an enjoyable time for the kids.”

This is county fair season with many fairs taking place now through Labor Day weekend. Whether large or small, the fair is a longstanding family tradition that provides kids with experiences they will remember for a lifetime.

“It’s important for people to continue to support county fairs,” Gerrits said.

Tell us about your dairy 4-H projects and what you plan to show at the fair this year. My 4-H projects mostly consist of dairy animals. We have had the most success with Jerseys so far, but we do also show Holsteins and Ayrshires. This year, we have our most exciting lineup of heifers, including bred and owned and purchased heifers. I will be focusing on my summer yearling Jersey heifer.

What does your schedule look like leading up to the fair? Our show season begins as soon as it is warm enough to wash the heifers. We have our show heifers separated throughout the year to make sure they have their certain feed. We work closely with Richard Breunig, our nutritionist, to create a balanced diet for our show heifers. We clip our heifers for the rst time in early spring to remove their winter coat. We then continually clip them throughout the summer to maintain a short and healthy coat. For shows, we clip the heifers one or two days before the show. We get the heifers out every day and rinse them down – so that they grow better topline hair – and take them for a walk. Walking and training them is what takes the most time. They will usually go on 20- to 30-minute walks each day. Showmanship is valued to me, so I make sure our heifers are well trained. It takes a long time to gain the trust of these animals to the point where they aren’t scared of anything. As youth showmen, we are subject to many people being curious about our animals and coming up to us when we are with our animals. It is important to have animals that are comfortable with this exposure.

What are three things you must have with you at the fair? My tack box, lawn chairs and a speaker. Our tack box has everything we could possibly need in it, and we make sure to keep it full with the many sprays, creams and tools we use. Chairs and a speaker are essential for a good time at shows. Blasting music and chilling out with your friends and family is what makes these shows so memorable. It's a time when you get to hang out with the people you enjoy spending time with.

Natalie Mauk13 years old

Parents: Bryan and Brittney Mauk

Plymouth, Wisconsin Sheboygan County

Tell us about your dairy 4-H projects and what you plan to show at the fair this year. I will be showing three Holsteins at the Sheboygan County Fair this year. I plan to show a Red and White winter calf, a spring yearling, and a Red and White 2-year-old cow.

What does your schedule look like leading up to the fair? If we need to halter break our heifers, we start that process about three months before the show, depending on the animal age and their attitude. Once they are halter broke, I tend to walk them every day or every other day roughly a month before the fair. When we get to about two weeks before the fair, I try to walk them twice a day for about 10 minutes each time. Since we show our heifers at other shows throughout the year, they get clipped often. We try to rinse them down on a regular basis to help with hair regrowth as that is very important. Our show animals mainly get fed grain, protein pellets and grass hay. We have a separate barn where we keep our show heifers, which makes it easier to feed them and work with them. My job is to always make sure their pack is clean and that they always have a good pile of hay in front of them.

What are three things you must have with you at the fair? Every year, I like to bring snacks and drinks with me to the fair as you don't know when your 4-H club will get hungry. Another item we always have with us is a water ltration device to help lter the water to encourage our animals to drink. I would say the last thing that we must have at the fair is a clipping chute to get them ready on show day.

What do you enjoy doing at the fair when you are not showing? I enjoy hanging out with other people at the shows. Most youth exhibitors are welcoming and friendly. It’s a positive experience playing music, playing beanbag toss, and enjoying rides and food that the fair has to offer.

Describe a challenge you faced in preparing for the fair or while showing and how you overcame it. The hardest struggle isn’t the time or effort you put into your project but having to experience losing one of your animals. Losing a show animal is one of the worst experiences you can go through as a young kid. You work with that animal for its whole life and watch it grow up from a calf, so losing it is like losing a member of your family. This, however, makes you a stronger person and makes you value life more than you would have.

How has showing dairy animals helped shape the person you are? You become responsible for the life of an animal. You also get to learn the feeling of winning, but more importantly, you get to learn how to lose with dignity. No one ever wins every class they are in or show they are at, which just gives you something to work harder toward.

What is your most memorable moment from the county fair? The most memorable moment from the county fair was winning best of show with my heifer, Spark. This was the rst Jersey heifer we had ever shown and would lead to many more shows and the start of our Jersey herd. She won the entire fair, and then later that night, she gave birth to a healthy calf in the barns at the fairgrounds while crowds of people watched. The barn was completely full with people observing this common occurrence for farmers, but a once-in-a-lifetime event for most individuals.

Tell us about your farm and family. We have a double-16 swing parlor where we milk around 550 cows. Our milk is then shipped to BelGioioso Cheese. Our farm is around 650 acres. We have workers who do most of the milking. Our family consists of me and my brother, Thayne, who takes care of all the show heifers; my sister, Caylee, who enjoys showing pigs as her summer project; and my parents, Matt and Kim. Kim takes care of all our calves on the farm, and Matt does all of our breeding and feeding of our animals. Then, my aunt Erin helps with the treatment of sick cows on the farm. My cousins, Maggie and Delaney, also share an interest in showing dairy animals. My brother and I have really grown because of showing animals. We are both passionate about what we do and are always nding ways to make our show string better. It fuels a friendship between us instead of just being brothers.

What do you enjoy doing at the fair when you are not showing? There are a lot of things I enjoy at the fair when I am not in the show ring, but the most important one is spending time with friends and getting to know more people. We go on rides, eat lots of food, walk the barns and play games.

Describe a challenge you faced in preparing for the fair or while showing and how you overcame it. One challenge that I have been facing this year is that one of my heifers likes to side step and swing in the show ring. This has been a challenge for me and a hard thing to try and correct. I have been working with her on loud sounds and having my siblings walk on her sides and behind her. I also try to walk her in unfamiliar places to hopefully get her used to change.

How has showing dairy animals helped shape the person you are? Showing dairy animals has taught me to be responsible and to work hard. It has also helped me manage my time wisely and to always be patient. It has also provided me with many cool opportunities such as showing at World Dairy Expo, being on a dairy judging team and meeting new people.

What is your most memorable moment from the county fair? My most memorable moment so far was at last year's county fair when I won a clipping chute for winning the premier exhibitor contest.

Tell us about your farm and family. My family consists of my parents, Bryan and Brittney, and my siblings: Braxton, Jayden and twins Rayah and Rori. I am the oldest, and we live right on our dairy farm. My dad and grandpa, Kyle, own and operate the farm together. They do all the work themselves from milking the cows to the crops. We do not have any employees. We milk 60 cows twice a day in a tiestall barn and farm about 400 acres of land. We ship our milk to Henning’s Cheese in Kiel, Wisconsin. I would say that we really are a small family farm.

High-performance separation

Maximize your manure’s potential with the new GEA SlopeScreen™ separator and OptiClean™ automatic cleaning system. The improved modularity of the SlopeScreen combined with the superior cleaning power of OptiClean delivers adaptability, reliability and efficiency using less labor.

Maximize your manure’s potential with the new GEA SlopeScreen™ separator and OptiClean™ automatic cleaning system. The improved modularity of the SlopeScreen combined with the superior cleaning power of OptiClean delivers adaptability, reliability and efficiency using less labor.

17 years old

Parents: Jay and Cheryl Heeg

Colby, Wisconsin Marathon County

Tell us about your dairy 4-H projects and what you plan to show at the fair this year. This year, I have about eight dairy 4-H projects. I have never had this many, but I am excited to overcome any challenges that come along the way. Since my county fair and Wisconsin State Fair are the same week, the past couple years, I have decided to attend the state fair instead. The state fair rule is that you only are allowed to take two animals, with the exception being if you take a cow; then you can take three animals. I plan on taking my Red and White summer yearling and my Red and White spring yearling.

What does your schedule look like leading up to the fair? My heifers get fed their usual grain twice a day with unlimited hay. A couple days before the show, we like to give them beet pulp. They will also all get rinsed twice a week. I wash them a day before we clip them so that the hair is easier to work with. During this period, I also walk them to perfect their pace and teach them how to set up. I normally start training the older calves and yearlings during the fall and winter months. As we get into the spring, I start to train the younger calves in June. This whole process before a big show like the Wisconsin State Fair can take weeks, but the overall experience takes months if you want to get it right.

What are three things you must have with you at the fair? Allergy medicine, a good pillow and a pair of comfortable shoes. Allergy medicine is a huge priority for me as I’m severely allergic to the straw, shavings and hay. I would honestly not make it through a show without it. A good pillow is always necessary to get the best sleep you can, whenever and wherever you can. The week gets to be extremely tiring, so sleep is cherished. A pair of comfortable shoes is also a must as the long week and the miles walked take a toll on your feet and body. It is so nice to just wear something comfortable after a long day of constantly moving.

What do you enjoy doing at the fair when you are not showing? I enjoy walking through all of the other barns, looking at other exhibitors’ animals, and talking and connecting with other people in the dairy industry or friends from other counties.

Describe a challenge you faced in preparing for the fair or while showing and how you overcame it. The rst year I ever showed at my county fair was a huge disappointment. As someone who just stepped foot in the show ring, I was already nervous, but what happened to me escalated my emotions very quickly. My calf was not cooperating, and I let go of the halter. She ended up putting her head down, and the halter slipped off. I stood there absolutely shocked while many adults rushed to grab my calf and try to get the situation under control. That was a huge challenge in my show career, and I promised myself it would never happen again.

How has showing dairy animals helped shape the person you are? Showing dairy cattle has shaped me to be the person I am today in so many ways. I have been given so many wonderful opportunities to be able to reach out to other people in the agriculture and dairy industries. It has given me a new appreciation for all the hard work and long hours put in day in and day out that my family does for us all to be able to live our dreams. I never cease to see all the sacrices that are put in by everyone involved, and it truly makes me happy. Showing has also given me a new drive and motivation to always be able to put my all into everything I do and to work hard for all my successes in life. I have been around this industry my entire life, and it has shaped me and made me who I am today. That is something that I am extremely proud of.

What is your most memorable moment from the county fair? A couple years ago, I won junior champion Red and White and reserve supreme heifer. I was so incredibly proud of myself, my animals and especially my family to be able to make my dreams nally come true. It will always be a special moment for me, with a special heifer.

Tell us about your farm and family. My family farm is Heeg Brothers Dairy LLC in Colby, Wisconsin. We are currently milking 1,350 cows with 1,400 youngstock that we raise ourselves. We are farming 3,300 acres. My grandpa, dad, uncles, cousins, myself and employees are all involved in the farm. There are three generations working at the farm together. We milk in a double-14 parallel parlor. We are currently in the process of building a barn with eight robotic milking systems. Our milk is shipped to Mullins Cheese in Knowlton and Marsheld, Wisconsin.

Aidan Hernandez

14 years old

Parent: Kitt Westpfahl

Tomah, Wisconsin Monroe County

Tell us about your dairy 4-H projects and what you plan to show at the fair this year. I am planning to show two dairy heifer calves at the county fair this year. One of the calves is a spring dairy Holstein calf and the other calf is a winter dairy crossbred heifer.

What does your schedule look like leading up to the fair? I started training the calves when they were 1 week old. They have been getting fed fresh hay bales and corn along with fresh grass.

What are three things you must have with you at the fair? The three things I must have with me at the fair are the feed for the heifers, the show halters and the hose to wash off the heifers.

What do you enjoy doing at the fair when you are not showing? At the fair when I'm not having to deal with the heifers, I normally talk to other people, and on the last day of the fair, I pull in the antique/farm tractor pull.

Describe a challenge you faced in preparing for the fair or while showing and how you overcame it. A challenge that I've had with the fair is trying to keep the heifers clean when they're eating the hay bales. The way I have overcome that challenge is feeding them less dry hay so that the hay doesn't get caught in their hair.

How has showing dairy animals helped shape the person you are? It has taught me a good work ethic and responsibility.

What is your most memorable moment from the county fair? The rst year I showed, my mixed breed dairy heifer took rst place and got champion in mixed breed.

Tell us about your farm and family. My mom and grandparents farm on a 200-plus-acre dairy farm, and we milk 50 cows. The milk gets shipped to Grassland Dairy Products. The cows are Milking Shorthorns, Holsteins and Jersey crossbreds.

Cecelia Dittrich

16 years old

Parents: Don and Billie Dittrich Waumandee, Wisconsin Buffalo County

Tell us about your dairy 4-H projects and what you plan to show at the fair this year. I plan to show my Jerseys that I bought with my money from my summer job and from my meat project from the fair. I have a 2-year-old Jersey cow named Minnie and a fall calf named Santenna. I also will be showing a 2-year-old Holstein cow that I have shown since she was a summer yearling. I also have a summer yearling named Bio who is the granddaughter of my rst cow I showed. All my animals are registered.

What does your schedule look like leading up to the fair? I train my animals year-round. I show at two other shows with the rst one being in June. As soon as school is out, I start working with them on halters. They will get clipped at least twice before the fair. I work with them whenever I can between my summer jobs and farm chores. Time depends on the animal. Some train by the third day, and some take all summer. Washing and tying them up daily helps the most, along with walking them to water versus having water in front of them.

What are three things you must have with you at the fair? A good pair of clippers for trimming and tting the animal. Feed and water for the animal, along with beet pulp and a good attitude. An animal can tell if you are moody.

What do you enjoy doing at the fair when you are not showing? I help in the 4-H food stand, and I like to teach younger dairy members about showing. I also enjoy fair food.

Describe a challenge you faced in preparing for the fair or while showing and how you overcame it. I always have to show against my brother or sister every year. I challenge myself to hope to do better than both of them. Showmanship is always my goal. To me, that is the best award a person can win.

How has showing dairy animals helped shape the person you are? It challenges me to work harder on a project.

What is your most memorable moment from the county fair? My rst year winning showmanship – it was my very rst trophy – and my rst year showing in third grade.

Tell us about your farm and family. We live on a 100-cow registered dairy with 200 acres of tillable land. We have 99% Holsteins. I have three Jerseys. My brothers have a Milking Shorthorn and a Brown Swiss as well. My dad does all the milking and breeding. My brother Korlen does our feeding. My brother Jordon helps with hay when needed. I also have two sisters who help milk when needed and two younger brothers who scrape and do heifer and calf chores. My mom works off the farm for Farm Service Agency. We ship our milk to Ellsworth Creamery.

Describe your farm and facilities. We farm with our dad, Clifford, at Hageman Farms, which has been in our family since 1962. We milk 120 cows twice a day in a stanchion barn. Cows go outside daily and spend time on pasture during the summer. We raise all of our youngstock in bedded pack barns and on pasture.

What forages do you harvest? We harvest haylage and corn silage. We also green chop daily during the growing season and feed this fresh forage to our milk cows.

How many acres of crops do you raise? We raise about 800 acres of crops. This includes 350 acres of corn, 300 acres of soybeans and 150 acres of an alfalfa grass mix.

What quality and quantity do you harvest of each crop? We ll a 20-by70 Harvestore silo with rst-crop haylage and also do 300 big square bales of rst-crop hay. We harvest 150 to 200 bales of second-crop hay and about 100 bales of third-crop hay. We mix fourthcrop hay with corn silage in one of our silos, and we feed that to cows when they are in the barn in the winter. We run two choppers and do every other load corn silage and haylage. We try to

acres.

do the best we can with our forages every time. We usually hit a protein level of 22%. Our nutritionist describes our corn silage as about as good as you can get it.

Describe the rations for your livestock. We do not feed a total mixed ration to our milking herd. Instead, we green feed during the summer months or when we can – it could be spring, summer and fall. We bypass the silos and go out and cut it and feed it green.

We’ve been doing this since about 1983, and we bypass a lot of expense this way. There is labor involved in that one guy has to go out and chop it every day. The cows really like this feed. Milk production goes up, but butterfat and protein go down. In the barn, we run two Harvestores at once – one with corn silage and one with haylage – and mix feed that way for our milk cows. We also feed them shelled corn by hand with protein mix. Dry cows run with the milking herd and eat pretty much the same diet. Our breeding-age heifers clean up after the cows and also receive minerals. Younger heifers are fed our lower-quality hay – perhaps something that got rained on – as well as a grain mix.

Describe your harvesting techniques for alfalfa and corn silage. Daryl does most of the harvesting with help from Clayton. We mow our hay, putting two windrows together. We run it through a v-rake 12-foot Haybine, doing 24 feet together, and then run it through a John Deere 5830 chopper. Big squares are made with a Case IH LBX332 baler with inoculant on it. We’ve been using inoculant because we have better results and it’s cheaper to throw away.

Turn to FORAGE | Page 20

“We tried other products, and we found out: Udder Comfort™ is the one that really works. It’s the best for fresh cows, and for any type of swelling, any cow with elevated SCC or a hard quarter, mastitis, even an injured quarter,” says Brad Palmer of Pigeon Cove Farms, Warfordsburg, Pennsylvania.

“We got back on the Udder Comfort last year for its effectiveness and ease of use. Spraying fresh udders with Udder Comfort after each milking for 5 days after calving really helps our milk quality,” he adds.

Three generations are involved in the operation: Brad and Linette and their son Logan and daughter Hailey and Brad’s parents Lonnie and Debra.

They milk 440 Holstein and Jersey cows, averaging 94 pounds with SCC 140,000.

“We like using Udder Comfort in the parlor. It delivers better coverage and better results,” adds Hailey. She does herd health and breeding while Logan is mostly involved in crops and feeding. Hailey also shows Ayrshires, a breed she loves that her mom grew up with.

Acid is more expensive, but it keeps better. Inoculant has to be thrown out after two days, but it’s machine friendly and doesn’t cause rusting like acid would. We’ve been pretty impressed with what you can do with inoculant. There are no burnt bales. We cut hay every 28 to 30 days. We try to get four cuttings or whatever Mother Nature will allow. We like to get alfalfa in the early bud stage. This year, we were unhappy with the amount from our rst cutting, so for second crop, we decided to let it grow for an extra week, and we ended up getting an extra half bale per acre. We’re letting it get more mature. With drought conditions, we have to nd a way to feed these animals, or we’ll have to buy expensive hay. We cut corn when it is as close to perfect as we can get it. We run it through a kernel processor on the chopper and throw it in the silo. We like to have 45% moisture for chopping corn.

What techniques do you use to store, manage and feed your forages? We have six Harvestore silos we use for storing haylage, silage and shell corn. Silos are an excellent feed keeper. You are not going to nd feed any better than that. It’s like a big refrigerator, but it’s not refrigerated. The biggest gripe people have about silos is the expense. Daryl does most of the work on

the Harvestores, which saves a lot of money. We only use our best-working unloader in the wintertime to avoid issues. We feed big square bales in the barn using a two-wheeled cart instead of carrying them. This way, cows can’t get to it as much while we’re moving it, which allows us to feed twice as fast. We started with big bales in 2013. For shelled corn, we make sure to stay above 22% moisture or else starch ends up in the air, and you’re breathing that in all the time. Corn is cleaner at 22% and softer for cows’ mouths. The drier it gets, the sharper it gets. This helps with ease of feeding.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? Around 1995, we started planting soybeans to loosen the soil and put nitrogen back in the ground. It helps improve the soil itself as well as soil workability. We use soybeans for crop rotation and also as a cash crop. We also changed our corn silage variety for the silos. Cows can do better on different varieties. We might do something more resistant to tar, and we mix it up depending on what’s going on.

Describe a challenge you overcame in reaching your forage quality goals. We found out we really have to watch our

corn silage. You have to be aware of what can happen and stay on top of what’s new with things like blight, mold and bugs. We have also learned to hit the alfalfa as soon as we see it blooming to get the most out of it. Our dad was always looking for growth to get volume, but if it’s dry, it can get woody. You have to nd that perfect balance.

How do quality forages play a part in the production goals for your herd? It’s everything. We try to get as much out of the herd as we can. To do that, we have to get the best feed into them. That helps cut the costs of buying proteins.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? Kernel processing.

This cracks the kernels and breaks them down so they are ready for cows to eat in the corn silage. As a result, cows digest the corn better. Also, when we rake hay, we rake early when it’s dewy, which helps keep the leaves on – that’s where the protein is. We have gotten better at that over time, but Mother Nature plays a part in our success every day.

hrs., #558869.............. $349,000

JD S660 2014, PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S780 2020, PRWD, Duals, 1030 hrs., 749 Sep. hrs., #188309.............. $409,000

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD S780 2018, 2WD, Duals, 1215 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S690 2012, PRWD, Duals, 2312 hrs., 1645 Sep. hrs., #551148............ $149,000

JD 9770 STS 2011, PRWD, Duals, 3576 hrs., 2560 Sep. hrs., #555084 .... $116,900

JD S790 2020, PRWD, Tracks, 804 hrs., 584 Sep. hrs., #554727 ............... $509,000

JD S780 2022, PRWD, Floaters, 238 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S770 2022, PRWD, Floaters, 36 hrs., 20 Sep. hrs., #563704 ............... $546,000

JD S790 2018, PRWD, Duals, 1643 hrs., 1218 Sep. hrs., #549845............ $309,000

JD S790 2018, PRWD, Duals, 1852 hrs., 1407 Sep. hrs., #549847............ $295,000

JD S790 2018, PRWD, Duals, 1459 hrs., 1055 Sep. hrs., #549846............ $329,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Singles, 25 hrs., 20 Sep. hrs., #560619 ................. $639,500

JD 9870 STS 2010, PRWD, Duals, 3394 hrs., 2260 Sep. hrs., #554931 .... $118,900

JD S690 2016, PRWD, Duals, 2544 hrs., 1820 Sep. hrs., #547267............ $219,900

JD S780 2018, PRWD, Duals, 1622 hrs., 1131 Sep. hrs., #276170............ $305,000

JD S770 2021, 2WD, Duals, 718 hrs., 585 Sep. hrs., #560264 .................. $425,900

JD S780 2019, 2WD, 627 hrs., 460 Sep. hrs., #559821 ............................ $359,000

JD S790 2021, PRWD, Duals, 705 hrs., 526 Sep. hrs., #555189................ $499,500

JD S780 2019, PRWD, Floaters, 1289 hrs., 889 Sep. hrs., #275242 .......... $349,000

JD S680 2012, PRWD, Duals, 2500 hrs., 2000 Sep. hrs., #554973............ $129,900

JD 9750 STS 2003, 2WD, Duals, 4830 hrs., 3367 Sep. hrs., #565004 ......... $37,500

JD S680 2014, PRWD, Duals, 2321 hrs., 1575 Sep. hrs., #555096............ $169,900

JD S790 2022, PRWD, Duals, 145 hrs., 90 Sep. hrs., #557140.................. $629,900

JD S790 2022, PRWD, Duals, 428 hrs., 302 Sep. hrs., #552839................ $579,500

JD S780 2020, PRWD, Duals, 932 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1562 hrs., 1131 Sep. hrs., #549680............ $319,000

JD S780 2021, PRWD, Duals, 654 hrs., 469 Sep. hrs., #191047................ $489,000

JD S780 2019, PRWD, Floaters, 1604 hrs., 1145 Sep. hrs., #549684 ........ $319,000

JD S780 2022, PRWD, Tracks, 337 hrs., 251 Sep. hrs., #563618 ............... $619,000

JD S780 2022, PRWD, Duals, 426 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Tracks, 316 hrs., 231 Sep. hrs., #563619 ............... $619,000

JD S780 2022, PRWD, Duals, 454 hrs., 347 Sep. hrs., #563635................ $549,000

JD S690 2017, PRWD, Duals, 1433 hrs., 1187 Sep. hrs., #549457............ $280,700

JD S780 2022, PRWD, Duals, 241 hrs., 183 Sep. hrs., #554094................ $565,000

JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000

JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

JD S780 2019, PRWD, Duals, 1559 hrs., 1058 Sep. hrs., #549682............ $319,000

JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646............ $219,900 JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

............ $549,900

JD S790 2018, 2WD, Duals, 1579 hrs., 1128 Sep. hrs., #273973 .............. $289,000

JD 9770 STS 2011, 2WD, Duals, 3460 hrs., 2570 Sep. hrs., #555709 ......... $92,500

JD S790 2022, PRWD, Tracks, 38 hrs., 21 Sep. hrs., #553771 ................... $695,000

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 .... $34,900

JD S780 2020, PRWD, Duals, 955 hrs., 659 Sep. hrs., #188459................ $419,000

JD S780 2022, PRWD, Duals, 462 hrs., 345 Sep. hrs., #553598................ $549,000

JD S770 2022, PRWD, Duals, 270 hrs., 195 Sep. hrs., #554014................ $560,000

JD S780 2022, PRWD, Tracks, 299 hrs., 238 Sep. hrs., #554013 ............... $619,000

JD S780 2020, PRWD, Duals, 1545 hrs., 1204 Sep. hrs., #531610............ $349,000

JD S790 2021, PRWD, Tracks, 734 hrs., 530 Sep. hrs., #191075 ............... $549,500

JD S680 2015, PRWD, Duals, 2585 hrs., 1865 Sep. hrs., #190078............ $174,500

JD 9760 STS 2004, PRWD, Duals, 4389 hrs., 3109 Sep. hrs., #564023 ...... $53,500

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Duals, 91 hrs., 56 Sep. hrs., #563620 ................... $579,000

JD S780 2020, PRWD, Duals, 1488 hrs., 1145 Sep. hrs., #191082............ $349,000

JD X9 1100 2021, PRWD, Tracks, 942 hrs., 735 Sep. hrs., #552917.......... $749,000

JD X9 1100 2021, PRWD, Tracks, 876 hrs., 715 Sep. hrs., #552921.......... $769,000

JD S790 2019, PRWD, Duals, 1772 hrs., 1426 Sep. hrs., #532032............ $299,000

JD S780 2020, PRWD, Duals, 1076 hrs., 784 Sep. hrs., #188458.............. $409,000

JD S790 2018, PRWD, Duals, 1315 hrs., 940 Sep. hrs., #554633.............. $329,000

JD S790 2021, PRWD, Singles, 937 hrs., 770 Sep. hrs., #557277 ............. $479,000

JD S790 2021, PRWD, Duals, 585 hrs., 449 Sep. hrs., #556669................ $499,500

JD S690 2017, PRWD, Duals, 2103 hrs., 1461 Sep. hrs., #552684............ $249,900

563-422-5355 Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The

Mt Horeb, WI 800-872-3470 MINNESOTA

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced

Mora, MN 320-679-1029

Pierz, MN

320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN 218-632-5416

PLATTEVILLE, Wis. – Alexis Blankenberg fell in love with the Brown Swiss breed when she was young enough to show in the peewee class. At the beginning of her high school years, she used money from her savings to buy seven Brown Swiss heifers and two cows. Four years later, she has over 100 animals in her breeding program.