WANT TO WIN $100 CASH?

See page 7 of this section for details!

See page 7 of this section for details!

Volume 25, No. 13

August 26, 2023

HAZEL GREEN, Wis.

Troy Leibfried grew up helping on his family’s dairy farm and always knew a career in agriculture was in his future. After graduating from Southwest Wisconsin Technical College with a degree in farm operations and management, he joined his dad Aaron and great-uncle Francis on the home farm near Hazel Green.

Today, the 21-year-old is planning for more responsibilities on the dairy when Francis retires next year while also running his own beef operation that he purchased in April.

“When I was in school, there were a lot of 21-year-

olds who would have loved to be doing what I’m doing, but they didn’t have anyone in the industry,” Troy said.

Troy’s farm is a portion of a relative’s farm. His parents purchased the 50 acres of pasture and cropland and buildings until Troy was able to secure nancing, at which point he bought the farm from his parents.

Aaron said he is happy to provide the opportunity for his son.

“He’s going to have to get some breaks,” Aaron said. “There’s no way a 21-yearold can get into it otherwise.”

Plans for the dairy continue to evolve with the times as well. Troy, Aaron and Francis milk approximately 190 cows with a robotic milking

MADISON, Wis. — On July 5, Wisconsin Gov. Tony Evers signed the 2023-25 state biennial budget into law. With dollars invested in areas including agricultural infrastructure to meat processing, the budget contained a variety of items seen as wins for agriculture and the dairy industry.

“A highlight was certainly the Agricultural Road Improvement Program which allocated $150 million to improve agricultural roads throughout the state,” said Chad Zuleger, director of government affairs at Dairy Business Association and Edge Dairy Farmer Coopera-

tive. “The whole ag coalition came together in support of this and put together a really good plan.”

The agricultural community also received outside support from the Wisconsin Counties Association and the Wisconsin Towns Association. The plan is not only to repair rural roads used by agriculture but to also improve those roads so that they can no longer be posted once a project is nished.

“This plan will improve roads that our producers and processors use on a daily basis that are subject to weight limits during times like spring thaw, causing detours and re-

routes and adding cost to fuel and wait times,” Zuleger said. “It’s a really signicant investment — maybe the most signicant investment in ag infrastructure in a generation.”

Previously, a provision prohibited federal funds from being used on bridges less than 20 feet long, which Zuleger saw as a problem.

“In a rural community, you can be dealing with culverts that could be 10 or 15 feet and even smaller bridges or easements into bridges,” Zuleger said. “The state program includes those types of roads, bridges and culverts under 20 feet. With these funds, we should be able to do a lot of repairs and really improve the roads that are

used to generate more economic activity. We are thrilled to have this enacted.”

Increased funding for the cover crop insurance rebate program was another big win for agriculture. The program provides a $5 per acre rebate on cover crop insurance to incentivize farmers to plant cover crops. The program’s funding was doubled from $800,000 to $1.6 million.

“I’m excited to see that program take off,” Zuleger said. “It’s really changing the landscape as we’re seeing elds go from brown to green with a lot of cover cropping. This is a really good investment.”

The Nitrogen Optimization Pilot Program through the Wisconsin Department of Agriculture, Trade and Consumer Protection was established last budget cycle and received $2 million in the current budget.

This program provides grants up to $50,000 to individual farmers or groups of farmers to study impacts of nitrogen on cropping and water quality. Done in partnership with the University of Wisconsin, the goal is to use strategies that will minimize the impact of commercial fertilizers on the land.

The dairy processor grant program also received increased funding of an additional $500,000.

“Our partners in the processing world are critical to our producers’ success, and we are ecstatic about the increased funding put toward technology and utilizing best practices,” Zuleger said. “This bolsters a processor’s ability to do business in Wisconsin and continue to grow.”

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

In June, the Farm Service Agency reported a margin of $3.65 per hundredweight above feed costs. That’s the smallest level since the Dairy Margin Coverage program was authorized in the 2018 farm bill. American Farm Bureau Federation economist Danny Munch said it is the sixth straight month of margins below the $9.50 per hundredweight trigger. “That’s the rst time the program’s catastrophic $4 protection level had been breached,” Munch said. Feed costs, he said, are continuing to chip away at the bottom-line for dairy farmers.

Farm bill promise: On time and highly effective House Agriculture Committee Chair Glenn “GT” Thompson said he has thousands of objectives but a single goal for the farm bill. “The one goal is to get this done in a bipartisan, bicameral way on time and highly effective,” Thompson said. With only a dozen days on the congressional calendar before the expiration of the current law, the deadline is looming. “I only have control of the House Agriculture Committee, and we’re going to do our job,” Thompson said. “When we can do markup and go to the oor really depends on leadership; I’m still hoping and praying it is before the end of September, but the ag committee will be ready to go.”

SNAP nutrition incentives

Federal relief for distressed loans

sidered distressed, nancial assistance is available. This automatic relief is part of the Ination Reduction Act. Approximately 3,500 borrowers are eligible for this assistance. Since August 2022, more than 20,000 distressed borrowers received similar assistance.

Net income declines nearly 2% for Farm Credit System

Butter market rallies

Ag Insider

2011 N-H TD-5050, Cab, 193 Hours, Hi Crop ..............................................$42,500

1982 White 2-155, 5750 Hours, Nice Looking ..............................................$19,500

1974 Oliver 1655, Diesel, Cab, 9700 Hours ..........................................$8,500

A-C 7000 ................................................$9,500

1961 A-C D-15 .......................................$5,900

USED SKIDSTEERS

2018 Bobcat V-519, 300 Hours............$69,500

(2) T-650, Glass Cab with A/C, 2 Speed, 300 Hrs & Up ...................Starting at $49,500

2021 S-76, 2500 Hours .......................$43,900

2020 S-66, Glass Cab w/Air Cond, 2 Speed, 1800 Hours .........................$47,900

2014 Toro 22321, 1251 Hours, Tracks Good, Gas ...............................$15,900

USED TILLAGE

2016 W-R 13QX2 53’ 3 Bar Harrow

w/Rolling Baskets ..............................$69,500

2012 W-R 13QX2 50’, 5 Bar Spike Harrow ...............................................$28,500

2004 W-R Excel 38’, 4 Bar Spring

Tooth Harrow .....................................$12,900

1997 W-R Quad 5, 32’, 3 Bar Spring

Tooth Harrow .......................................$7,500

W-R 2500, 28’, 4 Bar Spring Tooth Harrow .................................................$6,950

Kewanee 620, 18’ Disk ...........................$2,000

(3) W-R 513 Soil Pro, 9 Shank............................Starting at $25,000

2011 W-R 5800 Chisel Plow, 39’ .........$25,500

2012 G-P TCN-5107, Disc Chisel, 7 shank ..............................................$10,900

J-D 2700 Plow, 4 Bottom, Vari Width ....$1,500

USED PLANTERS

White 6700, 12x30, Vertical Fold ...........$7,500

USED HAY EQUIPMENT

(2) N-H 316 Discbine, 15’ Cut .............................Starting at $28,900

2020 N-H 512R, 12’ Mega Cutter, Used Very Little .................................$28,350

1997 N-H 1465, 9’ Haybine ....................$9,500

New Idea 5212 .......................................$8,950

John Deere 260 Discmower ...................$3,500

N-H 790, 824 Cornhead, Hayhead..........$7,950 Meyer 500TSS Forage Box.....................$7,500

2020 N-H 560 Rd Baler, Specialty Crop, 4000 Bales ...............................$46,500

2016 N-H 460 Rd Baler, CropCutter .....$28,500

1995 N-H 660 Rd Baler ..........................$4,950

rms merge

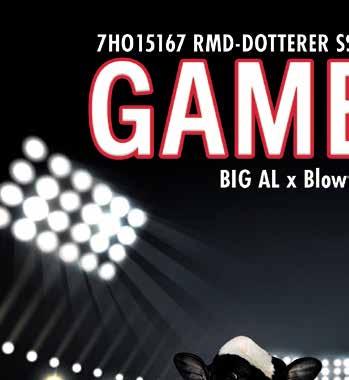

The four individual cooperatives that make up Select Sires have voted to merge. The new Select Sires Member Cooperative will be operational Oct. 1. Chris Sigurdson, who is the current general manager for COBA/Select Sires and Minnesota/Select Sires, will serve as the CEO for the merged A.I. rm.

Losses for Beyond Meat

For the rst six months of the scal year, Beyond Meat suffered a loss of $112.5 million. That compares to a loss of nearly $198 million in the same period one year ago. During the second quarter, sales for the plant-based protein products declined 24%. U.S. retail sales dropped 34%, but international foodservice business rose 19%.

WDE to include dairy symposium

World Dairy Expo will feature a dairy symposium that is part of the Dairy Business Innovation Initiatives, which were established in the 2018 farm bill. The Oct. 3 symposium will include a panel with representatives from each of the DBI initiatives, highlighting how it inuenced their farm, business, research and careers.

Suputo reports nancials

Suputo reports rst quarter net earnings of $141 million, up from $139 million in the same quarter last year. The company’s president and CEO, Lino Saputo, said Saputo delivered solid results despite signicant commodity market headwinds and lower consumer demand.

Strike continues at New Dairy Select Milk

Union workers at New Dairy Select Milk at De Pere, Wisconsin, have now been on strike for over a month. New Dairy Select Milk is a subsidiary of Borden Dairy and was formerly known as Morning Glory. The labor dispute is over employee health care benets.

UW-Madison CALS Awards

The University of Wisconsin-Madison College of Agricultural and Life Sciences has announced its 2023 Honorary Recognition, Distinguished Alumni and Distinguished Service Awards. Hoard’s Dairyman Managing Editor Corey Geiger will receive the Honorary Recognition Award. George Shook, who was a member of the UW dairy faculty, will be recognized with the Distinguished Service Award. The awards will be presented Oct. 19.

Apply for YDLI

The application deadline for the Holstein Federation’s Young Dairy Leaders Institute is Sept. 15. This program is open to young people involved in the dairy industry, ages 22-45. Wisconsin dairy farmer Mitch Kappleman is an alumni of the program and said he made connections that will last a lifetime. “With YDLI, I learned a whole new group of friends, and I think meeting people with similar activities, similar age, similar point in their careers was my favorite part,” Kappleman said. The applicants selected will be notied in early October.

Emmi Roth expands

Emmi Roth is building a new headquarters and cheese conversion plant at Stoughton, Wisconsin. Cheese produced at other Emmi Roth plants will be broken down into shreds. An additional 120 people will be hired to support the new facility.

DBA/Edge announce promotions

Dairy Business Association and Edge Dairy Cooperative announced the promotions of Lauren Laubscher and Alicia Reschke. Laubscher is now the member services manager, and Reschke is the member services compliance and regulatory representative. Previously, Laubscher worked for Genex Cooperative and Sanimax. Reschke had been with Renard’s Cheese.

WFBF names communications coordinator

Wisconsin Farm Bureau has hired Kylie Ver Kuilen as its new communications coordinator. Most recently, Ver Kuilen had a similar role for the Association of Program Directors in Surgery.

Trivia challenge

Michael Dykes is the president and chief executive director of the International Dairy Foods Association. That answers our last trivia question. For this week’s trivia, how many servings of dairy products do Americans consume every day? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

system. Francis is in charge of herd health and dairy calves, while Aaron does regular feeding and manure hauling. Troy raises crossbred calves and is involved with the eldwork as well.

The Leibfrieds have a long history of dairying. Aaron farmed with his dad and grandfather and purchased the present site in 2000. After transitioning to organic in 2007, Aaron’s dad and grandfather joined his operation, along with Francis. Now they are working on bringing Troy in and allowing Francis to retire.

“We’re going to start out with me taking over the dairy portion, including my uncle’s part of it, and let Troy take the machinery and land part of it,” Aaron said. “Obviously, we’ll work side by side every day.”

The organic herd is fed a total mixed ration while also rotationally grazing. This combination can be challenging when relying on robotics to get milking done, Troy said. Cows have access to pasture overnight while the weather is cool, which can cause a bottleneck in the robots in the morning. Some mornings there are as many as 40 cows that have not visited the robot within 12 hours, but by that evening, there are hardly any.

“They’re pretty good at going through on their own during the day,” Troy said. “Closer to 7 a.m., Dad will feed, so that will take some of them away to go eat.”

The pellets that are fed in the robot to encourage cow visits are a challenge to procure as well since there are

limited manufacturers, Aaron said. Fortunately, one of the manufacturers is in Wisconsin. They are able to get a semi load delivered every three weeks for an economical price.

The four robots are capable of handling about 240 milk cows, but Aaron and Troy are not pushing for capacity at the moment. They are instead focused on making sure a smooth generational transition is possible and trying to manage just as much work with one fewer person. They would like to stay away from needing extra labor if they can.

Troy hopes to continue to establish his beef herd as well. He started with 30 purchased beef cows in September 2022. He experienced a steep learning curve right away when the animals did not calve in right away but instead calved over the next nine months, with the last one being born in June. After a hard winter of calving and making early culling decisions, Troy then experienced the drought and had to supplement hay already.

“When you rst get into it, it seems like nothing goes right,” Troy said. “But, that’s with anything; you live and learn.”

Troy is optimistic about his beef herd because the prices have been good. Aaron said he has seen organic milk prices double one year and drop in half the next throughout his career, but he is relatively optimistic about the future of dairy as well.

“The market has improved,” Aaron said. “Things are looking good.”

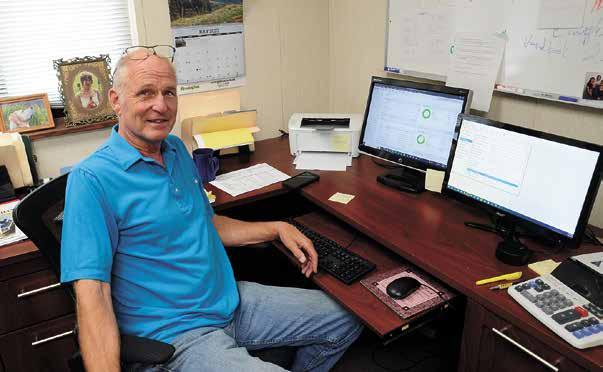

WAUPUN, Wis. — When asked what his favorite thing is about being a veterinarian, Dr. Al Martens said, “The people.”

This vet’s closest friends were made on the farm as he became much more than a veterinarian to his clients. He was a person who farmers conded in about all of life’s problems, not just those concerning their fourlegged creatures. As a result, clients became lifelong friends.

“I can look back and say, I treated all these cows, but the memories are the people,” Martens said. “They

Dr. Al Martens takes a break from his work July 25 at Waupun Veterinary Service in Waupun, Wisconsin. This summer, Martens celebrated his 45th anniversary of being a veterinarian.

were the best part of it. The farmers were my best friends, and I learned so much from them.”

This summer, Martens celebrated 45 years of being a veterinarian.

“It’s kind of bittersweet, like you’re at the end,” Mar-

tens said. “But I probably won’t ever retire. I like looking forward to coming to work every day. I enjoy the challenge.”

Martens no longer makes farm calls. Instead, his focus has shifted to business management in the last

ve years, and now Martens spends most of his time at the clinic.

“I’ve had three rotator cuff surgeries, two back surgeries, and some other orthopedic procedures, and I don’t want to get hurt,” Martens said. “I have a lot of

arthritis in my hands and elbows, so I’m not able to run the ultrasound either.”

Martens grew up in a small town north of Detroit, Michigan. His dad was an auto engineer, and Martens said he did not have much dairy exposure other than visits to a friend’s farm and his second cousins’ farm in Cambria, which is how he later came to work in Waupun. Martens attended veterinary school at Michigan State University, which is where he met his wife, Bev, who became a small-animal veterinarian.

“I really wanted to work with dairy cattle; I’m not sure what the inspiration was,” Martens said.

Martens became a veterinarian in 1978 at the age of 23. Fresh out of vet school, he was the second vet to join the practice started by Dr. Jim DeYoung in Waupun that would become known as Waupun Veterinary Service in 1989. On Martens’ rst day at the practice and

Turn

after only two hours on the job, DeYoung left for a week-long vacation.

DeYoung’s faith in the new veterinarian was strong, and in 1979, he made Martens a partner in the clinic. Martens had four days off every month — two Saturdays and two Sundays — and received two weeks of vacation each year.

“We worked more hours back then but had big breaks,” Martens said. “We were slower in the summer and had a lot of free time in the afternoons. The day is busier now for vets, scheduled with calf work, nutrition work and other specialty tasks.”

Martens said every week brought something good.

“Sometimes, it might just be having a live calf,” he said. “You might have struggled with a DA surgery, not knowing how it’s going to turn out, but then you nd out a couple days later that the cow is doing great.”

In the earlier part of his career, Martens also worked on pigs, draft horses and veal calves.

“It was really fun working with those animals,” Martens said.

After having their rst child in 1982, Marten’s wife started a small clinic at their house.

“While the kids were growing up, she saw clients during the day, and in the evenings, we did surgeries together,” Martens said. “It was neat — the kids would do their homework in the clinic as Bev and I did surgery on dogs and cats.”

During his career, Martens witnessed many changes in the dairy industry. The average farm size was 55 cows when he started. Today, the clinic has two 8,000-cow herds. Herd checks took less than an hour, and afterward, Martens would join the family for breakfast.

“That was always special,” Martens said. “Now, herdsmen do the herd checks at 50% of our farms.”

Martens said the days when the vet was a close family friend of the farmer are not as evident anymore, especially on larger farms.

“Today, the herdsman separates the vet from the owner,” he said.

Communication has also changed a lot since Martens’ early days as a vet.

“We used to use a twoway radio to communicate,” he said. “We had one at the vet’s house and one at the ofce. We shared the radio with a school bus service. We’d be talking about disgusting stuff like uterine and udder infections, and

the kids could hear it on the bus.”

Distance with the radios was limited, and Martens said such a service would now only cover 10% to 20% of the clinic’s coverage area. Now, communication is done via texting and a program that enables all the vets in the ofce to see everyone’s schedules.

For 25 years, Martens logged about 25,000 miles every year. From freezing

rain to blizzards, he went out in all kinds of conditions.

“For years, we never had a day that we didn’t run a call,” Martens said. “Even during the terrible blizzards of the early 1980s, we ran a call every single day. We never closed. One time, all three of our vet trucks got stuck in the snow, and a farmer got us out.”

Martens said emergencies were once common, but now, there are not nearly as

many.

“Things are so different today in that farmers handle a lot of emergencies themselves,” Martens said. “Herdsmen are really good, especially in the bigger herds. So now if we get a call, it’s a C-section, fetotomy or uterine torsion —something really complicated.”

Turn to MARTENS | Page 9

The clinic began doing milk culturing in 1983 and expanded their lab around 1993 to include two fulltime technicians who do culture work that comes in from all over the state. The clinic also does cultures on bedding sent in from across the U.S.

“I’m always looking at new business opportunities,” Martens said. “We use a lot of technology and are always thinking, ‘What can we do different?’ That’s how we grew the practice.”

When Martens read about a new blood test for detecting pregnancy in cattle 15 years ago, he wanted to pursue the technology even though the clinic had just purchased ve portable ultrasound units for a substantial amount of money.

The other vets at the clinic resisted the blood test idea, thinking it would put them out of business with the money just spent on ultrasounds. But after his partner, Dr. Monty Belmer, saw the blood test in action while doing nutrition consulting work in Pennsylvania, he said, “We have to do it.”

“It’s been huge for our clinic,” Martens said. “Now we have a fulltime tech on it.”

The clinic expanded offerings in its blood lab to include testing for bovine viral disease and sheep and goat diseases, while also becoming federally licensed to test for Johne’s disease.

“The labs have been a home run

for our clinic,” Martens said.

Martens has watched the practice grow to now include 15 largeanimal vets, eight of whom are partners.

“Being partners to these vets keeps me here today,” Martens said. “We have a bunch of young people working at the clinic. Half of our vets are less than 10 years out of school. They’re the future — not me — and I like mentoring them.”

When he is not working, Martens’ hobbies encompass his love for nature and the great outdoors. His adventurous spirit has taken him to the wilderness of Alaska to go white water rafting, kayaking and shing.

“I’ve been on some crazy raft trips and done some crazy wilderness stuff,” Martens said.

This veterinarian also loves to hunt, especially with dogs at his side, and enjoys hunting pheasant, duck and grouse. Martens is also an avid hockey lover who coached the sport for 30 years and still plays twice a week.

“From skating to coaching, hockey has been huge in my life,” Martens said.

Martens has no plans of slowing down as he enters his 46th year as a doctor of veterinary medicine. With many fond memories wrapped into a fullling career, Martens has no regrets — only gratitude.

“I have no complaints,” he said. “I would do it all over again in a heartbeat.”

The new budget also included increased funding for meat processors. Zuleger said capacities and shortfalls in the supply chain were brought to light during the pandemic, pinpointing the need for increased infrastructure within the processing community.

“We saw incredible delays as a result of shutdowns and supply chain breakdowns,” Zuleger said. “This budget includes increased grants to start new meat processing facilities and allow current facilities to improve and take advantage of new technologies. Every dairy farmer is also a beef producer, and we’re delighted about this funding. This is a signicant improvement that all of agriculture can applaud.”

The budget will also maintain funding for Wisconsin’s agricultural exports initiative.

“We export a lot of dairy products, particularly in the cheese markets, and this funding helps processors and producers innovate in that value chain as farmers are asked to do more on the sustainability side,” Zuleger said.

Established in the last budget, the goal is to increase exports across commodities by 25% by the year 2026.

“Dairy exports have really taken off and earned over a 30% increase in the rst two years of this program,” Zuleger said.

Well compensation and well abandonment grants received an increase of $1 million.

SMITH’S OF WI LLC

“We advocated strongly for expansion of this program and increasing eligibility of these funds,” Zuleger said. “The problem still is that eligibility requirements are so stringent that very little of that money ever gets allocated. We continue to work with the legislature to expand that eligibility.”

The producer watershed grant program is an area where Zuleger felt the budget fell short. He said the budget for this program was not increased even though farmer participation in watershed programs is on the rise. These programs provide grants to groups implementing sustainable practices like cover cropping and no till to prevent erosion and runoff.

“We want to come back to this in the next session and try to boost funding for this program,” Zuleger said. “The governor signed a program this session to expand the eligibility to farmers who are involved in a watershed so they can participate in more than one watershed group; therefore, we expect greater participation going forward.”

The farmland preservation program did not receive an increase in funding, which was also a disappointment to Zuleger.

“We’re going to continue to work on that,” he said. “If we can’t get it through the budget, then we would like to get standalone legislation. This program hasn’t been adjusted in almost 20 years, and we want to increase some of the rates for protecting agricultural production lands.”

DBA and Edge Dairy Farmer Cooperative would like to see the credit of $7.50 per acre bumped up to $10, and the $10 per acre category increased to $12.50. The most signicant part, however, is to reduce enrollment from 15 years to 10.

“This is a high priority for us moving forward,” Zuleger said. “It’s time to modernize this program and look at incentives so we can keep agricultural lands in Wisconsin in production and protect lands from development or rezoning.”

DBA and Edge Dairy Farmer Cooperative also advocated this session to support and enhance managed grazing efforts.

“This is generally not something we put up as a priority, but through collaboration with clean water partners, we are advocating for a pilot program of minimal funding for farmers who want to transition acres into grazing,” Zuleger said. “This can provide signicant environmental benets.”

Funding for grazing did not get put into the budget, but DBA and Edge Dairy Farmer Cooperative are drafting a bill and working with the Legislature for the remainder of this session to provide funding to new farmers for fencing, watering, etc.

“We are looking to get $1.25 million over two years,” Zuleger said. “This is another effort to promote water quality efforts, and we are using an allhands-on-deck approach.”

One item left on the table was the University of Wisconsin Farm and Industry Short Course program, which has transitioned to the UW-River Falls campus. Zuleger said 24 students are enrolled for this fall.

There was a $700,000 request to help establish the program at UW-River Falls, but this funding became a casualty during budget discussions that cut other university funding. DBA and Edge Dairy Farmer Cooperative have helped introduce new legislation to provide the needed funds.

“We’re going to see this new bill move this fall and get the additional funding to help transition that program to UW-River Falls,” Zuleger said. “This money will help the school get their infrastructure set up.”

Zuleger said all of these programs are primarily bipartisan in their support. He also said the entire ag coalition in Wisconsin worked collaboratively during this session to get funding for various programs.

“We pushed forward together,” Zuleger said. “As legislators deliberated, they heard from dairy farmers, beef farmers, soybean farmers, potato growers, etc., who were all singing the same tune. There is still work to be done, but a lot of exciting things are going on, and overall, this was a pro-ag budget.”

• $150 million for a new Agricultural Road Improvement Program.

• $12.5 million to assess local bridges and culverts that are 20 feet or less in length.

• $2 million for meat processor grants.

• $500,000 per year for grants to dairy processors.

• $2 million for the Wisconsin Agricultural Export Promotion program.

• Farmer mental health funding of $100,000 per year.

• $2 million for Nitrogen Optimization Pilot Program grants.

• $70,000 per year for livestock premises registration.

• Additional $50,000 per year for Wisconsin Agriculture in the Classroom program.

• $1.6 million for cover crop rebates.

• $22,176,500 in funding for county conservation departments.

• $125 million to address PFAS contamination.

• $1 million in 2024-25 for well compensation and well abandonment grants.

• $6.5 million for rural nonpoint source water pollution abatement grants.

• $200,000 per year for Targeted Runoff Management grants.

• $3 million reallocated to fund the Food and Farm Exploration Center in Plover, Wisconsin.

“This plan will improve roads that our producers and processors use on a daily basis that are subject to weight limits.

... It’s a really signicant investment — maybe the most signicant investment in ag infrastructure in a generation.”

CHAD ZULEGER, DIRECTOR OF GOVERNMENT AFFAIRS AT DAIRY BUSINESS ASSOCIATION AND EDGE DAIRY FARMER COOPERATIVE

LETTER TO THE EDITOR

When asked about rising grocery prices, Ford said, “You know what could be self-protective for us? To get some immigration reform. If we’re two and a half million workers short, 20% of produce in the Central Valley, bread-basket area didn’t get harvested because we have no labor.”

In June, the unemployment rate was at 3.6%, or 6 million individuals.

The reason Americans don’t do this work is because it doesn’t pay enough.

The cornerstone of the American dream is home ownership. I don’t think Americans harvesting produce in the Central Valley could afford to buy a house on the wages their employers are paying.

In the May 13 Dairy Star, Cole Hoscheit, of Caledonia, Minnesota, said that his farm is improving lives in Mexico. His employees are building houses in ve years. Most people in the United States borrow money from a bank on a 30-year mortgage. I don’t know of anyone who can afford to build a house in ve years.

can dream happen for his employees. The adage, “Hard work pays off,” does not apply to Americans working agricultural jobs.

Ford also said, “(Immigrants) don’t take jobs (from Americans). These jobs are hard.”

I agree with Ford that these are hard jobs, but saying that Americans won’t do hard work is simply not true.

According to National Milk Producers Federation, after World War II, there were 3.5 million dairy farms. Now, there are under 30,000 in the United States, according to a USDA release in 2022.

Hard-working dairy farmers have been forced out of business by dairy farmers who, for decades, have been breaking federal immigration laws to hire illegal immigrants who will work for less money than Americans, giving them an unfair advantage over people who abide by the law.

Working with cattle is not only a hard job, but it’s dangerous. It should be a high-paying job and, quite frankly, should pay better than a CEO.

I do agree with Ford that grocery prices are too expensive. Large food companies are to blame; some are making a prot of billions of dollars a year.

Joe Schindler Red Lake Falls, Minnesota

DHIA PROFILE

How many years have you been a director for DHIA? I have been a Minnesota DHIA director since 2006. This hardly seems true as I have enjoyed representing all of Minnesota’s DHIA farmer members on both the state and national level as a delegate to national annual meetings. My children were so young back then but have grown up understanding the importance of DHIA, good record keeping and the value of DHIA test day information.

What are your duties as director? My duties as a DHIA director currently include being the secretary/treasurer, representing Minnesota as a delegate for the national DHIA meetings, serving on the national DHIA scholarship committee and attend meetings (both board meetings and our annual meeting) in person or via Zoom. I have also served on several committees nationally and served as scholarship committee chairman.

What do you like about this role? I enjoy being part of a like-minded group who purposefully keep the importance of DHIA testing alive, keep costs reasonable to farmers and are always looking for ways to improve for Minnesota DHIA and their farmers.

Why is DHIA important to you? Growing up on my family farm, Hinckley Holsteins, we used DHIA testing for as long as I can remember. My parents, Dale and Marlys Hinckley, instilled in me how important it was to have accurate records and know the composition and amounts of milk each cow produced. When I married into another dairy farm family in 1996, DHIA was not being used at that time; though, it had been in the past. I recall our rst test when we purchased the herd and being excited to get results to dissect which cows really were pro table. Cow No. 25 was the one my mother-in-law raved about, but when I received my results, this cow had a high somatic cell count and both low fat and protein tests. Clearly, she wasn’t my best cow. Through the years, we have purchased animals to add to and grow our herd, and each time, we only looked at DHIA herds. Since 2007, we have had daily milk weights in our new parlor, but I’ve always believed there is more to the picture than just pounds of milk per day. Some of your highest producers may not be your most pro table. I also nd value in milk pregnancy testing. I have regular herd checks and a great relationship with our vets, but I nd it very convenient in using the test at busy times for my dairy when I don’t have anyone around to help me sort for ultrasounds or for con rmation checks in later lactation.

DHIA: Now MORE than ever

Sauk Centre, MN • Buffalo, MN 763.682.1091

www.mndhia.org

USED TRACTORS

CIH 8950 1,600 hours ..............................$165,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 8920, FWA, 2600 hrs ........................$110,000

CIH 7240, 2,500 hours, coming in ...........$110,000

CIH MX120, 2WD, 3,800 hrs......................$72,000

CIH MX110, FWA, 1600 hrs. ......................$65,000

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 1026 hydro .....................................Coming In

IH 806 ....................................................$11,000

JD 2755, 5,600 hrs. ...............................$16,000

JD 4020, new clutch ..............................$11,000

TILLAGE

527B ripper ............................................$13,500

CIH 530B................................................$18,000

CIH 527B................................................$19,500

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate II 26’, w/28’ pull crumbler $31,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

CIH Tigermate 200 28’ w/basket ............$37,000

CIH Tigermate 200 37’ w/basket ...................Call

JD 714 11 shank chisel plow .................$14,000

CIH 5700 chisel plow, 23’ ......................$16,000

CIH 4800, 28’ ...........................................$6,500

CIH RMX 340 25’ disc w/mulcher ..........$42,000

......................................................$6,500

J&M 540 box .............................................$13,500

Parker 4800 box...........................................$8,500

Unverferth 7250 grain cart .........................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

Beth Ford, CEO of Land O’Lakes, was interviewed by Time magazine.

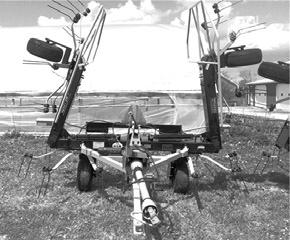

The Nolden family committed to their dairy career in 1996 when they started milking in their current site, Narrows Dairy Farm near Rock Springs. For 14 years, the family worked together to milk their cows three times a day in a double-6 parallel parlor.

Meanwhile, robotic milking systems were being developed and perfected. When the federal approval was passed for robots, Ken Nolden started to think about implementing the technology on his family’s farm.

“The pace of three times a day milking started to wear on us, and the idea of robots seemed pretty interesting,” Ken said. “We started studying on it.”

After learning more about the systems, robots were installed at Narrows Dairy Farm in 2010. The family continues to rely on robots for milking,

The Nolden family — Heather (front, from le ), Julia and Emily; (back, from le ) Tammi, Ken and Mathew — take a break Aug. 22 at their farm near Rock Springs, Wisconsin. The Noldens hosted a farm tour July 18 in conjunc on with Wisconsin Farm Technology Days

and today, Ken milks 160 cows with Tammi and their son, Mathew.

That technology is one reason Narrows Dairy Farm hosted attendees of the Wisconsin Farm Tech Days July 18 as part of a six-stop tour circuit associated with the event

in Baraboo. The Noldens were able to share with guests their experience of transitioning to a robotic system.

Prior to installing robots, the cows stood in the holding pen for up to six hours per day just waiting to be milked. After transitioning to robotics,

the cows live a relaxed life of strolling over to be milked one moment, eating the next and then returning to their stalls.

“We certainly accomplished more exibility,” Ken said. “It’s been really good for us as far as productivity.”

Mathew joined the opera-

tion after coming home from college. Ken said having two people to share the challenges of farming is an important factor of their success with the robots. When a robot has a problem, it rst calls Mathew and then Ken.

Mathew said the number of calls from the robot depends on how they manage the equipment. A call from a robot might mean a major breakdown, or it might mean supplies are low. If uids are kept full and maintained, there will be fewer calls.

“It goes down to the way you choose to maintain your equipment,” Mathew said. “Some people like to deal with things as they arise, and some people work toward maintaining so that there are less of these call outs.”

Mathew said he is able to make many repairs himself, but keeping parts on hand can be costly. If there is a technical issue that the technician needs a key to x, then his hands are tied.

After 10 years with their robots, the Noldens sold their existing robots and upgraded to two Lely Astronaut A5 units. The upgrade has decreased the number of calls, which Mathew said is probably due to new technology and simply

Let us help you sow the seeds of your farm’s success. Our vast farming experience combined with our years of ag lending experience make us an invaluable addition to your farm business.ABBY WIEDMEYER/DAIRY STAR

The Nolden daughters — Emily (from le ), Julia and Heather — help take care of calves Aug. 22 on their farm near Rock Springs, Wisconsin. The girls help their grandma over the summer while their mom works in town and their dad works with the cows.

newer equipment.

When upgrading the robots, the Noldens also remodeled the barn so that the robots would be in a centralized location. This allowed for one robot room between the two machines versus before when they were on separate sides of the barn. Mathew said it made chores difcult because a person had to try to be in two places at once to check on things.

The cows visit the robots on a voluntary basis. Protein pellets are fed during milking to encourage cows to visit the robot. The Noldens have added molasses to the pellet mix, which signicantly increased the cows’ enthusiasm for milking time.

Ken monitors the milk production through the reports the robot provides. The cows at Narrows Dairy Farm are producing 81 pounds of milk per day on average.

“It’s nice to see certain numbers, but the pounds of solids per day is all the magic on the paycheck,” Ken said. “It’s key to the operation.”

Ken and Mathew watch their cow numbers closely because they have their robots at maximum capacity. The biggest thing they watch for is if rst-

lactation animals have room to learn the robot. If that becomes questionable, then culling decisions are made to create more room.

They also need to watch production because their milk is shipped to Scenic Central Milk Producers, which has a growth program that limits the amount of milk farms can ship.

Ken and Mathew agreed that the exibility of their time has made the biggest impact on their lives and business. To be able to continue eldwork without stopping to milk and to have more freedom to attend family events has been valuable to family relationships, Ken said.

“I really enjoy the life I’m living milking with robots,” Ken said. “The truth is, we do very little go-away vacation because I feel very good about what I’m doing.”

It also allowed for Mathew to join the operation and have a secure family life with his wife, who works off the farm, and their children, who spend a lot of time with their dad at the farm.

Ken said the legacy is rewarding.

“Life is all about the next generation,” Ken said. “That’s very important.”

475 cows

Of all the tractors you've owned, what is your favorite? On the farm side, my favorite tractor is a John Deere 4020 that we have repainted and saved as a collector. The tractor was purchased from my father in 2002 and has 4,600 original hours on it.

Why is it your favorite tractor? My overall favorite tractor is our John Deere 6030 pulling tractor that we call the Badger Deere. We run the tractor-pulling circuit in the 4.1 limited pro-stock tractor class. Tractor pulling has been a tradition in our family for many years. What kind of work do you use it for on the farm? It is only used for recreational purposes.

What is your favorite task to do with the tractor? I can remember I started pulling tractors when I was 8 years old on a John Deere 4020 that we used on the farm. The enjoyment grew from there into many years of competing with other pullers and meeting people all over the country.

If money was no object, what tractor would you purchase? I would purchase a classic John Deere 6030 tractor that has been refurbished as a collector. This series of John Deere tractor, in my opinion, was the powerhouse of its day.

During the year, what is your favorite job involving a tractor? I enjoy planting corn in the spring and chisel plowing in the fall. Tractor pulling would be my favorite, of course, if it was really a job.

Tell us about your family and farm. Our family is continuing to grow each year. My wife, Christine, and I have two sons who are married and a daughter. Our oldest son, Collin, and wife, Jessie, both work on the dairy farm. They currently have three children: Carson, Chloe and Caden with baby No. 4 due in March 2024. Our other son, Casey, and his wife, Brianna, are expecting their rst child in January 2024. Casey and Brianna both also work on the dairy as well as farm 500 acres of crops on their own and have beef cattle. Our daughter, Cammie, is in her second year of college at Luther in Decorah, Iowa. We also have two full-time non-family members who have been working for us for 10 years. My parents, Dwight and Shirley, take care of the heifers on another farm. Shirley is also the secretary of the dairy. Our dairy operation is one that is ever evolving. We own and operate about 800 acres in Vernon County, Wisconsin. All land is currently growing corn and alfalfa that is used solely for the dairy. We purchased six Lely robots two years ago, switching from organic dairying to conventional. Our milk is currently being shipped through Scenic Central Milk Producers.

Duane Wolfgram, pictured with his nephew Jamie Schmitz. Kendall, Wisconsin Monroe County

40 cows

Of all the tractors you've owned, what is your favorite?

My favorite tractor would be the AllisChalmers Model C that my dad bought brand new in 1949. He paid $1,000 for it from Steffen Equipment in Elroy. I still have it even though it doesn’t run anymore. It is a gas engine and came with implements. It is around a 20-horse tractor. Why is it your favorite tractor? It’s my favorite because I learned to farm on it. It was the rst tractor my dad ever bought because he had been farming with horses his whole life.

What kind of work did you use it for on the farm? We did everything with it at rst until Dad bought a more powerful tractor ve years later. Mostly we would pull the hay fork with it and use it for cultivating or running the one bottom plow.

What was your favorite task to do with the tractor? It was not the handiest tractor actually because it was not very powerful, so I did not have a favorite chore with this one. I was probably 7 years old when I learned to drive it, and I could not reach the pedals. It also had no brakes at all. When I worked with Grandpa, he was on the grain binder, and I was on the tractor. We would go around the eld while my dad watched. My grandpa would give me the thumbs up to go faster, and when we came back around closer to my dad, my dad would give me the thumbs down to go slower. That’s the way we went all day.

If money was no object, what tractor would you purchase? I would have to look around and see what’s out there. I know I would not buy any new technology. Even if money was no object, I would still have to deal the price down, and it would have to include a new cap.

During the year, what is your favorite job involving a tractor? I do a lot of tractor driving still, and I like all of it. I hate winter and am always glad when spring comes and I can get back outside in the elds. I like baling hay and planting corn.

Tell us about your family and farm. I farmed with my dad growing up. Then we got my grandpa’s farm and bought the farm in between us. Alan Thompson owned it before us; he is Tommy Thompson’s uncle who is the former governor of Wisconsin. We were told that they built our barn in 1898 and bought it out of a Sears and Roebuck catalog, but I have no way of knowing that for sure. Now I farm with my nephew Jamie Schmitz. We ship our milk to Grassland Dairy Products and milk in a tiestall barn. We crop around 320 acres.

Of all the tractors you've owned, what is your favorite? My favorite tractor is the Oliver 1550 that my grandpa bought new in the late 1960s. It has a narrow front, a three-point hitch and a gas engine that produces 53 horsepower. The tach says that it has 3,200 hours on it. Why is it your favorite tractor? The Oliver 1550 has been a trouble-free tractor for the most part. My nephew from Chicago recently graduated from college and dropped by our farm on a westward road trip he was taking. I put him on the Oliver and had him drive it even though he had never been on a tractor before. Driving his great-grandfather’s tractor was a huge thrill for him and created some great memories.

What kind of work do you use it for on the farm? I put a sprayer on the Oliver’s three-point hitch and use it to spray ies in our barns. The tractor only runs for an hour once a week or so during the warm months. I change the oil every other year to keep its lters and oil fresh,

What is your favorite task to do with the tractor? I don’t really like eldwork. What I enjoy the most is working with and caring for our dairy cattle. Spraying ies with the Oliver is very satisfying because at the end of the process you can see dead ies.

If money was no object, what tractor would you purchase? I would like a John Deere 6155R with short axles and all of the bells and whistles. We are currently using a similar tractor on our feeder wagon, and it’s already got quite a few hours on it. When I was 33 years old, I bought a John Deere 4440 and put it on the feeder wagon. Years later, when I sold the 4440 to a mechanic in central Iowa, it had over 30,000 hours on it.

During the year, what is your favorite job involving a tractor? I own a John Deere 4020 that has an open station. One of my favorite things is giving our ve grandchildren rides on that tractor. It’s a great way to spend time with them and create lasting memories. Tell us about your family and farm. My wife, Mary, and I farm with her brother and her father. We milk our cows in a double-8 parabone parlor and bed our free stalls with sand. Our fresh cow pen has a bedding pack, and our maternity pen is bedded with sawdust. We trim hooves every other Tuesday and perform herd health checks on alternating Tuesdays. We ship our milk to Associated Milk Producers Inc. in Sanborn, Iowa.

Lewis Shallow, pictured with his son, Thaddeus, and dad, Jeff Lena, Wisconsin

Oconto County

42 cows

Of all the tractors you've owned, what is your favorite? One of the favorite tractors on the farm would be Dad’s 1953 John Deere 50. It’s a simple old John Deere two-cylinder.

Why is it your favorite tractor? It’s been in the family since 1953. Grandpa bought it on an auction when the tractor was nine months old. When Dad started farming in the 1970s, he ended up with it as his rst tractor.

What kind of work did you use it for on the farm? It did a lot more work in its past than it does currently. For Grandpa, it was the baling tractor. Every summer, it would bale 20,000 small square bales with a John Deere 14T baler. When Dad was starting out farming, the 50 spread manure daily with an International box spreader. It raked hay, pulled a drag, grain drilled and pulled wagons.

What is your favorite task to do with the tractor? Many of the tasks the 50 had in the past have now been delegated to more modern tractors, but it still pulls a lot of wagons. Whether on the at rack hauling in round bales or pulling

Seth Anderson

Seth Anderson

Ettrick, Wisconsin

Trempealeau County

200 cows

Of all the tractors you've owned, what is your favorite? A 1947 Oliver 77 Row-Crop. It may not be my favorite tractor, but it has the most meaning to me and the farm. My grandpa bought it new in the late 1940s after trading in their Oliver 70. At only 37 horsepower, it was the only tractor on the farm for many years. It was equipped with a two-row mounted cultivator (that we still have) and a belt pulley.

Why is it your favorite tractor? I'm sentimental about the history of our century farm, and this tractor was a big part of it. I enjoy hearing about it from my dad's cousin who grew up here and operated the tractor as a youth while helping my grandparents with chores.

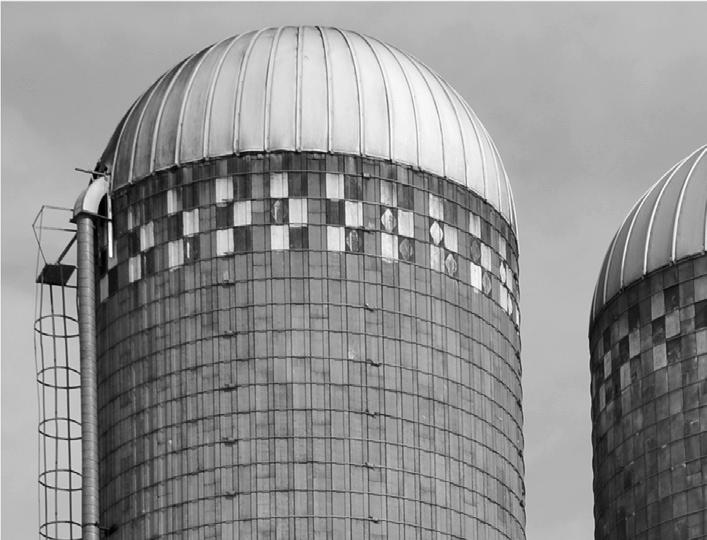

What kind of work did you use it for on the farm? As the sole tractor for many years, it had all the roles of a tractor — from tillage and planting to pulling the hay loader and hoisting loose hay into the barn. During my childhood, it ran the Fox blower to ll our 30-foot silos, raked hay and was on the GrainO-Vator feed wagon all winter. Now its main job is unloading 16-foot chopper boxes all summer.

a few chopper boxes of silage, it’s good to keep it in use. It is also used to move stuff around the yard a lot. If we need to move machinery around the yard or the shed, it’s easy to back stuff up with the narrow front end.

If money was no object, what tractor would you purchase? Probably a late John Deere Generation II model like a 4455 or 4760 with low hours. Those models have proved their dependability, and there is a reason their value is skyrocketing.

During the year, what is your favorite job involving a tractor? I really like planting row crops. It’s just enjoyable putting seeds in the ground. It’s the rst part of the crop year and what you waited for all winter. We started experimenting with no-till and cover crops recently, and that cut down on a lot of tillage, but at the same time added some new things.

Tell us about your family and farm. The farm consists of my parents, Jeff and Darlene; my sister, Darcy; my spouse, Skhyler; and our 15-month-old son, Thaddeus. We currently milk 42 cows — primarily Holstein with a couple of Brown Swiss tossed in. We ship our milk to Dairy Farmers of America. For land base, there are 200 acres divided up in a rotation of alfalfa, corn and soybeans. The beans are sold, but everything else remains on the farm. The alfalfa is put into haylage, baleage and dry hay, and the corn is divided for silage and shell corn. We grind the shell corn and mix it with dried soybean protein for the cows. Milking takes place in a traditional stanchion barn, while the animals are on pasture for as much of the year as possible. All animals are raised on the farm.

What is your favorite task to do with the tractor? My favorite task (and really its only job) is unloading chopper boxes. It's easy to get on and off the back, and the left-hand PTO lever is easy to reach from the ground. A shade umbrella helps keep me from burning in the sun. It gets a workout sometimes when the wagons get heavy, pulling and scratching with all its might.

If money was no object, what tractor would you purchase? It would have to be a larger Case IH MFD cab tractor that's pre-emissions with the Cummins engine. We lean toward red tractors. The Magnums have proven to be incredibly reliable. We do have an 8920, but the newer cab on later models would be nice to have.

During the year, what is your favorite job involving a tractor? I really enjoy chopping hay, but Dad gets that job while I unload wagons. I just enjoy cleaning off a eld and pushing tractor and chopper to their limit to harvest as fast as possible.

Tell us about your family and farm. My wife, Erin, and I farm full time with our kids, Otto, Eleanor and Ivan, along with the help of my parents, Byron and Lorna, who still help every day with chores and feeding cows. Erin's dad, Dan, helps with eldwork and hauling manure since retiring from dairy farming himself a few years ago. We have one full-time employee who helps us with milking, along with a few neighbors and an uncle who are great help with eldwork. We milk 200 cows in a double-10 parallel parlor we built new with a freestall barn in 2016. We ship our milk to Westby Cooperative Creamery.

Describe your farm and facilities. Our cows are housed in sand-bedded free stalls and milked in a double-8 herringbone parlor. We have modied our existing buildings over the years to get everything how it is today. This farm has been in my family for 111 years, and I was raised here. This is my 51st cropping season. My wife Pat and I are senior partners, and we farm with our daughter, Angie, and her husband, Donald, and our son, Dan, and his wife, Michelle. The grandkids work when their schedule allows. My nephew, Ben Herricks, is the main feeder, and he is invaluable. He has worked here for over 20 years and knows everything going on.

What forages do you harvest? Corn silage, alfalfa, rye and oats.

How many acres of crops do you raise? 1,400 acres.

What quality and quantity do you harvest of each crop?

We raise 300 acres of alfalfa, 100 acres of nurse crops (rye and oats) and 1,000 acres of corn. Half the corn is for si-

lage and half is for grain. We raise HarvXtra Alfalfa, which is a low lignin feed, and strive for a relative feed value of 200. We raise brown midrib corn silage, and our goal with that is to harvest as high energy, palatable feed as we can.

Describe the rations for your livestock. We feed a high-forage diet to all of our animals. Rye and oats are fed to the dry cows and heifers. The milk cows are fed alfalfa haylage, BMR corn silage, ne-ground corn, soybean meal and a protein mix. The quantity of each ingredient is adjusted according to production groups.

Describe your harvesting techniques for alfalfa and corn silage. We harvest all of our own crops together with the Brueggen family in Norwalk, Wisconsin. We have worked together to get our crops done for over 40 years. Our No. 1 rule for working together is, if a decision is not good for both of us, then we need to rethink it. They also milk close to 600 cows, so we are working together to feed 1,200 cows, which justi-

Jack Herricks takes a break Aug. 16 at his farm near Cashton, Wisconsin. Herricks farms 1,400 acres and milks 600 cows with his family, and 2023 is the 51st cropping season of his farming career.

es having larger equipment. We harvest our alfalfa every 28-30 days and get it done in three days. It’s important

to get it done in a short time frame to achieve consistent feed. Corn silage takes about a week.

What techniques do you use to store, manage and feed your forages? We store our forages in bunkers. We store half of our shelled corn in a bunker and the other half in Harvestore silos. When we are harvesting, we make sure feed is packed tightly in the bunker. The single biggest factor in management is taking monthly inventory of our feed. We know when our feed is going to run out, and we are able to plan better that way.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We raise the same crops, but the genetics have changed dramatically. We have also changed the soil health of our land. Most of our land has over 4% organic matter. Each percentage increase of organic matter gives the soil the capacity to hold another inch of rain. So, on a year like this, we can hold 2 more inches of rain than a lot of land.

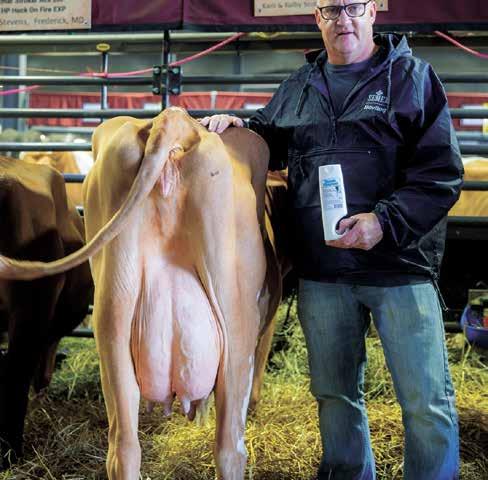

“Only Udder Comfort™ will do! We love it for swelling and for fresh cows. We never want to use anything else because this works so well,” says Kevin Stoltzfus of Warwick Manor Guernseys, the herd in East Earl, Pennsylvania that produces the Golden Guernsey Milk for Yoder’s Country Market in New Holland.

Kevin and Dina and children Kolby, Karli and Kaila are all involved in the dairy. Karli and Kolby brought 4 homebred Guernseys to the 2022 World Dairy Expo. ‘Peachey’ was bred-and-owned champion of the junior show, ‘Scotch’ (pictured above) was res. int. champion of the junior show, and ‘Senora’ top lifetime production cow of the open show. Of their 50 milking Guernseys, 12 made the 2022 Top-100 Component Queen Cows of the breed, averaging 25,110M 5.9F 3.3P; with 89-pt average score, 5 nominated AA in milking form.

“When something works, we stick with it. We use Udder Comfort on all fresh cows 2x/day for a week after calving. We start heifers prefresh, 1x/day for a week before calving,” says Kevin. “We also use it before, during and after showing.”

We also have the following Skidloaders in stock for parts:

We are also a dealer for DEKA BATTERIES Nice selection in stock!

We are also a dealer for NORDEN SKID LOADER ATTACHMENTS

And we also have your full line of hyd hose and fittings in stock stop in for your hyd hose needs 1/4”, 1/2”, 5/8”, 3/4”, 1”, 1-1/4”!!!

Jack Herricks inspects corn silage Aug. 16 on his farm near Cashton, Wisconsin. Feed inventory is taken monthly, which allows the family to plan for carryover; this way, the feed has enough me to ferment and cows never have to eat green corn silage.

Fine-ground corn is stored in Harvestore silos and bunkers at the Herricks farm near Cashton, Wisconsin. Milk cows are fed corn silage, alfalfa haylage, ne-ground corn and a protein mix.

How do quality forages play a part in the production goals for your herd? It helps us be low-cost producers because high-quality forage means less purchased feed. Approximately 80% of our feed is home grown.

2000 Gravity Flow wagon, Knowles running gear, clean ....................................................

Lundell 1290 Gravity Flow wagon, front & rear ladder, Lundell running 2070 gear, rear hitch...

Parker 2100 Gravity Box, LH discharge, Lundell 1670 running gear, right off farm, nice .........

Parker 2100 Gravity Box, LH discharge, John Deere running gear, right off the farm, nice......

Sudenga Hi-Ef swing hopper auger, 61’X8”, 540 PTO, hyd lift, manual hopper jogger, right off the farm, ready for work ....................................................................................................

Ez-Flow 220 Gravity Box, Ez-Flow 672 running gear, right off farm, nice ...................................

Killbros 350 Gravity Box, Huskee running gear, right off the farm, field ready ..........................

John Deere 640 Roll Bar Rake, ground drive, super clean, field ready..........................................

Need your A/C hoses replaced? It’s easy! Send us your old ones and we will make new ones for a fraction of the cost of new OEM!!!

Describe a challenge you overcame in reaching your forage quality goals. We have added a lot more storage space. This makes keeping track of inventory easier. We always have a goal to have enough corn silage until January of the next year so that we never have to feed green corn silage. More storage space has helped us reach that goal.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? I started farming by making 12,000 to 14,000 small square bales a year and using a onerow, pull-type chopper. So there have been big changes in my career. Now, we can harvest more acres and feed more cows per manhour than we once did.

1/2” thick x 16” wide

12’ long $35 • 16’ long $47

White Corrugated PVC liner panels

40” wide x 16’4” long $1950

White smooth PVC sheeting

4’ x 8’ x 1/2” thick $5750

FACTORY SECONDS. QUANTITY DISCOUNTS.

DELIVERY AVAILABLE

715-644-2350

Chippewa

Duals, 1272 hrs., 90 Sep. hrs., #557140................ $629,900

JD S790 2021, PRWD, Singles, 937 hrs., 770 Sep. hrs., #557277 ............. $479,000

JD S790 2022, PRWD, Duals, 25 hrs., 20 Sep. hrs., #560618 ................... $639,500

JD S790 2022, PRWD, Duals, 230 hrs., 155 Sep. hrs., #563325................ $599,900

JD S790 2022, PRWD, Singles, 480 hrs., 314 Sep. hrs., #563815 ............. $579,500

JD S790 2021, PRWD, Duals, 833 hrs., 551 Sep. hrs., #565421................ $499,900

JD S790 2022, PRWD, Duals, 461 hrs., 368 Sep. hrs., #566460................ $624,900

JD S790 2022, PRWD, Duals, 333 hrs., 239 Sep. hrs., #566637................ $589,900

JD S790 2022, PRWD, Duals, 455 hrs., 316 Sep. hrs., #566694................ $579,900

JD S780 2020, PRWD, Duals, 1489 hrs., 1145 Sep. hrs., #191082............ $349,000

JD S780 2020, PRWD, Singles, 1551 hrs., 1204 Sep. hrs., #531610 ......... $349,000

JD S780 2019, PRWD, Duals, 1600 hrs., 1058 Sep. hrs., #549682............ $319,000

JD S780 2020, PRWD, Duals, 1290 hrs., 941 Sep. hrs., #550187.............. $369,000

JD S780 2018, PRWD, Duals, 1521 hrs., 1130 Sep. hrs., #551736............ $305,000

JD S780 2022, PRWD, Duals, 453 hrs., 353 Sep. hrs., #552362................ $549,000

JD S780 2022, PRWD, Floaters, 395 hrs., 323 Sep. hrs., #553546 ............ $549,900

JD S780 2022, PRWD, Tracks, 304 hrs., 238 Sep. hrs., #554013 ............... $619,000

JD S780 2022, PRWD, Duals, 242 hrs., 183 Sep. hrs., #554094................ $565,000

JD S780 2022, PRWD, Floaters, 242 hrs., 170 Sep. hrs., #554623 ............ $569,000

JD S780 2022, PRWD, Floaters, 255 hrs., 177 Sep. hrs., #554707 ............ $569,000

JD S780 2022, PRWD, Floaters, 142 hrs., 91 Sep. hrs., #554708 .............. $574,000

JD S780 2022, PRWD, Floaters, 191 hrs., 131 Sep. hrs., #554709 ............ $569,000

JD S780 2022, PRWD, Floaters, 190 hrs., 139 Sep. hrs., #554710 ............ $569,000

JD S780 2018, 2WD, Duals, 1217 hrs., 826 Sep. hrs., #555412 ................ $319,000

JD S780 2021, PRWD, Duals, 799 hrs., 607 Sep. hrs., #556191................ $479,900

JD S780 2020, PRWD, Duals, 933 hrs., 640 Sep. hrs., #557137................ $419,000

JD S780 2019, PRWD, Duals, 1287 hrs., 931 Sep. hrs., #558869.............. $349,000

JD S780 2022, PRWD, Tracks, 300 hrs., 280 Sep. hrs., #561020 ............... $623,000

JD S780 2022, PRWD, Duals, 465 hrs., 374 Sep. hrs., #563633................ $549,000

JD S780 2022, PRWD, Duals, 469 hrs., 347 Sep. hrs., #563635................ $549,000

JD S780 2022, PRWD, Tracks, 243 hrs., 192 Sep. hrs., #563701 ............... $619,000

JD S780 2022, PRWD, Duals, 427 hrs., 307 Sep. hrs., #563710................ $549,000

JD S780 2020, PRWD, Duals, 964 hrs., 740 Sep. hrs., #564897................ $419,500

JD S780 2022, PRWD, Floaters, 8 hrs., #565897...................................... $629,900

JD S780 2018, PRWD, Duals, 2753 hrs., 1901 Sep. hrs., #567178............ $234,900

JD S780 2022, PRWD, Duals, 250 hrs., 165 Sep. hrs., #567271................ $585,000

JD S780 2021, PRWD, Duals, 500 hrs., 300 Sep. hrs., #567515................ $519,900

JD S770 2018, PRWD, Duals, 2261 hrs., 1652 Sep. hrs., #549678............ $259,900

JD S770 2022, PRWD, Duals, 273 hrs., 195 Sep. hrs., #554014................ $560,000

JD S770 2021, PRWD, Duals, 568 hrs., 486 Sep. hrs., #554050................ $405,000

JD S770 2021, 2WD, Duals, 720 hrs., 585 Sep. hrs., #560264 .................. $425,900

JD S770 2022, PRWD, Floaters, 36 hrs., 20 Sep. hrs., #563704 ................ $546,000

JD S770 2022, PRWD, Duals, 269 hrs., 148 Sep. hrs., #567222................ $564,900

JD S770 2022, PRWD, Duals, 148 hrs., 91 Sep. hrs., #567225 ................. $574,900

JD S760 2019, 2WD, Duals, 1206 hrs., 871 Sep. hrs., #565714 ................ $279,900

JD S690 2017, PRWD, Duals, 1433 hrs., 1187 Sep. hrs., #549457............ $280,700

JD S690 2015, PRWD, Tracks, 2400 hrs., 1615 Sep. hrs., #550872 ........... $232,900

JD S690 2012, PRWD, Duals, 2313 hrs., 1645 Sep. hrs., #551148............ $149,000

JD S680 2017, PRWD, Duals, 1516 hrs., 1053 Sep. hrs., #273646 ........... $219,900

JD S680 2014, PRWD, Duals, 2349 hrs., 1668 Sep. hrs., #531966............ $195,000

JD S680 2013, PRWD, Duals, 2485 hrs., 1604 Sep. hrs., #551147............ $165,000

JD S680 2012, 2WD, Duals, 2756 hrs., 2032 Sep. hrs., #552659 .............. $119,900

PRWD, Duals, 1732 hrs., 1317 Sep. hrs., #532082............ $189,500

JD S660 2012, 2WD, Duals, 1643 hrs., 1188 Sep. hrs., #554132 .............. $179,900

JD 9870 STS 2009, PRWD, Duals, 3579 hrs., 2579 Sep. hrs., #563914 ...... $94,500

JD 9870 STS 2008, PRWD, Duals, 3261 hrs., 2494 Sep. hrs., #566621 ...... $97,500

JD 9870 STS 2011, 2WD, Duals, 3650 hrs., 1750 Sep. hrs., #567383 ....... $109,900

JD 9860 STS 2004, PRWD, Duals, 3924 hrs., 2537 Sep. hrs., #559820 ...... $55,000

JD 9860 STS 2005, PRWD, Duals, 4528 hrs., 3240 Sep. hrs., #564977 ...... $59,900

JD 9770 STS 2011, PRWD, Duals, 2537 hrs., 1813 Sep. hrs., #566823 .... $129,900

JD 9760 STS 2004, PRWD, Duals, 4389 hrs., 3109 Sep. hrs., #564023 ...... $53,500

JD 9760 STS 2007, 2WD, Duals, 3169 hrs., 1965 Sep. hrs., #566814 .......$74,900

JD 9750 STS 2003, 2WD, Duals, 5105 hrs., 3367 Sep. hrs., #565004 ......... $37,500

JD 9670 STS 2010, 2WD, Duals, 2525 hrs., 1667 Sep. hrs., #566916 ....... $114,900

JD 9570 STS 2011, 2WD, Singles, 2019 hrs., 1231 Sep. hrs., #555820 .... $132,500

JD 9570 STS 2009, 2WD, Duals, 2367 hrs., 1597 Sep. hrs., #556547 ....... $104,900

JD 9560 STS 2004, 2WD, Duals, 4638 hrs., 2982 Sep. hrs., #567094 .......$52,500

Case IH 2388 1998, 2WD, Singles, 3876 hrs., 2943 Sep. hrs., #549406 .... $34,900

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

VIROQUA, Wis. — The rain dampened the ground but not the spirits of the 38 youth attending the annual Day of Dairy Aug. 14 in Viroqua.

Individuals aged 8-17 years old from across Vernon County gathered at the Vernon County Fairgrounds to learn the basics of fair etiquette, dairy nutrition, cattle marketing and other opportunities in the industry through hands-on instruction and guest speakers.

Organized by members of the Vernon County Dairy Youth Fund Committee, the event is geared toward preparing youth to show at the Vernon County Fair but also brings in guests to share their experiences with the kids.

This year’s guest speakers included Dennis Nerison, who owns and operates Nerison Livestock; Wayne Kruizenga with Koon Kreek Feeds; and Garrett Nielsen, who discussed

calf care. The event was facilitated by Gail Klinkner and Ashley Olson.

“Day of Dairy has become a agship educational event for the kids,” Olson said. “Not only does it teach them about getting their heifer ready for show and what to expect at fair, it also allows them to meet other dairy youth in the county who they might only see a couple times of year.”

The day began with washing heifers which belonged to various members of the junior dairy club. Attention was given to the different products that are safe to use on cattle as well as techniques and frequency.

While the heifers dried off, kids were instructed on how to build a proper bedded pack at the fair. This started with spreading out straw topped with wood shavings. A special technique that was demonstrated was when there is no frame behind the pack, a board is used to straighten the back of the bedding pack.

The importance of cleanliness was stressed throughout the day. Animals were then brought in and lined up by size.

Greg Wubbenhorst showed participants how to tie a slip knot.

Nielsen spoke to the group about calf care. He specied that all calves require the same care of clean bedding, fresh feed and water, regardless of their breed or whether they become a show animal or not. Nielsen emphasized the importance of vaccinations as well.

“Anyone who’s ever lived on a farm knows that if any disease starts going through, if

you’re not vaccinating, you’re in trouble,” Nielsen said.

“That’s just the way it is.”

Later, Kruizenga spoke to the group about the different types of feed that are available for dairy animals. He has owned Koon Kreek Feeds in Coon Valley for 29 years and said dairy show animals require a different feed than beef steers in a lot.

“The biggest thing is to start them out right,” Kruizenga said. “They need higher

protein and less grain.”

Klinkner talked to the kids about how to dress for showing and different supplies that are needed to prepare animals for the show ring. Besides white pants and dress shirts for showing, she discussed where to clip the animals, how to blow dry a top line and the importance of y spray.

“If the ies are on you biting, then they are on your animals too,” Klinkner said.

Since showing requires a lot of supplies, the kids went home with a calf pail, a halter and a brush as a starter kit for their showing career.

The Vernon County Dairy Youth Fund’s mission includes supporting dairy youth through activities and educational events. The nancial support for the club originates through funds raised during the Cheese of Champs sale at the Vernon County Fair. Half of the funds raised each year are returned to dairy youth winners of showmanship, while the other half goes to the Dairy Youth Fund.

This was the seventh year that the Day of Dairy was held. Olson said it has an important impact on the youth of Vernon County.

“It is great to bring in different speakers with agriculture backgrounds to get the kids thinking about future careers,” Olson said. “I truly enjoy being part of this annual event and thank all the sponsors that make this event successful.”

When it came time for the league’s state tournament in July, Fargo 12U AllStars was the lone team that entered.

“Little League is not super huge in North Dakota, although I have a feeling it’s going to get a lot bigger now, but it’s not huge by any stretch,” Molden said. “Usually, there’s only about three teams in the state tournament.”

Pa.

— From the crack of the baseball bat to the pulsating of a milking unit, Todd Molden has traversed the world of baseball and that of a dairy farmer.

The two have collided recently for Molden, who is the herdsman of the North Dakota State University Animal Sciences Dairy Cattle Research and Teaching Center in Fargo, North Dakota.

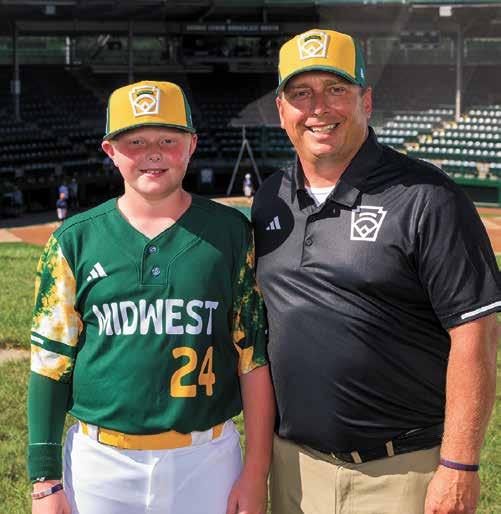

As an assistant coach, Molden helped lead a group of 12 talented youth to appear in the Little League World Series Aug. 16-27 in South Williamsport.

The Fargo 12U All-Stars is the rst North Dakota team to reach the pinnacle appearance in the tournament’s seven-decade history.

Molden and his wife Tania’s oldest son, Jackson, is the catcher on the team. Siblings Amelia and Christian have been cheering on the team during their journey to Little League headquarters.

Molden, who oversees the 100-cow dairy farm at NDSU in addition to student employees, has been juggling the three roles of coach, father and herdsman throughout the season.

The squad then departed Aug. 2 to travel to the eight-team Midwest Region Tournament Aug. 4-11 in Whitestone, Indiana.

After defeating Kansas 15-1 Aug. 4 in the quarternals, Fargo 12U AllStars faced Wisconsin Aug. 5 and won 16-2. A loss to South Dakota followed Aug. 9 by a score of 7-3. The team was not deterred and came back to win the next day over Iowa 12-7.

The win set up a championship game of neighboring states Aug. 11. In the end, North Dakota was the victor 9-7 to secure their spot in the world series.

“The last play was a ground out to our shortstop, and he made a nice play,” Molden said. “It was so much fun to watch the celebration, knowing how hard these kids worked. They do anything we ask them to, and it’s just so fun to see that emotion in them come out.”

With no time to relax, and with a ood of local support behind them, the team and their three coaches set off on a bus at 7 a.m. the next day.

We had one cow in particular that had been with us for most of our dairy career. Her name is Hot Chocolate, and she was born about a week before Thanksgiving in 2017.

That was not a good morning. One of our 3-year-old cows, No. 112, freshened the day before, and we were really excited to see how she turned out. Unfortunately, 112 prolapsed her uterus and died during the night. I discovered her early the next morning when I went out to milk. I was so heartbroken and disgusted at the tragic way that this beautiful animal had suffered before death.

The feeling of failure was strong that morning. It took me a while to get over the shock and be able to go back in the barn to start chores.

By Abby Wiedmeyer Staff Writer

By Abby Wiedmeyer Staff Writer

When I nally did drag my sad self back to the barn, I set up the milkhouse and pushed the milker cart down the walk to start milking. The calving pen was down at that end of the barn, and when I approached, I saw that another cow had calved in the night. There was a small, white, fuzzy calf curled up in the corner and a fresh cow who had thankfully already dumped her cleanings and nothing else.