VISIT US AT WORLD DAIRY EXPO!

BOOTH EH 3806

Volume 26, No. 15

“All

Volume 26, No. 15

“All

By Stacey Smart stacey.s@dairystar.com

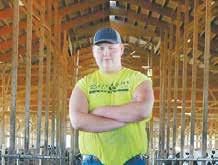

WAUPACA, Wis. — Josh and Amy Karpinski are paving the path for a bright future at Sheridan Flats Dairy. After completing an expansion this year that included building a new freestall barn and adding 125 cows, the couple has entered a new phase of their farming career.

“It’s been a big year of changes,” Amy said. “We were at 200 cows for a long time, and now we’ve grown to a number that ts our farm well.”

Amy is the fourth generation on her family’s farm near Waupaca where they milk 320 cows and farm 300 acres. She and Josh formed an LLC with

her parents, Mark and Dawn Anderson, two years ago.

“My parents are mostly retired now, so it’s Josh and me doing the day-to-day work with help from one part-time and three full-time employees,” Amy said.

Growth was inevitable for the family who had come to a crossroads.

“We were at the point that we either had to grow in some capacity or get out, and getting out wasn’t an option,” Amy said. “Things were not cash owing with 200 cows. My parents still take a paycheck, and three years ago, Josh quit his full-time job in town.

September 28, 2024

By Sarah Middendorf sarah.m@star-pub.com

MCBAIN, Mich — JP

Koop of Lucky 7 Dairy recognizes he is a lucky man to be living past the rst day of corn silage harvest this year. The day started normally enough. But when his chopper spout touched a lowhanging power line, the day went south as both he and the chopper became electried. Koop, his wife, Suzanne, and one of his seven children, Gavin, milk 1,800 cows in a double-25 parlor and freestall barn and farm around 3,400 acres near McBain. Koop is a newcomer to the dairy industry. He purchased his rst dairy farm six years ago.

Ironically, Lucky 7 Dairy kicked off the corn silage harvest Sept. 12 with a meeting to go over safety concerns and pray for a safe harvest. They began by opening some of the elds.

“The guy I was loading said, ‘Hey you are getting close to that line. Move over to the right a little bit,’” Koop said. “Before he got the words out of his mouth, the spout on my chopper had touched the powerline. As soon as it touched … it had pretty much welded itself to my spout.”

Koop said he tried to move it away but it blew out the hydraulic cylinder that controlled the spout.

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Cheyenne Middendorf • cheyenne@star-pub.com

Nadiia Griepentrog • nadiia@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, South Dakota) 605-951-5270 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and opinions

columnists and

“I quickly turned around because I knew I was in trouble,” Koop said.

“I looked at my head (on the chopper) and there were sparks ying out of that big time. So, I quickly stood up, opened the door and walked out onto the platform outside the door.”

At that moment, the chopper’s back tires were already blown and on re and the front tires were smoking.

from the tires would soon no longer provide some insulation from the electrical current when the steel rims touched the ground.

by

Koop said he was standing there wondering whether the power line was going to blow a fuse or breaker which would shut off the power.

“I still don’t know how I did this, but I stood up on the handrail on the side of the chopper,” he said. “Clearly, I had good balance for a little bit. I got as low as I could and stood up and jumped as hard as I could.”

“It was a mainline so I suspected there wasn’t any sort of breaker,” Koop said.

“I debated, ‘Alright is the re department going to get here in time?’ I (didn’t) have that kind of time because the rims were going to touch the ground.”

Koop realized time was ticking because the rubber

Before he jumped, he looked at the ground and it was smoking due to the stray voltage hitting the ground.

“I thought, ‘Well I’m dead on the chopper for sure and I’m probably dead when I hit the ground,’” Koop said. “I’ll get electrocuted, but at least there’s a chance (to survive).”

He jumped roughly 10 feet from the handrail to the ground.

Turn to LUCKY 7 | Page 5

Karpinskis build new barn as phase one of expansion First Section: Pages 1, 6 - 7

Schlies managing herd for more milk, better health First Section: Pages 29, 31

Plain, WI

Ladysmith, WI

Sawyer, Rusk County farmers deal with losses from wildlife damage First Section: Pages 12 - 13

Wisconsin 4-H judging takes Harrisburg by storm First Section: Pages 26 - 27

Bovine twins inseparable at Ederer family dairy Second Section: Pages 12 - 13

Dolans launch safety day after power take-off accident First Section: Pages 32 - 33

Richmond, Floodquist use Dairy Grazing Apprenticeship for nonfamily farm transition Second Section: Pages 10 - 11

Tomah, WI

Sisters focus on Wisconsin products at Twin Peaks Ice Cream Second Section: Pages 27 - 29

Brillion, WI

FFA: Behind the Emblem Third Section: Pages 10 - 11

For additional stories from our other zone, log on to www.dairystar.com

“After installing our first SCR system 10 years ago we noticed better herd health, drop in death loss, and increased pregnancy rate. I like being able to virtually monitor cow health and activity without having to be physically on the farm. We most recently upgraded our SCR collars a few summers ago and love how advanced and precise the technology is.”

- Majestic View Dairy, Amanda Buschor

“Of course, I’m not a gymnast where I could stick the landing,” Koop said.

When he fell, he received electric shocks through his hands, knees, feet and stomach. He was unable to stand up but managed to crawl his way out of the ripple effect of the power, which radiated roughly 10-12 feet from the source. He was then able to stand up and run away. He was later told there were roughly 180,000 watts of electricity surging from the line.

He ran towards the road to get away but was getting weaker and fell. Some of Koop’s workers grabbed him and helped him across the road.

“You don’t have much time at all to think,” Koop said. “A whole bunch of stuff happened right. I surely feel blessed to be here today and it sinks in a little more every day.”

Koop said reghters and power company workers came to talk to him because they were surprised that he was alive and responsive.

The reghters told Koop he was fortunate the ground was dry and not wet, otherwise it would have conducted electricity better.

When Koop jumped off the chopper, he bruised his heel on the landing. The doctor also told him his muscles were going to be sore from the electricity. He said they

were.

Koop said his CLAAS dealer, Burnips Equipment, had a loaner chopper sitting in his parking lot before he had even gotten home from the hospital. The dealership heard about the accident and knew he would need another one, so they sent one before anyone from the farm called them.

“That’s pretty good customer service,” Koop said.

Suzanne made a post on Facebook about the accident.

Koop said most of the comments say, “Thank God you are OK.”

“I have had so many peo-

ple say, ‘Hey we are praying for you,’ or ‘We are so glad you are here,’” Koop said.

A power company from Kansas reached out to Koop and asked if they could use the pictures to teach about power and electricity and what to do in case of an accident.

“There (are) a lot of people with honest and true heartfelt concern and praising God that I am alive,” Koop said. “I am new to the farming community and just seeing the support from across the world, I am so pleased to be a part of the farming community.”

(Le ) The burned-out shell of a self-propelled chopper sits in a chopped corn eld Sept. 20 at Lucky 7 Dairy near McBain, Michigan. The dairy started chopping silage Sept. 12.

(Below) The remains of a selfpropelled chopper sit Sept. 20 at Lucky 7 Dairy near McBain, Michigan. The spout on the chopper touched the bo om wire on a power line and was electried.

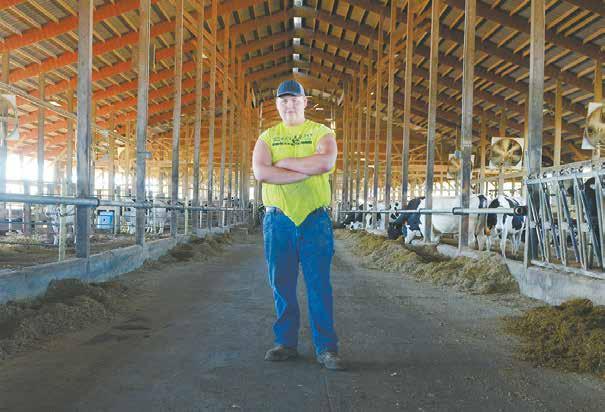

STACEY SMART/DAIRY STAR

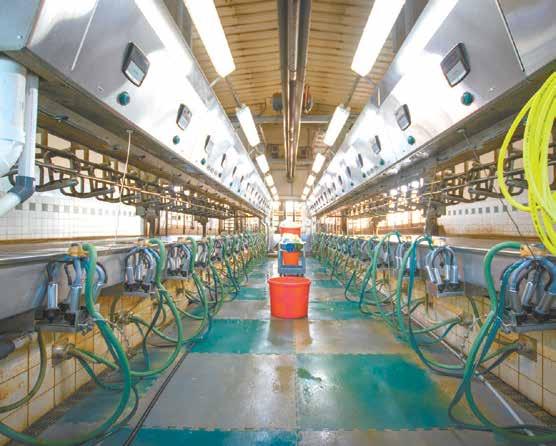

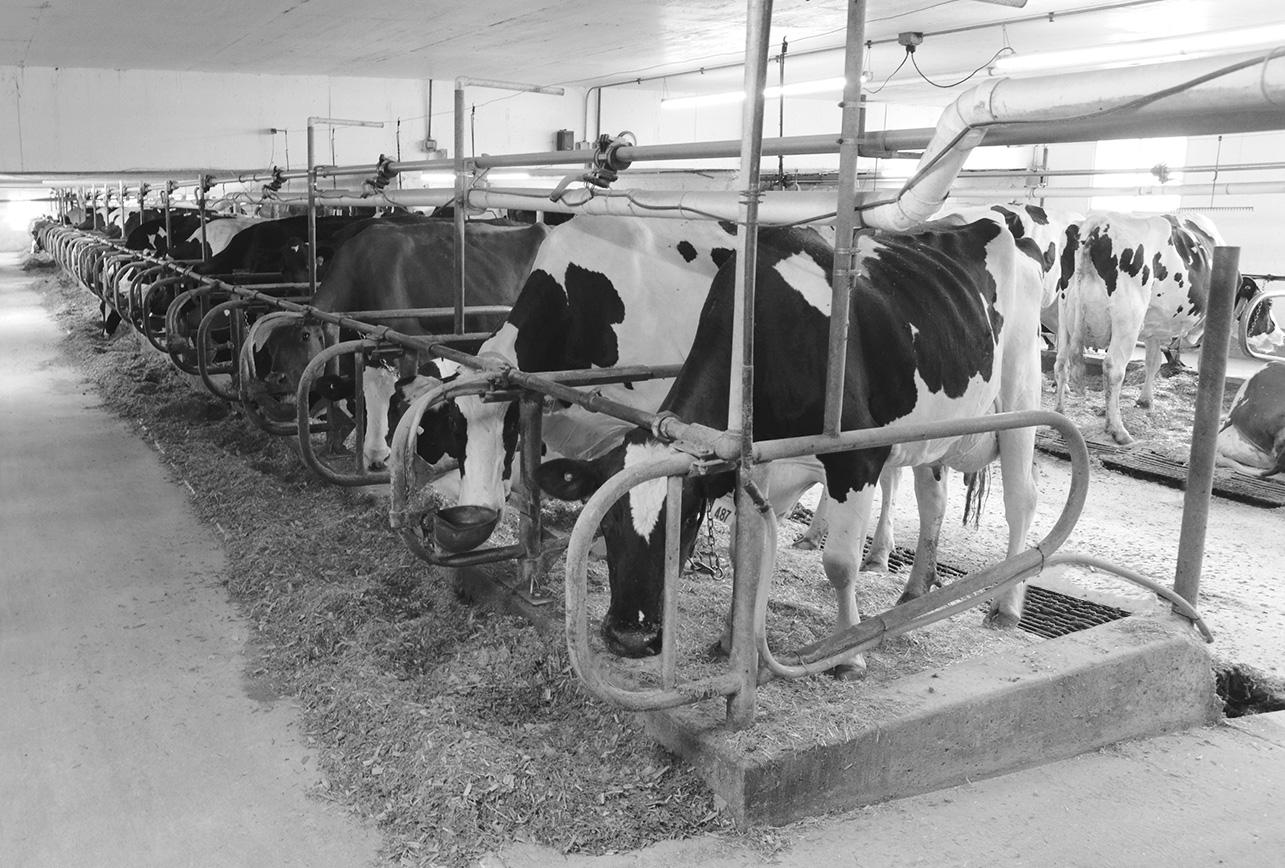

Cows relax in sand-bedded stalls Sept. 17 in the new freestall barn at Sheridan Flats Dairy LLC near Waupaca, Wisconsin. The tunnel-ven lated barn also features 55-inch cyclone fans above the inside rows of stalls and 36-inch fans on the outside rows.

We had more expenses on the family side since he was no longer providing our health insurance.”

Furthermore, their barns were at capacity, not properly ventilated and in need of maintenance.

“We used to have bad crowding in the summer,” Amy said. “Hoof health would deteriorate from standing, and milk production would drop.”

Since Jan. 31, cows live in spacious accommodations that accentuate comfort while easing the workload for the Karpinskis and their staff. The barn’s features have benetted cow health and reproduction. The herd, which is primarily Holsteins, also includes 10 Brown Swiss along with Holstein-Brown Swiss crosses, Holstein-Normande crosses and Holstein-Jersey crosses.

Putting all their milk cows under one roof, the tunnel-ventilated barn is 330 feet by 125 feet with a 21-foot-high ceiling. The 280-stall barn includes a pre-fresh pen, maternity pen and calf warming room.

“Cow comfort is our rst priority,” Amy said. “Ventilation in the new barn is a big upgrade from what we had. In the old barns, we just had fans above the free stalls.”

The fans are variable speed and adjust according to temperature. In addition, Josh said tunnel ventilation keeps pests like birds and ies out of the barn.

“We have had no dip in milk production this year,” Amy said. “We used to struggle a lot with conception rates too, but now they keep going up.”

Rising more than 10 points, their conception rate is now at 47%.

“Our conception rate skyrocketed since moving into the new barn,” Amy said. “Before, cows were heat-stressed in summer and cold-stressed in winter, which had a negative impact on conception. Now, we’re getting more cows pregnant sooner. We also used to have a lot of retained placentas, but that stopped like a light switch since moving into the new barn.”

The barn features alley scrapers to provide continuous cleaning, replacing the need to clean via skid loader. Removing tasks like this from the to-do list has given employees more time to properly move cows, Amy said.

The barn runs on automation, ensuring ventilation and cleaning systems operate without the need for human intervention.

In addition to a wall of fans on the end of the new barn, fans are also placed strategically throughout the building to maximize airow. Fifty-ve-inch cyclone fans are located above the inside rows of stalls while 36-inch fans keep cows on the outside rows cool. Automatic curtains are located on the intake end of the barn. Eleven fans in the ridge continuously push the air out.

A complete air exchange occurs throughout the barn every 90 seconds.

“Once the ventilation system and alley scrapers are set, you don’t have to touch them,” Josh said.

A better manure system was also part of the design. A pit within the barn agitates the manure, and once it is full, manure is sent out to the lagoon.

“In the old barns, I had to pump out the pit, and we were doing a lot of daily hauling,” Josh said.

Turn to KARPINSKIS | Page 7

sures 330 feet by 125 feet and has a 21-foot-high ceiling.

LED lighting illuminates the barn, creating a bright workspace. Amy said they received rebates from Focus On Energy for the fans and lighting.

Headlocks are another feature of the new barn that was missing from the old barns. They also installed a footbath cows walk through when coming back from the parlor.

The new barn is connected to the old barns and milking parlor. Milking about 50% more cows with the same amount of resources, the Karpinskis continue to milk twice a day in their double-9 parallel parlor built by Amy’s dad 25 years ago.

“We can still push a lot of cows through it,” Amy said. “We changed the routine in the new barn, and we can milk those extra 120 cows in the same amount of time that we milked 200. We have no downtime in the parlor anymore. It’s much more efcient.”

Better cow ow is a primary reason for the increased productivity. The Karpinskis made changes to the exit of the parlor and begin fetching the next group before one group is done. After they are milked, cows are sent to a holding area off the exit until the next group is in the parlor. Removing the footbath from the exit has also eliminated bottlenecks in

the parlor.

“The setup is easier on employees, and we did not have to add any new people,” Amy said. “It’s nice having the same payroll cost.”

The Karpinskis still utilize their older facilities, with the best of the old barns serving as housing for far-off dry cows.

“Dry cows were stressed before, but post-calving illnesses have dropped right off,” Amy said.

The Karpinskis use their old calving area as a fresh pen/hospital pen, which is located next to the parlor.

“One of the ways we were able to expand was by increasing our feed inventory, but we didn’t need that much more land to feed these added cows,” Amy said. “We feed a high-corn silage diet and very little alfalfa. With corn silage, you get so much more from one crop tonnage-wise.”

The Karpinskis plan to grow again. Phase two of the expansion will include another manure pit, a new milking parlor and more free stalls.

“We’re not afraid to grow,” Amy said. “You have to do what you have to do to pay the bills, as long as you can take care of your cows.”

By Danielle Nauman danielle.n@dairystar.com

HUMBIRD, Wis. —

Ever since its inception, World Dairy Expo has been intertwined in the life of the Pralle family of Selz-Pralle Dairy near Humbird.

“Expo was the family event — it was our family vacation, it was what we did,” Pam Selz-Pralle said. “I didn’t ever go to homecoming in high school, because it was always during Expo.”

Pam and her husband, Scott Pralle, milk 450 cows on their Clark County farm. The dairy is home to Joliam Holsteins and their three children: Ryan, Jessica and Nicole.

“We’d get our yellow Kent bags and go around and pick up all the things,” Pam said. “Going to Expo was the rst time I ever went to a Burger King, coming into the west side of Madison. It was a big deal for us farm kids from central Wisconsin.”

Scott’s rst Expo experience came in college.

NAUMAN/DAIRY

The Pralle family — David Trimner (le ), Jessica Pralle-Trimner, Sco Pralle, Pam Selz-Pralle, Nicole Pralle and Ryan Pralle — gathers in front of the milking parlor Oct. 9, 2021, at Selz-Pralle Dairy near Humbird, Wisconsin. The Pralle family has par cipated in World Dairy Expo da ng back to Pam’s father’s involvement in the event’s rst year.

“My dad was always on the Tri-State board or involved with (National Association of Animal Breeders), so my parents would go for meetings and I’d stay home and take care of things,” Scott said. “Once I got in college, I started helping Tom Morris and Jim Hoskens with their show string.”

Growing up, Pam never realized the extent to which her family had been involved in the earliest days of WDE. Her father, John Selz, sat on the board of directors of the Wisconsin Holstein Association when the rst event took place in 1967 and was

involved in the beginnings of the show. He was elected president of the WHA in 1968 and continued to be involved with Expo.

“Going through old papers of my dad’s, I found old minutes and letters on letterhead from before the show was actually even called

World Dairy Expo — when it was called the World Food Expo,” Pam said. “They were things that Mrs. Hetts would have typed up on old carbons and old mimeographs — really just fascinating to read.”

As a student at the University of Wisconsin-Madison, Pam recalls working with the Badger Dairy Club at WDE.

“Back then the BDC students provided nightline services in all the barns,” Pam said. “We’d walk around keeping the animals clean. Barb (Natzke) and I always liked doing the Milking Shorthorn barn. They showed early in the week, and never got upset if animals got too dirty — so we were able to run around and have some fun, too.”

Pam recalls when Expo hosted social events for exhibitors and dairy enthusiasts.

“I remember the square dances, the big parties they would have, and the dances they would have in the Forum building,” Pam said.

While Expo has changed over the years, the primary reason the Pralles attend remains the same.

Combining the robustness and adaptability of Fleckvieh with the excellent milk production and solid conformation of Dutch Red and White Holstein creates a powerhouse of genetic benefits. This blend enhances overall herd performance and longevity, ensuring healthier cows and higher yields. Delve into this crossbreeding strategy for a superior, well-rounded dairy herd.

“It is really about the cows and the people,” Pam said. “It’s a social gathering, a place to see everyone. And it is like the art fair, the breeding art fair. You go to see the daughters of the bulls you might like to use, and really just everything about the industry.”

Not every idea that came home from Expo turned out to be a good one, Pam said.

“One year we went down to Madison, and all those (Hilltopper) Warden daughters were winning — they were big, powerful, massive heifers,” Pam said. “We came back home and started using Warden. That was a disaster — they didn’t milk, they didn’t breed back.”

Scott was surprised to hear Warden had been a service sire in the Joliam herd.

“Your dad used Warden?” he said.

Pam laughed in reply.

“They were impressive to look at,” she said. The Pralles admit they use fewer of the bulls siring the show-winning Holsteins these days, recognizing the importance of staying true to their own breeding goals.

“Everyone comes home, all excited to use the new bull siring all the show winners,” Scott said. “I usually tell them that we’ll just hold off for a while and see how they turn out.”

Keeping that focus has allowed the Pralles to nd success within their own herd.

“We focus on breeding cows that are functional and well-balanced,” Pam said. “They need to look good, but they need to earn their keep. We’ve got 50,000-pound cows and 96 Excellent scored cows walking around out in the barn.”

While they do not breed cattle to create an Expo winner, they said they enjoy marketing competitive animals.

“Even if you’re not trying to breed those types of animals or using those bulls, you can still enjoy your time at Expo,” Pam said.

When it comes to visiting the trade show, Pam has traded in her yellow Kent bag for a more streamlined approach.

Turn to PRALLES | Page 11

Visit us at World Dairy Expo booth 669 in the Trade Center

Us for a Quote

The comment period for the Federal Milk Marketing Order reform process wrapped up earlier this month. American Farm Bureau Federation Chief Economist Roger Cryan said his organization is not happy with the U.S. Department of Agriculture’s approach for make allowances.

“Those make allowances were already big enough that cheesemakers have been building a lot of new plants and plant expansions,” Cryan said. “The cost survey data USDA used to raise those make allowances is badly biased. It’s based on voluntary surveys from small, high-cost processing plants that are not representative of the dairy manufacturing business generally.”

A decision on the nal FMMO changes is expected before the end of the year.

Ad hoc disaster and farm bill passage needed

A farm crisis is on the horizon. U.S. Senate Agriculture Committee Ranking Member John Boozman made that point in a speech on the U.S. Senate oor Tuesday. The Arkansas Republican said market prices are far below the cost of production, and many farmers will be unable to secure an operating loan next year. Two recommendations were made.

stringent rules and the environmental activist group wants the court to reconsider. A decision may not happen for over a year.

CHS returning patronage and equity redemptions to owners

CHS Inc. plans to return $600 million in cash patronage and equity redemptions to its owners in the calendar year 2025. Based on business done with CHS in scal year 2024, which ended Aug. 31, 2024, the CHS board has elected to return $300 million in cash patronage and $300 million through equity redemptions to CHS owners. This is the third-highest amount of cash returns to owners in CHS history.

By Don Wick Columnist Ag Insider

“We need to provide emergency assistance to address the economic losses that farmers are facing associated with the 2024 crop,” Boozman said. “Farmers across the country need a bridge to help their family farms survive into next year.”

Boozman said ad hoc emergency assistance does not reduce the need to pass a new farm bill this year.

“The window to make this happen is closing quickly,” he said.

Farm Credit Administration: ag economy outlook

The Farm Credit Administration has released its quarterly report on the farm nancial situation. High corn and soybean yields are anticipated, but the large supplies are pressuring commodity prices. Livestock producers are being helped by cheap feed. The strong nancial positions in 2021 and 2022 provided a cushion for the current downturn in the farm economy. With a drop in liquidity, the FCA expects more reliance on operating lines of credit. Year to date, the FCA has had earnings of $3.9 billion. That’s up 12% from the same period last year.

Colombia is calling for an additional 4.86% tariff on U.S. milk powder exports, claiming the product is unduly subsidized. The preliminary tariff will be in effect for four months while an investigation takes place. The U.S. Dairy Export Council and the National Milk Producers Federation are disappointed in the preliminary ruling. The dairy groups said the claims are baseless.

In the September supply-demand report, the U.S. Department of Agriculture lowered its forecast for 2024 and 2025 milk production. For this year, milk production is forecast at 225.9 billion pounds. That’s down from 226.3 billion pounds in the August report. In 2025, milk production is projected to total 227.9 billion pounds, down from 228.2 billion pounds a month earlier. The downturn is based on lower cow inventories and a reduction in growth in milk per cow. USDA is predicting Class III milk prices to average $19.45 per hundredweight, up from $18.40 per cwt. in August. For 2025, Class III prices are forecast at $19.60, up from $18.65 per cwt.

The Ninth Circuit Court heard oral arguments late last week in a lawsuit seeking stricter regulations for large-scale livestock operations. The lawsuit was led by Food & Water Watch. In 2017, the court denied a petition for more

Newton moves to Terrain

A well-known agricultural economist is the new executive head of Terrain’s team of ag economists and analysts. Most recently, John Newton was the chief economist for the U.S. Senate Agriculture Committee Republican Caucus. Before coming to Capitol Hill, Newton was chief economist for the American Farm Bureau Federation and National Milk Producers Federation. Newton succeeds Don Close, who launched Terrain in 2022. Close will remain with Terrain and focus on cattle and beef analysis. Terrain provides economic analysis for AgCountry Farm Credit Services, American AgCredit, Farm Credit Services of America and Frontier Farm Credit.

Miller joins Dairy Farmers of Wisconsin

Ben Miller is the new senior vice president of industry relations for Dairy Farmers of Wisconsin. For the past eight years, Miller has been the assistant vice chancellor for government affairs and strategic partnerships for the University of Wisconsin-Madison.

Costello continues her commitment to FFA

The new executive director of the Wisconsin FFA Alumni and Supporters is Tari Costello, of Waupun. For the past 27 years, Costello was an ag teacher and FFA advisor for Waupun Area High School. During her career, Costello was recognized as Wisconsin Association of Agriculture Educators Outstanding Agriculture Educator, Wisconsin High School Teacher of the Year, Wisconsin Agri-Science Teacher of the Year and Wisconsin Farm Bureau Outstanding Agriculture Educator. She received a Herb Kohl Teacher Fellowship award and is an honorary Chapter, State and American FFA Degree recipient. Costello is an alumnus of the University of Wisconsin-River Falls and a native of Alma, Wisconsin.

New dairy item on Domino’s menu

Macaroni and cheese is now on the menu for Domino’s Pizza. There are two options: 5-Cheese Mac & Cheese and Spicy Buffalo 5-Cheese Mac & Cheese.

“Domino’s is continuing to innovate with intent and expand our menu with additions that cater to what our customers want,” said Kate Trumbull, Domino’s senior vice president, chief brand ofcer.

Trivia challenge

“The Golden Age” is the theme for the 2024 World Dairy Expo. That answers our last trivia question. For this week’s trivia, what color are the shavings in the Coliseum at the 2024 World Dairy Expo? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

A paper shows le erhead for the World Food and Agricultural Founda on, the precursor to what is now World Dairy Expo. The artwork for the logo for the event has remained the same throughout its history

“I typically go through the trade show to look for specic things, based on the current technology,” Pam said. “One year it was to look at milk taxis, another year it was to look for things to improve upon our freestalls and decrease our sand usage.”

The educational opportunities that Expo added have sparked interest in the Pralle family.

“There are always some seminars I enjoy taking in,” Pam said. “Since you can’t be there every single day, it is nice to now have the option to watch or listen remotely, and also to have them available on-demand.”

With their own family, the Pralles continued the Expo tradition as their children grew up.

“We took our kids down to compete in the junior show and do showmanship and the tting contest,” Pam said. “They were all involved with

Badger Dairy Club and had that experience, too. Now they’re following in their grandpa’s footsteps.

She said they volunteer and have been elevated to take on leadership roles within Expo. Jessica and Nicole work together as the superintendents of the youth contests, overseeing the tting and showmanship contests.

Watching their children take on those roles has really driven home the idea that Expo is a generational event.

“Who would have ever thought Jessica would work alongside and learn from people like Verlo DeWall and Bill Hageman, Sr., as a volunteer?” Pam said. “These young people are working with the older generation, developing those relationships because they all have something in common: a love for the artistry of breeding.”

“It helps me keep track of the cows that need to be bred, and I keep an eye on the days in milk and the days open.”

What tests do you use and what do you like about those tests? I use tests for somatic cell count, butterfat and protein. I like to identify the high somatic cell cows so I can take them out of the line and use that milk for calves or something else.

Which is your favorite and why? My favorite test is the somatic cell count test, just so I know which ones I need to keep an eye on. I either treat them, cull them or use them to feed calves.

How does testing with DHIA bene t your dairy operation? It helps me keep track of the cows that need to be bred, and I keep an eye on the days in milk and the days open. I use their records a lot. Each month it gives you a list of cows to breed or which ones need to be pregnancy checked.

Tell us about your farm. We typically have about 90 cows and we milk our herd in a tiestall barn. We grow our own feed, harvesting alfalfa, high-moisture corn and corn silage. We buy our protein from the local elevator. We get help from my dad, Harvey, and my brother, Dan, helps with eld work. We ship our milk to First District Association.

CIH 8920, 2WD, 3,500 hrs ......................$84,000

CIH 8920, 2WD, 6,700 hrs. .....................$65,000

CIH 8920, 2WD, 4,100 hrs ......................$72,000

CIH 8920, FWA, 2,600 hrs ....................$110,000

CIH 8910, 1955 hrs., 2WD, like new .....$105,000

CIH 7120 2WD Magnum, 4500 hrs. .....Coming In

CIH 7120, 2WD, 5800 hrs. ......................$55,000

CIH MX120, 2WD, 3,800 hrs. ..................$72,000

CIH MX120 w/loader ...............................$75,000

CIH C90, 4,000 hrs. ........................................Call

IH 1456, cab ............................................$22,000

IH 1466 w/cab, 3854 orig. hrs...............Coming In

IH 1256 ....................................................$16,000

IH 1086, 9,700 hrs. w/ldr. ........................$23,000

IH 686 ......................................................$14,000

TILLAGE

CIH Tigermate II, 26’ ...............................$28,000

CIH Tigermate II 26’ w/rolling basket.......$32,000

CIH Tigermate 200 w/basket, 34’ ............$42,500

CIH Tigermate 200, 28’ w/rolling basket..$40,000

CIH Tigermate 200 28’ w/basket .............$37,000

CIH RMX 370, 23’, nice ..........................$32,000

CIH RMX 340 28’ w/mulcher ...................$35,000

CIH 3800 16’ disc ......................................$9,500

CIH 530C Ripper, nice ............................$31,000

CIH 527B .................................................$17,500

IH 1466, 6800 one-owner hrs. ..............Coming In

JD 2700 5-shank ripper ...........................$17,000

DMI Tigermate 26’ field cultivator ............$16,000

By Danielle Nauman danielle.n@dairystar.com

Wis. —

In the north woods of Wisconsin, farmers are facing challenges from wildlife that are damaging crops, and a lack of compensation for those damages.

“This has been a prolonged problem, and it hasn’t gotten any better,” said Mike Robers, a Sawyer County dairy farmer. “It’s continually getting worse. We’ve got to get compensated for our losses because we can’t keep losing that kind of money.”

Robers milks 430 cows with his family on their Exeland dairy farm, raising 850 acres of crops to feed the herd.

Along with Sawyer County grain farmers Dale and Connor Beissel of Winter, Robers hosted a Wildlife Damage Forum Sept. 19 in Ladysmith. They explained the plight farmers in Sawyer and Rusk Counties face dealing with

heavy crop damage caused by deer, bear and elk.

Farmers can enroll in Wildlife Damage Abatement and Claims Program said Seth Zesiger, assistant district supervisor the U.S. Department of Agriculture Animal and Plant Health Inspection Service Wildlife Services. But the program does not make farmers whole.

In 2020, the top seven claims submitted in Rusk and Sawyer Counties totaled $194,449, with $67,919 in damages being paid out.

Recent years have had similar outcomes for farmers in the region. The top three claims in the two counties, led in 2021 totaled $75,504 with $28,930 paid out; while the top four claims in 2022 totaled $131,271 with $40,000 being reimbursed.

Farmers who chose to participate in the program must meet certain criteria. The must exceed or being likely to exceed $1,000 in crop damages to receive a damage shooting permit. They must exceed a $500 deductible to receive a damage claim. Farms must be open to public hunting. Rented crop land can only be eligible for the program if the landowner is open to public hunting, which Robers said many are not willing to agree to. If land-owners do not agree, the

Rob Summer

and

age to a corneld Sept. 20 near Ladysmith, Wisconsin. Robers

language in crop damage programs.

damage on their property is not counted in overall totals.

“Participants in the damage program are obligated to let hunters on their property for whatever species they want to collect damage claims for,”

Zesiger said. “The whole program is funded by hunting license sales. Anytime anyone buys a license, a portion of that money goes to fund this program.”

According to Zesiger, the

Cover Crops & Cover Crop Mixing Available!

CERTIFIED & QUALITY ASSURED WINTER WHEAT

Sunburst, 50# .............................$19.99

Awnless, short height, excellent straw strength, and high yield potential.

L-024, 50# ...................................$20.99

Awnless, medium-full maturity with high yield potential and very good test weight. Medium height with good standability.Winter hardiness is excellent.

L-031, 50# ................................$20.99

Awnless, med.-early maturing excellent test weight and straw strength received a star in 2024 Wis. Winter Trials.

Sittin’ Pretty 50# ........................$20.99

Tip Awned, medium-early maturity with high yields and good test weight. Medium height with good standability.

L-920, 50# ...................................$15.99

Awnless, medium-early maturity, medium tall height, very good standability, test weight and high yielding.

Pro 410 Brand, 50# ....................$20.99

Awned, high-yielding, very good winter hardiness, excellent lodging resistance.

COMMON WINTER WHEAT

Kaskaskia, 50# ...........................$17.99

Awned, white chaffed, medium height, very good winter hardiness, high yields and test weights

Winter Rye Grain, 50# ................$16.99

Winter Triticale, 50#...................$21.99

A hybrid of winter wheat and winter rye

funding not only funds the positions of those who work with the program, but it also pays for abatement assistance and is applied to crop damage claims.

“The property has to be Turn to WILDLIFE | Page 13

LAWN GRASSES

Athletic Lawn Mix, 50 lbs .............$129.95

Sunny Lawn Mix, 50 lbs................$139.95

Shady Lawn Mix, 50 lbs ................$129.95

Perennial Ryegrass, 50 lbs ............$109.95

Creeping Red Fescue, 50 lbs .........$129.95

Kentucky Bluegrass, 50 lbs ...........$129.95

Turf Type Tall Fescue, 50 lbs ..........$109.95

White Dutch Clover, 50 lbs............$269.95

WILDLIFE FOOD PLOT SEED

Wildlife Clover Mix, 50 lbs ............$239.95

Brassica Brunch, Mix 3 lbs ..............$16.99

Chicory, 1 lb .....................................$7.95

Widow Maker Brassica, Mix 3

corn

open to hunters — it’s going to help everybody,” Zesiger said. “If you’re having trouble with deer, have people come in and shoot deer; if you’re having trouble with bear, have people come in and shoot bear.”

According to Robers and Dale Beissel, farmers are capped at $10,000 for crop damage reimbursement, regardless of the extent of the actual damages suffered.

“Most years I don’t go over the cap, but I’m pushing for the guys who do,” Robers said. “If we want to stay in business, we can’t keep eating these kinds of losses. It has to be compensated for. If I were to go downtown and ask any of the business owners if they were willing to donate $15,000 or more each year to charity, how easily could they do that? ... Dale has been having these kinds of losses for over 30 years.”

The charity Robers refers to is feeding the vast population of deer and bear, native to the area, along with the growing elk herd that was introduced into the region.

In Sawyer and Rusk Counties, Highway 27 largely serves as what Beissel refers to as a dividing line between public lands to the east and private land, largely agricultural, to the west. Beissel farms on both sides of the highway.

“It’s like the bears have radar, they know when that corn is ready,” Beissel said. “There is a predominant west wind, they can smell the corn. They migrate to the corn in August and will stay for nearly two months, before going back to the wooded public lands.”

Most years, Beissel said he exceeds the damage cap by at least $40,000.

“Bears aren’t stupid, they want the best part of the eld,” Beissel said. “They’ll move through the eld testing until they nd the area they want to eat at. You’ll see them sitting down — they’ll swipe an armload over to them, eat that; then they’ll move to the next spot and do the same thing.”

While the program provides ag tags for the bear and deer to be hunted as a means of abatement, Robers questions

the impact those tags have.

“There really aren’t that many bears killed on crop damage tags,” Robers said. “The bulk are killed in this area, and I push it heavy. We shot 15 bears on my farm each year for three years running.”

While the affected farmers in Sawyer and Rusk Counties push for increased compensation for their lost yields, Robers said he needs the abatement as much as the compensation.

“I need all the crops I grow — every stalk, every kernel — to feed my cows,” Robers said. “I feed high-moisture corn. With compensation, I can buy corn, but it’s likely going to be dry corn and doesn’t t in our ration. Our herd averaged 105 pounds per cow for the rst six months of this year. You don’t mess around with rations when they’re producing like that.”

Robers said that while he does not regularly exceed the reimbursement cap, his tonnage loss is grievous.

“Out of 600 acres of corn I planted this year, they’ll take six or seven,” Robers said. “If you gure you’re getting 150-bushel corn, that’s nearly 1,000 bushels. If you’re getting 30 tons of corn silage, that’s over 200 tons. It adds up fast.”

Robers and Beissel agree they are relieved to only deal with deer and bear damage and have not suffered damage from elk, thus far.

Zesiger said deer and elk damage look similar. The elk go through a eld eating everything while deer will eat the tops of the plants off early, stunting growth. When the grain is ripe, the deer will eat that, along with the alfalfa they eat all summer.

Robers and Beissel are looking to legislators to help with the problem

“We need changes in the way the bills are written,” Robers said. “We would like to have language included that at least lets us trap and relocate bears on rented land where the land owner does not want public hunting. ... We could mitigate some of the damage, even if we couldn’t get paid for it.”

CowScout offers round-the-clock cow health monitoring; with pertinent individual information on: » Heat activity

Rumination time

Idle time

Eating time

“TheGE

“The GEA CowScout system is helping us catch cows in heat earlier, even those showing more subtle signs we normally wouldn’t have seen. It’s helping us diagnose health issues earlier too, like mastitis, DAs, Ketosis, & even foot issues. Even the obvious health challenges are being caught a day or two earlier than we would have found before. We’re seeing great results with CowScout. It’s doing all the things Leedstone said it would!”

Ben, MN

Wilfred Owens Frederic, Wisconsin Polk County 650 cows

When did you start chopping and how many acres do you plan to chop this year? We started chopping Sept. 17. We have about 400500 acres to chop.

Who helps with corn silage harvest and what are their roles? We typically have about seven people helping us with our corn silage. We chop with two pull-type choppers and have four people hauling wagons and one person to push silage.

What are your goals when harvesting corn silage? I don’t like silos to run. We try to get it done by about 65% moisture, but don’t always succeed. This year is going to be a poor crop. We’ve chopped a lot of corn that was only 6-7 feet tall. We had too much moisture when we planted. We no-tilled into corn stalks, and they did exactly what they were supposed to do — form a mulch. The plants were yellow and looked poor for a long time.

What are your preservation and storage methods for your corn silage? We store our silage in bunker silos, and use an inoculant.

What have you changed during the growing season or harvesting within the last couple years? We have not really changed anything in the last few years.

What percentage of your ration is corn silage? About 60% of our roughage is corn silage, with about 40% being haylage. This winter will probably be more haylage. We made lots of that this year.

What is the most enjoyable aspect of corn silage harvesting for you? There is always a relief when it is nished, knowing you have feed on hand for the winter. I do enjoy getting out in the elds and seeing how the crops look. You never really know until you get out into it.

Tell us about your farm. Owens Farms Inc. is a family-owned farm. In addition to my brothers, Walter and Roger, and me, our children are involved as the next generation. We milk 650 cows, selling our milk to the First District Association. We crop just over 1,500 acres, of which about 1,000 acres are corn.

Tom Wegner

Wegnerlann Dairy

Ettrick, Wisconsin

Trempealeau County

600 cows

When did you start chopping and how many acres do you plan to chop this year? We started on Sept. 7 and will chop 500 acres.

Who helps with corn silage harvest and what are their roles? We work with a custom harvesting crew. They deliver the feed to the silage pad. We are in charge of pushing, packing and covering.

What are your goals when harvesting corn silage? 10,000 tons with 68%-69% moisture.

What are your preservation and storage methods for your corn silage? Feed is stored on a concrete pad in a drive-over pile. It is covered with Feed Fresh plastic and tires.

What have you changed during the growing season or harvesting within the last couple years? What was the benet? Nothing during growing and harvesting, but for storage, we started using Feed Fresh plastic. We had been using an oxygen barrier and 5 mil plastic and we were getting lots of spoilage on top.

What percentage of your ration is corn silage? 50%.

What is the most enjoyable aspect of corn silage harvesting for you? The smell of the rst load. And, when the last tire goes on the pile.

Tell us about your farm. Wegnerlann Dairy is an LLC between my parents, Jeff and Betty Wegner, and my wife, Annaliese, and me. We milk in a double-8 parallel parlor. Cows are housed in sand-bedded free stalls. Milk is shipped Dairy Farmers of America Inc.

Don Boland

Mount Sterling, Wisconsin

Crawford County 170 cows

When did you start chopping and how many acres do you plan to chop this year? We started chopping Sept. 17 and only have 12 acres this year.

Who helps with corn silage harvest and what are their roles? I chop and my cousin, Sean, unloads.

What are your goals when harvesting corn silage? Maximum tonnage with soft kernels at maturity from silage-specic hybrids.

What are your preservation and storage methods for your corn silage? We bag it all.

What have you changed during the growing season or harvesting within the last couple years? What was the benet? We have backed off on our corn silage acreage and are debating whether we should keep growing it considering lower commodity feed prices and ever-increasing input costs. We have booked some feed to replace it and will see how it goes.

What percentage of your ration is corn silage? We have fed about 15 pounds year-round to the milk cows in the past.

What is the most enjoyable aspect of corn silage harvesting for you? Finishing.

Tell us about your farm. We have a 170-cow, springfreshening seasonal herd. My cousin Sean, his daughter, Danielle, and I provide most of the labor. We milk in a swing-12 parlor and our milk is marketed through Scenic Central Milk Producers.

Anthony Brossard

Beaver Dam, Wisconsin Dodge County 400 cows

When did you start chopping and how many acres do you plan to chop this year? We started chopping Sept. 17 and will chop about 230 acres. We have a lot of carry over silage from last year, but with all the rain we had in spring and early summer, some of our crops are uneven in the drowned-out spots. We’re going to chop about the same amount as other years to get enough silage. Our yield is surprisingly good considering all the rain we had. We had just shy of 16 inches from late May to early June. We had late corn we didn’t get planted until the middle of June, but the warm weather we’ve had is pushing it along, and it’s going to catch the stuff we’re chopping so we can go right into it.

Who helps with corn silage harvest and what are their roles? A young guy, Alex, who works full time for us, runs one of the pack tractors. Marcus and Matthew, who help us part time, take turns running the other pack tractor. Three retired gentlemen run our silage trailers, and I run the chopper.

What are your goals when harvesting corn silage? I try to be in that 66%70% moisture range. I try to get started once it hits 70%, especially in dry weather because it dries down 0.05%-1% moisture per day. This year, we’re chopping a lot of 20–25-ton corn. The third day in, we were running 30 tons to the acre. That’s exceptionally good for this year and is usually our goal. We grow a lot of low-lignin silage hybrids.

What are your preservation and storage methods for your corn silage? We put inoculant on with the chopper to help with fermentation. We store it in a large bunker silo that is double covered with plastic. We pack plastic along the walls and fold it in. We do two layers of plastic across the whole pile to make sure we get all the seams overlapped and covered.

What have you changed during the growing season or harvesting within the last couple years? What was the benet? We always side-dressed some nitrogen and switched to doing 32% nitrogen with Y-drops a few years ago and saw a big benet. We get really good, consistent yields. We don’t have to put a lot of nitrogen on because of all the manure we have. We put a little pre-plant down (urea) to get the corn started and then side-dress with the 32%. We try to side dress when the corn is at least 3 feet tall and close to tasseling.

What percentage of your ration is corn silage? About 50%.

What is the most enjoyable aspect of corn silage harvesting for you? We are all sick of hay by the time we get done with the fourth crop and enjoy the change of pace with doing corn silage. Chopping corn is fun because you don’t have to windrow it like hay or merge it. And if you get a little rain, it doesn’t slow you down.

Tell us about your farm. My grandpa, Walter Warner, started the farm in the early 1930s. My parents, Dennis and Carol Brossard, were the next generation to farm here, and my sister, Andrea, and I are the third generation. When I graduated from the Farm and Industry Short Course in 1997, our family was milking 40 cows in a stanchion barn and we have slowly grown from within. Today, we milk twice a day in a double-12 parallel parlor and sell our milk to Cedar Valley Cheese, which makes some of the best string cheese you can buy. We have four full-time milkers and two part-time calf feeders and relief milkers as well as one full-time guy who feeds and does other outside chores. We also have part-time seasonal help for harvest. We farm about 800 acres and raise all our replacement heifers. About 80% of our cows are bred to beef, and we raise some steers that eat the refusal feed from our milk cows. Virgin heifers are bred to sexed semen for replacements. My wife, Christie, and I have three young kids — Lucas, Ava and Lillie.

Describe your farm and facilities. I used to milk 80 head with my brother on our home farm and kept our show cattle where I currently farm. When we sold the other farm, I began farming here. This farm has been in our family for almost 150 years. The cows are housed in what used to be a show barn that contains 20 tie stalls and four box stalls. There are also seven stalls for calves. I used to have a show pack across from the calf stalls where cows stood just like they would at a show. From early spring to late fall, the cows are outside day and night on pasture. They are hardly ever on concrete. I have no barn cleaner or silo unloader, so most everything is done with skid loader or by hand. I’ve always bred for type. The forage has to be pretty good to get the pretty girls to milk. I still breed to show, but it’s harder to get away now. I do some merchandising of cattle and periodically place cattle in sales.

What forages do you harvest? I harvest hay, baleage and corn silage.

How many acres of crops do you raise? I raise 300 acres total. This includes 150 acres of corn (50 acres corn silage and 100 acres grain) and 150 acres of alfalfa (100 acres pure alfalfa and 50 acres alfalfa grass, festulolium and other mixes.) I sell some grain corn and some alfalfa.

What quality and quantity do you harvest of each crop? For alfalfa, I try to make half dry hay and half baleage. The baleage is really good quality to feed my cows. I shoot for 25%35% moisture for the baleage. If it’s wetter, it’s harder on the baler. If it feels dry, I like to do it immediately. I try to make the best straight alfalfa with as much protein as I can. For dry hay, I shoot for 17% moisture. I do 250 big squares and 100 big round bales. For baleage, I do 250 bales. I had massive crops this year on the ground. It was amazing the amount of hay that was out there. I would be happy with half that amount in a typical year. For alfalfa, I have planted mixed varieties, and it works pretty well. They kind of compete against each other. I’ve had pretty good luck that way, and they get through winter a little better. For corn silage, I plant a different hybrid every year that goes grain or corn silage. I shoot for around 60% moisture. For the rest of the corn, I lean towards grain with a 95-100day maturity. I have sandy loam soil, and a cover crop has really helped. It gives the soil some body, and you see green through the fall. If I get corn off early enough, I usually plant rye as a cover crop before the ground freezes.

Describe the rations for your livestock. I do not feed a total mixed ration. I feed free-choice baleage all day and limited corn silage. In winter, I feed fourthcutting baleage, corn silage, and big squares of alfalfa. Cows also receive grain, protein and mineral in the barn. I individualize their feed in winter and pump more protein. I give more feed to higher-producing animals but

mostly feed everyone as a group. Bred heifers and dry cows roam on about nine acres of pasture and also eat dry hay and corn silage. Younger heifers receive higher protein and less ber. Everyone gets free-choice mineral and salt.

Describe your harvesting techniques for alfalfa and corn silage. I try to get four cuttings of alfalfa every 28-30 days. For the grass/alfalfa, I shoot for three cuttings in between the four cuttings of alfalfa. The rst and fourth cuttings of alfalfa I usually wrap as baleage. I have an individual wrapper that I bought ve years ago that saves me a lot of time. I used to use a sickle cut mower on my alfalfa, but now I use a discbine. It goes so much faster; you can cut a lot of feed. I also use an individual bale squeezer for doing hay. It ops bales on their side and stacks them 2-3 high, and they seal better with the weight. I found that helps a lot, especially if you go 6-8 months before feeding. You have less spoilage as it maintains quality better. For corn silage, I have a processor on my chopper. I pretty much do the harvesting myself except for a guy who helps me unload. I was done chopping corn silage around Labor Day this year. I rent a bagger and have two wagons for unloading. I also use a line wrapper that I borrow from a custom guy that uses a little less plastic because you don’t have to do the ends.

What techniques do you use to store, manage and feed your forages? I chop enough corn silage to ll my two 9-foot by 200-foot bags. It takes 35 acres to ll the two bags.

Dean Nelson • Central and Northern Minnesota • Grove City, MN

US Hwy. 75 At IA/MN Stateline • Steen, MN • 507-392-2870

“Cows

Ms

at 2022 World Dairy Expo,

Saucier Photo (At, right) Black Velvet at 2024 Wisconsin Summer Championship, after winning 1st Production Cow, Best Uddered, Bred and Owned, Senior, and Grand Champion. She is bred and owned by Triple T, Vierra Dairy, and Duckett Holsteins, Rudolph, Wisconsin. Duckett Holsteins is home to Black Velvet, Footloose and other elite cows. Triple-T had a top 2023 BAA of 115.6 and is home to Vierra Dairy’s show string with four World Dairy Expo Grand Champions.

“We use a lot of Udder Comfort.™

It’s great for our fresh cows at home and keeps the udder quality while showing,” says Mike Duckett, Duckett Holsteins, Rudolph, Wis., home to Ms Beautys Black Velvet-ET EX96, owned by Duckett, Vierra Dairy, and Triple-T. Mike and Julie Duckett provide her daily care. She won it all recently at the 2024 Wisconsin Summer Championship.

“We let cows be cows. Cows love Udder Comfort. So do we. Every fresh cow gets it here, and we use it before and after showing. It’s the best product to get texture and quality back into udders,” says Nathan Thomas, Triple-T Farm, North Lewisburg, Ohio, breeder of elite cows like Black Velvet.

Both the Ducketts and Thomases have had their own Grand Champions and All-Americans over the years. They pursue genetic excellence and enjoy raising their children in this life they love, breeding, milking, and caring for elite dairy cattle.

STACEY SMART/ DAIRY STAR

I make baleage as well as round bales and big squares of dry hay. I put acid on dry hay as a preservative with the baler. I like doing that because you get more leaves. It clumps and hangs together making it easier to carry around. I feed free-choice hay and baleage. I keep roughage in front of the cows at all times. It keeps them healthy and the rumen doing what it’s supposed to be doing.

Throughout your career, have you changed the forages you plant, and how has that decision helped your operation? I usually look at the breakdowns of varieties of alfalfa. I want something that falls right back for a 28-30-day cut. I aim at seeds that give four cuttings in dry ground or wet ground. I also pay attention to digestibility on the grass varieties and winter hardiness on alfalfa. Mixing varieties helps. When it comes to alfalfa, lower lignin is better quality. They make genetic improvements for a reason, and the genetics in it are key. Digestibility and how it works with another crop are also factors for me. In corn, I look for high digestibility yet also something that

Rick Frozene checks the quality of a fourth-crop dry hay bale Sept. 17 on his farm near Wes ield, Wisconsin. Frozene tries to get four cu ngs of alfalfa spaced 28-30 days.

will dry down for shell corn.

Describe a challenge you overcame in reaching your forage quality goals. Weather is a constant challenge. You have to have rain to make hay, and you have to have dry weather to make hay. The wrapper helps a ton. If it looks like it’s going to rain, we’ll bale and wrap. That’s a big change from years ago.

How do quality forages play a part in the production goals for your herd? I breed for type, not milk. But the better forage I can put up, I can at least get milk if I’m not getting to show. Also, when you feed quality forages to youngstock, they grow better, and you can cut back on other proteins.

What are management or harvesting techniques you have changed that have made a notable difference in forage quality? Using equipment such as a wrapper, bale squeezer and discbine have allowed me to make better-quality forages in less time.

Contact one of the following dealers to learn more:

IOWA Prairie Land Ag Supply Inc.

Rock Valley, IA

712-476-9290

United Dairy Systems, Inc. West Union, IA 563-422-5355 Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN 320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

By Steve Vavrus, Bridgette Mason and Ed Hopkins

Editor’s Note: The following climate summary was provided by the Wisconsin State Climatology Ofce.

The last month of meteorological summer ended with an intense heatwave; however, temperatures averaged near normal for August and the entire summer.

Wisconsin experienced a “temperature parfait” during August, consisting of three distinct thermal periods. The month started with several days of hot weather, beginning with scores of stations reaching at least 90 degrees Aug. 1. A 94-degree afternoon greeted visitors at the opening of the Wisconsin State Fair in West Allis.

The statewide average temperature from August 1-5 was 5 degrees warmer than normal. A long stretch of comfortable conditions immediately ensued, with temperatures running below normal by 2 degrees until Aug. 23. However, the taste of early fall was displaced by an intense heat wave during the nal week of August that led to a statewide average temperature of 5 degrees warmer than normal, matching the warm conditions that started the month.

For August as a whole, these temperature swings mostly canceled each other and resulted in a Wisconsin monthly average of 67.7 degrees, only 0.5 degrees warmer than normal.

For the second year in a row, a lateAugust heat wave generated the hottest weather of the year and led to the National Weather Service issuing an excessive

heat warning. A slew of daily temperature records was set throughout the state during the heatwave from Aug. 26-29.

The highest temperature of the year (98 degrees) occurred at three locations: Beloit and Brodhead in the far south and Mondovi in the west. The heat was accompanied by stiing humidity, with widespread dewpoint temperatures in the middle to upper 70s and a couple of stations (Boscobel and Lone Rock) touching 80 degrees.

This combination of extreme heat and moisture produced dangerously high heat indices of at least 110 degrees in a few places. This heat wave was shortlived and considerably less intense than the August 2023 event, when the air temperature alone exceeded the century mark in many places and included a statewide maximum for the year of 105 degrees.

Wisconsin saw a statewide average of 4.28 inches of precipitation this August, which was 0.38 inches above the 1991 to 2020 normal of 3.90 inches. Despite August’s near-normal statewide amounts, rain fell infrequently, with measurable rainfall (at least 0.01 inches) occurring on fewer than half the days of August.

Southwestern Wisconsin was particularly parched as it saw just 6-9 days of rainfall by the end of August, resulting in precipitation amounts of only 50%-75% of normal for many counties. In contrast, central and northwestern Wisconsin compensated for the days of minimal precipitation with widespread high rainfall intensity events of 4-8 inches, resulting in accumulation well over 100% of normal. A few counties even neared 200% of normal.

A few rounds of thunderstorms the rst week of August brought torrential downpours and reports of funnel clouds. However, the funnel clouds were shortlived and dissipated before reaching the ground.

Another round of severe storms struck Wisconsin in late August, coinciding with the extreme heat. By the end of the month, the hot and humid weather broke following a cold front, but along with the cold front came three tornadoes: two EF0s and one EF1. The EF1 tornado traveled 6.6 miles near Beldenville (Pierce County). One of the EF0 tornadoes crossed the St. Croix River and entered Pierce County. The other EF0 traveled 1 mile along Interstate 94 near Wilson (St. Croix County).

These three tornadoes bring this year’s count to 45, making it the thirdhighest total since records began in 1950. Although this year has appeared active in terms of the number of tornadoes, the 21 conrmed tornadoes for summer 2024 tied 1967 for 15th place, well behind the 58 tornadoes that hit the state in the summer of 2005. Of the 21 tornadoes this summer, half were weak EF0s.

Much like August itself, this year’s meteorological summer featured temperatures very close to normal throughout Wisconsin. The statewide summer average was 67.3 degrees, 0.1 degree above the 1991–2020 average, in sharp contrast to the fourth hottest summer on record experienced by the nation as a whole. Only in a few scattered places did daily average temperatures stray more than a degree from normal.

Hot weather in 2024 has been brief and — except for the late-August heat wave — not especially intense for Wisconsin.

In a typical year there are 10 days of at least 90 degrees at Wisconsin’s rstorder weather stations (Eau Claire, Green Bay, La Crosse, Madison, Milwaukee and Wausau). By the end of summer this year, only six such hot days have occurred.

It also appears that Wisconsin will

not record a 100-degree temperature in 2024. The absence of triple-digit heat is something that has become common in recent years, even though Wisconsin’s annual maximum temperature used to regularly surpass 100 degrees, based on data back to the 1880s.

Abnormal dryness reappeared in northern and southwestern Wisconsin by the end of July and end of August, respectively, as a result of below-normal precipitation. Despite the highly varying precipitation pattern, meteorological summer ended with a statewide average of 15.73 inches, a noteworthy 3.09 inches above normal and the sixth wettest summer on record.

The abundance of rainfall the rst half of the summer made for difcult working and growing conditions. In August, nearly six days per week were suitable for eldwork according to the National Agricultural Statistics Service. Despite the early summer challenges, Wisconsin’s corn and soybeans continued to progress, with a majority of crops remaining in good to excellent condition and hovering right around the ve-year average pace throughout the summer.

While odds are again leaning toward a warm upcoming season (September through November) throughout most of the country, there is no indication whether Wisconsin or the Upper Midwest will experience an unusually wet or dry autumn. The National Weather Service’s outlook issued last month calls for a 40%-50% chance that Wisconsin’s fall season will be warmer than normal, with a somewhat stronger likelihood in the eastern portion. Since the late 1990s, nearly three out of four autumns in the state have been warmer than the long-term average (1895-present).

Maternity Warden provides 24/7 close-up pen monitoring, allowing calving, and healthier on-farm births.

What if you had the power to ensure every calf birth could be a success?

• Receive

• Create

• Eliminate

• Dispatch

• Reduce

• Ensure

By Danielle Nauman danielle.n@dairystar.com

HARRISBURG, Penn.

Just a month after placing second in the Wisconsin 4-H State Dairy Judging Contest, four young dairy enthusiasts from Pierce County, Wisconsin, traveled over 1,000 miles to compete in the All-American Dairy Show Invitational Youth Dairy Cattle Judging Contest in Harrisburg. The team won the contest and two members ranked rst and second as individuals overall.

The team — coached by Bob Traynor and Peter Coyne — consisted of Braeden Bechel, Hannah Fesenmaier, Ava Kolodzienski and Abby Thompson.

Bechel topped the contest and placed fth in reasons, while Kolodzienski placed second and was 10th in reasons. As a team, the group placed third in oral reasons. Bechel won the Guernsey breed, leading his team to a rst-place nish in the breed. Fesenmaier was the high individual in the Jersey breed.

While competing in the contest, the four judged 10 classes — ve classes of cows and ve classes of heifers — and gave four sets of oral reasons, including a set on one of the heifer classes.

“We had a really good trip,” Traynor said. “We were pretty proud of them. Peter and I have both been coaching for 39 years, and this was just a blast.”

This year’s team is the second the pair have taken to the contest in Harrisburg. They have their sights set on next year with all four members of this year’s winning team returning and some young judges they are excited about moving up.

“We’re liking our chances for next year, and for our future,” Traynor said.

He said that Braeden and Ava are well seasoned and that Abby and Hannah are young and very talented. He said with it being only Hannah’s second year with reasons and Abby’s second year with judging that placing in the Top 20 in a national contest is impressive.

“We just plan to keep

petitive; I’ve been doing well this year,” Bechel said. “The classes were kind of tough, in my opinion, and I didn’t think my reasons went that well. I started out thinking I could have done better, but it worked out OK.”

Bechel began his 4-H judging career young and has enjoyed building his skills.

“I really enjoy the reasons,” Bechel said. “I like talking about why I like the cows. Sometimes my coach and I don’t agree on placings, but I can usually talk my way out of it.”

Everyone on the team played a role in their success.

“Everyone has their job, on the team,” Bechel said. “Reasons are my strong point, and Ava is probably the best at seeing the cows. Hannah and Abby are very consistent and always turn in very solid scores every single time. It takes all of us to achieve success.”

Kolodzienski agreed that seeing the cows is her strong point, although that was not always the case.

developing,” he said. “These kids are really into practices. ... When you’re coaching, that’s just gravy. It’s a lot of fun to coach when the kids really

want it.”

Bechel said his rst trip to Pennsylvania will be one he is unlikely to forget.

“I thought I could be com-

“I started judging in fth grade, and I wasn’t very good at it,” Kolodzienski said.

The Pierce County 4-H judging team — Peter Coyne (from le ), Abby Thompson, Braeden Bechel, Ava Kolodzienski, Hannah Fesenmaier and Bob Traynor — earned top honors in the All-American Dairy Show Invita onal Youth Dairy Ca le Judging Contest Sept. 15 in Harrisburg, Pennsylvania. The team earned the right to compete at the contest a er placing second in the Wisconsin 4-H State Dairy Judging Contest.

“Then something just clicked when I was in seventh or eighth grade, and I started to get better. Now the placings are the easy part for me, but I still struggle sometimes with reasons. I’d prefer to do placings and type analysis questions.”

Bechel and Kolodzienski agree that judging has opened doors they never expected.

“I’ve never played sports, so this is my thing,” Kolodzienski said. “Being good at something is rewarding. It takes you out of your shell and makes you try new things.”

Both say they have beneted from improved communication skills.

“I was never very good at giving speeches in school,” Bechel said. “But as I’ve gotten better at giving reasons, I’ve gotten better at public speaking overall.”

Kolodzienski agreed.

“It’s not the easiest thing to do, to stand in front of a random stranger and tell them what you think when you don’t know if you’re right or wrong,” Kolodzienski said. “I’ve developed more condence in expressing my thoughts.”

The social aspect of dairy judging is important too, the pair said.

“I love meeting people through dairy judging,” Bechel said. “I’ve made a lot of new friends, who I share a passion with.”

Kolodzienski said she enjoys the

camaraderie and close relationships built with her coaches and teammates.

“(We) have a lot of fun together,” Kolodzienski said. “It makes judging exciting, and it makes us all want to do better, because of that closeness.”

Building those relationships has happened over the years of learning and competing together.

“It’s not necessarily the easiest thing to learn, but stick with it,” Kolodzienski said. “Once it starts to make sense, you’ll start to love it. The more you practice, the better you’ll get.”

Success with oral reasons grows with practice, too, Bechel added.

“Don’t be too rough on yourself at the start and don’t be scared of reasons,” Bechel said. “Focus on your TAQs, they’ll help you with reasons later on. It all comes with age, time and practice.”

Because of their attitude and work ethic, Traynor said he and Coyne have no doubts this team has yet to complete their story.

“In the last three contests this year, I’ve written down what I expect the day before and then I share it with them after the contest is done, to see how close I come,” Traynor said. “For this contest, I predicted they would win the contest and we’d have at least two in the top 10. I thought we’d be in the top three teams for reasons, and that we’d have a couple of breed winners. They completely exceeded my expectations.”

Optimizing your milking system is a delicate balancing act of many individual components that all work together. Trust the milking experts at GEA with your parlor. Our team has the farm experience, and the best selection of liners to help you achieve a maximum milking performance, day after day.

By Stacey Smart stacey.s@dairystar.com

DENMARK, Wis. — Jeremy Schlies is the reason cows still ll the barn at Old Settlers Dairy. The 23-year-old’s passion for bovines is reected in the decisions he makes and the tasks he does.

“I kind of always knew I wanted to farm,” Jeremy said. “I don’t know what the heck else I would do. I love it.”

Jeremy farms with his dad, Dave, on their 90-cow dairy near Denmark. Even before he graduated from the Farm and Industry Short Course at the University of Wisconsin-Madison in 2022, Jeremy had a knack for herd management and nding ways to get more milk out of the cows.

“The cows are the priority of every day,” he said. “They’re our bread and butter and how we structure ourselves. At the end of the day, it’s satisfying for me to do a good job with them. I’m very hands-on.”

Jeremy is the fourth generation on the farm that Dave and his brother, Don, own in partnership. Dave owns two-thirds and Don owns one-third. Don hauls milk for R. Schlies Transfer Inc., which he owns and operates as a full-time business. Don’s and Dave’s father started the business in 1968 as a can route.

“Jeremy is the main culprit of why there are cows here,” Dave said. “He’s the driving force.”

With his forward mindset, Jeremy has taken the farm in a new direction.

“I had some ideas and felt we needed to make some changes to set the building blocks for more production,” he said.

His dad said he can relate to his son’s thinking.

“Jeremy has different ideas than me, I had different ideas than my dad, and my dad had different ideas than his

dad,” Dave said. “That’s just the way it is. At our size, you can’t meet benchmarks, you have to exceed them. You have to do better each day.”

Jeremy agreed.

“We have to stay viable with the times,” he said. “If I can make some small improvement, that means a lot to me. Facilities only mean so much. What are the meat and potatoes behind it?”

The Schlieses milk twice a day in a tiestall barn, with father and son milking together every morning.

“Dad and I do quite a bit together,” Jeremy said. “I couldn’t do it by myself.”

They also receive help from four part-time employees.

Jeremy’s mom, Julie, is a fthgrade teacher and drives the chopper in the summer. The Schlieses farm 490 acres. Don and his sons, Jacob, Jeffery and Ryan, help with eldwork as well. Don’s wife, Wendy, works for a law rm in Green Bay.

Dave is in charge of feeding calves, and Jeremy takes care of feeding cows.

“I took a lot of time in school to learn how to manage and improve on that,” Jeremy said. “I take pride in put-

ting a good ration in front of the cows, and I’m big into watching dry matter. That has made a huge difference.”

As he worked to get more feed into the cows, Jeremy increased feed pushups. Their cows eat an average of 62 pounds of dry matter per day, which has risen by 7 pounds. The increase in dry matter intake has given way to an increase in milk production as well.

The farm has a rolling herd average of 34,600 pounds of milk, 1,281 pounds of butterfat and 1,102 pounds of protein. Jeremy said he aims for 7.5

pounds of solids per cow. A total mixed ration is fed to nearly every animal on the farm and customized for milk cows, dry cows, heifers and steers.

The tiestall barn is tunnel-ventilated and features timed LED lighting. Jeremy also installed more fans to improve ventilation.

“I take a lot of pride in making sure the cows are comfortable,” he said. “Cows also get exercise yearround, which is a big priority for us.”

Dave saw the future in Jeremy, and from making enhancements in the barn to updating the milkhouse, he gave his son a foundation to take him into the future. Adding new stalls, mangers and plumbing to the barn in 2013 is one such example.

“My dad could tell when I was young that I had interest in the farm,” Jeremy said. “I give him credit for seeing that in me and building respectable facilities for these animals.”

Jeremy makes all breeding and health decisions. The Schlieses follow an extensive vaccination program and recently rewrote their vaccine protocol.

Jeremy is 10 years into developing a herd of registered Holsteins and has bred several Excellent cows.

“I only have one grade cow left,” he said. “I have an interest in valueadded, and registered cattle is that for me.”

Building pedigrees and solid production is Jeremy’s focus, and he hopes to market more of his cattle going forward.

The European Conference on Precision Livestock Farming was held recently in Bologna, Italy. This event happens every other year. This year, it brought together about 400 researchers and industry representatives from 30 countries for a few days to learn and network about precision technology. There were a few plenary talks to start the morning and afternoon sessions, and then concurrent breakout sessions, with two out of ve each day focusing on dairy technology research.

By Marcia Endres University of Minnesota

On the rst day, Dr. Alex Bach, a former student of the University of Minnesota graduate dairy nutrition program, gave a thought-provoking talk on “Precision feeding technologies and strategies to improve prots, health, and reproductive performance of dairy farms.” Some of the key messages to take home include: — Most farms groupfeed cows, and there is a challenge of different, individual cow intakes within the group, but we balance rations for average pro-

duction of the pen.

— We use models to estimate net energy, rumen degradable protein, metabolizable protein, etc.

— We use table values for some nutrients — does one size t all?

— With all this noise, how do we precisely account for nutrient requirements vs. supply?

— Before thinking about precision feeding, we need to x the basics rst.