By Dan Wacker dan.w@dairystar.com

Wis. — Growing up, Trent Hendrickson discovered his passion for dairy cattle. On his parents’ farm, JeffreyWay Holsteins, Hendrickson took the reins as tour guide, showing people around. Now, he has the reins on his own farm and a herd he has developed as one of the top herds nationally.

This year, Hendrickson earned the 2024 Distinguished Young Holstein Breeder award from Holstein Association USA. The award is presented to breeders between the ages of 21 and 40.

“The award is something that we dreamed about but never realized we could win,” Hendrickson said. “I am really honored. It was a goal of ours, and accomplishing it meant a lot.”

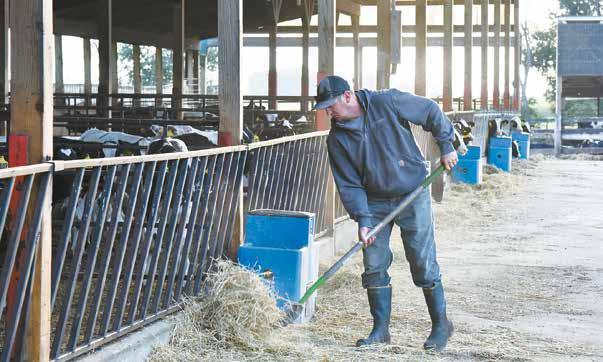

Trent, along with his wife, Kelsey, farm with their four young children, Trevor, Grace, Lee and Jeffery. The family currently milks

380 cows on their farm, Trent-Way Genetics, near Blanchardville. Cows are milked twice a day in a tiestall barn, averaging 28,000 pounds of milk, with tests of 4.2% butterfat and 3.2% protein. Hendrickson has bred 85 Excellent cows and put the farm among one of the top Holstein herds nationally, earning a 109.5% BAA.

Hendrickson was recognized at the Holstein Association’s annual convention June 24-27 in Salt Lake City, Utah.

“It was my rst time on an airplane.” Hendrickson said, “It was pretty out there. It was over 100 degrees, but seeing the snowcaps on the mountains was an interesting experience.”

Hendrickson was named a delegate for the national convention, and while in Salt Lake City, he sat in on meetings to develop a better understanding of how the Holstein Association operates.

“My goal is to get more involved with the dairy cattle breeding aspect, taking on more of a leadership role at some point,” he said.

Hendrickson traces his passion for the dairy industry and genetics back to his roots.

“Growing up, my parents had a really good herd of cows at Jeffrey-Way Holsteins,” he said, “They were

very successful with their T cow family and always had a lot of foreign visitors. I loved being the tour guide and seeing their eyes light up. That’s my favorite thing about our current farm too. When peo-

ple walk into our barn, and their jaws drop. That’s been my real passion.”

At Trent-Way Genetics, Trent and Kelsey focus on Red & White genes.

“Ninety percent of our herd is Red or Red factor,” Hendrickson said, “That’s been our biggest focus. That gene pool is really small, so we focus on bringing in generational type bulls to match up with our Reds.”

Sometimes the trait looked for does not present itself in all generations. Because of that, Hendrickson takes his time when selecting what is going into their next generation.

“We’ll get black and white calves, but we always make sure they’re a Red carrier,” Hendrickson said “We want to keep the Red factor going.”

The focus at Trent-Way Genetics is not on creating an extreme cow, but rather, on developing an animal that is solid in all aspects. This includes focusing on health traits, somatic cell count, positive components and milk production.

“One of our focuses is phenotypical,” Hendrickson said. “Being rightsided linear with good feet and legs and a good udder is important to us. We want a balanced cow. We focus on type, but we try to bring in that type and commercial and meet in the middle.”

As part of developing a balanced cow, Hendrickson said foresight is not

just for the here and now, but also for the future of the cow and the breed.

“Longevity is our goal,” Hendrickson said. “We want old cows. Old cows help make you money, and we want to breed cows that last a long time. We also want to breed the kind of cows that can t into any situation from free stall to headlocks and that aren’t too big for parlors.”

Giving customers an option to build Red genetics into their own herd is something Hendrickson strives for as well.

“My dream is to be that renowned breeder that bred a lot of good customer satisfaction bulls,” Hendrickson said. “We want to be known as someone who helped improve the Red & White breed or the Holstein breed in general. We want to pass on genetics we think are helpful for the industry.”

That dream is being realized with Trent-Way-Js Rompen-Red-ET, a bull Hendrickson bred that is at stud for Select Sires Inc.

“We get messages from people about how happy they are with his offspring,” Hendrickson said.

All bulls bred by Trent-Way Ge-

Con nued from HENDRICKSON | Page 4

netics trace back to the Roxy cow family. A current dam at their farm with sons in A.I. is Trent-Way Parfect Essay-RC VG-87. She recently produced 32,000 pounds of milk with tests of 5.2% butterfat and 3.4% protein.

“She emphasizes what we want right now and the cow we’re trying to breed with high components, good milk and good type,” Hendrickson said, “She’s special to us, and I think we’ll have a lot of A.I. interest in her sons and grandsons.”

Along with the high genomic breeding, TrentWay Genetics still dabbles in show-type breeding. The family had a heifer that was a Reserve Junior All-Wisconsin Summer Yearling. This year, Trent-Way Genetics will have two heifers at World Dairy Expo.

“The main goal right now is to take care of the cattle we have and make sure they’re comfortable,” Hendrickson said, “We want to maintain what we have.”

The extension of the freestall barn is just a part of what Hendrickson and his family plan to do. They also have thoughts of adding a parlor.

“To be honored by the Holstein Association — the people we’ve looked up to while we’ve developed our own herd of cows — is a dream come true.”

TRENT

HENDRICKSON,

DAIRY FARMER

Along with taking care of their herd, they have their sights set on more.

“Our next step would be to get into marketing more highend cattle,” Hendrickson said, “I would possibly like to do a sale every year, and to do that, we need to have nice facilities.”

When Trent and Kelsey started their journey in 2011, they had 55 cows. Today, that number is upwards of 380. With the increase in herd size comes an increase in facilities.

The couple is currently in the process of adding 400 feet to the freestall barn, complete with a dry cow area.

The Hendrickson family knows the work that went into growing their herd to the caliber it currently is to gain national recognition.

“To be honored by the Holstein Association — the people we’ve looked up to while we’ve developed our own herd of cows — is a dream come true,” Hendrickson said. “It’s pretty awesome to get that recognition and have those people recognize you.”

Chicago Mercantile Exchange barrel Cheddar set a record high on Wednesday, hitting $2.6225 per pound, eclipsing the previous $2.53 high Nov. 2, 2020. It closed Friday at $2.59 however, up 10.50 cents on the week, up 49 cents in four weeks, and 99 cents above a year ago when it had dropped 21 cents to $1.60.

Cheddar block, after gaining almost 24 cents the previous three weeks, went in the other direction, as new capacity comes online. The blocks fell to $2.2450 on Wednesday and rallied Thursday but backtracked Friday to close at $2.2375, down 3.75 cents on the week, and 45.75 cents above a year ago when they lost a dime and dipped to $1.78. The inverted spread grew to 37.75 cents Wednesday, just shy of the record 38.5 cents in November 2019, and stood at 35.25 cents Friday.

There were seven CME sales of block on the week and 11 of barrel, as traders awaited the afternoon’s August milk production report.

Midwest cheesemakers are beginning to shift to retail holiday baskets and packages, according to Dairy Market News. Production remained inconsistent for the third consecutive week as multiple plants have been running lighter schedules due to maintenance and/or plant updates. Barrel processors have only recently begun to be able to offer loads to customers and some say this is the rst instance of extra barrels being available since the early weeks of summer, which helps explain the record price. Milk availability is improved but only due to the plant downtime. Mid-week milk prices were above Class III but the wide price spread is viewed as an indicator of potential market instability, warns DMN.

Milk demand from Western cheese manufacturers is steady to strong. However, milk availability varied due to bottling demand and milk production dips. Cheese production is steady to strong. Stocks are accommodating obligations and spot demand, however, are reportedly tight, barrels especially. Domestic cheese demand is steady to lighter. Export demand is more mixed, according to DMN.

Cash butter fell below the $3 mark on Thursday, the rst time since May 29, and closed Friday at $2.9725 per pound, down 15.75 cents on the week, lowest since April 30, and 2.75 cents below a year ago when it jumped 28.25 cents and hit $3 per pound. There were 14 sales on the week.

Central butter production is busier than seasonally expected, says DMN. Cream availability remains ample within the region and from Western sources as school bottling spins off and fat components continue to trend higher. Some butter makers have said the last two weeks of regular churning schedules were not expected to last as long as they have, but now, some

expect cream availability to last at least into the following week.

Butter demand is picking up the holiday pace and customers are adding to orders to prep for the holiday push, according to DMN.

Butter production in the West is steady to strong. Some manufacturers continue to build inventory ahead of fourth-quarter maintenance projects. Fourthquarter bookings are stronger, but export demand varies from light to moderate.

Grade A nonfat dry milk closed Friday at $1.38 per pound, down 1.25 cents on the week but 21 cents above a year ago. There were 32 sales on the week.

Dry whey nished at 58.75 cents per pound, 1.75 cents lower but 28.50 cents above a year ago, on 12 CME sales for the week.

July’s dairy supply and utilization data tells a behind-the-scenes story. While cheese prices saw great strength, it was due more to supply than demand, according to Betty Berning, a dairy economist with HighGround Dairy Inc.

Speaking on the Sept. 23 “Dairy Radio Now” broadcast, Berning said American cheese utilization has been down every month of 2024, Cheddar vats have put out less product, and the tight milk supply is a factor. However, fast food chain offerings have been strong, she said, and, “When you think about what goes on a cheeseburger, it’s processed cheese made with barrel cheese.”

Total domestic cheese utilization was up 0.8% but off 0.4% year to date. Exports totaled 88.7 million pounds, up 9.6% from July 2023, and up 22.1% year to date.

“For the rst time in 2024, both domestic utilization and commercial butter exports marked growth above the prior year,” Berning said. Domestic use was up 5.5% and exports were up 15.4%. The CME price has slipped, she said, but is still historically high.

Nonfat-skim milk powder utilization was down 19.2%, the lowest since 2014, according to HGD. Domestic use was down 70% and year to date was down 41.1%. Exports were up 10.8% in July but down 8.5% year to date. HGD attributes the higher CME prices to nervousness about the milk supply.

Dry whey usage was down 28.6% domestically while exports were up. HGD points out that dry whey production sharply declined between May and July due to manufacturing issues and said, “Limited supplies are behind the price rally above 50 cents per pound on the CME, rather than hearty demand.”

Income over feed costs, while not an exact science, are headed to levels that are historically high, Berning said. “There’s great opportunity for producers to lock in margins into next year and ensure they can maintain prots, pay down debt, invest in operations, feed a higher quality ration, or do whatever is

needed to take advantage of these very good milk prices.”

Fluid milk sales were up in July after dipping 2.9% in June. The U.S. Department of Agriculture’s latest data shows packaged sales at 3.4 billion pounds, up 4.3% from July 2023.

Conventional product sales totaled 3.1 billion pounds, up 3.7% from a year ago. Organic products, at 257 million pounds, were up 11.7% and represented 7.6% of total sales for the month.

Whole milk sales totaled 1.3 billion pounds, up 4.7% from a year ago and 2.5% year to date, representing 37.9% of total sales for the month of July.

Skim milk sales, at 146 million pounds, were down 8.7% from a year ago and down 12.3% YTD.

Packaged uid sales for the seven months totaled 24.7 billion pounds, up 1.1% from 2023. Conventional product sales totaled just under 23 billion pounds, up 0.7%. Organic products, at 1.8 billion pounds, were up 6.8% and represented 7.1% of total milk sales in the seven-month period. The gures represent consumption in Federal Milk Marketing Orders, which account for about 92% of total uid sales in the U.S.

The October Federal Order Class I base milk price was announced by the USDA at $23.17 per hundredweight, up $1.57 from September, $3.70 above October 2023, and the highest Class I price since November 2022. It equates to $1.99 per gallon, up from $1.67 a year ago. The 10-month Class I average stands at $20.02, up from $19.09 a year ago, and compares to $23.73 in 2022.

Dairy farm margins were at to slightly higher over the rst half of September as milk prices continued to advance while feed costs were steady to slightly higher, according to the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC.

“Spot milk availability continues to be limited for processors who are paying premiums of up to $4 per cwt. over Class prices, the highest spot price for milk in mid-September since 2010,” the MW said. “Dairy product prices continue to be supported at lofty levels, helping to drive strength in Class III and Class IV milk.”

“Butter prices have maintained at $3.00 per pound or higher in spot CME trade since late May, with European prices exceeding $4.00 due to the fallout from bluetongue disease. Cheese prices are likewise rm.”

“Year-to-date through July, Cheddar vats have turned out 8% less product compared to the same period in 2023, while strong international demand for cheese has helped boost exports. The U.S. exported more than 100 million pounds per month in March, April and May, with export shipments exceeding 85

million pounds both in June and July,” said to the MW. “Exports to Mexico through the rst six months of the year were nearly 250 million pounds, up 39% from 2023. Exports to Mexico have set new monthly records now for 14 consecutive months.”

“Exports of other dairy products have likewise been impressive. July whey exports were up 22.4% year over year, led by a 34% increase in shipments to China. U.S. exports of nonfat dry milk hit a 14-month high in July and outpaced July 2023 by 10% with shipments to Mexico setting a record for the month, up 20% from a year ago,” the MW concluded.

The USDA’s latest livestock slaughter report showed an estimated 231,300 head of dairy cows were slaughtered under federal inspection in August, up 5,400 from July, but 43,900 head or 16% below August 2023.

Slaughter for the week ending Sept. 7 totaled 47,700 head, down 6,500 from the previous week, and 6,900 or 12.6% below a year ago. Year to date, 1,894,100 dairy cows had been culled, down 311,700 or 14.1% from 2023.

The week’s crop progress report showed 45% of U.S. corn was rated mature as of the week Sept. 15, up from 29% the previous week, 3% behind a year ago, but 7% ahead of the ve-year average. Sixty-ve percent was rated good to excellent, up 1% from the previous week, and compares to 51% a year ago. Nine percent had been harvested, up 1% from a year ago, and 3% ahead of the ve-year average.

Forty-four percent of the soybeans were dropping leaves, 3% behind a year ago, but 7% ahead of the ve-year average. Sixty-four percent were rated good to excellent, down 1% from the previous week, but compares to 52% a year ago. Six percent have been harvested, 2% ahead of a year ago, and 3% ahead of the average.

The agriculture department’s monthly Livestock, Dairy, and Poultry Outlook, issued Sept. 18, mirrored milk price and production projections in the Sept. 12 World Agricultural Supply and Demand Estimates report.

The Outlook said “Despite some uctuations, dairy product consumer price indexes have generally risen in 2024, contrasting with the broader decline in overall product and food CPIs. The recent decline in the food service sector, particularly restaurants, may be also underlying the decline in the domestic consumption of dairy products.”

“The National Restaurant Association’s Restaurant Performance Index has been consistently lower in 2024 compared to the previous year, suggesting that restaurants are facing challenges such as reduced consumer spending, rising costs, and shifts in consumer preferences, all likely impacting demand for dairy products from the foodservice sector,” the Outlook said.

“Improved margins are likely to create incentives for farmers to increase their herds in 2025,” according to the Outlook, “However, the tight supply of heifers will moderate growth in the rst half of the year.”

“The forecast for the 2025 dairy herd was unchanged at 9.360 million head. With lower 2024 forecasts for milk per cow and expected steady increases in milk solids components, the 2025 forecast for yield per cow was lowered 30 pounds to 24,345 pounds. U.S. milk output is projected at 227.9 billion pounds, 300 million pounds lower than last month’s forecast,” according to the Outlook.

The weighted average in Tuesday’s Global Dairy Trade was up 0.8%, following its 0.4% slip Sept. 3.

Volume climbed to 85.6 million pounds, up from 84.5 million, and the average metric ton price inched up to $3,883 U.S., from $3,833.

The rise was led by Mozzarella cheese, up 4.5%, following a 7% rise last time. Cheddar was up 2.9%, after a 0.9% advance. Lactose was up 3.5% after dropping 8.9%. Skim milk powder was up 2.2%, following a 4.5% rise, and whole milk powder was up 1.5%, after dropping 2.5%. Butter was down 1.7%, after slipping 0.9%, and anhydrous milkfat was down 1.2%, following a 0.7% rise last time.

StoneX says the GDT 80% butterfat butter price equates to $2.8969 per pound U.S., down 5.7 cents from Sept. 3, and compares to CME butter which closed Friday at $2.9725. GDT Cheddar, at $2.0145, was up 5.3 cents, and compares to Friday’s CME block Cheddar at $2.2375. GDT skim milk powder averaged $1.2740 per pound, up from $1.2486, and whole milk powder averaged $1.5640 per pound, up from $1.5404. CME Grade A nonfat dry milk closed Friday at $1.38 per pound.

Analyst Dustin Winston said, “North Asian purchases fell from last year’s levels but still made up more than half of the purchase volume in this GDT. Skim milk powder continues to be a large factor in their purchase volume. The Middle East and North America were the only regions to increase their purchase volume from both last year and last event,” Winston said.

The Federal Reserve lowered its interest rate by a half percent or 50 basis points, the rst cut since Covid. “Recent indicators suggest that economic activity has continued to expand at a solid pace,” the Fed said.

“Job gains have slowed, and the unemployment rate has moved up but remains low. Ination has made further progress toward the committee’s 2% objective but remains somewhat elevated.” “The economic outlook is uncertain, and the committee is attentive to the risks to both sides of its dual mandate.”

Thursday, October 3rd • 11 a.m.

Early Consignments

COMPLETE HERD DISPERSAL (530) Head. Herd consists of 340 milking cows. 15 dry cows. 110 bred heifers, 63 open heifers 6 months and up. 3 breeding bulls including 2 Brown Swiss. Cows are housed in sand bedded free stalls, milked in a parallel parlor. Not pushed for production. Tank average 60-65 lbs. Primarily Holstein with some cross bred cows mixed in. Some cows for every budget! Cows and heifers all in good body condition!! Monroe WI.

COMPLETE HERD DISPERSAL (45) Holstein Tie stall cows and heifers. Tank avg currently 55lb. 4.0F x 3.19P SCC 150. Not pushed with lots of upside potential! Ration consists of Haylage and dry grain, mineral and No TMR or extra protein. Majority of cows are in 1st and 2nd lactation as owners have dispersed the older and lower production cows the past 6 month and are now offering the best of herd today. Bred primarily to young sires from Central Star. Steven & Ina Brozinski from Genoa have operated this dairy herd for 30 + years and due to health issues will be transitioning to beef.

COMPLETE ORGANIC HERD DISPERSAL (15) Holstein Cows and heifers. Mostly R&W or RC and bred Polled for last 6 yrs. Several outstanding red cows in this group! Ernest Borntrager, Lafarge WI (20) REGISTERED MILKING SHORTHORNS. (9) Cows, (11) Heifers. Coming from consignors like Rovin, Wide Open, and Game Day Farms!! Cows are in all stages of lactation and include a fancy Presto daughter as well as an outstanding St. Clare. Heifers will range from 6 moths old to springing. There will be some polled animals, roan color, and A2 sired!!

(8) Fancy Registered Jersey heifers coming from Tom and Donna Leum Viroqua. All due for October &November. 7 are A2A2 and bred to sexed semen! Everything is genomic tested and will have paperwork available. Also 1 grade heifer. The Leum’s have done an outstanding job breeding registered Jerseys and are selling their heifers as they come close as they are retiring from farming.

(2) Registered Jerseys. 4 year old Colton daughter milking 60 lbs with a 6.0F and a bred, Kidrock heifer out of an EX95 dam!!

By Danielle Nauman danielle.n@dairystar.com

COLFAX, Wis. — When John Richmond graduated from college, he knew he wanted to dairy farm. However, as a rst-generation farmer, he also knew he was facing an uphill climb to follow his dream.

“I didn’t grow up on a farm, but I always helped on farms my family members owned,” Richmond said. “But I was always in line behind their children to take over the family farms, and I knew that starting out from scratch was not truly feasible.”

Richmond shared his story during a River Country Resource Conservation and Development Council Inc., pasture walk hosted at his farm Sept. 20.

Through connections made while attending the University of Wisconsin-River Falls, Richmond learned of the Dairy Grazing Apprenticeship program, which put him in connection with Charles and Karen Floodquist. The Floodquists wanted to see their farm contin-

ue as a dairy farm in the future, following their own retirement.

“We worked with the DGA for about two years,” Richmond said. “Our involvement with that program is probably why we are as far into a transition plan as we are.”

Richmond began working with the Floodquists as an apprentice in 2015. They began a transition plan in 2018.

Richmond and the Floodquists are about midway through their transition. Richmond has purchased the cows, along with some equipment, while working on a land contract lease.

“I gure it will take me another three years to nish paying off the equipment,” Richmond said. “Then hopefully things will be in a better place for purchasing the farm. Land prices right now are unsustainable.”

Richmond is milking 150 cows and raising about 150 head of youngstock on the Chippewa County dairy farm owned by the Floodquists near Colfax. Richmond practices managed grazing for the entire herd. Although the farm is not certied organic, Richmond values and largely adheres to the principles of both organic production and grazing management.

“We do spray our corn,” Richmond said. “That is really the only thing (that stands) between us and being organic.”

Richmond is farming 500 acres, with about 350-400 acres in permanent pasture. He does little to no-tillage on the farm and follows regenerative farming principles.

He tills to transition land. Other than that he does not want to till it. He overwinters his cattle in a different spot each year and then follows it with corn.

“I push the grasses,” Richmond said. “Most of the farm is what naturally grows here. It seems like all the plants that grow in Wisconsin are here on this farm. Nothing seems to be completely taking over, so I just go with the ow.”

When he plants a new-seeding pasture to follow a stand of silage corn, Richmond uses a little bit of everything, except for tall fescue.

“I plant a lot of orchard grass because it grows well here,” Richmond said. “Maybe at certain times of the year it’s not the best to make milk, but I want to plant what grows and does well here.”

Everything Richmond grows on his farm is fed to his herd. His only feed purchases include a grain supplement mix and calf grain.

Richmond’s herd is housed outdoors most of the year. There is a freestall barn for milk cows to live in during the winter months, but dry cows and youngstock are all wintered outside.

“If you provide them with good nutrition and maybe a windbreak, that’s all they really need,” Richmond said.

The animals in Richmond’s herd are bull-bred. He typically raises bull calves from the cows he believes to be the best cows in his herd. These most closely embody the goals he has for his cattle: protable, hardy and low maintenance.

He puts the bulls in with his herd beginning July 1 and they remain with the cows until January. This limits his calving season from early April through

early October.

“I have no interest in calving from mid-October through mid-March,” Richmond said. “I just don’t have the facilities for it.”

Richmond recently began raising his milk calves in outdoor group housing on a lime base bedded with cornstalks.

“It started by accident — one year I had way more calves than individual hutches,” Richmond said. “At that time, bull calves weren’t worth much, so I made a group pen and put all my bull calves in there together. They did great.”

This year, Richmond began raising all his calves that way and has been pleased with the results.

Calves are grouped by age, and using a 5-nipple mob feeder, each group is fed as much whole milk as they will drink, an average of 1-2 gallons per calf.

“My calf nutritionist told me my biggest problem was that I wasn’t feeding my milk warm enough,” Richmond said. “Now I use an old pasteurizer to heat the milk to just over 100 degrees. That, along with feeding as much as they will drink has made an amazing difference.”

Richmond has also begun putting straw into a feeder and putting the grain on top which he said he feels has improved the health of his calves.

“They’re just like little kids — they are into everything, they want to eat everything,” Richmond said. “My calf health this year has been phenomenal, signicantly better than it previously was.”

With his interest and adherence to organic practices, Richmond says he has not ruled out the idea of establishing an organic certication in the future.

“I have dreams of being an organic grass-fed producer, but I do like feeding corn silage,” Richmond said. “You just can never say, never.”

By Dan Wacker dan.w@dairystar.com

PLAIN, Wis. — Twins are not uncommon in cattle. In fact, about 3-5% of bovine pregnancies result in twins. What is uncommon is the bond formed between a set of twins on Ed Ederer’s dairy farm near Plain.

Ederer is a second-generation farmer milking 51 cows in a stanchion barn. He farms the land he grew up on, which has been in his family for 101 years. Never in his years of farming did he think he would see the kind of bovine connection that two twins have formed on his farm.

“Every time we see one, the other is right there or not far behind,” Ederer said. “They always eat at the bunk together, head out to pasture together, come in for milking together.”

Their connection as sisters is obvious, but it was not a connection Ederer forced.

“They were born and raised here, but when we started, we put them in separate huts,” Ederer said. “Even then, they were always together.”

They would spend time by the calf panels of their huts so

they could be as close together as possible.

Ederer could tell that they were forming a connection, a stronger connection than that of typical cows in a herd.

“It was something I hadn’t ever seen,” Ederer said. “When one would calve, the other would be right there making sure that she was OK. When they’d bring the babies home, they (would) walk together to make sure everyone made it back safely.”

The rest of the herd does not mess with them.

“One time I saw one of the twins getting pushed on a little bit from this other cow,” Ederer said. “All of a sudden, here comes her sister running down the pasture. She pushed that other cow away and stuck up for her sister right there.”

The twins are on their fourth lactation together after having their rst calves within a week of one another.

They have such a connection that Ed and his son, Kyle, knew that something was wrong when neither of them came back from the pasture one day.

“We were bringing them all down for milking and we

Twin cows lay next to one another in the pasture of Ed Ederer’s farm near Plain, Wisconsin. The cows are in their fourth lacta on and are generally found together on the farm.

couldn’t nd the twins,” Ederer said. “We saw one up near some brush we had laying, and Kyle said, ‘I bet she’s up there calving.’ So, we went up there to check it out, and sure enough, the other was back behind the brush having her calf and her sister was right there to make sure it was all going alright.”

Almost all his herd Ederer has developed from calf to a producer in the barn. That development is what makes Ederer proud of what he does.

“You have the calf, and

you see it grow up and become part of the herd, and if it’s really a good one it just makes you feel good,” Ederer said. “Seeing the progression of these cows becoming a better herd has been amazing.”

Milking his cows has become more than just his nightly routine Ederer said. It has become his most relaxing time of the day.

“When you milk in the morning, you’re thinking about all the stuff you need to accomplish during the day,” Ederer said. “But at night, you can

just relax. I do my best thinking during night milkings.” His state of mind during his nighttime milkings has become something his kids and sons-in-law have noted.

“I think all three of my sons-in-law asked for my permission to marry my daughters while I was milking,” Ederer said. “One, they knew where to nd me, and another is that they’d know that’s when I would be most relaxed.”

Turn to EDERER | Page 13

From when he started, to where he is now, a lot has changed on the Ederer farm.

“When we started, we were milking with buckets,” Ederer said. “My rst job was changing the straps on those Surge buckets, then it progressed to cans, and by the time we had our rst child, we put our pipeline in.”

Ederer credits that evolution in technology, specically the pipeline, with his ability to keep going.

He also credits Kyle.

“Kyle handles all the feeding now,” Ederer said. “I’m so thankful that Kyle came back to help me after high school. I couldn’t still be doing what I’m do-

ing without him. And (I’m thankful too for) my wife, Pat, of course. She was a city girl when I met her, but without her love and support, I wouldn’t have been able to do this.”

With the help of his children, and some advice from his father, Ed, Ederer’s family has helped him continue working with his livestock.

“My dad always told me, ‘You be a good shepherd to your animals, and they’ll take care of you,’ and these girls have,” Ederer said. “They put a roof over our heads, put food on the table and, at some point, they’ll help me head into retirement.”

e Dair y Herd d Disper sal Tuesday y October r 1 st at t 11:00 0 am

80 Holstein milking cows and 60 head of heifers selling from this top-quality herd. Parlor/Free-stall. Cows are currently averaging 80lbs.with a SCCof 50. Full DHIA records on herd. Many bred to Angus bulls. * ** * Attention n Daair ymen, , this is s a complete e group p of f youngstock k from m weaned d calves s to o springer s. . All l young sttock k has been n housed at their r heifer r grower s far r m and d have e done e an n excellent job! Thesse e are e the e kind d all dair ymen n are looking g for!!!

m Small Beef Herd Dispersal-7 Beef cows that are a mix of Hereford, Black and Red. Also 3 yearling Black bulls, 3 yearling heifers.1 mature Hereford breeding bull. 7 spring born calves.

Wisconsin:

Abts Equipment LLC

New Franken (920) 866-2485

Gillett (920) 866-2485

Argall Dairy Systems, Inc.

Belleville (608) 424-6110

Platteville (608) 348-3385

Fuller’s Milker Center LLC

Lancaster (608) 723-4634

Richland Center (608) 723-4634

Gehring Sales & Service, Inc.

Rubicon (262) 673-4920

Joe’s Refrigeration, Inc.

Withee (715) 229-2321

Leedstone, Inc.

Menomonie (866) 467-4717

Midwest Livestock Systems

Menomonie (715) 235-5144

Redeker Dairy Equipment

Brandon (920) 960-9260

The Scharine Group Inc.

Whitewater (608) 883-2880

Tri-County Dairy Supply Inc.

Janesville (608) 757-2697

Iowa:

Langs Dairy Equipment

Decorah (563) 382-8722

Precision Dairy Equipment

Elkader (563) 245-2560 Minnesota:

Gorter’s Clay & Dairy Equipment, Inc.

Pipestone (507) 825-3271

Leedstone, Inc.

Melrose (888) 267-2697

Glencoe (877) 864-5575

Plainview (800) 548-5240

Midwest Livestock Systems

Zumbrota (507) 732-4673

South Dakota:

Midwest Livestock Systems

Renner (605) 274-3656

Minnesota. All of the help for the day arrived by 10 a.m. at the farm.

By Emily Breth emily.b@star-pub.com

GIBBON, Minn — Anyone driving past Bode Dairy the morning of Sept. 18 was welcomed by a line of tractors hitched to boxes and the smell of freshly made corn silage.

Cody Bode operates Bode Dairy with his dad, Arlen, uncle, Vance, other family members and hired help. The farm has been in the family for 99 years and has slowly grown over the years. Currently, around 600 cows are milked three times a day in a double-12 parallel parlor.

The morning routine started as normal with the hum of the milking compressor starting at 3 a.m. as two hired hands got to work with the rst milking. The cows are milked at 3 a.m., 11 a.m.

and 6 p.m., with each milking taking around six hours to complete.

Josh Jutz, a hired hand who takes care of the feeding, starts mixing the rst total mixed ration for the cattle at 3 a.m. as well.

Bode arrived at the farm at his normal time to check if any cows needed to be bred.

“I usually start breeding at 7:30 a.m. then get started with grain chores, which is around 8 a.m.,” Bode said. “That is mostly what I do in the morning.”

Grain chores consist of feeding calves in three barns. Along with the grain, Bode also feeds hay to the oldest calves.

The rst non-daily chore of the day came when Arlen started to ll the grain drill with alfalfa seed.

“He just seeded in some alfalfa spots that have

drowned out so that there would be something there to grow back next year,” Bode said. “He only had to seed between 5-10 acres.”

After Arlen got on his

way with the planter, Bode started preparing for the task of the day: chopping.

“We started chopping (Sept.) 13 and nished by 10 p.m. on the 19,” Bode said.

“That’s kind of a record for us. I’m pretty proud of how quick we got it done this year.”

Turn to BODES | Page 16

As Bode started servicing the chopper, one of the farm workers, Jared Swanson, started his morning chores of breeding heifers.

Once done with that task, Swanson greased the blade tractor to get ready for another day of chopping. By 10 a.m. all the help for chopping was at the farm talking and getting their boxes ready.

“In total we chopped 460 acres of silage and about 5060 acres of that was Sudan grass,” Bode said.

With the wet spring, spots in the corn elds drowned out, so the Bode family decided to sow Sudan grass into it.

“It worked really well,” Bode said. “I was worried

that I would have to cut it with a mower and then chop it, but the corn head picked it up and fed it in really well.”

Bode said the grass did well in the low spots since it could handle the wet conditions, which was the reason the family planted it there.

“It really took off and yielded great,” Bode said. “There was a lot of material there.”

By the end of the silage harvest over 500 loads were brought back to the pile averaging 14 tons per load and a little over 15.25 tons per acre.

Turn to BODES | Page 17

“It’s always a very demanding task to get done because you have to make feed for the whole year, so it is relieving and I am so excited about setting a record for getting it done,” Bode said. “We just went after it.”

Each year Bode is in charge of running the chopper or blade tractor. His favorite part is being able to switch jobs and drive other equipment, breaking up the harvest season.

The team for the day consisted of Bode, Swanson and his dad, Duane, Merlin Schwecke and Glenn Muaer. Bode ran the chopper, Swanson packed and the other three hauled the silage to the pile.

“I feel very blessed with all the help we get from friends, neighbors and family during this time,” Bode said. “They are reliable and not afraid to put in the work.”

Paul Mueller Company’s Milk Tower™ features Mueller® Temp-Plate® heat transfer surface that removes more heat from milk in the same amount of time, compared to other silos. Reach maximum cooling efficiency and maintain temperature even when the tower is not 100 percent full.

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Redeker Dairy Equipment Brandon, WI

Stanley Schmitz Inc. Chilton, WI

Tri-County Dairy Supply Janesville, WI

Fuller’s Milker Center

Lancaster, WI; Richland Center, WI

Eastern Iowa Dairy Systems Epworth, IA

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

United Dairy Systems West Union, IA; Monticello, IA

Gorter’s Clay & Dairy Equipment Pipestone, MN

Leedstone Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Monroe Westfalia Surge Monroe, WI

Lely Center Monroe Monroe, WI

Total Dairy Service Kewaunee, WI

Midwest Livestock Systems Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Ederer Dairy Supply Plain, WI

Professional Dairy Services Arlington, WI

By Stacey Smart stacey.s@dairystar.com

KEWAUNEE, Wis. — Twenty-ve years ago, Delmar and Christine Pekarek purchased a farm they could call their own. After renting a farm and also helping his father farm, Delmar was ready for a new beginning.

“I’m living my dream,” Delmar said. “I believe in working the land and watching my calves become milk cows. And I love seeing a bulk tank full of milk.”

The Pekareks milk 100 cows in a herd consisting of 50% Linebacks and 50% Holsteins at Norman Linebacks Dairy near Kewaunee. They ship their milk to Scray Cheese Co. in De Pere.

“I’m 51 years old and feel I’m the last of the old-school farmers left in my area,” Delmar said. “The 40 to 50-cow herds around here are dropping like ies. There are a lot of big farms, but I try not to worry about it and just do my own thing.”

Delmar grew up on a dairy farm a mile down the road.

“My dad had four farms, and I used to pass through here on the way to our farm in Casco,” Delmar said. “My dad was old-fashioned and didn’t want to modernize, but I had a different way of farming. I’m a cow guy, but my dad was more about machinery.”

Delmar decided to go out on his own. He and Christine rented a 40-cow farm three miles from their current farm.

“I drove past here then too and also bought small bales from the guy who owned this place,” Delmar said.

After driving past the farm thousands of times, they purchased it in 1999. The Pekareks had found their piece of paradise where they would raise their family and develop a herd of cows that looked a little different than those around them.

“Some say Linebacks are a beef breed,” Delmar said. “That’s OK because I like to be different.”

The Pekareks got into Linebacks in 2007 when they bought a herd of cows that contained a few Lineback animals.

“I kind of like the breed, and we kept building from there,” Delmar said. “I’ve never used sexed semen, so it’s been a slow process. Linebacks are durable and seem to last. They also have nice components and test a little higher.”

Christine likes the Linebacks’ temperament as well as their looks.

“I think they’re more docile,” she said. “And they’re pretty.”

The Linebacks are also hard workers.

“Some of our biggest producers are Linebackers,” Christine said. Most of their Linebacks are purebred. In addition to the traditional black and white Lineback, the Pekareks also have red and white Linebacks.

“We started crossbreeding some of our Linebacks with Dutch Belt, and we breed a lot of Holsteins to Lineback,” Delmar said. “We also have a Jersey Dutch Belt.”

Turn to PEKAREKS | Page 20

The Pekareks also plan to experiment with another cross: Lineback females and an Ayrshire bull they are raising. All cows in the barn are bred via A.I., while heifers and outside cows are bred by a bull.

“There are three to four Lineback sires we use for A.I.,” Delmar said. “There is a small amount of bulls to pick from.”

According to the American Lineback Cattle Registry, the breed has four distinctive color patterns: Classic White Witrick, Dark Sided Witrick, Dark Speckled Witrick and Gloucester. The Pekareks have all four types on their farm.

Taking advantage of two milking methods for efciency, the Pekareks milk simultaneously in a tiestall barn and a 3-stall step-up parlor.

“I milk in the parlor; Christine milks in the barn,” Delmar said. “She’s small and skinny whereas I’m tall and big, so this arrangement works well for us.”

The same cows go through the parlor each day — up to 51 head — while the barn holds 65 head.

“We don’t have to switch doing it this way,” Delmar said.

Cows are milked twice a day, and a high school kid helps milk at night. Christine returned to the farm full time in 2018 to help Delmar after working at BelGioioso Cheese Inc. for 16 years while their four kids were growing up.

“This isn’t a job; it’s a lifestyle, and I wouldn’t trade doing it for the job I did before,” Christine said.

Delmar’s brother, Darrell, comes every morning to help on the farm as well. In addition, one of their daughters who works at Agropur helps too. Their two sons, who both work at machine

A black Lineback and a red Lineback eat hay Sept. 12 at Norman Linebacks Dairy near Kewaunee, Wisconsin. The Pekareks like the durability, components and temperament of the Lineback breed.

shops, help their parents with mechanical tasks.

“They can x anything,” Christine said.

Delmar is hoping his youngest son might take over the farm someday.

“There always has to be farmers,” he said. “We feed the world, and I don’t want to see the dairy industry destroyed.”

The Pekareks farm 80 acres and rent another 55 from Delmar’s brother.

“Somehow, there have always been enough acres to feed our cows,” Christine said.

The Pekareks started out milking 35 cows and later added 40 stalls onto

the barn while also putting in the parlor. The parlor is located on the end of the barn in what was previously a lean-to loang area.

“We’ve improved the farm a lot over the years,” Delmar said.

Delmar and Christine converted the barn from stanchions to tiestalls, put in a manure pit, added fence line feeding outside, put a new roof on the barn and transformed the car garage into housing for youngstock where the speckled faces of the younger generation can be found.

“We have a good group of Linebacks coming up,” Delmar said. “The

future is looking good.”

Delmar and Christine said they enjoy walking into a barn lled with cattle of unique markings and appreciate the little things found in each day.

“I don’t know what’s going to happen once the small farms are gone,” Christine said. “Where is our food going to come from?”

Delmar agreed.

“No matter who you talk to, there’s nothing like small-size farming, and it’s gone to the wayside,” he said. “This is our life. I don’t know what will happen, but you just have to keep going. Never give up.”

By Emily Breth emily.b@star-pub.com

RUTHTON, Minn. — From chasing calves in the pen to the buckle in the ring, Sadie DeRuyter has been striving for greatness within the National Little Britches Rodeo Association.

DeRuyter is the 13-year-old daughter of dairy farmers Richard and Stephanie DeRuyter. The DeRuyters milk 100 cows in a parlor and farm 200 acres growing alfalfa, corn and barley.

Sadie has been participating in the NLBRA circuit since 2017.

“My favorite part is competing, setting personal records and meeting goals,” Sadie said.

Every weekend from March to October Sadie can be found competing in three rodeos: one each on Friday, Saturday and Sunday. She also competes in local barrel races.

This year Sadie competed at the NLBRA’s National Finals, which took place at the Lazy E Arena in Guthrie, Oklahoma. The DeRuyter family spent nine days at the event as Sadie competed in barrel racing, goats, poles, breakaway roping and trail events.

Trail riding requires riders to complete a series of obstacle courses. Her best performance was during her trail competitions, where she received a spot in the short go-round.

“To qualify for the short round, you have to place in the Top 20 in the rst and the second rounds,” Stephanie

said. “Sadie placed 8th in the short goround.”

During the rst round Sadie nished in fth place earning 136 points. Sadie then took 14th place in the second round to secure her place in the short round.

After her nal round and score were added up Sadie was awarded two buckles and a pennant for her placings in her trail rounds and world score.

Throughout her time at the nals for her trail competition, Sadie earned sixth place for an average score, seventh with her world score and eight in the short round.

Her average score is based off her top ve rounds prior to nationals combined with her scores at the nals. Her average is then added to her top scores to determine her rank throughout the nation.

“When she was given her placings, I was excited and very proud of her hard work,” Stephanie said. “Sadie said later on that it was a very surreal moment for her.”

The NLBRA was founded in 1952 with the focus of creating a circuit for youth to strive in. It is one of the oldest rodeos in the U.S. for youth.

Each year they will put on over 500 rodeos in 33 states. Throughout the nation, more than 3,300 kids participate. NLBRA awards nearly $400,000 in scholarships, awards and jackpot dollars annually at its championship rodeo.

As Sadie ended this season, she is already preparing for the next.

Turn to DERUYTER | Page 22

While competing with riders closer to her age in the NLBRA, Sadie also has competed in adult leagues. Earlier this year, Sadie competed in adult barrel racing and took third place.

From the barn to the rodeo sidelines, Sadie’s family are her biggest supporters. Her siblings, Levi, Dyland, Isaiah, Sierra, Clay and Kai, travel to her performances whenever possible.

“Her younger brother, Kai, and I always go to the rodeos,” Stephanie said. “Her dad and Clay stay at home and handle chores when we are gone. If the rodeo is closer, they will come and watch.”

When at home, Sadie’s chores consist of caring for the calves, chickens, goats and, of course, her horses.

Sadie has ve rodeo horses —

Cowboy, Dutch, Cactus, Spice and Smokey — that she works and trains. Sadie rides at least once a day putting in more hours than her family can count.

“She has always loved horses and riding,” Stephanie said.

While her weekdays are lled with chores and training, each weekend Sadie can be found at a variety of rodeos.

Within Minnesota, South Dakota and Nebraska, Sadie can get her qualifying rounds in to earn a trip to the National Finals. To qualify for the nal rodeo, riders have to place in the Top 6 at six different rodeos.

“Sadie has been performing really well so she has been able to get her six wins in without having to go farther away,” Stephanie said. “The farthest one, (besides nationals) we have gone

consultant said it was a total loss. The corn is yielding around 200 bushels per acre. We have been chopping our sorghum sudangrass, which has been yielding good, but it is dry. The sunflowers are doing decent, but only have two heads on them. We will probably be planting triticale mixed with barley in the next 2 weeks. A lot of people have been holding off to see if we can get some moisture since there is probably not enough to sprout anything.

It’s been a dust storm out here these last couple weeks. I was able to cut about half of my alfalfa around Sept. 17. I am going to make it into small squares. The other half I am hoping to graze. We started taking out corn silage on Sept. 13 and finished most of it on the 17. We have 25 acres left that were planted late. We yielded about 11.5 ton per acre. The neighbors started combining, as far as I saw, on Sept. 23 and everyone was going.

I chopped for a neighbor yesterday (Sept. 24) and have to chop for another one tomorrow. We will probably get at ours later this week. The moisture was in the mid-60’s. We like our corn to by around 67-68% for the bunker. We plan to chop around 300 acres and we usually have four haulers, one packer and one running the blade tractor. In the area, some people are done with silage, some are well on their way and some haven’t started. We’ve been working on meadows. We have six to eight meadows that we do. There are some soybeans near here that came out yesterday. I was told they were busheling very well. Wayne,

We are planning to start baling our fifth-cutting hay tonight (Sept. 24) or tomorrow. It might be a little shorter on yield than fifth cutting has been in past years, but it is hard to tell until it is rolled up and I can count bales. As for corn silage we chopped from Sept. 17-19. Moisture was just a hair lower in spots, but we still averaged 63% with 25-27 ton per acre. As for soybeans I have not seen any of the neighbors going, but they look like they will be going tomorrow (Sept. 25) or later in the week.

We are done chopping except for a couple loads that we left for the adjuster. We started Sept. 15 and we finished yesterday (Sept. 24). We did 110 acres and put it all in a bunker. The crop was really inconsistent and the moisture was as well. Some was too dry and some was too wet. We have cobs that are 28% and some with green husks. It varies so much in the field. We also did some custom chopping. There are few people around here starting with soybeans. There are some out near Glencoe and Willmar. Ours are getting close. We are also getting the tillage equipment ready.

If you have to score teats you have a problem. Veterinarians tell farmers score teat ends! How has this become such a problem with hundreds of liners all claiming to be gentle? This tells you how much damage milking systems cause. You can’t see the real damage done to teat ends which is in the canal. The NMC has no solutions - only lower SCC with higher cull rates which has not solved the problem and cost you money. Trident™ pulsation stops teat damage which leads to lowering cull rates and better milk quality and production.

More milk and great for the environment

We finished our silage Sept. 11 and we just finished our neighbors on Sept. 21. We had the right moisture and dry weather, so we did not have to play around in the mud. We have our fourth-cutting alfalfa down. It has only had less than a half inch of rain, so it’s not the best yield we have had this summer. Our soybeans are looking like they are just about ready and a few of our neighbors started Sept. 22-23. From what we have heard they are getting about 50 bushels an acre. There are definitely areas where they are doing better and worse than that though.

DENNIS BURKLE

We are half done with silage. It’s taking a long time for it to get ripe. We put our silage in a bag and target 65% moisture. Some stuff we did earlier was closer to 70%. I would say 40% of the soybeans are out. Mine are just starting to bleach out. Near Cedar Rapids the combines are going and the crop is averaging 45-60 bushels per acre. It’s been nice in the fields. We plan to do high moisture corn next and blow it in the silo. I talked to a couple custom guys and they said they are switching over to ear corn. I seeded some rye where we chopped 30 acres of corn.

HAUSCHILDT

Most of the storms went north of us and we only got about two-tenths of rain. Combines are getting out and starting to roll. Yields have been all over the board. I’ve heard anywhere from upper 20s to upper 50s. Corn silage is the same way, I’ve heard anywhere from 17 to 30 tons per acre. We wrapped up fourth-crop hay and now we’re in that no cut zone. If we get the warm weather they’re talking about, there’s a chance to get another crop off. It is getting to be that time of year when things can be pretty hectic. Let’s hope we can get this weather to hold, we don’t need the rain now.

We finished up fourth-crop hay the week of Sept. 16. It was put up as silage and dry hay. This week we are cleaning calf pens, moving calves and doing catch up. Corn silage is not quite ready to go. Anyone in the area who has tried it says it is juicing. Sometime in the next week we will give corn silage a try. A bunch of soybeans are starting to come out as well. Some soybean plants are still green and other soybeans are getting too dry and at 9% moisture. We also grow potatoes for fun using antique potato equipment. We planted 700 hills this year and they are starting to dry down.

We had an inch of rain last week. We are nearly done with corn silage and it is yielding very well, better than I thought it would. We’re averaging between 30 and 32 tons per acre. It helps that it is 12 to 13 feet tall. We’ll lose about seven or eight acres to bear damage. I only ran the irrigation maybe twice this summer, the least I’ve ran it in the 12 years since having it. Our alfalfa yields were phenomenal, too, and the quality was good. We just tested our second crop and it came back at 228 relative feed value.

JULKA

We finished corn silage Sept. 12. It yielded really well, averaging 28 ton per acre. In some spots, corn was taller than the chopper, and in others, it was 2 feet tall, but all in all it averaged well. We started harvesting soybeans Sept. 17 and had 160 acres in by Sept. 24. Yields were roughly 65-75 bushels per acre. It’s very dry. In the lower spots that got drowned out this spring, the plants were still green, so we went around some areas we’ll have to get later. We seeded 130 acres of winter wheat Sept. 21. As soon as we’re done with beans, I bet we can start diving into high-moisture corn.

We had 0.7 inches of rain last week, but within five miles of us, they had over 2 inches. We started our corn silage Sept. 20 and finished Sept. 21. It yielded well, about 23 to 25 tons per acre at 67% moisture. We are all done harvesting now and we have plenty of feed. We are hauling manure and putting in winter wheat. Beans in our area are probably about two weeks off, if it stays as dry as it has been.

We finished chopping corn silage Sept. 24. We had good tonnage per acre with an 18-ton average. We started harvesting soybeans Sept. 19 and had 78 acres done by the 24th. Daryl’s son, Lee, said the yield was average in low spots and better on higher ground. We were waiting for it to dry so we can do more. A lot of soybeans around us came off the week prior before the rain. Fitchburg, WI

By Dan Wacker dan.w@dairystar.com

TOMAH, Wis. — When heading south out of Tomah on Highway 131, there is one stop for ice cream enthusiasts before settling into their trip. On the corner of Hertz Avenue sits a yellow farmhouse with a gravel parking lot and a wraparound driveway. This is Twin Peaks Ice Cream LLC, a business owned and operated by twins Karen Olsen and Kathy Yenter.

The two opened the business in 2021 to provide a place for families to gather and enjoy delicious Wisconsin ice cream on the southern end of town.

“We started this because I couldn’t get a twist cone anywhere,” Kathy said. “We wanted

a spot for families to gather and provide affordable ice cream.”

Outside the shop is a shaded seating area with four round tables and four chairs at each table. Surrounding the seating area are tractor tire ower beds with space for kids to play and families to visit.

“We sometimes have people that will hang out here for two hours,” Kathy said. “The kids can be out playing in the dirt, playing on the tires — the same thing our kids did here — while their families are able to sit and visit and enjoy some ice cream.”

The sisters said the spot is perfect for unwinding and catching up.

“There’s not as much electronics going on, which is nice,” Karen said. “You can look out and see kids running around and playing in the yard, playing with each other. Eventually we want to get some more things to help keep the kids occupied, (like) swings.”

Inside the farmhouse are two seating areas, as well as a consignment shop lled with a variety of handmade products. The

Turn to TWIN PEAKS | Page 28

The GEA SW Cable Drive Unit is an efficient system with easy operation that requires minimal maintenance. Our unique design moves the drive unit laterally which keeps wear to a minimum. Elevating the drive unit over the cross gutter allows easy access and keeps the working area clean.

vendors range in age from a 14-year-old candle maker to a 90-year-old creator of table runners. All items in the consignment shop are locally made.

“I’ve stayed on this end of Tomah basically my entire life,” Kathy said. “This end of town is where we wanted to start our business. So, we started at the interstate and worked south and got this far and got someone to sell us the property.”

Although new to the twins, the property has ties to the family from before they took ownership. Karen and Kathy learned from family members that their great-greatgreat-grandparents had purchased the farm and the property many years ago. Their great-grandfather built the house where they are currently running their business, and their grandfather was born there.

Now, a room that once held their family gatherings holds spaces for families from all over the area to gather and enjoy a scoop. The dining room holds six tables, the menu board and a classic jukebox. The front porch has been converted for more seating.

The kitchen remains the kitchen. There, Karen, Kathy and their eight employees dish out ice cream cones, shakes, malts, sundaes and even offer brats, hot dogs and chips on the menu for those passersby who are looking for a full lunch.

The sisters said they emphasize ensuring their products are from local businesses or entrepreneurs.

“It was important for us to use Wisconsin products, and to keep everything local as much as we can,” Kathy said. “I don’t think there’s enough of that in our area. … Why not have something from within Wisconsin, in Wisconsin?”

Twin Peaks Ice Cream serves Cedar Crest Ice Cream and Classic Mix soft serve from a dairy wholesale company located in Baraboo.

Cedar Crest has been family-owned since 1976, a fact that was important to Karen and Kathy when choosing which ice cream to put in their shop.

“It also helps that there are a lot of people around here that love Cedar Crest,” Karen said.

Its affordability is something that helps set Twin Peaks Ice Cream apart the sisters said. Pricing was a key component for Karen and Kathy in this venture.

“We want this place to be family-oriented,” Karen said. “We have grandkids and every time we’d take them out to ice cream it would be at least $30.”

The sisters’ shop is connected to the

Turn to TWIN PEAKS | Page 29

community. The Tomah VA Medical Center brings a bus of patients to their shop to give patients a chance to get out into the countryside and to foster community between the center and a local business.

Karen and Kathy had help getting started, visiting with another ice cream shop a few miles east on Highway 21.

“We worked really closely with Rocky Road Ice Cream in Necedah,” Kathy said. “Lori (Winter) was so good about helping us get started. She has almost the same exact setup there on 21 and G. She gave us some information on the style of equipment she uses, how many people she employs. All of that was extremely helpful.”

The sisters rely on word of mouth and Facebook for advertising. They have worked with the Wilton Library for a Halloween event, providing frozen treats as well as hosting a “Back to the 50s Car Show” in August.

Their goal of strengthening their community one scoop at a time has also led to more recognition around town for the Tomah natives.

“(When we) go out to dinner with our spouses, we get the kids in the corner sneaking looks at us because, to them, we’re the ice cream lady,” Kathy said. “Not that they know us, but they know our shop and have seen us out here.”

Recognition extends beyond the humans who operate the shop.

“I come walking in with my cat, and I had a family recognize my cat and say, ‘Hey look, it’s the ice cream cat,’” Karen said. “We’ll have customers that come in just to see the cat. They’ll come out to see her and get ice cream as a secondary thought.”

Visitors who arrive at Twin Peaks Ice Cream, will be greeted by Kathy’s black cat, Ivy. The unofcial mascot of the shop, Ivy spends her days lounging around the yard looking for new patrons to say hello to.

Together at their shop, the sisters have created a recipe for conversations in the countryside and quality time with friends and family over a frozen scoop of Wisconsin dairy.

Hybrid Flex Stalls combine the exibility of poly and the stability of a steel structure. This unique combination delivers maximum comfort for the cow without compromising the strength of the stall. Heavy-Wall Poly Pipe reduces bruising on the animal and allows for the animals movement when entering and leaving the bed. Our Zig-Zag Neck Rail gives each animal more space to stand, and also centers them in the bed while giving side support to the stalls.

For all your hydraulic connection applications, we provide a wide variety of hydraulic connection options, including Flat-Face couplers, Poppet-Style couplers, Screw-Type couplers, Volvo TEMA couplers, and Multi-Coupling units. With name brands like Faster, Stucchi, Parker, and Holmbury, we can provide custom hydraulic options to best t your needs!

units. With name we can provide custom hydraulic

MultiCoupling units significantly improve the ease of connecting hydraulic lines

1 6-oz. container of plain yogurt (I prefer Greek yogurt)

Blend all ingredients in a blender until smooth. Pour into a cup and enjoy.

1 8-oz. package cream cheese, softened 1 cup apple butter

Blend cream cheese, apple butter and peanut butter with an electric mixer on medium speed until smooth. Cover bowl with plastic wrap and refrigerate for 1-4 hours before serving. Eat with sliced apples/pears or graham crackers.

3/4 cup sugar

cup cornstarch

cups

Combine sugar and cornstarch in a small saucepan. Slowly whisk in the milk. Bring to a boil over medium heat. Reduce heat and simmer for about 1.5-2 minutes or until it thickens. Whisk constantly to avoid burning. Remove from heat. Whisk in the peanut butter and vanilla extract until the pudding is smooth. Allow to cool slightly, about ve minutes.

Assemble parfaits by putting about 1/4 cup of pudding mix in the bottom of a cup and sprinkling with chocolate chips. Repeat three more times to create four layers total.