TECHNIQUES FOR CRAFTING GREAT WINE FROM EXPERTS IN FRANCE, NEW ZEALAND, AND THE UNITED STATES

KEYS TO BLENDING VINIFERAS & HYBRIDS

WHAT’S IN A NAME?

MAKING CHARBONO/ BONARDA/DOUCE NOIR

BACKYARD VINEYARD QUESTIONS ANSWERED

Calibrating Wine Testing Equipment Pro Tips For Hybrid Winemaking Award-Winning Home Wine Labels

WINEMAKERMAG.COM

FEBRUARY - MARCH 2022 VOL.25, NO.1

2022 A Premium Performance with Five Spectacular Wines. Craft with passion. enjoy in good cheer. Learn more at rjscraftwinemaking.com or bsghandcraft.com

28 THE BEST OF BOTH SPECIES

Vitis vinifera grapes are often thought to be the species used to make wine in the premier wine regions, while French-American hybrid grapes are those used in regions vinifera grapes can’t be grown. However, each species brings something unique to the bottle and it may just be that blending grapes of both species will result in just what your wines need.

by Maureen Macdonald

34 BELLA TOSCANA!

A group of WineMaker readers were recently accompanied by Publisher Brad Ring on a winery and food tour through Tuscany. We share the highlights and photos from Italy’s renowned wine region.

36 OLD WORLD TO NEW

Sauvignon Blanc wines came to fame in France’s Loire region, but they have also achieved success in New Zealand, the U.S., and elsewhere. Four winemakers from these top Sauvignon Blanc-producing regions share their techniques that result in wines of varying character and flavors.

by Danny Wood

by Danny Wood

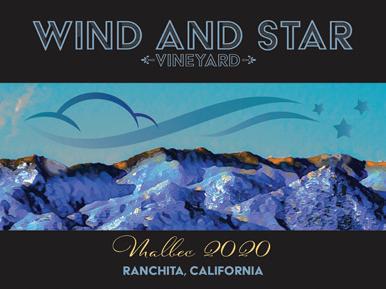

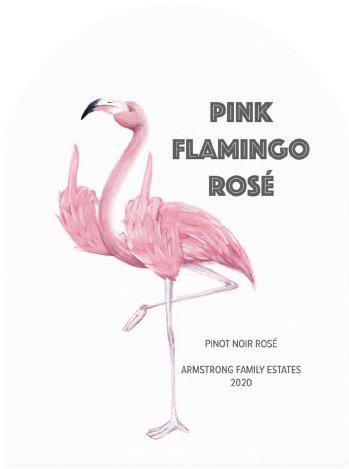

42 2022 LABEL CONTEST WINNERS

Hundreds of home wine labels were entered in WineMaker’s 22nd Annual Label Contest. We share all of the winning labels that make the bottles look as good as the wine inside tastes.

2 FEBRUARY - MARCH 2022 WINEMAKER

features contents February-March 2022, VOL. 25 NO. 1 WineMaker (ISSN 1098-7320) is published bimonthly for $26.99 per year by Battenkill Communications, 5515 Main Street, Manchester Center, VT 05255. Tel: (802) 362-3981. Fax: (802) 3622377. E-mail address: wm@winemakermag.com. eriodicals postage rates paid at Manchester Center, T, and additional mailing offices. O TMA T end address changes to WineMaker, P.O. Box 469118, Escondido, CA 92046. Customer Service: For subscription orders, inquiries or address changes, write WineMaker, P.O. Box 469118, Escondido, CA 92046. Fax: (760) 738-4805. Foreign and Canadian orders must be payable in U.S. dollars. The airmail subscription rate to Canada and Mexico is $29.99; for all other countries the airmail subscription rate is $46.99. 34 28 42 36

Still Only One Original!

Original Alljuice

FORMAT + OPTIONAL = YIELDS READY IN 23 L 4 kg 23 L * 8 WEEKS 6 US gal 8.8 lb 6 * US gal

Experienced winemakers looking to complement their skills will be rewarded with our most popular shelf-stable flagship vinification product. Explore the possibilities with superior quality 100% GRAPE MUST varietals sourced from the finest regions around the world.

The ORIGINAL ALLJUICE will instantly become one of the best additions to your cellar.

NO water has been removed from our 100% GRAPE MUST therefore, NO water needs to be added. Our 23 L/6 US Gal. shelf-stable vinification products are available year-round & produce quality wines unmatched by those from a concentrate product, guaranteed. With a little more patience, watch for the characteristics to develop.

BEER MALT Sign up to our newsletter MOSTI MONDIALE.COM Sharing GOOD TIMES & GOOD WINE Happy HOUR is BACK! MOSTI MONDIALE OFFICIAL DISTRIBUTOR CONCENTRATED BREWING MALTS!

100% GRAPE MUST

departments

8 MAIL

A reader seeks advice on how to calculate sugar additions for backsweetening. Plus, a former (two-time) Winemaker of the Year winner explains why more expensive is not always better, especially for winemakers just dipping their toes in the hobby.

10

CELLAR DWELLERS

With a range that stretches from Missouri all the way up towards the Hudson River in New York, Vignoles is a popular hybrid white grape varietal. Learn about it along with the basics of pH meters and catch up on the latest news and events.

14 TIPS FROM THE PROS

Hybrid grapes pose certain challenges to winemakers including higher acidity and lower tannins. Three cool-climate winemakers share their advice to create a balanced wine from these grapes.

16 WINE WIZARD

When a winemaker gets their hands on some highly coveted Cabernet Sauvignon grapes, he wants to make sure that the oak quality matches the grape. But he balks at the price tag of a new oak barrel. Get some tips for high-quality oak alternatives and ways to correct a raspberry wine with weird numbers.

20

VARIETAL FOCUS

Grape varietal names can be a confusing world, typically because one grape varietal may have over a dozen names based on location. But in this case, one grape name has an array of grape varietals. Get the scoop on onarda Argentine, one whose history is finally making sense thanks to DNA analysis.

47 TECHNIQUES

What good is having a thermometer or titration kit if the numbers you are getting from them are off? Make sure you are properly calibrating all your wine testing equipment.

50

BACKYARD VINES

The reader letters have been piling up, so Wes decides it’s come that time again to pick up the pen and share some of the most useful questions (and his answers) that readers have sent to him over the past year regarding backyard viticulture.

56

DRY FINISH

Fifty years ago a hobby winemaker decided to “go pro” by opening his own home winemaking supply shop. To attract customers, he started a winemaking club. The Purple Foot Wine Club is still going strong and wants to raise a toast to mark the occasion.

4 FEBRUARY - MARCH 2022 WINEMAKER

53 SUPPLIER DIRECTORY 55 READER SERVICE where to find it ® 20 Photo courtesy of Wikipedia Commons

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 5 WHEN: Starting February 2022! SAVE: Up to 15% Off Or More TIP: Best Time To Order Custom Speidel Wine Tanks! PRESEASON SALE! ORDER EARLY & SAVE 15% MOREWINE.COM Crusher Destemmers • Wine Pumps • Plate Filters • Wine Presses • Speidel Wine Tanks • Bottle Fillers • And More! • Looking for Bottles, Caps and Closures? 888-539-3922 • waterloocontainer.com Like us on Facebook! • Extensive inventory of ready-to-ship bottles, caps and closures • No MOQ on most items – we serve all sizes of customers • Industry expertise to guide you through the packaging process • Quality products and customization to create or enhance your brand You Can Rely on Us

EDITOR

Dawson Raspuzzi

ASSISTANT EDITOR

Dave Green

DESIGN

Open Look

TECHNICAL EDITOR

Bob Peak

CONTRIBUTING WRITERS

Chik Brenneman, Alison Crowe

Dominick Profaci, Wes Hagen

Bob Peak, Phil Plummer, Alex Russan, Jeff Shoemaker

CONTRIBUTING ARTISTS

Jim Woodward, Chris Champine

CONTRIBUTING PHOTOGRAPHERS

Charles A. Parker, Les Jörgensen

EDITORIAL REVIEW BOARD

Steve Bader Bader Beer and Wine Supply

Chik Brenneman Baker Family Wines

John Buechsenstein Wine Education & Consultation

Mark Chandler Chandler & Company

Wine Consultancy

Kevin Donato Cultured Solutions

Pat Henderson About Wine Consulting

Ed Kraus EC Kraus

Maureen Macdonald Hawk Ridge Winery

Christina Musto-Quick Musto Wine

Grape Co.

ene pa iani American Wine Society

Jef Stebben Stebben Wine Co.

Gail Tufford Global Vintners Inc.

Anne Whyte Vermont Homebrew Supply

EDITORIAL & ADVERTISING OFFICE

WineMaker

5515 Main Street

Manchester Center, VT 05255

Tel: (802) 362-3981 Fax: (802) 362-2377

Email: wm@winemakermag.com

ADVERTISING CONTACT:

Kiev Rattee (kiev@winemakermag.com)

EDITORIAL CONTACT:

Dawson Raspuzzi (dawson@winemakermag.com)

SUBSCRIPTIONS ONLY

WineMaker

P.O. Box 469118

Escondido, CA 92046

Tel: (800) 900-7594

M-F 8:30-5:00 PST

E-mail: winemaker@pcspublink.com

Fax: (760) 738-4805

Special Subscription Offer

6 issues for $26.99

Cover Photo Illustration: Charles A. Parker/Images Plus

What type of wine do you like to enjoy on a cold winter night?

Can I say a Cognac . . . ? I mean it is grape-based. Because a Cognac sitting by a crackling fire it sno falling outside seems about my ideal winter night. But a Port wine would be my ne t up. omet ing about the warming sensation and sweetness of Port ma es it t e perfect inter nig tcap.

A cold winter’s night immediately brings to mind sitting comfortably in front of a roaring fireplace fire at home. But what to drink? I believe a nice tawny Port is always a go-to, but what screams the holidays and cold winter night to me is mulled wine. I make this at home with my Concord based offdry wine. To each bottle of wine I add 1 4 cup of sugar and a simple mulling spice tea bag. e spices typically include cinnamon, cloves, all spice and a bit of orange peel. I allo these to simmer in the wine and sugar in a teapot. erve in a clear glass punc cup. ot ing arms the heart and soul more than enjoying this warm wine with your loved ones on a cold winter night.

Salute!

PUBLISHER

QBrad Ring

ASSOCIATE PUBLISHER & ADVERTISING DIRECTOR

Kiev Rattee

ADVERTISING SALES COORDINATOR

Dave Green

EVENTS MANAGER

Jannell Kristiansen

BOOKKEEPER

Faith Alberti

SUBSCRIPTION CUSTOMER SERVICE MANAGER

Anita Draper

Plan Your First Vineyard

Planting a vineyard is a lot like deciding to have a baby. When confronted with all the responsibilities and tasks associated with parenthood — or vineyard ownership — you might feel suddenly overwhelmed. Planning is key to success. https:// winemakermag.com/article/559-planyour first vineyard

MEMBERS ONLY

Winemaking Tips From Bordeaux

Bordeaux wine styles are the dreams, the ultimate goal of Cabernet and/or Merlot winemakers. Get some pointers for crafting your own Bordeaux-style red blend. https://winemakermag.com/ technique/bordeaux-winemaking-tips

Blending Red and White

All contents of WineMaker are Copyright © 2022 by Battenkill Communications, unless otherwise noted. WineMaker is a registered trademark owned by Battenkill Communications, a Vermont corporation. Unsolicited manuscripts will not be returned, and no responsibility can be assumed for such material. All “Letters to the Editor” should be sent to the editor at the ermont office address. All rights in letters sent to WineMaker will be treated as unconditionally assigned for publication and copyright purposes and subject to WineMaker’s unrestricted right to edit. Although all reasonable attempts are made to ensure accuracy, the publisher does not assume any liability for errors or omissions anywhere in the publication. All rights reserved. Reproduction in part or in whole without written permission is strictly prohibited. Printed in the United States of America. Volume 25, Number 1: February-March 2022.

You know from art class that red and white make pink, but is the same true for wine? Often rosés and blush wines are made from red grapes briefly e posed to the skins and then vinified as a white wine. ome pink wines, however, are a different breed. https://winemakermag.com/article/96blending-red-and-white-tips-fromthe-pros

MEMBERS ONLY

O beat Reds

Getting sick of the same old Cabernet or Merlot? Try a red wine that’s more out of the mainstream, like Carménère, Charbono, Dolcetto, Montepulciano, or Tinta Cão. https://winemakermag.com/article/ offbeat-reds

On a cold winter night I love a big glass of Italian Amarone while sitting by a roaring fire and letting the warmth of t e ames open t e avors and aromatics of this classic.

MEMBERS ONLY

* For full access to members’ only content and hundreds of pages of winemaking articles, techniques and troubleshooting, sign up for a 14-day free trial membership at winemakermag.com

6 FEBRUARY - MARCH 2022 WINEMAKER

suggested pairings at ®

WINEMAKERMAG.COM

WineMakerMag @WineMakerMag @winemakermag

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 7 www.lallemandbrewing.com/wine FULL

RANGE OF PREMIUM WINE YEAST K1 ™ (V1116) FRESH

AND FRUITY STYLES EC1118 ™ THE ORIGINAL “PRISE DE MOUSE”

71B ™ FRUITY AND “NOUVEAU” STYLES D47 ™ FOR COMPLEX CHARDONNAY QA23 ™ FOR COMPLEX SAUVIGNON BLANCS

™

speidel-stainless-steel-tanks.com The laser-welded cooling jacket enables e ective temperature control up to an operating pressure of 6 bar which is one of the best performances on the market. Play it Safe!

RC212

FOR PINOT NOIR STYLES

CALCULATING SUGAR ADDITIONS WHEN BACKSWEETENING

I ust finished reading the Tips from the ros article acksweetening Fruit Wines” in the June-July 2021 issue and was wondering if you could clarify Rex Johnston’s statement “. . . we begin with 10% by weight sugar and make additional solutions up to 20% . . .” Ten percent of what weight? The weight of the 5- to 10-gallon (19- to 38-L) batch? The weight of the fruit used? Is the weight of the combined sugar and liquid used to make the sugar solution, or just sugar for the computation?

Thanks for clarifying this; otherwise it’s a good short piece.

Rich Torquemada • Stevensville, Montana

Here is what Rex had to add in order to clarify his statement: “The wine fermented to dryness can be considered to have 0% sugar by weight. If you weigh 90 grams of 0% sugar wine and add 10 grams of sugar, you will have 10% by weight of sugar in the fermented wine. Similarly, you prepare 12% by weight, 14% by weight, 16% by weight, 18% by weight and 20% by weight. Then you get about four friends who each have six glasses with about 15 mL of each solution in front of them. Then you all come to agreement as to which tastes best.”

Now, if you are wondering how to determine the weight of your wine that’s already inside a carboy there are a couple approaches. Since you should be doing these sweetening tests as bench trials where you are drawing samples anyways, you should be able to do some math to figure out how much the entire 5 gallons (19 L) weighs by multiplying the sample to equal 5 gallons (19 L). Or, if you have an empty carboy that is identical to the one you have filled, weigh the empty one and deduct that weight from the full one (and in the future, make note of the weight of each empty carboy so you know).

YOUR FIRST WINE KIT

I was one of four amateur winemakers invited to participate in a recent WineMaker ive Chat a free monthly benefit for digital members) and would like to further explain my thoughts on a topic that was discussed. I was the only winemaker on the panel who recommended buying an inexpensive wine kit to cut your teeth on if you are new to the hobby. The others recommended buying the best kit you can afford and follow the directions to a tee. I

Maureen Macdonald is a University of Vermont graduate with 17 years professional experience in the beverage and wine industry. She has experience in both viticulture and enology as a Field Manager and Head Winemaker for commercial vineyards. After years of working as a consultant to many vineyards, she now is the Head Winemaker for Hawk Ridge Winery in Watertown, Connecticut, where she makes 30 different wines. When she isn’t hard at work in the lab or winery, she is often judging commercial and amateur competitions or making hard cider and beer at home.

Maureen has experience making wines from both hybrid and vinifera grapes in Connecticut. In this issue, she writes about the benefits of blending these two species to create balanced wines, beginning on page 28.

Danny Wood is an Australian-based journalist who lived in Kansas City, Missouri, for a decade before moving home with his family. He’s made wine in his basement, worked in wineries, and is a former editor of Midwest Wine Press. He also studied enology while in the United States and judged the occasional wine competition, but was really smitten by vino (and his American wife) while living in Spain, reporting for BBC News. In past issues of WineMaker, anny has profiled oel Peterson and Ravenswood Winery, written stories on Australian winemaking, fermenting with wild yeast, essential winemaking techniques, the varieties of Chardonnay, Malbec, Tempranillo, and many other topics.

Beginning on page 36, Danny shares the advice from four renowned winemakers across the world to crafting a crisp Sauvignon Blanc.

Wes Hagen is the Consulting Winemaker and Brand Ambassador for J. Wilkes

Wines in Santa Maria, California after 21 years of making and growing wine for Clos Pepe Vineyards in the Santa Rita Hills of California. He does home vineyard consultations, writes AVA petitions, lectures, and writes on wine and viticulture. He is also WineMaker’s longtime “Backyard Vines”columnist, and the author of the 80-page special issue The Best ofWineMaker:Guide to Growing Grapes (https://winemakermag.com/store/special-issues/guideto-growing-grapes). Got grape growing questions? Hit him up on social media at Facebook: Wes Hagen, Twitter: @jwilkeswines, Instagram: J.Wilkes_Wines

Wes answers dozens of grape growing questions from home viticulturists every year, and each year we pull together a collection of some of his best responses. The most recent edition of “Ask Wes” makes up his “Backyard Vines” column beginning on page 50.

8 FEBRUARY - MARCH 2022 WINEMAKER contributors

MAIL

disagreed. I did say that if you screw up you wouldn’t feel as bad screwing up with an inexpensive kit, but I never had the chance to further explain my differing opinion. Here is my further explanation on why I suggest new winemakers begin with an inexpensive kit.

I belong to several winemaking groups on acebook. The first thing I have noticed is that people want instant results. Most of the expensive kits need more time before you can actually drink them. Patience is often not something newbies want to deal with. Inexpensive wine kits are good, fun, easy, cheap, and quick. Kind of gets you hooked.

Newbies also often don’t want to invest a lot of money in a new hobby so they try to get by with minimal equipment. Some of the most common issues I’ve seen from new winemakers are:

• Not getting a hydrometer to see when fermentation is complete or not knowing how to read a hydrometer, which can result in a dry wine with residual sweetness. I have seen where people asked how to restart their fermentation because they thought their wine was finished so they added all the finishing packets only to discover later it was still sweet. I looked back at my beginning kits and they did contain potassium sorbate.

• Not knowing how to, or not having the ability to control the temperature of fermentation. I have seen the correct sized buckets that have bubbled over due to a very aggressive fermentation.

• Or how about the famous degassing volcano!? I remember the first time I tried to degas with the drill as the directions said. Yup, lost at least a gallon (4 L) of wine, if not more. I can chuckle

about it now, but I had wine everywhere. They definitely didn’t have that listed on the directions.

• Having too much headspace in their carboy when they are aging it because they don’t have the different sized carboys or ability to gas it or add enough sanitized marbles. I have even seen where people have added a gallon (4 L) of water (diluting it) to try and keep it topped up.

• Then there are the glass carboys that break too easy. They seem thick and tough right? I have dropped a full carboy on my kitchen tile floor and it did not break broke a tile but then again, I’ve also set a full carboy gently on my garage floor, fracturing it causing a loss of all that killer wine I worked so hard on (Petite Pearl).

• I have even seen many posts about how a winemaker started their wine and forgot about it during the aging process. The airlock went dry or they found it a year later. This is the hardest one because they went through all the steps and all the work only to lose their wine later. Life happens.

So, you see, this is why I recommend learning with less expensive kits. Inexpensive kits are great to help you learn the process and get your feet wet. Then you feel more confident being able to move on to the more expensive kits. Most important, you can be drinking those less expensive, tasty kit wines while feeling more confident about spending your hard earned money making those expensive, amazing kits that are out there!

Kathleen Ondrus • Fruita, Colorado

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 9

MAIL

RECENT NEWS

The European Union Approves Hybrid Grape Use

Some of the strict guidelines controlling protected designation of origin (PDO) has recently been modified by the uropean nion to include disease resistant hybrid grapes. Many hybrid grapes were created in France in response to the great phylloxera louse epidemic that began in the mid-nineteenth century and killed roughly 70% of France’s wine grape vines by 1900. The new varietals were a cross of the European Vitis vinifera wine grapes with native American grape species that were resistant to the phylloxera aphid. While the new hybrid varietals were utilized with great success in some parts of Europe, the process of grafting V. vinifera scions onto native American rootstock ended up being the solution most vineyards chose. But a few vineyards, most notably those in cold places, found that the “new” hybrids could outperform V. vinifera grape vines thanks to some cold hardiness from their North American DNA. Pockets of hybrid wine grape producers still exist in continental Europe today and they are especially popular in non-traditional wine grape growing regions like England and Scandinavia.

So while a few vineyards remained entrenched in growing and making wine from hybrid grape varietals surrounding PDOs, the PDOs outlawed the use of any of them in their wines because of the view that they produce inferior quality wines. The recent decision by the EU was based on the continent’s changing climate and the fact that the wine world will need to evolve to meet new challenges, especially those posed by disease pressure. The hybrid grapes are often more resistant to such pressure compared to the native V. vinifera cousins. This also allows vineyards to use less pesticide as well during the growing season. So maybe in a few years you will see Marquette blended in that Burgundian Grand Cru . . . ? Ha! Most likely not . . . but you just never know. Read more at:

https://eur-lex.europa.eu/eli/reg/2021/2117/oj

4, 2022

Distilling Boot Camp with Aaron Hyde. How to Distill book author Aaron Hyde will walk you through the small-scale distilling process over four hours. You’ll watch a live spirit distillation with cuts for whiskey, and Aaron will also discuss the distillation of most major spirits including moonshine, brandy, rum, whiskey, and gin. He’ll be answering your questions throughout the process as you learn the art of distillation using a small still. This class runs from 2 pm to 6 pm (Eastern).

https://winemakermag.com/product/distilling-online

18, 2022

GaragisteCon Online. A full day of live online seminars and Q&A panels for small-scale wineries and aspiring wineries. All attendees will have access to video recordings of all sessions. There are three learning tracks: Business/Sales, Winery Operations, and Start-Ups as well as Q&A sessions with leading small winery industry suppliers. Get your questions answered live by industry experts. Also attendees get to interact with other small wineries and wineries-in-planning to compare notes.

https://winemakermag.com/garagistecon

10 FEBRUARY - MARCH 2022 WINEMAKER

News

New

UPCOMING

EVENTS

FEBRUARY FEBRUARY

Photo courtesy of Shutterstock.com

AWARD-WINNING KITS

Here is a list of medal-winning kits for the White, Red, and Blush Table Wine Blends categories chosen by a blind-tasting judging panel at the 2021 WineMaker International Amateur Wine Competition in West Dover, Vermont:

Red Table Wine Blends

SILVER

RJS Craft Winemaking Okanagan

Meritage

Wine pert imited dition acific

Red Quartet

BRONZE

RJS Craft Winemaking En Primeur

Italian Super Tuscan

RJS Craft Winemaking RQ Australian

Pinot Noir Shiraz

RJS Craft Winemaking RQ Chilean

Cabernet Sauvignon Merlot Syrah

VineCo Passport Merlot Cabernet

Winexpert Classic Chilean Diablo

Rojo

Winexpert Limited Edition Chilean

Corazon

Winexpert Limited Edition South

African Blend

Winexpert Vintners Reserve Coastal

Sangiovese Syrah Tempranillo

Winexpert World Vineyard Trinity

Red

White Table Wine Blends

GOLD

RJS Craft Winemaking Crush Select acific uartet

SILVER

Wine pert imited dition acifica

White

Winexpert Limited Edition Yolo

White

Blush Table Wine Blends

BRONZE

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 11

www.ldcarlson.com

RJS Craft Winemaking Orchard Breezin’ Blush Crush

Awhite hybrid grape varietal whose parentage is currently unknown in a story of mistaken identity. Thought originally to be a cross between a Pinot Noir clone and one of Albert Seibel’s hybridized grapes, genetic testing has shown that the vines now labeled Vignoles are actually from a different line altogether with neither of these two found in its genes. This white grape is grown primarily in a belt stretching from the Hudson Valley region of New York to Pennsylvania through the lower Midwest; including Missouri, Indiana, Ohio, and Kentucky.

In the vineyard, Vignoles breaks bud late allowing it to escape most latespring frost events. On average it is known to take roughly 105 days to get the grape from bloom until harvest. Its thick skin allows some grape growers to leave it hanging long enough to produce ice wines, obtaining upwards of 30 °Brix. Botrytis is a threat with Vignoles, but can also be utilized by the winemaker to obtain a honey-like character in the wine, most notably if going for a Sauternes style of sweet wine.

Vignoles is considered a high-sugar, high-acid hybrid grape. Winemakers will typically need to provide some backsweetening at bottling to counter the acid levels with semi-dry wines being the most common table wine produced from the grape. There are some examples of dry varietal wines being produced. Blending is another common approach to producing wines with Vignoles.

12 FEBRUARY - MARCH 2022 WINEMAKER FrozenGrapesfromtheBest VineyardsinFreezersNowin California • Oregon • Pennsylvania ForPick-UporDirectShipping www.BrehmVineyards.com grapes@brehmvineyards.com 510-527-3675 POBox157,Underwood,WA98651 GRAPE PROFILE VIGNOLES

Photo courtesy of Double A Vineyards, Inc.

BEGINNER’S BLOCK

BY DAVE GREEN

pH METERS A

fter some convenience items like a racking cane and a wine thief are added to your winemaking equipment arsenal, a quality pH meter should be one of your next investments. Being able to get an accurate read on where your wine’s pH lands on the spectrum has huge implications not only for flavor and balance, but more importantly its microbial stability and impact on sulfite additions. It is probably the single most important number you can obtain while making wine.

pH METER BASICS

While the exact science of how a pH meter works is not all that important, a basic explanation is that the probe you submerge in your solution (wine) is reading the level of hydrogen ions. Because of the chemistry involved, pH meters are temperature-sensitive and readings can change depending on the temperature of your solution.

pH meters must be calibrated before each use with two solutions designed to specifically read p at a certain level. These are generally referred to as calibration reagents or buffers and the two that winemakers want to always have on hand is one at pH 4.01 and the other at pH 7. These reagents do need to be replaced periodically, so be wary of the expire date. Also be sure to secure the caps back on when finished with each use since evaporation will affect the reagents’ ability to properly calibrate your meter.

Finally, your pH meter’s probe needs to always be stored in one of the calibration reagents or in designated pH electrode storage solution and should never be left to dry out or stored in distilled water. There is a solution inside the probe that once dry will need to either be replaced or the whole pH meter will need replacing, depending on the model pH meter you choose.

CHOOSING A pH METER

While there is the more affordable

option of getting pH test strips, an investment in a decent-grade pH meter is highly recommended for anyone who wants to take their winemaking to the next level. A quality stick-type pH meter will start around $50, but can range up above $100 for the higher-end stick meters. Sticks are easy to use and a small footprint makes them easy to take with you and store away. The higher-end stick pH meters will have a feature called ATC, or automatic temperature correction, as well as enhanced pH precision. The beauty of the ATC feature is that if your juice is cold, it will adjust pH readings to correct the variance. One of the major issues with stick pH meters is that their design is really for handheld, quick readings. More advanced winemaking lab skills will find these shortcomings to be problematic.

Next up are the portable pH meters which, like stick pH meters, are easy to transport, but do have a slightly bigger footprint. These are a good mid-range meter that often will feature ATC and may or may not provide the precision of a stick pH meter. That depends on the models you are looking at. These start around $120 for a quality model with ATC.

A bench-top pH meter is only for beginning winemakers who believe in the “buy once, cry once” philosophy. A top-end, laboratory-grade model can run over $1,000, but more affordable options generally start in the $200 range. These should feature ATC as well as improved accuracy, precision, and the ability to replace the probe in case of failure. Many of these also now offer some sort of technological interactions as well, allowing you to log or chart readings to a computer or app. For those that want their pH meter to grow with their hobby, you’ll want to invest in one. But besides the higher price tag, they

also have a bigger footprint and lack the portability aspect.

Finally, choosing a known manufacturer like Hanna, Milwaukee, or Vinmetrica is a good choice for winemakers since they are well-known in the wine world and folks can easily get advice on them from fellow winemakers. Also, a precision level of ±0.01 is more than enough for even picky home winemakers. Steer clear of meters with more than ±0.1 pH precision as that is not good enough for winemaking.

pH METER USES

Getting a pH read on fresh juice or grapes is going to be key for several possible winemaking additions. Generally white and rosé winemakers are looking for juice to fall in the 3.0–3.4 range while red typically should be between 3.2–3.6. Winemakers can either acidify the juice or de-acidify if the juice falls far outside of its respective range. These are just generalizations though and should not be used as gospel. Other factors such as TA, or titratable acidity, may also be a factor. But if wine pH is too high, there are several potential problems, most notably: The wine is much more susceptible to infections, more sulfites are needed as p rises, and wine often tastes flat lacking any bite). When pH is too low yeast and other microorganisms winemakers want may struggle. It may also be overly harsh/sour on the palate.

A pH meter can offer more for winemakers than just getting a read of a juice or wine’s pH. With a few extra pieces of equipment, most notably a burette, winemakers can also get the TA levels as well (another important measurement for winemakers in tandem with pH). TA readings can be performed without a pH meter using phenolphthalein as a pH indicator, but the problem is that the indicator is pink and therefore does not work well on red wine. For that reason, it’s only suited for TA readings with whites . . . and you are much better off with a pH meter anyway.

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 13

Photos courtesy of MoreWine!

TIPS FROM THE PROS

BY DAWSON RASPUZZI

FINDING BALANCE WITH HYBRIDS

When is intervention necessary?

French-American hybrid varieties allow wine grapes to be grown in locations that European varieties cannot succeed. However, hybrids often require extra attention in the winery as they are notorious for higher acidity, lower tannins, and color instability. There are many ways to address these potential shortfalls, and the choices a winemaker makes can really show their talent. We asked three pros who grow hybrids to share their advice for crafting award-winning wines from them.

Giacomo “Jim” Verde retired from teaching biology in 2002 after 38 years. After visiting nearby vineyards in Connecticut he was impressed by the hardiness and quality of hybrids and planted some vines, which in four years produced a very good wine. By 2012 Verde Vineyards became a commercial winery located in Johnston, Rhode Island.

The hybrids we grow in our Rhode Island vineyard off Moswansicut Lake include the red varieties St. Croix and Petite Pearl, as well as the white grapes La Crescent, Itasca, and Cayuga White. Each has its own personality and although they are more resistant to diseases than the vinifera varieties, they still need to be sprayed with fungicides. La Crescent is particularly susceptible to downy mildew and Cayuga to sour rots. We also grow the vinifera varieties Merlot, Cabernet Franc, and Lemberger (also called Blaufränkisch). Of these three, Merlot presents the greatest challenge to grow in our region as it is susceptible to cold damage. The vineyard is about 20 miles from the Atlantic Coast where the winters are milder than much of New England, so we do have success with these varieties. The vinifera varieties need to be sprayed more often than the hybrids. New England weather is quite variable and poses challenges from year-to-year. This past July 2021 was quite rainy and humid and promoted the growth of fungal diseases, especially black rot. And we are always worried about cold spells, which are deadly for the vinifera. The hybrids have withstood many below-zero nights unscathed. While we are primarily talking about creating balance in the winery, it is important to understand the impact that weather and viticulture decisions play in the resulting grapes.

Our St. Croix is picked at 18 °Brix. As the grapes ripen more than that the

berries tend to fall off and of course there is always the danger of getting a “foxiness” to the wine. Foxiness means the wine will have the aromas of a wild grape (Vitis labrusca, called the fox grape) — a mutant of which is the Concord grape, which will give the wine aromas like Welch’s grape uice. The St. Croix hybrid is a genetic mixture of wild grape genes and varieties from Europe. The wild genes give the hybrid variety resistance to cold and indigenous diseases and the European varieties contribute pleasant flavors and aromas. For our other hybrids; Cayuga is picked at 19 °Brix while Petite Pearl, La Crescent, and Itasca are harvested at 24 °Brix. We make dry wines so sugar levels are controlled.

Since the hybrids are on the acidic side, choosing a yeast strain that reduces acidity is important. The addition of sugar also helps fight high acidity. Sometimes we also adjust acidity with a bit of potassium bicarbonate. Tartaric acid is reduced considerably by cold stabilization and by blending the red hybrids with red vinifera varieties. Most of our hybrids are used, however, to make varietal wines. We do not cold stabilize the reds.

The one hybrid/vinifera blend we make is called Surveyor, and is a blend of Cabernet Franc, Lemberger, Merlot, and St. Croix. It is a well-balanced red wine that is a combination of a true blend and field blend.

Tannin additions are uncommon for us as the hybrid grapes we grow actually come through with good balance. Enzymes are only used for the whites.

14 FEBRUARY - MARCH 2022 WINEMAKER

Since the hybrids are on the acidic side, choosing a yeast strain that reduces acidity is important.

e work with a lot of hybrid grapes including Cayuga White, Seyval Blanc, Vidal Blanc, Corot Noir, and Traminette, as well as a number of vinifera grapes including Chardonnay, Riesling, Cabernet Franc, Saperavi, Dornfelder, Zweigelt, and Lemberger. Corot Noir is the only red hybrid we grow — in a good year I am looking for 19–21 °Brix, 3.4 pH, and a titratable acidity (TA) of 8.0–9.0. Even in those ideal years I’ll usually add some sugar to result in an appropriate alcohol after fermentation (I typically try to make our Corot Noir at 11–12% ABV). Of course, not every vintage is ideal. I have harvested the Corot Noir at 16.5 °Brix, 3.1 pH, and a TA of 9.5. When we get grapes like that I’ll add sugar and do a full malolactic fermentation, as well as use different yeast strains to reduce the acid (usually Lalvin 71B-1122, but I have also

used CSM from Scott Labs and Lalvin ICV-GRE). I prefer that the grapes and growing season dictate the wine. Still, I am consistent with the wine style that Corot Noir makes annually — which is a dry red wine aged in barrels. I don’t normally blend it with a vinifera as we like the varietal character. This past year was wet and I found the grapes were a little behind normal, leading to a slightly later harvest, more sugar added, and more malolactic culture.

To help with the color in the Corot Noir I punch down the cap during fermentation at a high temperature of 85–90 °F (29–32 °C). I also use tannins and enzymes to stabilize the color. I use fermentation tannins from Scott Labs and, if needed, an aging or finishing tannin.

For home winemakers, the best advice is to get the best fruit possible. But even if it isn’t perfect, there are many options available to help you make a good wine.

We grow Marechal Foch and Leon Millot at our estate vineyard, and I also have experience with numerous other French hybrids: Seyval Blanc, Vidal Blanc, DeChaunac, and Geisenheim, to name a few. The only vinifera we buy is Riesling.

We rarely reach full ripeness in our climate so our expectations are a pretty low bar when it comes to the “typical” numbers winemakers in other regions are accustomed to. If we get to 20 °Brix and pH of around 3 or so we are pretty happy. The only adjustments I ever make to our crop is to add sugar to reach an alcohol level that is appropriate for any given wine (which generally range from about 10.5% ABV up to 13% ABV for our red table wines).

In a poor growing year I have had fruit come in with a Brix at 17 and a pH of 2.8 — way green. The only options with fruit like that are to either blend it off into another wine to alleviate the problem or craft a wine from it where those characteristics are an asset. Fruit always determines the wine that it

gets crafted into. There is no point in trying to make a wine out of fruit that doesn’t have what it needs to succeed. No matter what you do, French hybrid is not going to ever magically evolve into vinifera. I run into so many wines where the winemaker thinks that oak will somehow turn a hybrid into Cabernet. Foolish. Make wine where the fruit is at its best. In the case of every hybrid I’ve encountered, that means fruit-forward with a light body — wines that are fresh and easy to drink.

When you have less than ripe fruit, which is very common in Wisconsin, you need to work the fermentation very hard to get everything available. In the case of color, that involves multiple pumpovers/punchdowns on a daily basis and maybe let a little more heat develop than would normally be tolerated.

The best advice I can give any winemaker, home or commercial, is to always start with the best fruit you can get your hands on. If you are a grower as well, concentrate on every best effort to bring in a quality crop. Good fruit is like a Porsche; there is no substitute.

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 15

James Baker is the Winemaker and Vineyard Manager at Hopkins Vineyard in Warren, Connecticut, where he has worked for 29 years.

Peter Botham has three years of professional training followed by 32 years of growing grapes and producing wine. He opened Botham Vineyards in Barneveld, Wisconsin in 1989, where he continues to make the wines more than three decades later.

W

BY ALISON CROWE

WINE WIZARD BARREL ALTERNATIVES

Also: Matching quality grapes with oak and the complexities of raspberry wine

QI MADE TWO BARRELS OF ALEXANDER VALLEY CABERNET SAUVIGNON THIS YEAR, AND THE BARRELS ARE PRETTY OLD, SO I DON’T THINK I’LL GET A LOT OF OAK AROMA OR FLAVOR OUT OF THEM. I REALLY DON’T WANT TO SPEND THE $2,000 (!) TO BUY A NEW BARREL AND AM WONDERING IF YOU COULD RECOMMEND HOW I CAN GET SOME GOOD AGING OAK ON THE WINE IN A WAY THAT’S NOT CHEAP TASTING BUT WOULD BE APPROPRIATE TO DO THE GRAPES THE CREDIT THEY DESERVE. I GOT THE FRUIT FROM A BUDDY WHO SUPPLIES LOCAL FAMOUS WINERIES AND I’D LIKE TO DO THE WINE JUSTICE . . . JUST NOT THOUSANDS OF DOLLARS WORTH, IF YOU GET MY MEANING.

WILLIAM SCHULTZ WINDSOR, CALIFORNIA

AHey, I see you, I hear you, and I’m so here for you! The average price for a French oak barrel has really become very high in the last couple of years (decades?) and winemaking is an expensive enough undertaking without loading all of that up-front cost into it. A new French barrel can easily cost over $2,000 and, as far as the straight-up oaky aromas and flavors are concerned, only have about three- or four-years’ life in them before they become relatively neutral storage vessels. As an old friend of mine would wryly sniff, “A used barrel is merely medieval Tupperware.” I don’t agree with him 100% but it is indeed true that the hint of vanilla and that kiss of toasty spiciness we love in a well-made wine becomes increasingly difficult to attain as a barrel gets older. While even neutral barrels provide a quality-enhancing dynamic aging environment where tiny bits of oxygen are allowed ingress over time, the aroma and flavor compounds we associate with top-quality wines, especially Cabernet Sauvignon, require at least a small amount of newer, toasted oak.

So, what’s a conscientious but impecunious winemaker to do? You can easily level up by introducing some delicious new non-coopered oak into the equation. What do I mean by “non-coopered oak” you may ask? It’s a term I came up with years ago to describe well-sourced, carefully toasted oak that just didn’t happen to be bent and built into a barrel. ar from the sawdust and factory floor sweepings of 20 years ago, the choice of “non-coopered oak” available to today’s winemaker is truly astounding. Just about every major cooper (barrel maker) I can think of is also offering a line or five of wood from their company, which can be administered in something other than barrel form. From small particles the size of a grain of rice to yard-long staves that can be built into aging stacks in stainless steel tanks or concrete eggs, there are many application types to choose from. Any toast level you’d want in a barrel can be found, from untoasted practically white wood all the way up to the highest, coffee-toffee char. In short, if you can dream it for your wine, you can probably find it.

If I sound like an oak-piece sales rep it’s because I really want to encourage

16 FEBRUARY - MARCH 2022 WINEMAKER

.

. . the aroma and flavor compounds we associate with top-quality wines, especially Cabernet Sauvignon, require at least a small amount of newer, toasted oak.

Photo courtesy of MoreWine!

New oak barrels can provide a lot of character to wine, but they are a sizable investment.

all home winemakers to give the world of non-coopered oak a spin. Gone are the days when you’d have to “pick-your-own” from a mystery bin of barrel-reject pieces in the back of a home winemaking supply store. Here are a few of the ways you can introduce oak into your winemaking:

• Oak in the red fermenter: I know it’s a little unorthodox but I learned it while I was working for Randall Grahm at Bonny Doon Vineyard (well, he is known as the King of Unorthodox Winemaking, after all . . .) and I’ve been a big fan ever since. The heat and increasing alcohol level of a red fermentation is the ideal time to get a jump on oak extraction and integration, which is why I highly recommend fermenting on about 1–1.75 g/L of small-particle oak.

A good standard item is something like French Medium Toast “pumpable-size” (so called because it’s small enough to go through a pump and hose) but not so small that it’s like fine sawdust. The smaller the particle the faster the e traction, and you can get a lot out of wood this size in the 7–14 days of your average red wine fermentation. There’s no need to “remove” the oak later, you just press it off and settle with the rest of your grape solids. You can also put larger oak pieces into food-grade mesh sacks and then suspend them in your tote or macro-bin. You can then re-use the chips if you want because it’s possible that they won’t have finished e tracting by the time the fermentation is complete. At the fermentation stage, oak can also serve as an antioxidant, a source of sacrificial tannins, and can even help support colored compounds. In my experience, light to medium oak toasts can also help reduce the perception of green and unripe characters if your Cabernet is leaning that way.

• Oak in the barrel: It’s time to bring some new oak back to your barrel! Whether it’s “chips in a sock” (like a tea bag), a cut-wood spiral, chains of pieces hooked together and passed through the bunghole, or even an elaborate internal scaffold; there are so many ways to put new wood into your barrel.

Coopers and oak-supply companies have come up with several inventive ways to get their product into our barrels. Do keep in mind, however, that some methods are easier than others. A metal infusion tube or nylon sock “tea bag” can be easier to remove than complicated, connected sticks. The many-pieced chains of wood sometimes get stuck into the barrel, making the barrel impossible to clean. At this point, you may just be better off doing the tea bag or sock. Some barrel companies offer a service where they remove the barrel head and actually build a scaffold of new wood inside (replacing the barrel head obviously . This way, your wine gets the double benefit of the aging dynamics of the barrel itself along with the new aroma and flavor compounds from the fresh oak.

• Oak Trials: Don’t forget, you can always do bench trials with oak chips. Though doing a bench trial of a large piece of stave wood is impossible, often the same company will sell the same wood (French, three-year aged) and toast level (say, Medium+ with half untoasted) in a chip or bean form so you should be able to get an approximate idea of what it might impart to your wine. It’s always good to have an idea of what such a substantial investment will impart on your wine.

Below is some information about barrel/oak/wood companies I’ve had some luck working with in the past few years. Please note, I do not have any endorsement agreements with anyone, nor is their mention here an indication of any kind of guarantee on my part. These are simply some of the companies I’ve dealt with in a positive way in my professional winemaking life in the last few years and I thought I’d pass on my experience to you. There are other products available in the hobby wine world, like Wine Stix, that I have not used.

Stavin (www.stavin.com): Stavin practically invented high-end, non-coopered oak in the United States and was a first mover in custom toasts and different flavor profiles back in the early 2000s. Their wood is carefully sourced in France, Hungary, or in the U.S. (depending on the origin of oak wanted)

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 17

Oak alternatives, or “non-coopered oak,” come in a wide array of formats and different ones can be used at different stages of the wine aging process.

Photo by Charles A. Parker/Images Plus

WINE WIZARD

and then is either fire toasted in a metal hoop ust like a barrel would be or, in some of their newer lines, kiln-toasted. One of their specialties is a product called Barrel Head, which is a very light toast and is great if your Cabernet has any green or unripe character to it.

Their delivery format is either “granular” (good for fermentation at about 1.5 g/L) or “beans,” which are cute little cubes about the si e of the end of my pointer finger. They are small enough to go nicely into a barrel sock type insertion but Stavin also sells perforated metal infusion tubes if you really want to give your barrel a good dose. Stavin also produces an interesting liquid oak additive called “Fire” that needs careful bench trialing to decide if it’s appropriate for your wine. Be careful, a little goes a long way and it’s expensive (but not as expensive as a new barrel!).

Radoux (www.tonnellerieradoux.com): A respected French barrel company, Radoux started working in the non-coopered business about ten years ago. Their Pronektar line offers powders, granules, segments, and staves. Their segments are about 2.5-in. square x 1 3-in. thick or 6-sq. cm x 1-cm thick providing an even toast while the staves are about the size and shape of a yardstick and come in mesh sacks or “fan arrays” held together by food-grade zip ties. These are great for hanging in porta tanks or small fermentation vessels but don’t fit into a barrel. Because the pieces of wood are bigger than a chip or bean, they do take longer to extract. In my experience this is very top-notch oak well worth checking out.

Barrel Mill (www.thebarrelmill.com): This is an unassuming, under the radar company that supplies whiskey barrels and various flavors of oak delivered in spiral form for wine aging. I’ve found their spirals to be quick-extracting, in about two months or so, and the flavors and aromas of the oak are pretty well-integrated in that short amount of time. Their barrel-insert spirals are quite affordable, at fractions of dollars per

gallon rather than tens or hundreds of dollars per gallon for a new or even once-used oak barrel. What’s pretty cool is that you don’t need to use the entire spiral all at once. In other words, if you want a lower oaking rate per gallon you could simply break off a piece of one and hang it in the barrel. Elegant, convenient, affordable, and tasty.

G3/Boise/Vivylis (www.g3enterprises.com): This is a large company that is supplying some innovative products to wine companies large and small. I’ve worked with some of their very quick-extracting chips, which they can provide in a wide range of flavors. These chips e tract to give you some good stuff” in as little as three weeks (though a full 8–10 weeks is preferred) and have less of a “chippy” fake taste than some other “chip-size” oak. Contact the company and request samples for big-bodied red wines. Their SC180XL and Phenesse Lush and Tradition chips do great with Pinot Noir. Cabernet might do better with something like their DC180 or other lines. You can do trials with small volumes before you decide what you’d like to use with your Cabernet (or other wines).

Long story short (and this is for all my readers, and not just our friend who wrote me this letter) — there is a whole new world of non-barrel oak out there that has been a professional wine industry “secret” for far too long. There are so many more sustainable and more environmentally friendly ways we can age our wine that doesn’t include the use of “medieval Tupperware making, transporting, filling, emptying, and cleaning barrels are a leading source of water and energy waste in the wine industry). As my mentor Randall Grahm used to say: “Winemaker, step away from the barrel.” What he usually meant was that we shouldn’t clobber our wines with unnecessary lashings of brand-new oak barrels. What he also meant, because we were living it daily in the cellar, was: “Winemaker, don’t be afraid to use oak that doesn’t come in barrel form.” I encourage you to expand your horizons in similar ways.

I NEED HELP IN SOLVING A RIDDLE WITH A HIGH TITRATABLE ACIDITY ( TA ) AND MEDIUM - HIGH p H RASPBERRY WINE. I AM AGING THIS RASPBERRY WINE CURRENTLY AND THE TA, POSTFERMENTATION IS ABOUT 13.4 WHILE THE p H IS 3.6. THAT SEEMS PRETTY FAR OUT OF LINE WITH WHAT NORMAL WINE SPECS ARE AND I’M NOT SURE HOW TO DEAL WITH IT. ALSO OF NOTE, I ADDED SOME CALCIUM CARBONATE AND THE p H/TA BALANCE DIDN’T REACT LIKE I EXPECTED IT WOULD. WHAT DO YOU RECOMMEND FOR CONTINUING TREATING/AGING OF THIS WINE?

HERE’S AN OUTLINE OF WHAT I DID ( EDITED FOR LENGTH ): PRIOR TO FERMENTATION, I ADDED THE CALCIUM CARBONATE AND AFTER TWO HOURS RACKED INTO A FERMENTATION BUCKET. I TOOK A SAMPLE AND MEASURED THE FOLLOWING SPECS: pH 3.54, TA 11.5, BRIX 22.

IT LOOKED LIKE THE CALCIUM CARBONATE HAD WORKED. I STARTED PRIMARY FERMENTATION USING LALVIN 71B AND ADDED YEAST NUTRIENT. AFTER PRIMARY FERMENTATION ENDED, I RACKED THE WINE OFF THE LEES INTO A 6- GALLON (23- L ) CARBOY: pH 3.6, TA 13.25 (??) HOW DID IT GO UP?

ONE WEEK LATER I RACKED AGAIN: p H 3.6, TA 13.5. I PROCEEDED TO DEGAS THE WINE AND ADDED ¼ TSP. OF POTASSIUM METABISULFITE POWDER AND FINALLY PLACED IN A REFRIGERATOR TO COLD STABILIZE. SO HOW WOULD THE WINE WIZARD PROCEED FROM HERE?

JEFF DAVIS MOUNT PLEASANT, SOUTH CAROLINA

18 FEBRUARY - MARCH 2022 WINEMAKER

Q

I really applaud you for keeping such detailed records and testing regularly. This really helps me when diagnosing issues and coming up with ways to help. I want to start off by saying that raspberries are a really high-acid fruit and that high titratable acidity won’t necessarily track with the pH like it does in wine from grapes.

For background (and to add to the fun of fruit winemaking), there can also be a considerable swing in pH/acidity and Brix depending on raspberry cultivar and growing season. In a study of four varieties in the 1980s and 1990s, a TA swing between 1.5% to 2.64% was observed. Buffering capacities for fruits will be different and we can’t expect a raspberry wine to behave like a grape wine, especially when the inherent chemistries are so different. Grapes are high in tartaric and malic acids especially, with smaller amounts of citric and other acids. Raspberries don’t have tartaric or malic acids and are very high in citric and ascorbic acid. In short, deacidification rules and practices that we may be used to in grapes won’t necessarily apply when producing a raspberry wine.

Since there isn’t any tartaric acid, your cold stability seeding step (seeding with potassium bitartrate crystals) won’t draw out tartrates like you’d expect from a grapebased wine. I am curious, however, if chilling the wine down had any effect of moving the TA down. It would definitely be worth it for you to do another TA and pH measurement

post-chilling to see where that moved your numbers. I’d be curious to see if freezing a small sample (and then measuring the pH and TA of the liquid on top of any precipitate) moved the TA and pH in a direction that you liked. But ultimately, “do you like the wine more?” is the real question. Because pH determines microbial activity (and affects color), I’m not sure I would add any more carbonates (potassium bicarbonate or calcium carbonate) to deacidify any further. Does the wine taste OK to you, even if the numbers are “out of balance” when we’re talking about table wine? If the acid tastes unpleasant to you, one trick is to balance it out with some sweetness and then sterile filter your final product. Can you add some sugar and alcohol like a non-harsh vodka or grappa) to make a sweet, boozy dessert wine? Sugar can cover up a lot of acid and help move a wine towards a more balanced state.

One of my favorite wines I ever had a hand in making was the famous Framboise dessert wine at Bonny Doon Vineyard. To make it (not that I can give away the exact formula), we took fresh raspberries and essentially macerated them in sugar syrup and neutral high-proof grape spirits. After a few weeks we pressed off and separated the solids from the liquids to create a sweet, higher-alcohol nectar. I know that’s not a traditional table wine and it’s very different than your product here, but I do think a lot could be achieved by adding some grape concentrate or sugar syrup and sterile filtering.

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 19

A

VARIETAL FOCUS

BY CHIK BRENNEMAN

BONARDA ARGENTINE

Or Douce Noir or Charbono . . .

What’s in a name? There is a lot in a name, but apparently, there is a considerable amount of subjectivity. As we focus in this issue’s topic, I was approached by the editors about a grape that goes by the name of Bonarda. Honestly, I was surprised that I didn’t know it as it was described to me. Did you know it is Argentina’s second most planted grape varietal after Malbec? So the research continued — surely there must be more information about this grape? But as I dug more into Bonarda, I found the information confusing. Well it turns out the grape I was researching is two, or maybe even seven, unique wine grape varieties depending on the story you want to believe. And the icing on the cake is that the “name” for the most abundant varietal of them, Bonarda, is not its proper name!

A grape varietal named Bonarda exists, but that is not actually the focus of this column. That grape is more properly known in Italy as Bonarda Piemontese, an aromatic, well-colored Italian red with small bunches and soft tannins. The resource goes on to say the name “Bonarda” is a misleading name applied to at least seven distinct varieties in northern Italy. Those varieties are Croatina, Durasa, Neretta Cuneese, Neretto Duro, Refosco Dal Peduncolo Rosso, Uva Rara, and Douce Noir. The last, Douce Noir, is where we will end up focusing our attention today . . . and we will soon see an interesting story unfold.

Until the end of the nineteenth century, Douce Noir was one of the most widely planted grapes of the Savoie region in eastern France. It was widely believed to have originated in the Piemonte region of Italy, where it was

often confused with Dolcetto (Dolcetto Nero). The confusion laid in the fact that the evidence tracing a variety’s origin many moons ago was based on ampelographic, or the morphologic features of the plant. White versus red fruit, leaf shape, hair patterns on the underside of the leaf . . . to name a few key ampelographic characteristics. And also, the written evidence needed to be teased from the journals of scientist and scholars. Some evidence was also contained in the municipal official scrolls. All of which took considerable time and effort for people trying to understand more about this grape.

Then along came science to the rescue. In 2006 and again in 2008, after bringing in A profiling, the research definitely supported the birthplace of Douce Noir to in fact be Savoie in France and not Piemonte of Italy. In Savoie it had many synonyms, and none of them mentioned Bonarda in their name. One of those synonyms was Charbonneau, which had also spread north to the Jura department.

Reading a little further into the name of French origin, it was further determined that a variety now cultivated in California, under the name Charbono, is identical to the Charbonneau/Douce Noir of Savoie. At some point the Charbonneau made it to Piemonte, where its name was Italianized to Charbono and lived out its life until it was no longer commercially cultivated there. The distance is not that far, maybe a couple of hundred kilometers (a little over 100 miles), so this makes a lot of sense, even without the historical records. The story goes on in that Charbono is thought to have been brought to California with Italian immigrants in the 1800s as the other northern Italian varietal, Barbera. But ampelographic evidence

20 FEBRUARY - MARCH 2022 WINEMAKER

Photo courtesy of Wikimedia Commons

Until the end of the nineteenth century, Douce Noir was one of the most widely planted grapes of the Savoie region in eastern France.

CALIFORNIA-STYLE CHARBONO Yield 5 gallons (19 L)

INGREDIENTS

125 pounds (57 kg) Charbono fruit

Distilled water

10 potassium metabisulfite M solution Weigh 10 grams of M , dissolve into about 50 mL of distilled water. When completely dissolved, make up to 100 mL total with distilled water.)

Tartaric acid

5 g Lallemand EC1118

10 g Diammonium phosphate (DAP)

10 g Go-Ferm

10 g ermaid or e uivalent yeast nutrient)

Malolactic fermentation starter culture (CHR Hansen or equivalent)

EQUIPMENT

15-gallon (57-L) food-grade plastic bucket for fermentation

5-gallon (19-L) carboy

1–2 one-gallon (3.8-L) jugs

Racking hoses

Destemmer/crusher

Wine press

Inert gas (nitrogen, argon, or carbon dioxide)

Ability to maintain a fermentation temperature of 85–90 °F (29–32 °C) TIP: You may have a need to keep it warm, in this case wrapping the fermenter in an electric blanket or other heat-generating source may be necessary.

Thermometer capable of measuring between 40–110 °F (4–43 °C) in one degree increments

Pipettes with the ability to add in increments of 1 milliliter

STEP BY STEP

1. Clean and sanitize all your winemaking tools, supplies, and equipment.

2. Crush and destem the grapes. Transfer the must or juice to your fermenter.

3. During the transfer, add 15 mL of 10 M solution. This addition is the equivalent of 50 ppm SO2

4. Take a sample to test for Brix, acidity, and p . eep the results handy. ayer the headspace with inert gas. eep covered and in a cool place overnight.

5. Go back to those lab results you took yesterday. Typical Brix for this style is 24–25 °Brix. Typical acid levels will be 0.65–0.7%. Adjust as necessary

using tartaric acid. If the acid is higher than 0.7%, don’t panic, this recipe calls for a minimum final acidity of 0.5%. Higher acid won’t hurt here.

6. Prepare yeast. Heat about 50 mL distilled water to 108 °F (42 °C). Mix the Go-Ferm into the water to make a suspension. Take the temperature. Pitch the yeast when the suspension is 104 °F (40 °C). Sprinkle the yeast on the surface and gently mix so that no clumps exist. Let sit for 15 minutes undisturbed. Measure the temperature of the yeast suspension. Measure the temperature of the must. You do not want to add the yeast to your cool juice if the temperature of the yeast and the must temperature difference exceeds 15 °F (8 °C). To avoid temperature shock, you should acclimate your yeast by taking about 10 mL of the must juice and adding it to the yeast suspension. Wait 15 minutes and measure the temperature again. Do this until you are within the specified temperature range. Do not let the yeast sit in the original water suspension for longer than 20 minutes.

7. The next day suspend the Fermaid in a little distilled water usually 0 mL). Add to must or juice and mix well.

8. You should see signs of fermentation within about one to two days. This will appear as some foaming on the must surface and it will appear that the berries are rising out of the container. This is referred to as the cap rise. You need to have on hand the ability to push the grapes back into the juice to promote color and tannin extraction. This is called “punching down” and this should be done three times per day using a clean utensil.

9. Monitor the Brix and temperature twice daily during peak fermentation (10–21 °Brix). Morning and evening is best and more often if the temperature shows any indication of exceeding 90 °F (32 °C). Place frozen water bottles in the fermentation if too warm then mix the must. Wait 15 minutes, mix, and check the temperature again. Do this as often as it takes to keep the temperature between 85–90 °F (29–32 °C). Do not cool off to less than 80 °F (27 °C).

10. At about 19 °Brix, dissolve the DAP

in a small amount of distilled water and mix into the must

11. When the Brix reaches 0 (about 5–7 days) transfer the must to your press. eep the free run wine separate from the press portion for now. Be sure to label your vessels.

12. Transfer the free-run juice to your 5-gal. (19-L) carboy and press fractions into the one-gallon (3.8-L) jugs. Your press fraction should only require 1–2 jugs. Make sure you do not have any headspace in the vessels. Inoculate with your malolactic (ML) bacteria. Check the manufacturer’s instruction on how to prepare and inoculate. Cover the tops with an airlock to allow CO2 gas to escape.

13. Monitor ML fermentation using a thin layer chromatography assay, available from most winemaking suppliers. Follow the manufacturer instructions.

14. When the ML is complete, add m of fresh M 10 solution per gallon (3.8 L) of wine. This is the e uivalent to 0 ppm addition. lace the wine in a cool place to settle

15. Consider adding some French and American oak chips to your press fractions. Do not treat the entire lot.

16. After two weeks, test for pH and SO2, adjust the SO2 as necessary to attain 0.8 ppm molecular SO2. (There is a SO2 calculator at www.winemak ermag.com/sulfitecalculator). Check the SO2 in another two weeks and adjust. Once the free SO2 is adjusted, maintain at this level. You’ll just need to check every two months or so.

17. Rack the wine clean twice over 6–8 months time frame to clarify. Fining and/or filtration are generally not needed if SO2 levels are maintained and if no surface films or indications of subsequent fermentations. Consult www.winemakermag.com for tips on fining and filtration if utilized.

18. Once the wine is cleared (about twelve months after the completion of fermentation) it’s time to organize a blending party to integrate the press/ oak fraction back into the free run. You may not need it all, use your judgement and make what you like.

19. If all has gone well to this point it can be bottled without filtration. Maintain sanitary conditions while bottling.

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 21

The Charbonneau/Douce Noir grape made it to Argentina under the name Bonarda.

from UC-Davis provided by Dr. Harold Olmo proved that this “Barbera” was actually Charbono/Douce Noir. Which led to the first labeled vintage of Charbono in California in 1 1, being produced by the famed Napa Valley winery, Inglenook.

Its migration away from Europe continued. The Charbonneau/Douce Noir grape made it to Argentina under the name Bonarda. DNA evidence does not support any similarities to Bonarda Piemontese or any of the six other aforementioned varieties of that Italian region other than the region from which it emigrated. Argentina now reports over 19,000 hectares of the misnamed “Bonarda.” To try to clear up the confusion, in 2011 the name Bonarda Argentine was given to the grape growing in the country. It is mostly cultivated in the Mendoza and San Juan regions where the hotter climates are ideal for it since it requires a long hangtime to get it to fully ripen. High-altitude vineyards can also do well with this vari-

BORDEAUX WINERY TOUR

September

18-23, 2022

Join us in Bordeaux, France as we explore one of the world’s great wine regions first-hand with insider tours and tastings on both the Left and Right Banks. We’ll visit Paulliac and Saint-Emilion with special wine tastings at local winery estates and venture into wine caves. We’ll have fun with a few blind tastings and a wine blending session. Finally, we’ll add to our wine knowledge by visiting a world-class interactive wine museum, La Cite du Vin.

etal with their more intense summer sunshine. This varietal’s second most planted region is in California and there are a few small pockets of vines found in Italy and its native home of France.

What of the wines made from this grape? It is red, deeply colored, and relatively light in tannin considering its color. This becomes the perfect combination for use as a blending wine. This also provides more clues into Bonarda’s importance in a blend, and not as a varietal wine.

What makes a grape varietal good for blending and how is it chosen to be a blending component rather than a varietal? Consider the marketing of commercial wines. The Old World wines were generally blended because of the local knowledge of the indigenous grapes and what was best for the local population. California, where Charbono was concerned, historically has focused on marketing wine from a variety

22 FEBRUARY - MARCH 2022 WINEMAKER VARIETAL FOCUS

Join WineMaker in Bordeaux in 2022!

For more details visit: winemakermag.com/trip with WineMaker Magazine

perspective. Therefore the focus on Charbono was to produce a varietal wine and enhance it over time with oak or oak-adjunct aging. In Argentina the variety plays a secondary role in taming the more noble Malbec, but there are now varietal wines coming out as well. These typically have low to no oak on them and are lower tannin, higher acidity, fruit-forward red wines.

From a winemaking standpoint, how do you decide whether to use Bonarda in a blend or as a varietal? With Bonarda having the ability to be wonderfully fresh and drinkable young red wines, to something that will hold up in a barrel, the blending game over time has been a combination of tradition, science, and the gut feeling and the passion of the people working the land. This is where your artful instinct comes in. Carefully consider your maceration technique (where the color will extract fast). When you move to press, start very light to express the free run, only to follow with a firmer pressing cycle that keeps that press fraction separate for later blending. For attempting a varietal wine, this is the preferable route.

I personally would not recommend an extended maceration as this will extract more potentially bitter compounds from the seeds, and also runs the risk of premature oxidation if the headspace is not adequately protected. Depending on the volume you are making, larger batches can go into a barrel, while smaller volumes should go to glass or stainless where the winemaker can experiment with oak adjuncts such as staves or chips. I just caution to not allow this wine to sit around on oak too long. When you get what you like, rack as you normally would and continue to age a few more months, where you will rack it again and taste to see if it is ready for the bottle.

Finally, in my research on this grape varietal I found out that Bonny Doon Vineyards was one of the few in California producing Charbono wines. nowing fellow WineMaker columnist Alison Crowe (Wine Wizard) worked for a number of years there, I emailed her for some input on working with this grape. Here is her advice:

“How you approach Charbono definitely depends on where you source

it and how you make/blend it. The only Charbono I’ve worked with is from a vineyard in southern Monterey County. We got more blackberry fruit character (without sweetness) rather than red color and red fruits, but there was a bright plum skin quality about it.

“The color was always very dark and one of the challenges tended to be in tannin management as well as in managing reduction (it had a tendency to throw H2S after it went dry). You want

to make sure it gets a lot of oxygen in the fermenter, as well as generous rackings during its life. Our versions could take a very robust oak regimen as well because of their tannin structure.

“I wouldn’t ferment Charbono on any tannin products unless the grapes are lacking the structure. When blending, we found it did well with something ‘sweeter’ like a Zinfandel or a Petite Sirah. On its own our Charbono wines were a little rough and angular.”

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 23

BE A PIONEER.

AND MALOLACTIC CULTURES PIONEERING PREMIUM YEAST

ENTER YOUR BEST HOMEMADE WINES IN THE WORLD’S LARGEST COMPETITION FOR HOBBY WINEMAKERS!

LAST CHANCE SEND YOUR ENTRIES NOW! ENTRY DEADLINE: MARCH 21, 2022

Enter your wines and compete for gold, silver and bronze medals in 50 categories awarded by a panel of experienced wine judges. You can gain international recognition for your winemaking skills and get valuable feedback on your wines from the competition’s judging panel.

Entry Deadline: March 21, 2022 5515 Main Street • Manchester Center, VT 05255 ph: (802) 362-3981 ext. 106 • fax: (802) 362-2377

email: competition@winemakermag.com

You can also enter online at: www.winemakercompetition.com

24 FEBRUARY - MARCH 2022 WINEMAKER

will be awarded thanks to our award sponsors:

Gene Spaziani Grand Champion Wine

WineMaker of the Year

Best of Show Red

Retailer of the Year

Best of Show White

U-Vint of the Year

Best of Show Dessert

Club of the Year

LALLEMAND BREWING

Best of Show Mead

Best of Show Country Fruit

Best of Show Sparkling

Best of Show Estate Grown

Best of Show Kit/Concentrate

Category Medals (gold, silver, and bronze) will be awarded thanks to our category sponsors:

18.Other White Vinifera Varietals

19.White Vinifera Bordeaux Style Blends

20.Other White Vinifera Blends

21.Cabernet Franc

34.Red Table Wine Blend (Any Grape Varieties)

35.Blush Table Wine Blend (Any Grape Varieties)

36.Grape & Non-Grape Table Wine Blend

37.Apple or Pear Varietals or Blends

38.Hard Cider or Perry

39.Stone Fruit (Peach, Cherry, Blends, etc.)

40.Berry Fruit (Strawberry, Raspberry, Blends, etc.)

41.Other Fruits

42.Traditional Mead

43.Fruit Mead

Moonlight Meadery

44.Herb and Spice Mead

45.Flower or Vegetable

46.Port Style

47.Sherry Style

48.Other Fortified

49.Sparkling Grape, Dry/Semi-Dry or Sweet

33.White Table Wine Blend (Any Grape Varieties)

50.Sparkling Non-Grape

WINEMAKERMAG.COM FEBRUARY - MARCH 2022 25

1.White Native American Varietal

2.White Native American Blend

3.Red Native American Varietal

4.Red Native American Blend

5.Blush/Rosé Native American 6.Red or White Native American Late Harvest and Ice Wine

7.White French-American Hybrid Varietal

Varietal

and Ice

8.White French-American Hybrid Blend 9.Red French-American Hybrid

10.Red French-American Hybrid Blend 11.Blush/Rosé French-American Hybrid 12.Red or White French-American Late Harvest

Wine 13.Chardonnay 14.Pinot Grigio/Pinot Gris 15.Gewürztraminer 16.Riesling 17.Sauvignon Blanc

Vinmetrica

Bader Beer & Wine Supply 25.Pinot Noir 26.Sangiovese 27.Zinfandel

Red Vinifera Varietals

Vinifera

Style Blends

Vinifera Blends

Beer & Winemaking Supply

Red Vinifera

Vinifera Late Harvest and Ice Wine

Five Star Chemicals & Supply, Inc. 22.Cabernet Sauvignon 23.Merlot

24.Shiraz/Syrah

28.Other

29.Red

Bordeaux

30.Other Red

Label Peelers

31.Blush/Rosé

32.Red or White

SPECIAL BEST OF SHOW MEDALS

RULES & REGULATIONS

1. Entry deadline for wines to arrive is March 21, 2022

Wines are to be delivered to: Battenkill Communications

5515 Main Street Manchester Center, VT 05255 Ph: (802) 362-3981

2. Send ONE (1) BOTTLE per entry. Still wines must be submitted in standard 750 ml wine bottles. Ice wines or late harvest wines can be submitted in 375 ml bottles. Meads and Hard Ciders can be submitted in 12 oz. or 22 oz. beer bottles. Sparkling wines must be in champagne bottles with proper closure and wire. All bottles must be free of wax, decorative labels and capsules. owever, an identification label will be required on the bottle as detailed in rule #5.

3. Entry fee is $25 U.S. dollars (or $25 Canadian dollars) for each wine entered. Each individual person is allowed up to a total of 15 entries. You may enter in as many categories as you wish. Make checks payable to WineMaker. Only U.S. or Canadian funds will be accepted. On your check write the number of entries (no more than 15 total) and the name of the entrant if different from the name on the check. Entry fees are non-refundable.

4. All shipments should be packaged to withstand considerable handling and must be shipped freight pre-paid. Line the inside of the box with a plastic trash bag and use plenty of packaging material, such as bubble wrap, around the bottles. Bottles shipped in preformed styrofoam cartons have proven reliable in the past. Every reasonable effort will be made to contact entrants whose bottles have broken to make arrangements for sending replacement bottles. Please note it is illegal to ship alcoholic beverages via the U.S. Postal Service. FedEx Air and FedEx Ground will destroy all amateur wine shipments so do not use either of these services. Private shipping companies such as UPS with company policies against individuals shipping alcohol may refuse your shipment if they are informed your package contains alcoholic beverages. Entries mailed internationally are often required by customs to provide proper documentation. It is the entrant’s responsibility to follow all applicable laws and regulations. Packages with postage due or C.O.D. charges will be rejected.

5 Each bottle must be labeled with the following information: Your name, category number, wine ingredients, vintage.

Example: K. Jones, 9, 75% Baco Noir, 25% Foch, 2016. If you are using a wine kit for ingredients please list the brand and product name as the wine ingredients. Example: K. Jones, 22, Winexpert Selection International French Cabernet Sauvignon, 2016. A copy of the entry form, listing each of your wines entered, must accompany entry and payment.

6. It is entirely up to you to decide which of the 50 categories you should enter. You should enter each wine in the category in which you feel it will perform best. Wines must contain a minimum of 75% of designated type if entered as a varietal. Varietals of less than 75% must be entered as blends. To make sure all entries are judged fairly, the WineMaker staff may re-classify an entry that is obviously in the wrong category or has over 5 percentage of a specific varietal but is entered as a blend.