WANT TO WIN $100 CASH?

See page 12 of third section for details!

See page 12 of third section for details!

September 23, 2023

MADISON, Wis. — The third week of September is National Farm Safety and Health Week. While preventing farm accidents is the focus of this annual promotion, it is also important to remember to prevent everyday wear and tear on joints and muscles. For people farming with a disability or health limitation, this becomes an even larger concern.

“For people living with disabilities, it’s really important to do the little things to help prevent wear and tear on your body,” said Andrea Klahn, outreach specialist at AgrAbility of Wisconsin. “Maybe it’s a better

seat on your tractor when you’re going to be in there for eight hours a day during harvest. We see a lot of farmers who have bad backs, hips and knees. A comfortable place for you to sit is very important if you have a bad back.”

AgrAbility of Wisconsin promotes success in agriculture for farmers and their families living with a farm injury, disability or health limitation, and is a partnership between the University of Wisconsin Extension and Easterseals Wisconsin. As a national program, AgrAbility has 22 projects funded by the U.S. Department of Agriculture.

“We come on your farm with a fresh set of eyes and make recommendations tailored to your operation, limitations and goals,” Klahn said. “When we

see clients who have sustained an on-farm accident and lost mobility or lost a limb, we can recommend assistive technology and equipment to help them continue to farm safely.”

Klahn said she has seen different incidents and also medical conditions like Parkinson’s disease, multiple sclerosis, hearing loss and vision loss. An AgrAbility rural rehabilitation specialist staffed by the Easterseals FARM Team works with each person to determine what equipment or tools would be of greatest benet to them. For example, one client with diabetes is switching his equipment from foot controls to hand controls as a safety measure because his reexes are getting slower.

One of the easiest things a

person can do to make a tractor safer ergonomically, Klahn said, is to add a step and handrail kit. These steps are lower and positioned at an angle while also featuring a handrail.

“That step is really high on a John Deere 4020, for example, and what goes up must come down,” Klahn said. “It’s hard on your knees. You should have three points of contact when getting in and out of a piece of equipment so that you are not jumping off and hurting your joints. It doesn’t feel that bad when you’re 22, but it’s going to hurt more when you’re 55.”

To avoid straining their neck, shoulders and back while driving a tractor, farmers may invest in a camera system or a better set of mirrors. This will

give drivers visibility of what is behind them without having to continually turn around.

Automatic hitches make work faster and easier, Klahn said, eliminating the need to get in and out of a tractor. Rollover gates have the same effect, removing the need to get in and out of a vehicle. Eliminating repetitive motions helps improve body mechanics.

Hearing protection is another area of prevention.

“Put a set of earplugs in all of your cab-less tractors,” Klahn said. “It’s so much cheaper to buy ear protection than to have hearing aids someday.”

Knee pads and anti-vibration gloves are also helpful items. These specialty gloves provide an extra layer of protection to reduce impact for tasks like roto tilling and push mowing or when using a chainsaw.

FORT ATKINSON, Wis. — As the leaves begin to change and the air becomes crisp, cows from all corners of North America will make their way toward the dairy industry’s World Dairy Expo in Madison.

Not every cow being loaded up for the trip is traveling with plans of circling the covered shavings. Two special cows are making the trip for a different reason.

Wooden carvings of two WDE supreme champions — Harvue Roy Frosty and Musqie Iatola Martha — have been donated to sell in an auction

to benet the National Dairy Shrine scholarship fund during the National Dairy Shrine annual awards banquet Oct. 2 at the Alliant Energy Center Exhibition Hall in Madison.

The pair of hand-carved wooden replicas of the two cows were donated by Scott Hussey, a dairy farmer, artist and former dairy cattle tter from Limington, Maine.

“Dr. Matt Iager contacted me last year about the possibility of doing two cows for a scholarship auction,” Hussey said. “Eventually, I decided to make supreme champions Martha and Frosty.”

In addition to the two past champions, a third lot will be sold allowing the successful bidder to work directly with

Hussey to create a cow of their choosing.

The process to creating the wooden replicas is pure enjoyment for Hussey.

“I love making these cows, bringing them to life,” Hussey said. “I worked and traveled as a tter for many years, so recreating some of these cows is something I really like doing.”

Hussey said it takes him two to three weeks to take one of his creations from a block of wood to the painted and shined nished product. He has made nearly 50 of the model cows in the past several years.

“I start out by studying the cow,” Hussey said. “My wife Angela and I gather as many pictures as we can, from as many angles as we can. The older the cow, the harder that part is.”

“All dairy, all the time”™

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Stacey Smart - Assistant Editor

262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

The government’s scal year ends at the end of the month, and Congress needs to pass a full-year spending measure or a continuing resolution to continue the current appropriations bill. If not, the country faces a government shutdown. The fate of the farm bill is also up in the air. “Some of the programs in the 2018 farm bill begin to expire at the end of September,” said Chris Galen, vice president of member services and governance, National Milk Producers Federation. “Most of them, including a lot of the dairy safety net, expire at the end of the calendar year.” Without action, Galen said, key farm programs will expire in the months ahead.

FMMO reform in sight

The hearing over the Federal Milk Marketing Orders may last well into October. This is the rst comprehensive hearing about federal orders in over 20 years. National Milk Producers Federation President and CEO Jim Mulhern said progress is being made, and the modernization of the milk pricing system is in sight.

USDA announces Milk Loss Program

Following widespread weather-related disasters, supply chain issues and volatile markets, the U.S. Department of Agriculture has announced Milk Loss Program assistance for eligible dairy farms. MLP assistance helps offset losses for the dairy farmers who dumped milk due to weather-impacted delivery or storage in 2020, 2021 and 2022.

Labeling change needed

Wisconsin Sen. Tammy Baldwin has renewed her plea for the Food and Drug Administration to stop letting nondairy products use product names like milk, yogurt and cheese. “We’ve got to insist that the Food and Drug Ad-

ministration do its job and enforce the standards of identity related to dairy products,” Baldwin said.

FCA offers mixed view of farm economy

In its quarterly economic report, the Farm Credit Administration said 2023 net farm income will be down sharply from last year. Falling commodity prices, high input costs and low government payments are all part of the story. However, nancial ratios remain positive. Farmland values remain strong, but the report cites a possible peak in land prices.

FAO: August food prices decline

World food prices fell to a two-year low in August. The Food and Agriculture Organization Price Index tracks most globally traded food commodities. The index cited a drop in prices for dairy products, vegetable oils, meat and cereals.

H-2A rule change proposed

New H-2A rules have been proposed by the Labor Department that “would strengthen protections for farm workers.” The proposal would make it easier for labor unions to contact and work with guest agriculture workers. It also

“After installing our first SCR system 10 years ago we noticed better herd health, drop in death loss, and increased pregnancy rate. I like being able to virtually monitor cow health and activity without having to be physically on the farm. We most recently upgraded our SCR collars a few summers ago and love how advanced and precise the technology is.” -

Con nued from AG INSIDER | Page 2 protects H-2A workers from retaliation if they meet with labor groups. Safety measures and language dealing with the recruitment of H-2A workers are also part of the proposal.

Agriculture Secretary Tom Vilsack traveled to a farm outside of Milwaukee, Wisconsin, to celebrate the oneyear anniversary of the Partnerships for Climate-Smart Commodities program. More than 140 projects got $3 billion in funding. The money had to be used in production agriculture or forestry and address climate change. Vilsack met with recipients of the climate-smart dollars, including Edge Dairy Farmer Cooperative, Organic Valley and the Nature Conservancy.

The National Association of State Departments of Agriculture has adopted policy action items, including a x for gaps in federal disaster programs. At the NASDA annual meeting in Wyoming, the state agricultural leaders endorsed clear labeling for cell-based meat products and policies to adopt a farmer’s right to farm.

Bismarck-based Prairie Farms shut down its milk bottling facility and has transitioned to a distribution-only facility. The Milk Producers Association of North Dakota released a statement saying, “The announcement came as a complete surprise and shocked everybody in the dairy industry, including dairy producers and plant employees affected by this decision.” North Dakota dairy farmers are working together to support their peers who lost their milk market and are in danger of losing their livelihoods.

Rob-See-Co has announced the establishment of its new forage division. The new division is being led by Scott Harris, who has previous experience with Masters Choice, a Rob-See-Co company. Amy Hoy, with 30 years of forage experience, will lead the silage portfolio.

DLF acquires Corteva alfalfa program

Denmark-based global seed company DLF has announced its acquisition of the Corteva Agriscience alfalfa breeding

program. This deal includes Corteva’s alfalfa germplasm and breeding program, the Alforex Seeds brand name, trademarks and commercial alfalfa varieties.

NMPF announces staff reorganization

Incoming National Milk Producers Federation President/CEO Gregg Doud began his work this past week as the organization’s chief operating ofcer. Doud will be in the COO role until current NMPF President/CEO Mulhern retires in January. The dairy group has also undertaken a staff reorganization. Three executive vice president positions were made. Paul Bleiberg will oversee government relations. Shawna Morris is in charge of trade policy and global affairs while Alan Bjerga leads communications and industry relations. Promotions also include David West to chief administrative ofcer, Stephen Cain to senior director of economic research and analysis, Beverly Hampton Phifer to senior director of FARM Animal Care, and Miquela Hanselman to regulatory affairs director. Staff receiving title changes with new responsibilities are Galen as senior vice president of member services and governance and Claudia Larson as senior director of government relations and head of nutrition policy.

Promotions announced at Edge Edge Dairy Farmer Cooperative has named Karen Gefvert as its director of government affairs and Travis Senn as its director of public affairs. Getvert joined Edge in 2022 in a public affairs role and previously spent time with Wisconsin Farm Bureau. Most recently, Senn was Edge’s director of communications. Senn previously worked for a dairy co-op in Florida in marketing and communications.

Trivia challenge

A turophile is a cheese connoisseur. That answers our last trivia question. For this week’s trivia, what are the four Hs referenced in the 4-H pledge? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

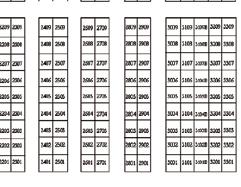

2WD, 3800 hrs. $72,000

CIH 8940, FWA, 4800 hrs. .........................$89,000

CIH 8920, 2WD, 7,900 hrs. ........................$59,000

CIH 8920, 2WD, 3,500 hrs. ........................$79,000

CIH 8910, 2WD, 4,100 hrs .........................$72,000

CIH 8920, FWA, 2600 hrs ........................$110,000

CIH 7240, 2,500 hours .............................$110,000

CIH 7120, FWA, 2,800 hrs. ........................$85,000

CIH MX120, 2WD, 3,800 hrs......................$72,000

CIH MX110, FWA, 1600 hrs. ......................$65,000

IH 1466 restored, new 20.4x38 Firestones$38,000

IH 1456, cab ..............................................$22,000

IH 966, w/cab .............................................$11,000

IH 806 ....................................................$11,000

JD 2755, 5,600 hrs. ...............................$16,000

JD 4020, new clutch ..............................$11,000

TILLAGE

CIH 527B................................................$19,500

CIH Tigermate II, 26’ ..............................$28,000

CIH Tigermate II, 26’ w/rolling basket ....$32,000

CIH Tigermate II 26’, w/28’ pull crumbler $31,000

CIH Tigermate 200, 30’ ..........................$44,000

CIH Tigermate 200, 28’ w/rolling basket$40,000

CIH Tigermate 200, 32’, w/4 bar drag ....$33,000

CIH Tigermate 200 28’ w/basket ............$37,000

CIH 5700 chisel plow, 23’ ......................$16,000

CIH 3950 25’ disc ..................................$23,000

CIH 4800, 28’ ...........................................$6,500

CIH RMX 340 25’ disc w/mulcher ..........$42,000

CIH RMX 340 28’ w/mulcher .................$44,000

CIH 25’ 3900 disc ..................................$15,000

CIH 1830 8RW cultivator .........................$4,250

DMI 530 ripper w/leads..........................$14,000

DMI 530B w/lead ...................................$16,500

JD 2700 5-shank ripper .........................$17,000

JD 714 11 shank chisel plow .................$14,000

Wilrich 5800 15’ chisel ..........................$22,000

Wilrich 657 DCR 15-shank disc chisel ...$32,000

CIH 7120 FWA, 2800 hrs. - $85,000

Sitrex QR12, QR10, QRS rakes ....................New

CIH 2388 ................................................$50,000

CIH 2206, 6R corn head .........................$15,000

CIH 1020 30’ bean head w/air reel .........$15,000

Kuhn 10-wheel rake w/center kicker wheels, like new ..................................................$8,500

Many sizes of rakes available

All Sizes of Sitrex Rakes.........................On Hand

GRAVITY BOXES & GRAIN CARTS

Many Sizes of Gravity Boxes ..................on Hand

(2) Demco 365, red & white.....................$4,200

(2) Demco 525 gravity box, R&W ............$8,000

(2) Brent 644 boxes, one w/roll tarp & fenders ............$14,500 one without $13,500 Brent 657 gravity box, green & black, fenders ................................................$23,000

(2) Brent 644 box, green ............................$16,500

Brent 644 w/roll tarp ..................................$19,000

(2) Brent 557 gravity boxes, w/roll tarp, red ......................................................$17,500

J&M 385, red ...............................................$6,500

J&M 540 box, red ......................................$13,500

(4) J&M Green 385 gravity boxes ............$5,000

Parker 4800 box, green ................................$8,500

Unverferth 7250 grain cart, red ..................$29,500

MISCELLANEOUS

New Red Devil & Agro Trend Snowblowers

Mandako Land Roller, 42’ ......................$32,000

Greenwald, MN • 320-987-3177

WWW.GREENWALDFARMCENTER.COM

Con nued from SHRINE SCHOLARSHIP | Page 1

Martha, Frosty and the cow of choice are not the only donations Hussey has made to support various youth scholarship funds. He sent replicas of Expo Holsteins Butz-Butler Gold Barbara and supreme champion Erbacres Snapple Shakira to the 2022 National Holstein Women’s Scholarship Organization to benet their scholarship fund. In 2023, a replica of S-S-I Doc Have Not 8784 was donated by Hussey to the NHWSO auction as well.

Earlier this year, Hussey donated a replica of the 1993 national champion Jersey, Pensmith TJ Mindy, to be auctioned off in memory of one of her owners, Michael Heath, to help establish a memorial fund in his honor.

“Donating these cows helps gain some exposure for what we’re doing by making them,” Hussey said. “It’s been the best form of advertising for us. But more importantly, these cows are raising money for good causes. These scholarship programs are important to the young people in our industry, and it is good to give back and help the future generations.”

NDS was established in the late 1940s for the purpose of preserving the history of the dairy industry while creating collaboration for the development of the industry.

Early in the history of the NDS, the Killdee Scholarship Fund in honor of H. H. Killdee, the dean of agriculture at Iowa State University, was established.

The original scholarship was given to a graduate student in the amount of $500. That scholarship continues today and is awarded to students who excel in the National Intercollegiate Dairy Cattle Judging Contest or the North American Intercollegiate Dairy Challenge.

The size and scope of the NDS scholarship program has grown. This year, 41 youth will receive $48,500 in scholarship awards at the annual banquet.

NDS Executive Director Mike Opperman said that each year at their banquet the NDS board holds an auction of dairy memorabilia to benet the scholarship fund. The scholarships are presented during the same banquet.

“We appreciate the support we get from people throughout the dairy industry,” Opperman said. “We are very grateful to Scott for giving of his time and talent, donating these beautiful cows.”

According to Opperman, it is that support from people involved in the industry that allows the NDS to continue increasing the investment they can make in the youth.

“Part of our mission is to inspire the youth who are the future of the industry,” Opperman said. “Through our scholarship fund, we are investing in creating the future leaders of our industry.”

Hundreds of dairy industry youth have beneted from the generosity of the those involved in the work of the NDS.

Ashley Hagenow, a 2023 graduate of the University of Minnesota-Twin Cities, is one of those students. During her schooling, Hagenow was the recipient of six NDS scholarships. In May, Hagenow was selected to serve as Wisconsin’s 76th Alice in Dairyland.

“I have been so blessed by the Dairy Shrine to have received scholarships throughout my schooling,” Hagenow said. “The nancial impact of Dairy Shrine scholarships to so many youth throughout the industry is immense.”

Financial support is not the only way Hagenow said she has beneted from the work of the NDS.

“Receiving the rst scholarship, even before I started college, really inspired condence in me as a young person in the dairy industry,” Hagenow said. “It encouraged me to keep going after the goals I had going into college, to stay involved and to keep pursuing new opportunities within the industry, and to continue trying to impact the dairy industry.”

Hagenow’s experiences as a scholarship recipient provided her with networking experiences that have impacted the development of her career path.

“As a scholarship recipient, the opportunity to attend the NDS banquet each year at World Dairy Expo and have the chance to connect with other scholarship recipients, dairy industry professionals and mentors is truly an incredible opportunity,” Hagenow said. “Now Dairy Shrine has other initiatives that include hosting networking and career development sessions. They really focus on youth and young professionals in the dairy industry. That is really important and comes in part from receiving scholarships from the Dairy Shrine and being made aware of some of those awesome opportunities.”

Con nued from AGRABILITY | Page 1

Grain bin indicators installed on grain bins alleviate a person from having to climb up and down to see where grain levels are at.

“This is one more opportunity to slip and fall,” Klahn said. “Falls are so dangerous, especially for older people. Your life expectancy can be really short after a fall.”

The Toolbox on the national AgrAbility Project’s website is an assistive technology database containing product ideas that can help make farming easier for people in a variety of situations.

“There are all sorts of items to help if you’re having back problems, arthritis, vision or hearing impairment, etc.,” Klahn said. “For someone with narcolepsy, there is an ear piece you can wear that will prompt you when your head starts to nod. It gives you a vibration to wake you up.”

As a certied assistive technology professional and program director for Easterseals Wisconsin FARM Program, Jeff Kratochwill helps implement various products and devices for people who have suffered an injury.

“Most of my work involves assistive technology assessments and trying to nd accommodations after a farmer has had an injury,” Kratochwill said. “For example, I’m currently working with a guy who had an arm amputation. He is having a tough time driving a skid (loader), so I am trying to gure out how to modify it so that he can drive the machine with one arm.”

Kratochwill said he also tries to prevent a secondary injury for someone with limited mobility. Rubberized alley mats in the center walk of a stanchion barn or parlor is a common safety feature he rec-

ommends.

“Standing on a rubber cushion instead of directly on concrete saves wear and tear on ankles, knees, hips and back,” he said. “There are manufacturers that make mats directly marketed for dairy applications. It provides some grip to prevent the farmer from slipping or sliding.”

For milking in a stanchion barn, Kratochwill said a track system that carries units can reduce joint stress. The system also incorporates a handrail which improves safety when crossing the gutter.

“Automatic takeoffs are usually combined with this system,” Kratochwill said. “A track system reduces repetitive bending and squatting, thereby conserving joints.”

A skid loader is another area of potential danger, especially for a person with limited mobility.

“I see a lot of farmers who have fallen or slipped when getting out of a skid (loader),” Kratochwill said.

“This is a high area of injury. Oftentimes, you’re stepping on a bucket that has manure, snow or ice on it. There is no cushion, and if you slip, you’re landing right on that steel. To have that kind of fall is disastrous for someone whose mobility is limited.”

A step and handrail system makes getting in and out of a skid loader safer.

“It takes a little extra time to drive up to the steps, but taking that time is much more valuable than time spent in the hospital after a fall — especially for a guy limited in mobility,” Kratochwill said.

“The steps keep you safe.”

In addition to the physical equipment and technology that can make farming easier, there are things all farmers can do to feel better that require no cost, such as stretching. According to a stretching

brochure created specically for farmers by the AgrAbility project in Nebraska, stretching increases exibility, improves range of motion, improves circulation and relieves stress.

“Farmers are tough, and they get used to the aches and pains, but it doesn’t always have to be that way,” Klahn said. “You don’t have to get used to that. You would never go in the eld without calibrating your planter or combine, so why not have a check-in with yourself? There is a lot of assistive technology out there, and sometimes it can be the little things that help improve your quality of life.”

An extra step and handrail kit like the one mounted to this tractor helps keep a farmer safe when climbing into and out of a tractor.

Andrea Klahn, of AgrAbility of Wisconsin, said a person should have three points of contact when getng in and out of a piece of equipment to avoid injuring their joints.

A skid loader is a vital tool, but it can also be challenging to get in and out of, especially for a farmer with a mobility concern. Consider adding steps with a handrail to prevent falls that can lead to major injuries.

Jen and Julie Orchard are doing something unique. These artisan butter makers are making butter from the cream of their cows’ milk, and to their knowledge, they are the only butter makers in the state doing so. The rich, golden milk of their farm’s Guernsey cows served as inspiration for their butter, which is slow churned in small batches.

“We make our butter the old-fashioned way,” Jen said. “We use batch churning for fuller avor and Europeanstyle cream tempering, which is gentler and provides a better mouthfeel to the butter.”

Cows are milked by two robotic milking systems at Gurn-Z Meadow Farm near Columbus where Julie and her husband, Ed Bacon, milk 120 Holsteins and registered Guernseys and farm 800 acres. The herd is about 40% Guernsey and 60% Holstein.

“We’re growing our Guernsey herd,” Julie said.

The breed is a family tradition for the Orchards dating

to 1945 when Jen and Julie’s grandfather began farming with Guernseys.

“All of our Guernseys originate from our grandfather’s herd,” Jen said.

In 2016, Jen and Julie were part of an American Guernsey Association research project on milk quality. After interviewing people making cheese, ice cream and other products with Guernsey milk and talking with experts at the Center for Dairy Research and Department of Agriculture, Trade and Consumer Protection, the siblings’ interest in doing something of their own was piqued.

“We had the right milk to make beautiful butter,” Jen said. “Guernsey milk has a high fat content and high amounts of beta carotene or Vitamin A, which gives it that beautiful, golden color.”

Julie nds the milk to be reminiscent of her childhood.

“I remember as a kid, the cream on top of the Guernsey milk was so golden and smelled so good,” she said.

Jen left a 15-year career in the biotech industry to create Royal Guernsey Creamery with her sister. Now, these seventh-generation dairy farmers

are producing a product that honors their heritage.

“I was looking for a way to get involved in the farm again, and this was a great way to do that,” Jen said. “Returning to the family farm was a driving force for me to start this business.”

The sisters received grant money from the Dairy Business Innovation Alliance to help fund their endeavor. The

entrepreneurs rent space at a local creamery but carry their own butter making license. Jen became a licensed cheesemaker, which she said was the fastest route to becoming a licensed butter maker. Now, Julie is apprenticing under Jen.

According to DATCP, Jen is one of 59 licensed butter makers in Wisconsin, and she is one of only four females in the state licensed to make both

butter and cheese.

Milk made on the farm on Monday and Tuesday is picked up and churned into butter within 48 hours. The cream must rst go through a tempering period of 18 to 20 hours before butter production can begin.

IBA carries an extensive line of nutritional supplements as well as the most complete line of hoof health products available in the industry today. Additionally, we offer syringes, needles, balling guns, magnets and many other animal health items.

• Hoof Health Products

• Boluses

• Pharmaceuticals

• Injectables

• Intramammary Infusions

• Dewormers

• Scours, Diarrhea Products

• Nutritional Products

CONTACT YOUR LOCAL DEALER:

Elsbernd IBA, Inc.

Elsbernd IBA, Inc. Calmar, IA • 563-419-6757

Calmar, IA • 563-419-6757

Valley Dairy Supply

Corona, SD • 608-432-5224

River Divide IBA Epworth, IA • 563-543-7710

River Divide IBA

Balzer IBA Owatonna, MN • 507-456-1617

Epworth, IA • 563-543-7710

Central Valley Dairy Brandon, SD • 605-467-0812

Dairyland Equipment Menahga, MN • 218-564-4958

IBA Fahrney, Inc

Elsbernd IBA, Inc.

Miller IBA Dairy Supply Goodhue, MN • 507-273-1026

Monroe, WI • 608-325-4248

Dairyland Equipment

Menahga, MN • 218-564-4958

Miller IBA Dairy Supply Goodhue, MN • 507-273-1026

Zumbro Ag Solutions

Zumbrota, MN • 651-380-2856

Pettit IBA Farm Supply Lewiston, MN • 507-269-5714

Calmar, IA • 563-419-6757

Manitowoc IBA

Whitelaw, WI • 920-732-4680

LakeView IBA Malone, WI • 920-378-2924

Innovative IBA Oconomowoc, WI • 608-347-4948

Balzer IBA

Owatonna, MN • 507-456-1617

BLUE MOUNDS, Wis. — Willi Lehner grew up as one of four cheesemakers in his family. Working for his dad at his cheese factory, he and his siblings each went on to sell artisan cheeses at the Madison farmers market. The last of the cheesemakers remaining in his family, Lehner has been making surface-aged cheese under his own brand of Bleu Mont Dairy since 1985.

“I like turning people on to good cheese,” Lehner said. “I learned the profession by default, and I guess I’m kind of good at it.”

Lehner is producing Bleu Mont Dairy bandaged cheddar and Big Sky Grana. Both cheeses are aged in an underground cave on Lehner’s homestead property near Blue Mounds.

The process begins at Henning’s Cheese Company in Kiel. Lehner works with the head cheesemaker, Kerry Henning, to ensure that he is working with the freshest milk. He prefers to make cheese from May through June, and then September and October. Lehner said this milk is better because the cows are on pasture and eating minimal silage, and experiencing less stress from heat.

Along with the fresh milk, Lehner uses veal rennet, specic cultures and primary fermenters.

When making bandaged cheddar, the curds are formed into 11-pound wheels. Each batch equates to around 3,500 pounds of cheese, or about 300 wheels.

A muslin cloth is pressed onto the cheese, and the wheels are transported to the cave on his property. The wheels sit on shelves in the cave to age for approximately 14-20 months, and the cloth stays on the cheese until the day it is sold. The cloth protects the cheese during the aging process.

Being underground, the cave has approximately 90% humidity and an average temperature of 55 degrees.

“That combination is what makes the cave unique,” Lehner said. “It makes it conducive to the microbes, molds and yeast, allowing the microbes to ourish on the surface.”

This atmosphere allows the cheese to be surface cured through the growth of mold. The mold that grows on the surface is not like mold that spoils cheese. These molds are not oxygen-starved like cheese wrapped in cellophane and stored in the refrigerator. Rather, the molds have microscopic roots called mycelium that

grow into the cheese. Mycelium gives off enzymes, and enzymes give the cheese avor.

The molds growing on the cheese are continuously evolving throughout the aging process. Lehner said there will be a whole series of molds on the cheese, and then two weeks later, it will have completely changed and have new mold colonies growing on the surface.

“It’s like a war going on the surface of the cheese,” Lehner said. “One group of invaders takes over the previous ones and it’s just ongoing.”

Most of Lehner’s sales are wholesale, but his cheese is available at select stores in Madison and the Dane County farmers market.

The process for surface-cured bandaged cheddar evolved in Great Britain in a time before plastic and refrigeration. When cheesemakers did not have good control over temperature and humidity, they started pressing muslin cloth onto the cheese that stays on until the cheese is cut.

“It’s an insurance policy to prevent the cheese from cracking,” Lehner said.

Lehner drew inspiration in part for his cheese making from his time in Switzerland, where he lived for 10 years in his 20s. The area farmers pool their cattle in the summer months up on the alpine pastures, which are 1,500 feet above the valley. A responsible son or daughter of one of the farmers, or a hired team, milks the cows and makes cheese in a copper kettle over a wood re like it has been done for centuries. After 90100 days, the cows are moved back down to the valley where the farmers had been making hay to feed over the winter.

“When I came back from Switzerland, I just knew there was so much more to cheese and butter,” Lehner said. “It’s so good. What we have just doesn’t compare.”

Since being back in Wisconsin and running his own cheese business, demand for Lehner’s product has grown. When he rst started, he built a small curing room where he aged 60 wheels of bandaged cheddar as an experiment.

“I looked at them and thought, ‘How am I ever going to sell 60 wheels of bandaged cheddar?’” Lehner said. “Now I’m making about 20 times as much.”

In a year’s time, Lehner sells about 1,200 wheels of cheddar.

Lehner’s property is powered by wind and solar energy. The cave is self-sufcient by design. He did a lot of research before building the cave and said it has outstripped his expectations.

“I wanted to do something where I was using the coolness of Mother Earth,” Lehner said. “Even though it cost three to four times as much as if I would have built an above-ground building, eventually energy savings is going to pay for it.”

HASTINGS, Minn. — Less than one month after the 110-year-old Hastings Creamery closed its doors, a re broke out the evening of Sept. 13. A creamery lled with more than a century of history went up in ames as re crews from at least 10 departments fought the blaze.

“There was a roof collapse and a signicant amount of re damage,” said John Townsend, Hastings Fire Chief. “We did not clear the scene until 6:44 p.m. the next day.

The Hastings Fire Department received a call at 10:30 p.m., and upon arrival, crews found ames and a large amount of heavy black smoke coming from the structure. There was an ammonia release coming from the building as well. Neighbors of the creamery were told to shelter in place and to keep their windows closed and air conditioning off due to the ammonia and heavy smoke.

Townsend said the four-alarm re was a challenge to put out because of the construction of the building and the conned spaces where the re was. Fire crews did not put anyone inside the structure. Instead, they used master streams from ladders and larger streams through accessways to keep a handle on the re and keep their staff safe.

The creamery was currently not in operation; therefore, no one was on-site, and no injuries occurred during the re.

The re took place on top of turmoil already surrounding the creamery which was forced to close Aug. 21 after failing to meet waste discharge requirements. In June, the creamery was temporarily suspended from discharging industrial waste for treatment at the Hastings Wastewater Treatment Plant for a minimum of 30 days. Prior to that, the creamery had received six notices of waste violations within seven months.

Hastings Creamery worked with multiple state agencies to try and nd a solution to their waste problem. Creamery owners had plans to construct an on-site wastewater processing system that would cost nearly $1 million. Unfortunately, they could not get things turned around in time and were forced to close.

Hastings Cooperative Creamery was founded in 1913 as a butter manufacturer and began bottling milk in 1920. In 2021, the creamery was purchased by a group of small organic farmers. It processed 150,000 pounds of raw milk every day that came from 45 farms in Minnesota and Wisconsin. The creamery processed milk, cream and buttermilk, and employed about 40 people.

The loss of the historic creamery leaves a hole in the community, which is mourning its destruction as the cause of the re remains under investigation.

“There are lots of different reasons why a re can start,” Townsend said. “Investigators are experts at guring it out, and that is what they are doing.”

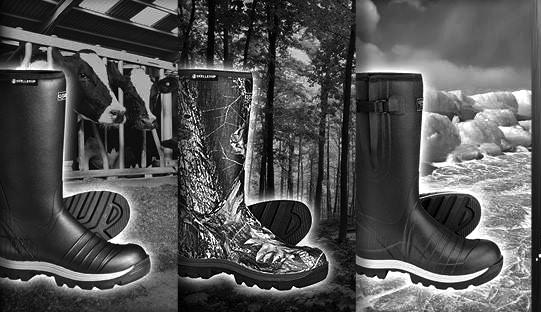

Sizes 5-15 (Whole sizes only)

Fully clad, UV resistant natural rubber upper

• Ergonomically designed to support the foot and prevent heel slip • Raised ribbing for forefoot protection

• Hardened rubber top cap and heel stiffener for protection and support • Cushioned rubber midsole with arch support • High abrasion, cupped rubber outsole designed to cushion and spread load • Tapered mud-release cleats

• Quatro Comfort System innersole – Poliyou® opencell foam with shock absorbing Politec® pads, • Odor resistant and moisture wicking

The non-insulated Quatro 13” he is also available in sizes 5 – 15

Also Available in 2 levels of insulated boots

“I don’t know anyone who can make butter as fresh as ours,” Jen said. “Milk is usually not sent to where the butter is being made — just the cream is. But in our case, the milk is sent directly to the creamery.”

One batch of Royal Guernsey Creamery butter makes 400 to 500 pounds of butter. The Orchards size their batches based on their equipment.

“We can make a lot of butter really fast; we just can’t package it quickly,” Julie said. “There is not a lot of packaging equipment that’s affordable for small manufacturers like us.”

Currently, the Orchards are making butter at least once a month.

“We’re making butter as needed since our business is in its infancy, but we’re going to have to ramp up production really hard this fall for the holiday season,” Jen said.

Jen said butter must contain 80% fat legally, but European butter contains a minimum of 82% fat, which is what the Orchards make.

“We add no water back; therefore, our butter has a lower water content than other butters,” Jen said. “Our butter is solid and creamy and so fresh. You can literally taste the sweetness of the cream.”

Jen and Julie were thoughtful about how they packaged their product. It would take a year to nd the right material — a gold foil — in which to wrap their prized butter.

“I feel like we nailed the packaging,” Jen said. “We didn’t want to just put it in a plastic tub. How you package butter and the materials you use really impact its taste. The foil not only looks nice but also protects the integrity of the butter and can handle freezing and thawing really well.”

From its shape to its coloring to its avor, Royal Guernsey Creamery butter is distinctly different. Focused on

traditional, sweet and savory, the Orchards offer butter in three avors — salted; cinnamon and sugar; and roasted garlic, cracked black pepper and parsley. The Orchards’ salted butter won grand champion butter at the Wisconsin State Fair this summer.

“That validated what we’re doing,” Julie said. “There’s so much trial and error in making butter. Not many people are doing it.”

Jen agreed. “Most of the literature about making butter comes from the 1930s,” she said. “There aren’t many current research articles out there. Even getting a butter apprenticeship is very difcult. It took a couple years to nd someone for me to apprentice under.”

Royal Guernsey Creamery butter hit grocery store shelves in January. The Orchards’ goal is to sell 50% of their product

online and 50% through local retail. Several stores carry Royal Guernsey Creamery butter, including Metcalfe’s Market in Madison and Wauwatosa; Jenifer Street Market in Madison; and Hill Valley Dairy cheese shop in Lake Geneva.

Julie Orchard packages bu er in March at Royal Guernsey Creamery near Columbus, Wisconsin. Every roll of bu er is hand wrapped in gold foil, and some days, the Orchards package 1,000 rolls of bu er.

“We’ve been selling online since December, and we expect sales to grow for the upcoming holidays,” Jen said. “I wouldn’t expect it, but we sell a lot of butter to the coasts. We sell a lot to California even though California is No. 1 in butter production. That was so surprising to us.”

The Orchards also offer a farm pickup option and have taken advantage of other opportunities to sell their butter, such as pairing it with sweet corn at a neighbor’s vegetable stand. An on-farm store is also a possibility, Julie said.

The sisters’ backgrounds are proving helpful in running their value-added business. Jen has experience in ship-

ping and logistics, while Julie brings knowledge in integrated marketing to the table.

“I like being able to remove boundaries,” Jen said. “I really appreciate being able to ship direct to the consumer and build direct customer relationships.”

The Orchards are about to enter their busiest season yet. In anticipation of the holidays, they are boosting butter production and have plans to offer gift boxes. Creating something special from their cows’ milk has allowed the Orchard sisters to share a piece of their farm with the rest of the country. And while doing so, they are adding value to their operation.

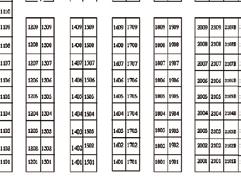

Sunburst, 50# . ...................................................................$19.99

Awnless, short height, excellent straw strength, and high yield potential.

L-024, 50# ...........................................................................$20.99

Awnless, mediurn-full maturity with high yield potential and very good test weight. Medium height with good standability. Winter hardiness is excellent.

Sittin’ Pretty, 50# ...............................................................$20.99

Tip Awned, mediurm-early rnaturity with high yields and good test weight. Mediurn height with good standability

L-920, 50# ...........................................................................$20.99

Awnless, mediurn-early maturity, medium-tall height, very good standability, test weight and high yielding

Pro 410 Brand, 50# ............................................................$20.99

Awned, high-yielding, very good winter hardiness, excellent lodging resistance COMMON WINTER WHEAT

Kaskaskia, 50# ...................................................................$18.49

Awned, white chaffed, medium height, very good winter hardiness, high yields and test weights

Winter Rye Grain, 50# ........................................................$17.99

Winter Triticale, 50#...........................................................$22.99

A hybrid of winter wheat and winter rye

When did you start and how far along are you on corn silage harvest? We are at the beginning of our own, and we are about a quarter of the way done.

How many acres will you chop and how does that compare to other years? We will chop 290 acres, and we usually chop 250. Since we’re just getting into it, we only have a little idea how it will yield. So far, it’s doing better than I thought it was going to. We will probably end up chopping about 40 acres more than usual.

Who is involved with chopping on your dairy and what is their role? We have two tractors pushing the pile, and they are driven by neighbors who we chop for. We have four trucks on the road, and those are driven by retired farmers. My dad and I chop, and if I’m not chopping, I’m pushing.

What challenges did you encounter during the growing season or while harvesting? Other than the dryness, we haven’t had any challenges really. We had some weed control where we had to respray 200 acres. That was due to lack of rainfall to activate the herbicides.

What is a management practice you changed that has improved your corn silage? I went away from brown midrib this year. I don’t know what the ramications will be yet, but I’m happy with the way the grain volume is so far in the silage. The non-BMR handled the drought a little better.

Tell us about a unique memory or day chopping corn silage. The worst is when it’s muddy.

Tell us about your farm and family. My dad and I operate the farm along with six full-time employees. My wife Miranda works at Organic Valley, and we have three daughters in high school and college. We raise our own youngstock, and my father-in-law has springing heifers and steers for us at his facility. We farm about 1,800 acres total. We raise 450 acres of alfalfa hay, and in addition to making corn silage for the cows, we chop additional corn silage at our heifer facility and the beef farm at my dad’s site. Our cows are milked in a double-8 parallel parlor and live in sand-bedded free stalls. We built the facility new in 1999.

Aaron Schroht Owatonna, Minnesota Steele County

75 cows

When did you start and how far along are you on corn silage harvest? We started the week of Sept. 17.

How many acres will you chop and how does that compare to other years? We chop 80 acres typically. We shoot to have 800 tons of corn silage each year.

Who is involved with chopping on your dairy and what is their role? I hire my dad Randy to chop, and I unload into the bagger. It takes us about a week to complete.

What challenges did you encounter during the growing season or while harvesting? We started out very wet and then got very dry during the last part of the summer. Though we experienced both excess moisture and dryness, we did not change our standard cropping routines.

What is a management practice you changed that has improved your corn silage? We added a processor a number of years back, and that has greatly improved the cows’ utilization of corn silage. We have gotten more production out of our cows and no longer see corn passing through in their manure.

Tell us about a unique memory or day chopping corn silage. I remember when I was younger climbing the silos to set the silo unloader and loving looking all around and seeing the countryside. I was the oldest child, so I got sent up to do the job.

Tell us about your farm and family. We milk in a 75-cow tiestall barn and have been shipping milk to Organic Valley for over 10 years. Besides the cows, my kids have some fair animals, including horses and pigs. We have 350 acres of crops and pasture. I have my wife, Beth, and our kids — Adeline, Weston, August, Olivia, Mckinzie, Devon and Sawyer. We also have help from my parents, Randy and Audrey, along with brothers, Thomas and David.

Dave Boehlke pictured with his daughter Rachel and wife Melissa Thorp, Wisconsin Clark County

Melissa Thorp, Wisconsin Clark County

72 cows

When did you start and how far along are you on corn silage harvest? We have not started our corn silage harvest yet. We tested the corn Sept. 12, and it was at 68% to 73%.

How many acres will you chop and how does that compare to other years? We will be chopping about 30-35 acres. That is normally what we chop.

Who is involved with chopping on your dairy and what is their role? We custom-hire for chopping, and my son Dan, friends and I haul and unload wagons. My wife takes care of hooking wagons so that we can keep rolling.

What challenges did you encounter during the growing season or while harvesting? The dry conditions have been a challenge this year, but timely rains have helped.

What is a management practice you changed that has improved your corn silage? We continue to do corn silage as we have in the past. We have not had any major issues.

Tell us about a unique memory or day chopping corn silage. One memory of chopping corn silage that comes to mind is the year our regular custom guy could not get through the elds due to everything being so wet. We had to hire a custom guy who had a self-propelled chopper and four-wheel drive tractors to haul loads.

Tell us about your farm and family. Our farm is located north of Thorp, Wisconsin. We farm 270 acres and plant corn, soybeans and alfalfa. Along with milking 65 Holsteins and a few Jerseys in a stanchion barn, we also raise dairy steers. My wife helps with milking, feeding calves, bookwork and whatever else needs to be done. My son works alongside me, doing crops, working on equipment and anything that needs to be done. We ship our milk to Mullins Cheese.

Rock County

150 cows

When did you start and how far along are you on corn silage harvest? We started corn silage harvest Sept. 5 and nished Sept. 9.

How many acres did you chop and how does that compare to other years? We chopped 78 acres. It was very surprising that it was similar to what we do every year. We were fortunate to get a speck of rain now and again to keep the corn fairly green. We yielded 220 to 230 bushels per acre, which surprises me tremendously with the lack of rainfall. The ears looked good and were lled out nice. The rows of kernels around the cob were comparative to other years.

Who is involved with chopping on your dairy and what is their role? My two sons and two grandsons do the chopping. My sons are twins, and Rich Jr. chops while Don packs the bunker. My grandsons, Christopher and Willie, switch off every other day hauling loads and milking cows. One hauls loads while the other does the noon and late-afternoon milking. One guy has to do two milkings by himself while we’re chopping. These four guys do a good job for us. All of them are attentive and are good workers.

What challenges did you encounter during the growing season or while harvesting? Rainfall was our biggest challenge. We had many long, dry spells during the growing season and got by with maybe a quarter-inch of rain once in

a while. There were times we would go for three weeks with no rain. We had a small breakdown with the chopper during harvest that slowed them up for part of the day, but other than that, we got by pretty good. It’s going to be difcult to do a high-moisture grain because there are green spots and dry spots in the eld. The combine doesn’t like really green corn, so it’s going to be touch and go on where we can do that.

What is a management practice you changed that has improved your corn silage? We changed the type of corn we plant to varieties that are recommended for corn silage. Years ago, we just picked one you want to mature around Labor Day. Now, we plant something really good for corn silage that yields very good bushels per acre.

Tell us about a unique memory or day chopping corn silage. We had such tall corn, and we didn’t have as good of machinery back then. We were only chopping two rows at that time whereas now we chop three. The tractor I usually had on the chopper traveled too fast, even in the slowest gear, so I had to put a smaller tractor on it. This tractor went so much slower in low gear that I didn’t have to be so careful about plugging up the chopper head.

Tell us about your farm and family. My wife, Shirley, and I farm with our sons and grandsons. Our daughter, Rene, is also part of the LLC and does herd health records weekly in addition to working off the farm as an ag loan ofcer. Shirley does the bookkeeping and makes meals to take to the eld to keep people moving through lunch and supper. My grandsons are the fth generation on this farm. My grandparents came from Scotland and landed in Canada before moving here. The original farm was 213 acres. Now, we farm over 1,000 acres. We milk three times a day in a double-8 parallel parlor and ship our milk to Dairy Farmers of America.

120 cows

When did you start and how far along are you on corn silage harvest?

We have not started chopping yet. We are checking moistures every ve days and still seeing more than 70%, so I anticipate we are at least a week off from chopping.

How many acres will you chop and how does that compare to other years? We will chop 125 acres, which is a little more than last year because I burned through my corn silage inventory faster this spring not knowing what our hayelds were going to look like after a crazy spring.

Who is involved with chopping on your dairy and what is their role? We hire Milk-n-More Farms and Harvesting to do our chopping. They do the chopping, hauling and packing. They try to get here as fast as they can once I tell them I’m ready to go and are an awesome crew to work with.

What challenges did you encounter during the growing season or while harvesting? This spring was an awesome spring for planting. We had all our corn in by May 20, and germination was good. After that, it became challenging with no rain for a month. Pre-emergent herbicide spray worked very poorly, so we had to respray Roundup on over half our acreage. On June 24, we received more than 2 inches of rain, and since then, we have received timely rains, so the corn has not been stressed. The yields will be good.

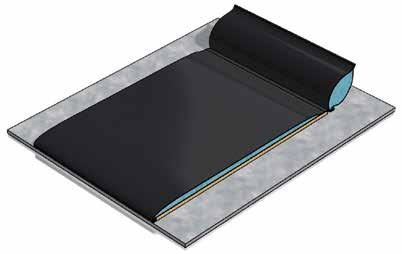

What is a management practice you changed that has improved your corn silage? We try to grow 95- to 100-day dual-purpose corn. I want to be at the high end of the yields and starch. I also believe in getting it packed well in the bunker and covering it with a vapor barrier and good 6-millimeter plastic. We are also very particular as to how we cover it. The sidewall tires must be touching each other.

Tell us about a unique memory or day chopping corn silage. My favorite memory happens every year when the pile is done and covered.

Tell us about your farm and family. Townline Acres is run by my parents, Doug and Cindy Breyer, me and my brother Derek Breyer. Derek and I are in the process of taking over the day-to-day operations and ownership. We also rely on one part-time hired hand who is vital to our success. We milk 120 registered Holsteins with two Lely A5 robots, raise 200 youngstock and farm about 500 acres, half owned and half rented. We grow alfalfa, grass and corn — all to feed our herd. Our milk goes to Mullins Cheese in Knowlton, Wisconsin.

Describe your farm and facilities. Heeg Bros. Dairy LLC started in 1999 when we combined our dad’s farm and my brother Mark’s farm. I farm with my brothers Mark and Gary. They each have a son who works on the farm, Nathan and Cory. Our dad, August, is 90 years old and hauls our milk four days a week, so we have three generations working together. We employee 22 full-time employees and farm 3,300 acres. Our current rolling herd average is 31,500 pounds of milk per cow. We are averaging 98 pounds per cow, per day, with 3.95% butterfat and 3.18% protein. We currently are building a new robot barn that will milk additional cows. We are hoping to start milking in it the beginning of November. We raise 1,420 heifers. We hire out manure hauling and spraying; otherwise, we do the rest of the eldwork ourselves.

What forages do you harvest? Pioneer Roundup Ready Alfalfa, Brevant brown midrib corn silage, oatlage for heifers, snaplage, low-moisture shelled corn and conventional corn silage for heifers.

How many acres of crops do you raise? We have 2,010 acres of corn, 790 acres of alfalfa and 500 acres of new-seeding alfalfa.

What quality and quantity do you harvest of each crop? For corn silage, we are looking for 66% to 68% moisture and harvest 28,000 tons. We cut alfalfa when it is just budding and like to harvest at around 60% moisture, harvesting about 9,000 tons. For snaplage,

we shoot for 45% moisture, harvesting 1,500 tons. We like the low-moisture corn in the low 20s for moisture and harvest 1,800 tons.

Describe the rations for your livestock. Lactating cows get BMR corn silage, alfalfa, snaplage, low-moisture corn and a protein mix which includes canola, soybean meal, Exceller Meal,

vitamins and minerals. We strive for 60% to 65% forage in the diet. Postfresh cows get the same forages plus 1 Turn to FORAGE | Page 20

“Comfort matters. For 10 years, we have been using Udder Comfort™ because it gets fresh cows off to a great start. Cows that start clean tend to stay clean throughout the lactation. So, we spray every fresh udder 2x/day for 3 to 7 days after calving and see their SCCs come down much faster,” says Mitch Breunig, Mystic Valley Dairy, Sauk City, Wisconsin, home to Jenny-Lou Holsteins, founded by his parents Jeanette and Louis. From balanced breeding and a focus on longevity came the legacy of Toystory. A goal today is high component, low SCC milk, shipping at least 8 lbs of solids and energy-corrected milk of 120 lbs/cow. The 450-cow freestall herd has an RHA of 33,102M 1394F 1071P and records to 55,000 with more than 60 past 150,000M lifetime.

pound of straw per cow, balanced for their intakes. Dry cows get corn silage, alfalfa, processed straw and protein mix. The heifers get oatlage, haylage, corn silage, weighback from the lactating cows and mineral mix only.

Describe your harvesting techniques for alfalfa and corn silage. We do our own harvesting using a Claas 980 chopper with a Scherer processor for corn, an Oxbo 35-foot merger, a Claas 30foot triple mower, three Meyer semi forage boxes and three Meyer straight truck mounted boxes.

What techniques do you use to store, manage and feed your forages? We store all cow feeds in cement bunkers. Heifer forages are stored in drive-over piles at the heifer site. All forages get an inoculant at harvest. We use a double layer of plastic on all bunkers and piles, an oxygen barrier and 6-mil plastic sheeting with tire sidewalls touching each other. Snaplage is stored in smaller bunker, and we use buchneri inoculant. For low-moisture corn, we store in smaller bunkers and put propionic acid on it. We use Feed Supervisor as our feed management software. This really helps keep track of feed inventory.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? We really like feeding BMR corn silage to cows because of the higher digestibility. However, it can be a challenge to grow, depending on the growing season. We put a fungicide on it to help protect it from disease. A couple years ago, we did plant a grass mix with alfalfa but only did that for

one year. We felt the cows did a little better with straight alfalfa.

Describe a challenge you overcame in reaching your forage quality goals.

Winterkill can be a challenge with alfalfa. This last spring, we did see winterkill in low areas on new-seeding elds. We were able to no-till into them with alfalfa because they were rst-year, and we ended up with a good crop.

How do quality forages play a part in the production goals for your herd? Forage quality is a huge part of our production and herd health goals. We strive for 60% to 65% forage in the lactating diet. We need highly digestible forages and good clean feed — meaning low mold and yeast numbers and ensiled at proper moistures.

“When I see the information that is gathered, it motivates me to want to do a better job.”

Which is your favorite and why? With the data collection, I enjoy the snapshot that my nutritionist prepares for me so I can see my strengths and weaknesses.

How does testing with DHIA bene t your dairy operation? When I see the information that is gathered, it motivates me to want to do a better job.

Tell us about your farm. My wife and I have 55 milk cows. We farm around 180 acres. We have three children and one on the way. I have been milking for 11 years.

Sauk

Buffalo,

Trevor and Alexandria Lisson Lisson Holsteins • Browerville, MN Milking 55 cowsWith DHIA for 11 years

JD

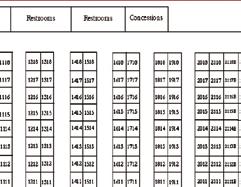

Sep. hrs., #554050 ..................................... $405,000

JD S770 2018, 2261 hrs., 1652 Sep. hrs., #549678 ................................. $259,900

JD S760 2019, 1206 hrs., 871 Sep. hrs., #565714 ................................... $279,900

JD S690 2017, 1433 hrs., 1187 Sep. hrs., #549457 ................................. $280,700

JD S690 2017, 2104 hrs., 1461 Sep. hrs., #552684 ................................. $249,900

JD S690 2017, 2508 hrs., 1605 Sep. hrs., #568113 ................................. $239,000

JD S690 2015, 2400 hrs., 1615 Sep. hrs., #550872 ................................. $232,900

JD S690 2016, 2544 hrs., 1820 Sep. hrs., #547267 ................................. $219,900

JD S690 2012, 2314 hrs., 1645 Sep. hrs., #551148 ................................. $149,000

JD S690 2014, 2280 hrs., 1440 Sep. hrs., #568112 ................................. $139,000

JD S680 2017, 1516 hrs., 1053 Sep. hrs., #273646 ................................. $219,900

JD S680 2014, 2349 hrs., 1668 Sep. hrs., #531966 ................................. $195,000

JD S680 2014, 2328 hrs., 1575 Sep. hrs., #555096 ................................. $169,900

JD S680 2013, 2485 hrs., 1604 Sep. hrs., #551147 ................................. $165,000

JD S680 2013, 2575 hrs., 1906 Sep. hrs., #563909 ................................. $160,000

JD S680 2012, 1493

JD S660 2012, 1643 hrs., 1188 Sep. hrs., #554132 ................................. $179,900

JD 9870 STS 2011, 3650 hrs., 1750 Sep. hrs., #567383 .......................... $109,900

JD 9870 STS 2008, 3261 hrs., 2494 Sep. hrs., #566621 ............................ $97,500

JD 9870 STS 2009, 3579 hrs., 2579 Sep. hrs., #563914 ............................ $94,500

JD 9860 STS 2005, 4528 hrs., 3240 Sep. hrs., #564977 ............................ $59,900

JD 9860 STS 2004, 3924 hrs., 2537 Sep. hrs., #559820 ............................ $55,000

JD 9770 STS 2010, 2058 hrs., 1558 Sep. hrs., #567790 .......................... $120,800

JD 9770 STS 2009, 3095 hrs., 2350 Sep. hrs., #568125 ............................ $99,900

JD 9750 STS 2003, 5105 hrs., 3367 Sep. hrs., #565004 ............................ $37,500

JD 9670 STS 2010, 2525 hrs., 1667 Sep. hrs., #566916 .......................... $114,900

JD 9650W 2000, 3680 hrs., 2665 Sep. hrs., #568122 ................................ $45,000

JD 9570 STS 2011, 2019 hrs., 1231 Sep. hrs., #555820 .......................... $132,500

JD 9570 STS 2009, 2367 hrs., 1597 Sep. hrs., #556547 .......................... $104,900

JD 9560 STS 2004, 4638 hrs., 2982 Sep. hrs., #567094 ............................ $52,500

JD 9600 1995, 4000 hrs., #568110 ........................................................... $28,900

JD 9600 1991, 5313 hrs., 3614 Sep. hrs., #567724 ................................... $24,900

Case IH 2388 1998, 3876 hrs., 2943 Sep. hrs., #549406........................... $34,900

Pickett Twin-Master 2019, #553918 ................................................... $187,000

IOWA

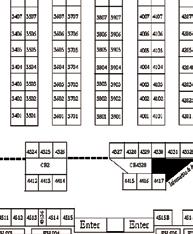

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United

United Dairy Systems, Inc. West Union, IA 563-422-5355

Monticello, IA 319-465-5931

Systems, Inc. West Union, IA 563-422-5355 Monticello, IA 319-465-5931

WISCONSIN

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service

Kaukauna, WI 866-335-2825

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment

Redeker Dairy Equipment Brandon, WI 920-346-5579

Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880

The Scharine Group Inc. Whitewater, WI 800 472-2880

Mt Horeb, WI 800-872-3470

Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Farm Systems

Melrose, MN 320-256-3276

Melrose, MN 320-256-3276

Brookings, SD 800-636-5581

Brookings, SD 800-636-5581

Advanced Dairy Mora, MN 320-679-1029 Pierz,

Advanced Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494

St. Charles, MN

507-932-4288

Wadena, MN 218-632-5416

VESPER, Wis. — As they close out a dairying career that has spanned over 45 years, Bob and Susan Miller are not entirely certain what life without their Holstein cows will look like.

“We did a lot of thinking coming to the decision to sell the cows,” Bob said. “It is probably the right decision, but that doesn’t make it the easy one. I know the toughest part will be putting the cows on the trailer, turning out the lights and shutting the door for that last time.”

After stringent culling decisions, the Millers are offering their remaining 40 cows and 10 springing heifers in their Ro-Lex Holsteins herd for sale privately through Premier Livestock and Auctions LLC in Withee.

If a private treaty sale has not taken place by the end of October, the herd will be offered through public auction

Bob and Sue Miller stand among their calves Sept. 13 on their farm near Vesper, Wisconsin. The Millers are selling their milking herd in October to close a more than four-decade career.

Oct. 25. They will be keeping their younger heifers and calves for the time being.

“We have always told our vet to let us know when it was time if we didn’t see it — if it got to the point where it was evident that we should quit because we can’t keep doing

things the way we feel they should be done,” Susan said. “Neither of us want to get to that point.”

The Millers are proud of the herd they have built, with high-type, registered cows that boast a BAA of 107.5, averaging 70 pounds of milk with

4.2% butterfat and 3.2% protein.

However, the cows and those statistics are not what bring them the most pride when they reminisce about their career.

“It really has been all about the people we have met and the

relationships that we have developed,” Bob said. “That is how we measure our success. A lot of people have helped us along the way, and we have tried to pay it forward and help others in return.”

Bob started farming in Blue Mounds after he nished school, before moving to the current farm in Vesper in 1992. Bob and Susan were married in 2000, and she joined him on the farm.

The move was not the easiest, Bob said, as he lost cows after the move and shortly after the start of the new year was out of feed.

“I was the new guy in the area, and I couldn’t nd anyone to lend me the money,” Bob said. “I talked to a neighbor who was also on the bank board, Fred Schill, and two hours later, he brought me an envelope with some money, so I could get feed. That man means the world to me. He picked me up at rock bottom. He told me to repay the favor by helping someone else someday, when they needed it the most.”

Another neighbor, Dan Hageman, helped Bob with equipment before he could afford to own everything he needed.

Turn

Having dedicated over 95 years to the dairy industry, it’s with good reason why the complete forages package from Pioneer delivers unrivaled performance. Contact your local Pioneer representative to see how your team of local experts can help you maximize ou r corn silage products, alfalfa varieties, inoculants and Plenish ® high oleic soybeans in your fields. Pioneer.com/ForagesPackage

The AquaStar mattress (middle) actively dissipates the cows' body heat. The lying area has a temperature of 24.8°C degrees. You can also see the Aquastar mattress beside the cow on the right remains cool as does the Aquastar mattress under her.

Aquastar from Bioret Agri takes comfort to a whole new level. Compared to sand or conventional mats which can trap heat under the cow, its unique aqua transfer technology cools the cow while reducing pressure points.

Aquastar provides the benefits of a latex mattress combined with a waterbed for 3"- 4" of pure comfort, with the option of adding Bioret Agri's proven Aqua Board® kneeboard. The Aqua Board® keeps cows centred on the waterbed so they stay cleaner and cooler. Aquastar and Aqua Board® are built to deliver outstanding performance, with components warranted for up to 15 years; the best in the business.

“When you’re older, you realize how valuable that was,” Bob said. “Two of the greatest honors I’ve had were to be asked to be a pallbearer at both Fred’s and Dan’s funerals. All of Dan’s pallbearers were guys he had helped out over the years. It was a privilege to perform that nal act for him.”

The Millers have added to their family with what they call their show kids. These youth are interested in showing dairy cattle and look to the Millers for guidance.

“Those kids have really become like family, and the relationships have lasted long beyond their own years of showing,” Susan said. “We enjoy working with them, and when we take the time to help and spend with them, they appreciate that. It makes them feel valued and important.”

Lending that helping hand to their friends when it is needed is not the only way the Millers chose to return the blessings they have been given. Volunteerism in the local dairy community is a common thread woven in their story.

The Millers are both involved with running the dairy cattle show at the Central Wisconsin State Fair. Susan has served as the superintendent for the past seven years and assisted with the show for several years before that. Bob is frequently found keeping the ring clean and performing other duties to keep the shows running smoothly.

“What we do at the fair wouldn’t be possible without the great crew we have had helping us out,” Susan said. “It is really not like work because the people make it enjoyable.”

Besides their work with the CWSF, Susan has volunteered her time as a chaperone for the Wood County dairy youth attending the Wisconsin State Fair junior dairy show for the past 10 years.

“Now that they are older, our show

kids put together a crew and take turns coming and helping me with chores while Susan is gone to state fair,” Bob said.

Susan appreciates the help Bob is given.

“I always tell people it takes six people to replace me at home,” she said.

The Millers are long-time active members of the Wood Area Holstein Breeders and have spent many years on the planning and selections committees for the group’s annual Purple Ribbon Classic Sale.

“People ask us why we volunteer so much time,” Bob said. “Our answer is that we look at the volunteers before us, and they are the people we want to be like. People like Jer Lang, Roger and Judy Heeg and Marge Lippert were the volunteers back then, and now it is nice to be included in the same category with people like that.”

The Millers are looking at retirement with trepidation.

“I really don’t know what we’ll do,” Bob said. “We don’t really have any hobbies, and we’ve never really traveled. Our hobbies have all been cow-related, like showing. Susan said we’ll just have to go get jobs to keep ourselves occupied.”

Despite the unknown, they take comfort in the fact their dairy farm community will continue to be a harbor for them.

“People who have never hit rockbottom don’t understand what it is like to be there,” Bob said. “I know what it is like, and I know how it feels to have someone give you a helping hand and expect nothing in return. If it wasn’t for some of the failures we have experienced, so many of the good things in our lives would probably have never happened either. It’s been a wild ride, but I wouldn’t change a thing.”

Which one do you prefer?

Many times, I have discovered that most farmers have a favorite. “I’m a cow man,” a farmer will tell me while another will say, “I’d rather be in the eld than in the barn.” Sometimes, however, these two parts of farming interest a farmer equally.

Where do you fall?

Having spent a total of about 10 minutes of my life driving tractor, I can say with certainty that I was a cow girl, not a crop girl. Being with the animals is what I loved whereas my dad loved working in the elds, planting and harvesting crops.

of hay go by. My dad preferred that my sisters and I took care of the cattle instead of baling hay, which I was totally ne with.

As a writer for Dairy Star, a certain amount of crop knowledge is a requirement. I knew the basics when I started, but I’ve learned so much about that side of things since I began working here. Now, when farmers spout off terms like RFV, BMR and LDMI, I actually know what they are talking about.

By Stacey Smart Staff Writer

By Stacey Smart Staff Writer

That’s not to say I never spent any time in the eld or failed to take notice of what was growing there. I admired my dad’s perfectly straight rows of corn and loved to ride the three-wheeler between lanes of freshly cut alfalfa. I also got lots of face-to-face time with the elds when I picked rocks every spring.

But crops are not my forte. I wasn’t involved with eldwork and know much more about livestock because in the barn was where I could be found most of the time. I never once felt ripped off for not being a part of the hot, backbreaking work of unloading and stacking small bales in the hay mow. I was perfectly content milking cows in the tunnel-ventilated barn and watching the wagons

So, thank you crop and weather guys, past and present. You’ve taught me a lot. Thank you also to every dairy farmer I have spoken with in the last ve years. You are a wealth of knowledge. Thank you, extension agents and other industry professionals. You are a wonderful resource to have in my back pocket. And nally, I thank my co-workers at Dairy Star for crop wisdom you have shared as well.

Thank you for the knowledge, everyone. I hope you keep sharing it. On-the-job learning is often the best kind of learning. The knowledge I have gained by working at Dairy Star goes far beyond crops to include all facets of the dairy operation. It’s amazing how much there is to learn in an industry that is ever-changing. Crops may not be my forte, but I’m learning every day.

WEST UNION, Iowa — If memories were made of diamonds and gold, then Norman Nabholz would be among the richest. He gladly shares his wealth by setting his stories down on paper, allowing others to live vicariously through his experiences.

“I have been blessed,” Nabholz said. “I have been able to count so many of the greats in this business as mentors and as friends.”

Nabholz grew up at Nabholz Farm near West Union where his family milked a herd of about 38 Jersey cows. He continues to reside at the farm today with his partner Gretchen Taylor, where they work with animals of top pedigrees.

“I have known a lot of great cow people, but I am not sure I have ever known any as great as my dad,” Nabholz said. “I didn’t realize it at the time, but he was.”

Nabholz recently completed his second book, “The Queens Caretakers.”

The idea for this book rst came to Nabholz nearly 10 years ago.

“I was doing a series of articles for Cowsmopolitan and began to think maybe I should put all of those stories together in book form,” Nabholz said.

Since then, Nabholz has spent time researching, conducting interviews, creating content, organizing and sourcing historical photographs.

While his rst book, “Millionaires in the Cornelds,” celebrated the history surrounding the National Cattle Congress held in Waterloo, “The Queens Caretakers” is

DANIELLE NAUMAN/DAIRY STAR

Norman Nabholz smiles as he looks over the proof copy of his latest book, “The Queens Caretakers,” Sept. 14 in his office at Nabholz Farm in West Union, Iowa. The book is the culmina�on of nearly 10 years of research and work by Nabholz.

a personal vantage point for Nabholz, featuring many people, places and cows that have played a role in his life.

“It’s about the people who took care of the cows,” Nabholz said. “A lot of them were my mentors; the herds were the idyllic herds that I wanted to pattern stuff after.”