WANT TO WIN $100 CASH?

See page 6 of the third section for details!

See page 6 of the third section for details!

VAN DYNE, Wis. – On April 6, Dan Liner gave a piece of himself to someone else. One neighbor saved another when Liner donated his kidney to Troy Stettbacher.

“It was no big deal,” Liner said. “I wanted to do it, and I would do it again.”

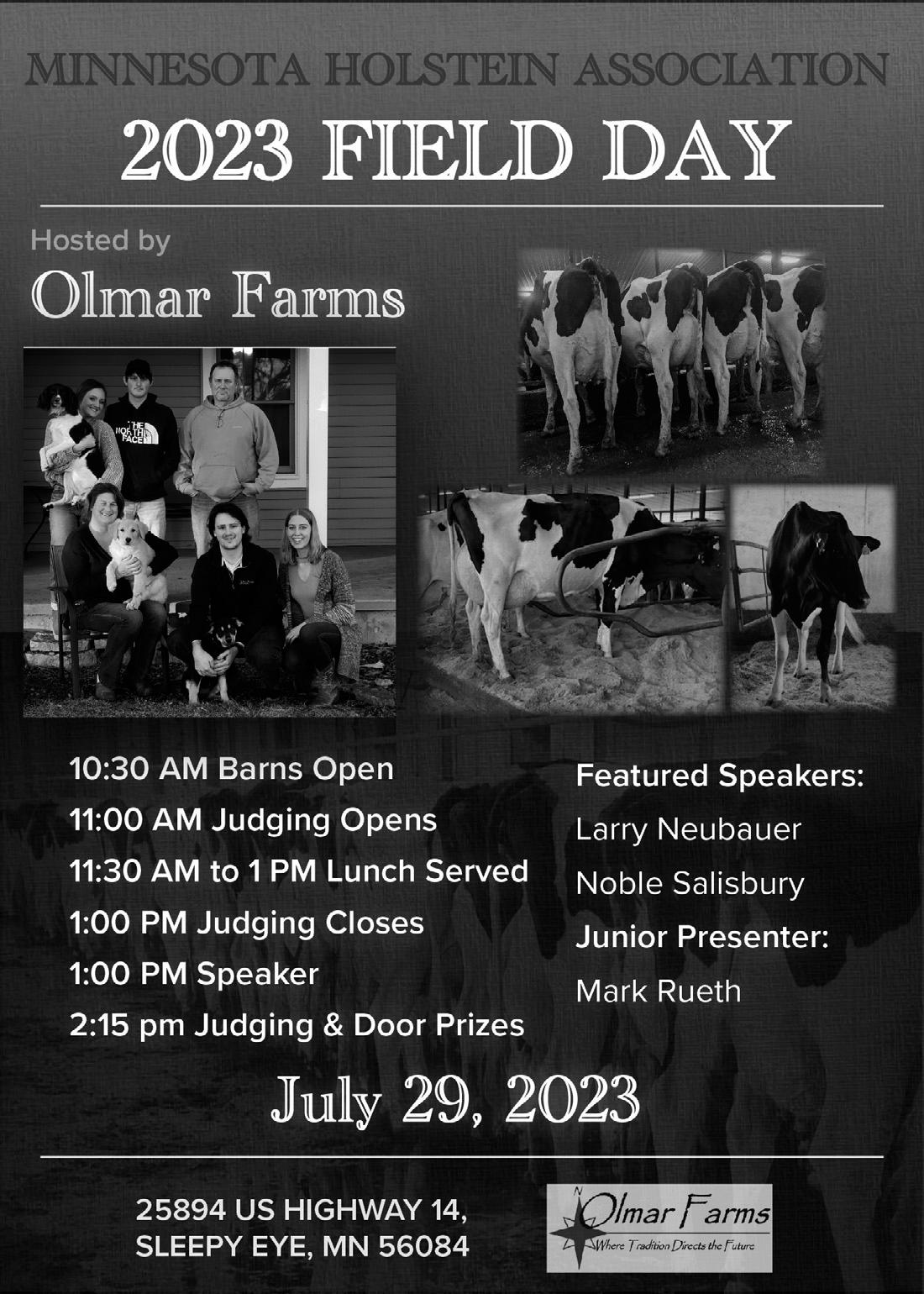

The Loehr family – Kurt (from le ), Sarah, Adella and Ainsley – pause for a picture October 2022 at World Dairy Expo in Madison, Wisconsin. The Loehrs were scheduled to host this year’s Fond du Lac County Breakfast on the Farm June 25 un l a re broke out on their farm exactly one week prior on June 18.

MALONE, Wis. – A heartbreaking situation led to a lastminute change in venues for this year’s Fond du Lac County Breakfast on the Farm.

Kurt and Sarah Loehr of Forest-Ridge Holsteins near Eden were set to host the breakfast June 25 until a re broke out on their farm exactly one week prior on June 18. The re destroyed the family’s barns, leaving the Loehrs with no place to house their cows.

Liner farms with his parents, Tim and Kathy, and his brother, Mike, near Van Dyne where the family milks 250 cows and farms 700 acres. Liner barely skipped a beat at the farm following his procedure. He spent one night in the hospital and went back to work not long after, starting out with lighter chores at rst.

“I feel no different today than I did before the surgery,” Liner said. “Other than the small scars I have, I wouldn’t know any different. I have no restrictions. I’m living my life the same as before. It was a fast recovery, and everything turned out perfect.”

Stettbacher was a week or two away from needing dialysis when he received Liner’s kidney. Stettbacher’s health was deteriorating quickly from polycystic kidney disease – a genetic disorder that can cause serious complications, such as kidney failure. His dad and brothers also had kidney transplants.

“Within hours, the new kidney turned my life around,” Stettbacher said. “I could see better. Before, things were blurry.”

Even Stettbacher’s thinking had been unclear, he said, confusion brought on because of the disease poisoning his body.

Turn to KIDNEY | Page 6

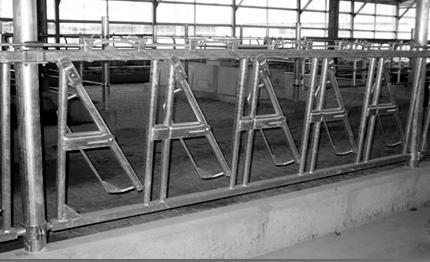

CADOTT, Wis. – Bob and Ryan Harm tried several ways to accommodate their growing herd of dairy cattle before settling on a plan for building the barn that will carry their family farm into the future.

“This is efcient enough that it can be done by one person,” Ryan Harm said. “We typically have three of us doing chores, and it goes pretty fast.”

Bob

Harm said the barn was built with an eye toward the future, allowing him to con-

tinue to operate on his own when his dad decides to retire.

“We had Lely come in and look at our plans and help us make sure it was set up for an easy conversion to robots in the future,” Harm said. “We have it set up so that we will be able to easily add robot rooms while not losing any stalls and keeping our existing parlor for fresh and treated cows.”

The Harms moved into their new 121-stall freestall barn July 28, 2022. Their herd of 130 cows are now milked in a single-13 parlor, and their milk is shipped to Grassland Dairy. Harm said a milking takes about two hours, estimating that each parlor shift takes about 12 minutes.

“All dairy, all the time”™

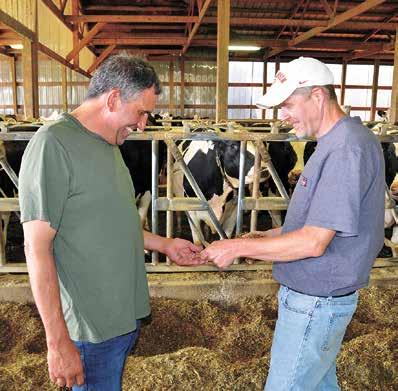

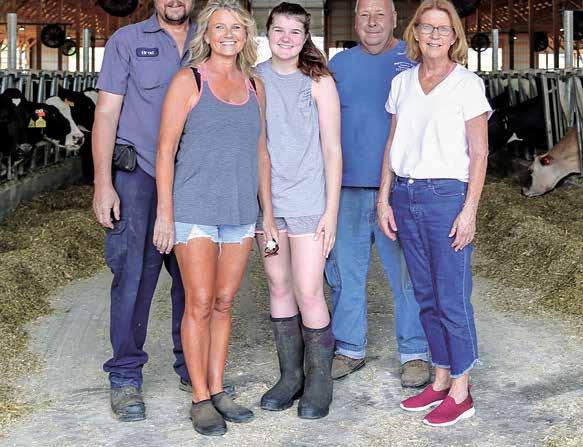

New facility provides cow comfort, labor efciencyDANIELLE NAUMAN/DAIRY STAR (le ) and Ryan Harm stand in their freestall barn and parlor June 20 near Cado , Wisconsin. Before building their facility, the Harms were milking their cows on two farms.

Published by Star Publications LLC

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

Two groups are calling on Agriculture Secretary Tom Vilsack to release the dairy checkoff program’s nancial information. Farm Action and the National Dairy Producers Organization said these annual spending reports are mandated by law but have not been released for the years 2020, 2021 and 2022. The two groups cite the current economic hardship facing dairy farmers in its criticism of the National Dairy Promotion and Research Program.

Preparing for the farm bill dairy title Senate Agriculture Committee Chair Debbie Stabenow and House Agriculture Committee Chair Glenn “GT” Thompson have experience with dairy policy. American Farm Bureau Federation dairy economist Danny Munch said that is positive news going into the farm bill process. The Dairy PRIDE Act is one priority, “making sure that products that are milk and dairy get those terms rather than some of the alternatives,” Munch said. Dairy Margin Coverage adjustments are also being sought. Trade issues are also addressed in the farm bill. Munch said Canada’s supply management program complicates the trade relationship. “There’s really no incentive for them to follow the rules that they signed up for in the U.S.-Mexico-Canada Agreement, and we don’t expect them to suddenly start following the rules and accepting U.S. dairy products into their country,” Munch said. “We’re continuing to work with the Trade Representative’s Ofce on our challenge within the trade agreement.”

Rural communities are faced with a shortage of essential veterinary services. The Veterinary Medicine Loan Repayment Program provides student loan reimbursement to veterinarians who practice for three years in federally

designated shortage areas. A similar program is available for medical doctors, but their loan repayments are exempt from federal withholding taxes. The VMLRP payments are not.

Year-to-date, nearly 76,000 more dairy cows have entered the beef chain than one year ago. In May, dairy cow slaughter totaled 249,000 head. That is 5,500 more than April and nearly 24,000 head more than May 2022. In a report prepared by Wisconsin Department of Agriculture, Trade and Consumer Protection livestock and meat specialist Jeff Swenson, the Holstein steer market has been trading steady to higher at $157 to $159. Cows were $2 to $3 higher with the bulk of the cows bringing anywhere from $69 to $101 per hundredweight. Dairy bull calves were mostly steady to lower at $100 to $310 per hundredweight.

Technological advances are being seen throughout the dairy industry, including robotic milking systems, genomics and electronic ID tags. Holstein Association USA and Zoetis have had a relationship for nearly 10 years, working on genomics. Zoetis Vice President of Precision Ani-

MN 56378-1246.

mal Health Dr. Jason Osterstock said the use of DNA testing offers insight into an animal’s potential contribution and value to the herd. Sexed semen, embryo transfers and in vitro fertilization are other examples of precision technology in the dairy sector. “I think we’re also going to see our ability to select for feed efciency, our ability to select for cows that produce naturally less methane; those are all going to unlock opportunities for us,” Osterstock said.

$1B-plus for broadband

Wisconsin will receive over $1 billion in federal funds to connect more people to high-speed internet. Wisconsin Sen. Tammy Baldwin supported the Broadband Equity Access and Deployment program. “No matter where you live in the state, you deserve access to reliable high-speed broadband, and these resources will help us do that,” Baldwin said. The rst 20% of funds will be awarded in 2024 and the remaining 80% in 2025.

Support for local roads

Gov. Tony Evers has signed the Local Roads Improvement Program. This program provides state support for local governments to deal with deteriorating county highways. There are also targeted investments that support agriculture.

Yara, DMI collaborate

Yara North America and Dairy Management Inc. have launched a new soil health collaboration. This work is meant to complement the Dairy Soil & Water Regeneration project and will explore the use of organic fertilizers derived from manure.

AJCA recognizes Owens

The American Jersey Cattle Association has honored Walter Owens of Frederic, Wisconsin, with its Distinguished Service Award. Owens served on the AJCA board from 2012-19 and now chairs the Junior Activity Committee for the All-American Show and events in Louisville, Kentucky.

Elite Breeder Award goes to Bomaz Farms

Holstein Association USA has honored Bomaz Farms of Hammond, Wisconsin, with its 2023 Elite Breeder Award. Bob and Kay Zwald operate the dairy farm with their son Tom and his wife Ashley and daughter Annette and her husband Steve Schalla The family has had more than 500 bulls in A.I. programs worldwide with the Bomaz prex.

Basse to chair Farm Foundation Board

AgResource Company President Dan Basse is the new chair of the Farm Foundation board. Natural Prairie Dairy owner Chris DeJong was elected vice chair and American Seed Trade Association President and CEO Andrew LaVigne is the treasurer. Six new board members were also elected: former Agriculture Secretary Mike Johanns, former Deputy Secretary of Agriculture Jewell Bronaugh, The Nature Conservancy global managing director Micheal Doane, Kinder Farms co-owner James Kinder, S2G Ventures managing director Christina Rohr and Farm Credit Council President/CEO Todd Van Hoose. The Farm Foundation is an accelerator for practical solutions for agriculture.

Armstrong steps away from the microphone

After 48 years as a farm broadcaster, Max Armstrong has retired. Fortyve of those years were with Orion Samuelson at WGN, U.S. Farm Report and This Week in Agribusiness.

Trivia challenge

It takes 12 pounds of whole milk to make 1 gallon of ice cream. That answers our last trivia question. For this week’s trivia, what American ice cream company bills itself as “the ice cream of the future.” We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Specializing

Con nued from KIDNEY | Page 1

“A lot of my blood levels were way out of whack,” Stettbacher said. “I was extremely low on red blood cells, and my skin was a bluish-yellow color. I didn’t have a lot of energy. I was sick and just trying to get by.”

It was through a Christmas card that Liner discovered how bad things had gotten for Stettbacher. He needed a kidney as soon as possible.

“I always knew Troy had this disease, but then I realized how serious it was,” Liner said. “I sympathized with him. How do you ask someone for a kidney?”

After reading the letter, Liner told his parents, “I could give him a kidney. I have two. I only need one.”

“It’s like a farmer coming over and asking for tractor parts – I have a lot of those to spare too,” Liner said. “It was a no-brainer. I was in the right situation in my life with no wife or kids to tell me no. Everything just lined up.”

Previously a dairy farmer as well, Stettbacher milked 150 cows up until 2020 where three generations of his family had farmed. Now, he does custom harvesting work, and the Liners are one of his customers. Five weeks after the transplant, Stettbacher was back on his tractor and able to do spring and summer eldwork.

“I feel great,” Stettbacher said. “All my vital numbers have ip opped.”

Liner and Stettbacher live 2 miles apart and have known each other for 20 years.

“We’ve become closer friends recently with everything that’s happened,” Liner said.

Stettbacher was in disbelief when he found out Liner wanted to donate his kidney.

“I thought, why?” Stettbacher said. “I asked him, ‘Are you sure you want to do it?’ Live donor transplants are not as popular as deceased donors. Not a lot of people are willing to get cut open for someone.”

Liner’s whole heart was into the endeavor. He wanted to be the one to save Stettbacher’s life. In early January, Liner got a blood test and found out he had the same blood type as Stettbacher – O positive – even though matching blood types was not a requirement, Liner said. Liner then went through a litany of health tests.

Finding the perfect match for a kidney donor is a lot like playing the lottery. The odds of coming across the right candidate in a timely manner are anything but good. But, Stettbacher was far luckier than most, nding his ideal match within several months of sending out his Christmas card.

“It’s really hard to get a match the rst try,” Stettbacher said. “There are so many things that could be in your family’s history. We didn’t really celebrate until Dan passed all of his tests. We were nervously waiting.”

Stettbacher and his wife, Paula, have two children – Hayden and Shalome. Shalome, who is 22, also got tested as well as other family members.

“Shalome really wanted to donate her kidney to her dad, but I didn’t want her to do it,” Liner said. “She’s too young. She has so much of her life ahead of her. I was the perfect person for it.”

Liner and Stettbacher were tested on eight categories and matched on six, resulting in a better match than Stettbacher’s daughter.

“I knew this is what I’m supposed to be doing, and I wanted it to be me all along,” Liner said. “I wasn’t getting tested just to get tested. I hoped I would be a match and be the one the doctors picked. I ended up being a very good match. The closer to the genetic match, the less chance of rejection.”

The transplant was done at Aurora St. Luke’s in Milwaukee. Originally planned for late June, both men pushed to get the procedure done sooner.

“We wanted to do it off season since our incomes rely on summer,” Liner said. “Doing the procedure in June was not as good for our schedules. Not only that, I could see Troy getting sicker, and I wanted to do it sooner. If you have a sick cow, you call the vet and they come out today.”

Liner was frustrated with waiting but understood the doctors did not want two sick people on their hands.

“The doctors were worried about me, too, and they did a really good job,” Liner said.

Liner’s determination to be a donor sped up the process.

“Dan was so strong about giving,” Stettbacher said. “For some people, it takes longer to think about it. It took ve months from the time I met with the coordinator to the time of the transplant. For many people, waiting for a transplant can take an average of six to eight years while also being on dialysis. It’s a huge problem. In the future, they’re hoping to have technology to grow kidneys from stem cells.”

Stettbacher is grateful for the fresh start he was given and the fact he was spared from undergoing dialysis.

“Your body can only handle so much dialysis,” he said. “It takes years off your life.”

Stettbacher spent ve days in the hospital after the transplant and continues to have weekly blood tests. He will also need to take rejection drugs for the rest of his life.

“I will always be in jeopardy of rejection, but taking drugs is a small price to pay,” Stettbacher said. “How lucky am I to be here?”

After the procedure, his numbers drastically improved. Stettbacher’s glomerular ltration rate, which is used to measure kidney function on a scale from 1 to 100, went from a score of 13 (which is considered kidney failure) before the surgery to a score of 70 (which is considered normal) following the surgery.

“The doctor told me to go live life,” Stettbacher said. “I went from having so many restrictions in my diet to having no restrictions. Before, I couldn’t have any meat hardly. It was kind of a bland life for a while.”

Humble about his generosity, Liner is happy to have played a role in his friend’s recovery.

“I did it for Troy as well as for his family,” Liner said. “It was a tiny price to pay for a few weeks of discomfort and worth it 1,000% to see Troy like he is now and how he’ll be into the future.”

“It’s been a challenging time for our family, but it could have been worse,” Kurt Loehr said. “We could have lost everything. We got all the animals out in time, but the re was moving so fast. Another 10 minutes and we would’ve lost all our animals and our house. It could have been a very different ending.”

Given the circumstances, the Loehrs decided their farm was not t for hosting the event.

“My parents were devastated,” Loehr said. “They were proud of what they had started and what we built upon. They were really looking forward to this opportunity of hosting breakfast on the farm and were sad it couldn’t happen.”

Loehr and his wife and daughters, Ainsley and Adella, were also disappointed in losing out on this special opportunity.

“As much pride as we took on how the outside of our buildings look, we took as much pride inside and were really looking forward to opening our barns up to the community and showing people how we care for our cattle,” Loehr said. “We have the opportunity to care for cattle from people all across the country.”

During a time of tragedy, another farm quietly stepped up to offer a new home for Fond du Lac County’s 34th annual Breakfast on the Farm. The Diederichs family of 3-D Dairy hosted the breakfast June 25 from 8 a.m. to noon on their farm near Malone.

“The 2023 breakfast was probably the most unique in the history of the county, but it went really well, and a great time was had by all,” said Amy Ries, director of agricultural programs at Envision Greater Fond du Lac AgriBusiness Council. “Our thoughts and prayers are with the Loehrs as they continue to get through this life-changing event.”

About 2,500 meals were served during the event. Two new items at the

Guests eat breakfast June 25 at the Fond du Lac County Breakfast on the Farm held at 3-D Dairy near Malone, Wisconsin. About 2,500 meals were served that day, which included pancakes as well as ice cream from the University of Wisconsin-Pla eville.

breakfast this year were pancakes as well as ice cream from the University of Wisconsin-Platteville in three avors made especially for the day – simply strawberry, Holstein swirl and ForestRidge mint.

“We went through 45 gallons of ice cream and many pounds of cheese,” Ries said. “We are back to pre-(pandemic) numbers and happy with the turnout.”

The location of 3-D Dairy enabled the Envision Greater Fond du Lac AgriBusiness Council to maintain the same parking and shuttle service that would be coming from the east side of Fond du Lac.

“By taking that shuttle, people would still get to the farm if they had already bought a ticket,” Ries said. “It was easier to pick a location that did not involve changing the shuttle.”

Having hosted breakfast on the farm in 2013, 3-D Dairy was not new to the event, which made planning easier.

“They knew the undertaking, and there were no surprises,” Ries said. “They had the capacity and the space to host. If the breakfast had to be switched, this location made it an easy switch. The really amazing detail is that two farms offered to host if Forest-Ridge was not able to. We picked the one that offered rst.”

Sixteen volunteers sit on the Fond du Lac Breakfast on the Farm committee, and about one-third of the committee members are dairy farmers. The committee smoothly overrode the logistical challenges of switching venues in one week’s time.

“In this tough situation, it’s still about the cause of celebrating agri-

culture in Wisconsin, in Fond du Lac County, and we knew the impact of not having the breakfast,” Ries said. “It was a huge relief when the Diederichses offered to host. This whole situation has really shown the strength and resiliency of agriculture. There is always that sense of community. Your neighbor has your back, and this too shall pass.”

Ries said during the breakfast, many people asked if they could donate to the Loehrs, and Envision Greater Fond du Lac Agri-Business Council had that option available, as a recovery fund had been set up for the family.

Loehr said he and his family plan to rebuild in some aspect.

“Our kids are so passionate about the Holstein cow, and we don’t want to take that opportunity away from them,” he said. “We did a lot of chores together as a family, and it was no longer work; it was fun. We don’t want to miss out on that.”

Whatever they do may be at a smaller capacity, Loehr said, but giving their children the opportunity to show cattle and be raised in the industry is important to the couple.

“Many of our decisions to rebuild will be based on our family’s values and how we want to raise our kids,” Loehr said.

Loehr and his family are grateful for all the friends, neighbors and volunteer reghters who came on Father’s Day to help put out the re and assist with moving cattle and serving food to the volunteers.

“There were 16 re departments – dads who gave up their time to be there – and we’re thankful for all the support we’ve had,” Loehr said. “It’s been a pretty uplifting time from a tragedy standpoint how the community has come together and supported us. It lets you know there are still good people in the world.”

spears, rock buckets

Large 8-10 Buckets

“We patterned it after a parlor we had looked at north of here,” Harm said. “We like it, and it works well for us, and it will work well with a future retro for robots. It’s nice to be able to watch the cows in the holding pen from the parlor.”

The barn’s dry cow, maternity and special needs areas are all located near the parlor.

The Harms breed all their cows to Angus and purchase their replacement animals.

“The one thing I wish we had done a little different was make our maternity area a little bit bigger,” Harm said. “There is enough room when there are just two cows, but if we have to have a third cow in there, you’d like to see them have a bit more room.”

The barn has three rows of free stalls, which are equipped with waterbeds and bedded with a mix of shavings and hydrated lime.

“The cows really seem to like the waterbeds,” Harm said. “It didn’t take long to be able to see how much more comfortable they were in here than before. People come in the barn and the cows don’t pay any attention to them; they don’t get up.”

The feed bunk area abuts the third row, and the cows are fed a total mixed ration with an overhead conveyor.

“The feed bunk is about 40 inches wide, so we don’t really have to push feed or have a feed pusher,” Harm said. “It’s always within reach, and there is never much to push up.”

At milking time, gates are closed to create the holding area, and the cows move around the barn, heading through a footbath at the far end. Gates are lowered from the ceiling to keep the rst group of cows milked separate from the last group. As cows leave the parlor, they move into the feed bunk section.

The new facility is scraped with an automatic barn scraper that the

Harms have set to run continuously.

“At rst I thought I’d only have it run like 12 times a day, but just having it run continuously keeps the barn so much cleaner,” Harm said. “It works great, because the barn isn’t set up so that cows are out of the pens enough to scrape with a (skid loader).”

The Harms broke ground on the project in late April and were relieved to have everything complete and ready for their anticipated July movein date.

Before moving into their new facility, the Harms milked in two barns.

“Chores took forever with the two barns,” Harm said. “We were never nished before 10 a.m. Now, we’re always done by about 8 a.m., unless one guy is doing it alone, and then it’s about an extra hour.”

Besides labor efciency, cow comfort was a driving factor in the Harms’ decision to build the new facility.

“We wanted to make things more efcient for us, and we really focused on cow comfort,” Harm said. “You can see the difference in the cows; they are so comfortable, so happy and relaxed.”

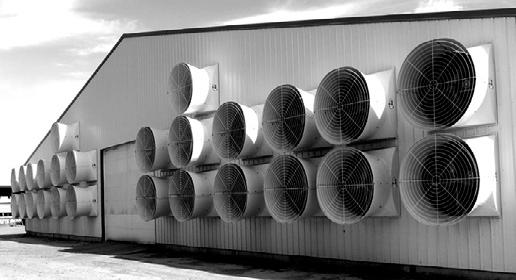

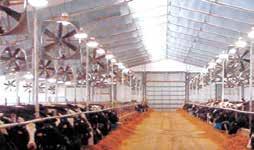

Harm said the barn has been easy to regulate as far as temperature, noting that the coldest it got in the winter was 44 degrees, and the tunnel ventilation has kept it comfortable in the hottest summer weather.

There is great airow through

here,” Harm said. “The cow comfort, labor savings and efciency has been amazing. I wouldn’t ever go back to a stall barn after being in this barn for a year. It is so nice having everything here, under one roof.”

hp)

60, 73

New Enterprise, PA 814-766-2246

Brubacker Ag Equipment, LLC Curtis & Boscobel, WI Podevels Sales & Service Marsh eld, WI

ATTENTION FARMERS...

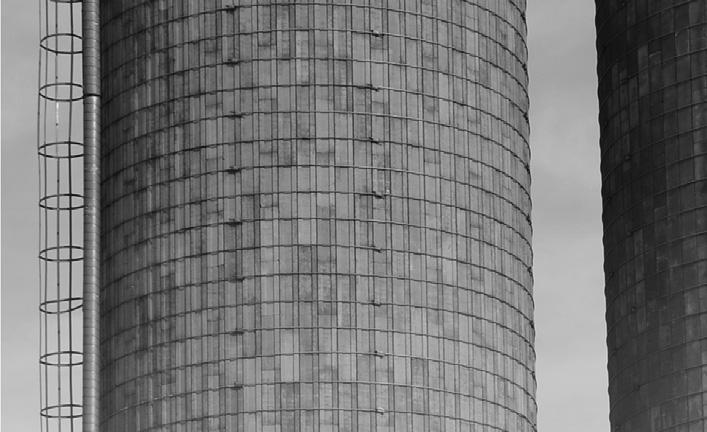

Are rocks, re-rod or holes showing in your bunker silo?

WE CAN RESTORE YOUR BUNKER TO LIKE NEW CONDITION!

BUNKER SILO RESTORATION/ REPAIR WITH JETCRETE

Approximately 1” of steel reinforced material added to bunker walls.

• High pressure water blasting of walls for excellent bonding.

• 6 gage heavy duty wire mesh installed

• Jetcrete -phnuematically applied concrete.

SILO RELINING WITH “JETCRETE”

BARN WALL & BASEMENT RESTORATION WITH “JETCRETE”

(Limestone, rock, block & concrete wall)

SERVING IA, MN, WI, IL AND SD

CONTACT: 800-866-7327

BECAUSE A FARM NEVER SLEEPS.

CHECKOUTTHE 7700SERIES

Waukon,IA

563-568-4526

AfterHours:

Ken563-380-3137•Dave563-380-8680 www.reiserimpl.com

HAY & FORAGE

‘20 Anderson Hybrid X, Custom Operator Pkg

Tubeline TL5500 Inline Wrapper

Hesston 565A Round Baler

Hesston 3986 14 Wheel Rake

‘20 MF 3983 Hicap Rake, 12 wheel

Claas 10’ - 10 Rotor Rake

Miller Pro 7914 Merger, 14’

‘15 Tonutti TCR 12 wheel rake

Tonutti 12 wheel Dominator rake

H&S 12 wheel rake

MF TD1620, 2 rotor tedder

‘17 JD 835 9’ MoCo, center pivot

JD 946, hyd. swing, rubber rolls

‘14 CIH DC112 Disc Mowland

Gehl 2450, 15’ hydro swing

disc mower

‘21 Rhino 3150-15’ Batwing Mower

Haybuster 2650 Bale Grinder

‘14 NDE 2906 Twin Screw TMR

MISCELLANEOUS

JD 146 Loader w/bucket

TRACTORS

‘21 MF 2850, CAH, hydro, loader, ONLY 139 HOURS!

MF GC2400, 60” deck, 500 hrs.

‘21 MF GC1723, ldr., mower, 180 hrs.

MF GC1705, w/60” deck ‘18 MF 1705, 60” deck, 200 hrs.

‘18 MF 1705, 60” deck, 300 hrs.

‘16 MF GC1705, 60” deck, 500 hrs.

‘07 NH TC34D, loader, 60” deck, 700 hrs.

‘88 MF 3650 WFWD, CAH, 5,100 hrs.

‘97 Kinze 2600, 31R15”

Sunflower 4211-9, disc chisel w/ buster bar

DMI 530B Disc Ripper

JD 712 9 shank disc chisel

CIH MRX690, 5 shank disc ripper disc

JD 980 Field Cult., 44’ w/harrow

CIH 4800 30’ Field Cult, w/3 bar coil

tine harrow

‘12 Case IH 1250, 16 row, 30 liquidloaded

Loftness 20’ Stalk Shredder, NICE!! ‘08 Agco 3000 Corn Head, 8R30, poly

Gehl 100 Feed Mill

‘21 Bobcat S76, CAH, SJC, 3,400 hrs.

‘21 Bobcat S76, SJC, 2,300 hrs.

‘21 Bobcat T870, SJC, high flow, 500 hrs.

‘20 Bobcat T770, CAH, high flow, SJC, 765 hrs.

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘14 Bobcat S770, 3,200 hrs.

‘15 Bobcat T750, A71, joystick, 3,400 hrs.

SKID LOADERS

‘18 Bobcat 3400 SideXSide, C/H, 6,700 miles

‘19

BOTTINEAU, N.D. – Visitors at Mount Rushmore National Memorial can indulge in a cold dairy treat that was made using a recipe that was written by Thomas Jefferson. The vanilla ice cream, which has been enjoyed by people from all around the world, is produced in Bottineau, a little prairie town located about 10 miles south of the Canadian border in north central North Dakota.

Pride Dairy was founded as Bottineau Co-op Creamery in 1930. Local farmers brought their milk to the creamery where it was bottled or made into butter. The co-op began to make ice cream in 1940. Due to the dwindling number of dairy producers in the state, the creamery stopped bottling milk in 1980 and shifted its focus to ice cream and butter.

The creamery was struggling to survive when it was purchased by Jeff Beyer in 2012. Beyer had worked at the creamery since he was 16.

Kriss and Tonya Allard bought Pride Dairy from Beyer in 2019.

“Tonya and I had operated a food distribution business called Sunrise Delivery since 2011,” Kriss Allard said. “A big part of our business was the home delivery of milk, so we were familiar with the retail side of the dairy business.”

The Allards decided to take the plunge into dairy processing despite the fact that much of the equipment at Pride Dairy was outdated and worn out.

“We could see that the creamery had a lot of potential,” Allard said. “They had great products and great people.”

Although butter is still a large part of the business, Allard said ice cream is their future.

“Our local customers told us not to change a thing, so we haven’t,” Allard said. “Our ice cream still contains 14% butterfat, just as it did when Bottineau Co-op Creamery started making it many years ago.”

cream makers. Xanterra challenged the makers to craft a vanilla ice cream made using the recipe that was written by Founding Father Thomas Jefferson in 1780. Jefferson had served the ice cream, which specically called for Madagascar vanilla bean pods, to visiting diplomats and dignitaries.

Several ice cream makers submitted their samples. In the end, Xanterra gave the nod to Pride Dairy, and their vanilla ice cream began to be offered at the Memorial Team Ice Cream Station at Mount Rushmore. Thomas Jefferson Vintage Vanilla Ice Cream quickly became one of the most popular treats sold at the memorial.

“Mount Rushmore goes through about 8,000 gallons of our vanilla ice cream during an average tourist season,” Allard said. “One of the biggest challenges was recreating the ice cream without using the raw eggs that were called for in President Jefferson’s original recipe.”

Vanilla is by no means the only avor of ice cream being produced at Pride Dairy. They offer 18 avors on a permanent basis along with a handful of seasonal avors. Pride Dairy also sells ice cream toppings, cheese and butter.

The lineup of dairy treats offered by Pride Dairy continues to grow.

“We sell ice cream in wafe cones at our ice cream shop,” Allard said. “One of our workers got the idea of making an ice cream sandwich based on our wafe cones. We will be launching our ice cream sandwiches soon.”

Like with every business, Pride Dairy has also endured its share of setbacks.

“A storm in April of 2022 severely damaged our roof,” Allard said. “As a result, our production was cut for the next seven months. But, I view every problem as an opportunity. We used that opportunity to rebuild our plant and improve its automation.”

Pride Dairy products are currently available only in North Dakota and at Mount Rushmore. That is about to change.

“We are working on a distribution agreement with Prairie Farms Dairy,” Allard said. “We hope to begin distributing our products to a much wider area here in the Midwest. Our TJ Vanilla ice cream will soon be available in many more retail outlets.”

Pride Dairy has added new equipment and will soon be ramping up its ice cream production.

‘00 Bobcat 331E, cab, 2,000 hrs.

‘18 Bobcat E50, long arm, 700 hrs.

‘16 Bobcat E26, long arm, CAH, 800 hrs.

‘18 Bobcat E42, long arm, thumb, 600 hrs.

Pride Dairy sources its milk from Prairie Farms Dairy.

Some years back, Xanterra Travel Collection, the company that manages tourist operations at Mount Rushmore National Memorial, put out a call to ice

“We are currently making about 8,500 gallons of ice cream per month,” Allard said. “We hope to double that over the next two months.”

Some of the old equipment that was used by Bot-

soon be available at several other na�onal parks as well.

tineau Co-op Creamery continues to perform its duties at Pride Dairy.

“Our Juneberry ice cream is still being made by the Cherry Burrell V2D ice cream churn, which was manufactured in the 1950s,” Allard said.

A big boost in production is not the only news regarding Pride Dairy’s ice cream.

“Xanterra will soon be offering Thomas Jefferson Vintage Vanilla Ice Cream at Glacier National Park, Yellowstone National Park and Grand Canyon National Park,” Allard said.

intake

“They have also started selling it at The Oasis at Death Valley, a luxury resort that’s located northwest of Las Vegas.”

People are encouraged to visit North Dakota’s only remaining small town creamery. At Pride Dairy’s ice cream shop, visitors can enjoy an ice cream sundae and purchase any of a number of their products to take home.

“Everyone is excited when they walk into our ice cream shop,” Allard said. “They leave feeling perhaps a little bit guilty but also very satised.”

We utilize the Johnes test, standard plate count, somatic cell count, and mastitis culture tests.

Which is your favorite and why? I like the somatic cell count test to see if there are certain cows that have a chronic high

How does testing with DHIA bene t your dairy operation? DHIA bene ts the dairy by being an independent source helping us make decisions regarding herd health and productivity.

Tell us about your farm. I farm here with my brother, Perry, and my sisters, Brenda and Becky. We are a second generation family farm. We raise our youngstock, nish out our dairy steers, and farm about 900 acres.

Sauk Centre, MN Buffalo, MN 763.682.1091

“Boy it s hot out. I have a hard time keeping my dry matter

WESTBY, Wis. – Pete Kondrup has been elbowdeep in the dairy industry since he was a young high school kid working in his father’s cheese plant. After channeling that dedication to dairy as Westby Cooperative Creamery’s manager for the last 19 years, he has now handed off the responsibilities to JD Greenwalt.

Kondrup said he is proud of the work he did in his time at the creamery.

“It’s always great to work with a lot of people and see them grow (while) also giving the farmers in our area a market and being able to give people a fair price for their milk, either organic or conventional,” Kondrup said.

When Kondrup joined the operation in 2004, the

creamery was strictly a conventional dairy plant. As the organic market started to appeal to producers, however, Westby patrons were converting and forced to choose a different milk processing plant that would accept organic milk.

Kondrup convinced the board to begin producing organic products to allow their patrons to stay loyal.

“It opened up a whole new marketing world for us to say the least,” Kondrup said. “It was a tough decision for the board because it was seven conventional farmers, and not all of them were into the whole organic thinking.”

Kondrup said it was one of the biggest changes to take place in the rst couple years under his management. It is a change that has stood the test of time, since today more than half of the creamery’s patrons are or-

ganic producers. The availability of organic products also appealed to wholesale customers, which had been lacking at Kondrup’s onboarding.

Although Westby Cooperative Creamery was reaching out to new customers and encouraging them to commit to long-term contracts, many customers were ex-

cited to carry both conventional and organic products. When Kondrup joined the team, there were over

100 farmers depending on the creamery to provide them with a secure market. He said he enjoyed the challenges that came with that as well as working with the people internally at the creamery.

“I’ve had a lot of success with growing people within the creamery, so I’m proud of that,” Kondrup said. “It kind of gave me a challenge to do something good for a large group of people.”

operative has seen over the last two decades.

Greenwalt is especially looking forward to working with the board members, who are also member-owners.

Westby’s new manager, Greenwalt, comes from rural Iowa and is personally familiar with how integral the agricultural industry is to strengthening people and communities.

“Being part of a community is one of the primary reasons I wanted to join the Westby team,” Greenwalt said. “To be able to partner with our board members who are the direct owners of our business, our decisions do become part of our families.”

Greenwalt brings over 30 years of experience in manufacturing, sales and customer relations. Greenwalt said he is condent that combining that experience with Westby’s award-winning products and loyal customer base will continue the trajectory of success that the co-

“Each of our contributions are critical to ensure the health of our entire coop,” Greenwalt said. “This helps me realize how personal this business is to all of our farmer-owners and employees.”

While Greenwalt realizes the dairy industry can be difcult to navigate due to its volatility, he said the future is bright for those with a stable market, such as Westby Cooperative Creamery. He said he is excited to be a part of the solution to making agriculture a strong part of the economy.

“I have seen too many families and neighbors struggle through the realities of agriculture,” Greenwalt said. “I honestly want to help enable family farms to still be a viable lifelong career choice.”

Kondrup agreed.

“A lot of farms have disappeared,” Kondrup said. “Westby continues to be successful and allow the farmers who are staying in to hopefully make some money.”

“The

CowScout system is helping us catch cows in heat earlier, even those showing more subtle signs we normally wouldn’t have seen. It’s helping us diagnose health issues earlier too, like mastitis, DAs, Ketosis, & even foot issues. Even the obvious health challenges are being caught a day or two earlier than we would have found before. We’re seeing great results with CowScout. It’s doing all the things Leedstone said it would!”

Kristin Quist (pictured with husband Jacob)

Jo Daviess County

450 cows

Describe the facilities you utilize for your milking herd and youngstock. We have a 4-row freestall barn with sand bedding for milking cows. Dry cows are housed in sand-bedded free stalls and have access to pasture when weather is permitting. Calves are housed individually for 5-7 days. Then they go on an automatic calf feeder until weaned. Calves are raised in group pens on the farm for six months then go to a heifer raiser until two months before calving.

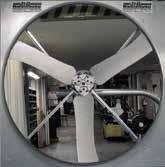

What are the most productive methods you use to reduce heat stress incidences in your milking herd? We have fans over all free stalls for milking and dry cows. Additionally, there are sprinklers over the milk cows in the freestall barn. Fans and sprinklers are in the holding pen as well.

What do you do to treat a cow for heat stress? For heat stressed cows, we will IV with uids and cool with fans and water as needed.

In your dairy career, what has been the best management practice you have incorporated to help animals with heat stress? We added fans over the feed aisles in the freestall barn and more fans in holding pen a few years ago, and that was a big improvement for cow cooling. We turned our fan settings down to turn on at 65 degrees. The sprinklers turn on automatically at 70 degrees, and from there they are set on a timer.

Tell us about your most challenging summer conditions and how that affected your herd. Our most challenging time in heat is our pre-fresh cows right now. They have to eat outside with an uncovered bunk. We are working on xing that this year to have a covered bunk and more cooling to provide a better environment for them to keep consistent feed intakes.

Tell us about your farm and family. My parents started farming here 50 years ago with 30 cows. Today my wife, Natalie, and I along with our ve kids own and operate the farm. We milk three times a day in a double-10 parallel parlor. We have six full-time employees. We still have three of our original employees who started with us 16 years ago. We ship our milk to Rolling Hills Milk Cooperative. Three years ago, we started hosting events on our farm to help educate consumers. We now host tours, farm camp for kids, night on the farm for adults along with a few other special events.

Morning Star Dairy La Crosse, Wisconsin La Crosse County

470 cows

Describe the facilities you utilize for your milking herd and youngstock. Our cows and youngstock are housed in sand-bedded free stalls. The cows are in two barns, and the heifers are in one. Calves are kept in huts. Our heifer barn does not have fans, but it does have curtains and is wide open to allow air ow. The cow barns have lots of fans and very good air movement. I have sprinklers along the feed bunks in the cow barns, but I have stopped using them in the last few years. I have found that it added humidity to the already humid air. We used to drop in milk and our somatic cell count would go up in summer, but since quitting the fans, things have remained steadier. Our cows remain around 100 pounds per day all throughout summer.

What are the most productive methods you use to reduce heat stress incidences in your milking herd? We do not overcrowd. We are pretty religious on only stocking 10% above capacity since there is usually someone in heat and walking around anyway. It seems to be a nice number for us.

What do you do to treat a cow for heat stress? I guess I really haven’t had any for quite a while. If we did, we would put them in the special pens by themselves and make sure they did not have to compete with other cows. They would have their own water and feed. But, we have very few incidents of heat stress.

In your dairy career, what has been the best management practice you have incorporated to help animals with heat stress? Lots of fans to encourage air movement. It can be warm air, but if it’s moving, it helps the cattle. Another thing is insulated roofs. We had one barn with insulated roofs and one without, and the insulated barn was a lot cooler, so we have since insulated the second barn. This helps them stay warmer in winter as well.

Tell us about your most challenging summer conditions and how that affected your herd. Back when I rst started, none of my freestall barns had curtains –it was solid steel walls. We had major heat stress then. There were no fans or curtains or insulated roofs. In 40 years, we’ve changed a lot, and all of our barns have been rebuilt.

Tell us about your farm and family. I’ve been here for about 40 years. My youngest son, Cameron, farms with me. Three and a half years ago, we built a new parlor. My milk goes to a cooperative called First District Association out of Minnesota, and our milk goes to Kwik Trip. It’s basically a load a day. I’m only 8-10 miles from Kwik Trip in La Crosse, Wisconsin, so it works out.

Deer Park, Wisconsin Polk County 1,350 cows

Describe the facilities you utilize for your milking herd and youngstock. We have conventional freestall barns with natural ventilation. Those cows are milked in double-9 parlor. We have positive-pressure ventilation in the robot facility and group-housed calf facilities.

What are the most productive methods you use to reduce heat stress incidences in your milking herd? Feedline sprinklers and fans are the most productive methods we have in reducing heat stress. We have been transitioning all of our panel fans to VES fans.

What do you do to treat a cow for heat stress? We will cool her down, soaking her to the hide, treat her with uids and what seems t based on signs she is showing.

In your dairy career, what has been the best management practice you have incorporated to help animals with heat stress? By far, investing in mechanical ventilation in our most recent facility, but we wouldn’t be without our sprinklers either.

Tell us about your most challenging summer conditions and how that affected your herd. This summer has been one of the most challenging so far with the early heat, high humidity and smoke from the Canadian wildres. Thanks to our investment for heat abatement in the past, and our most recent investment in smaXtec, we have been able to catch cows suffering from heat stress earlier than we’ve ever been able to.

Tell us about your farm and family. I farm with my husband, Jacob, and parents, Kevin and Roxie Solum, as well as our 20 non-family employees. We ship our milk to Burnett Dairy. Two-thirds of our herd are milked in our parlor and one-third in our robot facility.

Matt Berning (pictured with wife Natalie)

Berning Acres Menominee, Illinois

John Schaller (pictured with son Cameron)

Matt Berning (pictured with wife Natalie)

Berning Acres Menominee, Illinois

John Schaller (pictured with son Cameron)

Belle Plaine, Minnesota

Carver County

450 cows

Describe the facilities you utilize for your milking herd and youngstock. Our dairy barn is a curtainside freestall barn with a double-10 milking parlor. We have a bedding pack barn for our freshening cows. Our calf barn is a group penned setup with automatic calf feeders. Weaned calves are on a bedding pack until they are 7-8 months old and then in the freestall barn until they are brought into the close-up barn.

What are the most productive methods you use to reduce heat stress incidences in your milking herd? Sprinklers, fans and y control. The holding area has been crucial to keep the cows as cool as possible so we have sprinklers on a timer along with fans blowing over them to help the cooling effect through evaporation. Once they leave the parlor and return to the freestall barn, there are also bunk-line sprinklers on a temperature-controlled timer and fans to help cooling. Fly control is huge to keep cows from bunching together while in the freestall barn. A few years back, we installed an automatic y sprayer system which was a game changer. Once you have it programmed, it automatically sprays the cows. Very rarely do we have bunching, and we no longer have to spray the barn itself for ies.

Erin RasmussenHerdsperson at Spotted Cow Acres Owen, Wisconsin Clark County

420 cows

Describe the facilities you utilize for your milking herd and youngstock. The main barn is a freestall barn. Our six robotic milking pens are setup as direct ow. We have six classic DeLaval robots and two DeLaval V300 robots that were just installed June 28. Our dry cows, pre-fresh and fresh pen are free stalls; that pen is also in the main barn. The main barn stalls are all lled with sand. We have multiple fans in every group. Three large fans blow on the cows in the stalls and feed lane in every group. We also have fans with misters on them in the holding pens. The misters are turned on when the barn temperature reaches 75 degrees. On the south end of the barn, we have a curtain that is open all day and night, depending on the weather, to help with ventilation and keep the barn cool. There are 12 large fans sucking air out of the barn as well to help with ventilation. Every cow in our main barn gets a CowManager ear tag. These tags have changed the way we monitor our cows and have helped improve our herd. They have helped increase reproduction and allow us to monitor cows by watching the rumination. We used to have heifers in three barns located on the property, but now all the heifers are in one place. This barn has curtains on the north and south side that are open when the weather is nice. It also has an abundance of fans. The heifer barn is a freestall barn with mats in the stalls. Our calf barn has an automatic calf feeding system. We thoroughly clean the system once a day. There are four pens in the calf barn that are bedding packs. Two pens are for older calves that are getting weaned off milk, and the other two pens are for younger calves. The bedding pack is cleaned once weekly unless it needs to be cleaned more often. The calf barn has curtains that are open when the weather is nice, and there are fans above the feeders. There are also tunnel ventilation fans in the barn.

What are the most productive methods you use to reduce heat stress incidences in your milking herd? We use sand-bedded free stalls to help keep the cows cool and a cross-ventilated barn to help to help pull in cool air. We do not overcrowd groups. We have misters attached to fans above the holding pens to keep cows cool in holding pens, and we provide fresh, cool feed to reduce the feed heating too fast. Due to having robots, the cows are not in one area all at once, so they are spread out, which also helps them stay cool. We also clean out water tanks twice a week to provide the cows with fresh water during the warm months.

What do you do to treat a cow for heat stress? Honestly, we have very few heat stress incidences since installing the fans and sprinklers. On rare occasions we do have one, we will douse her down with cool water and get her in front of a fan along with offering her some water with electrolytes.

In your dairy career, what has been the best management practice you have incorporated to help animals with heat stress? I don't think there is one specic thing but rather a bunch of things that helps them cope with the heat. You need sprinklers, fans, abundant clean water, fresh high-quality feed and most of all comfortable stalls for them to lie down.

Tell us about your most challenging summer conditions and how that affected your herd. Probably the biggest challenge is trying to keep the tank average consistent through the hot spells of the summer. Even with all the heat-abatement tools, we still see some drop in pounds of milk especially when the heat index rises into the upper 90s.

Tell us about your farm and family. I farm with my parents, Lee and Mary Muehlenhardt, my sister and brother-in-law, Shari and Nate Gerdes, and their two kids, Kailyn and Hunter. My wife Beth is a full-time fourth grade teacher who also helps with odds and ends at the farm, and my two sons, Miles and Oliver, love to help on the farm too. My niece and nephew along with my sons are the sixth generation. We raise our dairy heifers and about 90% of our steer and beef crosses. We raise corn, soybeans and alfalfa on owned and rented ground. Our milk is shipped to Agropur in Le Sueur, Minnesota. We milk three times a day with the help of ve employees. We have a double-10 herringbone parlor with automatic takeoffs, and we use a RFID system which reads the ear tags of the cows and gives us milk weights on the cows three times a day.

What do you do to treat a cow for heat stress? We honestly do not have very many cows that suffer heat stress. Preventive care is always the best method. We do not vaccinate or move cows on hot days to prevent more stress. If we do have a cow with heat stress symptoms, we IV her with hypertonic saline solution. After that, we provide the cow with hay and access to fresh feed and water. This cow is monitored closely and tracked on the ear tag system.

In your dairy career, what has been the best management practice you have incorporated to help animals with heat stress? A best management practice that we have incorporated to help animals with heat stress is using the ear tag system to monitor activity and rumination better. We get an alert that a cow isn’t doing well before she is down, so we are able to treat her better. We saw improvement in the cows when we added misters to the fans in the barn. The cows enjoy the cool mist. The cows seem to move to the holding pen more often to get to the mister. This also means that the cows are going to the feed lane more often and consuming the correct number of vitamins and minerals. We have a highly ventilated barn due to having so many fans, so the barn stays cool in the summer.

Tell us about your most challenging summer conditions and how that affected your herd? We face the most challenges during the warmer months like July and August. Once it gets hot and stays hot, like most farms, we will drop in milk production. The most important thing to remember is to always try to keep the cows as comfortable as possible and moving through the robots and eating properly.

Tell us about your farm and family. Spotted Cow Acres was established in 2015. This is a fourth-generation family farm. We milk roughly 400 Holstein cows and raise our replacement heifers, and we ship our milk to Lynn Dairy. We sell extra colostrum, and the rest of the fresh cow milk is pasteurized and transferred to the calf barn where it is fed through automatic calf feeders. I have worked at Spotted Cow Acres for ve years. I started out at the farm doing chores part time and worked my way up to becoming the fulltime herdsman. Jared Eloranta is the owner of Spotted Cow Acres, and his father Wayne helps with just about everything on the farm. Wayne takes care of the heifer barn, calves, calf barn, maintenance on all the equipment and the main barn. Joan, Jared’s mother, does all the running for parts and bookwork for the farm. Mike, Jared’s brother, helps on the weekends by feeding cows or helping with eldwork. If eldwork ends up being on a weekday, Mike will come in the evenings and help also. We also have two part-time high school students who milk fresh cows and do daily farm chores. During eldwork time, we also have a couple individuals who help haul chopper wagons.

Wet or dry hay. Part-time, full-time or custom operations. Vermeer has the round baler you need to put up dense, high-quality bales you can be proud of.

6140

Describe your farm and facilities. We have sand-bedded free stalls and one pen with water beds. We milk three times a day in a double-12 parallel parlor.

What forages do you harvest? Haylage, corn silage, high-moisture corn and winter rye.

How many acres of crops do you raise? We raise 1,250 acres.

What quality and quantity do you harvest of each crop? We have 500 acres of hay and 700 acres of corn. We get our corn silage rst from the corn acres and whatever corn is left goes for high-moisture corn. We aim for 160180 relative feed value on alfalfa at 55% to 63% moisture for haylage. We look to harvest about 28 tons per acre on corn silage at 64% to 69% moisture.

Describe the rations for your livestock. All of our animals are on a total mixed ration. Heifers: grass hay, corn silage, mineral mix and haylage. Fresh cows: corn silage, haylage, soybean meal and dry corn. Dry cows: corn silage, dry hay and winter rye. Our rations are balanced by Chad Kieffer of Ag Partners.

Describe your harvesting techniques for alfalfa and corn silage. For alfalfa, we cut it, merge it and chop it with a Krone chopper. We harvest all of our own feed. Our cutting interval is 24 to 28 days on alfalfa.

What techniques do you use to store, manage and feed your forages? We have drive-over piles. We used to make a lot of bags, and then we converted to drive-over piles. We were making a lot more feed, and piles took less space.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We haven’t changed how we harvest our crops too much over my career. We started planting rye a few Turn to FORAGE | Page 20

years ago. Planting rye means we can get manure down in the summer, and we have feed for heifers and dry cows.

“We tried other products, and we found out: Udder Comfort™ is the one that really works. It’s the best for fresh cows, and for any type of swelling, any cow with elevated SCC or a hard quarter, mastitis, even an injured quarter,” says Brad Palmer of Pigeon Cove Farms, Warfordsburg, Pennsylvania.

“We got back on the Udder Comfort last year for its effectiveness and ease of use. Spraying fresh udders with Udder Comfort after each milking for 5 days after calving really helps our milk quality,” he adds.

Three generations are involved in the operation: Brad and Linette and their son Logan and daughter Hailey and Brad’s parents Lonnie and Debra.

They milk 440 Holstein and Jersey cows, averaging 94 pounds with SCC 140,000.

“We like using Udder Comfort in the parlor. It delivers better coverage and better results,” adds Hailey. She does herd health and breeding while Logan is mostly involved in crops and feeding. Hailey also shows Ayrshires, a breed she loves that her mom grew up with.

Describe a challenge you overcame in reaching your forage quality goals. Harvesting crops in a timely manner and facing delays due to rain.

How do quality forages play a part in the production goals for your herd?

It plays a big part. We adjust our nutrition plan if needed to obtain our production goals. If we start having issues, we recheck our samples and do a walk through on our cows to see if anything has changed. We don’t focus on our

milk as much as we used to. We focus on our components. The cows produce in the 4% to 5% range for protein and 4.2% to 4.5% for butterfat.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? We make sure our hay is cut when it is optimal for best quality feed. We make sure our corn silage is processed properly.

hrs., #558869.............. $349,000

JD S660 2014, PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S780 2020, PRWD, Duals, 1030 hrs., 749 Sep. hrs., #188309.............. $409,000

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD S780 2018, 2WD, Duals, 1215 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S690 2012, PRWD, Duals, 2312 hrs., 1645 Sep. hrs., #551148............ $149,000

JD 9770 STS 2011, PRWD, Duals, 3576 hrs., 2560 Sep. hrs., #555084 .... $116,900

JD S790 2020, PRWD, Tracks, 804 hrs., 584 Sep. hrs., #554727 ............... $509,000

JD S780 2022, PRWD, Floaters, 238 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S770 2022, PRWD, Floaters, 36 hrs., 20 Sep. hrs., #563704 ............... $546,000

JD S790 2018, PRWD, Duals, 1643 hrs., 1218 Sep. hrs., #549845............ $309,000

JD S790 2018, PRWD, Duals, 1852 hrs., 1407 Sep. hrs., #549847............ $295,000

JD S790 2018, PRWD, Duals, 1459 hrs., 1055 Sep. hrs., #549846............ $329,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Singles, 25 hrs., 20 Sep. hrs., #560619 ................. $639,500

JD 9870 STS 2010, PRWD, Duals, 3394 hrs., 2260 Sep. hrs., #554931 .... $118,900

JD S690 2016, PRWD, Duals, 2544 hrs., 1820 Sep. hrs., #547267............ $219,900

JD S780 2018, PRWD, Duals, 1622 hrs., 1131 Sep. hrs., #276170............ $305,000

JD S770 2021, 2WD, Duals, 718 hrs., 585 Sep. hrs., #560264 .................. $425,900

JD S780 2019, 2WD, 627 hrs., 460 Sep. hrs., #559821 ............................ $359,000

JD S790 2021, PRWD, Duals, 705 hrs., 526 Sep. hrs., #555189................ $499,500

JD S780 2019, PRWD, Floaters, 1289 hrs., 889 Sep. hrs., #275242 .......... $349,000

JD S680 2012, PRWD, Duals, 2500 hrs., 2000 Sep. hrs., #554973............ $129,900

JD 9750 STS 2003, 2WD, Duals, 4830 hrs., 3367 Sep. hrs., #565004 ......... $37,500

JD S680 2014, PRWD, Duals, 2321 hrs., 1575 Sep. hrs., #555096............ $169,900

JD S790 2022, PRWD, Duals, 145 hrs., 90 Sep. hrs., #557140.................. $629,900

JD S790 2022, PRWD, Duals, 428 hrs., 302 Sep. hrs., #552839................ $579,500

JD S780 2020, PRWD, Duals, 932 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1562 hrs., 1131 Sep. hrs., #549680............ $319,000

JD S780 2021, PRWD, Duals, 654 hrs., 469 Sep. hrs., #191047................ $489,000

JD S780 2019, PRWD, Floaters, 1604 hrs., 1145 Sep. hrs., #549684 ........ $319,000

JD S780 2022, PRWD, Tracks, 337 hrs., 251 Sep. hrs., #563618 ............... $619,000

JD S780 2022, PRWD, Duals, 426 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Tracks, 316 hrs., 231 Sep. hrs., #563619 ............... $619,000

JD S780 2022, PRWD, Duals, 454 hrs., 347 Sep. hrs., #563635................ $549,000

JD S690 2017, PRWD, Duals, 1433 hrs., 1187 Sep. hrs., #549457............ $280,700

JD S780 2022, PRWD, Duals, 241 hrs., 183 Sep. hrs., #554094................ $565,000

JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000

JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

JD S780 2019, PRWD, Duals, 1559 hrs., 1058 Sep. hrs., #549682............ $319,000

JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646............ $219,900 JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

............ $549,900

JD S790 2018, 2WD, Duals, 1579 hrs., 1128 Sep. hrs., #273973 .............. $289,000

JD 9770 STS 2011, 2WD, Duals, 3460 hrs., 2570 Sep. hrs., #555709 ......... $92,500

JD S790 2022, PRWD, Tracks, 38 hrs., 21 Sep. hrs., #553771 ................... $695,000

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 .... $34,900

JD S780 2020, PRWD, Duals, 955 hrs., 659 Sep. hrs., #188459................ $419,000

JD S780 2022, PRWD, Duals, 462 hrs., 345 Sep. hrs., #553598................ $549,000

JD S770 2022, PRWD, Duals, 270 hrs., 195 Sep. hrs., #554014................ $560,000

JD S780 2022, PRWD, Tracks, 299 hrs., 238 Sep. hrs., #554013 ............... $619,000

JD S780 2020, PRWD, Duals, 1545 hrs., 1204 Sep. hrs., #531610............ $349,000

JD S790 2021, PRWD, Tracks, 734 hrs., 530 Sep. hrs., #191075 ............... $549,500

JD S680 2015, PRWD, Duals, 2585 hrs., 1865 Sep. hrs., #190078............ $174,500

JD 9760 STS 2004, PRWD, Duals, 4389 hrs., 3109 Sep. hrs., #564023 ...... $53,500

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Duals, 91 hrs., 56 Sep. hrs., #563620 ................... $579,000

JD S780 2020, PRWD, Duals, 1488 hrs., 1145 Sep. hrs., #191082............ $349,000

JD X9 1100 2021, PRWD, Tracks, 942 hrs., 735 Sep. hrs., #552917.......... $749,000

JD X9 1100 2021, PRWD, Tracks, 876 hrs., 715 Sep. hrs., #552921.......... $769,000

JD S790 2019, PRWD, Duals, 1772 hrs., 1426 Sep. hrs., #532032............ $299,000

JD S780 2020, PRWD, Duals, 1076 hrs., 784 Sep. hrs., #188458.............. $409,000

JD S790 2018, PRWD, Duals, 1315 hrs., 940 Sep. hrs., #554633.............. $329,000

JD S790 2021, PRWD, Singles, 937 hrs., 770 Sep. hrs., #557277 ............. $479,000

JD S790 2021, PRWD, Duals, 585 hrs., 449 Sep. hrs., #556669................ $499,500

JD S690 2017, PRWD, Duals, 2103 hrs., 1461 Sep. hrs., #552684............ $249,900

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service

Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029

Pierz, MN 320-468-2494

St. Charles, MN

507-932-4288 Wadena, MN 218-632-5416

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

GENOA, Wis. – The Goedes are experts when it comes to chickens, sheep and hogs. Now they are relearning the dairy industry while building up their herd.

The Goede family welcomed attendees of the National Jersey Convention June 22 for a tour of their farm near Genoa.

Joel and Jenny Goede both grew up milking cows, but they did not reenter the dairy scene as adults until 2019.

Joel’s home farm was a dairy farm for 85 years before an accidental re burned the barn down in 1999. Joel was a teenager at the time and uncomfortable with committing to rebuilding the dairy at such a young age. So, his dad, Lorn, found a job off the farm and the family moved on from dairy farming.

When Joel took a job with a neighboring dairy farm, however, he discovered a passion for Jersey cows that took hold of him and would not let go.

“My love for Jersey cows grew,” Joel said. “It wasn’t long before I knew I wanted to milk Jerseys one day.”

Twenty years later, Joel nally returned to dairy farming with his wife Jenny and their four children by his side. Today, the family milks 110 Jersey and Holstein cows.

The road back to cows took a detour when the family built two laying hen barns, one in 2004 and the other in 2005, raised a ock of 80 sheep that still thrives and created one farrow-to-nish hog operation that they ran for 10 years before letting it go to start the dairy farm.

Having worked with Organic Valley to market eggs and hogs, the Goedes knew they wanted to keep their land certied organic and stay in the niche market with dairy as well. Their milk is now shipped to Organic Valley. They started out with 60 cows and have grown within the quota system that Organic Valley has in place.

Cows are housed in a sand-bedded freestall barn and milked in a double-8 parallel parlor. The cows utilize the farm’s 95 acres of pasture to obtain 40% of their diet by grazing from May through December, if weather allows.

Joel said the pasture provides a lot of hay to the cows.

“In a decent year with a decent rainfall, we can’t keep up,” Joel said. “But, obviously we’re not afraid to feed at the bunk a little bit to get them to produce.”

Cows have access to a total mixed ration in the freestall

barn year-round. In the grazing months, hay is taken out of the TMR to compensate for the time spent grazing. In all seasons, the cows end up with a diet that relies heavily on hay. This allows their corn to be saved for the chickens.

“We are still running about 15,000 laying hens right now, and they’re a big user of corn,” Joel said. “So, we don’t want to use all of our corn for the dairy.”

Paul Mueller Company’s Milk Tower™ features Mueller® Temp-Plate® heat transfer surface that removes more heat from milk in the same amount of time, compared to other silos. Reach maximum cooling efficiency and maintain temperature even when the tower is not 100 percent full.

Central Ag Supply

Advanced Dairy Spring Valley, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Juneau, WI; Baraboo, WI

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

Central Ag Supply

Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc.

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Redeker Dairy Equipment

Brandon, WI

Stanley Schmitz Inc. Chilton, WI

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Total Dairy Services Kewaunee, WI

United Dairy Systems West Union, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Gorter’s Clay & Dairy Equipment Pipestone, MN

United Dairy Systems West Union, IA

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

Cuba City, WI

Monroe Westfalia Surge Monroe, WI

J. Gile Dairy Equipment, Inc.

Stanley Schmitz Inc. Chilton, WI

Tri-County Dairy Supply Janesville, WI

Tri-County Dairy Supply

Fuller’s Milker Center

Janesville, WI

Fuller’s Milker Center

Professional Dairy Services Arlington, WI

Cuba City, WI

Professional Dairy Services

Lancaster, WI; Richland Center, WI

Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

Arlington, WI

Redeker Dairy Equipment Brandon, WI

Eastern Iowa Dairy Systems

Gorter’s Clay & Dairy Equipment

Pipestone, MN

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Midwest Livestock Systems

Zumbrota, MN; Menomonie, WI; Renner, SD

Glencoe Co-Op Assn. Glencoe, MN

S&S Dairy Systems St. Charles, MN

Monroe Westfalia Surge Monroe, WI

Glencoe Co-Op Assn. Glencoe, MN 1-800-MUELLER

Epworth, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Heifers are kept at Jenny’s parents’ home farm from 6 months old until two weeks before calving. Jenny’s dad takes care of them and gets them bred, which Joel said they are thankful for.

Joel’s father and step-mother are equal partners in the limited liability company. Lorn is the main equipment repair man and also works beside Joel. Lorn’s wife, Teresa, contributes in numerous ways as well.

“We’re so blessed to have her help every day,” Joel said. “She’s picking eggs, mowing lawn, gardening, and she still has lunch every day at 12:15 for anyone, whoever is out here.”

Jenny said one of the biggest challenges on their dairy has been relearning the dairy industry that she and Joel were out of touch with for two decades.

“We both grew up milking, but for 20-30 years, we hadn’t kept up on cow treatments, and we knew nothing about organic cow treatments,” Jenny said. “We had to start from scratch, really.”

Their veterinarian, Anne Marie Elwing, has been involved in educating the family about protocols, vaccination schedules and herd health practices. Jenny said she and Joel can both IV cows and blood test for

ketosis as well as maintain an effective post-calving protocol. Jenny said that Elwing is also conscious of their Dairy Herd Improvement Association records and stays on top of trends within their herd to help the couple make decisions in breeding and culling.

“She’s been great because she’ll come out when she needs to, but she’s also really great about teaching,” Jenny said.

The Goedes have leaned on technology to help manage their herd, using activity collars to detect heats. The herd is somewhat seasonally bred, so the collars have been helpful this spring in nding the cows that do not show heat, Jenny said. The collars have also aided in determining when a cow is off feed.

They have also just started to dabble in genomic testing. With Elwing’s help and direction from Zoetis, they have started by testing the 40 weaned heifers they have. They are hoping to gauge where the herd is at right now, healthwise. Once they have a benchmark of health, they plan to utilize data from the genomic tests to make better culling decisions and maintain a healthier herd overall.

“I’m interested in seeing ones that are known for mastitis or ketosis because we are a little limited on what we can do,” Jenny said. Even though they had to go back to the starting line when reentering the dairy industry, Jenny is condent that, with the organic milk price and solid milk market in place, their farm will be sustainable.

“The core of Organic Valley’s program is milk, so we’re excited to be a part of that,” Jenny said. “They’ve

always been about supporting family farms, and by us diversifying from eggs into milk, they’re helping us keep the next generation on the farm.”

Joel agreed.

“Organic Valley literally started in this valley a long time ago, and it’s been a great co-op to work for,” Joel said. “We’ve been pretty involved, and while everybody has their ups and downs, we’re proud supporters.”

USED TRACTORS

CIH 215 Magnum, 2,500 hrs., FWA .....$138,000

CIH 8950 1,600 hours ..............................$165,000

CIH 8920, 2WD, 1000 hrs. .........................$13,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 8920, FWA, 2600 hrs ........................$110,000

CIH 7240, 2,500 hours, coming in ...........$110,000

CIH MX120, 2WD, 3,800 hrs......................$72,000

CIH MX110, FWA, 1600 hrs. ......................$65,000

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 1086, nice..............................................$21,000

IH 806 ....................................................$11,000

JD 2755, 5,600 hrs. ...............................$16,000

TILLAGE

527B ripper ............................................$13,500

CIH 530B................................................$18,000

CIH 527B................................................$19,500

CIH 870 7-shank ....................................$38,000

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate II 26’, w/28’ pull crumbler $31,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

JD 714 11 shank chisel plow .................$14,000

CIH 5700 chisel plow, 23’ ......................$16,000

CIH 4800, 25’ ...........................................$6,500

CIH RMX 340 25’ disc w/mulcher ..........$42,000

CIH 25’ 3900 disc ..................................$15,000

CIH 183 12R cultivator .............................$4,250 Brillion 9-shank disc chisel ......................$4,000

DMI 530 Ecolo-Tiger w/basket ...............$12,000

DMI 530 ripper w/leads..........................$14,000

DMI 530B w/lead ...................................$16,500

HAYING & FORAGE EQUIP.

Sitrex QR12, QR10, QRS rakes ....................New Kuhn 10-wheel rake w/center kicker wheels, like new ..................................................$8,500

Many sizes of rakes available

All Sizes of Sitrex Rakes.........................On Hand

GRAVITY BOXES & GRAIN CARTS

(2) Demco 365 .........................................$4,200

Many Sizes of Gravity Boxes ..................on Hand Brent 657 gravity box, green & black, fenders ................................................$23,000

(2) Brent 644 box .......................................$18,000 Brent 644 ...................................................$16,500

J&M 385 ......................................................$6,500

J&M 540 box .............................................$13,500

Parker 4800 box...........................................$8,500

Unverferth 7250 grain cart .........................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

MADISON, Wis. – Looking back on his 25-year career with the University of Wisconsin-Madison, Ted Halbach sees a great deal of memories and experiences, all of which he said are a privilege to have been a part of.

“I have enjoyed, without a doubt, all of the roles I have held during my time at UW,” Halbach said. “I cannot speak more positively about my experiences.”

Halbach rst came to UWMadison in 1998, taking on a role that was comprised of outreach as the Extension’s dairy youth specialist and instruction. Halbach took over teaching and dairy-judging coaching duties formerly held by Dr. David P. Dickson.

Later during his tenure, Halbach spent time as the director of the Farm and Industry Short Course program before returning to the dairy science department as a faculty instructor, teaching dairy management courses with a partial Extension appointment.

Halbach will ofcially retire from his role Sept. 1.

“I have been in the class-

room from day one; that is a role I have always enjoyed,” Halbach said. “I had the opportunity to interact with so many talented students and to watch them learn and grow as individuals, in addition to continuing to learn along the way myself.”

Taking on those roles was a career change for Halbach, who had previously operated a 500-cow commercial dairy in Arizona with his father. After his father passed away, Halbach sold the cows rather than committing to the large-scale expansion he knew would be required to continue the dairy. After that decision, Halbach said he was open to a new opportunity.