USDA announces historical investment in agriculture

Projects to receive $2.8B for climatesmart production practices

By Abby Wiedmeyer abby.w@dairystar.com

ARKANSAW, Wis. – Agriculture Secretary Tom Vilsack announced details of the U.S. Department of Agriculture’s Partnerships for Climate-Smart Commodities program Sept. 14. The program is investing up to $2.8 billion in 70 selected projects under the rst pool of funding.

“It’s a tremendous opportunity for American agriculture to not only improve the bottom line but to improve conditions on the planet,” Vilsack said. “(We want to be) in a position where internationally we can say to the rest of the world, ‘Follow us. We’re leading.’”

Vilsack was joined by representatives from Organic Valley, Edge Dairy Farmer Cooperative and The DeLong Co. Inc., who are participating in the program, at a press conference Sept. 15 at the Anibas family farm near Arkansaw.

The purpose of the program is to fund pilot projects that will create market opportunities for American commodities produced using climate-smart production practices. The program comes in response to the challenges facing producers today and a growing demand for sustainably produced products from the export market.

Recipients of the program were selected from more than 1,000 applications from food companies. Originally, $1 billion was allocated from the Commodity Credit Corporation to the project. After receiving so many applications, however, additional funding was set aside for the program.

“Basically, we have a $3.5 billion initiative,” Vilsack said. “What we are announcing is 70 projects in the larger grant pool,

Tragedy strikes Jefferson County dairy

Plucinskis’ barn destroyed in re Sept. 11

By Stacey Smart stacey.s@dairystar.com

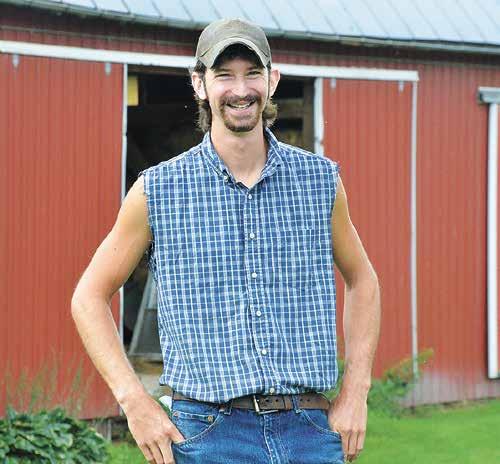

JEFFERSON, Wis. – The hopes and dreams of Derek and Meg Plucinski crumbled to the ground the day their barn caught re. As they helplessly watched smoke and ames engulf the classic red tiestall facility, the couple wondered what the future would hold.

“I cannot believe this happened,” Meg Plucinski said. “It’s all so hard. This is our future, and our kids’ future. Without our milking facility, there’s not much to do. That’s our source of money. But God uses all things for good, so I’m focusing on that.”

The Plucinskis milk 40 cows and farm 300 acres on the organic dairy farm they rent near Jefferson. The young dairy farmers created D&M Family Farm when they began renting

Waupun State Farm, dairy processing plant offer opportunity to prisoners

By Stacey Smart stacey.s@dairystar.com

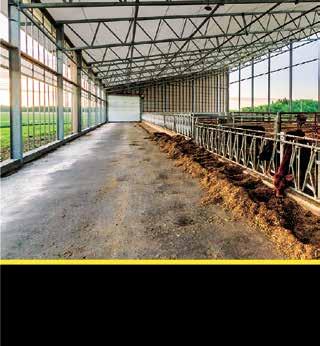

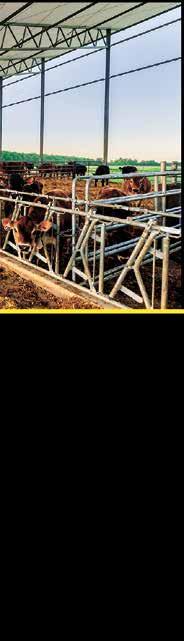

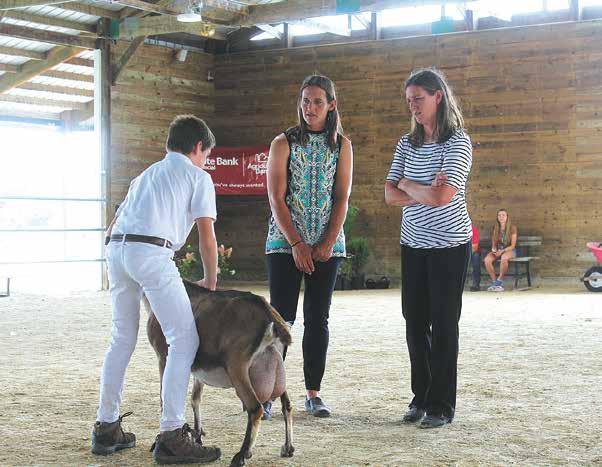

WAUPUN, Wis. – From the road, it looks like any other farm. White barns and buildings sit wide open to the world at the end of a long, tree-lined drive. There is nothing to indicate that much of the labor on this farm near Waupun is supplied by men in state custody.

Waupun State Farm is part of the Bureau of Correctional Enterprises. The 360-cow, 1,700-acre dairy farm employs prisoners from the John C. Burke Correctional Center – a minimum security facility in the city of Waupun.

There are no wire fences here. The prisoners get a taste of freedom when they work on the farm.

“Most of the men work-

the farm July 1, 2018. The farm has been organic since 2006.

The Plucinski farm is also home to a variety of other creatures including free-range chickens –100 meat birds and 60 layers –turkeys, ducks, geese, goats and pigs. The family runs an on-site

store where they sell chicken, pork, beef, turkey and eggs grown on their farm.

Sept. 11 was supposed to be a relaxing day away from the farm, but things soon turned tragic. The Plucinskis and their

Outside the fence

children – Wyatt, Fitzgerald, Eleanor and Elvira – were headed to Wisconsin Dells when they got a call from their landlord saying the barn was on re.

ing here are toward the end of their sentence,” said Jason Hensel, farm supervisor. “This is a chance for them to prove themselves.”

Secretary Kevin Carr toured farm and dairy Sept. 8. BCE director Wes Ray led the tour.

“From growing crops to maintaining livestock to producing milk, we’re doing a tremendous job with helping people change their lives and gain meaningful employment when they leave our care,” Ray said.

Forty men from the center work on the farm – 28 on day shift and 12 on night shift. This work release program is designed to help reformed prisoners successfully transition back into their community one day.

Craig, from Washington County, has been working on the farm for four months. He started out scraping manure and moving cows and is now a milker. He starts his shift at 4 a.m. and is done at 11 a.m. In custody since 2018, Craig is scheduled for release October 2024.

“This is hard work,” he said. “I did construction my whole life, but it’s eye open-

“All dairy, all the time”™

STACEY SMART/DAIRY STAR Wes Ray, director of the Bureau of Correc�onal Enterprises, (le�) and Jason Hensel, supervisor of Waupun State Farm, led a tour Sept. 8 at the Waupun State Farm located near Waupun, Wisconsin. The 360-cow, 1,700-acre dairy farm employs prisoners from the John C. Burke Correc�onal Center.

Wisconsin Department of Agriculture, Trade and Consumer Protection Secretary Randy Romanski and Wisconsin Department of Corrections

STACEY SMART/DAIRY STAR

The Plucinskis’ barn lies in ruins Sept. 14 three days a�er a re took down the 48-stall �estall barn near Jefferson, Wisconsin. All of the farm’s bedding and dry hay for the winter was lost.

DAIRY ST R September 24, 2022Volume 24, No. 15

Turn to VILSACK | Page 7

Turn to PLUCINSKIS | Page 6

Turn to WAUPON | Page 8

VISIT US AT THEAT THE WORLD DAIRY EXPO OCTOBER 4-7•BOOTH MC 33

www.dairystar.com

ISSN 020355

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: (320) 352-6303

Fax: (320) 352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor (320) 352-6303

• tiffany.k@dairystar.com

Danielle Nauman - Staff Writer (608) 487-1101

• danielle.n@dairystar.com

Stacey Smart - Staff Writer (262) 442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff writer 320-352-6303 • grace.j@star-pub.com

Jan Lefevbvre - Staff Writer 320-290-5980 • jan.l@star-pub.com

Maria Bichler - Copy Editor 320-352-6303

Consultant Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260

• jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin) 320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI) 920-979-5284

• kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Advertising

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters

Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC.

The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces.

POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246.

U.S. milk output is continuing to grow but at a slower pace compared to what was expected one month ago. U.S. Department of Agriculture Outlook Board Chairman Mark Jekanowski said his group has knocked 300 million pounds off this year’s milk production forecast based on smaller cow inventories. USDA is projecting next year’s milk output at 228.8 billion pounds. That’s up 1% from this year. “Dairy product demand is relatively strong, especially for cheese,” Jekanowski said.

Consumer dairy prices rise

Retail dairy prices are on the rise. According to CoBank, August butter prices were nearly 25% higher year over year. Milk prices at the supermarket are up 17%, and yogurt is 16.1% higher. Ice cream prices rose 14%, and cheese is up 13.5%. The prices for all food consumed at home were up 13.5%.

Record farm income

The Food and Agricultural Policy Research Institute expects U.S. net farm income to reach a record $148 billion this year. That’s twice the level seen just ve years ago. FAPRI said the high commodity prices will buffer the largest ever year-to-year increase in farm production costs.

Ag economy barometer gets boost in August

Farmer sentiment increased slightly in the August Ag Economy Barometer. According to the survey presented by Purdue University and the CME Group, farmers were less worried about their farm’s nancial situation. Center for Commercial Agriculture Director Jim Mintert said commodity prices improved from mid-July to mid-August. Since then, there has been some weakness in prices. Mintert said there are still concerns about what ination

could bring to the farm in 2023. “People are uneasy when considering what margins will look like going into 2023,” Mintert said. “We asked more specically about ination. More producers in this survey are expecting a higher rate of ination than previously.”

The calm before the real storm

Global strategist Jacob Shapiro kicked off the Next Five Years executive conference, saying it will be a time of great volatility. That is not necessarily a bad thing.

“I’m actually pretty optimistic about the next ve years,” Shapiro said. “When you get beyond the next ve years, I get a little bit scared.” While there is opportunity in the short-term for U.S. agriculture, it is not coming from China. Shapiro sees more prospects from in Sub-Saharan Africa, Southeast Asia and Latin America. “It looks like the U.S. and China are on a collision course,” Shapiro said. “When you look at previous eras where you have rising and falling powers like we have right now, it usually ends in some kind of cataclysmic conict. The last true multipolar era was the 1890s that ended with World War I and World War II; unfortunately, that is the trajectory we’re on.” Shapiro said the next two years will be “the time to buckle your seatbelts” for higher energy prices.

By Don Wick Columnist

Page 2 • Dairy Star • Saturday, September 24, 2022 Dairy Prole brought to you by your North America dealers.More milk production in 2023

Ag Insider Turn to AG INSIDER | Page 5 DAIRY ST R

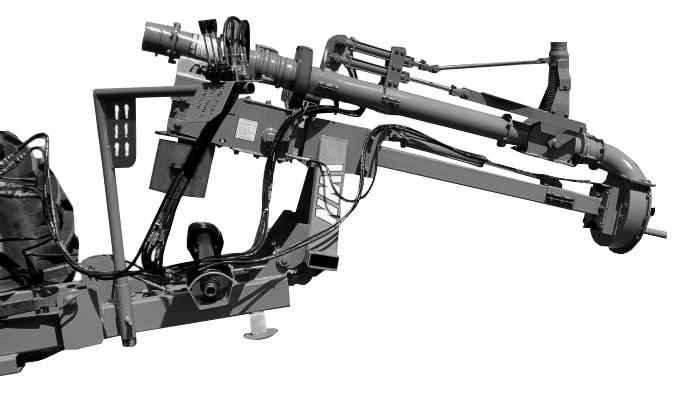

Visit your local Wisconsin KUHN livestock dealer today! INVEST IN QUALITY ® www.kuhn.com Farmers' Implement Allenton D & D Farm Supply Arcadia Chili Implement Chili Cherokee Garage Colby Beaver Machine Coleman Kalscheur Implement Cross Plains Komro Sales & Service Durand Hillsboro Equipment Hillsboro W. H. Lien Hixton Eron Equipment Junction City Luxemburg Motor Co. Luxemburg Lulich Implement Mason Persha Equipment Mayville Lindstrom Equipment Mondovi East Side Farm Equipment Monroe Midwest Machinery Osceola New Richmond Turtle Lake Steinhart's Farm Service Platteville Gruett's, Inc. Potter Priebe Sales & Service Ripon Tesch Bros. Implement Seymour Riesterer & Schnell, Inc. Shawano Eis Implement Two Rivers Gibbsville Implement Waldo Carl F. Statz & Sons Waunakee Spiegelberg Implement Weyauwega Triebold Implement Whitewater A.C. McCartney Durand, IL Peabudy's North Pecatonica, IL BOTEC ® 4100 SERIES 4-Auger Mixers 360 and 480 cu. ft. capacity • trailer and truck models CONSISTENT , MORE THOROUGH MIX Auger design provides a fast, thorough and consistent mix Large discharge allows for quick, even ration unloading Roughage and grain auger options handle a variety of materials Lower horsepower requirement for economical fuel usage Stop by and visit us to check out what’s new at Stopbyandvisitustocheckoutwhatsnewat Sto p bp y a nd visit us to check out whats new at OCTOBER 4 - 7 • MADISON, WI • BOOTH: TM F

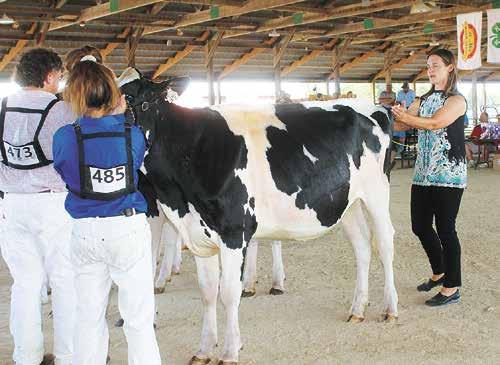

Columnists For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, September 24, 2022 • Page 3 Each generation of Eickelkraut family puts individual stamp on farm First Section: Pages 23, 25 Belleville, WI McFarlandale Dairy hosts community for on-farm event First Section: Page 31 - 32 Watertown, WI Mertens family hosts daughter’s wedding on goat farm Second Section: Pages 12 - 13 Thorp, WI Women in Dairy: Stephanie Hammerly First Section: Page 29 Wisconsin Dells, WI Waupun State Farm, dairy processing plant offer opportunity to prisoners First Section: Pages 1, 8, 9 Waupon, WI Salbers left conventional farming methods behind 20 years ago Second Section: Pages 6 - 7 Browerville, MN Bue, Stetzer team up to judge Central Wisconsin State Fair First Section: Pages 26-27 Marsheld, WI What are some of the biggest safety concerns farmers need to consider? First Section: Pages 15-16 FROM OUR SIDE OF THE FENCE: Zone 2 Zone 1 Ag Insider Pages 2, 5 First Section Pa Fir Fi s Ramblings from the Ridge Page 36 First Section Ram fro R Pa Farmer and Columnist Page 35 First Section Dairy Good Life Page 39 First Section Just Thinking Out Loud Page 38 First Section Ju O F Something to Ruminate On Page 37 First Section So R P Firs The “Mielke” Market Weekly Pages 8 - 9 Second Section www.automatedwastesystems.com (712) 439-2081 Watertown, SD (605) 753-0300 Hull, IA COMPLETE MANURE EXPERTS Winghaven Pizza Farm celebrates ve years in business First Section: Pages 10 - 11 Galesville, WI Ninnemann Enterprises embraces robotic retrotted tiestall barn First Section: Pages 12 - 13 Wausau, WI

(2) N-H 499, 12’ Haybine ..............Starting at $3,450

‘97 N-H 1465, 9’ Haybine...............................$9,500

N-H 790, 824 Cornhead, Hayhead .................$7,950

H&S 7+4, 14’ Forage Box and Wagon............$3,750

Meyer 4516 Forage Box .................................$7,500

‘16 N-H 460 Rd Baler, CropCutter ................$28,500

‘12 N-H BR-7080 Rd Baler, Net & Twine

‘95 N-H 660 Rd Baler

‘20 N-H BC-5060 Baler w/thrower

‘07 H&S HDX-17, 17 Wheel Rake

Tonutti V14, 14 Wheel Rake

New Idea 402 Rake N-H 144 Invertor............................................$2,500

USED MISC

‘14 H&S 550 Hydra Push Spreader

‘16 N-H 185 Spreader

(2) H&S 270 Spreaders at $7,500.00 Gleaner R-60 Case IH 1660 Case IH 1660

Page 4 • Dairy Star • Saturday, September 24, 2022 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Advanced Dairy Systems 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 Anderson Dairy Systems, Inc. 1312 13 1/2 Ave. • Barron, WI 54812 (715) 537-3300 Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 1467 West 5th Street • Winona, MN 55987 (507) 452-5532 Leedstone 222 E Co Rd 173, Melrose, MN 56352 (320) 256-3303 24260 Cty. Rd. 27 • Plainview, MN 55964 (507) 534-3161 Athman Dairy Inc. 238 Main Street North • Pierz, MN 56364 (320) 468-2494 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Professional Dairy Systems 1449 Homecrest Ave. • Wadena, MN 56482 (218) 632-5416 Leedstone 1720 Freitag Dr. • Menomonie, WI 54751 (715) 231-8090 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Fuller’s Milker Center, Inc. 423 U.S. 61 • Lancaster, WI 53813 (608) 723-4634 278 W. Court St. • Richland Center, WI 53581 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 Get your cows’ teat ends in TOP CONDITION! • Dual Germicide: Primary: Chlorine Dioxide promotes a quick kill. Secondary: LAS promotes a long-lasting kill. • Effective against ALL Mastitis-Causing Organisms • Contains Lactic Acid to promote Teat Exfoliation • Teat skin conditioning – 12.4% skin conditioning package • Green coloring for easy identification BEFORE Exfoliation AFTER Exfoliation TEAT END ISSUES? THE NEXT GENERATION INNEXT ON-FARM WATER TREATMENT Chlorine Dioxide Technology HIGHLY EFFECTIVE AGAINST: Prototheca • Staph Aureus • Mycoplasma • Pseudomonas Dirty Water? • Respiratory Issues • Scours • Crypto • Salmonella • E-coli GREATLY REDUCED: Pure 3000 CLEAN IT UP WITH Removes IRON, MANGANESE and SULFUR in water! HEALTHIER CALVES HEALTHIER COWS LED Lighting LED Long Day Lighting Parlor LED Lighting Sales & Installation Fuller’s Milker Center is a preferred trade Ally with Focus on Energy (800) 887-4634 • Lancaster, WI (608) 647-4488 • Richland Center, WI fullersmilkercenter.com Focus on Energy’s Bonus Rebates until Dec. 15th on LANO Equipment of Norwood 952-467-2181 A family business since 1946 with the Lanos: Jack, Paul, Bob and Andy USED EQUIPMENT FROM A NAME YOU CAN TRUST! CHECK OUT OUR LARGE SELECTION OF HAY EQUIPMENT AND TRACTORS! Many used & new skidloaders ON HAND USED TRACTORS ‘63 A-C D-15 Series II, Loader, 3 Pt. .............$6, 500 ‘62 JD 2010RU, Gas 1085 hrs. ......................$8,900 ‘72 JD 4000, Diesel,.....................................$18,500 USED SKIDSTEERS ‘13 5600 Toolcat, 575 hrs. ..........................$46,500 ‘17 T-650, Glass Cab with A/C, 2 spd, 2400 hrs .....................................................$49,900 ‘15 T-450, Glass Cab & Heater, 2 spd, 3500 hrs. ....................................................$32,500 (2) S-770, Glass Cab w/ A/C, 2 spd, 2500 hrs & Up ............................Starting at $35,900 (2) S-650, Glass Cab w/ A/C. 2 spd, 500 hrs & Up ..............................Starting at $28,500 (2) S-590, Glass Cab w/ A/C, 2 spd, 450 hrs & Up ..............................Starting at $29,500 ‘16 S-570, Glass Cab w/ A/C, 2 spd, 7000 hrs ...$22,900 ‘19 S-550, Glass Cab w/ A/C, 2 spd, 1500 hrs ...$30,900 ‘19 S-450, Glass Cab & Heater, 2500 hrs. ...$24,500 (2) S-185, Glass Cab with A/C. 2 spd, 1800 hrs & Up ............................Starting at $17,900 ‘18 Cat 236D, 775 hrs ..................................$43,900 Cat 926 Loader ............................................$22,900 USED TILLAGE ‘13 W-R 13QX2 60’, 3 Bar Harrow w/Rolling Baskets ........................................................$36,900 ‘12 W-R 13QX2 50’, 5 Bar Spike Harrow .....$28,500 ‘12 W-R 13QX2 47’, 3 Bar Harrow w/Rolling Baskets ........................................................$34,500 ‘04 W-R Excel 38’, 4 Bar Harrow .................$12,900 ‘10 Krause 4850-15, 15’ ..............................$18,900 I-H 720 Plow, Coulters, 5 Bottom ..................$1,150 ‘11 Landall 3130, 36’ Roller .........................$18,900 DMI ET5 Ripper .............................................$7,500 USED PLANTERS White 6100, 12x30, Verticle Fold .................$10,900 White 6700, 12x30, Verticle Fold ...................$7,500 USED HAY EQUIPMENT ‘12 N-H H-7450, 13’ Discbine ......................$20,500 ‘20 N-H 210, 10’ Discbine ............................$23,500 ‘14 N-H H-7230, 10’ Discbine ......................$18,900

Wrap ............................................................$15,300

.....................................$4,950

...............$24,900

................$12,900

...........................$4,100

...........................................$850

.............$28,000

..................................$12,900

...........Starting

‘90

Combine.............................$9,900 ‘87

Combine ..........................$11,500 ‘87

Combine ..........................$15,500

Putin, Xi collaborate

Russian President Vladimir Putin and Chinese President Xi Jinping met for a face-to-face meeting in Uzbekistan. In addition to security issues, the two leaders agreed to cooperate more on trade and agriculture.

USDA invests in climate-smart projects

USDA is investing up to $2.8 billion for 70 projects in the rst Partnerships for Climate-Smart Commodities funding pool. Climate Scaling Mechanisms for Agriculture’s Regenerative Transformation projects include a market-based program with Truterra to increase adoption of climatesmart farming practices to produce grain and dairy products. Another example would be a Dairy Farmers of America pilot project using the cooperative business model to capture the nancial benets at the farm level. South Dakota State University received $80 million to create marketing opportunities for bison and beef producers who use climate smart grazing and land management practices.

CHS shares prots with ownermembers

CHS plans to return $1 billion in cash patronage and equity redemptions in calendar year 2023. This will be the largest cash distribution in CHS history.

DATCP budget request

The Wisconsin Department of Agriculture, Trade and Consumer Protection has released its budget request for the 2023-25 biennial budget. The list includes $2 million per year for county conservation funding, $1 million per year for the Wisconsin Initiative for Agricultural Exports, $200,000 per year for the Dairy Processor Grant Program and $100,000 per year for the Farmer Mental Health Assistance Program.

Northeast organic dairies nd new markets

Nearly 90 organic dairy farms in the northeastern United States received termination notices last year from Horizon Organic. Sixty of those farms have joined Organic Valley and eight have joined Stonyeld. Thirteen dairy farms left the business and at least one shifted to a conventional milk market.

Digital tickets available for WDE World Dairy Expo is introducing new digital admission passes. The digital tickets can be purchased before Expo. WDE General Manager Laura Herschleb said this is a move toward efciency. “Expo recognizes that attendees only have so much time to spend at the event and they want that

time spent on the grounds not waiting in line,” Herschleb said. WDE will be held Oct. 2-7.

Leopold Conservation Award to be presented this fall

The nalists have been selected for the Wisconsin Leopold Conservation Award. The $10,000 award is presented each year by the Sand Country Foundation, American Farmland Trust, Wisconsin Farm Bureau and Dairy Farmers of Wisconsin. Full Circle Farm, of Seymour, Wisconsin, has nearly all of its 240 acres in pasture, building soil organic matter while sequestering carbon. Joe Hovel, of Conover, Wisconsin, is the president and founder of Partners in Forestry Landowners Cooperative and works to protect ecologically important habitat. Noll’s Dairy Farm, of Alma, Wisconsin, restored and manages an ecologically rare dry bluff prairie and practice conservation on their farm. Tomandl Farms, of Medford, Wisconsin, hosts pasture walks at their three dairy farms where they highlight the benets of conservation and rotational grazing. The award will be presented in November.

WFBF nalists named

The Wisconsin Farm Bureau has named four nalists for its Outstanding Agriculture Professional Award. The nalists include Christa Hoffman of Shawano County, who is a business development administrator for URUS. Amy Silver of Green County is an agricultural lender at State Bank of Cross Plains. Julie Sweney of Dodge County is director of communications and marketing for FarmFirst Dairy Cooperative. Julie Wadzinski of Barron County is a farm operations instructor at Northwoods Technical College. This award recognizes agricultural individuals who have not received most of their income from a farm in the past three years. The award will be presented at the WFBF annual meeting in December.

Trivia challenge

Grilled cheese is the most popular cheese recipe in the United States. That answers our last trivia question. For this week’s trivia, who invented chocolate milk? We will have the answer in the next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Dairy Star • Saturday, September 24, 2022 • Page 5 BENEFITS OF USING DIRECTIONAL DRILLING INSTALLATION INCLUDE: Continuation of Normal Operation Avoidance of identi ed Infrastructure Installation Maintain Integrity of Driveway, Roadways, Buildings, and Natural Features Little to No Disturbance to Wetlands or Other Sensitives Areas Many Unique Installation Capabilities Vs. Open Cutting/Digging (Entering underBuildings or Tanks) Minimal Site Restoration PRODUCT INSTALLATION Gas Lines Power Wire/ Lines Communication/ Fiber Optic Water Lines/Water Mains Drainage/ Tile Lines Forced/ On Grade Sewer Manure Transfer Lines Land Improvements Drain Tile Design/ Installation • Ditch Cleaning & Grading • Fenceline Clearing Changing weather and higher inputs got you down? Using Drain Tile to manage excess moisture in the soil pro le is the foundation for increasing pro tability per acre. - Less compaction - Better soil Structure - Allows more days per year for eld operations - More Yields with same or less inputs Contact us m line!today to see how we can improve your botto MIKE HAESE MECHANDISER 920-372-8549 ext: 1595 We can Supply your Bulk Feed and Bedding! Animal Feed Products: • Canola Meal • Corn Gluten Pellets • Dry Distillers Grain • Feed Quality Wheat Straw • Hominy • Oat Hulls • Soy Hull Pellets • Soybean Meal • Western Dry baled hay & Local dry baled hay • Wet Corn Gluten Feed • Wet Distillers Grain • Whole Fuzzy Cottonseed Animal Bedding Products: • Bedding Straw • Green Cut Sawdust • Kiln Dried Sawdust • Screened Freestall Sand We understand that running out of product has a negative impact on your margins. We have developed a network of storage facilities to draw from in case of a supplier shortage or breakdown, with a large trucking base to ensure timely delivery. www.SevenOaksTeam.com Call Us to Discuss Your Project Now! Chad Van Asten 920-450-2844 www.SevenOaksTeam.com Con nued from AG INSIDER | Page 2

15255 10th St. NW · Cokato, MN 320-286-6284 www.hobartsales.com On Hand & Ready to Go! NEW, REBUILT, USED 50Years

“We don’t ever get away,” Plucinski said. “We do all the work ourselves around here, and all week we planned to take this trip that Sunday.”

The Plucinski family left their house at 8:15 a.m. and by 8:54, they received the dreaded call.

“We only got to Waterloo and made it back to the farm by 9:25 a.m.,” Plucinski said. “We could see the re from the hill when we drove down the road. It was a big re, and the smoke was so thick, it was hard to see the house. I remember thinking, ‘I can’t believe this is happening; this is our farm.’”

Pieces of their future are now scattered everywhere. But, Plucinski does not view any situation as hopeless. Her undaunted faith is seeing her and her family through this nightmare that life has thrown their way. Thankfully, no people or animals were hurt in the re. Cows were on pasture, and the only animals in the vicinity of the re were seven calves huddled in the back of a nearby hoop barn that started to melt.

“The smoke went in the opposite direction, so all the calves were ne,” Plucinski said. “Derek was down there all day checking on them. The kids and I were in the house. We just stood and watched in disbelief out the window.”

Numerous re departments worked to extinguish the re that raged persistently on a miserably wet and rainy day. Days later, the remains of the barn still smoldered. The cause of the re is not yet known.

“It was an emotional moment with it being 9/11,” Plucinski said. “That’s signicant to us and seeing all the retrucks here really struck a chord.”

When nding a temporary home for their cows, the Plucinskis had to choose organic. For this reason, they were unable to move the cattle to Plucinski’s parents’ farm. Milk cows are being housed a half hour away at another organic farm that is on the same milk route as the Plucinskis. Derek drives back and forth to help with milking.

“We have to try and get organic feed,” Plucinski said. “All of our bedding and dry hay for the winter was destroyed in the re. It’s a lot of labor to make small square bales, and poof; they’re gone. Lots of people are offering us feed, and I feel bad turning it down, but we can only feed organic. A big chunk of our income comes from being organic.”

None of their equipment was damaged, and Plucinski said they have crops to harvest, which they are thankful for. The Plucinskis recently expanded their herd, buying 25 cows as they work toward their goal of milking 75 head. The couple is transitioning to seasonal calving and is currently in the middle of their calving window.

“The last two months were really tight with milk and money,” Plucinski said. “The cows were just freshening, and now, they’re gone. We needed that money.”

A shamble of dreams lies where the 48-stall tiestall barn once stood. Little treasures are strewn about in the rubble, like the red gate Plucinski recently purchased and the milk cart she bought

her husband for his birthday.

“There’s a lot of sentimental value there, but I know what each item costs too, and everything adds up,” she said. “I look at it all and see money that’s gone. It’s tough seeing where the calving pen once was. I always set my kids there to play with the calves.”

The barn is a complete loss as well as a grain bin containing oats and peas that was just harvested by the Plucinskis. One of the silos was lled with ames and will not be used for corn silage this year.

“We loved the beautiful old barn,” Plucinski said. “It was full of nostalgia. I loved that it was handmade by people, not machines. There was so much history here.”

The Plucinskis had removed the stanchions from the barn, and nine months ago, they put in a 6-stall walk-through milking parlor on one end of the barn.

“It was extremely devastating watching an excavator smash what we just built,” Plucinski said.

“It was a homemade system that was really well set up for Derek to milk alone because we couldn’t get help.”

Seeing the generosity of their community has been a bright spot in the darkness, as people reach out with donations of food, money and gift cards.

“People want to help, and we are so grateful,” Plucinski said. “We have complete strangers sending money through Venmo or dropping stuff off at our house. But, there’s also so much power in prayer. We believe in that. We don’t know what our future holds, but we feel a sense of community holding us up.”

On the day of the re, help also came spilling in from every direction.

“There were people everywhere along with cattle trucks lined up to move cattle,” Plucinski said. “It brought me to my knees in gratitude. When something like this happens, you see the amazing people that are out there. From those working in the industry to a neighbor driving by, you see the people who truly care from their heart.”

While smoke continues to billow from the ruins, an eerie silence lls the farm.

“Our goal right now is to rebuild,” Plucinski said.

But, not owning the farm has thrown another wrench into an already bad situation.

“We were getting ready to buy the place on a land contract and were in the process of transferring ownership from our landlord,” Plucinski said. “We had until the end of the year to button everything down. Now, I don’t know what will happen. If we can’t get the cows back here in a reasonable timeframe, we won’t be able to rebuild, and that’s terrifying. The farm is our everything, but we stand to lose it all.”

Uncertain of the future, the Plucinskis are holding fast to their faith and praying that a new beginning on the farm they have called home for the last four years is in store for their family.

“Please keep praying for us,” Plucinski said. “We can feel the prayers and feel God’s hand working here. We trust his plan.”

PHOTO SUBMITTED

The Plucinski family –(from le ) Meg holding Elvira, Fitzgerald, Wya and Derek holding Eleanor – milk 40 cows and farm 300 acres near Jefferson, Wisconsin. The organic farmers’ dairy barn was destroyed in a re Sept. 11.

PHOTO SUBMITTED

The Plucinski family –(from le ) Meg holding Elvira, Fitzgerald, Wya and Derek holding Eleanor – milk 40 cows and farm 300 acres near Jefferson, Wisconsin. The organic farmers’ dairy barn was destroyed in a re Sept. 11.

Page 6 • Dairy Star • Saturday, September 24, 2022 800 776 7042 | coburn.com WEAR Work Approved Dairy UtiliSleeve Dairy UtiliApron • Comfortable & lightweight • Fully adjustable fit • Waterproof EVERYDAY WORKWEAR www.LangeAgSystems.com Lange Ag Systems is proud to offer Grain Bags, Silage Bags & Bunker Covers from Up North Plastics and Feed Fresh Silage Covers & Custom Size Bunker Covers from Raven! Willmar, MN • 320.231.1470 LANGE AG SYSTEMS SPECIALIZES IN: NEW FACILITIES NO JOB TOO BIG OR TOO SMALL RETROFITTING & REMODELING TURNKEY PROJECTS BARN DESIGN INSTALLATION, MAINTENANCE & REPAIRS EXPANDING OR REMODELING YOUR LIVESTOCK OPERATION? 800-289-6225 www.transourceusa.com ‘17 Volvo CE L60H 3,990 hours Call for Price ‘21 Volvo CE EC380EL 544 hours Call For Price ‘21 Volvo CE L180H 409 hours Call for Price PREMIUM PRODUCTS BACKED BY SUPERIOR SUPPORT Sioux Falls, SD • Rapid City, SD • Aberdeen, SD • Sioux City, IA Con nued from PLUCINSKIS | Page 1

Producers in all 50 states will participate in the program including an array of commodities. The USDA expects more than 50,000 farmers to participate in the effort and up to 25 million acres of land across the U.S. to be impacted with climate-smart practices. Vilsack said he expects 100 new market opportunities to become available. It is also anticipated the program will bring the agriculture sector’s carbon footprint closer to neutral.

“We are hopeful that by the time it’s all said and done, roughly 50 million metric tons of greenhouse gas, or CO2 equivalent, is either prevented, eliminated or stored,” Vilsack said.

The program is voluntary, provides incentives for participation without penalizing early adopters, educates the markets to get a higher value for products produced and also encourages partnerships.

Universities, environmental groups, farm groups, processors, retailers and energy companies are just some of the groups forming partnerships in the program. The partnerships are encouraged so data can be accurately collected and analyzed, thus ensuring appropriate value to the outcomes.

Nicole Rakobitsch, sustainability manager at Organic Valley, said the funding will take the company’s carbon insetting program from a one-year pilot program to a multi-year program. Within ve years, she anticipates there will be more trees planted, solar energy systems on farms, increased use of diverse cover crops, increased intensity of grazing and use of feed supplements to reduce entire emissions on dairy farms.

Tim Trotter, CEO of Edge Dairy Farmer Cooperative, said the funding will allow farmers to be innovative with their on-farm practices, which should allow the next generation to carry on within the dairy industry.

Matthew Woods, of The DeLong

ABBY WIEDMEYER/DAIRY STAR

U.S. Secretary of Agriculture Tom Vilsack speaks at a press conference Sept. 15 at the Anibas family farm near Arkansaw, Wisconsin, about the U.S. Department of Agriculture Partnerships for Climate-Smart Commodi es program that was announced Sept. 14.

Co., said the funding will be used to offer per acre direct incentives for farmers who use climate-smart practices on those acres.

“It’s going to cover things like cover crops, nutrient management programs, no till and windbreak establishments,” Woods said. “We are going to be recording on-farm data from those acres that they enroll.”

Vilsack said when he came back to the department, one of the rst things that landed on his desk was a report that indicated 89.6% of farms in the country do not generate the majority income for the family on the farm.

“This means that those farms, somebody’s working off the farm,” Vilsack said. “We can’t say that we’ve got a completely successful model if only 10% of the folks in agriculture are able to make a living off of what they do and what they love to do. So, our task at USDA is to gure out more and better markets.”

GRAPHIC SUBMITTED

GRAPHIC SUBMITTED

Dairy Star • Saturday, September 24, 2022 • Page 7 Treat lagoon sludge naturally with BEEF & DAIRY LAGOON SPHERES! • Reduces solids & build up • Easy to use, NO mixing required • Cost effective • Works at the bottom where problems occur WHEN TO USE • Need to reduce sludge layer • Improve deep pit storage capacity • Helps reduce crusting Bioverse, Inc. 2220 Research Lane, Worthington, MN 56187 Phone: 507-727-1000 • Toll Free: 866-272-3775 myhealthyfarms.com • Increase nutrient values of manure • Make pumping easier • Reduce odor allocating $2.8 billion to those 70 projects.”

Con nued from VILSACK | Page 1

a.m. and is done at 11 a.m. In custody since 2018, Craig is scheduled for release October 2024.

“This is hard work,” he said. “I did construction my whole life, but it’s eye opening all that goes into farming. I grew up in rural Wisconsin with farms all around me, but I was never on a farm before here. I’ve learned a lot about cows, and I’ve learned to be patient.”

Craig said time spent working on the farm helps with his rehabilitation.

“I like being able to get away and feel like a normal person a little,” he said. “You have a lot of time out here to reect on yourself. When you’ve been in prison and come to the farm, you realize what you’re missing. It’s wide open here, and I think it makes you feel better about yourself.”

The recent completion of a $6.5 million investment in Waupun State Farm is propelling the operation into the future. A transition barn built in 2021 houses dry and pre-fresh cows as well as the herd’s highest producing animals.

“This barn is focused on cow comfort and a healthy environment, offering superior ventilation,” Hensel said.

The 170-stall barn contains sand and straw bed pack areas. One side is for highproduction animals milking 90 to 130 pounds per day. The

other side of the barn houses dry cows pens for cattle one to two weeks away from calving.

In addition, the facility project included increasing manure pit capacity from 1 million gallons to 4 million gallons.

“The bigger manure pit allows us to more carefully and

cost efciently manage manure and its placement on our acres,” Ray said. “We have to take good care of the land.”

Cow comfort and highquality animal care are top priorities at Waupun State Farm. DATCP inspects the farm every other year, and the facility regularly receives high marks

and awards for farm operations and quality milk production, Romanski said.

Cows are milked twice a day in the farm’s double-10 herringbone parlor and average 90 pounds of milk per cow per day. All cattle on the farm are bred with A.I.

“Genetics are important to

us,” Ray said. “We breed for the quality replacement heifers.”

Eleven state employees, including Hensel, work at Waupun State Farm alongside the prisoners.

Hensel grew up on a dairy farm near Fond du Lac and has worked at Waupun State Farm for 20 years; he has been the farm supervisor for six years. Each employee is a security position. For example, Hensel is a lieutenant, and the BCE’s agriculture manager is a captain. All staff have a security background and are equipped with the training and experience necessary to diffuse a potential negative situation.

The privilege to work outside the fence depends on where a person is at in their sentence and when their return home is scheduled. Each one is reviewed by the center superintendent and warden. Offsite approval is earned through a record of good behavior, compliance and rule following. The prisoners are workers on the BCE farm, which makes starting pay is $0.55 an hour with the potential to earn $1.65 per hour.

Donald, from Dunn County, takes care of calves and has been working on the Waupun State Farm for nine months. He works 9 a.m. to 9 p.m., and his responsibilities include newborn calf care, clean-

STACEY SMART/DAIRY STAR

Donald, a prisoner from the John C. Burke Correc onal Center, bo lefeeds a calf Sept. 8 at Waupun State Farm near Waupun, Wisconsin. Donald has been working on the farm for nine months and typically works 12-hour days caring for the calves.

STACEY SMART/DAIRY STAR

Donald, a prisoner from the John C. Burke Correc onal Center, bo lefeeds a calf Sept. 8 at Waupun State Farm near Waupun, Wisconsin. Donald has been working on the farm for nine months and typically works 12-hour days caring for the calves.

Page 8 • Dairy Star • Saturday, September 24, 2022 PULASKI WAREHOUSE, INC. Fall Planting Good Selection of Small Farm Seed, Alfalfa, Clover, Grasses, Etc. CRP & Pollinator Mixes CALL US Cover Crops & Cover Crop Mixing Available! CERTIFIED & QUALITY ASSURED WINTER WHEAT Gold Reserve, 50# ......................$19.99 Awnless, medium tall height, excellent test weight and good standability, very good winter hardiness and high yielding Sittin’ Pretty 50# ........................$19.99 Tip awned, medium height, excellent standability L-920, 50# ....................................$19.99 Awnless, medium height, very good standability, test weight and high yielding L-024, 50# ...................................$21.99 Awnless, medium maturity, medium height with good standability, high yield potential, very good test weight Pro 410 Brand, 50# ....................$21.99 Awned, high-yielding, very good winter hardiness, excellent lodging resistance COMMON WINTER WHEAT Kaskaskia, 50# ...........................$18.49 Awned, white chaffed, medium height, very good winter hardiness, high yields and test weights Winter Rye Grain, 50# ................$17.99 Winter Triticale, 50#...................$21.99 A hybrid of winter wheat and winter rye LAWN GRASSES Athletic Lawn Mix, 50 lbs .............$179.95 Sunny Lawn Mix, 50 lbs................$199.95 Shady Lawn Mix, 50 lbs ................$189.95 Perennial Ryegrass, 50 lbs ............$159.95 Creeping Red Fescue, 50 lbs .........$239.95 Kentucky Bluegrass, 50 lbs ...........$199.95 Turf Type Tall Fescue, 50 lbs ..........$139.95 White Dutch Clover, 50 lbs............$209.95 WILDLIFE FOOD PLOT SEED Wildlife Clover Mix, 50 lbs ............$219.95 Brassica Brunch, Mix 3 lbs ..............$15.99 Chicory, 1 lb .....................................$7.95 Widow Maker Brassica, Mix 3 lbs....$15.99 Dwarf Essex Rape, 50 lbs ................$62.95 Turnips-Purple Top, 50 lbs ..............$99.95 Buck Forage Oats, 50 lbs .................$37.95 Buck Buffet Fall Forage Mix, 25 lbs .$16.95 Austrian Winter Peas, 50 lbs ...........$45.95 MILK REPLACER PRODUCT PROTEIN FAT PER 50# BAG 20/20 All Milk Incredi-Blend 20% 20% $83.99 22/20 All Milk Incredi-Blend 22% 20% $87.99 22/20 MEDICATED 22% 20% $88.99 All Milk Incredi-Blend We take care of calves, naturally! lection of Small Farm LAWNGRASSES PRODUC T ME In ca We carry a full line of Purina, Big Tine & Antler King blocks SEE US FOR SUPPLEMENTAL DEER/WILDLIFE FEED, MINERALS & ATTRACTANTS New Optimum Whitetail Mineral Now Available! FERTILIZER WINTERIZER 12-0-18 + FE (Covers 10,000 sq. ft.)...50 Lbs........$23.99 Pelletized Lime 40 Lbs..................$6.49 PULASKI WAREHOUSE, INC. 5777 Quarry Drive - Pulaski, WI 54162 2-1/2 Miles South of Pulaski on Hwy. 32 or 2 Miles North of Hwy. 29 on Hwy. 32, Then 1/2 Mile East of Hwy. 32 on Quarry Drive Phone: 920-822-3536 WWW.PULASKIWAREHOUSE.COM HOURS: Mon.-Fri. 8-5; Sat. 8-Noon

Con nued from WAUPUN | Page 1

Turn to WAUPUN | Page 9

ing and bedding hutches, and feeding calves. Calves are fed pasteurized milk out of treated and fresh animals that is distributed through a portable milk dispenser.

“There’s more to farming than I thought,” said Donald, whose rst job on the farm was a second shift milker. “I had never been on a farm before I came here, and I’ve learned a lot about cattle and calves. I don’t mind the long, 12-hour day. I’m grateful to be out here and be part of a team.”

Donald has been with the Department of Corrections for two years and is scheduled for release September 2023.

“This is my fourth incarceration, but the worst is behind me,” he said. “I’ve done a lot of changing, and it’s all for the better. I like being out here and being productive rather than sitting and dwelling on what I don’t have. I’m thankful for this opportunity. The freedom to be here all day and work with the calves is awesome.”

Anthony, from Cincinnati, Ohio, has been on the farm team for three months. He started as a scraper and now works at the equipment operator level mixing feed and feeding cows.

“I was a carpenter for 20 years, and that’s hard work in itself,” he said. “And, then I come here and have a whole new respect for farmers.”

Anthony has spent eight years with the department and is scheduled to be released next June.

“I put myself in this position,” he said. “It’s my fault. But, I like it here on the farm. I’m not behind a fence. When you’re in prison, you have lots of time to reect on your past. Hours

and days in a room changes how you think and feel. I’ve learned a lot of patience and learned it’s possible to work with others and accept people for who they are.”

The BCE also operates a dairy farm near Oregon, Wisconsin, that milks 180 cows. Milk from both farms is shipped to Waupun Dairy, which is also part of BCE. The dairy processing plant opened in 1994 and is located adjacent to the John C. Burke Correctional Center. Twenty-six inmates work at Waupun Dairy as well as ve civilians.

Waupun Dairy produces skim milk, vanilla and chocolate ice cream, and sherbet in orange and lime avors which they supply to correctional and mental institutions in Wisconsin and Minnesota.

Working on the farm or at the dairy is a form of rehabilitation and an opportunity to learn work skills and life skills, increasing the likelihood of one’s success when reentering society. Many return to their community and never misstep again. However, some will nd their way back to prison more than once.

“We work as well as we can to closely replicate private sector job selection and employment,” Ray said. “We want to get persons in our care thinking, feeling and behaving like they’ll need to in order to succeed when they go home. We are focused on these men’s successful futures. If working at the farm or dairy is an advantage to them, then it’s an advantage to their family and the whole community when they return home.”

HARD DEMANDS HARD-WORKING DIESEL.

Dairy Star • Saturday, September 24, 2022 • Page 9 LED LIGHTING Sales & Installation LED Long Day Lighting Parlor LED Lighting STEVEN ZIEGLER, ZIEGLER DAIRY FARMS, MIDDLETON, WI LED Lighting installed 2020 • Parlor and Freestall barn “Since we first purchased LED Barn Lights in 2018 we have continued to update our existing barn lighting and seen even more savings on our energy bills.” fullersmilkercenter.com FOCUS ON ENERGY’S BONUS REBATES UNTIL DEC. 15! ZIEGLER’S SAVED OVER 50% WITH REBATES! (800) 887-4634 • Lancaster, WI (608-647-4488 • Richland Center38241 County 6 Blvd. Goodhue, MN 55027 (651) 923-4441 Wil-Rich 3400 Field Cultivator w/4-Bar WR Coil Tine, 28’6”............................................................................ $9,900 Wil-Rich 5800 Chisel Plow 43’ .................................. $21,000 Wil-Rich 5800 Chisel Plow 45’ ............................... Coming In HAY & FORAGE, STALK CHOPPERS NH H7450 Discbine, 2011 Drawbar Hitch ................. In Shop NH RB560 2017 Round Baler 1,416 Bales, Like New $29,500 MF 1358 8’4” 3-Pt Disc Mower .............................. Coming In Vermeer 504 Pro Round Baler With Cutter, 11,500 Bales ............................................................. $28,500 Krone V180 Xc T Crop Cutter, 5,764 Bales ............... $43,000 JD 3950 Forage Harvestor W/7’ Hay Head Consigned $4,500 ‘09 H&S GM170 Feed Mill ......................................... $19,500 H&S HDX 14 Wheel Rake .......................................... $15,300 ROW CROP, DRILLS & SPRAYERS Hardi NP1100 80’ Boom, Foam, 463 Pump, 2500 Rate Controller,..............................................Coming In Hardi Navigator 3500, 2013 60’ Boom, Foam, 463 Pump, 5500 Rate Controler............................... $21,500 Hardi Navigator 4000, .............................................Coming In CIH 5100 Grain Drill 12’ W. 6” Spacing. No Small Seeds. .....................................................Coming In Great Plains YP1225-24 Twin Row 30” Planter, Finger Pick-Up, 400 Gal LF ...................................... $74,000 JD7000 12r-30” Planter, No Fert, No Row Cleaners, Consign ....................................................................... $7,500 White 9816 Planter 16r30, 750 G Lf, Yetter Clean Sweep Row Cleaners........................... $84,000 GRAIN EQUIPMENT Good Selection Of Used Augers .........................................Call MISCELLANEOUS Bobcat TS44m Tree Spade On Consignment ........... $15,000 Bobcat 94” Snow Pusher Looks Like New ................. $3,200 Bush Hog TD-1500 Tri-Deck Finish Mower 15’ ........ $10,500 Bush Hog BH217rotary Cutter 2020 .......................... $3,900 Bush Hog Sq 840 3-Pt Rotary Cutter. ........................ $2,400 Bush Hog 3008 8’ 3pt Rotary Cutter Consigned ........ $5,300 Landpride 48” Box Blade Bb1248 ................................... $550 Merry Mac TPH-12 3pt Wood Chipper ....................... $1,200 Massey Ferguson 2320 54” Mid-Mount Mower Deck $1,100 Meyer 80” Skid Steer Mount Snowpusher, (Has Rubber Edge) ..........................................................$900 SUPER SPECIALS TRACTORS MF 8670 FWA Tractor w/ 1,662 hrs. 2013 ............. $164,000 MF 5711 CAB FWA Tractor, 946x Loader, 614 hrs ... $67,000 MF GC1725M Compact w/ DL95 Loader, 60” Deck, 234 hrs........................................................................ $14,500 NH T4.75 CAB FWA, Loader. 2017 w/ 550 hrs ......... $49,000 COMBINES & HEADS ‘10 Gleaner R76 Combine, Duals, 1787 Sep, 2751 E. Hrs CDF Rotor.......................................... Coming In ‘05 Gleaner R75 Combine, 2,204 Sep, 3,133 E. Hrs Coming In Gleaner 3000 /Challenger CH630 6R30” Corn Head, Single Point............................................................ Coming In ‘10 Gleaner 9250-35 Draper Head.......................... Coming In Gleaner 8200-35 Flex Head With Orbit Reel 2009 .... $20,000 Gleaner 8200-35 Flex Head With Crary Air Reel .... Coming In ‘13 Geringhoff Rd630 Corn Head, Gleaner Mounts.. $32,000 ‘00 Geringhoff Rd630 Corn Head, Consigned, Gleaner Mounts ........................................................ $14,000 Gleaner 300 Series Pick-Up Header Melroe Pickup, New Belts .................................................................... $4,500 Gleaner 313 Pick-Up Header ....................................... $3,500 SKIDS, TRACK LOADERS, TELE-HANDLERS, & EXCAVATORS ‘07 Bobcat S185, Cab, 4900 Hrs ........................... Coming In ‘19 Bobcat S595, Cab Hvac, 4,330 Hrs, H/F Control, 2 Spd, .................................................... In Shop Bobcat 753, Open Cab, 5,700 Hrs .......................... Coming In ‘19 Bobcat T595 Track Loader, Cab ........................ Coming In ‘21 Bobcat T66 Track Loader, Hvac Cab, Joystick, 375 Hrs .................................................................. Coming In Bobcat T770 Track Loader, Hvac Cab, H/F Controls .. In Shop Bobcat Toolcat 5600 With 3,000 Hrs ........................ $26,000 ‘99 Deere 270 Skid Steer H/F Controls, Open Rops, 14-17.5 Tires ............................................................ $19,500 Mustang 3300v, Cab w/Heat. H/F Controls ............ Coming In TILLAGE/FIELD CULTIVATORS DMI Tigermate 21.5’ Field Cultivator, w/5-bar spike tooth .................................................... $9,500 DMI Tigermate 32’ Field Cultivator w/3-bar coil tine . $9,500 ‘10 Sunflower 1435-26’ Disc ..................................... $31,000

WORK

A

A more complete additive package for a more complete burn. Keeping your o -road engines on point. Diesel that doesn’t mess around. Madison, SD (605) 256-4516 © 2022 CHS Inc. Cenex® is a registered trademark of CHS Inc.

Con nued from WAUPUN | Page 8

Partying with pizza

Winghaven Pizza Farm celebrates ve years in business

By Abby Wiedmeyer abby.w@dairystar.com

By Abby Wiedmeyer abby.w@dairystar.com

GALESVILLE, Wis. – Among the emerging craft beer and wine scene developing through southern Trempealeau County sits Winghaven Pizza Farm. The land that the Grover family claimed in 1852 near Galesville has seen a lot of changes during the last 170 years, most recently emerging as a rural venue to offer pizza.

Rob Grover, along with business partner and friend Greg Roskos, opened Winghaven Pizza Farm in 2017 as a way to utilize the land that was so dear to the Grover family and honor the love of food that Roskos’ late mother instilled in him. This combination produced a special place where local residents can enjoy a stone-red pizza, live music, drinks and a sense of community.

“With our heritage and knowing that there are so many farmers that have long legacies, we really wanted to be a part of supporting that,” Grover said. “To support the people in our community (who) have supported us is important.”

Winghaven cooks homemade, stone-red pizzas in a food truck on the property. On a busy night, Grover and Roskos, along with their staff which includes Grover’s sister, Sarah, will cook as many as 130 pizzas and host close to 300 people.

Recipes for the pizzas are developed by Roskos and Sarah. During a three-day weekend, the farm will typically go through 75 pounds of cheese. They use a three-cheese blend and mozzarella.

“We are pretty committed to getting the cheese from Wisconsin if we can,” Grover said. “We are kind of chasing prices right now like a lot of people.”

The top selling pizza is what they refer to

as the local classic, which includes pepperoni, sausage, green peppers and mushrooms. The group will also have specialty pizzas on occasion, such as the loaded mac and cheese pizza which is the September feature. Toppings include macaroni and cheese, pulled pork and barbecue sauce.

“We love our specialty pizzas,” Grover said. “But, we also know that especially in a rural area, you need the every-man’s pizza.”

Pizzas are cooked in a commercial food trailer that houses ve stations. A garlic butter is brushed on the crust before moving to the pizza maker, who assembles the sauce and toppings. Next, the pizza is put in an electric stone oven to bake. Baking takes about three minutes. Once nished, the expediter boxes the pizza and announces the name of the customer to come pick it up.

The oven cooks the 14-inch pizzas at 650 degrees.

“It makes a really crispy, aky crust,” Grover said. “We really like it. The electric oven is nice because it doesn’t put off any smoke.”

Guests eat on picnic tables in the renovated, three-sided barn and listen to a live band while they wait for their orders. They can enjoy drinks from the bar and fresh cheese curds from Ellsworth Creamery while they wait.

A lot of times, as many as 50 people show up at once when they open at 4 p.m. This sometimes creates over an hour wait for pizza.

“That’s why we have a band and a bar,” Grover said. “We’re not fast food, but it is good food and a great experience.”

Grover said that part of the experience people enjoy is the scenic farmland.

“It’s been a lot of dairy farmers that have held these elds together through generations,” Grover said. “One of the things that make people want to come out here is we’ve held on to our rural character and that wouldn’t have happened if it wasn’t for

ABBY WIEDMEYER/DAIRY STAR

The Grover siblings, Rob and Sarah, stand outside their pizza farm Sept. 14 near Galesville, Wisconsin. The siblings run an outdoor pizza venue with Rob’s business partner, Greg Roskos.

“One of the things that make people want to come out here is we’ve held on to our rural character and that wouldn’t have happened if it wasn’t for local dairy farmers.”

ROB GROVER, WINGHAVEN PIZZA

Page 10 • Dairy Star • Saturday, September 24, 2022 717.354.5040 | New Holland, PA Horning Row-Independent Cornheads make harvest a breeze. Built tough, these cornheads minimize breakdowns, freeing up your time and money. 320-200-1221 Visit us at www.justinaddy.com Avon, MN Covering MN, SD, IA, & WIDrink Milk Graduate of the Dairyland Hoof Care Institute Proud member of We do wide grooving and mini grooving Help keep your cows safe. Hoof trimming since 2003 WE OFFER COMPLIMENTARY: UDDER SINGEING TAIL TRIMMING Keep your cows cleaner, healthier & save time! MINI GROOVER Grooves concrete that has been already grooved. CALL FOR ALL YOUR CONCRETE GROOVING NEEDS Blue Hilltop, Inc. Dana Berreau 507-879-3593 / 800-821-7092 Box 116, Lake Wilson, MN 56151 Your Mixer, Spreader, Hay Processor Headquarters We carry:

PEOPLE MOVING PRODUCT

Turn to WINGHAVEN | Page 11

local dairy farmers.”

The connection to the dairy industry is also evident when neighboring farmers come for a pizza after chores. Grover said he considers dairy farmers to be partners in the pizza business.

“Without dairy farmers putting out a consistent product that people want to use, and having proximity to those products, we wouldn’t have a business,” Grover said. “We’re a pizza farm not a potato soup farm.”

Grover said purchasing trends of consumers in his area have evolved to

supporting more local vendors over the last couple years.

“The impulse to support local got so intense when (the coronavirus pandemic) hit,” Grover said. “People more than ever want a story and to know where their food comes from.”

Grover and Roskos hope to increase production as demand increases. Possibilities include upgrading the food trailer to accommodate cooking more pizzas. They also hope to add more frozen ice cream products and diversify the cheese curd avors.

Which favorite The SCC our favorite because it use it to ensure quality of milk. The too so those are

How does testing with DHIA bene t your dairy operation? It helps us monitor production and assists us in keeping our SCC low. It also aids in our breeding program.

Tell us about your farm. Brian’s parents, years ago, rented/or did shares on this farm and milked here for a period of time before they found their forever farm. Many years later, in 2000, Brian found himself here purchasing the farm. He started milking in 2002. I joined him in 2012 and a perfect farming match was made. It warms our hearts that we are milking in the same barn his parents once did.

Sauk Centre, MN Buffalo, MN 763.682.1091

What are some of the DHIA tests you use?

“It helps us monitor production and assists us in keeping our SCC low.”

PHOTO SUBMITTED

Guests enjoy pizza at Winghaven Pizza Farm near Galesville, Wisconsin. On a busy night they will serve 130 pizzas.

Dairy Star • Saturday, September 24, 2022 • Page 11

www.mndhia.org DHIA: Now MORE than ever

Julia and Brian Libbesmeier 63 cows • Watkins MN Close to 20 years with DHIA We use several: the SCC, butterfat, protein, pregnancy and Johnes tests.

is your

and why?

is

helps me catch cows with a higher cell count early. We

our SCC stays low and we are selling a higher

protein and butterfat tests play a part in the milk quality

important tests to us also.

Con nued from WINGHAVEN | Page 10

CENTRE DAIRY EQUIPMENT AND SUPPLY INC. Henning Area 218-849-0211 Jon Stein 320-352-5762 • 1-800-342-2697 40625 State Hwy. 28 • Just West of Hwy. 71 • Sauk Centre, MN AND SUPPLY INC. SERIOUSLY COMFORTABLE BOOTS A boot that works as hard as you do is nearly impossible to fi nd - but your search is over! Backed by over 70 years of footwear manufacturing expertise, the Quatro Boot is hand-built specifically specifi for the agribusiness industry and crafted with the highest level of comfort and durability in mind to provide you all-day comfort! One of the best boots available for hunters & farmers. Outdoor people NEED these boots! THE WORLD’S MOST COMFORTABLE BOOTS Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere Amino acids • Bypass protein OUR GREAT SERVICE OFFERS: Easy accessibility • Quick loading times Are you ready for a BETTER roasted soybean? KLC Roasted Soybeans have quality and consistency If these are not consistent neither is production

Keeping dairy in the cards

Ninnemann Enterprises embraces robotic retrotted tiestall barn

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

WAUSAU, Wis. –

The Ninnemann family of Wausau wanted to continue dairying on their Marathon County farm; but they knew in order to do so, they would have to make some changes.

Ninnemann Enterprises is a fth-generation family dairy farm operated by brothers Herb and Fred Ninnemann, along with Fred’s three sons, Aaron, Adam and Alex. They recently retrotted their 115-cow tiestall barn into a 125-cow freestall barn equipped with two Lely A5 robotic milking systems.

The Ninnemanns shared their retrotted barn during an open house Sept. 8.

“My dad and my uncle are getting older, and we needed to reduce the amount of physical labor they were putting in,” Aaron said. “My brothers didn’t want to milk cows for the rest of their lives, and I work full-time off the farm too.”

Automation has

intrigued the Ninnemanns for a few years, but they said investing in a new facility to make that transition was not possible for their family farm.

“I called up Seehafer and asked them if they had ever successfully put robots into a tiestall barn,” Aaron said. “I was surprised to learn they had, and he gave me some places to go tour. Adam and I went to one, and we were sold. We knew how we were going to move the farm forward as a dairy.”

Retrotting their existing facility made nancial sense for the Ninnemanns.

“We had a nice barn that was in good, solid shape,” Adam said. “We have a stationary mixer upstairs in the barn. Our manure lagoon was connected to the barn and in excellent condition.

Retrotting allowed us to work with what we had rather than take on the debt that would come with a new building.”

An addition to the tiestall barn was made to house the robots and add

extra stalls.

In order to complete the renovation, the Ninnemanns sold their herd of cows in May 2021, keeping only a handful of dry cows. The family spent the next three months working on turning their tiestall barn into a

freestall barn.

Aug. 22, 2021, marked the startup of the new system for the Ninnemanns. The brothers agreed the transition went well.

“The rst week the hours were long, but it wasn’t really hard,” Adam

said. “The cows adjusted and settled in pretty well, all things considered.”

To restock their herd, the Ninnemanns purchased 75 cows from one herd

PHOTO SUBMITTED

The Ninnemann family – (from le ) Alex, Aaron, Adam, Herb and Fred – converted their 115-cow estall barn into a 125-cow robo c freestall barn on their Wausau, Wisconsin dairy.

Turn to NINNEMANN

Page 12 • Dairy Star • Saturday, September 24, 2022

| Page 13

Lely Juno automatic feed pusher Lely Luna cow brush 114015 Scheuer Creek Rd Marshfield, WI 54449 715-387-3789 or 800-700-3684 2401 S. Black River St Sparta, WI 54656 608-269-1383 Lely Astronaut A5 automatic milking system www.goseehafer.com EASYFIX Freestalls offer superior cow comfort, greatly enhance cow welfare, increase productivity and maximise performance. They remain the safest and most comfortable freestall on the market! Congratulations Ninneman Dairy

to add to their own dry cows that were calving back in. Once those initial cows became accustomed to the routine of robotic milking, they lled out the remainder of the herd with cows purchased at livestock sales.

The cows exit the robots through a foot bath, which Aaron said runs each day from morning until the afternoon.

“We might run it too much, but we have also seen zero foot issues,” Aaron said. “The cows are now only trimmed after dry off. Running the foot bath has just become part of the routine.”

Cows are fed a total mixed ration three times daily using carts. Along with the milking robots, the Ninnemanns also purchased an automatic feed pusher.

“We run the Juno every hour on the hour,” Aaron said. “It’s maybe a little more often than it needs to be, but we found it was complicated keeping track of where it was in its schedule and knowing when we could go through with the carts to

put out more feed.”

To convert the stalls in the tiestall barn, they installed exible stall dividers and placed mats in each of the stalls.

“We really liked the exibility of the dividers but also how sturdy they are,” Adam said. “The cows really aren’t able to get themselves caught under the stalls, and they seem very comfortable laying in them.”

Stalls are bedded by hand daily. The Ninnemanns bed with a paper byproduct. That byproduct is then mixed with lime to make a bedding that the Ninnemanns have been happy with thus far.

“We weren’t interested in the wear and tear on the equipment that comes with sand, and we have an earthen lagoon,” Aaron said. “This is heavy enough it stays up in the stalls, there isn’t a lot of dust, and it absorbs really well.”

Because of the single-row setup, an alley scraper was installed that runs continuously to keep the freestall walkway clean.

“Taking care of the herd is easily a one-person job even with feeding and bedding by hand,” Adam said. “Everything just works out very efciently.”

Despite the jobs that require manual labor, Aaron said they could not be happier with their choice to install the robotic milking system.

“You learn so much about the cows from the robots,” he said. “The data is astounding, and I really enjoy looking at and analyzing it.”

Fetch cows have not presented much of an issue for the Ninnemanns. When cows that are late in their lactation start stretching out their robot visits, the Ninnemanns let them go as long as 14 to 16 hours before seeking those cows out.

Considering the added technology has allowed his family’s dairy farm to continue, Adam said others should consider changing the way they farm as well.

“If someone is thinking about robots, I would encourage them to just pull the trigger and do it,” Adam said. “We have no regrets looking back. It really changes your life in the best possible way.”

DANIELLE NAUMAN/DAIRY STAR

The Ninnemann family used exible stall dividers to convert their estall barn into a freestall barn. They milk 125 cows.

DANIELLE NAUMAN/DAIRY STAR

Cows at Ninnemann Enterprises eat a total mixed ra on Sept. 8 during an open house at the Marathon County farm near Wausau, Wisconsin.

Dairy Star • Saturday, September 24, 2022 • Page 13 866-503-0902

Con nued from NINNEMANN | Page 12

Page 14 • Dairy Star • Saturday, September 24, 2022 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH Vermeer vertical mixers are built to enhance feeding routines for producers looking to optimize ration costs and help reduce feed waste. These mixers create a consistent and thorough ration with a variety of feedstuffs due to a proven mixer tub and screw design. Available in a range of capacities, thesevertical mixers can handle a wide assortment of feedstuffs. Steerable Series Spreaders Excellent maneuverability and control on all types of terrain. LIQUID MANURE TANKS, PUMPS AND AGITATORS Powerful PTO Pumps & Agitators To Handle Liquid Manure Available In Sizes From 355 Cu. Ft. To 1,580 Cu Ft. Penta 5530 HYDRA-SPREAD Av VS420 Ver m feedi ration mixer a var and s LIQU PUM M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution.www.dairylandsupply.com SPREADERS Available in Sizes from 320-1520 Cu. Ft. • Universal skid steer mount • Tube steel construction • 5’-10’ widths available • Replacement tires, back drags ad parts available MANURE ALLEY SCRAPERS Most Models In Stock. Service & Installation Available. Parts On Hand. • Optional feeding con gurations inside and outside • The most ef cient bedding door available Calf Hutches Happy Fall Y’all!

F r o m O u r S i d eFrom Our Side

O f T h e F e n c eOf The Fence

Dan Bragger Independence, Wisconsin

Dan Bragger Independence, Wisconsin

400 cows

Is there certain equipment maintenance that you believe is vital to ensure farm safety?

The biggest part is training people and knowing how to handle the various machines. Also, realizing who can handle certain situations based on their experience.

What are some of the biggest safety concerns farmers need to consider? Be aware of your surroundings, and remember to slow down when driving through yards and be conscientious of other people.

What are some words you try to live by with farm safety? There is zero tolerance for accidents. You don’t want anyone to be injured; you always want to be cautious and think ahead of time about what could go wrong and do what you can to prevent it. Keep shields in place, make sure the equipment you are using can handle the job, and keep warnings in place.

What is the worst accident or near accident that happened on your farm? After that accident, how did that change your protocols? Fifteen years ago, I lost the lower part of my leg. I was in too much of a hurry and wasn’t thinking about what I was doing. My leg got caught in an auger that I stepped into when it was dark. It was early in the morning on the day before Christmas, and I was thinking about everything else. I forgot to turn the switch off and stepped right into the auger. Now, I have a prosthesis. I learned to slow down and prioritize what I am doing and not everything else that’s going on.

Tell us about your farm. We raise chickens with Pilgrim. My brother and his wife have a pullet barn. I have two broiler barns with my wife. We have the dairy. We raise soybean, hay, corn and some rye. We run about 1,500 acres.

Troy DeRosier Osceola, Wisconsin 160 cows

Is there certain equipment maintenance that you believe is vital to ensure farm safety? Power take-off shields as well as any other shield covering a moving part are vital.

What are some of the biggest safety concerns farmers need to consider? Manure pits are deadly. Make sure people, pets, animals, etc., can’t get into them. Silo gases are also deadly. A neighbor recently suffered complications from silo gas from a pile he had packed the day after lling; it was a totally calm morning.

What are some words you try to live by with farm safety? Take your time, and be alert to your surroundings. We have one life to live. Don’t cut it short. Your family needs you.

What is the worst accident or near accident that happened on your farm? After that accident, how did that change your protocols? I fell into our under-barn manure pit and lived. Now, all accesses are completely covered at all times, and we take no short cuts that are at all risky. When I was much younger, I witnessed a farmer I was helping get caught in a PTO; it totally destroyed his leg, but he lived. It only took a second, and his life was changed forever.

Tell us about your farm. We milk 160 cows and are a non-GMO dairy with a creamery on the farm. We process about one-third of our production into uid milk, cheese and butter. We have a slatted oor barn with tunnel ventilation. We milk in a double-12 parallel parlor. We farm 750 acres.

Cody Bode (holding his son, Rhett) Gibbon, Minnesota 600 cows

Is there certain equipment maintenance that you believe is vital to ensure farm safety?

If you keep up on maintenance, you will have less accidents.

What are some of the biggest safety concerns farmers need to consider? When working with livestock, you always need to be careful. Animals can be unpredictable. And, anytime you work with tractors or skid loaders, the operator has to be mindful of their surroundings.

What are some words you try to live by with farm safety? Stop and look.

What is the worst accident or near accident that happened on your farm? After that accident, how did that change your protocols? My father got his ankle in a silo unloader, and thankfully, it shut off right away because it wasn’t working properly. He survived, but, we have since eliminated silo storage.

Tell us about your farm. We milk 600 cows with my uncle, father, myself and about 20 employees. We raise our youngstock and harvest our own feed.

Turn to OUR SIDE | 16

What are some of the biggest safety concerns farmers need to consider?

Dairy Star • Saturday, September 24, 2022 • Page 15 Star Blends has been helping Midwest farm families by providing, high-quality feed, dairy nutrition, and commodity contracting for more than 20 years. Our state of the art mill can accuratelyblend anything from a custom pre-mix to complete feed, in balancing diets, or work with your private nutritionist or dairy consultant. Contact Star Blends at: 800-462-4125 or StarBlends.com Feeding your animals like they’re our own y

Page

DAIRYSTAR DAIRYSTAR.COM COMKNOW WHERE TO GO FOR YOUR DAIRY NEWS

Krista Dolan Dodgeville, Wisconsin 260 cows

Is there certain equipment maintenance that you believe is vital to ensure farm safety?

All equipment should be properly maintained before or after each use to ensure that all parts are operating correctly.

What are some of the biggest safety concerns farmers need to consider? A farm is a dangerous place for people of all ages. It’s important to be aware of your surroundings on the farm when operating machinery. You also need to take into consideration your clothing when

working around machines with moving parts.

Do not wear loose clothing, keep your hair tied back if it is long, and keep shoe laces tied, etc.

When operating a piece of equipment, you need to be knowledgeable about the terrain. Take into consideration your speed and parking, etc.

What are some words you try to live by with farm safety? Go the extra mile even if it is going to take you ve extra minutes. It could be worth it in the long run.

What is the worst accident or near accident that happened on your farm? After that accident, how did that change your protocols?

In August 2017, my oldest son was caught in a power take-off at the age of 9. The shirt he was wearing was too large for him, and it got caught as he went to shut off the broken chopper

box. He was own to the University of Wisconsin Children’s Hospital in Madison, Wisconsin, with severe injuries. After eight months of healing and therapy, he made a full recovery. We couldn’t be more thankful. After the accident, we threw away any farm clothing that had holes, made sure all clothing was properly tted to the person wearing it and removed strings from hoodies. We also took the time and replaced all the power take-off shields on the chopper boxes that we owned to make sure they were in proper condition.

Tell us about your farm. My husband, Ryan, and I co-own Dolan Farms LLC with his parents, Paul and Mary. We have two sons, Kaleb and Gage. We milk 260 Holsteins two times a day and raise all our replacement heifers and feed.

Tom Gregory Kimball, Minnesota 670 cows

Tom Gregory Kimball, Minnesota 670 cows

Is there certain equipment maintenance that you believe is vital to ensure farm safety? Keep the power take-off shaft shields in proper condition, and clean windows in cabs to see people and equipment around you. Keep re extinguishers where needed.

What are some of the biggest safety concerns farmers need to consider? Be aware of your surroundings. People become distracted by walking, talking and not paying attention. People stare at cellphones and are unaware that you might not be able to see them while running equipment.

What are some words you try to live by with farm safety? Always be careful when operating large or small equipment. Be careful of your surroundings, people and so forth. Haste makes waste. Don't fully trust the animals because you never know what they are capable of doing.

What is the worst accident or near accident that happened on your farm? After that accident, how did that change your protocols? My granddaughter sipped some detergent. We were not sure how much. My daughter, after reading the label, called 911 and rescue came. It was decided that she should go to the hospital for further examination. She was observed for half a day at the hospital; luckily, she was OK. Now, we keep all chemical and detergents out of reach of children.