DAIRY ST R25

Volume 25, No. 14

Deafness not a deterrent for Rickert

By Stacey Smart stacey.s@dairystar.com

ELDORADO, Wis. —

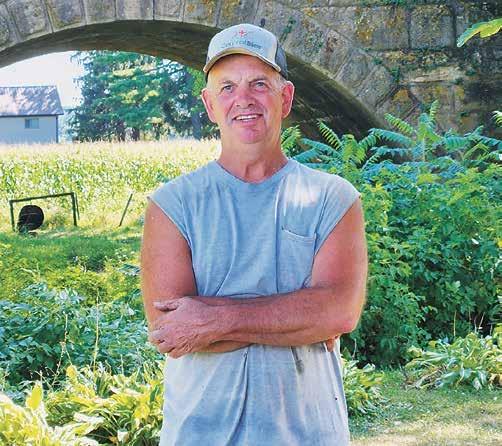

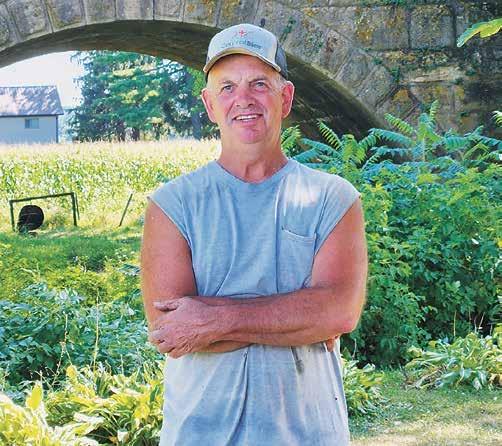

When meeting Andrew Rickert for the rst time, it can be hard to tell he is deaf. Born with normal hearing, Andrew’s world did not turn silent until around 20 months of age after he contracted spinal meningitis. Exposed to a year and a half of sounds would provide him with audible speech later in life.

“Andrew’s speech is so good because he heard for 1.5 years compared to a person born deaf,” said his dad, Jim. “The memory of speech makes a difference.”

Farming in silence

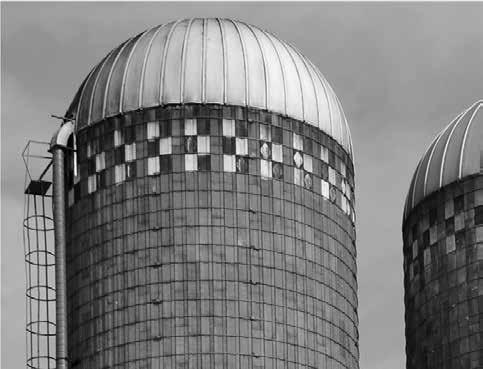

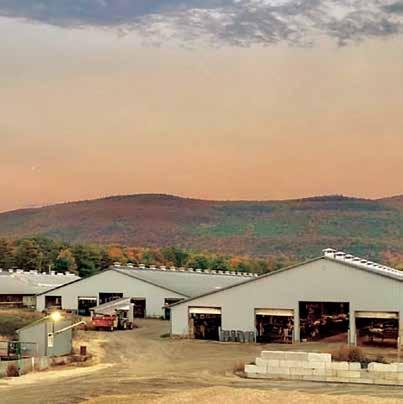

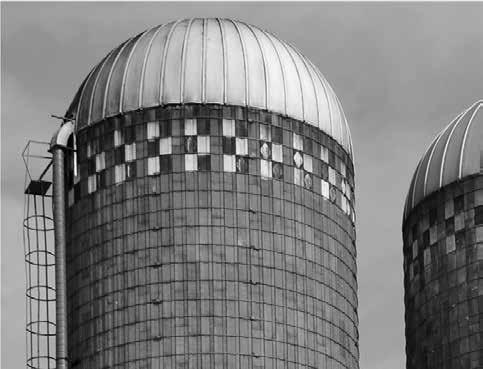

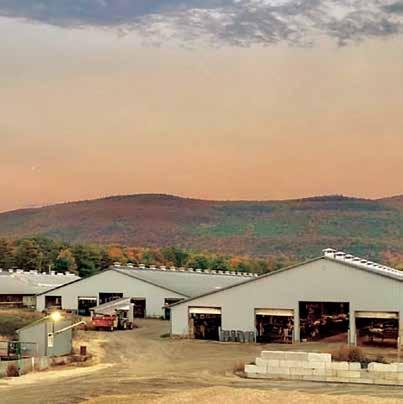

Miles, Emma, Jonah and Micah — farm with Andrew’s parents, Jim and Kelly; his grandfather, Don; Jim’s brother, Greg; and Greg’s son-inlaw, Andy DeVries. The Rickerts milk about 1,000 cows and farm nearly 2,100 acres at Rickland Dairy near Eldorado.

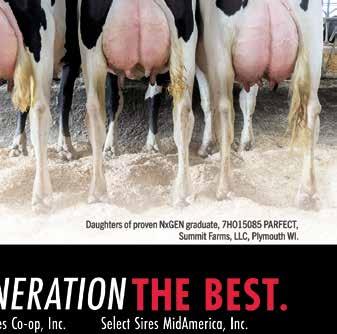

Cows are milked three times a day in a double-16 parallel parlor with a rolling herd average of 30,000 pounds of milk, 3.8% butterfat and 3.1% protein.

Emma, Miles, Shannon and Andrew — milk about 1,000 cows and farm nearly 2,100 acres at Rickland Dairy near Eldorado, Wisconsin. Andrew has been deaf since around 20 months of age a�er contrac�ng spinal meningi�s.

Andrew is good at reading lips and can understand much of what people say. He can

then respond verbally. “People know they have to face me so I can read their

lips,” Andrew said. Andrew and his wife, Shannon, and their kids —

The Rickerts are passionate about registered Holsteins, and this year, the family received a special honor when they were named Wisconsin’s 2023 Distinguished Holstein Breeder.

The family has bred or developed over 110 Excellent cows and sent 97 bulls to stud.

The difference 2 cents can make

Dairy Checkoff Reform Proposal seeks to divert portion of dollars to food banks

By Stacey Smart stacey.s@dairystar.com

TAYLOR, Wis. — Tom Olson has an idea. He believes his idea will move a lot of dairy product while putting dairy checkoff dollars to good use. As a result, he is seeking a 2-cent slice of the dairy checkoff.

In the Dairy Checkoff Reform Proposal, Olson is asking Congress to amend the Dairy Product Stabilization Act of 1983 to allow dairy producers to divert 2 cents out of the 15 cents per hundredweight they pay to a parent food bank in their state.

Two cents can add up quickly. In 2019, the U.S. produced 218 billion pounds of milk, Olson said. The to-

tal checkoff of 15 cents per hundredweight equaled $327 million that was paid in by dairy farmers. Two cents per hundredweight would equal $43.6 million per year that could be spent on dairy products for food banks.

“The checkoff was supposed to help the farmer keep farming,” Olson said. “But when you look at the declining dairy farm numbers since 1983 when the checkoff was started, it is impossible to say this program helped the dairy industry.”

Olson milks 30 cows near Black River Falls and is the president of the Dairy Pricing Association. His proposal is an extension of what DPA does on a regular basis. Based

in Taylor, DPA has been buying and donating dairy products since 2011. The money raised by this dairy farmerfunded group comes from approximately 200 members in 10 states.

DPA is a grassroots, voluntary dairy farmer organization that uses producer assessments to purchase excess dairy products from the marketplace. These products are then donated to humanitarian causes that do not displace existing sales. DPA is a regular, active buyer in the daily cash-traded block cheddar cheese market, which the group sees as a benet to milk checks across the nation.

DPA’s mission is to promote domestically produced dairy products and establish the minimum price the dairy industry receives for its pro-

duction. At the same time, they maintain a level of milk production to meet the needs of the consumer.

“The need for dairy products for use in food banks across the nation is unbelievably large,” Olson said. “The dairy donation program that started during (the pandemic) has ended and left a lot of low-income people struggling to keep dairy in their family’s diet.”

After the program ended, Olson received a call from the Jackson County housing and urban development program which was looking for more donations of dairy products.

“Some of the people they serve are handicapped or elderly, and all are low income,” Olson said. “They’re all on a real tight budget and have to choose how to spend money, whether it be on food or medicine.”

As a result, DPA bought and sent 534 pounds of ched-

dar cheese to Jackson County in July. The county has 90 recipients who qualify for the HUD program.

“They were really happy to get the cheese,” Olson said. “It made these people’s day.”

When stores remove dated products from the dairy case, Olson said low-fat and non-fat milk is what does not sell and is then donated. Under his proposal, farmers would have the ability to donate 11 million gallons of whole milk or a whole array of dairy products to food banks and soup kitchens annually.

“Food banks have different needs across the nation, but they all have one thing in common and that is the need for dairy products,” Olson said. “When I look at what food banks receive for donations, the thing I see that is in short supply is whole milk.”

September 9, 2023

“All dairy, all the time”™

C E L E B R A T I N G 2 5 Y E A R S

Turn to RICKERT | Page 6 Turn to CHECKOFF | Page 8

Tom Olson Dairy farmer

STACEY SMART/DAIRY STAR

The Rickert family — Micah (front, from le�) and Jonah; (back, from le�) Jim, Kelly,

LOOK INSIDE FOR OUR WORLD DAIRY EXPO PREVIEW EDITION! PREVIEW

Published by Star Publications LLC

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Jan Lefebvre - Assistant Editor

320-290-5980 • jan.l@star-pub.com

Maria Bichler - Assistant Editor

maria.b@dairystar.com • 320-352-6303

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer

320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN) 320-352-6303 (ofce)

320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, Southwest Wisconsin)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (Northeast WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) bob.l@star-pub.com

A hearing on possible reform of the Federal Milk Marketing Orders is underway near Indianapolis. “The last time we had a big process like this was about 20 years ago,” said Stephen Cain, director of economic research and analysis, National Milk Producers Federation.

“We’ve developed a big package that we think will help the U.S. dairy farmer, but we’re not the only kids on the block; there’s other groups in there that will have different opinions.” This hearing process is expected to last a few weeks. A recommendation from this hearing will likely happen in February or March, and a nal decision is expected next summer.

Common ground in FMMO hearings

The FMMO hearings are a drawn-out process. Edge Dairy Farmer Cooperative Public Affairs Director Travis Senn is not surprised, saying there is a lot of ground to cover. “There’s discussion on milk composition, looking at component levels in how milk is priced,” Senn said.

“There are also discussions on Class III and IV pricing factors; that’s primarily going to discuss the make allowance.” There are numerous ideas being proposed, but Senn said there is a lot of commonalities. “I think everyone involved in this is looking for a modernization of the system we have currently and how can we make what we have better,” he said.

EPA, Corps issue new WOTUS denition

The Environmental Protection Agency and Army Corps of Engineers have issued their shared nal rule amending the denition of the Waters of the United States. This change was necessary after a recent Supreme Court decision. The EPA plans to lead a webinar detailing the updated WOTUS denition Sept. 12.

Farm bill faces hurdles

According to Russell Group President Randy Russell, the farm bill is facing a few hurdles before it can cross the nish line. Nutrition programs will likely be a point of contention, especially with House Republicans only holding a four-seat margin. “As you pick up Republicans because you make changes to SNAP, you likely lose Democrats, so it’s a real balancing act,” Russell said. Food security is considered national security, and Russell sees that coming up in the farm bill debate.

Helping to ll the gap

CoBank released a study that considers how beef on dairy genetics is affecting the supply chain and the beef market. CoBank Lead Animal Protein Analyst Brian Earnest said beef-dairy crosses are helping to ll gaps left by the shrinking U.S. beef herd. “We wanted to explore what it means to utilize more common beef genetics in the dairy industry and the effects on the beef supply chain from the cattle feeders to the packing community,” Earnest said. Earnest is seeing more beef-dairy genetics adopted in recent years.

Page 2 • Dairy Star • Saturday, September 9, 2023 Dairy Prole brought to you by your North America dealers.

Ag Insider Turn to AG INSIDER | Page 5 DAIRY

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com Deadlines The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order. Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes

Dairy Star, 522 Sinclair Lewis Ave.,

Centre,

© 2023 Star Publications LLC

Federal Milk Marketing Order reform By Don Wick Columnist

ST R

Subscriptions One

to

Sauk

MN 56378-1246.

General Manager/Editor

Conditioners INVEST IN QUALITY ® www.kuhn.com Farmers’ Implement Allenton D & D Farm Supply Arcadia Cherokee Garage Colby Beaver Machine Coleman Kalscheur Implement Cross Plains Komro Sales & Service Durand Eron Equipment Junction City Luxemburg Motor Co. Luxemburg Riesterer & Schnell Marion Lulich Implement Mason Lindstrom Equipment Mondovi East Side Farm Equipment Monroe Midwest Machinery Co New Richmond Steinhart Farm Service Platteville Gruett’s Inc. Potter Gibbsville Implement Waldo Carl F. Statz & Sons Waunakee A.C. McCartney Durand, IL Peabudy's North Pecatonica, IL Visit your local KUHN Hay and Forage Dealer today! THE HAY AND FORAGE TOOL SPECIALISTS Mowers Mergers Rotary Rakes Wheel

Tedders Harvesting high-quality hay and forage is the focus of KUHN's hay tool innovation. Our commitment is to help you gain a maximum return on investment by providing products known for performance, reliability, and longevity. THE MOST

time,

and improve

Mower

Rakes

COMPLETE HAY LINE Cut • Dry • Harvest Save

money

hay quality with KUHN.

For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, September 9, 2023 • Page 3 Dairy Checkoff Reform Proposal seeks to divert portion of dollars to food banks First Section: Pages 1, 8 Taylor, WI Kids Corner: The Mogas Third Section: Pages 10 - 11 Spencer, WI UW-River Falls students win new product competition First Section: Page 9 River Falls, WI Dairy’s Working Youth Third Section: Page 9 Barron, WI What do you enjoy about your position as a milk hauler? First Section: Pages 15 -16 FROM OUR SIDE OF THE FENCE: Zone 2 Zone 1 Larsons carry on family tradition with high-producing herd, top-notch people Third Section: Pages 2 - 4 Evansville, WI Deafness not a deterrent for Rickert First Section: Pages 1, 6 - 7 Eldorado, WI 7 generations of work, success First Section: Pages 31 - 32 Lyndon Station, WI Dairy Prole First Section: Page 33 Norwalk, WI Women in Dairy First Section: Page 29 Fennimore, WI Columnists Ag Insider Pages 2, 5 First Section Pa Fir Fi s Ramblings from the Ridge Page 36 First Section Ram fro R Pa The “Mielke” Market Weekly Pages 6 - 7 Second Section Veterinary Wisdom Page 37 First Section Vet V W Pa Firrs From the Zweber Farm Page 38 First Section F Zwe P Fir Country Cooking Page 22 Second Section y n C C P The NexGen Page 39 First Section COMPLETE MANURE EXPERTS We are your “Waste System Specialists”! Hull, IA • (712) 439-2081 Watertown, SD • (605) 753-0300 www.automatedwastesystems.com

Page 4 • Dairy Star • Saturday, September 9, 2023 S ONE SHO • 9 EMOLLIENTS - Ultimate teat conditioning • USE PRE & POST • GREEN COLOR for High-Vis Marking Max Protection until the next next milking D UA L G E R M I C I D E DUAL GERMICIDE C H LO R I N E D I OX I D E CHLORINE DIOXIDE THE PREMIER GERMICIDE ON THE MARKET economical and more effective than iodine! SAVE UP TO $1/GALLON over Iodine! FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Anderson Dairy Systems, Inc. 1312 13 1/2 Ave. • Barron, WI 54812 (715) 537-3300 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 THE NEXT GENERATION IN ON-FARM WATER TREATMENT Chlorine Dioxide Technology HIGHLY EFFECTIVE AGAINST: Prototheca • Staph Aureus Mycoplasma • Pseudomonas Dirty Water? • Respiratory Issues • Scours • Crypto • Salmonella • E-coli GREATLY REDUCED: Pure 3000 CLEAN IT UP WITH Removes IRON, MANGANESE and SULFUR in water! HEALTHIER CALVES HEALTHIER COWS WEAVER Equipment, LLC. has been dedicated to providing dairy stalls and crowd gate solutions since 1994. Our current lineup includes various stall systems, flexible cabinet designs, CIP drawers and cabinets as well as several crowd gate options. Our focus continues to be to provide solid craftsmanship, designs, and services combined with obvious cow comfort features so every farmer has maximum uptime and production. PARLOR STALLS (800) 887-4634 | Dairy Supply Online: www.dairysupplyonline.com 423 US Hwy 61 N Lancaster, WI 53813 900 US Hwy 14 W Richland Center, WI 53581 www.a lb any Ch rys l er.com www.a lb any Ch rys l er.com www.a lb any Ch rys l er.com www.a lb any Ch rys l er.com www.a lb any Ch rys l er.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysle r.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com www.albanyChrysler.com 34650 225th Ave. - Albany, MN 56307 320-845-2801 • 800-392-3426 SALES HOURS: Mon.-Thurs. 8:30 AM - 7:00 PM; Fri. 8:30 AM - 6 PM; Sat. 8:00 AM - 3:00 PM SERVICE HOURS: Mon.-Fri. 7:00 AM-5:00 PM; Sat. 7:00 AM - 1:00 PM 2021 RAM 1500 NIGHT EDITION 2021 RAM 2500 BIG HORN 2020 RAM 1500 BIG HORN UT5147, One Owner, 6.5ft Box, Hemi Engine $46,990 UT5086, One Owner, 8.4inch Touch Screen Radio, Anti-Spin Rear Axle $38,990 UT5118, Blind Spot, One Owner, Back-Up Camera $47,990 UT5071, One Owner, 5.7l Hemi V8, Black 20 Inch Wheels $42,990 UT5117, One Owner, Touch Screen Radio, Back-Up Camera $36,990 UT5149, One Owner, 3.6l VVT 6 Cylinder Engine, Gun Box $49,990 2019 RAM 1500 LAR AMIE 2020 RAM 1500 NIGHT EDITION 2023 RAM 1500 BUILT TO SERVE SPECIAL EDITION

Con nued from AG INSIDER | Page

Hastings Creamery reverberates through dairy community

The closure of the Hastings Creamery has left dairy farmers on both sides of the river without a place to sell their milk. “About 14 or 15 producers that are involved with Hastings are from Minnesota, but the majority, 25 or 26, are from Wisconsin,” said Minnesota Agriculture Commissioner Thom Petersen. The Minnesota Department of Agriculture and Wisconsin Department of Agriculture, Trade and Consumer Protection are trying to nd a home for the milk displaced by the closure, but most dairy processors are already operating at capacity.

Interest rate hikes likely

The Personal Consumption Expenditures price index rose 3.3% in July. That’s up from 3% in the June report. This rate is down from the peak of 7% last summer, but it remains well below the 2% growth rate sought by the Federal Reserve Bank. The ination rate is being monitored closely as the Fed considers additional interest rate increases.

Hurricane impacts butter market

As Hurricane Idalia hit the Southeast, cream volumes were redirected away from the southern states. As a result, Total Farm Marketing’s market update suggests cream is more readily available. That could keep short term pressure on the butter market.

Trade advisory committees appointed

The U.S. Department of Agriculture has announced the members of its Agricultural Policy Advisory Committee. The list includes Michael Dykes of the International Dairy Foods Association and Jim Mulhern of the National Milk Producers Federation. The Agricultural Trade Advisory Committee in Animals and Animal Products membership includes Jaime Castaneda of the National Milk Producers Federation, Cassandra Kuball of Edge Dairy Cooperative, Michael Lichte of Dairy Farmers of America, Ken Meyers of MCT Dairies, Patricia Smith of Dairy America and Chad Vincent of Dairy Farmers of Wisconsin.

Sustainably produced

Canola is grown primarily for the oil, but the Canola Council of Canada is also advocating canola meal as part of

the dairy ration. CCC Canola Utilization Director Brittany Wood said cows fed canola meal as the primary protein source produce more milk. Canola meal is also promoted as a sustainably produced dairy feed. “We have done some research to look at methane emission when cows are fed canola meal, and we have ndings that support that canola meal-fed cows are producing less methane than when fed other protein ingredients, say soybean meal, for example,” Wood said.

Jones picked for FDA post

Jim Jones has been appointed as the rst deputy commissioner for human foods at the Food and Drug Administration. Most recently, Jones has led his own environmental consulting rm. He previously spent more than 30 years at the EPA.

Edge adds Hensley to team

Laura Hensley is the new communications lead for Edge Dairy Farmer Cooperative. Most recently, Hensley was an account director at a Wisconsin marketing agency called C.O.Nxt.

WBA recognizes Bock, Kujawa

The Wisconsin Bankers Association has presented its Leaders in Banking Excellence Award to Michael Bock and the late John Kujawa. Bock is with the Dairy State Bank at Rice Lake. Kujawa was the president emeritus at Farmers and Merchants Bank of Berlin.

UWRF honors Graham

Dr. James Graham is the rst recipient of the University of Wisconsin-River Falls Excellence Award in Service. Graham is a professor of agricultural education.

Trivia challenge

On average, Americans consume 1.4 servings of dairy products every day. That answers our last trivia question. For this week’s trivia, what is a turophile? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network, based in Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two adult sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Dairy Star • Saturday, September 9, 2023 • Page 5 www.midwestlivestock.com ZUMBROTA, MN 800-233-8937 RENNER, SD 605-274-3656 MENOMONIE, WI 715-235-5144 F A N S | G A T E S | S T A L L S | H E A D L O C K S | R U B B E R | C U R T A I N S | M A N U R E S Y S T E M S Celebrating 50 years in business! Hinsch Dairy, Goodhue, MN

TURNER VERTICAL LIFT UPDATE BEFORE AFTER 608-524-9958 » www.forwardfarmlines.com RUGGED, RELIABLE, and ECONOMICAL

2X8

2

320-836-2145 or 800-450-2145 www.famofeeds.com Check out our newly redesigned website to nd a Famo Feeds dealer near you! At Famo Feeds, we strive to provide the best support for your operation and work to accommodate your specific needs. From calf to cow and everything in between! TRUST THE EXPERTS • Milk Replacers • Starter Feeds • Protein Concentrates • Premixes • Minerals • Animal Health Products • Lick Tubs FEED THEM FAMO!

Repair vs. Replace

Electronic Dairy Board Repair Service

Specializing in: WestfaliaSurge, BouMatic, & DeLaval pulsators & Takeoffs, circuit boards, Mueller milk tank circuit boards.

Call: (c) 406-590-7764 www.circuit xer.wixsite.com/

Andrew is the fourth generation on his family’s farm that dates back to 1936. Over the last decade, he has been transitioning into an owner. Andrew currently works full time on the farm and also hauls the farm’s milk in addition to working full time at Saputo. Andrew manages heifers and steers, helps with eldwork and manure hauling, and also hauls and chops straw and hay for feed preparation.

When Andrew got his commercial driver’s license, the farm bought three tankers. He recently helped another farm start hauling their own milk and assists them in taking their milk in. Most days, he hauls three or four loads.

He also works 12-hour shifts at Saputo from 6 p.m. to 6 a.m. 15 nights per month. Starting in the cheese plant, Andrew now works in the intake department.

“The job provides health insurance for my family,” Andrew said.

Being a part of the deaf community is how Andrew met Shannon, who is an American Sign Language-certied interpreter. The couple met in Milwaukee in 2006 at a comedy show for deaf people and interpreters. Four months later, they were engaged.

Shannon interprets in the community in all facets — from factories and hospitals to schools, theaters and retailers. She previously worked at the University of Wisconsin-Milwaukee for 14 years and began freelancing in the community when Andrew started working at Saputo.

When he was 4 years old, Andrew received a cochlear implant which restored his hearing to about 75%. He was the youngest person in Wisconsin at the time to have the procedure, which was done in Indianapolis in 1987.

“It was pretty scary,” Kelly said. Jim agreed.

“The operation was considered experimental at the time, and there was no place around here that did it,” he said.

Andrew’s response to the implant was instantaneous.

“You could see it in his eyes when they hooked it up and he could hear again,” Kelly said.

The following months were lled with Andrew trying to learn different

year later,

could recognize what the sounds were, and it made sense to him.

“He could even hear a dog barking in the house next door,” Kelly said. “When we were in a store, he could hear people talking on the intercom and would ask, what did they say?”

The Rickerts went back and forth to Indianapolis many times for checkups.

“Rehab was an indescribable amount of work,” Jim said. “They tested sounds to set a map on the implant while determining which sounds were too loud and which were too quiet.”

Andrew’s hearing is different from someone who is not deaf, Kelly said. He hears in tones, amps and frequency which have been adjusted as needed. He can hear 16 different tones. Electrodes were placed into the cochlea during the operation, and the internal piece implanted is the original. The external device is replaced every ve years.

“This is the only thing I’ve ever known,” Andrew said. “Without the external device, I can’t hear anything.”

He turns the device off when he is on the farm because it will short out with moisture or dirt. He will put it on for meetings and other occasions.

Andrew began signing as soon as his parents discovered he was deaf.

“The whole family learned how to sign too,” Kelly said. “We all took a class.”

Not only did Andrew’s parents and younger brother, David, learn how to sign, but so did grandparents, aunts and uncles. Andrew relied not only on signing to communicate, but he also read lips and talked.

After learning sign language so she could communicate with her son, Kelly decided to make a career out of signing and became a licensed educational sign language interpreter. She has been interpreting in schools since 1994.

Growing up, Andrew attended a grade school in Oshkosh that had a regional deaf program. From fth through eighth grade, he went to a local school that had an interpreter. His high school years were spent at Winnebago Lutheran Academy where his mom

Page 6 • Dairy Star • Saturday, September 9, 2023 507-879-3593 – 800-821-7092 Box 116, Lake Wilson, MN 56151 – www.bluehilltop.com 507-879-3593 – 800-821-7092 Box 116, Lake Wilson, MN 56151 – www.bluehilltop.com Blue Hilltop, Inc.

2660 BALEBUSTER BALEBUSTER

With big bales getting bigger and heavier, the 2660 has been made even more durable than previous models. Featuring an increased diameter of the rotor shaft and bearing, as well as the conveyor shaft. The chain attachment to the slats is more durable. Also, the width of the table has been increased to eliminate dead spots where material can build up. The loader forks have been moved over to help center the bale while loading in the bale chamber.

www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage!

boumaticboardrepair

Con nued from RICKERT | Page 1 Turn to RICKERT | Page 7

STACEY SMART/DAIRY STAR

Emma Rickert feeds grain to calves Aug. 17 while her dad, Andrew, pushes the feed cart on their farm near Eldorado, Wisconsin. When he was 4 years old, Andrew received a cochlear implant, which restored his hearing to about 75%. sounds. A

he

was his interpreter. She interpreted for Andrew for two years until he told her he wanted to be on his own. Andrew was the third generation in his family to attend the University of Wisconsin Farm and Industry Short Course where he also had an interpreter.

Andrew’s oldest two children, Miles and Emma, know the basics of sign language, and Jonah and Micah are always learning more signs. When communicating with their dad, Andrew’s children use gestures when needed, but Andrew said he understands his family well because he is around them all the time. Texting is another form of communication that has been a great help to Andrew.

“Texting puts him on the same level with other people,” Kelly said.

Never content to settle for mediocre, Andrew was a go-getter who always pushed himself to achieve everything he was capable of. He was successful at showing cattle and consistently placed near the top or took rst place in showmanship. In 2001, he took reserve champion of the junior show at Wisconsin Championship Show.

“We were blessed with being able to have a cow board at Tom and Kelli Cull’s of Budjon Farms and be in their show string,” Andrew said. “Showing allowed me to meet famous people in the industry.”

Andrew was also active in Junior Holsteins, and in 2004, he was one of six youth in the nation to be named a Distinguished Junior Member by Holstein Association USA, the highest honor given to a Junior Holstein member. Andrew was also named Wisconsin Outstanding Holstein Boy that year.

Andrew’s deafness impacted and inspired those around him. For example, one of his 4-H friends became an audiologist because of her friendship with Andrew.

Involved in 4-H and Junior Holsteins, Andrew’s children are following in their father’s footsteps. They show dairy and beef cattle, and each one showed a steer they sold at the meat auction this summer at their county fair. Miles won the 3-year-old quality milk award, and Micah won reserve champion at little britches show in the 6-year-old division. The kids also partake in the fair’s pedal tractor pull. Miles has participated in dairy bowl since age 8 and went to state for dairy judging.

The kids are also involved in many sports, including basketball, baseball, volleyball, soccer, softball and ag football. Emma’s dream is to play volleyball at the University of WisconsinMadison and attend vet school there.

Miles, Andrew’s oldest son, covers a lot of his dad’s work on the farm when Andrew is hauling milk or working at Saputo. This includes cleaning heifer barns, giving calves feed, hauling manure, running the footbath, bedding animals and helping check postfresh cattle on weekends.

Andrew’s busy lifestyle is lled with his family and the farm and other facets of the dairy industry. Determined to excel, Andrew was never concerned with what he did not have, and instead, he fully utilized the gifts and talents he did have.

“If I encountered a challenge while growing up, I always found a way to overcome it,” Andrew said. “I always felt like everyone else.”

Dairy Star • Saturday, September 9, 2023 • Page 7 ★ TrelleborgLugGeometryprovides premiumfeedcompactionandtillagetraction ★ On-Farm Tire&Wheel Service VeteranOwned&OperatedSince1983 SaleEnds09/22/23CashorGoodCheckPrices SILAGETRUCKTIRE&WHEELPACKAGES BUNKERRIMS Deeplugsformaximumtraction FallTire ‘’SweetSpot’’ Rebuild your packing tractor rims! 4tiresonhubpilotrims Alliance331 600/40x22.5$6,350 600/50x22.5$6,995 700/40x22.5$7,200 TrelleborgT423 620/50x22.5$7,850 650/45x22.5T440$6,200 40mph SharpAngelsforPackingTightly NewInStock 71070R42 Trelleborg TM-900 18@$3,675 Allaince AgriStarII 16@$2,250 New ChangeOver 71070R42 Firestone MaxiTrac 4@$2,550 Trelleborg VF80070R38 16@$3995 NewTires InStock RebatesAvailable RebatesAvailable Con nued from RICKERT | Page 6 Call Us At (715) 223-3361 Or visit us on-line at www.cloverdaleequip.com N13835 County Rd. E - Curtiss, WI 54422 HOME OF THE CLOVERDALE MIXER IN STOCK EQUIPMENT! McHale V6750 4 IN STOCK McHale V660 3 IN STOCK New Anderson Hybrid X New Anderson RB200 Artex SB450 & Hoosierland 1450 ALSO IN STOCK: Artex SB200 & Hoosierland 1300

ST R

Con nued from CHECKOFF | Page 1

Under Olson’s proposal, the parent food bank would oversee distribution of money to local food banks and soup kitchens with this money earmarked to be used for dairy products only. Producers in every state would choose where the 2 cents is sent and would also have the choice to pull it from their state checkoff or national checkoff.

“Checkoff dollars would be diverted for a better use under my proposal,” Olson said. “It’s going to move a lot of dairy product versus what the money is doing now. Right now, it’s pretty much just advertising. But it’s a form of advertising too when you’re getting milk, cheese, yogurt and ice cream in front of people.”

Olson was invited to the Congressional Agriculture Committee Meeting held in La Crosse Aug. 16. The

hearing was a listening session with members of Congress on farm bill priorities to learn what farmers would like to see changed in a farm bill. Olson’s proposal was sent home with members of Congress that day. The proposal is also being sent to all 51 members of the House ag committee.

“This proposal can stand alone,” Olson said. “It doesn’t have to be done through the farm bill.”

DPA is looking for signatures of support for the Dairy Checkoff Reform Proposal to present to Congress. Dairy producers and consumers can sign the proposal on DPA’s website.

“We hope to get as many signatures as we can,” Olson said. “I urge dairy farmers to sign this proposal and help put our checkoff dollars to good use.”

Page 8 • Dairy Star • Saturday, September 9, 2023 ARCADIA, WI D&D Farm Sup. 608-323-7001 DECORAH, IA Lang’s Dairy Equip. 563-382-8722 FREEPORT, MN Arnzen Construction 320-836-2284 Hartung Sales & Serv. 320-836-2697 JANESVILLE, WI Tri-County Dairy Sup. 608-757-2697 LANCASTER, WI Fuller’s Milker Center 800-887-4634 LEWISTON, MN Lang’s Dairy Equip. 507-452-5532 MARSHFIELD, WI Podevels Farm Serv. 715-384-6193 800-742-5748 MELROSE, MN Farm Systems 320-256-3276 MENAHAGA, MN Dairyland Equip. 218-564-4958 MT. HOREB, WI The Scharine Group 608-437-5557 PENNOCK, MN D&D Ag Supply & Construction 320-599-4466 RICHLAND CENTER, WI Fuller’s Milker Center 800-887-4634 ROCK VALLEY, IA Prairie Land Ag Sup. 712-476-9290 SAUK CENTRE, MN Dairyland Supply 320-352-3987 800-338-6455 SPARTA, WI Preston Dairy Equip. 608-269-3830 ST. CHARLES, MN Advanced Dairy 507-932-4288 WEST UNION, IA United Dairy Systems 563-422-5355 WHITEWATER, WI The Scharine Group 608-883-2880 WITHEE, WI Hoover Silo Repair 715-229-2527 www.jdmfg.com Family Owned & Operated in Eau Claire, Wisconsin Where to buy : : #RequestTheTest RequestTheTest Something new is coming... YOU DESERVE MORE makes the best fans in the world. SUPER MAGNUM

Find up-to-date dairy industry information right in your mailbox. Features from the barn, markets, columnists, profiles, opinions from your neighbors and timely dairy information Subscribe Today! ONLY $40.00 FOR A 1-YEAR OUTSIDE THE U.S. $120 Clip & Mail with Payment: DAIRY STAR 522 Sinclair Lewis Ave. • Sauk Centre, MN 56378 Name ________________________ Address______________________ City__________________________ State________ Zip________________ A Gift from: all“Alldairy, the time”™ The Dairy Star is currently sent out free to all registered dairy producers in Minnesota, Iowa, North Dakota, South Dakota, Wisconsin, Norther IL and UP Michigan. DAIRY

or Scan to Subscribe!

A smooth dose of dairy

UW-River Falls students win new product competition

By Abby Wiedmeyer abby.w@dairystar.com

RIVER FALLS, Wis. — Five University of Wisconsin-River Falls students were recognized July 17 as winners of the 2023 Dairy Management Inc. New Product Competition with their original dairy product, RootCurd.

Dr. Rohit Kapoor, vice president of product research at DMI, said the goals of the competition are to inspire the next generation of dairy scientists and to fuel product innovation into the marketplace.

“You may not end up seeing the exact same products which win these competitions as such, but processors always keep an eye out,” Kapoor said. “They get inspired by these concepts.”

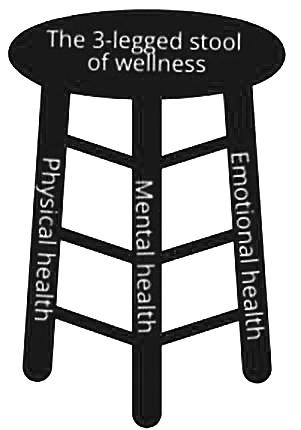

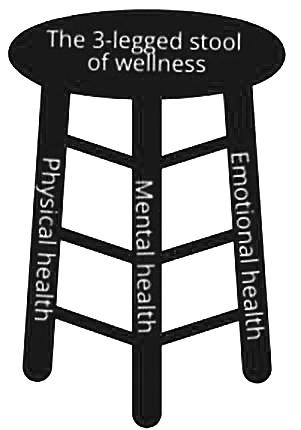

The competition is based on a specic theme each year that is grounded in consumer research and trends. This year, the competition was focused on creating a dairy product that had calming effects, since consumers are constantly looking for products to enhance their emotional and mental well-being.

The winning team was comprised of ve undergraduate students: Kate Petersen, Yihong Deng, Rafael Larosiliere, Anna Euerle and Ashley Gruman.

RootCurd is a smooth pudding featuring root curry and lavender that contains 89% dairy ingredients.

Gruman said the process for creating a new product from start to nish provided many learning opportunities.

“The biggest takeaway from the competition was having all these ideas, excitement and energy to create this product but you always forget about all the issues you’re going to run into and all the things you’re going to have to overcome,” Gruman said. “It took a lot of patience and trial and error.”

The team started ideating in October 2022. They narrowed their ideas to two products and eventually went ahead with the product they thought would turn out the best. They used the test kitchen at the university and met every week to research and experiment with prototypes.

Once they decided on the concept of RootCurd, they ran into challenges, especially achieving the desired puddinglike consistency. After weeks of trial and error, they determined that even minor components like the rate of heating in the

pan and the storage temperature of ginger were all having an effect on the product.

“That was one of our biggest challenges,” Gruman said. “Once we gured that out, things went pretty smoothly.”

Another aspect of the product that coincided with consumer trends is the clean label. RootCurd is made up of ve ingredients, all of which are considered wholesome and nutritious. It is sweet with a little spice and boasts a high-protein, low-calorie content that includes 20 grams of protein. It comes in a yogurtsized package.

The team’s advisor, Dr. Grace Lewis, said that they would follow the exact same procedure for weeks and end up with different results. The nal product report was due in April, by which time the team had worked out all the kinks.

“The students overcame a lot of challenges along the way,” Lewis said. “They worked really hard.”

The competition provides real life experience to students who are all on the path to a food science career. Lewis said one of the students on the team was able to bypass the rst round of interviews when joining the industry because of their contest experience.

“Going through this process is so fundamental for the real-world experience that many companies require for entry-level positions,” Lewis said. “The industry recognizes this competition as some initial experience.”

Kapoor agreed.

“The larger impact is the type of ex-

perience that Ashley and her team members get with the whole process of trying to nd a solution when you are kind of stuck in a rut,” Kapoor said. “Those are real life experiences of what a food scientist would experience in the industry when they are working for a company.”

The winning team was awarded an $8,000 cash prize to split between the ve members. Gruman said this will help those continuing on to graduate school, like she is, and provide a head start for those heading to the workforce.

The top three participating teams were able to attend the Institute of Food Technologists’ FIRST (Food Improved by Research, Science and Technology)

conference in Chicago where winners were announced. Lewis said she is grateful for DMI supporting a portion of the travel cost to help make the experience possible since the event offers a good networking opportunity for the students.

Kapoor said the competition is further fueled by the participation of industry sponsors who served in the competition as judges.

“We are very proud that our dairy farmers have recognized that this has a signicant value and continue to support this competition,” Kapoor said. “It’s a perfect collaboration between dairy farmers and the processors to realize this great initiative.”

Dairy Star • Saturday, September 9, 2023 • Page 9 PARLOR STALLS • STALL SYSTEMS • CABINETS • CIP DRAWERS • CROWD GATE “Cows flow through the parlor well and I like that the parlor is run on air. The cabinets keep the electrical protected and out of the way, but can be easily accessible if needed. Fuller’s helped us develop our vision and provide us phenomenal service.” Jenny Toberman • Bagley, WI WEAVER PARLOR INSTALLED 2020 (800) 887-4634 | Dairy Supply Online: www.dairysupplyonline.com 423 US Hwy 61 N Lancaster, WI 53813 900 US Hwy 14 W Richland Center, WI 53581

PHOTO SUBMITTED

Five University of Wisconsin-River Falls students — Rafael Larosiliere (from le ), Anna Euerle, Kate Petersen, Ashley Gruman and Yihong Deng — celebrate July 17 as winners of the 2023 Dairy Management Inc. New Product Compe on with their original dairy product, RootCurd. The product is a smooth pudding featuring root curry and lavender.

ABBY WIEDMEYER/DAIRY STAR RootCurd (front, center) pudding was the winning product in the 2023 Dairy Management Inc. New Product Compe on produced by a team of ve students from the University of Wisconsin-River Falls. Its sweet and spicy avor featured soothing lavender and root curry and is made with 89% dairy ingredients.

Advanced kernel processing is the secret to a perfect dairy dinner. Experience KP Rolls with square-edged tooth engineering. They serve up the feast—fair and square.

Iowa, North Dakota legalize sales of raw milk

A dairy producer, legislator, veterinarian weigh in

By Stacey Smart stacey.s@dairystar.com

Editor’s note: Dairy Star aims to provide our readers with a closer look into relevant topics to today’s dairy industry. Through this series, we intend to examine and educate on a variety of topics. If you have an idea for a topic to explore in a future issue, send Stacey an email.

HARLAN, Iowa — After nearly two decades of trying to legalize the sale of raw milk in Iowa, supporters of this legislation nally saw success July 1.

On that day, farm-to-consumer sales of raw milk in liquid form became legal in the Hawkeye State.

“It was high time this type of legislation be passed,” said Esther Arkfeld, who owns and operates De Melkerij micro-dairy near Harlan. “Raw milk has nally become a topic that can be openly discussed. Now that laws have changed, this opens things up for us, and our customers are much happier.”

Working closely with Sen. Jason Schultz, who had been leading the raw milk bill for 17 years, Arkfeld played a role from a grassroots perspective in helping that legislation pass.

717.354.5040

55” Panel Fans

“It’s more of a people’s bill allowing that neighbor-to-neighbor transaction; it wasn’t a producers’ bill,” Arkfeld said. “This bill would not cover larger producers, but the law does allow small farms to be able to meet a niche demand.”

The law in Iowa states that a herd can only have 10 active lactating animals. Arkfeld milks four A2A2 Jerseys and has been running a herdshare program for about 1.5 years. Customers buy shares of a cow, and each share entitles a person to 1 gallon of raw milk each week. Customers can purchase multiple shares or half shares. They also pay a monthly boarding fee for every share to pay for the care of their cow.

Arkfeld has more than 20 customers, and each one buys anywhere from 1 to 3 gallons of milk per week. Arkfeld doubled in size from two to four cows around the time the legislation passed.

“We’re very small in the dairy world, but our biggest objective is quality over quantity,” Arkfeld said. “I have a long waiting list and could add to my herd and be up to 10 cows, but I want to make sure our quality doesn’t suffer. I don’t want to overextend ourselves.”

• The highest air ow in a circulation fan - 33,900 CFM.

• Cast aluminum blades have a lifetime warranty.

• Totally enclosed maintenance free, high ef ciency motors have a full two year warranty.

Model VP CA: Belt Drive, 1 HP, 115/230 volt, 9.6/4.8 amps single phase one speed 587 rpm

To ensure the milk she sells is safe for human consumption, Arkfeld follows strict protocols. Under mentorship of the Raw Milk Institute, she has put a risk analysis plan in place and conducts bacteria testing multiple times per month to ensure her processes are working. Yearly health testing of animals and proper veterinary care are also part of the puzzle, she said.

“The Raw Milk Institute is a wonderful resource whether you’re milking just one cow for your family or milking 600 cows,” Arkfeld said.

Arkfeld’s farm is currently the only Raw Milk Institute-certied dairy in Iowa.

“I comply with their certication and testing requirements,” Arkfeld said. “Our Iowa law has incorporated testing requirements, but mine are a little stricter.”

On Aug. 1, on-farm raw milk sales became legal in North Dakota as well. Like in Iowa, farms are free to sell milk directly to the customer for his or her own personal consumption. The bill was sponsored by Rep. Dawson Holle. Holle and his family milk 900 cows on their fthgeneration dairy farm near St. Anthony. Holle believes the new law presents opportunities to North Dakota’s dairy farmers.

“It opens the area of family farms to be scalable once again,” Holle said. “You don’t have to have a 1,000-cow dairy; you can have a 100-or-less-cow facility.”

Holle said he has seen raw milk sell for $15 to $20 per gallon.

“You don’t need that many cows when producing raw milk,” he said. “It cuts out the middleman and just benets the customer and farmer. The farmer gets as much bang for their buck.”

According to the North Dakota Department of Agriculture, as of July 1, there were 33 Grade A dairy farms in North Dakota.

“The number of dwindling farms in North Dakota is another reason I introduced this bill,” Holle said. “We lose one to two farms every year, and we have to do something about it. That’s one of the reasons I decided to get involved in legislation in the rst place.”

Before raw milk sales were legal in North Dakota, the state offered a herdshare program.

“That idea is not really scalable,” Holle said. “You either do a herdshare program or sell your milk to a processor. There was no area for any of those small-town farmers wanting to milk 10 to 40 cows. There was no way to make money.”

When over 50 people came to testify in favor of raw milk at a hearing, Holle said he knew the demand for this product was large.

“These people drank raw milk and thought it was crazy you can’t buy it unless you own a share,” Holle said. “I saw this raw milk movement taking place. The support it had was amazing.”

Holle also sees the legalization of raw milk as a benet to the small-town community.

“When people realize their food is shipped from out of state or from different parts of the state into their local towns, they want to do their part to support the area surrounding them,” Holle said. “If they are supporting local dairy farms, then hopefully the community as a whole will see a rise in economic activity.”

Drinking raw milk comes with potential risks, and many public health experts discourage its consumption.

“There are many different bacteria and parasites in raw and unpasteurized milk, and some can be very serious, even fatal,” said Dr. Joni Scheftel DVM, MPH, DACVPM. “This is why we recommend milk be pasteurized because it kills all the pathogens that can make you sick.”

Scheftel is the state public health veterinarian at the Minnesota Department of Health and supervisor of their Zoonotic Diseases Unit. Scheftel said the most common bacteria people get from drinking raw milk is Campylobacter, which causes fever and diarrhea. About 20% of people with this infection are hospitalized, but deaths are rare.

The most serious bacteria found in raw milk is E.coli O157, Scheftel said. The effects of this bacteria are often most detrimental to children who encounter it.

About 34% of people with E.coli O157 are hospitalized. Approximately 14% of children less than 5 years of age and 9% of children 5 to 9 years of age go on to develop a serious complication called Hemolytic Uremic Syndrome. HUS results in destruction of red blood cells and kidney failure, potentially requiring blood transfusions, dialysis and kidney transplants. Some children do not survive.

Parents whose children were in the hospital with HUS infections have told Scheftel statements such as, “I thought I did my homework. I thought I understood the risks, but I never knew how sick my child could get from drinking raw milk.”

“I’ve heard those words many times,” Scheftel said. “No matter how clean a farm is or how careful farmers are with their equipment, these germs are a natural part of cow manure and may accidentally get into milk. This is why we pasteurize milk — to make it safe to drink.”

Although she does not recommend people drink raw milk, Scheftel said she is not against the raw milk law in Minnesota which allows on-farm sales.

“If you want raw milk, you can go to a farm and pick it up,” Scheftel said. “This limits the number of people consuming raw milk, and the law is fair, because there is such a strong demand for it. However, I would be totally against the sale of raw milk at the retail level.”

In both Iowa and North Dakota, raw milk may not be sold at the retail level as it is in some states, such as California and Pennsylvania.

In Iowa, Arkfeld plans to continue with her herdshare program rather than selling direct to the consumer.

“Herdshare allows me to know how much milk to produce because I know how much milk my customers need

Page 10 • Dairy Star • Saturday, September 9, 2023

| New Holland, PA

A CLOSER LOOK

Turn to RAW MILK | Page 11

Esther Arkfeld Dairy farmer

Rep. Dawson Holle North Dakota

Dr. Joni Scheftel DVM, MPH, DACVPM MN Dept. of Health

Shawn Plaff Plaff Public Affairs

133 Atlantic Ave. NE • Pennock, MN 320-599-4466 NEW High Pressure Fog Ring Now Available

each week,” Arkfeld said. “They know it’s going to be as fresh as possible. We always have extra milk, so we might expand and sell a few gallons here and there.”

Arkfeld said many of her customers could not consume pasteurized dairy but found they are able to consume raw dairy.

“By no means is one better or worse than the other,” she said. “I believe there is room for both and a need for both.”

Growing up in Europe, Arkfeld said it was ne to drink raw milk.

“It was no big deal,” she said. “But when we moved to the U.S., we found things are very different.”

In Wisconsin, proposals like those in Iowa and North Dakota have come through over the past 15 years, but they were never passed. Wisconsin does not allow on-farm sales of raw milk, except at the incidental level.

Wisconsin Statute 97.24 prohibits the sale or distribution of non-Grade A milk to consumers, and states that Grade A milk must be pasteurized, which has been the law since 1957.

However, Wisconsin does allow incidental sales of raw milk directly to a consumer at the dairy farm where the milk is produced, for consumption by that consumer (or the consumer’s family or nonpaying guests). But those sales are also illegal if done as regular business or if they involve advertising of any kind.

“Fortunately, lawmakers and governors of two different parties have realized the signicance of Wisconsin’s nearly $50 billion dairy industry and the potential damages a raw milk outbreak could cause that industry,” said Shawn Pfaff, independent contract lobbyist and president of Pfaff Public Affairs.

A former spokesperson for the previously active Wisconsin Safe Milk Coalition, Pfaff was part of the effort to defeat proposed raw milk legislation in the state in 2015. Prior to that, Gov. Jim Doyle vetoed legislation to legalize the sale of raw milk in 2010, which was shot down again in 2013 by Gov. Scott Walker.

“It’s impossible to make an unsafe product safe,” Pfaff said. “There’s a reason we have pasteurization. It kills the bacteria found in milk, making it a safe product to drink.”

Scheftel said that bacteria in milk today is more virulent and resistant to antibiotics compared to bacteria of the past, increasing the likelihood that it will cause serious illness in people. An example is E.coli O157, which did not exist before 1982.

Every year, 60 to 80 cases of sickness caused from consuming raw milk pop up in Minnesota. But Scheftel said this is a gross undercount and only includes people who went to the doctor, had the organism cultured, reported they drank raw milk and agreed to be interviewed.

“The number of people who get sick each day from drinking raw milk is much higher than those we can identify,” Scheftel said.

Of the people interviewed, Scheftel said nearly 40% are less than 10 years of age. Among children less than 5 years of age who got sick from drinking raw milk, she said 76% receive the milk from their own farm or a relative’s farm.

“There is no safe raw milk,” Scheftel said. “My recommendation is to drink pasteurized milk on and off the farm.”

For Arkfeld, her journey into milking cows and drinking their raw milk began six years ago when she discovered her daughter could not consume pasteurized milk.

“Dairy products have wonderful nutritional benets, and when we found that raw milk outlet, we were able to provide my daughter with good nutrition,” Arkfeld said.

Despite the possible dangers that drinking raw milk can present, a demand for this beverage does exist, and Arkfeld said she goes above and beyond to ensure its quality.

“Your end customer is going to consume raw milk the way you produce it, and you have to make sure you do it in the best, most proper and caring way possible,” Arkfeld said.

DHIA believers for over 50 years!

What are some of the DHIA tests you use?

We utilize the Johnes test, standard plate count, somatic cell count, and mastitis culture tests.

Which is your favorite and why? I like the somatic cell count test to see if there are certain cows that have a chronic high

How does testing with DHIA bene t your dairy operation? DHIA bene ts the dairy by being an independent source helping us make decisions regarding herd health and productivity.

Tell us about your farm. I farm here with my brother, Perry, and my sisters, Brenda and Becky. We are a second generation family farm. We raise our youngstock, nish out our dairy steers, and farm about 900 acres.

Dairy Star • Saturday, September 9, 2023 • Page 11 320-808-3936 300 E Main St. Osakis, MN 320-859-5340 Visit us online at www.osakissilo.com 24 Hours 7 Days A Week Call Anytime The Best Service Crews, The Best Replacement Parts, The Best Service... That’s The Osakis Silo Advantage To You!!! EVERYTHING SILO Fall Pre-Chopping Schedule is Filling Up Fast! DON’T’ DELAY, CALL TODAY!

Con nued from RAW MILK | Page 10

Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere AN EXCELLENT CHOICE IN BALANCING YOUR RATIONS Are your cows getting the Amino Acids they need? Energy Protein Amino Acids Bypass Protein KLC roasted beans have an excellent Amino Acid profile, made nutritionally available through our unique roasting process. Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org

Now MORE than ever

DHIA:

Rhonda Kuechle Kuechle Dairy • Watkins, MN Milking 240 cows With DHIA since 1970

CO2 reduction: The invisible new asset

Midwest Forage Association holds carbon credit seminar at

By Amy Kyllo amy.k@star-pub.com

By Amy Kyllo amy.k@star-pub.com

SPRING VALLEY, Minn. — Carbon credits could be one way for farmers to make more money on cash crop elds. This relatively new marketplace creates opportunities to be paid for incorporation of environmentally friendly practices.

“Carbon Credit Talk” was led by Ryan Stockwell of Indigo Ag and Matt Kruger of Truterra. The seminar was part of Midwest Forage Association’s forage eld day and dairy tour Aug. 8, the afternoon portion of which was hosted at Nate Heusinkveld’s dairy near Spring Valley.

A carbon credit represents 1 ton of sequestered carbon dioxide or avoided carbon dioxide emissions.

day

These credits have value in today’s increasingly climate-aware business culture.

“This a tradeable asset,” Stockwell said. “This is a representation of something that we cannot see.”

Stockwell said carbon credits are important for companies trying to reach environmental goals, especially for those with emissions which are difcult or costly to eliminate.

Carbon credit buyers include companies like Walmart, Anheuser-Busch, The North Face, Nestlé and Shopify. Stockwell said that products with a sustainability attribute grow 2.7 times faster in market share than

their peers.

“This is a market-driven reality, and they are trying to keep up and be competitive in their market spaces,” Stockwell said. “They have emissions that they can’t get rid of, and that’s where carbon credits come into play.”

Though the buyers’ actual emissions may remain the same, their overall balance sheet of carbon emissions is closer to equilibrium thanks to carbon credits purchased from a eld which may be hundreds or even thousands of miles away from their operation.

The value of the carbon credits on a eld depends on individual factors. Stockwell said a carbon credit’s worth on the market is $30 to $50 dollars.

“This is the cherry on top” Stockwell said. “This isn’t the ice cream when it

comes to income.”

Kruger said farmers in Minnesota last year made $1.50 per acre to $36 per acre because of carbon credits with an average of $12 per acre.

“Are you going to get rich?” Kruger said. “No, you’re not getting rich off this. ... Is the price going up? Yes, every year the price per metric ton has been going up.”

There are two ways to earn money off of carbon sequestration and avoided carbon emissions: carbon credits and supply chain inset.

Carbon credits function by establishing a baseline of cropping practices on a piece of property. Then, carbon credits can be created by farmers additionally incorporating practices which increase carbon sequestration or avoidance compared

to earlier practices.

Supply chain inset is a newer market which gives farmers a premium on crops grown in a way which incorporates carbon sequestration and avoidance management practices. Supply chain inset is a way for farmers who have established carbon reduction practices to be paid for their efforts. In the carbon credit sphere, there are two main ways to create additionality to carbon reduction after a baseline has been established. The rst is incorporating cover crops and the second is reducing tillage. Stockwell said carbon sequestration practices are benecial to a farm beyond the money gained by carbon credits.

Page 12 • Dairy Star • Saturday, September 9, 2023 MINNESOTA Mid-Central Equipment Henning, MN Northland Farm Systems Inc. Owatonna, MN SOUTH DAKOTA Lake County International Madison, SD IOWA Mark’s Tractor & Implement Osage & Dumont, IA Reiser Implement Waukon, IA WISCONSIN D&D Equipment Chilton,WI Lindstrom Equipment Mondovi & Menomonie,WI Luxemburg Motor Company Luxemburg, WI CONTACT YOUR LOCAL GEHL DEALER TODAY! SOLID DESIGN *ATPARTICIPATINGDEALERS EXPIRES 3.31.21 ON ALL NEW GEHL SKID STEERS AND CTLS LOW-RATE FINANCING CASH BACK UP TO $2, $2,500 CALL YOUR LOCAL GEHL DEALER TODAY! Turn to CARBON CREDIT | Page 13

eld

Ryan Stockwell Indigo Ag

Matt Kruger Truterra

“You’re increasing water holding capacity and inltration, and improving your drainage,” he said. “There are so many agronomic values, so this should make agronomic sense for your farm.”

Carbon credits are veried through registries. Stockwell said these registries ll a role similar to the U.S. Department of Agriculture’s certied organic seal to help buyers understand that they are getting a legitimate product.

Stockwell gave several items to consider when choosing a carbon credit company. First, he said it is important to make sure the company chosen has an adequate customer base so that there will be a market for the carbon credits.

The second thing Stockwell said to consider when choosing a carbon credit company is their prot structure. Some companies buy carbon credits wholesale and sell them at retail while other companies struc-

ST R

ture it so that the more money a farmer makes the more money the company makes. Choosing a company with the latter structure helps ensure the company has a farmer’s best interest in mind.

The nal three factors to consider, Stockwell said, are a company’s payment rates, making sure that the crop grown and land is eligible, and ensuring that the carbon credits the company issues are registry-issued credits.

Kruger, who has family members who dairy farm, said that, currently, carbon credit systems do not function well on dairy farmland. Corn silage elds end up scoring low for carbon credits because of the amount of biomass being removed from the elds. Manure incorporation, depending on how it is done, can also create additional tillage, which is negative for creating additionality.

Health Report

Flags animals falling below optimal health; track condition progress

Breeding Report

IDs animals in heat by Breeding

Window & Heat Index

Tags Maintenance Report Alerts you to tags not read by the system & abnormal readings

Group Routine Report

Provides insight into daily routines & herd activity

Group Heat Stress Report

Displays current status & trends of behavior (panting, ruminating, eating)

Dairy Star • Saturday, September 9, 2023 • Page 13 Melrose, MN Brock Zierden—320.293.6192 bzierden@Leedstone.com Glencoe, MN Paul Becker—320.510.0200 pbecker@Leedstone.com Plainview, MN & Menomonie, WI Darren Pieper—715.307.5750 dpieper@Leedstone.com • Leedstone.com/equipment-team • Family & veterinarian owned since 1994 • CONTACT YOUR LEEDSTONE REP TODAY! SCR-ALLFLEX (SENSEHUB) MONITORING IS NOW AVAILABLE AT YOUR LEEDSTONE LOCATION Gain reliable, consistent data to help you manage your cows on an individual level. The leading monitoring technology & service you already know as SCR Dairy or Allflex Dairy monitoring are now fully integrated within SenseHub Dairy.

your cows better tomorrow than you do today!

Know

Get SenseHub —this unique, full-solution approach helps you simplify tasks, improve herd health & increase reproduction rates. S B) YOUR EQUIPMENT DEALERSHIP (SENSEHU CR LFLEX Do You Have Your Bunker Covers? Contact us at 877.608.3877 to order them today! p is wing m, 5% pen ningful d of 30 y: A low ows int mayfeed N Stre Figure 1: Group Heat Stress Graph Figure 2: Group Heat Stress Graph 2 tinereport intothe edailyroutine rtantfactor n.Over mination scan muchperienced mparing o-week sedto such eduleas lock e ging.used tepen ding NCYHE OF UTINES Figure Figure2: Con nued from CARBON CREDIT | Page 12 N6503 Pit Road Mount Calvary, WI, 53057 920-922-9966 americanimplement920@gmail.com IMPLEMENT INC White 2-135, duals, front weight Call for Pricing WE BUY SCRAP METAL! John Deere 310A Excavator Call for price Oliver Super 77 3,372 hours $4,000 USED PARTS AVAILABLE! Glenco soil finisher Call for price John Deere 12 row vacuum planter Call for price

We can help you with your farm or small business websites, printing & sign needs! For more information, contact your area rep listed on Page 2 of the First Section. DAIRY

WEB DESIGNS

Page 14 • Dairy Star • Saturday, September 9, 2023 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH Steerable Series Spreaders Excellent maneuverability and control on all types of terrain. LIQUID MANURE TANKS, PUMPS AND AGITATORS Powerful PTO Pumps & Agitators To Handle Liquid Manure In Stock WE ARE YOUR NEW TRIOLIET DEALER! In Stock Penta 6730 Parts in Stock! Many Different Sizes In Stock Parts In Stock HYDRA-SPREAD In Stock 12” VERTICAL PIT PUMP Pump 12,000 GPM with more efficiency and less foam • Unique agitator • Triple port outlet • White iron pump housing Parts In Stock Spreaders Maximum Spreading Ef ciency Maximize your productivity and performance with the KUHN Knight SLC 100 Series ProTwin® Slinger® manure spreaders. Truck-mount and trailer models are available with capacities ranging from 2,600 to 5,000 gallons. In Stock Parts In Stock VT600 T WIN-SCREW VERTICAL MIXER S Sto Stoc M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com Parts In Hand In Stock Designed to Suit your Needs Stock HOLY COW!!! Have you seen the inventory at Dairyland Supply lately? SAVE TIME & MONEY! AGRI-CHOPPER SUPERCART SUPER Parts In Hand Parts In Stock

from our side our side OF THE FENCE THE

What do you enjoy about your position as a milk hauler?

Kyle Hemmersbach Muscoda, Wisconsin Hemmersbach Trucking

16 years of experience

Tell us how you became involved in hauling milk.

My grandpa, Leo Hemmersbach, had a milk route out of Cashton, Wisconsin, for many years. Then my dad had his route as well. In 2014, I bought the truck and route from my dad, and we created Hemmersbach Trucking. We went to three trucks right away.

Tell us about a typical day. My company has 17 trucks, and we haul 1.5 million pounds a day. Personally, I drive the oldest truck in the eet — a 2009 Mack. I pick up six farms overnight. It comes out to three loads for a total of 225,000 pounds. I start at 4 p.m. and drive until about 6 a.m. A lot of our farms are on three-times-per-day milking, so the best windows to pick up are between 6-8 p.m. and 2-4 a.m.

What do you enjoy about your occupation? I enjoy the challenge. It’s challenging mentally to try and stay on top of everything and make all the logistics work. It’s a demanding, yet rewarding job.

What are the biggest challenges with hauling milk? Employee retention and keeping employees happy, maintaining schedules and making sure everyone has time off, and making sure I also get time with my family. Another big challenge is accommodating milking schedules as farms grow and move to milking three times per day. It reduces the windows of opportunity for picking up their milk.

What is your favorite time of year to haul milk? Typically, fall is my favorite because the crisp, cool evenings are nice after a hectic summer. But, it is hard to top that rst uffy snow. Driving at night, I often make the rst tracks on the road, and there is something really satisfying about a nice 10-degree snow when you get out of the truck and the snow crunches under your feet.

Tell us about a unique time when you had trouble hauling and how you overcame it. The coronavirus pandemic was the worst, trying to maintain logistics and keep employees and farmers protected. We had a couple employees get sick, and we just had to wait it out like everyone else. Hauling at night helped with some of that because there was less interaction. Also, anytime I have a takeover of milk from another hauler, where we are trying to blend routes, is a challenge. I try to work with the eld reps and the farms to cater to everyone’s milk schedules as best as we can.

What things are essential for you to have when there is a busy day ahead? I used to listen to the radio, but now I end up talking on the phone a lot. I spend a lot of the night driving, talking with employees, and during the day there are always business calls. I always bring a book with me though, so when I have down time waiting for milk to pump, I can catch a half hour or 45 minutes doing some reading. All the other guys have XM radios in the trucks.

What do you enjoy doing in your spare time? Being a dad to my four kids — Matthew, Anntonio, Aidenn and Merridith.

Emma

Vine Neillsville, Wisconsin Vine Trucking

One year of full-time experience

Tell us how you became involved in hauling milk. I became involved when my dad was given an opportunity to own his own business, which was luckily milk hauling. Instead of sitting at home, I would go in the truck with dad, and it just became a nice routine in my life. I ended up really enjoying it and couldn’t seem to stay away from the truck and not go to work.

Tell us about a typical day. I haul three loads a day, which amounts to 150,000 pounds of milk. I usually work 10-12 hours. I drive a Kenworth W900.

What do you enjoy about your occupation? It is nice being in my own truck, going about my day and doing my own thing, but then when I get to farms or the milk plant, it’s always nice to see all the familiar faces. I enjoy the interaction.

What are the biggest challenges with hauling milk? I would say when the unexpected happens — unexpected weather or even just something breaking on the truck. You never plan it, and when it happens, it can go from an early, easy day to a long catching-up day.

What is your favorite time of year to haul milk? I would say fall or closer to the wintertime because I enjoy being challenged. I enjoy trying to navigate the roads and gure out a route and what I can and can’t do. It really does challenge me to keep going and not give up. Driving in the winter can be really scary, but you’ll never learn until you do it.

Tell us about a unique time when you had trouble hauling and how you overcame it. I was driving the whole winter by myself. This is my rst year with my commercial driver’s license, and I was so used to being with my dad and knowing what to do; we were a team. When it came to being stuck or dealing with the worst snowstorms by myself, I had to really focus and rely on myself to not give up. The job has to get done, and you can’t just up and quit. It was scary for it being my rst year, but I achieved it.

What things are essential for you to have when there is a busy day ahead? I denitely need snacks. I always have to have my favorite songs and a pack of gum, so at least if I’m running behind and having a bad day, I have those to keep me sane.

What do you enjoy doing in your spare time? I enjoy spending time with friends and my family when I have a chance. With having this type of job and lifestyle, I never really know when I will have a day off, so when I do have a day off, I try to make the most of it.

Michael Petersen pictured with his son

Noah Random Lake, Wisconsin

Irv Lepp Milk Transit

Four years of experience

Tell us how you became involved in hauling milk. I started hauling milk due to my grandfather, Irv. He has been hauling milk for over 50 years. I rode along while growing up but never thought I would become a milk handler. One day, he mentioned selling his route. As this is a legacy he has had for many years, I couldn't overcome it coming to an end. I stepped up to the plate and said I would like to carry on his legacy.

Tell us about a typical day. A typical two-load day starts at 2 a.m. and goes until 3:30 p.m. We haul around 100,000 gallons of milk per day. On a single-load day, we start at 7:30 a.m. and are done around 4:30 p.m. On those days, we haul 50,000 gallons of milk. As of now, we currently pick up 12 farms. We are a one-truck operation and run a Western Star.

What do you enjoy about your occupation? One of the enjoyments of hauling milk is getting to communicate with our farmers. As we pick them up every day, each one creates a special bond in the work environment. There is never a dull moment.

What are the biggest challenges with hauling milk? One of the biggest challenges with hauling milk right now is supply and demand. Someday, we would like to grow as a company, but along with that, there is a shortage of nding drivers.

What is your favorite time of year to haul milk? My favorite time to haul during the year would be fall with its comfortable working temperatures. With that being said, you also get to see the joy of the farmers as the end of harvest season comes with their hard work that year completed in the elds.

Tell us about a unique time when you had trouble hauling and how you overcame it. As much as nobody likes having troubles, one of a trucker’s worst nightmares is breaking down while hauling milk. As many of you know, pick-up times are on tight schedules. In most cases, we can overcome and repair on the spot, but in some cases, we do bring out a spare truck.

What things are essential for you to have when there is a busy day ahead? Some essential things to help get through the day are a nice, fresh donut followed with energy drinks. I also like listening to the Octane station on the radio.

What do you enjoy doing in your spare time? When I’m not hauling milk, I spend my time enjoying it with my son and daughter. I also enjoy outdoor activities, wrenching on vehicles and riding motorcycles.

Dairy Star • Saturday, September 9, 2023 • Page 15 Turn to OUR SIDE | Page 16

Appleton, WI | Grooving America’s dairies since 1992! WE GROOVE SLATS! | SERVICING THE ENTIRE U.S. 608-225-3595 | www.PandDBarnFloorGrooving.com CONCRETE FLOOR GROOVING: P & D Grooving cuts grooves 3/4” wide, spaced 3-1/2” in between grooves, to give you protection against slips and falls that cause serious injuries to your cattle! I GROOVE NEW AND OLD CEMENT: To give maximum protection, we recommend “double cutting” where there are no existing grooves to make a diamond pattern or cutting diagonally over existing grooving to make a diamond pattern. Call Doug Today! ING: / ed 3-1 2” ainst r cattle! FREE STALL ALLEYS CROSS OVERS | RETURN ALLEYS “Grooving Doesn’t Cost... It Pays!” ROOVENEWANDOLDCEME HOLDING PENS COW YARDS Recommended by veterinarians, nutritionists, breeders and hoof trimmers BEFORE GROOVING AFTER GROOVING BARN FLOOR GROOVING AND • Reduce Injuries • Increase Milk Production • Increase Heat Detection • Better Drainage Prevent your cows from doing the splits! CONCRETE PRODUCTS 1-800-982-9263 Serving Minnesota, Iowa and Wisconsin Since 1965 www.alsconcreteproducts.com AL’S FEED

• Fence line feed bunk with slanted back • 15” feed trough depth • 24” high front side (Also available in 18-1/2” height for smaller cattle) • Deep Feeding Capacity • Long Service Life & Cattle Safe • Available in 12”, 14” and 16” depths • 38” wide, 34-1/2” high on back side • 24” high on front side • 20” deep feed trough • 6” feed saver lip ALSO AVAILABLE: • Cattle Slats • Holding Tanks • Cattle Guards • Bunker Silo Pictured with optional guard rail post mounted on the inside of the bunk or can also be placed outside. Fence Line Feed Bunk H- Feed Bunk Super High Capacity Fence Line Bunk J-Bunks & H-Bunks available for large and small animals

BUNKS

Ian Wetterau

Richeld, Wisconsin

Wetterau Homestead Inc.

Nine years of experience

Tell us how you became involved in hauling milk. My dad bought his rst milk route in 1982 and started a trucking company hauling milk. He bought several routes in the years stretching up to today. I took over hauling milk when I turned 18. I was part time through college, hauling mostly on weekends, and then began hauling full time after college. My dad is still involved in the business, but I do the milk hauling every day.

Tell us about a typical day. I start about 2 a.m. and pick up a load of eight to nine farms. I then dump it off at the milk plant and go out and pick up another load. After I drop off my second load at the plant, I wash my truck. I’m usually done around 1 p.m. I have about 18 stops total from Washington, Ozaukee, Sheboygan and Dodge counties. The two co-ops I haul for are Dairy Farmers of America and Family Dairies USA. A lot of the milk goes to Kemps as well as a couple of cheese plants. I haul about 13,000 gallons per day in my Peterbilt 389 seven-axle straight truck that has a 6,500-gallon tank.

What do you enjoy about your occupation? I enjoy driving through the countryside and being a part of agriculture. I also enjoy talking with farmers. I grew up around these people and have known all my farmers my whole life. It’s kind of like we’re family because I’m on their farm every day, and I become part of their operation. It’s really nice to pick up their milk and talk with them and be a part of feeding the world.

What are the biggest challenges with hauling milk? It takes a very hardworking and strong-willed person to do this job. It’s seven days a week, 365 days a year. There’s no stopping it. It doesn’t matter what the weather is or how you’re feeling healthwise. You

Paul Dwyer Tomah, Wisconsin Dwyer Milk Transport

41 years of experience