WANT TO WIN $100 CASH?

See page 4 of second section for details!

See page 4 of second section for details!

Volume 25, No. 12

ITHACA, N.Y. – After a year of dismal milk prices for dairy farmers, hopes turn to rumors that the trend might be about to change.

With prices wallowing in low numbers in July – Class III milk at $13.77 per hundredweight, a drop of $1.14 from June – better days cannot come soon enough. Yet, with so many factors being at play when it comes to prices and predicting those prices, farmers must make daily decisions while standing on shaky ground.

Christopher Wolf, a professor of agricultural economics at Cornell University in Ithaca, has been watching the ever-dropping markets. He said those complex factors make market predictions more challenging today.

“With 18% or so of milk equivalents being exported, the marginal unit of milk is priced by international markets,” Wolf said. “The result is that the products which the U.S. exports – especially powders – have prices highly correlated with world prices. Additionally, corn and soybean markets are very international (and) directly impact the cost of producing milk.”

At the global level, many more variables are added to the prediction puzzle.

“The result is that international weather and, particularly, economic or military conicts can directly affect the farm milk price in the U.S.,” Wolf said. “Weather adds a great deal of uncertainty with, for example, the

WAVERLY, Minn. – When Swedish ancestors of Bill and Steve Uter established Merryville Farm near Waverly in 1877, hands and pails were the components of their milking system.

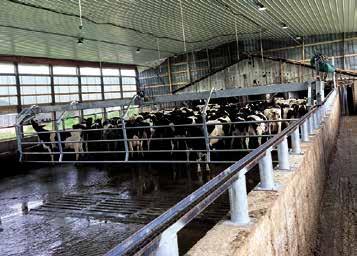

Today, Bill and Steve, along with Bill’s son, Mike, milk 285 cows using a DeLaval robotic milking system with four units, which were added three years ago in a retrotted, guided-ow system. Robotic feeders are used in the calf facility, and, this year, a Valmetal automatic bedding system was installed in the freestall barn, allowing the Uters to bed stalls without entering pens. The system is the rst one installed in Minnesota.

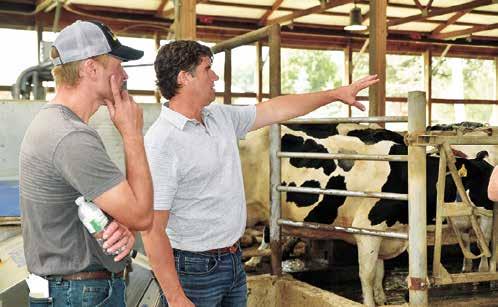

The Uters’ use of technology was the topic at hand Aug. 1 during the University of Minnesota Extension’s Summer Dairy Field Day at Merryville Farm.

During the introduction, Bill explained why the family added specic technologies. He and Steve both worked in agricultural business before

taking over the farm from their parents, Ron and Kay, in 1994.

“Then it was the original 40-cow tiestall barn and a hay shed, and we had a little bit of land to work with and some supportive parents,” Bill said. … “We are featuring (how we added) technology to an existing setup.”

Bill said lack of labor was a factor in adding technology.

“We’ve reduced our labor signicantly and boosted efciency through production per cow,” he said.

In the freestall barn, the farm’s most recent technology was showcased – the automatic bedding system. Part-time Merryville Farm employee Dylan Marketon demonstrated the system by running the bedding cart over one side of the barn using an application on his phone while Steve explained the system.

“This is the third machine like this used in the United

States,” Steve said.

The other two are in Wisconsin, and the Uters visited one of those sites. After much consideration, the Uters chose to proceed with the Canadian company.

“We do both drop bedding and spread bedding on the cows,” Steve said. “What (the system’s bedding cart) does is ride rails (at the ceiling) that go all the way around the barn on the outsides then curl on the ends and come back over the top of the insides over the cows.”

The bedding is made by grinding straw and mixing it with sawdust using a vertical mixer. It is then automatically fed into the bedding cart.

The system can be programmed to disperse different amounts of bedding as needed. The barn has a tail-to-tail conguration for stalls.

The cart comes back to its base to rell and keeps working until the barn is done for each bedding time, which happens twice a day at 5:30 a.m. and 4:30 p.m., taking a little over an hour each time.

“Before we had this, we were going in there with a cart and a shovel and bedding the stalls – a two-hour-aday job, a horrible job, with the dust and the physical labor and the cows in there,” Steve said. “The reason we used the cart and shovel is we didn’t

“All dairy, all the time”™

Published by Star Publications LLC

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

The U.S. Department of Agriculture has scheduled a national hearing to review Federal Milk Marketing Orders for Aug. 23 near Indianapolis, Indiana. Thirty proposals were submitted and 21 are in the scope of the hearing. Associated Milk Producers Inc. Chair Steve Schlangen said the numbers used in many of these proposals are still outdated. “They’re not anywhere close to where they should be as far as what it really costs to make milk into cheese and whey,” Schlangen said. “With the numbers we’re using right now to create a Class III price, the costs are from 2005. … Labor was $10 an hour then.” Schlangen also wants the farm bill to include mandatory reporting of production costs in the dairy plants and surveying every two years “so that this thing doesn’t get way out of line like it has been.”

The 2018 farm bill changed the way farmers are paid for Class I uid milk, and the decision was made without a hearing, comment period or producer referendum. The Class I price now uses an average price, rather than the “higher of” pricing method. “We hope Congress is ready to make a simple four-word change in the dairy title of the 2023 farm bill,” said Laurie Fischer, CEO, American Dairy Coalition. “If the ‘higher of’ method was still in place, the August Class I mover would have been $18.29 (per hundredweight), not $16.62.” ADC reports the net loss realized by dairy farmers since the average method was implemented has now topped $1 billion. “Go back to the ‘higher of’ (pricing method) by the fastest means possible,” Fischer said.

Interest rates rise

The Federal Reserve bumped interest rates by a quar-

ter percentage point to a range of 5.25% to 5.5%. Interest rates are now at a 22-year high. Fed Chair Jerome Powell would not rule out another rate hike at the central bank’s September meeting.

Impact still to be seen

MN 56378-1246.

Don WickVirginia Tech Professor Emeritus Dr. David Kohl spoke at the Bell Bank AgViews Live Conference in Fargo, North Dakota; Sioux Falls, South Dakota; and Wisconsin Dells, Wisconsin. “Navigating these interest rates is going to be very critical for the next two or three years; these are the fastest rising interest rates since the 1980s,” Kohl said. “We haven’t felt the impact because oftentimes we haven’t paid down on the operating loans.” Kohl said ination, economic growth and unemployment are all factors that must be considered before interest rates can decline.

Milk production edges higher

Milk production in the 24 major dairy states totaled 18.1 billion pounds in June, up 0.2% from one year ago. Minnesota milk production rose 1.6% with the addition of 4,000 cows to the state herd in the past year. Wisconsin milk output was up 1% with cow numbers down 2,000 head. South Dakota milk production increased 6.9% with

13,000 cows added to production since June of last year. Milk production rose 2.5% in Iowa with 6,000 more cows.

Too many cows in the system, an oversupply of milk and milk dumping have all been market factors this summer. Total Farm Marketing senior marketing advisor Bryan Doherty said the milk price has improved. “When the market turns, the market will often nd that sellers have got their solid position or shorts, and you have speculators already jumping on the long side,” he said. That brings additional volatility to the marketplace. Doherty said this is a time for dairy farmers to start hedging, “but, do it lightly (and) let the trend be your friend right now.”

Protecting farmers, consumers

USDA is partnering with attorneys general in 31 states to address anticompetitive market conditions in agriculture. The state attorneys general will now have additional authority to conduct investigations into price gouging, conicts of interest and anticompetitive behavior in the food and agriculture sectors. Minnesota Attorney General Keith Ellison is part of this effort and said unfair markets in agriculture result in articially high prices. The Minnesota AG’s Ofce is part of a lawsuit that claims Syngenta and Corteva exclude generic competitors with their customer loyalty programs.

Minnesota Sen. Tina Smith has introduced a bipartisan bill titled Agriculture Skills Preparation for Industry Recruitment Efforts Act. This proposal would address workforce shortages in the ag industry. “It creates a way to do work-based apprenticeships and handson training from working with other farmers, training in dairy management or meat processing,” Smith said. The ASPIRE Act would allow more people to enter into the agricultural industry and address other challenges like access to capital, rising farmland prices and operating loans.

A new option for haymakers

New Holland Agriculture North America has a new header for its Speedrower PLUS Series self-propelled windrowers. The new Durabine

413 PLUS disc header features a cut width of 13 feet. This gives haymakers an additional size to choose from in its Durabine Plus Series.

Minnesota dairy farmer joins Edge board

Brady Janzen, who is a partner with Riverview Dairy at Morris, Minnesota, will serve an interim term on the Edge Dairy Farmer Cooperative board. Janzen lls a vacancy left by Mitch Davis, who sold his Minnesotabased dairy farms and transitioned to an advisory role. Edge is based in Green Bay, Wisconsin, and serves dairy farmers in Illinois, Iowa, Kansas, Minnesota, Nebraska, Ohio, South Dakota and Wisconsin.

MAAE award winners named

The Minnesota Association of Agricultural Educators presented Doug Hanson of Willmar, Minnesota, with its Lifetime Achievement Award. Hanson is a former ag teacher at Willmar High School and coordinated the Minnesota FFA career development contests. Former Minnesota FFA advisor Joel Larson was recognized for Outstanding Service. The University of Minnesota-Crookston is the Outstanding Post Secondary/Adult Programs award winner. The Academy for Sciences and Agriculture charter school is the Outstanding Middle/Secondary Program. Eric Sawatzke of West Central Area Schools is the Outstanding Ag Education Teacher of the Year. Tori Barka of Kerkhoven-Murdock-Sundburg received the Early Career Teacher Award. Minnesota Farmers Union was honored for outstanding cooperation, and Compeer Financial was recognized with the Business and Industry Award.

Trivia challenge

National Ice Cream Day is celebrated on the third Sunday of July. That answers our last trivia question. For this week’s trivia, how many gallons of milk does the average American consume per year? We will have the answer in our next edition of Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

large effects of the Pacic currents changing from La Nina to El Nino. The Russian invasion of Ukraine has impacted feed and energy prices, etc.”

Both at home and abroad, fears of recession have hurt milk pricing, especially for Class III milk, over the past year, along with other contributors. Plus, many factors are interdependent in intricate ways

“Cheese prices drive other prices as it is the largest use of milk,” Wolf said. “The most recent Cold Storage report put total natural cheese stocks at slightly more than 1.5 billion pounds, up a bit from the previous year. Of course, the important value is stocks-to-use rather than the stock value in isolation. Commercial disappearance depends on domestic and international consumption. The fear of a potential recession – which looks increasingly unlikely but you never know – dampens the forecasts for consumption.”

The coming months are predicted to be better for prices, Wolf said, but possible variables are ever-present.

“Margins are really low at the current time,” Wolf said. “Dairy Margin Coverage (is at) $3.65 per cwt for June and in the same neighborhood for July. This is not sustainable, and the markets expect adjustments (by) culling cows and other ways of cutting back production. The milk and feed markets are currently predicting a recovery in margins by November to closer to long-run averages – not great but much better than today. This

will depend on feed prices and weather, along with many other factors.”

If prices do improve as predicted, the roller coaster of milk pricing does not bring a sense of security even in better market times. However, Wolf said, stability is not always a good thing.

“There are many dimensions of farm milk price,” Wolf said. “It is not necessarily better to have no variation in milk price. Consider periods where the price was very low but stable.”

Predictability, Wolf said, is more important than stability for dairy farmers.

“We expect seasonal variation and can manage through it if it behaves predictably,” Wolf said. “However, I would argue that what farmers really need are adequate prices. If prices received are adequate, then the rest takes care of itself. The U.S. dairy industry has done a better job in recent years of looking for innovation in product form and place, and that will continue to be important to growing markets both domestically and abroad.”

Wolf also sees a role government can play.

“As an economist, I want to see the government intervening where there are potential market failures –information problems, market power discrepancies, etc. The DMC and Dairy Revenue Protection are valuable risk management programs. Federal Milk Marketing Orders modernization is a good idea to keep the underlying structure viable.”

want to move the cows. If we would have to move the cows over from where they are lying to this alley to bring in a loader to bring the bedding in, we would lose 8-10 pounds per day just by the disruption of their schedule.”

If bedding lands directly on cows, Steve said, they simply shake it off.

“We put the rail system in ourselves,” Steve said. “We cut the metal, designed and built the brackets, had them galvanized, put them up, and put the rails in.”

The rails are 40 feet long and 330 pounds each, so even getting them into the barn was a challenge, much less lifting them.

“It was quite a project,” Steve said. “That’s why there’s probably only three of them in the United States.”

They began in early August 2022, installing up to 10 brackets each day as other farm work allowed. They also built an apparatus to hang on the rails, or I-beams, so they could use a trolley on each rail that was in place and roll the next rail into place from it and attach it to that previous one. Time only allowed for placing two or three rails each day.

Including waiting times for parts to arrive or to be galvanized, the process was completed by the end of November, but they then had to wait for corner pieces to be shipped. The Uters were -

nally able to begin using the system three months ago.

In another session, Bill, along with Randy Kuechle from Farm Systems in Melrose, explained the robotic milking system on the farm, which incorporates guided ow. Younger cows are kept on one side of the barn and older cows on the other. The Uters also use their parlor for milking special-needs cows, which typically number around 40.

“We take a conservative approach with everything,” Bill said. “We wanted to make sure we had enough milk owing at all times before we populated this (freestall) barn, and we just kind of stuck with it. … We did not put the milk catches on our robot. (Milk from) every cow in (the freestall barn) goes into the bulk tank.”

The Uters looked at both guided-ow and free-ow systems for the barn when retrotting it with robots and saw pros and cons with each. In the end, mostly due to not having options for expanding the barn because of where it sits, they chose guided ow.

“The free ow would have gobbled up a lot of stalls,” Bill said. “The main part of the barn was built in 1994, and we built it as a cold barn. The alleys are narrow; they were never designed for scrapers. We’ve added on to each side of the barn since then, and we can move more cows with the

guided-ow system and not have a lot of congestion at the front of the barn. We didn’t need that big waiting area compared to a free-ow situation.”

Bill said the system is working well and increasing milk production.

“We didn’t want to be fetching cows all the time,” Bill said. “With this system, if there’s a cow that’s in the (needing-to-be-milked) list,

we simply get her up, and she walks down and milks herself.”

Currently, after a cow walks in and the gate closes, the robot cleans and dries the teats, milks the cow, sprays and dries the teats again, and releases the cow in, on average, 6 minutes and 30 seconds. The robots read the collar of each cow, knowing its size, teat placement, milking schedule and other data. If

it is not time for a cow to be milked again, she is sent back around the guided ow.

Mike was on hand at the farm’s calf facility to talk about the robotic feeding system. When Bill and Steve rst took over the farm, heifers were purchased, as was their feed. As they acquired land to rent and later buy, they added heifer facilities and more of

Turn to UTERS | Page 9

Con nued from UTERS | Page 8

their own feed. Currently, the Uters grow all of their own forages but purchase grain for the calves and the milking ration.

“All of our bull calves we sell within the rst week or two,” Mike said. “The robots here are able to handle 120 calves, but we built this barn so we could feed 60 heifer animals, and if something were to happen to the farm, we could do 120 bull calves.”

Heifer calves are rst put in hutches for a maximum of 14 days. Then they move into the barn to the young-calf pen for two to three weeks for priority feeding with two of the robots, each with two nipple stations. From there, calves are moved to the oldercalf pen, which also uses robotic feeding. In the past, all calves were fed by hauling whole milk from the barn, so labor has been reduced by automating feeding.

The Uters raise their heifer calves. When heifers are conrmed pregnant, they go to a neighboring farm until up to three weeks pre-fresh, and then they are brought back to the Uters’ farm to calve. Mike said the farm usually adds around one to two calves per day.

In another session, Barry Visser of Vita Plus described the Uters’ feeding ratio. The farm has two bunkers of corn silage. The Uters have their silage custom chopped.

“About 40% of the dry matter the cows are eating is from that corn silage,” Visser said.

Other forage is in the form of baleage and a small amount of wet brewers grain, a byproduct from nearby breweries.

The Uters use a partially mixed ration, purchasing a complete grain mix with corn, vitamins, minerals and most of the protein. They also have soybean meal kept separate so that if they get higher-protein baleage, they can easily lower the soybean meal to adjust.

Lastly, they use two kinds of pellets for their guided-ow system. One reason pellets were selected by the Uters over meal feed was for time ef-

ciency through the milking system.

“Meal feeds can’t be eaten quite as quickly as pellets” Visser said. “With guided ow, you can get by with feeding cows a little less pellets because they are guided in as opposed to free ow.”

At the nal breakout session, Zach Uter, Steve’s son and a data analyst at UMN, along with Jim Salfer, of UMN Extension, discussed the economics of using robotic systems. Zach talked about efciency in the system being a top priority for prot. Breeding for cows with somewhat smaller frames and specic body types becomes part of the equation so that they t better through the guided-ow system.

“Breeding has changed; we’re looking for cows that not only produce as well as they are right now but also let down their milk faster,” Zach said. “We’re also looking for teat placement and length because it makes it just that much quicker for the robot to attach, and then we’re looking at cows that are more docile, not as aggressive, because, with the robots, there is more of a chance for them to be bullied.”

Merryville Farm has changed in many ways since Bill and Steve took the reins 30 years ago, but with regular maintenance checks, all new systems are running smoothly. Bill said he only receives an alert call by the robotic milking system around once every couple of weeks.

“When we were in the parlor, that was 24 man hours a day, getting 280 cows milked, and then we still had to go out and do our chores,” Bill said. “As annoying as getting a call once in a while is, you just remember and think about how it was.”

“When we were in the parlor, that was 24 man hours a day, getting 280 cows milked, and then we still had to go out and do our chores. As annoying as getting a call once in a while is, you just remember and think about how it was.”

BILL UTER, DAIRY FARMER

563-568-4526

AfterHours:

‘20 Anderson Hybrid X, Custom Operator Pkg

Tubeline TL5500 Inline Wrapper

Hesston 565A Round Baler

Hesston 3986 14 Wheel Rake

Hesston 12 wheel Bifold Rake

‘20 MF 3983 Hicap Rake, 12 wheel

Miller Pro 7914 Merger, 14’

H&S 12 wheel rake

‘21 Rhino 3150 15’ batwing

MF TD1620, 2 rotor tedder

‘22 MF 1393 13’ center pivot disc

mower cond.

‘17 JD 835 9’ MoCo, center pivot

JD 946, hyd. swing, rubber rolls

‘14 CIH DC112 Disc Mowland

Gehl 2450, 15’ hydro swing disc mower

Haybuster 2650 Bale Grinder

‘14 NDE 2906 Twin Screw TMR

JD MX7 3PT Brush Mower

(2) ‘21 Rhino 3150-15’ Batwing mowers

JD 146 Loader w/bucket

Gehl 100 Feed Mill

‘94 MF8570 combine, 2500 hrs.

‘21 Bobcat S76, CAH, SJC, 3,400 hrs.

‘21 Bobcat S76, CAH, SJC, 1,800 hrs.

‘21 Bobcat T66, CAH, 700 hrs.

‘21 Bobcat T870, SJC, high flow, 500 hrs.

‘20 Bobcat T770, CAH, high flow, SJC, 765 hrs.

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘14 Bobcat S770, 3,200 hrs.

‘15 Bobcat T750, A71, joystick, 3,400 hrs.

‘14 Bobcat S750, A71, ACS, 4,100 hrs.

‘18 Bobcat S650, SJC, 9,000 hrs.

‘19 Bobcat S570, CAH,

FARLEY, Iowa – What do an auto repair shop, a baseball training facility and an ice cream shop have in common? In Farley, they all come with the name Delaney.

Delaney’s Ice Cream Shoppe was born of the business transformation brothers Matt and Jason Delaney began three years ago. Delaney’s Auto and Ag Center and Repair rst existed in Cascade then expanded to Farley where Matt began offering ice cream in the waiting area.

“I was looking for something unique to separate us from the competition,” Matt Delaney said. “(Ice cream) was the extra cherry on top.”

For the rst year, ice cream co-existed with the original business, but by the second summer, the Delaneys bought the attached hardware store. After remodeling, Delaney opened a separate ice cream business while his brother created Between the Laces, a baseball and softball practice business.

cream, and they have great names.”

All told, Delaney has accessed 65-75 of the company’s 100-plus avors at one time or another.

“That’s why we sell so many,” he said. “We market for the 30% of customers who come in and want something new. That’s what separates us from all the other ice cream stores.”

In addition to the agship store in Farley, ice cream is beginning to be offered at the Cascade location of Delaney’s Auto and Ag Center and Repair. In the future, ice cream offerings could be expanded there.

There is also an ice cream trailer, which Delaney calls a mobile barn, which offers ice cream and snow cones. It goes to Dyersville’s Field of Dreams nearly every weekend and to the Eagles Club on Fridays. Community events and ball games are also on the schedule.

Delaney gives 10% of proceeds to schools when the trailer is used at school events and runs a reward program with schools at the shop. He also has a relationship with the county dairy promotion association for which Delaney’s Ice Cream Shoppe won the Golden Butter Knife award this year.

Like any business, running an ice cream shop is not without challenges.

‘17 Cat 272D2XPS, 1,700 hrs.

‘20 Bobcat V923 Telehandler, 1,100 hrs.

‘19 Bobcat 5600 Toolcat, high flow, loaded, 360 hrs!

‘18 Bobcat 5600 Tool Cat, high flow, loaded, 452 hrs!

“It’s his dream, my dream and what we do for a living,” Delaney said. “It was a great decision. Ice cream is like coffee: It doesn’t matter what you have for money; you treat yourself.”

Today, Delaney’s Ice Cream Shoppe goes through an average of about 90 3-gallon containers of ice cream each week, sometimes needing as much as 120 containers.

The store regularly offers 46 avors of Chocolate Shoppe Ice Cream, made in Madison, Wisconsin. Delaney credits the ice cream brand for much of the store’s success.

“We did a lot of research for a year and a half,” Delaney said. “Hands down, this was the best ice

“Help is the biggest thing, that and watching your spending,” said Delaney, who said he probably focuses about 60% of his time on the ice cream business. “The automotive business is still my bread and butter.”

Delaney has found good help from young people who were raised on farms.

“Your farm kids are the ones who know how to work,” he said. “Their parents make their kids work. I can’t focus all my time here, so we need people with initiative who are problem solvers, and those kids come from that background.”

Delaney said Delaney’s Ice Cream Shoppe is managed like a family.

A mobile unit ou i ed to resemble a barn is parked June 27 and is part of Ma Delaney’s ice cream business in Farley, Iowa. The trailer goes to community events and helps organiza ons raise funds by selling ice cream and snow cones.

“We try to have a lot of fun, but we have to work at the same time,” he said. Delaney’s eventual goal is to have one year-round ice cream store and two seasonal ones along with two more mobile units.

With a wife and two children who also need his attention, Delaney is

working to balance his time. Meanwhile, he remembers the words of an aunt who often said, “There’s always room for ice cream.”

That is good because ice cream shop owners get to take home the leftovers.

We usually do the standard tests. We’ve also used the pregnancy test.

Which is your favorite and why? I really like the production and the breeding records.

How does testing with DHIA bene t your dairy operation? It helps us manage our dairy more ef ciently. If I have a high somatic cell count cow, it costs me money to have her in the herd. DHIA provides me with the information that helps me make decisions on my herd’s performance.

Tell us about your farm. I farm here with my brother, David. We are the third generation of Names to farm here. We milk our cows in a double 8 herringbone parlor. The cows are outside on pasture or bedding pack 365 days a year. We farm 750 acres of corn, soybeans and alfalfa.

Sauk Centre, MN Buffalo, MN 763.682.1091

By Tiffany Klaphake tiffany.k@dairystar.com

By Tiffany Klaphake tiffany.k@dairystar.com

NEW ULM, Minn. – Like many girls, Maggie (Sellner) Kohout had dreams about her wedding day while growing up. However, when the big day arrived, it ended up looking nothing like what she had envisioned.

“Actually, it went better than I could have dreamed,” Kohout said. “I always wanted the big church wedding, but this way I could decide how everything should go.”

Kohout and her husband, Tyler, were married in a church with a small ceremony Aug. 4. Then, they held a large gathering Aug. 5 for 320 of their closest friends and family at the Sellner family farm, home of the bride’s family.

“We had the emotional day at the church on Friday, and then everything was so sentimental at the farm on Saturday,” Kohout said. … “It’s been fun being able to share that passion for the outdoors with Tyler and throw the farm into the mix.”

The farm, near New Ulm, is where Loren and Heidi Sellner milk 175 cows using a robotic milking system with three units.

Not having grown up on a farm himself, Tyler quickly started helping at his then girlfriend’s farm. Being an electrician, Tyler’s skills allowed him to be hands-on at the farm and help with electrical work on the robots.

The young couple had been dating for several months when Kohout

knew she had met the man for her. It was the day she saw Tyler carry a wet newborn calf into the calf barn on her parents’ dairy farm without anyone asking him to.

Haylee Sellner (front, from le ), holding Colby Sellner, Maggie Kohout, Heidi Sellner and Gracie Sellner; (back, from le ) Adam Sellner, holding Peyton Sellner, Tyler Kohout and Loran Sellnergather Aug. 5 at the Sellner family’s farm near New Ulm, Minnesota. The Kohouts were engaged and exchanged vows at the farm. Turn

“I had been thinking about (having a wedding) on the farm ever since my brother did his wedding on the farm three years ago,” Kohout said.

“He got married during (the coronavirus pandemic) and started the whole wedding-on-the-farm thing.”

Kohout said Tyler knew how much the family farm meant to her, and he elicited the help of Kohout’s mom and sister, Gracie, when he wanted to propose. Using four calves as a canvas at the Sellner farm, the women painted the words, “Will you marry me?”

When Kohout saw the decorated calves, she enthusiastically said yes to Tyler, and as the young couple walked out of the calf barn, they were soon greeted by many of their family and friends.

“I was like, ‘What the heck? How did they all know?’” Kohout said. “It was fun to have all our friends there right from the start of our adventure together.”

Kohout utilized family friends to help with the various tasks of the wedding. She asked one to be the photographer, one to do the owers, one to do the alterations to her wedding dress and one to ofciate the outdoor ceremony at the farm.

“We wrote our own vows to say at the farm so that all of our friends could hear how much we love each other,” Kohout said.

To help give the wedding a coun-

try air, the Kohouts used a hay wagon as their getaway vehicle and took pictures with the farm and cows in the background.

“Because Tyler proposed to me (with words painted) on the calves, we had written on the baby calves, ‘We do,’ for the wedding,” Kohout said.

The Kohouts each have a fulltime job off the farm but continue to help the Sellners several days a week, as do each of Kohout’s siblings. Her brother Adam works in construction but helps with eldwork. Gracie helps their mom take care of the calves. Kohout and her new husband help as needed with eldwork, feeding calves and various tasks.

“It takes a family to run a farm,” Kohout said. “Without family, it would be really hard to keep going.”

Together, they will continue to help as needed on the Sellner family farm while starting their own family and careers in New Ulm.

“Being able to share my family with Tyler’s family out where my family started was super special for us,” Kohout said. “It’s where we spent so much of our time together in the summer. It was nice to share that with all our family and friends.”

Karen VonRuden Owatonna, Minnesota Steele County

Karen VonRuden Owatonna, Minnesota Steele County

What are your main responsibilities as coordinator of the dairy show at your county fair? It starts with encouraging our exhibitors to bring their cattle to our fair. I send out an exhibitor letter in July to all previous exhibitors, and most entries are now done online though the fair website. I also nd the judges for each open class show, colored breeds show and Holstein show in conjunction with the Minnesota District II Show. I also organize the identications, stalling, herdsmanship, ring and table help at the shows and ring maintenance.

What do you enjoy about this role? We have many youth exhibitors, so we focus on nding judges who are great with youth. Last year, we had 22 novice calf and 34 youth showmanship entries. Our goal in Steele County is to get the exhibitors at a young age and keep their interest through the years. It’s like a giant family-friend reunion to all the generations out in the show ring and working together.

What is the most challenging part of this position? On March 13, 2019, our cattle barn collapsed due to snow load. Plan A: Could we use a tent for this year and plan to build following the 2019 fair? It’s not a good idea to tie cows to tent poles. Plan B: Start fundraising and planning for the new barn. We were all very excited that Plan B was chosen. The Steele County Free Fair board worked hard gathering input, ideas and sponsors. The “Cattle Haven” was completed and used in 2019.

How many head of dairy cattle on average are exhibited and by how many exhibitors? Steele County has been able to maintain about 90-100 head of cattle. Last year, we had 17 herds/exhibitors. Many of these herds have several animals that are also leased to 4-H’ers and shown in the open shows too.

What is something unique to your county's dairy show?

We have four dairy shows in all: junior dairy club show, 4-H show, open colored breeds show and open class Holstein show. We have several great sponsors: Our Milk House Fund (used to subsidize our exhibitors for milk produced at the fair), Herdsmanship (rst through third place and for our judges) and novice calf (T-shirts and medallions).

Can you share a favorite memory from the years you have served as coordinator? My favorite memory has to be from 2019 and moving into the new cattle barn. It was just an all-around interesting year. I had been the superintendent since 2014 and thought things should start to become easier. With the new barn, I started placing the exhibitors in their stalling areas and my phone began ringing. As we well know, cows like to stay in the same stall, and exhibitors are no different. The beautiful new barn brought many great changes such as high ceilings and bright lighting.

When do you start preparing for next year's county fair, and what do those rst tasks involve? We have an exhibitor meeting on Sunday afternoon, the last day of our current fair. I get a list for potential judges, and we discuss changes or suggestions to consider for next year.

What are your main responsibilities as coordinator of the dairy show at your county fair? Greg Nelson and I work together as dairy superintendents. We are responsible for verifying how many dairy animals each family is bringing to the fair, coordinating stalling assignments, lining up judges, making sure the barn is ready for exhibitors, arranging help to run the shows and answering questions and solving problems throughout the fair. During the show, Greg is making sure all exhibitors and animals are ready to go into the show ring on time while I emcee the show.

What do you enjoy about this role? I enjoy watching the kids as they progress and improve with their showing abilities and animals, and I enjoy being able to catch up with all of the other dairy families each year.

What is the most challenging part of this position? Greg and I have been doing this together for many years, so we have a mutual understanding of how things need to efciently get done, but stalling is probably the hardest part each year. We have just under 200 animals sign up, so it’s a puzzle trying to make sure everyone ts and can be tied next to other people they have requested. Luckily, our exhibitors are amazing and are understanding if things get a little squished or they end up in a different spot than the previous year.

How many head of dairy cattle on average are exhibited and by how many exhibitors? Meeker County doesn’t have a lot of dairy farms within our county, but we have an amazing number of dairy animals that get exhibited at our county fair. About 10 years ago, numbers really increased, and we have been at a steady 175-190 head that are exhibited between about 16 and 20 families. We also have an incredible 4-H dairy lease program. About half of our 4-H kids are non-dairy farm kids, but they have partnered with our fabulous dairy farm families to lease cattle and have loved the experience.

What is something unique to your county’s dairy show? We really do have great quality shows for all of the breeds. There will be animals from almost all of the breeds that go on to show, and do well, at state and national shows. We get comments from judges all the time that they didn’t expect the quality of animals throughout all of the breeds. It makes for a really fun show to watch.

Can you share a favorite memory from the years you have served as coordinator? Maybe not a favorite, but certainly a memorable moment was when my daughter’s 4-H calf came off the trailer and took off down to the midway. It took a while to catch her, but it made for an interesting rst day of the fair. Our family talks about that incident every year now. Many years have passed, so we can laugh about it now.

When do you start preparing for next year’s county fair, and what do those rst tasks involve? We have an exhibitor meeting at the fair with everyone the night after our show. We discuss how everything went that year and talk about suggestions for changes or improvements for next year. It’s helpful having everyone’s perspectives and input as we make plans.

Jim Klein Waconia, Minnesota Carver County

What are your main responsibilities as coordinator of the dairy show at your county fair? I am in charge of getting the dairy judges, coordinating the show and coordinating the stalling in the dairy barn for our county fair.

What do you enjoy about this role? I have liked working the dairy people over the years. I get to know a lot of folks and gain a personal connection to farm families. It’s fun seeing the kids grow up. I have been serving in this role for 18 years.

What is the most challenging part of this position? Finding the dairy judges. There are so many county fairs in two months’ time. The judges get booked up pretty quick.

How many head of dairy cattle on average are exhibited and by how many exhibitors? We average about 150 dairy animals that are exhibited by about 25 exhibitors. Both these numbers have been going down in our county over the last number of years.

What is something unique to your county's dairy show? We are lucky enough to have enough animals that we have a colored breed show ring and a Holstein show ring. We have the two show rings for the 4-H dairy show, open class dairy show and the FFA dairy show. We have kids coming in from other counties to show at our FFA show.

Can you share a favorite memory from the years you have served as coordinator? Not a specic one memory, but the expression on a kid’s face when they win champion or grand champion is priceless.

When do you start preparing for next year's county fair, and what do those rst tasks involve? We will start preparing for next year’s show in October. We will start by answering questions from new families that are interested in showing cattle. They like to know what they should have for the upcoming year for supplies and about showing cattle. By late winter or early spring, we start working on getting people lined up for judging.

What are your main responsibilities as coordinator of the dairy show at your county fair? As the dairy superintendent of the Stearns County Fair, my duties include making sure there is a place to stall the dairy animals at the fair, making sure the milking parlor is operational and running the open class dairy show.

What do you enjoy about this role? I enjoy trying to make the entire dairy side of the fair run as smoothly as possible to make it a great experience for the exhibitors, especially the 4-H exhibitors. We try to keep the shows well organized and moving efciently to get exhibitors in and out in a timely fashion, and make sure right animals are in the right classes. Many of the 4-H kids are unfamiliar with how a dairy show runs or where they need to be and when, so making it as organized as possible helps reduce the confusion and potential chaos, so the kids have a positive experience and enjoy it.

What is the most challenging part of this position? Every year it seems we are tight on space, but we seem to make things t. I know exhibitors would appreciate more room, but we are limited by the facilities we have. All our livestock species numbers are strong, so we can’t borrow space from other species either. It can also be a challenge at times coordinating all the volunteers. We run two rings for our shows, so that requires twice as many people. Most of us only do this once or twice a year, so remembering what needs to be done and how it needs to be done requires some effort. I am incredibly blessed to have a pool of great people to draw from to assist in making these shows happen. My goal during the show is to be able to simply oversee things and have people lined up to handle the necessary tasks.

Suzanne Souza Ortonville, Minnesota Big Stone County

What are your main responsibilities as coordinator of the dairy show at your county fair?

As a University of Minnesota Extension Educator, my responsibilities include nding a judge for the show, securing award sponsors, making sure 4-H’ers have their paperwork in on time for our May 15 4-H afdavit deadline as well as fair entry deadline, and lining up volunteers to serve as superintendents and announcers.

What do you enjoy about this role? What I enjoy most about coordinating a 4-H dairy show is hearing the excitement in the youth when they stop by the ofce throughout the year, talking about their dairy projects and the anticipation of the upcoming show. The smiles on their faces when they arrive on the fairgrounds to hang out with fellow 4-H dairy exhibitors. On show day, the wonderful sound of clippers buzzing as the youth do their touch ups as the smell of Final Bloom spreads throughout the air. The moment has arrived as they enter the show arena to showcase their work as well as their dedication to their dairy animal. That is what I have enjoyed over the last 20 years.

What is the most challenging part of this position? There are always challenges, but what I found to be most challenging is nding judges. It seems judges are becoming few and far between, and to be able to nd one during a week when three or more fairs are happening in the area or to come to a show right in the middle of the work week is a challenge. I have reached out to local universities to recruit from their dairy judging teams, which has been a blessing.

How many head of dairy cattle on average are exhibited and by how many exhibitors? We had between 25 and 30 head of cattle shown by 17 youth at this past county

How many head of dairy cattle on average are exhibited and by how many exhibitors? We typically have somewhere in the neighborhood of 125 to 135 head of 4-H animals exhibited by 45 kids. Most years, we get an additional 30 to 40 head that come in for the District 8 Holstein Show and our open class show. Our numbers have been very consistent over the past 10 years. Every year we wonder who will take the place of our outgoing 4-H’ers, but it seems like we ll those spots pretty consistently. What is something unique to your county's dairy show? We are one of the state’s largest 4-H dairy shows.

Can you share a favorite memory from the years you have served as coordinator?

I have lots of memories of lots of kids having success at our fair, but there are two that stand out to me. One is of a young lady whose grandmother approached me several years ago about leasing a heifer from me so her granddaughter could participate in the dairy project. This was all very new to her and really required her to step out of her comfort zone. She denitely rose to the challenge and has gone on to become very active in 4-H and has become quite successful with her dairy projects. A second memory happened just last year when two graduating 4-H’ers presented me with an engraved plaque as a thank you for my time as a 4-H leader during their 4-H careers. It was unexpected and touching.

When do you start preparing for next year's county fair, and what do those rst tasks involve? I start preparing for next year even before the current year’s show happens. I usually try to keep a list of thoughts of things I should remember to do for next year before, during and after the show. From the fair board side, we begin our meetings in February, so there are some things that might get addressed then, but most preparation begins in earnest in April or May. The biggest thing I need to do at that point is secure a judge for the open shows. After that, I work with 4-H to address any changes that need to happen with that show. I usually try to start recruiting volunteers about a month ahead of time.

fair. The majority of the dairy animals shown for the past 10 years have been leased and have helped increase the numbers at our county 4-H show. In Big Stone County, 4-H youth who are leasing the majority of the animals do not live on farms but in town. We have two or three families that own animals and live on farms, but we are continuing to see more youth, especially rst-generation youth in the program, want to experience learning about dairy cattle and proudly walking into the show ring.

What is something unique to your county's dairy show? I would not say we have anything unique, but we do have some things that we are very proud of. First, our 4-H dairy youth are always helping one another and supporting each other for the months leading up to the show and the day of the show by helping each other and giving some last-minute advice to younger or new youth entering the show ring. Our county’s American Dairy Association gives each dairy participant a coupon to the malt wagon and sponsors our dairy class awards. The local cheese factory provides our showmanship awards. All in all, we have an awesome support system. They go out of the way to support our show and 4-H dairy kids whenever possible.

Can you share a favorite memory from the years you have served as coordinator? One that comes to mind is when we had a 4-H youth who was new to the project and leasing a dairy animal win overall dairy showmanship as a sixth grader, topping older youth who had been showing for numerous years. This young lady, leading up to the fair and show, was always looking for input and advice on what she could do to improve her showmanship skills. The smile on her face that day after being given the overall showmanship trophy was priceless. If I can share advice from this, it is don't feel that you already know everything. There is always something new that can be learned whether it be a clipping tip or how to better control your dairy animal in the show ring by changing how you hold the halter. Always look for ways to improve.

When do you start preparing for next year's county fair, and what do those rst tasks involve? We start preparing once the current fair is done. We start looking for potential judges and award sponsors and planning showing and tting clinics to help our 4-H dairy youth improve their skills. One thing that is under discussion is changing our show day and time to accommodate our busy 4-H youth involved in the dairy project.

Describe your farm and facilities. We have a freestall barn with waterbeds, and we milk our cows in a swing-16 parlor. Our herd average is 28,000 pounds with 4.3% butterfat and 3.2% protein. We have 350 cows, 300 of which are milking. We also have 300 heifers and raise our calves. We also raise 200 steers. We have three fulltime workers who do milking and help with chores. We can feed all the cows in two hours.

What forages do you harvest? We have 180 acres of alfalfa, 600 acres of corn and 200 acres of grass hay, and we also raise 110 acres of soybeans.

How many acres of crops do you raise? Around 1,100 acres.

Describe the rations for your livestock. Our cows get 50 pounds of corn silage, 30 pounds of haylage, 20 pounds of earlage, 3 pounds of soybeans, 3 pounds of soybean meal and some liquid protein mineral mix. The dry cows get grass hay, haylage, corn silage and mineral mix. The heifers are

on their dairy near Sauk Rapids, Minnesota. They milk 300 cows, raise 300 heifers and 200 steers on their farm in Benton County.

fed grass hay, haylage, corn silage and mineral.

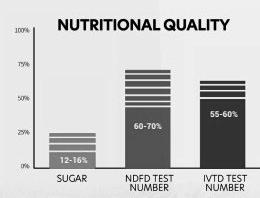

What quality and quantity do you harvest of each crop? We try to harvest the haylage at 180-200 relative

feed value on about 180 acres. The corn silage is a brown midrib variety, and we harvest around 200 acres at 66%-68% moisture. The earlage is about 40% moisture, and we have around

150 acres of that. This year, we planted a 98-day variety.

Describe your harvesting techniques for alfalfa and corn silage. The alfalfa is cut, merged, chopped at

65% moisture and put on a pile. The corn silage is chopped at 66%-68% moisture and piled. We usually take the rst cutting around Memorial Day. We participate in a scissor cut through the University of Minnesota.

What techniques do you use to store, manage and feed your forages? The alfalfa and corn silage are piled and faced daily. The earlage is in bags or in the silo. They are fed with the mixer.

How does quality forages play in the production goals for your herd? Feeding quality forage keeps cows healthy and producing a high amount of quality milk with less purchased feed. You make the best quality forages you can so you don’t have to buy your milk through purchasing feed to make up for poor quality forages. Turn

“We decided to get more regimented with our use of Udder ComfortTM and saw our SCC drop from 200,000 to 120,000. Whether they have visible swelling or not, we make sure to apply the Udder Comfort spray to all fresh udders after each milking during the first 5 to 7 days after they calve. We see SCC drop right down.”

- Kyle Hirt, Mithva Farms, New Woodstock, NY 100 cows, 80 lbs/cow/day, 120,000 SCC

“We’ve relied on Udder Comfort for over 10 years as the best tool to get cows through transition and into milk faster with healthier udders. Using the Udder Comfort Battery-Operated Backpack Sprayer, we now are getting our fresh cows sprayed consistently 3x/day for a week after calving, and in 3 months, our SCC came down from 165 to 137,000.” - Scott Stempfle, Stempfle Holsteins, Maynard, IA

“Udder Comfort is something we don’t cut. It gets swelling out faster. We see faster, better milkouts and higher quality milk. We do every fresh cow for a week after calving. We mark high-count cows on DHIA and do them too. We tried other brands. They don’t work. Udder Comfort is the one that works!”

- Matt Nealy, Nealand Farms, Newville, PA 400 cows, 92 lbs/cow/day, 100,000 SCC

What are management or harvesting techniques you have changed that has made a notable difference in forage quality? The biggest change we made is when we switched to bags and silos to piles. It enabled us to harvest at a better moisture for a more digestible feed. Our window for chopping is wider, and we can harvest at a quicker pace because we aren’t unloading into a bagger. It’s also allowed for quicker feeding times. This year, we bought a triple mower that has allowed us to cut in the morning and chop in the afternoon with the exception of the rst crop. We updated our pro-

cesses four years ago, and that does a better job annihilating the kernel. We also put in a 200-by-300 tar pad three years ago. That has allowed us to have all our feed in one spot which makes feeding quicker plus we don’t have to deal with any mud.

Describe a challenge you overcame in reaching your forage quality goals. Switching to a BMR corn helped with the health of the cows. We wanted to get to a more digestible feed. We switched six years ago and have had less instances of displaced abomasum.

...... $55,000

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD 9870 STS 2010, PRWD, Duals, 3394 hrs., 2260 Sep. hrs., #554931 .... $118,900

JD 9870 STS 2008, PRWD, Duals, 3261 hrs., 2494 Sep. hrs., #566621 ...... $97,500

JD S660 2012, 2WD, Duals, 1643 hrs., 1188 Sep. hrs., #554132 .............. $179,900

JD S660 2014, PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S670 2013, PRWD, Duals, 3169 hrs., 2161 Sep. hrs., #566670............ $141,100

JD S670 2016, 2WD, Duals, 1269 hrs., 964 Sep. hrs., #552767 ................ $237,900

JD S680 2012, PRWD, Duals, 3219 hrs., 2222 Sep. hrs., #552735............ $139,000

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S680 2012, PRWD, Duals, 2500 hrs., 2000 Sep. hrs., #554973............ $129,900

JD S680 2014, PRWD, Duals, 2324 hrs., 1575 Sep. hrs., #555096............ $169,900

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646............ $219,900

JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

JD S680 2013, PRWD, Duals, 2851 hrs., 1892 Sep. hrs., #566617............ $147,000

JD S680 2012, 2WD, Duals, 2631 hrs., 1790 Sep. hrs., #548165 .............. $147,500

JD S680 2013, PRWD, Duals, 2575 hrs., 1906 Sep. hrs., #563909............ $160,000

hrs., #560264 .................. $425,900 JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S770 2022, PRWD, Duals, 273 hrs., 195 Sep. hrs., #554014................ $560,000

JD S780 2018, PRWD, Duals, 1521 hrs., 1130 Sep. hrs., #551736............ $305,000

JD S780 2019, PRWD, Duals, 1286 hrs., 931 Sep. hrs., #558869.............. $349,000

JD S780 2020, PRWD, Duals, 1031 hrs., 749 Sep. hrs., #188309.............. $409,000

JD S780 2018, 2WD, Duals, 1215 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S780 2022, PRWD, Floaters, 242 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S780 2022, PRWD, Floaters, 141 hrs., 91 Sep. hrs., #554708 .............. $574,000

JD S780 2022, PRWD, Floaters, 254 hrs., 177 Sep. hrs., #554707 ............ $569,000

JD S780 2022, PRWD, Floaters, 185 hrs., 139 Sep. hrs., #554710 ............ $569,000

JD S780 2022, PRWD, Floaters, 189 hrs., 131 Sep. hrs., #554709 ............ $569,000

JD S780 2022, PRWD, Floaters, 225 hrs., 169 Sep. hrs., #554706 ............ $569,000

JD S780 2020, PRWD, Duals, 933 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1562 hrs., 1131 Sep. hrs., #549680............ $319,000

JD S780 2021, PRWD, Duals, 655 hrs., 469 Sep. hrs., #191047................ $489,000

JD S780 2022, PRWD, Tracks, 337 hrs., 251 Sep. hrs., #563618 ............... $619,000

JD S780 2022, PRWD, Duals, 426 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Tracks, 318 hrs., 231 Sep. hrs., #563619 ............... $619,000

JD S780 2022, PRWD, Duals, 468 hrs., 347 Sep. hrs., #563635................ $549,000

JD S780 2022, PRWD, Duals, 241 hrs., 183 Sep. hrs., #554094................ $565,000 JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000 JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

2019, PRWD, Duals, 1596 hrs., 1058 Sep. hrs., #549682............

$349,000

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Duals, 91 hrs., 56 Sep. hrs., #563620 ................... $579,000

JD S780 2020, PRWD, Duals, 1488 hrs., 1145 Sep. hrs., #191082............ $349,000

JD S780 2020, PRWD, Duals, 1026 hrs., 590 Sep. hrs., #566462.............. $419,000

JD S780 2022, PRWD, Duals, 452 hrs., 353 Sep. hrs., #552362................ $549,000

JD S790 2018, PRWD, Duals, 1647 hrs., 1218 Sep. hrs., #549845............ $309,000

JD S790 2018, PRWD, Duals, 1461 hrs., 1055 Sep. hrs., #549846............ $329,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Singles, 25 hrs., 20 Sep. hrs., #560619 ................. $639,500

JD S790 2021, PRWD, Duals, 705 hrs., 526 Sep. hrs., #555189................ $499,500

JD S790 2022, PRWD, Singles, 477 hrs., 314 Sep. hrs., #563815 ............. $579,500

JD S790 2022, PRWD, Duals, 334 hrs., 269 Sep. hrs., #554381................ $579,500

JD S790 2022, PRWD, Duals, 460 hrs., 368 Sep. hrs., #566460................ $624,900

JD S790 2022, PRWD, Duals, 1272 hrs., 90 Sep. hrs., #557140................ $629,900

JD S790 2022, PRWD, Duals, 432 hrs., 302 Sep. hrs., #552839................ $579,500

JD S790 2021, PRWD, Duals, 833 hrs., 551 Sep. hrs., #565421................ $499,900

JD S790 2022, PRWD, Duals, 455 hrs., 316 Sep. hrs., #566694................ $579,900

JD S790 2018, PRWD, Duals, 1576 hrs., 1000 Sep. hrs., #552352............ $329,000

JD S790 2022, PRWD, Duals, 230 hrs., 155 Sep. hrs., #563325................ $599,900

JD S790 2022, PRWD, Duals, 333 hrs., 239 Sep. hrs., #566637................ $589,900

JD S790 2022, PRWD, Tracks, 39 hrs., 21 Sep. hrs., #553771 ................... $695,000

JD S790 2021, PRWD, Tracks,

1/2” thick x 16” wide

12’ long $35 • 16’ long $47

White Corrugated PVC liner panels 40” wide x 16’4” long $1950

White smooth PVC sheeting

4’ x 8’ x 1/2” thick $5750

FACTORY SECONDS. QUANTITY DISCOUNTS. DELIVERY AVAILABLE

Chippewa Valley Dairy Supply

6053 CTY. HWY. G • STANLEY, WI 54768 • Andrew Zimmerman

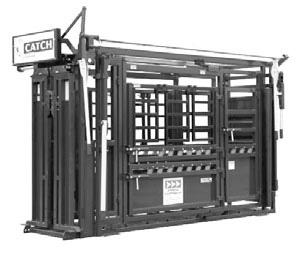

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA

712-476-9290

United Dairy Systems, Inc.

West Union, IA

563-422-5355

Monticello, IA

319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI

715-772-3201

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029

Pierz, MN

320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN

218-632-5416

By Alex Middendorf Staff Intern

By Alex Middendorf Staff Intern

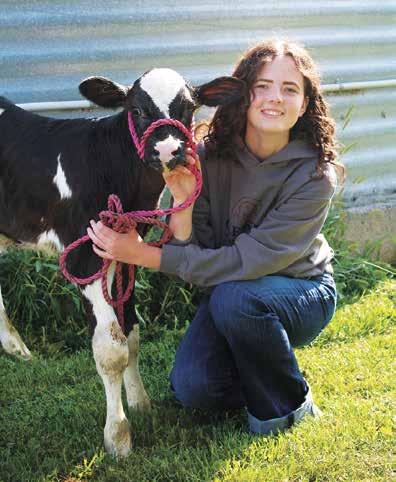

WAVERLY, Minn. – After graduating from high school and choosing to attend the University of Minnesota-Crookston, Katherine Hills realized she was leaving the world of dairy she had grown up in around her home near Monticello.

“I don’t tend to see a lot of dairies in the Crookston area,” Hills said. “There are more beef and horses up there.”

Hills said she wants to bring dairy awareness to her college area, which she is able to do as a 2023 Princess Kay of the Milky Way nalist.

“Everyone is affected by dairy,” Hills said. “I want to share that with as many people as possible.”

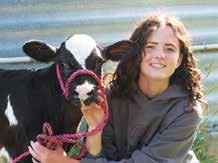

Hills is the daughter of Nicole Hills. She grew up visiting and assisting at Glessing Family Farm, operated by her grandparents, aunt and uncle. The family milks around 80 cows near Waverly. When at the farm, Hills’ responsibilities include feeding the calves and heifers and feeding and water-

ing the herd of milking goats.

At UMN-Crookston, Hills is entering her junior year, where she is studying animal and equine science with a preveterinary emphasis. She plans to stay in the agriculture eld after graduating.

Like many others in agriculture, Hills found her passion for the industry when joining her local 4-H chapter at the age of 13.

“Before that, I had enjoyed riding on the (utility vehicle) with Grandma and playing with the cats,” Hills said. “Once I joined 4-H and began to participate in the lease program, I started to become more hands on with dairy, and I found I really enjoyed it.”

Hills showed rabbits and dairy goats through 4-H and became involved in the industry in new ways as she grew older.

“Dairy started to pull me more and more,” Hills said. “I joined dairy project bowl, then became a dairy ambassador and nally, a dairy princess.”

Hills carried that love of dairy with her to college and has been a dairy advocate ever since.

“I go to school at a college that doesn’t have an established dairy program,” Hills said.

am grateful to have

found people who are also passionate about dairy the way that I am.”

Hills is also an ofcer of the dairy club on the Crookston campus and uses this as an opportunity to spread dairy awareness around campus.

“I encourage people to choose any kind of dairy that ts their diet and nancial means,” Hills said. “Anyone can enjoy dairy. Even if they are lactose intolerant, there is lactose-free milk. There are many different ways to t dairy into your diet.”

When her love of dairy led her to the judging for Princess Kay of the Milky Way, Hills prepared as best she could and went into judging with the mindset that the competition would be strong.

“There were a lot of really qualied individuals there,” Hills said. “Any one of them could have been chosen.”

Hills was sitting alongside her mother at home when she found out she was one of the 10 young ladies selected to vie for the title.

“I was shaking,” Hills said. “(Rachel Rynda, the current Princess Kay) mentioned swing dancing, and that’s when I realized that she was talking about me.”

“Somehow, I still managed to nd dairy-loving people up there, and I

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

WATERVILLE, Minn. – As a child, a creative imagination was all it took to transport Emma Kuball, while she played among the tree roots in a ravine creek on her family farm, into make-believe adventures amid mountains and jungles. Or, back in the barnyard, the cotton seed pile provided ber she could pretend to hand weave into thread for cloth for use on the Oregon Trail.

Beyond her imaginary escapades, the real experiences of Friday pizza nights, of debating with siblings while she fed calves and of making a “mean apple pie” from pasture apples, all anchor Kuball’s story in farm and family. Now, that story will be adding some sparkle as she competes for the 70th Princess Kay of the Milky Way.

Kuball is the daughter of Nate and Shannon Kuball. She and her family milk 240 cows on their farm near Waterville.

Kuball is the sixth generation on her family’s farm. Her ancestors immigrated in 1890 from Germany and purchased the farm in the early 1900s. Today, Kuball can regularly be found milking in the double-6 parlor in their over 100-year-old barn.

Besides milking, Kuball also helps clean the barn, feed calves and help with farm upkeep. Her favorite job is cow and calf care.

“Cows don’t only trust us to care for them; they trust us to care for their calves too,” Kuball said. “It’s such an honor and a privilege to be able to do that.”

A key message for Kuball is the care and love farmers have for their animals.

“We are always doing things to make sure that they’re comfortable and that they are living their best life,” Kuball said.

Kuball said she feels it is important to use examples when sharing about animal care.

“If you just tell someone that we care for animals, it’s going to go straight over their heads,” she said.

Though Kuball grew up working

and adventuring on her family’s farm, in high school she came to a turning point. Over time, she had become frustrated with farming life, wishing she could be like her friends whose summers consisted of sleeping in. When a leadership opportunity passed, she realized her life was not going where she wanted it to. Then the coronavirus pandemic hit.

“Everything seemed to kind of fall apart,” Kuball said. “I kind of just sat around and moped every day until I realized one day that that’s not OK. That’s not what I should be doing, so I decided to rediscover my love for the dairy farm.”

Kuball’s rediscovery started with walks on the farm where she began to appreciate what she had taken for granted, and she started to nd her place again.

Today, Kuball said she realizes this love for the dairy industry is one of her strengths.

“It’s easy to love something that’s easy,” she said. “It’s more difcult to love something that’s difcult, and dairy farming is difcult. ... It’s a more powerful story to say, ‘Oh, we just had acres and acres of crops go down in a storm, yet we’re still able to feed our animals because we know that needs to happen.’”

Kuball is not the rst Princess Kay

nalist in her family. Her aunt, Cassie Kuball, was a nalist in 2002. Just two years ago, her older sister, Kelsey, was a nalist. The family plans to do a photo shoot with their three butter sculptures.

As a sophomore studying agriculture education at the University of Wisconsin-River Falls, Kuball said if she is crowned Princess Kay, her biggest priority will be children’s education.

“If we can get (children) dairy knowledge when they’re younger, they might have a positive experience and be like, ‘Oh, I trust that now because

that princess came and talked to me,’” Kuball said.

Kuball said the numerous school and day care visits that Princess Kay makes represent a chance to help con-

rm that she is going in the right direction with her life if she is chosen.

Kuball enjoys working with children whether it is through nannying or on an ofcial visit as the Minnesota FFA president.

“It lls my cup,” she said. “I just am so happy after I’m done with those visits. It gives me hope for the future.”

Kuball served as the Minnesota FFA Association president from April 2022 to April. She said the experience helped her as a nalist by developing her public speaking skills, networking skills and even media skills through an interview thanks to an FFA connection.

Kuball has experience being both a leader and a follower. She said she remembers being between two siblings who were both trying to lead as they worked together on the farm. Because of that experience, she wants others to know that people can be leaders even if that has not always been their experience.

“Just because you’re a follower in one situation doesn’t mean you’re not a leader in another situation,” she said.

Kuball’s investment in the agriculture community is rooted in a grateful spirit.

“It’s such an honor and a privilege to be able to help feed the world,” she said. “There was a quote that said, ‘Even kings are fed from elds.’”

PINE ISLAND, Minn.

– As a nalist for the Princess Kay of the Milk Way, Anne Simpson’s favorite dairy princess moments are tossing out cheese sticks to crowds at local parades.

“I love it when the adults are screaming for cheese,” she said.

Riding in parades might not allow her to talk to consumers as much as other occasions do, but for her, the interactions at these events fuel her.

“To see that excitement for the dairy industry from the public helps light a re in me,” Simpson said. “People do love dairy, and it’s not a dying industry. ... People still enjoy these products, and we need to continue to ght for these products.”

Simpson, who is the daughter of Jeff and Cheryl, grew up helping on the farm of her grandparents, Jim and Lynette Miller. They sold their dairy cows in 2005, but Simpson remained involved in the dairy community by showing dairy cattle, participating in dairy

judging through 4-H and FFA, and competing in dairy bowl for 4-H.

“My willingness and my drive is to still be involved in the dairy industry and nd what’s next even though the opportunities seem to close,” Simpson said.

Simpson is going into her sophomore year at Iowa State University in Ames, Iowa, where she is studying animal science in the pre-veterinary track. This past semester, Simpson worked in dairy research at ISU, and with this experience, she said she wants to share how dairy farmers continuously use science to be sustainable.

“Dairy farmers are always working to be progressive,” Simpson said.

Simpson worked with a nutrition trial surrounding a feed additive for reducing inammation. Her job was to track feed intake.

“There’s always research being done, especially in the dairy industry, to try to improve efciency and use less resources and make healthier cows,” she said. “Having that research background, I can say, ‘Oh, I’ve lived it. I’ve done it. I know this is happening. I’ve seen it.’”

Simpson said an important way dairy princesses impact their local communities is by displaying the strength and resilience of the dairy community.

“The dairy industry still is there, and they’re still going strong, and they’re still ghting,” she said. “One of the biggest impacts on the public is just helping them see that ... in

a real way.”

Simpson, who is lactose intolerant, also hopes to relate her experiences with dairy products to consumers going through similar nutrition challenges and emphasize the many ways to consume dairy products even with lactose intolerance or sensitivity.

“A lot of people switch to

milk alternatives because they are lactose free,” she said. “I can relate with them and (say), ‘Oh look, you could still enjoy dairy like I do.’”

Beyond having a platform to share her experiences, being a Princess Kay nalist gives Simpson a special connection

Katherine Hills stands with her mother, Nicole Hills, July 25 at Glessing Family Farm near Waverly, Minnesota. Glessing Family Farm is owned and operated by Hills’ aunt and uncle.

As a dairy princess for the past few years, Hills has looked to be the go-between for dairy farmers and consumers.

“Dairy princesses are amazing at conveying the message that dairy is nutritious and delicious,” Hills said. “Princesses are able to make important relationships with consumers.”

These relationships are built through connections, and Hills said she enjoys making those connections with the public.

“If consumers can see that they’ve made a real connection with a dairy princess or a dairy farmer, they are more likely to remember that dairy is a good product,” Hills said. “Those connections are really rewarding.”

Con�nued from SIMPSON | Page 26

Hills said she is excited to continue to meet people throughout the rest of her summer as a nalist and as the coronation approaches.

“One of my favorite things about being a dairy princess is being able to meet so many different people from many different walks of life,” Hills said.

Never wanting to take anything for granted, Hills said she is grateful for these opportunities that have been placed in her path.

“Not everyone has the opportunity to be so involved in this wonderful industry in so many different ways,” Hills said. “I just want to take every opportunity I am given when it comes to sharing my dairy story.”

Je

ff, Anne and Cheryl Simpson smile May 17 at Anne’s grandparents’ farm near Pine Island, Minnesota. Simpson’s grandparents sold the dairy herd in 2005, but Anne remained ac�ve in the dairy community by showing cows and par�cipating in dairy programs through 4-H and FFA.

with her mom, Cheryl (Miller) Simpson, who was rst runner up for Princess Kay in 1998. Now, 25 years later, Simpson is excited to have the same opportunity to compete.

Simpson’s mom has her butter sculpture, and they are planning a photo shoot together with their butter twins. After photos are complete, Simpson hopes some of the butter will go toward Thanksgiving dinner and her grandma’s toffee bars.

If Simpson is crowned Princess Kay, she wants to prioritize the perspectives of those she represents.

“I really would like to … hear from farmers,” she said. “What are some issues that you see … or different things that can be highlighted that aren’t highlighted that might be different from what I see as a college student?”

With a welcoming smile, Simpson has already been connecting with consumers all summer long.

“Having that positive, welcoming energy helps people, whether it’s little kids feeling less scared to come up to me or just adults feeling like I’m not judging them for not knowing (about dairy),” Simpson said.

As a dairy princess, Simpson has attended Dairy Night at the Rochester Honkers baseball game, visited the Olmsted County Breakfast on the Farm, ridden in multiple parades, served ice cream, made appearances at the Olmsted County Fair and been interviewed by KTTC News.

Simpson has also been involved in dairy through 4-H and FFA. She has participated in dairy judging where she has qualied for state multiple times and even nished second in the state in 4-H. She also has had the honor of presiding as the Region VIII president for Minnesota FFA.

The dairy industry is not the only agriculture community Simpson is part of. She also owns a meat goat herd. As she looks to the future, she is considering getting a Ph.D. in ruminant nutrition, tying together her love of dairy cows and goats. Her dream is yet one more way Simpson is choosing to stay connected to the dairy community.

“It’s helped me grow, and it’s been such a huge part of who I am,” Simpson said. “That’s why I want to keep involved.”

How did you get into farming? I grew up on a dairy, hog and beef operation. Lisa grew up on a dairy farm that also nished hogs and steers. We met through 4-H in the dairy barn.

What are your thoughts and concerns about the dairy industry for the next year? First and foremost, we need a fair price for what we produce. Longer term, we need the freedom to farm. It shouldn’t matter the size or type of operation we choose for ourselves. There is room for all who want to produce quality food.

What is a recent change you made on your farm and the reason for it? Ours is a simple and basic operation. The biggest change we’ve made was to eliminate the barn cleaner and pour a new walkway to clean the barn with a skid loader.

Tell us about a skill you possess that makes dairy farming easier for you. My passion has always been to breed and develop long-lived, high-type cows. It is more fun to work with good cows and people. We house a couple of cows for a friend. In turn, he can step in and take care of the farm when we need to get away.

What is the best decision you have made on your farm? About 10 years ago, we started working with Priority IAC, a smart bacteria and nutrition company. Their strains of bacteria and nutrition principles are different from most. Healthy cows are easy to work with. Nutrition feeds the microbiology. Microbiology feeds the body.

What are three things on the farm that you cannot live without? The skid loader is my right-hand man. Cordless tools, especially my drill for sampling hay, moving the y tape or putting displays up at a cattle show. The Priority IAC StartUp Gel; it xes the pH and gets animals eating and drinking quickly.

What strategies do you use to withstand the volatile milk prices? We keep a close eye on expenses and try to live within our means. We shop around

Tom and Lisa Hurley of Grand Meadow, Minnesota | Mower County | 24 cows

for our forages. A surplus of bred heifers will have to be sold as the barn only holds so many.

How do you maintain family relationships while also working together? Tom does the milking and day-to-day chores. Lisa takes care of the bookwork and registering cattle.

What do you enjoy most about dairy farming? Watching a new calf develop into an excellent, long-lived cow. But, it’s also the people in the industry –friends you can share the good, bad and ugly with and working with organizations to move the industry forward.

What advice would you give other dairy farmers? Stay true to yourself and farm. Change things when it can make your farm better.