WANT TO WIN $100 CASH?

See page 7 of this section for details!

See page 7 of this section for details!

August 26, 2023 Volume

FALCON HEIGHTS, Minn.— Excitement matched the heat index the evening of Aug. 23 as the Minnesota dairy industry gathered to crown the 70th Princess Kay of the Milky Way at the Minnesota State Fairgrounds in Falcon Heights.

Little did Emma Kuball know, as she said from the stage that the cool temperature of the butter booth was going to feel like paradise, that the very next day she would be escaping the heat as the new Princess Kay of the Milky Way.

After being crowned the goodwill ambassador to the state’s dairy farm families, Kuball’s initial remarks were lled with gratitude.

“You have all made me who I am today, and you’re the reason that I’m up on this stage,” she said. “Thank you so much.”

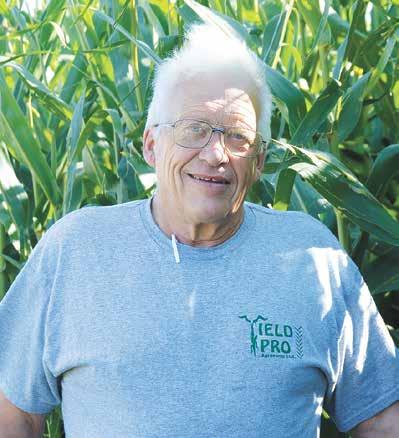

Molden

Molden

From the crack of the baseball bat to the pulsating of a milking unit, Todd Molden has traversed the world of baseball and that of a dairy farmer.

The two have collided recently for Molden, who is the herdsman of the North Dakota State University Animal Sciences

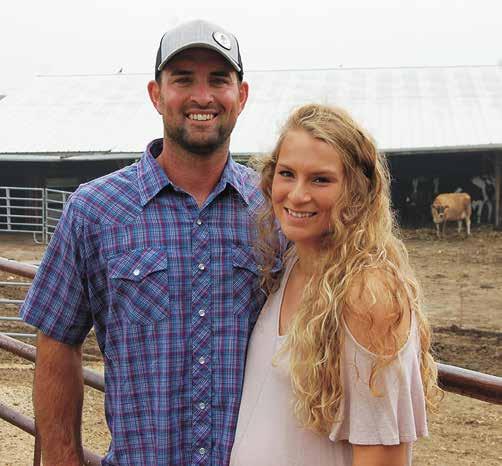

Wickenhausers

Growing up, Caleb Wickenhauser always wanted to head to the barn after school, and to this day, he can recognize a cow by looking at its udder.

“Dad always said if I had paid as much attention in school as I did to the cows, I would have been on the honor roll,” Caleb said.

Caleb was not alone in his passion; his brother Jared also liked the cows. Recently, the

AMY KYLLO/DAIRY STAR

Caleb (from le ), Allen and Jared Wickenhauser stand Aug. 2 on their dairy farm near Cologne, Minnesota. The Wickenhausers milk 100 cows, farm 350 acres and raise 35 to 40 dairy steers. Turn

The

“All dairy, all the time”™

Published by Star Publications LLC General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

DeadlinesHouse Agriculture Committee Chair Glenn “GT” Thompson said he has thousands of objectives but a single goal for the farm bill. “The one goal is to get this done in a bipartisan, bicameral way on time and highly effective,” Thompson said. With only a dozen days on the congressional calendar before the expiration of the current law, the deadline is looming. “I only have control of the House Agriculture Committee, and we’re going to do our job,” Thompson said. “When we can do markup and go to the oor really depends on leadership; I’m still hoping and praying it is before the end of September, but the ag committee will be ready to go.”

Dairy disaster

A handful of dairy leaders testied during the farm bill listening session at Farmfest. Ron Behounek, who farms with his sons at Hayeld, Minnesota, described the current dairy program as a disaster. “In 2022, we were paid $22.23 per hundredweight; our last check we got was $11.80,” Behounek said. “Can any of you guys cut your wage in half and make it? By December or maybe January, you’re going to see dairy farmers going bankrupt and being foreclosed on. It’s as simple as that.”

Former House Agriculture Committee Chair Collin Peterson said the House and Senate committee leaders are saying the right things, but there are some problems with the new farm bill. “In this debate, you’ve got people saying they won’t support a farm bill unless there’s more money in it for reference prices or whatever, and you’ve got other people saying they want cuts in spending in the farm bill,” Peterson said. In the House, the GOP has a four-seat majority. “There’s at least 20 of these Freedom Caucus people

Get the farm bill done right

The current farm bill expires Sept. 30, but it is unlikely a new farm program will be in place by that time. “The goal is now to get it done by the rst of the year, but that is still a massive lift,” said Gary Wertish, president of Minnesota Farmers Union. “We really want the farm bill done right rather than just getting it done.” He cites consolidation as having a signicant impact on agriculture, and it should be addressed in the new farm bill.

and

INVEST IN QUALITY ® www.kuhn.com KuhnNorthAmerica.com INVEST IN Q UALITY w ww. k u h n.com Ku hnN o r t hAm er Visit your local KUHN livestock dealer today! ri i r c ca a c o om m INVEST IN QUALITY www.kuhn.com Lindell Sales & Service Cannon Falls, MN HammellEquipment Chatfield, MN Eitzen, MN Adkins Equipment Detroit Lakes, MN Isaacson Sales & Service Lafayette, MN Blue Hilltop Lake Wilson, MN Schlauderaff Implement Litchfield, MN Fluegge’sAg Mora, MN Northland Farm Systems Owatonna, MN Lake Henry Implement Paynesville, MN Minnesota Ag Group Plainview, MN Dairyland Supply Sauk Centre, MN Woller Equipment Swanville, MN WernerImplement Vermillion, MN Anderson Bros. Edgeley, ND Duppong's, Inc. Glen Ullin, ND Enerbase Cooperative Minot, ND Roeder Brothers Inc. Bellevue, IA Maquoketa, IA Kunau Implement DeWitt, IA Preston, IA Bodensteiner Implement Elkader, IA Rexco Equipment Farley, IA Burco Sales Independence, IA Engel Agri-Sales Sac City, IA DeeImplement of Waukon Waukon, IA SL 100 SERIES PROTWIN® SLINGER® Spreaders 1,000 - 2,400 gallon capacities trailer models side-discharge FAST. CONSISTENT. VERSATILE.

2011 N-H TD-5050, Cab, 193 Hours, Hi Crop ..............................................$42,500

1982 White 2-155, 5750 Hours, Nice Looking ..............................................$19,500

1974 Oliver 1655, Diesel, Cab, 9700 Hours ..........................................$8,500

A-C 7000 ................................................$9,500

1961 A-C D-15 .......................................$5,900

USED SKIDSTEERS

2018 Bobcat V-519, 300 Hours............$69,500

(2) T-650, Glass Cab with A/C, 2 Speed, 300 Hrs & Up ...................Starting at $49,500

2021 S-76, 2500 Hours .......................$43,900

2020 S-66, Glass Cab w/Air Cond, 2 Speed, 1800 Hours .........................$47,900

2014 Toro 22321, 1251 Hours, Tracks Good, Gas ...............................$15,900

USED TILLAGE

2016 W-R 13QX2 53’ 3 Bar Harrow

w/Rolling Baskets ..............................$69,500

2012 W-R 13QX2 50’, 5 Bar Spike Harrow ...............................................$28,500

2004 W-R Excel 38’, 4 Bar Spring

Tooth Harrow .....................................$12,900

1997 W-R Quad 5, 32’, 3 Bar Spring

Tooth Harrow .......................................$7,500

W-R 2500, 28’, 4 Bar Spring Tooth Harrow .................................................$6,950

Kewanee 620, 18’ Disk ...........................$2,000

(3) W-R 513 Soil Pro, 9 Shank............................Starting at $25,000

2011 W-R 5800 Chisel Plow, 39’ .........$25,500

2012 G-P TCN-5107, Disc Chisel, 7 shank ..............................................$10,900

J-D 2700 Plow, 4 Bottom, Vari Width ....$1,500

USED PLANTERS

White 6700, 12x30, Vertical Fold ...........$7,500

USED HAY EQUIPMENT

(2) N-H 316 Discbine, 15’ Cut .............................Starting at $28,900

2020 N-H 512R, 12’ Mega Cutter, Used Very Little .................................$28,350

1997 N-H 1465, 9’ Haybine ....................$9,500

New Idea 5212 .......................................$8,950

John Deere 260 Discmower ...................$3,500

N-H 790, 824 Cornhead, Hayhead..........$7,950 Meyer 500TSS Forage Box.....................$7,500

2020 N-H 560 Rd Baler, Specialty Crop, 4000 Bales ...............................$46,500

2016 N-H 460 Rd Baler, CropCutter .....$28,500

1995 N-H 660 Rd Baler ..........................$4,950

of incentives for young people to take over the farm as well as immigration reform,” Klobuchar said. Senate Agriculture Committee Chair Debbie Stabenow is not seeking reelection. Klobuchar is the second-ranking Democrat on that committee and is the likely next chair. “We always like to have someone in that role from the Midwest,” Klobuchar said. “We know the many years when Collin (Peterson) was chair and ranking member and how helpful that was; it is exciting for me personally, but also for the state.”

Margins at lowest level since DMC’s authorization

In June, the Farm Service Agency reported a margin of $3.65 per hundredweight above feed costs. That’s the smallest level since the Dairy Margin Coverage program was authorized in the 2018 farm bill. American Farm Bureau Federation economist Danny Munch said it is the sixth straight month of margins below the $9.50 per hundredweight trigger. “That’s the rst time the program’s catastrophic $4 protection level had been breached,” Munch said. Feed costs, he said, are continuing to chip away at the bottom-line for dairy farmers.

SNAP nutrition incentives

Legislation has been introduced in both the House and the Senate to expand the incentives for dairy product purchases for the participants in the Supplemental Nutrition Assistance Program. The 2018 farm bill included inducements for uid milk purchases. The new bills call for incentives for additional dairy products, including cheese and yogurt.

Butter market rallies

Cash butter reached a 2023 record high price at mid-month. It was also the day with the highest volume of trades for a single session since 2004. DairyVisor President Joe Spader said the butter supplies are short, causing the market to rally. “With cow numbers declining and the heat stress on cows, I think butter production has dropped a bit,” Spader said. Additionally, butter in cold storage is depleting quicker than normal. Class III milk is in a similar situation with a drawdown in milk production driving the markets.

A.I. rms merge

The four individual cooperatives that make up Select Sires have voted to

merge. The new Select Sires Member Cooperative will be operational Oct. 1. Chris Sigurdson, who is the current general manager for COBA/Select Sires and Minnesota/Select Sires, will serve as the CEO for the merged A.I. rm.

For the rst six months of the scal year, Beyond Meat suffered a loss of $112.5 million. That compares to a loss of nearly $198 million in the same period one year ago. During the second quarter, sales for the plant-based protein products declined 24%. U.S. retail sales dropped 34%, but international foodservice business rose 19%.

Hoefs to lead MBOAH

Dr. Brian Hoefs is the new executive director of the Minnesota Board of Animal Health and the state veterinarian. Hoefs succeeds Dr. Mario Garcia, who served the agency until April of this year. Hoefs has been in an interim role since that time. Hoefs joined MBOAH in 2019 and oversaw swine, equine and livestock concentration points. Hoefs is the 11th executive director in MBOAH’s 120-year history.

Hall of fame honors for DeVelder

Donn DeVelder has been inducted into the South Dakota Co-op Hall of Fame. Born and raised in South Dakota, DeVelder began his career with Associated Milk Producers Inc. in 1984 as a eld representative and served in several roles focused on milk marketing, human resources and member services. In 2015, DeVelder was named AMPI’s copresident and CEO with Sheryl Meshke. DeVelder retired at the end of 2022.

Trivia challenge

Michael Dykes is the president and chief executive director of the International Dairy Foods Association. That answers our last trivia question. For this week’s trivia, how many servings of dairy products do Americans consume every day? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Caleb said he and Jared have liked the parlor concept from the time they were kids visiting an uncle who had a parlor.

Previously, the Wickenhausers were milking in a 38-stall stanchion barn. In it, they had to make 2.5 switches per milking, and the whole process took three hours.

The stanchions were worn out, so the Wickenhausers priced a new parlor but found the cost to be high. Their solution was buying a parlor on auction.

After purchasing the parlor, they had it pulled from its old barn in 2021, and then everything paused as it sat in a shed for a year. In July 2022, the Wickenhausers began demolition of half of their stanchion barn. They cut the number of stanchions down to less than half and work began on installing the parlor.

By October 2022, the parlor was installed. The cows adjusted quickly and were transitioned within a week.

Once the parlor was complete, work began on ripping the stanchions out, which the Wickenhausers had milked in while the parlor was being installed to create the new holding area. While they did this, they had the challenge of continuing to milk the cows in the new parlor setup with no area to hold the cows.

“When the parlor was done and the holding area wasn’t, getting the cows in there to get milked, that was the worst,” Caleb said.

By December 2022, the holding area was complete, and by January, the palpation rail, which was the last piece of the project, was installed.

The nished setup has the barn divided in two. The back is a holding area. A wall down the middle of the barn has two doorways for cows to enter the front of the barn, which has a double-8 parabone pit parlor. Originally, the parlor they bought was a double-10, but the previous owners milked Jerseys, so the Wickenhausers had to remove units.

They also decided to update the computer systems on the parlor.

The Wickenhausers used multiple contractors for aspects of the project and had a good experience with each of them.

“(We’re) just thankful everybody got here to do their work when they

were supposed to,” Jared said.

Because they installed a used parlor, the Wickenhausers were able to save signicantly. Another cost saving factor was that they did not need new buildings. They were able to keep everything, including the milkhouse, and only the interior of the stanchion barn changed.

“We weren’t sure what we would use this existing barn for,” Jared said. “(We) didn’t want to have a new building and then have this sit empty.”

Milking time in the new setup only takes two hours, including cleanup. The Wickenhausers have also seen a reduction in mastitis.

If they were to do it again, the Wickenhausers said, they know of some things they would change. They would add more slope to the holding area and add a drain in front of the wall dividing the holding area from the parlor, which tends to get a pool of water. They also would have raised the ceiling.

For chores, Jared is the main milker each day. Caleb starts chores with scraping and moving cows and then joins Jared in the parlor. Allen works on feeding calves and heifers as well as mixing and feeding the total mixed ration.

Allen started on the farm in 1977, and Caleb and Jared are the fth generation of their family to be dairy farmers. Their grandpa is tending to youngstock on a different farm at 87 years of age.

Both brothers have spent their full careers on the farm.

“It’s all I know,” Jared said. “I like the cows.”

Caleb agreed.

“I always liked the cows,” he said. “(I like) being able to be outside and work outside instead of looking at a computer screen or papers all day.”

The Wickenhausers said they appreciate that dairy farming allows them to have their own schedule and experience something different each day.

Although the Wickenhausers are unsure of the exact future of their farm, they said they want to expand some aspect of it whether it is the cows, cash crops or nishing more steers. Caleb said the new parlor gives them the option to milk more cows if they want to.

Kuball is the daughter of dairy farmers Nate and Shannon Kuball of Waterville.

“It was just a dream come true,” Kuball said. “Right now, I’m just so grateful for all the amazing people I’ve been able to meet.”

Makenzie Alberts, representing Dodge County, and Megan Ratka, representing Stearns County, were runners-up.

Kuball is a sophomore studying agriculture education at the University of Wisconsin-River Falls. With her major, she recognizes how the school visits that are part of Princess Kay’s role will affect her.

“I’m really excited to see how my major and what I’m learning in school will pay off in the classroom visits that I do,” Kuball said. “Also, I can see how the classroom visits will pay off in my schoolwork because it’ll be a really cool meshing experience.”

Kuball’s goal as Princess Kay is education.

“I really hope to educate people about the importance of dairy farming — the importance of the dairy community, how dairy products really affect consumers’ health and how many amazing nutrients are in dairy products,” she said.

Kuball and her family milk 240 cows on their farm in Rice County. Kuball said she has learned integrity through the farm and that the animals need to be cared for regardless of the weather extremes of cold or heat.

“I really learned the value of hard work,” Kuball said. “It doesn’t matter how many things you have to do in a day, there’s always time to do the important things.”

Kuball’s father, Nate, was planning to bale hay on the days immediately following coronation. His plans changed.

Kuball’s mother, Shannon, said having her daughter honored is meaningful.

“When you put your whole life into something like the dairy industry, to

know that your daughter is going to be representing all of the hard-working people all across the state; I don’t even know if words could be there,” she said. Other honors included Gracie Ash, of Mille Lacs County, being appreciated by her fellow nalists with the title of Miss Congeniality.

This year, the scholarship winners were Alberts, Kuball and Ratka.

At the coronation, the rst Princess Kay of the Milky Way Eleanor Maley Thatcher, who passed away since the last coronation, was honored.

To celebrate the Princess Kay program entering its seventh decade, all of the past Princess Kays in attendance were welcomed on stage in the order of their reigns.

Kuball will spend all 12 days at the Minnesota State Fair, representing the dairy community. Her rst two days will include many hours spent in a 40-degree rotating glass cooler as she has her likeness sculpted into a 90-pound block of butter by Minnesota artist and butter sculptor Gerry Kulzer.

“I’m really looking for-

ward to meeting the people who come into the butter booth,” Kuball said. Throughout the fair, Princess Kay will be joined by the nine nalists, visiting

with attendees in the Dairy Building, spending time at the Moo Booth, appearing in the daily parade and doing media interviews with television, radio and print.

Dairy Cattle Research and Teaching Center in Fargo, North Dakota.

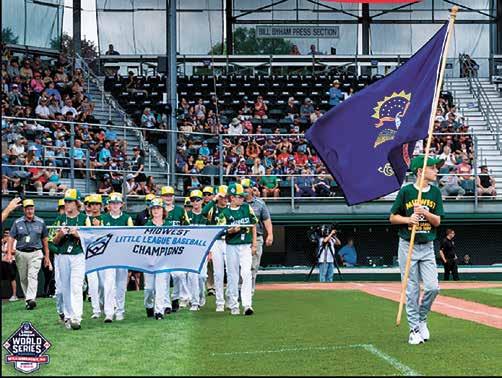

As an assistant coach, Molden helped lead a group of 12 talented youth to appear in the Little League World Series Aug. 16-27 in South Williamsport.

The Fargo 12U All-Stars is the rst North Dakota team to reach the pinnacle appearance in the tournament’s seven-decade history.

Molden and his wife Tania’s oldest son, Jackson, is the catcher on the team. Siblings Amelia and Christian have been cheering on the team during their journey to Little League headquarters.

Molden, who oversees the 100cow dairy farm at NDSU in addition to student employees, has been juggling the three roles of coach, father and herdsman throughout the season.

When it came time for the league’s state tournament in July, Fargo 12U All-Stars was the lone team that entered.

“Little League is not super huge in North Dakota, although I have a feeling it’s going to get a lot bigger now, but it’s not huge by any stretch,” Molden said. “Usually, there’s only about three teams in the state tournament.”

The squad then departed Aug. 2 to travel to the eight-team Midwest Region Tournament Aug. 4-11 in Whitestone, Indiana.

After defeating Kansas 15-1 Aug. 4 in the quarternals, Fargo

12U All-Stars faced Wisconsin Aug. 5 and won 16-2. A loss to South Dakota followed Aug. 9 by a score of 7-3. The team was not deterred and came back to win the next day over Iowa 12-7.

The win set up a championship game of neighboring states Aug. 11. In the end, North Dakota was the victor 9-7 to secure their spot in the world series.

ADULTS: $20

($17 IN ADVANCE)

CHILDREN: $9

First come, first serve for sign up! Mutton Busters must be at least 4 years of age and under 40lbs! Ready to see if you’re tough enough to try out our

“The last play was a ground out to our shortstop, and he made a nice play,” Molden said. “It was so much fun to watch the celebration, knowing how hard these kids worked. They do anything we ask them to, and it’s just so fun to see that emotion in them come out.”

With no time to relax, and with a ood of local support behind them, the team and their three coaches set

off on a bus at 7 a.m. the next day.

“There was no time,” Molden said. “Basically, as soon as we won it, we had a meeting with the parents to explain what was about to happen. And then from there, they put you on a bus.”

Upon arriving at Little League headquarters, the team has navigated once-in-a-lifetime experiences, with media requests, events and opportunities tailored to the 20 national and international teams in attendance. A parade was held for all the teams through the streets of Williamsport. Molden said thousands of spectators were in attendance.

“It’s pretty amazing what they do for these kids,” Molden said. “They treat them like rock stars.”

Fargo 12U All-Stars, referred to as Midwest in the world series, drew a bye for the opening round Aug. 16 and fell to Southwest 6-2 Aug. 18 at Howard J. Lamade Stadium.

The double-elimination tournament bracket set up a MidwestMountain game Aug. 20. Ultimately, Midwest exited the world series when the game ended 7-1.

“When it became clear we wouldn’t win, I was still just so proud of them and all that they accomplished,” Molden said. “Nobody will ever be able to take away those accomplishments from them. I am sad that we are done with this group, but I hope many of them continue to play together, because this is a special group of players.”

Molden grew up on a dairy farm near Appleton, Minnesota, and, from a young age, learned and excelled at the sport of baseball. Molden traded a player’s jersey for a coaching spot in the dugout of an American Legion team while he was still attending Ridgewater College in Willmar, Minnesota.

When Molden moved to Fargo, North Dakota, and his oldest son began with Fargo Youth Base-

ball, Molden once again assumed a coaching role.

With so many memories wrapped in a baseball glove, Molden was quick to admit this latest experience will forever be at the forefront.

“The moment it hit me was when we came up from underneath Lamade Stadium onto the ineld

and you walk up the steps and you see it,” Molden said. “If you’re a baseball fan, you’ve watched the games, and now you get to see rsthand. You’re right on the eld where all these games have been played all these years. It was pretty special.”

The signicance of this milestone may be muddled by the excitement for the 12 players, but this time will be etched in their memories for years to come. From Molden’s perspective as a father and a coach, he is proud of not only his son but the 11 young men on the team.

“To be able to be there with Jackson is incredible,” Molden said.

“I know how hard he works at it and how much he wanted this. But you know, I’ve spent so much time with all these boys, you almost feel like you have 12 sons out there. It’s really fun to be able to be a part of that.”

While Molden has been occupied with all things baseball, the academic year at NDSU has begun. Molden said he is grateful for his assistant herdsman, Bob Brown.

“He’s great with the students, and he works his tail off,” Molden said. “He loves the cows, and luckily, Bob is a sports fan too and knows how important family is.”

Molden said he sees similarities

in the values instilled on a dairy farm and those learned on the diamond.

“As anyone who has dairy farmed knows, you have to work hard, and you are going to get out of it what you put into it,” Molden said. “These kids have bought into that mentality. Dairy farmers will do anything for their cattle and for their family as they’re trying to handle the day-to-day stuff on a dairy farm. These kids work super hard and play hard for each other, and they know that they have to put in a lot of work, and they do that. They’ve been rewarded with success because they work so hard.”

“As anyone who has dairy farmed knows, you have to work hard, and you are going to get out of it what you put into it. These kids have bought into that mentality.”

TODD MOLDEN, NDSU HERDSMAN AND ASSISTANT COACH

BY SMITH’S OF WI LLC

BY SMITH’S OF WI LLC

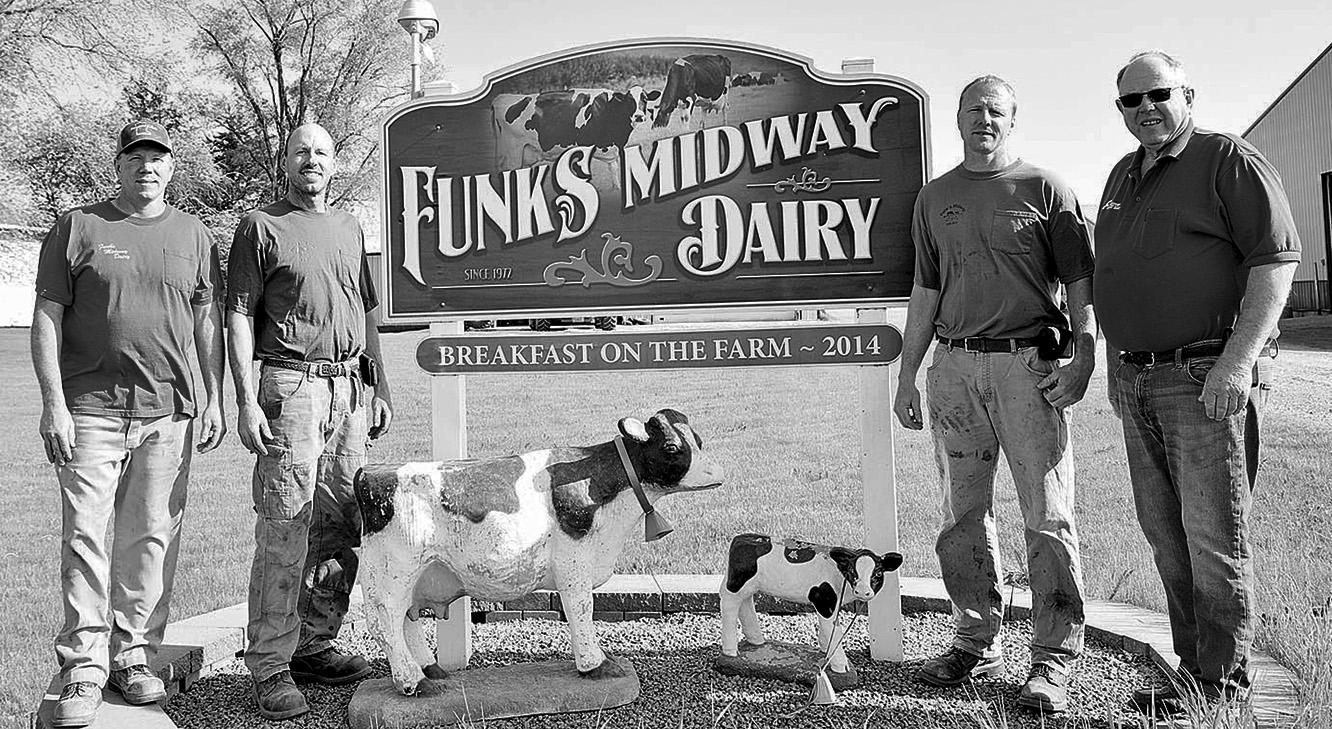

MELROSE, Minn. — When brothers Greg, Carl and Jeff Funk chose to follow in the footsteps of their parents, John and Dorothy, and make dairy farming their career, they also began a line of expansions and upgrades to the family’s farm.

Today, Funk’s Midway Dairy near Melrose milks 700 cows — 560 in a double-12 parlor three times a day and 140 with two Lely A5 robotic milking systems. The Funks raise their own heifers and crops and manage the farm’s manure.

The processes on their dairy farm were shared Aug. 8 during the Central Dairy Field Day coordinated by University of Minnesota Extension.

Carl explained the roles each brother plays in the day-to-day operations. Jeff handles cow reproduction and calves, Greg manages forages and maintains equipment, and Carl oversees milking. Their father, John, helps with farm work wherever needed.

Assistant herdsman Juan Rocha, who has been employed at Funk’s Midway Dairy for six years, also helps with human resources. The farm has 13 fulltime employees.

“(Rocha) helps us manage our employees,” Carl said. “He translates and has been able to nd some of our employees. He’s been a great asset.”

Carl also gave a short history of the farm’s expansions.

In 2002, the Funks added onto their freestall barn to include 388 stalls. In 2015, a bedding pack barn was built for special needs cows and calving. Also that year, a parlor addition helped the Funks milk three times a day more comfortably. Then, in 2016, the Funks purchased a neighboring farm and installed a robotic milking system.

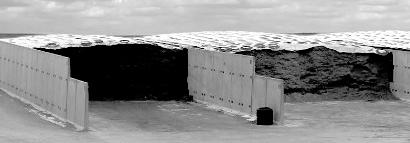

Greg talked about the farm’s emphasis on quality silage in their bunkers.

“We have two layers of plastic on top of all our feed — oxygen barrier and the black and white plastic — and we put tire on tire; there’s no exception,” he said. “If we don’t have enough tires, we go get some more. We believe you cannot space your tires out and still get good quality on top.”

Corn silage quality, Greg said, also includes other considerations.

“What we’re going to harvest this fall will not get fed for at least three months so that it has time to ferment,” he said. “With our dual-purpose hybrid corn, we’re focusing on digestibility.”

Since the farm does not have enough manure storage, the Funks direct pump about 2 million gallons of manure in the spring.

“We do drag line all our manure,” Greg said. “We

can pump direct anywhere 2 miles around here. We have land that’s up to 5 miles away, and for that (the manure) has to hit wheels. We can run that distance with ve trucks and still keep the system up and running.”

Their trucking of manure takes place in the fall.

“We put on anywhere from 7,000 to 12,000 gallons (of manure) per acre,” Greg said. … “Our concern with manure is that we’re going to build phosphorous, but we test our soils every three years, and we’ve proven that we can actually maintain or even drop the phosphorous levels in our soils even with those manure rates.”

The Funks also raise soybeans and alfalfa. Trucks haul the soybeans to Mankato to be sold and then return with soybean meal.

The Funks harvest their hay between 48% and 60% moisture. Greg said their ideal is in the low 50s. They also harvest corn silage at 62%-67% moisture.

There are a number of meadows around their two sites, and the Funks chop rst-crop meadow hay, which they feed from December to April. Greg said, since they do not own their own baler, it is cheaper to chop it.

“It’s been a real plus for us,” Greg said. “Our cows have told us that it’s worth our time to try to get those forage boxes in our meadows and get that product off of there in a chopped manner.”

At the milking parlor, Carl described the milking procedures used at the parlor and at the farm’s other site where the robotic milking system is located. There, 140 milking cows are housed along with 60 dry cows. The site has two robots with the option to add one more.

At the parlor, the Funks installed cow brushes about four years ago.

“It wasn’t really the silver bullet that we wanted, but it helped and made things easier,” Carl said. “We had a double-8 parlor then, and the stalls were narrower, so in 2015, we added four stalls and went bigger. We never had to check for stray voltage since that change, and the only reason was that (the cows became more) comfortable.”

He said the change did not improve somatic cell count numbers like they had thought. What did make a change in those numbers, he said, surprised him. Three years ago, they stopped using a crowd gate at the entry to the parlor. They had thought it was helping them avoid having to chase cows.

“We were wrong,” Carl said. “Now, the cow gate is just used as guide. It’s been night and day since we made that one change.”

Since eliminating the crowd gate, both farm sites have had a SCC under 100,000 this year.

The Funks dairy herd averages 4.3% butterfat. Milking visits to the robots average 2.8 to 2.9 visits per day, which is an improvement Carl attributed to switching feed used to guide cows to the robots.

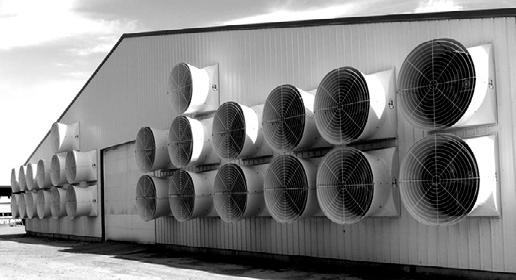

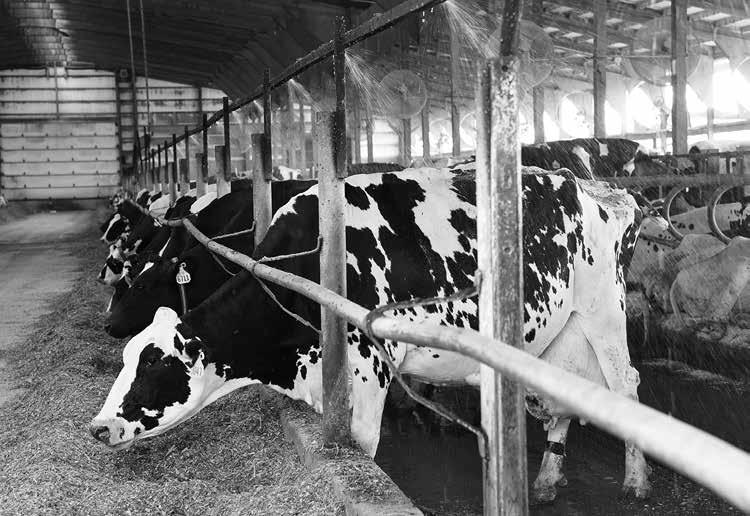

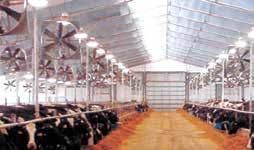

Sprinklers cool cows Aug. 8 at Funk’s Midway Dairy

The sprinklers are set to turn on automa cally at about 65 degrees, and as the temperature goes up, they spray longer and more o en.

“In April, we decided to switch to cracked corn and soybean meal as one of our feeding ingredients there — before that, we just used two different kinds of pellets — and it was like a light switch went on,” Carl said.

At that site, the Funks have an automatic feed pusher, and manure is vacuumed up by two collectors. At the parlor, they have scrapers. Although the robots have added in labor savings, the best benet, Carl said, is exibility of time.

“How do you put a dollar value on exibility?” he said. “Man, that’s been rewarding.”

To milk 550 cows at the parlor takes six hours, three times each day, with an extra hour each time for cleanup. At the robot barn, workers spend 2.5 hours in

the morning and 1.5 hours in the evening, but that includes taking care of the dry cows.

Jeff said the farm has ve types of bedding being used across its sites. In the freestall barn in which he spoke, there are two types of bedding: water beds and a bed pack with shavings. He said he personally likes the 3-inch foam mattresses best for overall durability and cow comfort but prefers waterbeds for cows with sore legs.

The Funks incorporate sprinkler systems and fans for cow comfort. For y control, the Funks have a spray system on the ceiling with nozzle heads.

Tell us about your farm. Our farming operation, Little Valley Dairy, is managed by myself and my husband Donny, along with two of our children. Nick works full time for CHS but works alongside us evenings and weekends. Nick also takes time off during chopping and in the fall during harvest. Our daughter Clara is a full-time student at the University of Minnesota-Twin Cities majoring in animal science. Whenever Clara is home, she participates in milking, youngstock chores, calf feeding and eldwork. Besides operating the 180-cow dairy, we also farm 600 acres of cropland we own, 380 acres of cropland we rent and about another 370 acres of pasture and woodland.

How many years have you been a director for DHIA? I have been a Minnesota DHIA director since 2006. This hardly seems true as I have enjoyed representing all of Minnesota’s DHIA farmer members on both the state and national level as a delegate to national annual meetings. My children were so young back then but have grown up understanding the importance of DHIA, good record keeping and the value of DHIA test day information.

What are your duties as director? My duties as a DHIA director currently include being the secretary/treasurer, representing Minnesota as a delegate for the national DHIA meetings, serving on the national DHIA scholarship committee and attend meetings (both board meetings and our annual meeting) in person or via Zoom. I have also served on several committees nationally and served as scholarship committee chairman.

What do you like about this role? I enjoy being part of a like-minded group who purposefully keep the importance of DHIA testing alive, keep costs reasonable to farmers and are always looking for ways to improve for Minnesota DHIA and their farmers.

Why is DHIA important to you? Growing up on my family farm, Hinckley Holsteins, we used DHIA testing for as long as I can remember. My parents, Dale and Marlys Hinckley, instilled in me how important it was to have accurate records and know the composition and amounts of milk each cow produced. When I married into another dairy farm family in 1996, DHIA was not being used at that time; though, it had been in the past. I recall our rst test when we purchased the herd and being excited to get results to dissect which cows really were pro table. Cow No. 25 was the one my mother-in-law raved about, but when I received my results, this cow had a high somatic cell count and both low fat and protein tests. Clearly, she wasn’t my best cow. Through the years, we have purchased animals to add to and grow our herd, and each time, we only looked at DHIA herds. Since 2007, we have had daily milk weights in our new parlor, but I’ve always believed there is more to the picture than just pounds of milk per day. Some of your highest producers may not be your most pro table. I also nd value in milk pregnancy testing. I have regular herd checks and a great relationship with our vets, but I nd it very convenient in using the test at busy times for my dairy when I don’t have anyone around to help me sort for ultrasounds or for con rmation checks in later lactation.

DHIA: Now MORE than ever

Sauk Centre, MN • Buffalo, MN 763.682.1091

www.mndhia.org

GREAT SLECTION OF USED GRAVITY BOXES ON HAND! BOXES

CIH 8950 1,600 hours ..............................$165,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 8920, FWA, 2600 hrs ........................$110,000

CIH 7240, 2,500 hours, coming in ...........$110,000

CIH MX120, 2WD, 3,800 hrs......................$72,000

CIH MX110, FWA, 1600 hrs. ......................$65,000

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 1026 hydro .....................................Coming In

IH 806 ....................................................$11,000

JD 2755, 5,600 hrs. ...............................$16,000

JD 4020, new clutch ..............................$11,000

TILLAGE

527B ripper ............................................$13,500

CIH 530B................................................$18,000

CIH 527B................................................$19,500

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate II 26’, w/28’ pull crumbler $31,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

CIH Tigermate 200 28’ w/basket ............$37,000

CIH Tigermate 200 37’ w/basket ...................Call

JD 714 11 shank chisel plow .................$14,000

CIH 5700 chisel plow, 23’ ......................$16,000

CIH 4800, 28’ ...........................................$6,500

CIH RMX 340 25’ disc w/mulcher ..........$42,000

CIH RMX 340 28’ w/mulcher .................$44,000

CIH 25’ 3900 disc ..................................$15,000

CIH 1830 8RW cultivator .........................$4,250

DMI 530 Ecolo-Tiger w/basket ...............$12,000

DMI 530 ripper w/leads..........................$14,000

DMI 530B w/lead ...................................$16,500

HAYING & FORAGE EQUIP.

Sitrex QR12, QR10, QRS rakes ....................New

Kuhn 10-wheel rake w/center kicker wheels, like new ..................................................$8,500

Many sizes of rakes available

All Sizes of Sitrex Rakes.........................On Hand

GRAVITY BOXES & GRAIN CARTS

(2) Demco 365 .........................................$4,200

Many Sizes of Gravity Boxes ..................on Hand

Brent 657 gravity box, green & black, fenders ................................................$23,000

(2) Brent 644 box .......................................$18,000

Brent 644 ...................................................$16,500

J&M 385 ......................................................$6,500

J&M 540 box .............................................$13,500

Parker 4800 box...........................................$8,500

Unverferth 7250 grain cart .........................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

“I enjoy being part of a like-minded group who purposefully keep the importance of DHIA testing alive...”

“It’s a y-mist system; it runs four times a day for about a minute and a half,” Jeff said. “It works well.”

The Funks incorporate regular footbath schedules and do their own hoof trimming. They also raise their calves in a facility a mile away, using a cooling compressor truck to run waste milk to them.

“We love it since we went to that with the calves; they are so much bigger and stronger,” Jeff said.

In the freestall barn next door, Rocha discussed the farm’s breeding system. The farm uses 70% Holstein semen and 30% beef semen.

Rocha said a team of four works together to breed cows.

“We always have 4% difference between each (team member) for conception rates,” Rocha said. “We have a goal on the farm — that’s why we always have over 50% conception. We have a herd check every two weeks, and the boss always pushes us to meet 80% of conception on every herd check. Somebody always says, ‘That’s too high,’ but that’s possible when you do things with passion. If you are always learning, the results show up by themselves.”

To pinpoint best times of day to breed individual cows, the team uses data from activity collars but also keeps track themselves by watching and writing down signs of cows being in heat.

The team also tries to avoid any stress in those cows to increase breeding success.

“We always try to move the cows nice and slow,” Rocha said. “I like to use the scrapers so that we don’t have to use skid loaders. It’s still clean but calmer.”

With many moving parts in the Funks’ large farming operation, Carl said teamwork and communication are key.

Greg Funk shows comparison photographs Aug. 8 illustra�ng how wrapping the sides of bunkers in addi�on to carefully covering silage makes a big difference in quality of that silage on his family’s dairy farm near Melrose, Minnesota. Funk’s presenta�on was part of a eld day coordinated by University of Minnesota Extension.

“We meet almost every morning for breakfast,” Carl said. “We all have our separate areas, but we all kind of help out in all areas. We talk a lot, maybe too much at times, but we usually feel like the end result is what we wanted.”

sow the seeds of your farm’s success. Our vast farming experience combined with our years of ag lending experience make us an invaluable addition to your farm business.

Beth Ford, CEO of Land O’Lakes, was interviewed by Time magazine.

When asked about rising grocery prices, Ford said, “You know what could be self-protective for us? To get some immigration reform. If we’re two and a half million workers short, 20% of produce in the Central Valley, bread-basket area didn’t get harvested because we have no labor.”

In June, the unemployment rate was at 3.6%, or 6 million individuals.

The reason Americans don’t do this work is because it doesn’t pay enough.

The cornerstone of the American dream is home ownership. I don’t think Americans harvesting produce in the Central Valley could afford to buy a house on the wages their employers are paying.

In the May 13 Dairy Star, Cole Hoscheit, of Caledonia, Minnesota, said that his farm is improving lives in Mexico. His employees are building houses in ve years. Most people in the United States borrow money from a bank on a 30-year mortgage. I don’t know of anyone who can afford to build a house in ve years.

I wonder if Americans could build houses in ve years on the wages dairy farmers are paying. Looks like the cornerstone of the Mexican dream is home ownership also. Hoscheit is making the Mexi-

can dream happen for his employees. The adage, “Hard work pays off,” does not apply to Americans working agricultural jobs.

Ford also said, “(Immigrants) don’t take jobs (from Americans). These jobs are hard.”

I agree with Ford that these are hard jobs, but saying that Americans won’t do hard work is simply not true.

According to National Milk Producers Federation, after World War II, there were 3.5 million dairy farms. Now, there are under 30,000 in the United States, according to a USDA release in 2022.

Hard-working dairy farmers have been forced out of business by dairy farmers who, for decades, have been breaking federal immigration laws to hire illegal immigrants who will work for less money than Americans, giving them an unfair advantage over people who abide by the law.

Working with cattle is not only a hard job, but it’s dangerous. It should be a high-paying job and, quite frankly, should pay better than a CEO.

I do agree with Ford that grocery prices are too expensive. Large food companies are to blame; some are making a prot of billions of dollars a year.

Joe Schindler Red Lake Falls, Minnesota

Joe Schindler Red Lake Falls, Minnesota

90 cows

Of all the tractors you’ve owned, what is your favorite? I can’t pick just one; I like them all. We’ve got all John Deere equipment, but the most used one is our 7930. The engine puts out around 220 horsepower.

Why is it your favorite tractor? I really like the tractor for how smooth it is. The 7930 is maneuverable and versatile. We use it for a lot of different jobs. It’s easy for me to drive because it is all a simple hand lever, and I don’t have to do as much gear shifting.

What kind of work do you use it for on the farm? It’s on the baler right now, but we also use it for cutting hay and chopping. It does all our planting.

What is your favorite task to do with the tractor? I like working on chopping silage with it. It makes the job easier.

If money was no object, what tractor would you purchase? It would be a John Deere, of course. We have all we need right now, and I haven’t looked at new tractors in quite some time. I’m not sure what I would get.

During the year, what is your favorite job involving a tractor? Baling. It’s not difcult with the new balers. They tell you when it is full, and you pull the lever to release the hatch on the back.

Tell us about your family and farm. I farm with my wife, Jenny, and son, Jason, and his wife, Kari. Jason and Kari’s children often come to help on the farm as well. We milk 90 cows in a double-3 tandem parlor. The parlor has been replaced twice, and it’s been on the farm for around 50 years. The cows are housed in a tiestall barn and bedded with chopped bean straw. We also farm 800 acres of cropland, consisting of a corn, soybean and alfalfa rotation.

Of all the tractors you've owned, what is your favorite? The International Harvester 706. I bought the tractor in 1985, and the sales person let me try it for a week. Then, I bought it. It has 80 horsepower, and I don’t know the hours because the gauge doesn’t work. I put a cab on the tractor ve years after I had it.

Why is it your favorite tractor? The memories of the way I bought it and all the work it has done on the farm. I always like when I get on the tractor. I remember picking corn after we put the cab on and thought that was so nice.

What kind of work do you use it for on the farm? I use it for raking hay and hauling hay wagons. The hydraulics is not working now, but when I get it xed, I will put it on the manure spreader.

What was your favorite task to do with the tractor? I used to moldboard plow and disc with the 706.

If money was no object, what tractor would you purchase? An IH tractor with front-wheel assist because it would get you through the muddy conditions.

During the year, what is your favorite job involving a tractor? Chopping silage. I really enjoy seeing the silage blown into the boxes and clearing the eld. It’s nice knowing you have feed for the next year.

Tell us about your family and farm. I milk with my son, Nicholas, and Sally. We milk in a tiestall barn. Nicholas does the milking, and I feed the cows and the calves. Sally cleans the milkhouse when he is done milking. We also farm 152 acres, 80 of which is open. We raise corn and alfalfa. We ship our milk to Bongards.

Tom FuechtmannNew Munich, Minnesota

Stearns County

70 cows

Of all the tractors you've owned, what is your favorite? I have three White 2-105 tractors. I bought two with the farm in 2000, and then I bought the other one at an auction in St. Nicholas. They have 14,000, 8,100 and 5,600 hours on them and have around 115 horsepower.

Why is it your favorite tractor? I like the Perkins motors in them. I never have issues with the Perkins motor.

What kind of work do you use it for on the farm? I use them for everything: cutting and raking hay, hauling forages and gravity boxes, and anything that comes up. I have one on our 430-bushel spreader, and it doesn’t even fuss.

What is your favorite task to do with the tractor? Cutting hay because they are such smooth-riding tractors.

If money was no object, what tractor would you purchase? I don’t have any interest in new tractors because I am comfortable with these. Too much of the price of new tractors goes into benet packages for CEOs.

During the year, what is your favorite job involving a tractor? Cutting hay. I put in air seats in the 105s. They don’t have the cab-forward design, and they just oat through the elds. I grew up with these. They made this place, and they belong here. Tell us about your family and farm. We milk in a tiestall barn. I farm here with my son, Tanner, and we milk 70 cows. We also have 450 acres, 350 of which are tillable. We raise corn and alfalfa. We have irrigation on 250-275 acres. We ship our milk to Associated Milk Producers Inc.

Melvin Bayerl Winsted, Minnesota McLeod County Ralph Schleper Bowlus, Minnesota Morrison County 40 cowsAustin Hayeld, Minnesota

Dodge County

50 cows

Of all the tractors you've owned, what is your favorite? My favorite tractor by far is the 2008 John Deere 7230, 135 horsepower with front-wheel assist. It has 6,000 hours, and we bought it in 2010. It has a self-leveling loader which makes it a versatile tractor.

Why is it your favorite tractor? My favorite part of this tractor is the buddy seat which is often occupied by one of our grandchildren, making it the greatest tractor ever. This tractor gives a smooth ride, and the cab is pretty quiet. They have spent countless hours with me doing homework, telling stories and singing songs.

What kind of work do you use it for on the farm? We use it for tillage, harvesting silage, baling hay, cleaning, feeding, mowing, moving round bales and snow removal. It's cool in the summer and warm in the winter, has great visibility, is quiet and has power shifting on the go.

What is your favorite task to do with the tractor? My favorite task is baling. I feel so fortunate to be able to work with our family. It is not uncommon to

Darrel Nyhof

Sioux Center, Iowa

Sioux County

500 cows

Of all the tractors you've owned, what is your favorite? My favorite tractor is the Oliver 1550 that my grandpa bought new in the late 1960s. It has a narrow front, a three-point hitch and a gas engine that produces 53 horsepower. The tach says that it has 3,200 hours on it.

Why is it your favorite tractor? The Oliver 1550 has been a trouble-free tractor for the most part. My nephew from Chicago recently graduated from college and dropped by our farm on a westward road trip he was taking. I put him on the Oliver and had him drive it even though he had never been on a tractor before. Driving his great-grandfather’s tractor was a huge thrill for him and created some great memories.

What kind of work do you use it for on the farm? I put a sprayer on the Oliver’s three-point hitch and use it to spray ies in our barns. The tractor only runs for an hour once a week or so during the warm months. I change the oil every other year to keep its lters and oil fresh,

have four generations working at once. Our daughters have taken off work and made special trips to the farm to help us during this time. Baling requires several hands. We make a big lunch and eat together which provides lots of laughs and problem solving.

If money was no object, what tractor would you purchase? If money were no object, we would probably choose the John Deere 6R 145 with a buddy seat and front-end loader.

During the year, what is your favorite job involving a tractor? My favorite job with a tractor is putting up hay, both bales and chopping, which can be challenging. We want to cut the hay during the right stage of maturation; however, weather can be a big factor as well. Trying to chop it before it dries out too much yet after the dew in the morning and moisture at night requires good planning and patience. It always smells great, and I have the best view from my workstation. I'm pretty lucky.

Tell us about your family and farm. Jeffrey and I truly have a family-operated, sustainable, sixth-generation farm. We have a tiestall barn with comfort stalls and have shipped our milk to Associated Milk Producers Inc. for about 40 years. We milk about 50 registered Holsteins twice a day. We farm about 700 acres of corn, soybeans, sweet corn, alfalfa and sometimes peas. Jeffrey and Bonnie do most of the milking while Jeffrey's father tends to the calves and cats. I spend more time on the tractor than in the barn due to past injuries, and our grandchildren, Lane and Owen, are getting to be good dairymen too.

What is your favorite task to do with the tractor? I don’t really like eldwork. What I enjoy the most is working with and caring for our dairy cattle. Spraying ies with the Oliver is very satisfying because at the end of the process you can see dead ies.

If money was no object, what tractor would you purchase? I would like a John Deere 6155R with short axles and all of the bells and whistles. We are currently using a similar tractor on our feeder wagon, and it’s already got quite a few hours on it. When I was 33 years old, I bought a John Deere 4440 and put it on the feeder wagon. Years later, when I sold the 4440 to a mechanic in central Iowa, it had over 30,000 hours on it.

During the year, what is your favorite job involving a tractor? I own a John Deere 4020 that has an open station. One of my favorite things is giving our ve grandchildren rides on that tractor. It’s a great way to spend time with them and create lasting memories.

Tell us about your family and farm. My wife, Mary, and I farm with her brother and her father. We milk our cows in a double-8 parabone parlor and bed our free stalls with sand. Our fresh cow pen has a bedding pack, and our maternity pen is bedded with sawdust. We trim hooves every other Tuesday and perform herd health checks on alternating Tuesdays. We ship our milk to Associated Milk Producers Inc. in Sanborn, Iowa.

Describe your farm and facilities. Our cows are housed in sand-bedded free stalls and milked in a double-8 herringbone parlor. We have modied our existing buildings over the years to get everything how it is today. This farm has been in my family for 111 years, and I was raised here. This is my 51st cropping season. My wife Pat and I are senior partners, and we farm with our daughter, Angie, and her husband, Donald, and our son, Dan, and his wife, Michelle. The grandkids work when their schedule allows. My nephew, Ben Herricks, is the main feeder, and he is invaluable. He has worked here for over 20 years and knows everything going on.

What forages do you harvest? Corn silage, alfalfa, rye and oats.

How many acres of crops do you raise? 1,400 acres.

What quality and quantity do you harvest of each crop?

We raise 300 acres of alfalfa, 100 acres of nurse crops (rye and oats) and 1,000 acres of corn. Half the corn is for si-

lage and half is for grain. We raise HarvXtra Alfalfa, which is a low lignin feed, and strive for a relative feed value of 200. We raise brown midrib corn silage, and our goal with that is to harvest as high energy, palatable feed as we can.

Describe the rations for your livestock. We feed a high-forage diet to all of our animals. Rye and oats are fed to the dry cows and heifers. The milk cows are fed alfalfa haylage, BMR corn silage, ne-ground corn, soybean meal and a protein mix. The quantity of each ingredient is adjusted according to production groups.

Describe your harvesting techniques for alfalfa and corn silage. We harvest all of our own crops together with the Brueggen family in Norwalk, Wisconsin. We have worked together to get our crops done for over 40 years. Our No. 1 rule for working together is, if a decision is not good for both of us, then we need to rethink it. They also milk close to 600 cows, so we are working together to feed 1,200 cows, which justi-

Jack Herricks takes a break Aug. 16 at his farm near Cashton, Wisconsin. Herricks farms 1,400 acres and milks 600 cows with his family, and 2023 is the 51st cropping season of his farming career.

es having larger equipment. We harvest our alfalfa every 28-30 days and get it done in three days. It’s important

to get it done in a short time frame to achieve consistent feed. Corn silage takes about a week.

What techniques do you use to store, manage and feed your forages? We store our forages in bunkers. We store half of our shelled corn in a bunker and the other half in Harvestore silos. When we are harvesting, we make sure feed is packed tightly in the bunker. The single biggest factor in management is taking monthly inventory of our feed. We know when our feed is going to run out, and we are able to plan better that way.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We raise the same crops, but the genetics have changed dramatically. We have also changed the soil health of our land. Most of our land has over 4% organic matter. Each percentage increase of organic matter gives the soil the capacity to hold another inch of rain. So, on a year like this, we can hold 2 more inches of rain than a lot of land.

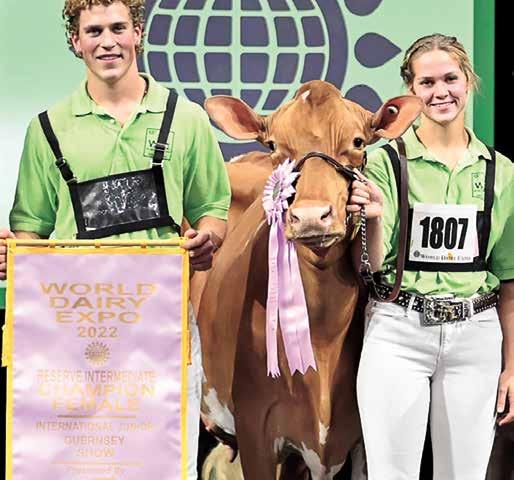

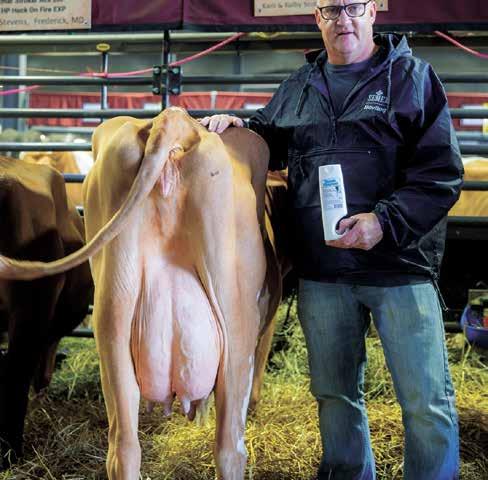

“Only Udder Comfort™ will do! We love it for swelling and for fresh cows. We never want to use anything else because this works so well,” says Kevin Stoltzfus of Warwick Manor Guernseys, the herd in East Earl, Pennsylvania that produces the Golden Guernsey Milk for Yoder’s Country Market in New Holland.

Kevin and Dina and children Kolby, Karli and Kaila are all involved in the dairy. Karli and Kolby brought 4 homebred Guernseys to the 2022 World Dairy Expo. ‘Peachey’ was bred-and-owned champion of the junior show, ‘Scotch’ (pictured above) was res. int. champion of the junior show, and ‘Senora’ top lifetime production cow of the open show. Of their 50 milking Guernseys, 12 made the 2022 Top-100 Component Queen Cows of the breed, averaging 25,110M 5.9F 3.3P; with 89-pt average score, 5 nominated AA in milking form.

“When something works, we stick with it. We use Udder Comfort on all fresh cows 2x/day for a week after calving. We start heifers prefresh, 1x/day for a week before calving,” says Kevin. “We also use it before, during and after showing.”

We also have the following Skidloaders in stock for parts:

We are also a dealer for DEKA BATTERIES Nice selection in stock!

We are also a dealer for NORDEN SKID LOADER ATTACHMENTS

And we also have your full line of hyd hose and fittings in stock stop in for your hyd hose needs 1/4”, 1/2”, 5/8”, 3/4”, 1”, 1-1/4”!!!

Jack Herricks inspects corn silage Aug. 16 on his farm near Cashton, Wisconsin. Feed inventory is taken monthly, which allows the family to plan for carryover; this way, the feed has enough me to ferment and cows never have to eat green corn silage.

Fine-ground corn is stored in Harvestore silos and bunkers at the Herricks farm near Cashton, Wisconsin. Milk cows are fed corn silage, alfalfa haylage, ne-ground corn and a protein mix.

How do quality forages play a part in the production goals for your herd? It helps us be low-cost producers because high-quality forage means less purchased feed. Approximately 80% of our feed is home grown.

2000 Gravity Flow wagon, Knowles running gear, clean ....................................................

Lundell 1290 Gravity Flow wagon, front & rear ladder, Lundell running 2070 gear, rear hitch...

Parker 2100 Gravity Box, LH discharge, Lundell 1670 running gear, right off farm, nice .........

Parker 2100 Gravity Box, LH discharge, John Deere running gear, right off the farm, nice......

Sudenga Hi-Ef swing hopper auger, 61’X8”, 540 PTO, hyd lift, manual hopper jogger, right off the farm, ready for work ....................................................................................................

Ez-Flow 220 Gravity Box, Ez-Flow 672 running gear, right off farm, nice ...................................

Killbros 350 Gravity Box, Huskee running gear, right off the farm, field ready ..........................

John Deere 640 Roll Bar Rake, ground drive, super clean, field ready..........................................

Need your A/C hoses replaced? It’s easy! Send us your old ones and we will make new ones for a fraction of the cost of new OEM!!!

Describe a challenge you overcame in reaching your forage quality goals. We have added a lot more storage space. This makes keeping track of inventory easier. We always have a goal to have enough corn silage until January of the next year so that we never have to feed green corn silage. More storage space has helped us reach that goal.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? I started farming by making 12,000 to 14,000 small square bales a year and using a onerow, pull-type chopper. So there have been big changes in my career. Now, we can harvest more acres and feed more cows per manhour than we once did.

1/2” thick x 16” wide

12’ long $35 • 16’ long $47

White Corrugated PVC liner panels

40” wide x 16’4” long $1950

White smooth PVC sheeting

4’ x 8’ x 1/2” thick $5750

FACTORY SECONDS. QUANTITY DISCOUNTS.

DELIVERY AVAILABLE

715-644-2350

Chippewa

Duals, 1272 hrs., 90 Sep. hrs., #557140................ $629,900

JD S790 2021, PRWD, Singles, 937 hrs., 770 Sep. hrs., #557277 ............. $479,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Duals, 230 hrs., 155 Sep. hrs., #563325................ $599,900

JD S790 2022, PRWD, Singles, 480 hrs., 314 Sep. hrs., #563815 ............. $579,500

JD S790 2021, PRWD, Duals, 833 hrs., 551 Sep. hrs., #565421................ $499,900

JD S790 2022, PRWD, Duals, 461 hrs., 368 Sep. hrs., #566460................ $624,900

JD S790 2022, PRWD, Duals, 333 hrs., 239 Sep. hrs., #566637................ $589,900

JD S790 2022, PRWD, Duals, 455 hrs., 316 Sep. hrs., #566694................ $579,900

JD S780 2020, PRWD, Duals, 1489 hrs., 1145 Sep. hrs., #191082............ $349,000

JD S780 2020, PRWD, Singles, 1551 hrs., 1204 Sep. hrs., #531610 ......... $349,000

JD S780 2019, PRWD, Duals, 1600 hrs., 1058 Sep. hrs., #549682............ $319,000

JD S780 2020, PRWD, Duals, 1290 hrs., 941 Sep. hrs., #550187.............. $369,000

JD S780 2018, PRWD, Duals, 1521 hrs., 1130 Sep. hrs., #551736............ $305,000

JD S780 2022, PRWD, Duals, 453 hrs., 353 Sep. hrs., #552362................ $549,000

JD S780 2022, PRWD, Floaters, 395 hrs., 323 Sep. hrs., #553546 ............ $549,900

JD S780 2022, PRWD, Tracks, 304 hrs., 238 Sep. hrs., #554013 ............... $619,000

JD S780 2022, PRWD, Duals, 242 hrs., 183 Sep. hrs., #554094................ $565,000

JD S780 2022, PRWD, Floaters, 242 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S780 2022, PRWD, Floaters, 255 hrs., 177 Sep. hrs., #554707 ............ $569,000

JD S780 2022, PRWD, Floaters, 142 hrs., 91 Sep. hrs., #554708 .............. $574,000

JD S780 2022, PRWD, Floaters, 191 hrs., 131 Sep. hrs., #554709 ............ $569,000

JD S780 2022, PRWD, Floaters, 190 hrs., 139 Sep. hrs., #554710 ............ $569,000

JD S780 2018, 2WD, Duals, 1217 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S780 2021, PRWD, Duals, 799 hrs., 607 Sep. hrs., #556191................ $479,900

JD S780 2020, PRWD, Duals, 933 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1287 hrs., 931 Sep. hrs., #558869.............. $349,000

JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Duals, 469 hrs., 347 Sep. hrs., #563635................ $549,000

JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000

JD S780 2022, PRWD, Duals, 427 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Floaters, 8 hrs., #565897...................................... $629,900

JD S780 2018, PRWD, Duals, 2753 hrs., 1901 Sep. hrs., #567178............ $234,900

JD S780 2022, PRWD, Duals, 250 hrs., 165 Sep. hrs., #567271................ $585,000

JD S780 2021, PRWD, Duals, 500 hrs., 300 Sep. hrs., #567515................ $519,900

JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S770 2022, PRWD, Duals, 273 hrs., 195 Sep. hrs., #554014................ $560,000

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S770 2021, 2WD, Duals, 720 hrs., 585 Sep. hrs., #560264 .................. $425,900

JD S770 2022, PRWD, Floaters, 36 hrs., 20 Sep. hrs., #563704 ................ $546,000

JD S770 2022, PRWD, Duals, 269 hrs., 148 Sep. hrs., #567222................ $564,900

JD S770 2022, PRWD, Duals, 148 hrs., 91 Sep. hrs., #567225 ................. $574,900

JD S760 2019, 2WD, Duals, 1206 hrs., 871 Sep. hrs., #565714 ................ $279,900

JD S690 2017, PRWD, Duals, 1433 hrs., 1187 Sep. hrs., #549457............ $280,700

JD S690 2015, PRWD, Tracks, 2400 hrs., 1615 Sep. hrs., #550872 ........... $232,900

JD S690 2012, PRWD, Duals, 2313 hrs., 1645 Sep. hrs., #551148............ $149,000

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646 ........... $219,900

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S660 2012, 2WD, Duals, 1643 hrs., 1188 Sep. hrs., #554132 .............. $179,900

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD 9870 STS 2008, PRWD, Duals, 3261 hrs., 2494 Sep. hrs., #566621 ...... $97,500

JD 9870 STS 2011, 2WD, Duals, 3650 hrs., 1750 Sep. hrs., #567383 ....... $109,900

JD 9860 STS 2004, PRWD, Duals, 3924 hrs., 2537 Sep. hrs., #559820 ...... $55,000

JD 9860 STS 2005, PRWD, Duals, 4528 hrs., 3240 Sep. hrs., #564977 ...... $59,900

JD 9770 STS 2011, PRWD, Duals, 2537 hrs., 1813 Sep. hrs., #566823 .... $129,900

JD 9760 STS 2004, PRWD, Duals, 4389 hrs., 3109 Sep. hrs., #564023 ...... $53,500

JD 9760 STS 2007, 2WD, Duals, 3169 hrs., 1965 Sep. hrs., #566814 .......$74,900

JD 9750 STS 2003, 2WD, Duals, 5105 hrs., 3367 Sep. hrs., #565004 ......... $37,500

JD 9670 STS 2010, 2WD, Duals, 2525 hrs., 1667 Sep. hrs., #566916 ....... $114,900

JD 9570 STS 2011, 2WD, Singles, 2019 hrs., 1231 Sep. hrs., #555820 .... $132,500

JD 9570 STS 2009, 2WD, Duals, 2367 hrs., 1597 Sep. hrs., #556547 ....... $104,900

JD 9560 STS 2004, 2WD, Duals, 4638 hrs., 2982 Sep. hrs., #567094 .......$52,500

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 .... $34,900

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

AUSTIN, Minn. — One Mower County dairy farm is enabling kids to experience dairy. Roger and Lori Read, alongside their son and daughter-in-law, Greg and Heather, are in their 28th year of leasing dairy animals to their local 4-H dairy project.

“Most of our 4-H leases are kids who live in town,” Lori said. “They have no opportunity to take a dairy animal otherwise.”

The Reads milk 125 mostly Brown Swiss cows with a couple of Holsteins on their 320-acre farm near Austin. They began leasing in 1995 after a local family who was no longer dairying still wanted to be part of the dairy project.

Since then, every year they have somewhere from ve to 13 kids lease animals from their farm.

This year, the Reads had eight or nine lessees who took 19 animals to their county fair during the second week of August. Roger and Lori own the animals, but Heather has managed the lease program since 2016 when she married Greg.

For the Reads, their motivation comes from the relationships built through leasing.

“The reward is the fun that we have with (the kids),” Lori said. “They always come back and talk to us.”

The Reads have even been invited to weddings of former lessees.

Lori said her proudest moment leasing came when one of their lessees, Julia (Mullenbach) Merten, walked across the stage at the Princess Kay of the Milky Way coronation.

Merten, who grew up in town, had begged her parents to let her lease a cow, and when she was in sixth grade, they decided to let her. Through the Reads, Merten experienced the dairy community and went on to become a Mower County Dairy Princess and Princess Kay

nalist, majored in dairy science and now has a job in the greater agricultural community.

“She’s almost like a summer daughter,” Lori said.

“We’ve had a few of those where they just t in so well.”

Lori said that Merten’s show cow, Burner, remembers Merten, who occasionally shows her in an open class

but has not shown her for 4-H in ve years.

“It’s just amazing,” Lori said. “They built such a bond over those years.”

Kids begin asking to lease as early as the Minnesota State Fair, but most kids start looking at calves in October. The real picking begins around Easter time, and by mid-May, the show string is determined.

The Reads have quality animals to choose from and have been honored multiple times for their genetics and accomplishments.

Two things are required from the Reads’ potential lessees. First, the parents must be involved, and second, the kids must take part in showmanship at the fair.

“You don’t become a better show person unless you continue to work at it,” Lori said. “That showmanship class is always good for you.”

Lori said they want the kids who lease to learn responsibility and a work ethic. The kids help to care for their animals and prepare them for the fair. They also help with putting up small square bales of hay used at the fair. She wants them to know that, if they put the work in to prepare, they can also have a lot of fun.

Leadership is another quality Lori has seen the kids learn through leasing.

“The older kids teach the

involved, and the kids must take part in showmanship at the fair.

younger kids,” she said. “My niece brought her daughter over two weeks ago, and here is my granddaughter Jennifer teaching her. ... Jennifer’s 6, teaching the 4-year-old how you approach a cow. ... Pretty soon my 4-year-old niece was brushing and washing that

little heifer calf.”

Lori said they have seen shy kids grow condence through their time of showing.

The Mower County dairy project is not extreme competition, Lori said, which is

something she and her family have strived for. When her children originally started showing in the project, people would not talk to them until after the show was over.

“We swore that we wouldn’t do that and our kids

wouldn’t be that way,” Lori said. “They would help whoever asked.”

Roger said one of the bigger challenges of leasing is keeping the kids from getting discouraged.

“(You) just have to keep encouraging them,” he said. “We’ve never had anybody quit.”

The Reads open their farm for tours. Locally, they host a high school class and 4-H clubs. Because of their high genomics animals, they hosted tours for international guests attending the World Brown Swiss Conference held in conjunction with World Dairy Expo last fall. Within her leasing of animals, Lori especially values the friendships she forms with the kids.

“Even though we’re older, it doesn’t mean that we can’t understand some of the stuff that the kids are going through,” she said.

Lori said the kids keep her and Roger young and that Roger even likes their music. Roger is quick to qualify, however, that he only likes some of their music.

With so many nding fulllment from their lease program, including themselves, the Reads said they will continue leasing as long as they have cows on their farm.

SPICER, Minn. — When Kari (Schroht) Reuvers signed up in April of 1978 to compete in the dairy princess competition for Steele County, she was a senior at Owatonna High School and living on her family’s dairy farm outside of town. It was the silver anniversary of the program’s existence, having been ofcially launched statewide in 1954 when Eleanor (Maley) Thatcher was crowned as the rst Princess Kay of the Milky Way.

Today, Reuvers lives in Spicer, where she raised her two sons. She has worked at Conway, Deuth & Schmiesing, a certied public accounting rm in Willmar, for the past 34 years.

The spring she decided to vie for a spot as a dairy princess, Reuvers had stiff competition at the county level. Over 20 young women had signed up

as well.

“I guess it was kind of expected from me to run,” Reuvers said. “My mom and dad were really involved in dairy (organizations), and they did a lot through the creamery, so it was always a given that I would run for it. I thought it would be fun. I never expected to win.”

Although Reuvers had no experience in pageant competition, she was familiar with the show ring.

“I was in 4-H; I showed cows and showed pigs,” Reuvers said. “I had a horse, but no one ever let me bring my horse to show. That was kind of a sore subject. She’d get loose and run the cattle through the fence. (My family) said, ‘What a waste of money. We have to make hay for that?’”

Reuvers grew up knowing the value of hard work. Her family’s farm was already a century farm when her parents, Jerry and Berniece, raised her and her three brothers on it. The farm is still in the family today with Reuvers’ nephew at the helm.

“I milked, and I did eldwork,” Reuvers said. “I did whatever we were doing at the time.”

Until second grade, Reuvers even attended the same

country school across one of their farm elds that her father had attended. When the school closed, she had to transfer to the much larger school in Owatonna.

“I remember how terried I was,” Reuvers said. “I thought I needed to be really nice to everybody so that I could t in.”

She said she later wondered if that mindset was good training for being Princess Kay.

In high school, she and her siblings had to schedule school activities around each other so that there were enough hands to help at home. Since her brothers wrestled, she did recreational softball and volleyball instead of school sports.

Then in 1977, their barn burned.

“We saved all the animals and found a barn on the other side of Owatonna to use,” Reuvers said. “It was a 20-mile drive to go milk. Over there, we had to use cans where we at least had had the pipelines in our barn.”

Farm life became more hectic until the Schrohts were able to build a new tiestall barn and begin milking their 75 Holsteins in it.

We had one cow in particular that had been with us for most of our dairy career. Her name is Hot Chocolate, and she was born about a week before Thanksgiving in 2017.

That was not a good morning. One of our 3-year-old cows, No. 112, freshened the day before, and we were really excited to see how she turned out. Unfortunately, 112 prolapsed her uterus and died during the night. I discovered her early the next morning when I went out to milk. I was so heartbroken and disgusted at the tragic way that this beautiful animal had suffered before death.

The feeling of failure was strong that morning. It took me a while to get over the shock and be able to go back in the barn to start chores.

By Abby Wiedmeyer Staff Writer

By Abby Wiedmeyer Staff Writer

When I nally did drag my sad self back to the barn, I set up the milkhouse and pushed the milker cart down the walk to start milking. The calving pen was down at that end of the barn, and when I approached, I saw that another cow had calved in the night. There was a small, white, fuzzy calf curled up in the corner and a fresh cow who had thankfully already dumped her cleanings and nothing else.

The satisfaction of this new life was buried under the fog of grief and bitter feelings that I was still harboring from the death of 112. I milked the rest of the cows while my husband mixed feed and got 112 out of the barn. By about 8 a.m., I was done milking, and the kids had all made their way out to the barn. They ranged from about 4 to 10 years old at the time.

When I went to get the calf out of the pen, I had a heck of a time catching it because it was so spunky and noisy (always a good sign). As I approached, it took off with a beller. It was a few minutes before I could corner it and get it in the cart to wheel down to the milkhouse. The fog on my heart lifted a little bit as I got a good look at this healthy little calf. It was a heifer out of another great homebred cow, and she was mostly white with a little pink nose.

When I brought her in the warm milkhouse, all the kids fell in love with her right away. She was tted with a calf coat and fed colostrum, which she drank without any problems. A friend of the family had shown up to go hunting in the meantime and was making hot chocolate for the kids. As they crowded around the feed cart, the new calf kept trying to snitch a sip of their drinks.

In a unanimous decision, the calf was named Hot Chocolate. Our oldest daughter wrote out an ear tag with the number 186 and Hot Chocolate.

As Hot Chocolate grew, she held a special place in my heart because taking care of her that morning was like balm on a sore heart. When 112 tragically left our lives, Hot Chocolate entered it and completed the circle of life that keeps so many of us going.