DAIRY ST R

March 11, 2023

First Section

March 11, 2023

First Section

Where dairy in the Central Plains comes together

maria.b@dairystar.com

SIOUX FALLS, S.D. – The Central Plains Dairy Expo is coming up. And with a full agenda, dairy producers and industry professionals from across the region should take note.

The annual dairyfocused event is March 28-30 at the Denny Sanford Premier Center in Sioux Falls.

This year’s expo features more than 300 exhibitors and 60 breakout sessions, including 10 sessions presented in Spanish. Trade show exhibitors will highlight innovative products, services and technologies rele-

vant to today’s dairy industry. Speakers amassing the two-day event will bring prominent presentations to the forefront for farmers and professionals alike.

“Every minute that dairy farmers attend Central Plains Dairy Expo will be spent in a very valuable way,” said Renee Brod, executive director of CPDE.

“The exhibitors that are attending are 100% dairy focused. They all have passion and desire to help dairy farmers and the dairy industry grow with the products and services they offer. All of our exhibitors and speakers will have information dairy farmers will nd benecial.”

CPDE will commence at 5:30 p.m. March 28 with its free Welcome Reception featuring Sara Evans, a multi-platinum entertainer

and the fth-most played female artist on country radio. Brod said CPDE allows attendees time for learning

as well as fun.

“They will be able to connect and network with other dairy producers,” she said. “They are not only get-

ting a priceless education from our seminars

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: (320) 352-6303

Fax: (320) 352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell)

320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Tiffany Klaphake - Assistant Editor

320-352-6303 • tiffany.k@dairystar.com

Maria Bichler - Assistant Editor

320-352-6303 • maria.b@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Stacey Smart - Staff Writer

262-442-6666 • stacey.s@dairystar.com

Abby Wiedmeyer - Staff Writer

608-487-4812 • abby.w@dairystar.com

Grace Jeurissen - Staff Writer

320-352-6303 • grace.j@star-pub.com

Jan Lefebvre - Staff Writer

320-290-5980 • jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks

320-352-6303 • joyce@dairystar.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, SD)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Amanda Hoeer (Eastern Iowa, SW WI)

320-250-2884 • amanda.h@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Kati Kindschuh (NE WI and Upper MI)

920-979-5284 • kati.k@dairystar.com

Julia Mullenbach (SE MN and NE IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN)

320-260-1248 (cell) • bob.l@star-pub.com

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication. Subscriptions

One year subscription $40.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

led by experts that are coming in to hold these breakout sessions, but they are also going to have afternoon and evening time where they can share what is going on in their lives with their passions around the dairy industry with others who are doing the same thing.”

The Central Plains Dairy Foundation’s fth annual Dairy Forward Auction is back this year with proceeds supporting dairy scholarships, workforce grants and community diversity programs in Iowa, Minnesota, Nebraska, North Dakota and South Dakota.

The March 28 silent auction features wine and cheese baskets, dairy art, concert tickets, hunting and shing trips, tickets to sporting events, livestock supplies and equipment and more.

The Prayer Breakfast will begin at 7 a.m. March 29. This year’s breakfast features Tim Lovelace, a Grammy and Dove Award nominated artist. This free event will showcase Lovelace, a nationally sought-after storyteller and musician.

The trade show doors open at 8:30 a.m. March 29 and features a free wine and cheese social starting at 4:30 p.m. Other complimentary items for CPDE visitors to enjoy include doughnuts, grilled cheese sandwiches and ice cream novelties. There will be a beer garden at the convention center. Proceeds from the 16-ounce tap beers will go toward CPDF’s initiatives. Tickets for the beer garden can be purchased online at https://e. givesmart.com/events/uP9/.

Educational breakout sessions will begin at 8:30 a.m. March 29. This year’s sessions will include several panels. A farm bill forum will be comprised of congressional representatives and their staff. Speakers will address Federal Milk Marketing Order reform, crop programs, and food and school lunch programs.

“With continued changes to the dairy industry and potential legislative changes to the farm bill in 2023, you do not want to miss this

year’s Central Plains Dairy Expo,” said Kris Bousquet, president of the Central Plains Dairy Association. “This year contains education and networking opportunities that are sure to have an impact on your business.”

A panel of farmers and processors will discuss the dairy industry in the next 10 years, and three dairy farmers will lead a panel discussion titled, “When do robots make sense? Understand the decisions involved in switching to automation.”

March 30 beings with a free pancake breakfast at 8 a.m. followed by a full day of trade show and breakout sessions.

New to CPDE this year are Ed Shed presentations. Found in the arena, Brod said these informal 30-minute exhibits will share the latest and greatest in research, product innovation and tools for a dairy farmer’s toolbox. These will be presented by Ralco, MGK Insect Control Solutions, Bio-Vet Inc., Cargill and MB Nutritional Sciences LLC.

“Our initial intent with this was to have it be product focused,” Brod said. “But, we really have some high impact big hitters coming in to talk in that informal format as well.”

Future Connections will be unveiled at CPDE. The new feature is geared toward the dairy industry’s up and coming generation.

“We are trying to create an ongoing platform at expo that will connect young dairy enthusiasts,” Brod said. “We want to help them connect and inspire them while bringing relevant dairy topics to the forefront for them.”

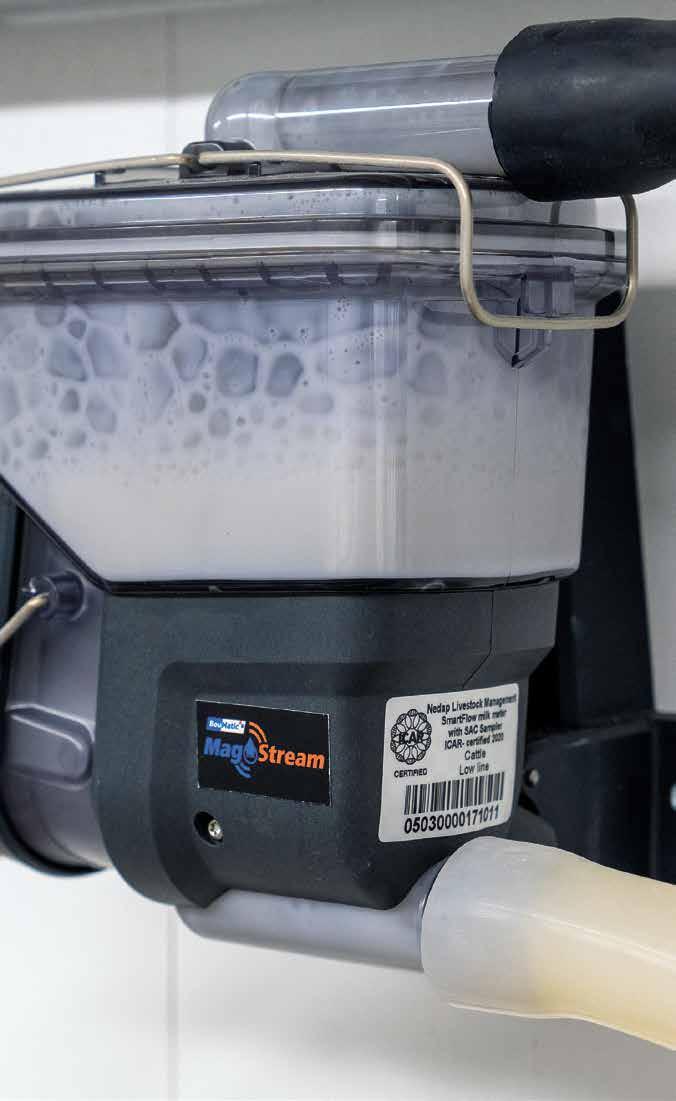

Dr. Jeffrey Bewley, from Holstein Association USA, will keynote Future Connections at 3:30 p.m. March 29. He will present, “Smart Dairy Technology, Excitement with Cautious Optimism.”

Bewley is a dairy analytics and innovation scientist and has worked with more than 50 dairy technologies during the last 18 years.

“He is going to speak to all the technology he has tested,” Brod said. “He is going to have a conversation with participants so they can understand more of the technologies that are up and coming.”

Attendees should preregister and can nd more information at www.centralplainsdairy.com.

By Jerry Nelson jerry.n@dairystar.com

By Jerry Nelson jerry.n@dairystar.com

Milk and commodity prices are inherently volatile, and dairy operators need to use every tool available to help them remain protable.

This topic will be explored in-depth during a breakout session that will be conducted by Jeff Toll, account executive with Chicago-based Commodity & Ingredient Hedging LLC. Toll is slated to give his presentation, “Dairy Margin Outlook and Strategies to Consider,” at 9 a.m. March 29 during the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“I want to help producers gain an understanding of today’s dairy and feed market fundamentals and how this volatility impacts the producer’s margins,” Toll said. “I will review the importance of having a margin management plan and walk through an education on different contracting tools to optimize exibility and protect protability.”

Jeff Toll Commodity & Ingredient Hedging LLC

Recent history provides a vivid illustration of the many ways extreme price volatility can affect a dairy operation’s bottom line.

“At this same time last year, forward margins for what is now spot rst quarter 2023 were projecting positive returns of over $4 per hundredweight for a model dairy operation,” Toll said. “That was around the 99th percentile of historical protability when looking back over the previous decade. Currently, that same rst quarter margin is now only barely breakeven on the open market.”

Dairy farmers are no strangers to price swings, but the past year has seen some truly neck-snapping changes, Toll said. Operators who made use of the tools available to them were able to cushion the blow by evening out some of the peaks and the valleys.

“Many things have transpired over the past year to impact the price of milk as well as the cost of feed for this marketing period, but in the big picture, the opportunity to protect a historically high level of protability was real,” Toll said. “And, it is now lost if there was no risk management plan in place to secure it.”

Despite recent drops in milk prices, there are opportunities for dairy operators to remain protable.

“Looking ahead later this year into fourth quarter of 2023 or rst quarter of 2024, positive margins are still projected for this same model dairy, and producers may want to consider defensive strategies to protect against the possibility of falling milk prices and/or rising feed costs,” Toll said.

During his breakout session, Toll plans to explore the current fundamentals of both the milk and feed markets as well as discuss forward margin opportunities that currently exist.

Toll said a variety of strategies could be considered to protect future price risk to secure forward margins. Toll will review basic option structures including calls and puts in addition to insurance market alternatives such as Dairy Revenue Protection or Dairy Margin Coverage to accomplish this.

“I hope to help dairy operators become more informed about ways to protect forward protability in their operations so they can take charge of their bottom lines,” Toll said.

4,000 cows

How many years have you attended Central Plains Dairy Expo? I have attended CPDE for three years.

Why is attending CPDE important to you and your dairy? It’s a great fellowship and networking opportunity.

What are three must do’s when you attend CPDE? The Prayer Breakfast was a great time last year; that’s an important part. My other two must do’s are ice cream and great food.

What seminars or booths are you interested in seeing? This year we are interested in seeing what new technologies are available and what’s new to the industry.

What have you incorporated on your farm from a previous CPDE? We are new to South Dakota so developing the relationships we are making out here. That’s the most important thing we’ve found. It is not particularly a product but getting to meet people face to face that we are doing business with.

What is your most memorable experience at CPDE? I got a bunch of free hats last year; that was pretty memorable.

What would you say to encourage other farmers to attend CPDE? It’s a great time of visiting and fellowship. Everybody is pretty relaxed and there to eat, greet and have a good time.

Tell us about your farm. We milk in an 80-stall GEA rotary parlor. We are mainly a Jersey herd. We employ 18 people. Some of my employees have been with me for about 25 years. We ship our milk to Agropur in Lake Norden, South Dakota. We purchase our feed from local farmers. We are having fun dairying in South Dakota.

Want to use recycled manure solids (RMS) as a sustainable bedding source? Worried about environmental mastitis and milk quality? Consider CERTILLUS™ Eco Dairy Bedding. By using beneficial bacteria to target pathogenic threats, it can help lower SCC counts and minimize concerns.

To learn more, visit booth H102 at Central Plains Dairy Expo, contact your ARM & HAMMER™ representative or visit AHfoodchain.com.

“It’s a great fellowship and networking opportunity.”MINNESOTA SOUTH DAKOTA RDOequipment.com

With exceptional support, quality service and reliable parts, RDO Equipment Co. is your

WATER MATTRESS

The AquaStar mattress (middle) actively dissipates the cows' body heat. The lying area has a temperature of 24.8°C degrees. You can also see the Aquastar mattress beside the cow on the right remains cool as does the Aquastar mattress under her.

Aquastar from Bioret Agri takes comfort to a whole new level. Compared to sand or conventional mats which can trap heat under the cow, its unique aqua transfer technology cools the cow while reducing pressure points.

Aquastar provides the benefits of a latex mattress combined with a waterbed for 3"- 4" of pure comfort, with the option of adding Bioret Agri's proven Aqua Board® kneeboard. The Aqua Board® keeps cows centred on the waterbed so they stay cleaner and cooler. Aquastar and Aqua Board® are built to deliver outstanding performance, with components warranted for up to 15 years; the best in the business.

Water Top Cover Latex Foam

Kneeboard

Sustainable innovation

519-320-0902

Water Pouch

By Stacey Smart stacey.s@dairystar.com

By Stacey Smart stacey.s@dairystar.com

When mating cows and heifers, feed efciency is a trait dairy farmers can start selecting for. By achieving the same level of growth and milk production with fewer inputs, a farmer can keep more money in their pocket.

“This is an opportunity to improve protability because feed is such an incredible expense on a dairy,” said Peter Dueppengiesser, central U.S. sales manager at STgenetics. “It’s also an opportunity to be greener.”

During his presentation, “The Genetic Fingerprint of Efcient Feed Conversion,” at the Central Plains Dairy Expo in Sioux Falls, South Dakota, Dueppengiesser will share information on Ecofeed® – a feed conversion index developed by STgenetics that identies animals with superior feed conversion.

“I feel Ecofeed is going to be very impactful because the difference in feed efciency between animals can be extreme,” Dueppengiesser said.

“Selecting for feed efciency provides an opportunity to save on feed costs.”

Dueppengiesser will speak at 4 p.m. March 29 and 10 a.m. March 30.

Dueppengiesser will highlight recent advancements in Ecofeed and discuss how it can improve the overall sustainability of the dairy industry while positively impacting a dairy producer’s bottom line.

one that has not been available before,” Dueppengiesser said. “And it’s very effective. It goes right to your bottom line based on the protability of feed conversion. If cow A is producing 100 pounds of milk, but cow B can produce the same with less intake, she’s going to be more protable.”

Ecofeed is a feed efciency measure for both dairy and beef cattle, and all the bulls in STgenetics’ lineup have an Ecofeed measurement. The company did trials on thousands of heifers to measure daily intakes and weight gains.

Ecofeed score as well.

“There are other measures of feed efciency, but they are highly correlated with body size,” Dueppengiesser said. “Ecofeed measures true feed efciency independent of body size.”

When comparing bulls, a farmer may decide to choose bull A if his daughters convert the same amount of feed better than the daughters of bull B, resulting in better feed conversions per pound of milk.

“Feed efciency is an independent measurement,” Dueppengiesser said. “You can select for Ecofeed without negatively or positively inuencing any other traits. It’s a protability measure, and our farms are putting emphasis on it.”

Peter Dueppengiesser STgeneticsDueppengiesser said dairy farmers are using the information provided by Ecofeed to make breeding decisions. When selecting genetics, farmers can rank for feed efciency along with other traits like Total Performance Index, net merit and udder composite, among others. According to Dueppengiesser, the heritability of feed efciency is reasonable and comparable to other traits.

“This is yet another measure but

“We started by measuring feed efciency with heifers to determine how much feed it takes for growth,” Dueppengiesser said. “Now, we’re doing it with milking cows, too, to learn how much feed it takes to produce a pound of milk. Feed efciency varies greatly between the progeny of one bull compared to another sire.”

During his talk, Dueppengiesser will share data along with details of the scoring system used to rank bulls on feed efciency. Bulls are ranked on a scale where a score of 100 is neutral. For every 10 points above this score, animals are consuming 1 pound less dry matter with equal performance. Heifer calves genomically tested through STgenetics can receive an

Dueppengiesser sees the benets of Ecofeed extending past the farm and positively impacting the environment as well.

“Dairymen are getting pressure to be greener, and this is an opportunity to really impact that area,” Dueppengiesser said. “If cattle can produce the same with less feed and we can select on that genetically, it can be a huge win for the industry because then we produce the same with less. Not only does the dairy prot but so does the consumer and the environment. It’s a win-win.”

“ We move heifers

5 to 6 months

right away and we don’t see them lying

rarely have

stalls

As a journalist who spent her career sitting down with dairy farmers and telling their stories, Peggy Coffeen has heard from farmers about what keeps them up at night. A lot of it has to do with managing employees.

“How many times have you heard that cows are easy, people are hard,” Coffeen said. “There is a new level of information that people are seeking and so much of it is around how to learn and manage people.”

Coffeen is the founder of the “Uplevel Dairy Podcast.” She will present “Set yourself up for success: How to retain, engage and empower employees” at the Central Plains Dairy Expo in Sioux Falls, South Dakota. She will speak at 10:30

a.m. March 29 and 9:30 a.m. March 30.

Coffeen said managing employees is a common challenge for dairy producers.

“The retention, engagement and empowerment were denitely key things that came up,” Coffeen said.

“How can we not just attract people, but keep them? How do we get them to care more about what we are doing, and how can we get them to take on larger roles and leadership, managing other people?”

The presentation will include ve things that ef-

fective dairy managers are doing differently, featuring examples and stories from managers she sat down with on her podcast. Coffeen said an effective manager does not have a phone that rings constantly and does not lose sleep worrying about who will or will not show up for a midnight shift change.

“They’re the people who are saying that turnover isn’t what keeps them up at night,” Coffeen said. “It tells you that they’re not constantly under re. They’re able to delegate and motivate their teams.”

One commonality Coffeen has discovered in talking with effective managers is what one producer refers to as shoulder time. It is the intentional effort to talk with every single employee every single day.

“It’s meeting people where they’re at,” Coffeen said. “The intention of having those conversations and that time together is a huge part of making employees feel like they are in the right place, and that’s such a foundational step in that bigger piece of retention that can

get you to those next levels of engagement and empowerment.”

This presentation, sponsored by the Golden Calf Company, will also include how founders Andy and Dagmar Bechtel support these same success factors with their products, services and technologies for helping dairy producers achieve their calf health goals.

Sometimes, the need for a higher level of employee engagement comes when producers go through an expansion. The owner needs to transition from being the person who is good with cows to the person who is good with people.

“It’s kind of that jumping point,” Coffeen said. “I’m looking through the lens of 1,500 cows or more. That seems to be in my mind where the layers of management start to form.”

Coffeen said there are takeaways that will apply to anyone, but a lot of the conversations surround farms with multiple layers of management. Some of the producers she will reference in

her presentation manage 50 employees or more.

Coffeen is taking the experiences and stories from her podcast guests, as well as friends in the industry, and presenting them as a way to be a resource for the industry.

“I consider it almost like an anecdotal study,” Coffeen said. “Being able to collectively take a couple of steps back and say what can we learn and capsule from these people that are doing things right and put it in a perspective that others can take home and implement so that they can improve their retention and engagement.”

Coffeen’s goal with the presentation is to help effective managers share their wisdom with others.

“I see their skills, and I see their leadership and the things that they are doing that make them unique and inspire me,” Coffeen said. “I can share that with other people who can grab a few nuggets that will help them with their daily management in some way or be inspired to do something different.”

Tom

Tom

Goodwin, South Dakota Deuel County

Goodwin, South Dakota Deuel County

1,200 cows

How many years have you attended Central Plains Dairy Expo? I have attended the expo every year since it started. I haven’t missed even one.

Why is attending CPDE important to you and your dairy? It’s a great opportunity to talk to other dairy farmers and get new ideas.

What are three must do’s when you attend CPDE? I have to look at all of the displays, attend some of the breakout sessions and visit with people.

What seminars or booths are you interested in seeing? I don’t have anything particular in mind. I am looking forward to seeing everything.

What have you incorporated on your farm from a previous CPDE? We got some ideas at the expo that helped us out when we decided to expand our dairy facilities.

What is your most memorable experience at CPDE? I have especially enjoyed many of the speakers and the musical performances at the Welcome Reception.

What would you say to encourage other farmers to attend CPDE? Take a day off and come to the expo and see what you can learn. A person needs to be exposed to new ideas.

Tell us about your farm. I farm with my brothers Mike, Pete and Rick. Our mother, Orma, is still involved with the dairy at age 91. She continues to paint murals on our farm buildings. My sons, Joe and Donald, have become involved with the operation as has my nephew, Brad, who is in charge of the crops. We have 15 employees and sell our milk to Valley Queen Cheese Factory in Milbank, South Dakota.

“Take a day off and come to the expo and see what you can learn. A person needs to be exposed to new ideas.”

Fieber

5:00 PM Doors Open

5:30 Welcome Reception Program Begins

9:00 PM Sheraton Hospitality Room

6:30 AM Ag Prayer Breakfast

8:30 AM Trade Show Floors Open

8:30 AM Silent Auction Opens

8:30-10:30 AM Free Donuts

8:30 AM-5:30 PM Breakfast Bar & Beer Garden Open

8:30-9:30 AM BREAKOUT SESSIONS

Sustainability: not one-size-fits-all and what consumers really think! - Dr. Marissa Hake (Sponsored by TechMix, LLC) MR 6/7

SPANISH SESSION: ¿Que te dicen los números sobre el manejo de tu rebaño lechero? - Patricia Villamediana & Maristela Rovai

MR 11

(Sponsored by SDSU)

9:00-9:30 AM ED SHED SESSION: Non-antibiotic alternatives that work for raising healthy calves - David P. Casper (Sponsored by Ralco) Ed Shed

9:00-10:00 AM BREAKOUT SESSIONS

Dairy Margin Outlook and Strategies to Consider

- Jeff Toll (Sponsored by CIH/Commodity & Ingredient Hedging, LLC) MR 8/9/10

A Global Perspective on Sustainability: Opportunities and Definitions - Fabian Bernal M.S., PAS (Sponsored by DeLaval Group) MR 1/2 Next generation of dairy insights - Stephanie De Vries

(Sponsored by VAS)

“Sugar: What’s the Sweet Spot?” - Dr. Rick Lundquist

(Sponsored by Westway Feed Products)

10:00-10:30 AM ED SHED SESSION: Fly control: An integrated pest management approach for dairy facilities - Christy Jones

(Sponsored by MGK Insect Control Solutions)

12:00-1:00 PM BREAKOUT SESSIONS

Dairy Markets from a Global Viewpoint

- Mary Ledman (Sponsored by Edge Dairy Farmer Cooperative) MR 8/9/10

Common Stressor that Cause Inflammation and Potential Dietary Strategies to Manage it - Lance Baumgard

(Sponsored by United Animal Health) MR 14

Mycoplasma, the Cunning Chameleon - Dr. Matt Boyle

(Sponsored by Zoetis Animal Health) MR 12

12:30-1:30 PM Making the most efficient milk: a proven concept to produce more without breaking the bank. - Dr. Andre Pereira

(Sponsored by Land O’Lakes/Purina/Croplan) Premier Center

1:00-2:00 PM Calf Care Seminar: Common problems that challenge your calf program when protocols drift

- Mario Solis Flores (Sponsored by Form-A-Feed) MR 6/7

1:00-1:30 PM ED SHED SESSION: Manage heat stress to improve milk production and profitability - Tim Thompson

(Sponsored by Cargill/Provimi) Ed Shed

1:30-2:30 PM The Changing Tide of Terms and Conditions in Insurance

Coverage - Allen Schlenker (Sponsored by Marsh McLennan Agency) MR 8/9/10

2:00-2:30 PM ED SHED SESSION: Nutritional Strategies to Address Emerging Challenges with Beef x Dairy Calves. - Michael A Ballou, Ph.D.

(Sponsored by MB Nutritional Sciences, LLC) Ed Shed

2:00-3:00 PM Hay Supplies, Use, and Left-Overs - Jack Davis

(Sponsored by Northern Forage Association) MR 11

2:00-4:30 PM Free Ice Cream

2:30-3:30 PM BREAKOUT SESSIONS

TMR fermentation characteristics of top-producing herds with over 7 lbs of components - Kai Yuan, Ph.D., PAS

10:00-11:00 AM

BREAKOUT SESSIONS

10:30-11:30 AM

MR 14

MR 12

Ed Shed

Reducing Pathogen Loads in Recycled Manure Solids Used as Dairy Bedding - Ben Saylor, Ph.D., PAS

(Sponsored by Arm & Hammer Animal Nutrition)

MR 13

SPANISH SESSION: Salud y bienestar de las becerras, soy yo responsable? (Calf health; am I responsible?) - Jorge Luna

(Sponsored by Zoetis Animal Health)

Sustainability for Profit: A Producer Panel

- Panel of Producers (Sponsored by Feedworks USA, Ltd.)

BREAKOUT SESSIONS

MR 11

MR 6/7

Maximizing raw material utilization and feed efficiency

- Dr. Amanda Gehman (Sponsored by Alltech) MR 1/2

Trace Mineral Supplementation is NOT for Dummies!

- Craig Louder, DVM (Sponsored by Axiota Animal Health, Inc) MR 12

Dairy market outlook: consumers take the wheel

- Ben Laine (Sponsored by Farm Credit) Premier Center

Set yourself up for success: How to retain, engage and empower employees - Peggy Coffeen

(Sponsored by Golden Calf Company) Room MR 8/9/10

Managing Transition Cow Inflammation on the Farm

- Barry Bradford, Ph.D. (Sponsored by Phibro Animal Health) MR 14

11:00 AM-1:00 PM Free Grilled Cheese Sandwiches

11:00 AM Dairy Girl Network Luncheon

11:00-11:30 AM ED SHED SESSION: Transition cow success: Technologies and economics - William A. Zimmer D.V.M. (Sponsored by Bio-Vet, Inc.) Ed Shed

11:30 AM-12:30 PM BREAKOUT SESSIONS

When do robots make sense? Understand the decisions involved in swiching to automation. - Andy Meyer, Dan Venteicher and Bill Demerath

(Sponsored by Gorter’s Clay & Dairy Equipment/LELY) MR 6/7

Transition cow management: Solutions for dry matter intake to enhance colostrum, health, and productivity

- Gustavo Schuenemann, D.V.M., MS, PhD.

(Sponsored by Jefo Nutrition USA Inc) MR 13

SPANISH SESSION: Herramientas visuales de capacitación en las lecherías para motivar y retener a los empleados (On-Farm Visual Training Tools to Motivate and Retain Employees)

- Jorge Delgado (Sponsored by Alltech) MR 11

(Sponsored by Quality Liquid Feeds, Inc.) MR 6/7

Farm Bill Panel - Congressman Brad Finstad, Congressman Don Bacon, Dorothy Clark and Nick Lunneborg MR 12/3/14

3:30-4:30 PM Smart Dairy Technology, Excitement with Cautious Optimism - Dr. Jeffrey Bewley (Sponsored by Holstein Association USA, Inc.) MR 1/2 4:00-5:00 PM

The Genetic Fingerprint of Efficient Feed Conversion

- Peter Dueppengiesser (Sponsored by STgenetics) MR 6/7

SPANISH SESSION: Diez puntos clave para una buena inmunización del ganado lechero (Ten key points for a good immunization of dairy cattle). - Tiago Tomazi

(Sponsored by Merck Animal Health in Spanish) MR 11

4:30-5:30 PM Free Wine & Cheese Social on the Trade Show Floors

5:30-7:30 PM Dairy Checkoff Taste and Learn Experience

- Molly Pelzer, Midwest Dairy MR 8/9/10

5:30 PM Trade Show Floors Close

8:00 AM

Show Floors Open

8:00-10:00 AM FREE Pancake & Sausage Breakfast

8:00-9:00 AM SPANISH SESSION: Herramientas visuales de capacitación en las lecherías para motivar y retener a los empleados (On-Farm Visual Training Tools to Motivate and Retain Employees)

- Jorge Delgado (Sponsored by Alltech in Spanish) MR 12

8:30-9:30 AM

TMR fermentation characteristics of top-producing herds with over 7 lbs of components - Kai Yuan, Ph.D., PAS

(Sponsored by Quality Liquid Feeds, Inc.) MR 6/7

Mycoplasma, the Cunning Chameleon - Dr. Matt Boyle

(Sponsored by Zoetis Animal Health) MR 13

9:30-10:00 AM ED SHED SESSION: Recent practical impacts of rumen-protected B vitamins in the Upper Midwest - Dr. Gerald D Mechor MVSc

(Sponsored by Jefo Nutrition USA Inc.) Ed Shed

9:30-10:30 AM BREAKOUT SESSIONS

Common Stressor that Cause Inflammation and Potential Dietary Strategies to Manage it - Lance Baumgard

(Sponsored by United Animal Health) MR 14

9:30-10:30 AM

Set yourself up for success: How to retain, engage and empower employees - Peggy Coffeen (Sponsored by Golden Calf Company) MR 8/9/10

SPANISH SESSION: ¿Que te dicen los números sobre el manejo de tu rebaño lechero? - Patricia Villamediana & Maristela Rovai

(Sponsored by SDSU)

11:30 AM-12:30 PM “Sugar: What’s the Sweet Spot?”- Dr. Rick Lundquist

(Sponsored by Westway Feed Products) MR 3

12:00 PM Silent Auction Closes

12:00-1:00 PM The Changing Tide of

10:00-11:00 AM

BREAKOUT SESSIONS

Dairy in the next 10 years: Perspective from farmers and processors - Panel of Farmers & Processors

(Sponsored by Edge Dairy Farmer Cooperative)

Sustainability for Profit: A Producer Panel

- Panel of Producers,(Sponsored by Feedworks USA, Ltd.)

MR 12

Reducing Pathogen Loads in Recycled Manure Solids Used as Dairy Bedding - Ben Saylor, Ph.D., PAS

MR 3

MR 6/7

Making the most efficient milk: a proven concept to produce more without breaking the bank. - Dr. Andre Pereira

(Sponsored by Land O’Lakes/Purina/Croplan)

The Genetic Fingerprint of Efficient Feed Conversion

- Peter Dueppengiesser (Sponsored by STgenetics)

11:00 AM-1:00 PM Free Grilled Cheese Sandwiches

11:00 AM-12:00 PM BREAKOUT SESSIONS

MR 1/2

MR 13

(Sponsored by Arm & Hammer Animal Nutrition) MR 14

SPANISH SESSION: Diez puntos clave para una buena inmunización del ganado lechero (Ten key points for a good immunization of dairy cattle). - Tiago Tomazi

(Sponsored by Merck Animal Health) MR 12

Bacteria: The Key to Healthy Cows - Craig Louder, DVM

(Sponsored by Axiota Animal Health, Inc) MR 13

A Global Perspective on Sustainability: Opportunities and Definitions - Fabian Bernal M.S., PAS (Sponsored by DeLaval Group) MR 1/2

Managing Transition Cow Inflammation on the Farm

MR 8/9/10

When do robots make sense? Understand the decisions involved in swiching to automation. - Andy Meyer, Dan Venteicher and Bill Demerath (Sponsored by Gorter’s Clay & Dairy Equipment/LELY)

Maximizing raw material utilization and feed efficiency

- Dr. Amanda Gehman (Sponsored by Alltech)

MR 14

SPANISH SESSION: Seminario en Crianza de Becerros: Problemas mas comunes que afectan el programa de crianza de becerros cuando los protocolos establecidos se desvian involuntariamente. - Mario Solis Flores

(Sponsored by Form-A-Feed)

11:30 AM-12:30 PM BREAKOUT SESSIONS

MR 12

Sustainability: not one-size-fits-all and what consumers really think! - Dr. Marissa Hake (Sponsored by TechMix, LLC)

MR 1/2

Next generation of dairy insights - Stephanie De Vries

(Sponsored by VAS)

4-D Ag World/4-D Ag Fashion .......................................................C

A Bar K Trailers .......................................................................A219

A1 Mist Sprayers ....................................................................A513

ABS Global ..............................................................................C306

ADA Enterprise Inc ..................................................................A115

Adisseo ...................................................................................C328

Archer Daniels Midland Company ...........................................C632

Advanced Ag Products ............................................................C804

Afimilk .....................................................................................A306

Ag Processing, Inc. ................................................................C628

Ag Property Solutions .............................................................C904

Ag United of South Dakota/South Dakota Dairy Producers .........BB

Agpro, Inc ...............................................................................A312

Agri Feed International, LLC ....................................................C407

Agri-King, Inc. .........................................................................C404

Agri-Placement Services, Inc. .................................................A103

Agri-Plastics/Agri-Comfort ......................................................C724

Agri Pro Enterprises ..............................................................A1113

AgriSteel .................................................................................C500

AgroChem USA, LLC ...............................................................C730

Agromatic ...............................................................................C704

Agropur, Inc. ...........................................................................C122

Agrovive Biologicals ................................................................C332

AHV USA .................................................................................A505

Albers Dairy Equipment ..........................................................C507

Alltech .....................................................................................C415

Amelicor..................................................................................H113

American AGCO Trading Co. ...................................................C629

American Dairymen/Twin Rivers Media...................................C128

American Jersey Cattle Association ........................................H100

American Wagyu Association ................................................A1103

AMPI .......................................................................................A400

Anez Consulting, Inc. ..............................................................C633

Animal Health International .....................................................C530

Animat Inc.............................................................................A1011

Arm & Hammer Animal Nutrition ............................................H102

Armor Animal Health ...............................................................C228

Arnolds of Kimball, Inc............................................................C433

Artex Manufacturing/Farmers Union Industries ......................A406

Balchem Corporation ..............................................................A106

Bazooka Farmstar .................................................................A1008

BECO Dairy Automation ..........................................................H110

Big Bear Genetics ....................................................................A410

Bioret Agri .............................................................................AF111

Bio-Vet Inc. .............................................................................H113

- Barry Bradford, Ph.D. (Sponsored by Phibro Animal Health) MR 6/7 1:00-3:00 PM Silent auction item pick-up

Hay Supplies, Use, and Left-Overs - Jack Davis

(Sponsored by Northern Forage Association) MR 11

SPANISH SESSION: Salud y bienestar de las becerras, soy yo responsable? (Calf health; am I responsible?) - Jorge Luna

(Sponsored by Zoetis Animal Health) MR 12 3:00 PM Trade Show Floors Close

MR 6/7

BioZyme, Inc .........................................................................A1106

BluTeQ Infrared Drying Solutions ............................................A303

Boehringer Ingelheim ..............................................................C211

Bohning Ag .............................................................................A413

BouMatic .................................................................................C232

Bovine Hoof Adhesives/Glue-U Inc. ........................................A313

Butler Machinery Company .....................................................A803

Byron Seeds, LLC ...................................................................H132

CalfStart LLC ...........................................................................H121

Calf-Tel ...................................................................................C400

Cambridge Technologies .........................................................C309

Canarm AgSystems.................................................................A205

Central Confinement Service LLC............................................A108

Central Life Sciences ....................................................................M

Central Valley Dairy & Midwest Dairy Robotics .......................A402

Chamberlain Oil Co., Inc. .....................................................A1104

Chr. Hansen.............................................................................C114

CIH/Commodity & Ingredient Hedging, LLC ...........................C113

Cloverdale ...............................................................................A800

Corteva Agriscience MCS, LLC - Dairyland Seed ...................A600

Countryside Dairy/Countryside Environmental Solutions ........C304

Creative Genetics of California, Inc. ........................................C703

Crystal Creek Natural ..............................................................A209

Cumberland Valley Analytical Services ....................................H127

Current Defense ......................................................................A116

Midwest Dairy Solutions .........................................................C230

Dairy Farmers of America .....................................................AF102

Dairy Star ................................................................................C220

Dairyland Laboratories ............................................................C604

DairyVisor Inc. ........................................................................C304

Datamars Livestock.......................................................................T

Dave’s Repair ..........................................................................C818

DeHaan, Grabs & Associates, LLC ..........................................C835

Dellait - Animal Nutrition & Health ..........................................C301

Deluxe Animal Health .......................................................C610 & B

Development Resources of Iowa, Inc. .....................................C600

Diamond V ..............................................................................C402

DM Concrete Grooving..................................................................Z

Diesel Machinery Inc...............................................................C832

Doda USA .............................................................................A1003

Dordt University ............................................................................L

EASYFIX Livestock Comfort ....................................................C731

Edge Dairy Farmer Cooperative ...............................................C330

Elanco Animal Health ..............................................................C427

Ellis Design and Coatings ......................................................A1111

ENDOVAC Animal Health .........................................................C200

Equipment Blades ...................................................................A315

Essential Water Solutions, Inc.................................................A405

Ever.ag ....................................................................................C708

Evergreen Village ..................................................................A1107

Evolution Spray Foam .............................................................A309

Excel Machine & Mfg ..............................................................C901

Faber’s Farm Equipment..........................................................C121

FAMO Feeds, Inc. ....................................................................C702

Farm Inc ..................................................................................C609

Farm Systems .........................................................................A313

FarmFirst Dairy Cooperative ....................................................C734

Supervisor Systems ................................................................C527

Feedworks USA, Ltd. ...............................................................C511

FERA Diagnostics and Biologicals Corp ..................................C327

Fermented Nutrition ..............................................................A1210

Fieber Van’s Implement Inc. ....................................................C828

Form-A-Feed ...........................................................................C134

Frontier Mills Inc. ....................................................................H125

GEA Farm Technologies Inc. ...................................................C618

Genex Cooperatives, Inc. ........................................................C101

Golden Calf Company..............................................................C430

Gorter’s Clay & Dairy Equipment.............................................C521

Gorter’s Clay & Dairy Equipment/LELY ....................................C318

Hanson Silo Company .............................................................C518

Hatfield Mfg. Inc. ....................................................................C902

Hawke & Company Ag ............................................................C824

Hawkins Inc. .........................................................................A1109

Heart of America DHIA ............................................................H126

Hoard’s Dairyman .........................................................................G

Hoppe Roofing Inc. .......................................................................C

Hover Chute ............................................................................C509

Hubbard Feeds Inc. .................................................................C115

Hundertmark Cleaning Systems, Inc. ....................................A1013

I-29 Moo University Collaboration ..........................................A203

Intercomp .............................................................................A1012

Interstate Commercial Laundry, LLC ..............................................F

Iowa Area Development Group ...............................................C605

J & D Manufacturing ...............................................................C826

J. B. Hunt Ag Services ..................................................................X

Jefo Nutrition USA Inc ............................................................H135

Johnson Concrete Livestock Waterers ....................................H134

EXHIBITORS CONTINUED ON NEXT PAGE

Johnson Engineering Group, LLC .........................................A1108

Jones-Hamilton Co .................................................................A111

K2S Engineering Inc................................................................C806

Kampert Ag LLC ......................................................................A212

Kemin Animal Nutrition & Health ............................................C209

Kent Nutrition Group ...............................................................C607

Kooima Ag ..............................................................................C626

Kuhn North Amercia ................................................................C822

Kunafin “the insectary” .........................................................A1105

KVK USA ...............................................................................A1014

Lallemand Animal Nutrition .....................................................C208

Land O’Lakes/Purina/Croplan ..................................................C215

Landmark Builders ..................................................................A510

Lange Ag Systems, Inc. ..........................................................A902

Lankota ...................................................................................A607

Lawley’s, Inc. ..........................................................................C603

Leedstone ...............................................................................C321

Legend Rubber Inc..................................................................A515

Maas Energy Works ................................................................A802

MAI Animal Health ..................................................................A104

Marloo Equipment...................................................................C809

Marsh McLennan Agency........................................................C411

Masters Choice/Rob-See-Co, LLC ...........................................A107

MB Nutritional Sciences ...............................................................C

McFinn Technologies ..............................................................A511

McLanahan .............................................................................C701

MEDA/Chemstar & Milk-Rite USA .........................................AF100

Mensch Mfg ............................................................................C613

Merck Animal Health ...............................................................C206

MGK Insect Control Solutions .................................................C602

Micro Technologies and MWI Animal Health .........................AF105

Midwest Ag Supplements .......................................................C308

Midwest Dairy ........................................................................C204

Midwest Livestock Systems, LLC............................................C624

Minnesota Department of Agriculture .....................................C303

MN DHIA (MN Dairy Herd Improvement Assoc.) ..................AF104

MTech Dairy Solutions ............................................................C326

Axiota Animal Health, Inc ........................................................H111

Munters ..................................................................................C111

National Cattlemen’s Beef Association ....................................A211

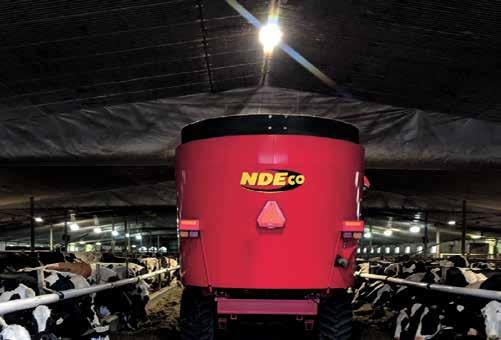

NDE co / New Direction Equipment Co....................................A603

Nebraska NSDA - AFAN .................................................................N

Neogen..........................................................................................H

NeoSpectra by Si-Ware ...........................................................A210

Nextire Inc. & Forklift Tire Inc. ................................................C510

New Vision Co-op ...................................................................A211

Norbco ..................................................................................A1213

North Central Steel Co.............................................................A307

Northland Farm Systems ......................................................A1003

Novita Nutrition (NovaMeal)....................................................C331

Novus International .................................................................C935

NuAge Builders .......................................................................A412

Nu-Force Water Technologies, LLC .........................................A208

Nuhn Industries Ltd ................................................................A619

NutraDrip Irrigation ...............................................................A1211

Nutrient Advisors ..........................................................................Y

Osakis Silo Repair DBA: WW Erection ....................................C728

Pacer Technology, Inc ...........................................................A1114

Pacific Ag, Pacific Ag Renewables ................................................Q

Passion Ag ..............................................................................A411

Phibro Animal Health ..............................................................C221

Pifer’s Auction & Realty ........................................................AF109

Pioneer Seeds .........................................................................H101

Pivot Bio .................................................................................C300

PortaCheck Inc ........................................................................A314

Post Equipment Company .......................................................C424

Powerlift Hydraulic Doors .......................................................A414

Prairie Farms...........................................................................A105

Prairie Land Ag Supply Inc......................................................C235

ProfitProAg .............................................................................A206 Progressive Dairy....................................................................H115

Promat ....................................................................................A310

Provimi North America............................................................H122

PSI Power Washer ........................................................................P

Puck Enterprises ...................................................................A1203

QC Supply ...............................................................................C906

South Dakota State University, College of Ag, Food & Environmental Science ...................................................K Soy Best ..................................................................................C226

Steelwerx ................................................................................C807

Steffes Group ........................................................................A1010

Steuart Labs ............................................................................C501

STgenetics ..............................................................................C224

Stuhr Enterprises LLC ..........................................................A1207

Sun-North Systems, Ltd .........................................................A602

Superior Attachments Inc. ............................................................V

TechMix, LLC ..........................................................................C109

TerraKat LLC ...........................................................................A109

The Coburn Company Inc. ......................................................A113

TLAY Dairy Video Sales ...........................................................C124

Trans Ova Genetics .................................................................C534

TranSource Truck & Equipment Inc .........................................A615

TriCal Superior Forage.............................................................C630

Trioliet B.V. ..............................................................................C324

Tri-State Neighbor ...................................................................H124

Tunnel Plus .............................................................................A612

Udder Comfort Inc. ...............................................................AF110

Udder Health Systems, Inc......................................................H109

Udder Tech Inc. .......................................................................C126

United Animal Health ..............................................................C202

V & M Distributing ..................................................................C810

Valley Dairy Farm Automation Inc. ..........................................C635

Valley Queen Cheese ...............................................................H128

Van Beek Natural Science........................................................C504

Van Bruggen & Vande Vegte, PC .............................................H108

Van Zee Enterprises Inc./Rock Valley Precast ...............S & outside

VAS .........................................................................................C103

Vaxxinova ................................................................................C528

VES-Artex................................................................................C531

Vetagro Inc..............................................................................C708

Vision Electric .........................................................................A204

Vita Plus Corp. ........................................................................C107

Vosterman’s Ventilation ........................................................A1205

Westway Feed Products ........................................................AF107

Wieser Concrete Products Inc.................................................C729

XF-Nebraska............................................................................C706

Ymker Insulation Inc. ..............................................................A304

Y-TEX Corporation ......................................................................AA

Automation Center Inc. .................................................C830

Sioux Dairy Equipment ...........................................................C615

Sioux Nation Ag Center ...........................................................A305 smaXtec Inc ............................................................................A415

Zimmerman Manufacturing.....................................................A213

ZISK app .................................................................................H120

Zoetis Animal Health ...............................................................C218

MISSED

CONCEPTION

Sauk Centre, MN

320-352-5762 • 800-342-2697

Fuller’s Milker Center, LLC

Lancaster, WI • 800-887-4634

Richland Center, WI • 608-647-4488

Midwest Livestock Systems, LLC

Zumbrota, MN • 800-233-8937

Menomonie, WI • 715-235-5144

Renner, SD • 800-705-1447

Leedstone, Inc.

Melrose, MN 320-256-3303 • 800-996-3303

Glencoe, MN

320-864-5575 • 877-864-5575

Plainview, MN • 800-548-5240

Menomonie, WI • 715.231.8090

Monroe WestfaliaSurge

Monroe, WI • 608-325-2772

Preston Dairy Equipment

Sparta, WI • (608) 269-3830

Sioux Dairy Equipment, Inc.

Rock Valley, IA 712-476-5608 • 800-962-4346

Colton, SD Service 800-944-1217

Edgerton, MN Chemical Sales 507-920-8626

Central Ag Supply Inc.

Juneau, WI • 920-386-2611

Baraboo, WI • 608-356-8384

Eastern Iowa Dairy Systems

Epworth, IA • (563) 876-3087

J Gile Dairy Equipment

Cuba City, WI • (608) 744-2661

Kozlovsky Dairy Equipment

Kaukauna, WI •920-759-9223

Weston, WI • 715-298-6256

Stanley Schmitz, Inc.

Chilton, WI • 920-849-4209

Tri-County Dairy Supply

Janesville, WI • (608) 757-2697

By Maggie Molitor Sta

Writer

By Maggie Molitor Sta

Writer

In the past few years, dairy farmers in the Upper Midwest have been faced with additional hardships ranging from ination to natural disasters. Among the multitude of scal responsibilities farmers have incurred, insurance remains an important topic of conversation.

“We have seen a plethora of derechostyle storms in the past two years,” said Allen Schlenker, risk management consultant with Marsh & McLennan. “Farmers often don’t realize how vulnerable they are to a major loss if they don’t have the right coverage in place. This can significantly impact their nancial well-being.”

Allen Schlenker Marsh & McLennanThe increased risk farmers are facing has initiated changes in insurance coverage. Schlenker and his colleague, Kendall Woodward, will share more about these changes and what farmers can do to ensure they are properly covered in a session titled “The Changing Tide of Terms and Conditions in Insurance Coverage,” at 1:30 p.m. March 29 and noon March 30 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

“We are trying to continuously educate dairy farmers, and farmers in general, about why they should be the having a constructive conversation about how things are valued and what’s going to be paid in the event of a loss,” Schlenker said.

Schlenker said the insurance industry, like any other business, is looking to turn a prot despite increasing their payouts in recent years due to natural disasters. In the insurance world, decreasing an expense sometimes equals not paying as much in claims.

Some of the major changes and trends Schlenker is seeing in terms of insurance contracts at renewal are increasing deductibles, the addition of wind-hail deductibles, and exclusions for cosmetic damages to roof

and siding and application of co-insurance. These small changes could end up being nancially fatal to a business at the time of a great loss, Schlenker said.

“I want farmers to have a heightened awareness of the changes that are going on within their insurance program,” Schlenker said. “Their farms are a business, and if they are not approached as one, they can leave themselves pretty vulnerable.”

Schlenker said additional types of coverage are becoming increasingly benecial to dairy farmers. As the industry and society shifts, coverages such as cyber liability and employment practice liability insurance are becoming more relative and necessary.

Another effect the recent economic state has on insurance policies is increased ination causing property to be under insured. As pricing for materials and labor increases so does the property’s coverage value. The difference between what the reconstruction costs actually are and what the dairy has a structure insured for becomes a cost the dairy farmer has to bear. This may be determinantal to a farm’s nances, Schlenker said.

“We are seeing an average inationary increase of anywhere between 10% to 12% just for building materials and labor alone,” Schlenker said. “This dramatically impacts the cost to reconstruct dairies.”

As farmers renew their insurance year to year, Schlenker emphasizes the importance of fully understanding their coverage and risk. He encourages farmers to negotiate deductibles and rates.

“If you are just renewing your plans, crossing your ngers and hoping you’re covered, you’re really leaving yourself vulnerable to some big losses unless you really sit down and analyze your risk appetite,” Schlenker said.

Schlenker intends for the session to shed light on the importance of these conversations and clear communication between dairy farmers and their insurance agents.

“We hope to encourage the dairy farmer to bring up these important points with their current agent to make sure that they are insured to value and that they have the right coverages in place,” Schlenker said.

Molly Pelzer, CEO for Midwest Dairy, will lead the “Dairy Checkoff Taste and Learn Experience” at the Central Plains Dairy Expo in Sioux Falls, South Dakota. Those attending the session will get to see and sample some of the dairy products checkoff dollars are helping to create. Both Midwest Dairy and Dairy Management Inc. are sponsoring the session.

Attendees can take in the session at 5:30 p.m. March 29.

Food scientists and staff who work behind the scenes to research, create and market new products will join Pelzer in presenting. The taste and learn experience will feature brands and new dairy foods and beverages launched with partners over the past year.

“During this event, we will feature checkoff partnerships with Taco Bell, DARI LLC, General Mills and Pizza Ranch,” Pelzer said. “Each of these partnerships will have its own taste and learn sampling ‘station’ to allow farmers to learn more about why we partnered with them as well as taste some innovative dairy products that consumers are enjoying in the market-

place today.”

The tasting is geared toward bringing attendees awareness and excitement about new products in a fun but meaningful way.

“These products range from cheesy breadsticks to innovative beverages that meet consumers’ needs to eat on the go,” Pelzer said. “A variety of different products will be provided to sample. But, this experience will be more than yummy dairy treats. We will provide industry research and information on why checkoff and our partners are targeting certain product categories and the opportunity these products allow for in the marketplace.”

“Midwest Dairy and DMI are committed to implementing a shared strategy from the national to regional level to impact dairy sales and trust,” Pelzer said. “Nationally, DMI’s Wellness Insights and Innovation team’s work has led to impactful results and relationships with General Mills and Taco Bell, which will be showcased to demonstrate the why behind these partnerships as well as the tremendous opportunity these partners have to impact dairy sales.”

The presentation will offer a chance for farmers to meet some of those working to advance and strengthen dairy demand.

research with impactful partners who have like-minded goals to advance their business decisions and lead to positive impacts for dairy.”

The presentation will address building trust in the dairy industry, which Pelzer said is another important goal of the checkoff program.

“Midwest Dairy is committed to working with and through partners to positively impact dairy sales and build trust in dairy foods and dairy farmers with consumers,” Pelzer said. “This session will demonstrate how checkoff has worked with these partners on menu innovation and product innovation. We will also highlight how partners use checkoff research, consumer marketing and insights on consumer trends to grow dairy sales.”

Molly PelzerThe session will cover both national and regional dairy innovation and promotion.

“Regionally, Midwest Dairy is excited to showcase our partnerships with DARI LLC, a regional partner founded by dairy farmers introducing a new Moo’v product to store shelves in April, as well as Pizza Ranch, sharing samples of a reformulated cheesy ranch stick which includes 50% more cheese than the original recipe,” Pelzer said.

Besides DMI co-sponsoring the event, the company is an important partner to Midwest Dairy, Pelzer said.

“During the taste and learn experience, attendees will also have the chance to engage with some of the talent behind these partnerships, including dairy scientists, dairy processors, brands, and national and regional checkoff staff,” Pelzer said. “Behind every partnership is a commitment from both partners and checkoff to bring dairy to life in new and compelling ways.”

Pelzer said it is important to share what goes on behind the scenes to ensure checkoff dollars are used wisely.

“Dairy checkoff is grounded in research and based on science,” Pelzer said. “Our goal is to ensure that the research checkoff is investing in – whether that be nutrition science, product development, consumer insights or packaging – is heavily used to help the industry. Midwest Dairy’s goal is to share our intelligence and

In turn, the session offers those at Midwest Dairy a chance to meet with the farmers they serve.

“This will be a unique experience that will allow us to not only have conversations but also allow for a hands-on viewing of products that checkoff dollars have helped create and promote,” Pelzer said. “Through this event, (attendees) can not only experience products but also have deep conversations about the impacts they are having on dairy sales.”

Midwest Dairy’s regional staff will also host a booth at CPDE.

“Please stop by booth C204 to ask questions and learn more about the impact checkoff dollars are having across our 10-state region,” Pelzer said.

By Tiffany Klaphake tiffany.k@dairystar.com

By Tiffany Klaphake tiffany.k@dairystar.com

New technology features within VAS’ DairyComp and PULSE Platform allow farmers to receive realtime herd alerts via text or email, helping them better manage animal care.

As VAS has added more modules and features to its PULSE Platform, farmers can receive animal health data to share directly with team members. This information, according to Stephanie De Vries, a farm performance consultant with VAS, can help farmers better understand herd health on a herd- and individual-cow level, helping them make data-driven decisions for the future.

“We are creating a hub for dairymen to be able to have all of their data in one place,” De Vries said. “We continue growing PULSE platform which allows dairymen to not only have their information in the cloud, but also allows them to have other modules and to go in and dissect their information.”

De Vries will present “Next generation of dairy insights” at 9 a.m. March 29 and 11:30 a.m. March 30 at the Central Plains Dairy Expo in Sioux Falls, South Dakota.

De Vries serves farmers across South Dakota, North Dakota, Nebraska, Missouri, southwestern Minnesota and western Iowa. She said VAS is the global market leader in connecting dairy management systems. The PULSE Platform brings a farmer’s DairyComp, FeedWatch and WeighComp data together as well as information from more than 40 integrations from industry-leading partners. Each system has its own plethora of features and modules that can be accessed through the platform.

HealthVAL is a module within

the platform that dials into the diseases affecting a herd. It tracks all health events associated with each animal and helps calculate the health-related costs for each animal. Farmers can also benchmark their performance against herds of similar size and region.

“At a glance, a farmer can assess their herd and just gather insight about the health events that are happening on their farm and see what each cow is costing them and determine what they want to do in the future,” De Vries said. “That’s why HealthVAL is so important.”

The system is pre-populated with health event costs based on research from the Journal of Dairy Science, or farmers can input their own values. Adding health events such as mastitis, pneumonia or vaccinations is key to generating accurate reports that can help farmers make protocol adjustments to improve overall herd health. DairyComp users can already access HealthVAL through the PULSE platform.

“The benet of having all this information is knowing where your bottom line is and how much you are actually spending on each animal,” De Vries said. “We can dial in and see if there is one animal that is costing you a lot of money.”

For example, if a rst-lactation cow has had numerous health events, then the farmer can determine if the cow will be a good longterm producer or if culling would be a better decision.

“I stress that with my dairies that if you aren’t putting something in (the system), you aren’t going to be getting anything out,” De Vries said. “Management has to be able to input data accurately in order to get useful information out.”

Most importantly, De Vries said the PULSE Platform allows farmers to collaborate more effectively with their consultants, employees and other team members. De Vries encourages not only producers to attend the breakout session but also consultants because she said it is helpful for every team member to understand.

“The benet of having these tools is to make those executive decisions and make sure your dairy is protable,” De Vries said. “Providing data-driven decisions is what DairyComp always has been and always will be.”

- White, South Dakota

- White, South Dakota

360

How many years have you attended Central Plains Dairy Expo? We have attended CPDE for eight years.

Why is attending CPDE important to you and your dairy? We like to go to get away and also pick up on new advancements in the industry.

What are three must do’s when you attend CPDE? The Zoetis meeting is always No. 1 for me. I also enjoy the Welcome Reception entertainment and attending breakout sessions.

What seminars or booths are you interested in seeing? I don’t have any specic ones to look for. I’m always interested in new technology and ways to reduce input costs.

What have you incorporated on your farm from a previous CPDE? A few years ago, we ran across and purchased a water ltration system that removes chlorine and other toxins that are harmful to cows.

What is your most memorable experience at CPDE? I always enjoy the entertainment because the artists are usually ones I’ve never seen before.

What would you say to encourage other farmers to attend CPDE? It is a great place to get away from the farm for a day and come home with new ideas that will benet your operation.

Tell us about your farm. The family members involved include my grandpa, Ronald; my parents, Gary and Holly; my wife, Morgan; and my brother, Tim. We milk 360 cows twice a day in a double-10 parabone parlor. We farm 1,700 acres where we grow corn, soybeans, wheat and alfalfa. We also have 350 acres of pasture that we use for breeding-age to close-up dairy heifers, dry cows and 50 Red Angus cows.

Proper

These corn roots show enhanced root health from biologically treated manure applied in a strip-till application. Growers who understand the value of bioaugmented manure can reduce plant nutrient cost, improve soil and plant health, improve crop residue decomposition, detoxify the soil (reduce salts) and improve

“It is a great place to get away from the farm for a day and come home with new ideas.”

Don’t miss this all dairy event, highlighting valuable updates in the dairy industry and new products and services giving you successful ways to improve your dairy operations.

•Free Ag Prayer Breakfast

•Over 300 Exhibitors

•Foundation Auction

•Educational Sessions

•Industry Experts

•Producers Attend for Free

By Danielle Nauman danielle.n@dairystar.com

By Danielle Nauman danielle.n@dairystar.com

For a dairy cow, the transition period is a make-or-break time. What happens during the transition period can set a cow up for success or just as easily for failure.

Providing the tools needed to navigate that period of a cow’s life has been what Dr. Gustavo M. Schuenemann has dedicated his life’s work to.

At the Central Plains Dairy Expo, Schuenemann will share insight on navigating the transition period in the breakout session

“Transition cow management: Solutions for dry matter intake to enhance colostrum, health and productivity” at 11:30 a.m. March 29 in Sioux Falls, South Dakota.

“Poor feeding management can substantially reduce the DMI of pre- and postpartum cows,” Schuenemann said. “That leads to excessive body weight loss and increased incidence of stillbirth

and metabolic diseases early in lactation regardless of housing system.”

Schuenemann works with Ohio State University’s Department of Veterinary Preventive Medicine. His time is divided between extension, teaching and focusing on research related to dairy cattle health and management with an emphasis on transition dairy cow management.

“The transition period is perhaps the single most important period in a cow’s life,” Schuenemann said. “It has direct implications for lifetime performance of both lactating cows and newborn ca lves.”

Schuenemann denes the transition period as the three- to four-week period prior to and after parturition. He said during that time, quality feed ingredients and dietary formulation are both important.

“Optimizing DMI is perhaps the biggest opportunity in most dairy farms,” Schuenemann said. “DMI regulation is a complex, integrated process that insures adequate supply of energy to meet the important nutrient requirements the cow has.”

Schuenemann said the nutritional requirements of a dairy cow change throughout her lactation. Factors that impact a cow’s daily consumption include physical limitations (or gut ll), metabolic status and farm factors such as management, facilities and environment.

“To formulate and manage efcient diets (for dairy cattle) requires accurate

Turn to SCHUENEMANN | Page 3

Con nued from SCHUENEMANN | Page 2

estimates of DMI,” Schuenemann said. “Therefore, the factors inuencing DMI must be understood.”

Dairy farmers can promote positive feed behavior by making small changes such as increasing bunk space per cow, increasing the frequency of feed delivery and increasing the amount of resting surface and space per cow.

Schuenemann said that through his work with dairy producers within their various management systems, he found several common factors that all play a role in successful transition cow management.

“I quickly recognized that cow comfort and management consistency are perhaps the biggest opportunities to improve productivity, longevity and the overall protability of dairy operations,” Schuenemann said.

als and vitamins in the transition diet are vital to promoting the process of synthesizing and transferring colostrum immunoglobulins inside the mammary gland.

“The transition period is perhaps the single most important period in a cow’s life. It has direct implications for lifetime performance of both lactating cows and newborn calves.”

“Prepartum dairy cows are often vaccinated to prevent cases of mastitis and calf diarrhea. Transferring blood immunoglobulin inside the mammary gland is an active and specic process, requiring large quantities of calcium and energy to produce the best quality colostrum,” Schuenemann said. “Prepartum animals that are losing body weight prior to calving due to inconsistent nutrition management, high mycotoxin concentrations in feed or a sudden drop in water intake could negatively alter DMI and thus affect both colostrum volume and quality.”

• Reduce mastitis cases

• Lower somatic cell count

• Decrease labor expense

• Save on bedding costs

• Improve cow comfort

• Increase milk production

Scraper

• Quick attach to skid steer or side mount for tractors

• Raises to a vertical position for transport and at an angle for low door openings

• Brushes off organic material faster than normal scraping

• Drier and cleaner mats for less bacteria growth

• Advanced manure managment

• Automatically adjusts to variable widths

• Speeds up labor-intensive job

• Automatic hydraulic float

Each calf born is a benefactor of the success of its mother’s transition period through the quality of the colostrum produced.