WANT TO WIN $100 CASH?

See page 4 of second section for details!

See page 4 of second section for details!

Volume 25, No. 12

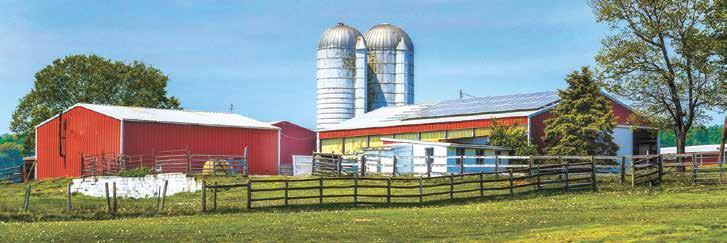

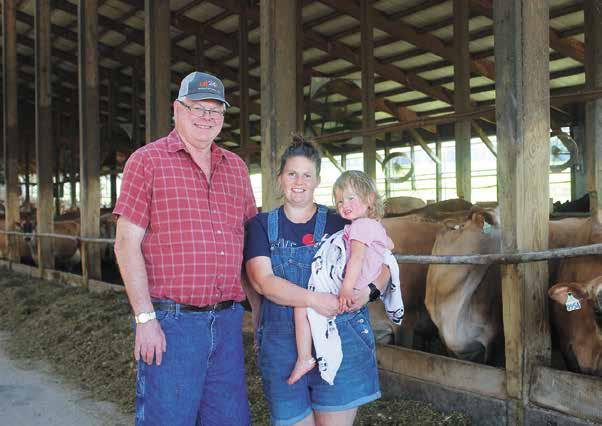

CASHTON, Wis. – Driving through the residential streets of Cashton, people pass houses, children on bikes and perhaps the occasional Amish horse and buggy. Right in the heart of the downtown residential streets, they will also nd a fully operational dairy farm. This is where the Trescher family has farmed since 1909.

“With our location, every single load of forage in and manure out is on a residential street, so it can be a little challenging from time to time,” Steve Trescher said. “But, I grew up here, my dad grew up here, and I guess we’re getting by.”

Steve and his wife, Annette, have been married for 36 years

and have continued the Trescher family’s legacy of farming in town.

The Trescher family’s farm was a tour stop June 23 for attendees of the National Jersey Convention.

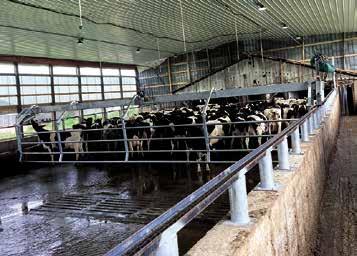

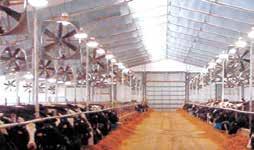

The Treschers milk 70 cows in a 50-stall tiestall barn. The tiestall is bedded with sand and

holds mostly Jersey and JerseyHolstein crossbred cows, while a freestall barn houses the Holsteins. The herd is intermingled during milking time when they switch groups. Their son Derek

helps with feeding and hauling manure every day.

Running a dairy farm in the residential area of town has presented challenges. The Treschers said they do their best

to be as neighborly as possible by not doing eldwork after 10 p.m., keeping baleage plastic

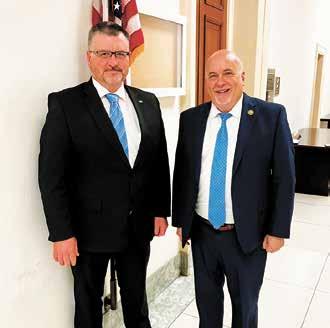

BERLIN, Wis. – As both a dairy farmer and president of Wisconsin Farm Bureau Federation, Kevin Krentz is in a unique position to ensure the voice of dairy farmers is heard not only at the state level but also at the national level.

“This is the biggest voice the Farm Bureau has had in dairy in a long time,” Krentz said. “We are a major part of the discussions on the Federal Milk Marketing Order process as well as the farm bill. It’s good for farmers to have that extra voice.”

Krentz

ly, and their business partner, Cory Biely, milk 600 cows and farm 1,400 acres near Berlin. Krentz is in his third year serving as president of WFBF and has made two trips to Washington, D.C., this year with a third trip planned for the fall. During each visit, Krentz spends time with lawmakers and has found them to be receptive to his and other farmers’ ideas.

“They want to hear from us and know what our priorities are,” Krentz said. “That’s one thing that’s always impressed me since I became a Farm Bureau member is the respect and willingness of our elected ofcials to want to sit down and listen – not only from Madison but also D.C.”

In June, a Farm Bureau leadership group that Krentz is part of met with congresspeople and full groups of constituents and senators to discuss farm bill priorities. During the

week of July 10, those conversations continued when Krentz was in Washington to attend American Farm Bureau Federation meetings and talk with lawmakers about FMMO pricing reform.

“We need a pricing system that works for dairy farmers,” Krentz said. “We also need to continue to better our tools available to protect ourselves in the dairy industry whether that be Dairy Margin Coverage or Dairy Revenue Protection programs to provide that safety net. We need to continue to solidify those programs.”

Krentz met with the staff of Sen. John Boozman, RArk., ranking member of the Senate agriculture committee; the staff of Sen. Debbie Stabenow, D-Mich., chairwoman of the Senate agriculture commit-

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

The U.S. Department of Agriculture has scheduled a national hearing to review Federal Milk Marketing Orders for Aug. 23 near Indianapolis, Indiana. Thirty proposals were submitted, and 21 are in the scope of the hearing. Associated Milk Producers Inc. Chair Steve Schlangen said the numbers used in many of these proposals are still outdated. “They’re not anywhere close to where they should be as far as what it really costs to make milk into cheese and whey,” Schlangen said.

“With the numbers we’re using right now to create a Class III price, the costs are from 2005. … Labor was $10 an hour then.” Schlangen also wants the farm bill to include mandatory reporting of production costs in the dairy plants and surveying every two years “so that this thing doesn’t get way out of line like it has been.”

The 2018 farm bill changed the way farmers are paid for Class I uid milk, and the decision was made without a hearing, comment period or producer referendum. The Class I price now uses an average price, rather than the “higher of” pricing method. “We hope Congress is ready to make a simple four-word change in the dairy title of the 2023 farm bill,” said Laurie Fischer, CEO, American Dairy Coalition. “If the ‘higher of’ method was still in place, the August Class I mover would have been $18.29 (per hundredweight), not $16.62.” ADC reports the net loss realized by dairy farmers since the average method was implemented has now topped $1 billion.

“Go back to the ‘higher of’ (pricing method) by the fastest means possible,” Fischer said.

Dairy Business Innovation Act introduced

Wisconsin Congressman Derrick Van Orden has introduced the Dairy Business Innovation Act, which would allocate an additional $16 million per year to USDA to support dairy businesses. This program provides technical assistance to dairy businesses through research institutions or industry exports. Van Orden said the bill “will ensure Wisconsin dairy farmers’ continued ability to feed the world.” Wisconsin Sen. Tammy Baldwin introduced the companion bill in the upper chamber.

Interest rates rise

Don WickThe Federal Reserve bumped interest rates by a quarter percentage point to a range of 5.25% to 5.5%. Interest rates are now at a 22-year high. Fed Chair Jerome Powell would not rule out another rate hike at the central bank’s September meeting.

Impact still to be seen

Virginia Tech Professor Emeritus Dr. David Kohl spoke at the Bell Bank AgViews Live Conference in Fargo, North Dakota; Sioux Falls, South Dakota; and Wisconsin Dells, Wisconsin. “Navigating these interest rates

Con nued from AG INSIDER | Page 2 is going to be very critical for the next two or three years; these are the fastest rising interest rates since the 1980s,” Kohl said. “We haven’t felt the impact because oftentimes we haven’t paid down on the operating loans.” Kohl said ination, economic growth and unemployment are all factors that must be considered before interest rates can decline.

Milk production edges higher

Milk production in the 24 major dairy states totaled 18.1 billion pounds in June, up 0.2% from one year ago. Wisconsin milk output was up 1% with cow numbers down 2,000 head.

Too many cows in the system, an oversupply of milk and milk dumping have all been market factors this summer. Total Farm Marketing senior marketing advisor Bryan Doherty said the milk price has improved. “When the market turns, the market will often nd that sellers have got their solid position or shorts, and you have speculators already jumping on the long side,” he said. That brings additional volatility to the marketplace. Doherty said this is a time for dairy farmers to start hedging, “but, do it lightly (and) let the trend be your friend right now.”

Disaster declaration praised Wisconsin Gov. Tony Evers has praised Agriculture Secretary Tom Vilsack for issuing a disaster declaration for 27 Wisconsin counties due to drought. “We’re continuing to do everything we can to support farmers and their families, and we appreciate the help from our federal partners and USDA Secretary Vilsack to support our state’s farmers,” Evers said. This designation allows the Farm Service Agency to extend emergency credit to farmers recovering from a national disaster.

Strike at De Pere plant

Members of Teamsters Local 662 are on strike at New Dairy Select Milk in De Pere, Wisconsin. New Dairy Select Milk is a subsidiary of Borden Dairy and was formerly known as

Morning Glory. The striking workers are seeking a better healthcare plan. This facility produces sour cream for well-known brands, including Taco Bell and Wendy’s.

A new option for haymakers

New Holland Agriculture North America has a new header for its Speedrower PLUS Series self-propelled windrowers. The new Durabine 413 PLUS disc header features a cut width of 13 feet. This gives haymakers an additional size to choose from in its Durabine Plus Series.

Edge Co-op lls board vacancy

Brady Janzen, who is a partner with Riverview Dairy at Morris, Minnesota, will serve an interim term on the Edge Dairy Farmer Cooperative board. Janzen lls a vacancy left by Mitch Davis, who sold his Minnesota-based dairy farms and transitioned to an advisory role. Edge is based in Green Bay, Wisconsin, and serves dairy farmers in Illinois, Iowa, Kansas, Minnesota, Nebraska, Ohio, South Dakota and Wisconsin.

Hromyak appointed Farm Bureau Foundation executive director

The Wisconsin Farm Bureau has named John Hromyak as its foundation director. Most recently, Hromyak was the director of the Agrace Hospice Care Foundation. Previously, Hromyak was the executive director of the Wisconsin FFA Foundation.

Trivia challenge

National Ice Cream Day is celebrated on the third Sunday of July. That answers our last trivia question. For this week’s trivia, how many gallons of milk does the average American consume per year? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

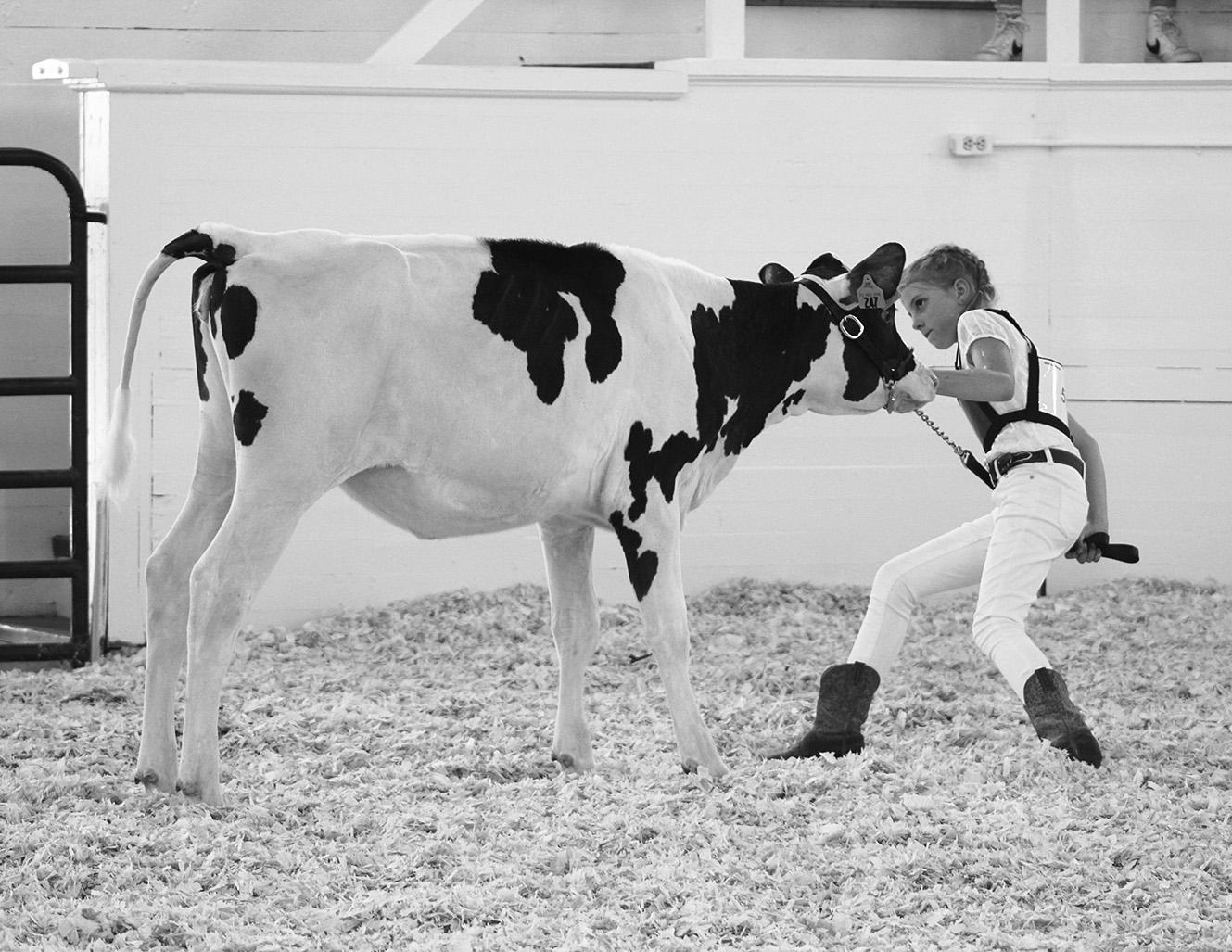

Anne e Trescher visits a calf June 23 on her farm in Cashton, Wisconsin. Anne e and her husband, Steve, have been farming together for 36 years.

contained and keeping the roads clean. They achieve this by having blacktop driveways so the mess cleans off on their property instead of on the residential roads.

Steve and Annette said there are benets to living in town such as the cows being on village water and the milkhouse operating on village sewer. There is also village electric service to the farm, eliminating the need for a backup generator.

They also realized that they had fewer solicitors because salesmen never thought to look for a farm down a residential street. Annette said nobody ever found them until they hosted a dairy breakfast in 1998.

When Steve’s dad was operating the farm, they had 12 cows and sold all of the milk out of the basement to the people in town until 1969 when pasteurization was made mandatory.

“You wouldn’t believe how many people tell me they remember buying milk from my dad,” Steve said. “Everybody in town got milk here. Things have denitely changed.”

While their children were growing up, Steve said it was normal for the town kids to ride their bikes right through the barn during milking while making their way around town with friends.

“When the kids got older, town kids were here and they had opportunities that other town kids wouldn’t have,” Steve said. “And, my kids had opportunities that other country kids wouldn’t have.”

The Treschers were originally an exclusively Holstein herd, but when Annette joined the operation, she brought her beloved Jerseys with her. She traded her beef cows for ve Jersey heifers, which she brought to the Trescher farm. Everyone had to learn how to manage Holsteins and Jerseys side by side.

“It was an adjustment for me,” Annette said. “Everyone has had a little bit of a learning curve over the years as to how to manage them.”

When she moved her rst group of heifers to the farm, Annette’s dad had told her to wait to breed the Jerseys so they would be big enough to compete with the Holsteins. The Treschers found out that they did not have to worry about the Jerseys competing. In fact, Annette said the Jerseys tend to boss the Holsteins around.

One challenge they have faced has been feeding the two breeds. The cows are fed a total mixed ration, but with them both being milked in the same stanchion barn, feed cannot be separated between the Jerseys and Holsteins. Annette said she thinks the Jerseys could produce a higher fat content if they were fed a separate ration. Even with the current feed, however, the Jerseys ranked seventh in the U.S. in mature equivalent milk production among other registered Jersey herds of a similar size.

“I’m pretty proud of how hard they work,” Annette said. “But, I could challenge them if I had a different facility.”

Feed is grown on the 300 acres the family farms. The land is a combination of the Trescher home farm and Steve’s mother’s home farm. They grow corn and alfalfa for feed.

“We have just as much land here as we would in the country,” Steve said.

The Treschers said they also have good neighbors.

“Thirty-six years ago, every single neighbor was a retired farmer,” Annette said. “That is no longer the case. We are lucky that we have very understanding neighbors now.”

tee; and the staff of U.S. Rep. Glenn “GT” Thompson, R-Pa., chairman of the House agriculture committee.

“Congressman Derrick Van Orden was at the reception I attended for Sen. Thompson, and although I didn’t get a chance to speak with him that night, I want to thank him for all the work he’s done for agriculture in Wisconsin,” Krentz said.

In May, the National Milk Producers Federation put in a petition to the U.S. Department of Agriculture to hold a hearing on FMMOs to make changes that can ultimately provide farmers with a more consistent paycheck. The AFBF came out in support of that petition. After 30 days, USDA did not fully accept NMPF’s proposal but did ask other groups to submit proposals.

On June 16, a prehearing webinar took place in which 12 organizations submitted approximately 38 proposals for changes in FMMOs. AFBF was one of those groups, Krentz said. In July, the USDA voted to move forward with the hearing process, which is set to begin Aug. 23 in Carmel, Indiana.

Krentz said a number of proposals have been submitted to increase the make allowance, which he said will be a major part of the scope moving forward.

“We need some offset for make allowance increase, moving back to higher of with Class I mover versus average of,” Krentz said. “This will help put money back into the order.”

But in order to support a make allowance, Krentz said he wants a clear picture of what the make is.

“I would like to see a regular mandatory survey of that make,” he said. “Only 30% of the milk plants participated in the last survey. That’s not giving us a clear picture. Understanding the make and what it should be to produce an adequate or fair make allowance is important.”

The last time yields were adjusted was almost 15 years ago, Krentz said. Therefore, yield factors may need to be adjusted.

Krentz would also like to disincentivize depooling.

“Negative producer price differentials have hurt farms a lot in a number of areas in Wisconsin over the past few years,” Krentz said. “We really need to look at PPDs and keeping them as positive as possible or better than that. That way, farms can manage by understanding what their premiums are moving forward

over for that class price. That has to be a major part of this reform.”

Krentz said farms with Dairy Revenue Protection in place based on Class III and Class IV prices are not covered under DRP when PPDs go negative.

“That is a major challenge we have had,” Krentz said. “Farmers can put tools in place to protect themselves, but if tools work against them or if the pricing system works against those tools, it’s not good for anybody.”

Getting as much product as possible priced into the market is another area to look at, according to Krentz.

“This will help ensure we’re getting a fair price on the milk check and getting paid to what we should be getting paid,” Krentz said. “We also have to look at individual orders. There is huge diversity within our orders around the country.”

Krentz wants to ensure that an order cannot be eliminated. Currently, if an order has a change, it can be brought forward, but if it reaches a vote and producers vote it down, that order is eliminated.

“We need a process to bring potential changes forward without the threat of losing the order,” he said. “This would give us exibility within different orders.”

The current farm bill expires at the end of September, and legislative portions of the FMMO pricing reforms will likely be attached to the new farm bill, Krentz said.

“We need to keep pushing to get the farm bill done ASAP so we can continue to support agriculture,” he said.

The Farm Bureau is hoping the next farm bill will continue to build on conservation and offer more in the way of risk management.

“Bolstering the Dairy Margin Coverage program is extremely important,” Krentz said. “We would also like to expand the list of specialty crops covered under crop insurance.”

Krentz said the timing of their June visit was interesting because it fell during the week Congress was asked to submit priorities for the farm bill.

“It was a perfect time to be having some of those discussions and letting them hear the priorities of Wisconsin when submitting their priorities,” Krentz said.

Another group of young farmers is going to

Washington in September, Krentz said, which hits at the right time once again.

“Lawmakers will be getting close to end discussions on the farm bill, and our farmers could have a major impact in those discussions,” Krentz said. “There is nothing more impactful than getting members in front of legislators.”

Krentz expects the FMMMO hearing process to take approximately 12 to 18 months. Depending on the scope and changes desired, implementation may take some time as well, Krentz said.

“We as farmers have a strong voice within our FMMOs and need to continue to use that voice whether verbally at a hearing or through the voting process when the hearing process continues,” Krentz said. “It is extremely important for our farmers to be part of that voting process.”

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

When Wisconsin author Michael Perry sent his latest book, “Forty Acres Deep,” to publishers in New York, they had no interest in printing the piece. Written about a middleaged farmer who is struggling to save his pole sheds from collapsing under the endlessly falling snow, the book describes a lonely, desperate man at the end of his rope. As the main character reects on the state of his farm after selling his dairy cows, giving up on beef farming and nally letting his elds go fallow, he obsesses over saving the pole sheds while battling a mental struggle concerning the value of his own life.

While the publishing company did not think there was an audience for such a plot, Perry knew there was a need for farmers in the Midwest to be represented. After consulting with his farming friends, he self-published the novel, and people across the Midwest are identifying with the story.

Farmers and readers came together July 18 to discuss the book and the current issues facing Wisconsin farmers, with the author present. Joy Kirkpatrick, from the University of Wisconsin Extension, moderated a farmer panel discussion at the Octagon Barn in Spring Green that included local farmers Dorothy Harms, Robert Nigh and David Unbehaun.

The event was funded by the U.S. Department of Agriculture as part of its National Institute of Food and Agriculture’s Farm and Ranch Stress Assistance Network.

Harms said there were scenes in the book that truly resonated with her.

“It was really important to get an accurate reection of what farmers face when they are trying to get through each day and how they identify with those struggles,” Harms said.

“(Perry) did a great job when he talked about the core of how farmers think; the work just has to be done.”

Nigh said the consolida-

tion of the dairy industry creates a loss of connections within communities, which was shown in the book as well.

Nigh said he has found that making an intentional effort to reach out to fellow farmers and neighbors with a phone call or text message just to check in has helped him to retain a sense of community.

“It’s important to reach out and have a condante that you can talk to,” Nigh said. “I feel better after I’ve done that, and I’m sure that I did more for myself than I’ve done for them.”

Other challenges that were discussed were labor shortages, market prices, the lack of milk market opportunities available, transfer of farmland and government regulations.

In terms of federal, state or local policy, the panel had ideas about what changes could be made to increase mental wellness in the rural areas. Harms said more funding for crisis worker training for suicide prevention should be zeroed in on. Instead of being treated like a criminal when a family member calls emergency services, she hopes there could be a more effective resource available through law enforcement

and medical professionals.

Unbehaun said people doing business with farmers should engage in some sort of training to help be a resource for their customers.

“A lot of the contact that farmers make is with people they do business with,” Unbehaun said. “Maybe we’re asking too much of these individuals, but they may be able to identify if somebody might be having an issue or if something is developing or changing in their attitude.”

There are programs that help promote and train activelistening skills, being able to ask the questions to get people who may be in crisis to a safe place. A recently launched resource is a national suicide hotline, accessible by dialing 988, that has received 995,000 calls from Wisconsin alone since its launch last year. The hotline is available to anyone struggling with mental wellness; they do not have to be in crisis to be able to utilize the resource.

Other resources mentioned were the Wisconsin Farm Center, Farmer Angel Network and Farm Well Wisconsin.

Nigh acknowledged the changing landscape of modern agriculture with a nod to the younger generations attempting to make a living from farming.

“The new generation is working even harder because they have jobs in town for one spouse or maybe both,” Nigh said. “There’s a lot more information out there, and you need to be able to digest that because just working hard doesn’t get you where you need to be. This book really does epitomize struggles, but there’s a lot more.”

With the struggles facing farmers today, the panel was eager to point out opportunities in agriculture that were not always popular. Harms’ family converted their dairy operation into an agritourism venue, which allowed them to transition to the fth generation on their farm.

The possibility of more farmers moving to regenerative agriculture was brought up as well. The lifestyle seems to be more exible in allowing time for the pursuit of off-farm income as well as down time, Nigh said.

The conversation circled back to the rural community again and again.

“We’re a unique set in our economy,” Nigh said. “We need to focus on rural issues and small towns because a vital part of our economy is being challenged – the core of our lifestyle, our small towns, our churches and our schools.”

ITHACA, N.Y. – After a year of dismal milk prices for dairy farmers, hopes turn to rumors that the trend might be about to change.

With prices wallowing in low numbers in July –Class III milk at $13.77 per hundredweight, a drop of $1.14 from June – better days cannot come soon enough. Yet, with so many factors being at play when it comes to prices and predicting those prices, farmers must make daily decisions while standing on shaky ground.

Christopher Wolf, a professor of agricultural economics at Cornell University in Ithaca, has been watching the ever-dropping markets. He said those complex factors make market predictions more challenging today.

“With 18% or so of milk equivalents being exported, the marginal unit of milk is priced by international markets,” Wolf said. “The result is that the products which the U.S. exports – especially powders – have prices highly correlated with world prices. Additionally, corn and soybean markets are very international (and) directly impact the cost of producing milk.”

At the global level, many more variables are added to the prediction puzzle.

“The result is that international weather and, particularly, economic or military conicts can directly affect the farm milk price in the U.S.,” Wolf said. “Weather adds a great deal of uncertainty with, for example, the large effects of the Pacic currents changing from La Nina to El Nino. The Russian invasion of Ukraine has impacted feed and energy prices, etc.”

Both at home and abroad, fears of recession have hurt milk pricing, especially for Class III milk, over the past year, along with other contributors. Plus, many factors are interdependent in intricate ways

“Cheese prices drive other prices as it is the largest use of milk,” Wolf said. “The most recent Cold Storage report put total natural cheese stocks at slightly more than 1.5 billion pounds, up a bit from the previous year. Of course, the important value is stocks-to-use rather than the stock value in isolation. Commercial disappearance depends on domestic and international consumption. The fear of a potential recession – which looks increasingly unlikely but you never know – dampens the forecasts for consumption.”

The coming months are predicted to be better for prices, Wolf said, but possible variables are ever-present.

“Margins are really low at the current time,” Wolf said. “Dairy Margin Coverage (is at) $3.65 per cwt for June and in the same neighborhood for July. This is not sustainable, and the markets expect adjustments (by) culling cows and other ways of cutting back production. The milk and feed markets are currently predicting a recovery in margins by November to closer to longrun averages ¬– not great but much better than today. This will depend on feed prices and weather, along with many other factors.”

If prices do improve as predicted, the roller coaster of milk pricing does not bring a sense of security even in better market times. However, Wolf said, stability is not always a good thing.

“There are many dimensions of farm milk price,” Wolf said. “It is not necessarily better to have no variation in milk price. Consider periods where the price was very low but stable.”

Predictability, Wolf said, is more important than stability for dairy farmers.

“We expect seasonal variation and can manage through it if it behaves predictably,” Wolf said. “However, I would argue that what farmers really need are adequate prices. If prices received are adequate, then the rest takes care of itself. The U.S. dairy industry has done a better job in recent years of looking for innovation in product form and place, and that will continue to be important to growing markets both domestically and abroad.”

Wolf also sees a role government can play.

“As an economist, I want to see the government intervening where there are potential market failures –information problems, market power discrepancies, etc. The DMC and Dairy Revenue Protection are valuable risk management programs. Federal Milk Marketing Orders modernization is a good idea to keep the underlying structure viable.”

563-568-4526

AfterHours:

‘20 Anderson Hybrid X, Custom Operator Pkg

Tubeline TL5500 Inline Wrapper

Hesston 565A Round Baler

Hesston 3986 14 Wheel Rake

Hesston 12 wheel Bifold Rake

‘20 MF 3983 Hicap Rake, 12 wheel

Miller Pro 7914 Merger, 14’

H&S 12 wheel rake

‘21 Rhino 3150 15’ batwing

MF TD1620, 2 rotor tedder

‘22 MF 1393 13’ center pivot disc

mower cond.

‘17 JD 835 9’ MoCo, center pivot

JD 946, hyd. swing, rubber rolls

‘14 CIH DC112 Disc Mowland

Gehl 2450, 15’ hydro swing disc mower

Haybuster 2650 Bale Grinder

‘14 NDE 2906 Twin Screw TMR

JD MX7 3PT Brush Mower

(2) ‘21 Rhino 3150-15’ Batwing mowers

JD 146 Loader w/bucket

Gehl 100 Feed Mill

‘94 MF8570 combine, 2500 hrs.

‘21 Bobcat S76, CAH, SJC, 3,400 hrs.

‘21 Bobcat S76, CAH, SJC, 1,800 hrs.

‘21 Bobcat T66, CAH, 700 hrs.

‘21 Bobcat T870, SJC, high flow, 500 hrs.

‘20 Bobcat T770, CAH, high flow, SJC, 765 hrs.

‘21 Bobcat T770, 407 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘14 Bobcat S770, 3,200 hrs.

‘15 Bobcat T750, A71, joystick, 3,400 hrs.

‘14 Bobcat S750, A71, ACS, 4,100 hrs.

‘18 Bobcat S650, SJC, 9,000 hrs.

‘19 Bobcat S570, CAH,

FARLEY, Iowa – What do an auto repair shop, a baseball training facility and an ice cream shop have in common? In Farley, they all come with the name Delaney.

Delaney’s Ice Cream Shoppe was born of the business transformation brothers Matt and Jason Delaney began three years ago. Delaney’s Auto and Ag Center and Repair rst existed in Cascade then expanded to Farley where Matt began offering ice cream in the waiting area.

“I was looking for something unique to separate us from the competition,” Matt Delaney said. “(Ice cream) was the extra cherry on top.”

For the rst year, ice cream co-existed with the original business, but by the second summer, the Delaneys bought the attached hardware store. After remodeling, Delaney opened a separate ice cream business while his brother created Between the Laces, a baseball and softball practice business.

cream, and they have great names.”

All told, Delaney has accessed 65-75 of the company’s 100-plus avors at one time or another.

“That’s why we sell so many,” he said. “We market for the 30% of customers who come in and want something new. That’s what separates us from all the other ice cream stores.”

In addition to the agship store in Farley, ice cream is beginning to be offered at the Cascade location of Delaney’s Auto and Ag Center and Repair. In the future, ice cream offerings could be expanded there.

There is also an ice cream trailer, which Delaney calls a mobile barn, which offers ice cream and snow cones. It goes to Dyersville’s Field of Dreams nearly every weekend and to the Eagles Club on Fridays. Community events and ball games are also on the schedule.

Delaney gives 10% of proceeds to schools when the trailer is used at school events and runs a reward program with schools at the shop. He also has a relationship with the county dairy promotion association for which Delaney’s Ice Cream Shoppe won the Golden Butter Knife award this year.

Like any business, running an ice cream shop is not without challenges.

‘17 Cat 272D2XPS, 1,700 hrs.

‘20 Bobcat V923 Telehandler, 1,100 hrs.

‘19 Bobcat 5600 Toolcat, high flow, loaded, 360 hrs!

‘18 Bobcat 5600 Tool Cat, high flow, loaded, 452 hrs!

“It’s his dream, my dream and what we do for a living,” Delaney said. “It was a great decision. Ice cream is like coffee: It doesn’t matter what you have for money; you treat yourself.”

Today, Delaney’s Ice Cream Shoppe goes through an average of about 90 3-gallon containers of ice cream each week, sometimes needing as much as 120 containers.

The store regularly offers 46 avors of Chocolate Shoppe Ice Cream, made in Madison, Wisconsin. Delaney credits the ice cream brand for much of the store’s success.

“We did a lot of research for a year and a half,” Delaney said. “Hands down, this was the best ice

“Help is the biggest thing, that and watching your spending,” said Delaney, who said he probably focuses about 60% of his time on the ice cream business. “The automotive business is still my bread and butter.”

Delaney has found good help from young people who were raised on farms.

“Your farm kids are the ones who know how to work,” he said. “Their parents make their kids work. I can’t focus all my time here, so we need people with initiative who are problem solvers, and those kids come from that background.”

Delaney said Delaney’s Ice Cream Shoppe is managed like a family.

A mobile unit ou i ed to resemble a barn is parked June 27 and is part of Ma Delaney’s ice cream business in Farley, Iowa. The trailer goes to community events and helps organiza ons raise funds by selling ice cream and snow cones.

“We try to have a lot of fun, but we have to work at the same time,” he said. Delaney’s eventual goal is to have one year-round ice cream store and two seasonal ones along with two more mobile units.

With a wife and two children who also need his attention, Delaney is

working to balance his time. Meanwhile, he remembers the words of an aunt who often said, “There’s always room for ice cream.”

That is good because ice cream shop owners get to take home the leftovers.

We usually do the standard tests. We’ve also used the pregnancy test.

Which is your favorite and why? I really like the production and the breeding records.

How does testing with DHIA bene t your dairy operation? It helps us manage our dairy more ef ciently. If I have a high somatic cell count cow, it costs me money to have her in the herd. DHIA provides me with the information that helps me make decisions on my herd’s performance.

Tell us about your farm. I farm here with my brother, David. We are the third generation of Names to farm here. We milk our cows in a double 8 herringbone parlor. The cows are outside on pasture or bedding pack 365 days a year. We farm 750 acres of corn, soybeans and alfalfa.

Sauk Centre, MN Buffalo, MN 763.682.1091

PLATTEVILLE, Wis.

– Plans are underway for a new Dairy Pilot Plant and Training Center to be built at University of WisconsinPlatteville’s Pioneer Farm.

Progress on the project has been given a boost thanks to a $1 million donation from Compeer Financial. The donation is the biggest gift Compeer has ever given one individual entity for a project. UW-Platteville’s professor of dairy and animal science Tera Montgomery said the university has a long-standing relationship with Compeer.

“The school of agriculture has worked with Compeer Financial for a very long time, so we knew they were going to be a good partner of the Dairy Pilot Plant and Training Center,” Montgomery said. “In our conversations, they said they felt like it hit all the different points of what was important to them

eville,

to cost a total of $10 million

in terms of rural vitality and helping farmers and others in agriculture.”

Plans for the pilot plant are about 80% complete. Montgomery anticipates the nished project to cost approximately $10 million. Funding is being pursued through gifts and grants, which allows the project to move more quickly and give the donors a say in the deci-

sions if they so choose.

Because of the nature of the funding process, a timeline is difcult to form.

“I would love to say in two years during June Dairy Month we will have a grand opening, but I can’t say that,” Montgomery said. “I can’t really see it happening any faster than that just because of some of the tasks that need to be accomplished.”

When the funding goal is eventually reached, the Dairy Pilot Plant and Training Center will be built at the university’s school farm where the 200-head of dairy cattle are milked with a parlor and two robots. The goal is to provide education, outreach, research and training for students, producers and consumers.

The building will feature a production oor with ob-

servation windows, packaging capabilities and a store front. The area will serve as a host for any equipment that is brought in to experiment with. The entire design is plug and play with drop down electrical from the ceiling. Montgomery said it will provide proof of concept for a place where innovative dairy products can be made.

The store will sell ice cream from the university’s student-led ice cream business, Pioneer Sweets. It will also offer local products and provide an observing opportunity for people in the store to see and hear what is happening on the production oor.

Montgomery hopes local farmers and consumers will feel a positive impact from the Dairy Pilot Plant and Training Center.

“It’s meant to inspire people and get them to think of what they could potentially do on their own farms,” Montgomery said. “We can show people what is really possible with farm to fork.”

The university plans to hire an agricultural business faculty member who can help analyze data for people who

Con nued from UW-PLATTEVILLE | Page 12 are using the pilot plant and guring out how to launch their ideas.

The benets will extend to university students as well, with the opportunity to research and train close to campus. Ultimately, the Dairy Pilot Plant and Training Center will allow the current trajectory of the research center to continue with its momentum. Some projects that have been funded through the Dairy Innovation Hub, for example, could be expanded with the new facility.

One of the current research projects in the dairy food science area at UWPlatteville involves a new technology developing plasma-activated water. Plasma-activated water is antimicrobial in nature and could be used to eliminate bacteria where it is not wanted such as while cleaning surfaces or growing plants like alfalfa.

together, the cost of travel and accommodations are more expensive than in the rural setting of Platteville.

“There’s a lot of training that happens across the state that can now have another place where we can meet and get some perspectives on how to do things differently,” Montgomery said. “We can’t and won’t replace UW-Madison’s Center for Dairy Research, but we can be an extension of what they are accomplishing there.”

Montgomery said she would like to see this project go so well that it can be duplicated elsewhere in the state. Her hope is that the investment in the dairy industry will continue to be a priority across Wisconsin.

Logistics play a role in the planning of the new facility as well. Montgomery said while UW-Madison is a well-known place to bring scientists

“The more we know, the better resource we can be for future students, for current farmers and for alumni and everyone,” Montgomery said. “It’s a process, but that’s the awesome thing about Compeer stepping up and saying they want to help us get there faster.”

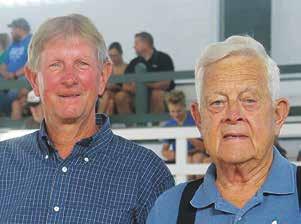

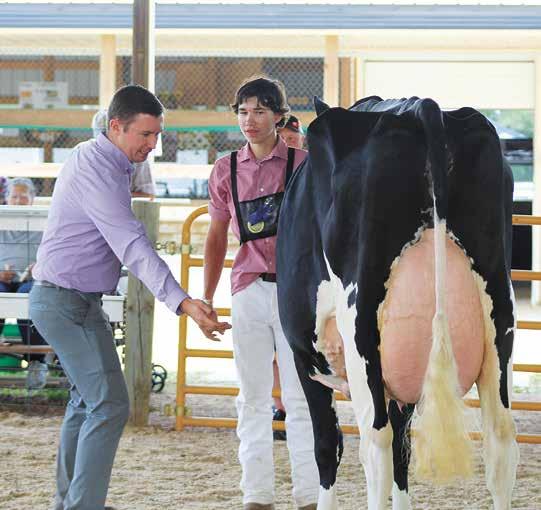

John Slipek (left) and Gary Beastrom Abbotsford, Wisconsin and Athens, Wisconsin Marathon County

John Slipek (left) and Gary Beastrom Abbotsford, Wisconsin and Athens, Wisconsin Marathon County

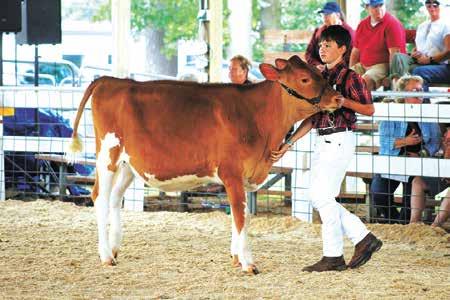

What are your main responsibilities as coordinators of the dairy show at your county fair? We take care of organizing all the entries and paperwork for the Wisconsin Valley Fair. We also line up all of the sponsors. At the fair, we check everything in and clean up the paperwork. Then, we oversee the show to make sure it runs smoothly. We ensure there are no issues and record the placings. We also oversee our heifer program, selecting youth who apply for the program, working to nd them calves and sponsors, and making sure the projects go well throughout the year. There is a lot of paperwork and organizing with that project.

What do you enjoy about this role?Slipek: I enjoy it because I grew up with it, and I like being involved. I have been doing this for 49 years. It really t in well with my role as an agriculture teacher, and it was something I wanted to continue doing, even after retiring from teaching. It really is my niche. I love being around the animals, the show and the kids. I have worked with multiple generations of many of these families that exhibit at the fair. Beastrom: It keeps me in touch with the students and the kids. I started as a superintendent 17 years ago, after I retired from teaching agriculture in Athens. I really enjoy working with the students involved in the heifer program. We work with them in the fall when they submit their applications, nd calves and sponsors for them, and then check in with them to make sure things are going well. I also serve as the superintendent of the plant and soil sciences department.

What is the most challenging part of this position? Getting all of the paperwork organized and ready for show morning is the most challenging part. We have to check all of the papers and health work. There are substitutions we need to make sure get put into the right class, and we take out all of the scratches. Then we need to make sure all of the kids

Melinda Goplin Galesville, Wisconsin Trempealeau County

What are your main responsibilities as coordinator of the dairy show at your county fair? As the junior dairy superintendent, I work with the open show superintendent to organize entries, check everyone in and stall everyone according to space needs. I also organize show helpers to take care of the book, the placings, ribbons, a ring person and someone to help check in, help order awards, and make sure the judge knows which class is coming in and make everything run smoothly.

What do you enjoy about this role? I like seeing the kids working on their projects – from unloading them off the trailer to getting them washed and t – and getting excited about doing chores and nally taking them in the ring for the award for the work they’ve done. I like to see the older members step up into a leadership role to help the younger members too.

What is the most challenging part of this position? It requires me to neglect my own three children who also show. I need to be helping everyone else instead of just them. When they were younger, it was harder, but the place where we keep the cattle has stepped up, and my husband helps. It’s kind of a family ordeal because my dad is the ring man, my sister keeps records, a friend keeps books and other friends help.

are in the correct showmanship group. We try to get that all done before show morning to make sure everything is up-to-date and correct to help expedite the show. We have a great staff of volunteers. They all know where everyone is located in the barns, and that helps.

How many head of dairy cattle on average are exhibited and by how many exhibitors? We have about 225 head here this year exhibited by over 60 exhibitors from about 20 4-H clubs and FFA chapters. We are pretty close to last year. Our numbers have been steady lately. We have students leaving the program who used to show quite a few animals, but we have new kids coming into the program too. On Sunday, we have a Little Britches program to allow kids too young to show in the actual show the opportunity to show a calf. We don’t have as many kids living on farms, so we try to help them have these experiences. Our calf program helps with that, and we have dairy farmers who are willing to let kids show their animals.

What is something unique to your county's dairy show? We have a heifer program where youth can apply for a calf and then work with and show that heifer for two years. We have a heifer sale on Saturday night, where those heifers are sold. It is an open sale, and it is kind of the parting point in the program. The youth can either chose to buy their heifer back or she can be sold to another buyer. There are 34 kids involved in that program this year, and we have 17 heifers selling. About 70% of the heifers are bought back by the kids. Can you share a favorite memory from the years you have served as coordinator? Slipek: I have so many memories, I’m not sure how I could ever pick out a favorite. I would say the whole experience is a favorite memory. We have a great fair, great facilities and great kids from great families taking part. Beastrom: I taught agriculture for 32 years in Athens, so I have been involved with the fair for many, many years. The friendships I’ve made and the connections with the community are important to me. You know the people you can count on for just about anything.

When do you start preparing for next year's county fair, and what do those rst tasks involve? It is an on-going process. We have been working on next year’s fair before this one even started. We’ve been doing this for so long that the basics are a well-oiled machine, so we focus on trying to improve each year. We make minor changes from year to year, taking into account things the exhibitors suggest and ask for. We spend time each year working with the heifer program, going through the application process, nding and selecting heifers for the recipients, and then we keep in touch with them throughout the year as well as organizing the sale for each year.

How many head of dairy cattle on average are exhibited and by how many exhibitors? The numbers have denitely declined in the 20-some years. Most recently, it’s between 70 and 90 head total between the open and junior shows and probably about 20 exhibitors. A lot of our exhibitors are managerial, so they don’t own the animals themselves. There are about seven area farms that allow others to use animals for the fair.

What is something unique to your county's dairy show? We run our open show and junior show together on one day, which not everyone does. Our adults who bring their strings are showing in the same classes as the juniors, so it’s two shows in one. The juniors are automatically entered into both shows.

Can you share a favorite memory from the years you have served as coordinator? My favorite memories are always the senior showmanship and the Roy Berge awards. Roy used to manage the Trempealeau County farm in the 1970s. He always supported youth, and we continue to recognize youth in the junior class for the best t and trained. The judge watches for around 10 exhibitors throughout the day to come back in and compete for the Roy Berge award. We encourage the judge to ask them questions about how they were trained and tted to t into the methodology of the award.

When do you start preparing for next year's county fair, and what do those rst tasks involve? We’ll sit down in fall and review all the rules and regulations and make changes if we need to. That usually happens in November so that the fair book gets to the printer. It’s a 365-day job contacting sponsors and making sure there are people willing to donate prizes to exhibitors. Amy Schaefer and I work together because she is the open show coordinator. I have been the junior show coordinator for 26 years.

What are your main responsibilities as coordinator of the dairy show at your county fair? Green County has one of the largest junior dairy shows aside from the Wisconsin State Fair, and my rst responsibility for the fair is serving as fair board president. In coordinating the dairy show, my main responsibilities include getting judges, following up with dairy numbers reported from each club so that I can stall animals, and lining up volunteers who act as superintendents during the show. These ve people take care of all the workings of the show, including check-in and everything that goes along with that. What do you enjoy about this role? Everything we do with the fair is all about the kids, and I love being available to help. I’ve been on the fair board for 11 years, and everything at the fairgrounds is based on the youth. Our fairgrounds are privately owned, which is a rarity in the state. Income generated throughout the year is used to maintain the grounds so that it can be a place for youth to practice and/or show off what they learned in 4-H or FFA. My favorite part about this role is based on that.

What is the most challenging part of this position? It’s hard when mistakes are made that could affect the outcome of a person’s fair. There are rules to follow regarding entries, etc., and it can become challenging if a mistake is made when exhibitors are entering information. Some rule books would prevent a youth from showing at all if an animal is entered into the wrong class or has an incorrect registration number listed. We try to bridge that gap and make everybody aware. When it comes to check-in, we have to make a decision. What we’ve adopted is not perfect, but it allows the exhibitor to show in the proper class and receive the ribbon. However, they are not eligible for the premium and cannot move onto the championship round. Those are the tough things about the fair. Some people don’t like these rules, but if there are no rules, it ends up a free-for-all. It’s a real challenge, and we

Tony Fincutter Elkhorn, Wisconsin Walworth County

What are your main responsibilities as coordinator of the dairy show at your county fair? As the dairy superintendent for the junior and open shows, my main responsibility is raising funds for awards. The year I took this position over, we could no longer sell milk from show cows. The milk was the only source of income we had, and we were left with guring out how to raise funds so we could give back to the kids. We have two main sponsors for the open show that buy plaques and awards for each breed champion and supreme champions. For the junior show, my wife and I send out letters to local businesses – people I do business with on our farm – and we get a lot of great donations. We buy all the awards and give out almost $2,500 in cash prizes for showmanship and breed champions.

What do you enjoy about this role? I really enjoy working with the kids, especially the new incoming ones. This year, we have about nine new kids coming into show for their rst year. This is the next generation of kids whose parents I coached years ago.

What is the most challenging part of this position? Getting everything organized. Everyone enters more animals than they’re going to bring, and when they get to the fair, I go around and mark off those not coming. Hopefully, we get all the animals marked off so that the show goes smoothly and we’re not waiting for people to bring animals that aren’t there. The other challenge is getting all our work done at home during the fair. We have a dairy farm, and to get to the fair on time, we start chores at 3:30 a.m. on show days. My son also shows in the open show. He started in Little Britches, then he did the junior show, and now he is 30 years old and still showing.

have to provide education from front to back. If you allow the kid to be part of the process of entering the animal instead of just the parent doing it, then they have a better understanding of how it all works and any mistakes that were made. Sportsmanship comes into play here and how you answer adversity. Part of that challenge is why I enjoy what I do.

How many head of dairy cattle on average are exhibited and by how many exhibitors? We still have a lot of farms in Green County, and there were nearly 200 animals to check in for the junior and open show this year. Our numbers went up in 2023 after dwindling, and we doubled the number of open-class animals shown. We also had an overall increase this year in the number of exhibitors for the rst time in a while. We had 84 junior show exhibitors and 24 open-class exhibitors.

What is something unique to your county's dairy show? The sheer size of the show is unique and takes us two days to complete. Our county is so competitive with registered cattle, and it’s a really tough show, especially on the registered side. The sponsorships within the county are also unique. We have families that sponsor breed awards, such as our Nelson McCammon Brown Swiss award. For many years, the winner of this breed received a $500 award. Dairy is pretty special here and is a big part of what our county is, and it shows up at the fair.

Can you share a favorite memory from the years you have served as coordinator? I don’t know if it’s a single memory, but rather, it’s the relationships built with exhibitors, including those who have aged out. I try to be approachable, and it’s neat when exhibitors search me out. They come up and either thank me or the other volunteers for the experience or the help. We have good conversations, even leading up to the fair. The relationships that have been built are part of the reason why people still get along even if issues arise. These relationships are one of the favorite things I get out of the fair.

When do you start preparing for next year's county fair, and what do those rst tasks involve? The process to prepare for next year’s fair starts pretty much right after the current fair is nished. We already have a meeting scheduled for some time after the state fair to go over how things went this year and to look at any rule changes or tweaks to make things clearer. We also start getting prospective names for judges so that we can have those nailed down by the rst of the year because good judges get booked quickly.

How many head of dairy cattle on average are exhibited and by how many exhibitors? There are about 150 animals shown between the junior and open shows. In the junior show, we have 55 exhibitors showing around 130 animals. Many of those animals are also shown in the open show by about 60 to 70 exhibitors. All breeds are shown separate; we don’t combine. This year, cattle numbers have increased a little for the junior show. On Sunday, we have the 2-year-old all-breed futurity. Exhibitors wear formal wear, and there is a best-dressed award and highest placing junior award.

What is something unique to your county's dairy show? We give out cash awards from the money we raise. We also have a quality milk sale where the kid whose cow has the lowest linear somatic cell score for her age group can sell a gallon of milk between the heifer and cow shows. It’s not an actual gallon of milk but rather a pitcher with a Milk Chug in it. It’s a way for exhibitors to raise money for themselves. These pitchers have sold anywhere from $650 up to $2,800 per pitcher. It’s a great thing for the kids because they put a lot of money and time into showing and usually don’t get much return.

Can you share a favorite memory from the years you have served as coordinator?

We had an exhibitor who lived in Green County on a family member’s farm during the summer and showed their cattle at the state fair and Walworth County Fair because she was from this county. She thought her junior year would be her last year to show because her parents wanted her to stay home and earn money for college. I asked my wife and son, “What if we let her show something from our farm?” They agreed, and when we called her family, they jumped at the chance. She came out here every day after graduating from high school. She showed a heifer and big red cow, and that cow won supreme champion. It was pretty exciting for her family.

She also won the quality milk award with that cow and got to keep the money for college.

When do you start preparing for next year's county fair, and what do those rst tasks involve? I normally line up judges for next year’s fair as soon as we are done with this year’s fair. I call judges personally. The judge we will have this year for our junior show has judged at World Dairy Expo in both the junior and open shows. Last year’s judge also judged at WDE as an associate judge for the Ayrshire show. Six weeks after the fair, I attend a meeting for fair superintendents and again in January or February. Around April, I start sending letters to get donations for the junior show.

Steve Fronk Rice Lake, Wisconsin Barron CountyWhat are your main responsibilities as coordinator of the dairy show at your county fair?

As the dairy superintendent, I do pretty much everything to get the show organized. Ahead of the show, I take care of lining up the judge, the sponsors for the awards, the volunteer help for show day; and I also work out the stalling. Once the fair starts, I take care of checking everything in, deleting all the scratches and making sure everything is listed correctly. On show day, I check animals into the ring and just make sure everything runs smoothly.

What do you enjoy about this role? I just like doing it. I enjoy being around the kids and all their families. It is a real community experience. I have also worked with the judging team and the state fair kids. I have been the dairy show superintendent for 23 years, and I’ve got some families where I’m working with a third generation of exhibitors. It’s a lot of work, but I don’t mind that.

What is the most challenging part of this position? Show morning is by far the most challenging part. There’s always last-minute stuff that needs to be taken care of. I make sure the show starts on time and runs smoothly.

How many head of dairy cattle on average are exhibited and by how many exhibitors? We have about 120 head shown by 55 exhibitors this year, and that has been a pretty steady number.

What is something unique to your county's dairy show? It is very much like an annual get-together in our county, and it is important to the agriculture sector in Barron County. There is a lot of history, and everyone wants to maintain that history. Everyone leaves with a smile on their face.

Can you share a favorite memory from the years you have served as coordinator? My favorite memory has just been watching all these kids grow up to become good people and to have been able to play a role in their experience. Personally, I was recognized a couple of years ago for 20 years of service in this role, and I was also given the Friend of the Holstein Cow award.

When do you start preparing for next year's county fair, and what do those rst tasks involve? I am continuously working to make our show better. I already started preparing for the 2024 fair, even before the 2023 fair began. I have next year’s judges booked, and I am continually looking for new sponsors and working with current sponsors.

Describe your farm and facilities. We have a freestall barn with waterbeds, and we milk our cows in a swing-16 parlor. Our herd average is 28,000 pounds with 4.3% butterfat and 3.2% protein. We have 350 cows, 300 of which are milking. We also have 300 heifers and raise our calves. We also raise 200 steers. We have three fulltime workers who do milking and help with chores. We can feed all the cows in two hours.

What forages do you harvest? We have 180 acres of alfalfa, 600 acres of corn and 200 acres of grass hay, and we also raise 110 acres of soybeans.

How many acres of crops do you raise? Around 1,100 acres.

Describe the rations for your livestock. Our cows get 50 pounds of corn silage, 30 pounds of haylage, 20 pounds of earlage, 3 pounds of soybeans, 3 pounds of soybean meal and some liquid protein mineral mix. The dry cows get grass hay, haylage, corn silage and mineral mix. The heifers are

on their dairy near Sauk Rapids, Minnesota. They milk 300 cows, raise 300 heifers and 200 steers on their farm in Benton County.

fed grass hay, haylage, corn silage and mineral.

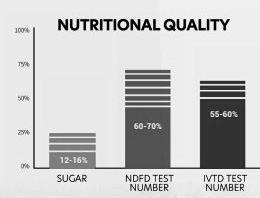

What quality and quantity do you harvest of each crop? We try to harvest the haylage at 180-200 relative

feed value on about 180 acres. The corn silage is a brown midrib variety, and we harvest around 200 acres at 66%-68% moisture. The earlage is about 40% moisture, and we have around

150 acres of that. This year, we planted a 98-day variety.

Describe your harvesting techniques for alfalfa and corn silage. The alfalfa is cut, merged, chopped at

65% moisture and put on a pile. The corn silage is chopped at 66%-68% moisture and piled. We usually take the rst cutting around Memorial Day. We participate in a scissor cut through the University of Minnesota.

What techniques do you use to store, manage and feed your forages? The alfalfa and corn silage are piled and faced daily. The earlage is in bags or in the silo. They are fed with the mixer.

How does quality forages play in the production goals for your herd? Feeding quality forage keeps cows healthy and producing a high amount of quality milk with less purchased feed. You make the best quality forages you can so you don’t have to buy your milk through purchasing feed to make up for poor quality forages. Turn

“We decided to get more regimented with our use of Udder ComfortTM and saw our SCC drop from 200,000 to 120,000. Whether they have visible swelling or not, we make sure to apply the Udder Comfort spray to all fresh udders after each milking during the first 5 to 7 days after they calve. We see SCC drop right down.”

- Kyle Hirt, Mithva Farms, New Woodstock, NY 100 cows, 80 lbs/cow/day, 120,000 SCC

“We’ve relied on Udder Comfort for over 10 years as the best tool to get cows through transition and into milk faster with healthier udders. Using the Udder Comfort Battery-Operated Backpack Sprayer, we now are getting our fresh cows sprayed consistently 3x/day for a week after calving, and in 3 months, our SCC came down from 165 to 137,000.” - Scott Stempfle, Stempfle Holsteins, Maynard, IA

“Udder Comfort is something we don’t cut. It gets swelling out faster. We see faster, better milkouts and higher quality milk. We do every fresh cow for a week after calving. We mark high-count cows on DHIA and do them too. We tried other brands. They don’t work. Udder Comfort is the one that works!”

- Matt Nealy, Nealand Farms, Newville, PA 400 cows, 92 lbs/cow/day, 100,000 SCC

What are management or harvesting techniques you have changed that has made a notable difference in forage quality? The biggest change we made is when we switched to bags and silos to piles. It enabled us to harvest at a better moisture for a more digestible feed. Our window for chopping is wider, and we can harvest at a quicker pace because we aren’t unloading into a bagger. It’s also allowed for quicker feeding times. This year, we bought a triple mower that has allowed us to cut in the morning and chop in the afternoon with the exception of the rst crop. We updated our pro-

cesses four years ago, and that does a better job annihilating the kernel. We also put in a 200-by-300 tar pad three years ago. That has allowed us to have all our feed in one spot which makes feeding quicker plus we don’t have to deal with any mud.

Describe a challenge you overcame in reaching your forage quality goals. Switching to a BMR corn helped with the health of the cows. We wanted to get to a more digestible feed. We switched six years ago and have had less instances of displaced abomasum.

...... $55,000

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD 9870 STS 2010, PRWD, Duals, 3394 hrs., 2260 Sep. hrs., #554931 .... $118,900

JD 9870 STS 2008, PRWD, Duals, 3261 hrs., 2494 Sep. hrs., #566621 ...... $97,500

JD S660 2012, 2WD, Duals, 1643 hrs., 1188 Sep. hrs., #554132 .............. $179,900

JD S660 2014, PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S670 2013, PRWD, Duals, 3169 hrs., 2161 Sep. hrs., #566670............ $141,100

JD S670 2016, 2WD, Duals, 1269 hrs., 964 Sep. hrs., #552767 ................ $237,900

JD S680 2012, PRWD, Duals, 3219 hrs., 2222 Sep. hrs., #552735............ $139,000

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S680 2012, PRWD, Duals, 2500 hrs., 2000 Sep. hrs., #554973............ $129,900

JD S680 2014, PRWD, Duals, 2324 hrs., 1575 Sep. hrs., #555096............ $169,900

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646............ $219,900

JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

JD S680 2013, PRWD, Duals, 2851 hrs., 1892 Sep. hrs., #566617............ $147,000

JD S680 2012, 2WD, Duals, 2631 hrs., 1790 Sep. hrs., #548165 .............. $147,500

JD S680 2013, PRWD, Duals, 2575 hrs., 1906 Sep. hrs., #563909............ $160,000

hrs., #560264 .................. $425,900 JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S770 2022, PRWD, Duals, 273 hrs., 195 Sep. hrs., #554014................ $560,000

JD S780 2018, PRWD, Duals, 1521 hrs., 1130 Sep. hrs., #551736............ $305,000

JD S780 2019, PRWD, Duals, 1286 hrs., 931 Sep. hrs., #558869.............. $349,000

JD S780 2020, PRWD, Duals, 1031 hrs., 749 Sep. hrs., #188309.............. $409,000

JD S780 2018, 2WD, Duals, 1215 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S780 2022, PRWD, Floaters, 242 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S780 2022, PRWD, Floaters, 141 hrs., 91 Sep. hrs., #554708 .............. $574,000

JD S780 2022, PRWD, Floaters, 254 hrs., 177 Sep. hrs., #554707 ............ $569,000

JD S780 2022, PRWD, Floaters, 185 hrs., 139 Sep. hrs., #554710 ............ $569,000

JD S780 2022, PRWD, Floaters, 189 hrs., 131 Sep. hrs., #554709 ............ $569,000

JD S780 2022, PRWD, Floaters, 225 hrs., 169 Sep. hrs., #554706 ............ $569,000

JD S780 2020, PRWD, Duals, 933 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1562 hrs., 1131 Sep. hrs., #549680............ $319,000

JD S780 2021, PRWD, Duals, 655 hrs., 469 Sep. hrs., #191047................ $489,000

JD S780 2022, PRWD, Tracks, 337 hrs., 251 Sep. hrs., #563618 ............... $619,000

JD S780 2022, PRWD, Duals, 426 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Tracks, 318 hrs., 231 Sep. hrs., #563619 ............... $619,000

JD S780 2022, PRWD, Duals, 468 hrs., 347 Sep. hrs., #563635................ $549,000

JD S780 2022, PRWD, Duals, 241 hrs., 183 Sep. hrs., #554094................ $565,000 JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000 JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

2019, PRWD, Duals, 1596 hrs., 1058 Sep. hrs., #549682............

$349,000

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Duals, 91 hrs., 56 Sep. hrs., #563620 ................... $579,000

JD S780 2020, PRWD, Duals, 1488 hrs., 1145 Sep. hrs., #191082............ $349,000

JD S780 2020, PRWD, Duals, 1026 hrs., 590 Sep. hrs., #566462.............. $419,000

JD S780 2022, PRWD, Duals, 452 hrs., 353 Sep. hrs., #552362................ $549,000

JD S790 2018, PRWD, Duals, 1647 hrs., 1218 Sep. hrs., #549845............ $309,000

JD S790 2018, PRWD, Duals, 1461 hrs., 1055 Sep. hrs., #549846............ $329,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Singles, 25 hrs., 20 Sep. hrs., #560619 ................. $639,500

JD S790 2021, PRWD, Duals, 705 hrs., 526 Sep. hrs., #555189................ $499,500

JD S790 2022, PRWD, Singles, 477 hrs., 314 Sep. hrs., #563815 ............. $579,500

JD S790 2022, PRWD, Duals, 334 hrs., 269 Sep. hrs., #554381................ $579,500

JD S790 2022, PRWD, Duals, 460 hrs., 368 Sep. hrs., #566460................ $624,900

JD S790 2022, PRWD, Duals, 1272 hrs., 90 Sep. hrs., #557140................ $629,900

JD S790 2022, PRWD, Duals, 432 hrs., 302 Sep. hrs., #552839................ $579,500

JD S790 2021, PRWD, Duals, 833 hrs., 551 Sep. hrs., #565421................ $499,900

JD S790 2022, PRWD, Duals, 455 hrs., 316 Sep. hrs., #566694................ $579,900

JD S790 2018, PRWD, Duals, 1576 hrs., 1000 Sep. hrs., #552352............ $329,000

JD S790 2022, PRWD, Duals, 230 hrs., 155 Sep. hrs., #563325................ $599,900

JD S790 2022, PRWD, Duals, 333 hrs., 239 Sep. hrs., #566637................ $589,900

JD S790 2022, PRWD, Tracks, 39 hrs., 21 Sep. hrs., #553771 ................... $695,000

JD S790 2021, PRWD, Tracks,

1/2” thick x 16” wide

12’ long $35 • 16’ long $47

White Corrugated PVC liner panels 40” wide x 16’4” long $1950

White smooth PVC sheeting

4’ x 8’ x 1/2” thick $5750

FACTORY SECONDS. QUANTITY DISCOUNTS. DELIVERY AVAILABLE

Chippewa Valley Dairy Supply

6053 CTY. HWY. G • STANLEY, WI 54768 • Andrew Zimmerman

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA

712-476-9290

United Dairy Systems, Inc.

West Union, IA

563-422-5355

Monticello, IA

319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI

715-772-3201

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029

Pierz, MN

320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN

218-632-5416

FREDERIC, Wis. – Neither Walter Owens nor his daughter, Michelle Moore, have ever known a day without Jersey cows, and that suits each of them just ne.

“It has been a good thing to have Jerseys my whole life,” Owens said. “The Jersey cow has been good to our family over the years, and it is hard to imagine what life would look like without them.”

Owens and Moore were each honored by the American Jersey Cattle Association during the organization’s annual meeting in June. Owens received the Distinguished Service Award while Moore was named a Young Jersey Breeder for their efforts in their family’s dairy farm.

Owens Farm Inc. is home to 685 milking Jersey cows near Frederic. The family markets the milk produced through First District Association in Litcheld, Minnesota. They crop 1,800 acres, both owned and rented, raising alfalfa and corn to feed their herd. All of their

youngstock is raised on the farm. The Owenses invested in a new calf barn in 2016, followed by a heifer barn in 2018.

Jersey cows rst came to the Polk County dairy farm in 1943, shortly after Owens’ father, Harold, took over the family farm.

“My dad believed early on that there was more prot per acre with Jerseys,” Owens said. “They haven’t proven him wrong yet.”

Since that time, both the farm and the herd of Jerseys have grown. Owens and his brothers, Wilfred and Roger, mark the third generation of their family to operate the farm. The fourth generation consists of Owens’ children, Brandon, Jeff and Michelle (Moore); Wilfred’s children, Steven and Doug; and Roger’s children, Chris and Julia.

Moore moved home and began working on the farm in 2012, shortly after graduating from the University of Wisconsin-River Falls.

“I worked off the farm for a while; it was a good experience, but it didn’t take me long to realize that it wasn’t what I wanted to do,” Moore said. “I

missed the cows and realized the farm is where my heart was.”

Having the farm to come home to, Moore said, is something she appreciates.

“I’m grateful that the farm was available for me to join, as

a career,” Moore said. “For a young person to start out in this industry these days is tough. Being able to become a part of something that was already established and successful has allowed me to do the things I love doing.”

Turn to OWENS/MOORE | Page 25

“There is nothing like a Jersey,” Moore said. “They are smart little animals. They are the ideal co-workers.”

With so many members of the fourth generation making the decision to return to the farm, each family member has been able to specialize their talents. Owens works mostly with the cow herd, and Moore focuses on calves.

“We are all able to ll in where needed,” Owens said.

The family relies on its herd.

“One thing we have become very proud of is that our herd is homebred and stayed that way as we have grown over the years to bring more family into the farm as both ownership and employees,” Owens said. “It has probably been at least 40 years since we last purchased an animal.”

Early on, the family came to appreciate the value in registered Jerseys, becoming avid supporters and active members of the AJCA and the Wisconsin Jersey Breeders Association.

“Dad would add registered cows to the herd as he could,” Owens said. “He kept incredibly detailed records and always bought registered bulls so it was easy to register the last grade cows through the genetic recovery program, and by the late 1970s, all of the cows had papers.”

Registered dairy cattle opened up markets for his fam-

ily, Owens said, that might not have existed otherwise.

“We have been able to put a number of bulls into A.I.,” Owens said. “We used to show quite a bit, and we did fairly well at some of the bigger shows. We have sold cattle in state and national sales, as well as through private treaty. That was all possible because of the added value of the registered cow.”

That appreciation of registered Jerseys led the Owenses to connect with fellow breeders and invest their time in the AJCA and WJBA.

“We were really born into that mindset,” Owens said. “My parents got involved locally and in the state association. I served on the state board, and that just naturally grew into service on the national board when I was appointed to ll Chris Sorenson’s term when he was elected as the AJCA president.”

Owens ran and was reelected to the national board twice. Later, he was appointed to an open board position for National All-Jersey, the milk and cattle marketing arm of AJCA.

Through the NAJ appointment, Owens traveled to Washington, D.C. to meet with congressional leaders, advocating for the needs of dairy farmers – Jersey breeders, in particular.

“The experiences I had on the boards have all been good,”

Owens said. “We all have the same goal but have different ideas for getting there. We all want to improve the Jersey breed and help create protability. We just about always ended up coming to a consensus, no matter what the discussion was.”

Involvement in leadership is important, Owens said.

“The people I have met,

the connections I have made and the friendships that have developed have been the most rewarding part of service,”

Owens said. “Those are things that would be missing from my life if I hadn’t gotten involved.”

The work accomplished by the boards Owens has served on plays a role in giving his family the opportunity to con-

tinue the tradition of Owens Farms Inc.

“Having your children grow to love the same thing you love and want to make that their life’s work, that is a gratifying feeling,” Owens said. “We must have been doing something right that our farm is growing soundly for the fourth and hopefully fth generations.”

By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

APPLETON, Wis. – Every July, Mark and Steve Petersen open their farm to fellow antique tractor lovers. For the past 30 years, likeminded people with a passion for the classics get together on a Monday night to check out tractors, cars, trucks and lawn mowers that have been lovingly restored to prime condition.

The Old Iron Event, as it is called, started at 5 p.m. July 10 and went well past dark. The long-standing event attracts hundreds, including many retired farmers and non-farm folks who share an interest in old tractors and cars. Each year, tractor speak lls the air as families and friends bond over their favorites.

“We have a lot of new neighbors, and we tell them to come by too so we can get to know each other,” Mark said. “It helps create a better relationship with us as an urban farm.”

The Petersens milk 50 cows and farm 300 acres near Appleton. In their spare time, the brothers have a knack for restoring old tractors – a hobby started long ago.

“Mark once found an old WC Allis for sale for $100,” Steve said. “We cleaned it up, threw a paint job on it, then thought, why not do another one? We did it when tractors weren’t so expensive.”

Members of the Fox Valley Two-Cylinder Club and beyond bring their nest to the event. This year, more than 40 pieces were parked at the Petersen farm, but some years, there are more than 200.

The Petersens’ AllisChalmers 180 tractor and manure spreader were on display, along with a Massey Ferguson Super 30, an Allis-Chalmers 170, a Ford 1917 TT truck –one of only three made in 1917 – and many other antiques on wheels.