WINEMAKING

TIPS FROM DOWN UNDER

AUSTRALIAN WINEMAKERS SHARE ADVICE ON MAKING SHIRAZ, SÉMILLON, & GSM

SO, YOU WANT TO GO PRO?

TROUBLESHOOTING UNDERWHELMING GRAPES

CRAFTING YOUR OWN BRANDY

HARDY & VERSATILE FRONTENAC WINES

Crafting Age Worthy Wines Hot Tips For Mulled Wine Top Home Wine Winners

WINEMAKERMAG.COM

OCTOBER - NOVEMBER 2021 VOL.24, NO.5 +

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 1 From BIG to small we do it all! @mustfabricate 365 La Fata Street. St. Helena CA 94574 Shipping Nation Wide Orders@mustfabricate.com 707-963-4966 / 707-967-0553 www.mustfabricate.com

26 MAKING MULLED WINE

As autumn rolls into winter, it’s time to heat things up with mulled wine. A holiday tradition around the world, mulled wines usually include spices, citrus fruits, and wine served hot to take the chill away.

by Bob Peak

by Bob Peak

30 2021 WINEMAKER INTERNATIONAL AMATEUR WINE COMPETITION

An overview of this year’s wine competition, which received nearly 2,000 entries from across the U.S., Canada, and as far away as Australia.

32 WINEMAKING FROM DOWN UNDER

Australia produces a lot more than Shiraz and budget wines with kangaroos on the label. Get an inside look

at how ussie winema ers are i in the re utation of the wines from Down Under, with tips for creating their most touted styles in your home winery.

by Danny Wood

by Danny Wood

40 DISTILLATION 101

When your wine is done fermenting, that doesn’t necessarily mean it has to be aged or packaged. Where legal, the next step may be distilling it into brandy.

by Aaron Hyde

by Aaron Hyde

46 GO PRO

Many hobby winemakers spend evenings sipping their wine and wondering if their hobby could become a profession. If you are serious about it, here is what you need to consider to get that career jump started.

by Christina Musto-Quick

2 OCTOBER - NOVEMBER 2021 WINEMAKER

features contents October-November 2021, VOL. 24 NO. 5 WineMaker (ISSN 1098-7320) is published bimonthly for $26.99 per year by Battenkill Communications, 5515 Main Street, Manchester Center, VT 05255. Tel: (802) 362-3981. Fax: (802) 3622377. E-mail address: wm@winemakermag.com. eriodicals osta e rates aid at anchester enter and additional mailin offices end address chan es to WineMaker, P.O. Box 469118, Escondido, CA 92046. Customer Service: For subscription orders, inquiries or address changes, write WineMaker, P.O. Box 469118, Escondido, CA 92046. Fax: (760) 738-4805. Foreign and Canadian orders must be payable in U.S. dollars. The airmail subscription rate to Canada and Mexico is $29.99; for all other countries the airmail subscription rate is $46.99. 26 40 46 32

MOREWINE.COM • ABSOLUTELY EVERYTHING FOR WINEMAKING LARGEST SELECTION OF FERMENTERS! ITALIAN FUSTIS GERMAN MADE SPEIDEL TANKS CARBOYS & DEMIJOHNS TESTING EQUIPMENT Limited Stock... Act NOW & Save! END OF SEASON SALE! Accurate pH, SO2 & TA Tests! Affordable Malolactic Test Kit! EVERYTHING YOU NEED, IN STOCK AND READY TO SHIP! HIGH QUALITY WINE & MUST PUMPS FREE SHIPPING ON WINE KITS! HUGE SELECTION OF CORKS! MALOLACTIC BACTERIA & NUTRIENTS

departments

8 MAIL

A reader asks about the best way to do rackings when aging wine in a barrel, and another praises a recent “Reader Tip” we ran where the winemaker forgoes pressing and instead makes a second wine by adding water and sugar to the grapes after collecting the free run juice.

10 CELLAR DWELLERS

The earliest known alcoholic beverage uncovered on Earth was a mead from northern China. Get familiarized with the great and storied world of honey-based wines. Also learn about a grape that hails from southern Italy that hasn’t seen much growth overseas . . . yet; as well as the latest news, products, and upcoming events.

14 WINE WIZARD

What is the best way to store oak barrels that don’t have wine in them? Get the answer from the Wine Wizard, as well as her advice for a case of oversulfited wine removin white film from a lass car oy and five ti s for a roo ie winema er

18 VARIETAL FOCUS

Scattered throughout the Upper Midwest and Rockies, Frontenac wines are ma in waves as winema ers learn to coa a lot of avor from this red grape. Chik Brenneman offers several tips and tricks to working with this hybrid varietal.

55 TECHNIQUES

When you set your sights on making a “keeper” wine, one you plan to lay down for several years, there are certain techniques you can employ to make sure it doesn’t round the bend too soon. Learn how to make that wine worth holding on to.

58 BACKYARD VINES

Not every harvest is going to be perfect. When the grapes come in at less than ideal num ers or with other aws ma e sure you re well positioned and able to make the best of an inferior harvest. Plus, learn how to identify what went wrong in the vineyard so the same mistakes aren’t repeated in future vintages.

64 DRY FINISH

In our annual Reader Survey, hobby winemakers looking to go pro usually account for about 1 in 5 readers. Here is the story of one couple who made the leap and some of the details about how they’re making it work.

4 OCTOBER - NOVEMBER 2021 WINEMAKER

52 DISTILLATION SPECIAL ADVERTISING SECTION 61 SUPPLIER DIRECTORY 63 READER SERVICE where to find it ® 18 Photo courtesy of Shutterstock.com

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 5 www.lallemandbrewing.com/wine FULL RANGE OF PREMIUM WINE YEAST K1 ™ (V1116) FRESH AND FRUITY STYLES EC1118 ™ THE ORIGINAL “PRISE DE MOUSE” 71B ™ FRUITY AND “NOUVEAU” STYLES D47 ™ FOR COMPLEX CHARDONNAY QA23 ™ FOR COMPLEX SAUVIGNON BLANCS RC212 ™ FOR PINOT NOIR STYLES Looking for Bottles, Caps and Closures? 888-539-3922 • waterloocontainer.com Like us on Facebook! • Extensive inventory of ready-to-ship bottles, caps and closures • No MOQ on most items – we serve all sizes of customers • Industry expertise to guide you through the packaging process • Quality products and customization to create or enhance your brand You Can Rely on Us

EDITOR

Dawson Raspuzzi

ASSISTANT EDITOR

Dave Green

DESIGN

Open Look

TECHNICAL EDITOR

Bob Peak

CONTRIBUTING WRITERS

Chik Brenneman, Alison Crowe

Dominick Profaci, Wes Hagen

Bob Peak, Alex Russan

Jeff Shoemaker, Gene Spaziani

CONTRIBUTING ARTISTS

Jim Woodward, Chris Champine

CONTRIBUTING PHOTOGRAPHERS

Charles A. Parker, Les Jörgensen

EDITORIAL REVIEW BOARD

Steve Bader Bader Beer and Wine Supply

Chik Brenneman Baker Family Wines

John Buechsenstein Wine Education & Consultation

Mark Chandler Chandler & Company

Wine Consultancy

Kevin Donato Cultured Solutions

Pat Henderson About Wine Consulting

Ed Kraus EC Kraus

Maureen Macdonald Hawk Ridge Winery

Christina Musto-Quick Musto Wine

Grape Co.

Gene Spaziani American Wine Society

Jef Stebben Stebben Wine Co.

Gail Tufford Global Vintners Inc.

Anne Whyte Vermont Homebrew Supply

EDITORIAL & ADVERTISING OFFICE

WineMaker

5515 Main Street

Manchester Center, VT 05255

Tel: (802) 362-3981 Fax: (802) 362-2377

Email: wm@winemakermag.com

ADVERTISING CONTACT:

Kiev Rattee (kiev@winemakermag.com)

EDITORIAL CONTACT:

Dawson Raspuzzi (dawson@winemakermag.com)

SUBSCRIPTIONS ONLY

WineMaker

P.O. Box 469118

Escondido, CA 92046

Tel: (800) 900-7594

M-F 8:30-5:00 PST

E-mail: winemaker@pcspublink.com

Fax: (760) 738-4805

Special Subscription Offer

6 issues for $26.99

Cover Photo Illustration: Shutterstock.com/Open Look

PUBLISHER

Brad Ring

QASSOCIATE PUBLISHER & ADVERTISING DIRECTOR

Kiev Rattee

ADVERTISING SALES COORDINATOR

Dave Green

EVENTS MANAGER

Jannell Kristiansen

BOOKKEEPER

Faith Alberti

WEBSTORE MANAGER

Julie Ring

SUBSCRIPTION CUSTOMER SERVICE MANAGER

Anita Draper

Pinot Noir is my favorite fermentation. It is sometimes called the heartbreak grape and said to e diffic lt to make into wine, t find sing homegrown fruit every year to be very rewarding. The vintage variation is fascinating, given that it is from the same vineyard and handled the same way, harvest after harvest.

My favorite grape variety is Pinot Noir, both to make and to drink. It can be so very versatile; sip it on its own or enjoy with a wide variety of foods. In the cellar it can star in so many different wine styles: From sparkling (who doesn’t love bubbles?) to rosé (rosé all day, yay!) to elegant reds to “chewier” styles, providing you can get it quite ripe and it’s coming from an AVA like Sonoma County’s Petaluma Gap, where the skins just naturally grow thicker. I’ve found that Pinot Noir rarely disappoints, either in the cellar or, ultimately, in the glass.

All contents of WineMaker are Copyright © 2021 by Battenkill Communications, unless otherwise noted. WineMaker is a registered trademark owned by Battenkill Communications, a Vermont corporation. Unsolicited manuscripts will not be returned, and no responsibility can be assumed for such material. All “Letters to the Editor” should be sent to the editor at the ermont office address ll ri hts in let ters sent to WineMaker will be treated as unconditionally assigned for publication and copyright purposes and subject to WineMaker’s unrestricted right to edit. Although all reasonable attempts are made to ensure accuracy, the publisher does not assume any liability for errors or omissions anywhere in the publication. All rights reserved. Reproduction in part or in whole without written permission is strictly prohibited. Printed in the United States of America. Volume 24, Number 5: October-November 2021.

Red Hybrid Color Stabilization

Red wines from hybrid grapes can be frustrating — one day you have a deep garnet wine and the next you are wondering where the color went. Color stabilization is the key, and there are techniques to help. https:// winemakermag.com/technique/redhybrid-color-stabilization

MEMBERS ONLY

Make Wines To Age

It starts with great fruit, but to make age-worthy red wine the winemaker must also consider acidity, tannins, sulfur dioxide, oxygen, cellaring conditions, and how all of these factors (and others) relate to each other. https://winemakermag.com/ technique/1498-wines-to-ageadvanced-winemaking

Super Syrah!

Syrah can do well in a wide variety of climates and produces wine in a number of styles, from drink-it-today fruity to structured and age-worthy. With a name change to Shiraz, it became Australia’s most widely planted red starting in the 19th century. Syrah makes mouth fillin wine stron on fruit ut also delivers earthy, peppery-spicy, mineral, smoky and even “meaty” overtones. https://winemakermag.com/ article/648-super-syrah

MEMBERS ONLY

Post-Harvest Vineyard Cleanup

Don’t neglect your vineyard just because the grapes have been harvested. Here’s the cleanup that needs to take place. https://winemakermag.com/ article/post-harvest-cleanup

MEMBERS ONLY

* For full access to members’ only content and hundreds of pages of winemaking articles, techniques and troubleshooting, sign up for a 14-day free trial membership at winemakermag.com

6 OCTOBER - NOVEMBER 2021 WINEMAKER WINEMAKERMAG.COM suggested pairings at ®

WineMakerMag @WineMakerMag @winemakermag

What’s your favorite grape varietal to work with?

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 7 It'sTimetoMakeWine Contact fordetailsonthehighestqualityandvarietyofwinemaking grapesandjuicesinNewEngland!GrapesandJuicesfromalloverCalifornia-Central Valley(AncientVine,King'sRiverRanch),Lodi(MettlerRanch,ContraCosta),Suisun Valley(Lanza-MustoVineyards),PasoRobles,Napa,Sonoma,andWashingtonState (RattlesnakeHills,CandyMountain,WahlukeSlope),andevenjuicesfromItaly! www.juicegrape.com-877.812.1137-sales@juicegrape.com

RACKING DURING BARREL MATURATION

Bob Peak provided a very timely article in the June-July 2021 issue on the growing pains with aging and packaging big batches. We have one from ma in allons of wine in our first vin tage to now over 150 gallons (568 L) from our acre of estate vines. Production now consists of using multiple 14.5- and 29-gallon (55- and 110-L) barrels in addition to carboys and other containers. So our question stems around racking of wines and barrel management. With carboys it was no big deal to have extra carboys on hand for racking purposes. The same can’t be said about barrels and having an empty barrel sitting around for months for the next racking. So what should one do? In the past I’ve not done any rac in and only em ty the arrel when the wine is finished and ready for the bottling phase. Should I reconsider this approach and erform the normal rac in rotocol his would essentially mean racking out of the barrel into another container, clean out the barrel, and then rack the wine back into the same barrel. I always thought this would induce unnecessary oxygen exposure from the second racking, but perhaps this is not of major concern?

Ken Stafford • Fiddletown, California

WineMaker ’s “Techniques” columnist and Technical Editor Bob Peak responds: “Most years I make about 50 gallons (190 L) of wine, but a few times I have gone over 100 gallons (380 L), so I get right into the range you are talking about. My experience from when I was a partner at The Beverage People showed me that quite a few home winemakers — especially those considering commercial production — run into the same concerns.

“My barrel program is entirely red wine, and I will assume yours is, too. Red wine is relatively resistant to oxidation with its polyphenolic content and can usually tolerate some air exposure, providing yo eep yo r l te level p aro nd pp . ordin ly here how I handle racking my hectoliter barrels, which I do just once or twice during 9 or 10 months of barrel aging:

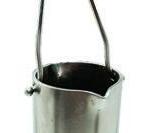

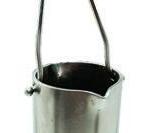

“Suppose I have 26 gallons (100 L) of wine in the barrel to rack. I usually also have a few carboys of the same wine because volumes are npredi table. li e to ni h ith t one ine o don t ant a barrel-aged 26 gallons (100 L) and, say, three 5-gallon (19-L) carboys of neutral-aged wine at bottling time. So, on racking day, I pump out the barrel ith y little fle ible i peller p p into y allon

Danny Wood is an Australian-based journalist who lived in Kansas City, Missouri, for a decade before moving home with his family. He’s made wine in his basement, worked in wineries, and is a former editor of Midwest Wine Press. He also studied enology while in the United States and judged the occasional wine competition, but was really smitten by vino (and his American wife) while living in Spain, reporting for BBC News. In past issues of WineMaker anny has rofiled Joel Peterson and Ravenswood Winery, as well as written stories on fermenting with wild yeast, essential winemaking techniques, the varieties of Chardonnay, Malbec, Tempranillo, and many other topics.

In this issue, Danny gives us an inside look at what’s happening in the wine world Down Under, with tips from three pro Aussie winemakers about making their most popular wines, starting on page 32.

Aaron Hyde began homebrewing in 1996 with his father in the kitchen. From there he picked up home distilling in 2008, piecing together a still from an old keg and copper piping. As the owner and operator of Brewstock Homebrew Supply in New Orleans he used to provide educational classes on brewing and winemaking. He currently manages global product strategy for Bevie, providing high-quality equipment and ingredients to homebrewers and distillers across the globe. aron has certifications in rewin maltin and distillin through the Institute of Brewing & Distilling, as well as certificates in winema in and viticulture from avis and Texas Tech, respectively. In 2021 he authored How to Distill for the hobby distiller and manages the website www.howtodistill.com, which provides supplementary information and support to the book. resh off ettin his first oo u lished aron shares an adapted excerpt from How To Distill with readers starting on page 40.

Christina Musto-Quick is a third-generation wine grape broker, home winema er and certified sommelier with a Masters in Wine Business from Sonoma State University. She is a longtime member of the American Wine Society, Co-Founder of The Women Winemakers of New England, and works at Musto Wine Grape Company in Hartford, Connecticut as Head of Sales, Marketing, and Winery Consulting. Growing up in the wine grape industry, Christina is passionate about all things wine and winemaking. Besides her job at Musto Wine Grape, Christina often contributes to WineMaker magazine, o rnal, and CTVisit.com when she isn’t geeking out about wine grapes.

Beginning on page 46, Christina explores what it takes to turn your winemaking hobby into a career.

8 OCTOBER - NOVEMBER 2021 WINEMAKER contributors

MAIL

(200-L) stainless steel variable capacity tank. I use ½-inch tubing and a corresponding racking cane and I have a stainless steel mesh pre lter on the p p.

“When the barrel is empty, I take it outside my little wine barn and hose it out with unchlorinated well water. I turn it upside down to drain for a few minutes. During this time, you could install the lid on the tank and blanket it with inert gas, but I don’t usually do that. do ho ever add pp of l te in a ol tion to the wine in the tank. After draining the barrel to the point of mostly not dripping, I take it back inside and position it on blocks on the floor a ain. then p p the e tra arboy into the barrel after ta ting each one — wouldn’t want to add a spoiled batch to the larger lot . hat ay that ine et o e barrel e po re too. l te that wine with 20 ppm. My tank is on a hydraulic ATV lift (sold for doin oil han e on it ha a lb. lift apa ity to in he hi h. o lift it and drain ine by ravity ba into the barrel ntil it i topped p. hen ll o e of tho e e tra arboy ith hatever i left in the tan . e e tra one pre anitized, because I don’t want to take the time to wash the ones I just emptied while everything is in progress. Now the wine is resting in barrel a ain ith e tra arboy on the ide and a ee or o later te t for l te to a e re till above pp free. hen bottling day comes, I taste all the vessels separately and then pump the to ether into the tan . add a nal pp of l te rai e the tan a ain and bottle on the floor by ravity.

on e lo t a in le arboy to o idation don t no hy b t

it didn’t pass the taste test so I poured it out without adding it to the blend. have never had ine fro the barrel ho e e ive o idation. In fact, my oldest barrel-aged wine, following the process deribed here for one year of a in i a ono a alley abernet a vi non that i till drin in very ni ely year later.

PRAISE FOR THE NO PRESSING TECHNIQUE

Back when I didn’t mind spending time on things that took time, I used to always make a “false wine” from the press cake (by adding some water and sugar to soak on the skins). I found that when making red hybrid wines, they were always a bit short of tannin and texture in general. A small amount of false wine beefed up the tannin and the fact that it contains water, it also softened the very strong acids we get in Michigan with hybrids. As I am tasting the wines I’ve made over the past 40 years, the ones made with the addition of about 10% or so false wine have held up much better and have better balance than those made with chemical de acidification and tannin added

I read with amazement Ed Armes’ “No Pressing Technique” description in the April-May 2021 Cellar Dwellers. He accomplished exactly what I was accomplishing but with a lot less work (by adding water and sugar to the must after collecting the free run wine, without pressing). He did not mention this, but his techni ue li e mine oth de acidifies and adds tannin and structure with minimal physical exertion. Smart man!

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 9

MAIL

Brian Cain • via email

RECENT NEWS

Slowing Grape Ripening Can Help Improve Wine Quality

or y a colla orative team from oth ustralia and the twea ed with cro load and irri ation levels on a ernet auvi non ra es in order to ad ust the harvest dates hat they found was that y delayin the harvest y three wee s there was a si a le chan e in the ra e character ater ri enin meant increased levels of monoterpenes and norisoprenoids; both of which are considered aroma enhancers in wine hey also found decreases in reen aroma com ounds li e yra ines esides the aroma, they also found the phenolic character of the grapes to be greatly enhanced with greater anthocyanin content, total phenolic content, glycosides, and other pigments. If you find that you re harvestin your ra es earlier and earlier you may want do some more digging into this study: https://pubs.acs.org/doi/abs/10.1021/acs.jafc.1c01229

New Products:

Finer Wine Kits

A new line of wine kits has been introduced for the production of standard 6-gallon (23-L) wines. Finer Wine Kits’ juices and skins are stored cold and shipped in insulated packaging to maintain the grapes’ integrity and avor hese its are not ultra asteuri ed so e tra care is needed for handling prior to fermentation, but this also means they do not receive the harsh treatment re uired for ultra asteuri ation iner ine its are availa le in oth whites and reds ed wine its come with the option of single or double packs of grape skins. Each kit comes with an 11-page illustrated manual with instructions. Weighing under 20 lbs. (9 kg) means they’re easy to handle and ship. Also, keep your eyes out for the new fruit wine line coming this autumn. iner ine its are currently e clusively availa le throu h a el eelers com

SafCider Yeast

Fermentis has announced a new line of yeast strains geared s ecifically for ciderma ers here are many different ways to produce a cider across the globe and there are many cidermakers who want to innovate and create a new style of cider to feed diversity in this cider world hen ic in a yeast strain for your cider you must consider that different cider styles re uire different technical demands from the yeast. To make this selection process easier for the cidermaker, Fermentis has created four new cider strains to o tain the cider rofile they desire af ider for alanced ciders af ider for fresh and cris cider af ider to rin sweetness to your cider and af ider to ma imi e the fruitiness of your ciders hese strains are availa le in sachets for cider roduction at home o discover more visit www fermentis com

OCTOBER 8

e istration deadline for the merican ine ociety

Amateur Wine Competition. Open to all amateur winemakers and includes still fortified and s ar lin wines made from vinifera, native and hy rid ra es lso ud ed y certified ud es will e wines and ciders made from fruit ve eta le ower honey and rasses he cost is mem er non mem er er en try or more information visit htt s www awscom etitions com on-line-entry

NOVEMBER 5

he th nnual mateur inema in om etition will ta e lace on ovem er ntries will e acce ted from cto er st throu h ovem er th ntries should e shipped to or dropped off at The Home Wine, Beer, and Cheesema in ho in oodland ills alifornia ees are er entry he mateur is s onsored y the ellarmasters of Los Angeles Home Winemaking Club. More information and registration forms can be found at www.CellarmastersLA.org

10 OCTOBER - NOVEMBER 2021 WINEMAKER

News

New

UPCOMING EVENTS

AWARD-WINNING KITS

Other Red Vinifera Varietals

Mosti Mondiale Nebbiolo

RJS Craft Winemaking RQ Eminence

Spanish Tempranillo

SILVER

Cellar Craft Showcase Barbera

Cellar Craft Showcase Carménère

Master Vintner Winemaker’s Reserve

Carménère

GOLD FIND OURPRODUCTS INYOURLOCAL HOMEBREW /HOME WINE MAKING SHOP

RJS Craft Winemaking RQ Carménère

RJS Craft Winemaking RQ Mouvèdre

Vineco Atmosphere Nebbiolo

Vineco Atmosphere Viognier Red

Vineco Passport Series French Grenache

Vintner’s Cellar Supreme Bergamais

Winexpert Limited Edition Italian Barbaresco

Winexpert Private Reserve Italian Nebbiolo

Winexpert Selection Italian Montepulciano

BRONZE

Mosti Mondiale Fresco Montepulciano

Mosti Mondiale Meglioli Sicilian

Primitivo

RJS Craft Winemaking En Primeur

Spanish Grenache

RJS Craft Winemaking En Primeur

Winery Series Carménère

RJS Craft Winemaking Cru

International Chilean Malbec

RJS Craft Winemaking Cru

International Italian Nebbiolo

RJS Craft Winemaking RQ Italian

Nebbiolo

RJS Craft Winemaking RQ Spanish

Monastrell

Vineco Passport Series Nero d’Avola

Vintner’s Cellar Supreme Lambrusco

Winexpert Limited Edition Italian Negroamaro

Winexpert World Vineyard Chilean Malbec

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 11

Here is a list of medal-winning kits for the Other Red Vinifera Varietals category chosen by a blind-tasting judging panel at the 2020 WineMaker International Amateur Wine Competition in Manchester, Vermont:

Winexpert Eclipse Italian Nebbiolo Our RedStar rangeisevolving. Newnames,the same tradition. PREMIER CUVEE• PREMIER BLANC• PREMIER COTE DES BLANCS • PREMIER CLASSIQUE• PREMIER ROUGE AFermentisbrand

Ao ular ra e native to taly s oot heel more s ecifically the southern Puglia region of Italy, Negroamaro means “black” and “bitter” in Italian. Folks in North America are much more familiar with one of this grape’s blending partners, Primitivo, more commonly referred to as Zinfandel. Primitivo though is not actually native to the Puglia region. But unlike Primitivo, Negroamaro has not widely seen success here in North America. There is very limited acreage planted in California (41 acres) and Texas (14 acres), but due to its drought resistance and love of warmer temperatures, don’t be surprised to see more interest in the future. It is considered a fairly neutral grape with notes of dark berry fruit and tobacco. The translated name does not actually apply to the wine which it produces as they are neither black in color nor bitter on the tongue. It does have a nice medium finish o while e roamaro is est nown as a lendin varietal wines made from the grape are known to produce lush, berry characteristics.

While fresh-grape winemakers may be out of luck sourcing Negroamaro grapes here in North America, kit and juice winemakers should have better access. Keep your eyes out for special releases from kit producers and from importers of Italian juices. Bottle shops with a solid Italian wine section likely have a good selection of commercial wines from Puglia made from Negroamaro grapes. Rosé wines made from Negroamaro are some of the highest regarded expressions of wines made from this grape varietal. If you do try any, might we recommend pairing it with a nice Amaro as a post-dinner digestif.

12 OCTOBER - NOVEMBER 2021 WINEMAKER GRAPE PROFILE

NEGROAMARO

Photo courtesy of Wikimedia Commons

BEGINNER’S BLOCK HONEY-BASED WINES

BY DAVE GREEN M

ost all of the honey-based wines fall into the larger category of meads. Given the history and ubiquity of honey-based wines throughout the world, it’s not surprising they are an amazingly diverse class of wines. Different regions around the world have different specialties and different names for the various meads and honey wines, making for a fairly complex and often misunderstood beverage. Love them or not, it’s an interesting study of both history and experimentation possibilities with a dizzying array of combinations and variations. Let’s start off with the intricacies of honey before jumping into a few of the more popular variants.

Most folks know that the qualities of honey produced from bees is de endent u on the source owers Honey derived from orange blossoms when compared to honey from buckwheat is going to taste wildly different. And just as with grape varietals, these different honey types will also produce different tasting meads. Meadmakers may want to blend different honey types to produce a more com le avor rofile or ee the honey as a single varietal to highli ht the ualities of a certain ower ty e or source re ion or a first time meadmaker blending honey types may be a safe way to go or opting for a more neutral-tasting honey like clover is a good starting point.

THE WORLD OF MEADS

A honey-based wine can be sweet, semi-sweet, or dry depending on the goal of the meadmaker (or the conditions provided to the yeast). Carbonation is also an option for meadmakers that may like to add some spritz to their mead. Carbonation can range from seemingly almost still to Champagne-level of bubbles.

Standard Mead: What most folks refer to as traditional mead, it’s typically fermented from either a single honey

type or a blend of two or more honey types. They will typically clock in between 7-14% ABV.

Hydromel (Session) Mead: At its core, this is a more watered-down version of standard mead, clocking in between 3.5-7% ABV. This requires skill from the meadmaker in order to make the mead taste full-bodied and these will often be carbonated for added mouthfeel.

Sack Mead: On the other end of the spectrum, sack mead is a potent concoction in the 14%+ ABV realm. A clean fermentation where the yeast can properly finish while ee in the alcohols hidden is a challenge.

Melomel: To keep things simple, we can say melomel is a honey-based wine that has some sort of fruit added. There are an abundant number of sub-categories of melomels based on what fruit is added, most notably cyser (apple mead) and pyment (grape mead). The sky is the limit as to what combination of fruits (dried or fresh) a meadmaker can mix in with the various honey varieties to create their melomel beverage.

Metheglin: Also a very broad category, but generally this refers to honey wines that have been spiced. A meadmaker can use herbs, vegetables, or other spices to create their metheglin. Technically fruit can also be added to a spiced mead and the resulting beverage will still be called a metheglin. Spices like vanilla, ginger, chamomile, and lavender are just a few that are popular among meadmakers.

Braggot: Just as pyment is a cross of wine and mead, braggot is a cross of beer and mead. Where a honey beer ends and braggot begins is a little blurry, but generally a braggot should have honey/mead notes come through in either the nose and or avor ut there is no definitive line in the sand se aratin the two classifications

There is also a whole world to explore of different honey-based wines from around the globe. Ethiopian t’ej, Polish czworniak, Mexican acan, Nepalese dandaghare, and Finnish sima are just a few examples of some of the different honey-based wines to research.

FEEDING THE YEAST

One of the biggest challenges for meadmakers is the balance of yeast nutrients. Honey doesn’t afford meadmakers the nutrients, most notably nitrogen, that yeast require for a proper and clean fermentation. This is why historically meadmakers needed to add things like grape juice or unfermented beer to the honey in order to provide some nutrients for yeast. But even with those additions, meadmakers are encouraged to add more nutrients. Too much though and the mead can be detrimentally affected. his is the fine line meadma ers need to walk. How much nutrients to add is highly dependent upon your starting material, but generally meadmakers will slowly “feed” the yeast over several weeks of fermentation.

OTHER POSSIBLE ADDITIONS

Think about what other additions grape winemakers may add and most all of them are possibly used in honey-based wines as well. Tannins, acids, oak, fortifying liquors, etc. are just a few e am les of additions you ll find in honey-based wines. The selection of yeast can also greatly affect the final roduct ome meadma ers may purposefully add non-Saccharomyces strains like Brettanomyces or bacterial strains to et a different rofile

If you would like to try your hand at honey wine and would like to learn more, I recommend either The Compleat Meadmaker by Ken Schramm or The Complete Guide to Making Mead y teve iat r you can find several great articles at winemakermag.com found under “Meadmaking.”

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 13

WINE WIZARD

BY ALISON CROWE

PRESERVING OAK BARRELS

QGOOD DAY! I WAS NOT ABLE TO FIND HOW TO PRESERVE AN OAK BARREL AFTER ITS USE. I HAVE DONE FOUR WINE BATCHES IN IT AND NOW I FEEL THAT IT’S NOT GIVING ME THE SAME EFFECT AS FOR TASTE. I WOULD LIKE TO SAVE THE BARREL AND PLACE IT IN MY WINE CELLAR, JUST DO NOT WANT IT TO CRACK. ANYTHING YOU CAN SUGGEST?

GATES LEGAULT SUDBURY, ONTARIO

GATES LEGAULT SUDBURY, ONTARIO

Aell the first thin always say is full arrel is a ha y arrel hat means that the arrel is est stored with wine in it he acidity of the wine enerally reds tend to e a of ish ee s s oila e micro es at ay and of course the wet ness of the wine ee s the wood nice and swollen or those times when we can t ee our arrels full of wine however we do need to have a ac u lan his is where a ood arrel stor a e solution comes in asically what you re oin to do is fill your arrel with an acidulated sulfur dio ide solution which mimics the a ove salu rious effects don t attem t to drin it however ere s the reci e o ee one arrel of citric acid of otassium meta isulfite owder nou h water to fill the arrel rocedure ill your arrel a out halfway with water f ossi le use a car on loc filter to remove the chlorine from the water as chlorine can contri ute to or the cor ed aroma defect which could infiltrate your ar rel he water could e warm or cold ut warm water will hel the chemicals dissolve faster and more thorou hly o not use hot water which will cause the sulfur dio ide in the owder to

volatili e and otentially not only urn your nose hairs off ut also to dissi ate more uic ly ut on a res irator that has cartrid es that are a roved for sulfur dio ide as as well as eye rotection issolve the citric acid in a out a allon of warm water and add to the half full arrel ith your arrel stirrer you have one of those ri ht or a lon dowel or rod mi the solution into the water y the way you can use tartaric acid too it s ust much more e ensive than citric acid ontin ue fillin the arrel until it s a out of the way full hen dissolve the owder into a out a allon of water warm water is here ust not hot and add to the arrel a ain mi in thorou hly om letely to u the ar rel with water o with a wooden un or a un you don t care a out ruin in as stron sulfur dio ide solutions is sulfur dio ide li uid or as will de rade and crac silicone un s over time nother cellar tric is to cover your un with lastic wra efore sealin u the arrel

ractice ood safety techni ues at all times around sulfur dio ide es e cially when acids and sulfur dio ide mi is much more effective at lower s which is what you want ut that also renders it more volatile and dan erous lush any s ills with lenty of clean water and don t allow any un

14 OCTOBER - NOVEMBER 2021 WINEMAKER

Photo by Charles A. Parker/Images Plus

For those times when we can’t keep our barrels full of wine, however, we do need to have a backup plan.

versulfited wine film on a car oy and e inner ti s

masked people or your pets in the area while you’re working. y ee in your arrel filled with the a ove solution and y chan in it out every one to two months you should e a le to ee your arrel sound and sweet when you don t have wine in it owever the est way to ee a arrel oin is to keep it full of your aging wine . . . and to address one of your other comments, indeed after four batches of wine I would

e ect the arrel to not e contri utin much avor or aroma to the wine. This is where I really like to add oak beans, stic s or s irals to my wine in arrels ou et the enefit of the aging dynamics of the barrel and can add some more fresh wood for further avor and aroma develo ment ou can read a out my recommended roducts here htt s winemakermag.com/wine-wizard/is-oak-sanitation-necessary

QI WAS WONDERING IF THERE WAS SOMETHING THAT COULD BE DONE FOR A BATCH OF WINE THAT HAS BEEN OVER- SULFITED? MY WINE HAS BEEN BOTTLED, SO I WON’T BE DOING ANY MORE RACKINGS AND I CAN’T GIVE YOU SPECIFICS ON HOW MUCH I’VE OVER- SULFITED AS I DON’T HAVE THE PROPER EQUIPMENT TO CHECK IT.

WHAT I CAN TELL YOU IS I CLEANED AND TRIED TO SANITIZE ALL THE BOTTLES WITH POTASSIUM METABISULFITE (3 TABLESPOONS FOR EVERY 4 LITERS/1.1 GALLONS OF WATER ) BUT FORGOT TO RINSE THE BOTTLES BEFORE BOTTLING. THE WINE IS NOW VERY HARD TO DRINK AND THE SULFITES ARE TOO HARSH TO HANDLE. I ALSO PUT IN 9 ML OF A 10% SOLUTION AT THE LAST RACKING . . . THE CARBOY USED HOLDS ONLY 20 LITERS (5.25 GALLONS ) OF WINE.

Aince you can t measure your free and total let’s do some numbers to see what kind of a potential problem you might be facing. First off, let’s talk about your bottle-rinsing solution of 3 tablespoons per 4 liters of water. 3 tablespoons of KMBS otassium meta isulfite owder is e uivalent to a out x 13 g (approximate weight of a tablespoon of KMBS), or rams ivide y and your concentration is or m or hat s a retty stron solution and let’s say that about 1 mL of that solution hung around in your wine ottle which would contri ute of owder er ottle ow is only sulfur dio ide so then the full contri ution is or m of total er m ottle

Let’s turn that into a language we’re more familiar with when tal in a out sulfur dio ide levels m or m f your ottles are m ottles that s or m sulfur dioide er liter of wine m hat s not a hu e addition ut if you already had a hi h level oin into ottlin it certainly will add to it. As a point of reference, I typically like to bottle with a free not total which we ve ust calculated level of around 25–30 ppm, depending on the pH and the amount of already in the wine y total at ottlin de endin on the a e of the wine and how many additions ve had to ma e over a wine s lifetime tend to hover around m s another reference oint the le al limit of total in commercial wine in the U.S. is 350 ppm.

ow let s loo at how much you added in your last addition, or 9 mLs of a 10% solution at your last racking. Your car oy is volume solution can also e written as g/100 mL, or 100 g/L. Since I don’t know whether you’re talking a out a solution as which is or as it s hard to do the ne t ste ut m oin to assume you ve ot a 10% solution as KMBS. So, to 20 L of wine you added 9 mL of a 10 g/100 mL solution. In 1 of the mLs of your solution there

are of so you ust added total or of n m terms you added m or m total as sulfur dio ide not free ust total

One of the challenges here is that I don’t know what the free and total level of your wine was efore that addition f you d een ee in your wine at a out m free say for a year or so and then added a total hit of m on to of that lus the m leftover from your rinsin solution it s not too much of a stretch to think you could be looking at a free of etween m de endin on the underlyin chemistry of your wine. And indeed, that’s enough “extra” free to where could see you thin in the wine was a little hard to handle at the moment ou re even in hi her territory if you were talking about your 10% solution being “as sulfur dioxide,” in which case you’d be adding 900 mg/20 L, or 45 ppm total as sulfur dioxide.

So what can one do if one’s added too much sulfur dioxide to a wine ince they ve een all ottled u it s a little hard to affect any kind of change, unless you want to open them all up and decant them . . . which you could do. My recommendation is to send a sample of the wine to be tested at your closest wine lab. Ask your local fermentation supply shop for contacts if you don t have one already d li e you to actually see your free and total num ers efore you em ar on any treatment because in this case sometimes the cure can be worse than the disease f indeed you do have unnaturally hi h levels of free how hi h it is will dictate my advice to you f your free SO is around m and your total is under m my advice is that you do nothin and ust wait he free level will o down over time so chec on how a ottle tastes in another month or two. You might be pleasantly surprised.

f your free is over m and your total level is over 200 ppm, it’s unlikely that the wine will return to “drinkable” anytime soon. In which case, the best choice is to open all the bottles, decant (under a blanket of CO2 gas or argon to protect

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 15

DOMENIC MORDA NIAGARA- ON -THE - LAKE, ONTARIO

it from o y en and lend the over sulfited wine with wine that has lower levels his is a reat solution ut only if you ha en to have e tra wine lyin around that has lower levels of free ou may now that one of my mantras is never lend a loser ut in this case the wine may e fine it ust needs its free levels alanced out a it efore you lend however do send your ros ective lenders out to a la to measure their free and total to see if the math even wor s out t s a ood idea to have the free oin to ottle never e a ove m and ideally ee it etween m deendin on the of the wine hi h wines need more here are some eo le who say that over sulfited wine can e treated with hydro en ero ide ut as ve never done it and as hydro en ero ide is a owerful o idi er and can utterly ruin your wine don t recommend it nstead d o with

one of the a roaches ve discussed ou don t want to create an even i er ro lem y tryin to solve the first one when it s ossi le that all you need to do is wait ince the earlier calculations don t im ly ross over sulfitin here will mention one other ossi le sulfur stin ro lem winema ers encounter hydro en sulfide rotten e odor ou could try a enny test or if you have any co er sulfate solution i ette a dro of that into a lass with m s of wine to see if it hel s f either of those tests resolve the sulfur situation you will then need to do a ro er ench trial to determine what s the smallest addition needed to solve the ro lem then add that amount to the atch or more instructions on this chec out my ine i ard column in the une uly issue or at htt s winema erma com wine wi ard ro erly adding-copper

Aow loo s li e you ve ot a serious case of in round the ar oy han s for sendin in the icture always love it when readers do that ecause es ecially in cases li e these it ives me a ood visual to o from can see that es y stain on the inside of the nec of your car oy ne te is a reat cleaner ut m not so sure it s stron enou h for your ur oses here i e it won t really hel you et that film off

f were you d ma e sure you had a stiff ristled car oy rush f your local home rewin fermentation su ly store doesn t have one you can find one online y enterin those terms into your search en ine of choice ou want a rush with an angled handle and/or an angled brush, so you can get into every curve and corner of your fermentation vessels

ather than use ne te a ain d use somethin that s a stron er ase which will hel to rea u the residue around the nec area classic that love is ero ycar which is the trade name for a asic hi h owder of sodium car onate and sodium ercar onate which also releases hydro en ero ide when added to water su est an overni ht soa in a stron a out cu owder to a allon of water m owder to a liter of water ero ycar solution followed y a hard scru with your an led rush and then a rinse with acidulated water li e citric f that doesn t wor you could try a little a rasive cleanser li e ar ee er s riend or even omet cleanser ust don t use anythin with leach lways follow any asic cleaner with an acidulated water rinse and then a re ular water rinse to ma e sure you ve removed anythin that mi ht chan e a wine s ou definitely don t want any asic

residue han in around inside your car oy ve ot a retty ood feelin that with an overni ht ero ycar soa you should e a le to scru off that film f not then it mi ht ust e a ermanent stain on the inside of your vessel f a stron ase solution won t ta e it off and you ve scru ed u and down d ust live with it t s unli ely that at that oint it will dissolve off into your wine

16 OCTOBER - NOVEMBER 2021 WINEMAKER WINE WIZARD

- - ) ) Q

hoto courtesy of teve uer

I’M JUST STARTING OUT MAKING WINE AND I’M A LITTLE PETRIFIED OF MAKING SOME ( OK, A LOT ) OF MISTAKES AS I GO ALONG. DO YOU HAVE ANY ADVICE?

MARIA LATHAM DULUTH, MINNESOTA

AWinemaking is always a learning process and even those of us that have been doing this for a long time still learn a lot every harvest and all year-round! However, that being said, I do have some tidbits for new winemakers. In my Winemaker’s Answer Book s ell out what thin are ro a ly the to five “Rookie Mistakes” that those new to winemaking are prone to make:

- Picking grapes too early or too late: Once you pick you can’t go back and the path to wine is already laid out before you. Pick your reds at 22 °Brix and you should make a rosé . . . wait for riper fruit to make a “proper” big red wine.

- Inappropriate must adjustment: You can make little tweaks by adding acid (if pH is too high), water (if too ripe), or, in the case of home winemakers, a little sugar if needed to boost alcohol. Overdo it, however, and you’ve just thrown the whole balance off.

- Not understanding the destructive power of oxygen: Oxygen can ruin wine, oxidizing its bright color and encouragin s oila e micro es lways ee finished wine away from oxygen by keeping your aging containers fully topped up to minimize exposure. There are many small tricks to minimizing exposure to oxygen but topping up is the most important.

- Not understanding the constructive power of oxygen: Yeast need some oxygen while fermenting and it can help tannin development in young wines. Embracing oxygen early on while a wine is still producing carbon dioxide (which protects the headspace) is a good idea. Just make sure the wine is protected once it stops producing its own carbon dioxide gas or oxidation and spoilage may result.

- Keeping inadequate records: Did you make a wonderful wine? If you weren’t writing down what you were doing, you’ll never be able to recreate it! Similarly, if you don’t like what you did, you won’t know what to avoid doing next time.

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 17

Q

VARIETAL FOCUS

BY CHIK BRENNEMAN

FLEXIBLE FRONTENAC

Making a case for this hybrid

Recently in the WineMaker Harvest Online Boot Camp, I discussed at length about harvest wine style and technique decisions. This topic had me deep in thought about how best to convey that information to our diverse audience around the globe. The challenge with presenting a topic like that, as well as writing about varieties that have regional importance rather than global resti e centers on the s ecific variety potential, or actual harvest parameters. We all should understand that the best wines come from a variety grown on the right site, whether it is a hybrid or pure Vitisvinifera. Pure vinifera has its place in the temperate zones of the Northern and Southern Hemispheres. But it is the fringe areas, perhaps too wet, too hot, or too cold, that grape breeders have focused on developing varieties that will thrive there. In their minds they are looking for traits to overcome the environmental adversity the new vine will experience. But they also need to ask the question: Is it going to make a good wine? And to what style of wine makes the variety shine. Frontenac is our focus in this issue because of its versatility on the winemaking front.

Also known as MN1047, this University of Minnesota hybrid was originally bred in 1978. It is a hybrid of Landot Noir and Vitis riparia #89 (MN89). In its lineage are also percentages of V. labrusca, V. vinifera, V. aestivalis, V. lincecumii, V. rupestris, V. cinerea, and V. berlandieri. With an abundance of native-American varieties, it is not surprising that it possesses good all-around disease resistance, except for foliar phylloxera, to which it is

highly susceptible. A color mutation appeared in 1992, which was released in 2003 under the name Frontenac Gris. Another color mutation appeared in a vineyard in Québec in 2005, which was named Frontenac Blanc. All three varieties are productive, vigorous, cold-hardy, with loose bunches of small- to medium-sized berries capable of high sugar and acidity levels. It buds early in the season making it prone to frost damage. It ripens mid to late season.

Frontenac is a regional grape. It is widely grown across the Upper Midwest of the U.S. with some vineyards reported as far west as Nevada. I am personally involved in a project in northern Utah where it is planted with other cold-hardy hybrids. I am excited to be working on this as there is no better way to learn about a grape than to cut your teeth with it. Frontenac is made in a variety of styles, such as sweet or dry rosés, dry red, and Portstyle wines. Frontenac Gris is made into dry white styles, and Frontenac Blanc, with the best styles reported to be dessert or Port-style wines to take advantage of its high acidity. Also understand that this is not the gospel, as many styles are possible.

As we went over in the Harvest Boot Camp, picking your style depends on the following harvest parameters: The overall condition of the fruit, sugar, acidity, pH, and tannin. I have always said that a great winemaking effort is the result of some great fruit, coming from a great vineyard, and tended by a great person. That said, the zones that these varieties are bred for actually have real weather. While they can be fairly immune to diseases, there are the physical dangers of late-spring frost, extreme heat, severe storms with hail,

18 OCTOBER - NOVEMBER 2021 WINEMAKER

Photo courtesy of University of Minnesota Horticultural Research

Frontenac is made in a variety of styles, such as sweet or dry rosés, dry red, and Portstyle wines.

DRY RED-STYLE

FRONTENAC

INGREDIENTS

125 lbs. (57 kg) Frontenac fruit

Distilled water

otassium meta isulfite solution ei h rams of dissolve into about 50 milliliters (mL) of distilled water. When comletely dissolved ma e u to mL total with distilled water.)

5 g Lalvin D254 yeast (Premier Cuvée can be used as a substitute)

5 g Diammonium phosphate (DAP)

5 g Go-Ferm ermaid or e uivalent yeast nutrient)

alolactic fermentation starter culture ansen or e uivalent

EQUIPMENT

15-gallon (57-L) food-grade plastic bucket for fermentation

5-gallon (19-L) carboy

1–2 one-gallon (3.8-L) jugs

Racking hoses

Destemmer/crusher

Wine press nert as nitro en ar on or car on dioxide)

Ability to maintain a fermentation temperature of 81–85 °F (27–29 °C)

Thermometer capable of measuring between 40–110 °F (4–43 °C) in one degree increments.

Pipettes with the ability to add in increments of 1 mL

STEP BY STEP

1. Clean and sanitize all your winema in tools su lies and e ui ment

2. Examine your fruit and remove and poorly colored clusters and clusters showing signs of rot.

3. Crush and destem the grapes. Transfer the must to your fermenter.

4. urin the transfer add m of solution his addition is the e uivalent of m 2.

5. a e a sam le to test for ri acidity and ee the results handy

6. Layer the headspace with inert gas and ee covered ee in a cool lace overnight.

7. he ne t day s rin le the ermaid directly to the must and mix well.

8. Prepare yeast. Heat about 50 mL distilled water to i the Go-Ferm into the water to make

Yield 5 Gallons (19 L)

a suspension. Take the temperature. Pitch the yeast when the suspension is rin le the yeast on the surface and gently mix so that no clumps exist. Let sit for 15 minutes undistur ed easure the tem erature of the yeast suspension and the must. You do not want to add the yeast to your cool juice if the variance in temperature exceeds 15 °F (8 °C). To avoid tem erature shoc you should acclimate your yeast by taking about 10 mL of the must juice and add it to the yeast suspension. Wait 15 minutes and measure the temperature again. Do this until you are within the specified temperature range.

9. hen the yeast is ready add it to the top of the must. Do not mix it in yet.

10. You should see signs of fermentation within one to two days. This will appear as some foaming on the must surface and it will a ear that the berries are rising out of the medium. You need have on hand the ability to push the grapes back into the juice to promote color and tannin extraction.

11. onitor the ri and tem erature twice daily during peak fermentation down to ri ornin and evenings are best and more often if the temperature shows any indication of e ceedin in which case you would activate your cooling system i the must ait minutes mix and check the temperature again. Do this as often as it takes to keep the temperature between 80–85 °F (27–29 °C). Do not cool off to less than heat it if necessary

12. t a out ri dissolve the in a little water and mix in.

13. hen the ri reaches ero a out days transfer the must to your ress and ress the ca e dry ee the free run wine separate from the press portion for now.

14. Transfer the wine to your carboys and jugs. Your press fraction may only e a allon or two a e sure you do not have any headspace. Place an airlock on the vessel(s). The fermentation may perk up a little here as the primary fermentation completes. When activity starts to slow taste the wine for sweetness or send a sample to an outside lab. The wine is considered dry

if the residual sugar is less than 2 g/L.

15. Inoculate with your malolactic acteria over the to s with an airloc to allow 2 to escape.

16. onitor the fermentation usin a thin layer chromatography assay available from most home winemaking supply stores.

17. hen the is com lete add m of fresh solution per gallon (3.8 L) of wine. This is the e uivalent to m addition

18. easure the and titrata le acidity ost im ortantly you want a finished TA of about 6.5-7.5 g/L. If the has not reduced the acidity to this ran e consider settin u a deacidification bench trial using potassium car onate 2 3).

19. Place the wine in a cool place to settle fter two wee s test for 2 ad ust the 2 as necessary to attain m molecular 2. (There is a sim le 2 calculator at www. winemakermag.com/sulfitecalculator). hec the 2 in another two weeks and ad ust nce the free 2 is adusted maintain at this level ou ll ust need to chec every two months or so and before racking.

20. Rack the wine clean twice over 6–8 months to clarify. Consider during this period using some oak chips to add some oa flavors ut do not expose the wine too long to the oak. The amount of oak to add is your preference onsider the amount contact time is ased on the amount used ne to two wee s sometimes less is sufficient for this volume aste fre uently to your preference of extraction.

21. nce the wine is cleared it is time to move it to the bottle. This should be about eight months after the completion of fermentation.

22. a e the ro ect fun y havin a blending party to integrate the press fraction back into the free run. You may not need it all use your ud ment and make what you like.

23. f all has one well to this oint iven the uantity made it can ro ably be bottled without filtration. That said maintain sanitary conditions while ottlin nce ottled you ll need to periodically check your work by opening a bottle to enjoy with friends.

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 19

Moving to the wine phase, natural deacidification can be achieved via a malolactic fermentation (MLF).

and then, early winter. Hopefully that great person can make the best and deliver fruit that the winemaker can make visual assessments and react accordingly when the fruit is delivered. Rot or poor-quality fruit needs to be sorted out. Recent research has shown as the percentage of rot increases in a s ecific maceration its characteristics in the wine chan e Some might not perceive this, others will. A very good resource for growing grapes in cold climates is Growing Grapes in Minnesota, 10th Ed., by the Minnesota Grape Association.

I have seen where some wineries in Michigan are experimentin with ash d tente rocess in which the must is heated to 175–185 °F (80–85 °C) and then moved to a vacuum chamber where the cells burst, releasing all of their contents. The heat will kill off unwanted molds, denature deleterious enzymes, and improve and stabilize color. We will e wor in with ash d tente on the tah ro ect and am excited as it has been a process used in Europe for some time now. The practice is certainly not practical for the home

winemaker, but it stresses the importance of taking care of your fruit when it comes in. In the absence of sophisticated methods, the home winemaker needs to be diligent about sorting out bad fruit and understanding the relationship between pH, acidity, and sulfur dioxide (SO2).

Second to fruit quality when choosing the style are the remaining four parameters: Sugar, acidity, pH, and tannin. There has not been a lot of tannin research with Frontenac and one study I read fell short of recommendations for making wine. They worked with berry chemistry, which showed tannins are generally low with similar, and statistically insi nificant differences etween two vineyards one in Iowa and the other in South Dakota. Tannin levels in St. Croix and Marquette were also included with similar results. Thus, the variable here are the two climates. So, for maximum extraction for the home winemaker, getting some good heat in the fermentation (80–85 °F/27–29 °C), and a longer maceration would e the first lace would start

20 OCTOBER - NOVEMBER 2021 WINEMAKER VARIETAL FOCUS QUALITY, FRESH PRESSED GRAPE JUICE VINIFERA - FRENCH HYBRID NATIVE AMERICAN 2860 N.Y. Route 39 • Forestville, N.Y. 14062 716-679-1292 (FAX 716-679-9113) OVER 20 VARIETIES OF GRAPE JUICE... PLUS Blackberry, Blueberry, Strawberry, Red Raspberry, Cherry, Peach, Plum, Cranberry and Rhubarb We Ship 5 Gallon Pails of Juice Nation-Wide by U.P.S. WALKER’S... GROWING SINCE 1955, SUPPLYING AWARD WINNING JUICE TO OVER 300 WINERIES IN 37 STATES Walkers Qrtr-pg Ad.qxp_Layout 1 12/3/18 9:33 AM Page 1

Sugar, acidity, and pH take us back to the vineyard where the local weather in uences hotosynthesis s we learned in grade school, sunlight is needed for photosynthesis, the process of sequestering atmospheric carbon dioxide and converting it to sugar to e translocated to the erry rontenac can attain upwards of 24–25 °Brix if left han in lon enou h n alifornia, we see dangerous rises in pH and si nificant decreases in acidity with varieties we select for a longer hangtime in our a riculture climate his is not the case for rontenac ra es he hi h acid levels enefit from the increased han time alic acid is ein respired by the berries, thus a decrease in overall acidity, with no effects on re orted ovin to the wine hase natural deacidification can e achieved via a malolactic fermentation areful attention to taste and lab results factor in better-informed decisions on style ty e his is an important aspect of my approaches in winemaking, even commercially, to sometimes see what have rather than tellin the wine where to o

o do this you have to understand the following relationship:

sweetness ↔ acidity + astringency/ bitterness

his is a eneral relationshi that can e used with all wines and foods t says that the erce tion of sweetness is related to the sum total of acidity and the astringency/bitterness com onent n the case of rontenac the low tannins put more emphasis on the acidity component to balance the su ar and vice versa f see hi h acidity want to sweeten the wine y possibly fortifying with ethanol before the end of fermentation to stop it, or ac sweeten if missed the earlier o ortunity to fortify hile li e wines with crisp acidity, it sometimes has to e tamed ower acidity can wor with higher sugars but consider fortifying after the fact he ossi ilities are endless and it takes knowledge and e erience to et the alances ri ht t may not ha en your first time around ut over time you will et a feel for it Keep in mind my general philosophy of wor in with what have not what want ort of a minimalist and more

importantly, opportunistic approach to uality winema in ines of the red version e hi it avors of cherry lac currant and lum ome will erceive chocolate as the wines a e he ris version features peaches, apricot, and citrus, but the wines will show some coloration ome say the ris will e re laced y the Blanc version and made into white Port-style or dessert style wines, with no coloration

No matter the style you desire to make you have a lot of opportunities with rontenac y advice to ros ective rontenac winema ers is to have a plan but be sure to keep an open mind to moving outside the bubble and experimenting when the grapes throw you a curve all have always said that life is not always the destination, but the ourney his is so true with rontenac as you choose your style ty e i and match you will find your atch

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 21

BE A PIONEER.

AND MALOLACTIC CULTURES PIONEERING PREMIUM YEAST

ENTER YOUR BEST HOMEMADE WINES IN THE WORLD’S LARGEST COMPETITION FOR HOBBY WINEMAKERS!

DON’T WAIT SEND YOUR ENTRIES NOW! ENTRY DEADLINE: MARCH 21, 2022

Enter your wines and compete for gold, silver and bronze medals in 50 categories awarded by a panel of experienced wine judges. You can gain international recognition for your winemaking skills and get valuable feedback on your wines from the competition’s judging panel.

Entry Deadline: March 21, 2022 5515 Main Street • Manchester Center, VT 05255 ph: (802) 362-3981 ext. 106 • fax: (802) 362-2377

email: competition@winemakermag.com

You can also enter online at: www.winemakercompetition.com

22 OCTOBER - NOVEMBER 2021 WINEMAKER

will be awarded thanks to our award sponsors:

Gene Spaziani Grand Champion Wine

WineMaker of the Year

Best of Show Red

Retailer of the Year

Best of Show White

U-Vint of the Year

Best of Show Dessert

Club of the Year

LALLEMAND BREWING

Best of Show Mead

Best of Show Country Fruit

Best of Show Sparkling

Best of Show Estate Grown

Best of Show Kit/Concentrate

Category Medals (gold, silver, and bronze) will be awarded thanks to our category sponsors:

34. Red Table Wine Blend (Any Grape Varieties)

35. Blush Table Wine Blend (Any Grape Varieties)

36. Grape & Non-Grape Table Wine Blend

37. Apple or Pear Varietals or Blends

38. Hard Cider or Perry

39. Stone Fruit (Peach, Cherry, Blends, etc.)

40. Berry Fruit (Strawberry, Raspberry, Blends, etc.)

41. Other Fruits

42. Traditional Mead

43. Fruit Mead

Moonlight Meadery

44. Herb and Spice Mead

45. Flower or Vegetable

46. Port Style

47. Sherry Style

48. Other Fortified

49. Sparkling Grape, Dry/Semi-Dry or Sweet

50. Sparkling Non-Grape

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 23

1. White Native American Varietal

2. White Native American Blend

3. Red Native American Varietal

4. Red Native American Blend 5. Blush/Rosé Native American 6. Red or White Native American Late Harvest and Ice Wine

9.

11. Blush/Rosé French-American Hybrid 12. Red or White French-American Late Harvest

Wine 13. Chardonnay 14.

15.

16.

17.

21. Cabernet

Five

Supply,

22. Cabernet Sauvignon 23. Merlot Vinmetrica 24. Shiraz/Syrah Bader Beer & Wine Supply 25. Pinot Noir 26. Sangiovese 27. Zinfandel 28. Other Red Vinifera Varietals 29. Red Vinifera Bordeaux Style Blends 30. Other Red Vinifera Blends Label Peelers Beer & Winemaking Supply 31. Blush/Rosé Red Vinifera 32. Red or White Vinifera Late Harvest and Ice Wine 33. White Table Wine

7. White French-American Hybrid Varietal 8. White French-American Hybrid Blend

Red French-American Hybrid Varietal 10. Red French-American Hybrid Blend

and Ice

Pinot Grigio/Pinot Gris

Gewürztraminer

Riesling

Sauvignon Blanc 18. Other White Vinifera Varietals 19. White Vinifera Bordeaux Style Blends 20. Other White Vinifera Blends

Franc

Star Chemicals &

Inc.

Blend (Any Grape Varieties)

SPECIAL

SHOW

BEST OF

MEDALS

RULES & REGULATIONS

1. Entry deadline for wines to arrive is March 21, 2022

Wines are to be delivered to: Battenkill Communications

5515 Main Street Manchester Center, VT 05255 Ph: (802) 362-3981

2. Send ONE (1) BOTTLE per entry. Still wines must be submitted in standard 750 ml wine bottles. Ice wines or late harvest wines can be submitted in 375 ml bottles. Meads and Hard Ciders can be submitted in 12 oz. or 22 oz. beer bottles. Sparkling wines must be in champagne bottles with proper closure and wire. All bottles must be free of wax, decorative labels and ca sules owever an identification la el will be required on the bottle as detailed in rule #5.

3. Entry fee is $25 U.S. dollars (or $25 Canadian dollars) for each wine entered. Each individual person is allowed up to a total of 15 entries. You may enter in as many categories as you wish. Make checks payable to WineMaker Only U.S. or Canadian funds will be accepted. On your check write the number of entries (no more than 15 total) and the name of the entrant if different from the name on the check. Entry fees are non-refundable.

4. All shipments should be packaged to withstand considerable handling and must be shipped freight pre-paid. Line the inside of the box with a plastic trash bag and use plenty of packaging material, such as bubble wrap, around the bottles. Bottles shipped in preformed styrofoam cartons have proven reliable in the past. Every reasonable effort will be made to contact entrants whose bottles have broken to make arrangements for sending replacement bottles. Please note it is illegal to ship alcoholic beverages via the U.S. Postal Service. FedEx Air and FedEx Ground will destroy all amateur wine shipments so do not use either of these services. Private shipping companies such as UPS with company policies against individuals shipping alcohol may refuse your shipment if they are informed your package contains alcoholic beverages. Entries mailed internationally are often required by customs to provide proper documentation. It is the entrant’s responsibility to follow all applicable laws and regulations. Packages with postage due or C.O.D. charges will be rejected.

5 Each bottle must be labeled with the following information: Your name, category number, wine ingredients, vintage.

Example: K. Jones, 9, 75% Baco Noir, 25% Foch, 2016. If you are using a wine kit for ingredients please list the brand and product name as the wine ingredients. Example: K. Jones, 22, Winexpert Selection International French Cabernet Sauvignon, 2016. A copy of the entry form, listing each of your wines entered, must accompany entry and payment.

6. It is entirely up to you to decide which of the 50 categories you should enter. You should enter each wine in the category in which you feel it will perform best. Wines must contain a minimum of 75% of designated type if entered as a varietal. Varietals of less than 75% must be entered as blends. To make sure all entries are judged fairly, the WineMaker staff may re-classify an entry that is obviously in the wrong category or has over ercenta e of a s ecific varietal but is entered as a blend.

7. Wine kits and concentrate-based wines will compete side-by-side with fresh fruit and juice-based wines in all listed cate gories.

8. The origin of many Native American grapes is unknown due to spontaneous cross-breeding. For the purposes of this competition, however, the Native American varietal category will include, but is not limited to, the following grape families: Aestivalis, Labrusca, Riparia and Rotundifolia (muscadine).

9. For sparkling wine categories, dry/semidry is defined as residual su ar and sweet as >3% residual sugar.

10. Contest is open to any amateur home winemaker. Your wine must not have been made by a professional commercial winemaker or at any commercial winery. No employee of WineMaker magazine may enter. Persons under freelance contract with Battenkill Communications are eligible. No person employed by a manufacturer of wine kits may enter. Winemaking supply retail store owners and their employees are eligible. Judges may not judge a category they have entered. Applicable entry fees and limitations shall apply.

11. All wines will be judged according to their relative merits within the category. Gold, silver and bronze medals within each category will be awarded on point totals and will not be restricted to the top three wines only (for example, a number of wines may earn enough points to win gold). The Best of Show awards will be those wines clearly superior within those stated catego-

KEY DATES

Entry deadline for wines to arrive in Vermont: March 21, 2022

Wines judged: April 22-24, 2022

Results first announced at the WineMaker Magazine Conference in San Luis Obispo, California June 4, 2022

(Results posted on winemakermag.com)

ries. The Grand Champion award is given to the top overall wine in the entire competition.

12. The Winemakerof the Year award will be given to the individual whose top 5 scoring wine entries have the highest average judging score among all entrants.

13. The Club of the Year, Retailer of the Year and U-Vint of the Year awards will be based on the following point scale: Gold Medal (or any Best of Show medal): 3 points

Silver Medal: 2 points

Bronze Medal: 1 point

The amateur club that accumulates the most overall points from its members’ wine entries will win Club of the Year. The home winemaking retail store that accumulates the most overall points from its customers’ wine entries will win Retailer of the Year. The U-Vint or On-Premise winemaking facility that accumulates the most overall points from its customer’s wine entries will win U-Vint of the Year.

14. The Best of Show Estate Grown award will be given to the top overall scoring wine made with at least 75% fruit grown by the entrant. Both grape and country fruit wines are eligible.

15. All entrants will receive a copy of the judging notes for their wines. Medalists will be listed by category online.

16. All wine will become the property of WineMaker magazine and will not be released after the competition.

17. All decisions by competition organizers and ud es are final

24 OCTOBER - NOVEMBER 2021 WINEMAKER

Deadline: March 21, 2022

Entry Fee: $25 (U.S.) or $25 (Canadian) per wine entered

Number of entries _____ x $25 (US) or $25 (CD) = $________Total (limit of 15 entries per person)

q Enclosed is a check made out to “WineMaker” in the amount of $_________.

Name___________________________________________________________________________

Address_________________________________________________________________________

City________________________State/Prov______Zip/Postal Code____________________

Telephone_______________________________________________________________________

E-Mail____________________________________________________________________________

Winemaking Club:________________________________________________________________

Winemaking Retailer:_____________________________________________________________

U-Vint / On-Premise Store:________________________________________________________

Wine Ingredients and Percentage: Please list fruit varieties and percentages used in each wine. Example: “75% Baco Noir, 25% Foch.” If you are using a wine kit for ingredients, please list the brand and product name as the wine ingredients.

Example: “Winexpert Selection International French Cabernet Sauvignon.”

Wine 1 Entered:

Category Number__________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ____________________________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 2 Entered:

Category Number___________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 3 Entered:

Category Number__________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

ENTRY FORM

Please note that you can also enter online at:

winemakercompetition.com

Remember that each winemaker can enter up to 15 wines. If entering more than eight wines, please photocopy this entry form. Entry shipment includes ONE BOTTLE of wine per entry. 750 ml bottle required for still wines. Ice or late harvest wines can ship in 375 ml bottles. Still meads can ship in 12 oz. or 22 oz. beer bottles. Sparkling wines must ship in champagne bottles with proper closure and wire.

Send entry form and wine to:

Battenkill Communications

5515 Main Street

Manchester Center, VT 05255

Ph: 802-362-3981 • Fax: 802-362-2377

E-mail: competition@winemakermag.com

If entered online at winemakercompetition. com, please print a copy of your entry form and send it along with your wine.

Wine 5 Entered:

Category Number_________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 6 Entered:

Category Number__________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 7 Entered:

Category Number__________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 4 Entered:

Category Number___________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Enter online at: winemakercompetition.com

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

Wine 8 Entered:

Category Number__________________________________________________________

Category Name____________________________________________________________

Wine Ingredients and Percentage

Vintage ______________________________________________________

Are at least 75% of the ingredients grown by you? q yes q no q I feel it necessary to decant this wine_______hours before serving.

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 25

DON’T WAIT — ENTER NOW!

By Bob Peak

What’s your favorite serving temperature for red wine? Cold? Cellar temperature? Room temperature? How about hot?

Hot, spiced wine has been enjoyed for two millennia or more. When the Roman Empire expanded across Europe, vineyards and wine soon followed. Especially in colder climates, heating and spicing red wine became common practice. As this spicy beverage spread to new areas, regional specialties and national names for it developed. Most commonly “mulled wine” in English-speaking North America (more on “mulled” later), it is vin chaud or hot wine in French. In German-speaking countries, you would most likely encounter the popular winter beverage Glühwein, describing hot, spiced wine as glowing or smoldering. Variations on gløgg or glögg appear in the various languages of the Nordic countries. In many regions, serving mulled wine is associated with the Christmas season, Saint Lucia’s Day on December 13, and the year-end astronomical solstice. In South America, where it might be unpleasantly hot for mulled wine at that time of year, it is served on the opposite side of the calendar. Brazilians enjoy vinho quente during the Festas Juninas, a festival period encompassing the nativity of St. John the Baptist on June 24. Similarly, Chileans toast with their vino navegado on June 23, St. John’s Eve, in celebration of the same saint.

26 OCTOBER - NOVEMBER 2021 WINEMAKER

WINEMAKERMAG.COM OCTOBER - NOVEMBER 2021 27

Photo courtesy of Shutterstock.com

MAKE YOUR OWN MULLED WINE

Now that you know more about the history, are you ready to make some mulled wine? I have included my personal recipe at the end of this story and I think it’s great, but there’s no reason you can’t make up your own for friends and family as cooler weather is upon us in the Northern Hemisphere. You probably have some homemade red wine in the cellar, spices in the kitchen, and possibly some citrus fruit readily available. World recipe variations provide plenty of range for exploration, although some features appear commonly.