By Amy Kyllo amy.k@star-pub.com

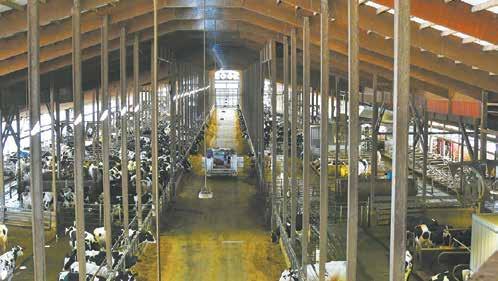

GOODHUE, Minn. — For many, bringing robots onto the farm means shuttering their parlor to collect dust. But for the Voth family, the addition of ve Lely robotic milking units does not preclude 400 cows from being milked in their parlor.

The Voth family — Brad and Denise, and their sons, Brady and Nathan — milk 700 cows on their farm near Goodhue. The family has two herds housed under one roof with 300 cows in the robotic herd and 400 cows in the parlor herd.

The split is complete, with different patron numbers, nancials and milking facilities separating the two.

The Voths said they wanted to look at the nancial viability of the two management styles. With their split setup, they said they are able to make an “apples to apples” comparison of the two.

“The biggest thing was probably just testing out if we wanted to actually stick with robots or not, rather than jump two feet in right away,” Brady said.

The Voths milk three times a day in their double-12 parallel parlor. In the robotic milking units, the cows are averaging 2.8 visits a day. Productionwise, the two herds are within 1-2 pounds of milk of each other. Nathan said consistency between the two has remained across their comparison.

“We’ve tested the waters of technology and robotics,” Nathan said. “We don’t have to second guess anymore if it is worth it or not worth it.”

The family said they had decided during planning that if they did not like the robotic milking units they could always sell them.

“We’ve kind of always set things up here to give us options so that if one option doesn’t work, we’re not tied to it,” Nathan said. “We can go a different direction.”

Initially when considering how to move their operation forward with their aging parlor, which was built in 1995, the Voths considered putting in a rotary parlor. However labor problems turned them to robotic milking units.

“Like everybody else, we were struggling with labor,” Nathan said. “Finding people and the right people that want-

cows with ve robo c milking units and a double-12 parallel parlor.

ed to be here consistently. … It kind of rethought our mind to, ‘What if we can keep doing what we’re doing with less?’”

The Voths toured 10-12 robotic dairies as well as three carousel parlors before their project was completed.

Construction began in the summer of 2022. The Voths retrotted part of their freestall

barn and added a lean-to addition to help house the robot rooms.

The retrotting was minimal because of how the freestall barn was built for the possibility of robotic milking units.

“That probably solved a lot of even more headaches that we could have had,” Nathan said.

During the project, they also put on a 40- by 70-foot addition that houses an ofce, a bulk tank room, a changing room and rooms for equipment.

Con nued from VOTH | Page 3

January 3, 2023, was the launch day for the robotic milking units. Brad said because of their parlor, the adjustment did not have to be immediate, however, within a week, the robotic milking units were full.

“My biggest thing is we had people that came and showed up and helped us and that was tremendous,” Brad said.

Now that the robotic milking units are installed, their seven dairy employees start their shifts in the milking parlor and nish at the robotic milking units fetching cows, cleaning and

scraping. The robotic milking units also allow for more time to work on parlor maintenance.

Brady said their farm has experienced a change of pace since the robotic milking units.

During the project planning process, Nathan was able to utilize his previous career in commercial construction. Before returning to the family farm in 2019, he had worked for seven years in the industry and was able to put to use knowledge in drafting, drawings and blueprints.

With Nathan’s expertise, the family brought their ideas to life and presented them to their builders. Brady said this saved time.

“(If) we had a thought in our mind, that we wanted to change something to see how it looked … it was pretty easy for us to spin something,” Brady said.

When it came to returning to the farm as a career, Nathan said his parents did a good job of making a return “appetizing.”

“They set it up for future generations to take it on,” he said. “You have something to go back for and there’s opportunities still there.”

Brady said his parents farmed progressively, which was attractive. Brady joined the farm in 2010 after going to college for industrial maintenance and small engines.

Brady and Nathan are both fathers and said they like to bring their children out to the farm.

“I came back for the lifestyle,” Nathan said. “I enjoy … working with animals and being here and working with family.”

Denise said they are thankful their sons returned.

“We’re really blessed,” Denise said. “They work right next to us, and now we get to see their children grow up beside them and work and play.”

Looking to the future, the Voths plan to continue to use forethought and technology to keep their farm moving forward.

“We’d be comfortable with adding more robots,” Brady said. “(But) we always will work with maybe a parlor on the side.”

To help Wisconsin Spanish dairy workers and the Spanish dairy community to get the most current and up-to-date research information, the University of Wisconsin-Madison, Division of Extension has developed the Dairy Spanish Webinar El “Break” Info-Lechero 2.0.

This webinar series offers updates on a variety of dairy topics covering: reproduction data management, animal welfare, animal nutrition, genetics selection, gnvironment and more. These webinars will occur every Wednesday, September through November from noon until 1 p.m. CST. The dairy Spanish webinars are going to be in Spanish only.

PDP is bringing the annual leadership conference for students ages 15 to 18 to University of Wisconsin-Platteville on Sept. 21. This year’s interactive, high-energy conference combines leadership development training with hands-on experiences in dairy foods and bio-char labs as well as a campus tour. The conference begins at 9 a.m. and concludes at 6:15 p.m., with training materials, meals and a Stride T-shirt included in registration.

The Annie’s Project Retreat is being offered by the U of M Extension Women in Ag Network in partnership with the Friends of Frog Tree Farm, located north of Wadena, MN., on Saturday- Sunday, Sept. 21-22. Annie’s Project is for any farmer or rancher looking to understand farm management and decision-making topics better. Annie’s Project is designed to empower farm businesses in today’s complex, dynamic world of agriculture.

The event will include a variety of engaging workshops, insightful speakers and numerous networking opportunities. These activities are designed to address the unique challenges and opportunities faced by women in the agricultural sector. Whether you are an urban farmer, a rural farmer, or anywhere in between, your perspective and experience are invaluable to our collective success.

Wisconsin Schools of Grazing, organized by GrassWorks, Inc., University of Wisconsin Lancaster and Marsheld Agricultural Research Stations, UW-Extension, and the U.S. Department of Agriculture — Natural Resources Conservation Service, are back by popular demand. This highly anticipated event will take place:

— Sept. 27-28 at the UW Lancaster Ag Research Station

These two-day workshops are specically designed to equip farmers with the practical skills and knowledge necessary for successful managed grazing. As soil health and regenerative agriculture increase in popularity, the program aims to address the increasing need for in-depth, practical education in this eld.

Farmers, producers, consumers and anyone interested in connecting with Iowa’s organic community and learning more about organic production are encouraged to join the Iowa Organic Association at one or more of our Field Days this fall. These unique on-farm events offer an incredible opportunity to explore an array of organic farming practices and resources developed to encourage and support greater participation in the organic market.

Field Day topics range from organic dairy processing, organic crop production, hands-on eld demonstrations, to ISU’s mung bean research efforts, a Seed Savers Exchange farm tour and introduction to new-emerging organic markets for Iowa producers. Whether you are just getting started with organic farming or looking to transition your operations, our Field Days cover essential topics to cultivate your own organic journey.

Overview of Events

— 9/28: Cultivating Resiliency through Intergenerational Collaboration: Tour of Organic Greenhouse, Straw Bale House, and Farmer Panel.

For more information or to register for any of the 2024 Field Days, please contact Roz Lehman, Executive Director, at roz@ iowaorganic.org or 515-608-8622.

Match Made In Heaven: Livestock + Crops is a collaboration of over 50 agriculture and natural resource groups in Illinois, Indiana, Iowa, Minnesota, Missouri and Wisconsin. Participating organizations include crop and livestock associations, state and federal agencies, universities, soil and water groups, and both crop and livestock farmers. This project is a collaboration among groups that do not always get to work together: crop and livestock associations, universities, public agencies and conservation organizations. They are nding common ground and putting our heads together to move shared interests forward.

The eld day will take place, Oct. 3, 9:30 a.m. – 3 p.m., near Lodi, WI at the Ron Schoepp Farm. The events of the day will feature year-round custom grazing dairy heifers, grazing crop residues, cover crops in corn-soy-wheat-cover crops rotation and preventing soil nutrient loss next door to Lake Wisconsin.

The U.S. Department of Agriculture announced the August Federal Order Class III milk price at $20.66 per hundredweight, up 87 cents from July, $3.47 above August 2023, and the highest Class III price since November 2022. It put the eight-month average at $17.75, up from $16.98 a year ago and compares to $22.54 in 2022.

Late Friday morning Class III futures portended a September price at $22.81; October, at $23.06; November, at $22.63; and December at $21.79 per cwt.

The Class IV price is $21.58, up 27 cents from July, $2.67 above a year ago, and the highest Class IV since December 2022. Its average now stands at $20.49, up from $18.59 a year ago, and compares to $24.83 in 2022.

Adding fuel to the milk price re, conrmation has been made on three Central Valley California dairies of the Highly Pathogenic Avian Inuenza. Milk output was already struggling there, and generally milk output falls 10%-25% in dairy cattle. The so-called bird u has hampered milk output in at least 13 other states, with 17 cases reported in the last 30 days. Meanwhile, the USDA has authorized a eld safety trial of a vaccine for bird u in dairy cattle.

After jumping 17.25 cents the previous week, cash block Cheddar closed the holiday-shortened Labor Day week at $2.27 per pound, up 6 cents on the week, highest since June 9, 2022, and 34.50 cents above a year ago, as traders awaited Friday afternoon’s July dairy products report. The barrels nished at $2.2750, 1.50 cents higher, 44.75 cents above a year ago, and just a half-cent above the blocks. There were seven Chicago Mercantile Exchange sales of block on the week and ve barrel.

Cheese contacts tell Dairy Market News that demand is steady to strong, depending on the variety. Some processors have shifted back to barrels due to the bullish trend. Plant downtime, unrelated to the holiday weekend, continued to be reported by some Midwest contacts, but it has not necessarily prompted an inux in milk. Early in the week, Midwest cheesemakers reported that the holiday-related spot milk at at Class had disappeared and by mid-week prices were starting above $1 above Class III. A number of cheesemakers said they were not even receiving spot milk offers. Cheesemakers continue to suggest that market price upticks have yet to deter customer interest and some say it has actually spurred buyers to make deals to assure coverage.

Class III milk demand is generally strong from cheesemakers in the West. However, with most school institutions back in session by midweek, milk supplies were not abundant, says DMN, and butter price strength was giving incentive to allocate milk fats in that direction.

Manufacturers are running steady production and

block capacity is increasing as new facilities come online. Domestic cheese demand is steady but is moderate from international buyers.

Butter fell to $3.1475 Wednesday but closed Friday at $3.1750, a half-cent higher on the week, and 49.50 cents above a year ago, with 22 sales on the week.

Butter churning shifted into high gear this week in the central region, particularly the Midwest. Plants in the South have generally had more spot cream available throughout the summer than their Upper Midwest counterparts, said DMN, so the uptick in churning has been less dynamic there. Plant managers did not expect the availability of cream to last beyond the weekend. Butter demand is gathering its seasonal strength from both retail and food service customers.

Western manufacturers indicate retail churning is strong to steady, while bulk lines are at a much lighter pace. Butter inventories are comfortable for anticipated fourth-quarter demand. The holiday weekend brought mixed cream demand with a few facilities enjoying some downtime. This contributed to looser cream supplies for parts of the region. Some believe lower temperatures recently should allow more requests for cream from the West into the Midwest to be accommodated. Butter demand varies from stronger to steady, said DMN.

Grade A nonfat dry milk closed Friday at $1.3650 per pound, up 3.50 cents on the week, highest since Dec. 8, 2022, and 26.50 cents above a year ago. There were 19 loads nding new homes on the week.

The whey closed Friday at 58.75 cents per pound, 2.75 cents higher, highest in four weeks, and 28.50 cents above a year ago, with ve sales put on the board.

U.S. dairy exports remained strong in July, up 7.8%, according to HighGround Dairy’s Alyssa Badger in the Sept. 9 “Dairy Radio Now” broadcast. She said that while exports to Mexico in June were down, month to month and year to year, they turned around in July and were up 21% from July 2023. Exports to China were also higher, she said, as well as to Southeast Asia, up 24%.

Cheese exports totaled 88.7 million pounds, up 9.6%, though Cheddar was down 28.9%. Badger said that when these cheese purchases were booked, U.S. prices, although competitive, were not at a steep discount to the global market as they were earlier in the year, so, “This is really good news.” And cheese moving across the southern border to Mexico leapt to its second-highest level ever.

Nonfat/skim milk powder exports hit 159.4 million pounds, up 10.8% from July 2023, and surely helped put CME prices where they are. HighGround Dairy said July’s sailings were the highest since May 2023, with increased shipments to Southeast Asia and Mexico. Demand from China remained lackluster,

down 21%, and the smaller exports are keeping yearto-date totals behind, down 8.5%.

Whey exports remained strong, totaling 29.6 million pounds, up 15%, though YTD are down 2%. China was the top destination, according to HGD. Butter exports amounted to 6 million pounds, increasing for the second month in a row, up 16.3% from a year ago but down 8.6% YTD. Badger said U.S. prices are not at a huge premium to Oceania, and European prices are also higher than ours, so that has helped U.S. exports. We were still a net importer however. Butter imports totaled 13.9 million pounds, up 44.8%, while cheese imports totaled 36.1 million pounds, up 9.8% from a year ago.

Tuesday’s Global Dairy Trade auction saw its weighted average slip 0.4%, following a 5.5% jump on August 20. Volume jumped to 84.5 million pounds, up from 77 million. The average metric ton price slipped to $3,833 U.S., down from $3,920.

The declines were led by lactose, down 8.9%, followed by whole milk powder, which was down 2.5% after gaining 7.2% on August 20. Skim milk powder was up 4.5%, after a 4.0% gain. Butter was off 0.9%, after rising 3.7%, while anhydrous milkfat was up 0.7% after jumping 4.8% last time.

Buttermilk powder was up 8.4% and GDT Cheddar was up 0.9%, after slipping 0.2% on August 20. Mozzarella was up 7.0%.

StoneX says the GDT 80% butterfat butter price equates to $2.9538 per pound U.S., down 1.4 cents from August 20, and compares to CME butter which closed Friday at $3.1750. GDT Cheddar, at $1.9615, was up 2.3 cents, and compares to Friday’s CME block Cheddar at $2.27. GDT skim milk powder averaged $1.2486 per pound, up from $1.1955, and whole milk powder averaged $1.5404 per pound, down from $1.5794. CME Grade A nonfat dry milk closed Friday at $1.3650 per pound.

Analyst Dustin Winston said, “North Asia market share, which includes China, stayed even with the last event and increased from last year. We are hearing anecdotal reports that physical distributers were caught short on SMP and WMP leading to this resurgence in demand. With domestic prices in China being so competitive, it is likely this is a momentary interest for the region. The Middle East was weak this event.”

In other trade news, the U.S. and Chile approved an agreement that further enhances the existing U.S.Chile Free Trade Agreement. A press release from the International Dairy Foods Association stated the agreement will formalize protections for U.S. cheese exports to Chile, which make up over half of all U.S. dairy exports to Chile and exceeded $55 million in 2023.

“Chile, which makes up well over half of U.S. cheese exports for the continent, is by far the largest U.S. cheese market in South America. Chile recently concluded negotiations for a free trade agreement with the European Union which sought protections for its geographical indications, including popular U.S. cheese exports to Chile such as parmesan, gruyere and feta,” the IDFA said. “At the urging of IDFA and fellow industry representatives, the Biden administration engaged in negotiations on an exchange of letters to attach to the existing U.S.-Chile free trade agreement that would further protect some U.S. cheeses from losing access once the EU’s GI (European Union Geographical Indications) commitments enter.”

The Consortium for Common Food Names, the National Milk Producers Federation, and the U.S. Dairy Export Council also commended the agreement saying that it safeguards the rights of U.S. cheese and meat exporters to use certain common names such as ‘parmesan’ and ‘prosciutto’ to market and sell their products in the Chilean market.

Falling corn, soybean, and hay prices nudged the U.S. milk feed price ratio a little higher, up for the fth time in the past six months. The USDA’s latest Ag Prices report has the July ratio at 2.50, up from 2.36 in June, and compares to 1.37 in July 2023. The index is based on the current milk price in relationship to feed prices for a ration consisting of 51% corn, 8% soybeans and 41% alfalfa hay. One pound of milk would purchase 2.50 pounds of dairy feed of that blend.

The all-milk price averaged $22.80 per cwt, with a 4.07% butterfat test, unchanged from June, which had a 4.10% test, but is $5.50 above July 2023, which had a 3.99% test.

The national corn price averaged $4.24 per bushel, down 24 cents from June, and was $1.98 below a year ago. Soybeans averaged $11.30 per bushel, down 50 cents from June, and $3.40 per bushel below a year ago. Alfalfa hay averaged $183 per ton, down $12 from June, and $63 per ton below a year ago.

Looking at the cow side of the ledger, the July average cull price for beef and dairy combined crept to $142 per cwt, up $4 from June, $31 above July 2023, and $70.40 above the 2011 base average.

Milk production margins moved to the highest level since November 2014 at $13.68 per cwt and 53 cents per cwt above June, said dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri.

“Income over feed costs in July was above the $8 per cwt level needed for steady to higher milk production for the 10th month in a row,” Brooks said. “Input prices were lower in July with all three commodities remaining in the top nine for July all-time. Feed costs were the ninth highest ever for the month of July and the 91st highest of all time.”

“Milk income over feed costs for 2024, using August 30 CME settling futures prices for Class III milk, corn, and soybeans, plus the Stoneheart forecast for alfalfa hay, are expected to be $14.08 per cwt, a gain of 53 cents per cwt versus last month’s estimate. Income over feed would be above the level needed to maintain or grow milk production, and up $6.08 per cwt from 2023’s level.”

Meanwhile, the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC. said, “Dairy margins continued to strengthen the second half of August, particularly in deferred marketing periods, as milk prices rallied sharply while feed costs were steady to slightly higher.”

The MW reported “Conrmation that at least three dairies in California have reported HPAI in their herds caused milk prices to surge as the state produced 18% of U.S. milk and cheese output last year with the eight counties of San Joaquin Valley housing 16% of the nation’s milking cow herd. A widespread outbreak in California is likely to have a far greater impact on milk and dairy product production, with Class IV Milk particularly affected as the state con-

tributed 32% of U.S. butter production and 42% of U.S. NDM output in 2023.”

A continued decline in year-over-year milk production and tight stocks of dairy product inventories are likewise providing support to the milk market, according to the MW, which detailed July output as well as the July cold storage data.

Dairy cow slaughter for the week ending August 24 totaled 51,500 head, down 3,000 from the previous week, but 7,700 or 13% below a year ago. Year to date, 1,792,200 dairy cows had been culled, down 301,400 or 14.4% from 2023.

The latest crop progress report showed 90% of the U.S. corn crop was at the dough stage, as of the week of Sept. 1, up from 84% from the previous week, 2% behind a year ago, and equaled the ve-year average. Sixty percent was dented, 2% behind a year ago, and 2% ahead of the average. Sixty-ve percent was rated good to excellent, unchanged from the previous week, but compares to 53% a year ago.

Ninety-four percent of the soybeans were setting pods, up from 89% the previous week, even with a year ago, but 1% ahead of the ve year average. Sixty-ve percent were rated good to excellent, down

2% from the previous week, but compares to 53% a year ago. In politics, the Wisconsin-based American Dairy Coalition says it has four areas of concern in the USDA’s proposed Federal Milk Market Order amendments in its nal decision. The ADC presented its views in an August 29 webinar and urged farmers to ask questions before the public comment period closes Sept. 13. The webinar is posted at https://www. youtube.com/watch?v=lZdBfgJLO-U

Consigned by John Boschma. Rex-PP- Red x Esteem DOB 6/01/23 Polled, A1A2, Proven Breeder, aAa 513 Lamar Weaver, Unity Macnut-PP x Black Onyx DOB 6/13/23 Polled, A1A2, Proven breeder, aAa 453, Lamar Weaver Redgard xRex-PP R&W 17-Month-old, Polled Proven and A2A2 Coming from Andy Hershberger, Cashton. R&W Polled Lineback 13 mo. Consigned by Tony Reis We have quite a number of cow sized Holsteins being consigned for today. Expect at least 15 to 20 of these. Special Items

100 Units of Semen. Bosside Redeye Axel-P *RC 840003213193586 DOB 12/26/21 Polled and A2A2, From John Boschma

Fort Atkinson Hay

Sept. 4, 23 loads

Sept.

$50-152.50/ton Mixed

$92.50-95/ton Straw

$67.50-125/ton Corn

$50/ton

By Danielle Nauman danielle.n@dairystar.com

COLBY, Wis. — Jim and Jenny Briggs yearned for the days when people knew all their neighbors and community members were connected, so last year they decided to resurrect an old family tradition of hosting neighbors and friends for what would become an annual community Labor Day gathering.

“The Labor Day get-together is something my grandparents did on our family’s home farm in Medway, Massachusetts, starting back in the 1960s,” Jim said. “I have fond memories of all the neighbors and farm help being there that day, of the bond we had with our community.”

The Briggses milk 100 cows, primarily Jerseys, between two farms, with a focus on rotational grazing. Jenny works off the farm as a nurse, yet remains active in the dayto-day farming operations.

“We moved here 10 years ago,” Jenny said. “We didn’t know anyone, but we feel like this is home, where we were meant to be.”

At their rst Labor Day get-together last year, the

Briggses hosted around 50 people on their farm. This year, they estimate about 70 people came to spend the afternoon.

“We wanted to carry on the family tradition as well as to show our appreciation for everyone who has welcomed us here and helped us out along the way,” Jim said. “We have some of the best friends and neighbors here that anyone could ask for.”

Hosting a gathering of that size might be intimidating for some, but the Briggses handle it with nesse.

“I like cooking, and I like people,” Jim said. “That makes it less like work and more something we just enjoy doing.”

Jim and Jenny rolled out the red carpet with smoked brisket, chicken wings and a variety of homemade pizzas.

Because of their shared appreciation for good food, cooking and unique recipes, the planning and preparation for the event came easily, Jenny said.

“I did the brisket a couple of days ago, so it could just go in the crock pots today,” Jim said. “I made the pizza dough yesterday and we got all the toppings prepared so that everything was ready to be put together today.”

Homemade pizza is a favorite and a specialty of Jim’s. He enjoys experimenting with new recipes and combinations

of toppings. In addition to the traditional standbys of pepperoni and meat-lovers pizzas, the Briggses served up pizzas made of garlic pesto, chicken Caesar, taco and both buffalo and barbecue chicken.

“Maybe it’s just my Northeast roots, but having good pizza is really a thing for me,” Jim said.

To authenticate their pizza even further, the Briggses recently purchased an outdoor pizza oven.

“I like pizza, I like making

pizza and I’ve been wanting one of these for a while now,” Jim said.

The outdoor oven gives Jim more freedom from the kitchen during the event, Jenny said.

“Last year he just made the pizzas in our stove,” Jenny said. “Since we got this, I think we’ve had different kinds of pizzas every day this week, testing out new recipes, working on making the menu for today. He’s a good cook, and he enjoys it.”

Regardless of the type of pizza he is making, Jim said he is sure to load them up with several different kinds of cheese — from the standards to unique specialty cheeses. His appreciation of pizza and people have Jim contemplating establishing himself in the pizza business in the future as either a retirement plan or perhaps a supplementation to the farm.

Turn to BRIGGS | Page 11

Briggs rolls out pizza dough while his wife, Jenny Briggs, prepares the toppings for homemade pizzas Sept. 2 at their farm near Colby, Wisconsin. A er moving to the area 10 years ago, the Briggses said hos ng the Labor Day gathering is a way they can repay the kindnesses that have been shown them.

The Briggses made homemade ice cream during the get-together to serve their guests, another throwback to the Labor Day gatherings Jim recalls on his grandparents’ Massachusetts dairy farm.

To add to the atmosphere the Briggses invited an area musician, Roger Jokela, to play throughout the afternoon.

“When we were looking for a farm in the area, we spent the summer living in a camper at a local campground,” Jenny said. “Roger played there maybe four or ve times that summer, and we got to know him and just kept in touch over the years.”

life, how we love our cows and what we do here, and how good dairy is for you.”

Sharing the story of the small dairy farm, especially with the pressures farms like the Briggses are facing in today’s economy is important, Jim said.

“We just love bringing people out here to the farm — especially our friends and my co-workers who don’t have that experience.”

JENNY BRIGGS

Part of the appeal of hosting a gathering of their friends and neighbors is to share their farm, the work they do and the life they love.

“We just love bringing people out here to the farm — especially our friends and my co-workers who don’t have that experience,” Jenny said. “That is how we can share our way of

“We can’t all be 2,000-cow dairies, but we’re all important to our communities and our local economies,” Jim said. “Even if we wanted to expand here, we couldn’t — we’re landlocked on all sides, pretty much. But there has to be a way to somehow make it work for all of us.”

With the sun shining, balmy temperatures and a breeze, surrounded by their neighbors and friends, the Briggses appreciated the beautiful day on their family dairy farm.

“It’s really a perfect day for it,” Jenny said. “We had chore help this morning, and now we’re surrounded by the friends and neighbors that have made us feel so home here — this is what truly makes home feel like home.”

DANIELLE NAUMAN/DAIRY STAR

Heifers graze in a pasture Sept. 7 at Marshland Dairy near Spencer, Wisconsin. Marshland Dairy was the site of the Spencer FFA Alumni and Supporters Annual Fall Harvest Breakfast.

By Danielle Nauman danielle.n@dairystar.com

SPENCER, Wis. — Josh and Sarah Moga work hard to produce a nutritious, quality product for consumers. Along with providing wholesome milk, they believe it is important to share the truthful story of dairy farming with those consumers.

The Mogas, along with their three children, Kolton, Kameron and Kasen, milk 90 registered Jerseys at Marshland Dairy near Spencer. The Mogas crop about 300 acres, growing feed for their herd.

With a focus on cow families and improving their herd through genetics, the Mogas pride themselves in breeding Jersey cows with good udders

who are functionally sound and able to thrive in a variety of management systems.

A refurbished Lely A3 robotic milking unit installed in July 2023 has helped the Mogas streamline their labor needs. Most of the herd is milked with robots, while a small number of cows continue to be milked twice daily in the farm’s existing double-6 parlor.

The installation of the robotic milker allowed Josh to take a full-time, off-farm job working for Seehafer Refrigeration Inc.

The Mogas served as hosts for the Spencer FFA Alumni and Supporters Annual Fall Harvest Breakfast held Sept. 8.

Turn to MOGAS | Page 13

“If we want people to consume our milk and dairy products made from the milk, we need to let them see what goes into producing it, and let them know it is safe and healthy,” Josh said. “That is why it is important to open up the farm to visitors and to take animals to fairs — to give them that experience.”

In addition to serving as breakfast hosts, the Mogas have hosted other tours and frequently exhibit at a variety of fairs to help share their story.

“I went to school in Spencer, and Mr. (Mark) Zimmerman was my FFA advisor,” Sarah said. “He had approached us about hosting the breakfast, but we wanted to wait until we had things set up the way we wanted them. Now seemed to be the right time to go ahead and have the breakfast.”

The breakfast featured rafe baskets to raise money for the Mark L. Zimmerman Memorial Scholarship Fund.

In the days before the breakfast, the Mogas found themselves busy preparing to host their friends and neighbors for a day on the farm.

“It’s a nice opportunity to try and get the little things done that always seem to get pushed aside on a regular basis,” Sarah said.

On the morning of Sept. 7, the Mogas headed to the barn for their normal chores — which included milking 16 cows in the parlor and checking on the 70 cows going through the robot. Once the cows were milked, the animals fed and the barns cleaned for the morning, the Mogas took the morning off to go to their son’s football game.

After the game, they returned to the farm, nishing the nal preparations for the breakfast.

Josh and Sarah worked on cleaning out and bedding heifer sheds and calf barns. Spencer High School student, Jakob Soback, volunteered on the farm, helping to sweep down the freestall barn, readying everything for visitors.

“With all the rain this year, it’s been a challenge keeping everything dry this summer,” Josh said. “I’m thankful for the nice weather we’ve been having lately, it’s made things a lot easier to get ready for having an event like the breakfast on the farm — a lot better now than it might have been back in June.”

The weather this year has presented the Mogas with many challenges.

Turn to MOGAS | Page 14

“Our rst crop was awful — the cows dropped almost 20 pounds when we started feeding that,” Josh said. “We knew we had to do something or it was going to be a really rough fall.”

The Mogas sourced sweet corn silage from another area of the state and have recently begun feeding that to their cows.

“The cows seem to love it, and we’re already back up 7 pounds of milk,” Josh said. “The biggest problem with it is that the robotic feed pusher sometimes gets hung up on a corn cob.”

Going into the harvest season, the Mogas have already contracted their ground corn, with plans to harvest everything they have grown this year as corn silage.

“It’ll be close, we’ll probably be some short, but it will be close,” Sarah said.

As a way to try and make their silage stretch, the Mogas are considering downsizing their herd again, and only using the robot for milking.

“We’re as low on heifer numbers as we’ve been in a long time,” Josh said. “We’ve sold a bunch as replacements this year, and we’ve been breeding a lot to beef. We’re getting pretty good money for our Jersey-beef cross calves considering we used to almost give away our Jersey bull calves.”

While the volatility of markets and increasing inputs require dairy farmers to continually pivot in their operations to maintain protability, the Mogas said they are up to the challenge.

“This is what we love to do, that’s why we’re doing it,” Sarah said. “And we want to share our story with our consumers and build their condence in what we produce.”

Sarah

Wisconsin. The Mogas have been raising fewer heifers in recent years, u lizing beef semen to breed the lower end of their herd.

There are only a few moments in life when we truly feel a sense of community, surrounded by the people who cheer us on in everything we do. I experienced this on the evening before opening day of the 2024 Minnesota State Fair. I was honored to stand amongst an exceptional group of young women who shared a love and passion for dairy. As I was crowned the 71st Princess Kay of the Milky Way, I was overcome with emotion at the proud and supportive looks from parents, mentors, role models and friends. This moment captured the epitome of the dairy community — a community built on support, teamwork, dedication and encouragement.

and express our passion for dairy. Following the interviews that morning, I stepped into the butter booth in the dairy building, where butter sculptor Gerry Kulzer began creating my likeness from 90 pounds of butter. Watching him in action was incredible, and I was amazed by his talent and the intricate process of creating those remarkable creations. After my time in the butter booth, I was blown away by the curiosity people had about dairy farming, dairy products, and, of course, butter sculpting.

By Rachel Visser 71st Princess Kay of the

I grew up in McLeod County just west of Hutchinson, where I truly found my place in the dairy community. Growing up, I loved hearing stories about my dad’s childhood on the farm and my grandparents’ dairy farm. But it was in third grade that I started my own dairy story. I began showing dairy cattle with a neighboring farm through the 4-H lease program, where I worked with show heifers and helped out on the farm. Over the last 11 years, I’ve become more involved in the daily chores at Stadview, a farm near Litcheld, and have had countless opportunities to share my passion for dairy with others. Looking back 11 years on the young girl who just wanted to show a calf, I’m incredibly thankful for the experiences that allowed me to grow, learn and build my own dairy story. I remember those rst few summers at the McLeod County Fair, where I met the county dairy princesses and Princess Kay nalists. My goal of one day becoming a nalist and Princess Kay grew from a combination of these interactions and my eagerness to fully immerse myself in the dairy community.

I am beyond excited to be fullling the dream I started as a young girl and honored to represent Minnesota’s dairy farmers throughout the next year. While the coronation was a whirlwind of emotions and a moment I’ll never forget, the 12 days that followed were equally memorable. I kicked off the Minnesota State Fair at 5:30 on the morning of opening day (Thursday, Aug. 22) outside the main gates of the fairgrounds. Finalists Grace and Miranda joined me as we met with TV and radio broadcasters to share the excitement of the coronation, promote the Flavor of the Fair

Among countless meaningful conversations, the additional nalists and I attended the milking demonstration, judged the amateur butter sculpting contest, visited with fairgoers in the Moo Booth and joined Fairborne and Fairchild in the parade around the fairgrounds each day. Some of my most unique and memorable experiences from the fair include taking photos inside the butter booth for the Star Tribune, celebrating the accomplishments of 4-H members at the dairy shows and Minnesota 4-H Dairy Showcase, visiting with Governor Tim Walz, and sitting for a painted portrait by artist Kickliy. In between the events around the fairground, I completed a total of 39 media appearances throughout the fair.

The 12 days spent at the Great Minnesota Get-Together were the perfect way to kick off this dream come true. I am proud to represent Minnesota’s dedicated dairy farmers over the next year and cannot wait to meet all of the farmers behind this incredible opportunity. The dairy community is like no other, and I am so excited to share this with those I get to meet.

Princess Kay of the Milky Way, Rachel Visser, serves as the Minnesota dairy community’s goodwill ambassador. Rachel grew up in Hutchinson, Minnesota working on a neighboring dairy farm. She attends the University of Minnesota double majoring in Agricultural Food and Business Management and Agricultural Communications and Marketing. Her favorite dairy food is cheese sticks. Her parents are Barry and Shannon Visser. Princess Kay is very active doing school visits and events representing dairy farmers, and sharing the importance of dairy farming and dairy foods at appearances across Minnesota.

was 80 degree and sunny last week and we have the same weather this week. All of eastern New York is chopping. I can only imagine how many tons of corn is harvested each day. We’ve done four-cuttings of alfalfa and finished around Labor Day. We will do a fifth cutting on some chosen acres. The soybeans are changing color fast. Everything in this area is lining up to be a little early. We are probably a week ahead. After corn is done, then it will be hay, haul manure and get the cover crop on as quick as we can.

Our third-crop alfalfa had a good yield like it has been all summer and we are about five days away from starting fourth crop. I got first crop off of the new seeding alfalfa that I sowed under the oats. That was put up around Sept. 5. The neighbor started to take out corn silage Sept. 9 and I am hoping to start either Sept. 13 or 14. The neighbors also told me their soybeans are doing pretty good; however, it was a rough year disease wise. I got my millet cut off and baled it Sept. 2. It averaged about a bale per acre.

We are probably 10 days to two weeks out from chopping corn. The corn is at every stage, some is dented and others have white cobs. We are putting knives in the chopper and getting it ready for silage. A neighbor did take out one bag of silage. We did third-crop hay Sept. 3-4. It was a nice crop of hay, just a little less than second crop. We chopped all 150 acres. We are making second-crop meadow hay. We probably can get 1/3 to 1/2 way into the meadows. Some are too wet, so we haven’t been in them.

We were able to get our fourth-crop alfalfa chopped around Aug. 21, however, it did get a little shower of rain on it. It seems to be coming back really well and it is just about ready to get cut again for fifth crop. I have seen some people starting to take out corn silage. We are not quite ready, but are planning to start making silage within the week of Sept. 15. The soybeans in the area are not starting to turn yellow. 0.1 inch of rain.

We are opening up a corn field for a neighbor today (Sept. 10) and we have a couple more to do later this week. I hear the corn is still running 72-74% moisture in the fields. We plan to start this weekend or early next week. There is no chopping happening right now in our area. Some of the corn is falling because the roots never went down. There is no strength in the stalk and there are some diseases. We have 50 acres of third-crop hay to bale and were able to get some meadow grass. Our soybeans have been pretty good, but the roots are short. I don’t know how long they will be standing. There are a lot of soybeans on the plants and they are starting to turn.

A lot of people started chopping already. We ran out of silage, so we green chopped some of it. We cut it and put it in a windrow to let it dry for a day. When we chopped it the moisture was around 63%. The soybeans are starting to change color. We are getting ready to do fourth-cutting alfalfa. We might hold off for a week so we are able to get silage done first. The pastures are looking nice, we are on our second rotation through with the cows. The forage mix we planted into the rye ground is starting to come up now.

We chopped 20 loads of corn silage last week but mine is still too wet. I am just about out of feed and have been blending the old with the new. It’s pushing 30 ton an acre real comfortably. It’s a healthy plant and I think the fungicide helped. We might do one more bag this week but go all out next week. We are done with fourth-crop hay. We were able to round bale 60 acres and the rest we chopped. The soybeans are starting to turn. I have not seen any white mold; I was concerned. I think some guys will take some soybeans out in the next 7-10 days. We cleaned some piles and hauled that on the corn silage fields.

Over the last two weeks, we’ve had 0.4 of rain. We’ve had a really nice stretch of weather. We got fourth-crop alfalfa finished and the beans are starting to turn. We’re starting to see some corn silage get chopped. The moisture is right around that 70%, but haven’t heard anything on yields. Beans are starting lose their leaves and everything is progressing really nicely. We have had a couple reports of anthracnose setting in on the corn and that could hurt some test weights. We’re 250-300 heat units behind, so we need this gorgeous weather to continue.

We began chopping corn silage Sept. 9, and so far, yields are good. It’s been dry, which is OK for corn silage. The corn is really drying down. Beans are changing fast, and once corn silage is wrapped up, we will start eyeing up some beans. Our fourthcrop alfalfa was awesome. Yields were very good. We did cut new seeding for a third time this year. We usually only do it twice, but it was really tall, so we took it again. We seeded our cover crops Sept. 6, and we will plant wheat the week of the Sept. 16. Pretty much everyone in the area is doing corn silage.

We have been doing a lot of baling hay. In the past few weeks, we have done about 400 big square bales. There has been a lot of hay out there this year. We have also been working on fourth-crop alfalfa and are trying to get that done in the next few days. There are a lot of neighbors making dry hay. One neighbor has started chopping corn silage. In the next two to three weeks, we plan to start corn silage. The corn is starting to fire at the bottom a little bit. Soybeans are starting to turn, some fields more than others.

We had 8 inches of rain in two days last week. It has been warm and windy enough that we are drying out well from that. We’re about a week off of corn silage yet, but it looks like it should be a very good crop. I’m guessing 30 tons per acre, but 35 tons on the irrigated ground. That is much needed after the last couple of years. We are chopping fourth-crop hay today (Sept. 11), that looks good. We are getting close to having two years worth of alfalfa on hand. The beans are starting to turn now, too.

We have had 0.5 inches of rain in the last two weeks and we’re drying out. We have enough feed and it’s time for the corn to start drying down. We are finishing up the end of our fourth crop. The yields are okay, not great, but we chopped it at 27%. We’re about 10 days off of corn silage. We checked some yesterday (Sept. 10) and it was still pretty wet. The yields should be great, the cobs are huge. The beans are doing well, too.

The crops are turning so fast you cannot keep up. We started chopping corn Aug. 29. We are mixing it with new seeding alfalfa, which had oats and peas on for a cover crop. We filled a 40-foot bag for heifers and started filling one of our Harvestore silos. It’s been drying down rapidly. We’re filling a second silo already. Many people in the area are chopping corn. We cut our fourth-crop hay Sept. 9. This is laying on the ground to blend with corn for the silo to feed in the winter. I started green feeding fourth crop the week of Labor Day. It looks very nice. Our soybeans are turning fast.

SHERRY NEWELL/DAIRY STAR

Natalie Paino smiles July 16 next to her new processing facility space located on her family’s farm near Plaineld, Iowa. Hightail was one of ve dairies to receive a Choose Iowa Dairy Innova on Grant for value-added processing.

By Sherry Newell Staff writer

PLAINFIELD, Iowa — What looks like an enclosed trailer sitting next to the farmhouse at White Gold Dairy, does not provide housing for workers or a family member. Instead, it is a shipping container intended to be the home of milk processing for Natalie Paino’s value-added business.

Paino is making her living through her home-delivery ice cream business, Hightail, and working on the farm of her parents, Terry and Kelly Eick. Recently, she signed a deal to provide her ice cream to a bookstore that is opening a coffee shop in nearby Cedar Falls.

The 24-year-old started Hightail while in college, using commercial ice cream mix to create and package ice cream in a kitchen at her grandmother’s assisted living facility. As a recipient of one of ve Choose Iowa Dairy Innovation Grants awarded last spring for onfarm processing, she is in the rst phase of moving the business back to the farm.

“It’s very scary — a big step,” Paino said. “It’s always been my dream to do this. Ice cream was a stepping stone … there was minimal risk.”

She chose the shipping container model for processing after attending a cheese course at the University of Wisconsin-Madison. She also took an ice cream course at Pennsylvania State University. A 15-gallon pasteurizer, a lab, a drying rack, a refrigerator and storage are housed in the container, items for which she used her Iowa grant of nearly $19,500.

The program is a cost-share to help dairies with less than 50 employees and

matches up to $100,000 per project.

Before being awarded the Iowa grant, Paino was the recipient of $50,000 from the Dairy Business Innovation Alliance, a partnership between the Center for Dairy Research at UW-Madison and the Wisconsin Cheese Makers Association.

It will not be the cows 100 yards away that will supply her plant. Instead, Paino will have a second shipping container in which she plans to store milk from two cows. It will have a 60-gallon bulk tank. That container is now on order and due to arrive this fall.

“I will have a totally separate facility (from the family),” she said. “It’s a way to navigate the state regulatory issues.”

In addition, the separate facility eliminates any issues with the farm’s current processor, Wapsie Valley Creamery Inc., and solves the problem of knowing how much milk she can process.

“There is no way I would be able to process milk from 53 cows,” she said. “I’d rather do our (unique) thing than create a giant creamery.”

With the family’s herd having bred for A2/A2 milk over recent years, Paino expects to use that additional marketing niche going forward. She also hopes to build on the market she currently enjoys with her ice cream, where she has a customer base of about 300,000 people. She is counting on the nostalgia of home delivery to continue growing the market.

Her rst batch of curds was made in August and consumed at home. She hopes to ramp up cheesemaking next. Fluid milk processing will take more planning.

Paino said her steps toward completion have been slow, as she adjusts to being a new mom to her daughter, Stella, and spending time with her husband, Marquise. But, she is still enthusiastic and said she feels fortunate.

“A lot of dairy farmers would like to do this,” Paino said. “The dairy business is evolving.”

By Emily Breth emily.b@star-pub.com

Dr. Andrea Mongini shared tips to keep goats healthy, focusing on pregnancy toxemia, at a webinar hosted by Iowa State University Extension and Outreach.

“Pregnancy toxemia occurs in the last month of gestation when the energy intake is less than energy demand,” Mongini said. “There are two types — fat does or ewes with ketosis (and) thin does or ewes with severe negative energy balance.”

Providing little to no grain for goats in their close-up period will cause pregnancy toxemia, Mongini said. Goats need extra protein in their diet. The most severe cases of pregnancy toxemia take place without it.

Taking a closer look into each of the two types of illness can help producers better understand what is happening with their herd Mongini said. One of the rst things to note in fat does with ketosis is that it is associated with hepatic lipidosis during the last month of gestation. However, this is not the only cause of pregnancy toxemia.

To identify these does, producers have to pay attention to the amount of fat behind a doe’s elbow. However, there are more ways to diagnose these does. The

biggest indicators are whether they have trouble getting up or have a decreased appetite, said Mongini.

They can also be tested with a urine dipstick or a beta-hydroxy-butyric-acid meter. Sometimes it can be smelled.

In thin does, many factors can trigger the disease and help detect if the does is suffering from starvation pregnancy toxemia. This includes large litter size, geriatric does, parasites, poor mobility and poor nutrition.

Once a doe has pregnancy toxemia, the next step is to determine the stage of the illness. There are three different stages. Stage one is classied with swollen distal extremities, walking stify or pain in their lower legs, along with having a poor appetite.

The severity of the illness in this stage depends on stage of lactation. If the doe is 1-2 weeks from parturition it is classied as a mild case and the doe can survive to kidding. If the doe is 3-4 weeks to parturition it is classied as a severe case.

“This is the period when the kids are having their growth spurt,” Mongini said.

Stage two of pregnancy toxemia is seen through early neurologic signs such as weakness, visual decits, head pressing and tremors. Other signs include not being able to stand, blindness or star gazing and anorexia.

Stage three includes severe polio or neuro signs, periods of somnolence and uid build-up on the lungs with labored breathing. At this stage the kids or lambs

will not survive.

Basic treatment for pregnancy toxemia can be simple or complicated. If the doe is anorexic, she will need calcium borogluconate. It is recommended to give 75-90 milliliters either all at once just under the skin or the dose can be split and given twice a day.

They should also receive unixin through an IV and 70-90 mL of propylene glycol.

“You have to be very careful to not overuse propylene glycol because it is an alcohol and it will kill the rumen microbes,” Mongini said. “Too much of a good thing can deningly occur with propylene glycol.”

If the doe is down, she should receive uids and unixin along with an IV with lactated ringer’s solution, dextrose and potassium chloride.

Further treatment depends on the stage the doe is in. Mongini said during stage one, producers will want to complete a physical exam to determine what caused the illness and treat that rst.

Producers will also want to change the diet the doe is receiving Mongini said. The grain should be increased to 1.5-2 pounds per day.

“The goal is to get them eating quickly,” Mongini said. “If we can catch them at this phase, we can reverse them and they will be ne.”

Once a doe reaches stage two, producers must continue stage one treatment and ensure the doe is getting hydrated.

By stage three, the doe will need to

receive 2 cubic centimeters of prostaglandin F2alpha and 40 ccs of dexamethasone, both delivered as an intramuscular shot. This should induce labor and birth should occur within 36 hours.

A cesarean section should be performed if the doe becomes critical, or the kids are not coming within 36 hours. At this stage it is very unlikely the kids will survive Mongini said, but there is a chance for the doe to pull through.

After talking about treatment, Mongini moved on to prevention management.

“We should be trimming hooves three times a year on goat dairies,” Mongini said.

Another method Mongini mentioned was having multiple dry pens: one for average healthy does and another one for weak and thin does or any doe that catches a producer’s eye.

“If she stands out for any reason she needs to go into a separate pen,” Mongini said.

Having multiple pens also gives the does more room to eat, said Mongini.

Three other areas of importance are parasite control, body condition monitoring and nutrition management.

“In a (total mixed ration) setting it is really dangerous because the grain is being diluted out,” Mongini said. “Often we will try to nd a way to top dress grain on top of the TMR for the last few weeks of gestation, especially if pregnancy toxemia has been an issue.”

I can see the signs of fall all around me these days. Early morning school bus routes. Drooping ears of corn. The sound of sandhill cranes congregating for their southward trip. It also signals

a menu lled with meals on wheels to be served in the harvest elds. Here are some harvest meals to keep everyone lled up and fueled up for a safe harvest season.

Homemade Beef Rice-A-Roni by Miranda Green

1 cup regular long-grain rice (not instant)

1/2 cup broken thin spaghetti

2 tablespoons butter

2 3/4 cups beef broth (may need more for rice to cook)

2 teaspoons beef bouillon

1 teaspoon onion powdered

4 1/2 teaspoons Worcestershire sauce

1 1/2 teaspoon soy sauce

1/2 teaspoon garlic powder

1/2 teaspoon black pepper

3 tablespoons chopped carrots

In a large skillet, melt 2 tablespoons butter. Add broken pasta, rice and carrots. Cook until lightly browned and carrots are tender. Add remaining ingredients. Bring to a boil. Reduce heat to low and cover. Cook 15–20 minutes, stirring occasionally, until water is absorbed. Yield: 4 servings. (Won’t use boxed stuff again.)

Country Sweet Potatoes by Anne Orish from the book “Undo It”

1 1/4 pounds sweet potatoes

1 cups thinly sliced red onion

1 cup low sodium vegetable broth, plus more if needed

2 teaspoons chopped fresh thyme or 1 teaspoon dried, divided

1 1/4 teaspoons chili powder, divided 1/2 teaspoon dried oregano 1/2 teaspoon garlic powder

1/4 teaspoon ne sea salt

1/8 teaspoon fresh ground pepper

8 lime wedges, for garnish (optional)

Peel sweet potatoes and chop into 1/2-inch chunks (about 4 1/2 cups). In 12-inch heavy-bottomed skillet over high heat, combine sweet potatoes, onions, vegetable broth, 1 teaspoon thyme (or 1/2 teaspoon dried), 3/4 teaspoon chili powder, oregano, garlic powder, salt and pepper. Bring to a boil. Reduce heat to medium-high. Cook, stirring frequently, until potatoes are tender and liquid is mostly evaporated, about 10 minutes. If liquid evaporates before potatoes are tender, add additional vegetable broth as needed.

Stir in remaining thyme, and chili powder. Taste for seasoning. Add more salt and/or pepper as needed. Serve warm with lime wedges if desired.

Apple Pie Bars

2 1/2 cups our

1 cup shortening

2 tablespoons sugar

1 teaspoon salt

1 egg yolk

2/3 cup milk

4-5 apples or 1 can pie lling

1/2 cup our

1 cup sugar

1 teaspoon cinnamon

3-4 teaspoons butter

Mix our, shortening, sugar and salt until crumbly. Mix egg yolk and milk and pour over our mixture. Mix until it forms a soft ball. Roll half of this in a 12-by-10 pan. You can patch this dough very easily.

Combine apples, ½ cup our and 1 cup sugar if not using pie lling. Fill pan with apple mixture. Dot with butter. Roll out remaining crust and place on top of apple mixture. Press sides well to seal. Bake at 375 degrees for 35 minutes. Drizzle with powdered sugar frosting.

Rosemary’s Coffee Shop Scones

3 cups our

1/2 cup sugar

1 tablespoon baking powder

1 teaspoon salt

1 stick cold butter

1 cup cream

In a food processor, add the dry ingredients and mix on low for a few seconds to blend. Add any additional dry avorings and mix again. Measure out heavy cream and add a dash of vanilla. Cut butter into small chunks and add to food processor. Immediately start mixing on low and add cream slowly. Mix until crumbs are pea- to marble-sized. Dump dough on surface. Fold in any fruit (dried blueberries, craisins, apricots, etc.). Shape into a 6-inch disc. Cut into eighths. Bake at 400 degrees for about 20 minutes. (I shape the dough on

a piece of parchment paper lining my baking sheet. Once cut, I will separate the pieces to give them space to expand and bake.)

Apple Spice Mufns by Anne Orish from the book “Undo It”

2 tablespoons ax seed meal

1 1/2 cups whole wheat our or glutenfree our

1/2 cup old-fashioned rolled oats

2 teaspoon cinnamon or pumpkin pie

spice

3/4 teaspoon baking powder

3/4 teaspoon baking soda

3/4 teaspoon ne sea salt

1/2 teaspoon powdered stevia

1 1/4 cups applesauce

1/2 cup apricot fruit spread

1 cup grated apple (about 1 apple)

2 teaspoons vanilla extract

1/2 cup raisins

In a small bowl, mix axseed meal with 1/4 cup water. Set aside for 10-15 minutes. The ax will absorb the water and create a thick gel.

Preheat oven to 350 degrees. Line a nonstick mufn pan with paper liners. In a medium bowl, whisk together all dry ingredients. In a large bowl, stir together apple sauce, apricot spread, grated apple, ax mixture and vanilla. Stir in half the dry ingredients then add the remaining half and stir gently until combined. Add raisins and stir lightly to mix. Spoon 1/3 cup batter into each mufn cup. Bake about 25 minutes. Don’t overbake. Remove pan from oven and let cool for a few minutes before removing mufns from pan.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

1 pound rhubarb cut into ¼ inch pieces (3-4 cups)

1 cup white sugar

1 3-ounce package of strawberry gelatin

Preheat oven to 350 degrees. Grease 9- by 13-inch baking pan. Spread rhubarb evenly on the bottom of the pan. Sprinkle sugar over rhubarb, followed by gelatin and then the cake mix. Pour water and melted butter over the top. Do not stir. Bake for 45 minutes or until rhubarb is tender.

Cake:

1/2 cup butter

2 cups zucchini

1/2 cup oil

1 1/3 cups sugar

2 eggs

1 teaspoon vanilla

1/2 cup sour cream

2 1/2 cups our

4 tablespoons cocoa powder

1 teaspoon baking soda

1/2 teaspoon baking powder

1/2 teaspoon salt

1/2 teaspoon cinnamon

Topping: 1/2 bag chocolate chips 1/4 cup brown

Preheat oven to 350 degrees. Grease a 9- by 13-inch cake pan and set aside. Mix all cake ingredients together. Pour into cake pan and bake for 10 minutes. While that is baking, mix chocolate chips and brown sugar together for the topping. After cake has baked for 10 minutes sprinkle the topping evenly on top and bake for an additional 15-20 minutes.

1 pie crust

10 ounces frozen raspberries or strawberries

1 3-ounce package raspberry or strawberry gelatin 3/4 cup boiling water

package yellow cake mix 1 cup water 1/4 cup melted butter 2 teaspoons lemon juice 2/3 cup fruit juice water Dash of salt

egg whites 1/4 cup sugar

Bake pie crust according to package directions. Thaw and drain the raspberries or strawberries, saving the fruit juices for later. Combine the gelatin and boiling water, stir until dissolved. Add lemon juice and fruit juice water to the gelatin, stir gently to combine. Chill until partially set. Remove from refrigerator and beat until soft peaks form. Then fold in drained berries. In a separate bowl combine dash of salt and egg whites. Beat until soft peaks form, slowly adding in 1/4 cup sugar. Continue beating until stiff peaks form. Fold into berry mixture. Pour into cooled pie crust and chill until ready to serve.

Secure your tires and Secure Covers with us too!

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation