3 minute read

Derrick screens raise potash and phosphate recovery, reduce cost

0.50 mm Potash Screening, Chile - (9) 5-deck Stack Sizers.

In late 2020, three five-deck high-capacity stack sizer® screens fitted with 850-micron Polyweb® screen panels will be installed in australia for sulfate of potash recovery. this will be the first installation of stack sizers for this application in australia. these highcapacity, small footprint screens will produce significantly higher yields than the previous equipment used in the application, allowing recovery operations to focus on capturing as much product as possible with minimal additional work. Derrick’s unique Polyweb urethane screen panels on the stack sizer reduce near-size blinding to maintain optimum efficiency, while offering unmatched panel life. Working together with global potash producers to improve mill recovery and efficiency, Derrick continues to develop proprietary high-capacity, high-efficiency, robust and reliable screening solutions for the potash industry. the Derrick stack sizer replaces conventional high-amplitude horizontal banana-type screens before the screening surface. Compared with the low-screening efficiency of conventional screens, the stack sizer offers lower circulating loads, low structural maintenance costs, and reduced brine spray on the screen deck to liberate fines, thereby raising productivity and process efficiency.

In early 2020, Derrick introduced its latest screening innovation, the superstack® to the world and it soon caught the attention of the potash industry. With its eight vibrating screen decks operating in parallel, combined with a 30 to 35 per cent increase in effective screening width compared with Derrick’s 5-Deck stack sizer, this novel machine exceeds the stack sizer’s capacity by two-and-a-half to three times.

SuperStack enters South Africa

In 2018, Derrick-africa recommended 10 5-Deck stack sizers to a major phosphate producer to upgrade their plant, but were not considered purely on price. In early 2019, Derrick re-attempted to enter the phosphate market by offering superstack screens instead of stack sizers. once again, the offer was rejected due to uncertainty of the new technology. In January 2020, however, Derrick re-visited the producer in Cape town and offered them four superstacks instead of 10 5-Deck stack sizers. they showed that the superstacks would result in significantly reduced infrastructure. through a cost-benefit analysis, Derrick’s offer won the $2.3 million tender, allowing the first superstack installation to proceed in africa.

Michelle lawrence, Coo, kropz says, “the four superstacks offer an elegant and cost-optimized solution to increasing throughput of the milling circuit and top-size presentation to the flotation circuit. We look forward to recommissioning the plant

and working together with Derrick to maximize overall efficiencies.”

the superstack’s demonstrated safety and maintenance, environmental, and societal benefits include:

Safety and Maintenance

• Totally enclosed, lubricated-for-life vibratory motors • Lightweight, easy-to-install screen panels • Front-to-back screen panel tensioning reduces changing time to less than one minute per panel • Exceptionally low maintenance requirements

Environmental

• Low, 10 HP power consumption • Sacrificial, replaceable anodes help prevent corrosion on the live frames in the harsh potash environment • Stainless-steel support structure and porcelain-coated screen frame construction for long-term durability • Reduced infrastructure

Societal

• Maximum efficiency in recovery and improved grade to ultimately increase crop yields

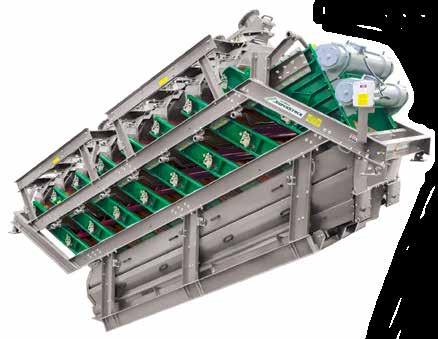

Stainless-steel version of SuperStack for potash/ phosphate.

SuperStack in phosphate recovery

Phosphate recovery applications have opened new opportunities for both the superstack and stack sizer screens in south africa and florida in the U.s. In florida, five stack sizers have replaced Derrick Multifeed screens for a long-term (30+ years) Derrick customer. this firm concluded that the time was right to upgrade their operation to the latest proven Derrick technology.

The future of SuperStack in potash/phosphate industry

through successful installations, the superstack is demonstrating efficiency and cost savings in the recovery of potash and phosphate. successful installations are expected to rise as its reputation expands, making it an important element in serving the ever-expanding need for these vital agricultural products throughout the world.

for more information, contact: amit Jain Mining & Industrial Division Derrick Corporation email: ajain@derrick.coms

Principles of Operation – SuperStack.