“All

Blue is for memories

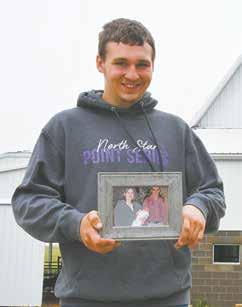

AMY KYLLO/DAIRY STAR

Ethan Neumann holds a photo of his parents and him as an infant outside the barn Aug. 15 on his family’s farm near Plainview, Minnesota. Each year, Neumann buys a ribbon at the blue ribbon auc on at the Wabasha County Fair in honor of his dad, Jared, who passed away at the age of 25 when Neumann was a baby.

Neumann buys ribbon in honor of late father at 4-H auction

By Amy Kyllo amy.k@star-pub.com

PLAINVIEW, Minn. — For Ethan Neumann, the Wabasha County 4-H and FFA blue ribbon auction is a place where he honors his late dad, Jared Neumann, with a purchase of a ribbon alongside his grandma, Roxann Neumann.

“It’s just something to do in memory of Dad, since he always liked to give back,” Neumann said.

The 17-year-old will be a senior in high school at Plainview-ElginMillville this fall. Neumann helps on the farm alongside his mom, Amanda Bedtke, and his stepdad, Adam Bedtke. The Bedtkes milk 50-70 cows on their organic dairy farm. They also farm 175 tillable acres plus 75 pasture acres. They grow rye, corn, hay and oats.

Visser crowned 71st Princess Kay

Minnesota dairy industry welcomes new representative

By Amy Kyllo amy.k@star-pub.com

FALCON HEIGHTS, Minn. —

If newly-crowned Princess Kay of the Milky Way Rachel Visser could have just one dairy product for the rest of her life, she would choose butter. Visser will be immersed in churned cream as her likeness is sculpted the rst two days of the Minnesota State Fair into 90 pounds of her favorite dairy product.

“(Being Princess Kay) is super exciting,” Visser said. “It almost doesn’t feel real, but I’m so excited for the next 12 days at the state fair

Connec ng consumers to dairy

The Millers host Family Night on the Farm

By Amy Kyllo amy.k@star-pub.com

LEWISTON, Minn. — Flanked by bunkers and bags of silage, attendees of Family Night on the Farm walked onto the Miller family’s Winona County farm site with the faint, sweet smell of silage in their noses.

Miller’s Clear Crest Farm, located near Lewiston, hosted the community event Aug. 8. The Miller family — Pat, Robb and Kathryn, Luke and Amie, Bradley and Lilly, Ella Miller, Janae Salvetti and Gavin Salvetti — milks 700 cows three times a day in a rotary parlor.

This was the rst time the family had hosted the event.

“At the end of the day, not everybody gets to see a cow get milked,” Luke Miller said.

DAIRY ST R

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and

“We’re just glad to provide that opportunity and we hope that all the kids, all the family members ... really had a good impression. ... We (want them to) know that (we) are producing a good quality product.”

The event was immersive. Outside the freestall barn, Jo Priem and her family were looking at the cows. Priem grew up on a dairy farm and said she likes her young boys to see how she grew up.

In the maternity area, Daphne Breitlow, a young girl who is usually anxious around animals, is reaching through the gates, touching the cows and even getting a few slobbery licks in return.

By the bulk tanks, a small crowd of people get a tour from Jacob Hornberg of Lang’s Dairy Equipment.

Attendees of the event could purchase a meal that included a hotdog or hamburger, potato chips, baked beans, string cheese, milk and a root beer oat. Activities included barrel train rides for the children, a bounce house, a petting zoo, tours, educational and business booths, wagon rides and more.

Leading up to the event, the Miller family had a busy season. A rainy spring slowed their eldwork and Bradley Miller, the next generation at Miller’s Clear Crest Farm, got married in June. The Winona County Fair in July added to the family’s workload before they

Robb, Luke and Pat Miller share informa on about their farm Aug. 8 at Family Night on the Farm at Miller’s Clear Crest Farm near Lewiston, Minnesota. This was the Miller family’s rst me hos ng the event.

could prepare for the event.

“It was kind of crammed into a couple of weeks, but we got it done,” Miller said.

The Winona Area Chamber of Commerce worked on the logistical details, leaving the family to get the farm prepared.

“It ... actually felt good to just go

do some cleaning that you normally wouldn’t do,” Miller said. “The chamber of commerce really did a good job, all we had to do was concentrate on getting the farm ready.”

Long Prairie, MN

Sartell, MN

MN

Des Moines, IA

Winona, MN

Avon, MN

MN

SD

For additional stories from our other zone, log on to www.dairystar.com

Stan Breitlow, a Winona native and chair of the Winona Area Chamber of Commerce, attended with his young family. The Breitlows said the yearly event helps them feel connected.

“It keep(s) it real,” Breitlow said. “You can know where your food comes from, where your meat comes from, where your milk comes from, and the amount of work it takes.”

The family has been attending the event for several years.

“The girls love it,” Breitlow said. “(My daughter has) been asking me a bunch of great questions about cows.”

The Breitlows said they appreciate being able to talk with experts about whatever is on their minds regarding the dairy industry.

Scott Ellinghuysen, a dairy production consultant with Ag Partners who works with the Miller family, was stationed in the feed alley in the maternity area of the free stall answering questions and helping the children interact with the cows.

“They just want to go up and touch a nose,” Ellinghuysen said. “I’ve been trying to help them just put their hand in there and hold it, let them touch you. That’s been working well.”

He said attendees were asking him questions about how long a cow milks and how soon calves are taken away from their mothers. They also

asked questions about how cows are fed and the purpose of the activity collars worn by the cows.

The Miller family’s farm began in 1936 when Luke and Robb’s grandfather, John, purchased the rst 80 acres for his 20 cows. Today the family farms over 1,500 acres of alfalfa, triticale, corn and soybeans.

In 1969, the rst parlor was built on the farm, and in 1972, Luke and Robb’s parents, Jack and Pat, took over the farm. In 1992, they added on to the parlor.

Luke and Robb joined the farm in 2003, and they built the rotary parlor setup in 2018.

“Conservation was in our mind when we built this facility,” Robb Miller said. “We invested in many efciencies.”

The most recent member of the dairy is Robb’s son, Bradley, who represents the fourth generation.

Though Jack has passed, Luke said his father would have enjoyed hosting the event. Luke said the family’s new rotary parlor facilities made it possible for them to have the

AMY KYLLO/DAIRY STAR

(Le ) Paul Woltmann carries his daughter, Madison, on his shoulders Aug. 8 at Family Night on the Farm at Miller’s Clear Crest Farm near Lewiston, Minnesota. Her parents said Madison had been talking about tractor rides all day in an cipa on of the event.

(Below) The Breitlow family — Stan (from le ), Molly holding Penelope and Daphne — looks at cows in the maternity area Aug. 8 at Miller’s Clear Crest Farm near Lewiston, Minnesota. The family has been a ending Family Night on the Farm for several years.

event at their farm.

The evening brought approximately 2,500 people to the farm.

“We’re very thankful (for) everybody that came out tonight,” Luke said.

Raths (le )

Neumann’s dad had had a pacemaker since he was an infant and passed away during a procedure to replace the battery at the age of 25 when Ethan was a just baby.

“It was entirely unexpected for things to go that way,” Amanda Bedtke said.

Neumann has been going 50/50 on a ribbon with his grandma since he was old enough to be eligible for 4-H.

“It’s a family tradition,” Neumann said. “Every year, Grandma and I get to hang out with each other for the day and walk around the fair.”

Beforehand, they get together to decide on a budget. The pair tries to buy a ribbon from someone their family has some connection to but does not worry about species.

Neumann’s dad had a custom bailing and wrapping business. As he bids on a ribbon, Ethan said he sometimes imagines what it would be like if he was bidding on behalf of that business instead.

“I think he’d be proud,” Neumann said. “(We’re) doing something in memory of him.”

His mom agreed.

“I think he’d be proud that it’s seless,” Bedtke said. “When you make money in the auction, ... you have a little bit to put in your project, and then you put more into someone else’s future.”

The ribbon is one of the ways that Neumann honors his dad. Each year on his dad’s birthday, as well as the day he passed, Neumann, his grandparents and the rest of the family have a meal in honor of his dad. Growing up, his grandma would bring cinnamon rolls on both dates for his entire class in school. Neumann said his classmates grew to look forward to those days.

When Neumann was 8 years old, he and his mom joined Adam on his farm. Adam had known Jared, so Bedtke said he will share memories of Jared with Neumann.

Neumann has been helping on the farm since he was a child. He started with a smaller workload such as helping with calves. Now he does eldwork, hauls most of the manure, helps with dehorning and vaccinations, and occasionally milks.

“(It’s) something that I enjoy, and

late father, Jared.

I’ve always enjoyed,” Neumann said. “I always love being outside, but I’ve just been around farming my whole life, and it’s something that I’ve kind of gotten used to.”

Besides helping on the dairy, Neumann also owns 15 Simmental beef cows. Neumann was a recipient of a beef heifer through the Minnesota Beef Expo’s Minnesota Youth Beef Experience Program. The program was a yearlong process that required him to apply, do cattle evaluations and research what beef breed he wanted to work with. Once he had the animal, he connected with an assigned mentor to make breeding decisions and work with a nutritionist and veterinarian on a feeding plan and vaccine protocols.

Bedtke said Neumann has been learning animal husbandry skills, like how to deliver a calf and manage the beef herd. This year, Neumann helped one of his beef cows with a breached birth with the coaching of his parents. The calf had expired, so he helped the cow take on a dairy calf.

“He spent that time every day out there, making sure that it was nursing and grafting the calf onto the cow,” Bedtke said. “It’s been fun watching him learn those things.”

After his rst delivery, Neumann was able to deliver a dairy calf when his parents were away from the farm.

“Your dad would be super proud of your ability to do those things,” Bedtke said.

Neumann said his dad was someone who did not put himself in the forefront.

“He was a more behind-thescenes type of guy,” Neumann said. “I’m just following in his footsteps.”

Besides buying ribbons, Neumann is also active in 4-H and FFA showing beef at the Wabasha County Fair, the open class FFA show at the Olmsted County Fair and the Minnesota State Fair.

When it comes to the future, Neumann plans to carry on honoring his dad with ribbons.

“I’ll continue as long as I can, buying something down there every year,” Neumann said. “It’s just fun to give back because other people do it for you. They buy your ribbon. So, it feels good to do it for someone else too.”

and the next year ahead.”

Visser is the daughter of Barry and Shannon Visser, of Hutchinson. The 19-year-old, representing McLeod County, will be a sophomore at the University of Minnesota where she studies agricultural and food business management and agricultural communications and marketing.

“I really got my start in the dairy community through working on the farm,” Visser said. “I really want to share that it’s the people around me who have fueled my passion, and that’s the case for anybody. It’s the people around them who encourage them to do what they love and to share their passion, whether it is the dairy industry or something different.”

Visser did not grow up on a dairy farm, but became involved in the dairy industry 11 years ago when she showed her rst Jersey calf.

Visser works for Chad and Stacy Bohn, who own Stadview dairy farm located near Litcheld. Visser is involved on the farm and helps care for her leased and owned show animals.

“I fell in love with the hardworking dairy farmers, and I wanted to learn everything about what they did to produce healthy dairy products,” Visser said. “I’m super excited to share the dairy story, not only my story, but from farmers across the state of Minnesota.”

Katie Ketchum, representing Winona County, and Grace Woitalla,

representing Stearns County, were named runners-up.

The trio of Visser, Ketchum and Woitalla also received three $1,000 scholarships given by Midwest Dairy.

Mackenzie Moline, representing Nicollet County, was named Miss Congeniality.

Visser said one of her goals as Princess Kay will be to work with children.

“I love working with kids,” Visser said. “If I can connect with them with my love for dairy, that would be awesome.”

Visser’s parents said they felt honored for Visser to be among the other nalists for Princess Kay. They said a trait that stands out to them about their daughter is her drive.

“When she nds something that she’s passionate about, she will give it 110% whether it’s helping out on the farm, (or) whether it is advocating for the industry,” Shannon said.

Her father agreed.

“Her best day at the fair is when she gets to talk to fair goers and gets to share her passion for the industry and talk about the great work farmers do every day,” he said.

Visser will be spending the rst 12 days of her reign at the Great Minnesota Get-Together.

“I’m really super excited to get to know the fairgoers and share a little bit about my passion for dairy,” Visser said.

One of her rst duties as Princess Kay will be to have her likeness sculpted in butter by Gerry Kulzer. Visser said she likes to put butter on everything and is not concerned with nding uses for her sculpture.

Visser will not be alone at the state fair; her family will also be at the fair all 12 days showing. Her sisters, Hannah and Kayla, said they are proud of their sister.

“She can always bring people together no matter who she’s around or who she’s with,” Hannah said. “She can always bring people together and just create a community.”

Visser is grateful for the dairy farmers she is representing.

“Thank you for the hard work that they do,” Visser said. “I look forward to learning more about what they’re doing on their farms and promoting their story and what they’re doing to produce healthy dairy products.”

USDA releases proposed changes to Federal Milk Marketing Orders

Economic experts weigh in on proposals

By Stacey Smart stacey.s@dairystar.com

Editor’s Note: This is part one of a two-part series discussing recommendations resulting from the Federal Milk Marketing Order hearing process.

MADISON, Wis. — On July 1, the U.S. Department of Agriculture issued their recommended decision on the Federal Milk Marketing Orders hearing process. From August 2023 to January, the USDA considered 22 proposals during 49 hearing days.

To help dairy producers and other industry professionals understand what was proposed, Professional Dairy Producers invited three economic experts to participate in a Dairy Signal webinar July 10: Dr. Charles Nicholson from the Department of Animal & Dairy Sciences and Agricultural & Applied Economics at the University of Wisconsin-Madison; Christopher Wolf, E.V. Baker Professor of Agricultural Economics and Director of Land Grant Affairs at Cornell University; and Mark Ste-

phenson, retired from UW-Madison as Director of Dairy Policy Analysis.

The recommended decision included ve categories of amendments: milk composition factors, barrel cheese price, make allowances, base Class I skim milk price, and Class I and Class II differentials. Participants can comment on the proposed amendments by Sept. 13, and the USDA will consider those comments and possibly make changes before the nal amendment is released.

Wolf said the USDA proposes to update milk composition factors to bump up closer to the average for milk production in the U.S. This would equate to 3.3% for protein and 6% for other solids, totaling 9.3% non-fat solids. Currently, it is at 9% non-fat solids.

Secondly, the USDA proposed removing the 500-pound barrel cheese and using only the 40-pound cheddar block to determine the monthly average cheese price when deciding component values.

“Right now, we have a weighted average split between barrels and blocks and there’s been some volatility in recent years,” Wolf said. “When it was originally proposed, there was the idea the barrels would usually be about 3 cents a pound discount to the blocks. Some of those relationships

have moved around, sometimes in unexpected ways, for people in the last few years.”

An increase in make allowances was also proposed. The make allowance accounts for the manufacturing costs of turning milk into various products. The proposal increases cheese from 20 cents to 25 cents per pound, butter from 17 cents to 22.5 cents, non-fat dry milk from 16.8 cents to 22.7 cents and dry whey from 20 cents to 26.5 cents. The last time make allowances were changed was in 2008.

“The reason farmers care about this is that if everything else stays the same, increasing that manufacturing allowance is going to lower the component price, which is the milk price,” Wolf said. “What specic effect it’sgoing to have depends on where you’re located, the current situation with premiums, what products we’re talking about and the length of run.”

Wolf shared an example of the butterfat price when comparing the proposed make allowance to the old make allowance. If the butter price is $2per pound, and the yield is 1.211, under the old make allowance the butterfat price would be $2.21 per pound. Under the new make allowance, the butterfat price would be $2.15 a pound.

“If we were to multiply that through by your butter yield right now, then we’d be talking about possibly a quarter per hundredweight, but that’s assuming that nothing else is changing in the base part of your price,” Wolf said.

Stephenson said the make allowances are being used to back calculatethe value of milk brought into a plant.

“If you don’t change this make allowance at all over time, you end up not being able to recapture the margins needed to pay for the milk,” Stephenson said.

The industry had reached that point, he said, and that was part of what was seen with much of the depooling that was occurring. A manufacturing plant is not required to be pooled or participate in federal orders. If they cannot recover milk costs with their product prices, then some might choose to opt out of the federal milk marketing order.

“Bringing these make allowances back up takes you in the right direction,” Stephenson said. “They have been updated to probably current average costs but not all the way.

The KUHN Knight HP 170 M ProPush® hydraulic push-type spreader is designed to haul and spread solid materials from dairies and feedlots, including gutter manure, yard scrapings, bedding pack and feedlot manure. The HP 170 M features a heaped capacity of 700 ft³.

Over the last decade, we’ve seen premiums erode between processors and farms. That’s an indication we’ve got a problem with our pricing formulas. Hopefully this price increase gives us a little bit more margin where we can begin to see premiums grow again.”

In the base Class I skim milk price category, Wolf said the proposed change is to essentially undo what was changed in the 2018 farm bill that went into effect May 2019.

“They moved away from the ‘higher of’ for the Class I, Class III and Class IV to make an ‘average of’ plus 74 cents,” Wolf said. “The new proposalgoes back to the higher-of and that’s certainly something producers have paid a lot of attention to in the last few years as we’ve seen Class III and Class IV diverge in such that higher-of would have been a higher base Class I skim milk price.”

A lot of discussion during the hearing focused on use of or potential use of risk management by uid processors and the growing extended shelflife marketing Class I, Wolf said. Class I processors want to think about longer-term agreements and want the ability to know what that was going to be further out so they could assign a three month or a six month or longer contract.

“USDA did what I think is a clever solution,” Wolf said. “For extended shelf life, they changed the base Class I milk price to be a 24-month rolling average with a 12-month lag so that extended shelflife processors will have some idea what that price is going to be, and they can think about using that for risk management.”

For Class I and Class II differentials, USDA proposes keeping the $1.60 base differential and adopting modied location-specic Class I differential values.

“They’re proposing for Class I differentials based on location across every county in the U.S.,” Wolf said.

Nicholson believes USDA recognized they are taking money out of the hands of farmers to some extent with the increase in make allowances, however, he said raising the Class I differential side is a way of trying to perhaps put money back into the pools shared among dairy farmers by charging the beverage milk processors more for the farm milk used in their products.

“At the end of the day, this isn’t something USDA just says, ‘OK we’re going ahead and doing this,’” Nicholson said. “This is something producers and co-ops are going to have the opportunity to vote on. But if you don’t agree to these changes, then essentially you end up in a situation where there’s no price regulation for your particular area at all. Ultimately, the decision is in the hands of dairy producers and their co-ops.”

Wolf recommends dairy producers have discussions with their co-op board or processor to gauge their thoughts on the proposed amendments and potential impacts of those amendments. Stephenson said if a person does not like the changes, reverting back to the previous federal orders is not possible.

“Either you accept all these changes, or you don’t have a federal milk marketing order,” he said. “Your vote needs to be thinking about, am I better with this modied order or having no order at all?”

PTO GENERATORS

Nolt’s Welding & Repair

Vice-presidential pick Walz highlights his connection to agriculture

The presumptive Democratic presidential candidate Kamala Harris introduced her vice-presidential pick at their rst campaign stop. Minnesota Governor Tim Walz referenced his 12 years in Congress in his speech. “I worked across the aisle on veteran’s issues, agriculture and ways to grow rural economies; I learned the value of compromise without compromising my values.” Walz represented Minnesota’s First Congressional District in southern Minnesota and was a member of the House Agriculture Committee. Walz is now in his second term as governor. “Minnesota’s strength comes from our values, our commitment to working together, to see past our differences, always to be willing to lend a helping hand,” Walz said. “Those are the same values I learned on the family farm.”

More farmer engagement urged

To reduce nitrate contamination, the Minnesota Pollution Control Agency is proposing changes to its feedlot permits. “Farmers are going to be hit with a lot of different regulations and we haven’t seen a lot of farmer engagement, which is pretty surprising because this could be some pretty big changes as far as manure transfer and some of the other things farmers are doing, especially in cold weather temps that could change things drastically in a big swath of the state,” said Joe Smentek, Executive Director, Minnesota Soybean Growers Association. The public comment period has been extended to Sept. 3. “Whether they think it is good or think it is bad, let PCA know.”

Minnesota Farmers Union welcomes Walz pick

Blue Hilltop, Inc.

507-879-3593 / 800-821-7092

Timing becomes a farm bill hurdle

By Don Wick Columnist Ag Insider

Minnesota Farmers Union President Gary Wertish believes the selection of Governor Tim Walz for the Democratic vice-presidential role is good for the state and for agriculture. “When’s the last time we had someone on a national ticket that served on the House Agriculture Committee,” Wertish said. “Governor Walz has done that. As governor, he’s done a good job. He’s been thrown a few curveballs with COVID and the unrest. He’s seen challenging times, but overall has done well.”

Howard Olson, the senior vice president of policy and public affairs at AgCountry Farm Credit Services, met with lawmakers at Farmfest. That follows a trip to Washington D.C. the previous week for the National Council of Farmer Cooperatives meeting. The biggest farm bill hurdle appears to be nding a way to pay for the various priorities. “No one seems to be able to see how we’re going to unlock that and where can we come together on that.” Timing is another problem. Even if the farm bill was passed today, it wouldn’t take effect until the 2025 crop year. “Farmers won’t see the benet of new reference prices until the fall of 2026.” A vote during the lame-duck session or another farm bill extension are both possible.

Klobuchar: farm policy has seen much a larger divide

The current farm bill expires at the end of September. Minnesota Senator Amy Klobuchar said common sense must prevail so Congress can nalize the farm bill. “We must get it done,” Klobuchar said. “We’ve already seen the effect on prices with corn prices alone down 33% since last summer. Right now, we’ve got different versions, but the policies aren’t that different. We’ve had much wider divides in the past when it comes to ag policy.”

H5N1 testing to expand

USDA ofcials are emphasizing beef and dairy products are safe, but testing for avian inuenza is being expanded. Beginning in mid-September, USDA will test culled dairy cattle. Meat coming from dairy cattle will not enter the food supply until test results are known. Nearly 200 dairy herds in 13 states have been conrmed to have H5N1 since March.

National Milk Producers Federation, U.S. Dairy Export Council challenge Colombia trade allegations

According to the NMPF and USDEC, Colombia’s decision to initiate countervailing duties on U.S. milk powder exports is not warranted. A preliminary decision on this trade challenge is expected this fall. Meanwhile, the dairy groups are asking the U.S. government to “leverage all available tools” to prevent this allegation from setting a precedent.

Loan volume totals for young, beginning and small farmers

At its monthly meeting, the Farm Credit Administration board reviewed its work with young, beginning and small farmers. Twenty-three percent of the Farm Credit System’s total loan volume went to this category in 2023. By loan count, this group represents 53% of all Farm Credit System loans.

Class III milk price projections updated

In its August supply and demand report, USDA lowered its milk production forecast for 2024 and 2025 from last month. The prices forecast for 2024 cheese, nonfat dry milk and whey were raised from July while the butter price was lowered. For 2024, the projected Class III milk price is now at $18.40 per hundredweight. It is $18.65 per cwt for 2025.

Spot milk supplies: tight to nonexistent

According to the U.S. Department of Agriculture’s Dairy Market News, cheesemakers in the Upper Midwest are saying spot milk supplies are tight to nonexistent. Dairy processors are reportedly contacting nearby dairy plants and seeking out extra milk, but there is none to offer. The report said some farmers in the region are voicing concerns about forage availability and quality. Hay supplies are tight in some portions of the Midwest, but sufcient elsewhere.

Brown is on the job with Minnesota FFA

The Minnesota FFA Association has named Dr. Thomas Brown Jr. as its new executive director. Brown has nearly 20 years of experience in agricultural education and is an agribusiness instructor and former department chair at South Central College in North Mankato.

A promotion for Dauer

The Minnesota Farm Bureau Federation has promoted Loren Dauer to public policy director. Dauer has been a public policy specialist since February. Before that, Dauer was a district outreach representative for Minnesota Representative Brad Finstad

Trivia challenge

McDonald’s sells more cheeseburgers than any other fast-food restaurant. Wendy’s is ranked second. That answers our last trivia question. For this week’s trivia, what is the most popular milkshake avor in the U.S.? We’ll have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Celebrating faith, family, farming

Life Celebra�on at Nathan and Samantha Middendorf’s farm near Long Prairie, Minnesota. The Wolbecks milk cows near Sauk Centre.

Middendorfs host rural life mass

By Tiffany Klaphake tiffany.k@dairystar.com

LONG PRAIRIE, Minn. — Samantha Middendorf and her husband, Nathan, both grew up on dairy farms

Turn to MIDDENDORFS | Page 12 in central Minnesota. Now they are raising their own family on a farm instilling the same values they were raised with.

“(Faith) is something that has always been important to us,” Middendorf said. “Our parents raised us with a strong faith and passed that mentality onto us and now we are passing it onto our children.”

We like the milk pregnancy test because it has accurate results, it’s safer and less stressful on the cow, it’s safer for us, and we have less vet bills. How long have you been using the DHIA pregnancy test? Since it came out, maybe around 2013. We switched 100 percent to it and haven’t looked back.

Why did you choose to use it? We chose to use it because we didn’t like separating cows every month for pregnancy checks. What are some other tests you use through DHIA? We do the normal monthly testing, and manure sampling yearly.

Why is testing with DHIA valuable to your dairy?

The value we get out of it is seeing the performance on a cow level, making culling decisions based on SCC, fat, protein etc. Also, the record keeping of cow and heifer events has helped better our management.

Tell us about your farm. I farm with my dad, Lyle, and mom, Shannon, on about 800 acres. We like trying new rotations of crops and utilize no-till practices. I have a sister in Buffalo, New York and a brother in Idaho dairy farming. We milk in a double-9 parallel parlor, with sandbedded free stalls. We raise our own replacements, utilize Cowmanager on all animals, and sell our milk to First District Association.

SUPER SPECIALS

TRACTORS Massey Ferguson GC1725M Subcompact

‘04 AGCO RT150, 5534 hrs., CVT trans., cab susp., duals, 14.9x46 rear .................................................... $59,000 COMBINES & HEADS

‘10 Gleaner R76 Combine, duals, 1800 SEP............ $86,000

‘05 Gleaner R75 Combine, Duals, 2,204 Sep, 3,133 E. Hrs.. $49,000

Gleaner 3000 8-Row 30” Corn Head, single point.... $20,000 ‘09 Gleaner 3000 /Challenger CH630 6R30” Corn Head, Single Point ................................................................ $16,000

‘12 Gleaner 8200-25 ex head w/crary air reel ......... $26,500

Gleaner 8200-25 ex head ......................................... $15,000

‘10 Gleaner 8200-30 Flex head, w/Crary Air Reel, serial #AHW08230 ................................................... $26,000

‘09 Gleaner 8200-35 Flex Head w/Orbit Reel ........... $15,000

‘04 Gleaner 8000-30 Flex Head .................................. $6,000

‘14 Harvestec 6308C 8-row 30” cutter corn head, Gleaner mounts ........................................................ $39,000

‘14 Harvestec 6308C 8-row 30” cutter corn head, Gleaner mounts ................................................... Coming In

‘08 Harvestec 4312C 12 row 30” Cutter Corn Head, Gleaner Mounts ........................................................ $18,500

‘06 CIH 2208, 8R30” Corn Head .................................. $9,500 Gleaner 313 Pick-Up Header ...................................... $3,500 Massey Ferguson 9250-35 Drapper head ...........

Nathan and Samantha hosted the Rural Life Celebration mass Aug. 18 for the Diocese of St. Cloud. The mass was presided over by Bishop Patrick Neary and several other local priests.

“It’s a good thing to have in the area,” Middendorf said. “We have the space for it so we decided to go for it.”

The Middendorfs milk 63 Holstein and Brown Swiss cows and farm 260 acres west of Long Prairie. The couple also has two young children, Noah and Logan, and a baby due in November.

On top of helping her husband with the day-to-day operations of their dairy farm, Middendorf is a full-time teacher at Christ the King Catholic School in Browerville. Middendorf’s commitment to teaching about agriculture in her classroom earned her recognition as the Todd County Soil and Water Conservation District Teacher of the Year for 2023. She went on to win the same title for Minnesota.

The Middendorfs utilize cover crops, manure management and annual soil sampling. They also have modied their equipment to incorporate notill practices so they can maintain and improve soil health. Nathan works with the local SWCD each time he makes upgrades to the farm.

The events of the Rural Life Mass took place in the al-

falfa eld close to their farm site. There was one large tent set up for the mass and two smaller tents for the meal that followed the mass. The large tent that was used for mass had 250 small square straw bales arranged inside for seating. Attendees were encouraged to bring their own chair

to ensure seating for everyone. It was estimated that 650 people attended the event.

“We planned it out with the hay cuttings so the eld would be available to use for the day,” Middendorf said. “During clean up, even the bishop helped stack straw bales into the truck. It really

was a team effort; it wasn’t just us.”

Middendorf said planning for the event started back in January.

“Fr. Mitch and Fr. Omar actually approached my mother-in-law, Denise, about hosting it rst,” Middendorf said.

“But their yard is a lot more

condensed, so we decided to host.”

Much of the planning for the event was done by a committee consisting of members of the area catholic community that the Middendorfs belong to and from the Diocese of St. Cloud.

“A diocesan planning committee came out and checked out our farm and agreed that it will work to have it out here,” Middendorf said. “We have a good committee from our (Anglican Catholic Church) that took care of different aspects of the day.”

Along with the catholic mass that took place, Catholic Century Farm and Catholic Rural Business awards were presented. Clasemann Dairy LLC was recognized as a Catholic Century Farm and Mid-American Auction Co. was presented with the Catholic Rural Business award.

“It was a good celebration of people we know and those we don’t but have that same connection of rural life and faith,” Middendorf said.

For the Middendorfs, faith and farming go hand in hand.

“(Faith) is something that farmers often rely on when out in the eld or in the barn,” Middendorf said. “Sometimes you just got to stop and say a little prayer and God is always listening.”

Turn to MIDDENDORFS | Page 13

Combining the robustness and adaptability of Fleckvieh with the excellent milk production and solid conformation of Dutch Red and White Holstein creates a powerhouse of genetic benefits. This blend enhances overall herd performance and longevity, ensuring healthier cows and higher yields. Delve into this crossbreeding strategy for a superior, well-rounded dairy herd.

A endees sit on straw bales Aug. 18 during the Rural Life Celebra on mass held on the Middendorf farm near Long Prairie, Minnesota. The event had about 650 people a end.

Middendorfs received many comments throughout the day about their farm and family.

“It wasn’t just our family that did this,” Middendorf said. “Just like how our faith brings us together and closer to God, this event brought a lot of people together to celebrate Him.”

One of the families that attended the Rural Life Celebration was Josh and Becky Wolbeck of Sauk Centre. The Wolbecks milk 65 organic Jersey cows at their family farm.

“We wanted to attend the event to support the Middendorf family,” Becky Wolbeck said. “It is a lot of

work putting something like this on.”

Just before the mass started, Neary let the Wolbeck family view the handcarved pastoral staff he uses for the mass.

“(The bishop) let Josh and our son, John hold his pastoral staff,” Wolbeck said. “Bishop Neary told us it took 165 hours for someone to hand carve it.”

The Wolbecks said there were many highlights from the day.

“The fellowship was great because we got to meet people outside our own parish that share the same appreciation for faith, family and farming,” Wolbeck said.

from our side our side OF THE FENCE THE

What is your favorite agricultural-related activity or booth at the fair?

Lincoln Langerock

Marion, South Dakota

Turner County

180 cows

Which fairs do you attend each summer? The Turner County Fair in Parker, South Dakota.

What are your favorite attractions at the fair? I have three favorite attractions at the Turner County Fair. They are the pork sandwich stand, the beef sandwich stand and the homemade ice cream stand. Besides enjoying the food, I usually go to the enduro races and watch some friends run their cars and my hometown re department keep the event running smoothly.

Are you involved in the fair? No.

What is your favorite agricultural-related activity or booth at the fair? My favorite ag-related exhibit is the Rivers Edge Bank Ag Education Center. They have lots of different farm animals in there, and I think it’s a great way for lots of kids to get an up-close look at things you would see on the farm. This year, they also had a fake Holstein with an udder that they could pretend to milk.

What could be incorporated into the fair that is dairy or agriculture related? I think our fair does an amazing job of promoting and educating people about agriculture. There are many different ag organizations that run booths and set up exhibits. There’s farm equipment there to look at and 4-H events going on all the time.

What is your favorite fair food and best memory of a previous fair? Some of my best memories at TCF probably came from wristband day as a kid. You’d get a wristband for unlimited rides for ve hours and just spin in circles and eat ice cream until you were sick.

Tell us about your farm. My brother, Landon, and I have been dairy farming since 2017. Our cows are in a freestall barn and get milked in a double-8 parabone parlor. Our milk goes to Associated Milk Producers Inc. in Freeman, South Dakota.

Allamakee County 65 cows

Which fairs do you attend each summer? I attend the Allamakee County Fair every summer. I’ve been going to the fair since I was a child.

What are your favorite attractions at the fair? I enjoy going to the tractor pull at the Allamakee County Fair.

Are you involved in the fair? I am not at this time. Our kids were active in the fair and we have helped in the dairy booth in the past scooping ice cream and making cheese curds and malts.

What is your favorite agricultural-related activity or booth at the fair? I enjoy going to the dairy show on Saturday and watching the calves and cows be shown.

What could be incorporated into the fair that is dairy or agriculture related? Our fair does a great job at all they do. They have a peewee dairy show. They have ag olympics. There is a dairy auction selling milk from the grand champion cow: the money goes to grand champion winner, the dairy kids and a small amount goes to the fair to keep up with improvements. I would roughly guess we generate $20,000 or more at the auction. The auction has been going on for probably 15-20 years. I donate $100 every year.

What is your favorite fair food and best memory of a previous fair? WW Homestead Dairy deepfried cheese curds. My best memories of the fair were when my children were showing cattle.

Tell us about your farm. Our farm is Kandy-Bahr Holsteins. In our 50 years of farming, we have gone from a grade Holstein herd to all registered. My wife, Rhonda, and I do all the milking, chores and etc. The cows are milked in a tiestall barn and housed in a freestall barn. Our milk is sold to Foremost Farms USA.

Rick Balzer Owatonna, Minnesota

Steele County 140 cows

Which fairs do you attend each summer? I attend the Steele County Fair.

What are your favorite attractions at the fair? I like to look at the grains and grass exhibits that local farmers and my son, Scott, bring in to see how we place against others.

Are you involved in the fair? I am a board member of the Steele County American Dairy Association and take care of the milking contest that features Bella, the stationary fake cow. We have about 20 participants this year. Last year, I had a pastor's theme. I thought, “Wow, I am going to have a Holy Cow.”

What is your favorite agricultural-related activity or booth at the fair? Bella the fake milking cow.

What could be incorporated into the fair that is dairy or agriculture related? Maybe butter making and past and future farming practices.

What is your favorite fair food and best memory of a previous fair? The footlong corndog is my favorite food. My best memories at the fair were several fairs that had kid pedal tractor pulling contests. We took our four boys to them and met a lot of good people.

Tell us about your farm. Our farm is Balzer Family Dairy. I do heifer, calf, tractor driving and general eld chores. Cathy, my wife, does calf, bookwork, household chores and whatever chores are needed. Scott, our son, does all the chores in the two robot barns and takes care of the steers and lots of maintenance all around the farm. Kayle, Scott’s wife, keeps track of their 2-1/2-year-old and also works from home. They have another little one on the way. Our milk is sold through First District Association.

Page 16

August 24, 2024

Con nued from OUR SIDE | Page 15

Nick Stadick

New Ulm, Minnesota

Brown County 160 cows

Which fairs do you attend each summer? The Brown County Free Fair in New Ulm is in early August. I attend it multiple days and nights each year.

What are your favorite attractions at the fair? My favorite attraction at the Brown County Fair is the Demolition Derby. Also, the nightly live music and beer garden are some of my favorite things at the fair.

Are you involved in the fair? My parents, along with my aunt and uncle, Rich and Jackie Griebel, volunteer each year at the American Dairy Association’s milk shake stand. My brother and I help when needed.

What is your favorite agricultural-related activity or booth at the fair? My favorite agricultural-related activity at the fair is looking at all the animals and 4-H projects in the barns.

What could be incorporated into the fair that is dairy or agriculture related? Brown County does a good job incorporating dairy and agriculture into the fair as it is a rural county. Agriculture is a big part of the surrounding community. Many events and booths are sponsored by ag businesses and organizations.

What is your favorite fair food and best memory of a previous fair? I have cheese curds and a milkshake every time I go to the fair. One of my favorite memories is the combine demo they held in the grandstands when I was young.

Tell us about your farm. My parents, Mike and Tammy, along with my brother, Jake, and I are all full time on the farm. We also have one high school employee who helps as her schedule permits. We milk 160 cows on a farm just south of New Ulm. We milk twice a day in a 12-cow swing parlor and the cows are housed in a 4-row sand-bedded freestall barn that we built in 2012. We raise our own replacement heifers and cross-bred calves up to 500 pounds. Jake does all our breeding and herd health. Our milk is shipped to Bongards. Rain has been plentiful in our area this summer. We hope to chop corn silage the rst or second week of September.

Amy Roller

Hewitt, Minnesota

Otter Tail County 90 cows

Which fairs do you attend each summer? We always attend our home fair, Wadena County, and the Clearwater County Fair and the Minnesota State Fair when we can.

What are your favorite attractions at the fair? I just love being right in the dairy barn but enjoy the moo booth at the State Fair a lot, too.

Are you involved in the fair? I'm just a regular 4-H mom at the fair now.

What is your favorite agricultural-related activity or booth at the fair? My favorite activity is the dairy show. I've shown dairy at the county fair every year of my life, except one year of college. Now I get to enjoy helping and

watching my kids learn and do the same things. I have the best memories with some of my favorite animals and people at the dairy show.

What could be incorporated into the fair that is dairy or agriculture related? I think it's a great time to help educate the public. Using tools like informational signs around the barns or having the radio stations cover things going on in the barns might be helpful.

What is your favorite fair food and best memory of a previous fair? My favorite food is milkshakes. My family frequently visits the shake stand. One of my best memories was our oldest daughter showing her rst calf during the fair in Bagley. The junior calf class partici-pants each got great ribbons and a medal and she walked out of the ring and down the barn with her head held so high. She was so proud of herself and her calf. I just loved that.

Tell us about your farm. We milk 90 cows in a swing-10 parlor that we built in 2016. We sell our milk to Lakes Community Cooperative in Perham. My husband, Ryan, and I took over the dairy in January 2023. His parents, Gene and Brenda, still help with chores and his dad crop farms on the side. Our kids, Macy, Charlie and Caleb, help with calves. We also fatten steers and we grow 450 acres of crops, including corn, sorghum sudan grass, alfalfa and oats.

Information at your ngertips- Easy, clean, fast. When you are looking for resources you’ll nd them on our site. Our clean, easyto-navigate site makes it simple to locate the information you’re searching for.

Describe your farm and facilities. We have a lot of family members that help on the farm. Our daughter, Leann, and her husband, Chad, help a lot. They do a milking a day and help with hay and silage harvest. Their children, Blake, Luke and Brooke, are here all the time during the summer and on the weekends during the school year. Our son, Allen, and his wife, Heather, help with eldwork as well. Our granddaughter, Avery, milks weekday mornings during the summer. Reed and Veda help when available. The grandkids all like being on the farm. We milk in a double-5 herringbone parlor. Cows are housed in a sand-bedded freestall barn with an open lot. We have drive-by feeding.

What forages do you harvest? We harvest Northrup King corn silage, Croplan alfalfa haylage and grass haylage for the dairy cows and heifers.

How many acres of crops do you raise? We grow 200 acres of corn, 100 acres of alfalfa and 70 acres of grass.

FORAGE PROFILE

Describe the rations for your livestock. All animals are fed a total mixed ration. All the dairy cows get the same ration. They get alfalfa

haylage, corn silage and a grain mix. Dry cows get corn silage and grass haylage with a dry cow protein in their ration. Heifers get corn silage,

some alfalfa and a grass haylage along with heifer protein.

What quality and quantity do you harvest of each crop? For corn silage, we like to chop between 65%70% moisture and this usually yields 1,600 tons. We like to chop alfalfa at 60%-65%. Our goal for alfalfa haylage is above 170 relative forage quality. Most of the time it is between 180-200 RFQ. We have had as high as 265. We put up about 1,200 tons.

Describe your harvesting techniques for alfalfa and corn silage. All our forage is stored in ag bags. We bought our rst bagger 40 years ago and have been very happy with the feed quality. Corn silage is chopped with a pull-type chopper with a kernel processor. Alfalfa is harvested every 30 days starting the last week of May. It is put in wind rows when cut and chopped when ready. We never turn the hay or double the wind rows so that we don’t lose any leaves. This also to limits compaction on the eld as much as possible to prolong the life of the stand. Our stands usually last 4-5 years.

Turn to FORAGE | Page 20

Wall and Ceiling Panels

•Easy To Clean

• Quick And Easy To Install

• Hidden Fastener

• Low Maintenance

• Mold and Mildew Resistant

• Distinctive Tongue and Groove System

• Seamless Appearance

• Economical

• No Painting Required

Chippewa Valley Dairy Supply 6053 CTY. HWY. G • STANLEY, WI 54768 • Andrew Zimmerman

HEINEMAN FARMS, Attica, N.Y., 65 Holsteins, 26,037M and Ayrshires 19,480M SCC 137,000, 3rd gen. Gordon and Sue Heineman, 4th gen. Angela and Dave Fuller WDE 2023 Grand, Senior, and Reserve Intermediate Champion Ayrshires (Photos: WDE 2023 Grand; Angela with nieces Esther and Eva; Esther with Nat’l Spectacular Grand)

“We’ve used Udder Comfort™ since we got samples at the 2009 World Dairy Expo. We learned to use the spray when they bag up to calve because we don’t have to touch the udder. I love how awesome it works without massage. For prefresh, I use Udder Comfort spray, switching to lotion after calving,” says Angela Fuller, Heineman Farms, Attica, New York. She and her husband are partners with her parents, milking 65 Holsteins and Ayrshires.

Angela has loved showing Ayrshires since 7. At World Dairy Expo 2023, she had two homebred champions. Grand and senior was 4-yr-old Heineman Reagan Roz EX93, dam of their AI bull (Rage at ST Genetics). Reserve Intermediate was 3-yr-old Heineman Kingsire Cold Brew EX90. Niece Esther’s junior-3 was grand champion of the 2024 National Summer Spectacular.

“I love raising the babies, watching them develop and seeing cow families develop. It’s very rewarding. I love this product for fresh cows, hard quarters, and when we show,” says Angela. “It soothes any discomfort or inflammation.”

EH 2809, 2909 in Exhibition Hall at WDE 2024

What techniques do you use to store, manage and feed your forages? We store the feed in bags. That way we can use each bag individually for whichever animals it works best for based on quality. We have one eld of grass hay that we don’t apply any manure to. That way phosphorus levels stay low. This haylage is kept separate for the dry cows.

How do quality forages play in the production goals for your herd? Having top-quality forages allows us to feed less grain and expensive proteins. Every forage is tested, and our nutritionist provides us with a ration. If we are feeding a very high-quality alfalfa, we will then add some high-quality grass haylage to the TMR. Any time I change a forage I get a new ration.

What management or harvesting techniques have changed that have made a notable difference in forage quality? As stated earlier, buying our rst bagger 40 years ago really helped us harvest and store top-quality feed. We have also been using roundup-ready alfalfa since it became available. This has really helped provide highquality haylage. Before we

had a bagger, we made small square bales.

Describe a challenge you overcame in reaching your forage quality goals. Bagging our forages and tiling elds has probably been the most benecial to harvesting forages that allow our cows to milk well and stay healthy.

#567629

JD 560M 2020, 3950 BC, #574425

JD 560M 2019, 13,791 BC, #582581

JD 560M 2019, 6500 BC, #567208

JD 560M 2019, 17,500 BC, #575405 ...............................................

JD 560M 2018, 8000 BC, #574492 ..................................................

JD 560M 2018, 2550 BC, #574158

566 1999, #578058 ......................................................................

567 2006, 16,700 BC, #584096

568 2008, 33,640 BC, #582414

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Convenience of upright storage

Janke gets rst Greenline Silo

By Sarah Middendorf sarah.m@star-pub.com

HUMBIRD, Wis. — Zach Janke wanted a new silo with the convenience of bottom unloading and the ability to make drier feed have a longer shelflife.

“I love all my silos,” Janke said. “I am a silo guy and like being in the feed room, out of the elements.”

Janke and his wife, Abby, milk 88 cows in a tiestall barn and farm 400 acres of land. The Jankes built their rst two silos in 2014.

They recently built a Greenline Silo, a poured concrete silo, that is 24 feet-by-124 feet with 111 feet of feed storage space. There is a 15-inch oor and a 6-inch poured concrete at roof. It also has an 8-foot walk-in basement. Janke said they are still working on a capacity chart but are estimating the silo to hold 11,00015,000 tons of feed.

When picking out a silo, Janke had a conversation with Marvin Reiff, creator of the Greenline Silo, about building a silo on his farm.

“I told him I want it so there is a great big hole in the oor and I want an auger to bring the feed out from the cutter chain,” Janke said. “I told him (Reiff) I want to do it differently.”

After that conversation, Janke said that Reiff took his suggestions and made them better to create the Greenline Silo.

During the process of building and operating the silo, Janke said there were challenges that they faced and had to overcome since this was the prototype.

“(Problems) that we have had are xable the next time or just a simple x that we can do on our own,” Janke said. “It was a lot of trial and error.”

At the open house Janke

hosted Aug. 7-8, they aimed to test how much feed the silo could unload in one minute.

Based on the number of times the conveyor circled and the weight of each load dropped, they estimated that around 1,600 pounds per minute of corn silage could be unloaded. The speed for haylage is half as fast, so delivery would be around 800 pounds per minute,

said Janke.

The Jankes like to have haylage at about 45% moisture or less and silage at 55% or less. Dry feed is less acidic for the cows and is a sweeter, better-smelling feed. If the haylage gets dry enough it will not lose as much of the sugars in the fermentation process. Janke is working toward having a drier haylage for his cows with the help of the silo.

“You can see a huge difference in the wear in the chain life and the unloader life on wet feed versus dry feed,” Janke said.

Janke opted for the poured concrete silo because the sun can penetrate less. There is more insulation and it is harder for the sun to get through 6 inches of concrete than a different type of silo wall.

The unloading system runs off one 30-horsepower electric motor. Janke said it is pretty efcient. The unloading system is all automatic.

“One thing that I love is if something happens it’s not like we are completely out of business,” Janke said. “We can completely unplug the automatic programming and use manual levers.”

Turn to JANKE | Page 25

COMPACT LOADER PLUS ATTACHMENT SAVINGS

Bobcat of Brookings, Inc.

Brookings • 605-697-5544

Aldrich Tractor, Inc. Verdale • 218-445-5430

Farm-Rite Equipment, Inc. Dassel • 320-275-2737

Farm-Rite Equipment, Inc. Long Prairie • 320-732-3715

Farm-Rite Equipment, Inc. St. Cloud • 320-240-2085

Farm-Rite Equipment, Inc. Willmar • 320-235-3672

While having the same cutter chain as a Harvestore silo, the Greenline Silo does not have a conveyor chain. Rather the feed is collected by a four-foot turn table with an extension arm and is then dropped through a central hole and conveyed out.

“Anything the cutter chain brings to the center of the silo drops away from it and is out of the way,” Janke said. “That’s what gives it its capacity.”

The cutter arm sits on a turn table and has the ability to slide in and out. At its shortest length, it is 30 inches away from the wall and at its longest, it is 1 inch away from the wall. It can move back and forth to any length in between.

At shutdown it goes into its shortest length making it easier to start because it is retracted. Once it gets fully started and the pounds per square inch is low enough it starts extending and going into longarm mode.

Within the silo there is an inventory monitor called SmartBob. A cable with a weight on the end of it, connected to a timer, drops into the silo until it hits the feedline then lifts up. The monitor calculates distance as it is pulling the cable back up. This measures the feet of feed in the silo. Janke has it set to measure once a day.

Janke currently has rst, second and third crops in the silo.

ULLOM/DAIRY STAR

Visitors peer into the silo unloader during the open house Aug. 8 at Jankes’ Never Rest Farms near Humbird, Wisconsin. The Jankes were able to unload about 1,600 pounds per minute of corn silage from the silo.

“I do like it better than the other two (silos),” Janke said. “You can be lling it and feeding out of it at the exact same moment.”

Janke’s other silos are a Harvestore and a top unload silo.

“That’s one benet you don’t have to climb or pull the unloader up (in a top unload),” Janke said.

Compared to a Harvestore, Janke said the accessibility to the unloader is a lot better. He can get right at the unloader in the Greenline silo to look at something or work on it.

“You can visually see what the cutter chain is doing instead of in a Harvestore, (where) it’s kind of guesswork since you obviously can’t see through (the wall),” Janke said.

Janke said he really likes the silo compared to a forage pile or bags since he does not have to worry about the outside elements.

“There’s no mud, plastic to deal with or feed waste,” Janke said.

Outstanding in her eld

Udermann named Farmfest Woman Farmer of the Year

By Tiffany Klaphake

SARTELL, Minn. — Being awarded for the work Kirsten Udermann does on a daily basis is not something she expected to happen.

Udermann was recognized Aug. 8 at Farmfest located in Morgan as the Farmfest Woman Farmer of the Year.

“I was denitely surprised and happy,” Kirsten said. “It is still settling in. All of the women sounded impressive, they all could have won.”

According to Farmfest, the Woman Farmer of the Year award honors the hard-working female farmers across Minnesota who devote their time to raising crops, livestock and their families. Five nalists were up for the annual award.

Kirsten, her husband, Alex, and his brother, Jake, and their parents, John and Mary Lou Udermann, operate Meadowbrook Dairy near Sartell. The family milks 80 cows in a tiestall barn along with raising replacements, 300 steers and 1,000 acres of

crops. They also do custom manure hauling and custom no-till planting.

Kirsten’s main duties on the farm are feeding the calves, milking cows and overseeing the vaccination and breeding program.

“Pretty much anything that has two or four legs around here Kirsten takes care of,” Alex said.

Kirsten and Alex have three children, Kallie, Zoey and Aubrey, and baby number four is due in October.

Kirsten said she was nominated by Danielle Isaacson from the Minnesota Department of Agriculture in May. Kirsten then had to ll out an application about her involvement on the farm and in her community. In June it was announced that Kirsten was named one of the top ve nalists.

“They liked that we are water-quality certied and have all ve endorsements,” Kirsten said.

Kirsten received a $1,000 prize for being selected as the winner.

The Udermanns are also involved with the young cooperative board with their milk

cooperative, volunteer with their county fair, donate meat to their church festival and host eld days on their farm,

where they focus on regenerative practices.

“It’s hard to get away with the kids and the cows but we

do what we can,” Kirsten said.

Alex agreed.

“I’m a big believer in doing the right thing and helping when we can,” he said. “It doesn’t cost anything to be a nice person and volunteer and to put a smile on someone’s face.”

The young couple agrees that there are a lot of women in agriculture that deserve this award.

“Nowadays, everywhere you go in agriculture, there are women that are behind the scenes or on the front lines working in agriculture,” Alex said. “There are a lot of women in ag that don’t get the recognition they should.”

It takes a strong woman to raise a family and a farm, Alex said.

“I really appreciate the fact that Kirsten is the best mom for our kids and calves,” Alex said. “The level of patience and desire to raise good healthy children and calves is something that is beyond my words to describe.”

Kirsten said she is proud of her success as well as the farm’s success.

“(To be Farmfest Woman Farmer of the Year) is a great accomplishment,” Kirsten said. “It’s fun to be part of the backbone of agriculture and to keep things running smooth in the home and at the farm.”

IN DAIRY women

Tell us about your family and farm. My husband and I have been married for nine years. We have a 6-yearold son, Bo. My husband and I were not raised on a dairy farm. Josh was raised on a hog and steer farm and I was raised on a hog and beef farm. Josh’s heart was set on milking cows, so he started milking them all on his own. A year later he met me. When I came to the dairy he rented, I saw a Jersey cow named Rose but I called her Dolly. I fell in love with the dairy lifestyle. Bo helps us do chores. He pushes up feed for the milking cows and feeds grain to the heifers. We bought our dairy close to four years ago. We own 160 acres and rent more land.

What is a typical day like for you on the dairy? My husband and I milk the cows together in the morning. After that, I take care of the baby calves and the weaned heifers. Then I do my household chores while I am making dinner. Then I help Josh with anything if he needs help. Otherwise, there are plenty of other things to do. At night, I feed the heifers, get the milk house ready and scrape behind the cows. Then I normally start night milking while Josh is mixing feed. When he comes in, he helps with the rest of the milking. We bed and lime the cows after they are milked. Then I feed the baby calves milk, clean up in the milkhouse and go to the house and make supper.

What decision have you made in the last year that has beneted your farm? Fixing the farm. We are slowly improving the farm. Things needed to be updated.

Tell us about your most memorable experience working on the farm. There are so many, but one of them

Kristine Heinrichs Browerville, Minnesota Todd County 75 cows

is the time Josh proposed to me in the barn on one knee during morning milking. He used my favorite cow, Dolly. He bought a red neck strap and put “will you marry me” on it. Another one centers around Bo, who has been coming with us to the barn since he was 1. It has been so rewarding watching his love for the cows grow into wanting to have cattle of his own one day. He has this hope already. Another is seeing Bo and his best buddy, Oakley (his pup), playing and doing chores together. That is cute. It is also enjoyable to witness the birth of a calf. All the things in between we do together on the farm as a family are neat.

What have you enjoyed most about dairy farming or your tie to the dairy industry? The lifestyle denitely. I get the privilege of being a homemaker, caring for my family and farm and making food from scratch. I enjoy working as a family together and being our own boss.

What is your biggest accomplishment in your dairy career? Explain. Finally being able to buy our own dairy. My husband and I rented for nine years. We moved three times to rent different barns. We drove back and forth every day twice a day. Our little Bo came with us to the barn every day. Bo spent a lot of time there with us and made many memories. Then the day after he turned 3 years old, we bought our farm.

What are things you do to promote your farm or the dairy industry? I am on the Todd County American Dairy Association board.

What advice would you give another woman in the dairy industry?

That it is a commitment and a lifestyle that is sometimes demanding but also very rewarding in many ways. Always stay focused on the good and positive things. There are going to be hard days, but don’t let it get to you. Tomorrow will be better and always put your trust in God for he will take care of you.

What is a challenge in the dairy industry you have faced and how did you overcome it? Getting over stray voltage. We moved out of that barn and into another one. Our cows recovered wonderfully, and pounds of milk went up.

When you get a spare moment, what do you do? I do something relaxing.

Know your cow zones

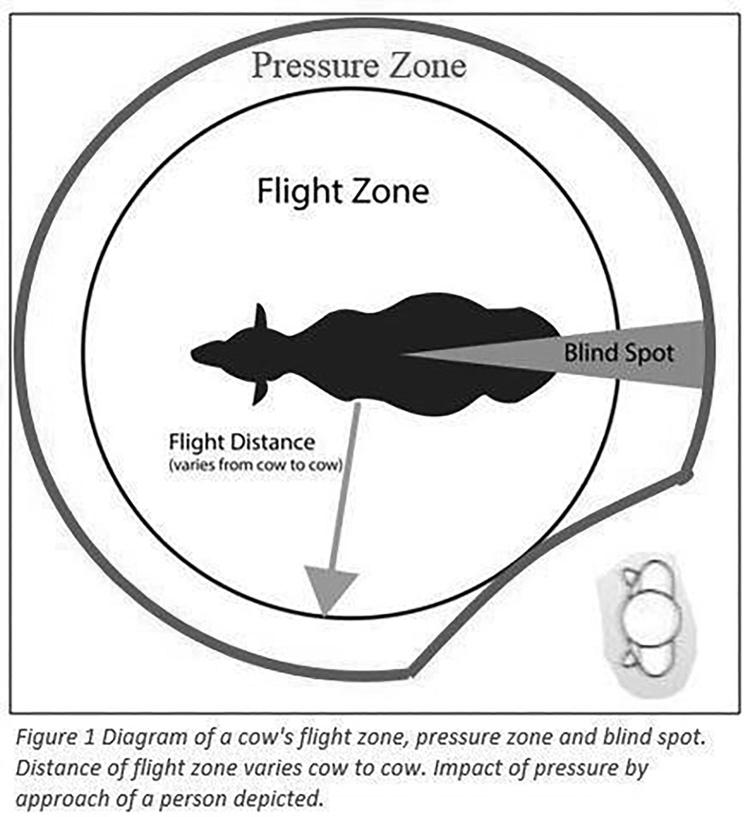

Working and moving cattle can be a stressful task for both the cow and person. However, it does not need to be. By understanding what cows want from you and guring out their comfort zones, you can become procient and move your cattle in a safe, effective and efcient manner.

Cows want to be able to see you, go around you, be with and go with other cows, and like to go back to where they came from. If a cow can hear you but cannot see you, she is going to get scared or nervous and will either kick at or try to get away from you as fast as she can. Cows want to be able to move freely and be with their peers. Cows are a herd animal and need friends for social health. Lastly, cows are routinecraving creatures. They like to be in places that they know and are comfortable with. Change can be very hard for some.

of the heifers may stop and look at you while others pay no attention. For the ones looking at you and that continue looking at you but remain standing there, you are in their pressure zone. They know where you are at all times and are keeping tabs on you.

Brenda Miller University of Minnesota

The ight zone is when you have entered an animal’s personal space, beyond her pressure zone, and they feel the need to ee. This is her bubble. We, as humans, usually have a boundary and when someone is standing a little too close, we too, feel the need to take a step away to feel comfortable again. So, if you are in that pen of heifers and start walking towards them, you may notice some will start walking (or running) away. They feel threatened, are not comfortable with your presence, and thus, leave until they feel comfortable again.

The pressure zone is the edge of a cow’s comfort zone. It is when a cow or animal is paying attention to you but has not yet moved away. She may be looking in your direction with her ears perked but is still standing where she is. For example, let’s say you are walking around in a pen or pasture of heifers. The moment you step into the pen a few

It is important to note that, like humans, every cow is an individual and has a different-sized pressure/ight zone. Some animals have little or no ight or pressure zones. Some of these may include show animals (they are usually so docile that they can be kind of a pain when you want to move them) and cows that may have experienced a major trauma. This group may have

...............................................................$9,950

‘18 J-D 3046R, Cab, 4x4, 470 Hours ..................$40,350 USED SKIDSTEERS

‘20 E50 Excavator, 5 Hours ................................$72,000 418 Mini Exc, 906 Hours .....................................$13,900

‘04 MT-52, 1238 Hours .......................................$17,900

‘20 T-870, Glass Cab with A/C, 2 Spd, 1475 Hrs $69,500

‘19 T-770, Glass Cab with A/C, 2 Spd, 870 Hrs..$65,000 ‘14 T-650, Glass Cab with A/C, 2 Spd, 2200 Hrs $43,900 ‘21 T-66, Glass Cab with A/C, 2 Spd, 290 Hrs....$62,500

‘17 T-595, Glass Cab with A/C, 2 Spd, 2370 Hrs $34,500

‘19 T-450, Glass Cab with A/C, 1400 Hrs ...........$33,500

(2) 2021 S-76, 680 Hours and up ......Starting at $42,500

‘15 S-770, Glass Cab with A/C, 2 Spd, 1775 Hrs $46,900

‘21 S-740, Glass Cab with A/C, 2 Speed, Hi Flow, 6600 Hrs ...........................................................$28,900

(2) ‘12 S-650, Glass Cab with A/C, 2 Spd, 2500 Hrs & Up .................................Starting at $28,900 ‘20 Kubota SVL75-2, Glass Cab with A/C, 345 Hrs .............................................................$59,900

USED TILLAGE

White 6700, 12x30, Verticle Fold ..........................$5,500

‘10 G-P YP1625A, 16x30, Center Fill .................$39,900 J-D 7200, 12x30..................................................$10,500 USED HAY EQUIPMENT

‘00 N-H 1441 Discbine, 15’ Cut...........................$11,900

‘12 N-H H-7230 Discbine, 10’ Cut .......................$18,500 (2) N-H 1411 Discbine, 10’ Cut ............Starting at $9,900

‘08 N-H 616 Discmower ........................................$5,500 AGCO 1326 Discmower........................................$3,250

‘20 N-H 560 Rd Baler, Specialty Crop, 4000 Bales ........................................................$46,500

‘11 N-H BR-7090 Rd Baler, Cornstalk Special, Netwrap.............................................................$23,900

‘96 N-H 664 Rd Baler, Twine only.........................$2,500 ‘89 N-H 855 Rd Baler, Twine

W-R 3400, 34’, 4 Bar Spring Tooth Harrow ..........$6,900 W-R 2500, 28’, 4 Bar Spring Tooth Harrow ..........$5,500 W-R 2500, 24.5’, 4 Bar Spring Tooth Harrow .......$3,600 Case I-H Tigermate 200, 27.5’, Rolling Baskets .$31,500 Case I-H 4300, 25’ ................................................$7,500 ‘13 W-R 513 Soil Pro, 7 Shank, Harrow..............$29,500 W-R 957, 9 Shank, Harrow .................................$12,900 Pepin Spike Harrow, 5 Section .............................$2,500 USED PLANTERS

been through a signicant event: trailer accident, tornado, barn re, etc. They may have a level of post-traumatic stress disorder and have an extra hard time processing new things or changes to their environment.

The largest blind spot is located directly behind a cow. When visually observing a cow, you will notice that her eyes are located on the side of her head, not in the front. This results in a vision of about 350. However, if something or someone is directly behind her, she must turn her whole head to see it. If you approach a cow from behind without letting her know you are there, it is probably not going to go well. Always approach a cow from the side or front so she knows you are there. No one likes getting a hoof to the leg or chest.

The next time you are in a barn, pen, or pasture, pay attention to the animals who are looking at you, walking away, or those who

Dana Adams adam1744@umn.edu 320-204-2968

Joe Armstrong armst225@umn.edu 612.624.3610

Luciano Caixeta lcaixeta@umn.edu 612-625-3130

Gerard Cramer gcramer@umn.edu 612-625-8184

Marcia Endres miendres@umn.edu 612-624-5391

are not caring at all that you are present. Remember, each cow or animal is an individual and has a different-sized personal comfort zone bubble. Be respectful of each individual and work to their level of comfort. By doing this, you will create a positive, efcient and safe work environment for both the cows and you as the handler.

Les Hansen hanse009@umn.edu 612-624-2277

Brad Heins hein0106@umn.edu 320-589-1711

Nathan Hulinsky huli0013@umn.edu 320-203-6104

Karen Johnson ande9495@umn.edu 320-484-4334

Emily Krekelberg krek0033@umn.edu 507-280-2863

Claire LaCanne lacanne@umn.edu 507-332-6109

Brenda Miller nels4220@umn.edu 320-732-4435

Isaac Salfer ijsalfer@umn.edu 320-296-1357

Jim Salfer salfe001@umn.edu 320-203-6093

Mike Schutz mschutz@umn.edu 612-624-1205

Melissa Wilson mlw@umn.edu 612-625-4276

Isaac Haagen hagge041@umn.edu 612-624-7455

Michael Boland boland@umn.edu 612-625-3013

Sabrina Florentino slpore@umn.edu 507-441-1765

Two

Twin

Can cows, solar panels coexist?

Solar farms are anticipated to cover 5.7 million acres to meet the rising demand for renewable energy. Land available for solar farm development is limiting this expansion. Efforts to increase public acceptance of solar farm development include coupling conservation and agriculture practices. Despite growing interest, there is limited science-based data summarizing the impacts of solar panels on plant and livestock growth and development in the Upper Midwest.

Farmers are increasingly interested in combining agriculture with solar energy production, a practice known as agrivoltaics. This approach allows farmers to use the same land for both farming and generating electricity, which can help make solar farms more acceptable to local communities by providing additional benets, such as agricultural products or wildlife habitats.

For dairy farmers, agrivoltaics offers an exciting opportunity. Traditionally, dairy farming relies heavily on fossil fuels for various tasks, from cooling milk to running tractors. But by installing solar panels on their land, farmers can generate their own electricity, potentially reducing their reliance on fossil fuels and cutting down on energy costs. This could help make dairy operations more sustainable and cost-effective.

There was no research on the use of a ground-mounted solar system to provide shade for dairy cows and to determine the effects on them. Therefore, our team wanted to investigate the effects of shade from solar photovoltaic panels on the production, health and behavior of pastured dairy cows. During the summer of 2024, a 500-kilowatt ground mount solar array was added to the existing pasture for shade for grazing dairy cattle (Figure 1). The Morris dairy operation milks 275 cows twice daily and is representative of a midsized Minnesota dairy farm.