3 minute read

A case for high performance

By Joe Mellott

Selecting products and services can be a difficult proposition. This couldn’t be truer than when selecting your new roof solution. Currently, there are hundreds of possible solutions, from traditional long-standing products, like built-up asphalt roofing, to novel newmarket solutions such as TPOs and vegetative roofing. Making the best decision could be the difference between long-term success and short-term failure. Roof installation is an expensive proposition and customers need to balance initial cost versus life cycle cost; performance versus economics.

High-Performance roofing provides long-term solutions.

When selecting your new roof, it’s important to consider a number of factors including: • Environmental conditions of the roof, extreme weather conditions, excessive precipitation, chemical exposure or roof top. • Desired service life of the system. • Energy expectations of the solution as a contributing factor to energy savings.

It is important to have detailed discussions with manufacturers and installers while making these decisions. The correct decision could mean 30 years of successful performance.

The two most critical factors involved in roof material design are: • Tensile strength. ARCHITECTURE & LANDSCAPE ARCHITECTURE 9355 Young Road Chilliwack, BC V2P 4S3 Tel: 604|793|9445 design and construction of school facilities in British Columbia. • Elasticity (rubber modification).

Roofs can begin to fail from man-made and natural occurrences such as dropped equipment, the impact of hail and extreme foot

Over 90 years of collective experience in the planning,

Roofing systems have additional environmental and application demands. Fax: 604|793|9446 chp@chparchitects.com www.chparchitects.com

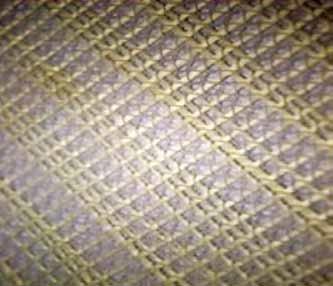

traffic. The use of high-strength tensile reinforcement helps roofs to resist damage caused by these natural occurrences. Tensile and tear-strength properties are two of the most important factors in determining roof life expectancy.

Roof tops expand and contract due to roof top temperature changes from day to night, summer to winter and during rain and snow. These movements can be well managed through the use of rubber-modified compounds (specifically SBS modified bitumen in the case of modified bitumen membranes). The sheets are welded together with heat, adhesives or hot asphalt. The roof becomes a continuous waterproofing layer of the modified compound. The more flexible the compound, the more thermal movement it can handle.

A good way to determine the level of rubber modification is to examine the low temperature flexibility (LTF) of the membrane. The higher the rubber content, the lower the passing LTF. Below the LTF

Roof split occurring due to movement in TPO leads to water penetration.

Tear propagation in commodity roofing can lead to water penetration. the roof may be too stiff. Over time, modified roofing systems become stiffer (due to exposure to UV light, heat, etc.) By designing products to have lower than normal LTF performance initially, down the road the roof will continue to perform at more normal low temperature conditions. Products age at different rates; designers should understand the properties and the aging of these properties when installing and selecting a roof.

Think of your roof as a continuous composite. The high tensile reinforcement resists impact and tear, the rubber-modified compound provides flexibility and resistance to temperature driven movements. Designing the roof for long-term performance requires the use of membranes with high tensile and tear strengths and very low LTF. Make a wise choice, not a short-term choice. It is your facility; they are your employees; it’s your equipment and your business.

About the Author

Joe Mellott holds several patents for roof-related innovations and received the 2006 Industry Statesman Award from the Roof Coatings Manufacturers Association (RCMA) for his work in advancing roof coatings industry technology. A graduate of Case Western Reserve University, Joe holds a BS in Engineering, is a frequent contributor of technical articles to industrial publications, and is a participant in innumerable roofing-related organizations. He has served as the technical chair, and formally the president of the Roof Coatings Manufacturers Association (RCMA); on the board of the Cool Roofs Rating Council (CRRC); and as a member of the Roof Consultant Institute (RCI), the National Roof Contractors Association (NRCA), and the Asphalt Roofing Manufacturers Association (ARMA).

For a free roof inspection or for more information, visit

www.garlandcanada.com or call Marisa Rea at 1 800 387 5991. b

High-tensile reinforcements eliminate splitting issues.