“All

Big win in stray voltage case

Vagts Dairy LLC triumphs with Iowa Supreme Court ruling in their favor

By Amy Kyllo amy.k@star-pub.com

WEST UNION, Iowa — Stacks of thick binders containing myriads of evidence and court documents lay on dairy farmer Mark Vagts’ dining table. Each binder is a visual representation of the Vagts family’s three-year litigation battle. The Vagtses sued Northern Natural Gas after stray voltage affecting their cattle was found on their farm.

On June 21, litigation with Northern Natural Gas came to a close with a ruling in the family’s favor from the Iowa Supreme Court. In the court ruling, Vagts Dairy LLC was awarded $4.75 million in damages.

“We’re lling in a big economic hole,” Mark said. “We’re not building a moun-

Dairy Farmers of America Pollock plant closes

By Sarah Middendorf sarah.m@star-pub.com

Pollock, S.D. — Dairy Farmers of America announced the closure of their dairy ingredient facility in Pollock to the public July 18. The facility will ofcially close Aug. 30.

“This was a difcult decision, but we have a responsibility to operate nancially sound businesses that bring additional returns to our family farm-owners’ investment in the Cooperative,” said the statement provided by DFA.

The facility has been operated by DFA since 1998 and originally produced mozzarella cheese. In 2002, they converted it to produce hard Ital-

tain. We’re lling in a hole.”

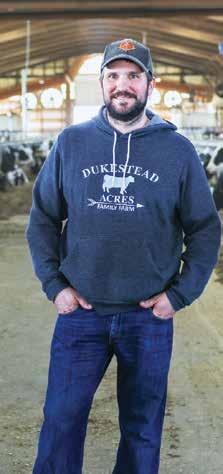

Vagts Dairy is owned by Mark and his son, Andrew. They milk around 500 cows with the assistance of employees.

“It was very emotional, very stressful,” Mark said. “Our life has not been a lot of fun because of that.

The Vagts family said they went into mediation and felt Northern Natural Gas was not interested nor did the family feel they made effort to acknowledge the problem.

“Northern Natural Gas did not take us seriously,” Mark said. “It’s kind of like David versus Goliath or worse, ... we’re throwing stones and they’re fully armored.”

Turn to VAGTS DAIRY | Page 2

Closing the doors

ceive milk until Aug. 29.

DFA said their customers will continue to be served by their ingredient facilities.

Due to the closure, there will be 33 full-time and four part-time positions affected and removed from DFA.

“Any decision impacting people’s livelihoods is one not taken lightly, and we will work with employees to help them through this transition,” DFA said.

All full-time employees will be receiving a severance package. DFA said they are searching locally for employment opportunities and providing resources to help aide in the transition to other employment for those affected.

well as the current supply dynamic.

According to DFA, there were many things taken into consideration when deciding to close the facility, including the analysis of new demand as

“As part of a coordinated, Cooperative-wide milk marketing and balancing optimization project, the decision has been made to close our dairy ingredient facility,” DFA said.

A ag u ers in the breeze in July at the Dairy Farmers of America Pollock facility in Pollock, South Dakota. The facility will be closing its doors Aug. 30. ian cheeses. On average, the facility processed 450,000 pounds of milk per day. DFA said they will continue to have space for the milk production at nearby facilities located in North Dakota and the upper Midwest. The facility in Pollock will re-

DFA is still determining what the next steps are for the building and the equipment inside.

“The employees at the facility have done an excellent job producing dairy ingredients, and we appreciate all their hard work and dedication,” DFA said.

DAIRY ST R

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

The Vagtses led suit in March 2021. In January 2023, the jury ruled unanimously in their favor after a nineday trial. After Northern Natural Gas appealed, it was taken before the Iowa Supreme Court in January.

The Vagts family’s farm was affected by DC stray voltage coming from a rectier, anode bed and nearby natural gas pipeline. The DC current created a constant exposure for the family’s cows from the voltage. This caused their immune systems to be in a continually heightened state, putting the cows at risk for secondary issues.

The pipeline causing the issue was put in on the Vagts family’s farm in 1964. Over time, the coating on the pipes can erode, causing oxidation and rust. This natural gas pipeline used a cathodic protection system as required by federal regulations. This protects the pipe from oxidation by having DC current run on the encased pipes. To accomplish this, a rectier converts alternating current power to DC power and sends it through the anode beds which act like a battery to electrify the pipeline.

In 2022, the Vagtses lost 76 cows, 27 of which they had to euthanize. Their herd death loss was over 17% — over three times the expected average of 5%.

Using Dairy Herd Improvement Association records, the Vagtses tracked death losses from over a decade and correlated them to the electrical activity. In 2013, Northern Natural Gas

Supreme Court ruled in their favor on their direct current stray voltage case against Northern Natural Gas.

replaced the anode bed and the rectier was turned off. At that time, their death loss dropped to 3%. Later that year, after the new anode bed and rectier had been installed, the Vagtses began to observe abnormal cow behavior.

The Vagts family’s original freestall barn was built in 2000. Then, in 2017, they built on an addition which brought the end of their barn 200 feet closer to the pipeline. Animals in the Vagts family’s calving pen, which was closest, had the most problems.

The Vagtses had three waterers destroyed because their cows were standing in them during all months of the year to ground themselves while they drank. Building guards did not remedy the issue.

The stray voltage was especially hard on older cows.

“We’ve always pushed for longevity anyway, so that was really hurtful,” Mark said.

Turn

and

and

PRODUCE UNIFORM, FLUFFY WINDROWS

Little Falls, MN

Hutchinson, MN

Sartell, MN

Albany, MN

Perham, MN

For additional stories from our other zone, log on to www.dairystar.com

Their cows suffered from compromised immune systems, metritis, high somatic cell count, low components and high feed intake.

“It was terrible,” Mark said. “We were still maintaining, but ... we were losing our butts nancially because we just weren’t getting components, which is a major driver of the market price.”

Not knowing what the problem was, the Vagts family looked into every aspect of their farm. They worked with their nutritionist and veterinarian; they investigated their milking equipment and other areas of the farm.

Finally, having exhausted their options, they brought in a stray voltage expert in September 2020, Lawrence Neubauer. Within 10 minutes he had detected stray DC voltage. Neubauer spent three days of testing, verifying and documenting his ndings.

In less than a year from discovering this, the Vagts family sued Northern Natural Gas. The Vagts family also worked with Allamakee-Clayton Electric Cooperative which supplies power to Northern Natural Gas and to their farm to resolve several other issues outside court.

The Vagtses had a discovery day for their court case where around 27 people from the opposing counsel came to their farm to inspect for issues that could be causing the problem.

The Vagtses said they would advise someone going through a similar case to make sure every aspect of their operation is in order.

“They’re just looking at everything,” Mark said. “They’re just trying to nd something that they can see that we might have done wrong (or to suggest that) we’re poor managers.”

At one point within the litigations process, Andrew was testing for stray voltage approximately every day. With this testing, they took photos with GPS location turned on to prove what was happening.

The Vagts family had to produce building plans, ve years of nancials, DHIA records, hoof trimming receipts, employee time sheets and more.

Andrew said it was frustrating to gather information for 3-4 years for the trial.

After the Vagts family’s lawsuit, in 2023 the rectier was removed, the anode beds were removed and a third anode bed was discovered at the site and removed. They uncovered and rewrapped the pipeline for nine-tenths of a mile. Within that distance, the crew found approximately 100 compromised areas to the pipeline coating.

Even though the issues have been xed, the problem has not fully gone away. The DC power must slowly drain from the farm soil, almost like a battery. This is different from AC stray voltage, which, when xed, gives immediate relief to the cows. The Vagtses were told by their veterinarian that it may take up to two years.

“It takes time for that to deplete the current even though things are xed, things are disconnected and moved out,” Andrew said.

Now that litigation is complete, the Vagtses can once again focus on being dairymen. Already, Mark said their cows’ health is better.

“We’re cautiously optimistic,” Mark said. “We’ve seen some improvements, but it’s not as quickly as what we’d like to see, of course.”

Tornado touches down

Several Stearns County farms suffer damage

By Meghan Kropp Contributing Writer

MELROSE/FREEPORT, Minn. — The weekend took an unexpected turn Aug. 3 in Stearns County as a tornado touched down.

Tanya Christenson, of Freeport, said she had just nished baling hay with her husband, Jason, and her father, Carl Schulzetenberg, when the storm hit. Three of her children, Addison, Jaci, and Kaylin, were at the Stearns County Fair in Sauk Centre.

“During chores, I was watching (the weather) but more for their sake than for ours,” she said. “You could tell it was going to storm, so we started putting stuff in the shed, like loads of straw and all the equipment.”

According to the National Weather Service website, an EF1 tornado touched down in the northwest corner of Melrose. The tornado, with peak wind speeds of 95 mph, traveled 5.4 miles, causing damage to homes and businesses, and ripping up many trees in the area.

Christenson said she was on the phone with her daughter while cleaning up and suggested places to go on the fairgrounds that could be safer for the kids, or to a godmother’s house nearby.

At that point, Christenson said she went to her home across the road, where she and her husband watched the storm from their front porch.

“You could see the rotat-

ing clouds come from both directions and kind of swirl,” she said. “When we were on the porch, we saw a couple of wall clouds.”

Christenson said the sky turned shades of green, pink and blue, and clouds were moving from the north and the west toward each other. Leaves and branches were ying outside, she said. The family went into the basement, where they could watch the storm from the back of the house.

“As soon as we went down, we saw our trampoline take off,” she said. “That’s also when it started hailing.”

After the storm passed, Christenson said her father went out into the corneld to pick up some branches and noted water up to his ankles. She estimates 3 inches of rain fell during the storm.

Christenson said many branches were taken down, as well as multiple trees.

“When we looked to the north, the dry cow shed had a tree go through the solar panel part of the roof,” she said.

While the equipment and milk barn faired the storm ne, Christenson said the door at the top of her silo and part of the roof were damaged.

“It’s a mess in there,” she said. “We only have two doors left, so I think we should be able to feed a good part of it before it goes bad.”

Christenson also said roughly 80 acres of meadow that the family had not been able to cut beforehand is under water again from the

storm and the rain from the following days.

The horse shed also was blown an estimated 50 feet away during the tornado, but the horses are OK, Christenson said.

“Luckily they didn’t run away; they kind of huddled together,” she said. “I think they were pretty spooked.”

Christenson said that this is the worst storm she has been through since dairy farming with her dad.

“I thought this was just going to be rain or even a thunderstorm,” she said. “I have seen enough of them, so I’m not usually too worried about them.”

However, with her children at the fairgrounds, Christenson said she was checking the radar more than she normally does.

“Once I knew they were ne there, I was glad they

broke. Then it started hailing.”

Middendorf said he moved a vehicle into the detached garage and was watching the storm from there.

“I could see limbs starting to fall from other trees and started hearing some deep cracks from the tree that was right next to the garage,” he said.

Middendorf decided not to stick out the storm in the garage but ran for the house. Had he taken his normal left from the garage instead of right, he would have been crushed by a tree that fell. Not even the elevator that broke the tree’s fall would have helped Middendorf said.

Less than a quarter of a mile away, Middendorf’s parents had three trees down, one of which went into the machine shed.

were there (because) it was worse here,” she said. “Everyone is OK. It could have been a lot worse.”

Christenson said now they are focused on cleaning up the damage and are thankful their buildings are still standing, as some in Melrose saw more destruction in the wake of the tornado.

Aaron Middendorf of Melrose, farms with his wife, Cheyenne, and parents. He said they were wrapping up baling hay when the storm hit.

“We got everything in just before it started storming,” he said. “I was out in the barn and had just got done helping put away everything and making sure the fans were turned down so nothing

“The biggest devastation was the trees going through the building,” Middendorf said. “There wasn’t that much for it to be a crop loss. There are still leaves on the corn. That was the biggest thing. There wasn’t a whole lot for devastation. It’s unfortunate that it happened, and it was a lot of work, but it was nothing too terrible.”

Middendorf said the storm made for a busy weekend cleaning up trees and damage, but the family got some help from Dave and Nancy Powell.

“You never think it’s going to happen to you until you’re in that situation,” he said. “I am probably going to stay inside the next time it storms like that.”

Understanding overseas needs

Temme visits Indonesia to promote US products

By Emily Breth emily.b@star-pub.com

WAYNE, Neb. — When the opportunity came to join an agricultural trade mission to Indonesia, Doug Temme did not hesitate to attend, even with the Wayne County Fair around the corner.

“The overall hope that we could help get people connected and get products moved to other countries was the biggest thing,” Temme said.

To attend this trip, Temme, who serves on the county fair board, had to

leave his 850-cow dairy in the hands of hired help. Temme left for the trip early July 13 and returned July 24.

“Without foreign trade, our markets would be a lot lower,” Temme said. “Anything we can do to inuence or add to it is great.”

Though he traveled with a group from the Nebraska Beef Council, Temme said the process for trade is the same for all agricultural products, including dairy. There are many steps that have to be completed before a trade agreement can be made, from setting tariffs and quotas to understanding personal beliefs and country expectations.

The most important aspect of successful trade relations is knowing the certication requirements and cultural aspects for citizens of the country Temme said. Currently, the population of Indonesia is just shy of reaching 280 million, with more than 80% Muslim.

“Having a better understanding of the Muslim faith helps us to know what is all entailed for a positive trade arrangement,” Temme said.

With a majority of the population belonging to the Islam faith, it is important for U.S. exports to be halal certied.

“I learned a lot of interesting facts about what halal was and how much went into getting it certied,” Temme said. “We even saw water that was halal certied. Basically, that means the well where the water was taken out of did not have pigs within a certain distance of it.”

Along with matching the needs and wants of another country, it was also important to ensure the full use of all resources Temme said. This includes being able to nd a trade agreement that allows for a two-way trade. Temme said most countries want this because it has potential to benet everyone.

“For Indonesia it takes 45 days for a shipment to get there from the U.S.,” Temme said. “Australia could get it there in 10 days. That makes a big difference for us because there is a long wait time.”

Prior to this trade mission, Temme had the opportunity to attend two others. His rst trip, to Japan, was with the Federation of State Beef Councils which is a division of the National Cattlemen’s Beef Association. The U.S. Department of Agriculture provides oversight for the organization.

The second trip for Temme was to Columbia,

“You meet people from around the world and you realize how much we are alike. We are just trying to make a living. The difference in culture was a big thing to see.”

DOUG TEMME, DAIRY FARMER

also with the Nebraska Beef Council and the Nebraska Department of Agriculture. Each of these trips provided Temme and his colleagues the opportunity to develop relationships that would normally be inaccessible.

Nebraska Beef Council members rotate who attends the trade mission trips according to member availability. Usually, 15-20 people participate.

The travel group included the Mark McHargue, the Nebraska Farm Bureau president, Director of the Nebraska Department of Agriculture, Sherry Vinton, Lt. Gov. of Nebraska Joe Kelly, a salesperson and individuals able to halal certify products.

“There were also university professors that gave presentations talking about the difference between U.S. beef and grass-fed Australian beef,” Temme said.

He said getting this opportunity to talk with others from different countries allowed for connections to be built and mutual understanding to be cultivated.

“You meet people from around the world and you realize how much we are alike,” Temme said. “We are just trying to make a living. The difference in culture was a big thing to see.”

BLAST FRESH

TOUGH & TOOTHY

Discover daring KP Roll engineering with an edge. Impressive crop mat penetration with incredible wear resistance. Turn your kernels into gold.

No apologies

The House Committee on Agriculture hosted a hearing on farm nancial conditions before breaking for the August recess, but the session started with a spirited exchange over the farm bill. Chairman Glenn “GT” Thompson defended the farm bill that passed out of his committee in late May. “I would not apologize for advancing a bill that seeks to put the farm back in the farm bill and I also won’t apologize for advancing a bill that was written by every member of this committee,” Thompson said. “Forty provisions that were put into this that were just led by my Democratic colleagues and I don’t put things in legislation just to buy a vote, I put it in there because it was great legislation.” Thompson also challenged Senate Agriculture Committee Chair Debbie Stabenow to unveil her farm bill text and not what he called “a partisan 90-page summary.”

“It’s much better than what we were facing earlier in the year,” said Mike North, producer division president, Ever Ag. With falling feed costs and rising milk prices, protability may be on the horizon. Despite that, North said expansion may be slow to happen. Rising interest rates, the cost of capital and the interest in beef-on-dairy are cited as reasons. “We also have HPAI that’s been found in dairy animals and reduced milk production and supplies so that’s taken away from it.”

55” Panel Fans

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

By Don Wick Columnist Ag Insider

Scott renews criticism of ag committee farm bill

House Agriculture Committee Ranking Member David Scott followed Chairman Glen“GT” Thompson’s opening statement with criticism. In particular, Scott argued the pending farm bill eliminates the U.S. Department of Agriculture’s ability to use Commodity Credit Corporation funds to support farmers. “Secretary (Sonny) Perdue used approximately $23 billion in CCC funds for the coronavirus assistance program and this helped our farmers survive lower prices that were arising as a result of COVID 12. We didn’t restrict the CCC when my friend Sonny Perdue was agriculture secretary and we must not do it now.”

National Milk Producers Federation welcomes Federal Milk Marketing Order recommendations

The USDA released its recommendations for modernizing the FMMOs in early July. Stephen Cain, senior director of economic research and analysis for the NMPF, is pleased with USDA’s recommendations to modernize the FMMOs. “Fundamentally, USDA agreed with our premise and methodology for all the changes we were asking for. They didn’t do it exactly the way we had hoped for, but in general, we’re very pleased with how USDA has come out with the recommended decision here.” Cain is surprised USDA removed barrels from the Class III formula. “In the long run, that’s going to be very supportive of dairy farmer revenue over the next few years and the future.”

Avian Inuenza Research and Response Act introduced

A bipartisan group of House members has introduced legislation to help dairy farmers impacted by avian inuenza. It codies the USDA rules that compensate dairy farmers for milk production losses due to the virus. It also prioritizes research for H5N1 and calls on USDA to create a dairy biosecurity education and training program.

Flu vaccination recommended for livestock workers

The Centers for Disease Control and Prevention is stepping up efforts to vaccinate livestock workers against the seasonal u. The CDC is worried that someone could be infected by the seasonal u and the H5N1 and develop an entirely new virus. States will split $2 million for the vaccine and $3 million to implement the program. Another $5 million will be spent on educating farm employees about the importance of biosecurity and the use of protective gear.

A Class III market reversal

The dairy market has seen a remarkable reversal higher since last winter. AgResource Company President Dan Basse said several factors are driving the change. “We’re still trying to decipher the impact on production relative to avian u, but longer term, there is optimism as European and southern hemisphere production is down and we start to see dairy markets improve in Class III prices, likely making it to the $21, $22 level as we go into the fourth quarter.”

Dairy herd expansion may be delayed Class III milk prices have been stronger lately.

Strong market for dairy springers

Springing dairy heifers are bringing top prices. “This dairy deal caught re,” said Mitch Barthel, owner, Perham Stockyards and Tri-County Stockyards. “ Weigh-up cows have been high, baby calves have been high and a lot of these dairy heifers have been bred to beef bulls and it has shortened up the heifer supply. Some guys are going through an expansion and want to get their stalls full so they end up buying up for these springers. They are in short supply. Baby calves are worth a lot and the weigh-up cow prices are high, driving up the value of dairy heifers.”

Risk management advised

Prices for beef and dairy cattle are favorable and likely will remain strong for quite some time. Independent consultant Nevil Speer said the market versus prices will remain through the rebuilding of herds, whenever that might be. Dairy heifers are of especially low supply and high demand while milk prices are also favorable. Speer says risk management during the good times is important to protect yourself during the bad times. “Typically, when we talk about risk management, producers turn to futures and options. The other tool that’s really important is livestock risk protection.” Speer notes basic business risk management is also important during favorable times. “Let’s try to reduce our debt service from year to year and let’s try to build up some working capital reserves.”

Milk production takes small dip in June

During June Dairy Month, milk production in the 24 major dairy states totaled 18 billion pounds. That’s down 0.8% from June of last year. South Dakota had the largest increase in milk production, up 8.3%. At the same time, Minnesota’s milk output declined by 1%. The South Dakota state dairy herd increased by 17,000 cows and Minnesota cow numbers declined 6,000 head.

H5N1 impacts Miracle of Birth Center

Milking dairy cows are not expected to be part of the Miracle of Birth Center at this year’s Minnesota State Fair. The threat of avian inuenza in dairy cattle is prompting the move. The Miracle of Birth Center will still have weaned dairy calves and dry dairy cows, but there won’t be any cows giving birth during this year’s fair.

Finding and keeping ag employees

AgCareers.com hosted its annual Agriculture and Food HR Roundtable Conference in Minneapolis. “We talk about talent development, acquisition, management, and retaining that talent,” said Bonnie Johnson, marketing manager, AgCareers.com. “The biggest topic that we hear a lot about now is retention, keeping the good employees that you have.”

Trivia challenge

September 18 is National Cheeseburger Day. That answers our last trivia question. McDonald’s sells more cheeseburgers than any other fast-food restaurant. For this week’s trivia, what fast food chain is second on that list? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

When is enough, enough?

I recently read an article that said Riverview LLP in western Minnesota was hoping to build a 25,000-cow dairy near Hillsboro, North Dakota. I was frustrated to read this because there already is plenty of milk. The milk price was low for a year and a half and just started to rebound this summer and they want to add 25,000 cows.

Won’t their plan of building a large dairy of that size ood the market with milk and milk products and drive the milk price down again and hurt many of the family farms that are the backbone for so many communities?

Another question that comes to my mind is: who is taking in all this

milk and why would they do that?

Don’t they realize that this oversupply of milk will drive the price down and eliminate many of the producers that have been shipping their milk to their plant for many years. Do they not care about their patrons that have been by their side for decades?

I believe the dairy industry would be better with 10, 2,500 dairies or 100 250 cow dairies than one 25,000 cow dairy.

How is this mega dairy good for the dairy industry? Many farms and businesses will leave the industry if this proposed plan becomes a reality.

Chuck Klaphake Sauk Centre, Minnesota

Amy Loeschke has accepted the role as General Manager at Minnesota DHIA, effective August 1, 2024.

Loeschke has had over 20 years of varied experience in leadership, research, education, and service to the dairy industry. She most recently has served as Director of Services and Support at Minnesota DHIA, where she has spearheaded a variety of projects that provide value for the organizations’ 1,000 plus members in the upper Midwest. Prior to that, Loeschke was a project leader and product consultant for an international dairy genetics organization.

Loeschke is a Minnesota native, having grown up on a dairy farm near Lanesboro. This was the foundation for her interest in dairy cattle and more specifically, dairy data and genetics. Amy brings with her to the position, PhD and Masters degrees in applied dairy breeding and a B.S. degree in Animal Science, all from the University of Minnesota-Twin Cities. During those years, she also led a one-ofa-kind genetic field study, allowing her to collaborate with commercial dairy farm owners and gain experience in navigating the dairy data stream both in the US and globally. Amy’s experiences have sparked her passion for innovative problem solving and knowledge transfer.

Loeschke is excited to expand the services and value that Minnesota DHIA offers to dairy producers while providing collaborative leadership to the organization’s dedicated field technicians and staff.

CowScout works 24/7 to monitor cow activity by identifying neck movements, such as snif ng and chin resting that indicate if a cow is in heat. With this real-time data, cows in heat can be properly identi ed, allowing for improved insemination results, higher pregnancy rates, shorter calving intervals and reduced insemination costs – all with lower labor inputs.

• Constant heat monitoring and display of the optimal insemination time

• Noti cation of reduced eating and rumination times to enable early detection of health problems

• Reliable animal identi cation in the milking parlor

• Clear, easy to understand graphical displays of activities, eating times and lactation phases in the web portal

• E-mail alerts for you and your staff or insemination technician

Minnesota State Fair bound

Dudens’ Jerseys selected for this year’s showcase herd

By Meghan Kropp Contributing writer

PRINCETON, Minn. —

Just a few more weeks remain as Kristin Reiman Duden and her husband, Thomas Duden, make the preparations needed to bring part of their herd to the Minnesota State Fair. The Duden’s Jerseys are this year’s showcase herd.

“It’s going to be a challenge, but it’s exciting to showcase our cows for the state fair,” Reiman Duden said.

At least 15 cows and two heifers are on the roster to attend the fair from Aug. 22 to Sept. 2. While at the state fair, the Jerseys will see a bit of pampering as they will be in constant view of the public, used for milking displays and part of media presentations.

Reiman Duden said due to safety concerns surrounding the highly pathogenic avian inuenza A, there will not be opportunities for the public to participate in hand-milking demonstrations this year.

“It’s always different it seems,” Reiman Duden said.

“There’s something cool for everyone to see.”

Reiman Duden said dairy cow breeds are put into a rotation, and each year a herd in that cycle is picked for the showcase herd. Ayrshires were the showcase herd last year, and 2022 was the year for

Brown Swiss.

During the Minnesota Purebred Cattle Association’s All-Breeds Convention, hosted by the Minnesota Holstein Association in the spring, Reiman Duden said the announcement was made that Jersey cows were the next in the rotation to be the state fair’s showcase herd.

“This is a positive light for the dairy community, and specically the Jersey breed,” she said. “I really enjoy being at fairs and being able to do that.” Reiman Duden said being the showcase herd allows her to represent her area, which she said has been seeing less dairy in lately.

Turn to SHOWCASE | Page 13

www.jdmfg.com www.jdmfg . com

The state fair also is a good place to reconnect with people, Reiman Duden said.

“You’ll always run into people you know,” she said. “It’s good to come and to visit.”

“Being

While Reiman Duden is looking forward to this opportunity, there are a few challenges that will need to be tackled. Finding and scheduling workers to help with the herd at the fair and feeding them within the budget set for her are some such challenges. Workers also need to be ready to answer questions fair visitors may have about the Dudens’ Jerseys, the breed and the dairy industry.

People working with the showcase herd will receive training to be ready to answer the questions visitors may have.

“It will be a new thing to tackle, but I am excited,” Reiman Duden said. “Being at the state fair is probably one of my favorite times of the year. There

are a lot of memories there.”

Reiman Duden also said they need to plan for someone to care for the rest of the herd not attending the fair.

“I’m fortunate,” she said. “My parents should be able to help with the day-to-day chores.”

The cows attending the fair are calm and easy to work with, Reiman Duden said. Some have been leased by other people for 4-H or FFA shows and some she has brought to open class events. Reiman Duden also plans to bring six to open class shows this year.

“There is a big sense of pride in being able to show your herd,” she said.

“There is a lot of pride in the animals, in your farm and in being part of this tradition. We care about our farms; we care about our cows. This is our way of life. We’re all doing the best we can.”

from our side our side OF THE FENCE

How has the rainfall in your area affected your crop production?

Brock Herman Manchester, Iowa Delaware County 40 cows

What crops do you produce? We have 200 acres of corn, 20 acres of oats, 40 acres of alfalfa and over 100 acres of soybeans.

Since April 1, how many inches of rain have you received? 23 inches

How has the rainfall in your area affected your crop production? We got the oats in late this year, but we had them in by the end of April. The corn planting drug on for a long time and we broke down. I was hoping to be done by May 5, but it was June before we nished with the corn and soybeans. The alfalfa has been hard to get harvested as well. Cuttings have been delayed due to all the rain. It’s been a good crop, but not a good quality crop. We bale it all in small squares and round bales. Since it kept raining, there weren’t enough dry days to get it harvested. Our oats are lying in the windrow, not combined now because we have had rain every day.

What is a challenge with eldwork you've faced this year? We just waited it out since we do a lot of it no-till. The conditions had to t for us to plant.

For this growing season, what was the biggest rain event? We received 11 inches in an 8-day time frame in May. There was standing water in the elds. We just had to wait it out and keep going.

Besides crop production, how has the rainfall affected your dairy farm? The crops look good now. We did have to add extra nitrogen because so much of it leached away. We did it three weeks ago, but we usually do it sometime in June. The pastures were muddy because of the excessive rain. We also had to move our calf hutches more to keep them clean.

How does this summer’s precipitation and temperature compare to others? I would say this is the wettest year I have seen. It’s not big oods but it has continuous rainfall making it wet all the time. This year not a whole lot of it ran off so it is just staying so wet.

Tell us about your farm. I took over from my dad in 1973, so I have been farming for 50 years. I milk my cows in a tiestall and stanchion barn. I ship my milk to Dairy Farmers of America. On the farm, my brother, Mark, and my daughter, Becca, help as well.

What crops do you produce? Corn: 1,000 acres; soybeans: 400 acres; hay: 350 acres; and oats: 60 acres.

Since April 1 how many inches of rain have you received? Not sure of the exact amount, but somewhere around 20-plus inches.

How has the rainfall in your area affected your crop production? The excessive rain has been hardest on our late-planted corn following rye. We struggled getting the soil dry enough to plant after injecting manure on it. It is a couple of weeks from tasseling yet.

What is a challenge with eldwork you've faced this year? We started off the planting season great. Oats were seeded early March. Most of the corn was in by the rst week of May. We then struggled getting 300 acres of rye harvested for feed. We had 100 acres laid in rows for almost three weeks before getting it baled for bedding. We changed our plan of planting soybeans on that ground to alfalfa. Our hay yields have been exceptional, and we have been lucky with the hay harvest.

For this growing season, what was the biggest rain event? The biggest rain event was 6.5 inches. We no-till all the soybeans and some corn. With that much rain in an hour, it still erodes.

Besides crop production, how has the rainfall affected your dairy farm? It has been a real struggle keeping all the cows and their pens clean and dry. Our 3-million-gallon manure pit has lled a month earlier than normal, so we will have to nd a place to haul before corn silage.

How do this summer's precipitation and temperature compare to others? Last year's drought was like having a vacation every day. We hardly bedded, and if we cleaned cow lots, we scraped up piles of dry manure. We think the temperature hasn't been that much different, but the humidity and excessive rain have been the most challenging.

Tell us about your farm. We are a family farm of three brothers—Raleigh, Eric and Jon—along with each of our families. We milk 550 cows three times a day in a double-12 parlor. Our milk is shipped to Associated Milk Producers Inc.

Adam Leitheiser Emery, South Dakota McCook County 63 cows

What crops do you produce? We grow 500 acres of corn and 500 acres of soybeans. We also grow 80 acres of alfalfa and 40 acres of oats.

Since April 1, how many inches of rain have you received? We have received between 15-17 inches.

How has the rainfall in your area affected your crop production? We have quite a few drown-out spots. I would say 5%-10% of the crop we won’t get anything from and 15% will have moisture damage from being too wet.

What is a challenge with eldwork you’ve faced this year? The biggest challenge has been it’s been too humid and it takes so long to dry the hay down. One eld took 10 days to dry. We were very lucky on our rst crop. We chopped half and dry-baled the other half without any of it getting rained on. Spraying has been a challenge, and we’ve just had to plow through a couple elds. We had a couple of elds that we didn’t get sprayed in a timely manner and it shows.

For this growing season, what was the biggest rain event? We had 10 inches in a day and a half. It washed out roads in the area.

Besides crop production, how has the rainfall affected your dairy farm? The big challenge was keeping the cows clean. I had to lock them out of the pasture for over two weeks so the lane could dry up. I also had to move some manure away from the barn because the cows couldn’t be in the pasture. Now we can nally haul on forage stubble or grass elds. We also fenced off a corner because of standing water. In the yard, I had to move some huts.

How does this summer’s precipitation and temperature compare to others? I think if it would stop now, we would have our regular growing season precipitation. The biggest problem is we had a lot of rain in over 2 inch increments and that caused a lot of problems. If the rain could have evened out that would have been great.

Tell us about your farm. I farm here with my wife, Greta, dad, George, and brother, Will. We share some equipment with my uncle. We milk our cows with ve units in a stanchion barn. We ship our milk to Associated Milk Producers Inc.

Kenny and Irvin

Frie (pictured with Ella and Levi)

Osakis, Minnesota

Douglas County 50 cows

What crops do you produce? We have 80 acres of alfalfa, 100 acres of soybeans, 100 acres of corn and 30 acres of oats.

Since April 1, how many inches of rain have you received? I didn’t keep a record on the rainfall totals but without a doubt it is a lot more than the past few years. I would say it is close to 30 inches of rain.

How has the rainfall in your area affected your crop production? The large amount of rain did provide the best quantity of rst cutting of hay that I can remember. I have also never seen hay come back so fast.

What is a challenge with eldwork you’ve faced this year? Starting at planting time it began to rain, and it got wet and stayed wet. The planting

Ted Filk

Hutchinson, Minnesota

McLeod County 80 cows

What crops do you produce? We currently have 170 acres of corn, 85 acres of spring wheat, 85 acres of soybeans and 70 acres of alfalfa.

Since April 1, how many inches of rain have you received? We have had 27 inches since April 6 when I seeded my small grain.

How has the rainfall in your area affected your crop production? Explain. Our corn is quite uneven, and spraying was a challenge for the co-op. Other than that, it went smoothly. We chopped the rst- and second-cutting hay and started chopping third and are waiting to nish. The soybeans look really good.

eldwork you’ve faced this year? Trying to get things done in a timely fashion. Planting and spraying the corn was really chal-

season was drawn out for several weeks, but we did manage to get everything planted in due time. The solution to getting the crops planted in the narrow time frame, was keeping the tractors rolling through chores. This was possible with the help of my wife, Katie, and the kids doing chores. There was a lot of late evenings.

For this growing season, what was the biggest rain event? Since I didn’t keep record of rainfall totals, I’m not sure which event brought the most rain. With the combination of all the rains it has put many areas of the elds under water, which is going to cause little or no yield at harvest time. We did receive 5 inches of rain Aug. 5.

Besides crop production, how has the rainfall affected our dairy farm? It is more difcult to keep the animals dry when it gets extremely wet. It takes a lot more bedding.

How does this summer’s precipitation and temperature compare to others? We are denitely way over the normal amount of rain for the year. The temperatures may have been slightly lower than average, but overall I believe we are really close to being on track for the heat units.

Tell us about your farm. We milk 50 cows in a tiestall barn. Irvin feeds the cows. Kenny and his kids, Levi, Ella, Hailey and Lexi, take care of the milking, calf feeding and bedding for the cows. Everyone works together as a family to get the job done. Our milk is shipped to First District Association in Litcheld.

For this growing season, what was the biggest rain event? We really didn’t have excessive rain but it seemed like it rained every day for a while. We would get three-fourths of an inch, an inch and then 2 inches, it was more of a cumulative amount than one event.

Besides crop production, how has the rainfall affected your dairy farm? We were going through excessive bedding indoors and outdoors. Also, with the growing crop we have nowhere to go with our pack manure that will go on our small grain elds when we get better weather. The cows are doing quite well because it hasn’t been excessively hot.

How does this summer’s precipitation and temperature compare to others? The last three years we were on the verge of a drought and last year, specically, if we didn’t have the snowfall, the crops would have suffered. It’s hard to comprehend how we can go from so dry to so wet in one calendar year.

Tell us about your farm. I farm here with my wife, Bobbi, and our son, Zachary. Our sons, Jacob and Joshua, and daughter, Ella, help on the farm when they can. We milk in a tie-stall barn and our milk goes to the First District Association in Litcheld. I am the fth generation on this farm site.

Describe your farm and facilities. We milk 700 registered Holstein and Jersey cows in a double-12 parallel parlor. The cows are housed in a modern, naturally ventilated, sand-bedded free-stall barn. We crop 2,000 acres, custom hiring all our crop work done; I manage all the inputs, spraying, seed selection, etc. The farm is owned by myself, my father, Matt Lippert, and my brother, Carl Lippert. Later this month, we are looking forward to hosting two on-farm events: a Professional Dairy Producers Agricultural Community Event Twilight Meeting August 27 and a second Twilight Meeting for the Wood Area Holstein Breeders August 30. We appreciate hosting events like this to help build community relationships and share our farm with the public as well as to offer our fellow dairy cattle enthusiasts an opportunity to socialize and network. Both events will be hosted at our recently renovated heifer facility.

What forages do you harvest? We harvest corn silage, snaplage, small grain forages like triticale, and haylage — alfalfa, grass and red clover. This year we will have some Yield Max Cocktail Mix of summer annuals like sorghum Sudan grass and Italian ryegrass. We also utilize some pasture.

How many acres of crops do you raise? We crop 2,000 acres — 700 acres of corn for silage, 300 acres of grain corn or snaplage, 200 acres of

soybeans and the balance is hay of some sort.

Describe the rations for your livestock. We try to feed as much forage as possible without sacricing milk

production, so it is a high corn silage diet. Right now, it is 25 pounds of corn silage dry matter and another 8 pounds of haylage. Currently, we are feeding straight triticale and corn silage; there is not any legume in the

ration – which is not the normal. The triticale has really saved us this year. There was a lot of rst crop but it was

“We’ve used Udder Comfort™ over 10 years: Blue spray on fresh animals and lotion with massage for any flareups. We tried others but always came back to this product because it works,” says Staci Sexton. In 2013, she started Schoene Kuh Dairy, today milking 60 registered Holsteins and Jerseys with a genetic focus on production, health traits, and components. Along with the Irish Ridge herd of her parents and brother, where she helps with herd work, 125 cows are milked at the Millville, Minnesota dairy farm that has been in the family over 160 years.

Schoene Kuh is German for ‘beautiful cow.’ Staci loves working with cows and genetics, earning progressive breeder and milk quality awards. Her 9th AI bull in 10 years is a homozygous polled, high cheese merit bull named King Kong.

“It’s exciting to breed, flush, and wait nine months hoping to get something great,” she says, and when it comes to first calvers “we use Udder Comfort to reduce swelling. Fresh heifers are comfortable with better, faster milkout. It’s easy to use and helps keep our SCC low.”

poor quality. We would rather not feed our rst crop to our cows if we can help it. Otherwise, the ration has some canola, corn gluten and a protein mix that is a little bit of Exceller, soybean meal, all our vitamins, some palm fat and dry grain corn. In the winter we feed snaplage and in the summer we feed dry grain corn. Our heifers are fed a very high-forage diet of corn silage, haylage and a touch of protein.

What quality and quantity do you harvest of each crop? We shoot for the highest quality forages we can make. When we do not succeed at that, hopefully we can feed it to dry cows and heifers. This year, we will be feeding a lot of rst crop to heifers. Other years we are making oatlage or elds we never get in rst thing in the spring to the heifers. Last year was a drought year; it was a whole different story. For corn silage, we aim for 20 to 24 tons per acre. We grow brown midrib on our better acres; not all of our silage is BMR but at least 50% is, usually. We end up cutting the grass, alfalfa and red clover on the same schedule, except on a year like this

year, where they get out of whack and then we’ll have the grass on a slightly more accelerated schedule. I told my custom guy that basically, we will just be making haylage every week for the next six weeks.

Describe your harvesting techniques for alfalfa and corn silage. Our harvesting technique is not fancy. Corn silage is chopped with a CLAAS chopper and run through a shredlage processor. Alfalfa is mowed with a triple mower, merged and chopped.

What techniques do you use to store, manage and feed your forages? Everything is stored in drive-over piles. Our haylage, if it is of good quality, we don’t make into new piles; we just open the end and keep adding so the cows can gradually transition from one crop to the next. We do not have the room to have that many piles, and in a year like this , it would just be an insane number of piles. We use an inoculant on everything.

How do quality forages play into the production goals for your herd? They are at least 50% of the equation.

If you don’t have quality forages for your cows, you have problems. Quality forages also really help hold costs down. If you can make good haylage and good, well-processed corn silage at the right moisture — nothing beats highly digestible, high-starch corn silage for cow feed. It can make or break you, I would say.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? Leaning on our custom guy to have big enough equipment to always get things done quickly has helped increase the quality and consistency of all our forages. Now that we are doing some of the winter small grains, having a tedder available in the spring is huge – you can’t hardly make good triticale without tedding it in May — it just does not dry down fast enough. As far as management, just really being in tune with soil fertility is important — getting lime where it needs to be, getting the pH where it needs to be. We had a really big focus on lime and tiledrainage and fertility. We have been doing a lot more low-disturbance and

no-till tillage, drag-lining manure whenever possible — really trying to reduce compaction by having less passes over the elds, less manure tankers out there. We also try to ensure having a cover crop of some sort out there all the time as well. Healthy soil makes healthy forages. We really tried hard this year with how wet it was to keep the passes of tillage to a minimum, and we really tried to stay out of wet spots. We have enough acres and a good enough rotation that we can be nimble in wet years, and I think that it is a really good position to be in. A good rotation helps us be in a better place — it spreads the risk out.

Describe a challenge you overcame in reaching your forage quality goals. In our location, drainage is huge, and so is trying to get fertility where it needs to be. We have some relatively low fertility ground in this area. Trying to reduce compaction by using fewer tankers, investing in tile and managing grass waterways are all big things we have been focusing on.

560M 2020, 9462

#567629

JD 560M 2020, 3950 BC, #574425

JD 560M 2019, 17,500 BC, #575405

JD 560M 2019, 13,791 BC, #582581

JD 560M 2019, 6500 BC, #567208

JD 560M 2018, 8000 BC, #574492 ..................................................

JD 560M 2018, 2550 BC, #574158

566 1999, #578058 ......................................................................

567 2006, 16,700 BC, #584096

568 2008, 33,640 BC, #582414

A-Star Services

Bongards’ Creameries

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51 Bongards, MN 55368 (952) 466-5521

Fax (952) 466-5556 110 3rd Ave. NE Perham, MN 56573 (218) 346-4680

Fax (218) 346-4684

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI

715-654-5252

Ederer Dairy Supply Plain, WI

608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Loeschke takes the lead

Minnesota Dairy Herd Improvement Association welcomes new general manager

By Meghan Kropp Contributing writer

BUFFALO, Minn. —

The start of the month brought some change to the Minnesota Dairy Herd Improvement Association as Amy Loeschke accepted the role of general manager.

“This (position gives me) a chance to give back to the dairy community, and to lead our staff and technicians through a time when we are seeing tremendous change in the industry,” Loeschke said.

the rst in the state to enroll with the herd management tool, Dart.

“That early exposure to new software and the staff helping our herd through that kind of transition was a neat experience,” she said.

With increased herd size being the most signicant trend in the industry comes challenges in getting farmers the data they need to make good decisions.

“Navigating the intersection of all these things is interesting and exciting,” Loeschke said.

Loeschke grew up on a dairy farm near Lanesboro, where her family was one of

Other experiences, such as being awarded a state fair trip with her dairy project a few years and attending the national dairy conference, helped her to learn more about the dairy industry, Loeschke said.

For Loeschke, her family’s farm became a foundation of interest in dairy cattle and more specically dairy data and genetics.

“When you grow up in dairy farming, it’s in your blood and ingrained in you from such a young age,” she said. “It’s hard to break away and do something different. I feel like I’ve lived and breathed dairy since I was 8-10 years old.”

Loeschke earned a doc-

torate and a master’s degree in applied dairy breeding and an undergraduate degree in animal science, all from the University of Minnesota-Twin Cities.

“I rst took up a pre-veterinary degree,” Loeschke said. “I transferred over to an animal science major. That was a much better t for me. It was more biologybased. Then, and even now, I had a high curiosity for biometrics.”

During her degree work, Loeschke led a one-of-a-kind genetic eld study, allowing her to collaborate with commercial dairy farm owners and gain experience in navigating dairy data both in the U.S. and globally.

“How do we get dairy farmers to that next level?” Loeschke said.

Minnesota DHIA helps farmers by providing data to manage healthier and more protable cows.

Before taking on the role of general manager, Loeschke worked as the director of services and support at the Minnesota DHIA, a position she held for roughly six months as she prepared to become the general manager.

“It was really getting to know the guts of the Minnesota DHIA system and how it turns data coming from the farm and lab into information that can improve performance and prot,”

AMY LOESCHKE, DHIA

Loeschke said the connection between dairy cattle biology and data is part of what drew her to the Minnesota DHIA.

“That really involved a variety of special projects, including getting to know the HerdHQ tools inside and out,” she said. She also spent time getting to know the eld services staff and their roles, and how the internal systems work for data handling.

“It was really getting to know the guts of the Minnesota DHIA system and how

it turns data coming from the farm and lab into information that can improve performance and prot,” Loeschke said.

Loeschke brings more than 20 years of experience in leadership, research, education and service in the dairy industry to her new role. Loeschke said she views her role as one that equips DHIA staff to provide value for the organization’s more than 1,000 members in the upper Midwest.

“What interested me most was the chance to help dairy farmers,” Loeschke said. “Being able to lead Minnesota’s dairy industry through this time of transition and being able to inspire our eld technicians and eld services team to help dairy farmers solve their most pressing problems is very rewarding. Spearheading new challenges that are coming onto the scene of the dairy industry will be more important than ever.”

Loeschke said she is excited to expand the services and value Minnesota DHIA offers to dairy producers while providing collaborative leadership to the organization’s dedicated eld technicians and staff.

Minnesota DHIA’s previous general manager was Bruce Dokkebakken, who took the role in 1998.

Rest Assured It’s the Right Fit

Able to handle milk flow rates of 20 to 40 gallons per minute, Paul Mueller Company’s HiPerChill™ L package chiller is ideal for large dairy operations with exceptional 24/7 milking demands.

Have questions about proper chiller sizing? Consult The Milk Cooling Systems Specialists™ at Mueller®.

Central Ag Supply

Juneau, WI; Baraboo, WI

Advanced Dairy Spring Valley, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

Central Ag Supply Juneau, WI; Baraboo, WI

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc.

Cuba City, WI

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

J. Gile Dairy Equipment, Inc.

Cuba City, WI

Monroe Westfalia Surge Monroe, WI

Redeker Dairy Equipment Brandon, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Professional Dairy Services Arlington, WI

Stanley Schmitz Inc. Chilton, WI

Professional Dairy Services Arlington, WI

Redeker Dairy Equipment Brandon, WI

Tri-County Dairy Supply Janesville, WI

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Redeker Dairy Equipment Brandon, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Stanley Schmitz Inc. Chilton, WI

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Eastern Iowa Dairy Systems Epworth, IA

Total Dairy Services Kewaunee, WI

Stanley Schmitz Inc. Chilton, WI

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Tri-County Dairy Supply Janesville, WI

Tri-County Dairy Supply Janesville, WI

United Dairy Systems West Union, IA; Monticello, IA

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Eastern Iowa Dairy Systems Epworth, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

United Dairy Systems West Union, IA

Monroe Westfalia Surge Monroe, WI

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Gorter’s Clay & Dairy Equipment Pipestone, MN

Lely Center Monroe Monroe, WI

United Dairy Systems West Union, IA; Monticello, IA

Leedstone

Total Dairy Service Kewaunee, WI

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Midwest Livestock Systems Zumbrota, MN; Menomonie, WI; Renner, SD

Midwest Livestock Systems Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Glencoe Co-Op Assn. Glencoe, MN

Ederer Dairy Supply Plain, WI

S&S Dairy Systems St. Charles, MN

Monroe Westfalia Surge Monroe, WI

Professional Dairy Services Arlington, WI

Glencoe Co-Op Assn. Glencoe, MN

From ambassador to dairy princess

Welgraven ready to share her knowledge, passion for dairy

By Sarah Middendorf sarah.m@star-pub.com

RUTHTON, Minn. — Katelyn Welgraven’s growing knowledge and passion for dairy set her on the path to becoming a Princess Kay of the Milky Way nalist.

Welgraven is one of the Princess Kay nalists chosen May 12.

“Being a nalist just means I get to keep spreading (knowledge) and I know I will always be a part of the dairy industry,” Welgraven said.

Welgraven is the daughter of Keith and Jeanna. Welgraven grew up on her family’s dairy farm near Ruthton, where they milk 100 cows. Welgraven is in charge of caring for the calves as well as helping her dad with other tasks.

A sophomore at the University of South Dakota, Welgraven is majoring in elementary education with a minor in deaf education.

Welgraven is active in college as a member of the Kappa Alpha Theta sorority. She is an executive board member for the Coyote Crazies as well, which allows her to support peers involved in different organizations across the college, from athletics to theatre.

When she was younger, her dad periodically asked her if she was going to be a dairy princess in the future. She would always tell him, “No.”

“I was more of a tomboy-type of girl,” Welgraven said.

Once Welgraven reached eighth grade, she decided she was going to become a Pipestone County Dairy Ambassador. She wanted to try it out and see if she liked it.

“It just grew my love and knowledge for dairy,” Welgraven said.

She decided to continue and applied to become the Pipestone County Dairy Princess. In doing so, she also took the next step to compete in the Princess Kay of the Milky Way program. Last May, Welgraven and other eligible county dairy princesses throughout Minnesota attended the Midwest Dairy May Leadership Event. They received additional training, were interviewed and compet-

ed to be nalists for this year’s Princess Kay of the Milky Way.

At a workshop at the May Leadership Event, Welgraven said she learned few people are allergic to dairy products. Some believe they are intolerant to dairy and will quit consuming it. Instead, Welgraven suggests incorporating lactose-free real dairy products into the diet.

Welgraven also had the opportunity to hear about food safety and sustainability, trends in the dairy industry and different kinds of cheese.

A day after the leadership event concluded, 10 nalists were announced in a video premiering on the Princess Kay Facebook page.

Welgraven was watching a play at her high school at the time.

“I actually didn’t nd out until an hour later that I was a nalist,” Welgraven said.

She was getting notications on her watch but did not want to look at them until intermission when she could watch the announcement video. When she learned she was one of the nalists, she became emotional.

“I just started kind of crying in the hallway,” Welgraven said.

She found a friend at the event and shared the news.

Welgraven looks forward to interacting with the public, especially with young children because they get excited when they see a princess.

“Seeing more of the state and having conversations with more people of all different ages would be cool,” Welgraven said.

She said she also enjoys handing out cheese sticks during parades. Welgraven said when she is in a parade, the crowd will stand up as she goes by because they know there is a chance they may get cheese from her.

If crowned, Welgraven said her biggest goal would be to visit more high schools throughout the year. She enjoys helping students learn more about the dairy industry.

“I just want to get high schoolers and middle schoolers more interested,” Welgraven said.

Investing in the agriculture community

Nelson looks to advocate for the industry

By Amy Kyllo amy.k@star-pub.com

OWATONNA, Minn. — Princess Kay nalist Afton Nelson may not have grown up on a dairy farm, but she has felt the investment of the agriculture community in her life.

“They do a lot and it goes unseen most times, but I really want to be able to be an advocate for them and be able to share their story,” Nelson said.

Nelson is the daughter of Tim and Stacy Nelson. This is the 20-year-old’s third year serving as a Steele County Dairy Princess.

“(Dairy) farmers are very hard working; they work 24/7,” Nelson said. “It’s kind of nice to have us as ag advocates and promoters to be able to go out and talk to the consumers that the hardworking farmers aren’t able to do because they can’t just leave the farm in the middle

Claremont.

“(It) is this amazing couple that decided to let a bunch of kids out on their farm and learn about the different breeds, how the farm works,” Nelson said.

She remembers having a showcase at the end of the week where she got to lead a Brown Swiss calf. She has liked the Brown Swiss breed ever since.

“The passion was instantly there,” Nelson said. “I’ve always loved animals.”

When Nelson was old enough to join 4-H she did so. By 2016, she bought her rst dairy cow. Now, Nelson and her brother, Kellen, own ve cows together: Dakota, Danish, Dunkin, Donut and DoorDash.

Nelson works for sisters Traci and Lacey Nelson, who operate a farm near Ellendale, where they milk 40 cows.

Nelson has been leasing dairy cattle from the sisters for years. Now, for the past two years they also house her cows in exchange for labor.

“It still didn’t fully process until the picture came up,” Nelson said. “Then I screamed, I was like, ‘I got it.’”

Nelson had her introduction to the dairy community at cow camp held at Glenn Johnson and Deb McDermott-Johnson’s farm near

Turn to NELSON | Page 27 of milking.” Nelson found out she was a Princess Kay nalist watching the announcement video on her phone by herself.

“If one of them is going to be gone that’s when we primarily try and almost clear our schedules,” Nelson said. “We’re going out as much as we can.”

Nelson helps with many chores around the farm including feeding calves moving heifers, cleaning pens and milking. She said her favorite chore is feeding.

“I just love being at the farm in general,” Nelson said. “It’s super relaxing and rewarding.”

She said the reward is found in things like being part of the team to help a premature calf survive.

“We may have gotten frustrated in the process of trying to get her to drink out of the bottle and drink out of the bucket,” Nelson said. “But, it’s rewarding to know ... she’s still here.”

Nelson said she also has gotten to know her animals well. Among these is a cow that likes to lick off the hat of one of the people at the farm where she works. If she doesn’t do that, Nelson knows she’s not feeling well.

“It’s the little things,” Nelson said. “You know so much about the animals and their personalities that you’re able to tell when they’re off.”

If Nelson is named Princess Kay, she said she wants to prioritize onfarm events and working with children. She said she feels breakfasts on the farm, daycares and school visits are the best way to interact with this audience.

“It’s just kind of cool to be able to connect the dots for the kids,” Nelson said. “Older consumers even don’t even quite understand how the whole process works.”

She said one of her favorite county princess activities is making butter with kids at breakfast on the farm.

“They always ask so many questions,” Nelson said. “It’s just kind of fun to watch the light bulb go off.”

In addition to her work with 4-H, Nelson also participated in FFA, where she earned her American FFA Degree. She also won at the state level with entrepreneurship and placement supervised agricultural experiences and dairy cattle handlers activity. Before the national competition for handling, Nelson injured her knee and had the added challenge of competing on crutches.

“Everybody looked at me like, I think you’re in the wrong spot,” Nelson said.

Through this experience, she said she became known as the comeback kid in her chapter. Nelson said she is a determined person who perseveres through obstacles. She said she can see how her character traits of determination and perseverance would affect her reign if she is the next Princess Kay.

“I’ll never back down,” Nelson said. “Even if my schedule can get busy, I always want to do everything and anything I can.”

Nelson said she is looking forward to the Princess Kay judging in August and the Minnesota State Fair.

“(I look forward to) being able to interact with the community members ... and consumers too throughout the whole process,” Nelson said. “I do it on the county level, but being able to do it at the state fair with people from all over the state and some from even different states, it’ll be really cool.”

Get Ready for Haying Season New & Used Available

McHale Balers

Anderson Wrappers

Mega Round Bale Carrier

Hybrid Flex Stalls combine the exibility of poly and the stability of a steel

the bed while giving side support to the stalls.

HOSE ENDS

QUICK CONNECTS

For all your hydraulic connection applications, we provide a wide variety of hydraulic connection options, including Flat-Face couplers, Poppet-Style couplers, Screw-Type couplers, Volvo TEMA couplers, and Multi-Coupling units. With name brands like Faster, Stucchi, Parker, and Holmbury, we can provide custom hydraulic options to best

Pursuing her passion

Visser named nalist for Princess Kay of the Milky Way

By Tiffany Klaphake tiffany.k@dairystar.com

HUTCHINSON, Minn. — Rachel Visser did not grow up on a dairy farm, but that did not stop her from getting involved in the dairy industry.

“Once I got involved in the dairy industry, I quickly fell in love with the community and the people,” Visser said. “I quickly developed a passion for dairy, and I wanted to continue to share with others by promoting the hard work that farmers put into producing products we enjoy.”

Visser, the daughter of Barry and Shannon Visser, started leasing and showing dairy cattle when she was in third grade. Visser works with Chad and Stacy Bohn of Litcheld on their farm, Stadview. The couple milks 27 cows and focuses on developing a high-quality show herd. Visser feeds the cows and calves at the farm and works with her leased and owned animals to prepare them for shows.

“I got involved in showing dairy cattle and started getting more involved working on the farm,” Visser said. “I’ve met so many wonderful people and had the opportunity to travel to different shows.”

To further her passion for the dairy industry, Visser, along with her sisters, Kayla and Hannah, have each started buying and selling their own dairy animals, which are housed at Stadview Dairy.

As a McLeod County Dairy Princess and Princess Kay of the Milky Way nalist, Visser’s passion for dairy and knowledge of the industry has been enhanced.

“This platform also helps me learn more about the industry,” Visser said.

Some highlights from her time as a McLeod County Dairy Princess are engaging with consumers — especially

children.

“I really enjoy talking with kids and hearing their perspective,” Visser said.

“From seeing cows for the rst time (to) teaching them about the industry and dairy products, it’s always fun to see their reaction to seeing something new.”

Visser was able to share her reaction to being named a top 10 nalist with her family. She and her family were visiting her grandparents, and they all sat down together to watch the live broadcast.

“I was super excited and surprised when I heard my name,” Visser said. “Sharing the moment with my family was super cool. It was denitely memorable.”

Another high point of the day for Visser was hearing fellow McLeod County Dairy Princess McKenna Wright be announced as a nalist.

Visser said a highlight of being a 2024 Princess Kay of the Milky Way

nalist has been meeting the other nalists.

“I really enjoy getting to know the other girls from across the state who also have a passion for their community (and) the dairy industry,” she said. “(I enjoy) hearing their stories and getting to learn from them.”

Having attended the Minnesota

State Fair for the past several years showing dairy cattle, Visser will be attending the annual event in a different capacity this year.

“I am really looking forward to the (Minnesota) State Fair as a nalist and (am looking forward to) engaging with fairgoers that way,” Visser said. “I have had a lot of experiences at the fair with showing dairy (cattle), so I have been able to visit with fairgoers that way. I am excited to continue to do that in a slightly different role this year as a nalist.”

This fall, Visser will be a sophomore at the University of Minnesota in St. Paul. She is majoring in agricultural and food business management and agricultural communications and marketing.

“My passion for agriculture and the dairy community denitely inuenced where I went to school and what my major would be,” Visser said. “I am a numbers person, so something in nance where I can combine my passion for the dairy industry and agriculture as a whole and my love for numbers is what I want to do.”

When Visser shares with consumers, she uses her dairy background to help them understand what dairy farmers do each day.

“Something I focus on a lot ... is the hard work and dedication farmers put into each and every one of their animals,” Visser said. “It’s not an easy job, but farmers focus a lot of time, passion and care on their animals. When people understand this, they will have a much better understanding of what we do.”

Goal setting

Reection occurs throughout everyone’s lives. Whether it is after a test in fourth grade, across from a spouse at the altar, or with your banker at the end of the scal year, reection is constantly occurring. Reection can be leveraged on the farm to allow movement and progress toward big goals. This article will review “SMART” goals, why to bother, and encourage producers to be exible enough to both stay true to the goals and embrace pivoting to confront new situations.

Many producers use winter snowstorms or the glimmer of a sparkling new year to make goals. Frequently, goals are mental goals made on long car rides, but occasionally they are recorded in a phone voice-to-text note and tucked away. To get the most mileage out of goal setting, consider following the SMART goal format: specic, measurable, attainable, relevant and timebound. Following this format will allow the goal-setter to know where they have been so they can acknowledge progress towards their goal.

into smaller tasks. What is validating for all members of the farming enterprise regarding goal setting is the sense of accomplishment when goals are completed promptly. This acknowledgment of success creates a perfect time to reect on progress and the relevancy of the big goal to the operation.

By Dana Adams University of Minnesota

Goals rarely spontaneously happen. They are typically a conscious effort achieved by reecting on what is needed. Progress towards completing goals can include organizing tasks to complete the goal, setting aside time to focus on the task and tracking progress. Reection during and after allows farms to tailor what they do to achieve the most success.

Big goals are frequently aspirational and can be daunting to address. Just like how a parent will cut up a hot dog into little pieces for youth to eat, big goals can be more manageable when scaled down