Sulfite Use Facts & Myths Blend Bordeauxs Like A Pro Award-Winning Home Wine Labels WINEMAKERMAG.COM FEBRUARY - MARCH 2023 VOL.26, NO.1 UNDERSTAND & ADJUST pH 10 WAYS TO GROW BETTER WINE AMERICA’S ORIGINAL HYBRID: NORTON YOUR FIRST WINE LEARN STEP-BY-STEP HOW TO CRAFT YOUR OWN WINE FROM GRAPES & KITS

Crazy Delicious Mix it up! LUSCIOUS LYCHEE MARTINI! AVAILABLE SPRING 2023 — LIMITED TIME ONLY! Wine & Cocktails – yes please! Exciting notes of slightly sweet and exotic Lychees mixed with a splash of Green Tea to deliver a tropical and refreshingly crisp white wine perfectly timed for Spring’s cocktail season. Indulge in Orchard Breezin’ Luscious Lychee Martini, a lightly floral sipper best served ice cold or mixed to make crazy delicious cocktail concoctions! © 2022 RJS Craft Winemaking Learn more at rjscraftwinemaking.com or bsghandcraft.com For a selection of Orchard Breezin’ cocktail recipes please visit WWW.RJSCRAFTWINEMAKING.COM/RECIPES

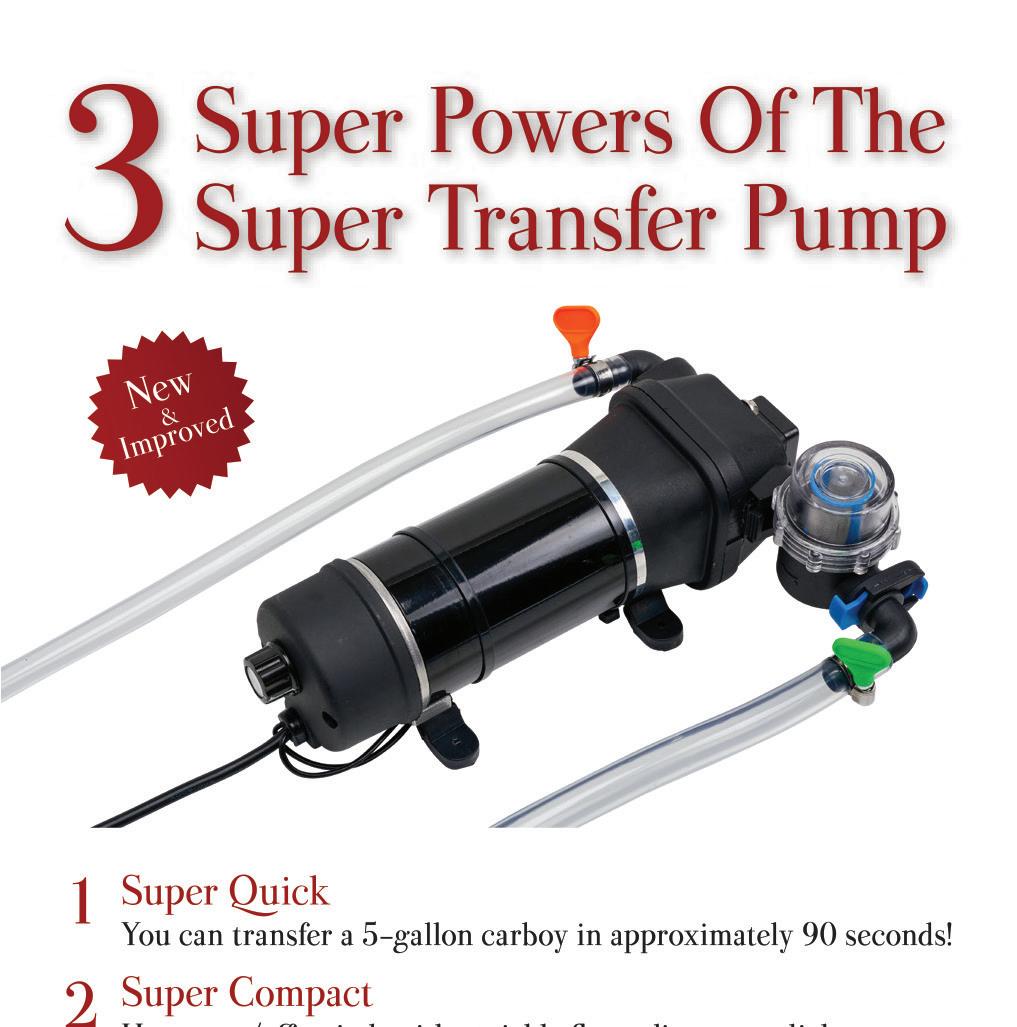

• Full Day of Live Online Seminars and Q&A Panels

• Access to Video Recordings of All Sessions

• 3 Learning Tracks: Business/Sales, Winery Operations, and Start-Ups

• Get your Questions Answered Live by Industry Experts

• Interact with Other Small Wineries and Wineries in Planning

• Q&A Sessions with Leading Small Winery Industry Suppliers

Register Now And Save $100 WineMakerMag.com/GaragisteCon BIG

WINERIES FEBRUARY 17, 2023

IDEAS FOR SMALL-SCALE

26 CRAFT BEER- INFLUENCED WINEMAKING

A trend has emerged from the world of craft beer as some notable brewers have begun releasing wines. What sets these wines apart is an unusual approach of adding adjuncts and other techniques that are common in the world of beer. Learn what they are doing and how you, too, can make wine like a brewer.

by Wes Hagen

by Wes Hagen

32 WORLD - CLASS WEEK IN BORDEAUX

We recap and share photos from a weeklong trip WineMaker readers and Publisher Brad Ring spent visiting wineries and experiencing all that the famed French wine region of Bordeaux has to offer.

34 LET’S START MAKING WINE!

Are you or a friend new to the hobby of winemaking?

Don’t worry — WineMaker’s Technical Editor Bob Peak is here to explain the basics of making wine from grapes, juices, and kits.

by Bob Peak

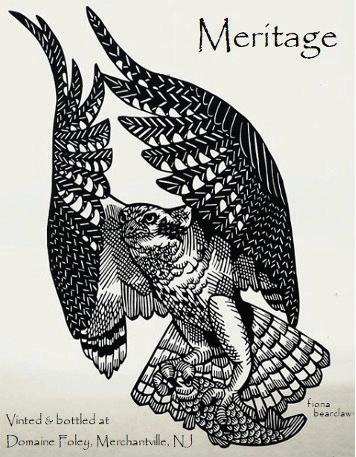

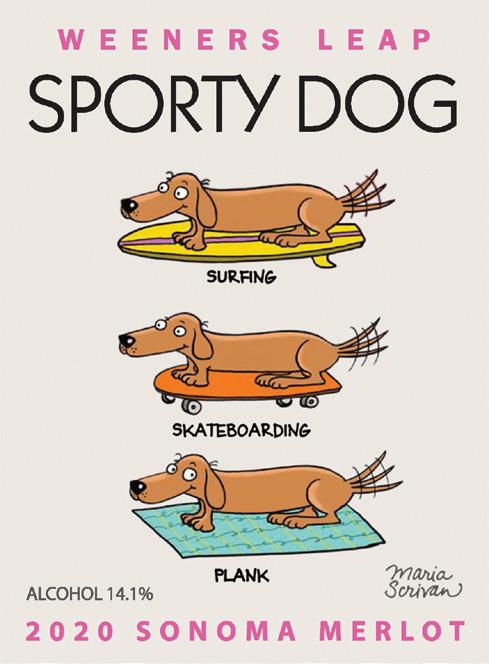

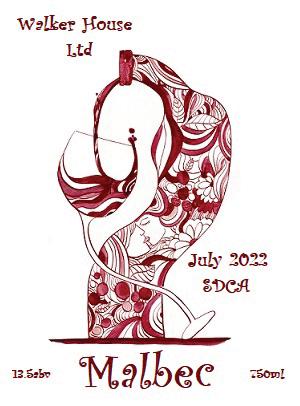

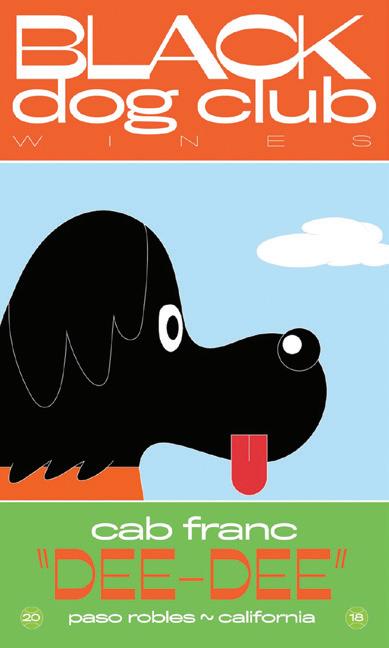

40 2023 LABEL CONTEST WINNERS

We received hundreds of entries into this year’s WineMaker Label Contest. It is time to reveal the winners.

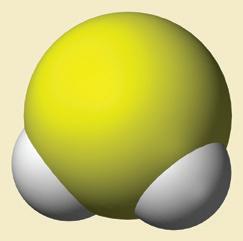

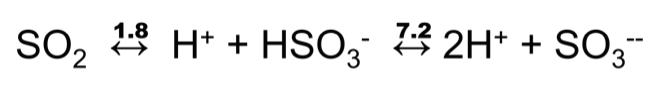

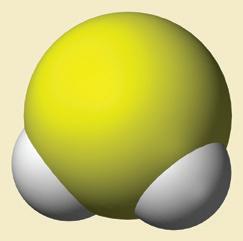

44 SULFUR DIOXIDE: FACT AND MYTH

Winemakers have a lot of misconceptions about sulfur dioxide and its use in winemaking. Though somewhat controversial, longtime wine educator Clark Smith shares his views that are backed by science.

by Clark Smith

2 FEBRUARY - MARCH 2023 WINEMAKER contents February-March 2023, VOL. 26 NO. 1 WineMaker (ISSN 1098-7320) is published bimonthly for $29.99 per year by Battenkill Communications, 5515 Main Street, Manchester Center, VT 05255. Tel: (802) 362-3981. Fax: (802) 3622377. E-mail address: wm@winemakermag.com. Periodicals postage rates paid at Manchester Center, VT, and additional mailing offices. POSTMASTER: Send address changes to WineMaker, P.O. Box 469118, Escondido, CA 92046. Customer Service: For subscription orders, inquiries or address changes, write WineMaker, P.O. Box 469118, Escondido, CA 92046. Fax: (760) 738-4805. Foreign and Canadian orders must be payable in U.S. dollars. The airmail subscription rate to Canada and Mexico is $34.99; for all other countries the airmail subscription rate is $49.99.

26 40 44 34

features

Wine analysis products for artisan winemakers

Set up your own lab and take control of your wine!

Or send us your samples

Lab Services also available

SO2 (Free & Total)

Titratable acidity (TA)

pH

Malic acid (MLF)

Residual sugar (new!)

Dissolved oxygen

YAN

ABV%

Also offering

Ideal for small to medium sized wineries

Family owned and operated for over 10 years! Located in Carlsbad, CA Vinmetrica.com • scan for additional info

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 3

departments

8 MAIL

Our digital member online live chats offer readers a chance to get their winemaking questions answered by wine experts. Plus, a reader asks where to look for advice on adjusting dessert wine kits. Turns out, he just needed to wait for the next issue to arrive!

10 CELLAR DWELLERS

When a hobby winemaker gets stuck quarantining in Jamaica during harvest, his wife picks up the torch. Learn the story behind the label it inspired as well as details about the chaptalization process, and get the latest in winemaking news, products, and upcoming events.

14 TIPS FROM THE PROS

Red Bordeaux-style blends are some of the most sought-after and complex wines being made around the world. We asked three expert winemakers on the West Coast for advice on crafting our own interpretations at home.

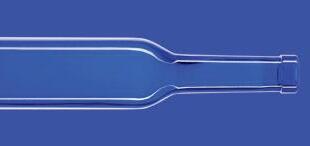

16 WINE WIZARD

Maintaining wine while it ages in oak is an important task. Make sure you are taking the appropriate steps. Also, a winemaker can’t get their latest wine to start fermentation. The Wine Wizard unravels the mystery behind the unfermentable juice.

19 VARIETAL FOCUS

A grape with a proud following regionally, Norton has roots that remain shrouded in a fog. Learn about its past, how to best tend to it in the vineyard, and bring out its bright qualities in the winery.

55 TECHNIQUES

If you are a winemaker looking to boost your wine’s quality, then tracking pH is a must. Bob Peak introduces the chemistry behind the numbers we obtain and how to use them to our advantage.

57 BACKYARD VINES

The 2023 growing season is just around the corner and it’s time to think about ways to improve your viticultural practices. Here are 10 tips every wine grape grower should be thinking about to get the best berries from their vines.

64 DRY FINISH

WineMaker’s Associate Publisher Kiev Rattee traveled to a friend’s vineyard to help with the most recent harvest. There is something magical about being part of a team helping pick the grapes that will become our treasured vinous beverage.

4 FEBRUARY - MARCH 2023 WINEMAKER

61 SUPPLIER DIRECTORY 63 READER SERVICE where to find it ® 19 Photo courtesy of Shutterstock.com

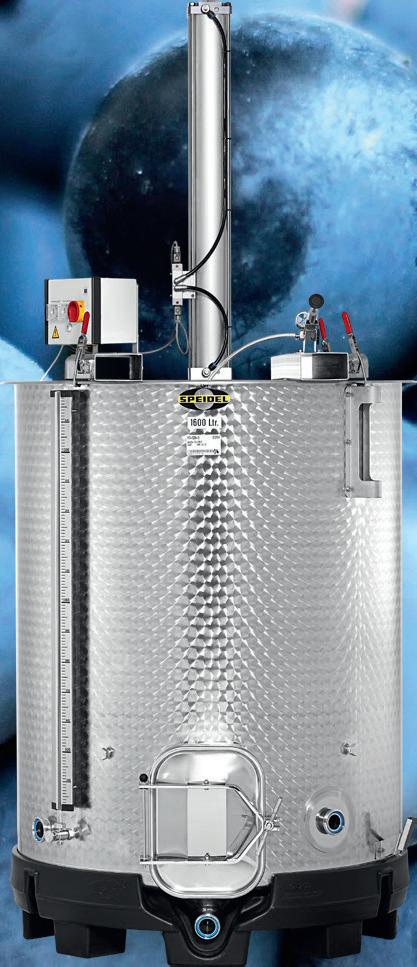

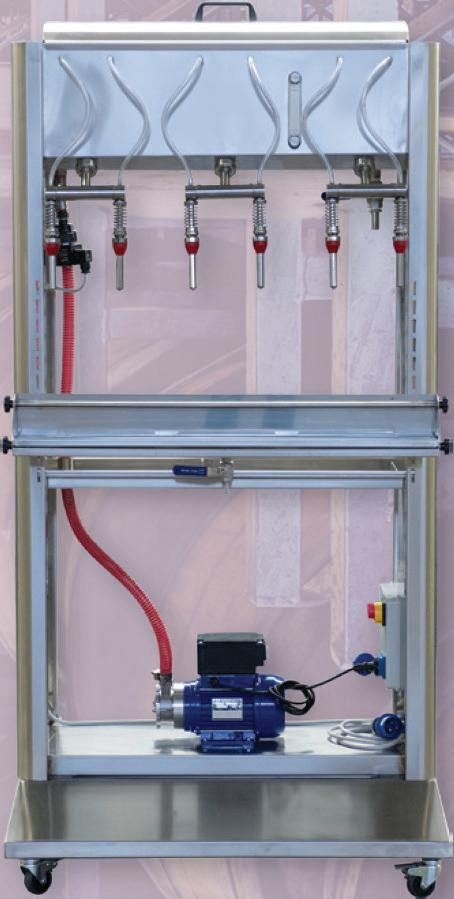

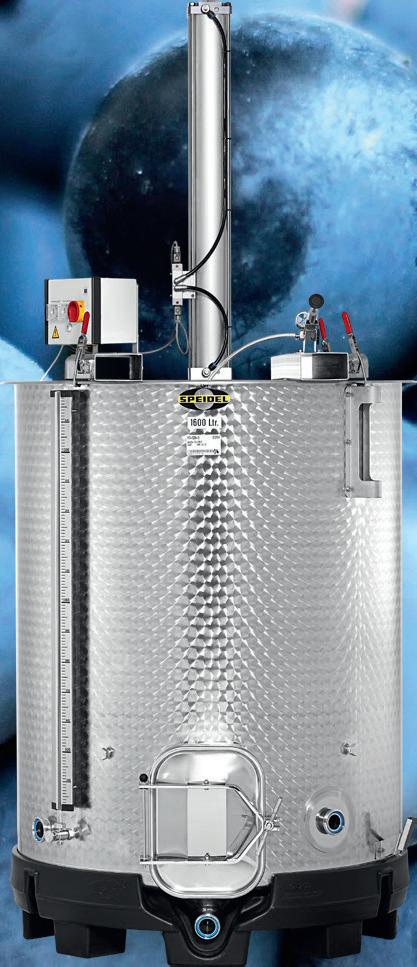

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 5 FO speidel-stainless-steel-tanks.com Simply twice mobile · Variable capacity tank FO With mash door and mounted mobile plunger · Can be used as storage or mash fermentation tank · Mobile plunger with proven Speidel technology Dual mobility due to PE transport base Easy handling and cleaning Made in Germany WHEN: Starting February 2023 SAVE: Up to 25% OFF TIP: Order your wine equipment now to save big and ensure availability. PRESEASON SALE! ORDER EARLY & SAVE UP TO 25% MOREWINE.COM Crusher Destemmers • Wine Pumps • Plate Filters • Wine Presses • Speidel Wine Tanks • Bottle Fillers & Corkers • Oak Barrels • Glycol Chillers • And More! •

EDITOR

Dawson Raspuzzi

ASSISTANT EDITOR

Dave Green

DESIGN

Open Look

TECHNICAL EDITOR

Bob Peak

CONTRIBUTING WRITERS

Dwayne Bershaw, Chik Brenneman, Alison Crowe, Wes Hagen, Maureen Macdonald, Bob Peak, Phil Plummer, Clark Smith

CONTRIBUTING PHOTOGRAPHER

Charles A. Parker

EDITORIAL REVIEW BOARD

Steve Bader Bader Beer and Wine Supply

Chik Brenneman Baker Family Wines

John Buechsenstein Wine Education & Consultation

Mark Chandler Chandler & Company

Wine Consultancy

Kevin Donato Cultured Solutions

Pat Henderson About Wine Consulting

Ed Kraus EC Kraus

Maureen Macdonald Hawk Ridge Winery

Christina Musto-Quick Musto Wine

Grape Co.

Phil Plummer Montezuma Winery

Gene Spaziani American Wine Society

Jef Stebben Stebben Wine Co.

Gail Tufford Global Vintners Inc.

Anne Whyte Vermont Homebrew Supply

Do you have a most

cherished bottle stored away in your wine cellar/rack?

I have a cherished wine bottle stored away that was purchased at the first winery I visited back in 2014, Bernardus Winery and Vineyard. My husband and I decided to save it for a special occasion. Then we kind of forgot about it. I found we still had it a few years ago and decided that we would pop it when our youngest son left for college. That’s now only a year and a half off!

PUBLISHER

Brad Ring

ASSOCIATE PUBLISHER & ADVERTISING DIRECTOR

Kiev Rattee

ADVERTISING SALES COORDINATOR

Dave Green

EVENTS MANAGER

Jannell Kristiansen

BOOKKEEPER

Faith Alberti

SUBSCRIPTION CUSTOMER

SERVICE MANAGER

Anita Draper

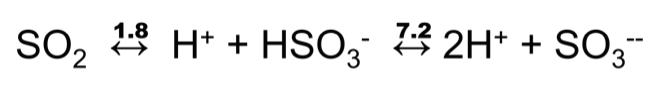

Solving the Sulfite Puzzle

Sulfite is the most effective and widely used preservative and sanitizing agent used in winemaking. Let’s try to demystify sulfite by reviewing some fundamental chemistry as it relates to winemaking. https://winemakermag. com/article/634-solving-the-sulfitepuzzle

MEMBERS ONLY

Modifying Wine Kits

The two changes discussed in this article are alcohol levels and tannin. It’s important to remember that any change you make is completely interconnected to the character of the wine in what can be very subtle ways. https:// winemakermag.com/technique/ modifying-wine-kits

Monitoring & Adjusting pH

EDITORIAL & ADVERTISING OFFICE

WineMaker

5515 Main Street

Manchester Center, VT 05255

Tel: (802) 362-3981 Fax: (802) 362-2377

Email: wm@winemakermag.com

ADVERTISING CONTACT:

Kiev Rattee (kiev@winemakermag.com)

EDITORIAL CONTACT:

Dawson Raspuzzi (dawson@winemakermag.com)

SUBSCRIPTIONS ONLY

WineMaker

P.O. Box 469118

Escondido, CA 92046

Tel: (800) 900-7594

M-F 8:30-5:00 PST

E-mail: winemaker@pcspublink.com

Fax: (760) 738-4805

Special Subscription Offer

6 issues for $29.99

Cover Photo: Shutterstock.com

I have a bottle of Domaine Chandon Brandy. It was given to me in 1996 by David Stevens who pioneered the project for them. We lost Dave in 2018, but his jokes and ever-present smile still live on today. At a time in my life when everyone was telling me I could do this or I could do that, he was the first person to ask me what I wanted to do. I believed with all my heart that his genuine and welcoming guidance helped me become the winemaker and person I am today.

I have a 2016 Black Hills Nota Bene that I am saving for something special. If you ever find a bottle from this South Okanagan Valley winery, I highly recommend you pick up a bottle. I think they’re producing some of the finest wines from the region in their desert microclimate.

All contents of WineMaker are Copyright © 2023 by Battenkill Communications, unless otherwise noted. WineMaker is a registered trademark owned by Battenkill Communications, a Vermont corporation. Unsolicited manuscripts will not be returned, and no responsibility can be assumed for such material. All “Letters to the Editor” should be sent to the editor at the Vermont office address. All rights in letters sent to WineMaker will be treated as unconditionally assigned for publication and copyright purposes and subject to WineMaker’s unrestricted right to edit. Although all reasonable attempts are made to ensure accuracy, the publisher does not assume any liability for errors or omissions anywhere in the publication. All rights reserved. Reproduction in part or in whole without written permission is strictly prohibited. Printed in the United States of America. Volume 26, Number 1: February-March 2023.

pH greatly affects the taste of wine as well as microbial stability. It can make the difference between drinking the wine or pouring it down the drain. Make sure you know when it should be analyzed and make the necessary adjustments. https:// winemakermag.com/technique/1650monitoring-adjusting-ph

MEMBERS ONLY

Site Planning & Prep

For anyone who plans on creating a small-to-moderate-sized backyard vineyard, this column should be mandatory reading. Because the best advice one can receive is to spend a lot of extra time in the planning stage, which will save an exponential amount of time later. https://winemakermag.com/technique/ site-planning-and-prep-designing-amodern-backyard-vineyard

MEMBERS ONLY

* For full access to members’ only content and hundreds of pages of winemaking articles, techniques and troubleshooting, sign up for a 14-day free trial membership at winemakermag.com

6 FEBRUARY - MARCH 2023 WINEMAKER WINEMAKERMAG.COM suggested pairings at ®

WineMakerMagazine @WineMakerMag @winemakermag

Q

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 7 888-539-3922 • waterloocontainer.com Follow us on Facebook and Linkedin Looking for Bottles, Caps and Closures? • Extensive inventory of ready-to-ship bottles, caps and closures • No MOQ on most items – we serve customers of any size • Industry expertise to guide you through the packaging process • Quality products and customization to create or enhance your brand You Can Rely on Us www.lallemandbrewing.com/wine FULL RANGE OF PREMIUM WINE YEAST K1 ™ (V1116) FRESH AND FRUITY STYLES EC1118 ™ THE ORIGINAL “PRISE DE MOUSE” 71B ™ FRUITY AND “NOUVEAU” STYLES D47 ™ FOR COMPLEX CHARDONNAY QA23 ™ FOR COMPLEX SAUVIGNON BLANCS RC212 ™ FOR PINOT NOIR STYLES

LOVE THE LIVE CHATS

I have been a subscriber for years, but I just became a digital member a few months ago and really appreciate the live video Q&A sessions with winemaking experts. They offer another layer of value besides the printed issues of WineMaker magazine. Please keep continuing to host them.

Ian Hillman

• via email

Thanks for the feedback, Ian! We really enjoy these live video chats with authors as well. For those who may not be familiar, we host a monthly hour-long Q&A on Crowdcast that is a free benefit of being a digital member. Readers can submit any winemaking questions for the featured guest to answer. Check our homepage (www.winemakermag.com) and our social media feeds for updates as we tend to announce each guest a week or two prior to the events. We look forward to continuing these fun sessions that really allow participants to get their specific questions answered and have a better feel for our authors than they may be able to get from simply reading their stories in the magazine.

ADVICE ON ADJUSTING KIT WINES

Back in the early ‘90s I made wine in Ohio where I lived at the time. A year ago I started again and what a different landscape it is now for home winemakers in terms of supplies, kits, measurement tools, etc. I enjoy making wines from kits. How about more articles on manipulating kits to make different types of wine? Wine additions, flavorings, etc. would be great. How about getting those kit winners to share their recipes and secrets for others in your pages? I look at kits as a blank canvas. Having people who know more than I do about changing that blank canvas would make other people’s lives easier and tastier!

Mark Klinefelter • via email

We got some serious Nostradamus vibes here as this email came in a couple of days before the December 2022-January 2023 issue came out. But, for anybody else thinking the same thing — that it would be beneficial to hear advice about adjusting kits from award-winning winemakers who do it (particularly dessert kits) — check out the December 2022January 2023 issue! The cover story was exactly that — a roundtable with three home winemakers sharing ways they manipulate dessert kits to create something special and totally unique. We hope this article offered some ideas on how to paint that canvas!

Wes Hagen is a consulting winemaker and wine sales specialist for LXV Wine in Paso Robles, California, and Native9 Wines in Santa Maria, California. Wes has worn a lot of hats in the wine business: Winemaker and Vineyard Manager at Clos Pepe Vineyards for 20 years, Winemaker and Brand Ambassador for Miller Family/Bien Nacido for nearly a decade, AVA Petitioner with 4 AVAs submitted and approved, and writing for WineMaker, Somm Journal, Burgundy Report, LA Times Magazine, and other publications. Wes loves to travel, pour, and teach wine, and also authored the 80-page special issue: The Best of WineMaker: Guide to Growing Grapes (https:// winemakermag.com/product/guide-to-growing-grapes). Follow Wes on social media: Wes Hagen on Facebook, @weshagen on Twitter and @wes_hagen on Instagram. In addition to providing his top 10 tips for grape growers in his “Backyard Vines” column on page 57, Wes shares how craft brewers-turned-winemakers are bringing brewing practices to make unique wines starting on page 26.

Bob Peak is a former partner of The Beverage People Inc. in Santa Rosa, California (www.thebeveragepeople.com).

Before The Beverage People, he was the General Manager at Vinquiry, a company that provides analytical services to the wine industry. Bob has authored the “Techniques” column that runs in every issue since 2013, frequently writes feature stories, and has been the Technical Editor of WineMaker since 2017. He is also a frequent speaker at the annual WineMaker Magazine Conference.

Beginning on page 34, Bob explains for those new to the hobby how to make great wine at home from grapes, juice, and kits.

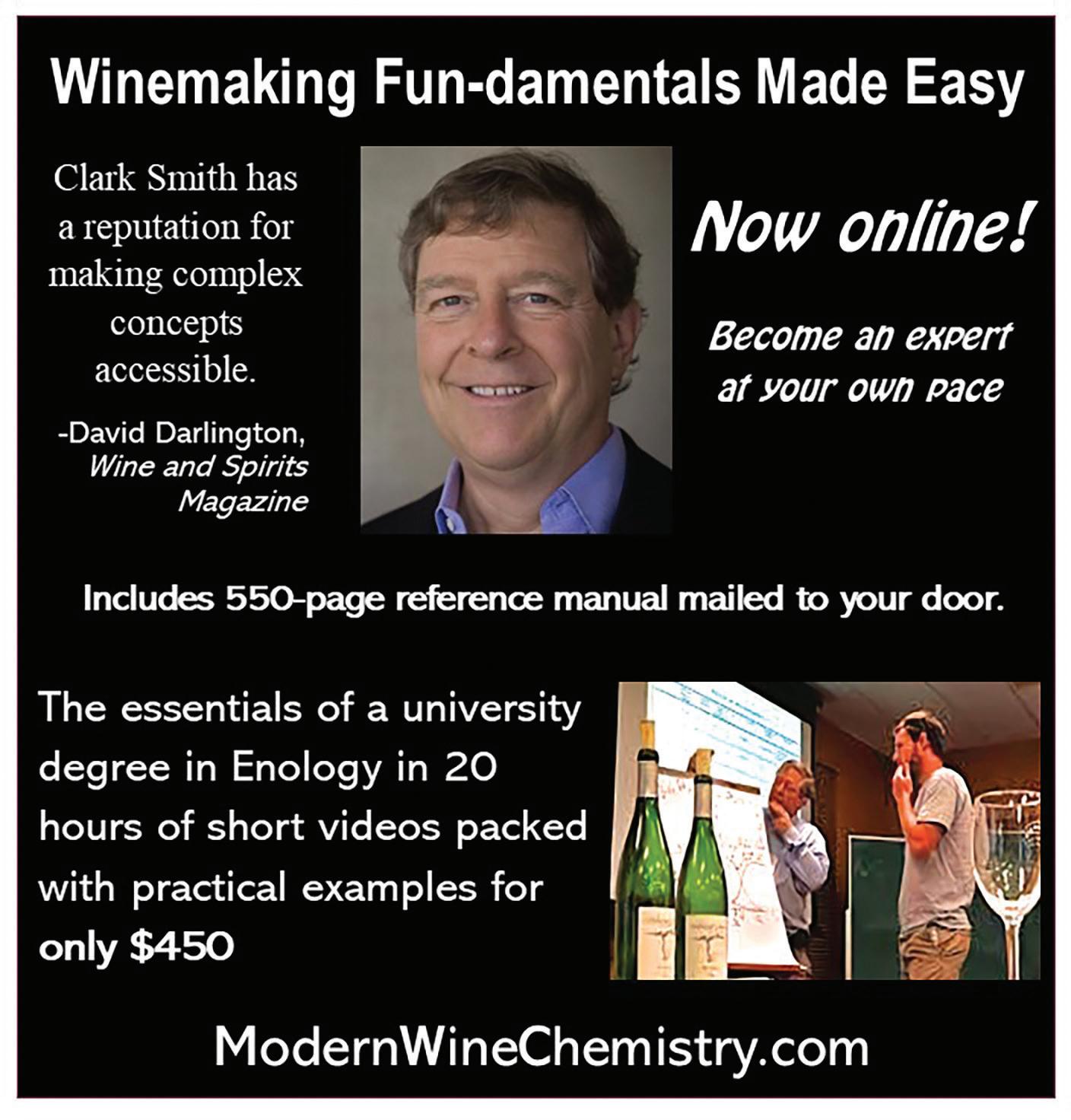

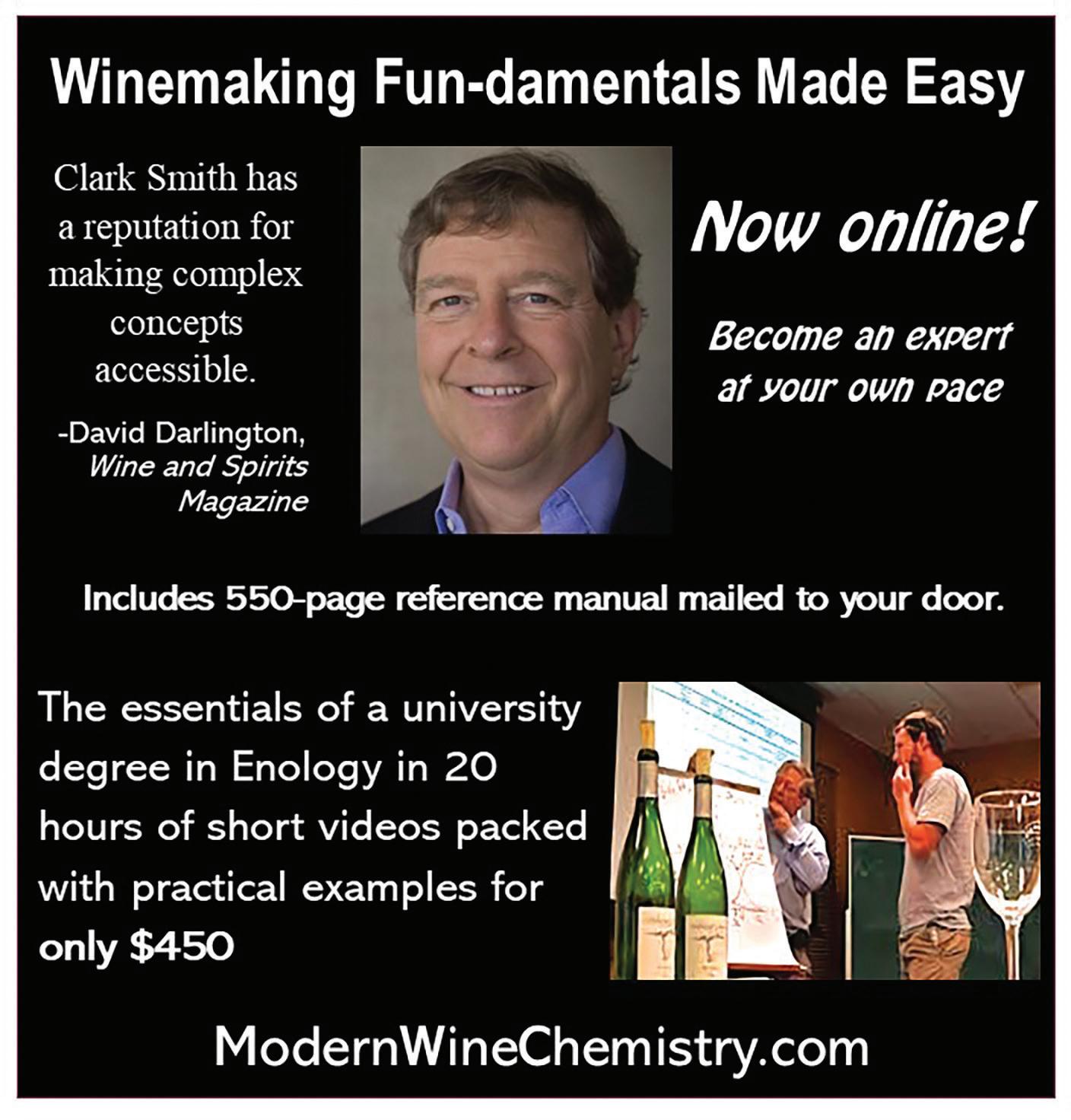

Clark Smith is one of California’s most widely respected winemakers. In addition to his own WineSmith wines, he has built many successful brands and consults for hundreds of wineries on five continents. His popular course, Fun-damentals of Winemaking Made Easy, has graduated over 4,500 winemakers to rave reviews. Winemaker, inventor, author, musician, and teacher, Smith was named the Innovator of the Year at the 2016 Innovation + Quality conference (presented by Wine Business Monthly), was named among Wine Business Monthly’s 2018 list of the 48 Most Influential People, and is considered among the world’s foremost experts on pairing wine and music. His revolutionary Postmodern Winemaking was Wine and Spirits magazine’s 2013 Book of the Year.

Beginning on page 44, Clark explains the common misconceptions winemakers often have about sulfur dioxide and its use in making wines.

8 FEBRUARY - MARCH 2023 WINEMAKER contributors MAIL

Ice Wine & Cider Hacks Verdejo: Spanish For Refreshing Clearing Up Your Wines -JANUARY 2023 VOL.25, NO.6

TOP 100 WINE KITS RANKED • DESSERT KIT TWEAKS & TIPS

WINE CHEMISTRY MADE PRACTICAL KIT WINES WORTH THEIR HEAT & COLD STABILIZATION MEDALS

QUALITY, FRESH PRESSED GRAPE JUICE

VINIFERA - FRENCH HYBRID NATIVE AMERICAN

2860 N.Y. Route 39 • Forestville, N.Y. 14062 716-679-1292 (FAX 716-679-9113)

www.walkerswinejuice.com

OVER 20 VARIETIES OF GRAPE JUICE... PLUS Apricot, Blackberry, Blueberry, Cherry, Cranberry, Peach, Pear, Plum, Pomegranate, Red Raspberry, Rhubarb and Strawberry

We Ship Juice in Quantities from 5 to 5000 gallons

WALKER’S... GROWING SINCE 1955, SUPPLYING AWARD WINNING JUICE TO OVER 800 WINERIES IN 37 STATES

(For inquiries email jim@walkerswinejuice.com)

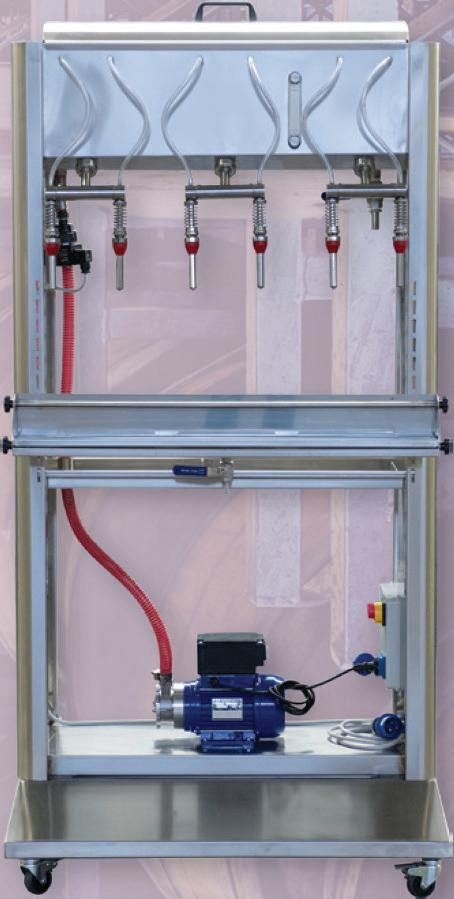

XPRESSFILL BOTTLE AND CAN FILLERS are handcrafted and custommade to order in the USA. We offer five types of fillers: Volumetric Filler, Level Filler, Carbonated Beverage, Counter Pressure Filler, and a Hot Fill Level Filler. With ten models to choose from, there is an XpressFill that will fit your needs. Order yours today!

Italian Wine Equipment in Stock!

Store Location: 575 3rd St. Building. A, Napa CA 94559

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 9

-

Expo Fairgrounds www.NapaFermentation.com

Inside the Napa

BOTTLE FILLING

FILL YOUR PASSION.

free) sales@xpressfill.com XPRESSFILL.COM XF460 VOLUMETRIC FILL Scan this code to view all of our products!

MADE EASY!

844.361.2750 (toll

RECENT NEWS

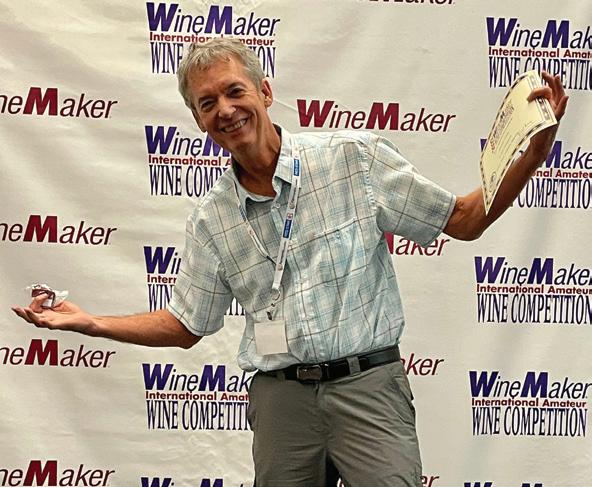

Raising a Glass to a Home Winemaking Legend

WineMaker is saddened to announce the passing of Rex Johnston, one of the most recognized home winemakers we know and a friend of the magazine. Following years of declining health, Rex passed away at the age of 83 near his home in Walnut Creek, California. Rex holds the record of being named the WineMaker International Amateur Wine Competition’s Winemaker of the Year an astonishing eight times since the first competition held in 2002. Since beginning entering amateur wine competitions in 2002, Rex won more than 150 Best of Show awards and 13 Golden Bears at the California State Fair Home Wine Competition. He was a member of the Sacramento Home Winemakers club where he was a mentor to other home winemakers and quick to share his experiences to further the hobby.

Rex began making wine at home from dandelions and fruits in 1965, but his sweet, dessert wines from grapes and fruits grown on and around his own property are the ones that would go on to garner so much attention. Rex and his wife, Barbara Bentley, were fixtures at the annual WineMaker Conferences for a decade, where Rex’s infectious smile and kindness was as memorable as the numerous walks he and Barbara would make to the winner’s podium each time his name was announced at the awards reception. It is with a heavy heart all of us at WineMaker magazine raise a glass of his Bentley Cellars Elephant Heart Plum Wine in Rex’s honor.

New Products

SmartRef Digital Refractometer

A new digital refractometer from Anton Paar is a portable smart pocket device suitable for a wide range of measurements in winemaking. The device offers more than 15 different measurement units with automatic temperature compensation (ATC). Depending on your need, SmartRef enables you to measure the extract or sugar content in wine or beer, the sweetness of fruit in the vineyard or garden/ orchard, the moisture of honey, the salt content of your aquarium or pool, and more. Measurement range is from 0 to 85 °Brix, is precise down to 0.2 °Brix, readouts occur in just two seconds, and only 0.4 mL of liquid is required. https:// www.anton-paar.com/us-en/products/details/smartref/

FRIDAY FEBRUARY 17, 2023

GaragisteCon Online is a full day of live online seminars and Q&A panels for small-scale wineries and aspiring wineries. All attendees will have access to video recordings of all sessions after the event. There are three learning tracks: Business/Sales, Winery Operations, and Start-Ups as well as Q&A sessions with leading small winery industry suppliers. Get your questions answered live by industry experts. Also, attendees get to interact with other small wineries and wineries-in-planning.

https://winemakermag.com/garagistecon

FRIDAY MARCH 17, 2023

Entry Deadline for the 2023 WineMaker International Amateur Wine Competition. Enter your wines, meads, and ciders to compete for gold, silver, and bronze medals in 50 categories awarded by a panel of experienced wine judges. You can gain international recognition for your skills and get valuable feedback on your wines from the competition’s judging panel. Entries must be received by March 17. Join in the excitement at the awards dinner on Saturday, June 3 at the WineMaker Magazine Conference in Eugene, Oregon. https://winemakermag.com/competition

10 FEBRUARY - MARCH 2023 WINEMAKER

News

UPCOMING EVENTS

AWARD-WINNING KITS

Chardonnay

GOLD

Wild Grapes Premium Australian

Chardonnay

Winexpert Reserve Chardonnay

RJS Craft Winemaking Grand Cru

Chardonnay

VineCo Original Series California

Chardonnay

Winexpert Chardonnay

Winexpert Private Reserve Dry Creek Sonoma Chardonnay

BRONZE

Mosti Mondiale Fresco Pinot

Chardonnay

RJS Craft Winemaking Cru

International California

Chardonnay

Winexpert Reserve Australian

Chardonnay

Sauvignon Blanc

GOLD

Winexpert Fumé Blanc

Winexpert Marlborough New

Zealand Sauvignon Blanc

Winexpert Private Reserve

Sauvignon Blanc

Winexpert Sauvignon Blanc

BRONZE

RJS Craft Winemaking Cru Select

Sauvignon Blanc

RJS Craft Winemaking RQ

Sauvignon Blanc

Winexpert Reserve California

Sauvignon Blanc

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 11

Here is a list of medal-winning kits for the Chardonnay and Sauvignon Blanc categories chosen by a blind-tasting judging panel at the 2022 WineMaker International Amateur Wine Competition in West Dover, Vermont:

SILVER

SILVER

STORY BEHIND THE LABEL

KENT NIENABER • HAM LAKE, MINNESOTA

Our Love Sick Marquette label was born out of a difficult situation that arose during COVID. In early September of 2021, my wife and I traveled to Jamaica. 2021 was unique in the fact that we had to be COVID tested to enter the country as well as for the return to the U.S. We have traveled to Jamaica every year since 2003 and this has become our special time away. As we neared the end of our trip, we looked forward to our plans to harvest our grapes from our small backyard vineyard. We have always enjoyed picking grapes and the camaraderie with friends as we work together bringing in the harvest. This is usually followed by a large meal to share in the celebration of the harvest and being with friends.

Two days before our departure, we

headed to the resort’s nurse station to get our testing done. To our surprise, I tested positive, which meant I was automatically quarantined to a room. My wife tested negative, so she was OK not to quarantine as long as she didn’t stay with me. I would now be quarantined for the next 10 days. It was very difficult for my wife to leave me in Jamaica. As she departed, I waved to her from the new “confines” of my room. Never in my life had I ever experienced a timeout of this proportion.

Upon her return home, she quickly got to picking the grapes and setting up the crusher. At this point, we began long-distance video chatting through all the steps of getting the equipment together, sanitizing, and testing. She did all the work of getting the harvest

PORTUGAL WINERY TOUR WITH WINEMAKER

June 24 – 30, 2023

in and getting the grapes on the road to fermentation. This included all of the testing in my lab, which she had never done before. As difficult as it was to be apart, she found strength to get it all done and we both enjoyed, to some degree, the video chats that brought some form of togetherness.

From the sun-kissed plains of the Alentejo wine region to the terraced hillside vineyards of the Douro River valley to the charm of Porto, what ’s not to love about Portugal? Join WineMaker Magazine for a comprehensive Portugal wine vacation visiting remarkable wineries and port wine lodges with in-depth wine tastings and winery tours geared towards our group of home winemakers. We will visit the Vinho Verde DOC, Douro River valley, and Porto in the north, and the Alentejo wine country further south outside of Lisbon Along the way we’ll visit a cork forest, delight in vineyard picnics, take a local cooking class, enjoy a Rabelo boat ride down the Douro River, explore several historic cities, and stay in luxurious hotels each night. Join us for an immersion in a rich wine experience in Portugal! For more details visit: winemakermag.com/trip

12 FEBRUARY - MARCH 2023 WINEMAKER

W ineMaker in Portugal in 2023!

Join

New Trip Date in Late June!

BEGINNER’S BLOCK

BY DAVE GREEN

CHAPTALIZATION: GET THOSE BRIX UP

Chaptalization is the act of adding sugar to juice or must in order to increase alcohol content post-fermentation. It’s a process that is illegal for commercial wineries in many locations, but when making wine with certain types of grapes or country wines, it’s basically required. If you are fortunate enough to live in a place where fully ripened, high-Brix grapes are guaranteed and you have no interest in any other form of wine than wine grapes, then I won’t fault you for moving on to the next article. For everyone else, knowing the why, what, when, and how of chaptalization can be a useful tool.

WHY CHAPTALIZE?

The concept is a rather simple . . . more sugar in the must often means higher alcohol wines (at least until the point where the alcohol becomes toxic to the yeast). That is the reason most winemakers add sugar, but there are other reasons to as well. So let’s start with the three primary reasons you may want to add sugar to your wine.

First off, higher alcohol wines are not preferred just because they get people drunk faster . . . but rather because they are more shelf-stable. The elevated ethyl alcohol concentration is lethal to many of wines’ spoilage organisms so the wine can last longer with diminished fears of contamination. The higher alcohol levels are one reason that wine can be safely stored away for months and even years when properly managed.

Another added benefit that can sometimes be overlooked is the fact that ethyl alcohol can also enhance the mouthfeel of a wine. So a boost may be warranted if your juice or grapes come in with low sugar readings. This is also one reason lower alcohol wines are often backsweetened in order to make up for that loss of character from alcohol.

A final reason winemakers may chaptalize their wine is called amelioration — when a overly acidic juice is watered down then sugar is added back to bring the sugar levels back

up. You will find this commonly with cold-climate hybrid wine grapes that can come in with titratable acid levels well over 10 g/L, a.k.a., very sour.

WHEN TO CHAPTALIZE

It is primarily juice and fresh fruit winemakers who are potentially looking at chaptalization. It is a general rule of thumb that kit wines have already been dialed in to a specific sugar and alcohol level for specific reasons. These decisions have been made for you. But if a kit winemaker insists on chaptalization, be sure to be prudent with additions as the wine can quickly lose balance.

When it comes to preferred sugar levels in the must prior to fermentation, a general threshold for wines that you plan to age for a reasonable amount of time is 22 °Brix. This should lead to a wine with an alcohol level around 12% ABV. A refractometer or hydrometer are two tools winemakers use to read a juice’s sugar level. While there are quite a few examples of commercial wines that fall below to well below this alcohol level (look no further than many of the wines produced in the Mosel region of Germany), enhanced care is needed. In particular, gentler handling and reduced aging capacity are commonly associated with these lower alcohol styles of wine (not to mention the winemaking skills needed to bring overall balance).

Mainly we talk about chaptalizing wine prior to fermentation, but there is no reason that a wine cannot be chaptalized later. In fact, during the Champagne method of producing sparkling wine, it could be said these wines are chaptalized after bottling. A sugar mixture is added (the liqueur de tirage) in order to obtain bubbles in the wine, which also raises the final alcohol level.

GENERAL GUIDELINES

The first guideline has to do with the maximum chaptalization recommended. 25 °Brix is generally what I would

say is the maximum a beginner to intermediate winemaker would want to add sugar until. After that, stuck fermentations become increasingly likely and more advanced techniques are required to prevent unbalanced wines and off-flavors from developing.

Next it is important to talk about how much sugar is needed to get you up to your desired alcohol level. Using the Brix scale is extremely easy since it’s just a measure of % sugar. If you have an accurate level of how many liters of juice or wine you have, then for practical purposes we can say 10 g of sugar per liter will add 1 °Brix. So if you have properly measured your grape juice and find it is 18 °Brix and you want to raise it to 22 °Brix and you have 25 liters, it’s simply the difference in Brix multiplied by 10 g per liter multiplied by the # of liters. In this case you will want to add (4 °Brix x 10 g/L x 25 L = 1000 g, or 1 kg, or 2.2 lbs.) of sugar. While this calculation is a bit simplified, it will get you in the ballpark for our winemaking purposes.

WAYS TO CHAPTALIZE

The most common way winemakers will chaptalize their wine is with common table sugar found at grocery stores. Make sure you spend a little time working out the math of the amount of sugar required as you may be surprised how much sugar is needed to bring the must up to 22 °Brix for that strawberry wine. A little heat applied to the must prior to the yeast addition will often be beneficial to get the sugar dissolved.

Concentrates, grape or otherwise, are another way that a wine or must can be chaptalized. Most of these come in around 68 °Brix, are often fruit-specific or varietal-specific (although not always), and vary widely in volume. One way to calculate how much to add to get to your target Brix is using Pearson’s Square. You can find instructions on using the Pearson’s Square calculation here: https://winemakermag.com/ article/the-pearson-square

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 13

BY DAWSON RASPUZZI

RED BORDEAUXSTYLE BLENDS

There are many ways to create red Bordeaux-style blends. Three American winemakers share their approach to making massively complex, high-end wines.

We tend to use cultured yeast for our Bordeaux varieties (at Jonata we grow Cabernet Franc, Cabernet Sauvignon, Merlot, Petit Verdot, and a unique Cabernet Franc clone). We often see rather low YAN (yeast assimilable nitrogen) numbers combined with moderate Brix levels (potential alcohols of 13.7–14.9%), so relying on the native flora and fauna can be a bit of a dicey plan. Generally with Bordeaux varieties we use RP15 yeast for most ferments. It gives us consistently dry wines with low volatile acidity (VA) and no issues with reduction. It also allows us to shift gears into malolactic fermentation (MLF) immediately after completion of primary with no issues. We occasionally utilize different yeast on smaller ferments for further complexity in future blending. For example, we have been experimenting with Alchemy IV in Merlot. It is a bit much on its own with loud notes of black licorice and powerful black fruit, but adds incredible dimensions when blended back later in the cellar.

We use a mix of medium and medium-plus toasted French oak with our Bordeaux varieties as we prefer the structural and textural impact from these. I find that many people focus on the wrong part of the relationship between oak and wine: The early aromatic and flavor contributions of oak. While I would never say this is of no consequence, I find so much more lasting contribution to wines in the structural and overall textural contributions of wood.

Most of our blending is done post-fermentation, usually the month before we bottle as we don’t often choose to rack our wines before 20 to 22 months. The primary reason for this is a phenomenon we saw in the

primeval Jonata days where our favorite fermentation lots from our initial vintage review tasted at 3–6 months post-harvest were almost always our least favorite lots at our final tasting prior to bottling at 18–24 months. The showy and flashy lots that shine early often fade and a blend made at 3–6 months (at least with wines from our unique properties) would ultimately be very underwhelming. In my experience, the tighter (often less expressive), better balanced, and more structurally sound wines tend to prevail in the long run and they often take months and years to truly understand in size, shape, and magnitude.

We work very hard to build wine blends to satisfy early with their generous and deep fruit, but primarily we focus on building a wine with structural integrity and overall freshness. For me these wines absolutely require a VERY high quantity of VERY high quality tannins. Without this backbone, the wines will always fall apart. It is also of the utmost importance to realize that structure without supporting fruit weight is also doomed to fail from imbalance.

As a home winemaker, always welcome experimentation as these grapes never cease to surprise. For better oak integration with new barrels, never underestimate the importance of high quality and clean lees. MLF in barrel also aids in this early process of marriage between oak and wine. Ditto on pressing back to barrel with a small amount of fermentable sugar to finish the last degree or so in the wood. To this extent, knocking the head out of a barrel and fermenting directly in the wood is also often a pleasant surprise. The most important thing to always remember is that you can only make fantastic wines from fantastic grapes. That is the key.

14 FEBRUARY - MARCH 2023 WINEMAKER

TIPS FROM THE

PROS

For better oak integration with new barrels, never underestimate the importance of high quality and clean lees.

Matt Dees is the Winemaker at Jonata Winery in Lompoc, California. He has a degree in soil science from the University of Vermont and previously worked at wineries in Napa, California, and Hawkes Bay, New Zealand.

R F

ed Bordeaux varieties we grow on DAOU Mountain include Cabernet Sauvignon, Merlot, Cabernet Franc, Petit Verdot, and Malbec (Cabernet Sauvignon and Cabernet Franc have demonstrated to be the two varieties that reign supreme here). We have also started experimenting in small quantities with Arinarnoa, which has been added to the red Bordeaux list in the last few years. The terroir makes it ideal for growing these varieties here. It’s a combination of European soils (calcareous soils) that are not generally found in California, and a climate that benefits from a maritime influence combined with higher elevation.

We have isolated our own native yeast for these wines that we nicknamed D20, which is now available worldwide to be purchased by other wineries (available from Enartis in large quantities) and has demonstrated that

or Bordeaux varieties, we grow Cabernet Sauvignon, Merlot, Cabernet Franc, Petit Verdot, and Malbec in the Red Mountain AVA, with first plantings of these vines being in 1990. I do multiple picks of the same block to get balance within the varieties naturally. Early picks tend to be lighter and have more acidity, with redder fruit character and later picks tend to be a bit heavier and rounder with a different aroma profile. I utilize all of these picks to create a common theme to the blends each year, but they are never quite the same. I prefer to do blends post-fermentation to really give each block a chance to shine and express itself. This gives me a chance to find the little nuances in all the varieties and blocks to really find layers of flavors.

We have used D254 yeast for years, but I have also liked the results from EC1118, and D21. Most of our production of estate fruit is now biodynamic and we do really like the complexity we get from the native ferments.

We believe wine is a reflection of place and time and embrace vintage variation. Our blending goals revolve around this philosophy. We don’t want to mask what nature gave us by using

it has a better ability to finish fermentations all the way to dryness as well as having better stabilization of color, which leads to a better texture.

Whenever possible, we like to coferment our varieties. We feel that the integration works better in these cases. However, it depends on the year and the block we are working with. We cannot force this process. Generally, the main blending occurs after fermentation and right at spring racking.

We use 100% French oak with all our wines and see complexity develop in the wine as it ages and incorporates beautiful subtle flavors accompanied by notes of vanilla, clove, and cigar box.

The goal of all of our blends is defined by tremendous elegance that is never sacrificed by power, which is what I would stress to home winemakers: Trust your palate. Never generate power at the expense of elegance. Let your wine be a work of art backed by science.

additives, so the goal in blending is always to create balance with aromas, textures, and flavors. I taste every lot monthly (we end up with about 100–120 different lots) and each new barrel annually and take notes to really get to know each wine and each barrel and what they are trying to express. These lots and notes end up on a very big spreadsheet and I use what we have done in the past as a starting point in blending and go from there. It takes months to really understand the wines and figure out where each should go.

Harvest timing is the most important factor for creating a balanced wine. Think about the style you are trying to achieve; picking for a style is much easier than trying to adjust a wine after picking. Using blending is the second component you have for stylistic success. If you like the aromas of later picked Cabernet, but it’s a bit flabby, that’s where a Petit Verdot would fit in nicely. It’s amazing what 3% of something can do to really fine-tune a wine.

These three pros had a lot more to say than we have room for on these pages. Check out even more of their advice at: https://winemakermag.com/article/ red-bordeaux-style-blends

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 15

Daniel Daou is the Co-Proprietor and Winemaker of DAOU Family Estates in Paso Robles, California, and is known for creating the luxury Cabernet revolution in Paso Robles. Daniel’s highly rated and revered wines have been declared by the world’s foremost wine critics as “rivaling the best wines in the world.”

Sarah Hedges Goedhart grew up immersed in the world of wine after her parents began Hedges Cellars in 1986. She earned degrees and took her first winery job in California before returning to Washington’s Red Mountain area to work at the family business in 2005. She has been the Head Winemaker at Hedges Family Estates since 2015.

WINE WIZARD

BY ALISON CROWE

OAK-AGING ADVICE

Also: Strategies for a chaptalization mistake

QI HAVE A MEDIUM TOAST 20- GALLON (76- L ) AMERICAN OAK BARREL AND I JUST PUT WINE IN IT THREE WEEKS AGO. HOW OFTEN SHOULD I CHECK IT TO TOP OFF, TASTE, AND MEASURE FREE SO 2? ALSO, HOW LONG CAN I EXPECT TO KEEP THE WINE IN THERE ( THIS IS A BRAND NEW BARREL )?

LARRY WHITE AUSTIN, TEXAS

AHi Larry, congrats on your new piece of equipment! I’m sure you’ll find it adds to the kinds of wine you can make. Since you just filled your barrel and it’s brand new, you might want to open the bung and check the wine level now, since it’s been three weeks. Sometimes new barrels are slightly dry and, even if you soaked it with hot water before filling, can sometimes “drink” a little of your wine as they saturate over time. Be sure to completely top up the barrel at this time.

You can certainly check in on the taste as well after three weeks, but it’d maybe be a bit of a waste of wine at this stage, because three weeks isn’t nearly enough to really move the needle on flavor or aroma development.

How long to leave it in the new barrel? Since I don’t know what kind of wine you have or what kind of style you’re shooting for, check out these guidelines, but note that these are for commercialsized 59-gal. (225-L) barrels. Smaller barrels have more oak wood exposure per gallon of wine and therefore will gain flavors faster. This means the smaller the barrel the shorter the time spent on oak. Contact time for wine — the Wiz’s general guidelines:

3–6 months: “Light oak” style white wine like a medium-oaked Chardonnay or Sauvignon Blanc.

6–8 months: Medium-heavy style white wine like a traditional Chardonnay

or a lighter-bodied red like a Pinot Noir.

8–12 months: This would be good for a medium-bodied red wine like a Paso Robles Cabernet, a Sonoma Merlot, or a Rhône-style red.

14–18 months: This would be considered a heavy approach for something like a big Napa Cabernet or Bordeaux-style red blend.

In the future you might want to consider experimenting with a mix of new and used barrels, because sometimes 100% new oak on a wine can be overwhelming. The first use of any new barrel is always the most extracted and sometimes that can be a little too harsh, especially for those lighter styles.

For whites and rosés be aware that you may pick up some darker color and, again, this might not be a good match with the kind of wine you’re trying to make. If you’ve got a crisp Sauvignon Blanc or a Riesling, for instance, both aromatically and color-wise I’d go with a “neutral” barrel or a stainless steel drum even. A “neutral” barrel means that so many batches of wine have been aged in it and passed through over the years that very little if any oak flavor, aroma, or color is left to be extracted into the wine. A used barrel like this (as long as it’s not leaking) is a serviceable container for aging wine and can be beneficial due to the microoxidation that occurs through the wood. Also, if you leave the wine on the lees during aging in the barrel it can add some additional character but won’t contribute any of the new oak aromas

16 FEBRUARY - MARCH 2023 WINEMAKER

Maintaining sulfite levels while your wine ages will help it fight off oxidative forces.

In the future you might want to consider experimenting with a mix of new and used barrels, because sometimes 100% new oak on a wine can be overwhelming.

Photo courtesy of Dominick Profaci

and flavors you might expect from a newer barrel.

You probably already know this, though not all readers might: Don’t put white wine into a barrel where you’ve aged red wine . . . unless you want to make rosé! If you’ve got a barrel you’re using to age red wine in, it’s pretty tough to clean the barrel enough to be able to subsequently age rosé or white wine in it without affecting that wine’s color. You’d be amazed how far soaked-in the wine gets. I’ve had some success soaking the barrel for a few days with a very strong sodium percarbonate solution (ProxyClean or Proxycarb are two commercial products), rinsing with water, then soaking in a tartaric acid solution for another day. After this treatment the barrel should be safely decolorized . . . and sadly, also stripped of much of the new oak aromas and flavors. Because of this, it’s always best to designate “white barrels” and “red barrels” from the beginning. You can always turn a white barrel into a red one but it’s always harder to go the other way.

Whatever you do, don’t use chlorine bleach on winery equipment of any kind, which can lead to TCA (2,4,6-trichloroanisole) contamination, more familiarly known as the “corked” wine aroma. The swampy-smelling TCA is generated when certain kinds of molds interact with chlorine molecules in their environment. Most often associated with corks (you’ve probably experienced the infamous restaurant cork sniffing tableside), TCA can also infiltrate cellars via cardboard, barrels, sacks of wood chips, and even drains. Because of this, chlorine-containing products of any kind have no place in a winery or cellar.

Always use carbon-block filtered water for your cleaning, sanitizing, and winemaking needs if your tap water contains any chlorine additive.

Winemakers who make wine batches at scale are able to use the new and neutral barrel mixes to their advantage by varying the percentage of each type. You may have heard the term “30% new oak” or “40% new, 60% used” in wine descriptions. What they mean is that in each case, 30% and 40% of the barrels in the batch were new, respectively. Mixing barrel ages is a great way to really dial in a style, and though I know most home winemakers (“microvintners,” I like to say) will never have batches large enough to properly go there, you can still achieve a certain amount of the same effect by aging your wine in a neutral barrel but introducing new wood into the barreled wine in the form of oak chips, beans, sticks, or spirals. In my Winemaker’s Answer Book (Storey Publishing) I show you how to make an oak chip infusion “sock” by stuffing toasted oak pieces into a nylon stocking, tying it up and leaving it with a string on the outside of the bung. This way you’d still be able to introduce some new oak character into your wine while being able to take advantage of the lees-stirring and aging dynamics of a neutral barrel. Added bonus? Once the wine’s oaky enough you can simply remove the oak sock . . . so no over-oaked wine!

All in all, if well taken care of, your barrel should last you for 10–15 years or so and, if you’re lucky and it’s well-made with no leaks, it could potentially serve you for much longer. I wish you well on your new-barrel journey!

QI STARTED A BATCH OF GRAPE WINE AND THEN ALSO USED A GLUT OF PLUMS TO MAKE PLUM WINE. THE GRAPE WINE IS DOING FINE AND THE PLUM WINE, TREATED IN MUCH THE SAME WAY, JUST ISN’T TAKING OFF. IT’S ALL IN THE BUCKET ( PLUMS, SUGAR, YEAST, AND YEAST NUTRIENTS ) BUT IT HAS NEVER FERMENTED. IT IS NEW YEAST AND THE BUCKET IS IN THE WARMEST PLACE IN THE HOUSE. THIS WAS TWO WEEKS AGO AND STILL NOT A SINGLE BUBBLE IN THE AIRLOCK. IT IS REGULARLY STIRRED. THERE IS A LITTLE FROTH ON TOP OF THE MIXTURE BUT NO VISIBLE FERMENTATION GOING ON.

I THOUGHT THE ROOM WAS TOO COLD ( WE’VE NOT YET PUT THE HEATING ON ) SO I USED A HEATER NEAR THE BUCKET NO LUCK. SO I PUT THE BUCKET IN THE AIRING CUPBOARD STILL NO LUCK. ( INCIDENTALLY THE GRAPE WINE I STARTED IN THE SAME WAY RESPONDED TO EXTRA SUGAR AND YEAST, BUT THIS HASN’T WORKED WITH THE PLUM ).

UNFORTUNATELY, I CAN’T REMEMBER EXACTLY WHAT THE STARTING GRAVITY WAS BUT CLOSE TO THAT OF A SWEET WINE. I ADDED MORE YEAST BUT NO LUCK. NO CAMPDEN TABLETS OR SULFITES HAVE BEEN ADDED. THE PLUMS WERE CLEAN AND JUST PICKED, WASHED, AND NO STONES WERE ADDED. SOME HAD PREVIOUSLY BEEN STEWED WITH SUGAR. WHEN I TAKE THE LID OFF THERE’S A STRONG BUT NOT UNPLEASANT SMELL, AND THERE’S FROTH ON TOP, BUT NO FERMENTATION. YEAST WAS ALWAYS PRESTARTED WITH LUKEWARM WATER.

WILL IT BY NOW ALL BE BAD AND SHOULD I JUST CHUCK IT? OR SHOULD I RACK IT INTO DEMIJOHNS AND ADD MORE YEAST? THERE’S ABOUT 6 LBS. (2.7 KG ) OF SUGAR IN THE 2 GALLONS (7.6 L )

CHERYL FELIX LINCOLNSHIRE, UNITED KINGDOM

It sounds like you’re doing a lot of things right, especially being that your grape wine has taken off, but your plum wine is just plum tuckered out.

Seems like you’ve got it in a warm enough spot and you’ve added all of the right things — you haven’t over sulfited it and you’d think that since your grape batch was happily fermenting your yeast strain and nutrients were working just fine.

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 17

A

WINE WIZARD

What does stick out to me a bit (and it took a couple of readings of your details plus a little math conversion to work out) is your starting Brix or sugar content. Though you don’t say what the plum’s initial Brix or sugar level was, you do mention that a portion of the plums were cooked with some sugar and that there were 6 lbs. (2.7 kg) of sugar added to 2 gallons (7.6 L). 6 lbs. = 96 oz. = 2.72 kg of sugar. Your volume is 2 gallons = 7.57 L of juice. That works out to be about 31.5–32 °Brix in sugar alone.

Add that on top of the natural sugar present in the plums, which, depending on the variety, could contribute between 10–20 °Brix themselves and you’re looking at a potential °Brix range of around 42–52! If you translate that into potential alcohol, that’d net you somewhere in the region of 24–30% alcohol. I don’t know of any wine yeast strain that can ferment anything higher than 18% alcohol to dryness. K1, BCS103, EC1118 (also known as Prise de Mousse or “PDM”) and a handful of others are good “power yeast” strains and must be used when faced with high Brix situations.

Needless to say, your Brix here is a little on the extreme side. Even if you use some high-Brix, dessert-wine type yeast and inoculation practices (more on that below), at that high of a sugar level you’re frankly going to eventually just encounter too much osmotic pressure from the sugar. The sugar may be too high for the yeast to get much of a foothold and unless you do multiple stepwise inoculations, “feeding” the fermentation with the high-sugar juice as you go, it’s possible the yeast might not even be able to start fermenting in an environment where the sugar content is that high. There’s a reason that jams, jellies, and fruits preserved with sugar manage to keep so well over time.

Yeast cell walls just aren’t built to handle sugar at the level your must appears to be and they’ll become what I call (the super-scientific enological term) “cranky.” When I’ve made dessert wines in the past (I once made Bonny Doon Vineyards’ “Vin de Glaciere” and “Framboise” earlier in my career) I experienced the full gamut of effects that maladjusted yeast can throw at you: Sluggish starts, high volatile acidity (VA), aldehyde production, off-aromas, oxidation, and of course the inevitable stuck fermentation. It takes a lot of winemaking derring-do to avoid these outcomes.

So, what to do in your situation? You have a few choices. First, you could add water (and maybe add a little more acid and yeast nutrient accordingly to make up for the extra volume of water) to dilute the sugar down into a more reasonable level. In my history of making sweet wines, I’ve never attempted a sweet wine (which will have residual sugar) above 32 °Brix. Dilution can affect flavors and aromas, however, and there usually is a point of diminishing returns that is dependent upon the flavor concentration in the fruit concerned.

You could give up on fermentation altogether and just fortify your plum solution with a lot of brandy, rum, or whisky (I’m serious!) to make a sort of alcoholic punch concentrate. You’d want your alcohol level to be at least 20%, so buy some booze and do your algebra accordingly.

This might be lovely spiced up with some cinnamon, orange peel, and nutmeg and bottled as gifts for the holidays. Just dilute with some sparkling water, serve over ice (or mull

with orange and cranberry juice) for festive, delicious cocktails. Since you’ve got 2 gallons (7.6 L) of the stuff it seems like it’s a workable volume for fortifying and then bottling up as thoughtful homemade gifts for loved ones.

Or . . . you could attempt a yeast inoculation and fermentation, in which case you’re going to want to follow all of my high-Brix fermentation tips, below:

-Start with a super-robust yeast strain: BCS103, EC1118 (a.k.a., PDM), or K1 are good choices. Basically, you want to choose something with the highest alcohol tolerance you can find. Low VA production is also a plus.

-Use a higher inoculation rate: Look at what the yeast manufacturer recommends and then increase it by 50%. This helps guard against the normal cell debilitation and death that can occur with high-Brix, as well as high osmotic pressure, fermentations.

-Add more nutrient than you normally would: I would do an increase of 30% over what you would normally use for a regular (22–25 °Brix) grape fermentation. This ensures that everyone has a chance to be fed. The risk is residual nutrient remaining in the wine to potentially feed spoilage organisms later, but this can be fixed by filtration and judicious watching and care of your aging wine later.

-Follow good inoculation protocols: Practice scrupulous sanitation. Use filtered (non-chlorinated) water. Measure temperatures accurately. Use a hydration-water yeast nutrient like Go-Ferm or FermStart in order to help build up the strongest cell walls possible. Follow yeast vendor’s directions for that particular organism.

-Pitch differently: Rather than hydrating dry yeast and tossing it all into the must/juice at once, a very sweet wine requires a very different approach. The first step is indeed the same: Hydrating the yeast (with hydration nutrient) in warm water to make sure it’s viable. Then, as opposed to tossing the yeast slurry into your juice/must, you’ll be gradually “feeding” your juice must into your yeast inoculation. Guidelines will differ based on your total volume and starting Brix, but basically the idea is to always make sure you’re never overwhelming your fermentation with sugar levels that are too high.

In your case, since you’ve got only two gallons (7.6 L) and you’d start with a yeast hydration solution of probably ¼ cup volume or so, I’d dilute maybe 25 mL of your juice/must with 50 mL of water, then add that to the hydrated yeast. Wait for good bubbling and activity to show (should be quick, probably about 30 minutes or so). Then proceed to add 50 mL of your juice/must diluted with 50 mL water to that, make sure you’re seeing good activity again (maybe around an hour or so). Then you should be able to feed direct small volumes of your juice/ must into the solution, monitoring activity by Brix drop.

Yes, this can be a laborious process and I’ve had sleepless nights doing it in the cellar. Eventually the fermentation will slow down and stick . . . and this is the ending point where you have to add SO2, chill it, settle, and eventually filter it before bottling. The hope is that by this point the VA won’t be too high and you’ll end up with something drinkable.

Which option to choose? I leave it up to you. Super-sweet juices and musts are always difficult to deal with and yours seems like no exception!

18 FEBRUARY - MARCH 2023 WINEMAKER

VARIETAL FOCUS

BY CHIK BRENNEMAN

NOTABLY NORTON

A grape of great character

In this issue we are going to cover some more ground on one of the first varietals I covered for WineMaker magazine. I wrote about Norton early in my tenure at UC-Davis and I was not yet working as the Supporting Winemaker for the Pierce’s Disease grapevine breeding program. At the time I was not really keen on what went into grape breeding. There are many such programs throughout the world that specialize in developing genetically disease-resistant varieties, striving to create better clones of our favorite wine grapes. But back in the 1800s, grape breeders were just looking for a grape that would survive the elements and produce grapes with characteristics similar to Vitis vinifera.

They worked with the several new species of grapes found native to North America. This time period led to a great many discoveries by folks experimenting with grape genetics and cross-breeding in this New World. It was during this time period that a man named Dr. Daniel Norborne Norton came along who discovered a new grape and the variety we know as Norton (or Cynthiana as it is sometimes called). While we will talk about the grape . . . this is better told as a tale of two Nortons!

While grape breeding was being carried out to produce grapes of better quality and disease resistance in the New World, the appearance of Norton seems so accidental. To learn the origins of the variety, we must talk about Dr. Norton of Richmond, Virginia; a medical doctor by training, who was also referred to as a backyard hybridist. Norton is the only commercial variety he gets credit for producing. But that’s just what leads to the mystery surrounding Norton, the doctor; Norton, the grape; and Norton, the wine.

TRACING ITS ORIGINS

Norton, the grape, is likely a cross between Vitis aestivalis and an unknown V. vinifera species. Dr. Norton reported that it was a hybrid of the variety Bland, a V. labrusca x V. vinifera hybrid, and Pinot Meunier. At the time, there was a possibility of some contribution of V. labrusca. An indicator of this connection is that Norton is poorly propagated from cuttings. However, our friends in the DNA lab determined that Norton is a hybrid variety whose ancestry “includes V. aestivalis and V. vinifera,” and excludes the Pinot Meunier theory. What they did come up with is that it could be a seedling of Enfariné Noir, a now almost extinct red variety from France, not known to be in North America. Only about one hectare (2.5 acres) currently exists in the Jura region of France. I scratch my head and wonder, where did that Enfariné Noir come from? Dr. Norton’s story is complicated, but this just added more mystery!

The investigations into this variety’s origins are all from secondhand accounts of Dr. Norton’s work. The story as presented by John McGrew, retired from the United States Department of Agriculture, goes somewhat like this: Sometime around 1820, Dr. Norton cultivated a seed that produced the vine that bears his name. Then by the 1830s it was commercially available. What is so intriguing is that Dr. Norton kept no records and the origins of the seed can only be surmised. Oh my, Enfariné Noir? He did not produce any other commercial varieties other than Norton. And the best account is that Dr. Norton didn’t even intentionally crossbreed two varieties, rather that he collected seeds, cultivated them and found a suitable variety for making wine. Or possibly, he was visited by the native fauna around

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 19

What they did come up with, is that it could be a seedling of Enfariné Noir, a now almost extinct red variety from France, not known to be in North America.

Photo courtesy of Wikimedia Commons

NORTON Yield 5 gallons (19 L)

INGREDIENTS

125 pounds (57 kg) fresh Norton fruit

Distilled water

10% potassium metabisulfite (KMBS) solution (Weigh 10 grams of KMBS, dissolve into about 50 mL of distilled water. When completely dissolved, make up to 100 mL total with distilled water.)

5 g Lalvin ICV D80 yeast

5 g Diammonium phosphate (DAP)

5 g Go-Ferm

5 g Fermaid K (or equivalent yeast nutrient)

Malolactic fermentation starter culture (CHR Hansen or equivalent)

EQUIPMENT

15-gallon (57-L) food-grade plastic bucket for fermentation

5-gallon (19-L) carboy (1–2) one-gallon (3.8-L) jugs

Racking hoses

Destemmer/Crusher

Wine press

Inert gas (nitrogen, argon, or carbon dioxide)

Ability to maintain a fermentation temperature of 81–86 °F (27–30 °C)

Thermometer capable of measuring between 40–110 °F (4–43 °C) in one-degree increments. Pipettes with the ability to add in increments of 1 mL

STEP BY STEP

1. Clean and sanitize all your winemaking tools, supplies, and equipment.

2. Crush and de-stem the grapes. Transfer the must to your fermenter. During the transfer, add 15 milliliters of 10% KMBS solution (This addition is the equivalent of 50 ppm SO2). Mix well.

3. Layer the headspace with inert gas and keep covered. Keep in a cool place overnight.

4. The next day sprinkle the Fermaid K directly onto the must and mix well.

5. Prepare yeast. Heat about 50 mL distilled water to 108 °F (42 °C). Mix the Go-Ferm into the water to make a suspension. Take the temperature. Pitch the yeast when the suspension is 104 °F (40 °C). Sprinkle the yeast on the surface and gently mix so that no clumps exist. Let sit for 15 minutes

undisturbed. Measure the temperature of the yeast suspension. Measure the temperature of the must. You do not want to add the yeast to your cool juice if the temperature of the yeast and the must temperature difference exceeds 15 °F (8 °C). To avoid temperature shock, you should acclimate your yeast by taking about 10 mL of the must juice and adding it to the yeast suspension. Wait 15 minutes and measure the temperature again. Do this until you are within the specified temperature range. Do not let the yeast sit in the original water suspension for longer than 20 minutes. When the yeast is ready, add it to the fermenter and mix.

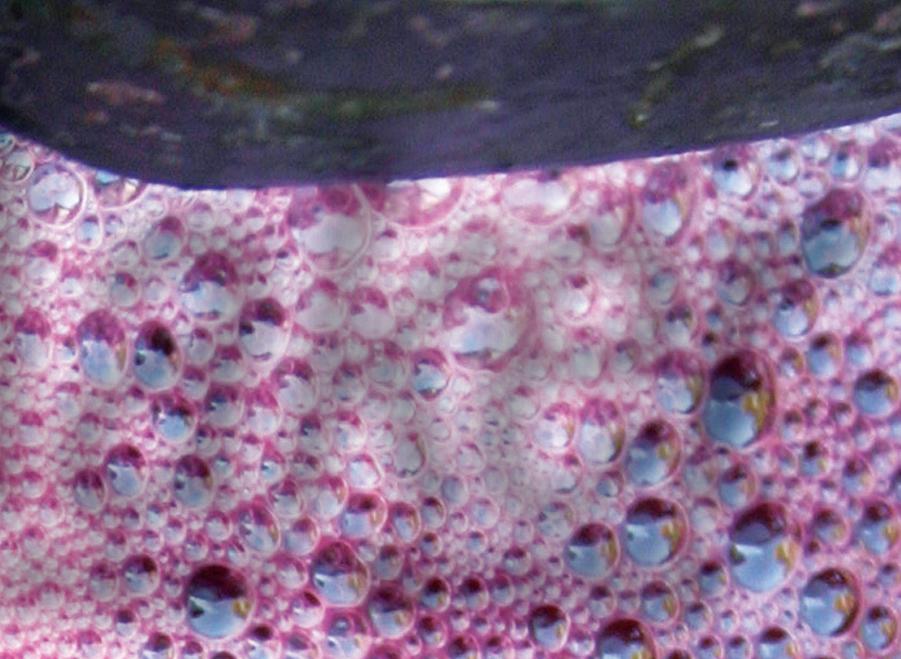

6. You should see signs of fermentation within about one to two days. This will appear as some foaming on the must surface and it will appear that the berries are rising out of the medium. This is referred to as the cap rise.

7. You need to have on hand the ability to push the grapes back into the juice to promote color and tannin extraction. This is called punching down and this should be done three times per day. Use a clean utensil or your hand to mix.

8. Monitor the Brix and temperature twice daily during peak fermentation (10–21 °Brix). Morning and evening is best and more often if the temperature shows any indication of exceeding 86 °F (30 °C), in which case add frozen water bottles to the fermenter. Mix the must. Wait 15 minutes, mix and check the temperature again. Do this as often as it takes to keep the temperature between 81–86 °F (27–30 °C). Do not cool off to less than 81 °F (27 °C). Alternatively, you may need to keep the must warm if you are in a colder climate.

9. At about 19 °Brix, sprinkle in the DAP and punchdown.

10. When the Brix reaches 0 (about 5–7 days), transfer the must to your press and press the cake dry. Keep the free run wine separate from the press portion for now. Be sure to label your vessels to keep the press portion separate.

11. Transfer the wine to your carboys or one-gallon (3.8-L) jugs. Your press

fraction may only be a gallon or two (3.8–7.6 L). Make sure you do not have any headspace. Place an airlock on the vessel(s). Label the vessels.

12. Inoculate with your malolactic (ML) bacteria. Check the manufacturer’s instruction on how to prepare and inoculate. Cover each vessel with an airlock to allow CO2 to escape.

13. Monitor the ML fermentation using a paper chromatography assay available from most home winemaking supply stores. Follow the instructions included in the kit.

14. When the ML is complete, add 2 mL of fresh KMBS (10%) solution per gallon of wine (0.5 mL per L of wine). This is the equivalent to ~40 ppm addition. Place the wine in a cool place to settle.

15. After two weeks, test for SO2, adjust the SO2 as necessary to attain 0.8 ppm molecular SO2. (There is a simple SO2 calculator at www.winemaker mag.com/sulfitecalculator). Check the SO2 in another two weeks and adjust. Once the free SO2 is adjusted, maintain at this level. You’ll just need to check every two months or so and before racking.

16. Rack the wine clean twice over a 6–8 month time frame to clarify.

17. Once the wine is cleared, it is time to move it to the bottle. This would be about eight months after the completion of fermentation.

18. Make the project fun by having a blending party to integrate the press fraction back into the free run. You may not need it all, use your judgment and make what you like. Fining with egg whites may be necessary to tame the tannins.

19. Filtration is generally not needed if SO2 levels are maintained and there are no surface films or indications of subsequent fermentations. Consult www.winemakermag.com for tips on fining and filtration if problems are evident. If all has gone well to this point, given the quantity made, it can probably be bottled without filtration. That said, maintain sanitary conditions while bottling. Once bottled, you’ll need to periodically check your work by opening a bottle to enjoy with friends. Have fun!

20 FEBRUARY - MARCH 2023 WINEMAKER

Richmond. Rather a bird or other animal consumed a grape in his garden and deposited the seed somewhere else in his garden where it sprouted and was discovered. Dr. Norton cultivated this “accidental” vine and after a few years, he realized that it had the desirable vigor characters, pest and disease resistance, and fruit quality to be a commercial variety.

It is not known how Norton, the vine, acquired its name from Norton, the person. The custom of the day was to name horticultural varieties after someone the discoverer held in high regard or another object of admiration. In the case of Norton, the wine, presumably Dr. Norton, the person, was a good winemaker, thus there was considerable demand for Dr. Norton’s claret.

With his discovery the good doctor likely had to find a way to produce the vines since the normal method of propagation was not successful. This could be the reason that it took many years for the vine to become available commercially. The normal methods of propagation of grapes were achieved by placing cuttings with exposed buds in a nutrient-rich soil, and allowing the buds to push, and then the roots follow. He likely experimented with different techniques and, having the green thumb he presumably had, he realized that the vines could produce roots by burying cuttings, which would sprout roots and then a shoot. Once the leaves are formed, he would dig up the now sprouting cane, isolate the new root and shoot growth, and presto, he had a vine genetically identical to the cutting he buried. This process came to be known as layering.

But this story as told is not without a controversy in itself. In 1861 an article was published in the Horticulturist by a writer who claimed that Norton, the grape, was discovered in 1835 by his father, Dr. F.A. Lemosy. The writer reports that it was found on a riverbank in the Richmond area and that Dr. Norton secured the variety from him. This controversy has been disproved based on a chronology of writings about Norton, the grape, at the time. It did seem to erase all the efforts that Dr. Norton had undertaken for the previous 40 years to promote the variety. Regardless of the origins, the popularity of the vine increased with plantings expanding to Missouri and other areas of the East and South because of the plant’s hardiness and propensity for making good wine. With the onset of Prohibition, many vineyards were replaced and the popularity waned, only to find new resurgence in recent decades. Norton is now heralded in cult-like settings in the wine regions of Missouri, Virginia, and Arkansas. Norton accounts for almost 18% of Missouri’s red grape production and is esteemed as the state’s grape.

NORTON VITICULTURALLY

This variety has small- to medium-sized compact bunches, with small, thick-skinned berries. It is vigorous and best grown on well-drained sandy or gravel soils. It is moderately suscep-

tible to Downey mildew, but resistant to many other fungal diseases. It is moderately cold-hardy, reported to survive to -10 to -15 °F (-23 to -26 °C).

The wines resulting from quality Norton grapes grown in the Midwest are in general characterized by high to very high acidity. The shorter growing seasons in the Midwest and East tend to force the grower’s hand in this arena, but in the finished wine often you’ll find it balances with the red and black fruit characters. One reference I found also described coffee, and bittersweet chocolate as flavor descriptors. The distinctive “foxy” character present in other North American grape varieties is not as prominent in Norton, which was one of the reasons that it held great favor as commercially viable wine among its critics. The wines are of medium-weight color and tend to have more anthocyanin color than other North American native reds. It is also reported to have twice as much resveratrol as Cabernet Sauvignon. Resveratrol is one of the antioxidants in red wines that is correlated with a decrease in the incidence of coronary heart disease. The commercially available wines are either off-dry or made into a Port-style. In Arkansas, it is referred to as the “Cabernet of the Ozarks.”

NORTON IN THE WINERY

From a winemaking point of view, Norton presents little trouble but needs some attention when it comes to the fermentation stage. While sugars at harvest are generally in the 22–24 °Brix range, if any particular season was short with an early fall, then chaptalization is often utilized. Being from California, where chaptalization is illegal for commercial wines, I only utilized this technique for research wines that we knew would have low sugars. A calculator found on the Winebusiness.com website is helpful for this process: https://www.winebusiness.com/calculator/winemaking/. The finished wine should have a final alcohol of somewhere in the 13% range for proper balance.

Norton can also tend to have high malic acid levels. Adjusting acidity at this stage is tough without getting an accurate malic acid level from a commercial wine laboratory. Your pH and titratable acidity (TA) measurements are key to whether or not to add acid at the must stage. I focus more on the TA than the pH at this stage. Therefore, I would not add any acid if your TA measurement was greater than 7.0 g/L. Rather I would wait until the completion of the malolactic fermentation, remeasure the TA, and adjust based on bench trials. There is no set rule on acidity adjustment, it just comes with time and familiarity with that particular grape.

So ultimately I have not solved the Norton origins mystery, but I like this story because it gets one’s mind working in the complexity of the genetics of the various Vitis species in all its wonderful forms. Seems that every time I bring up grapes and their origins, it is not always cut and dry.

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 21

The distinctive ‘foxy’ character present in other North American grape varieties is not as prominent in Norton . . .

ENTER YOUR BEST HOMEMADE WINES IN THE WORLD’S LARGEST COMPETITION FOR HOBBY WINEMAKERS!

LAST CHANCE — SEND YOUR ENTRIES NOW! ENTRY DEADLINE: MARCH 17, 2023

Enter your wines and compete for gold, silver and bronze medals in 50 categories awarded by a panel of experienced wine judges. You can gain international recognition for your winemaking skills and get valuable feedback on your wines from the competition’s judging panel.

Entry Deadline: March 17, 2023

5515 Main Street • Manchester Center, VT 05255 ph: (802) 362-3981 ext. 106 • fax: (802) 362-2377

email: competition@winemakermag.com

You can also enter online at: www.winemakercompetition.com

22 FEBRUARY - MARCH 2023 WINEMAKER

SPECIAL BEST OF SHOW MEDALS

Gene Spaziani

Grand Champion Wine

WineMaker of the Year

will be awarded thanks to our award sponsors:

Best of Show Red

Retailer of the Year

Best of Show White

U-Vint of the Year

Best of Show Dessert

Club of the Year

LALLEMAND BREWING

Best of Show Mead

Best of Show Country Fruit

Best of Show Sparkling

Best of Show Estate Grown

Best of Show Kit/Concentrate

Category Medals (gold, silver, and bronze) will be awarded thanks to our category sponsors:

34. Red Table Wine Blend (Any Grape Varieties)

35. Blush Table Wine Blend (Any Grape Varieties)

36. Grape & Non-Grape Table Wine Blend

37. Apple or Pear Varietals or Blends

38. Hard Cider or Perry

39. Stone Fruit (Peach, Cherry, Blends, etc.)

GLCC Co.

40. Berry Fruit (Strawberry, Raspberry, Blends, etc.)

GLCC Co.

41. Other Fruits

GLCC Co.

42. Traditional Mead

43. Fruit Mead

Moonlight Meadery

44. Herb and Spice Mead

45. Flower or Vegetable

46. Port Style

47. Sherry Style

48. Other Fortified

49. Sparkling Grape, Dry/Semi-Dry or Sweet

50. Sparkling Non-Grape

WINEMAKERMAG.COM FEBRUARY - MARCH 2023 23

1. White Native American Varietal

2. White Native American Blend

3. Red Native American Varietal

4. Red Native American Blend

5. Blush/Rosé Native American

6. Red or White Native American Late Harvest and Ice Wine

7. White French-American Hybrid Varietal

UWinemaker

15.

8.

White French-American Hybrid Blend

9. Red French-American

Hybrid Varietal

10. Red French-American

Hybrid Blend

11. Blush/Rosé French-American Hybrid 12. Red or White French-American Late Harvest and Ice Wine 13. Chardonnay

14. Pinot Grigio/Pinot Gris

Gewürztraminer 16. Riesling 17.

Sauvignon Blanc

18. Other White Vinifera Varietals

Cabernet

All

23. Merlot Vinmetrica 24. Shiraz/Syrah 25. Pinot Noir 26. Sangiovese 27. Zinfandel MoreWine!

Other Red Vinifera Varietals

Red Vinifera Bordeaux Style Blends Tin Lizzie Wineworks

Other Red Vinifera Blends Label Peelers Beer & Winemaking Supply

Blush/Rosé Red Vinifera

Red or

19. White

Vinifera Bordeaux

Style Blends 20.

Other

White

Vinifera Blends

21. Cabernet Franc Five Star Chemicals & Supply, Inc. 22.

Sauvignon

in One Wine Pump Company

28.

29.

30.

31.

32.

White Vinifera Late Harvest and Ice Wine

33. White Table Wine Blend (Any Grape Varieties)

RULES & REGULATIONS

1. Entry deadline for wines to arrive is March 17, 2023

Wines are to be delivered to: Battenkill Communications

5515 Main Street

Manchester Center, VT 05255

Ph: (802) 362-3981

2. Send ONE (1) BOTTLE per entry. Still wines must be submitted in standard 750 ml wine bottles. Ice wines or late harvest wines can be submitted in 375 ml bottles. Meads and Hard Ciders can be submitted in 12 oz. or 22 oz. beer bottles. Sparkling wines must be in champagne bottles with proper closure and wire or crown cap. All bottles must be free of wax, decorative labels and capsules. However, an identification label will be required on the bottle as detailed in rule #5.

3. Entry fee is $30 U.S. dollars (or $30 Canadian dollars) for each wine entered. Each individual person is allowed up to a total of 15 entries. You may enter in as many categories as you wish. Make checks payable to WineMaker Only U.S. or Canadian funds will be accepted. On your check write the number of entries (no more than 15 total) and the name of the entrant if different from the name on the check. Entry fees are non-refundable.

4. All shipments should be packaged to withstand considerable handling and must be shipped freight pre-paid. Line the inside of the box with a plastic trash bag and use plenty of packaging material, such as bubble wrap, around the bottles. Bottles shipped in preformed styrofoam cartons have proven reliable in the past. Every reasonable effort will be made to contact entrants whose bottles have broken to make arrangements for sending replacement bottles. Please note it is illegal to ship alcoholic beverages via the U.S. Postal Service. FedEx Air and FedEx Ground will destroy all amateur wine shipments so do not use either of these services. Private shipping companies such as UPS with company policies against individuals shipping alcohol may refuse your shipment if they are informed your package contains alcoholic beverages. Entries mailed internationally are often required by customs to provide proper documentation. It is the entrant’s responsibility to follow all applicable laws and regulations. Packages with postage due or C.O.D. charges will be rejected.

5 Each bottle must be labeled with the following information: Your name, category number, wine ingredients, vintage.