It may come as a surprise that content for the Winter issue of Interface is actually completed by the middle of September. The seemingly early due date is needed to allow for the design and production process required to create the beauty that you are looking at right now. I always struggle trying to figure out what to write about that will still have legs in three months (I can see the nodding heads). Our department is in the midst of our PhD qualifying exams, an annual fall event that stirs memories/nightmares even after [deleted] years have passed since my experience with it. For those readers who have not suffered through experienced such an exam, one component of all PhD qualifiers is an oral exam. Although it varies from department to department, the broad characteristics are the same: on the order of four faculty ask the candidate technical questions with the entire exam lasting ~ 2hrs. Sometimes questions are about a mini-proposal the candidate has written, sometimes the questions are about field-specific fundamentals. In all cases, the candidate is going through what will be one of the greatest anxiety-causing experiences of their professional life. It represents a critical professional gateway, and the anticipation of the event is almost as brutal as the event itself. But there is no path to a PhD without going through that gate.

Successful completion demonstrates not only a grasp of the subject matter, but also an ability to synthesize different aspects of the knowledge base as required to attack a technical question. In addition, professional life is largely an oral exam. Yes, we capture our thoughts and arguments in our papers in the academic world, but real-time technical discussions are often key in decisions about government policies, industrial directions, liability judgements, as well as scientific acceptance of one’s work. We have all had the experience of thinking of a better response than the one we gave minutes, hours, or days after an argument (for those of you who argue). The ability to think on one’s feet while under stress can be a key skill.

Because each questioner has a time limit (e.g., 20 min), they often cut the student off once it is clear that the student knows the answer, moving on to the next topic. One key goal is to find the point where the student doesn’t know the answer to determine their ability to think through problems, as that is the essence of research. As the sign outside my office says, quoting Albert Einstein: “If we knew what we were doing, it wouldn’t be research.” Somewhat counterintuitively, in many cases it is the students who have done very, very well academically who suffer the most. They are not used to not knowing the answer, as that is how they achieved their high grades. The first experience of the distress of being intellectually lost is jarring. For those who were a bit full of themselves, it is eye-opening to realize that maybe they aren’t all that and a bag of chips. Facing our own limitations is hard, but being okay with not knowing or being wrong is critical to successful research (not to mention life).

For many, if not most, students, the oral exam is a turning point in their development. After passing the gauntlet of questions from four grumpy faculty, students who had been lacking in self-confidence realize how smart they are. They become more willing to risk being wrong in the pursuit of understanding. For (sometimes) the first time in their life, they can tell that guy we all have on our shoulder who provides constant critiques that he can shut up. It divides their professional life into two eras: before the exam and after the exam. They even walk a bit taller. Of course, PhD oral exams have analogies in other career paths as well. Heather still vividly recalls every question posed during her anesthesiology board examination just as I still remember one of my examiners saying, “Well, no, not really,” after each of my answers to his questions. I still think my passing must have been due to a numerical mistake when scores were added. Of course, the $50 that I slipped the committee chair may have helped, too.

So, the moral of the story is that it is often via the scariest challenges that we grow the most (except those involving snakes). We often face them because we want something that is on the other side of them. It is during those times that we should be brave and scared. We need to believe in ourselves like we believe in others.

Until next time, be safe and happy.

Published by: The Electrochemical Society (ECS) 65 South Main Street Pennington, NJ 08534-2839, USA Tel 609.737.1902, Fax 609.737.2743 www.electrochem.org

Editor: Rob Kelly

Contributing Editors: Christopher L. Alexander, Chris Arges, Scott Cushing, Ahmet Kusolgu, Donald Pile, Alice Suroviec

Director of Publications: Adrian Plummer

Director of Community Engagement: Shannon Reed

Production Editor: Kara McArthur

Graphic Design & Print Production Manager: Dinia Agrawala

Staff Contributors: Frances Chaves, Genevieve Goldy, Mary Hojlo, Christopher J. Jannuzzi, John Lewis, Anna Olsen, Jennifer Ortiz, Beth Schademann, Francesca Spagnuolo

Advisory Board: Brett Lucht (Battery), Dev Chidambaram (Corrosion), Durga Misra (Dielectric Science and Technology), Philippe Vereecken (Electrodeposition), Jennifer Hite (Electronics and Photonics), Mani Manivannan (Energy Technology), Cortney Kreller (High-Temperature Energy, Materials, & Processes), John Weidner (Industrial Electrochemistry and Electrochemical Engineering), Jakoah Brgoch (Luminescence and Display Materials), Hiroshi Imahori (Nanocarbons), James Burgess (Organic and Biological Electrochemistry), Robbyn Anand (Physical and Analytical Electrochemistry), Ajit Khosla (Sensor)

Publications Subcommittee Chair: Colm O'Dwyer

Society Officers: Turgut Gür, President; Gerardine Botte, Senior Vice President; Colm O’Dwyer, 2nd Vice President; James (Jim) Fenton, 3rd Vice President; Marca Doeff, Secretary; Elizabeth J. Podlaha-Murphy, Treasurer; Christopher J. Jannuzzi, Executive Director & CEO

Statements and opinions given in The Electrochemical Society Interface are those of the contributors, and ECS assumes no responsibility for them.

Authorization to photocopy any article for internal or personal use beyond the fair use provisions of the Copyright Act of 1976 is granted by The Electrochemical Society to libraries and other users registered with the Copyright Clearance Center (CCC). Copying for other than internal or personal use without express permission of ECS is prohibited. The CCC Code for The Electrochemical Society Interface is 1064-8208/92.

ISSN : Print: 1064-8208 Online: 1944-8783

The Electrochemical Society Interface is published quarterly by The Electrochemical Society (ECS), at 65 South Main Street, Pennington, NJ 08534-2839 USA. Subscription to members is part of membership service. © Copyright 2022 by The Electrochemical Society. *“Save as otherwise expressly stated.”

The Electrochemical Society is an educational, nonprofit 501(c)(3) organization with more than 8,500 scientists and engineers in over 75 countries worldwide who hold individual membership. Founded in 1902, the Society has a long tradition in advancing the theory and practice of electrochemical and solid state science by dissemination of information through its publications and international meetings.

“... professional life is largely an oral exam.”

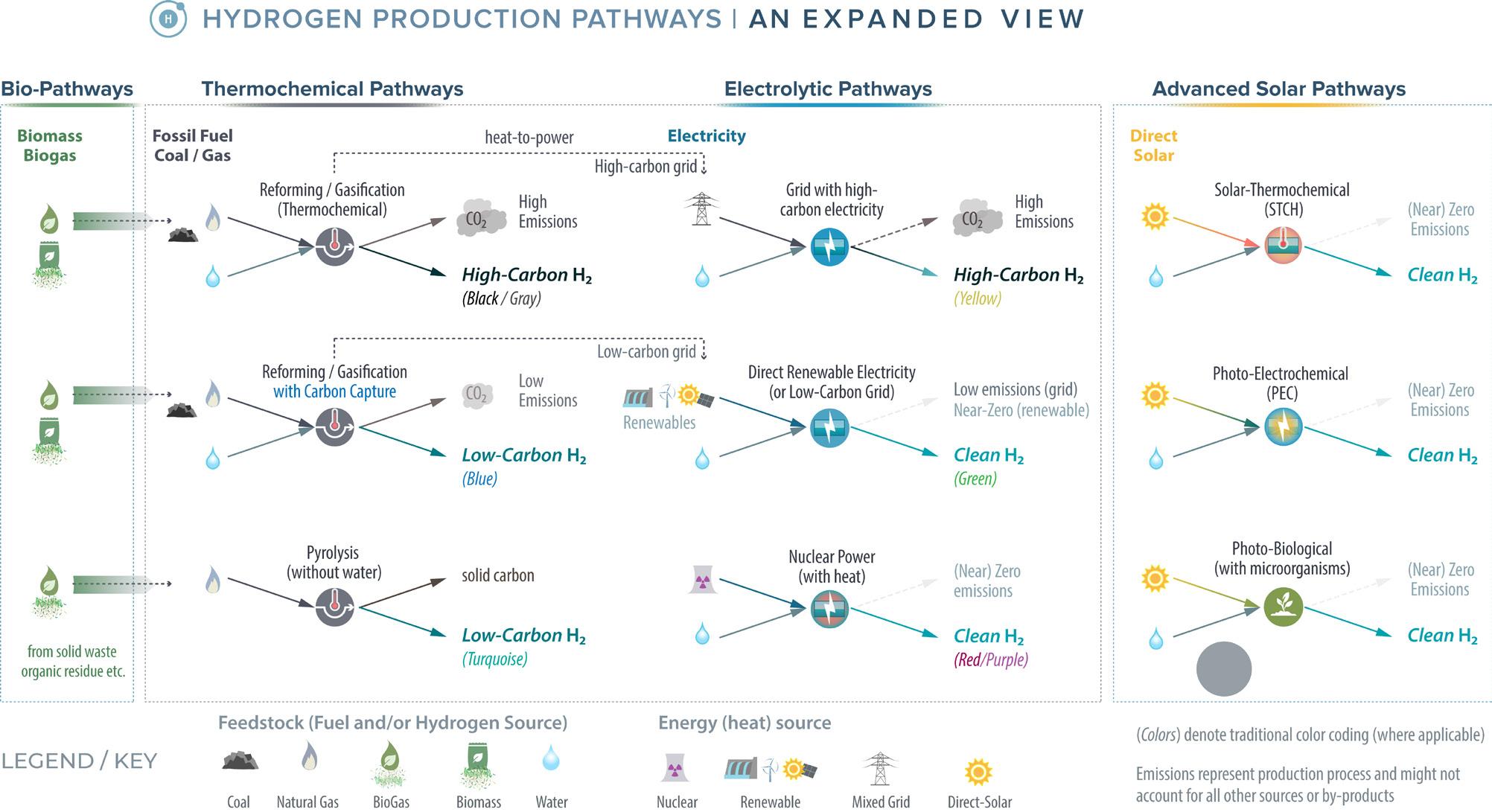

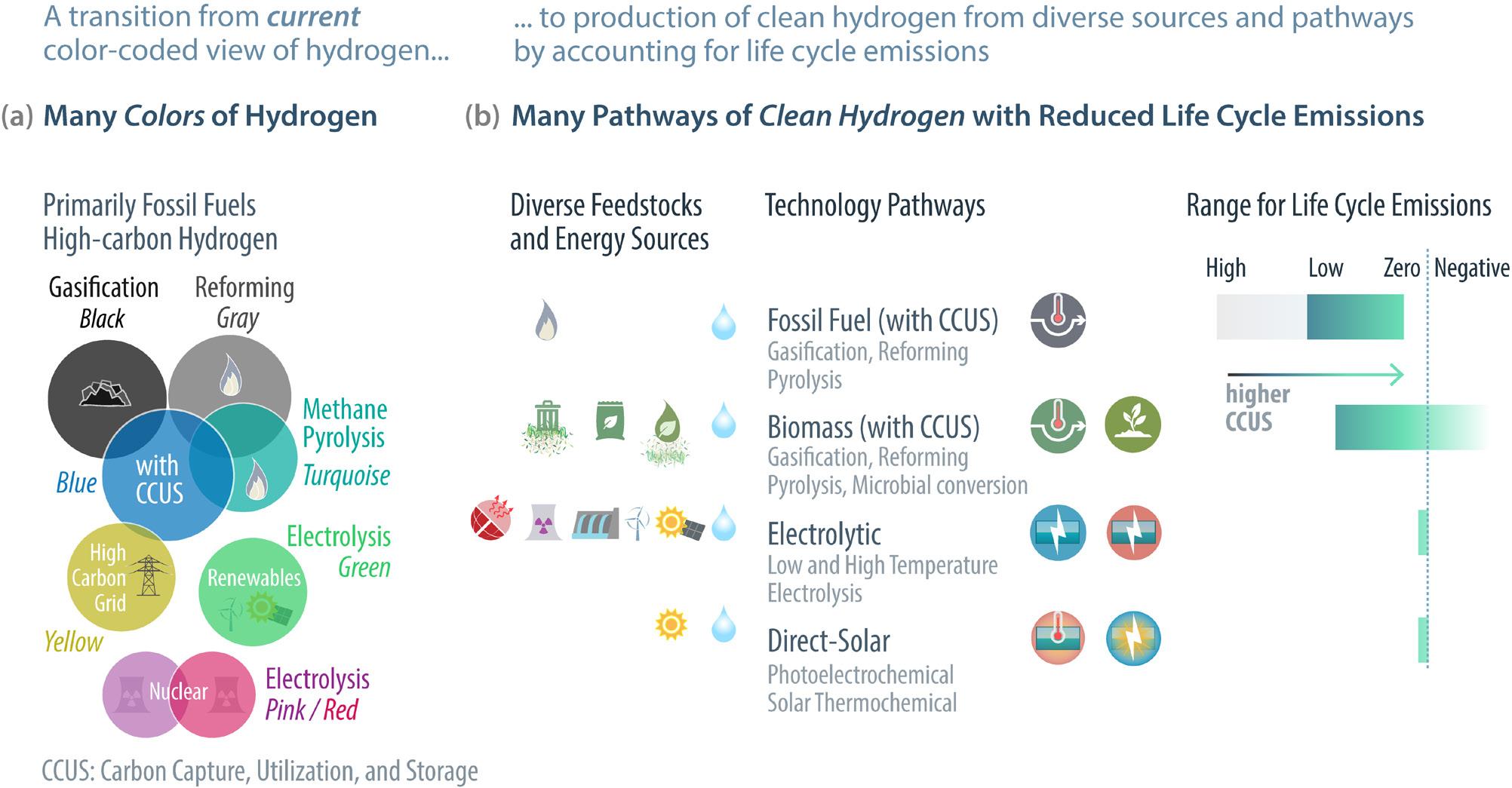

Expanding on my earlier statement in the summer 2022 issue of Interface,

I wish to share my views with you on the pressing challenges regarding sustainable energy and the environment. I will take an entirely global perspective in viewing these complex and difficult issues, irrespective of local or regional energy practices and trends that can mislead to tunnel vision. I would also note that the views expressed in this article are solely my own and do not necessarily represent or reflect the collective view of our Society.

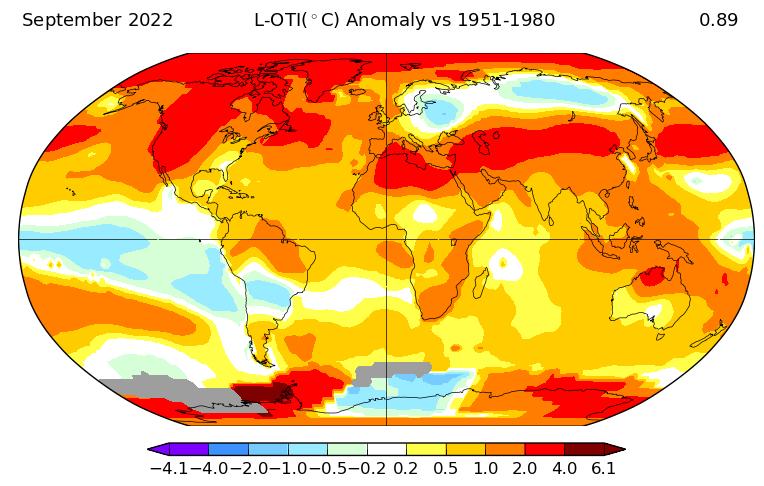

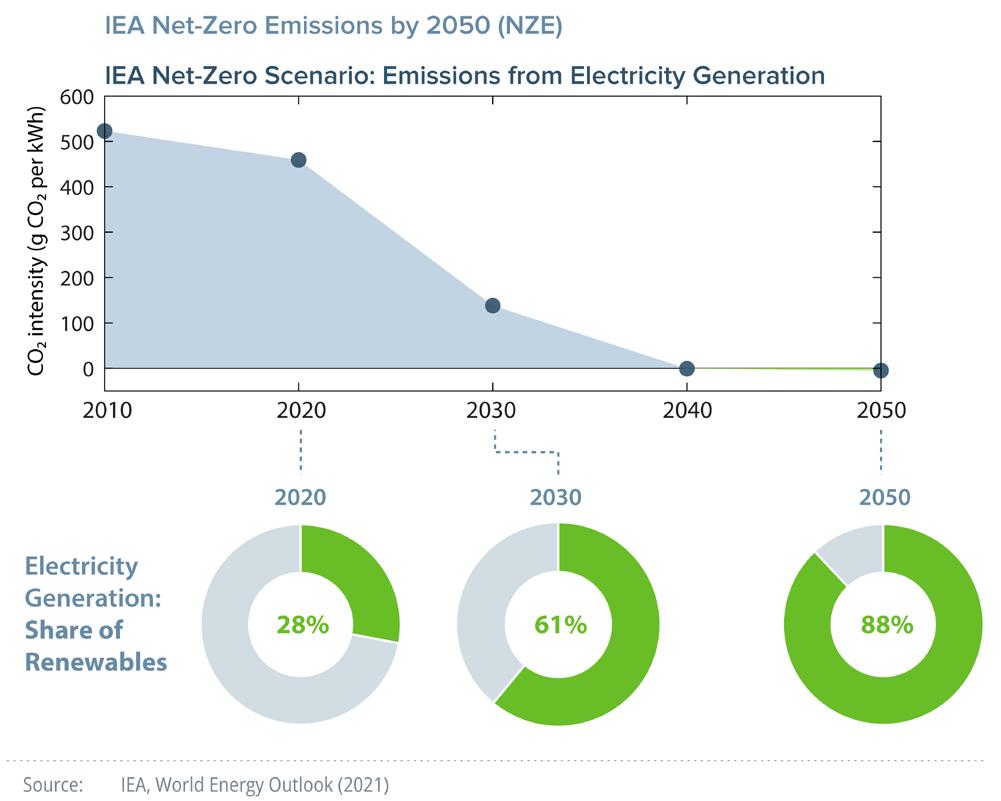

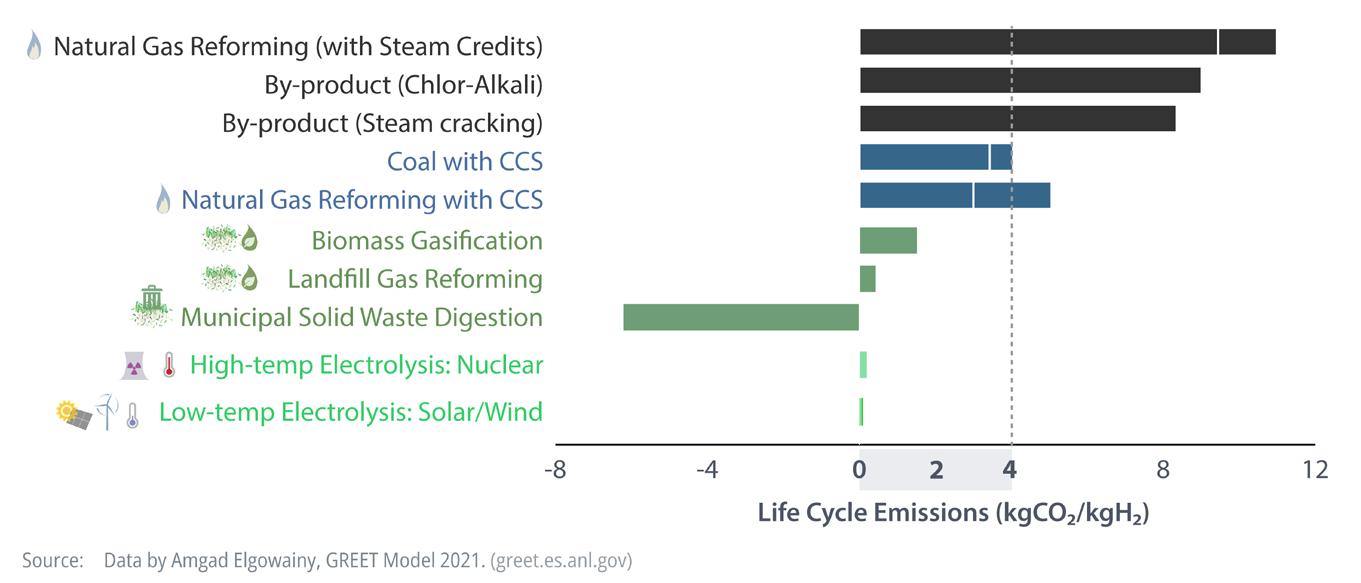

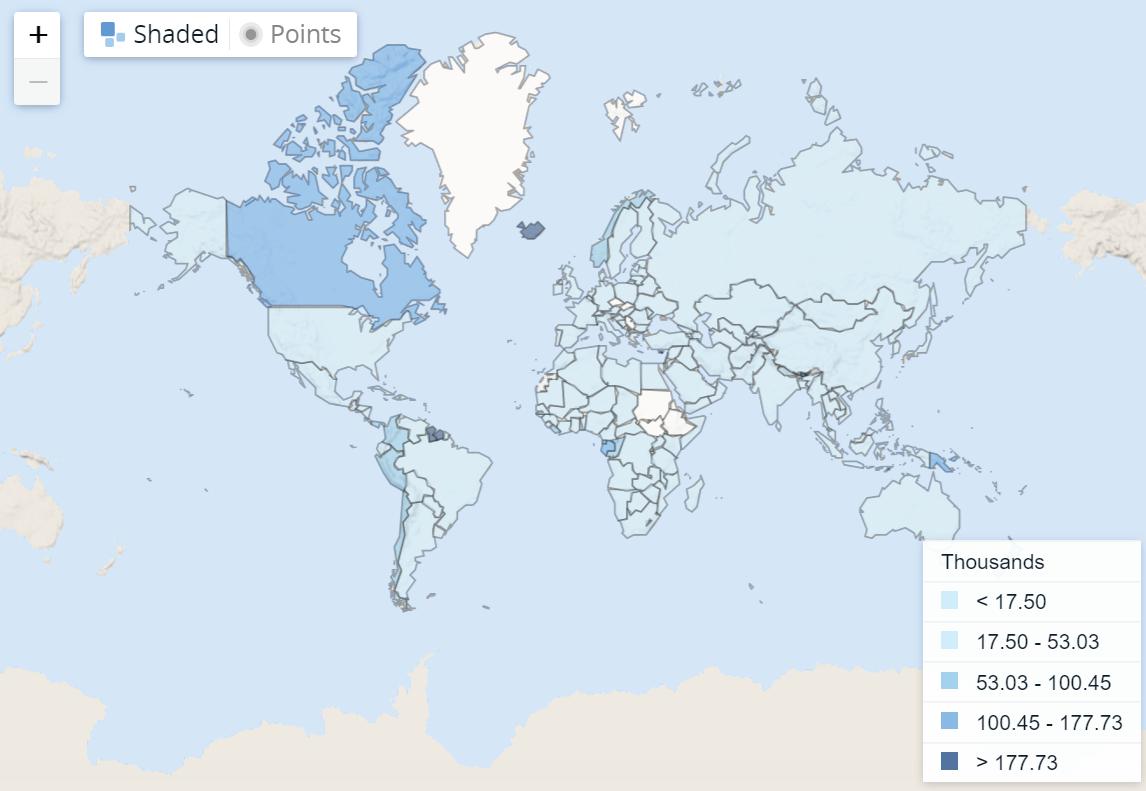

Energy is central to almost every aspect of life and human activity and has historically been dominated by fossil fuels that dramatically impact the climate and the environment. The resulting CO2 constitutes more than 80% of the total greenhouse gas emissions responsible for climate change and the continued warming of our planet (Fig. 1). Climate change is an existential problem. Being cognizant of this imminent danger, ECS recently issued a public statement pledging the commitment of its members to work toward sustainable solutions and advocating science-driven policies to combat climate change.

Pathways to transition into a clean sustainable energy economy pose serious challenges with difficult options. There is no silver bullet, no single recipe. Energy security requires a multi-pronged approach to achieve diversity in sustainable technologies and input sources. However, all technological options present their own advantages and pitfalls. Besides,

energy policies and practices significantly impact the climate, environment, food and water production, and even mass population migrations.

I truly believe that renewable energy represents the clean, sustainable future, and is essential for decarbonizing our energy economy, and in particular, electric power generation. Impressively, renewables have now achieved a global installed capacity of over 2,500 GW that provide more than 25% of the world’s electricity production.1 But there is still a long, winding, and rocky road ahead for full transition to zero-carbon energy. Moreover, most renewables such as solar, wind, marine, and geothermal are un-dispatchable sources (i.e., power that is not always available at the time of demand) with inherently intermittent and variable power outputs, which—without storage—pose challenges for grid management. For renewables to grab the lion’s share in the global electricity mix demands major advances in energy storage materials and technologies as well as upgrades to our electric grid systems.

In that regard, much progress has been made in Li-ion batteries, which have revolutionized portable electronics and transportation. I am proud to note that the impactful work of ECS members has contributed significantly to this remarkable achievement, as recognized by the 2019 Nobel Prize in Chemistry awarded to our longtime members Drs. Whittingham, Goodenough, and Yoshino, and by many ECS awards to our distinguished members. But there is still more needed to further grow renewables and decarbonize the global energy economy.

(continued on next page)

FROM

From the President (continued from previous page)

Clearly, large-scale energy storage is indispensable for renewables and is a critical component of the clean-energy economy. Unfortunately, the world lags far behind in adequate storage capacity, sometimes leading to negative pricing. For example, to store even four hours of the 2,500 GW renewable capacity would require 10,000 GWh of storage. But only 192 GW has so far been installed globally, providing only 800 GWh of storage capacity.2 And only less than four GW of the 192 GW of installed capacity is electrochemical storage, while 95% is made up by pumped-hydro storage that is available only in very select geographic regions. In reality, the shortfall may even be worse, as the US Department of Energy considers 10–12 hours of storage duration as the target for grid applications. Such deficiency in storage also presents an opportunity for ECS members to have dramatic impact.

Naturally, chemical fuels with exceptionally high energy densities (e.g., 33,570 Wh/kg for liquid H2 compared to 380 Wh/kg of theoretical energy density for Li-ion batteries) offer opportunities for long-term and large-scale energy storage and conversion, especially for non-carbon fuels such as green hydrogen and ammonia that yield environmentally benign products. These are all areas of primary interest and expertise of ECS members, where we can continue to make impactful contributions toward sustainable solutions.

Although renewables have recently made impressive gains, fossil fuels continue to provide about 80% of the overall energy needs of the world and nearly two-thirds of our electricity production. In all likelihood, dramatic or disruptive shifts are not expected for the near future. Indeed, the US Energy Information Administration International Energy Outlook 2020 projects that fossil fuels will still be responsible for 68% of the global energy mix in 2050. So, in my view, summarily wishing away fossil fuels would be quite shortsighted. Hence, there is an urgent need to develop advanced fossil fuel–based power technologies that allow total carbon capture to achieve zero-carbon power. We also need to implement and enforce an appropriate “price” for carbon emissions across the globe to incentivize investment in scalable carbon capture technologies. Currently, carbon trading prices are less than 50% of the estimated cost of capturing it, which provides no economic incentive to capture CO2 emissions.

The United Nations Environment Programme 2019 Emissions Gap Report urges a nearly 50% reduction in emissions of greenhouse gases to 25 GtCO2e (i.e., CO2 equivalent) by 2030 to limit the temperature rise to below 1.5oC. This target would have required annual reductions of 7.6% until 2030 if we had started back in 2020, which we did not, and will now require 15.4% annual reductions in emissions to achieve the same goal if action can be taken by 2025. I hope the global community will collectively commit to jump-start dramatic reductions by 2025 during the COP27 meeting in Egypt in November 2022 (shortly after the time of this writing).

In the meantime, energy-related CO2 emissions into the atmosphere have steadily grown to over 36 GtCO2 annually to push CO2 levels above 410 ppmv in the atmosphere. To be sure, capturing 36 gigatons of CO2 every year poses unprecedented industrial challenges. By comparison, the largest industrial capacities the world has built so far are 4.1 Gt/yr for cement production and 1.5 Gt/yr for petrochemicals. Obviously, these capacities are dwarfed by the annual CO2 emissions. Hence, carbon capture under the current status quo will require massive industrial buildup at unprecedented scales.

Based on the global landscape presented above, I posit that we modify our current energy strategy, which is built largely on reducing or eliminating carbon from the input side of energy and electricity production, but with little or no regard to CO2 released into the atmosphere on the output side. I urge equal emphasis be placed on the output side of energy production and that we implement CO2 capture—especially at point sources such as coal- and natural gasfired power plants, and steel and cement manufacturing.

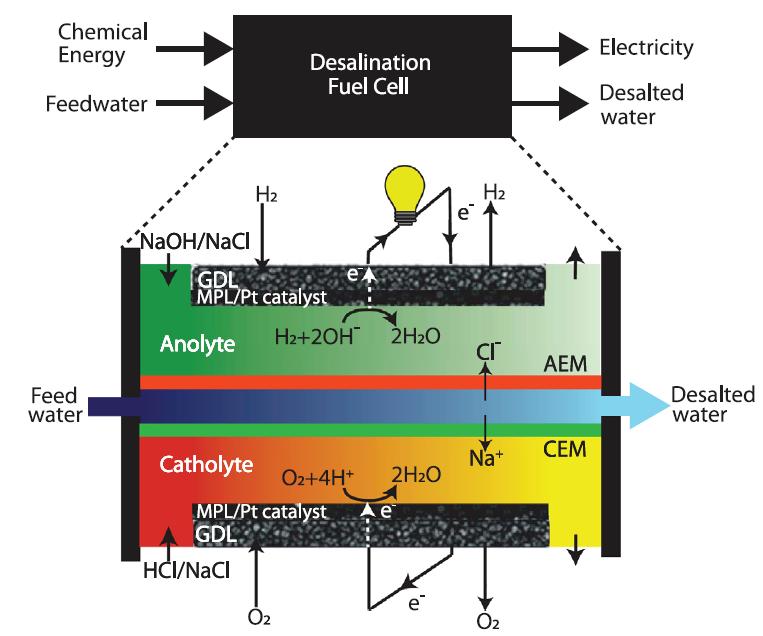

Given that combustion-based technologies with unabated emissions directly impact climate change, I also propose that we rapidly phase out air-based combustion of fossil fuels, and instead transition to oxygen-based conversion processes that negate the need for CO2 separation from flue streams and allow easy capture of CO2. This pathway may allow a smooth transition to achieve net-zero energy. In this regard, fuel cells offer efficient energy conversion and production of electricity from gaseous and solid fuels with full CO2 capture.

Pathways to commercializing energy technologies are typically risky and expensive. Economics frequently plays a decisive role in allocating resources and investments in new concepts toward a clean economy. However, deferred or missed opportunities in new technology concepts and investments may later cost us dearly in other ways. For example, between 2005 and 2019 the climbing cost of natural disasters linked to intensified climate change exceeded a total of $1.16 trillion in the United States alone.3

Although challenges to achieving sustainable energy are complex, I remain hopeful as solutions for such pressing societal challenges can only be guided and accomplished by science and innovation. Hence, the collective expertise and unique abilities of ECS members will be central to advancing sustainable solutions for many of these global grand challenges.

It is also clear that policies to address these pressing issues be built on science. Consequently, one of our responsibilities is to inform and educate the public and public officials to help implement sciencedriven policy decisions. We help accomplish this by publishing only high-quality, peer-reviewed work in our esteemed flagship journals, JES and JSS. Last year, we further expanded our journal portfolio by successfully launching two new titles, ECS Sensors Plus and ECS Advances. I strongly urge our members to support our journals with their high-quality work.

We also initiated collaborative efforts with industry and other professional organizations to develop education and training programs for a much-needed workforce skilled in energy storage technologies and materials, with an initial emphasis on Li-ion batteries. I call upon our members to contribute to such outreach efforts and devise new programs in their areas of expertise that further address global challenges.

In closing, transforming major segments of the global energy economy to clean and sustainable energy solutions requires a multidisciplinary, multi-pronged strategy as well as technological and resource diversity to ensure energy security while tackling climate change and global warming. Clearly, renewables are the cornerstone to achieving a sustainable future, but not without the availability of large-scale storage. In the meantime, transition will also require implementing carbon pricing as well as zero-carbon technologies for fossil fuels. I strongly encourage international collaborations and cooperation among our members to address these major global challenges. With our collective expertise and wisdom, I trust our ECS community will lead the way to further advance science and technology toward a sustainable future.

Turgut M. Gür ECS Presidenthttps://orcid.org/0000-0002-2218-4766

1. International Renewable Energy Agency (IRENA), Statistics Time Series

2. U.S. Department of Energy, DOE Global Energy Storage Database

3. A. B. Smith, “2018’s Billion Dollar Disasters in Context,” NOAA Climate.gov

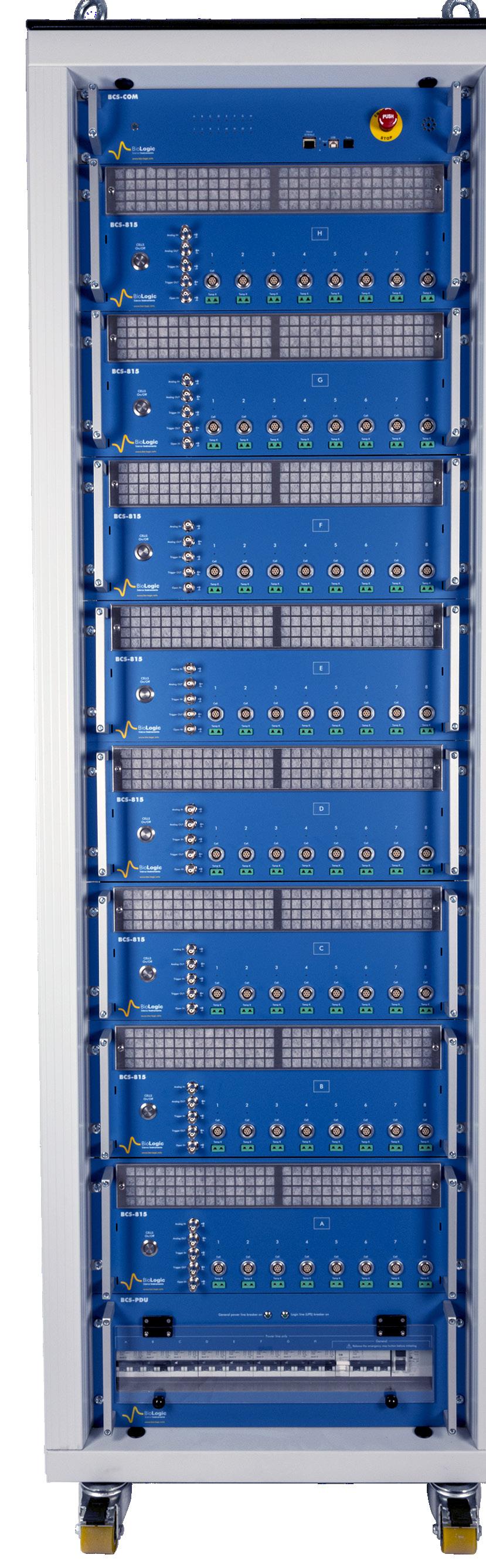

With outstanding resolution and research-grade precision and accuracy, BCS-800 Series battery cyclers stand out for advanced applications including dQ/dV, HPC & EIS.

www.biologic.net

Shaping the future. Together.

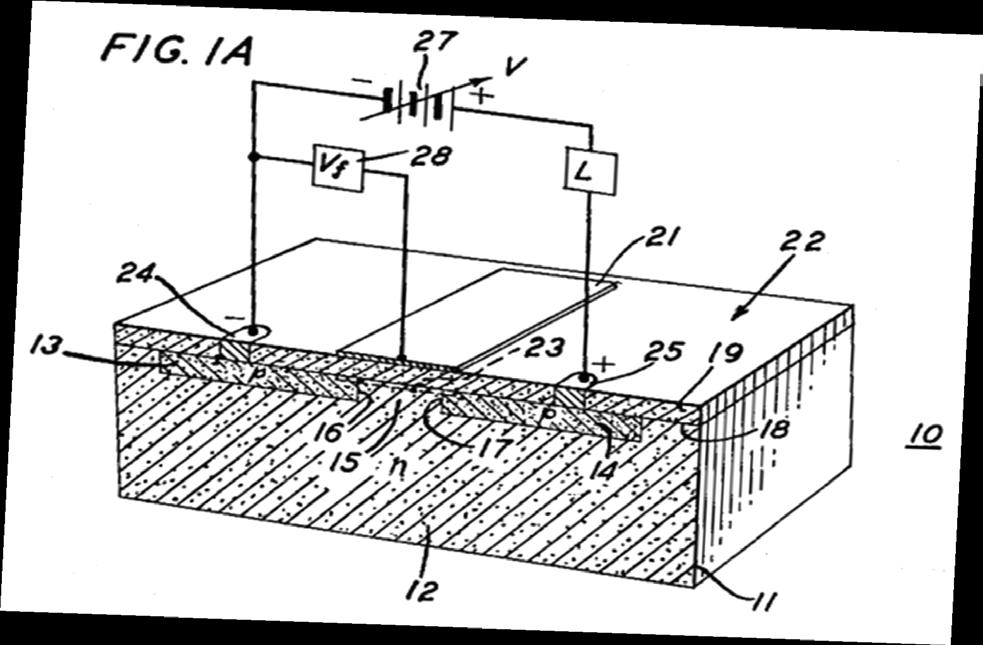

Electrochromic materials (ECM) change color or transparency when an electric field is applied. Over the last 50 years, these materials have been developed for a variety of commercial applications including window coatings, displays, mirrors, and sensors. These applications benefit from color tunability, fast switching times, and low power use due to the memory effect exhibited by many ECM where the color is held without the need for constant power. There are several categories of ECM including conductive polymers, organic transition metal compounds, transitional metal oxides, and Prussian blue-like compounds. [1]

The interaction of materials with light ultimately depends on their population of electrons in energy levels which are influenced by the molecular environment. Electrons may absorb energy from light to jump to higher energy levels and release energy to relax down to a lower energy level. The key point is that the energy absorbed or released is of a fixed value that corresponds to the energy difference between levels. Some wavelengths of light are absorbed while others are not because they do not fit the levels present in the molecular environment. Color, as seen by the human eye, is a result of the wavelengths of light that are not absorbed (i.e. the wavelengths that are transmitted or reflected) by the material. In the case of ECM, the molecular environment is altered when voltage is applied in a way that the absorption characteristics change. ECM are often applied as thin films on transparent materials so the resulting color changes appear as a tint or change in transparency/opacity; such is the case with smart windows. [2]

As there are several categories of ECM, there are also different mechanisms for the color changes that they exhibit. The following examples illustrate some of the molecular changes that occur in common ECM:

Transition metal oxides like tungsten trioxide (WO3) change from pale yellow to intense blue when reduction occurs. An electron is gained and tungsten transitions from WIV to WV, this is accompanied by the intercalation of charge-balancing cations from the electrolyte (M+) or protons (H+).

Prussian Blue is a pigment used extensively in inks and lacquers that exhibits electrochromic behavior. This coordination compound consists of cationic iron centers with anionic cyanide ligands. The iron centers are of mixed valence meaning that the iron in the structure exists as FeIII and FeII. Intervalence charge transfer between FeIII and FeII absorbs orange-red light,

giving rise to the typical blue color. When the majority of iron is in the reduced Fell state this charge transfer process is eliminated and the material is colorless. [3]

Passengers with the window seat traveling on Boeing’s 787 Dreamliner aircraft (image 1) can experience the colorchanging properties of ECM. Window shades have been replaced with dimmable windows that offer several levels of shading. This gives passengers the possibility to watch the view from their windows with their desired level of brightness, as opposed to the binary “open or closed“ window shades. Dimmable windows are also used in modern workspaces to improve the health and productivity of employees by reducing headaches and eyestrain and allowing optimal natural light levels that help workers feel energized [4]. Dimmable windows deliver significant energy and cost savings by blocking solar radiation and thus reducing the need for air conditioning.

Image 1: Electrochromic dimmable windows in the Boeing 787 Dreamliner.

Currently, researchers are investigating ways to derive more sustainability benefits from ECMs through the development of electrochromic energy storage (EES) devices. The EES concept integrates the smart color-switching functionality of ECMs with battery or supercapacitor-based energy storage. Thin-film batteries share structures and characteristics with ECM devices, for example, the intercalation of cations that accompanies color-switching reduction reactions is reminiscent of Li-ion batteries. Energy could be stored within the darkened state of an electrochromic window during the daytime to be used for electricity when the sun goes down [5]. A recent article published in ACS Applied Energy Materials describes an EES system based on nickel-carbonate-hydroxide (NHC) with high optical contrast in the colored/charged state that becomes colorless upon discharge. The NHC film employed has a unique structure made up of a dense underlayer with a porous nanowire surface that enables capacitive charge storage [6].

Evaluation and characterization of ECM is done on the

laboratory scale using a combination of electrochemical and spectroscopic techniques. Since the primary applications for these materials are either displays, or shading/ blocking light, there is a focus on the spectroscopic behavior as well as the visual appearance. When the ECM is used to display information the wavelength for the colored state of the ECM is extremely important. Human eyes are not equally sensitive to all colors, they are most sensitive to green. [1] Thus, ECM used in display applications are tested for the reliability of their coloring. For most applications is it also desirable to have an ECM that can reliably switch from bleached to colored state and back thousands of times; for window glazing the expectation is 40 000 switching cycles and a 20 year lifetime. This criterion is quantified as the cycle life.

For applications where the ECM is used in a large-scale device, the electrical resistance of the ECM and the overall setup is important. On the square-meter scale (i.e. in the case of windows) there can be a significant voltage drop from the electrical contacts and across the device. This can lead to slow or uneven coloration and an increase in the power required to accomplish the color change. Electrochemical impedance spectroscopy is used to predict how resistances within the material and the device will affect performance. [7]

The EES systems mentioned above introduce new evaluation criteria related to the material‘s ability to store charge. In general, the relevant evaluation parameters depend on the intended application for the ECM.[1] Several common parameters are listed and described in Table 1.

Electrochromic devices are already in use in daily life, often going unnoticed. They reduce annoying glare in automobile rearview mirrors, tint office windows, and frost glass panels for privacy in bedrooms and bathrooms. New applications extend beyond comfort and look towards sustainability as electrochromic devices strive to offer energy savings and perhaps even new options for energy storage. The future of electrochromic materials is bright, even when that means being “dim”.

[1] Kraft, A. Electrochromism: a fascinating branch of electrochemistry. ChemTexts. 2019. 5(1), 1-18. doi: 10.1007/s40828-018-0076-x.

[2] Shchegolkov, A.V.; et al. A Brief Overview of Electrochromic Materials and Related Devices: A Nanostructured Materials Perspective. Nanomaterials. 2021, 11, 2376-2408. doi: 10.3390/nano11092376.

[3] Mortimer, R.J. Switching colors with electricity. American Scientist. 2013. 101(1) doi: 10.1511/2013.100.38.

[4] Hedge, A. Daylight and the workplace study https://view.com/sites/default/files/ documents/research-brief-daylight-and-the-workplace.pdf

[5] Yang, P.; et al. Electrochromic energy storage devices. Materials Today. 2016. 19(7) 394-402. doi: 1-.1016/j.mattod.2015.11.007.

[6] Yin, X. Large-scale color-changing thin film energy storage device with high optical contrast and energy storage capacity. ACS Appl. Energy Mater. 2018, 1 1658–1663. doi: 10.1021/acsaem.8b00120

[7] Mohanadas, D. et al. Bifunctional ternary manganese oxide/vanadium oxide/ reduced graphene oxide as electrochromic asymmetric supercapacitor. Ceramics International. 2021, 47(24) 34529-34537. doi: 10.1016/j.ceramint.2021.08.368.

[8] Hassab, S. et al. A new standard method to calculate electrochromic switching time. Sol. Energy. 2018, 185 54-60. doi: 10.1016/j.solmat.2018.04.031.

[9] Lampert, C. et al. Durability evaluation of electrochromic devices – an industry perspective. Sol. Energy. 1999, 56 449-463. doi: 10.1016/S0927-0248(98)00185-8.

[10] Liu, Q. et al. Charge-transfer kinetics and cyclic properties of inorganic all-solid-state electrochromic device with remarkably improved optical memory. Sol. Energy, 2018. 174 545-553. Doi: 10.1016/jsol.mat.2017.09.012.

Coloration efficiency (CE)

Contrast ratio (CR)

The ratio of the change in optical density (OD) at a specified wavelength to the charge (Q) passed. Ideally, the CE is high corresponding to a large color contrast for little charge input. The CE value indicates the power consumption levels for the electrochromic device.

The ratio of light transmission (TM) in the bleached state to the TM in the colored state, at a specified wavelength. Ideally, the CR is high at wavelengths (λ) relevant to the application.

The transmission response at a fixed wavelength is measured in the colored and bleached states to determine the OD. Simultaneously, the charge (Q) passed during color switching is measured.

The transmission response at the wavelength of interest is monitored in the colored and bleached states to calculate the CR.

[1]

[1]

Switching time

Quantification of the time required to switch between colored and bleached states. This parameter is heavily influenced by the nature of the ECM and also by the test setup. The switching time measured at the laboratory scale may not be representative of the device in a large area (i.e. m2) application.

Cycle life Durability assessment of the ECM and device over typical lifetime conditions. Significant changes in switching speed, light transmission, visual appearance (i.e. inhomogeneity) throughout the lifetime test indicate that the device may not have acceptable performance in the target application.

Open circuit optical memory

Table 1:

Measurement of the device’s ability to maintain a defined state (i.e. colored or bleached) without applied power. Generally, the ECM will spontaneously bleach over time due to leakage currents or thermal changes. Having a high optical memory is desirable because this translates to low power consumption.

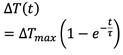

The transmission response at a fixed wavelength is monitored during applied potential pulses with varied pulse lengths. A plot of contrast vs. pulse length is modeled with the first-order differential equation to determine τ and ΔTmax

Performance parameters (i.e. contrast ratio, switching time), and visual appearance are monitored during an accelerated aging test protocol that involves subjecting the device to thousands of switching cycles in variable conditions (temperature, light exposure, humidity)

The desired state (generally colored or darkened) is applied and the power source is then removed (the system is put to open circuit conditions). Transmission and open circuit potential are monitored over time.

[1.8]

[1.9]

Parameters used for characterization and evaluation of electrochromic materials and devices.

Biographical sketches and candidacy statements of the nominated candidates for the annual election of ECS officers.

Gerardine (Gerri) Botte is Professor and the Whitacre Chair in Chemical Engineering at Texas Tech University (TTU), and the Founding Director of the National Science Foundation Engineering Research Center for Advancing Sustainable and Distributed Fertilizer Production (CASFER). A visionary and recognized leader in electrochemical science and technology, she has over 24 years of experience in the fundamental understanding and development of electrochemical processes as they relate to the intersection of energy, water, and food sustainability. In 2014, she was named Fellow of The Electrochemical Society for her contributions and innovation in electrochemical processes and engineering. Prior to TTU, Botte was University Distinguished Professor (lifetime award) and Russ Professor of Chemical and Biomolecular Engineering at Ohio University, Founder and Director of the Center for Electrochemical Engineering Research, and Founder and Director of the National Science Foundation Consortium for Electrochemical Processes and Technology—an Industry University Cooperative Research Center. She has 207 publications including 61 granted patents. An entrepreneur, Botte has been involved in the commercialization of technologies, and founded and co-founded companies. She received her PhD in 2000 (under Ralph White’s direction) and ME in 1998, both in Chemical Engineering from the University of South Carolina. Prior to graduate school, Botte worked in a petrochemical plant as a process engineer involved in the production of fertilizers and polymers. Botte completed a BS in Chemical Engineering at the Universidad de Carabobo (Venezuela) in 1994.

An active ECS member since 1998, Botte has served in leadership roles that include member of the Board of Directors and Executive Committee; Chair, ECS Industrial Electrochemistry and Electrochemical Engineering (IEEE) Division; and member, Interdisciplinary Science and Technology Subcommittee, Honors and Awards Committee, and ECS Fellows Award Committee. She has contributed articles to Interface, organized and co-organized nine Society symposia, and co-edited the corresponding ECS Transactions volumes,

Vimal Chaitanya is currently Professor and Director of Manufacturing Systems and Research Programs at New Mexico State University (NMSU). Previously, he served as the Vice President for Research (VPR) of NMSU for over 10 years. As VPR, he was responsible for the university’s entire research enterprise. The average yearly R&D expenditure for externally sponsored research was $142 million during his tenure as VPR. About 250 faculty and staff reported to him directly or indirectly. Prior to becoming VPR at NMSU, he founded and directed a state recognized center of excellence at University of Central Florida (UCF) with its own faculty lines and budget. He also developed and implemented dedicated MS and PhD programs in materials science and engineering.

Dr. Chaitanya has over 40 years of experience in research, which includes corrosion, hot corrosion, oxidation, solid state device processing, chemical mechanical planarization, additive manufacturing, and the food-energy-water nexus. As a faculty member, he has mentored many undergraduate and about 30 graduate students. He has received the Researcher of the Year Award five times, Teaching Award twice, UCF Leadership Award (1999), UCF Excellence in Professional Service Award (2002), and NMSU Synergy Faculty Leadership Award (2022).

As a student, he attended his first ECS meeting in 1982 and started contributing as a young faculty member with his students from 1986. He has been a regular attendee and member of ECS since 1994. Over the years, he has served on the Education Committee, Awards and Honors Committee, and Nomination Committee, while chairing various sub-committees, notably the ECS Summer Fellowship Subcommittee. He also served as lead organizer of the General Student Poster Session for several years and as organizer of various symposia. He has served in the ECS Dielectric Science and Technology Division as Chair and as a member of the ECS Board of Directors.

I am honored to be nominated as a candidate for the 3rd Vice President of The Electrochemical Society. If elected, I look forward to serving the interests of the Society and its members. Today, we

Francis D’Souza is currently Regents Professor of Chemistry and Materials Science and Engineering at the University of North Texas (UNT) and is also part of UNT’s Applied Materials and Manufacturing Processing Institute. Prior to joining UNT in 2011, he was Professor of Chemistry at Wichita State University (WSU). He received a PhD from the Indian Institute of Science, and held postdoctoral positions at the University of Houston and the Université de Bourgogne.

Dr. D’Souza’s research covers a wide area of chemistry, nanophotonics, electrochemistry, and materials science. Principal research interests include supra and nanomolecular chemistry of photosensitizercarbon nanomaterials, advanced functional materials for light energy harvesting and photovoltaics, electrochemical and photochemical sensors and catalysts, and nanocomposite hybrid materials for energy storage and utilization. Dr. D’Souza has authored or co-authored over 475 publications, given over 400 conference talks, and edited 10 Handbooks on Carbon Nanomaterials, resulting in over 21,000 citations with a cumulative h-index of 74.

Honors and awards include Fellow of The Electrochemistry Society, Fellow of the Royal Society of Chemistry, Fulbright Specialist Scholar, ACS-DFW Section Doherty Research Award, Chemical Research Society of India Medal, UNTResearch Leadership Award, UNT-Regents Professor, UNT-Toulouse Scholar Award, GIAN Fellow of Government of India, UNTDistinguished Professor, Japan Society for the Promotion of Science Fellow, and WSU Excellence in Research Award.

As an active member of The Electrochemical Society since 1993, Dr. D’Souza has served ECS at a number of levels. He was a member of the ECS Board of Directors from 2004 to 2008. He previously served as Chair, Vice Chair, Secretary, and Treasurer of the ECS Nanocarbon Division and is currently a Member at Large of that division. As Chair of the ECS Nanocarbon Division, he was instrumental in establishing and securing endowments for both the Smalley Research Award and the Young Investigator Awards. He continues to serve either as chair or member of several Society-level committees, including the Honors and Awards Committee, the Meeting Subcommittee, and the Fellow

(continued from previous page)

among others. She started the ECS IE&EE Division Outreach Program. Its first activity took place at the 210th ECS Meeting in Cancun in 2006; since then, it has taken place 16 times with at least 847 participants at different ECS meetings.

One of the things that makes me most excited about electrochemical and solid state science and technology is that it is a core platform with applications in different aspects of our lives. While exciting, there is still a lag in education about what electrochemical technologies can do. I believe that ECS, being the premier solid state and electrochemical science and technology society in the world, will lead a paradigm change mitigating this education gap while enabling sustainable education in the field. If elected, I will lead ECS to expand into programs that explain to different audiences the importance and fundamental principles of electrochemistry. For example, programs targeted to the next generation of scholars (STEM), industry, policy makers, and investors. We could find opportunities for all this during the biannual meetings. Outreach programs can become a continuous event in our biannual meetings to attract the next generation to electrochemical science. Such programs could include our ECS Student Chapters. Forums and sessions that discuss commercialization aspects of electrochemical-based technologies can become part of our programs and help reach out to funding agencies, policy makers, and investors. I will help facilitate joint collaborations between ECS, federal funding agencies, and industry to organize and sponsor symposia on topics regarding frontiers and opportunities for electrochemical technologies.

I am fully committed to, and supportive of, the ECS Free the Science effort. If elected, I will work with ECS and members to raise the resources to minimize the cost burden of open access. It is important to continue attracting young authors to submit their best papers to our journals and to support rising stars in electrochemical and solid state science. If elected, I will help generate resources to increase the number of awards for young authors. In addition, I think it is essential to consider dissemination of knowledge to attract the next generation and to engage industrial and policy makers. In that respect, education-based apps can play a significant role. I will seek partnerships with our members and industrial sponsors to develop such opportunities.

I applaud the ECS Diversity Statement. The symposium on diversity and inclusion at the 236th ECS Meeting in Atlanta is an example of many other initiatives that can

continue. I will lead ECS to implement best practices in diversity and inclusion and seek collaboration with other professional organizations to support these efforts.

ECS is an integral part of my professional career. It is my family, where I have been accepted and welcomed since I was a student, and where I interact with many distinguished scientists from all over the world who today are my peers and friends. It is an honor to be nominated for this position and I look forward to growing the ECS family and serving all of you.

Vimal Chaitanya (continued from previous page)face global challenges and opportunities in areas such as the water-energy nexus, solid state device design and fabrication, green manufacturing, material performance in harsh environments, etc. With its multiple divisions, global footprint, and talented membership, The Electrochemical Society is poised to contribute significantly. ECS has a history of shaping the future of science and scientists, and I will continue this legacy by following the footsteps of our visionary leadership and invest in it.

There is no better way to invest in the future of science and technology than to invest in the students, postdocs, and young scientists. If elected, I will bring my 20 years of administrative experience, zeal for research, and enthusiasm for STEM education to bear on the success of engaging young as well as budding scientists with our “member-driven” society. I will also work to create more opportunity for industries and industrial members to get directly involved with our academic researchers to create research and education frontiers that address the critical needs. In this equation, participation of federal funding agencies is important. If elected, I will seek to create forums for the participation of funding agencies in our meetings. I believe The Electrochemical Society can play a pioneering role in bringing all the stakeholders together to identify and resolve research challenges, develop an educated workforce, and work toward building a sustainable ecosystem.

COVID-19 pandemic has changed our perspective and challenged the way we do business. We learned to effectively communicate with each other, teach, and even perform experimental research remotely. ECS responded to the COVID challenge by hosting online and hybrid meetings, which broke all previous records for meeting participation. Various ECS committees continued their work unhindered through online meetings and digital media. This would not have been possible without the commitment of ECS membership and the dedication of ECS staff. I will work tirelessly

to search for and help implement practices in the new era which serve our needs.

I can adequately represent both wet electrochemistry and solid state sciences, having worked in both areas. I have the experience of working with faculty researchers from various disciplines to create opportunities and develop partnerships with industries and federal labs. I will work with all divisions, local sections, student chapters, and corporate affiliate members to develop programs and forums that can be locally disseminated to the public to bring awareness of the importance of electrochemistry and solid state sciences in daily life and create interest among the younger generations to pursue their education and careers in this field.

Finally, as a vice president of ECS, I will be committed to work together with all members, elected officers, and professional staff to identify and implement initiatives for sustained growth of ECS and to enable ECS members to reach their professional goals.

D’SouzaSubcommittee, as well as the Acheson, Bard, Callinan, Haddon, Smalley, and Wagner Award Subcommittees. To date, he has coorganized over 40 symposia for the fall and spring biannual meetings of the Society.

Dr. D’Souza has also served for the last 10 years as Technical and Associate Editor of the ECS Journal of Solid State Science and Technology.

It is my great honor to be one of the two candidates for the 3rd Vice President of The Electrochemical Society. Electrochemical science and technology now play a vital role in our modern life, several examples of which are in the production of renewable energy, energy storage, corrosion prevention, pollution control, sensors and biosensors, and greenhouse gas reduction, to name a few. Electrochemical science is also at the forefront of large-scale solutions to meet the challenges of climate change and global warming. If elected to a leadership role in ECS, my mission will be to establish stronger collaborative relationships among scientific communities, promote young scientists, help develop clean energy technologies, and bridge the gap between academia, industry, and policymakers, while also promoting equity, diversity, and inclusion at every level of the Society. I will continue to serve ECS and its members constructively, collaboratively, and respectfully, and look forward to the possibility of doing so in a higher leadership role in the future.

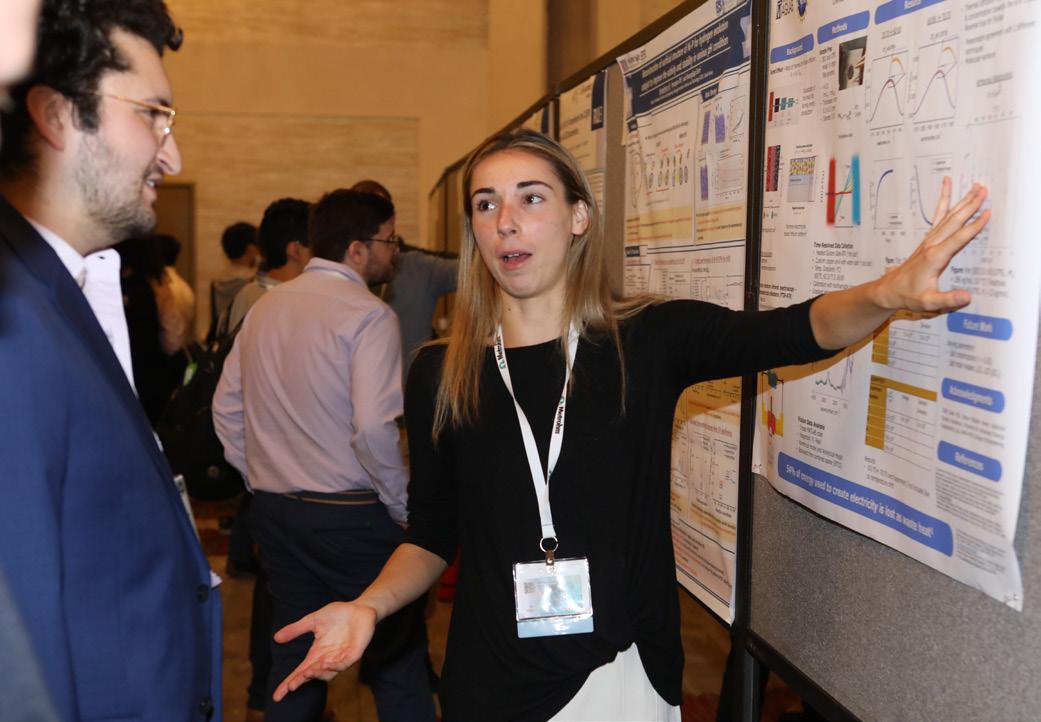

From October 9 to 13, 2022, the 242nd ECS Meeting—the Society’s second in-person and online meeting—convened in Atlanta, GA, with 2,619 participants (2,588 registrants and 31 non-technical guests) from 65 countries. The meeting encompassed 48 symposia with 441 sessions. A total of 2,628 abstracts were accepted with 1,869 oral talks, 616 posters, and 312 digital presentations, including 430 invited talks and 35 ECS award and keynote talks. Students presented 1,092 abstracts, with 762 oral talks and 366 posters. Digital content was uploaded by 269 digital presenters and included 312 digital presentation files, of which 109 were digital student presentations. (Recordings of the ECS Awards and Recognition Ceremony and Plenary Presentation are available on the ECS YouTube Channel at https://www.youtube.com/user/ ECS1902.)

More than 500 members came together at the second ECS Members Reception which preceded the Opening Ceremony on Sunday evening. Colleagues and new peers networked while enjoying a raffle, food, and open bar. Several members received prize giveaways as part of attending:

• Yudong Wang, University of Louisiana at Lafayette – ECS Lifetime Membership

• Marc Bertrand, Université de Montréal – $250 Amazon Gift Card

• Elsa Briqueleur, Université de Montréal – $250 Amazon Gift Card

•

The event was a success and will be part of the 243rd ECS Meeting in Boston, MA.

this was only the second in-person ECS Awards and Recognition Ceremony since 2019, Turgut explained that award winners from previous years would be acknowledged as well as 2022 award winners.

Turgut presented the 2022 Leadership Circle Award to Duracell Corporation (represented by Dan Gibbons, Principal Engineer and Research Fellow) for their 65 years of institutional membership and dedication to ECS.

Next, Turgut awarded the 2021 Norman Hackerman Young Author Award to Philip Minnmann and Simon Burkhardt from Justus Liebig Universität, Giessen-Institute of Physical Chemistry, for their JES article, “Quantifying the Impact of Charge Transport Bottlenecks in Composite Cathodes of All-Solid-State Batteries.” The award is for the best paper published in the Journal of The Electrochemical Society by a young author or co-authors in the preceding volume year.

Following introductory remarks, Turgut opened the Awards and Recognition Ceremony to celebrate the achievements of today’s greatest researchers in electrochemistry and solid state science. As

The 2021 Bruce Deal & Andy Grove Award for outstanding work published by a young author in JSS went to Franz Selbmann from the FraunhoferInstitute, for his paper, “LowTemperature Parylene-Based Adhesive Bonding Technology for 150 and 200 mm Wafers for Fully Biocompatible and Highly Reliable Microsystems.”

Turgut invited ECS Senior Vice President Gerardine (Gerri) Botte to recognize the next recipients. She thanked division chairs whose terms had ended for their dedicated service:

• Stanko Brankovic, Electrodeposition Division, 2017–2019

• Masayuki Itagaki, Corrosion Division, 2018–2020

• Petr Vanysek, Physical and Analytical Electrochemistry Division, 2019–2021

• Philippe Vereecken, Electrodeposition Division, 2019–2021

• Jakoah Brgoch, Luminescence and Display Materials Division, 2019–2021

Gerri then thanked Gessie Brisard, ECS Treasurer from 2018 to 2022, for her inspired stewardship of ECS’s finances, and 2021–2022 ECS President Eric Wachsman for his visionary leadership and for helping the Society emerge from the COVID-19 shutdown to better days ahead.

Gerri welcomed multiple years of new Fellows of The Electrochemical Society, starting with the members of the Class of 2020 present at the meeting:

• Rodney Borup, for seminal contributions to the understanding of polymer electrolyte fuel cell durability.

• Andrew Herring, for creative contributions to the science and technology of polymer electrolyte membranes.

• Stefano Passerini, in recognition of his outstanding contributions to the field of electrochemical energy storage.

• Venkataraman Thangadurai, for major contributions to the development of highly conductive solid electrolytes

• Jie Xiao, for her scientific and technical contributions in emerging electrochemical energy storage.

• Gleb Yushin, for his development and mass commercialization of low surface area size-preserving nanocomposites.

She then introduced the members of the 2021 Class of Fellows present at the meeting:

• Anja Boisen for her groundbreaking, impactful, and pioneering contributions to the field of nanomechanical sensors, and for being a role model who inspires women around the world.

• Stanko Brankovic for fundamental contributions to electrochemical material science.

• Douglas Hansen in recognition of distinguished contributions to the advancement of corrosion, biochemical, and electrochemical sciences and engineering.

• Jagjit Nanda for pioneering work on solid state batteries, Liion batteries, flow batteries, and service to the Society.

• Xiao-Dong Zhou for outstanding scientific and technological contributions to fuel cells, electrolyzers, and batteries, and for his dedicated service to the Society.

Gerri ended by recognizing the 2022 Class of Fellows:

• Michel Armand in recognition of his pioneering and outstanding contributions to the field of electrochemical energy storage.

• Perla Balbuena for contributions to the understanding of electron and ion transport mechanisms driving the formation of solid-electrolyte interphases.

• Gerbrand Ceder for pioneering work on designing and understanding battery materials using first principles computational modeling.

• Wilson Chiu for his contributions to fundamental understanding of 3D electrochemical and transport processes.

• Andrew Hoff in recognition of contributions to the advancement of science and technology in the areas of solid state electronics and bioengineering.

• Gao Liu for contributions to the fundamental understanding of the functions of the polymer binder in composite electrodes.

• Brett Lucht for outstanding contributions to the research and development of non-aqueous electrolytes for electrochemical storage devices.

• Janine Mauzeroll for the development of next generation electroanalytical tools for biological and corrosion research. (continued on next page)

(continued from previous page)

• Nguyen Minh for his impactful contributions to materials engineering, design, manufacturing processes, and systems.

• Deborah Myers for impactful and sustained contributions to electrochemistry and electrocatalysis.

• James Noël for impactful and sustained contributions in the areas of materials and corrosion science.

• Elizabeth Podlaha-Murphy for her seminal contributions in understanding the electrodeposition processes of alloy and composite materials.

• Vijay Ramani for fundamental and applied research contributions at the interface of electrochemical energy conversion and storage and materials science.

• Yasuhiro Shimizu for his groundbreaking, impactful, and pioneering contributions to the field of semiconductor gas sensors.

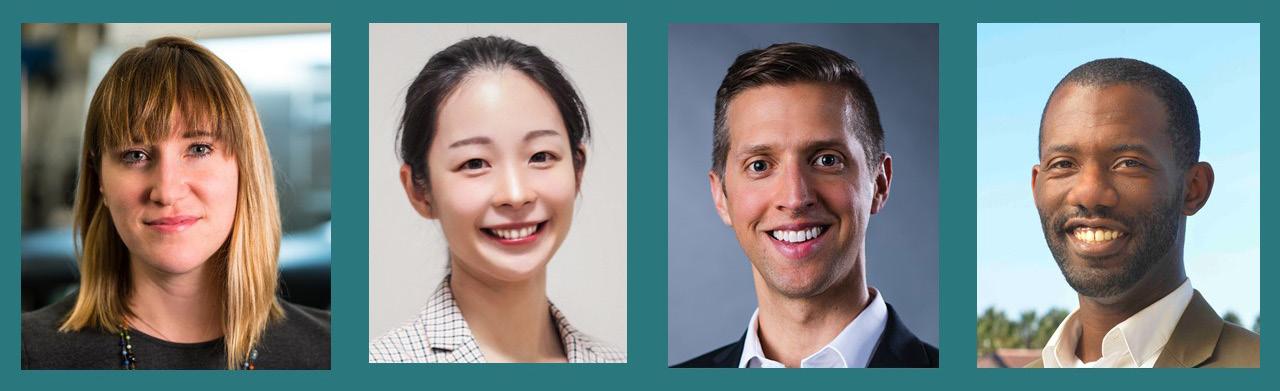

Turgut thanked Gerri and announced the 2022-2023 ECS Toyota Young Investigator Fellowship recipients. Each Young Investigator Fellow receives a one-year, $50,000 grant to pursue research in batteries, fuel cells and hydrogen, and future sustainable technologies. With this year’s recipients, we celebrate that the ECSToyota partnership has now provided over $1.4 million of support for young professionals and scholars! He noted that applications for the next Young Investigator Fellowships are due by January 31, 2023. The 2022-2023 ECS Toyota Young Investigator Fellows present their research at the 244th ECS Meeting in Gothenburg, Sweden, in October 2023. They are:

• Betar M. Gallant, Massachusetts Institute of Technology

• Yayuan Liu, Johns Hopkins University

• Jacob S. Spendelow, Los Alamos National Laboratory

• William Tarpeh, Stanford University

Turgut introduced the winners of the 2020 and 2022 Charles W. Tobias Young Investigator Awards which recognize outstanding scientific and/or engineering work in fundamental or applied electrochemistry or solid state science and technology by a young scientist or engineer. Bryan McCloskey, University of California, Berkeley, received the 2020 award for quantitative insights into oxygen activity and degradation mechanisms in high-energy batteries. He presented his award talk, “Understanding Reactivity at Electrode-Electrolyte Interfaces in Li-O2 and Li-ion Batteries” at the digital PRiME meeting in October 2020. The 2022 recipient is Fikile Brushett, Massachusetts Institute of Technology, for pioneering advances in understanding and controlling the fundamental processes that govern performance, cost, and lifetime of the next generation of flow electrochemical systems for energy storage and conversion. He presented his award talk, “Advancing Porous Electrodes for Electrochemical Systems” at the meeting.

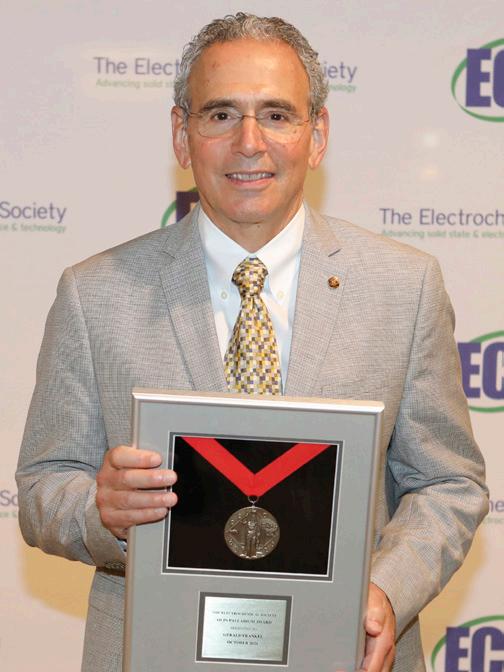

Turgut presented the 2021 Olin Palladium Award to Gerald Frankel, The Ohio State University, for sustained and seminal contributions in corrosion science. Prof. Frankel presented his talk, “Pitting Corrosion Retrospective” at the digital 240th ECS Meeting in October 2021.

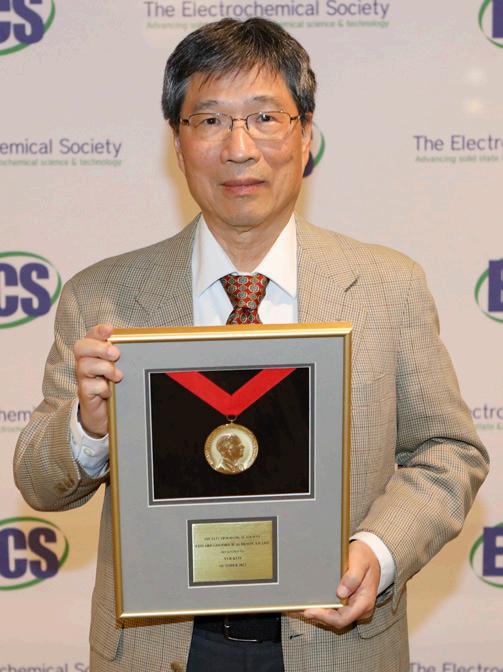

Two winners of the Edward Goodrich Acheson Award were honored. Esther Takeuchi, Stony Brook University, received the 2020 Acheson Award for inventive contributions to the Li/SVO battery, an enabling electrochemical technology discovery which has saved millions of human lives. Prof. Takeuchi presented her award talk, “Investigation of Batteries over Multiple and Length and Time Scales”, at the 240th ECS Meeting in October 2021. The 2022 Acheson Award was presented to Yue Kuo of Texas A&M, for exceptional contributions to solid state science and technology, and for outstanding service to The Electrochemical Society. Prof. Kuo delivered his award talk, “Exploration of Amorphous Thin Film Electronics,” at the meeting.

Winners of the 242nd ECS Meeting Z01 General Student Poster Session Awards, as well as Society, division, and section awards, were recognized throughout the course of the meeting, including some from years when in-person meetings were not held. These 2022 division awards were given at the meeting:

• Battery Division Early Career Award Sponsored by Neware Technology Limited: Feng Lin, Virginia Tech

• Battery Division Postdoctoral Associate Research Award Sponsored by MTI Corporation and the Jiang Family Foundation: Paul Coman, University of South Carolina

• Battery Division Postdoctoral Associate Research Award Sponsored by MTI Corporation and the Jiang Family Foundation: Alexis Maurel, University of Texas at El Paso

• Battery Division Research Award: Bor Yann Liaw, Idaho National Laboratory

• Battery Division Research Award: Atsuo Yamada, University of Tokyo

• Battery Division Student Research Award Sponsored by Mercedes-Benz Research & Development: Singyuk Hou, University of Maryland, College Park

• Battery Division Student Research Award Sponsored by Mercedes-Benz Research & Development: John Holoubek, University of California, San Diego

• Corrosion Division H. H. Uhlig Award: Mark Orazem, University of Florida

• Corrosion Division Morris Cohen Graduate Student Award: Mariko Kadowaki, National Institute for Materials Science

• Corrosion Division Rusty Award for Mid-Career Excellence: David Bastidas, The University of Akron

• Electrodeposition Division Early Career Investigator Award: Fudong Han, Rensselaer Polytechnic Institute

• Electrodeposition Division Research Award: Nikolay Dimitrov, Binghamton University (SUNY)

• Energy Technology Division Walter Van Schalkwijk Award in Sustainable Energy Technology: Katherine Ayers, Nel Hydrogen US

• High Temperature Materials Division J. B. Wagner, Jr. Young Investigator Award: Liangbing Hu, University of Maryland, College Park

• High Temperature Materials Division Outstanding Achievement Award: Scott A. Barnett, Northwestern University

• Industrial Electrochemistry and Electrochemical Engineering Division H. H. Dow Memorial Student Achievement Award: Arghya Patra, University of Illinois Urbana-Champaign

• Luminescence and Display Materials Division Outstanding Achievement Award: Kailash Mishra, OSRAM Sylvania Lighting Research Center (retired)

• Physical and Analytical Electrochemistry Division Max Bredig Award in Molten Salt and Ionic Liquid Chemistry: Tom Welton, Imperial College London

• Sensor Division Outstanding Achievement Award: Anja Boisen, Danmarks Tekniske Universitet

• Section awards from 2021 and 2022 were given at the meeting:

• 2022 Europe Section Alessandro Volta Medal: Jerry Barker, Faradion Limited

• 2022 Europe Section Alessandro Volta Medal: Stefano Passerini, Helmholtz Institute Ulm

• 2021 Europe Section Heinz Gerischer Award: D. Noel Buckley, University of Limerick

Christopher Jannuzzi, ECS CEO and Executive Director, provided the meeting’s introductory remarks. He welcomed event participants in Atlanta and those participating via video stream. Chris gave an overview of the week ahead and thanked symposia sponsors and exhibitors, meeting attendees, digital participants, volunteers, and staff. Chris noted the critical support that divisions and sections provide to students and early career attendees through their travel funding programs.

Turgut Gür, ECS President, took the floor and welcomed attendees and participants to the second in-person meeting since the pandemic. He described the unprecedented challenges facing the world that ECS members are playing a significant role in combatting, especially in the area of the climate change crisis. Turgut announced the board’s recent approval of the ECS Statement on Climate Change With this statement, ECS pledges to advocate for integrating science

in the implementation of effective strategies and sustainable solutions to battle climate change.

Turgut introduced the speaker delivering the 242nd ECS Meeting Lecture, M. Stanley Whittington, Distinguished Professor of Chemistry at the University of Binghamton of the State University of New York. Just before appearing at the last ECS meeting in Atlanta, Stanley learned that he, John Goodenough, and Akira Yoshino had received the 2019 Nobel Prize in Chemistry for the development of lithium-ion batteries. Turgut said how lucky we were to celebrate Stanley’s award with him at that meeting. He then stressed how much had happened in the world since that meeting, most of which underscores just how critical Stanley’s work is today, and will be for the foreseeable future and beyond.

Prof. Whittingham presented “The Critical Role of Energy Storage in the Electric Economy and Overcoming Climate Change” to a rapt audience. After a discussion of the history of the development of electric transportation and the Li-ion battery, he described the need for researchers to find new materials to make the next generation batteries that are lower cost, have a stronger domestic supply chain, and are safer. Prof. Whittingham reviewed some of the recent research trends that address these challenges. A Q&A session moderated by Jie Xiao followed the talk.

Jie

(continued from previous page)

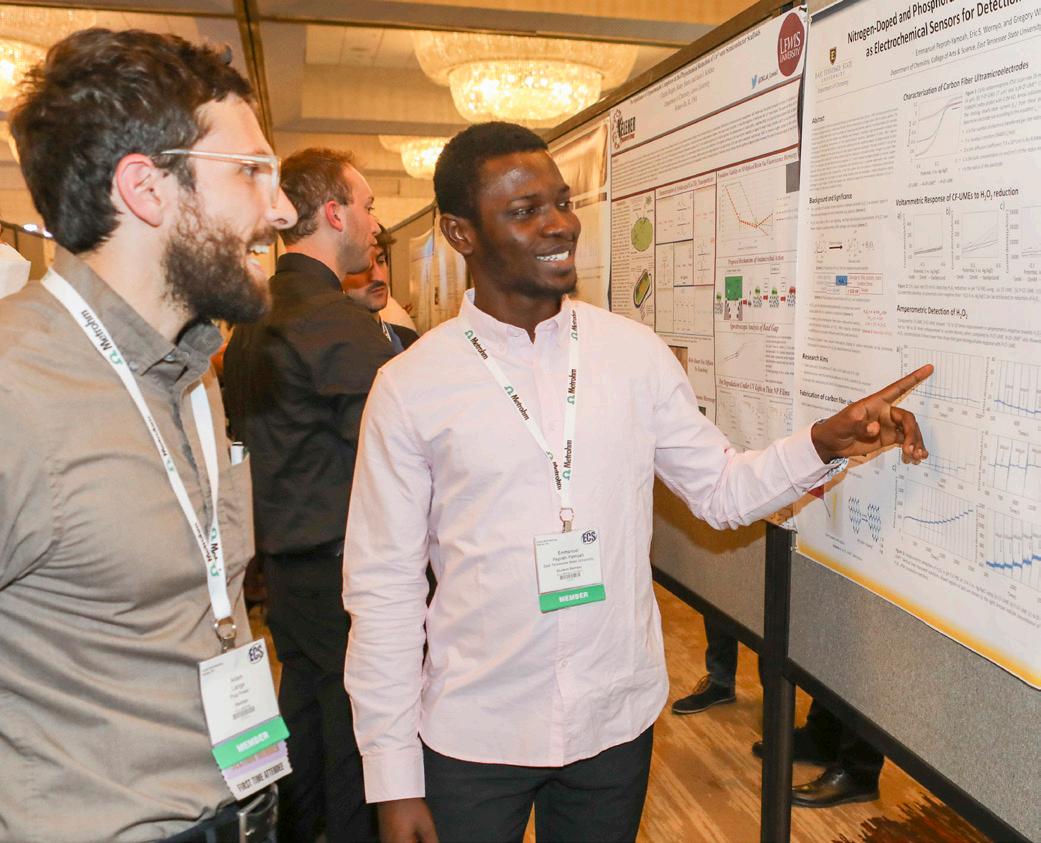

The Z01 General Student Poster Session presented 112 posters in person and digitally. The following won awards:

1st Place: $1,500 cash award

Emmanuel Peprah-Yamoah, East Tennessee State University Z01-2392 “Nitrogen-Doped and Phosphorus-Doped Carbon Fiber Ultramicroelectrodes As Electrochemical Sensors for Detection of Hydrogen Peroxide”

2nd Place: $1,000 cash award

Ashley Amalia David, Florida State University Z01-2380 “Analyzing the Soret Coefficient Using Time Resolved Fourier Transform Infrared Spectroscopy (FTIR)”

Thank you to the judges of the 242nd ECS Meeting Z01 General Student Poster Session.

In person:

• Stefan De Gendt, KU Leuven

• Uroš Cvelbar, Jozef Stefan Institute

• Jason Keleher, Lewis University

• John Staser, The Ohio State University

Virtual judges:

• David Hall, University of Cambridge

• Leah Rynearson, University of Rhode Island

• Bhuvana Vukkum, North Carolina State University

• Thad Druffel, University of Louisville

• William Mustain, University of South Carolina

• Sadman Sakib, McMaster University

Lucky visitors to the ECS Exhibit Booth won raffle prizes:

• ECS Lifetime Membership: Jiseon Choi, Korea Institute of Machinery & Materials

• Complimentary 2023 ECS Biannual Meeting Registration: Samantha Gateman, Western University

• ECS Monograph, LaQue’s Handbook on Marine Corrosion, 2nd Edition: Maitri Uppaluri, University of Texas at Austin

• 242nd ECS Meeting Exhibitor Raffle Basket: Current Chemicals

ECS extends its deepest gratitude to the general meeting sponsors for generously supporting the 242nd ECS Meeting. Thank you to the meeting symposia sponsors and exhibitors, whose support and participation contributed directly to the success of the meeting, for developing the tools and equipment driving scientific advancement, and for sharing your innovations with the electrochemical and solid state communities.

Meeting exhibitors displayed their products and services in the Exhibit Hall and Digital Exhibitor and Vendor Guide (DEVguide). Viewers can scan the latest electrochemistry and solid state science products with ease as the DEVguide navigates seamlessly on any platform.

SILVER

• American Elements

• Comsol, Inc.

• Metrohm USA, Inc.

• Pine Research Instrumentation

• Wildcat Discovery Technologies

BRONZE

• SK on

Almost 300 students and early-career professionals mingled in a relaxed setting and enjoyed light hors d’oeuvres and refreshments at the Student Mixer. Pine Research Instrumentation and Wildcat Discover Technologies sponsored the event.

•

•

• Gelest

• Case Western Reserve University (Case School of Engineering)

• Office of Naval Research

• QuantumScape

Students

SILVER

• Corning

• TEL

• GlobalFoundries BRONZE

• Applied Materials

• ASM

• Daicel

• Energy Assurance

• Lam Research

• LG Energy Solution

• Mitsui Kinzoku

• Sila

• U.S. Army Research Office

• Air Liquide Advanced Materials

• Arbin Instruments

• Covalent Metrology

• Lam Research

• Neware Technology Limited

• Nissan Group of North America

• Tecnochimica

• Admiral Instruments

• Advanced Cell Engineering

• Ametek-Scientific Instruments (PAR/Solatron)

• Arbin Instruments

• BASi

• BioLogic USA

• Calumix Technologies

• Comsol, Inc.

• Current Chemicals

• Cyclikal, LLC

• DataPhysics Instruments USA Corp.

• De Nora

• Department of Homeland Security Science and Technology Directorate

• ECS - The Electrochemical Society

• Gamry Instruments

• Hiden Analytical

• IOP Publishing

• IVIUM Technologies

• Malvern Panalytical Metrohm USA

• MTI Corporation

• OCI Vacuum Microengineering

• PalmSens BV

• Pamarco

• Pine Research Instrumentation

• Royal Society of Chemistry

• Scribner Associates

• SH Scientific Corporation

• Spectro Inlets ApS

• TA Instruments

• UL Research Institutes

• VSPARTICLE B.V.

• Wildcat Discovery Technologies

• Wiley

• Xenocs

• Zurich Instruments USA

JES is the flagship journal of The Electrochemical Society. Published continuously from 1902 to the present, JES remains one of the most highly cited journals in electrochemistry and solid state science and technology.

ECS Sensors Plus is a one-stop shop journal for sensors. This multidisciplinary, Gold Open Access journal provides an international platform for publishing high-quality impactful articles and promoting scholarly communication and interactions among scientists, engineers, and technologists whose primary interests focus on materials, structures, properties, performance, and characterization of sensing and detection devices and systems, including sensor arrays and networks.

ECS Advances is a multidisciplinary, Gold Open Access forum of peer-reviewed, high-quality content covering all technical areas supported by the Society. ECS Advances publishes full-length original work, brief communicationstyle papers, perspectives, review articles, and special issues.

As we entered the fall of 2022, an eerie trend in the publications community seemed to be impacting ECS and every publisher of peer-reviewed content, regardless of the subject matter. Our team of peer reviewers, which had been moving at a much slower pace over the last several months, appeared to be slowing even more, negatively impacting our peer review timelines. In some rare cases, our editorial teams struggled for weeks to garner the support of reviewers who turned down our requests to review manuscript submissions. Even our most committed reviewers declined to review manuscripts in their areas of expertise, citing lack of capacity to complete the reviews. Conversations with other organizations revealed that this trend was being experienced throughout the publications community.

This resulted in a call to action to activate and strengthen our pool of peer reviewers at the 242nd ECS Meeting. By engaging directly with meeting participants, we actively recruited postdoctoral ECS community members to review their fellow researchers’ manuscripts. We emphasized and elevated the message that all members of our constituency should be committed to the peer-review process. The efforts of peer reviewers support their own journey to publication.

Thus, where ECS and its constituents share the mission to advance science and technology by disseminating research, successfully disseminating this research depends on our constituents’ engagement and support of one another by reviewing the manuscripts of their subject-matter peers—lifting as we climb.

This message of mentorship and supporting scientific advancement through peer review is especially critical given the August 25 US Office of Science and Technology Policy (OSTP) memorandum calling for “free, immediate, and equitable access to federally funded research.” The memo created quite a stir among research community members receiving US federal government funding. However, here at ECS, we are ready for the road ahead and any turns it may reveal. All ECS journals are either Gold or Green Open Access; our member discounts make our open access article processing fees among the most competitive in our subject area; our publishing partner IOP is growing the reach of open access publishing by expanding the number of transformative agreements worldwide; and ECS authors can promote their work and related data on their personal website(s), institutional website(s), repositories, scientific social networks, and third-party websites. While many publishers are waiting for additional guidance from OSTP, ECS is ready and in position to provide the international scientific community with a forum to publish their work without fear of noncompliance.

While some look toward 2023 with speculation and perhaps fear of the unknown, ECS had the foresight in 2014 to launch Free the Science. Knowing that the future of science would be open, ECS adopted strategies to become a true community publisher for electrochemical and solid state science and technology research. We are ready for the road ahead!

The ECS Board of Directors met on Thursday, October 13, in conjunction with the 242nd ECS Meeting in Atlanta, October 9–13. This meeting was only the Board’s second in-person gathering since October 2019, and there was no shortage of important topics to discuss.

First and foremost was approving the 2023 budget.

Unlike budgets in recent years, which focused more on ensuring that ECS’s core programs and services were at least break-even, if not returning surplus to support the Society’s mission, this budget seeks to invest heavily in ECS’s future. The ECS Board approved a budget that contains nearly $1M in such investments, including launching a new education initiative designed to provide critical battery manufacturing workforce development resources; reaching out to new and potential members around the globe; hosting our first ECS meeting in Europe in well over a decade; and covering all 2023 article processing charges (APCs) in our two new OA journals, ECS Sensors Plus and ECS Advances. True, we are operating in a time of

rising interest rates and economic uncertainty, but given the strength of ECS’s operations and our financial reserves, we are uniquely positioned for growth in the coming years—if we make the proper investments now. This budget is the start of that growth!

In addition to the budget, the Board held in-depth discussions on divisions’ field of interest statements, especially with respect to nanotechnology; ways to redefine membership to include more of the broader ECS community as members; and the potential for establishing a simpler, more transparent reporting mechanism for division finances.

There was lively discussion over the course of the four-hour meeting, which concluded by thanking the following members whose terms had ended: Shirley Meng, Battery Division Chair; Jamie Noël, Corrosion Division Chair; and Jessica Koehne, Sensor Division Chair. Our sincerest thanks to Shirley, Jamie, and Jessica for their years of service and dedication to the ECS Board and the Society!

And of course, we welcomed new members who joined us for their first ECS Board meeting: Uroš Cvelbar, DS&T Division Chair; Qiliang Li, EPD Division Chair; Maria Inman, IE&EE Division Chair; Jeff Blackburn, NANO Division Chair; and Jennifer Hite, Chair of the Interdisciplinary Science and Technology Subcommittee. Welcome to the ECS Board, and here’s wishing you all the best as you begin your terms. The Society is grateful and honored that you are serving in this most important of capacities.

The Electrochemical Society Publications Subcommittee, Technical Affairs Committee, and Board of Directors congratulate the newly appointed and reappointed members of our Editorial Board. It is through the unwavering commitment of our Editorial Board Members that The Electrochemical Society family of journals continues to realize great success. Thank you for your service to ECS!

Nae-Lih (Nick) Wu

Associate Editor for Batteries and Energy Storage

January 1, 2014–December 31, 2025

Thierry Brousse

Associate Editor for Batteries and Energy Storage

June 1, 2012–December 31, 2025

Janine Mauzeroll

Technical Editor for Organic and Bioelectrochemistry

December 1, 2016–December 31, 2025

Xiao-Dong Zhou

Technical Editor for Fuel Cells, Electrolyzers, and Energy Conversion

January 1, 2020–December 31, 2026 JES & JSS

Kailash Mishra

Technical Editor for Luminescence and Display Materials, Devices, and Processing

October 1, 2011–September 30, 2023

Dirk Guldi

Technical Editor for Carbon Nanostructures and Devices

July 15, 2022–July 14, 2025

Won Bin Im

Associate Editor for Luminescence and Display Materials, Devices, and Processing

July 11, 2022–July 14, 2023

Stefano Cinti Technical Editor for Sensors

January 1, 2023–December 31, 2025

Netz Arroyo Technical Editor for Sensors

January 1, 2023–December 31, 2025

The Spring 2023 issue of Interface will be a Special Topics issue on Neuromorphic Computing.

Spring 2023 will also include the Highly Cited Researchers, columns from our new contributing editors, and Looking at Patent Law, as well as the latest news about people, students, and the Society.

Chair Maria Inman and Secretary/Treasurer Elizabeth Biddinger presented the 2022 IE&EE H. H. Dow Memorial Student Achievement Award to Arghya Patra at the 242nd ECS Meeting. Patra is a PhD candidate and Mavis Future Faculty Fellow in the University of Illinois Urbana-Champaign’s Department of Materials Science and Engineering. Dow Chemical Company funds the award to encourage promising young engineers and scientists to continue careers in electrochemical engineering and applied electrochemistry.

The award presentation took place before Patra gave his award talk, “Electrochemically Grown Highly Textured Thick Ceramic Oxide Films for Energy Storage: A New Manufacturing Paradigm for Cathode Materials.” In it, he described his work in Prof. Paul V. Braun’s research group on direct electrodeposition of thick ternary ceramic oxide films as an alternate scalable manufacturing technique for fabrication of binder-and-additive free cathode materials for secondary batteries.

Brett Lucht, Chair University of Rhode Island

Jie Xiao, Vice Chair

Jagjit Nanda, Secretary Xiaolin Li, Treasurer Doron Aurbach, Journals Editorial Board Representative

Dev Chidambaram, Chair University of Nevada Reno

Eiji Tada, Vice Chair

Rebecca Schaller, Secretary/Treasurer Sannakaisa Virtanen, Journals Editorial Board Representative

Uroš Cvelbar, Chair

Jožef Stefan Institute

Sreeran Vaddiraju, Vice Chair

Zhi David Chen, Secretary Thorsten Lill, Treasurer Peter Mascher, Journals Editorial Board Representative

Natasa Vasiljevic, Chair University of Bristol

Luca Magagnin, Vice Chair

Andreas Bund, Secretary Antoine Allanore, Treasurer Takayuki Homma, Journals Editorial Board Representative

Electronics and Photonics

Qiliang Li, Acting Chair/Vice Chair George Mason University

Vidhya Chakrapani, 2nd Vice Chair

Zia Karim, Secretary

Erica Douglas, Treasurer

Fan Ren, Journals Editorial Board Representative Jennifer Bardwell, Journals Editorial Board Representative

William Mustain, Chair University of South Carolina

Katherine Ayers, Vice Chair Minhua Shao, Secretary

Hui Xu, Treasurer

Xiao-Dong Zhou, Journals Editorial Board Representative

High-Temperature Energy, Materials, and Processes

Sean R. Bishop, Chair Sandia National Laboratories

Cortney Kreller, Sr. Vice Chair

Xingbo Liu, Jr. Vice Chair Teruhisa Horita, Secretary/Treasurer Xiao-Dong Zhou, Journals Editorial Board Representative

Industrial Electrochemistry and Electrochemical Engineering

Maria Inman, Chair Faraday Technology, Inc.

Paul Kenis, Vice Chair

Elizabeth Biddinger, Secretary/Treasurer John Harb, Journals Editorial Board Representative

Luminescence and Display Materials

Rong-Jun Xie, Chair

Xiamen University

Eugeniusz Zych, Vice Chair

Dirk Poelman, Secretary/Treasurer Kailash Mishra, Journals Editorial Board Representative

Nanocarbons

Jeff L. Blackburn, Chair National Renewable Energy Laboratory

Ardemis Boghossian, Vice Chair

Yan Li, Secretary

Hiroshi Imahori, Treasurer Francis D’Souza, Journals Editorial Board Representative

Organic and Biological Electrochemistry

Sadagopan Krishnan, Chair

Oklahoma State University

Song Lin, Vice Chair

Jeffrey Halpern, Secretary/Treasurer Janine Mauzeroll, Journals Editorial Board Representative

Physical and Analytical Electrochemistry

Andrew Hillier, Chair

Iowa State University

Stephen Paddison, Vice Chair

Anne Co, Secretary

Svitlana Pylypenko, Treasurer David Cliffel, Journals Editorial Board Representative

Larry Nagahara, Chair

Johns Hopkins University

Praveen Kumar Sekhar, Vice Chair

Dong-Joo Kim, Secretary

Leyla Soleymani, Treasurer

Ajit Khosla, Journals Editorial Board Representative

Sheikh Ali Akbar, Ohio State University

Shekhar Bhansali, Florida International University

Brett Lucht, University of Rhode Island

Vice Chair

Jie Xiao, Pacific Northwest National Laboratory Secretary

Jagjit Nanda, Stanford Linear Accelerator Center Treasurer

Xiaolin Li, Pacific Northwest National Laboratory Members at Large

Veronica Augustyn, North Carolina State University

Tom Barrera, LIB-X Consulting

Dominic Bresser, Karlsruher Institut für Technologie

Jason Croy, Argonne National Laboratory

Neil Das Gupta, University of Michigan

Robert Dominko, National Institute of Chemistry

Josh Gallaway, Northeastern University

Bing Joe Hwang, National Taiwan University of Science & Technology

Nobuyuki Imanishi, Mie University

Xiaolin Li, Pacific Northwest National Laboratory

Bin Li, Idaho National Laboratory

Boryann Liaw, Idaho National Laboratory

Jun Lu, Argonne National Laboratory

Yi-Chun Lu, The Chinese University of Hong Kong

John Muldoon, Toyota Research Institute of North America

Jennifer Rupp, Massachusetts Institute of Technology

Dan Steingart, Columbia University

Venkataram Thangadurai, University of Calgary

Roseanne Warren, University of Utah

Kang Xu, United States Army Research Laboratory

Guihua Yu, University of Texas at Austin

Marina Yakovleva, Livent Corporation

Won-Sub Yoon, Sungkyunkwan University

Dev Chidambaram, University of Nevada, Reno

Vice Chair

Eiji Tada, Tokyo Institute of Technology Division Secretary/Treasurer

Rebecca Schaller, Sandia National Laboratories

Members at Large

Yaiza Gonzalez-Garcia, Technische Universiteit Delft

Rajeev Gupta, North Carolina State University

Michael Rohwerder, Max-Planck-Institut für Eisenforschung GmbH

Eric Schindelholz, Ohio State University

Brendy Rincon Troconis, University of Texas at San Antonio

Hiroaki Tsuchiya, Osaka University

Larry Nagahara, Johns Hopkins University

Vice Chair

Praveen Kumar Sekhar, Washington State University Secretary

Dong-Joo Kim, Auburn University Treasurer

Leyla Soleymani, McMaster University

Michael T. Carter, KWJ Engineering, Inc.

Pengyu Chen, Auburn University

Bryan Chin, Auburn University

Seyedehaida (Aida) Ebrahimi, Pennsylvania State University

Jay Grate, Pacific Northwest National Laboratory

Peter Hesketh, Georgia Institute of Technology

A. Robert Hillman, University of Leicester

Gary Hunter, NASA Glenn Research Center

Takeo Hyodo, Nagasaki University

Sangmin Jeon, Pohang University of Science and Technology

Mira Josowicz, Georgia Institute of Technology

Jing Li, NASA Ames Research Center

Chung-Chiun Liu, Case Western Reserve University

Vadim Lvovich, NASA Glenn Research Center

Sushanta Mitra, University of Waterloo