2023/2024 in Hungary

Capacity increase and new capabilities

Hungary capacity overview 3 Füzesabony 4 Fosber S/Line 370 corrugator 5 Göpfert Ovation 13/21 7C printer 7 Bobst Mastercut 2.1 9 Bobst FFG 1636 flexo folder gluer 11

Content

Energy saving

Improved waste management

Material optimizition

Inbound logistics development

Capacity increase to support our growth ambitions

New capabilities in HQPP

Full scale of printing services: flexo, offset, digital, HQPP, screenprint

BRC certification for 2 sites

Qualitylab and equipments

Quality camera controls

Safety Guard

Q

€ Hungary 3

CAPACITY INVESTMENT SUSTAINABILITY OILOFTROPGNITNIRP

YTEFASDNAYTILAU

Energy saving

More performance with less paper

Automated internal logistics

+30% capacity increase in total

50% increased capacity on the corrugator

State-of-the-art HQPP 7 color HQPP printing machine

OILOFTROPGNITNIRP

YTEFASDNAYTILAU

Stepchange in product quality due to enhanced quality control systems

CAPACITY INVESTMENT SUSTAINABILITY

Q

€ Füzesabony 4

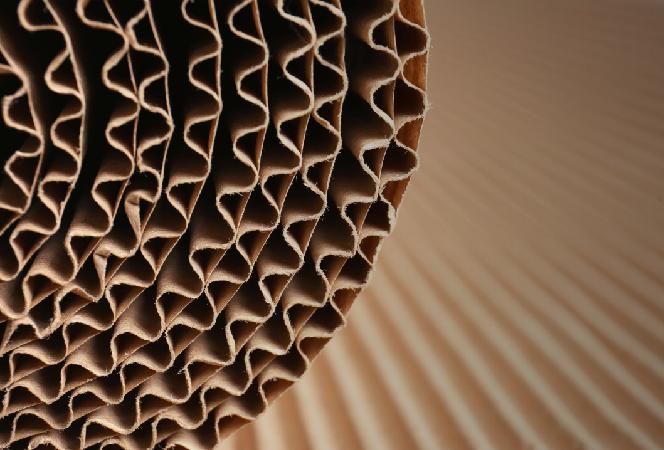

Fosber S/Line 370 corrugator

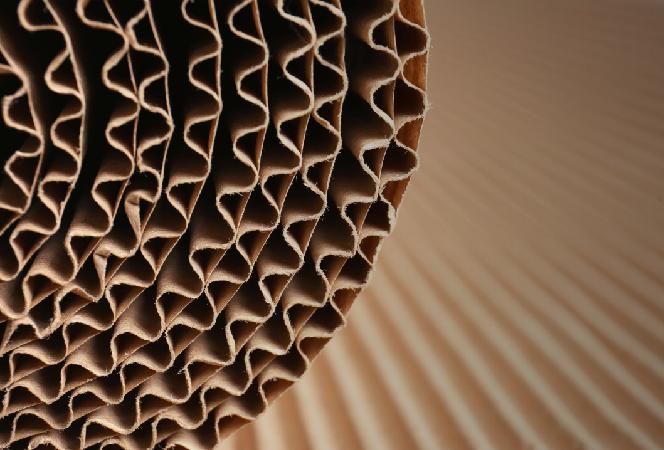

Empowering sustainability

The efficient use of materials and combined with the right grooves results in lighter cardboard sheets using a minimum amount of material while maximizing productivity protection. This has a positive effect on the carbon footprint and supports the achievement of sustainability goals and the fulfillment of customer needs.

Improving Performance

The new technology with precise setting and thoughtful raw materials usage increases the strength of the board. It provides reliability, which is crucial for the stability in the supply chain.

Driving e ciency

Faster production through short set-up times giving flexibility when switching between different types of boardgrade.

Boosting quality

The volume produced in 1 year in 3 shifts is more than twice as large as BARCELONA

Advanced quality assurance with camera systems, automatically monitorizing and adjusting the machine operation to ensure continuous quality.

Füzesabony 5 Fosber S/Line 370 corrugator

Fosber S/Line 370 corrugator

Technical parameters

• Max width: 2800 mm

• Max speed: 370 m/min

• Sheet capacity: average 28,000 m2/hour

• Flute types: C, B, R, E and ER, BC

• Automatic waste ejection

• Oil free slitting, oil free cutting

• Syncro Corrugator Control and Process Control

Füzesabony 6 Fosber S/Line 370 corrugator

Print that makes an impression

Packaging plays an important role in representing brands to consumers. Eye-catching visual appearance is key, whether the box is on store shelves or deivered to the door.

HQPP technology brings customized, close to photo realistic solution to life.

Optimization

It offers a high-quality alternative to offset printing for larger quantities. It gives opportunity to choose the right printing technology in line with your brand strategy.

Supreme quality

Monitoring system with cameras checks prints and removes defective prints automatically ensuring the highest quality.

Paper printed in 1 hour is enough to wrap the glass surface of the Louvre Pyramid 28 times

Füzesabony 7 Göpfert Ovation 13/21 7C Printer

Göpfert Ovation 13/21 7C Printer

High Quality Post Printer 7 colors

Technical parameters

• Up to 7 colors with IR and UV dryer / 6 colors + varnish

• Sheet dimensions:

min: 460mm x 600mm

max: 1,270mm x 2,100mm

• Print quality: coated - 122 lpi, Uncoated - 87 lpi

• Max print surface: 1,250mm x 2,100mm

• Max print speed: 14,000 sheets/hour

• Quality control

Füzesabony 8 Göpfert Ovation 13/21 7C Printer

Ultimate productivity in die cutting for exible service

The highest productivity is provided by speed, quick changeover, and allowing two or more blanks to be cut from a single sheet, which enables flexible service to meet customer needs.

Relability in quality

A fully automated register function ensures unmatched sheets are identified as cameras scan the registration marks printed on the sheets and then adjust the sheets for printing to reduce the registration to within 1/64".

Advanced processes for sustainability

The reduced scrap and the preservation of the sheet integrity contribute to the reduction of waste from production, thereby hitting sustainability goals.

Quantity of cardboard cut in 1 hour is equivalent to 2 football pitches

Füzesabony 9 Bobst Mastercut 2.1

Bobst Mastercut 2.1

Autoplaten® die-cutter

Technical parameters

• Capacity: 7,500 sheets/hour

• Sheet dimensions:

min: 730mm x 520mm

max: 2,100mm x 1,300mm

• Fully automated production line: Automatic loading

Separator

Stacking and pallettizing

10

Füzesabony Bobst Mastercut 2.1

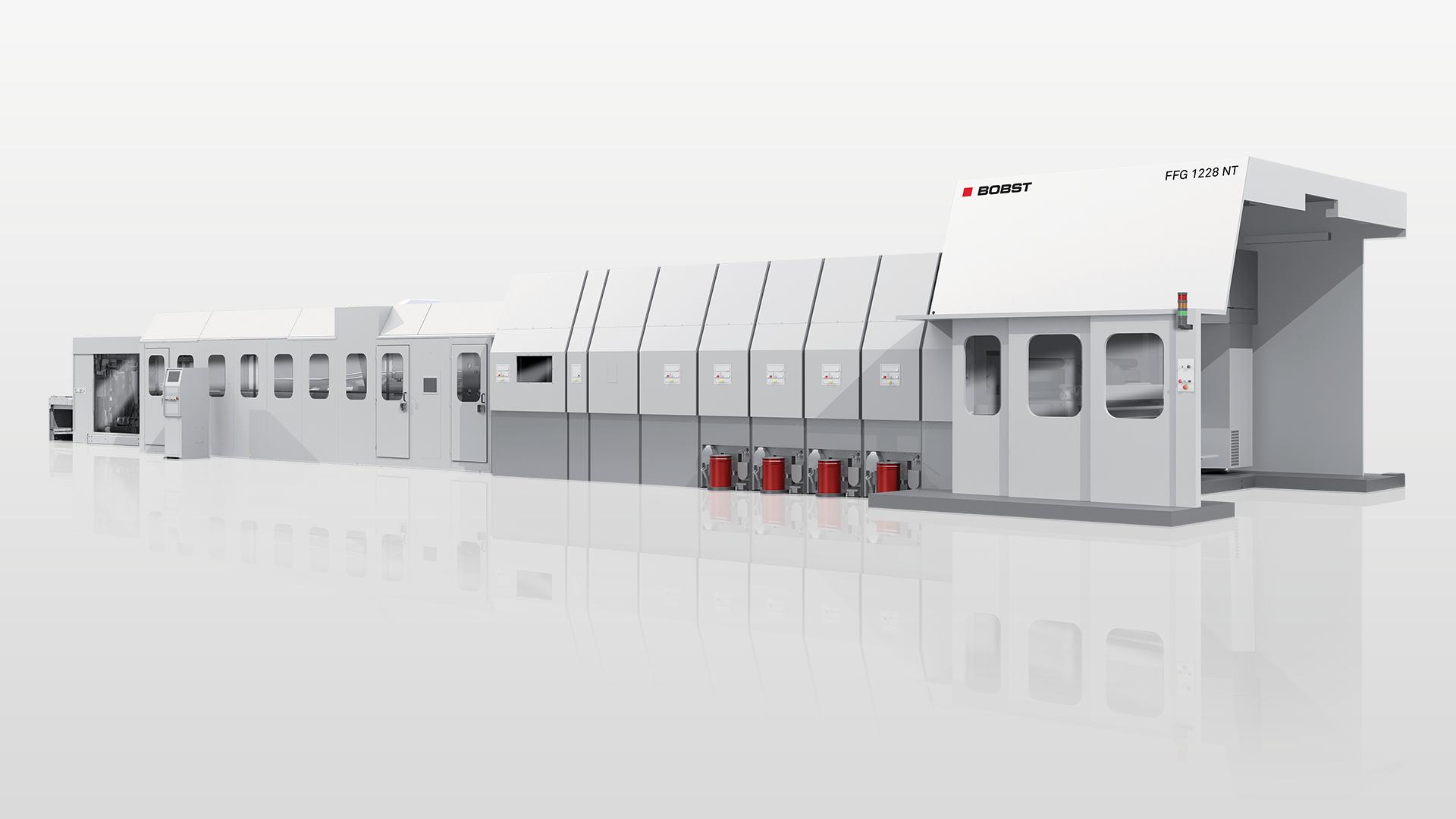

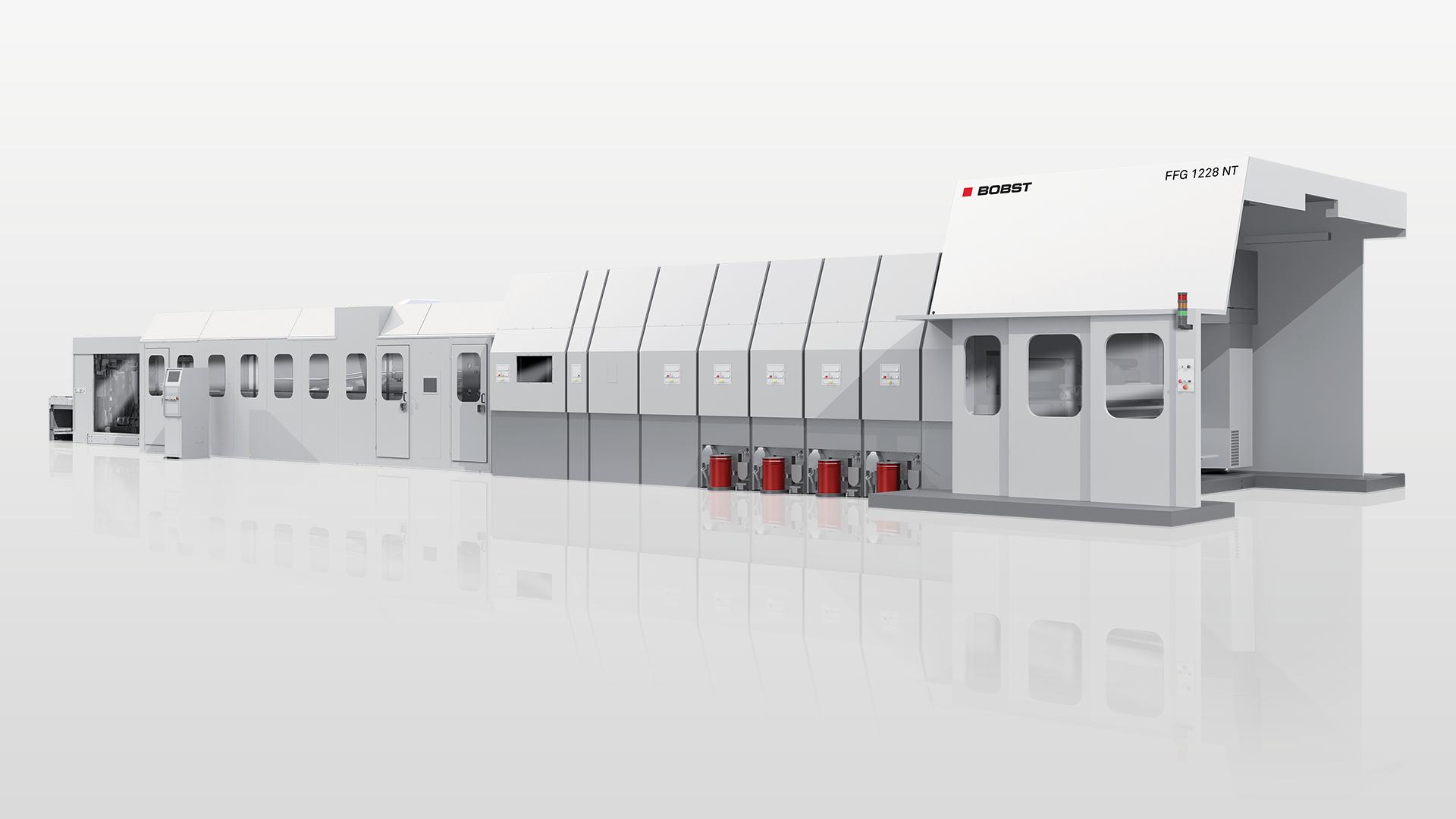

State-of-the-art large inliner

Multifunctionality

Thanks to the configuration with flexo-printer, die-cutter, folder, gluer we get packaging ready for shipment in one pass.

Optimal choice

It offers versatility in manufacturing with the ability to produce a wide range of boxes, from the RSC boxes to complex die-cut boxes, in either single-color or multi-color flexo printing, even in small order quantities.

Adding value for quality

Highest accuracy slotting and die cutting assure precise folding for perfectly produced packaging. Unmatched printing quality combined with complex die-cutting for added-value boxes.

From April 2024

glueing

printing cutting folding

stacking

Füzesabony 11 Bobst FFG 1636

Bobst FFG 1636

Flexo folder gluer

Technical parameters

• Production speed up to 33,000 boxes/hour

• Fully automated slotter

• Posilock system for quick change of die-cutting forms

• Cutting dimension:

min: 500mm x 700mm

max: 2,100mm x 3,600mm

• For one color and 3 color jobs

• High productivity on RSC (regular slotted container) boxes and complex die-cut boxes.

From April 2024

Füzesabony 12 Bobst FFG 1636

Get in touch

@dssmithgroup

At DS Smith we are committed to driving innovation and sustainability in partnership with our customers.

DS Smith

DSSmith.Group

ds.smith.sales@dssmith.com

Let’s create a sustainable packaging future, together!

Start the Cycle and get in touch today to develop eco-friendly solutions and understand more about what these trends could mean for your packaging design and messaging.