Published by:

DEL Communications Inc.

Suite 300, 6 Roslyn Road Winnipeg, MB R3L 0G5 www.delcommunications.com

Published by:

DEL Communications Inc.

Suite 300, 6 Roslyn Road Winnipeg, MB R3L 0G5 www.delcommunications.com

Message from the MPDA president, MaryAnn Mihychuk 5

MPDA board of directors 6

Benefits of joining the MPDA 6 Message from the Message of Natural Resources and Northern Development, the Honourable Greg Nesbitt 8

Lithium: Manitoba leading the way 10 MPDA members with active dispositions 12

Little Stull Lake Gold Project 13

Threeosix and Marcel Colomb First Nation sign joint venture 14

Works in progress: Makwa Mayville and Donner Lake Lithium Projects 15

Drill program a success at McFarlane Lake Mining West Hawk Lake 17

Thompson East – Bryce Bay: Ni-Cu-Co-PGE Project 18

MPDA short courses 20

©Copyright 2022. Manitoba Mining Review

All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without the prior written consent of the publisher.

Publications mail agreement #40934510

Return undeliverable Canadian addresses to: DEL Communications Inc.

Suite 300, 6 Roslyn Road Winnipeg, MB R3L 0G5

All mining and exploration property information presented in this publication is prepared by DEL Communications Inc. Descriptions of, or references to, mining and exploration properties within this publication do not imply endorsement of such properties by the Manitoba Prospectors and Developers Association Inc. (MPDA). The MPDA makes no warranty as to the completeness, timeliness or accuracy of any of the data included in this publication. All information conveyed by this publication is provided to readers for their own evaluation of such information. This publication could include technical inaccuracies or typographical errors. Any reliance on the information contained in this publication is solely at the reader’s own risk. MPDA specifically disclaims all warranties, express implied or otherwise, including without limitation, all warranties of merchantability and fitness for a particular purpose. In no event will MPDA be liable for any direct, indirect, special or consequential damages, or any other damages, whatsoever, for any use of, or reliance on, information provided by this publication, including without limitation any lost opportunity or profits, even if MPDA is expressly advised of, or otherwise aware of, the possibility of such damages, whether in an action of contract, negligence, tort or otherwise.

A year of transformation for Hudbay 22

Canadians want more mining: Can we deliver? 24

Association for Mineral Exploration presents Roundup 2023: ‘Critical to Our Future’ 26

First and Foremost (Lithium) 27 Aboriginal agreements and permitting 28

ACME Lithium: The future starts here 30

The Minago Nickel Project 33

Watson Gloves: Helping industry meet their sustainability goals 35

Gossan Resources: Thinking like an owner 37

Vale unveils plans for Thompson Mine and low-carbon activities 38

A day in the life of four prospectors ................................................................................. 39

Simplified charging 41

North Star Air: Moving your cargo (it’s what we do!) 44

Rockcliff Metals is poised for discovery and growth in a world-class VMS mining camp 45

Geochemistry lab on the prairies builds a global presence 47

Establishing a critical metals champion in Canada’s backyard 50

Platinum Diamond Drilling: Core reality 52

Snow Lake Lithium hosts LG energy solution as part of collaboration to create a lithium hydroxide processing plant 54

Canada's first solar glass plant on target 56

Rodren Drilling: Your partner for drilling solutions 58 Index to advertisers 59

I, first, would like to recognize that I am on Treaty One territory and the homeland of the Metis people. And, next, I want to thank the outgoing Board for their time and dedication to the MPDA.

We have had an exciting and productive year for the Association. We have successfully modernized our web page and financial systems and delivered 52 weeks of our radio show focused on the mineral resource sector with our partners, the Manitoba Treaty Commission and NCI-FM, and the many volunteers and guests who helped us make a quality production and build strong new relationships.

Additionally, our membership has tripled, and we recently hosted the successful Reconciliation Gala and we enhanced the Manitoba Convention by offering eight short courses. We have also become very active representing our members and industry by meeting with ministers and senior government representation and staffing our booth at the MEIA and PDAC conferences.

Volunteers are the foundation of the Association. Without their dedication and hard work none of these accomplishments would have been realized. To all of you, a heartfelt thank you. And, as I have been known to say, you are the heartbeat of the association. To the Board, it has been a pleasure working with you and I value each of your opinions and advice. To the

membership, sponsors, and partners, I thank all of you for sticking with us and supporting us through this past year and into the future. You are the association.

Mineral exploration discovers new sources of needed economic minerals and is the lifeblood of the mining industry. And that is an economic driver providing real new wealth for the people of Manitoba and Canada.

mining industry and the vitality of northern communities.

Our association members include prospectors, exploration companies, scientists, researchers, academics, operators, mining companies, contractors, supply and service companies, civil servants, legal, and financial sectors. These groups represent the wide range of the Manitoba exploration industry.

Manitoba is underexplored and holds great potential for new discoveries. Additionally, with the urgent need for new green critical minerals, exploration opportunities and potential growth can develop. Finding replacement mineral deposits is critical to the future of the Major Drilling is dedicated to providing world class service to our partners across Canada. Contact us to let our experienced teams help you make sure your next specialized

In the next year, we plan to reinstate Mineral-Mining Week in Manitoba and continue to raise positive solutions to the challenges we face.

MaryAnn Mihychuk President. ✖

The Manitoba Prospectors and Developers Association (MPDA) is an advocacy group focused on improving the state of mineral exploration in Manitoba. The MPDA members include prospectors, exploration companies, scientists, researchers, academics, operators, mining companies, contractors, supply and service companies, civil servants, and legal and financial sectors. We represent a wide range of the Manitoba mineral sector and bring diverse backgrounds, experience and ways of thinking to the table. Our collective objective is to develop productive and efficient ways of working with our industry and community partners, and to become one of the most attractive places to invest in the mineral business. Being a member is a great way to network, learn about key topics affecting the industry, and shape the future of Manitoban mineral exploration and extraction.

Expand your network with attendees from 120+ countries 1,100+ exhibitors showcasing the best in the industry Hundreds of hours of programming presented by industry experts Engage with private, retail and institutional investors and senior executives

As Minister of Natural Resources and Northern Development (NRND), I am honoured to provide an update to the Manitoba Prospectors and Developers Association on mining and exploration initiatives.

First, I’d like to say that it’s very exciting to begin this role during this historic and unprecedented time. I’m thrilled that Manitoba is experiencing the highest level of exploration expenditures in the history of the province. Natural Resources Canada has reported exploration expenditure intentions for 2022 at $154.6 million.

This past June, Manitoba sent its largest-ever delegation to the annual Prospectors & Developers Association of Canada (PDAC) in Toronto. Led by The Honourable Heather Stefanson, along with my colleague the Honorable Cliff Cullen, Minister of Economic Development, Investment and Trade, and myself, the province showed our commitment to the industry, our Indigenous partners and supported Manitoba’s efforts as we set the stage to become a top mining destination.

While at PDAC, we were proud to announce that the Manitoba government has approved our first potash development, allowing the Potash and Agri-Development Corporation of Manitoba (PADCOM) to start extraction

and production near the community of Russell. This is a significant step forward in our commitment to establish Manitoba as a global leader in sustainable mineral development.

The province continues to implement significant actions with a focus on economic recovery and growth.

• A new Consultation and Reconciliation Unit was created within our department to further Manitoba’s commitment to working with Indigenous governments to ensure that communities share in the benefits that result from sector growth.

• In 2019, the Mineral Development Action Plan and Protocol template was released to support First Nations participation in the development and implementation of protocol agreements. Since then, we have continued to engage First Nation governments to support participation in the mining sector. We have also adapted processes to incorporate remote and virtual delivery mechanisms. This enabled consultation processes with communities to continue despite public health related travel and gathering restrictions.

• The Manitoba Mineral Development Fund (MMDF), introduced in 2019, has been a tremendous success. To date, the fund has provided over $3.5 million to support 25 mining projects in the north.

• We have renewed our agreement with the Manitoba Chambers of Commerce to deliver MMDF with the mandate to invest $10 million over the next three years to increase exploration and mining activity and increase Indigenous participation.

• A new Business Development Services Unit with a dedicated Permit Office has been organized to focus on permit modernization. This new Office will improve

co-ordination as a single point of contact and source of information and continue to advance these initiatives and priorities:

• Online “MineManitoba” dashboard – designed to streamline the permitting process and provide a wide range of information related to exploration and mining activities.

• Tracking the status of permits submitted to ensure they are processed in a timely manner.

• Providing a concierge service for companies working in or looking to work in Manitoba.

• Supporting industry coordination with the Consultation and Reconciliation Unit to facilitate early engagement.

Manitoba has committed to undertaking the development of a Manitoba Minerals Strategy. The collective plan for growth is based on developing an investment friendly environment for mineral development, boosting geoscience knowledge,

and improving land-management and the participation of Indigenous communities.

The Manitoba Geological Survey is continuously updating Manitoba’s geoscience knowledgebase including a modernized, innovative Mineral Deposits Database, co-developed the Pan-Canadian Geoscience Strategy, and national participation in the collaborative Targeted Geoscience Initiative and Geo-mapping for Energy and Minerals (GEM) programs to advance sustainable and economic development of Canada’s mineral resources.

Our province’s natural resources wealth, including an abundance of critical minerals and renewable energy production, positions Manitoba for opportunities in the green energy and mining sectors. As we continue to move our economy forward Manitoba remains committed to working with our partners, industry, First Nations and northern communities to regain our status as one of the top jurisdictions in the world for exploration investment. ✖

In 2021, the Government of Canada released a list of 31 elements considered critical for the sustainable economic success of the country and its allies, and to position Canada as the leading mining nation. The advent of renewable energy and clean technologies, essential for the transition to clean energies and decarbonization of the Canadian economy, has brought critical minerals to the forefront of mineral exploration efforts across the globe, but particularly in Manitoba.

Manitoba is endowed with many critical elements, particularly lithium, which is hosted in hard rock in spodumene. Spodumene is a mineral rich in lithium and an important source of this element for use in ceramics, mobile phone and automotive batteries, medicine, and as a fluxing agent.

Manitoba is home to the Tanco mine, the only lithiumproducing mine in Canada and truly a one-of-a-kind lithium deposit hosted in hard rock. Tanco is also known for its historical production and vast resources of tantalum and cesium. The Tanco mine is located in the Archean Superior province (Figure 1) and the majority of the lithium mineralization at Tanco is associated with spodumene (Figure 2). The area surrounding the Tanco mine is denominated the Winnipeg River-Cat Lake pegmatite field and is laden with other granitic pegmatites that contain lithium and other critical elements (e.g., cesium, tantalum, rubidium).

Active exploration in this area is being carried out by several junior exploration companies. New Age Metals Inc. is the largest mineral claim holder in the Winnipeg River-Cat Lake pegmatite field, with three of the projects considered drill ready – Lithium One, Lithium Two, and Lithman West. New Age Metals has signed an exploration agreement with the Sagkeeng First Nation and will be working in partnership with them to conduct exploration activities. QMC Quantum Minerals Corp. has been focusing its exploration efforts along the Irgon Dike, a high-grade lithium pegmatite with nearterm production potential. This location is near developed infrastructure (e.g., road, rail, water and electricity) and close to the Tanco mine, where lithium ore can be processed.

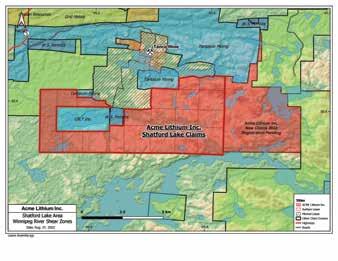

By Tania Martins and Michelle P.B. Nicolas, Manitoba Geological SurveyACME Lithium Inc. has properties in the Cat-Euclid Lake area straddling the prospective Cat-Euclid Lake shear zone and extending along the southeasterly trend of known pegmatite occurrences. Their exploration strategy includes a focus on spodumene-bearing pegmatites using remote sensing, structural geology, ground-based geological mapping, and geochemical sampling to localize targets for drilling.

In the Shatford lake area, the claims straddle a 15-kilometre long structural trend of the Greer-Shatford shear zone with numerous pegmatite dikes and favorable host rocks. Grid Metals Corp. holds claims for the Donner Lake Lithium property where there are four known spodumene-bearing pegmatites. Results from drilling in 2018 on the Main Dyke over a strike length of 775 m proved to be consistent with the historical drill results.

In Manitoba, within the Superior province, there is lithium associated with granitic pegmatites of similar age to Tanco at Cross Lake, God’s Lake, McLaughlin Lake, Red Cross Lake and Red Sucker Lake (Figure 1). All of these locations have various degrees of lithium enrichments and mineralization.

Another area also exceptionally rich in lithium is the Wekusko Lake pegmatite field, just east of Snow Lake, in central Manitoba. This area is home to a number of pegmatite dikes mineralized in spodumene. The Paleoproterozoic Wekusko Lake pegmatite field is known for its multiple lithiumbearing pegmatites and prospectivity for this and other critical elements (e.g., tantalum, cesium) hosted in granitic pegmatites. This area is close to the world-class Flin-FlonSnow Lake mining camp that is well-known for economic deposits of gold, copper-nickel, and copper-lead.

Recent work on the Wekusko Lake pegmatite, and increasing interest from exploration companies in the area, make this locale a prime target for exploration. The two major players in the area are Snow Lake Lithium and Foremost Lithium Resource and Technology.

Snow Lake Lithium holds the ground where the biggest known pegmatite is located, the Thompson Brothers project.

Figure 1: Geological map of Manitoba showing the locations of lithiumbearing pegmatite fields.

This is a high-grade lithium-bearing pegmatite dike partially outcropping at surface, which remains open along strike and to depth. Snow Lake Lithium suggests that an underground mining operation accessed via ramp is a possibility for exploiting this pegmatite. The company is actively drilling this, and the other pegmatites, in the region.

Foremost Lithium Resource and Technology holds the largest land package in the area, consisting of the Grass River lithium, Jean Lake Lithium-Gold, the Zoro Lithium projects, and the Peg North claims. Exploration on the properties is ongoing with a drone magnetic and LiDAR surveys, prospecting, mapping, and geochemical surveys. Drilling is planned for the 2022 fall/winter seasons.

Manitoba also has the potential to host lithium dissolved in brines in subsurface aquifers. These brines are accumulations of saline groundwater that occur in continental sedimentary basins and can be a source of dissolved trace metals, including lithium. Increased concentrations of dissolved metals in brines can be associated with the oilfields

(petrobrines), deep brines, salt solution-derived brines or brine springs. These occurrences are associated with the sedimentary rocks of the Phanerozoic Williston Basin in southwestern Manitoba.

Given the limited availability of lithium data in Manitoba’s saline groundwater, preliminary studies indicate that the best targets for exploration would be from the oilfield and deep brines. The mineral potential of these brines may serve as an excellent economic opportunity for oilfield operators to improve their profits and extend the life of marginal oil wells.

Due to the lack of geochemical information in deep aquifers, drilling to deeper horizons – generally deeper than 1,000 metres – below the currently producing oil horizons is required to test the potential of the deep brines. Exploration successes in Devonian-aged units in western Canada and the continuity of those aquifers and geology to the east, suggest that economic lithium brines are likely to occur in those equivalent units in Manitoba.

Both the water-producing oil wells and deep target tests would have the benefit of taking advantage of the array of infrastructure already in place for oil operations. The technology development to extract lithium from brines –such as the direct lithium extraction used by E3 Lithium – is also moving quickly, proving to be a cost-effective, efficient extraction method that may be a game changer for the lithium industry globally.

Canada has an opportunity to become a global leader in lithium production, with Manitoba already playing a leadership role. Aligning countless rich lithium deposits and potential with the provincial government's recent commitment to helping the province's mining sector, our province is in a great position to respond to the increased demand for battery materials, especially lithium. ✖

Figure 2:

BWR Exploration Inc.

Alfred Wikjord

CanAlaska Uranium Ltd.

CBSGeoscience

William Dusessoy

Garry Thorne

George M. Nykulaik

Gossan Resources Limited

Grid Metals Corp.

Hudbay Minerals Inc.

James Cruise Campbell

Kenneth Marlin Klyne

Chris Lytwyn

McFarlane Lake Mining Incorporated

Mount Morgan Resources Ltd.

Rashid Mumin

Norseman Supply

Peter C. Dunlop

Satori Resources Inc.

Stephen J. Lesavage

Strider Resources Limited

Tantalum Mining Corporation of Canada Limited

Vale Canada Limited

W.S. Ferreira Ltd.

Ronald Wiebe

BWR Exploration Inc.

ACME Lithium

Harold Westdal

William C. Hood

In October 2016, BWR Exploration entered into an agreement with Puma Exploration Inc. to acquire Puma’s 100per cent interest in the Little Stull Gold property in Northeastern Manitoba.

The 40,745-hectare project abuts the Ontario border and is less than 600 kilometres north-northeast of Winnipeg. The property comprises 22 mineral claims and is surrounded by two mineral exploration licenses.

BWR Exploration president and CEO Neil Novak says the 22 claims— originally staked by others in 1985 to 1986—have been assessment maintained and cover eight drilltested confirmed gold zones, within a six-kilometre segment of the Wolf Bay Shear Zone that extends for 43 kilometres in Manitoba.

“BWR acquired this multi-year exploration project with the aim to

commence diamond drilling, once an exploration work permit is issued by the Crown.”

For this project, BWR made three cash instalment payments of $50,000 each, with the first due upon signing the option agreement with Puma in July 2016. The second and third payments were due upon the renewal of the two mineral exploration licenses, both of which were paid in July 2017.

“A total of 10 million shares were also deliverable to Puma as part of the purchase price,” he adds. “The first $5 million share payment was paid upon regulatory approval of the acquisition, and the shares were put in escrow for release over three years. The remaining $5 million share payments were due in increments upon BWR successfully reaching exploration milestones, after an exploration expenditure of at least $1.5 million within the first three years.”

By Lisa KopochinskiBWR did not expend the required $1.5 million in a timely manner (no permit issued) and made a $3-million share final payment to Puma to cure the default.

Novak says the biggest challenge on this project, thus far, has been getting the Crown to provide timely issuance of a work permit through the facilitation of a meaningful consultation process with the Indigenous communities, that involves community consent to exploration in their ancestral lands.

“Over the past five years of discussion, I believe a prudent path of meaningful consultation should include input by the exploration/mining proponent very early in the consultation process. We need to explore ways and means for the Indigenous Proponents to get involved as an exploration partner as early as possible in the exploration/ development cycle.” ✖

Threeosix Industrial Services Inc. and Marcel Colomb First Nation recently signed a joint venture agreement where Threeosix will work with MCFN in pursuing specific contracts related to project development in MCFN's traditional territory, including around the town of Lynn Lake.

Threeosix, a Saskatoon-based professional and progressive multidiscipline industrial solutions provider and MCFN, a First Nation Band of approximately 450 Registered Swampy Cree and Rocky Cree formalized their relationship in fall 2021. They created a joint venture for all projects located in MCFN’s traditional territory. This agreement will provide longterm economic and social benefits for MCFN, including increasing its capacity to conduct business in the construction, mining, and support services industries.

“We’re excited to have formalized our relationship with Marcel Colomb First Nation and are optimistic about working together and learning from one another on a long-term basis,” says Threeosix president Scott Longmuir.

“The overarching goals for the business are to participate as one team, working collaboratively with clients in the area, through all aspects of construction. We’re very well-aligned in terms of ensuring that everything we do takes into consideration the environmental well-being of MCFN’s traditional territory, and their culture while maintaining a focus on the needs of our prospective clients.”

MCFN leader Chief Christopher Colomb says he is pleased with this joint venture and impressed with Threeosix’s approach to First Nation engagement.

“Our negotiations were done in a

respectful way, built on trust that recognizes and affirms our Inherent and Treaty Rights, while ensuring that our membership's socio-economic interests are strengthened for many years to come with a focus on capacity building, construction skills, and job creation. We are committed to ensuring that all development on our territory is carried out in a respectful manner that honours our natural environment, homelands, traditions, protocols and language.”

The agreement establishes the framework on how Threeosix and MCFN will work together going forward. Both parties are committed to ensuring MCFN meaningfully participates in projects located within its traditional territory. An executive committee, designed to stay in lockstep through all aspects of the business operations, maintains open collaboration between the parties and combines traditional values with industrial construction best practices. ✖

Grid Metals Corp. (TSXV:GRDM) will soon be moving to a prefeasibility study on its Makwa Mayville (Nickel Copper PGM Cobalt) property, while at nearby Donner Lake Lithium, the company has commenced resource drilling in October.

Located in the Bird River Greenstone Belt approximately 145 kilometres from Winnipeg, the Makwa Mayville Project consists of two open pit NI 43-101 resources containing nickel, copper, platinum group metals, and cobalt mineralization.

A preliminary economic assessment (“PEA”) was completed in April 2014 and authored by Roscoe Postle Associates Inc. Based on the PEA, the project is designed as a blast and haul open-pit operation with ore hauled to a mill at the Mayville site. A flotation circuit producing separate copper and nickel concentrates would be produced.

As part of followup exploration to add additional resource and enhance the project, Grid Metals conducted a deep penetrating electromagnetic survey at Makwa that identified a number of conductive targets located in close proximity to the open pit resource shell where the bulk of the mineralization occurs.

Since 2014, PEA metallurgical test work on samples from Mayville

showed improved nickel and cobalt recoveries from the samples tested. The test work concluded that marketable nickel and copper concentrates could be produced from the Mayville samples.

The Bird River Greenstone Belt in southeastern Manitoba hosts several pegmatite belts—including the worldfamous Bernic Lake pegmatite and the producing Tanco Mine.

The Tanco Mine—which has produced lithium, tantalum, and cesium products since 1968—was purchased for $130 million (U.S.) by Sinomine Resources, a Chinese company.

There has been intermittent exploration in the belt since the 1950s. And, with the recent rise of lithium prices, there has been a significant increase in exploration activity in the area.

Grid Metals has been exploring the

area for base metals since 2006 and has defined a NI 43-101 resource of nickel-copper-PGM-cobalt at Makwa, and a NI43-101 resource of coppernickel-PGM at Mayville. Both deposits are open pit.

The company acquired mining claims from Tantalum Mining Corporation of Canada originally for base metals, but the claims hosted a historical resource of lithium from two pegmatites, which are part of the Donner Lake Pegmatite field.

There are at least four known

pegmatites on the property. The pegmatites discovered to date in the Donner Lake area primarily been spodumene (lithium) bearing. The main dyke, which the company drilled in 2018, is an example of an Albite Spodumene subtype with most of the pegmatite core spodumene bearing.

In 2018, Grid Metal drill tested the main dyke over a strike length of 775 metres. Results were consistent with the historical drill results. The company also assayed for tantalum, cesium, and rubidium. In 2022, the company drilled at the northwest

dyke, which is located approximately 1.5 kilometres to the west of the main dyke. Again, consistent highgrade lithium values were obtained in almost all the drill holes.

Next exploration steps include completing sufficient drilling of the two dykes to be able to calculate a mineral resource, as well as to find additional lithium bearing dykes. Finding new pegmatite bodies geological mapping and geochemistry have proven effective in pegmatite exploration in the Donner Lake area with geochemical halos showing a strong correlation to the known dykes. The geological contact along strike to the northwest is the prime target for discovery of additional pegmatites. Work will continue throughout the year and Grid Metals is targeting a mineable resource of lithium and rare metals in the Donner Lake area.

As for costs and challenges, Grid Metals CEO Robin Dunbar says so far, they have spent $25 million on the two projects.

“We are currently well-funding with approximately $14 million in working capital. Drilling will start on both the lithium pegmatites and the base metal projects. There are plenty of challenges in this business, but we are in a great mining jurisdiction in Manitoba, are close to infrastructure, and have a great team. The metals we are defining are all used in the electrification of autos so there is a great amount of interest currently in what we’re doing. It’s full steam ahead, but with a keen eye on the horizon.” ✖

The West Hawk Lake property is a key portfolio project for McFarlane Lake Mining Limited, a Canadian gold exploration and development company with deep experience in mineral exploration, mine development, and mine financing.

Located within southeastern Manitoba, 53 kilometres west of Kenora and 130 kilometres east of Winnipeg, it is comprised of 23 mining claims totaling 336 hectares.

“The project started in December 2021 with line cutting and drilling in February and March of this year,” says McFarlane Lake Mining COO and

director Roger Emdin. “The project also included an induced polarization (IP) survey, which is geophysics to help locate potential targets, and diamond drilling.”

Historically, the property was explored by Goldbeam Resources in 1983 through extensive sampling from underground development and diamond drilling, and through a drilling program conducted by Canadian Star Minerals Ltd. in 2012. On February 6, 2022, McFarlane Lake initiated a 3,000-metre diamond drilling program on the property to confirm past

reported gold mineralization and follow up on geophysical targets.

Completed on May 25, 2022, the drill program was successful in confirming the existence of high-grade gold mineralization 100 metres below historical gold mineralization at the Waverly Raise Zone, and successfully established prospective trends in the Letain C zone and the Sunbeam zone. The project established continuity in gold mineralization which bodes well for future drilling. It also aligns with McFarlane Lake’s goal of developing compliant gold resources at West Hawk Lake, while continuing to explore at depth along the strike.

Following the successful drill program and other promising developments at the company that helped drive strong investor demand, McFarlane Lake closed a $1.29 million (Canadian) upsized private placement on September 19, 2022. The proceeds will be used to further explore either the West Hawk Lake and High Lake properties.

Adds Emdin, “There were no significant challenges on the project, but there were some unique issues in permitting and post project due to the property being located inside a provincial park.” ✖

The project areas are located eight to 30 kilometres east of Thompson and are held in two blocks referred to as Bryce Bay, located north of Bryce Bay and Thompson-East claims which are directly east of Thompson. A total of 15 claims ranging in size from 40 to 208 hectares have been staked and exploration is being conducted systematically. Access to the prospect area can be by four-wheel-drive truck, all-terrain vehicle, boat, and motor or snowmobile. Anglo American conducted exploration in the early 2000s in the Grass River and Thompson–East area. This included an airborne ‘spectrum’ (magnetic, electromagnetic, radiometric, and terrain) survey which delineated 27 em conductor zones that warranted follow-up ground work. Follow-up exploration included ground geophysical surveys and diamond drilled boreholes within selected conductor zones. Six of the highest rated conductor zones, some with multiple drill targets are all on claims staked by G. Thorne (Norcangeo).

To advance exploration and further delineate targets about 250 boreholes have been augured and sampled as part of till geochemistry exploration on the claims covering the TNB conductor zones and Bryce Bay claims. Three claim areas/ conductor zones are of particular interest based on ground

geophysics, diamond drilled cored boreholes, and rock and till assay values and are profiled below.

23:

Most of the recent exploration conducted on the Thompson East claims by Norcangeo has focused on Conductor Zone 23 as identified from the Anglo American “spectrum” airborne geophysical. The zone characteristics are:

• A very conductive, high amplitude, vertical to west dipping anomaly.

• Lack of a well-defined magnetic component.

• Conductive zone occurs at a shallow depth of less than 100 metres.

• Approximately 700-metre strike length conductor.

• Based on the spectrum survey and ground geophysics four drill targets have been identified along the conductor zone.

• Within the Guy claim area, 52 boreholes have been augured to refusal and the till lying directly over bedrock sampled as part of till geochemistry exploration.

15, 16, 17, and 18.

• Of over 250 overburden boreholes augured and sampled on the Thompson East or Bryce Bay claims Ni values of 131.5 and 90.0 ppm are recorded in boreholes down-ice of conductor zone 23. These values are the highest Ni values recorded of all the till assays to-date. Background till Ni values average about 30 ppm.

• An additional claim MB-13841 (Mill moo) has been recently staked (October 2022) on the north boundary adjoining MB11598 (Guy claim) to include the fourth drill target area of this conductor zone.

• A drill has been transported to the claim area with plans to begin coring a series of BQ-size boreholes. A 400-metre length waterline has been set-up and a three-metre length casing has been drilled through overburden deposits and into bedrock at the initial planned borehole location (Figure 1).

conductor zones. These conductors are located about 6 km directly east of the Thompson T1 and T3 mines and about one kilometre east of the Thompson mines settling ponds. Two highgrade conductors located in Conductor Zone 15 (Figure 1) were identified by the airborne spectrum survey and to the best of the writer’s knowledge have not undergone any additional ground geophysics or drilling. Another highly rated conductor zone target is located on MB Claim MB 11600 (Zone 18). Historical drilling indicates that the area of the claims is underlain by the Ospwagon Sediments, which include the Pipe Formation. The Pipe Formation is principal host to the rich magmatic nickel and copper deposits of the TNB. The location and highly rated geophysical anomaly make these zones excellent targets for additional airborne drone magnetic or ground geophysics and drilling.

Till of the Bryce Bay claims (MB 9514, MB10467, MB12045) located north of em conductor zones recorded by the anglo spectrum survey has anomalous high As, Au, Ag, Pt, Pd, and Cr concentrations. Of particularly interest are high As values of 505 ppm – 100 times soil background levels, indicating a potential Nikeline source, and elevated to high Au, Ag, and Cr concentrations. Initial channel sampling of a massive sulphide vertical dipping vein up- ice of the anomalous till provided Ag values of 3.13 ppm, Cu values of 8500 ppm and Co values up to 1610 ppm.

T3 Thompson Mines

Four claims (MB 12046, MB12048, MB11594, MB11600) were recently staked (2021) covering all or most of these four

Contact info: G. Thorne (204) 997-9087 norcangeo @shaw.ca ✖

COURSES – NOVEMBER 13-16, 2022 LUNCH AND 4 P.M. RECEPTION

Sunday, November 13

9 a.m. – 4 p.m. — SC22-1

Exploration for Critical and Precious Metal Rich Magmatic-Hydrothermal Deposits

Facilitator: Dr. Hamid Mumin, Brandon University

Magmatic-hydrothermal (MH) systems and their rich endowment of critical and precious metals. These systems include iron-oxide copper gold (IOCG) and a variety of related MH deposit types that include porphyry copper, epithermal, iron-oxide apatite, iron-sulphide copper gold, skarn, carbonatite, and albitite-hosted uranium. Critical, strategic, and precious metals hosted by these deposits include Cu, Fe, Au, Ag, U, REEs, Co, Bi, Zn, Pb, Mo, P, and others. Participants will be asked to examine some actual rock and drill core specimens, think about the discussions and questions raised throughout the course, and share their thoughts and experiences.

Monday, November 14 9 a.m. – 12 p.m. — SC22-2

Working Together in a Good Way

Facilitator: Dawna Atamanchuk, Workplace Education Manitoba

Working together means successful partnerships, which means success. Learn how to have positive communication and collaboration.

Monday, November 14 9 a.m. – 12 p.m. — SC22-3

Communicating Value to Prospective Employers

Facilitator: Gail Surman, Workplace Education Manitoba

Looking for jobs in the mineral resource industry? You will be able to identify your skills important to resource jobs and learn how to sell those skills to possible employers.

Monday, November 14 1 p.m. – 4 p.m. — SC22-4

Indigenous Engagement

Facilitators: Mike Sutherland, Peguis First Nation; Christian Sinclair; and Rob Houle, Talon Resources and Community Development Inc.

There are challenges in the engagement and consultation process in practice. This can result in delayed projects, increased costs, investor uncertainty, and negative impacts to company and community relationships. Learn lessons of success from three leaders in engagement.

Monday, November 14 1 p.m. – 4 p.m. — SC22-5

Water and Our Environment

Facilitator: Byron O’Connor, Pinchin

Protection of water is a key component of any social license for all aspects of mineral exploration and development. This course will describe the water cycle, show how water is used during exploration and development, talk about the impacts that exploration and advanced exploration/development can have on water, and provide examples of measures that can be put in place to mitigate these impacts. An overview will be provided of the regulatory framework in Manitoba regarding water management as it pertains to mineral exploration and development.

Tuesday, November 15 9 a.m. – 12 p.m. — SC22-6

Intro to Diamond Driller

Facilitators: Kevin Norberg, Rodren Drilling; Paul Gosselin, Gosselin Safety Consulting

An information session for those interested in learning about diamond drilling and the opportunities available within this growing local industry. Travel, salary, benefits, and work life.

Tuesday, November 15

1 p.m. – 4 p.m. — SC22-7

Intro to Core Technician

Facilitators: Angela Meek, Norseman Supply

An introduction into what a core technician is. Core facilities is where a tech manages the core and samples. This includes receiving, cutting, sampling, storage, and shipping with detailed records. They need to be highly organized, detailed, and able to operate a rock saw.

Wednesday, November 16 9 a.m. – 4 p.m. — SC22-8

A New Permit System: Start to Finish Facilitators: Jeff Kraynyk, Government of Manitoba; TBA

The Manitoba Government has a new permit system to address industry concerns. Natural Resource, Heritage Branch, and government staff will present.

Monday, November 14 12 p.m.

VIP Keynote Speaker Lunch: Bill Gallagher: Strategist/ Lawyer/Forecaster Tickets included with course registration, or $50 for non-registrants

I offer a strategic take on what works and what doesn’t in the volatile world of resource development.

There is a truism; it’s Indigenous people who determine resource projects in every region of the country. Thus, having the right engagement strategy is the key to project success.

After winning an unprecedented 300-plus court rulings in the Canadian resource sector, it’s Indigenous –Resource Rulers – who now determine the outcome of resource plays. Bill will speak to a way forward with new rules of engagement for resource development and for winning outcomes in the road-to-resources sweepstakes.Cost per course: MPDA member: $300 Non-member: $400 heathermiller.mpda@gmail.com mpda.ca

The past year has been one of transformative change at Hudbay. Mining the last tonne of ore at our 777 mine in June was a hugely symbolic moment for the company. A stateof-the-art mine and a flagship for our operations in Manitoba for 18 years, 777 represented the pinnacle of a century of shared success for Hudbay and the City of Flin Flon.

All of us at Hudbay hugely appreciate the efforts of the team in making the transition as seamless as possible, and I’d like to thank the people of Flin Flon for their patience and understanding.

Yet while one mining era comes to an

end, a new era begins – one that holds great promise – as we shift the bulk of our operations to Snow Lake. I’m truly optimistic for the future.

Our Lalor mine is currently the only operating gold mine in Manitoba, and the New Britannia mill, which was reopened last year, is currently the only facility producing gold. Both offer a whole new spectrum of possibilities in the region.

We’re further encouraged by the processing improvements we’ve been implementing at our Snow Lake mills aimed at increasing throughput and further improving recoveries. New

By Rob Carter, Vice-President, Manitoba Business Unit, Hudbay Minerals Inc.Britannia is seeing higher than targeted throughput rates and our Stall mill is on track to achieve higher gold and copper recoveries next year after the completion of a recovery improvement program.

All this means our annual gold production from Lalor and the Snow Lake operations is expected to increase to over 180,000 ounces on average over the next several years. This is a testament to the team’s many years of careful planning, strategizing and execution of a multiphased growth strategy in Snow Lake.

In these times, we at Hudbay also recognize there’s an additional existential element to what we do, namely with regards to climate change. Climate change presents huge challenges to our society, and we know northern regions are experiencing drastic change, and at a faster rate than the global average. Hudbay is one of the few miners in position to deliver the metals we need to support the transition to net zero and a greener economy, in an environmentally responsible manner. We take that responsibility seriously.

Our Manitoba operations use nearly 100-per cent renewable hydroelectricity to run the processing plants, which keeps greenhouse gas emissions and energy use intensity relatively low. We are always looking to improve operating efficiencies, for example optimizing throughput and recoveries, to further reduce emissions. The team’s dedication to delivering a more sustainable future

is tremendously impressive and the support we feel from our communities on that mission is hugely encouraging.

We don’t plan to rest on our laurels. Exploration is in Hudbay’s veins, and we’re excited about the potential of the region. A proven track record of continuous addition of reserves to our mines in Manitoba gives me great confidence that we’ll be operating well beyond the current 17-year mine life in Snow Lake.

Certainly, Hudbay’s presence in

Manitoba will look different beyond 2022. What is unchanged is our commitment to the province and to being a valued member of our communities. We are proud to have operated in the region for over 90 years. Our roots are here, and our future is here.

All of us at Hudbay look forward to growing, improving, and delivering value in Manitoba for many years to come. ✖

By now, it is a foregone conclusion that in order for net-zero to be achieved, the increased adoption of low-carbon technologies is essential, with mining propelling the current seismic energy transition. Electric cars cannot exist without lithium, nickel, and cobalt; nuclear energy without uranium; and wind turbines and solar panels without copper, zinc, iron, and steel making coal.

The enhanced understanding that mining has a significant role to play in the green tech revolution has led Canadians to show greater enthusiasm than ever before for the industry. In fact, in polling recently completed by Abacus Data, support was found to

be at an all time high, with 80 per cent reporting that they have a positive feeling about producers of minerals and metals in Canada and 84 per cent giving mining companies in Canada a good or acceptable performance in contributing new materials for use in greener and cleaner technologies.

This broad support may surprise many, but the reality is that Canada’s mining sector is widely considered to be a global leader in its commitment to strong ESG standards and community engagement, with made-in-Canada standards like Towards Sustainable Mining being adopted by mining chambers, including heavyweights like Australia and Brazil, around the world.

By Pierre Gratton, President and CEO, The Mining Association of CanadaWhat is clear is that this public support hinges in large part on mining companies making commitments to lower their environmental footprint and seeing them through. Polling found that 83 per cent say they would like to see more mining projects in Canada provided they have a plan to reduce GHG emissions. While mining has always been an energy-intensive industry, there has been a surge of innovation recently for Canadian mining companies to deliver these critical materials with sustainability and commitment to climate action, like use of renewable energy or decarbonizing equipment used on mining sites, at the forefront. The fact is, as one of the lowest carbon-intensity producers of mineral and metal products in the world, Canada fulfils the need for mined materials better than most competing mining jurisdictions.

In order for our goal of a greener future to come to fruition, we need metals and minerals, in enormous quantities. And in order for that to happen, more mines need to be developed. At present, from initial discovery to first breaking ground, a mining project in Canada takes on average 10 to 15 years before production can even commence, a massive impediment to our ability to be the mining powerhouse the world needs.

Industry is not alone in its concerns about being able to supply these critical materials. In late June, the Hon. Jonathan Wilkinson, Canada’s Minister of Natural Resources, stated that the

“average mine takes 15 years to bring into production and in the context of the energy transition, we don’t have 15 years if we’re actually going to provide enough of the minerals to be able to support just the battery development.” We agree, this timeline does not line up with the urgency of the global need and is a competitive disadvantage for Canadian mining companies when stacked up against other international leaders with far lesser ESG credentials and labour standards.

While recent commitments,

specifically those focused on critical minerals in the last Federal Budget, are positive, there is no doubt that our sector continues to face challenges when fulfilling the demand for our products, not only by companies within Canada but also by our allies. Support for our industry is strong, with leaders like Prime Minister Trudeau and Premiers from coast to coast to coast speaking to the importance of Canadian mining and critical minerals to low-carbon tech, but more action is needed to first get these mines off the ground.

In times of growing international uncertainty and supply chain issues, the world needs more Canadian mining and strides forward must be made to ensure the sector has the ability to provide a secure and stable supply of the minerals and metals essential to Canadians, our allies and businesses around the world. Canadians have voiced their support and the clean tech and auto industries are counting on us to deliver, now is the time to follow-through. ✖

JANUARY 23 TO 26, 2023

Registration for AME Roundup now open! AME Roundup returns to the Vancouver Convention Centre East on January 23 to 26, 2023.

"Responsible mineral exploration and development are critical to addressing our global challenges. The minerals and metals we discover ignite global supply chains, drive innovation and technology transformation, power new energy solutions, and help achieve a low-carbon future. They are 'Critical to Our Future,' and it starts with our passion, commitment, and expertise as an industry," said Kendra Johnston, AME president and CEO.

AME Roundup 2023 registration is available here. Early bird ticket pricing for attendees is open until December 9, 2022. This year, attendees can livestream technical and targeted sessions with select passes.

"Thank you to our patron sponsor, Teck Resources Limited, and our platinum sponsor, Newcrest Mining Limited. The support and leadership of all our sponsors enable us to make AME Roundup 2023 a reality for thousands of attendees,” continued Johnston.

In January 2023, geoscientists, prospectors, financiers,

investors, suppliers, governments, and Indigenous partners from around the world will gather in Vancouver with opportunities to learn, connect, and share the latest models, technologies and techniques.

Also returning in 2023 after a two-year hiatus is Discovery Day, AME's free, family-focused event held on Sunday, January 22, at the Vancouver Convention Centre East. AME invites all members of the public to experience mineral exploration and mining with displays, exhibitors and experiences in a fun, hands-on, interactive environment. See you at AME Roundup 2023!

Stay up to date on conference details, including program announcements, short courses, speakers and networking opportunities at roundup.amebc.ca or follow our AME Roundup social media channels:

@AMEroundup on Twitter @ameroundup on Instagram ame-roundup on LinkedIn

#AMERoundup2023 ✖

Foremost Lithium Resource and Technology has undergone a few changes recently, including updating their name from Far Resources Ltd. to the aforementioned, as well as a new board of directors and staff members.

The company is a hard-rock exploration company strategically located to capitalize on the world’s growing EV appetite with a primary focus on its five lithium lane projects in Snow Lake, Manitoba. It also has its Hidden Lake Lithium Project in the Northwest Territories, and its Winston Silver/Gold Project in New Mexico.

Dr. Mark Fedikow, vice-president of exploration, says Foremost Lithium has acquired highly prospective properties (referred to as “tier one”), such as Peg North, Jean Lake, Grass River, and Zoro.

“Peg North is the largest property we have,” Fedikow says. Peg North encapsulates the northeast extension of the Crowduck Bay Fault, which is the key metal genetic feature in Snow Lake geology for spodumene-bearing and barren pegmatite. The property also covers the northeastern trend of the Thompson Brothers Lithium Deposit (TBL).

The Jean Lake property hosts the high-grade “Beryl” pegmatite, originally discovered by Sherritt Gordon Mines in 1942 and rediscovered in 2021 by Foremost prospector Jake Ziehlke. Grab samples from the Beryl pegmatite assayed as high as 5.17 per cent Li2O.

“We have been actively exploring Jean Lake this past summer with an integrated program of UAV-assisted magnetic surveys, Mobile Metal Ions soil geochemistry, and boots-on-theground prospecting,” Fedikow says.

“Targets identified from our integrated exploration approach on the Jean Lake property will be drill-tested this year. We will also drill test targets developed on the Jean Lake property that appear to be related to the southwest extension of the trend line from the Thompson Brothers Deposit. Our LiDAR and UAVmagnetic work strongly suggest the TBL trend crosscuts the Crowduck Bay Fault and intersects the Jean Lake property.”

The Grass River property hosts 10 large exposed and underexplored pegmatites. There are also seven drill indicated spodumene pegmatites that were intersected by drilling in 1956 as a result of drill testing conductors related to base metal exploration in the area. Basically, they were discovered by accident. “We’ll likely follow up on those in 2023,” Fedikow says.

The Zoro project’s Dyke 1 has an inferred resource of 1.07 million tonnes at 0.91 per cent Li2O. There are also 15 additional dykes on the Zoro property with spodumene (some more than others), and most of them have been tested by only one drill hole. The drone magnetic survey has been completed, and Foremost Lithium is currently working with EarthEx Geophysical

Solutions Inc. on data interpretation. All eyes are focused on Snow Lake, Manitoba as the hub of battery metals. Snow Lake historically has always been a pro-mining community and Foremost’s properties are accessible with year-round access along powerlines and major road and railway routes. Adjacent with and comparable in scale and grade as their neighbour, Snow Lake Lithium’s project (11 million tons at 1.00 per cent Li2O), Foremost Lithium is looking forward to all upcoming exploration and drill programs. ✖

only a decade old and was the result of a major court case in Ontario

By Lisa KopochinskiMineral exploration continues to grow as more companies strive to build respectful and long-lasting relationships with First Nations people regarding land and treat rights.

And, while there is still progress to be made, it is encouraging that organizations are recognizing the benefits of developing partnerships to create and implement effective Aboriginal engagement strategies.

Robert Houle is president and co-founder of Talon Resources and Community Development, a company based at Wauzhushk Onigum First Nation in Kenora, Ontario that was incorporated in 2016 to assist First Nations wishing to get involved in the resource sector.

He recently spoke about Aboriginal engagement and permitting at a Manitoba Prospectors and Developers Association meeting and walked attendees through the process.

“Permitting in the mining industry is a provincial way of allowing proponents to do exploration work. It is essentially a license to begin looking for work for minerals. Aboriginal engagement is about looking into and discussing what the proponent wants to do, and if the community has any issues or land values in the area.”

The current and formal process of Aboriginal engagement and permitting is actually only a decade old. It was the result of a major court case in Ontario, which was instrumental to Aboriginal people asserting their rights to be in full consultation. And that’s where consultation and accommodation was born from.

“Prior to that, there was not a lot of First Nations engagement required,” says Houle. “It’s important that their land rights are respected, and traditional lands are not destroyed and that toxins are not left in the grounds. And,

— MaryAnn Mihychuk, MPDA presidentalso to keep pits clear and the clear cutting of forests. This Mining Act being put into place is a result of everything coming to a head.”

MaryAnn Mihychuk, president of the Manitoba Prospectors and Developers Association, agrees and adds that hundreds of court cases in Canada have set new standards and requirements in the resource sectors, and it is especially important for the mineral exploration industry.

“It is clear Indigenous rights must be respected and those that want to work on traditional lands must have an engagement plan based on respect and understanding. Every exploration project now needs acceptance from both the province (in the form of various permits) and the First Nations of the area.”

As with any agreement, there are pros and cons. For instance, Mihychuk says the main benefits of this engagement is a positive relationship between the First Nations and company.

“For the First Nations, it can mean a real say in land management as well as potential for economic benefits. For the company, it means access to the ground and potentially a business partner.”

As for cons, one of the problems is that engagement is

“EVERY EXPLORATION PROJECT NOW NEEDS ACCEPTANCE FROM BOTH THE PROVINCE (IN THE FORM OF VARIOUS PERMITS) AND THE FIRST NATIONS OF THE AREA.”

understood differently by almost everyone and expectations vary accordingly. This can cause misunderstanding and result in a breakdown of trust.

“Improvements in the form of government support is needed so First Nations can, for example, engage a knowledgeable mineral sector expert to assess the scope of the project and advise the decision makers on the opportunity,” she explains.

Houle agrees and adds, “There are always improvements, but until the government decides to make some serious commitments and changes, the key is for proponents to work diligently and have meaningful agreements with the First Nations. That will drive change.”

He stresses that these agreements are not a one-size-fitsall. Rather, they are a typical standard agreement for early exploration stages, which just tells the community that they will have meaningful employment and will be notified of activity in the area.

“And, if there are any issues that First Nations may have with regard to significant values, burial sites, trapping rights, the company will definitely work with them to come to a resolution.”

As for what the next two to five years holds for the mining industry, Mihychuk says exploration and supply companies will continue to partner with First Nations.

“The Province of Manitoba will also step up and formally partner with Indigenous Nations, with resource revenue sharing as in Ontario and B.C.”

Houle says that it is difficult to see a shift right now, but as the exploration process moves along, there will be different stages.

“For instance, you have staking of the land and then prospecting, which goes into exploration — if a company wishes to do this. Then there is advanced exploration, which triggers a more meaningful discussion and another agreement. From that stage, that is when the exploration companies are typically bought out by major mining companies.”

He adds that what is happening right now is that government is allowing anyone with a stake, claim or Indigenous background to have a seat at the table with the proponents, which is great. But what must be understood is that these companies have limited funds, so government is essentially driving a lot of these groups to go elsewhere or close their doors.

“Originally it was Section 35 which allowed First Nations. Now, it is the Metis that are getting their place at the table, which is fine. But the government has to deal with that and not tell the proponent to deal with them. It’s going to come to a head soon. I can see it.” ✖

“ABORIGINAL ENGAGEMENT IS ABOUT LOOKING INTO AND DISCUSSING WHAT THE PROPONENT WANTS TO DO, AND IF THE COMMUNITY HAS ANY ISSUES OR LAND VALUES IN THE AREA.”

— Robert Houle, president and co-founder of Talon Resources and Community DevelopmentRob Houle.

ACME Lithium (CSE: ACME) (OTCQX: ACLHF) is a mineral exploration company focused on acquiring, exploring, and developing battery metal projects in partnership with leading technology and commodity companies.

At ACME, the building blocks of the future are our focus today. We own 100-per cent interest in 37 mineral claims totalling approximately 6,882 hectares in the Bird River Greenstone Belt in southeastern Manitoba. Those claims translate to lithium mining and extraction in a market that is set to witness explosive growth in the coming years.

Our three projects in the pegmatite fields of southeastern Manitoba straddle the northern and southern limbs of the Bird River Greenstone Belt (BRGB). The BRGB is known to contain at least 10 pegmatite fields and host hundreds of individual pegmatite bodies, of which many are classified

as complex rare-element Lithium-Cesium-Tantalum (LCT) pegmatites.

Pegmatites are associated with granitic intrusions into structurally dilatant zones adjacent to major east-west shear zones in both limbs of the BRGB. Worldwide, LCT pegmatite deposits account for around a quarter of the world’s lithium production, most of the tantalum production, and all the cesium production.

In December 2021, ACME staked 21 claims totalling approximately 3,595 hectares in the Shatford Lake pegmatite field and six claims totalling 1,185 hectares in the Cat-Euclid Lake shear zone. Most recently, in September 2022, we staked 10 claims totalling approximately 2,102 hectares situated near Birse Lake, contiguous and directly east of ACME’s Shatford Lake project area.

Located approximately 165 kilometres east of Winnipeg, ACME’s Shatford Lake and Birse Lake projects are located strategically and contiguous to the south of Sinomine’s world-class Tanco Mine – a lithium, cesium, and tantalum (LCT) producer since 1969. Our Cat-Euclid Lake project is located about 35 kilometres further north.

The Shatford Lake claims straddle a 15 kilometres long structural trend of the Greer-Shatford Shear Zone with numerous pegmatite dykes and favourable host rocks. The northeast corner of the project’s ground abuts the Mineral Lease of the Tanco Mine, and the south shore of Bernic Lake with the Buck, Pelgi, and Dibs pegmatites nearby.

ACME’s Cat-Euclid Lake claims straddle the prospective CatEuclid Lake shear zone and extend along the southeasterly trend of known pegmatite occurrences. Australia’s Mineral Resources Limited (MRL), one of the world’s leading lithium producers with a market capitalization of over AUD$8 billion, recently signed a joint venture agreement with Lithium Canada Development (New Age Metals Inc.) to the west of ACME’s Cat-Euclid Lake lithium project.

With multiple North American projects in areas known for lithium development and exploration, ACME is poised to power the energy revolution.ACME Lithium Manitoba projects.

has numerous pegmatite

along its periphery. The project claim area has been filed with the Manitoba government and is subject to review and processing.

ACME is wrapping up an extensive summer exploration program at both Cat-Euclid and Shatford Lakes employing remote sensing, structural geology, ground-based geological mapping, and geochemical sampling to localize targets for drilling. Our exploration focus is on spodumenebearing LCT pegmatites that are a source for high quality lithium that can be converted to lithium carbonate.

At both projects, crews have focused on areas with abundant outcrop in favourable structural areas. Work has involved soil, rock sampling, and structural mapping to identify areas favored to host pegmatite bodies. An airborne geophysics survey was carried out by Dias Airborne with their state-of-the-art QMAGT system and is currently being processed and evaluated. Commencement of a project-

wide drill program is targeted for the fourth quarter of 2022, subject to permitting and access to drilling equipment and crews.

ACME is in the right place at the right time. There is rapid growth in the battery metals market and demand for lithium is surging as Canadian and U.S. governments actively focus on building a domestic lithium supply chain with North American automakers to produce electric vehicles. With our three projects in Manitoba and another two found in a highly prospective region for lithium production in Clayton Valley and Fish Lake Valley, Nevada, ACME aims to power the energy revolution.

Backed by an experienced management team who have successfully built and financed resource companies around the world, we are well funded by strategic investors and positioned to advance our exploration and development objectives through the near term. The future starts here. ✖

Flying Nickel Mining's (TSXV: FLYN; OTC: FLYNF) flagship Minago project in Manitoba encompasses a 197-squarekilometre prospective land package and hosts one of the largest greenfield open pit nickel sulphide deposits in Canada. Minago is located in the southern extent of Manitoba's Thompson Nickel Belt, North America's second most prolific nickel mining camp, having produced over five billion pounds of nickel since 1959. Since 1966, the Minago nickel sulphide project has received over C$70 million in investments.

Flying Nickel is currently working on a three-pronged development approach at Minago with exploration, permitting, and an updated feasibility study (2010) occurring in 2022. The company is committed to engagement with First Nation Stakeholders and is committed to beneficial partnerships with the communities.

In August 2011, the Minago Project achieved a major milestone when the Environment Act License (“EAL”) was issued by the province of Manitoba. The prior operator of the project subsequently filed a Notice of Alteration (NOA) to the EAL, in December 2013, related to relocation of the tailings management area to address First Nation concerns. Flying Nickel has submitted substantial updates to the 2014 NOA to the Manitoba Government for the 10,000 tonnes-per-day open-pit mining operation at Minago.

Manitoba Provincial Highway 6 and a high-voltage (230 kV) hydroelectric power transmission line both transect the Minago project area, making Minago potentially one of the lowest carbon-intensity nickel projects in the world. Several initiatives are being considered or taken to minimize the carbon footprint of a potential future mining operation at Minago. For mining, the Company is examining the use of a fully electric mine fleet. For ore and waste processing, the crushing, milling and flotation processes would be powered by renewable Manitoba hydroelectricity.

The Manitoba Agriculture and Resource Development Department (“ARDD”) has expressed support for the Minago Project, which would supply much-needed Class 1 high-purity nickel to make nickel-lithium batteries used in electric vehicles.

The project is expected to have an industry-leading low carbon footprint, lower than 99 per cent of existing global nickel production, according to a study by Skarn Associates, a metals and mining ESG research company, while processing 10,000 tonnes-per-day of mined material.

When in operation, the Minago project is expected to produce 0.99 tonne of carbon dioxide (CO2) per tonne of nickel-equivalent production over the life of the mine, about 97 per cent lower than the industry average of 33.4 tonnes of CO2 in 2021, the study found.

The nickel concentrate from Minago will be ideally suited to go into high-performance nickel batteries powering modern electric vehicles as well due is low GHG supply chain emissions and high-quality concentrate.

Minago has generally similar structural, geological, and mineralogical characteristics as deposits located on the

Type

Ni % Cut-off Category Tonnes (‘000) Ni % Nickel (‘000 lbs)

Open Pit 0.15

Measured and Indicated 33,750 0.59 438,995

Inferred 3,610 0.45 35,814 Underground 0.3

Measured and Indicated 31,910 0.65 457,271

Inferred 33,640 0.6 444,981

Combined 0.15/0.3 Measured and Indicated 65,660 0.62 897,483 Inferred 37,250 0.59 484,520

Thompson Dome to the north. Exploration to date has outlined 721.6 million lbs of measured and indicated nickel (44.2 million tonnes at 0.74 per cent nickel) and 318.9 million ls inferred nickel (19.6 million tonnes at 0.74 per cent nickel) in open pit and underground resources. The nickel mineralization at Minago remains open at depth beyond 350 metres and along strike.

Substantial volumes of nickel mineralization that are presently defined by drilling in the Nose Zone and North Limb Zone were excluded from the current MRE by the cut-off grades applied. The current optimized pit shell has a maximum depth of approximately 350 metres below surface.

Regionally, historical drilling completed five kilometres to the south of the Nose Zone (“South Target”), and three kilometres to the northwest of the North Limb Zone (“O Limb Target”) by Amax Exploration from 1969 to 1971 encountered nickel mineralization similar in style to that at Minago. The Company believes that these two specific areas represent high-priority targets for further

exploration and potential resource expansion.

The Minago MRE demonstrates that the Minago Project is one of Canada’s largest undeveloped sulphide nickel deposits. In the next 12 months, the Company intends to carry out core drilling programs at Minago to expand existing mineral resources, address updating of environmental permitting established in 2011 to operate the project, and update the historic feasibility study. ✖

Douglas

Tackling your company’s ESG goals isn’t easy, but it’s a whole lot easier now. Over the last four years, Watson Gloves has been busy innovating their product selection and now has over 80 sustainable glove styles that you can transition to, without sacrificing safety or your budget. As the leader of bringing sustainable offerings to the industrial glove market, Watson Gloves is ready to help your company transition to sustainable hand protection and help both sustainability officers and safety officers meet their goals. The time to change is now.

Innovation has been key to thinking outside of the box. The first sustainable item they brought to market in 2019 was Green Monkey disposable gloves. These gloves will decompose in landfill conditions in under 12 years, versus over 200 years for regular disposables. One year later, several glove styles were brought to market in which the yarn was made from recycled water bottles. We all know that plastic pollution is one of the big challenges facing society today. In fact, 59 billion empty water bottles are thrown out every year in the United States and Canada. Production of

Watson’s WasteNot ™ yarn is achieved by diverting PET water bottles from the landfill, breaking them down into chips, melting down into pellets, and spinning them into recycled polyester yarn. The result is 100-per cent postconsumer recycled yarn made from post-consumer plastic water bottles. Utilizing bottles that would otherwise end up in the landfill reduces soil contamination and water and air pollution and requires 59 per cent less energy to produce gloves than if virgin materials were used. In addition, rPET (re-purposed PET water bottles) uses 90 per cent less water to produce and there is a reduction of 32 per cent of CO2 emissions compared to virgin production. These numbers are significant. Transitioning will mean a big win for the environment.

Following this success, Watson Gloves continued to innovate and developed nitrile gloves that biodegrade in landfill conditions and in that biogas can be recovered to fuel our homes, businesses, and communities through landfill gas recovery in active landfills.

The demand for sustainable glove styles has rapidly grown as companies everywhere have become increasingly aware of their environmental footprint and set their own sustainability goals. As a result, Watson Gloves now offers several glove styles with Cut Protection, or Impact Protection, as well as warm winter gloves made with 3M EcoThinsulate™ Type EC.

Their latest development has been the Watson Energy Calculator. They can now help companies quantify how they can reduce their environmental footprint by transitioning to sustainable hand protection. Call them for a SWAT (Sustainable Watson Assessment Team) on-site audit. They

can assess your glove usage, make sure you’re using the best styles for the job, and suggest sustainable alternatives, showing you how transitioning to sustainable glove styles can mean reducing your environmental footprint through using the EPA warm model. Using the Watson Energy Calculator, they can now quantify usage of CO2, coal, water bottles, oil and gasoline in gloves using rPET vs gloves using virgin materials.

Increasing awareness of climate change and the catastrophic results mean urgent action is required by all of us to transition quickly to the most sustainable products in the market. Hand safety is, of course, of utmost importance, but products are now available that meet your safety, budget, and environmental needs. Visit watsongloves.com/services/ swat-hazard-assessment to request a no-cost, no-obligation site audit to reduce hand injuries, consumption, cost, and waste. The time to change is now. ✖

Things are ramping up for Vale’s Thompson Mine.

According to Gary Arnett, head of Vale’s Manitoba Operations, the Thompson orebody was first discovered in 1956 by Vale (formerly known as Inco), following the adoption of new exploration technology and the largest exploration program to-date in the company’s history. Mining of nickel from the Thompson orebody began in 1961.

In 2021, the Mine received $150 million to extend current mining activities, particularly Phase 1 of the Thompson Mine Extension Project, by 10 years while aggressive exploration drilling of known orebodies holds the promise of mining well past 2040.

“Phase 1 work is underway and includes critical infrastructure improvements, such as new ventilation raises and fans, increased backfill capacity, and additional power distribution,” Arnett explains. “The infrastructure changes are forecast to improve current production by 30 per cent.”

“We also have a CAD$236-million, five-year exploration strategy for Thompson to support approval of the Thompson Mine Extension Phase 2 that includes

development of new orebodies,” Arnett says, adding that Vale is advancing exploration studies on large ultramafichosted Nickel deposits.

There is a global movement to electric vehicles, renewable energies, and carbon reduction, which Vale is proud to be a part of. Thompson has become a hub for mineral activities for Vale due to the interest in and usage of nickel.

“We are proud that Thompson can be a part of that future and part of the low-carbon solution,” Arnett says.

Vale is a world leader in production and supply of nickel from a responsible source, and they’ve been involved in conversations with stakeholders at all points in the electric vehicle supply chain to explore potential partnerships, such as major carmakers, cathode producers, cell producers, and recyclers.

“We recently signed an agreement with electric vehicle manufacturer Tesla to supply nickel from our Canadian operations. We are also a supplier to Swedish lithium-ion cell producer Northvolt AB,” Arnett says.

For more information, visit vale.com. ✖

It was late in the year, snow on the ground, and crisp cold weather with the sun disappearing by 4:30 p.m. The November time change had taken place, so our group needed to be in the field at first light to get the work completed.

Our team—Chris Lytwyn, William Dusessoy, Chris Beaumont Smith, and myself—were staking a contiguous set of claims (25 in total) to complete a claim parcel. We each had to finish a side of a claim by taping, cutting posts and attaching claim tags. The logistics required four people to enter their area and connect claim lines to avoid crossing

natural barriers—such as rivers, stream, and swamps.

We drove two vehicles to an area outside Bissett—twoand-a-half hours from Winnipeg—as the four of us had to complete sections of new claims. There were three of us in a van, and one person in the other vehicle.

We arrived at our destination around 9 a.m., ensuring a radio check to keep all parties in communication. Two of us would be dropped off to spend the day in the bush, and the vehicles would head off to their respective locations, all meeting at this drop-off point around sunset.

The van floor, wheel well, brake line, and tire were all blown out.

At least, that was our plan. As the other vehicle headed off, we discovered a flat tire on our van. We happened to be carrying two spares so, with the tire changed, two of us headed off into the bush and the repaired vehicle headed off to its destination.

It was an uneventful day and both drivers finished around 3:30 p.m. and met up at the rendezvous site. We radioed the guys in the bush who said they would be out by dark, closer to 5 p.m. The lone driver headed back to Winnipeg and the other driver waited for his companions.

As the sun was setting (it was 4:30 p.m.) the awaiting driver headed down the road a few miles to take some sunset photos, and then made a U-turn when there was a loud explosion at the back of the vehicle. The rear tire had taken out the wheel hub, blown a hole in the van floor and ruptured the brake line, all while out of radio contact with the other guys. He drove back to the rendezvous point in the wounded vehicle as darkness set in.

Parked on the road, he struggled to release the rusted mechanism holding the spare wheel under the van with diminishing light. A vehicle showed up and a driver offered to help and provide much needed light.

Together, we jacked up the van, removed the tire, and the guys returned from the bush. The fellow who helped us looked at our tires and told us we were brave “to travel on those.” We got the spare on, pinched off the brake line, and headed home at 70 to 80 kilometres per hour.

There was no cell service, it was -7 degrees Celcius, and the van heater stopped working. As we approached civilization—there was a cell tower 20 kilometres ahead— and further ahead paved roads and a service station in

Lac du Bonnet, where we intended to fill up on our trip to Winnipeg.

Now 170 kilometres from home, we were cold, had not eaten for some time and were moving along, when we hear a loud startling bang at the back of the van, followed by a sudden stop. Upon inspection, the spare tire and wheel hub were gone.

We divided into teams. One went back down the road to find lug nuts, and the other two scoured the ditches for our elusive wheel, which thankfully we found and one lug nut. A short search along the path of the wheel revealed the missing brake drum as well.