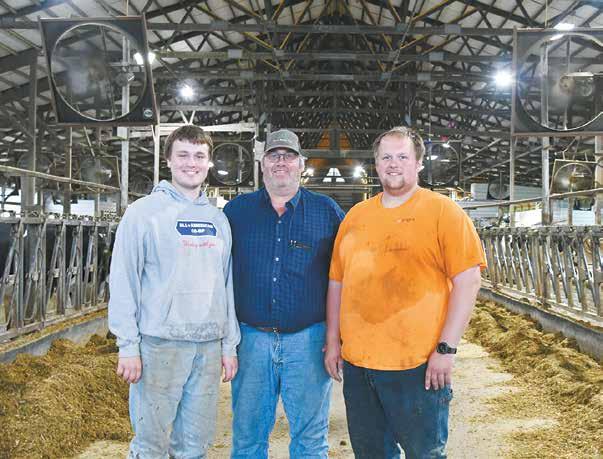

By Amy Kyllo amy.k@star-pub.com

Minn. — For the Twoheys, robotic milking units are creating a solution that will keep them dairy farming.

“We knew we wanted to continue milking cows, but we didn’t want to be the ones milking cows,” Jacob Twohey said. “The robots have kind of provided us that outlet.”

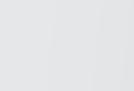

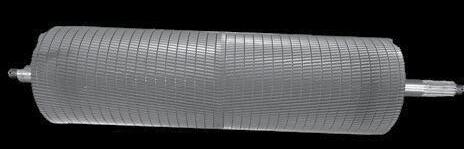

Twohey dairy farms with his parents, Ed and Sherri, and brother, Tim. The Twoheys milk 300 cows. They also farm 1,400 acres with Twohey’s uncle, Bill. In 2022, the family started milking their herd with a guided ow system with four DeLaval VMS V300 robotic milking units.

Previously, the Twoheys had milked in a double-8 parabone parlor that was retrotted in 2004 into a barn from the 1960s.

“The equipment wasn’t in terrible shape, but the facility itself was starting to get dated,” Twohey said.

Within their update, the Twoheys added 140 feet to their freestall barn, creating enough space for them to house their entire herd — including

dry cows — under one roof.

Instead of weekly trailering to move cows on and off their site, now the cows rotate through pens. With this change, the Twoheys also have CowManager data on their cows throughout their entire pregnancy. When the cows were offsite, this was not possible.

The new dry cow area is also an improvement versus their prior offsite location which was feedlot style. In their new setup, they have fans and sprinklers to increase cow comfort.

“The energy demands from the cow are certainly a lot lower than it was before,” Twohey said. “We’re going to see longterm impacts from this as we see more and more cows go through this cycle (with) calves being born through a dry period without as much heat stress.”

The Twoheys have reduced labor with the robotic milking units. Ed, Tim and Jacob are assisted by one full-time employee and one part-time employee.

“The biggest pusher for us to do this project in general was labor,” Twohey said. “We liked the idea of being able to cut back labor and not have scheduled milkings.”

Twohey said reduced labor has been the biggest positive change the robotic milking units have produced.

“Our reliance on employees is greatly reduced,” Twohey said. “If we have an employee

that can’t make it in for whatever reason now, we can divide up the tasks that employee was supposed to do fairly easily. ... It doesn’t change your whole day.”

Though they have reduced labor, a member of the family must be on call at all times.

“Before, in the parlor, when the employees left, everything was done,” Twohey said. “You weren’t going to get any calls.”

The Twoheys started considering robotic milking units about 10 years ago. In 2020, they started visiting with deal-

ers, and in the spring of 2021, they bought their robots. That fall, the barn addition started going up. Their robotic milking units’ start up date was Aug. 8, 2022.

Turn to TWOHEYS | Page 4

“The startup went as good as we could have hoped for,” Twohey said. “We had a lot of people on hand. ... Within a couple of days, we had ... some cows starting to go in on their own. ... It wasn’t a hard push to get every cow in at that point.”

The Twoheys sent all their cows through the robotic milking units the rst day. Twohey said he is glad they did not keep milking some cows in the parlor. To help the cows get used to the robots, they sent the cows through the robots for a week before the transition.

Within a few weeks of startup, the majority of the cows were going in on their own. The cows now average 2.65 visits per day.

Twohey said the guided ow reduces labor on fetching and gives them exibility on how many pounds of pellets they feed. Their cows receive an average of 5.5 pounds per day.

If he were to do it again, he said he would make some changes in the setup. He said he wishes they would have installed a buffer bulk tank so they could continue running the robots when the main bulk tanks get pumped and washed.

“That’s our biggest regret; that really interrupts cow ow,” Twohey said.

As well, he also would consider putting in two more robots so he could run fewer cows through each robot but have more cows overall. The barn has the capacity for more cows, but currently, their robots are their limiting factor.

Each member of the Twohey family has an area on the farm. Jacob works with the robotic milking unit maintenance, the cows, employees and barn maintenance.

“I do a lot of work on the robot,” Twohey said. “That’s a huge change. It’s a big, big part of my time commitment (to make) sure they’re running.”

Tim works with the calves, daily maintenance, equipment maintenance, bedding and all feeding. Ed works with the crops and oversees nances and bookkeeping.

“(I enjoy) being able to work with family,” Twohey said. “I think that’s a really great thing.”

In the future, Twohey has dreams of what could be next for his family’s farm. He said he would like to add two more robots within the next ve years. He also would like to buy more land and add onto their feed pad.

“When things are working well, ... I enjoy doing (dairy farming),” Twohey said. “I enjoy working with the cows. I enjoy the variety to my day, even though the same things have to get done.”

Wisconsin:

Abts Equipment LLC

New Franken (920) 866-2485

Gillett (920) 866-2485

Argall Dairy Systems, Inc.

Belleville (608) 424-6110

Platteville (608) 348-3385

Fuller’s Milker Center LLC

Lancaster (608) 723-4634

Richland Center (608) 723-4634

Gehring Sales & Service, Inc.

Rubicon (262) 673-4920

Joe’s Refrigeration, Inc.

Withee (715) 229-2321

Leedstone, Inc.

Menomonie (866) 467-4717

Midwest Livestock Systems Menomonie (715) 235-5144

Redeker Dairy Equipment Brandon (920) 960-9260

The Scharine Group Inc. Whitewater (608) 883-2880

Tri-County Dairy Supply Inc. Janesville (608) 757-2697

Iowa:

Langs Dairy Equipment

Decorah (563) 382-8722

Precision Dairy Equipment

Elkader (563) 245-2560

Minnesota:

Gorter’s Clay & Dairy Equipment, Inc.

Pipestone (507) 825-3271

Leedstone, Inc.

Melrose (888) 267-2697

Glencoe (877) 864-5575

Plainview (800) 548-5240

Midwest Livestock Systems

Zumbrota (507) 732-4673

South Dakota:

Midwest Livestock Systems

Renner (605) 274-3656

Mid-August Chicago Mercantile Exchange dairy product prices were mostly higher led by cheese topping $2 per pound, all of which drove Class III futures higher.

After jumping almost 11 cents the previous week, the Cheddar blocks closed Friday at $2.10 per pound, up 14.25 cents on the week, a price not seen since March 27, 2023, and 7.25 cents above a year ago.

The barrels nished at $2.2550, 25 cents higher, highest since June 9, 2022, 44.75 cents above a year ago, and 15.50 cents above the blocks. Sales for the week totaled 21 loads of block and eight of barrel.

The Aug. 13 Daily Dairy Report said, “New cheese capacity will be coming online later this year in the Southern Plains. Theoretically, cheese production will increase once the new plants are up and running, ipping the market balance back to heavy supplies and pushing prices lower. However, with low heifer and cow inventories, concerns about these plants having enough milk to run have been growing.”

Dairy Market News reports that Midwest cheesemakers continue to say milk is tight to tighter week over week. Mid-week reported spot prices were hovering in the same area as the previous week, but cheesemakers say milk availability is scarce for the most part. Some are still getting sufcient quantity but at increasing prices. And, as more schools reopen, a growing percentage of milk will go to Class I and expectations are that prices will be above Class III until Labor Day, at the earliest. Cheese demand is somewhat steady. Barrel producers have shifted their focus onto other varieties which could have been a factor in

the recent CME price surge. Block markets are also bullish, but not to the same extent, says DMN. Cheese inventories in the region range from balanced to tight. Western cheese production remains active. While most cheese makers are nding plenty of milk, supplies remain tight in parts of the West due to high temperatures. A few processors have adjusted their milk production caps to incentivize farms to ship more milk and keep cheese production full. Some contacts say there is plenty of cheese available, others suggest supplies are a little snug, but demand is steady to strong. With the start of school terms at hand, a few contacts report an uptick in retail and institutional food service purchases.

Butter jumped 4.25 cents Monday, gave back 2 cents Tuesday, and closed Friday at $3.18 per pound, up 8.25 cents on the week, the highest since Oct. 31, 2023, and 48 cents above a year ago.

There were 103 sales on the week, 51 on Thursday alone, the highest single-day total since Nov. 3, 2004, when butter only traded three days a week. Interestingly, there were 49 loads traded Aug. 16, 2023. This volume represents hundreds of thousands of pounds worth of butter moving through Chicago this week.

Butter demand in the Central region is starting to nd its seasonal groove, says DMN. In recent weeks, demand has been somewhat hit and miss. This week, however, butter producers say customers are more actively seeking product and are working on deals for the latter months of the year. Production is beginning to slide, said DMN. There were weeks in July when churning in the region was busier than expected, seasonally, but as cream availability has shifted noticeably downward in recent weeks, so has churning. Butter markets are in a “steadfast position,” said DMN, but few see anything below $3 per pound.

Western butter makers report retail butter output continues to churn at a healthy clip, while bulk butter lines are running much slower. Butter demand is strong and steady, with some requests of 10-20 loads from buyers who want to ensure coverage ahead of the late summer or early fall rush. Manufacturers are com-

fortable with their current inventory levels and production plans, said DMN.

Grade A nonfat dry milk saw its Friday nish at $1.2550 per pound, up 5.50 cents on the week, the highest CME price since Feb. 13, 2023, and 15 cents above a year ago, with 19 sales put on the board for the week.

The powder got some support from an Algerian tender announced Tuesday and higher Global Dairy Trade Pulse prices, according to StoneX. “A large volume was cleared. Ramadan demand will start right about now as the holiday will start earlier next year (Feb. 27-March 29) so those buyers were looking to stock up.”

Dry whey closed Friday at 55 cents per pound, down 1.15 cents on the week but 28 cents above a year ago, with three sales for the week.

It’s the age-old question: is supply driving the market or demand? We got a look at the latest Dairy Product Supply and Utilization data and HighGround Dairy’s Betty Berning reported highlights in the Aug. 19 Dairy Radio Now broadcast.

Total cheese usage was up 0.9% from June 2023, she said, the fourth month in a row to top a year ago, and driven primarily by the “other” category, particularly on exports. Export numbers have been strong for cheese throughout 2024, according to Berning, and a lot of Mozzarella and Gouda were exported.

The other side of the story is supply. “The smaller milk supply resulted in smaller cheese output in June and right now it’s summertime,” said Berning. Milk is very tight and with schools reopening, more milk will go to the bottle instead of the vat.

Berning said spot milk prices are running over Class, are the highest in a number of years, and have topped three-year averages. The downside however is the higher cheese prices will hurt exports as the U.S. will not be as competitive.

Butter utilization was down 1.1%, with domestic use down 2.0%, while exports were up 33.3%.

Nonfat/skim milk powder was down 15.1%, the lowest total for the month since 2014, according to HGD, which said, “Year-to-date usage nally passed the 1-billion-pound mark in June, a month later than in the past ve years when this threshold was crossed in May.”

Dry whey usage was down 6.5%, however, HGD said, “Despite waning domestic demand, limited inventories and rising exports helped propel the CME spot dry whey price to 62.50 cents per pound Aug. 1, the highest price since April 2022.”

The U.S. Department of Agriculture Department again lowered its 2024 and 2025 milk production

forecasts in its latest World Agriculture Supply and Demand Estimates report and blamed lower cow inventories for both years based on the most recent data in the milk production report. Output per cow was also reduced for both years.

2024 production and marketings were projected at 226.3 and 225.3 billion pounds, respectively, down 600 million on both from last month’s estimate. If realized, both would be down 100 million pounds or 0.04% from 2023.

2025 production and marketings were projected at 228.2 and 227.2 billion pounds, respectively, down 900 million pounds on both. If realized, both would be up 1.9 billion pounds or 0.8% from 2024.

Price forecasts for 2024 cheese, nonfat dry milk and whey were raised from last month based on recent price strength. The butter price forecast was lowered.

Cheese is expected to average $1.8250 per pound for 2024, up a half-cent from last month’s estimate, and compares to $1.7593 in 2023 and $2.1122 in 2022. The 2025 average was also raised a half-cent to $1.86 per pound.

The 2024 butter price average was lowered to $2.99 per pound, down 1.50 cents from last month’s projection, and compares to $2.6170 in 2023 and $2.8665 in 2022. The 2025 average was projected at $2.9850, up 2 cents from last month.

NDM is expected to average $1.1950 per pound in 2024, up a penny from a month ago, and compares to $1.1856 in 2023 and $1.6851 in 2022. The 2025 average was projected at $1.22, up 3 cents from a month ago.

Dry whey is expected to average 47 cents per pound in 2024, up 3 cents from last month’s estimate, and compares to 36.18 cents in 2023 and 60.57 cents in 2022. The 2025 average is projected at 45 cents, up a quarter-cent.

The Class III milk price forecast was raised, based on higher cheese and whey prices, and projected to average $18.40 per hundredweight in 2024, up 15 cents from last month’s estimate. That compares to $17.02 in 2023 and $21.96 in 2022. The 2025 estimate is $18.65, up 20 cents from last month’s projection.

The Class IV price was raised. Higher NDM prices more than offset the reduction in butter prices. The 2024 average was projected at $20.80 per cwt, up a nickel from last month, and compares to $19.12 in 2023 and $24.47 in 2022. The 2025 estimate was $20.95 per cwt, up 35 cents from a month ago.

This month’s U.S. corn outlook was for larger supplies, lower domestic use, greater exports and smaller ending stocks. Corn production was forecast at 15.1 billion bushels, down 1% from 2023, which if realized would still be the third highest on record for the U.S. The yield was forecast at a record high 183.1 bushels per acre, up 5.8 bushels from last year’s nal estimate of 177.3 bushels. Total planted area, at 90.7 million acres, is down 1% from the previous estimate and down 4% from a year ago. Area harvested was forecast at 82.7 million acres, down 1% from the previous forecast and down 4% from a year ago.

The crop production report indicates that yields are forecast above a year ago in Illinois, Indiana, Iowa, Missouri, Nebraska and South Dakota and down in Ohio. The season-average corn price was lowered 10 cents to $4.20 per bushel.

The soybean outlook includes higher production, exports, and ending stocks.

Production was forecast at a record 4.59 billion bushels, up 10% from 2023. Yields are expected to

average a record 53.2 bushels per acre, up 2.6 bushels from 2023. Area harvested was forecast at 86.3 million acres, up 1% from the previous forecast and up 5% from 2023. The season-average soybean price was forecast at $10.80 per bushel, down 30 cents from last month. Soybean meal was forecast at $320 per short ton, down $10.

Meanwhile, the latest Crop Progress report showed 94% of U.S. corn was silking, as of the week ending Aug. 11, up from 88% the previous week, 1% behind a year ago, and dead even with the ve-year average. Sixty percent was at the dough stage, even with a year ago, but 4% ahead of the ve-year average. Sixty-seven percent was rated good to excellent, unchanged from the previous week, and compares to 59% a year ago.

Ninety-one percent of the soybeans were blooming, up from 86% the previous week, 2% behind a year ago, but 1% ahead of the ve-year average. Seventy-two percent were setting pods, down 3% from a year ago, but 2% ahead of the average. Sixty-eight percent were rated good to excellent, same as the previous week, and compares to 59% a year ago.

Dairy cow slaughter continues to lag. The week ending Aug. 3 saw 51,200 head sent to slaughter, same as the week before but 9,300, or 15.4%, below a year ago. Year to date, 1,636,000 have been culled, down 276,700 head or 14.5% from 2023.

Tuesday’s GDT Pulse saw 4.4 million pounds of product sold, up from 3.86 million in the last Pulse, and the highest since March 12. Prices of skim milk powder and whole milk powder were both up from the July 30 Pulse.

Milk volumes are seasonally trending lower across most regions of the U.S., according to DMN’s weekly update. High temperatures and humidity are pressing milk volumes lower over most of the country. Lower volumes stretch from the Northeast and down the Atlantic Coast. Some larger farms in Florida are seeing more steady volumes, while other parts of the state are seeing steep declines.

Most of the West is dealing with lighter milk production with the Pacic Northwest conveying a slight increase. Demand for all Classes in the West has not changed and is steadily soaking up any multiples available. The Midwest is not immune to the doldrums of summer. Farm-level milk continues to decline as the summer temperatures climb. Spot milk in the Midwest is scarce and becoming more difcult to nd, said DMN.

Class I demand is ticking up as regions prepare for schools to restart in the coming weeks. The same can be said for cream and condensed skim milk. All regions of the country are experiencing strong demand and tight availability for cream and condensed skim milk. Some requests for condensed skim milk in the West could not be lled for lack of available stock. Class IV demand for cream is strong with butter makers as they keep busy production schedules.

Looking down under, DMN reports that Australian farmgate milk prices for the 2024-2025 season were cut close to 15% from several processors, amid increasing competition from imported dairy products. A spokesperson for a dairy farming group stated that input costs have increased in recent years and lower milk prices will add further pressure on dairy producers and could drive more dairy farmers out of business. A representative from a processor within the country noted lower priced butter and cheese imported into Australia is negatively impacting sales within Australia.

As always a good amount of late consignments of cows, heifers, steers coming in every week

on Labor Day • September 2nd Expecting 700 fed cattle. Auction starting at Noon with fed cattle ADVANCE NOTICE:

June New Zealand milk production data showed output down 1.1% on a tonnage basis compared to a year earlier. Export data showed a combined 10% decrease in value for milk powder, butter and cheese compared to June 2023. A group in New Zealand that forecasts dairy production predicts the volume of milk solids produced in New Zealand in July will decline 0.2% from 2023, but they anticipate the volume of milk solids produced in the country to increase from

from August

By Tiffany Klaphake tiffany.k@dairystar.com

DES MOINES, Iowa — New royalty was crowned Aug. 7 on the eve of the 2024 Iowa State Fair.

Haley Ronnebaum of Earlville was crowned the 2024-2025 Iowa Dairy Princess. Ronnebaum is the daughter of Mitch and Jenny Ronnebaum.

“I’m really excited,” Ronnebaum said. “It hasn’t fully sunk in yet, but I’m excited for what is to come.”

The judging process took place Aug. 6 and 7. It included a group interview, individual interviews and a prepared speech. There were eight candidates for this year’s contest.

“I knew I did my best,” Ronnebaum said. “Every single girl there could have made dairy princess; they were all so amazing. I denitely made a lot of friends.”

Ronnebaum grew up on her family’s 200-cow dairy farm, but the family sold the herd in December 2023. Now the Ronnebaums custom feed heifers and Ronnebaum works on a cousin’s dairy farm, KCCK Genetics. On the farm, Ronnebaum’s duties include scraping in the barns and checking on the heifers every day.

The 18-year-old was active in 4-H and FFA competing in dairy cattle judging and dairy quiz bowl. Ronnebaum is a freshman at Iowa State University where she studies

The new Iowa Dairy Princess, Haley Ronnebaum (le ) stands with new Iowa Dairy

Aug. 7 at the Iowa State Fairgrounds in Des Moines, Iowa. Both women will begin in their new role represen

dairy industry on Sept. 1.

dairy science with intentions to become a large animal veterinarian.

Being crowned Iowa Dairy Princess has been a dream of Ronnebaum’s for many years.

“I’ve always wanted to be the Iowa Dairy Princess,” Ronnebaum said. “For many years, I judged cattle at the Iowa State Fair and we would go down and watch the coronation.”

Ronnebaum said she is looking forward to the year ahead.

Turn to IOWA DAIRY PRINCESSES | Page 10

Fort Atkinson Hay

Ft. Atkinson, Iowa • 563-534-7513

Aug. 14, 48 loads

Small Squares

2nd crop

3rd crop

$125/ton 1 load

Rock Valley Hay Auction Co.

Rock Valley, Iowa • 712-476-5541

Aug. 15, 68 loads

Large Squares

1st crop

$95-97.50/ton

$100/ton 1 load Straw

1st crop

Straw

$120/ton 1 load

Large Squares

$150-190/ton 3 loads

$40-85/ton Grass

1st crop

2nd crop

3rd crop

$70-75/ton 2 loads

Rounds

$50-75/ton 2 loads

$65-130/ton 9 loads

$85-95/ton 3 loads Grass

$20-90/ton 12 loads Straw

$40-85/ton 8 loads

2nd crop

3rd crop

Grass

Straw

1st crop

2nd crop

3rd crop

Grass

Mixed

Straw

Corn stalks

$120-135/ton

$95-105/ton

$102.50/ton

$105/ton

Large Rounds

$92.50-112.50/ton

$90-125/ton

$125-130/ton

$30-120/ton

$57.50-110/ton

$115-130/ton

$42.50-45/ton

“I am looking forward to seeing Iowa and meeting farmers from across the state,” Ronnebaum said. “I know people from my area, but it’s always exciting to meet new people.”

Harley Baumler of Fort Atkinson was named 20242025 Iowa Dairy Princess Alternate for the upcoming year. Baumler is the daughter of Mike and Amy Baumler.

“I was surprised when I was crowned,” Baumler said. “I am condent that I will do well in this position. I am very excited for the upcoming year to represent the dairy farmers of Iowa.”

Baumler grew up on her family’s dairy farm, but the Baumlers have since sold their dairy herd. The family now owns about 20 cow-calf pairs.

The judging process for Iowa’s dairy royalty was conducted over two days. It included some fun and time for the girls to get to know one another.

“I felt very content after the interviews,” Baumler said. “I felt I answered the questions to the best of my ability. Whatever the outcome was I would’ve been happy because all the girls were very knowledgeable. I was condent whoever (won) the position would do an amazing job.”

Earlier this year, Baumler graduated from Ellsworth Community College with a degree in professional studies of agriculture. This fall she plans on continuing her education by attending Iowa State University and will major in agriculture and rural policy.

“I hope to work for a commodity group and oversee their government affairs and close the gaps between consumers and farmers to utilize the check off towards the farmer benet,” Baumler said.

This summer, as Baumler nishes up her internship with the Iowa Department of Inspections, Appeals & Licensing, she is getting ready to start her new role as the Iowa Dairy Princess Alternate.

“I am looking forward to connecting with the consumer,” Baumler said. “I also want to encourage other girls to run for Iowa Dairy Princess.”

Both women will begin in their new role representing Iowa’s dairy industry on Sept. 1.

gether since they got married 16 years ago and took over the farm from Paul’s dad, Allan, and uncle, LeRoy.

By Mark Klaphake mark.k@dairystar.com

AVON, Minn. — Taking on the daily tasks of dairy farming together as a family is a big part of why Paul and Becky Dobis relish dairy farming.

“It’s something that not a lot of people can do, so to me it’s a privilege to do it,” Paul said.

The high school sweethearts have been working to-

Working together for a common goal was on display Aug. 14 when the family’s biggest chore was to make small squares of straw on their 240-cow dairy near Avon.

The couple has six children, Anthony, Natalie, Mark, Felix, Eve and Abigail, and the task for that Wednesday was putting up straw in the hay mow of the old barn.

“When they are young, they each have their own responsibility like chickens or

Turn to DOBIS | Page 14

heifers to feed,” Becky said. “Sometimes they forget about it. But I tell (them) they need to be fed every day because they can’t feed themselves. We try to teach them to be responsible.”

The Dobis family started their day in their usual fashion; working in their 8-row cross-ventilated barn with four robots that was constructed seven years ago.

Around 6 a.m., Paul checked to see if there were any calves born overnight and handled any health-related issues with the cows and any breeding tasks. Shortly after, with the help of Anthony, he mixed feed for the dairy herd and the rest of the animals on

the farm.

Becky, who grew up on a chicken and beef farm, helped in the barn and then turned her attention to feeding calves.

“I always had an interest in it as a little girl and always said I would marry a dairy farmer,” Becky said. “It’s very peaceful, just being able to raise a family on the farm.”

Ben Schaefer, a 16-yearold who helps on the farm part time, came to the barn to help bring in fetch cows.

A short time later, Anthony and Mark made their trek to the barn to scrape the stalls and bed them with the bedding chopper.

By around 9:30 a.m.

STAR

Paul (le ) and Felix Dobis load a protein mixture into the total mixed ra on mixer Aug. 14 at their farm near Avon, Minnesota. The

family starts morning chores at 6 a.m.

chores were complete.

Next, family put their focus on baling straw. Paul was planning to ll the hay mow of their old milking barn. Throughout the year, the straw supply goes down daily as they are used to bed the calves that are housed in the old dairy barn, and six bales are shredded each day to put on top of the mats in the cross-ventilated barn.

Dobis purchases the straw from a retired dairy farmer,

LeRoy Gondringer.

After Dobis brought the tractor, baler and wagons to the eld, Gondringer ran the baler.

Becky and Felix towed the loads back and forth several miles with the pickup truck, while Natalie watched her two younger sisters in the yard.

Back in the farmyard, Paul and the boys hooked up the John Deere 530 and pulled the loads to the con-

veyor to be unloaded. Schaefer and Mark teamed up to unload while Paul and Anthony climbed in the dusty, warm hay mow to stack bales from the conveyor.

“The best part (of farming) is not having to drive into work and being able to work with family and being able to work for yourself,” Paul said.

Con�nued from DOBIS | Page 14

In between loads, the boys hung out in the shop.

Around 4 p.m., Kameron Sand, a part time employee, arrived and went to the barn to bring in fetch cows. Paul also spent time working on breeding duties and checked over the milking herd.

Around 6:30 p.m., approximately 800 bales had been baled and the last of the six and half loads were unloaded and piled in the barn. Together, the family had accomplished their big-

gest task of the day.

“The biggest thing is creating good habits in (our children’s) life,” Paul said. “(We are) teaching them hard work and with hard work pays of and you get rewards in life with hard work and then spending time with family.”

The family ate supper together and started thinking about Thursday.

“It felt good to get the straw done,” Paul said. ”Just a normal day, a different job but normal day.”

their dairy herd.

MARK KLAPHAKE/DAIRY STAR

LeRoy Gondringer lls a wagon full of small square bales of straw Aug. 13 on his farm near Avon, Minnesota. The Dobis family bought the straw from Gondringer.

By Danielle Nauman danielle.n@dairystar.com

ATHENS, Wis. — Dairy farming and processing their own milk had been a long-time goal for Daniel and Elaine Beachy — and a change they felt necessary to ensure the future of their organic dairy farm.

“Processing my own milk is a dream I carried since we had started farming,” Daniel Beachy said. “When the opportunity came to get started, we felt like it was a step we needed to take.”

The Beachys milk 33 A2A2 cows at Clover Meadows Family Farm, their grass-fed, organic dairy. They milk their cows in their 20-stall barn, which they use as a at parlor. After milking, the cows go out to pasture. During the winter months, they are housed on a bedded pack. Each of the Beachys’ cows have a name, and naming new calves is a family affair.

The Beachys own 60 acres and rent an additional 150 acres. The majority of their ground is used for grazing.

The road to processing their own highly-specialized milk has been long.

Beachy grew up just over the fence from their present-day home. A couple of years after their marriage, the farm they cur-

rently reside on became available for purchase. The young couple took the leap in 2007, launching their family dairy farm.

Until recently, the Beachys focused on milking a herd of Holstein cows. As they switched to the grass-fed model, they began breeding their cows to breeds that are more efcient grazers such as Fleckvieh and Normande. Their cows are primarily bred using A.I.

When they began farming, the Beachys shipped conventional milk to Grassland Dairy Products. They began the process to transition their land and herd to organic production in 2012.

“I liked the organic idea,” Beachy said. “I didn’t exactly like all the spraying, chemicals and antibiotics, and it was also a better milk market.”

The farm was certied in 2015, and they began shipping organic milk to Westby Cooperative Creamery.

“I shipped conventional milk for eight years — I saw $9 milk and I saw $23 milk,” Beachy said. “You never knew what you could expect. On the organic side, we saw $33 milk and that was good, but soon after we were in it, that market crashed off.”

A desire to control the price received kept the processing dream alive in the back of their minds.

“We were at a place where we felt like we either needed to get bigger or start processing on our own,” Beachy said.

Three years ago, an opportunity arose to pursue their processing dream.

DANIELLE NAUMAN/DAIRY STAR

Clover Meadows Family Farm grass-fed A2A2 cream line milk sits in the cooler awai�ng distribu�on Aug. 16 on the Beachy family’s farm near Athens, Wisconsin. The Beachys bo�le whole and chocolate milk in half-gallon glass bo�les. Chocolate milk is also bo�led in 12-ounce, plas�c grab-and-go containers.

The Beachy family — Carson (front, from le�) Daniel, Elaine holding Quinton, Darlissa and Lucinda; (back, from le�) Jeffrey, Marlita, Jason and Delmar — displays bo�les of their Clover Meadows Family Farm milk and yogurt Aug. 16 on their farm near Athens, Wisconsin. The Beachys have been processing their own grass-fed, organic A2A2 cream line milk for three years. Not pictured, Arlin Beachy.

“I worked with a fellow that was processing milk and was looking to get out of the business,” Beachy said. “I was able to purchase the processing equipment and roll into what he was doing as far as a market and everything.”

The market that the Beachys inherited was a 100% grass-fed, A2A2 market for whole milk. The Beachys changed their management style, adopting their herd to fully grass-fed, and selling any stock that were not A2A2.

“The pandemic showed us there isn’t really a good connection between the farms and the store shelves or the table,” Beachy said. “We feel we have a better connection with our consumers by processing our own milk, bringing the farm closer to the consumer.”

The Beachys process an average of 25,000-27,000 pounds of milk each month from their herd. They bottle cream line whole milk and chocolate milk and make ve avors of a Europeanstyle drinkable yogurt — plain, raspberry, wild berry, vanilla and orange. All the avors except plain are sweetened with locally sourced maple syrup.

“Our plant isn’t certied organic, although the farm is and all of the ingredients we use in the yogurt are,” Beachy said. “We just never went through that process to certify the creamery.”

Milk is bottled in glass half gallons and yogurt is bottled in quart-sized glass bottles, which the Beachys ask their customers to return to the stores from which they purchase. Chocolate milk and yogurt are also bottled in 12-ounce, plastic grab-and-go containers.

“I would say about 80% of our customers are really good about cleaning and returning the bottles,” Beachy said. “When we get them back, we spray and hand-scrub each one, then run them through a mechanical bottle washer to sterilize them.”

The Beachys wholesale their milk, delivering it themselves to about a dozen local stores within a 50-mile radius of their farm. They also work with an Appleton-based distributor that picks up weekly at the farm, stocking 25 stores in southwest Wisconsin.

A Golden Harvest Market truck also picks up a weekly order.

“How much of each product we make depends on sales,”

Beachy said. “Yogurt has an eight-week shelf life, while the milk has a 23-day shelf life. We can build up some stock on yogurt, but we run a tighter inventory on milk. I don’t like to process more than I need for the week.”

Throughout their three ears of processing, the Beachys say their in-store sales remain relatively consistent, year-round.

“That consistency in sales might be partly due to the specialty of our products,” Beachy said. “The cream line, A2, grass-fed milk is processed with low-temp pasteurization.”

The Beachys say it is rewarding to hear from customers who previously thought they could not consume dairy, but have discovered the A2 proteins in their products allow them to enjoy dairy again.

“What is the point of producing organic milk if it is homogenized and pasteurized to the point of killing all the benecial things?” Beachy said. “We want to get our milk to the shelves as fresh and unadulterated as possible. Our goal is to keep it simple and get good food out to the people and provide for our family.”

Mid-American Auction Hay sales start at 12:30 p.m. and are the 1st and 3rd Thursdays of the months of September thru May. September 5, 2024 September 19, 2024

By Tiffany Klaphake tiffany.k@dairystar.com

HOT SPRINGS, S.D. — Melissa Holt wears many different hats between working at home on her farm and at her restaurant, Two Cows Creamery & Bistro.

“I am not only a farmer, but a chef and a big foodie,” Holt said. “Food is important to me; the freshest I can get it is from a local farm.”

Holt and her husband, Scott Roi, own a farm where they raise four A2A2 Jersey cows, pigs, yaks and chickens and grow produce. On the farm as well are a hoop house and a greenhouse with geothermal heat.

Bistro are fresh year-round.

“We make homemade patties every day,” Holt said. “We cut potatoes for fries every day, we cut lettuce, tomatoes and onions every single day, and we make garlic aioli every day. Now one of our greenhouses is giving us a slew of cucumbers and we will make our own pickles with them.”

From June through September, Holt gets most of the produce from their high tunnel greenhouse and crop elds. From October until May, Holt utilizes her underground greenhouse.

“It is growing many of the same things we grow in the summer,” Holt said. “We also grow some tropical fruit. We have a bumper crop of passion fruit coming later this year. We also have a lot of citrus fruits, dwarf banana trees, guava, gs and grapes.”

Two Cows Creamery & Bistro

“We have dairy cows at home and a dairy plant in the basement of our shop,” Holt said. “So, we truly are a cow-to-cone operation.”

At any given time Two Cows Creamery & Bistro has 24-26 varieties of ice cream on hand, including sorbets and gelatos. In all, the ice cream and sandwich shop can make about 220 ice cream avors.

“We are changing out our ice creams every couple of days,” Holt said. “Our top ve avors are vanilla, chocolate, strawberry, cookies ‘n cream and expresso chip.

Holt, her husband and their team of employees make ice cream 3-4 days a week. Some of their unique avors are lemon berry cupcake, black raspberry chip and dragon fruit sorbet. Some avors, like South Dakota Cow Pie, were created by fans of Two Cows Creamery & Bistro.

“Once a year we have the public put in avor requests,” Holt said.” Then we pick which one we are going to make.”

Holt uses the produce from her farm and 15 other area farms to source ingredients used to create the vast menu of food and ice cream items.

“From my farm we get milk, pork, chicken and yak,” Holt said. “From my daughter’s ranch we get beef and from another local farmer we get lamb.”

Fresh produce such as herbs, potatoes, onions, carrots and garlic come from Holt’s farm and other local farms. Holt’s greenhouse and some at the other farms are underground so ingredients for items made by Two Cows Creamery &

The underground greenhouse uses dirt and an aquaponics system for growing the plants. The system has tilapia sh in the water.

The underground greenhouse is geothermally heated with pipes that go 10 feet into the ground. At night, hot air is naturally pulled up from the ground and during the day, the hot air from the greenhouse is pushed back into the ground.

“Here in Hot Springs, we have all this hot water and hot ground,” Holt said. “It is a full circle system.”

The few food items that Holt is not able to get from local sources are brought in, with an emphasis on quality.

Two Cows Creamery & Bistro started when the Holts reached a point in their life where they realized they needed to grow as much of their own food as they could.

“My husband, Scott, has an autoimmune disease,” she said. “I reached a point in my chef career that was frustrating seeing what was happening in the food world.”

Holt grew up gardening and with her chef background, already knew a lot about food. Her mom grew up on a farm and taught them a lot about farming, Holt said.

“At home I was grinding my own wheat, and we have some cows, so I was making my own butter,” Holt said. “It just grew from there.”

In 2020, Holt began selling ice cream at farmer’s markets.

“In the wintertime, people kept asking for ice cream and when were we going to open up a shop,” Holt said.

“I had a son selling farm products, so (we thought) why don’t we open an ice cream shop and sell farm products from other farms,” Holt said.

With her experience of growing her

own food and as a chef, Holt decided to combine her two passions and offer food as well as homemade ice cream.

“My best days are spent digging in the dirt,” Holt said. “My next favorite thing to do is our farm-to-fork dinners. I love to menu plan so they are a lot of fun.”

The rst winter after opening up their restaurant, Holt decided to host their rst farm-to-fork dinner as a ticketonly, themed event that occurred from October to April.

“We create it to be a little fancy,” Holt said. “Who wouldn’t want to go to a fancy French dinner in the middle of winter.”

The suppers were a hit and tickets sold out immediately. Each dinner in-

cludes an appetizer, a soup or salad, a sorbet, an entrée and a dessert. The dessert always compliments one of the custom ice cream avors Two Cow Creamery & Bistro creates.

“It’s also a way for me to feature different local farms,” Holt said. “During the dinner, I talk about those farms and farmers. I try to make those about other farms besides mine.”

Between the ice cream, restaurant and farm-to-fork dinners, Two Cows Creamery & Bistro’s process might be labor intensive, but the quality is worth it Holt said.

“It’s so fresh that you can taste the difference,” she said. “It supports the community and that’s really important to me.”

Crop and weather conditions in Dairy Star country

100 acres and put it in a bunker. We are cutting our sorghum sudangrass; it’s 8 feet tall. The neighbors are cutting fourth cutting alfalfa. The soybeans are 4 feet tall and have some yellow spots; nobody knows what it is. They look really good. The sunflowers planted after the wheat are 1 foot tall. We’ve cut some grass for a second time and are hoping to take a fall cutting as well. It’s really dusty and dry, the soybeans could use a boost of water.

Third-crop alfalfa came back really nice, once there is a good window of weather, we will start cutting it. All of the corn is tasseled, including the fields planted late. We gained some good height in the last two weeks. The soybeans are looking really good, they are no longer yellow from being too wet. We got our oats harvested, which averaged 80-bushels per acre. The straw averaged 2 bales per acre. People are still waiting for the wheat in the area to turn a little more. My millet is growing fairly well. I plan on chopping it about the same time as corn.

It’s been catchup on the farm right now. The thirdcrop alfalfa looks good and is coming; it should be ready in the next 7-10 days. There is a lot of hay out there. The corn is very uneven. In some fields the corn is tall and tasseled and in other areas it’s only waist high. It will be a long chopping season this year. A couple weeks ago we did the meadows. I think we are done with those for the year. They probably won’t dry out anymore because the days are getting too short. There is water everywhere and there isn’t much going on in the fields around here.

We got our third-crop of alfalfa put up around July 17 and are about two weeks from being able to do fourth-crop. Some of the pivot irrigators ended up running in the area to help the crops finish out nicely. We did have a chance of rain for the rest of the week, Aug. 7-10. Our corn is looking really good. I think we are about a month away from making silage. From the road, the neighbors’ beans are coming along nice. There are some people in the area that are crop dusting for insects and fungi.

We have harvested 1/3 of our oats and have 2/3 standing. We were swatting but we will probably try to straight cut the crop. Our wheat is ready as well, when the fields are ready we plan to do both. There looks to be a lot of straw. We are working on third -crop hay. We have 45 acres done and 100 left. It is purple and going down in spots. In our area the low spots have water standing in them 80% of the time. The corn is uneven, but the soybeans look really nice. We are hoping for drier weather this week.

Cornell QMPS has proven you can get more from your herd more staph-aureus and beef.

They started with 30 cows and 5 confirmed cases of staph-aureus and then milked the 15 with no staph-aureus with a GEA system and milked 15 cows with 5 cases of staph-aureus using CoPulsation™

When they finished the GEA group created 16 new cases while only one new case with CoPulsation™ Cornell reported a few cows died along the way - something many who milk with conventional systems experience routinely

We finished our rye harvest July 23 averaging 3040 bushels an acre. We ended up getting really nice round bales of straw from it. It was a little hard to get baled because we had humid weather. We are hoping to start our third-crop of alfalfa the week of Aug. 11. The soybeans and corn are coming along really nicely. The soybeans could use another shot of rain, but the corn is starting to catch up from all of the rain earlier this year. Our pasture was under 4 feet of water, but we were now able to put the cattle out there.

We got our third-crop hay done. We finished Aug. 3. It was a nice crop. We got our new seeding cut and it’s laying down now. We should be able to dry bale it tomorrow (Aug. 6). The corn we planted in early June is fully tasseled. I ordered fungicide to be applied on the corn. There is some northern blight, rootworm and japenese beetles in the field. The soybeans are canopied and really look good. There is not a weedy field out there. Within the next 7-10 days we will be on our fourth-crop hay.

Things are looking better and we have had some heat, but we could use more. It feels like there is some hope now. We were able to get our third-crop done, the yields were good and better than second-crop. There has been a lot of fungicide being sprayed aerially on corn and beans. The beans look much better and have nodulated. They are uneven in height, but they have a nice green color. The 30-inch beans have canopied. The corn is looking good. Everything except the low spots has tasseled completely and is setting on ears. The low and wet spots are just tasseling now. We are seeing a lot of compaction and tracks in the fields.

We finished third-crop hay July 25. It was pretty light as there was not a whole lot out there. It will be a couple weeks until fourth-crop, which is coming back strong. The crowns look healthy. We chopped new seeding alfalfa for the second time July 31 and Aug. 1. Some of the lower fields have a lot of water damage so we’re going to have to go in and reseed some of that. All of the straw is baled and chopped. We made a couple hundred bales and chopped 45 acres for bedding the last week in July. I’m thinking corn silage is going to be ready by late August or early September.

We have mainly been working on combining oats and baling straw. We have 65 acres left of the 130 acres of oats. The oats are yielding 100 bushels or more per acre. We had thought of doing 30 acres as oatlage, but with the rain, it was getting too old. We have started a little bit of third-crop. Our sweet corn is standing at a 45-degree angle from the rain we got the week of Aug. 5. It is tasseling, so I don’t know how it will do. From the road, all the neighboring crops look good. A lot of guys were spraying fungicides with helicopters and airplanes about a week ago.

We started cutting third-crop last week Monday July 29, but it was so foggy and had such a heavy dew we were having to quit by 7 p.m. There is a lot of thirdcrop, so we are running about two tons of dry matter per acre. We tested some and it came back between 170 and 180. Now we have standing water again in our alfalfa fields. We need to start on our sorghum sudangrass. We also need to get some manure hauled because our pit is about 6 inches from the top. The corn looks pretty good, it is fully tasseled and pollinated. The beans are waist-high, and talking with our seed rep, we are thinking 70-bushel beans are not out of the question.

We have had 3.4 inches in the last two weeks, 1.5 of that was last night (Aug. 5), so we are plenty wet again. We started our third-crop yesterday, it looks to be a bumper crop and the quality should be pretty good. We are 32 days on cutting it. The corn around here looks phenomenal, fully tasseled and the cobs are coming in. The beans in the area look great too. People are starting to combine wheat in the area as well.

Daryl baled a little third-crop Aug. 4, and we started mowing more Aug. 7. I cut some more second-crop hay on my land. I have a field that I cut four different times, and it got rained on every time I cut it. The corn we planted first is at the dough stage, and the kernels are getting ready to dent. That’s kind of a relief because we’re short on corn and now it’s going to be ready right on time when we’re going to run out. I thought we would have to buy some. We’ve been buying grain for our heifers all year. We usually have 2,000 bushels stored, but we’re buying it right from the co-op this year.

• Reduction and in many cases elimination of bacteria load in water.

• Improves medication performance in water, when used.

• Helping to improve profitability in these narrow margins

“Our

From the kitchen of Amber Pung, Freeport,

1 1/4 cup quick oats

1 1/4 cup our

1/4 teaspoon salt

3/4 teaspoon baking soda

1 cup brown sugar

1 cup butter, melted 1 bag milk chocolate chips

3/4 package Kraft caramels

Mix the rst six ingredients and press 3/4 of the mixture into a 9-by13 pan. Bake at 350 degrees for 10 minutes. While hot, sprinkle with chocolate chips. Melt Kraft caramels and heavy cream together; pour over chocolate chips. Sprinkle with the remaining crumb mixture. Bake for an additional 15-20 minutes.

From the kitchen of Amber Pung, Freeport, Minnesota

1 pound linguini pasta, cooked 1/2 cup soft butter

4 chicken breasts, cooked and cut up

2 cans cream of chicken soup

2 cups sour cream

1 teaspoon salt 1/2 teaspoon pepper

2 tablespoons Parmesan cheese

2 cups mozzarella cheese, shredded

In a large bowl combine butter, chicken, soup, sour cream, salt and pepper. Add cooked pasta and mix well. Pour mixture into a greased 9-by13 pan. Sprinkle cheeses on top. Bake at 350 degrees for 40-45 minutes.

32-ounce bag frozen, shredded hashbrowns

1/2 cup melted butter

1 can cream of chicken soup

12 ounces grated American cheese

6 tablespoons heavy cream 8 ounces sour cream 1 teaspoon salt

1/2 small onion, chopped 2 cups crushed cornakes

1/2 cup melted butter

Put hashbrowns into an ungreased 9-by-13 pan. Mix the other ingredients and spread over the hashbrowns. Top with cornakes and melted butter. Bake uncovered at 350 degrees for 45 minutes.

Holstein bull calves $500-750. Beef dairy cross calves $750 -925. See our website for more market report updates and early consignments! We Thank you for your business!!

‘20 Mustang 3300V NXT2, ISO/JS ctrls, dsl, 3300 lift cap, C/H/A, 2 spd, Hydra Glide, 5,090 hrs .........................$28,500

‘19 Mustang 2700V, ISO Ctrls, 72HP Dsl, 2700 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 14 Pin, Back Up Camera, 261 hrs.......................................$58,900

‘18 Mustang 1650RT, H/F Ctrls, Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 975 hrs$50,900

‘13 Mustang 2056 II, Case Ctls, Dsl, 2150 Lift Ca, C&H, 2 aSpd ........$29,500

‘20 Mustang 2150RT, JS Ctrls, 72HP Dsl, 18” All Season Tracks, 2300 At 35% - 3000 At 50%, C/H/A, 2 Spd, 2,265 hrs. ...................................$39,750

‘21 Mustang 1650R, H/F Ctrls, Dsl, C/H/A, SS, 3,640 hrs .................$32,900

Gehl V400, T-Bar Ctrls, Dsl, 4000 Lift Cap, C/H/A, 2 Spd, 2,570 hrs ............$37,750

‘15 Gehl R220, JS Ctrls, Dsl, 2500 Lift Cap, C/H/ A, 2 Spd, Hydra Glide, 3,125 hrs....................................$36,250

‘21 Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs.....................................$53,900

‘20 Gehl RT165, T-Bar H-Ctrls, 70HP Dsl, 15.5” All Season Tracks, 2100 Lift Cap, C/H/A, 1,875 hrs.......................$36,800

‘19 Gehl RT165, ISO/JS Ctrls, Dsl, 15 1/2 All Season Tracks, Lift Cap 1800 @ 35% And 2400 @ 50%, C/H/A, 2 Spd, 1,758 hrs. ..................................$41,750 ‘17 Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso Tracks HXD 450x86x58, Both Standard And Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty Till 6-30-26 or 1000 Hrs ..................$48,500

‘19 Gehl V270, JS Ctrls,

‘18 Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,600 hrs ....................$23,000

‘17 Gehl R220, H-Ctrl, Dsl, 2500 Lift Cap, C&H, 2 Spd, 4635 hrs .......$28,500

‘15 Gehl V330, ISO/H-Pattern, 73HP Dsl, 3300 Lift Cap, C/H/A , 2 Spd, 5,620 hrs...................................$25,500

Gehl R190, Dual-H Ctrls, Dsl, 2150 Lift Cap, C&H, 2 Spd, 6,130 hrs ......$22,500

‘21 Gehl R150, T-Bar Ctrls, Dsl, 1650 Lift Cap, C&H, 1,965 hrs .................$31,900

Gehl RT135, ISO Ctrls, 46HP Dsl, 1350 Lift Cap, C/H/A, SS, 107 hrs......$46,500

‘19 Gehl V270, JS Ctrls, Dsl, 2700 Lift Cap, C&H, 2 Spd, 250 hrs. ........$57,500 ‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650 Lift Cap, C/H/A, 2 Spd, 169 hrs.......................................$56,500

‘20 Deere 332G, ISO/Dual H-Ctrls, Dsl, 3600 Lift Cap, C/H/A, 2 Spd, 975 hrs.......................................$56,000

‘06 Bobcat MT52 standon ldr., 20HP dsl, tipping load 1600 lbs, standard auxiliary hyd, 411 hrs...............................$14,500

‘17 Case SV280, Switchable ISO/Dual H-Ctrls, Dsl, 2800 Lift Cap, Hi-Flow, C/H/A, 2 Spd, 360 hrs. ..............$55,500

‘20 Artex SBX950, 950 Bu, Cyclone Beaters, Raven w/ unlocks, CR7 Display ......................................$99,500

‘18 Artex SB600, 1 3/8 1000 PTO, Vert Beater ................................$47,500

‘20 Artex SBX800, 800 Cu Ft, Guillotine Endgate, 88C Apron Chain, Hyd Apron Pressure Relief Kit, Heavy Duty Vert Beaters, Teeth & Rippers Updated ...................................$57,500

Meyers VB750, 600 Bu, 482 Cu Ft Struck, Vert Beaters, 5 Pt Digi Star Scale, Nutra Tracker NT Scale Head, No GPS Puck Included .....................................$46,500

‘17 Kuhn Knight SLC132, 425 Tires, 3200 Gal ....................................$36,500 ‘17 Kuhn Knight 8124, 19L X 16.1 Flotation Tires, 2400 Gals, 500 Bu, Frt & Rear Splash Guards, Low Usage$34,500 ‘23 Kuhn Knight PS280, Accuspread Spinner Beater (Litter), Athne ScalesISObus, Light Kit, Headland De ector, Auto Chain Oiler ......................$116,000 Kuhn Knight SLC141, 28L-26 Tires, 4100 Gallons .............................$47,000 Kuhn Knight 8132, 1 3/8 1000 PTO, 3200 Gals ....................................$15,000

.......................$13,000 ‘20 MANITOU MLA-T533-145V+, Dsl, 7200 Lift Cap, C/H/A, Power Q-Tach, CVT Trans, 4,481 hrs. ..........................$95,500

‘11 H&S 5126, 2600 Gallons, 347 Cu Ft .....................................$8,900 NH 185, 170 Struck Cu Ft, 275 Bu, Upper Beater, T-Rod 67 Apron Chain, Poly Floor, End Gate ...................................$12,900 ‘19 Doda AFI-35, 1 3/8 1000 PTO, 6” .................................................$7,500

‘21 Artex SBX700, 726 Cu Ft, Guillotine Endgate, 88C Apron Chain With Tube Slats, Twin Vert Beater...............$53,500 ‘21 Artex SBX700, 726 CuFt, Guillotine Endgate, 88C Apron Chain W/Tube Slats, Twin Vert Beater...........................$57,900

Raking