The Brooklyn Brewery, currently located at 79 North 11th Street in Williamsburg, Brooklyn, is embarking on an expansion plan that includes possible relocation within Brooklyn for its current facility, as well as the establishment of a separate production facility capable of supporting the continued growth of the company while decreasing the reliance on contract-based production elsewhere. While the current location in Williamsburg has in many ways defined the ethos of the company and its growth, major transformation in recent years has altered the industrial character of the area. In spite of this, it is the Brewery’s desire to maintain its sense of identity, culture, and many aspects of its operations are inherently tied to its presence at the current location.

The current leasing conditions suggest that a move in the near future will be both imminent and strategic in the preservation of the Brewery’s ethos and the evolution of its narrative, which is indicative of Brooklyn’s status both locally and abroad. This report has been prepared in an effort to provide an overview for the significant expansion of the production capacity of the Brooklyn Brewery with the understanding that the craft beer market has expanded both domestically and internationally to historically unprecedented levels. These levels surpass both the existing production capabilities at the current facility and the desire to maintain current reliance on contract-based production methods in Utica, NY and elsewhere. This new facility will provide the sustainable production capacity to meet demand well into the future.

Through a series of meetings and interviews, the project team has documented specific program requirements for the new production facility. We have also begun to establish a criteria for site selection that will support the increased scale of production in a way that limits environmental impact and optimizes processing, storage, and distribution-oriented work flows. Our Production Overview in the following pages describes how this process is sequenced, staffed, and hygienically designed in accordance with the preliminary planning carried out by BeerBev, a process engineering consultant engaged to develop the technical plant design. Support and amenity spaces will augment the programming of the new facility.

Growing out of a critical response to questionnaires and general data collection among and within the members that constitute the Brewery’s current departmental clusters, Davis Brody Bond / Spacesmith has summarized both the quantitative and qualitative space needs for the new production facility in the pages that follow. The production program overview

describes allocation for the following types of spaces: Brewhouse, Processing, Ingredient Storage and Handling, Laboratory, Utility Plant, Workshop, Tank farm, Packaging, Warehouse, Distribution Corridor, Production Support, and Miscellaneous Breweryrelated program. The configuration of these spaces is guided by the principles of efficiency, openness and collaboration that characterize the operations at the current facility in Williamsburg. Integration of transportation infrastructure with the overall site planning has also been considered.

A host of Sustainability goals have been suggested for the new production facility. The facility’s production design could incorporate the following initiatives:

• High Efficiency Steam

• Heat & Water Recovery

• CO2 Reclamation

• Sustainable Waste Disposal

• Possible Rail Integration

Additionally, the following sustainable architectural initiatives have been identified as candidates for integration into the project:

• Environmentally Preferred Materials

• Solar and other Renewable Energies

• Green Roofs

• On-Site Effluent Treatment (depending on site selected)

This report quantifies spatial needs, optimal adjacencies, appropriate gradations between public and private space requirements, flexible work space allocations that anticipate growth and future needs, the consideration of new technologies, and the need for a more sustainable office with a significantly expanded production component. Most importantly, this document is meant to integrate the vision of Brooklyn Brewery’s second new home with an aesthetic of openness that invokes the distinction, collaboration, and fundamental creativity inherent to Brooklyn’s brand.

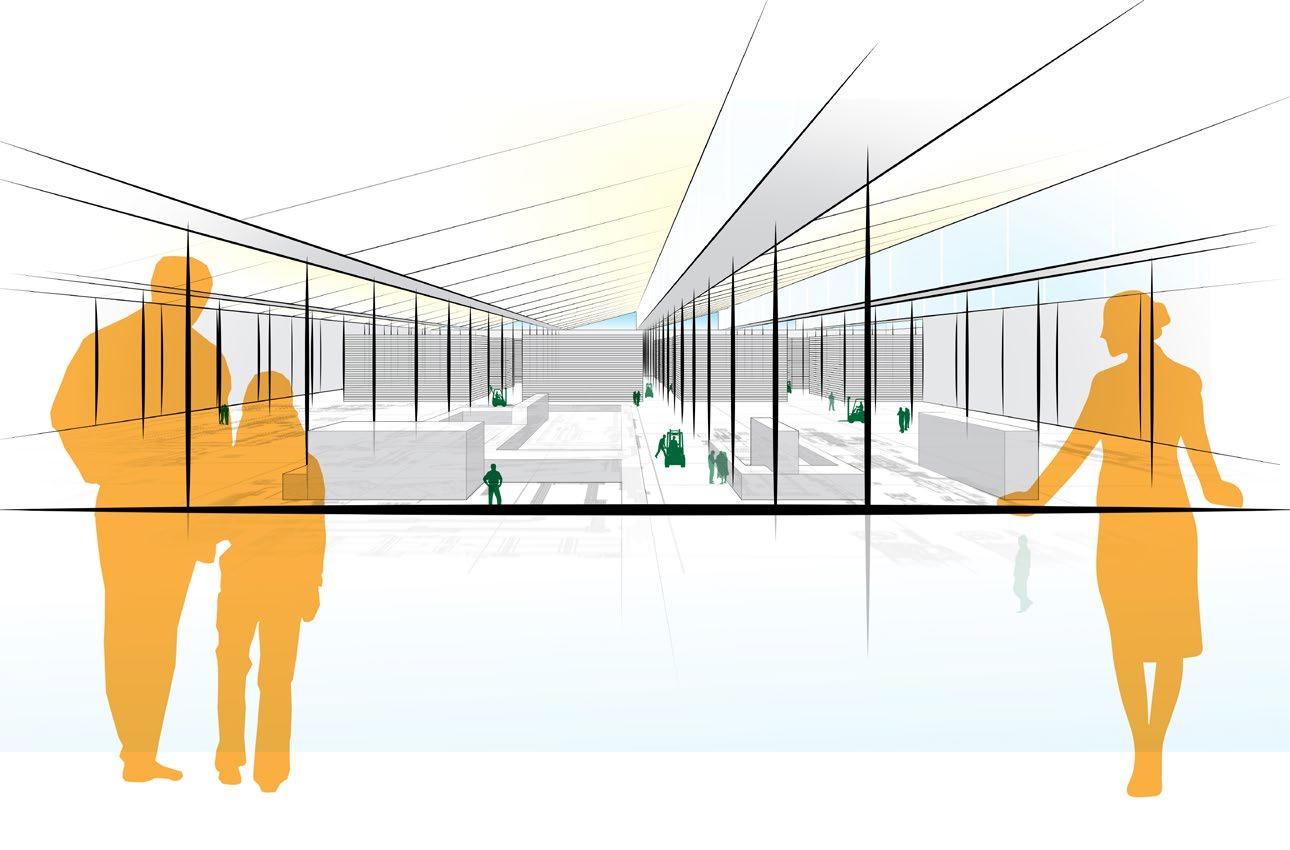

While Brooklyn Home will carry the spirit of the Brewery from Williamsburg to its new location in Brooklyn, the new production facility will expand the evolving brand on the level of production and embody that industrial aspect which has given the Brewery its current contextual point of reference. The secondary priority of the Visitor Experience and the multiplication of the Brooklyn Brewery aesthetic to site amenities will secure the new production facility as a competitive, global destination.

The overall programming process can conceptually be broken down into phases of collecting data, analyzing information, and drawing conclusions. This programming report is the byproduct of this process, the intent of which is to become a tool for both our client and the design team as we move into conceptual and subsequent design phases.

In order to facilitate the collection of data, a series of departmental programming meetings between Brooklyn Brewery and Davis Brody Bond took place at the Brooklyn Brewery during the second and third weeks of October 2015. Questionnaires were distributed prior to each session that provided an outline for each meeting. Brooklyn Brewery later submitted the completed questionnaires which were analyzed by the programming architects and used as the basis for recording space needs. Additional technical meetings with Beer Bev, the production engineer, were held on November 3, 2015 in order to discuss guiding design principles for the production brewery. The spatial, adjacency, and technical requirements for an optimized production brewery are documented within this report.

Through this series of meetings and interviews, the project team gained insight into both the quantitative and qualitative space needs for the Brooklyn Brewery. This information, coupled with schematic production plans and staffing projections provided by Beer Bev, form the basis of the production brewery program recorded in this document.

Ultimately, a new production facility for Brooklyn Brewery provides a path into the future for their continued growth. The craft beer market has expanded both domestically and internationally to historically unprecedented levels. A new production facility will allow Brooklyn Brewery to meet this increased demand well into the future. High level goals for a new production facility include:

• Create a production facility that is capable of supporting the continued growth of Brooklyn Brewery while decreasing reliance on contract based production.

• Build a state of the art brewery that is capable of efficiently and economically producing high volumes of beer while maintaining a paramount focus on quality.

• Provide in-house laboratory facilities.

• Provide a work environment that is conducive to worker health and happiness.

• Build spaces that encourage interaction and innovation amongst staff from all departments.

• Provide an environmentally sustainable brewing facility that decreases the environmental impacts of brewing.

• While the scale of public programming for the facility will ultimately be dependent on the site that is selected, the public programming that is provided should richly tell the story of Brooklyn Brewery, the powerful story of beer production, and provide opportunities for positive association to the Brooklyn brand and consumer education.

Site selection for the production facility will be highly informed by the technical requirements of brewing and packaging beer. It is vitally important that the specific site chosen is capable of providing the utilities demanded by the scope of production projected for this project. Additionally, it is important that the site is easily accessible to transportation networks utilized in bringing raw materials and finished goods to and from the site.

The following criteria represents a baseline for a production facility capable of producing annually 2,000,000 barrels of beer. Site selection criteria is directly tied to these production volumes. The exact volume that Brooklyn Brewery plans to produce at this facility continues to develop and will likely alter the utility requirements specified below.

• ± 400,000 sf of buildable area.

• 12‐inch water main capable of providing 2,500 gpm minimum at 30 psi minimum.

• Sanitary sewer service with a minimum discharge service capacity of 450 gpm.

• Minimum electric service requirements are 13.2KV (three phase service) and 175 Amps.

• Natural gas with a minimum capacity and pressure of 123 therms/hour and 5 psi.

• Access to rail spur.

• Proximity to container ports.

• Proximity to freeway and interstate systems. Ability for large trucks to easily enter and navigate the site.

• Soil load bearing capacity nominally 4,000 psf min.

• Appropriate zoning for the production of beer.

Presently, a large proportion of Brooklyn Brewery’s beer is produced under contract at the FX Matt Brewery located in Utica, New York. The new production brewery will be more technologically advanced than FX Matt in addition to being purpose built for the requirements of producing Brooklyn Brewery’s product lines. Warehousing and production functions will be consolidated within a single facility. It is anticipated that contract production at the FX Matt facility will be phased out once the new facility is at full production capacity.

The Campian Road Warehouse located in New Hartford, NY serves as Brooklyn Brewery’s primary distribution warehouse. The facility is 50,000 gross square feet in area with approximately 6,000 square feet of cold storage, and a mezzanine containing approximately 4,000 square feet of POS storage. The facility is owned by Brooklyn Brewery and operated / staffed by Oneida. This facility serves as a primary distribution point for Brooklyn’s products. Additionally, Point of Sale shipping in the form of ±15 direct retail sales to individual customers and ±5 palletized shipments to beer distributors occur on a daily basis. An approximately 150 square feet area is dedicated for picking and packing POS orders

Raw Material Flow into Brewhouse

Malt, water, hops, and yeast — the four prototypical ingredients in beer — must flow into the site and brewery becoming integral components of the overall production scheme. An efficient combination of rail and tractor trailer bring the raw materials into the brewery. Spent ingredients and waste are removed in a similarly thought-out fashion.

Provisions for storing ingredients is provided via a system of bulk malt silos, cold hop storage, and dry good storage areas. Raw water is brought into the brewery via a municipal water source, which is treated to meet brewing specification.

Production Process

Hot wort flows from the brewhouse, being chilled via a heat exchanger in route to fermentation tanks where the wort is aerated and inoculated with brewer’s yeast. From there the beer spends time within the fermentation tanks before being processed via centrifuges and filters in route to bright beer tanks where it is carbonated and conditioned. Once carbonated, the bright beer is sent to various types of packaging lines optionally pasteurized along the way. Once packaged, the beer is temporarily warehoused before being sent into distribution networks and throughout the globe.

Process Piping

A logical system of sanitary stainless steel process piping supported by pipe bridges connects all points through the production flow, carrying wort, finished beer, steam, water, cleaning products, glycol (or NH3), compressed air, carbon dioxide, and other components of the brewing process. The process piping connects to tanks located in the exterior tank farm and is integral to the overall production flow. All piping is capable of being cleaned in place via integrated CIP (clean in process) systems.

Many aspects of brewing are inherently unsustainable. Paramount to this is the fact that the process utilizes large amounts of water and energy during production, only a fraction of which is incorporated into the final product. The combustion of natural gas to fuel steam boilers, generation of CO2 during fermentation, requirements for mechanical refrigeration during fermentation, use of cold potable water within heat exchange processes, reliance on vehicular transportation to bring product to market, and waste materials from the production process all represent areas that are potentially detrimental to our environment. While these items can be seen as environmental liabilities, the can also be viewed as opportunities to incorporate sustainable processes and policies which not only mitigate the effect of brewing on the environment but are also economically efficient. Fundamental to the brewery’s design, the following strategies have been incorporated to bring a level of sustainability to the production process:

Highly efficient steam boilers are the most efficient and economical means to generate, transport, and implement the heat required during the brewing process. Natural gas powered boilers provide a relatively clean and efficient energy source.

Throughout the process heat exchangers can be utilized to recover heat input in the process via steam boilers and transfer it back into the process where it is required (heating mash strike water, e.g.) Water to cool hot wort prior to fermentation is recovered and used elsewhere in the process. Additionally, a system of condensers can be utilized to recover steam exhaust from brewhouse ventilation stacks.

Carbon dioxide is a natural bi-product of the metabolic activities involved in the fermentation of beer. CO2 is also a greenhouse gas. Capturing and purveying the gas created during fermentation and using it back in the process to carbonate beers and purge vessels can be economical at this scale and lower the carbon footprint of the brewing process.

Spent grain and kettle trub can be recovered from the process and diverted from the waste stream via agricultural operations where it can be utilized as a feed source. Recovered yeast can be autolyzed and recovered as an additional nutrient source.

Relying on rail for the transportation of raw materials and potentially finished goods utilizes far less fossil fuel during transportation than their tractor trailer equivalents. Locating the production facility adjacent to efficient rail infrastructure can dramatically decrease the brewery’s carbon footprint.

The brewery’s architecture presents an opportunity to integrate further sustainable strategies into the overall project. All of these strategies should be analyzed through a lens of economy in order to better understand their appropriateness for this specific project. A number of potential strategies which may be relevant and require further analysis during design are presented below.

Utilizing reclaimed materials, those with low embodied energy, rapidly renewable materials, and/or those manufactured via environmentally responsible processes should be considered throughout the projects. These opportunities can help to minimize the building’s environmental impact while also contributing to positive indoor air quality and reinforcing the broader brand strategy for Brooklyn Brewery.

The large footprint of the brewery and site make it a potential candidate for generating power via solar or wind energy. A value analysis incorporating life-cycle costs and pay-back should be undertaken in order to better understand the potential for power generation as it relates to this project. Bringing in a third part operator can minimize the maintenance burden on the brewery while providing a positive environmental impact as well as economic benefit to the brewery.

Green roofs can provide for a tertiary level of storm water treatment and retention as well as a reduction of the heat-island effect that can be associated with large expanses of roof. Additionally, they can offer an amenity for those occupying the building.

The site that is ultimately chosen for the brewery will inherently possess a unique set of environmental criteria (for example, a wetland) which must be understood in order to minimize any negative impacts the brewery may have on the surrounding natural environment. The environmental context of the brewery can become an amenity for brewery visitors and staff.

Common to many breweries of this scale is a provision for treating on-site brewery effluent prior to being discharged into the municipal water treatment infrastructure. This is typically incorporated into projects located in rural areas where the sewer infrastructure is not capable of handling large volumes of effluent like those produced from a brewery of this scale. Additional opportunities for power generation via bio-digesters could be considered if on-site effluent treatment is incorporated into the design.

Visitor experience related goals:

• Make control room & lab visible on tour

• Integrate views of the taproom / beer garden into the visitor path in order to activate sparsely populated space

NOTE: STAFFING DATA HAS BEEN INTERPRETED FROM BEER BEV PRODUCTION NUMBERS INDICATING STAFF MEMBERS DURING A SINGLE SHIFT.

STAFF

Brooklyn Brewery’s production facility is designed to produce very large quantities of high quality beer in a very efficient and economical manner. The brewery’s design incorporates a high level of automation minimizing the amount of manual labor required, particularly on the brewery’s hot-side of production.

The above diagram depicts the distribution of a single daytime shift of workers in the brewery. Based on this distribution, it becomes evident that the packaging lines become both a hub of not only mechanical might, but also human activity.

When looking at the distribution of workers in the brewery in relation the proposed path of visitors during a tour, it becomes clear that visitors may be left with the impression of a sparsely populated factory. In order to overcome this, it may be considered that the approach prior to starting a tour takes the visitor through publically activated spaces containing taprooms, retail stores, and/or public beer halls.

Utilizing public programming at the front-end of the visitor experience activates the space and provides another level of richness to the visitor’s experience.

* Production staff based on Beer Bev projected numbers at full build-out per shift. ** Staff TBD.

Brettanomyces Bruxellenis

Brettanomyces Bruxellenis

DATE

Note: Hygienic zoning information has been incorporated from Beer Bev’s memo provided on 11/9/2015.

04/11/2015

Production Areas are specifically designed for the purpose of producing, handling and packing beer. Within the production areas, different zones are defined by their hygienic needs.

BeerBev recommends the following zones:

REPORT Brooklyn Brewery Meeting @ DBB Manhattan, NYC areas, canteens and redundant buildings/rooms. The hazards created by pests and birds should to be controlled or reduced and also the introduction of unwanted materials into hygienic areas.

Zone B is a basic zone category where a basic level of hygienic design is applied. Open areas are allowed in a B-Zone. The B-Zone is used in breweries for areas where robust media and high temperature processing allow for a minimal amount of basic hygienic design.

Zone B0 is prescribed to areas outside of the buildings, but within the perimeter of the site, for the purpose of controlling and reducing hazards related to the outside environment.

Zone M is a medium level zone of hygienic design intended to protect the interior of food processing equipment susceptible to contamination by penetration. In an M-Zone, the building should be closed, watertight and be equipped with an appropriate ventilation system. The M-Zone is used in breweries for areas of closed processes like fermentation or filtering, where double-seated valves with dynamic seals are state-of-the-art. Providing a cleanable design for the exterior of equipment and a hygienic environment minimizes the potential for penetration through seals.

o Zone M , a zone of a medium level of hygienic design protect the interior of food processing equipment from contamination e.g. by penetration and control or reduce hazards that can affect a higher hygiene zone. In a M-zone, the building should be closed, watertight and be equipped by an appropriate ventilation system. The M-zone is used in breweries for areas of closed processes like fermentation or filtering, where double-seated valves with dynamic seals are state of the art. A cleanable design of the exterior of the equipment and a hygienic environment minimize the penetration trough the seals.

Zone H is a zone of high level hygienic design protecting product from contamination during open processing such as the bottling of beer. In an H-Zone, additional measures like an appropriate ventilation system are necessary. The H-Zone should be used for yeast culturing and propagation areas as well as filling stations where clean bottles and open filling equipment pose risks for contamination.

o Zone H, a zone of a high level of hygienic design protect product contamination during open processing e.g. bottling of beer. In a H-zone, additional measures like an appropriate ventilation system are necessary. The H-zone should be used for culturing /propagation and filling stations where clean bottles and open filling equipment are reasons for contamination from the environment and the exterior of equipment.

Zone B1 is prescribed to non-production areas like offices, workshops, power supply areas, canteens, and redundant buildings/rooms. The hazards created by pests and birds should be controlled to prevent the introduction of unwanted materials into hygienic areas.

o Regarding hygiene, CIP is considered as integral part of production. The various zones should be made clearly visible; the room arrangement of a building should correlate with the zoning concept.

o Hygienic Zoning shall be seen in correlation with Ventilation patterns;

To minimize interpretations within Hygienic Zoning herewith a patterning of the brewery production areas:

o In a warehouse area finished goods are handled and prepared for transport to the customers, where incoming materials other than “raw” materials or product ingredients are received from the supplier and stored for later use. Warehouse areas for raw materials and ingredients are production areas.

o An entrance is defined as a possibility, built on purpose to enter the production area i.e. for people, product, ventilation, utilities, electrical and communication wires.

Hygiene shall always be taken into account during the design of brewery machinery and equipment.

Equipment shall be capable of being easily cleaned and disinfected, and shall protect the product from becoming contaminated.

Equipment shall be constructed in such a way that penetration by micro-organisms external to the system is prevented. The main sources for penetration of closed process equipment are seals of valves and pumps.

The construction shall avoid the presence of dead ends, gaps, and cracks in which micro-organisms can shelter and multiply. In favorable conditions micro-organisms are capable of extremely rapid rates of multiplication.

The growth and accumulation of micro-organisms on processing equipment must be avoided. This is necessary to help ensure that micro-organisms do not penetrate the process equipment. Consequently the surroundings of process equipment shall be kept clean and dry.

The designer will need to find a compromise when the hygienic requirements are in conflict with other functional requirements imposed on the equipment. In such situations this may result in an increased frequency of cleaning, or more intensive cleaning. In this event the user’s instructions shall need to draw attention to the additional cleaning requirements.

In spite of the designer’s knowledge and experience of hygienic practices it may be necessary for the designer to take measures that provide for a capability of inspecting, testing and validating equipment with respect to its compliance with hygienic requirements. In critical situations it may be necessary to include the level of hygiene in the maintenance checklist.

Deviations from the hygienic requirements indicated are permissible only when it has been demonstrated that the equipment involved is capable of being cleaned and disinfected in an adequate manner, and when this demonstrated ability has been described in writing.

To ensure proper handling of finished goods and incoming materials:

• Floor areas should be easy to clean and of such materials that dirt accumulation is minimized.

• Walls and ceilings should be easy to clean and of such materials that dirt collection is minimized.

• Construction elements like columns, beams, and material stands should be positioned so that “ease” of cleaning is not compromised. Ceiling girder/beams should be covered by a casing to avoid dirt traps and “nesting areas” for birds or other vermin.

• Upper horizontal surfaces should be avoided where dust or condensate can accumulate.

• To minimize the entrance of birds, insects, and pests, doors should automatically open and close.

• Window glass should be unbreakable. If operable, window design should prevent insects from entering the building.

• Warehousing areas shall be provided with bird and insect-proofing materials.

The floor shall be easy to clean and repair if damaged. Floor coatings may contain volatile components requiring appropriate ventilation. Coatings should not be hazardous for the environment. Floors should be made of a material that is water-repellent, washable, antiskid, wear-resistant, non-toxic, and comply with the following criteria:

• Have a soft shine or matted color with a light reflection of at least: 50% and not more than 75%.

• Be free from cracks and splits. Floors must be mechanically stable to avoid holes and damage caused by forklifts and trucks.

• Be of non-absorbing smooth materials. If not properly finished, concrete is porous and can be attacked by oil, salt and various cleaning agents and disinfectants. Coating or sealing of existing concrete floors is recommended.

• Be resistant to products, intermediates, raw materials, acid-, caustic-, enzymatic- and oxidizing cleaning / disinfection agents normally used in a brewery environment.

• Should be capable of enduring localized temperature differences of at least 70 °C. The temperature difference typically occurs over a distance of centimeters.

• Floors must be easy to clean and disinfect and should have a high fouling resistance to ensure that basic hygiene can be assured. Floors must at all times remain clean. Food remains are easily spread throughout the brewery owing to the transportation of goods and personnel walking about.

• Have a run-off angle of 1-2%, so as to ensure that liquids are drained effectively. For instance, if tiles are grooved to improve their antiskid properties, no accumulation of water may result. In that case, the grooves must be aligned with the direction of the flow. The floor must remain fully self-draining.

• Have a closed sewer system by piping system poured into floor; with flanged runoff points, discharged in central collection pits with water lock and vent.

• The connection between floors and walls, construction beams, equipment construction stands inclusive of corners should have a smooth and rounded construction. This to prevent dirt built up and ensure proper run-off of liquid. The minimum radius at the connection should be 25 mm.

The ceiling must be easy to clean and properly maintain, taking into account the following criteria:

• Avoid passages from roof or ceiling to the production rooms; any roof passage should be inaccessible to animals and insects; a combination of a rodent and insect screen will offer sufficient protection.

• Have a soft shine or matted color with a light reflection of at least 50% and not more than 75%.

• Be of non-absorbing smooth materials, resistant to products, intermediates, raw materials, acid-caustic-, enzymatic- and oxidizing cleaning /disinfection agents as normally used in a brewery environment.

• Be easy to clean and have a high fouling resistance such that basic hygiene can be assured, e.g. beams have to be covered.

• Ceilings must be constructed so that dirt collection is minimized, e.g. baffles for noise reduction are to be avoided. A ceiling should be applied, which in addition to its hygienic properties also absorbs noise.

• The transition from the ceiling to the walls must be a round angle to allow easy cleaning. The ceiling and its transition to the wall must be sealed hermetically.

• The ceiling may not be a place where moisture condensates, neither on the inside nor on the insulated side. A double-ceiling system may be necessary.

• Suspended ceilings shall not have direct connection and/or unshielded entrance between the production area and the area above the ceiling.

The following section begins to logically break down the production brewery into functional program areas as illustrated in the diagram on the opposite page. Each of these specific areas have a unique set of requirements which are described within their individual sections.

The brewery is to be designed around an efficient flow of production. Layered throughout this are specific requirements for not only the production process, but also for those individuals working throughout the brewery as well as those that Brooklyn Brewery welcomes as visitors to the facility.

Paramount to the building’s overall design are the critical spatial relationships between individual program areas. The location of individual program areas within the brewery logically follows the flow of production and the requirements for bringing raw materials into the site and finished good out. This production flow dictates adjacency criteria for specific program areas.

Additional considerations for carefully transporting materials, product, and utilities through a distribution network of production piping needs to be carefully considered. Minimizing runs of piping, elbows, and dead-ends must be considered in the design.In addition to the areas related to production as specified by Beer Bev, the architectural team has identified additional production support spaces (number 12 below) which account for the spaces required to administer and support the production process.

The fundamental purpose of the Brewhouse is to process and transform the raw ingredients of brewing (malt, hops, water) into wort, a sugar rich liquid that is ultimately transformed through fermentation into beer. This wort is transferred at boiling temperatures from the brewhouse and then cooled via heat exchanger in route to the tank farm for fermentation.

The brewhouse occupies two levels within the brewery. The production vessels (mash tun, lauter tun, wort collection vessels, boil kettle, whirlpool, and mash filter) must be accessible from both the first floor undercarriage and top-side mezzanine. Adjacent to the brewhouse is a control room which acts as the nerve center for the entire brewery and is central to control of all processes.

The visitor tour progression may take visitors along the brewhouse mezzanine level deck. If this is incorporated into the design, physical separation must be in place to prevent visitors from contacting hot surfaces.

The structural design must be coordinated to provide for imposed loads by tanks and other equipment as well as connection points for a small crane / gantry that is required by the mash filter. Floor drainage at both the first floor and mezzanine level of the brewhouse needs to be provided via a network of floor and/or trench drains.

1. Primary pipe bridge transporting material and utilities to and from the brewhouse.

2. Malt conveyance from exterior bulk malt silos.

3. Hop storage in cold room.

4. Hop dosing tanks convey hops to boil kettle and whirlpool.

5. Sacked grain and sugar storage.

6. Vertical conveyer for sacked malt transports grain to mill plant above.

7. Wall to be capable of removal for future phased installation of lauter tun.

Control Room

Hygiene Zone: B1

Floor: TBD

Temperature: ± 68° F ±2° F (Winter) ± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Brewhouse (First Floor)

Hygiene Zone: B

Floor: Quarry Tile Resistant to pH 5-12

Temperature: ± 75° F ±20° F (Winter) ± 75° F ±20° F (Summer)

Humidity: Uncontrolled

Brewhouse (Mezzanine Deck)

Hygiene Zone: B

Floor: Quarry Tile Resistant to pH 5-12

Temperature: ± 68° F ±10° F (Winter)

± 72° F ±10° F (Summer)

Humidity: Uncontrolled

8. Expansion space to run secondary brewhouse in parallel with primary brewhouse.

9. Future lauter tun to be installed in brewery phase 2.

10. Mash tun.

11. Mash tun.

12. Mash filter. Provide beam to support procesS crane.

13. Wort collecting vessel.

14. Wort kettle.

15. Whirlpool.

Note: Motor control centers located on mezzanine and 2nd floor not shown.

The processing area contains equipment for yeast management, beer filtration, cleaning in place (CIP), steam condensation, heat exchange, as well as equipment providing for the ingress of specific ingredients into the brewing process (kitchen mixing and hop dosing areas).

The structural design must be coordinated to provide for imposed loads by tanks and other equipment. Floor drainage must be provided throughout via a series of trench drains.

CIP areas contain hazardous chemicals and may require specialized ventilation to exhaust chemical vapors. Additionally, there may be jurisdictional requirements for chemical containment if plastic vessels are utilized to store the concentrated CIP chemicals (caustics and acids).

Throughout the space is a network of elevated pipe bridges that transport product, raw materials, chemicals, and utilities throughout the space and interconnect with other areas within the brewery.

Yeast Management & Filtration

Hygiene Zone: H (yeast area), M (filtration)

Floor: Quarry Tile

Temperature:

Resistant to pH 5-12

± 68° F ±5° F (Winter)

± 68° F ±5° F (Summer)

Humidity: 35-42° F Dewpoint

Hop Dosing & Kitchen Mixing

Hygiene Zone: M

Floor: Quarry Tile

Temperature:

Resistant to pH 5-12

± 68° F ±10° F (Winter)

± 72° F ±10° F (Summer)

Humidity: ± 45% RH ±10%

CIP

Hygiene Zone: B

Floor: Quarry Tile

Resistant to pH 5-12

Temperature: ± 75° F ±20° F (Winter)

± 75° F ±20° F (Summer)

Humidity: Uncontrolled

NOTES

1. Truck CIP delivery.

2. CIP strorage tanks.

3. CIP vessels.

4. Hop dosing tanks and torpedos.

5. Kitchen mixing station.

6. Centrifuges and polish filters.

7. Yeast tanks.

8. Pipe bridge connecting CIP plant to primary pipe distribution.

9. Pipe bridge connecting filtration to primary pipe distribution.

10. Pipe bridge connecting yeast management to primary pipe distribution.

11. Primary pipe bridge.

A series of areas within the brewery are used to intake, store, and process raw ingredients for brewing. Sugar and special malt storage areas store super-sacks of grain (1,000-2,000 lbs) as well as small sacks of grain and sugar (50-55 lbs). This area should have exterior loading access for weekly deliveries of sacked goods, and be located adjacent to kitchen mixing in the processing area. Additionally, the space should contain a grain intake that is used to convey malt vertically up to the milling plant.

The cold ingredient storage is primarily used for hops and should be located with exterior loading access as well as adjacency to the hop dosing tanks in the processing area. Bulk malt reception should exist as an exterior area covered with a roof to protect it from weather. Rail cars are off-loaded with grain which is then stored in bulk malt silos. Malt is transferred via underground pneumatic conveyers from the malt silos to a mezzanine level milling plant where it is milled and transferred into the brewhouse. The milling plant contains multiple pieces of equipment to clean and mill the grain. Consideration for controlling grain dust and preventing explosion must be integrated into the design of the milling operation.

Additional rail-spur space is allocated along the bulk malt silos to allow rail cars to be parked and used for additional malt storage.

1. Bulk malt delivery via rail car. Covered malt reception for unloading.

2. Grain is conveyed to bulk malt silos for storage.

3. Grain is transferred from bulk malt silos to a 2nd floor mezzanine milling plant via an underground mail conveyer.

4. Small sacked grain and sugar delivery via truck.

5. Hop delivery via truck.

Waste material tanks for both spent grain and yeast should be located adjacent to the rear service yard so that spent material can be trucked out. These tanks will need to be connected to the brewhouse as well as yeast processing areas.

Cold Ingredient Storage

Hygiene Zone: B

Floor: TBD

Temperature: 7° F (By Vendor)

Humidity: By Vendor

Sugar & Special Malt

Hygiene Zone: B

Floor: Polyurethane

Temperature:

Resin Coated Concrete

± 75° F ±20° F (Winter)

± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

Milling Plant

Hygiene Zone: B

Floor: Polyurethane

Temperature:

Resin Coated Concrete

± 75° F ±20° F (Winter)

± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

6. Autolysed yeast is tranferred from yeast management area to a holding tank.

7. Yeast holding tank.

8. Spent grain transferred from mash filter.

9. Spent grain transferred from future lauter tun.

10. Spent grain holding tank.

11. Waste yeast and spent grain is removed from the site via truck transport.

The laboratories within the brewery are central to the overall quality assurance / quality control programs at the brewery. The microbiology and chemistry labs are outfitted with equipment required to provide analytical data at every step along the brewing process. The laboratories are used to test samples throughout the process. For the convenience of workers, it is optimal for the labs to be centrally located. It may be considered that the labs be highlighted along the public tour component of the program.

1. Lab pulls samples from every point in the production process.

2. Sensory tasting lab. Trained tasters are pooled from production and office staff come to this location for tasting panels.

Microbiology Lab

Hygiene Zone: H

Floor: TBD

Temperature: ± 68° F ±2° F (Winter)

± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Chemistry Lab

Hygiene Zone: H

Floor: TBD

Temperature:

± 68° F ±2° F (Winter)

± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Sensory Tasting Room

Hygiene Zone: B1

Floor: TBD

Temperature: ± 68° F ±2° F (Winter)

± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

AREA SUMMARY

Total:

MICROBIOLOGY LAB

The microbiology lab is used to perform a number of tasks including testing the purity, viability, and counts of yeast cultures, testing for microbiological contaminants in finished products, testing swabs pulled throughout the brewery for any microbiological contamination, and culturing yeast. A number of these processes require sanitary and sometimes sterile environments to prevent any environmental contamination.

Equipment List

Sink • Work Bench • Storage Cabinetry

Laminar Flow Hood • Microscope • Centrifuge

Incubation Cabinet • Shaker Table / Stir Plates

Refrigerator • Autoclave

CHEMISTRY LAB

The chemistry lab use speicalized equipment to process and provide analytic data for specific products throughout the process to ensure that it meets the brewing specification.

Equipment List

Sink • Work Bench • Benchtop pH Meter • Vent Hood

Benchtop Density Meter • Storage Cabinetry

Flammable Liquid Storage • Spectrophotometer

Gas Chromagapher • DO Meter / Piercer

SENSORY LAB

The sensory lab is used to blindly taste samples and provide sensory data and feedback. This process is used to ensure that products taste as intended, as well as to evaluate new recipes, processes, and ingredients. The room should be devoid of external influence including outside smells, noise, and visual distractions.

Equipment List

Table (8-person) • Sink • Storage Cabinetry

Dishwasher • Sink • Refrigerator

The utility plant provides for all of the utilities used throughout the production process.

The emergency generator provides capacity for life-safety systems as well as the safe shut down of brewing equipment in case of power failure. A fuel storage tank will be required, the location of which will need to be coordinated with the site design.

The steam boiler room will be designed to contain ultimately three steam boilers. This space may require fire separation as well as special seismic bracing for steam lines if they are operating under high pressure.

The CO2 plant is used to recapture and purify CO2 from the fermentation process which can be used to carbonate beer or purge vessels. Specialized CO2 detection may be required in this area. The refrigeration plant is used to provide cooling capacity for the fermentation tanks and will either be glycol of NH3 based. This areas will likely require room purge and possible containment in the event of a refrigerant leak.

Power Generator

NOTES

1. CO2 delivery via truck.

2. Exterior boiler exhaust stacks.

3. Fuel storage to be below grade or within exterior area-way. TBD.

4. Primary pipe distribution bridge.

5. Pipe distribution bridge serving utility plant.

The transformer room will require coordination with the local electric utility to ensure it meets their specification. Locations of water treatment, steam boilers, and power sub-stations will need to be coordinated with the points of entry for various utilities. There is a possibility that the utility plant will be designed as a micro-grid with operation being contracted out to a third party operator. This is to be determined at the time of this report.

Utility Plant

Hygiene Zone: B1

Floor: Polyurethane

Resin Coated Concrete

Temperature: ± 75° F ±20° F (Winter) ± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

The workshop spaces are used to service equipment throughout the brewery. Typically, packaging line require the most maintenance in a brewery due to their moving parts and requirements for changing over components depending on what is being packaged. Because of this, these spaces are most appropriately located adjacent to the packaging lines.

Workshop

Hygiene Zone: B1

Floor: Sealed Concrete

Temperature: ± 68° F ±2° F (Winter) ± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Spare Parts

Hygiene Zone: B1

Floor: Sealed Concrete

Temperature: Uncontrolled

Humidity: Uncontrolled

1. Spare parts primary services equipment in the packaging hall. Additionally, this space provides spare parts to the utility plant and other production areas.

2. The workshop primarily services equipment in the packaging hall. Additionally, the workshop provides servicing for equipment in the utility plant and other processing areas.

The tank farm is an exterior concrete pad holding the tanks used for fermentation, conditioning beer, and storing hot and cold water. Tanks in this area vary in size and will be built in a phased manner as capacity is required. The tank farm foundation will need to be designed to accommodate loads imposed by the tanks. The design will be based on geotechnical data, but will likely require the use of some localized piles.

Drainage from the tank farm will primarily be required for storm water. It is not anticipated that this area will need to provide for the drainage of brewery effluent. It should be confirmed with local utilities whether the rare discharge of brewery effluent into a storm water system can be accommodated.

The tanks are connected to the primary interior pipe bridge via a serious of valves. There will be numerous pipe penetrations in the exterior wall approximately 1m above the floor. During construction, a staging area of approximately 20m x 30m should be provided for the assembly and erection of tanks.

Wort travels from the brewhouse into fermentation tanks. Once fermentation is complete, the beer is transferred through filtration in the processing area and back to bright beer tanks in the tank farm where it is carbonated prior to packaging.

Tank Farm

Hygiene Zone: B0

Floor: Concrete

Fermentation Tanks

Water Tanks

Bright Beer Tanks

1. Bright beer tanks.

2. Fermentation tanks.

3. Water tanks and NH3 separators.

4. Primary distribution pipe bridge.

5. Pipe bridge distributing finished beer to packaging lines.

6. Pipe bridge to brewhouse.

7. Valve gallery connecting tank farm to primary pipe bridge.

8. Individual piping runs to each tank.

9. Tank farm expansion space.

The packaging hall processes finished beer from the bright beer tanks in the tank farm, and packages it into kegs, bottles, cans, and bulk tankers.These areas should utilize a high level of hygienic design due to the open processing of product post pasteurization. Access to natural light is desired in this area. Floor drains will be required adjacent to packaging lines. Clearances for maneuvering pallets of finished product on fork lifts will be required.

Bulk Tanker Filling

Hygiene Zone: M

Floor: Polyurethane Coated Concrete

Temperature: Uncontrolled

Humidity: Uncontrolled

Filling Lab

Hygiene Zone: H

Floor: TBD

Temperature:

± 68° F ±2° F (Winter)

± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Consumables Storage

Hygiene Zone: B

Floor: Sealed Concrete

Temperature:

± 75° F ±20° F (Winter)

± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

Packaging Hall

Hygiene Zone: M

Floor: Polyurethane Coated Concrete

Temperature:

± 68° F ±5° F (Winter)

± 68° F ±5° F (Summer)

Humidity: 35-42° F Dewpoint

AREA SUMMARY

Packaging CIP

Pasteurization

Kegging Line

Key Keg Storage

Canning Line

Bottling Line - Phase 1

Bottling Line - Phase 2

NOTES

1. Flash pasteurizers are capable of processing all product going into bulk transfer, cans, kegs, and bottles. Packaging lines can produce pasteurized and non-pasteurized product.

2. Pipe bridge carrying finished product to packaging lines.

3. Storage of glue, labels, and crown caps for packaging lines.

4. Bulk transfer stations that run CIP, CO2 purge, and fill bulk transfer tanks.

5. Bulk tankers shipped via truck and cargo ship.

The warehouse primarily functions to intake empty packaging and ship finished product from the brewery. Additionally, it contains a host of support spaces outlined in the area summary below.

1.

2.

3.

Warehouse

Hygiene Zone: B

Floor: Sealed Concrete

Temperature: ± 75° F ±20° F (Winter) ± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

The distribution corridor is the primary connecting path for all process piping in the brewery’s design. It serves to connect all areas within the brewery. All of the process piping is designed to be supported by a pipe rack situated above the walking path on the first floor, and below the mezzanine walk way.

This pipe rack connects to secondary pipe racks within the packaging hall, utility plant, processing area, and brewhouse.

Distribution Corridor

Hygiene Zone: M

Floor: Quarry Tile

Resistant to pH 5-12

Temperature: ± 75° F ±20° F (Winter) ± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

1. Secondary pipe racks connect to the primary pipe distribution corridor and carry various utilities and product to different areas within the brewery and packaging hall.

LOCATION TBD

The production brewing facility will likely contain other program elements that are focused on research and development as well as being visually appealing experiences for potential visitors. The adjacencies to other program elements and logistics associated with these spaces will be developed as the ultimate vision for the production facility is developed.

A pilot brewery can become a strong component of Brooklyn Brewery’s R&D program, allowing for pilot batches of new recipes to be brewed, as well as for the evaluation of raw materials such as hops and malts for technical and flavor performance as it relates to brewing. Additionally, the pilot brewery can provide an additional creative outlet for brewing staff to produce small experimental batches that would otherwise tie up the main production brewhouse. Locating the pilot brewery in proximity to laboratory spaces would likely be advantageous.

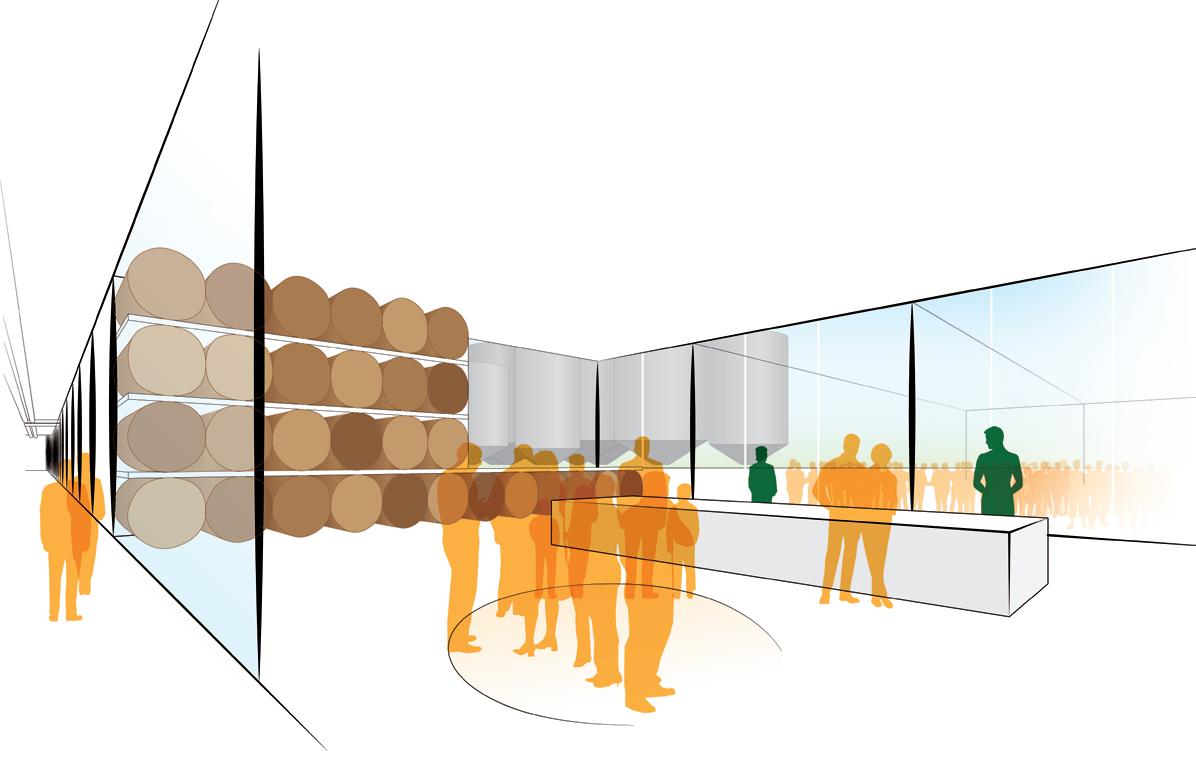

A small barrel showroom may be located near public areas in order to provide a visually rich element that also communicates the brewery’s efforts in the specialty of barrel aged beers.

Pilot Brewery

Hygiene Zone: M

Floor: Quarry Tile

Temperature:

Resistant to pH 5-12

± 68° F ±2° F (Winter)

± 72° F ±2° F (Summer)

Humidity: ± 45% RH ±10%

Barrel Showroom

Hygiene Zone: M

Floor: Polyurethane

Resin Coated Concrete

Temperature: ± 75° F ±20° F (Winter)

± 75° F ±20° F (Summer)

Humidity: ± 55% RH Max.

WAREHOUSE OFFICES PACKAGING

FIRST FLOOR FIRST OR SECOND FLOOR

The production facility will be designed with a number of support and amenity spaces illustrated in the diagram above.

Creating one unified break space for both production and office staff is desired as it encourages interdepartmental comingling which is a core tenet of the way in which Brooklyn Brewery operates. Depending on the physical size and ultimate layout of the brewery, a secondary small breakroom may need to be located near production or warehouse spaces. This room should always be considered subordinate to the main break areas. The primary breakroom will contain a pantry, dining space, potential beer taps, a lounge space, and other potential recreational elements.

During programming interviews, there was some desire stated in include an exercise room in the program. Further study and evaluation is needed to determine how frequently such an amenity would be used be the staff. An exercise room that is infrequently used is not a desired program element.

An appropriately sized locker and shower room should be provided for both production and office staff. The above diagram illustrates this adjacent to production and warehouse spaces as this staff is most likely to require locker and shower facilities. Locating these facilities adjacent to production areas will encourage office staff to come into the production spaces.

The logistics suite contains spaces supporting shipping to and from the brewery. A dispatch office contains space for two dispatchers to work. Direct access to the truck driver’s lounge as well as office support spaces is desired. Views to the outside truck yard is desirable. It is important for workers in this area to not feel remote from the rest of Brooklyn Brewery’s staff. This can be accomplished by locating these office spaces adjacent to shared spaces such as a small break room or the office spaces associated with warehouse workers. A driver lounge is provided as an amenity for truck drivers to wait as their trailers are loaded. This space should provide light refreshments (coffee), lounge space, and restroom facilities. Direct access from the exterior is the important. The design should be welcoming to drivers while also controlling access to other parts of the facility.

The office support area contains file storage, a copy room, and a small breakroom that supports the workers in the warehouse and packaging areas. This area can serve as a central connecting hub for workers in these parts of the brewery.

The warehouse office contains work space (desks, computers, and printers) for warehouse workers to complete paperwork and access computers. A Point of Sale (POS) retail shipping office should also be provided in this area. Within this space, retail point-ofsale retail orders are picked, packed, and shipped. Additionally, the point-of-sale manager prepares larger orders which are palletized and shipped. Point-of-sale functions are currently being accommodated at the New Hartford warehouse facility. The point-of-sale office should be located with some proximity to the warehouse spaces that are storing point-of-sale items as well as the staging areas where the items are being staged for shipment.

* Production staff based on Beer Bev projected numbers at full build-out per shift.

** Staff TBD.

*** Lockers are unassigned and accommodate the number of workers for a single shift.

**** Lockers are assigned. (3) shifts per day for brewery, utility plant, security, and workshop. (2) shifts per day for packaging and warehouse. (1) shift per day for office & lab.

The Brooklyn Brewery seeks to maintain the openness of their Williamsburg space in their future work environment. ‘No silos’ is a philosophy that was communicated to the programming team and is intended to prevent work taking place in isolation. Designing inviting spaces that promote collaboration is a key objective that will be guided by the following principles:

• Open space, visually and spatially connected and cohesive.

• Minimal closed-off space as needed for applicable program.

• Shell space will be a factor, but to extent viable the space should be more industrial and raw than finished and polished. Exposed structure, exposed ducting and services. Space shall reamain warm, comfortable and accessible.

• Design approach that evokes bespoke solutions and development including recycled materials.

• Feel should not be sleek, polished or selfconsciously modern.

Work station configuration and design contributes to the overall aesthetic and funtion of an office while most intimately influencing the staff’s personal space and work environment. Custom stations should be considered for the Brooklyn Brewery with an eye to the following advantages:

• Tailored to the users specific needs.

• Designed to suit the space.

• More control over the look & feel of the space.

• Allows for a space efficient layout and flexible space division.

• Creates unique / distinctive work spaces that encourage interaction and collaboration.

• Brooklyn Brewery’s personality is further expressed in the design of the space.

• Customized workstations can be complimented by ready made pieces.

• Request re-used / recycled materials.

• Potential partnership with local furniture makers and craftsmen.

BROOKLYN BREWERY

BROOKLYN HOME

OFFICE PROGRAM AREAS

SCALE: 1/8”=1’-0”

DEC 2015

LEGEND: (P) PRINTER

• 750 sf

• Clear ceiling height TBD

USE / FUNCTION

• Workstations/files

• Security:

• Audio / visual:

• Acoustics:

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

TBD

• Double monitor stations

BROOKLYN BREWERY

SCALE: 1/8”=1’-0”

• 750 sf

• Clear ceiling height TBD

• Day stations for sales team, event ambassadors, and other visitors

• Essential: need BB input

• Important: need BB input

• Normal: need BB input

• Security:

• Audio / visual:

• Acoustics:

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

TBD

ADDITIONAL NOTES

• Up to 10 positions w/power-data. 5 with fixed computers

• Adjacent storage for 12 box/files

CRITICAL DIMENSIONS

• Reception & Waiting 17’-6” x 13’-2” = 230 sf

• Clear ceiling height TBD

USE / FUNCTION

• Reception/waiting, shared lounge

ADJACENCIES

• Front door

• Security:

• Audio / visual:

• Acoustics:

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

BROOKLYN

SUSTAINABLE STRATEGIES

TBD

ADDITIONAL NOTES

• Power-data for guests

• Pantry 16’-4” x 21’-10” = 240 sf

• Lunch Room 17’-6” x 28’-0” = 600 sf

• Lunch Communal 17’-0” x 21’-10” = 510 sf

• Clear ceiling height TBD

• Staff pantry

• Reception/lounge

• Security:

• Audio / visual:

• Acoustics:

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

SUSTAINABLE STRATEGIES TBD

ADDITIONAL NOTES

• Beer taps

• Bottle beer storage

BROOKLYN BREWERY PRODUCTION FACILITY OFFICE PROGRAM AREAS

SCALE: NTS DEC 2015

Wellness/Counseling

• Wellness room 12’-0” x 10’-0” = 120 sf

• Restrooms & JC 24’-2” x 12’-6” = 520

• Lactation, nursing, couseling and other functions requiring privacy

• Restrooms

• Building core, wet columns, TBD

Restrooms & Janitor Closet

• Security:

• Audio / visual:

• Acoustics:

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

TBD

ADDITIONAL NOTES

• Sink/refrigerator for lactation

• Large Conference Room 17’-0” x 38’-0”= 640 sf

• Clear ceiling height TBD

• Meeting, conferencing, training

ADJACENCIES

• Reception/pantry

• Security:

• Audio / visual:

– Teleconferencing

– Level control for video

• Acoustics:

– Isolation from work areas

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

SUSTAINABLE STRATEGIES TBD

ADDITIONAL NOTES

BROOKLYN

• Medium Conf. 12’-6” x 21’-4” = 250 sf

• Phone Room 10’-0” x 6’-0” = 60 sf

• Clear ceiling height TBD

• Meeting, conferencing

• Private phone conversations

• Reception/pantry and/or distributed in department work areas

• Security:

• Audio / visual:

– Teleconferencing

• Level control for video

• Acoustics:

– Isolation from work areas

• Lighting / daylighting:

• Climate control:

• Ventilation:

• Special equipment / built-ins:

• Special finishes:

TBD

Inviting the public into a production brewery offers the opportunity to provide visitors with an inside look into the brewing process of a beverage they love. Through this exchange, the brewing process is de-mystified and becomes both relatable and all the more impressive by the shear grandeur of the equipment and process. Relating a trip to the brewery with a positive and enjoyable experience builds a powerful connection between the individual and the brewery. The challenge of integrating public programming with a production facility requires careful coordination, but offers a valuable asset to the brewery.

Ultimately, the scope of visitor space programming will be determined by a number of factors, including:

• Demographic make-up of area around the brewery. Public programming should ultimately relate to the location of the brewery.

• Physical access to the site for visitors.

• Physical size of the site and its ability to accommodate additional programming.

• Public programming elements that exist at other Brooklyn Brewery facilities.

At a minimum, the production facility will likely provide public tours as well as a retail store. In addition to this, there may be a food and beverage component in the form of a beer hall or beer garden. This programming may exist on day-one, be planned for future expansion phases, or possibly not planned at all if it is not determined to be feasible on the site or advantageous for Brooklyn Brewery.

The design of a retail space at Brooklyn Brewery’s production facility will be highly integrated with other public programming components. The tour, retail shop, and possible beer hall should be considered as a unified whole where the design of one element is interrelated with all other components.

From the time someone steps into the store to the time they check out, smart design decisions make a significant difference in regards to whether a sale is made or not. In retail stores, design decisions are made on the basis of generating sales. Successful merchandising displays will create a consistent design statement that complements the brand image of the Brooklyn Brewery. Presenting merchandise in an appealing manner is vital for product sales as are efficient circulation, signage and complementary lighting.

Goods must be exposed to potential customers and be within easy reach for examination and purchase. Merchandising solutions should be flexible and allow the store to change regularly enough to create a continued sense of novelty for repeat visitors also allowing the Brooklyn Brewery to test display strategies, change, and optimize them often. The store should provide opportunities to tell brand story and create an immersive experience while simultaneously encouraging a leisurely and prolonged stay.

There are two principal approaches to the store:

1. Shop as Satellite to Tasting Room

2. Stand-Alone Shop

For the first option, it is essential to achieve a balance between a deliberate sales demonstration and a passive yet effective merchandising solution. In the latter option the risk of over selling is lesser; guests are choosing to enter the store and the environment is not forced upon them.

Either strategy cannot feel forced or contrived. The experience should be authentic and product collaborations, new releases and other important product stories should be told through effective merchandising displays that are strategically placed and illuminated well.

In both models guests will be able to walk into and through the shop, browse and interact with the merchandise. It is therefore important to design displays that allow these actions to happen with ample circulation so as not to create “bottle-necks” when large groups of visitors are present. It is also essential the store be secure while open. Checkout counters shall be strategically placed to allow staff to keep an eye on all display units in order to reduce theft.

A. Store shall be located in a prominent location where guests have multiple opportunities to browse and purchase merchandise whether they are at the Brewery for a tour, a bite, an event or just stepping in to buy a couple of growlers or bottled goods.

B. Ideally within or near the Beer Hall/Tasting Room and main entry/exit.

C. Accommodate a variety of SKU’s including apparel, glassware and other novelties.

D. Digital displays can aid in telling product stories or serve as online ordering tools for customers.

E. A separate check-out counter or queueing strategy to be incorporated for beverage token sales.

F. Space shall accommodate groups of 15-20 people browsing.

It is still to be determined what the scope of food and beverage program will be included at Brooklyn Brewery’s new production facility. If Brooklyn Brewery chooses to implement food and beverage programming, possibilities include:

“The beer hall should maintain the feeling that you’re in a brewery.” The beer hall offers a Brooklyn Brewery branded experience for beer drinkers and beer fans. The atmosphere is convivial and festive, but not too loud or rowdy. A smaller scale company store should be considered for satellite retail opportunities. Reference: Brand Positioning Design Guidelines.

The arrival experience should feel open with no lines or ‘bottlenecks’ at the entry. A seat-yourself model is preferred.

Menu

“Less, Simple, Well Executed.”The menu will consist of casual, farm-to-table pub food that is sourced from Brooklyn Brewery friends when possible. Reference: Made in Brooklyn. Higher-end items can appear as ‘special’ or ‘surprise’ appetizers on the menu. Brooklyn Brewery menu development to date has been done by a team consisting of Ben Hudson, Gabe Barry, Erin McNair, and Chef Andrew Gerson.There should be commonality between the Brooklyn Home and Production Facility food and beverage menus.

The seating capacity for the food and beverage component is tbd.The seating arrangement should provide communal configurations. Reference: German beer hall model in NYC.

Bar

One large main bar is desired. The total number of bars and their configuration is to be determined.

Private tasting rooms provide flexibility by offering an intimate group or VIP experience when required. Barrel aged and rare bottles are possible themes for the space.

A demonstration kitchen will offer opportunities for expanded beer and food pairing programming. The kitchen will have technology to support video recording of live demos. A draft system and bottled beer refrigerator are required. The Brooklyn Brewery currently uses off-site facilities.

The demonstration seating configuration requires further investigation during programming. Of note, the off-site Brooklyn Kitchen facility has four shared tables with a total capacity of 28 ppl.

A dedicated event space provides the opportunity for expanded programming including conferences, community events, screenings, and performances. While the Brooklyn Brewery does not wish to operate an up-scale restaurant, this space provides the option for a higher-end private dining and beer pairing dinner experience.

An indoor/outdoor environment recalls some of Brooklyn Brewery’s favorite Williamsburg spaces such as Café Mogador and provides the opportunity to extend the outdoor season. No reservations and walk-up counter ordering set the vibe. Consider rooftop farming to complement the menu.

The Brooklyn Brewery would like to reduce their paper glassware / baskets / plates consumption. There is a preference for glasses and dishes which generate less waste.

Service in the out-of-doors requires additional investigation and is tbd.

The central kitchen will prepare food menu items for the beer hall, beer garden, demonstration kitchen, and event space. A food service consultant will be engaged to further define the kitchen design requirements based on the menu, number of patrons, level of service, etc.

In designing the brewery tour, the path should be a carefully considered sequential experience that is both educational and entertaining. For clarity, these types of paths often flow along the path of production giving a meaningful context around which a tour can be structured. Careful planning and thought should be spent in considering how guests enter the tour, move through the spaces, and ultimately finish the tour. Highlighting the most interesting aspects should be a priority while also bringing interest and intrigue to the more mundane aspects of brewing.

Along the way there should be individual moments or events that help to tell the story of Brooklyn Brewery and the beer that they are producing. These moments are unique and rich opportunities to present information in meaningful and captivating ways.

Possibilities include:

• Immersive sensory experiences with specific ingredients, such as stepping into a hop filled room to experience the intense aroma of fresh hops.

• Tasting opportunities along the way of specific beers. The beer should rightfully be a highlight.

• Overlooks and vistas should highlight specific pieces of equipment or processes and offer visual drama. Lighting and projected media can be considered to add visual intrigue and communicate specific ideas.

• Displays of meaningful artifacts can be used to tell the history of Brooklyn Brewery and brewing in NYC.

• Dynamic audio-visual displays can be used to show processes that may not be visible within the brewery.

• The tour should provide moments for interaction between Brooklyn Brewery and their visitors. Possibilities exist to allow visitors to communicate back to Brooklyn Brewery through interactive exhibits or displays.

• The tour can highlight the international appeal of Brooklyn Brewery and their global footprint.

2ND FLOOR (IF BUILT)

MEZZANINE

Develop sequence to get visitors up to 3rd floor Retail / Taproom

Option for an extended tasting in Taproom overlooking Packaging Hall

OVERVIEW OF PACKAGING PROCESS AT BROOKLYN BREWERY

VIEWS TO SITE

OVERVIEW OF SUSTAINABLE PROCESSES AT BROOKLYN BREWERY

VIEWS TO PACKAGING HALL

MEZZANINE

1ST FLOOR

VIEWS TO UTILITY PLANT

Develop sequence to get visitors down to 1st floor Retail / Beer Hall

VIEWS TO YEAST AREA

VIEWS TO TANK FARM

OVERVIEW OF FERMENTATION PROCESS PERSONAL STORY

TOUR GUIDES’ PERSONAL CONNECTION TO BEER

• ENCOURAGE DIALOGUE WITH TOUR MEMBERS

DYNAMIC SENSORY EXPERIENCE WITH EACH INGREDIENT

• HOP ROOM EXPERIENCE

• OVERVIEW OF WHAT EACH INGREDIENT DOES

• OVERVIEW OF THE HOT SIDE PROCESS

VIEWS TO SITE

VIEWS TO LABS

VIEWS TO BREW DECK

HISTORY OF BREWING IN BROOKYLN & STATEN ISLAND

• CONNECT BROOKLYN BREWERY’S HISTORY TO BROADER CULTURAL CONTEXT

• TELL THE STORY THROUGH SPECIFIC ARTIFACTS AND BREWERIANA