Once again, the Central Plains Dairy Expo plans to offer dairy producers and industry professionals alike a chance for educational offerings and network experiences March 19-21 at the Denny Sanford Premier Center in Sioux Falls, South Dakota.

“Given the ongoing changes in the dairy industry and potential legislative shifts in the farm bill for 2024, attending this year’s Central Plains Dairy Expo is essential,” said Kris Bousquet, Central Plains Dairy Association president. “The education and networking opportunities are sure to make a signicant impact on your business. I look forward to seeing you there.”

The annual expo will feature nearly 300 exhibitors as well as 65 educational sessions, including sessions available in Spanish.

The free Welcome Reception is available to all dairy producers, starting at 5 p.m. March 19. Entertainment is provided by country music artist Rodney Atkins, and complimentary appetizers, cheese charcuteries and a variety of ice cream will be available. Attendees must register to attend.

“To ensure a seamless experience, we ask that everyone registers online ahead of time on our website,” said Renee Brod, director of member services of CPDE. “If you register online, you get a name badge, and the name badge gets you into everything for the two and a half days — all the great things CPDE offers.”

Prior to past expos, there will not be a Central Plains Dairy Foundation auction at this year’s Welcome Reception.

The Lon and Kathy Tonneson Scholarship will be announced during the Welcome Reception.

“We are excited about awarding the scholarship live,” Brod said. “That is something we have never done before. The scholarship honors Lon and Kathy for the great work they put into establishing this expo

and bringing it to how fantastic it is today. They really did a great job in growing Central Plains Dairy Expo.”

In addition to educational offerings, CPDE offers attendees the chance to connect with fellow pro-

ducers during such events as the trade show, ag prayer breakfast, wine and cheese reception, pancake breakfast and beer garden — all of which is free to registered attendees.

www.dairystar.com

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303

Fax: 320-352-5647

Published by Star Publications LLC General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com Editorial Staff

Maria Bichler - Assistant Editor

maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks

320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN)

507-250-2217

• fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell)

bob.l@star-pub.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

“We are very excited that year after year we can offer CPDE for free thanks to our sponsors and exhibitors,” Brod said.

The Ag Prayer Breakfast will begin at 6:30 a.m. March 20. The breakfast features the Merrill and Marlys Nettinga family of M&M Dairy near Hull, Iowa. Merrill will share his faith-based journey and describe how the grace of God has helped his family build a sustainable farm business.

M&M Dairy is comprised of 100 Holsteins and 1,000 acres of corn and soybeans. Recently, the family installed two robotic milking units.

The trade show oor opens at 8:30 a.m. March 20. Free donuts will be served from 8:30-10:30 a.m., and the breakout sessions will go from 9 a.m. to 5 p.m. Free grilled cheese sandwiches will be served over lunch, with free ice cream being offered from 2-4:30 p.m. The wine and cheese social begins at 4:30 p.m., and the trade show closes at 5:30 p.m.

The trade show and breakout sessions continue March 21 from 8 a.m. to 3 p.m.

On March 21, the pancake breakfast will be open from 8-10 a.m., and the beer garden, grilled cheese sandwiches and ice cream will continue to be offered.

“If you want to see any new exhibitors, make sure you check the arena,” Brod said. “Included this year, there are few different tech companies, dairy consultants, a robotics company as well as a video surveillance company that are all new to expo.”

The Ed Shed is back this year in the arena. The sessions will be offered by Control Solutions, IDEXX, Nedap, TriCal Superior Forage, MGK, Land O’Lakes/CROPLAN, and the Dairy Calf and Heifer Association.

“These are set up as a TED Talktype space, very informal as you are passing by,” Brod said. “It’s a smaller area where you can have even more interaction with the speakers that are there providing a 30-minute educational session on the topic that they are an expert of.”

New this year, the I-29 Moo University Dairy Beef Short Course is

scheduled for March 21 as part of the nale for the CPDE. It will be held in the Denny Sanford Premier Center.

The focus of this year’s program is economics, marketing opportunities and genetics.

“We are excited for the new location,” said Fred Hall, dairy specialist with Iowa State University Extension and Outreach. “The larger venue allows for comfortable seating with tables and chairs and an enjoyable learning experience.”

Brod said she is excited about this year’s expo.

“We’ve had really great responses from a lot of exhibitors,” Brod said. “We are very happy about having a lot of new exhibitors into the arena. A wide variety of industries are going to be represented for all of the attendees, which makes it much more interesting and worth their while to come and see who is here.”

Attendees can pre-register online at www.centralplainsdairy.com. Onsite registration is also available. The Cvent Events app can be downloaded to stay up to date on events and offerings.

Melrose, MN 800-996-3303

Glenco, MN 877-864-5575

Plainview, MN 800-548-2540

Menomonie, WI 866-467-4717 ZUMBRO

Zumbrota, MN 651-380-2856

sioux

Rock Valley, IA 800-962-4346

Zumbrota, MN 507-732-4673

Menomonie,WI 715-235-5144

Renner, SD 605-274-3656

Central

Juneau, WI 920-386-2611

Baraboo, WI 608-356-8384

From the lowest supply of heifers in more than 20 years to a beef market that is booming, it can be a challenge to understand the volatility of markets and seek opportunities.

During her presentation, “Navigating the Dairy Markets,” at 10:30 a.m. March 20 at the Central Plains Dairy Expo, in Sioux Falls, South Dakota, Sarina Sharp will address multiple areas in the markets, answering questions such as: Are feed costs headed up or down? Is there room for more U.S. milk? Where are the heifers?

“What I think will be most interesting to dairy farmers is looking at the factors that have contributed to a shortage of dairy heifers,” Sharp said. “Are we going to continue to breed for beef calves, which will continue to shrink heifer supplies?”

The Jan. 1 estimate of heifer inventories showed a huge decline from 2022 to 2023 and a more modest decline from 2023 to 2024, Sharp said. That resulted in the lowest supply of heifers ready to calve and enter the dairy herd in 2024 since the U.S. Department of Agriculture began tracking those numbers in 2001.

“There was a big glut of heifers in the early 2000s once dairy producers started widely using sexed semen,” Sharp said. “That is still regularly used on dairy farms but so are beef genetics, and we’re making a lot fewer dairy breed heifer calves than in the past.”

Sharp sees that as an issue but said the industry is never going to run out of heifers

In addition to writing for the Daily Dairy Report, Sharp advises dairy producers on how to manage nancial risk using Dairy Revenue Protection, futures, options and cash contracts.

Sharp will cover the international and domestic feed, livestock and dairy markets in depth. She will begin with a look back to explain why prices are where they are today and provide an outlook going forward.

The shortage also lifts livestock values and will continue to do so. However, she said the shortage is a barrier to rapid expansion in the industry and raises the cost of lling a new barn.

From a cash ow standpoint, Sharp said there is an advantage to producing a beef calf and raising as few heifers as possible — maybe just enough for a person’s herd — or perhaps raising none.

“You could sell your heifers to someone else and buy mature heifers as you need them or sell them to a beef lot which has also contributed to a shortage of dairy heifers,” Sharp said.

Sharp said feed costs are at a threeyear low, and in the long run, those prices are likely to continue to drift lower.

“We have big corn inventories in the U.S., and the South American crop production is large,” Sharp said. “Therefore, I’m cautiously bearish of the feed market.”

Sharp will also address the supply and demand for U.S. milk.

“We have to keep growing exports if we’re going to continue to grow U.S. milk production,” she said. “I’m not worried it’s going to grow really fast due to a lot of red ink on dairy farms across the nation as well as the heifer shortage.”

Europe and New Zealand all have the same plan: to make less butter and powder and more cheese.

Domestically, Sharp said many areas have invested in cheese production, especially in the Central Plains region.

“What I think will be most interesting to dairy farmers is looking at the factors that have contributed to a shortage of dairy heifers. Are we going to continue to breed for beef calves, which will continue to shrink heifer supplies?”

SARINA SHARP

To have strong cheese exports, Sharp said making a greater share of milk into cheese is vital. There is both good news and bad news on this front. The good news is the record-shattering demand from Mexico, which Sharp said has been a reliable partner for the U.S.

The bad news comes in the form of softer demand from Asian markets, such as South Korea and Japan. To compound matters, Sharp said the U.S.,

“Are we going to continue to overwhelm cheese markets with big supplies, or does slow growth in milk production help to tighten things back up and stabilize cheese prices?” she said.

Due to slow global growth in milk production, Sharp said there is a rm oor under the Class IV milk price market.

“Although this is less relevant to most dairy producers in the Midwest, with tightened inventories, Class IV milk prices could shoot higher if demand for those products picks up,” Sharp said.

On the beef side, things are promising, and Sharp will dive into what producers can expect this year and beyond.

“The beef market is going to be very high for the next 18 months at least,” Sharp said.

Farmers attending the talk will also receive general advice on risk management strategies to protect their margins. Sharp said thin margins are the No. 1 concern facing dairy farmers in 2024.

Why is exhibiting at Central Plains Dairy Expo important to your business? I have so many cus-tomers who have already purchased from me, and they stop to see me. Many of those buy added products because what they have previously purchased has worked out so well for them.

What will you be highlighting at CPDE this year? Each year, our highlight is our hoof trimming chute. We also have on display our portable loading chute, maternity pen and our ATV drive-over gate.

How long has your business been exhibiting at CPDE? I have been exhibiting at the Central Dairy Plains Dairy Expo for 20 years.

What do you enjoy doing at the show when you are not working the trade show? When we are not at the show, we stay with my daughter and have such a fun time.

What do you hope to accomplish while at CPDE? Continue to inform customers just how useful, safe and helpful our products are for their operation.

Tell us a favorite memory you have from CPDE. Connecting with those who have already purchased our product and now love to reconnect.

A discussion on mastitis prevention often revolves around managing environmental factors and milking procedures.

Despite improvements in management, the incidence of mastitis has not been reduced in the last 30 years.

Craig Louder, with Axiota Animal Health, said there is a key tool to prevent mastitis in dairy cows.

“We’re great at being able to diagnose something,” Louder said. “We’re great at being able to nd out what bug is causing it. We’re great at trying to clean the environment and being aware of the bedding and the corrals the cows are in. But, we’ve forgotten about the cow’s role in the triad of disease. To me, that’s where trace minerals can play a role so that she can have what she needs to be able to resist disease, so the environment those pathogens are in aren’t able to overwhelm her.”

veterinarian for Axiota Animal Health and will be presenting information on injectable trace minerals during his presentation, “Your Best Shot at Udder Health: Helping Cows Combat Mastitis Through Strategic Trace Mineral Supplementation” at 1 p.m. March 20 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

Louder was a practicing veterinarian for 10 years before transitioning to his current position. He supports the sales and production team by diving deeper into the application of the commercial product to better understand where it is going to work and where it will not.

“There’s no product that’s going to work in every situation 100% of the time,” Louder said. “We want to make sure that we’re putting these products where we can get a benet and not be another added expense to a producer.”

Craig Louder Axiota Animal Health

Craig Louder Axiota Animal Health

Louder said that trace minerals are often fed through the ration, but trace minerals are poorly absorbed in cattle. Limitations on how well minerals can get into the cow’s system and be utilized put her at a disadvantage.

Injectable trace minerals provide an ideal form of delivery because they bypass many of the hurdles common to oral supplements.

Louder is the technical service

Now that the Federal Milk Marketing Order public hearings have wrapped up, dairy producers may be wondering where the industry goes from here.

To learn what could be in store for updates to the FMMO pricing structure, make plans to attend the “Federal Policy Update” breakout session at 12:30 p.m. March 20 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“Currently, (the U.S. Department of Agriculture) is sifting through more than 10,000 pages of transcripts of witness testimony from the hearings,” said Chris Galen, senior vice president of member services and governance for the National Milk Producers Federation. “They will then draft a recommended decision by mid-summer of how milk should be priced at the farm level for the next generation.”

Galen will serve as moderator of the session. Joining him are subject matter experts Stephen Cain, senior director of economic research and analysis with NMPF, and Chris Hoeger, vice president of procurement for Prairie Farms Dairy Inc.

Cain attended all the hearings, and Hoeger was one of the witnesses. Hoeger was also involved with the task force that put together proposals over two years and were submitted by NMPF.

“This is a complicated topic, and I encourage dairy producers to attend this session,” Galen said. “It will outline what is on the table for proposed changes and potential differences in future milk pricing.”

The ve-month-long hearing process that began Aug. 23, 2023, in Carmel, Indiana, concluded at the end of January. USDA is considering 21 proposals to amend the FMMO pricing system, which received its last comprehensive revision in 2000.

Five of these proposals were submitted by NMPF. This session will highlight those proposals, along with proposals submitted by other groups. Presenters will also assess how USDA will decide which proposals to adapt and the timeline for those decisions.

At the core of many proposals are ideas for modernizing the formulas that calculate the nal price farmers receive for their milk and updating Class I, II, III and IV prices.

“This is the heart and soul of what is at issue here,” Galen said. “We are going to discuss this in detail, including what direction we would like to change these prices and how it will impact a farmer’s milk check.”

Returning to the higher of Class I mover system is a priority in NMPF’s proposal, Galen said.

Con nued from UDDER HEALTH | Page 8

“With antagonism in the rumen and poor absorption rates in the small intestine, the injectables basically become our pass play where we can get a lot of yardage quickly, like in football,” Louder said. “We still have to have that good run game with oral minerals, but by strategically using the injectable minerals, we can target when we need it so we can make big gains in a hurry.”

When a cow is short on minerals, like just after calving, and the risk of mastitis is high, an injectable trace mineral can get her caught up quickly. Her immune system has what it needs to battle the pathogens she faces in early lactation.

Zinc is an example of a trace mineral that contributes to udder health because it is present in the skin and the keratin plug. Copper and selenium are known for their role in white blood cells.

In addition to udder health, trace minerals play a critical role in the function of processes throughout the body. They aid in vaccine response, early calf health and reproduction, Louder said.

“In order to prevent disease, we need to focus on all three aspects: the cow, the bug and the environment,” Louder said. “If we want a healthy cow, we need to focus on what the cow has already given us and not shortchange her. We can benet the cow while not forgetting the environment and the pathogens that she is dealing with.”

“In the 2018 farm bill, Congress changed how Class I milk is priced,” Galen said. “It used to be either the higher of Class III or IV of the preceding month, but they changed it to the average of the two. This shift has had negative economic consequences. It resulted in lost potential revenue, particularly in areas with a lot of Class I sales, like the Northeast.”

Galen said under this system, dairy farmers are exposed to unlimited risk on the downside, while benets on the upside are limited.

NMPF would also like to see manufacturing allowances for turning raw milk into cheese, whey, butter and nonfat dry milk adjusted on an interim basis. Galen said current FMMO make allowances have not kept up with the costs of manufacturing dairy products.

Groups that submitted proposals have until April 1 to submit briefs summarizing their view of what they heard during the hearings. Once a decision is presented this summer, the industry will have a period of time to

comment.

“No one is going to get 100% of what they want,” Galen said.

A nal proposal is then expected by late fall. From there, a calendar will be set for farmers and co-ops in each of the 11 federal orders to vote in favor of the proposal or have no federal order regulation.

“Change is coming,” Galen said. “There will be no status quo. The FMMO pricing system will not stay like it is now. You will either have a new proposal or choose to have a region that is unregulated, meaning there will be no federal order there. Idaho would be an example of a region with no federal order.”

Galen said that farmers’ milk checks will be different because of these proposed changes.

“We don’t know exactly how it’s going to be different, only that it will be different starting in 2025,” he said.

TUESDAY, MARCH 19

5:00 PM Doors Open

5:30 PM Welcome Reception Program Begins

9:00 PM Sheraton Hospitality Room

WEDNESDAY, MARCH 20

6:30 AM Ag Prayer Breakfast - Doors Open

8:30 AM Trade Show Floors Open

8:30-10:30 AM Free Donuts

11:00 AM-4:30 PM Beer Garden Open

8:30-9:30 AM

BREAKOUT SESSIONS

Myth vs. Reality: Maternal Antibodies and Calf Vaccination

- Jen Roberts (Sponsored by Boehringer Ingelheim Animal Health) MR 8

Leveraging Herd Insights for Better Decision Making

- Dylan Ash and Stephanie De Vries (Sponsored by VAS) MR 3

Not all carbohydrates are the same. How can more dietary sugar improve both rumen and cow performance?

- Mary Beth de Ondarza (Sponsored by Westway Feed) MR 12

9:00-10:00 AM

BREAKOUT SESSIONS

Mythbuster: The Truth About Lely Dairy Automation

- Lely North America Team (Sponsored by Lely/Gorter’s Clay & Dairy Equipment) MR 1/2

Calcium Magnesium Carbonates: The Swiss Army Knife of Feed Ingredients - Clayton Stoffel (Sponsored by Papillon Agricultural Company) MR 13

SPANISH SESSION: Comprenda cómo los procedimientos simples de ordeño pueden mejorar la eficiencia de las vacas y el control de la mastitis - Tiago Tomazi (Sponsored by Merck Animal Health) MR 9/10

9:00-9:30 AM ED SHED SESSION: ALFALFA: New & Improved!

“AA Series” - Jeff Jackson (Sponsored by Land O’Lakes/CROPLAN) Ed Shed

9:30-10:30 AM BREAKOUT SESSIONS

Volatile Profit Margins - Data and Tools at your Disposal

- Jeff Toll (Sponsored by CIH – Commodity & Ingredient Hedging) MR 6/7

Stop Clostridium Problems Before They Start - Troy Brown (Sponsored by Form-A-Feed) MR 14

10:00-11:00 AM

BREAKOUT SESSIONS

Using 3D Camera Technology to Accurately Measure Body Reserves, Growth and Locomotion in Dairy Cattle

- Fernando Diaz (Sponsored by Dellait - Animal Nutrition & Health) MR 8

Leveraging Alfalfa Technologies in a Changing Environment

- Randy Welch & Dr. Dan Putnam (Sponsored by Forage Genetics International) MR 12

10:00-10:30 AM ED SHED SESSION: The Good Neighbor: Premise Pest Control for Dairy Producers - Christy Jones (Sponsored by MGK) Ed Shed

10:30-11:30 AM

BREAKOUT SESSIONS

Navigating the Dairy Markets - Sarina Sharp (Sponsored by Farm Credit) Denny Sanford Premier Center

Economics of Transition Cow Health - Eduardo Ribeiro (Sponsored by Phibro Animal Health Corporation) MR 3

SPANISH SESSION: Optimización de la salud de las granjas lecheras: Claves para mejorar el período de secado y el manejo del calostro. - Maristela Rovai & Noelia Silva del Rio (Sponsored by SDSU Extension) MR 9/10

11:00 AM-12:00 PM BREAKOUT SESSIONS

The PPR Difference: A 3-step Process to Help Dairy Cattle Deal with the Multiple Mycotoxin Challenges that They Encounter Every Day - Joel Pankowski (Sponsored by Arm & Hammer Animal and Food Production) MR 14

Practical Applications for Raising Calves - Minnie Ward (Sponsored by Feedworks USA) MR 6/7

11:00-11:30 AM ED SHED SESSION: Using Actionable Insights to Let Cows be Cows - Matt Heisner (Sponsored by Nedap) Ed Shed

11:00 AM-1:00 PM Free Grilled Cheese Sandwiches

11:00 AM Dairy Girl Network Luncheon

11:30 AM-12:30 PM Managing Your Feed Center to Maximize Efficiency and Consistency While Reducing Shrink - Keith Sather (Sponsored by Supervisor Systems/ KS Dairy Consulting) MR 13

12:00-1:00 PM BREAKOUT SESSIONS

FORAGE 360: Forage Rotations and Planning - Jeff Jackson (Sponsored by Land O’Lakes/CROPLAN) MR 12

High Sand Reclamation: What Types of Sand Work Best?

- Renee Schrift (Sponsored by McLanahan Corporation) MR 1/2

SPANISH SESSION: Consejos prácticos para una correcta alimentación del recién nacido y el manejo del calostro

- Cristian Sosa (Sponsored by Golden Calf Company) MR 9/10

12:00-12:30 PM ED SHED SESSION: Taking Advantage of Triticale Flexibility - Racey Padilla (Sponsored by TriCal Superior Forage) Ed Shed

12:30-1:30 PM Federal Policy Update - Christopher Hoeger, Stephen Cain & Christopher Galen (Sponsored by Central Plains Dairy Association) Denny Sanford Premier Center

12:30-1:30 PM SPANISH SESSION: Respensando el tratamiento clinic de las mastitis – Daniela Bruno (Sponsored by Zoetis)

1:00-2:00 PM BREAKOUT SESSIONS

The Role of Biofilm in Bacterial Infections and Strategies to Mitigate It - Dr. Chris Chase (Sponsored by AHV USA) MR 8

Your Best Shot at Udder Health: Helping Cows Combat Mastitis Through Strategic Trace Mineral Supplementation

- Craig Louder (Sponsored by Axiota Animal Health) MR 3

Improving Dairy Profitability by Focusing on Forage Quality and Soil Biology - Evan Hansen and Dr. Kai Yuan (Sponsored by Quality Liquid Feeds) MR 13

1:0-1:30 PM ED SHED SESSION: Revolutionizing Reproductive Management: A Journey from Ultrasound to Sample-based Pregnancy Testing - Randy Gross and Darren Mueller (Sponsored by IDEXX) Ed Shed

1:30-2:30 PM

BREAKOUT SESSIONS

Engaging in Climate-Smart Projects to Monetize On-Farm Environmental Initiatives - Tim Baye, Lauren Brey, Lucas Sjostrom (Sponsored by Edge Dairy Farmer Cooperative) MR 6/7

Using Technology to Make Management Changes

- Sarah Anderson (Sponsored by Merck Animal Health) MR 1/2

SPANISH SESSION: Leadership for Hispanic Managers

- Jorge Delgado (Sponosored by Alltech) MR 9/10

2:00-4:30 PM Free Ice Cream

2:00-3:00 PM Milking Their Way: Producers Share Experiences with Rotary, Robots and Batch Milking - Sam Schwartz, Aaron Titterington, and Dr. Juan Velez (Sponsored by DeLaval) Denny Sanford Premier Center

2:00-2:30 PM ED SHED SESSION: Integrated Pest Management of Flies in Dairies - Danny McDonald, Ph.D. ( Sponsored by Control Solutions) Ed Shed

2:30-3:30 PM BREAKOUT SESSIONS

Domino Effect of Microbial Coinfections in Dairy Cows

- Beth Galbraith (Sponsored by United Animal Health) MR 8 Nonsevere Gram-negative Clinical Mastitis. To Treat or Not to Treat? - Daniela Bruno (Sponsored by Zoetis) MR 3

3:00-4:00 PM Optimize the End: Marketing Endpoints for Beef × Dairy Cattle

- Luke Fuerniss (Sponsored by Stgenetics) MR 1/2

3:30-4:30 PM Revenue Outside the Tank: What’s Your Farm Worth?

- Martha Baker (Sponsored by Alltech) MR 6/7

4:30 PM Wine & Cheese Social on the Trade Show Floors

5:30-7:30 PM Dairy Checkoff Taste and Learn Experience

(Sponsored by Midwest Dairy) MR 12/13/14

5:30 PM Trade Show Floors Close

THURSDAY, MARCH 21

8:00 AM Trade Show Floors Open

8:00-10:00 AM FREE Pancake Breakfast

8:00-9:00 AM BREAKOUT SESSIONS

The PPR Difference: A 3-step Process to Help Dairy Cattle Deal with the Multiple Mycotoxin Challenges that They Encounter Every Day - Joel Pankowski

(Sponsored by Arm & Hammer Animal and Food Production) MR 1/2

Economics of Transition Cow Health - Eduardo Ribeiro

(Sponsored by Phibro Animal Health Corporation) MR 12

SPANISH SESSION: Consejos prácticos para una correcta alimentación del recién nacido y el manejo del calostro

- Cristian Sosa (Sponsored by Golden Calf Company) MR 9/10

8:30-9:30 AM BREAKOUT SESSIONS

Practical Applications for Raising Calves - Minnie Ward

(Sponsored by Feedworks USA) MR 8

Optimize the End: Marketing Endpoints for Beef × Dairy Cattle - Luke Fuerniss (Sponsored by Stgenetics) MR 3

Managing Your Feed Center to Maximize Efficiency and Consistency While Reducing Shrink - Keith Sather (Sponsored by Supervisor Systems/ KS Dairy Consulting) MR 13

9:00-10:00 AM Sand Separation Systems and Fine Sand Capture Prior to Anaerobic Digestion - Renee Schrift (Sponsored by McLanahan Corporation) MR 6/7

9:30-10:00 AM ED SHED SESSION: Revolutionizing Reproductive Management: A Journey from Ultrasound to Sample-based Pregnancy Testing - Randy Gross and Darren Mueller (Sponsored by IDEXX) Ed Shed

9:30-10:30 AM BREAKOUT SESSIONS

Mythbuster: The Truth About Lely Dairy Automation - Lely North America Team (Sponsored by Lely/Gorter’s Clay & Dairy Equipment) MR 1/2

Improving Dairy Profitability by Focusing on Forage Quality and Soil Biology - Evan Hansen and Dr. Kai Yuan (Sponsored by Quality Liquid Feeds) MR 12

SPANISH SESSION: Repensando el tratamiento clínico de la mastitis - Daniela Bruno (Sponsored byZoetis) MR 9/10

10:00-11:00 AM FORAGE 360: Forage Rotations and Planning - Jeff Jackson (Sponsored by Land O’Lakes/CROPLAN) MR 13

11:00AM-3:00 PM Beer Garden Open

11:00 AM-1:00 PM Free Grilled Cheese Sandwiches

11:00 AM-11:30 PM ED SHED SESSION: Dairy Calf & Heifer Association: Growing your dairy’s future - David Casper (Sponsored by Dairy Calf and Heifer Association) Ed Shed

11:00 AM-12:00 PM BREAKOUT SESSIONS

Revenue Outside the Tank: What’s Your Farm Worth? - Martha Baker (Sponsored by Alltech) MR 6/7

Stop Clostridium Problems Before They Start - Troy Brown (Sponsored by Form-A-Feed) MR 12

Using Technology to Make Management Changes - Sarah Anderson (Sponsored by Merck Animal Health) MR 1/2

SPANISH SESSION: Comprenda cómo los procedimientos simples de ordeño pueden mejorar la eficiencia de las vacas y el control de la mastitis - Tiago Tomazi (Sponsored by Merck Animal Health) MR 9/10

for Better Decision Making

- Dylan Ash and Stephanie De Vries (Sponsored by VAS) MR 3

Not all carbohydrates are the same. How can more dietary sugar improve both rumen and cow performance?

- Mary Beth de Ondarza (Sponsored by Westway Feed) MR 13

Nonsevere Gram-Negative Clinical Mastitis. To Treat or Not to Treat? - Daniela Bruno in English (Sponsored by - Zoetis) MR 8

12:30-1:30 PM BREAKOUT SESSIONS

Myth vs. Reality: Maternal Antibodies and Calf Vaccination

- Jen Roberts (Sponsored by Boehringer Ingelheim Animal Health) MR 1/2

Milking Their Way: Producers Share Experiences with Rotary, Robots and Batch Milking - Sam Schwartz, Aaron Titterington, and Dr. Juan Velez (Sponsored by DeLaval) MR 12

SPANISH SESSION: Leadership for Hispanic Managers

- Jorge Delgado (Sponsored by Alltech) MR 9/10

SPANISH SESSION: El Efecto Dominó de las Coinfecciones Microbianas en Ganado Lechero - Beth Galbraith (Sponsored by United Animal Health) MR 6/7

1:00-2:00 PM BREAKOUT SESSIONS

Using 3D Camera Technology to Accurately Measure Body Reserves, Growth and Locomotion in Dairy Cattle

- Fernando Diaz (Sponsored by Dellait-Animal Nutrition & Health) MR 3

Leveraging Alfalfa Technologies in a Changing Environment

- Randy Welch (Sponsored by Forage Genetics International) MR 13

Making Sense of Feed Additives for Gut Health - Devan Paulus Compart (Sponsored by Papillon Agricultural Company) MR 8

1:00-3:00 PM Free Ice Cream

2:00-3:00 PM BREAKOUT SESSIONS

The Role of Biofilm in Bacterial Infections and Strategies to Mitigate It - Dr. Chris Chase (Sponsored by AHV USA) MR 6/7

SPANISH SESSION: Optimización de la salud de las granjas lecheras: Claves para mejorar el período de secado y el manejo del calostro - Maristela Rovai & Noelia Silva del Rio (Sponsored by SDSU Extension) MR 9/10

3:00 PM Trade Show Floors Close

Hubbard

J & D Manufacturing ........................................................C830

J. B. Hunt Ag Services...........................................................X

Jefo Nutrition USA Inc. ....................................................H135

Johnson Concrete Livestock Waterers ............................C904

Johnson Engineering Group, LLC .................................A1108

Jones-Hamilton Co. .........................................................A110

K2S Engineering Inc. .......................................................C800

Kemin Animal Nutrition & Health .....................................C209

Kent Nutrition Group ........................................................C607

Kooima Ag .......................................................................C626

Kuhn North Amercia ........................................................C822

Kunafin “the insectary”...................................................A1105

KVK USA .......................................................................A1014

Lallemand Animal Nutrition..............................................C208

Land O’Lakes/Purina/Croplan .........................................C215

Landmark Builders...........................................................A510

Lange Ag Systems, Inc....................................................A902

Lankota ............................................................................A607

Leedstone ........................................................................C321

Legend Rubber Inc. .......................................................AF105

Maas Energy Works ........................................................A802

MAI Animal Health ...........................................................A505

Marsh McLennan Agency ................................................C411

MB Nutritional Sciences .................................................H100

McFinn Technologies ......................................................A512

McLanahan ......................................................................C111

MEDA/Chemstar & Milk-Rite USA .................................AF100

Mensch Mfg .....................................................................C613

Merck Animal Health .......................................................C206

MGK Insect Control Solutions .........................................C602

Micro Technologies and MWI Animal Health ...................C832

Midwest Ag & Commercial Contractors, LLC. .................A115

Midwest Ag Supplements ................................................C308

Midwest Dairy .................................................................C204

Midwest Dairy Solutions ..................................................C230

Midwest Livestock Systems, LLC. ...................................C624

milc Group .....................................................................A1211

Minnesota Department of Agriculture ..............................C303

MN DHIA (MN Dairy Herd Improvement Assoc.) ..........AF104

MTech Dairy Solutions ....................................................C326

Munters............................................................................C935

NDE co / New Direction Equipment Co. ..........................A603

Nebraska State Dairy Association .........................................N

Neogen ..................................................................................H

Norbco ...........................................................................A1213

North Central Steel Co. ...................................................A307

Northern Plains Forage Association ......................................Q

Northland Farm Systems ...............................................A1003

NovaMeal by Novita Nutrition ..........................................C331

Novus International..........................................................C603

NuAge Builders................................................................A412

Nu-Force Water Technologies, LLC. .............................A1210

Nuhn Industries Ltd. ........................................................A619

.........................................................................C807

Steuart Labs ....................................................................C600

STgenetics.......................................................................C224

Straight Arrow Energy, LLC. ..........................................A1212

Sun-North Systems, Ltd. .................................................A314

Superior Attachments Inc. .....................................................V

Supervisor Systems.........................................................C527

TechMix, LLC ..................................................................C109

TerraKat LLC ...................................................................A208

The Coburn Company Inc. ..............................................A113

TLAY Dairy Video Sales ..................................................C124

TopCon ...........................................................................A410

Trans Ova Genetics.........................................................C534

TranSource Truck & Equipment Inc. ...............................A615

TriCal Superior Forage ....................................................C630

Trioliet B.V. ......................................................................C324

Tri-State Neighbor ...........................................................H107

Udder Comfort Inc. ........................................................AF110

Udder Health Systems, Inc. .............................................H109

Udder Tech Inc. ...............................................................C126

United Animal Health .......................................................C202

V & M Distributing ............................................................C802

Valley Dairy Farm Automation Inc. ..................................C635

Valley Queen Cheese......................................................H128

Van Beek Natural Science...............................................C504 Van

Ron Weiss

Territory manager with NDEco 23 years

Why is exhibiting at Central Plains Dairy Expo important to your business? It keeps us in touch with customers in the region and reinforces our brand recognition.

What will you be highlighting at CPDE this year? We will highlight the performance of our machines, durability upgrades, and local parts supply and support.

How long has your business been exhibiting at CPDE? Approximately 18 years. We have added more models over the years and moved into the arena to provide more space to show more than one model at the event.

What do you enjoy doing at the show when you are not working the trade show? I enjoy the entertainment, fellowship, food, cheese, wine and beer.

What do you hope to accomplish while at CPDE? Stay in touch with current customers, dealers, and show new prospects the advantage and value

of running an NDEco mixer.

Tell us a favorite memory you have from CPDE. Two or three years ago, both of my adult kids were able to spend time with me at the booth and meet a few customers and see more about what I have been doing for so many years.

Early in his career, Troy Brown gave himself the goal of spending 10% of his time working one-onone with his customers to improve their forage quality.

Brown is the forage product line manager for Form-A-Feed Inc. His breakout session will be held at 9:30 a.m. March 20 and 11 a.m. March 21.

“It’s always easier to be told how to farm than it is actually to farm,” Brown said. “I want to make it practical and understand the challenges that they face every single day.”

Brown will share about forage harvest and storage management, forage additive tools that can be used, and preventing and reducing pathogens in feed.

Brown said he focuses on forage management practices rst and utilizes tools such as additives second.

“This is where I was in my happy place because it really gave these producers the highest return on their investment of time,” Brown said.

Brown has spent about 37 years in the agriculture industry, with approximately 30 years focused on forage additives. He will be presenting “Stop Clostridium Problems Before They Start” at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“Ultimately, trying to help them become better forage producers is the bottom line (of this presentation),” Brown said.

“I’m constantly looking for ways to improve management practices which ultimately improve forage quality,” Brown said. “Additives are certainly very important, … but without good, sound management practices, all the additives in the world are not going to make a difference.”

Brown said in his years as a consultant, he has seen that high-quality forage can cover many mistakes on a dairy farm. He said dairy farmers with the most success are the ones who have good forage.

“You put high-quality forage in front of that animal, you get her bred back in a timely manner, and most of your problems on a dairy farm go away,” Brown said.

Brown said quality forage management happens in two areas: the aerobic area, which captures the management practices in the eld, and the anaerobic management that happens during storage. He said putting up good forage is simple but not easy.

Brown said air is the enemy in a fermentation feed storage system such as piles, bunkers, bags and upright silos.

“We need to extinguish the air as quickly as possible,” Brown said. “(Fermentation is) not going to occur if there’s trapped air somewhere in the system. Once we have fermentation, our desire then is to focus on how to prevent and reduce the negative effects of fermentation or the negative effects or presence of listeria and basically pathogens.”

Brown will also share three best practices for forage management.

He said the rst step is harvesting the forage at the proper moisture. Harvesting the forage too dry makes it difcult to pack and get all of the air out so it can ferment. Conversely, if it is harvested too wet, it has sub-optimal conditions to ferment because there is too much water in it for it to acidify.

He said the second step for good forage is to apply a lactic acid producing bacteria to direct the fermentation to the right place. Finally, the feed must be packed. Once the feed is packed, Brown said to make sure it is covered quickly with plastic if it is in a

storage system that needs this.

Brown said talking about quality forage is important to him because it is one way he can help farmers stay economically viable.

“It costs you the same amount of money to put up bad forage as it does to put up good forage,” Brown said.

Brown grew up on a beef farm. He worked on dairy farms in high school, and from there, his passion for the dairy community developed.

He attended college at the University of Wisconsin-River Falls for agribusiness. Brown joined Form-A-Feed seven years ago and brings over 35 years of forage management and consulting experience to speak from.

Brown said he considers himself a consultant rather than a salesman.

“Do what’s best for your customer rst,” Brown said. “Everything else just falls into place.”

Brown plans to speak for 30 minutes and allow 30 minutes for questions. He said he hopes people will come with questions.

“I try to keep it very practical,” Brown said. “I’m very conservative. My mentality is, ‘How can we do this without spending a lot of money?’”

Brown said he hopes his seminar will spur initiative. He said the information presented will not be new for farmers.

“They already understand, ... but sometimes hearing it and sometimes showing some economics (is helpful),” Brown said. “Hopefully, it creates action to go home and say, ... ‘I have been ignoring this part of my management for too long.’”

Thurs., March 21, 2024 • 9:30 am – 3 pm

Denny Sanford Premier Center • Sioux Falls, SD NEW DATE AND NEW LOCATION!

Enjoy more comfortable seating, tables and more room to learn.

9:00 am Registration

9:30 am Industry Outlook • Darrell Peel, Oklahoma State

10:30 am Beef on dairy economics: results of a video auction analysis • Dr. Ken Odde, Kansas State

11:30 am Q&A Session • Warren Rusche, moderating Noon Lunch

12:45 pm Genetic considerations for a more valuable calf Dr. Bob Weaber, Kansas State

1:45 pm How do dairy influenced cattle fit into value-based markets • Dr. Lauren Kimble, Select Sires

2:45 pm Q&A Session • Warren Rusche, moderating

3:15 pm Adjourn

As the weather warms, farmers will be welcomed by the usual swarm of ies that have decided to make their barns their homes.

Danny McDonald, a technical services manager with Control Solutions Inc., will be sharing information in a presentation, “Integrated Pest Management of Flies in Dairies,” at 2 p.m. March 20 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“Flies can have an impact on cattle weight and their rate of gain, and it can also have an impact on milk production,” McDonald said. “They can also be vectors of disease.”

This is why farmers must understand how to control the y population on their farms. There are many techniques to keep animals as healthy as possible.

“We are also going to go through the different techniques of the integrated pest management approach and go through products and how to use them and the different strategies,” McDonald said.

Danny McDonald Control Solutions Inc.

Danny McDonald Control Solutions Inc.

The presentation will be part of CPDE’s Ed Shed, which is available on the arena oor of the Denny Sanford Premier Center.

McDonald obtained his Ph.D. in entomology from Texas A&M University in 2012. For the past 19 years, he has studied pests and how to reduce their impact. He has been with his current employer for the past two years.

“We are going to be talking about the integrated pest management of ies on dairies,” McDonald said.

In his presentation, McDonald will share why it is important to manage ies.

Many processes can be used together to optimize the control of ies on a farm, McDonald said. These include pour-on products, surface or space spraying, insect growth regulators, biological controls and sanitation practices.

Along with this, the y population should be prevented starting at the source: manure. This is where insect growth regulators should be put into play.

The process used to manage the y population is based on its species.

“There are four y species that we are worried about, so we are going to learn about their biology and behavior along with why it is important to manage those specic species of ies,” McDonald said.

McDonald will be located at the Control Solutions booth in the trade show to answer questions before and after his presentation.

• INWOOD HATCHERY

Inwood, IA • 712-753-4736

• ROBERT FAUST

Strawberry Point, IA • 563-933-6561

• DAIRYLAND SUPPLY

Sauk Centre MN • 320-352-3987

• LINDELL SALES & SERVICE Cannon Falls, MN • 651-258-4311

• LEEDSTONE Melrose, MN • 800-996-3303

• SIOUX NATION VET SUPPLY Marshall, MN • 507-532-3716

• PIERZ CO-OP Pierz, MN • 320-468-6655

• RON MILLER Waconia, MN • 952-442-4808

• FLOODWOOD FARM & FEED Floodwood, MN • 218-476-2233

• BJERGA FEED Motley, MN • 218-352-6383

• FEDERATED CO-OPS Princeton, MN • 763-389-1567

• GORTER’S CLAY & DAIRY EQUIPMENT, INC. Pipestone, MN • 507-825-3271

• ADKINS EQUIPMENT

Detroit Lakes, MN

•

•

•

•

•

•Manufactured

•

•

•Modular

“The

Equipment sales at TranSource Truck and Equipment

Why is exhibiting at Central Plains Dairy Expo important to your business? It’s a great opportunity to socialize with our customers and show them the latest and the greatest products and equipment that we have to offer.

What will you be highlighting at CPDE this year? We will be featuring one of our new Volvo wheel loaders. We will also be running a dairy expo parts special.

How long has your business been exhibiting at CPDE? We have been exhibiting at the expo for more than 20 years. The expo has gotten bigger and better and has become one of the best shows out there. We like the expo’s location and the fact that there are so many dairies in this region.

What do you enjoy doing at the show when you are not working the trade show? I look forward to visiting with our customers and looking at other products at expo. I also enjoy eating the free ice cream and grilled cheese sandwiches.

What do you hope to accomplish while at CPDE? I hope to sell some products. I want to build relationships with new customers and maintain relationships with our current customers.

Tell us a favorite memory you have from CPDE. I enjoy hanging out with our customers during the social and bonding with them. I look forward to chatting with people and selling equipment to new and existing customers.

Garcia

Dellait will introduce its new three-dimensional dairy cow imaging system at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

Dellait, a global animal nutrition and health company that provides services and solutions to the livestock industry, is based in Brookings, South Da-

kota.

“The Dellait 3D biometric monitoring system equips dairy operators with the ability to conduct comprehensive monitoring of their cattle using advanced three-dimensional imaging technology,” said Myron Tiedeman, vice president of Dellait. “This innovative system signies the forefront of data gathering, offering a proactive and dependable approach to herd management.”

Dr. Alvaro Garcia, a dairy nutritionist with Dellait, will present a breakout session, “Using 3D Camera Technology to Accurately Measure Body Reserves, Growth and Locomotion in Dairy Cattle,” at 10 a.m. March 20 and at 1 p.m. March 21.

The Dellait 3D imaging system features a compact unit housing a powerful computer and a trio of

advanced cameras. This efcient setup, equipped with high-speed wi- connectivity, can be discreetly installed above the milking parlor’s exit alley. As each cow passes by, the system captures detailed 3D images with precision and efciency.

“The 3D imaging system will enable dairy operators to obtain body scores, changes in top lines, weights and heights, and detect signs of lameness daily,” Tiedeman said. “Early detection leads to prompt intervention, improved productivity and enhanced animal welfare.”

The system’s articial intelligence will help dairy operators analyze and track changes in each animal. For example, an unexpected decrease in a cow’s body condition score could be an indicator of incipient metabolic problems.

“Cattle metabolism responds to uctuations in weight and condition rather than static values,” Garcia said. “Nutritionists need to make timely adjustments based on these changes to enhance decision-making impact. Utilizing 3D cameras enables the quantication of these variations, facilitating necessary dietary and management strategies modications to achieve desired animal production and well-being goals.”

Farmers are cognizant of the labor savings that automation can bring to their operations.

Heat treated, mechanically extracted soybean meal

Excellent protein and energy source for lactating cows

High in intestinallydigestible, rumen undegradable (bypass) protein

Higher metabolizable energy than solvent extracted soybean meal products

Palatable to cows - all plant protein, no animal protein component

All natural, chemical-free process

Privately held company with excellent customer service

“Gathering information automatically and regularly can positively impact labor costs,” Tiedeman said. “Labor issues have become increasingly challenging. This makes it harder to maintain uniformity and consistency. The articial intelligence component of our system will continue to learn and thus aid dairy operators in achieving greater consistency. Our deep-learning A.I. will analyze the cows objectively and with reliable and repeatable results.”

Lameness presents signicant nancial burdens for dairy operators, potentially costing up to $300 per lame cow annually. These costs are attributed to a range of factors, including decreased milk production, diminished conception rates and prolonged calving intervals. Beyond direct economic losses, lameness also entails additional expenses related to veterinary care, treatment and labor, making it a multifaceted challenge that necessitates proactive management strategies. The 3D imaging system supports advanced detection, enabling farmers to take timely action and mitigate losses.

Collecting reams of information is of little use unless the operator has an uncomplicated way to access the data. The 3D system features a web-based app that displays information in a clean, easy-tounderstand format. An operator can log in from anywhere in the world on a personal computer, tablet or smartphone to view real-time data on each cow.

“Our interface is easy to use,” Tiedeman said. “We aim to simplify the lives of dairy operators by providing tools that offer readily accessible information. Dellait 3D will be a valuable tool that dairy managers can use alongside DairyComp and other software systems.”

Dellait is committed to taking a comprehensive approach, considering the entire cycle of feed, nutrition, management and technology to support its operators.

“Our company is dedicated to providing innovative solutions that address the challenges faced by dairy operators,” Tiedeman said. “From advanced 3D imaging technology to user-friendly interfaces, we are dedicated to equipping our customers with tools that enhance efciency and productivity. Dellait is committed to driving positive change in the dairy industry and helping our operators succeed in today’s dynamic market.”

Denny Sanford Premier Center, Sioux Falls, South Dakota

FREE ag PRAYER BREAKFAST

over 300 exhibitors

educational sessions

industry experts producers attend for free

FREE PANCAKE BREAKFAST

ED SHED PRESENTATIONS

WELCOME RECEPTION

WINE & CHEESE RECEPTION

FEATURING COUNTRY MUSIC STAR TUESDAY MARCH 19

When milking in tiestall and stanchion barns was the norm of the dairy industry, dairy farmers had frequent contact with their cows.

Since then, the dairy industry has moved toward freestall housing and robotic milking systems, and the focus has been on minimizing cow contact with the mantra of letting cows be cows.

Anderson will share how advances in monitoring technology are allowing dairy farmers to access real data about their animals, from birth on.

“There are so many management decisions that can be made based off the data that can be provided as we continue to improve the monitoring technology available through our SenseHub Dairy monitoring system,” Anderson said. “We have the ability to begin monitoring that baby calf on day No. 1 and follow her all the way throughout her life.”

Even with decreasing contact, dairy farmers can know more about their cows than ever before, thanks to the advances in monitoring technology.

Sarah Anderson, a dairy monitoring customer success specialist with Merck Animal Health, will lead a breakout session called “Using technology to make management changes” at 1:30 p.m. March 20 and at 11 a.m. March 21 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

SenseHub Youngstock is a new monitoring program that Anderson said she is excited to share with producers.

“This has been something dairy farmers have been asking for,” Anderson said. “I’m excited to see what we can do with it moving forward.”

Ear tags are applied to newborn calves. The SenseHub Youngstock algorithm is similar to the one used in the SenseHub Dairy program but specializes in calves and will monitor suckling behavior. Anderson said the system is designed to be used on bottle-fed calves that are individually housed.

Anderson said SenseHub Youngstock has been tested in three herds, with exciting feedback.

“The herds that tested the system said earlier interventions and treatments are being made, and they are seeing fewer calves needing retreating,” Anderson said. “The system also helps monitor protocols and protocol drift. The feedback we’ve received from the testing herds is that they can’t imagine being without the system after using it.”

Detecting illness visually in calves can be a daunting task, Anderson said, and in her presentation, she will detail how the system alerts calf raisers about calves that appear to be off.

“The SenseHub Youngstock tags are equipped with a ashing, white LED light that will activate when the health alert levels are triggered, giving a visual cue for calves needing intervention,” Anderson said. “It keeps it simple. When the light is on, something is off.”

As the heifers grow and prepare to enter the milking herd, Anderson said the tags can be switched to collars, or the animal can continue to wear an ear tag.

In addition to the advancements in monitoring calf health, Anderson said she is looking forward to sharing continued advancements made in the SenseHub Dairy system, particularly in the areas of detecting and mitigating the effects of heat stress on lactating cows.

“One thing we learned this past summer is that we can help with heat abatement by nding the coolest pens

in our barns and putting our highest producers in those pens,” Anderson said. “It’s simple, but it is effective.”

Anderson said add-ons such as sort gates and milking points can be incorporated through the SenseHub Dairy system to help enhance herd management while continuing to minimize direct cow contact each day.

“The monitoring technology isn’t anything new, but it is exciting because we are always improving it, making it better and increasing the information we can learn about our cows,” Anderson said. “People will especially enjoy learning about SenseHub Youngstock. It’s the newest and coolest thing, and people will see how that can benet their farms for themselves.”

Nutritional Support

Nutritional Support

• NFTA certified NIR forage lab

• Nitrate testing

• Complete lines of stock products

• Custom blending for any operation

• Minimal turnaround time

• Fleet of bulk and van delivery trucks

• Dairy, Beef Cow, Poultry, Swine, Goat supplements and Minerals

• Crystalyxand Ranchers Choice Tubs

“Over 35 years of service partnering with you”

“Over 35 years of service partnering with you”

Custom Feed Blending

Custom Feed Blending

• Canola Meal

• Soybean Meal

• DDGS

• Blood Meal

• Soybean Hulls

• Mono-Dical

• Soda

• JefoDairy Fat

• Calcium Carbonate

• Full assortment of VIT & Trace

• Yeasts and supplements

Call today to find out more

CALL TODAY TO FIND OUT

MORE AND EXPERIENCE THE DIFFERENCE

And experience the difference

Toll Free: (800) 955-2441

Phone: (605)665-2441

Toll Free: (800) 955 -2441

Frontiermills.com

Phone: (605) 665-2441

Frontiermills.com

BIGGERAUGERS.

BIGGERPERFORMANCE.

Ourcontinuous ightingsystempicksup morefeed,providesthebestliftactionand maintainsasteady,uniformreintroduction offeedbackintothemix.

ExperiencetheNDEcodi erence.

As 2024’s growing season approaches, there is more to think about than what to plant and when to plant it.

National alfalfa agronomist Randy Welch’s mantra is, “Don’t raise less than the best.”

Even as dairy farmers face tight margins, Welch suggests thinking about how today’s alfalfa seed decision will be impacting forage yield and quality four years from now.

Welch is an agronomist with Forage Genetics International. He will present “Leveraging Alfalfa Technologies in a Changing Environment” at 10 a.m. March 20 and 1 p.m. March 21 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

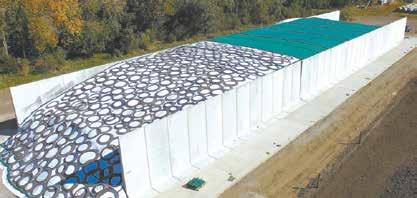

PHOTO SUBMITTED

Randy Welch will present “Leveraging Alfalfa Technologies in a Changing Environment” at 10 a.m. March 20 and 1 p.m. March 21 at the Central Plains Dairy Expo in Sioux Falls, South Dakota. Welch is an agronomist with Forage Gene cs Interna onal.

He plans to provide information on alfalfa technologies that can help handle current environmental conditions, advancing sustainability while maximizing production and growing the most nutritious forage for the dairy herd.

“Cutting corners by raising less

than the best yield and quality doesn’t change the cost for land, equipment and labor,” Welch said. “Many inputs remain the same. Cost per unit goes down with increasing yield and quality. Find the yield and quality limitations of your farm.”

Welch said forage digestibility drives milk production.

“Anything producers can do to increase forage digestibility will, in turn,

reduce the cost of production per unit,” Welch said. “Generally, if I raise better quality forage, I can reduce my feed cost.”

Welch said new technology, such as HarvXtra, in alfalfa addresses the challenge of raising better forage. HarvXtra is a genetic trait designed to help raise more digestible forage because it reduces the lignin content, improves forage digestibility and provides a wider harvest window.

Faced with an unusual winter preceded by drought across a good share of the Upper Midwest will present challenges for last fall’s alfalfa seeding, according to Welch. His concerns are twofold.

“Less than optimal water is on everyone’s radar,” Welch said. “The question is, ‘How do you manage soils to optimize water usage and retention?’”

Welch said he is concerned about herbicide carryover this spring because less moisture was available to decompose herbicides applied last year to the previous crops.

He has found herbicide labels vague when considering rotation to alfalfa in the spring. Tillage, rainfall, organic matter, date of application and soil texture could inuence the herbicide carryover risk from the previous herbicide.

Welch said producers should read the label of the previous herbicide carefully and consider whether additional tillage might help stir or dilute excessive carryover that could otherwise hurt the new alfalfa stand.

“Roughly one-half of my alfalfa trouble calls are related to herbicide carryover,” Welch said. “Farmers might see some bad spots in their stand and blame it on soil pH, disease or dry weather, but it could be leftover herbicide. It may be more noticeable this year. As we introduce more soil residual chemistry

to control weeds in corn, soybeans and wheat, there can be a negative inuence on new seedling alfalfa establishment.”

Welch said herbicide carryover requires “wait-and-see” management.

“Depending on how severe it is, many plants will tolerate the stress and ultimately recover,” he said. “On the other hand, if plants are outright killed and a thin stand results, waiting for the residual dissipation and replanting later is all growers can do.”

At the same time, soil compaction from numerous harvest operations and trips across elds can impact alfalfa’s root expansion and water usage. Technology will help better manage this in the future, Welch said.

Welch is condent today’s droughtresistant alfalfa varieties help ensure established stands will come back to full production this spring. His recommendations for any new seedings include choosing Roundup Ready alfalfa varieties as well as those with good disease resistance.

“It may have been dry last year, but it can be a wet spring,” he said. “That’s why we use maximum disease resistance in newer alfalfa varieties and new seed treatments that reduce diseases like Pythium during establishment.”

Welch said growers should consider AA disease-resistant alfalfa and varieties with UltraCut technology to combat new races of Aphanomyces and Anthracnose.

Those choices are among the items Welch plans to discuss with farmers as he brings them up to date on alfalfa technology during the CPDE session.

“You strive to raise the most crop and the best crop,” he said. “I want to raise the awareness of some of the issues 2024 may bring and help growers apply the tools to address them.”

Why is exhibiting at Central Plains Dairy Expo important to your business? We get to talk to both the dairy farm owners and their workers. We get feedback on what works and, more importantly, ideas on how to make our products better.

What will you be highlighting at CPDE this year? Ritchie water fountains.

How long has your business been exhibiting at CPDE? I’m not sure how long it’s been, but we have been exhibiting at the CPDE since it began at the old site in the Ramkota Convention Center. We get to show how our products have evolved over the years, from the all-steel fountains in the old days to the new, all-plastic models to the stainless-steel trough fountains. Our valves and many other features have also been updated.

What do you enjoy doing at the show when you are not working the trade show? I enjoy looking at all the other companies’ new products and improvements; watching the kids running around, investigating things; and seeing other exhibitors and friends.

What do you hope to accomplish while at CPDE? I hope to get more exposure in the dairy industry. I will also be answering questions and solving problems.

Tell us a favorite memory you have from CPDE. The year after the pandemic closed the show, a lot of new people from all over the country came to the Central Plains Dairy Expo. They were there to see new products and enjoy a minivacation. They came here because our state was open, and they could go to a restaurant and see a play, etc. It seems that many of them are still coming back year after year.

Minnie Ward has more than 20 years of raising calves under her belt. That experience tells her there are practical ways that work for raising calves. She plans to discuss those approaches in a session, “Practical Applications for Raising Calves,” at 11 a.m. March 20 and 8:30 a.m. March 21 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“Sometimes calf raisers get into the trenches and can’t see beyond this box (of practices) we created

for them,” Ward said. “There are things they might not even consider while they have their hands on the calf.”

For example, she said people may be so concerned about getting colostrum into the calf with a bottle or tube, they may not think about why the calf is not suckling or why it is slow to eat. A deeper understanding might help raise healthier calves.

“By giving (calf managers) the proper tools to use and understanding the whys and hows behind what we are asking them to do, we will help not only the calf but the person’s ability to understand the dynamics of their operation,” Ward said.

Ward plans to share the tricks she and her family use in their calf-raising operation, where they handle about 200 calves from birth to 4-5 months. She also has her own business, Everything Calves Consulting, and provides expertise to Feedworks USA by coaching its staff on calf raising.

Ward’s session will cover protocols calf managers should have in mind for calves at 5, 14 and 21 days, then on to post-weaning.

One piece of information she plans to share is from a recent Florida State University study that researched the in-utero calf and how colostrum absorption is impacted. With the calf inside the cow, she said, it is “cooked in a nice incubator.”

“How can that not affect it, with so much heat stress?” she said.

Ward also plans to talk about tube feeding and its implications for animal welfare.

“We all have to be concerned and diligent about handling our calves,” she said.

Ward said she hopes to emphasize the importance of having a very good calf person in the barn.

“It comes down to management,” Ward said. “If they don’t have the right person, their calf program is going to struggle.”

Another topic — hydration — relates directly to a new product Ward is using in a year-long research project for Feedworks USA. The company’s product is meant to be mixed with water and fed every day after the colostrum period to increase hydration without affecting milk intake.

Your future is now. And it starts with her. Help her maintain normal digestive health and support a functioning immune system with First Arrival® total eubiotics. This easy-to-feed product is available in powder or paste. Kickstart tomorrow’s production today.

“The rst 21 days are very signicant for keeping them hydrated,” Ward said. “We know that water drives dry matter intake, helps with circulation, builds that rumen and pushes them to eat more starter.”

Ward said, often, calf raisers only use electrolytes when it is extremely hot or if the calf is sick and scouring.

Be proactive with calf health. Scan for a free on-farm consultation with your local DBC representative.

“(Previously,) I was using a well-known product (on my calves), and I was diluting it because I wanted them to be hydrated,” Ward said. “This one is meant to be fed as oral hydration every day.”

While Ward said she understands calf raisers are reluctant to take more time or spend more money to add something new to their calf management, she believes using the product results in a healthier calf.

If a farm’s calf management does not include providing water, the product can be fed with milk.

“I understand the economics and time concerns, especially in winter,” Ward said. “I typically want hydration to be hydration and milk to be nutrition.”

Finally, Ward expects those attending her session may have questions relating to their challenges with calves during this year’s unusual winter.

“We typically go through a stretch of severe cold, which kills or retards the growth of pathogens,” Ward said. “I’m not going to say we haven’t enjoyed the (warmer) winter, but it’s had its challenges.”

Why is exhibiting at Central Plains Dairy Expo important to your business? Exhibiting is important to showcase our products, connecting with existing and potential customers, along with generating leads by engaging with attendees.

What will you be highlighting at CPDE this year? We will have two breakout sessions on Wednesday and Thursday, “MythBusters: The Truth about Lely Automation.”

How long has your business been exhibiting at CPDE? Gorter’s Clay and Dairy Equipment was involved since the beginning, participating for 23 years now. Over the last 23 years, the show has grown, which means our booth has grown. We change our booth with the trends and technology, and promote technology for the changing of the industry’s wants and needs.

What do you enjoy doing at the show when you are not working at the trade show? I personally enjoy exploring the exhibit booths and catching up with fellow industry colleagues. You create great friendships over the years, and this is the time to catch up with them.

What do you hope to accomplish while at CPDE? I hope to connect with potential customers, generate leads and showcase the products we have to offer along with strengthening our brand and reputation.

Tell us a favorite memory you have from CPDE. My favorite memories are always having fun at the concert with my fellow industry friends and customers.

Ed

HerbstGeneral manager at Sioux Dairy Equipment Inc.

24 years

Why is exhibiting at Central Plains Dairy Expo important to your business? It is a great venue to engage with a large group of our customers. What will you be highlighting at CPDE this year? We will be sharing videos of recent construction projects along with a few equipment items that help improve parlor efciency.

How long has your business been exhibiting at CPDE? We have been with CPDE since the beginning. We started with a single booth, and overtime, we grew into one of the larger booth spaces. We used to bring more equipment items to display and have shifted to providing an environment to help stimulate discussions about our customers’ current and future needs.

What do you enjoy doing at the show when you are not working the trade show? I like walking through

The advanced design of the CX74 housing and propeller produces a large volume of air and a high centerline velocity, exceeding any other fan in its class. Pairing the fan design with the all new Munters Drive G2 MAX EC Motor, takes the CX74 to the next level of both energy savings and control. Munters has over 10 years of experience engineering and producing EC motors. Trust the experience.

the show and seeing the new products and ideas on display.

What do you hope to accomplish while at CPDE? Continuing to show that we are an industry leader in dairy farm construction and equipment services.

Tell us a favorite memory you have from CPDE. When my boys can attend the show. It is great to see their excitement for the dairy industry.

This year’s Central Plains Dairy Expo Ag Prayer Breakfast will be led by the Merrill and Marlys Nettinga family of M&M Dairy of Hull, Iowa.

Merrill will share his faithbased journey and describe how God’s grace has helped his family build a sustainable farm business.

The free breakfast includes a hot breakfast buffet, yogurt, fruit, coffee and milk, and time for prayer and reection. Generous sponsors help offset breakfast costs. If you’d like to make a monetary donation during the breakfast, the proceeds will go to the Western Iowa Dairy Alliance’s banquet ministry. This group purchases numerous dairy foods for the meals and people they serve.

Ashley & Ellie will provide spirit-lifting music at the breakfast this year.

Ashley Egdorf is from Sioux Center, Iowa, where she resides with her husband, David, and their three daughters. She works part time as content coordinator for Text in Church. Ashley loves all things outdoors, singing and leading worship.

A Montana native, Ellie Waring grew up on a farm and now lives in Sioux Center, Iowa, with her husband, Colton, and two children. She is the creative director at RISE Ministries. Ellie is grateful for

the way God has used music in her life.

This duo regularly leads worship at the New Life Church in Sioux Center, Iowa. Occasionally, they provide music for the Mom Event, which is a community event for young mothers.

About the Nettinga family

M&M Dairy’s history dates to the 1940s when Garret Nettinga bought the farm. Following deployment from the Korean War, Garret’s son, Morris, bought the farm and began farming. He added beef cows and switched to dairy cows in the 1960s.

Morris and Vergie Nettinga grew their farm and had seven children. One child – Merrill –expressed interest in the farm. Merrill married Marlys in 1985 and took over the farm shortly thereafter, due to his father’s untimely death. They have two sons, Michael and Mitchell. Michael works for Lely and is married to Kylie, who is the Western Iowa Dairy Alliance executive director and former agriculture instructor at Western Christian High School in Hull, Iowa. Mitchell is married to Amber. Michael and Mitchell are the fourth generation to be a part of this family farm.

Today, M&M Dairy is composed of 100 Holstein cows and 1,000 acres of corn

and soybeans. Farm improvements have included barns, a shop, a silage pad, a lagoon and a herringbone milking parlor built in the early 2000s. Recently, the family installed two robotic milking units.

For crop production, they use minimum tillage methods

and cultivate in the spring. This past year, they tried their rst round of cover crops. All are welcome to the free CPDE Ag Prayer Breakfast March 20 at the Denny Sanford Premier Center in Sioux Falls, South Dakota.

In recent years, dairy producers have grown corn, soybeans and alfalfa on their land and not much else. As more research becomes available, the benets of rotating a variety of forages and adding cover crops in the rotation are being discussed.

“I help people grow the biggest pile of high-quality forage that we can,” Jeff Jackson said. “It’s (based on) decision making, management, variety selection and rotation selections.”

Jackson is the alfalfa and forage specialist with CROPLAN and will be discussing the benets of crop rotation and planning during his presentation, “FORAGE 360: Forage Rotations and Planning” at noon March 20 and 10 a.m. March 21 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

Jackson manages the U.S. brand for forage sorghum, grain sorghum and triticale.

Jackson said that ideally, land would have a winter cereal, a summer crop and something alive as many days as possible to gain more high-quality feed and a higher return on investment.

“There are a number of people who haven’t grasped how some of these other crops can t into their farms other than alfalfa and corn silage for feeding livestock,” Jackson said. “I hope there will

“There are a number of people who haven’t grasped how some of these other crops can t into their farms other than alfalfa and corn silage for feeding livestock. I hope there will be some questions so that we can do a little compare and contrast of different crops for inputs and outputs.”

JEFF JACKSON, CROPLAN

be some questions so that we can do a little compare and contrast of different crops for inputs and outputs.”