VOL. 33, NO. 2, Summer 2024 10 Meet the New Society Officers 61 Electrochemically Induced Deposition 47 Advancements in Electrodeposition for Precise Manufacturing and Sustainability 26 ECS Celebrates the Life of Allen J. Bard ELECTRODEPOSITION SPECIAL ISSUE: Frontiers of Electrodeposition (Present and Future) The Electrochemical Society

ECS, a prestigious nonprofit professional society, has led the world in electrochemistry, solid state science and technology and allied subjects since 1902, providing a rigorous and high-quality home for the whole community.

ECS is dedicated to moving science forward by empowering researchers globally to leave their mark on science. The Society connects a diverse and representative constituency of members and nonmembers to accelerate scientific discovery, facilitate the engagement of an inclusive network, and champion the dissemination of research to support a sustainable future.

For more information on becoming a member, or publishing in ECS publications, visit electrochem.org

BioLogic Potentiostats

Instruments for Electrochemists

SP-50e

1 channel

±1 A to 20 nA

Up to 1 MHz

SP-300

2 channels

±10 A to 100 fA

Up to 7 MHz

VMP-3e

16 channels

±1 A to 20 nA

Up to 1 MHz

VMP-300 16 channels

±150 A to 100 fA

Up to 7 MHz

From 1 to 16 channels, BioLogic offers a range of modular single and multichannel potentiostats.

Our range of Premium and Essential Potentiostats boast some of the most powerful specifications available: including up to 7 MHz EIS measurements with EIS Quality Indicators and up to 800 A with boosters.

So whether your area of expertise lies in energy or corrosion, material characterization or bio-molecular electrochemistry – we have a potentiostat to match your specific needs.

Shaping the future. Together. biologic.net

Artificial Intelligence?

Iadmit that I struggle with the issues surrounding artificial intelligence (AI). As a technologist, my knee-jerk reaction is that how it works is cool, and its potential for good amazing. As a pessimist, I can foresee an AI machine taking over writing these editorials and doing a better job of it. The more I read about it the more excited and scared I get. At its core, most AI is based on making mathematical correlations or connections among many, many pieces of information. Although this description is an oversimplification of only one part of AI, it helps a simple guy like me conceptualize what it does. Correlation is not causation, of course, but we of natural intelligence use it all the time. Sometimes, believing in the power of correlation can lead us astray. When a large language model is asked to write papers based on spurious correlations, the results can be hysterical. Paging through Spurious Scholar shows more than 4,000 fake papers that were generated by AI after being given a misleading correlation. My current favorite is one that links the number of B.A. degrees awarded in literature with the number of Google searches for “how to delete browsing history,” which has an R2 of 0.958. I have always been suspicious of my friends in the humanities, truth be told. Going beyond text, generative AI can use a tremendous amount of information to create images, although that does not stop it from producing nonsense at times, including the physically impossible, but hilarious, rendition of a mouse that was a figure in a published scientific article in a journal with an IF of 5.5. Google it (thus using AI to see its failures).

As with every new technology since the discovery of fire, people find ways to use it for evil. Technology is agnostic with respect to its use (but is that true for AI…). Using AI to create deep fakes or to amplify stupidity to the point of acceptance is an ongoing problem, although amplifying stupidity has been a cottage industry for some people for a long time. The deep fakes are the ones that scare me. In the absence of being in the physical presence of someone, it could get to the point where we won’t be sure of anything. With the stakes so high in elections, the use of AI to create and boost misinformation has its perfect customer. The good news is that there are white hats who are using AI tools to catch AI deep fakes. The bad news is that AI is getting better every day as a natural condition. The constant struggle between good and evil plays out in silico.

Having picked on AI’s foibles, let’s turn to its successes (at least partial). The use of AI in medical image analysis may eventually fundamentally change the way some diseases and conditions are detected from the gamut of medical images that are collected. That said, it still has a long way to go to be better than a human radiologist. Of course, I am thankful for AI when it alerts me when someone is using my credit card without authorization; it amazes me how fast it does it, and how rarely it is wrong. It is also being used to improve forecasting of weather and climate, assist in decision making, and for process optimization (thank you, Google Maps and Waze).

The optimist in me says that maybe this technological revolution will create more free time, as John Maynard Keynes predicted almost 100 years ago when he said that in 100 years, people would be working only 15 hours a week. My friends say that it has been successfully achieved already by university faculty, so maybe it wasn’t that wild a prediction. People can be so cruel.

Many years ago, I received an unsigned card. On the cover was a cartoon of a man holding a toaster and a butter knife. The caption on the front of the card is “Sometimes we are too smart for our own good.” The inside of the card reads “You don’t look to be in any trouble with that at this time.” So if you were looking for an answer to the question posed by the title, I am sorry to disappoint. But honestly, if you have read even one of my earlier epistles you should have known.

Until next time, be safe and happy.

Rob Kelly Editor

Rob Kelly Editor

Published by:

The Electrochemical Society (ECS) 65 South Main Street Pennington, NJ 08534-2839, USA

Tel 609.737.1902, Fax 609.737.2743

www.electrochem.org

Editor: Rob Kelly

Guest Editors: Philippe Vereecken, Luca Magagnin, and Natasa Vasiljevic

Contributing Editors: Christopher L. Alexander, Christopher G. Arges, Scott Cushing, Ahmet Kusolgu, Donald Pile, Alice Suroviec

Director of Publications: Adrian Plummer

Director of Community Engagement: Shannon Reed

Production Editor: Kara McArthur

Graphic Design & Print Production Manager: Dinia Agrawala

Staff Contributors: Frances Chaves, Genevieve Goldy, Mary Hojlo, Christopher J. Jannuzzi, John Lewis, Anna Olsen, Fern Oram, Jennifer Ortiz, Francesca Di Palo, JaneAnn Wormann

Advisory Board: Brett Lucht (Battery Division) Dev Chidambaram (Corrosion Division)

Uroš Cvelbar (Dielectric Science and Technology Division)

Luca Magagnin (Electrodeposition Division) Qiliang Li (Electronics and Photonics Division) Katherine Ayers (Energy Technology Division) Cortney Kreller (High-Temperature Energy, Materials, & Processes Division)

Maria Inman (Industrial Electrochemistry and Electrochemical Engineering Division) Eugeniusz Zych (Luminescence and Display Materials Division)

Jeff Blackburn (Nanocarbons Division)

Shelley Minteer (Organic and Biological Electrochemistry Division)

Stephen Paddison (Physical and Analytical Electrochemistry Division)

Larry Nagahara (Sensor Division)

Publications Subcommittee Chair: Francis D'Souza

Society Officers: Colm O'Dwyer, President; James (Jim) Fenton, Senior Vice President; Francis D'Souza, 2nd Vice President; Robert Savinell, 3rd Vice President; Gessie Brisard, Secretary; Elizabeth J. PodlahaMurphy, Treasurer; Christopher J. Jannuzzi, Executive Director & CEO

Statements and opinions given in The Electrochemical Society Interface are those of the contributors, and ECS assumes no responsibility for them.

Authorization to photocopy any article for internal or personal use beyond the fair use provisions of the Copyright Act of 1976 is granted by The Electrochemical Society to libraries and other users registered with the Copyright Clearance Center (CCC). Copying for other than internal or personal use without express permission of ECS is prohibited. The CCC Code for The Electrochemical Society Interface is 1064-8208/92.

ISSN : Print: 1064-8208 Online: 1944-8783

The Electrochemical Society Interface is published quarterly by The Electrochemical Society (ECS), at 65 South Main Street, Pennington, NJ 08534-2839 USA. Subscription to members is part of membership service. © Copyright 2024 by The Electrochemical Society. *“Save as otherwise expressly stated.”

The Electrochemical Society is an educational, nonprofit 501(c)(3) organization with more than 8,500 scientists and engineers in over 75 countries worldwide who hold individual membership. Founded in 1902, the Society has a long tradition in advancing the theory and practice of electrochemical and solid state science by dissemination of information through its publications and international meetings.

https://orcid.org/0000-0002-7354-0978

EDITOR

EDITOR The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 3

FROM THE

FROM THE

4 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

Advanced Features & Capabilities Are One Click Away! 2005

2007

LEADING ENEGRY CONVERSION AND STORAGE TECHNOLOGIES SINCE 1980 Fuel Cell Test | Electrolyzer Test | Membrane Conductivity Test | Redox Flow Cell Test

LET’S TALK UPGRADES

Model

Model

61 67

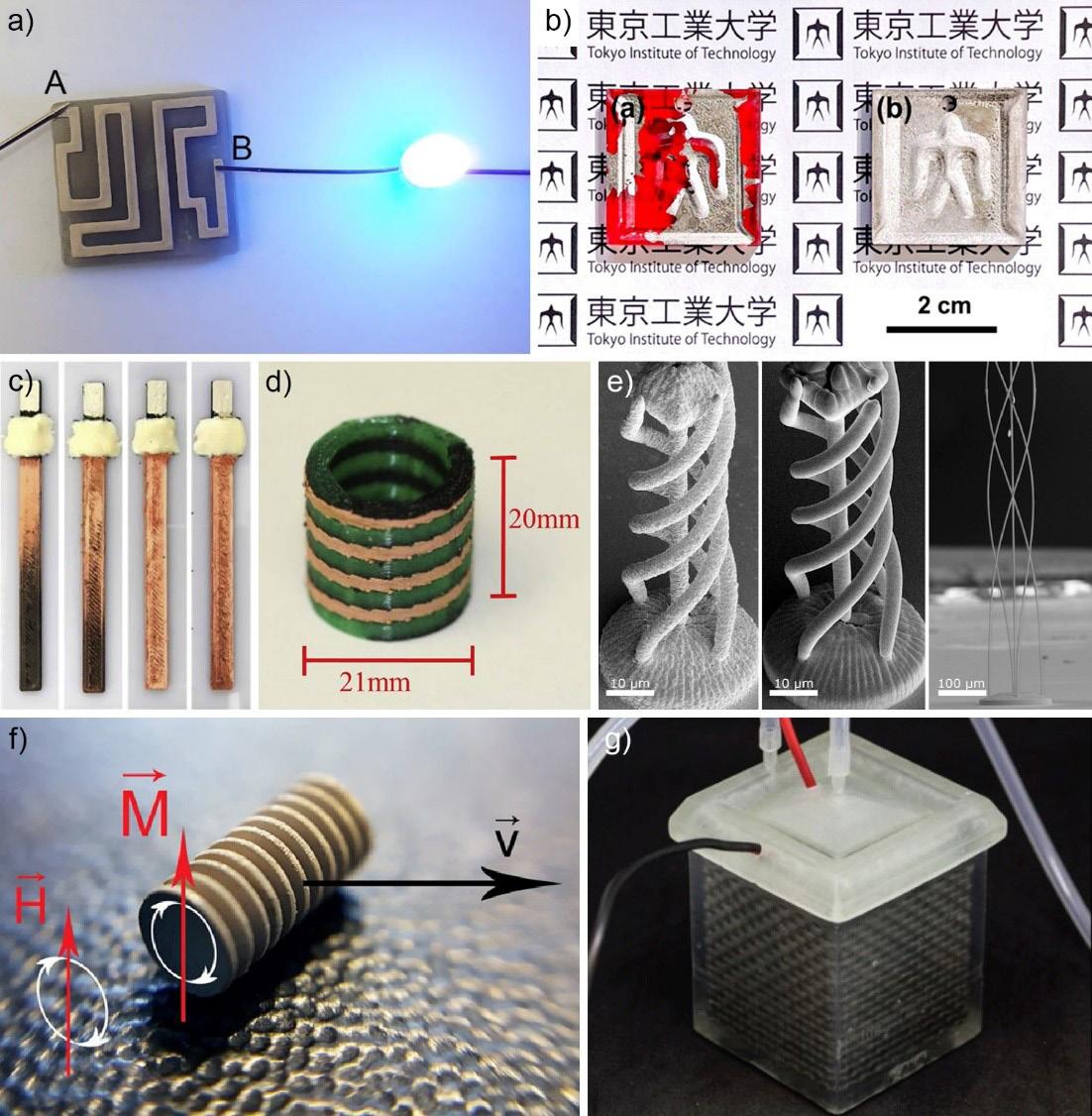

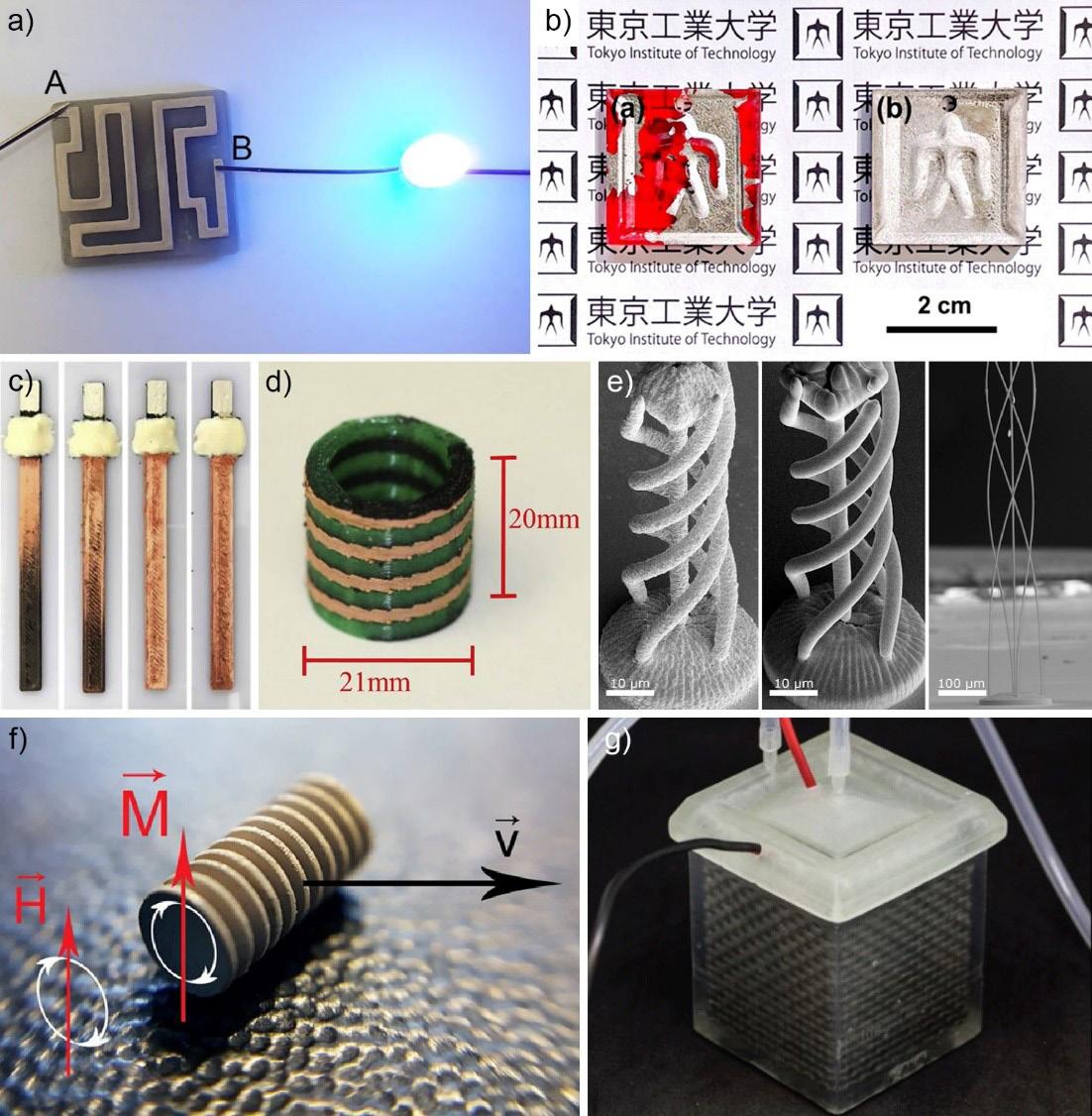

A Bright Future for Electrodeposition

by Philippe Vereecken, Natasa Vasiljevic, Luca Magagnin, J. X. Kent Zheng, and Martin Leimbach

Advancements in Electrodeposition for Precise Manufacturing and Sustainability

by Anar Badalbayli, Nicholas Sinclair, Roberto Bernasconi, Natalia Borisenko, Krishna Venkatesh, Adriana Ispas, Rohan Akolkar, and Luca Magagnin

Engineering Electrodeposition for Nextgeneration Batteries

by Stephen T. Fuller, Yonglin Huang, Ruixin Wu, Fudong Han, J. X. Kent Zheng, and Natasa Vasiljevic

Electrochemically Induced Deposition (ECiD): A Versatile Method that Greatly Extends the Portfolio of Surface Coatings and Materials Fabricated by Electrochemical Deposition

by Sai Gourang Patnaik, Genis Vanheusden, Ali Amir Saleh, and Philippe M. Vereecken

Electrochemically Induced Templated Sol-gel Deposition of Mesoporous Silica and Nanocomposites: The New Kid on the ECiD Block

by Genis Vanheusden and Philippe M. Vereecken

Vol. 33, No. 2 Summer 2024

3 From the Editor: Artificial Intelligence?

7 From the President: ECS United

10 Meet the New Society Officers

16 Society News

24 Websites of Note

26 ECS Celebrates the Life of Allen J. Bard

28 People News

32 Reports from the Frontier

38 Electrochemistry in Action

44 Tech Highlights

73 Section News

75 Awards Program

77 New Members

81 Student News

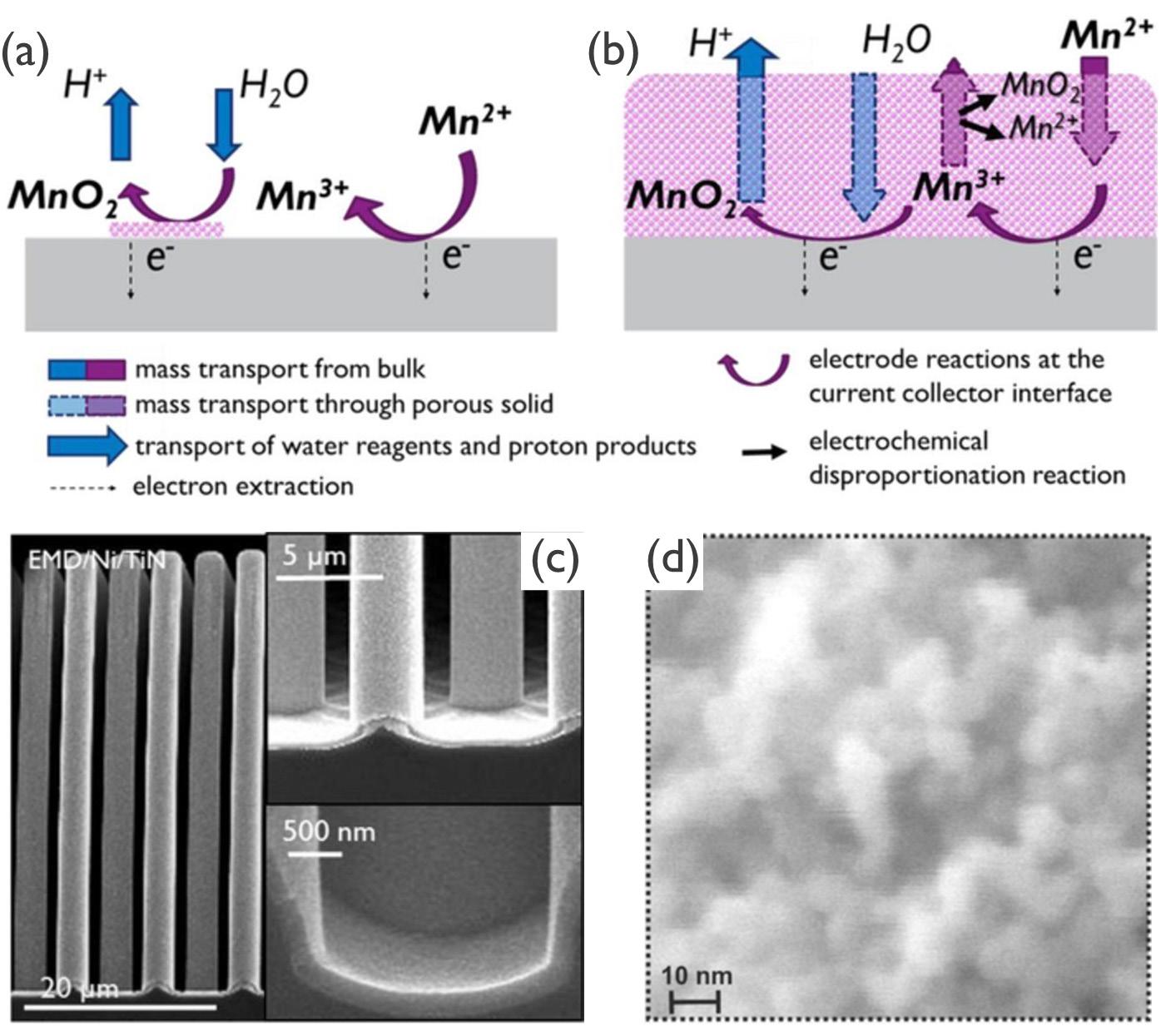

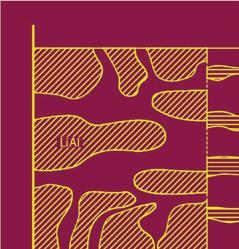

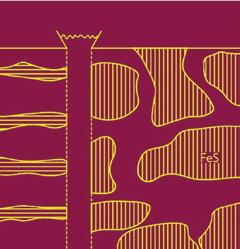

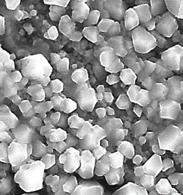

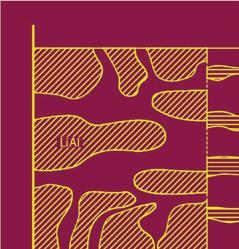

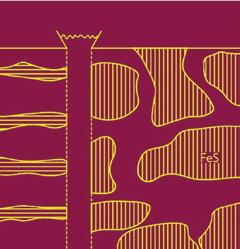

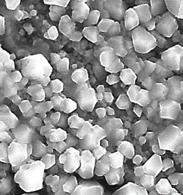

This issue's cover is an interpretation of an illustration and an SEM image of electrodeposition (Figs. 4 and 5), from Patnaik et al.'s article, “Electrochemically Induced Deposition (ECiD): A Versatile Method that Greatly Extends the Portfolio of Surface Coatings and Materials Fabricated by Electrochemical Deposition” (see p. 61).

Cover design: Dinia Agrawala

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 5

gamry.com Ph: +1 215 682 9330 INTRODUCING THE RxE 10K ROTATING ELECTRODE NEW RDE/RCE/RRDE Corrosion Catalyst Development Fuel Cell Research Kinetic Studies SELECT SPECIFICATIONS 50-10500RPM +/-1RPMAccuracy AnalogorDigitalControl

IECS United

t gives me great pleasure to write to you for the first time since becoming ECS President. I assumed the role following the 245th ECS Meeting in San Francisco, CA, which I certainly hope you attended. That amazing event featured 49 symposia with 439 sessions presenting more than 2,290 talks, 3,022 abstracts, and 701 posters by authors from 68 countries. Of these, 575 were invited talks, 25 ECS award and keynote talks, and 1,240 student abstracts, 842 oral talks, and 388 posters! If you were unable to attend, complete coverage of the meeting’s highlights and key moments is forthcoming in the next edition of Interface I would like to share with you my vision as President of this esteemed Society, and what I see are the main challenges and opportunities facing ECS in the year ahead.

ECS has led the forefront of electrochemical and solid state science and technology education and dissemination for over 120 years. The need for a cleaner, better, and more sustainable future has focused the Society’s thinking in the 21st century. Electrochemistry and the solid state disciplines are more important now than ever—and they have greater impact when united. Energy conversion and storage are the lungs, fuel, and muscles of the sustainable and mobile electric future; displays, processors, and semiconductor devices are the heart, brain, and nervous system. All are made possible by multiple forms of material science, electrochemical processes, optoelectronics, and more. ECS’s mission, in the round, is a driver for the sustainable electric future.

the US CHIPS and Science Act and the EU Chips Act. This will be part of a long-term vision to develop educational initiatives across major disciplines in ECS. It is important that the Society expands its leadership in providing industryfacing opportunities for re-skilling in the electrochemical and solid state science and technology disciplines that are central to workforce development needs—for all the technologies we use now and need in the future.

The Society has successfully launched ECS Sensors Plus and ECS Advances, new journals that open the door to full open-access publication. I commit to continuing these ongoing initiatives, including ECS for Sustainability launched by Past President Gerri Botte, and to foster new ones to maximize their impact, attractiveness, and accessibility to all authors across academia and industry R&D.

Of course, underlying the growth of our meetings, publications, education initiatives, and beyond are the people who make all that ECS does possible. Within the Society and throughout our worldwide membership, all forms of diversity are our strength. During this year, as the organization grows and expands in size and influence, the Ad-Hoc Committee on Diversity’s recommendations will be embedded in ECS’s future primary leadership and society-wide activities.

“Electrochemistry and the solid state disciplines are more important now than ever—and they have greater impact when united.”

Like many of you, I have made the Society my go-to place for presenting and publishing my work since my first conference presentation as a graduate student at the 199th ECS Meeting in Washington, DC. As an ECS member for the past 23 years, and active in electrochemical and solid state science research, I have seen how this scientific society tracks the ebb and flow in research priorities, new technologies, and international policies, and how they are mirrored in our meeting and journal content. Through uniting electrochemical and solid state science, ECS has core scientific expertise that is arguably the most critical and most relevant to the cutting edge of technologies we see today.

As ECS President, I will elevate our STEM education and outreach by ensuring the creation of new programs like our battery workforce development and upskilling education programs. I plan to work with the leadership team and divisions to scope out parallel opportunities articulated in

Continuing to support ECS Student Chapters around the globe is central to growing our international community and fostering diversity within ECS membership. Therefore, I call on ECS members to consider founding an ECS student chapter at their institutions. Doing so provides students with a direct pipeline to ECS. All students in the chapter receive complimentary ECS membership and the Society provides up to $1,000 annually to support chapter activities and events. Only six students are required to launch a chapter, so if you are interested, please click here

I very much look forward to working with you all as we advance the ECS mission in education and scientific impact. The quality and breadth of our core disciplines, united, will put ECS front and center in a sustainable future.

Colm O’Dwyer ECS President

http://orcid.org/0000-0001-7429-015X

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 7 FROM THE PRESIDENT

FROM THE PRESIDENT

ACTIVATE WITH ECS PUBLICATIONS

ECS TOPICAL INTEREST AREAS

Electrochemical

• Batteries and Energy Storage

• Corrosion Science and Technology

• Electrochemical/Electroless Deposition

• Electrochemical Engineering

• Fuel Cells, Electrolyzers, and Energy Conversion

• Organic and Bioelectrochemistry

• Physical and Analytical Electrochemistry, Electrocatalysis, and Photoelectrochemistry

• Sensors (Electrochemical)

Solid State

• Carbon Nanostructures and Devices

• Dielectric Science and Materials

• Electronic Materials and Processing

• Electronic and Photonic Devices and Systems

• Luminescence and Display Materials, Devices, and Processing

• Sensors (Solid State)

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 9

LEARN MORE

Meet the New Society Officers

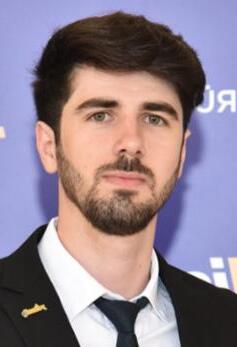

On May 31, 2024, the newly elected officers of The Electrochemical Society assumed their posts. We are pleased to welcome Colm O’Dwyer as President, Robert Savinell as Third Vice President, and Gessie Brisard as Secretary.

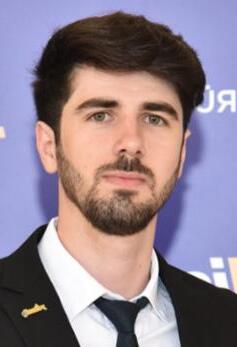

Colm O’Dwyer

Colm O’Dwyer ECS President, 2024–2025

Colm O’Dwyer is Professor of Chemical Energy in the University College Cork (UCC) School of Chemistry, and Principal Investigator at the Environmental Research Institute, Tyndall National Institute, and Advanced Materials and BioEngineering Research Centre. His research interests include 3D printed energy storage devices, materials science, and operando photonics for examining optoelectronic materials and energy storage materials.

Colm joined the Society as a graduate student in 2001 after attending the 199th ECS Meeting in Washington, DC. He has served ECS in numerous roles, including as Chair of the ECS Electronic and Photonics Division, and, with many colleagues, he has organized or co-organized about 40 ECS symposia since 2007.

As an award-winning advocate for open-access publication and open science, Colm has guest edited several JES and JSS special focus issues. What excites him most about ECS and its future are the many possibilities in education and engagement with society and industry, and how important electrochemistry and semiconductor science are in today’s world.

Colm completed his PhD in Semiconductor Electrochemistry and Physics at the University of Limerick (UL) in 2003. From 2008 to 2012, he was a Science Foundation Ireland Stokes Lecturer on Nanomaterials at UL; he then joined UCC in 2012. He has coauthored, with talented students, postdocs, and collaborators, ~300 peer-reviewed articles, book chapters, and ECS Transactions articles. Colm was one of the recipients of the 2017 Bell Labs Prize and is a Fellow of the Institute of Physics.

Colm’s life revolves around his family, his wife Gillian and children Caera and Aaron. They especially enjoy time outdoors in the hills and coastlines of Ireland—luckily, it’s a short trip to cliffs, caves, beaches, and mountains. He is adamant that the water feels warmer when swimming in the rain and wind (when you have no other choice). Rare cloudless nights are spent imaging nebulae and galaxies in the night sky.

10 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

2024

Members of the research family tree (students and advisors) together at the 236th ECS Meeting in Atlanta in 2019, with ECS Past President D. Noel Buckley (center) and David McNulty, University of Limerick (right).

Photo: Colm O'Dwyer

Colm hikes on a ridge in the Coomloughra Reeks with his wife Gillian and friends. Photo: Colm O'Dwyer

In December 2023, Colm captured the famous Orion Nebula (M42), Running Man Nebula (NGC 1977), and surrounding molecular clouds from a back garden in Cork.

The Electrochemical Society Interface • Summer 2023 • www.electrochem.org

Photo: Colm O'Dwyer

Colm spends rainy Sunday afternoons indoors with family. Photo: Colm O'Dwyer

Robert (Bob) Savinell

Robert (Bob) Savinell is Distinguished University Professor and George S. Dively Professor of Engineering at Case Western Reserve University (CWRU). He is also PI and Director of the DOE Emerging Frontiers Research Center on Breakthrough Electrolytes for Energy Storage (BEES). His research focuses on fundamental science and mechanistic issues of electrochemical processes, and device design and development. Bob co-invented the first high-temperature proton-conducting polymer membrane based on phosphoric acid doping of PBI and co-authored the first experimental paper reporting results of the all-iron flow battery.

Bob joined the Society in 1978 and has served the ECS Industrial Electrochemistry and Electrochemical Engineering Division in all its officer positions, including Chair, as well as on many ECS committees and subcommittees. He has been Editor-in-Chief of the Journal of The Electrochemical Society since 2013. Bob is a Fellow of The Electrochemistry Society and received the 2022 ECS Vittorio de Nora Award.

After receiving his PhD in Chemical Engineering from the University of Pittsburg, Bob joined CWRU in 1986 and was Director of the Ernest B. Yeager Center for Electrochemical Sciences for 10 years and Dean of Engineering for seven. He has been a visiting professor at the Massachusetts Institute of Technology, Yamanashi University, and Danmarks Tekniske Universitet. He is a Fellow of The Electrochemical Society, the American Institute of Chemical Engineers, and the International Society of Electrochemistry, and received the 2020 CWRU Frank and Dorothy Hummel Prize.

Bob and Coletta Savinell will celebrate their 50th wedding anniversary this August with their three children and six grandchildren. They often host holiday get-together dinners with 45 siblings, spouses, children, and grandchildren. Avid sailors, the Savinells race their 34-foot sailboat on Lake Erie during the summer with crews composed mostly of students and former students. Bob enjoys riding his motorcycle on day or multiday trips in the country.

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 11

Robert (Bob) Savinell ECS Third Vice President, 2024–2025

Bob and Coletta with children, spouses, and grandchildren.

Photo: Francis D'Souza

Bob, colleague Prof. Betar Galant, senior racing crew Nick Sinclair (left) and Evan Guarr (right), and former students prepare to race his 34-foot sailboat.

Photo: Robert Savinell

Bob pictured on a four-day road trip to the 2023 BMW rally in Virginia.

• Summer 2023 • 11

Photo: Robert Savinell

Bob and Coletta.

Photo: Robert Savinell

ECS Secretary, 2024–2028

Gessie Brisard

Gessie Brisard is Professor of Chemistry at the Université de Sherbrooke (UdeS). Her research focuses on analytical electrochemistry, electrocatalysis, and energy production and storage.

Gessie joined ECS as a student in 1986 and has served on the Society’s Sections Council, Meeting Committee, Interface Advisory Board, and Institutional Engagement Committee, as well as on the ECS Board of Directors in various positions, including Treasurer. She has also chaired the ECS Physical and Analytical Electrochemistry Division. Gessie has organized many ECS meeting symposia, including co-founding the electrocatalysis symposium. Gessie is a long-standing member of the ECS Canada Section, including service on the executive committee. The section received the ECS Gwendolyn B. Wood Section Excellence Award during her term as Chair. Gessie has organized multiple ECS Canada Section symposia and received the 1989 ECS Canada Section Student Award. After completing a PhD in Electrochemistry at UdeS, Gessie was a postdoc at Lawrence Berkeley National Laboratory. She joined UdeS in 1992, where she was Assistant Professor then Full Professor in the Chemistry Department, and Vice Dean of Academia and Secretary of the Faculty of Science. She developed research programs in electrocatalysis and worked on cathode material for lithium batteries, carbon dioxide reduction, and electrodeposition in ionic liquids. She collaborated with the Institut de recherche d’Hydro-Québec and Alcan-Rio Tinto on electrochemistry in nonaqueous solvents of the interfacial behavior of non-aqueous electrolytes, with application to lithium batteries and metal deposition in nonconventional media.

Gessie never misses an opportunity to mix business with pleasure, combining her passions with international business travel. An avid cyclist, she has admired hundreds of kilometers of breathtaking views from California to Italy on cycling trips with friends and students. She loves symphony and opera, attending performances at the prestigious Cleveland Orchestra, Munich Symphony Orchestra, New York Metropolitan Opera, and others. She always packs fabulous, elegant attire for these occasions (shopping is another great passion!).

Gessie Brisard

Gessie visits New York City with her sister, Nadia. Photo: Gessie Brisard

Gessie attends a performance at the Metropolitan Opera in New York City. Photo: Gessie Brisard

Shopping in New York City is a favorite pastime.

Gessie Brisard

Gessie visits New York City with her sister, Nadia. Photo: Gessie Brisard

Gessie attends a performance at the Metropolitan Opera in New York City. Photo: Gessie Brisard

Shopping in New York City is a favorite pastime.

12 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

Photo: Gessie Brisard

Gessie and Hubert Gasteiger on a 2018 bike trip in Italy.

Photo: Gessie Brisard

Gessie and friends bicycling through Italy in 2019

Photo: Gessie Brisard

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 13 ECS Advances ECS Journal of The Electrochemical Society ECS Journal of Solid State Science and Technology GOLD OPEN ACCESS >3 MILLION downloads OPEN ACCESS Average of 467 downloads per article Average of >1,000 downloads per article ECS Sensors Plus NEW LEGACY publications 2022 Impact Factor 3.9 2022 Impact Factor 2.1 120+ YEARS OF CHAMPIONING THE ACCELERATION OF SCIENTIFIC DISCOVERY

Journal of The Electrochemical Society

JES is the flagship journal of The Electrochemical Society. Published continuously from 1902 to the present, JES remains one of the most highly cited journals in electrochemistry and solid state science and technology.

ECS Journal of Solid State Science and Technology

and

and devices.

14 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

We are Family!

solid state

SUBMIT TODAY! SUBMIT TODAY! Visit Visit www.ecsdl.org www.electrochem.org/focusissues Review the amazing research published by ECS • Calls for upcoming focus issues • Links to published focus issues • Future focus issue proposals

JSS is a peer-reviewed journal covering fundamental

applied areas of

science and technology, including experimental and theoretical aspects of the chemistry and physics of materials

ECS Sensors Plus

ECS Sensors Plus is a one-stop shop journal for sensors. This multidisciplinary, Gold Open Access journal provides an international platform for publishing high-quality impactful articles and promoting scholarly communication and interactions among scientists, engineers, and technologists whose primary interests focus on materials, structures, properties, performance, and characterization of sensing and detection devices and systems, including sensor arrays and networks.

ECS Advances is a multidisciplinary, Gold Open Access forum of peer-reviewed, high-quality content covering all technical areas supported by the Society. ECS Advances publishes full-length original work, brief communicationstyle papers, perspectives, review articles, and special issues.

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 15

ECS Advances Visit www.electrochem.org/oa Learn more about our open access initiatives • Read articles published for free in 2023 in ECS Advances and ECS Sensors Plus • Our new Gold Open Access journals! SUBMIT TODAY! SUBMIT TODAY!

SOCIETY NEWS SOCIETY NEWS

From the Publications Director՚s Desk

In store for 2024

by Adrian Plummer, MPA, PMP, Director of Publications

The ECS Publications family started off 2024 celebrating another year of growth in our readership across the globe, with more than nine million downloads, driven by the continued growth of our open access content. As we move into 2024, ECS will celebrate two full years of the newest members of our journal family, ECS Sensors Plus and ECS Advances. Following two full years of consistent and quality publication of the best articles in electrochemical and solid state science, the applications for indexing with Web of Science and SCOPUS have been submitted. We are anxiously awaiting the indexing of these two amazing journals—making their mark in the scholarly record. The success of these two new journals thus far is a testament to the strength, dedication, and commitment of our amazing editorial teams and the support of our valued reviewers.

We are also excited to welcome a new Editor-in-Chief to our ECS Publications leadership team, Rohan Akolkar, who will be leading our ECS Advances gold open access journal. As a long-time member of ECS, a stalwart supporter of the ECS mission, a fiveyear member of the ECS Joint Journal Editorial Board, and as an Associate Editor for the Journal of The Electrochemical Society, in the Electrochemical/Electroless Deposition topical interest area, Rohan is uniquely suited to grow ECS Advances. As ECS Advances

is the only ECS publication that hosts all ECS topics, Rohan will need the support of the entire ECS community in his editorial vision. Let’s help Rohan in his effort to make ECS Advances a continued success story for ECS!

As a society publisher that carries a broader organizational mission to advance theory and practice at the forefront of electrochemical and solid state science, and to encourage research, discussion, critical assessment, and dissemination of knowledge in these fields, it is central to this mission that we are consistently assessing our publications, and how they are serving the scholarly record. Sadly, after an extended period of assessment, The Electrochemical Society Board of Directors, at the recommendation of the Technical Affairs Committee and the Publications Subcommittee, have decided to sunset The Electrochemical Society Transactions (ECST) proceedings publication after 18 years of publishing proceedings manuscripts for ECS and sponsored ECS Meetings. ECST will publish its final volume with the PRiME 2024 meeting. Presenters of work in select symposiums included in the 245th ECS Meeting and PRiME 2024 meeting will continue to have the opportunity to submit a full manuscript to ECS Transactions. In addition, ECS will continue to publish the extended abstracts of authors who present at ECS meetings, via the ECS Meeting Abstracts publication. Subscribers of ECST will continue to be able to access, read, and cite articles published in ECST from the ECS digital library on IOP Science. Starting with the 247th ECS Meeting, authors of select symposiums will have a new opportunity to publish proceedings manuscripts: Stay tuned! But as always, we look forward to publishing the highest quality, novel, and groundbreaking research in our family of journals!

Editorial Updates Summer 2024

Reappointments

Ariel Furst

Reappointed as Associate Editor, ECS Sensors Plus, for the term March 1, 2024 –February 28, 2025

Harshini Mukundan

Reappointed as Associate Editor, ECS Sensors Plus, for the term January 24, 2024 –January 23, 2025

Thomas Thundat

Reappointed as Associate Editor, ECS Sensors Plus, for the term April 10, 2024 –April 9, 2025

John Staser

Reappointed as Associate Editor, Journal of The Electrochemical Society, for the term February 20, 2024 –February 19, 2025

Peter Mascher

Reappointed as Technical Editor, ECS Journal of Solid State Science and Technology, Dielectric Science and Materials topical interest area, for the term May 1, 2024 – April 30. 2027

Thank You to our Departing Editorial Board Members

The Electrochemical Society wishes to express its gratitude to the Editorial Board members whose service on the Joint Journal Editorial Board ended as we started 2024. Thank you for your commitment and dedication to ECS and its mission to advance scientific discovery. We wish you the best in your future endeavors.

Amanda Clifford

Associate Editor, ECS Sensors Plus (ECSSP), March 1, 2023 –February 22, 2024

16 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

SOCIETY NEWS SOCIETY NEWS

ECS Appoints

Rohan Akolkar as Inaugural Editor-in-Chief of ECS

Advances

The ECS Board of Directors has appointed Professor Rohan Akolkar of Case Western Reserve University as the inaugural Editor-in-Chief (EiC) of ECS Advances (ECSA). ECSA is the only gold open access journal in the ECS publications portfolio that spans ECS’s full range of topical interest areas (TIAs). Rohan has been a member of the ECS Joint Journal Editorial Board for more than four years, following appointment by the ECS Publications Subcommittee as an Associate Editor for the Journal of The Electrochemical Society Electrochemical and Electroless Deposition TIA on September 1, 2019.

Rohan is the Milton and Tamar Maltz Professor of Energy Innovation at Case Western Reserve University (CWRU). He is an Ohio Eminent Scholar in Advanced Energy Research, serves as Faculty Director of CWRU’s Great Lakes Energy Institute, and holds a joint appointment as Chief Scientist at Pacific Northwest National Laboratory. His research spans many areas of electrochemical engineering: electrodeposition, electrometallurgy, and electrochemical materials development for applications in nanoelectronics, batteries, sensors, and in sustainable extraction and refining of critical materials. He has made important contributions to fundamental and applied electrochemistry, including patented electrochemical processes and materials which have enabled highperformance interconnects in advanced semiconductor devices; novel electrowinning and electrorefining processes for the sustainable extraction and recycling of metals; fundamental studies unraveling mechanisms of dendrite formation in batteries; and a novel patented sensor concept for detecting heavy-metal contaminants in water.

Rohan received a PhD in Chemical Engineering from CWRU in 2004. He worked in industrial research and development at Intel

Corporation for eight years before returning to CWRU as a faculty member in 2012. His research has been recognized by CWRU’s School of Engineering Innovation and Research Awards, the Norman Hackerman Young Author Award (2004) and the Electrodeposition Division Research Award (2023) of The Electrochemical Society, and numerous industry awards during his tenure at Intel. In 2021, he was elected Senior Member of the National Academy of Inventors. Over his 22 years of association with ECS, he has served as Associate Editor of the Journal of the Electrochemical Society (2019–2024), as a member of the ECS Honors and Awards Committee (2016–2019), and as Secretary of the ECS Electrodeposition Division. He is cofounder of a small business (Galvanix Inc.) in Ohio that aims to commercialize his invention of a novel electrolytic neodymium metal production process.

Please join us in welcoming Rohan to the Publications leadership team, and in cooperating and collaborating with him as he works to implement a new vision for ECSA that aims to make a stronger and lasting impact on the scholarly record.

ECS Advances

ECS Advances is a gold open access journal that covers all the technical areas supported by The Electrochemical Society. ECS Advances carries the broadest dissemination of electrochemical and solid state science and technology content among all journals in the field, coupled with a rigorous peer review. Enabling open access to scientific research is imperative to ECS in our mission to disseminate the best research in our technical fields as widely as possible. In the spirit of maintaining the ECS standard of excellence and quality scholarly publications, all papers submitted to ECS Advances are rigorously peer reviewed before acceptance.

ECS Board of Directors Report

The ECS Board of Directors held its spirited 90-minute March video conference meeting on the 22nd, with board members joining from locations around the globe.

ECS President Gerri Botte called the meeting to order and kicked off the 2024 governance year by thanking the Board for their continued leadership, support, and dedication. She then gave an important update on the work of the two Presidential Ad Hoc Committees launched at the start of her term, one dealing with diversity, equity, access, and inclusion, and the other addressing sustainability. Since the 244th ECS Meeting in May in Sweden, both committees have been hard at work advancing their respective goals, with motions expected at the next board meeting.

The Ad Hoc Committee on Diversity seeks to establish diversity oversight in our volunteer governance structure and create a new travel grant program aimed at increasing participation from underrepresented groups in the ECS community. The Ad Hoc Committee on Sustainability focuses on engaging the ECS community in exploring how electrochemical technologies can drive the transition to clean and renewable energy sources; protect the environment; mitigate climate change; and foster ecological, human, and economic well-being. Look for more to come from these critical working groups later this year.

Next, ECS Secretary Marca Doeff presented the previous board meeting minutes and had the pleasure of announcing the newly elected board members: incoming President Colm O’Dwyer, incoming Third Vice President Robert Savinell, and incoming Secretary Gessie Brisard. Congratulations to Colm, Bob, and Gessie!

Following the Secretary’s report, ECS Executive Director Chris Jannuzzi provided a brief overview of the past year, 2023, and updated the Board on new initiatives launched in 2024. Highlights included:

• Sustained growth and engagement across meetings, membership, and publications;

• Increased net assets, owing to strong revenue and significant gains in the Society’s investment portfolio;

• Over $700k in investment in new content and products to serve the ECS community and provide future resources to advance the Society’s mission;

• New initiatives for 2024, including a redefined membership model and a new education platform to help train technical professionals to work in ECS-related fields, beginning with batteries.

The meeting concluded with a report from ECS Treasurer Lisa Podlaha-Murphy, who outlined a proposal to revise the ECS division funding model. Now in its final stages, this 18-month long project is designed to streamline and simplify the process for providing financial resources for ECS divisions. A final vote on the revised funding plan is slated for the May board meeting.

Last, a motion to close the meeting was made, seconded, and unanimously approved.

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 17

Rohan Akolkar

SOCIETY NEWS SOCIETY NEWS

The 2024 Neal R. Amundson’s Lecture at the University of Guadalajara by Professor Gerardine G. Botte

by Norberto Casillas Santana

The Neal R. Amundson’s Lecture, held annually by the Department of Chemical Engineering at the University of Guadalajara, pays tribute to the distinguished professor Neal R. Amundson. It is the most prestigious and traditional scientific event in its field at the University of Guadalajara. It was established in 1999 thanks to the initiative of Professors Héctor Antonio Rodriguez Sanchez and Jorge Emilio Puig Arevalo, both distinguished alumni of the master’s and doctoral programs in Chemical Engineering and Materials Science at the University of Minnesota, with the approval of Professor Neal R. Amundson.

Since its establishment, the Neal R. Amundson’s Lecture has had as its primary goal to disseminate the latest developments in Chemical Engineering made by the most eminent professionals in the field worldwide through two keynote lectures. Additionally, it seeks to promote and strengthen collaborative links with other Chemical Engineering departments and scientific research institutions around the world.

For two decades, Professor Neal R. Amundson led the Department of Chemical Engineering and Materials Science at the University of Minnesota, earning the title of “Chief” and later considered by many the “Father of Modern Chemical Engineering.” Beyond his renowned academic career, Professor Amundson stood out for his generosity toward his former home, the Faculty of Chemical Sciences at the University of Guadalajara. He greatly supported the program by providing scholarships for master’s and doctoral degrees, so that students from the former Faculty of Chemical Sciences, now known as the Department of Chemical Engineering at the University of Guadalajara, could pursue graduate studies.

This support was a decisive factor that allowed for the elevation of the academic level of the faculty at the former Faculty of Chemical Sciences, at a time when the Department of Chemical Engineering and Materials Science at the University of Minnesota was considered the most prominent in the world. In return, the University of Guadalajara awarded Professor Amundson an honorary doctorate in 1999.

The University of Minnesota granted a total of 16 scholarships to students from the former Faculty of Chemical Sciences at the University of Guadalajara. Among the beneficiaries of this program, prominent figures stand out, such as two Presidents of the University Center for Exact Sciences and Engineering (CUCEI), a General President of the University of Guadalajara, a National Science Award winner, a director of a worldwide corporation in Latin America, a director of the national researchers’ system, a Secretary of the Interior for the State of Jalisco, as well as several members of the national system of researchers and distinguished professors from the Departments of Chemical Engineering and and of Chemistry at the University of Guadalajara, and from the Metropolitan Autonomous University in Iztapalapa.

Throughout its 25-year history, the Neal R. Amundson’s Lecture has seen the participation of more than 38 professors and researchers of the highest international level in the field of Chemical Engineering and related disciplines, including a Nobel Prize laureate.

The distinguished academics who have participated in the Neal R. Amundson’s Lecture in the field of electrochemistry include, in 2003, Professor Allen J. Bard, recognized as a “father of modern electrochemistry” from the University of Texas at Austin; in 2009, Professor Richard Compton of the University of Oxford in the United Kingdom, recognized as one of the most prominent researchers in the field of electrochemistry in the world; in 2018, Professor Jorge Ibáñez Cornejo from the Universidad Iberoamericana,

a distinguished Mexican scientist and humanist in the field of environmental and microscale electrochemistry; and, in this edition, the participation of the renowned Professor Gerardine (Gerri) G. Botte from the Texas Tech University, Fellow of the Electrochemical Society and current President. Prof. Botte is recognized for her innovations in electrochemical processes toward sustainability and circularity. Dr. Botte is the founder and director of the National Science Foundation Engineering Research Center for Advancing Sustainable and Distributed Fertilizer Production, CASFER. She is also the founding Director of the Institute for Sustainability and Circular Economy at Texas Tech University.

In her participation in the Neal R. Amundson’s Lecture, Professor Gerri Botte presented the keynote lecture entitled, “Electrochemical Engineering towards an Environmentally Viable Economy” and led a “Roundtable Discussion on Sustainability and Circular Economy.” This event was attended by graduate students from various disciplines taught at the University of Guadalajara, such as Chemical Engineering, Chemistry, Materials Science, and Water Technology from different university centers within the University of Guadalajara’s university network. The participating students had the opportunity to present parts of their research in a dynamic questionand-answer session directly with Professor Botte.

Following the conclusion of the event, a social gathering was organized with undergraduate and graduate students, providing the opportunity to interact directly with Professor Botte. Additionally, a working meeting was held with university authorities to explore the establishment of collaborative research projects between the University of Guadalajara and the Institute for Sustainability and Circular Economy.

Attendees were invited to be part of the upcoming Neal R. Amundson’s Lecture series, scheduled for the first week of October 2024. This event is part of the Chemical Engineering Week SIC 2024 and will commemorate the 25th anniversary of the Neal R. Amundson´s Lecture in the Department of Chemical Engineering at the University of Guadalajara.

Professor Norberto Casillas Santana is the Chair of the Mexico Section of The Electrochemical Society and Coordinator of the Amundson’s Lecture series at the University of Guadalajara.

18 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

The 2024 Neal R. Amundson’s Lecture at the University of Guadalajara included a roundtable discussion on sustainability and the circular economy.

SOCIETY NEWS SOCIETY NEWS

ECS Division Contacts

Battery

Brett Lucht, Chair

University of Rhode Island

Jie Xiao, Vice Chair

Jagjit Nanda, Secretary

Xiaolin Li, Treasurer

Doron Aurbach, Journals Editorial Board Representative

Corrosion

Dev Chidambaram, Chair

University of Nevada, Reno

Eiji Tada, Vice Chair

Rebecca Schaller, Secretary/Treasurer

Sannakaisa Virtanen, Journals Editorial Board Representative

Dielectric Science and Technology

Sreeram Vaddiraju, Chair

Texas A&M University

Eva Kovacevic, Vice Chair

Zhi David Chen, Secretary

Thorsten Lill, Treasurer

Peter Mascher, Journals Editorial Board Representative

Electrodeposition

Luca Magagnin, Chair

Politecnico di Milano

Andreas Bund, Vice Chair

Rohan Akolkar, Secretary

Adriana Ispas, Treasurer

Takayuki Homma, Journals Editorial Board Representative

Electronics and Photonics

Qiliang Li, Chair

George Mason University

Vidhya Chakrapani, Vice Chair

Zia Karim, 2nd Vice Chair

Helmut Baumgart, Secretary

Travis Anderson, Treasurer

Khanna Aniruddh Jagdish, Journals Editorial Board Representative

Fan Ren, Journals Editorial Board Representative

Energy Technology

Katherine Ayers, Chair

Nel Hydrogen

Minhua Shao, Vice Chair

Hui Xu, Secretary

Iryna Zenyuk, Treasurer

Minhua Shao, Journals Editorial Board Representative

High-Temperature Energy, Materials, and Processes

Cortney Kreller, Chair

Los Alamos National Laboratory

Xingbo Liu, Senior Vice Chair

Teruhisa Horita, Junior Vice Chair

Dong Ding, Secretary/Treasurer

Minhua Shao, Journals Editorial Board Representative

Industrial Electrochemistry and Electrochemical Engineering

Paul Kenis, Chair

University of Illinois at Urbana-Champaign

Elizabeth Biddinger, Vice Chair

Chockalingam Karuppaiah, Secretary/Treasurer

Paul Kenis, Journals Editorial Board Representative

Luminescence and Display Materials

Eugeniusz Zych, Chair

Uniwersytet Wrocławski

Chong-Geng Ma, Vice Chair

Marco Bettinelli, Secretary/Treasurer

Im Won Bin, Journals Editorial Board Representative

Nanocarbons

Jeff L. Blackburn, Chair

National Renewable Energy Laboratory

Ardemis Boghossian, Vice Chair

Yan Li, Secretary

Hiroshi Imahori, Treasurer

Dirk M. Guldi, Journals Editorial Board Representative

Organic and Biological Electrochemistry

Shelley Minteer, Chair University of Utah

Jeffrey Halpern, 1st Vice Chair

Sabine Kuss, 2nd Vice Chair

Ariel Furst, Secretary/Treasurer

Janine Mauzeroll, Journals Editorial Board Representative

Physical and Analytical Electrochemistry

Stephen Paddison, Chair University of Tennessee, Knoxville

Anne Co, Vice Chair

Svitlana Pylypenko, Secretary

Iwona Rutkowska, Treasurer

David Cliffel, Journals Editorial Board Representative

Sensor

Larry Nagahara, Chair

John Hopkins University

Praveen Kumar Sekhar, Vice Chair

Dong-Joo Kim, Secretary

Leyla Soleymani, Treasurer

Netz Arroyo, Journals Editorial Board Representative

Stefano Cinti, Journals Editorial Board Representative

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 19

SOCIETY NEWS SOCIETY NEWS

New Division Officers

Chair

Dielectric Science and Technology Division

Sreeram Vaddiraju, Texas A&M University

Vice Chair

Eva Kovacevic, GREMI/Université d’Orléans

Secretary

Zhi David Chen, University of Kentucky

Treasurer

Thorsten Lill, Lam Research Corporation

Members at Large

Gautam Banerjee, IBM Research

Vimal H. Chaitanya, New Mexico State University

Stefan De Gendt, imec

Dennis Hess, Georgia Institute of Technology

Hemanth Jagannathan, IBM Corporation Research Center

Zia Karim, Yield Engineering Systems

Steve Kilgore, NXP Semiconductor

Dong-Kyun Ko, New Jersey Institute of Technology

Paul Kohl, Georgia Institute of Technology

Hiroki Kondo, Nagoya University

Sunghwan Lee, Purdue University

Oana Leonte, Berkeley Polymer Technologies, Inc.

Durga Misra, New Jersey Institute of Technology

Yaw Obeng, National Institute of Standards and Technology

Neelakandan Santhosh Marath, Jožef Stefan Institute

Kay Song, Yield Engineering Systems

Kalpathy Sundaram, University of Central Florida

Mahendra Sunkara, University of Louisville

Chair

Industrial Electrochemistry and Electrochemical Engineering

Paul Kenis, University of Illinois at Urbana-Champaign

Vice Chair

Elizabeth Biddinger, City College of New York

Division Secretary/Treasurer

Chockalingam Karuppaiah, Vetri Labs

Members at Large

Christopher Arges, The Pennsylvania State University

Saket Bhargava, Dow Chemical Company

Gerardine Botte, Texas Tech University

Fikile Brushett, Massachusetts Institute of Technology

Damilola Daramola, Northeastern University

Luis Diaz Aldana, Idaho National Laboratory

James Fenton, University of Central Florida

Taylor Garrick, General Motors Holdings, LLC

Matthew Graaf, Corteva Agriscience

John Harb, Brigham Young University

Marta Hatzell, Georgia Institute of Technology

Shrisudersan Jayaraman, Corning, Inc.

Wenzhen Li, Iowa State University

Juan Lopez-Ruiz, Pacific Northwest National Laboratory

Trung Van Nguyen, University of Kansas

Mark E. Orazem, University of Florida

Tyler Petek, Lubrizol Corporation

Doug Riemer, TDK Ventures

Shrihari Sankarasubramanian, University of Texas at San Antonio

Robert Savinell, Case Western Reserve University

John Staser, Ohio University

Xiao Su, University of Illinois at Urbana-Champaign

Venkat Subramanian, University of Texas at Austin

William Tarpeh, Stanford University

Santosh Vijapur, Faraday Technology, Inc.

John Weidner, University of Cincinnati

Chair

Nanocarbons

Jeff L. Blackburn, National Renewable Energy Laboratory

Vice Chair

Ardemis Boghossian, École Polytechnique Fédérale de Lausanne

Secretary

Yan Li, Peking University

Treasurer

Hiroshi Imahori, Kyoto University

Members at Large

Noe Alvarez, University of Cincinnati

Mike Arnold, University of Wisconsin–Madison

Delphine Bouilly, Université de Montréal

Tatiana Da Ros, Università degli Studi di Trieste

Francis D’Souza, University of North Texas

Andrew Ferguson, National Renewable Energy Laboratory

Daniel Heller, Memorial Sloan Kettering Cancer Center

Mark Hersam, Northwestern University

Nicole Iverson, University of Nebraska–Lincoln

Markita Landry, University of California, Berkeley

Fernando Langa, Universidad de Castilla–La Mancha

Richard Martel, Université de Montréal

Nazario Martín, Universidad Complutense de Madrid

Shigeo Maruyama, University of Tokyo

Elisa Miller-Link, National Renewable Energy Laboratory

Anton Naumov, Texas Christian University

Roberto Paolesse, Università di Roma Tor Vergata

Slava V. Rotkin, The Pennsylvania State University

Ángela Sastre-Santos, Universidad Miguel Hernández de Elche

Steve Stevenson, Purdue University

Tomás Torres, Universidad Autónoma de Madrid

R. Bruce Weisman, Rice University

Yoko Yamakoshi, Laboratorium für Organische Chemie –ETH Zürich

Shangfeng Yang, University of Science and Technology of China

Ming Zheng, National Institute of Standards and Technology

20 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

2024-2025 ECS Committees

Executive Committee of the Board of Directors

Colm O’Dwyer

James Fenton

President, Spring 2025

Senior Vice President, Spring 2025

Francis D’Souza 2nd Vice President, Spring 2025

Robert Savinell

Gessie Brisard

Elizabeth Podlaha-Murphy

3rd Vice President, Spring 2025

Secretary, Spring 2028

Treasurer, Spring 2026

Christopher Jannuzzi Executive Director, Term as ED

Audit Committee

Gerardine Botte, Chair

Immediate Past President, Spring 2025

Colm O’Dwyer President, Spring 2025

James Fenton

Robert Micek

Senior Vice President, Spring 2025

Nonprofit Financial Professional, Spring 2025

Elizabeth Podlaha-Murphy Treasurer, Spring 2026

Education Committee

Alice Suroviec, Chair Spring 2025

Damilola Daramola Spring 2027

Samantha Gateman Spring 2026

David Hall Spring 2025

Stephen Maldonado Spring 2025

Elif Selin Sahin Spring 2025

Wen Shen Spring 2026

Maureen Tang Spring 2027

Fernando Garzon Spring 2028

Roseann Warren Spring 2028

New Student Member Spring 2026

Gessie Brisard

Secretary, Spring 2028

E. Jennings Taylor Chair, Individual Membership Committee, Spring 2026

Ethical Standards Committee

Gerardine Botte, Chair

Gessie Brisard

Immediate Past President, Spring 2025

Secretary, Spring 2028

Peter Fedkiw Past Officer, Spring 2026

Elizabeth Podlaha-Murphy

Treasurer, Spring 2026

Daniel Steingart Past Officer, Spring 2027

Finance Committee

Elizabeth Podlaha-Murphy, Chair

Gessie Brisard

Treasurer, Spring 2026

Secretary, Spring 2028

Paul Kenis Spring 2026

Dong-Joo Kim Spring 2025

Thorsten Lill Spring 2026

Robert Micek

Nonprofit Financial Professional, Spring 2025

Tim Gamberzky Chief Operating Officer, Term as COO

Honors and Awards Committee

Adam Weber, Chair Spring 2027

Elizabeth Biddinger Spring 2027

Stanko Brankovic Spring 2027

Mikhail Brik Spring 2028

Dev Chidambaram Spring 2026

Uroš Cvelbar Spring 2028

Alanah Fitch Spring 2025

Andrew Hoff Spring 2026

Shigeo Maruyama Spring 2025

Shirley Meng Spring 2026

Jean St-Pierre Spring 2025

Thomas Thundat Spring 2027

Siegfried Waldvogel Spring 2028

Colm O’Dwyer

Individual Membership Committee

President, Spring 2025

E. Jennings Taylor, Chair Spring 2026

Jedidian Adjetey Adjei Spring 2025

Uroš Cvelbar Spring 2026

Jiaxin Duan Spring 2025

Joshua Gallaway Spring 2027

Hussain Abdul Jabbar Spring 2027

Qizhi Liu Spring 2025

Shuthi T. Kumar Raj Spring 2025

Kent Jingxu Zheng Spring 2026

Gessie Brisard Secretary, Spring 2028

Alex Peroff Chair, Institutional Engagement Committee, Spring 2025

Institutional Engagement Committee

Alex Peroff, Chair Spring 2025

Vimal Chaitanya Spring 2026

Hanping Ding Spring 2026

Hemanth Jagannathan Spring 2026

Yaw Obeng Spring 2025

Santosh Vijapur Spring 2025

Yoko Yamakoshi Spring 2025

Jacob Ketter Spring 2027

Nominating Committee

Gerardine Botte, Chair

Immediate Past President, Spring 2025

Robert Savinell 3rd Vice President, Spring 2025

Mark Allendorf Spring 2025

Brett Lucht Spring 2025

Peter Mascher Spring 2025

Christopher Jannuzzi Executive Director, Term as ED

Technical Affairs Committee

James Fenton, Chair

Gerardine Botte

Senior Vice President, Spring 2025

Immediate Past President, Spring 2025

Francis D’Souza Chair, Publications Subcommittee, Spring 2025

Turgut Gür 2nd Immediate Past President, Spring 2025

Jennifer Hite Chair, Interdisciplinary Science and Technology Subcommittee, Spring 2025

Colm O’Dwyer President, Spring 2025

Robert Savinell Chair, Meetings Subcommittee, Spring 2025

Christopher Jannuzzi Executive Director, Term as ED

Publications Subcommittee of the Technical Affairs Committee

Francis D’Souza, Chair

Robert Savinell, Vice Chair

Robert Kelly

Vice President, Spring 2025

, Spring 2025

Editor-in-Chief (EIC), 5/31/2025

Ajit Khosla ECSSP, 10/21/2024

Krishnan Rajeshwar

Interdisciplinary Science and Technology Subcommittee of the Technical Affairs Committee

Jennifer Hite, Chair

Jeff L. Blackburn

Vidhya Chakrapani

Huyen

Rangachary Mukundan

James Noël Spring 2025

Alok Srivastava Spring 2027

Sreeram Vaddiraju Spring 2026

Symposium Planning Advisory Board of the Technical Affairs Committee

Robert Savinell, Chair

3rd Vice President, Spring 2025

Kathryn Ayers Chair, Energy Technology Division, Spring 2025

Jeff Blackburn Chair, Nanocarbons Division, Spring 2026

Dev Chidambaram Chair, Corrosion Division, Fall 2024

Jennifer Hite Chair, Interdisciplinary Science and Technology Subcommittee, Spring 2025

Paul Kenis Chair, Industrial Electrochemistry and Electrochemical Engineering Division, Spring 2026

Cortney Kreller Chair, High-Temperature Energy, Materials, & Processes Division, Fall 2025

Qiliang Li Chair, Electronics and Photonics Division, Spring 2025

Brett Lucht Chair, Battery Division, Fall 2024

Luca Magagnin Chair, Electrodeposition Division, Fall 2025

Shelley Minteer Chair, Organic and Biological Electrochemistry Division, Spring 2025

Larry Nagahara Chair, Sensor Division, Fall 2024

Stephen Paddison Chair, Physical and Analytical Electrochemistry Division, Spring 2025

Sreeram Vaddiraju Chair, Dielectric Science and Technology Division, Spring 2026

Eugeniusz Zych Chair, Luminescence and Display Materials Division, Fall 2025

Other Representatives

Society Historian

Roque Calvo Spring 2025

American Association for the Advancement of Science

Christopher Jannuzzi Term as Executive Director

National Inventors Hall of Fame

Adam Weber

Chair, Honors & Awards Committee, Spring 2027

John Muldoon Spring 2027

Bill Cohen Spring 2027

Elizabeth Podlaha-Murphy Treasurer, Spring 2026

E. Jennings Taylor Chair, Individual Membership Committee, Spring 2026

2nd

3rd Vice President

Interface

JSS EIC, 12/31/2024 Daniel Schwartz Spring 2025 Chunsheng Wang Spring 2025 TBD Fall 2024 Xingfan Jin Spring 2026 Marc Secanell Spring 2026 Meetings Subcommittee of the Technical Affairs Committee

Savinell, Chair 3rd Vice President, Spring 2025 Francis

Chair 2nd Vice President, Spring 2025 Xiaolin Li Spring 2026

Mascher Spring 2025 Xiao Su Spring 2027

Robert

D’Souza, Vice

Peter

Spring 2025

Spring 2025

Spring 2026

Spring 2026

Dinh

Spring 2026

Spring 2027

Jackson Spring 2025 Christopher Johnson Spring 2025

Spring 2027

Spring 2025

Alanah Fitch

David Hickey

Greg

Chockkalingam Karuppaiah

Luca Magagnin

Spring 2027

The Electrochemical Society Interface • Summer 2024 • www.electrochem.org 21 SOCIETY NEWS SOCIETY NEWS

2024 Leadership Circle Award Winners

The Electrochemical Society has honored long-term supporters with Leadership Circle Awards since the fall of 2002. These awards recognizing our partners in electrochemistry and solid state science are granted in the year an institutional partner reaches an anniversary milestone level. Congratulations to the ECS Institutional Partners who reached milestone levels in 2024. These companies have been tremendous partners with the Society over the years. Thank you for supporting our mission to advance theory and practice at the forefront of electrochemical and solid state science and technology, and allied subjects.

Gold Partner – 25 years

Teledyne Energy Systems, Inc.

Learn more about Teledyne Energy Systems at https://www.teledynees.com/ en-us

Silver Partners – 10 years

El-Cell GmbH

Learn more about El-Cell at http://www. el-cell.com/

Ford Motor Corporation

Learn more about Ford at http://corporate. ford.com/homepage.html

Ion Power, Inc.

Learn more about Ion Power at http://www. ion-power.com/

Metrohm USA, Inc.

Learn more about Metrohm at http://www. metrohmusa.com/

Western Digital Corporation

Learn more about Western Digital at https://www.sandisk.com/

Bronze Partner – 5 years

Pacific Northwest National Laboratory (PNNL)

Learn more about PNNL at https://www.pnnl.gov/ energy-storage

To learn more about the ECS Institutional Partnership Program, contact Anna Olsen, Senior Manager, Corporate Programs, at Anna. Olsen@electrochem.org

Creating Powerful Partnerships

ECS welcomes these great new additions to the institutional partnership program.

PalmSens BV

At PalmSens, we are committed to making electrochemistry easier, portable, and accessible for researchers and entrepreneurs. We provide a comprehensive range of instruments for electrochemistry, including the smallest potentiostat (EIS) module, the EmStat Pico, and our PalmSens4, which is one of the most versatile and compact EIS-capable devices in the market.

Learn more about PalmSens at https://www.palmsens.com/

Sensolytics GmbH

Sensolytics GmbH specializes in developing and manufacturing analytical systems for characterizing local electrochemical properties. Besides our highly modular scanning electrochemical microscopes

NEXT ISSUE OF IN THE

The fall issue of Interface will be a special issue on battery safety, guest edited by Paul Shearing and Thomas Barrera Fall 2023 will also include 245th ECS Meeting highlights, the 2024 Toyota Young

(SECM) with the first commercialized shear-force-based distance control unit, Sensolytics offers individual scanning droplet cell systems (SDC) for high throughput screening applications in academia and industry. In addition to tailored instrument solutions, developed in close cooperation with our customers and marketed through a worldwide distribution network, Sensolytics provides the widest range of SECM tips on the market, various accessories such as measuring cells or polishing equipment, and sample preparation devices.

Learn more about Sensolytics GmbH at https://www.sensolytics.de/ en/

ECS’s Institutional Partnership Program opens doors to a network that helps organizations meet business goals and objectives. Contact sponsorship@electrochem.org for more information.

Investigator recipients, Pennington Corner, features favorites like EChem Education, Tech Highlights, and Looking at Patent Law, updates on ECS journal impact factors, and the latest news about people, students, and the Society.

22 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org SOCIETY NEWS SOCIETY NEWS

The Electrochemical Society book series provides authoritative, detailed accounts on specific topics in electrochemistry and solid state science and technology. These titles are sponsored by ECS and published in cooperation with Wiley.

ECS members receive 20% off all Wiley books. ECS members use promo code ECS18 at checkout.

New

uly

practical, single-source reference on the unique nature of seawater as a corrosive environment. Explains practical corrosion control solutions via design, proper materials selection, and implementation of good corrosion control engineering practices.

21 - CD5827 ON THE MOST TRUSTED RESOURCES IN ELECTROCHEMISTRY SAVE 20%

INTERESTED

PUBLISHING WITH US?

IN

LaQue’s Handbook on

David

ISBN

SECOND EDITION ATMOSPHERIC CORROSION

Please contact publications@electrochem.org to discuss your idea.

Marine Corrosion, 2nd Edition

A. Shifler

978-1-119-78883-6 | J

2022 A

EDITED BY DAVID A. SHIFLER LAQUE’S HANDBOOK OF MARINE CORROSION THE ELECTROCHEMICAL SOCIETY SERIES SECOND EDITION

Shop the Latest ECS Titles at wiley.com

Christofer Leygraf Inger Odnevall Wallinder Johan Tidblad Thomas Graedel

Websites of Note

Selected for you

by Alice H. Suroviec

On The Line

A podcast hosted by Products Finishing for individuals in the world of finishing. This monthly podcast interviews experts about the latest trends in electroplating, electrocoating, and mass finishing. Recent topics include wastewater management, trivalent chromium processes, and automation trends in the industry.

https://www.pfonline.com/podcast

Chemistry for Your Life

Chemistry for Your Life is a chemistry podcast for those who are curious about how the world around them works. This weekly podcast, which has covered topics from PFAS to mosquito bites to the chemistry of kombucha, is wide ranging and entertaining.

https://chemforyourlife.transistor.fm/episodes

About the Author The Finish Line

The Finish Line podcast covers all things related to surface finishing, including electroplating, anodizing, powder and liquid coatings, electrocoat, PVD, pretreatment, and wastewater treatment. The podcast is a hosted by the Editorin-Chief of Finishing and Coating (www.finishingandcoating. com) an e-zine updated daily with the latest news in surface finishing.

https://finishingandcoating.com/index.php/podcasts

Alice Suroviec is a Professor of Bioanalytical Chemistry and Dean of the School of Mathematical and Natural Sciences at Berry College. She earned a BS in Chemistry from Allegheny College in 2000. She received her PhD from Virginia Tech in 2005 under the direction of Dr. Mark R. Anderson. Her research focuses on enzymatically modified electrodes for use as biosensors. She is a Fellow of the Electrochemical Society and Associate Editor of the PAE topical interest area for the Journal of the Electrochemical Society. She welcomes feedback from the ECS community. https://orcid.org/0000-0002-9252-2468

UPCOMING ECS SPONSORED MEETINGS

ECS, its divisions, and its sections sponsor meetings and symposia of interest to the technical audience ECS serves as well as ECS biannual meetings and ECS satellite conferences. A partial list of upcoming sponsored meetings follows. Consult the ECS website for a complete list.

2025

19th International Symposium on Solid Oxide Fuel Cells (SOFC-XIX)

July 13–18, 2025 | Stockholm, Sweden

The Brewery Conference Center

To request ECS sponsorship of your technical event or to learn what ECS sponsorship can do for your meeting, contact ecs@electrochem.org.

24 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org SOCIETY NEWS SOCIETY NEWS

2024 ECS Officer Election Results and 2025 Slate of Officers

The results of the 2024 ECS officers’ election are:

PRESIDENT: Colm O’Dwyer, University College Cork

3RD VICE PRESIDENT: Robert Savinell, Case Western Reserve University

SECRETARY: Gessie Brisard, Université de Sherbrooke

TREASURER Elizabeth Podlaha-Murphy of Clarkson University’s term of office was not affected by the election.

At the May 30 Board of Directors meeting, members voted to approve the ECS Nominating Committee’s recommended 2025 ECS Officers Election slate of candidates. The candidates on the ballot for the election taking place from January to March 2025 are:

PRESIDENT: James Fenton, University of Central Florida

3RD VICE PRESIDENT: Marca Doeff, Lawrence Berkeley National Laboratory E. Jennings (EJ) Taylor, Faraday Strategies, LLC

Full biographies and candidate statements will be included in the Interface winter 2024 issue

SOCIETY NEWS SOCIETY NEWS Your Lab in a Box. Integrated Temperature Chamber (10 to 80°C) No additional external devices needed for battery cycling Fully featured Potentiostat, Galvanostat and EIS

independent test channels, no multiplexing Ideally suited for High-Precision Coulometry Excellent accuracy and signal-to-noise ratio Small Footprint, Easy to Setup and Operate

cell wiring required, full remote control via LAN sales@el-cell.com Discover the PAT-Tester-i-16, our All-in-One Solution for Multichannel Battery Testing! +49 40 79012 734 Contact us for more information: www.el-cell.com

Sixteen

No

ALLEN J. BARD

by Frances N. Chaves

by Frances N. Chaves

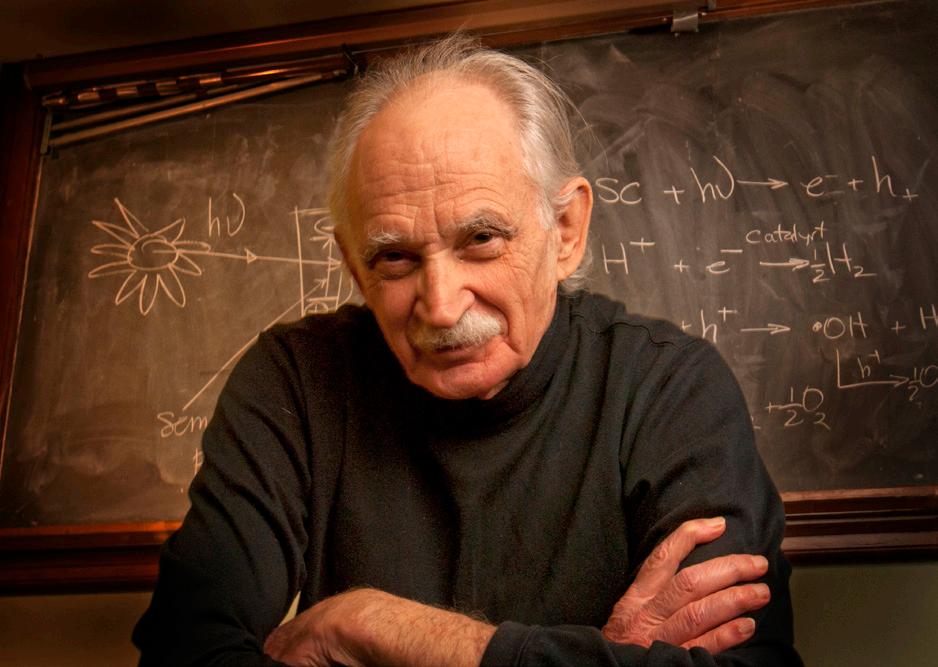

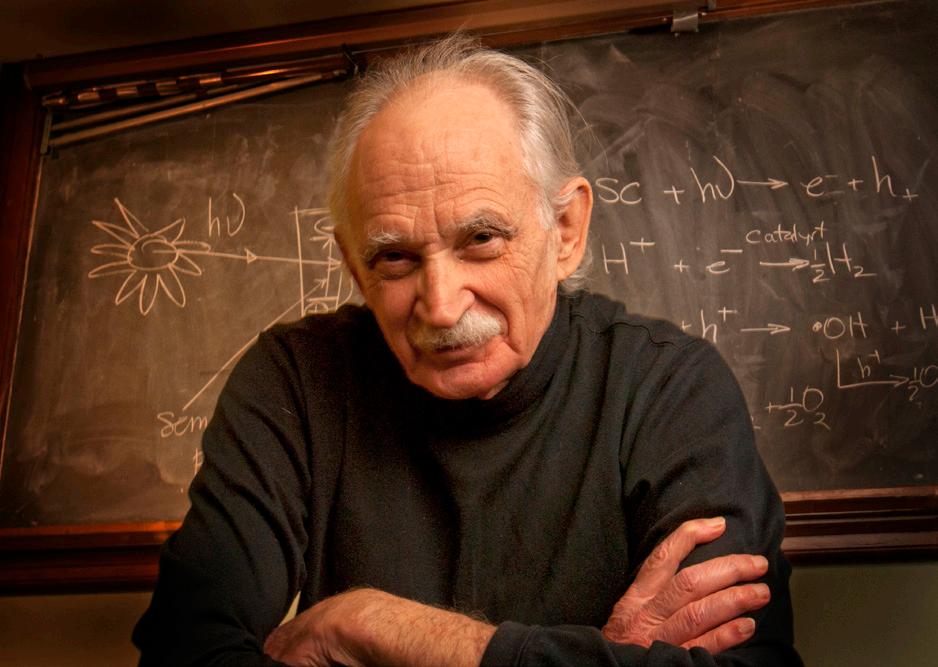

50+ YEAR SOCIETY MEMBER PIONEERED

The ECS community is mourning the passing of our colleague and friend, Allen (Al) J. Bard, on February 11, 2024. Throughout a distinguished career that brought him worldwide recognition for his pioneering scientific achievements, Al was a beloved and respected member of the ECS community as an author, Fellow, awardee, editor, meeting participant and organizer, and more.

“Al’s contributions to the advancement of electrochemistry and science are extraordinary, and his dedication to the advancement of many generations of younger scientists is legendary. If there is a common theme to his work, it is the pursuit of

fundamental scientific knowledge and discovery; Al was a fearless scientist, encouraging young scientists in his laboratory to constantly create and pursue their own ideas and experiments off the beaten path,” said Shelley D. Minteer and Henry White, co-editors of the Journal of The Electrochemical Society Focus Issue in Honor of Allen J. Bard

“Professor Bard was a humble genius who insisted that his students were his most important contribution. Certainly, ECS benefited largely from Bard’s commitment to teaching. Three of my fellow ECS presidents were his students: Larry Faulkner, ECS president from 1991 to 1992; Paul Kohl, ECS president from 2014 to 2015; and Johna Leddy, ECS president from 2017 to 2018,” said current ECS President Gerardine Botte. ECS Executive Director Christopher Jannuzzi added, “Professor Bard became an ECS member in 1965, setting a great example of service to the Society as a journal associate editor, chair of the ElectroOrganic Division (now the Organic and Biological Electrochemistry Division), and member-at-large of the ECS Texas Section. He enjoyed working with the Society’s governance and was especially proud to help establish organic/biological electrochemistry as an essential topical interest area for the Society, and, as a member of the

26 The Electrochemical Society Interface • Summer 2024 • www.electrochem.org

ECS CELEBRATES THE LIFE OF

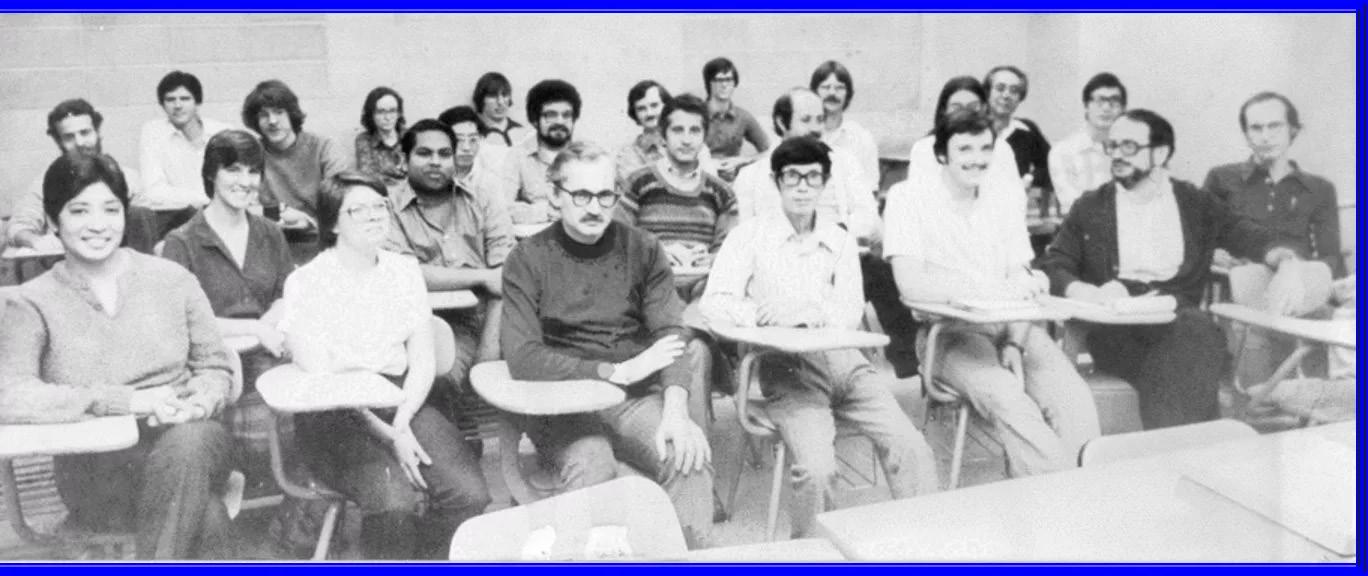

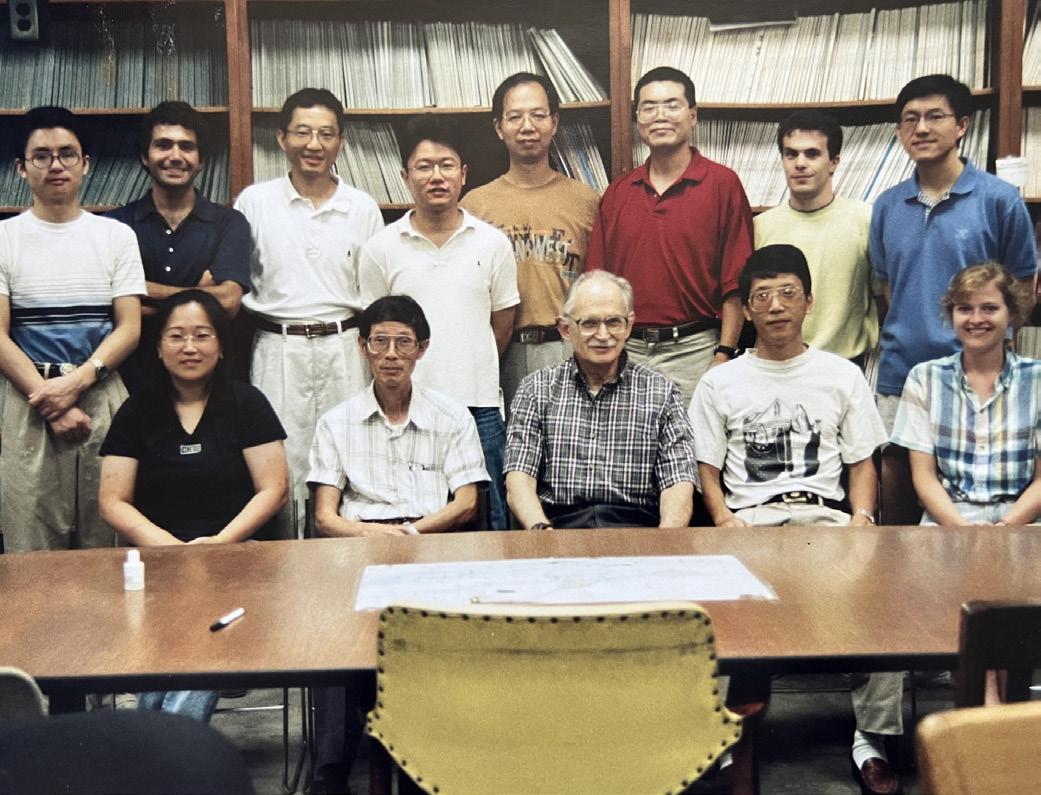

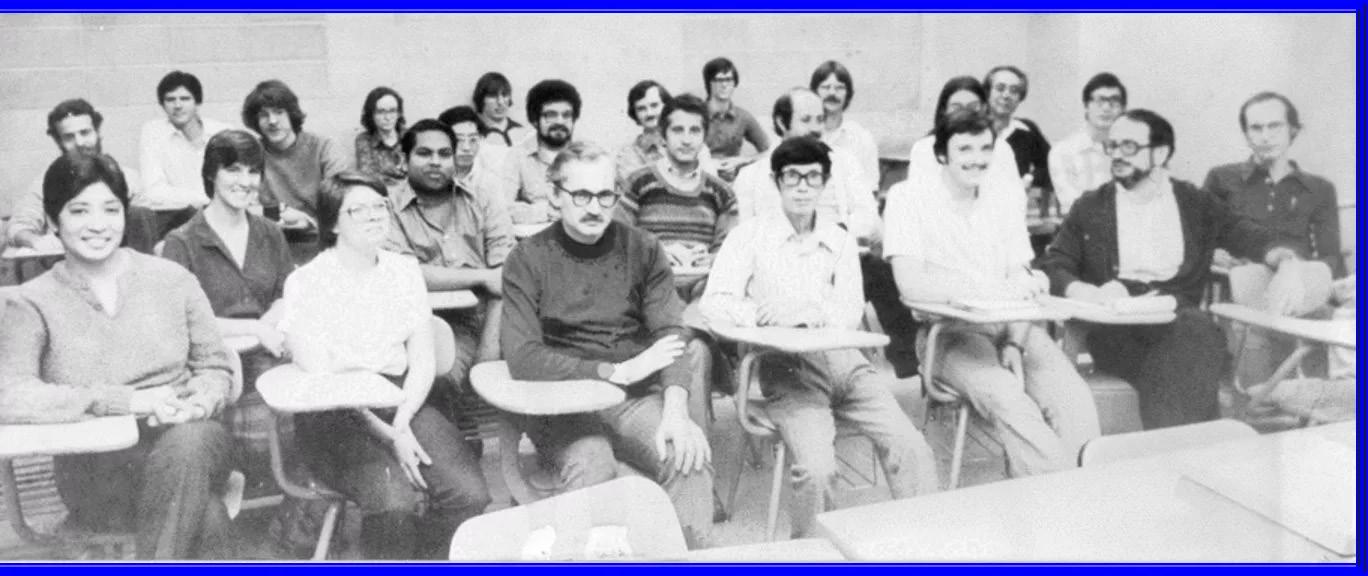

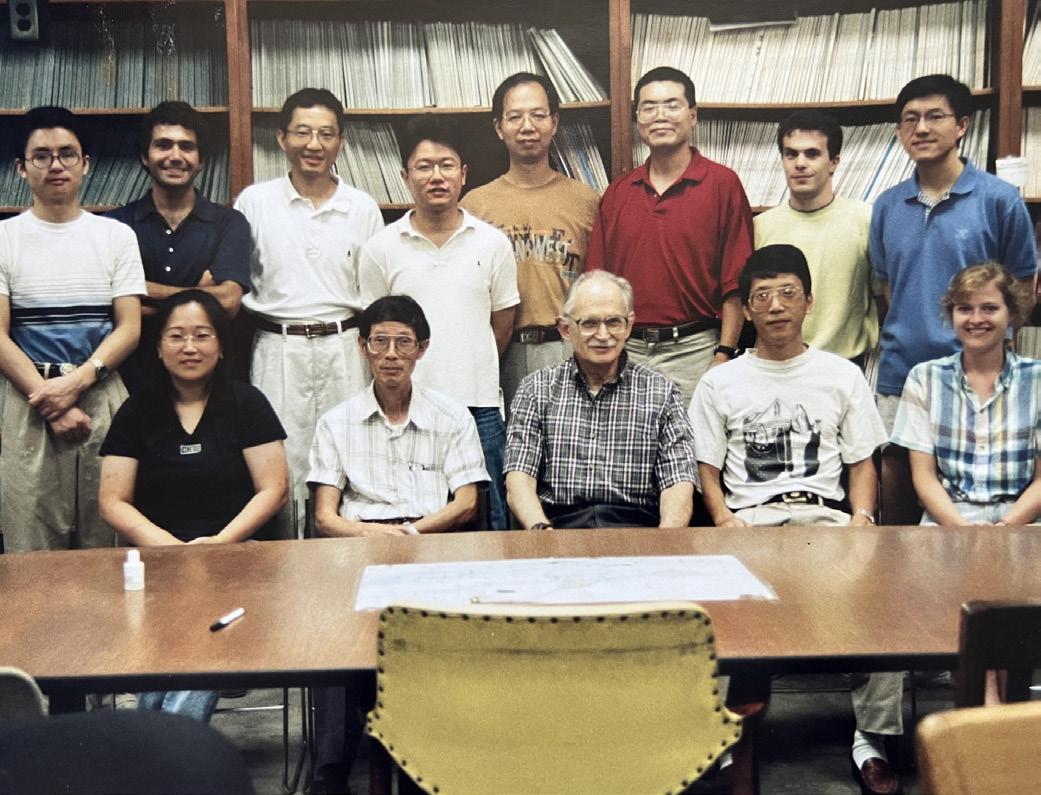

Bard Group picture from 1999 (shared by Shigeru Amemiya).

Allen J. Bard in 2011

ELECTROCHEMISTRY

What I am building is my students, and their students after them. And they will help build the edifice of science. That’s the most important thing that I do.”

Committee on the Free Dissemination of Research (2014–2015), he helped establish the Free the Science initiative.”

Life and Science

Al was born in New York City in 1933. In an ECS Masters Interview at the 227th ECS Meeting in May 2015, Al says he always knew he wanted to be a scientist and describes playing with his older brother’s chemistry set when he was only four or five years old! He attended the prestigious Bronx High School of the Sciences, then obtained his BS in Chemistry at City College of New York in 1955. After a brief stint in industry, he went on to Harvard University. There he was introduced to electrochemistry, which he said he “took to like a fish to water.” Under the supervision of renowned electroanalytical chemist James J. Lingane, Al received an MSc in 1956 and PhD in 1958. Norman Hackerman, University of Texas at Austin (UT-Austin) Chemistry Department Chairperson (and later president of the university), offered Al a teaching job with a salary of $5,200 a year and $5,000 for equipment. Although the New York native had never been to Texas, which he thought of as the Wild West filled with cowboys, he accepted the job. He taught there for 63 years—from 1958 until his retirement in 2021 as the Hackerman-Welch Regents Chair Professor and Director of the Center for Electrochemistry.

Al mentored more than 75 PhD students and 150 postdoctoral fellows. Their combined contributions to the field of electrochemistry are legendary, including electroanalytical techniques for evaluating electrode reaction mechanisms, simultaneous electrochemistry electron spin resonance (SEESR) techniques, nonaqueous solvents for investigating energetic species, electrogenerated chemiluminescence (ECL), polymer modified electrodes, semiconductor photoelectrochemistry, photocatalysis, scanning electrochemical microscopy (SECM), and single-particle collision electrochemistry.

The co-author of more than 1,000 publications (including 125 in the Journal of The Electrochemical Society) covering all areas of modern electrochemistry, Al produced 88 book chapters and other publications, and holds more than 30 patents. His 1980 book, Electrochemical Methods: Fundamentals and Applications, written with former student (and former ECS president) Larry Faulkner, is still the most widely used electrochemistry textbook. He served as Editor-in-Chief of the Journal of the American Chemical Society from 1982 to 2001. When asked in the Masters Interview how he produced this extraordinary volume of inventions and publications, he said, “I was very fortunate to have a lot of very good students.”

Awards and Accolades

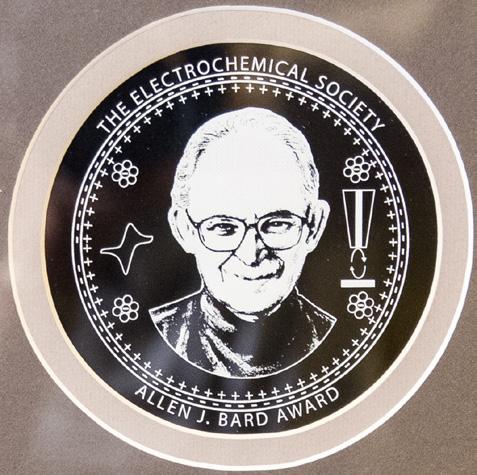

The Electrochemical Society named Al an Honorary Member in 2013 and Fellow of The Electrochemical Society in 1990. He received top ECS awards that include the 2007 Europe Section Heinz Gerischer Award, 1987 Olin Palladium Award, 1986 Henry B. Linford Award for Distinguished Teaching, and 1981 Carl Wagner Memorial Award.

ECS founded the Allen J. Bard Award in 2013 to honor the professor’s extensive contributions in the field of electrochemistry. The Bard award recognizes paradigm-shifting contributions in the field of electrochemical science and exceptionally creative

experimental or theoretical studies that have opened new directions in electroanalytical chemistry or electrocatalysis.

ECS published a focus Issue of the Journal of The Electrochemical Society in honor of Allen J. Bard in 2016. The 24 research articles in this special issue, many from former students and postdocs, covered the many electrochemistry topics impacted by Al during his career.

In 2013, President Barack Obama presented him with a National Medal of Science for Chemistry. At the awards ceremony, Obama said of Al and his colleague John B. Goodenough, “I am proud to honor these inspiring American innovators. They represent the ingenuity and imagination that has long made this nation great—and they remind us of the enormous impact a few good ideas can have when these creative qualities are unleashed in an entrepreneurial environment.”

Among the many awards Al received through his distinguished career are the 2019 King Faisal International Prize in Chemistry, 2014 Enrico Fermi Award, 2008 Wolf Prize in Chemistry, 2002 Priestley Medal, 1984 Charles N. Reilly Award in Electroanalytical Chemistry, and 1984 ACS Fisher Award in Analytical Chemistry. He was elected a Fellow of the American Academy of Arts and Sciences in 1990.

After Al

Al was asked about potentially significant areas of electrochemistry in the future. He replied, “I still think that eventually photoelectrochemistry will be a solution to the energy problem… It will take discoveries. But what I learned in my career is that discoveries do happen. You have to have faith; discoveries happen… and electrochemistry is the best way to get there.”

Al dismissed the notion that he is the “father of electrochemistry.” Rather, his primary focus was teaching and mentoring future generations of scholars and scientists. “What I am building is my students, and their students after them. And they will help build the edifice of science. That’s the most important thing that I do.”

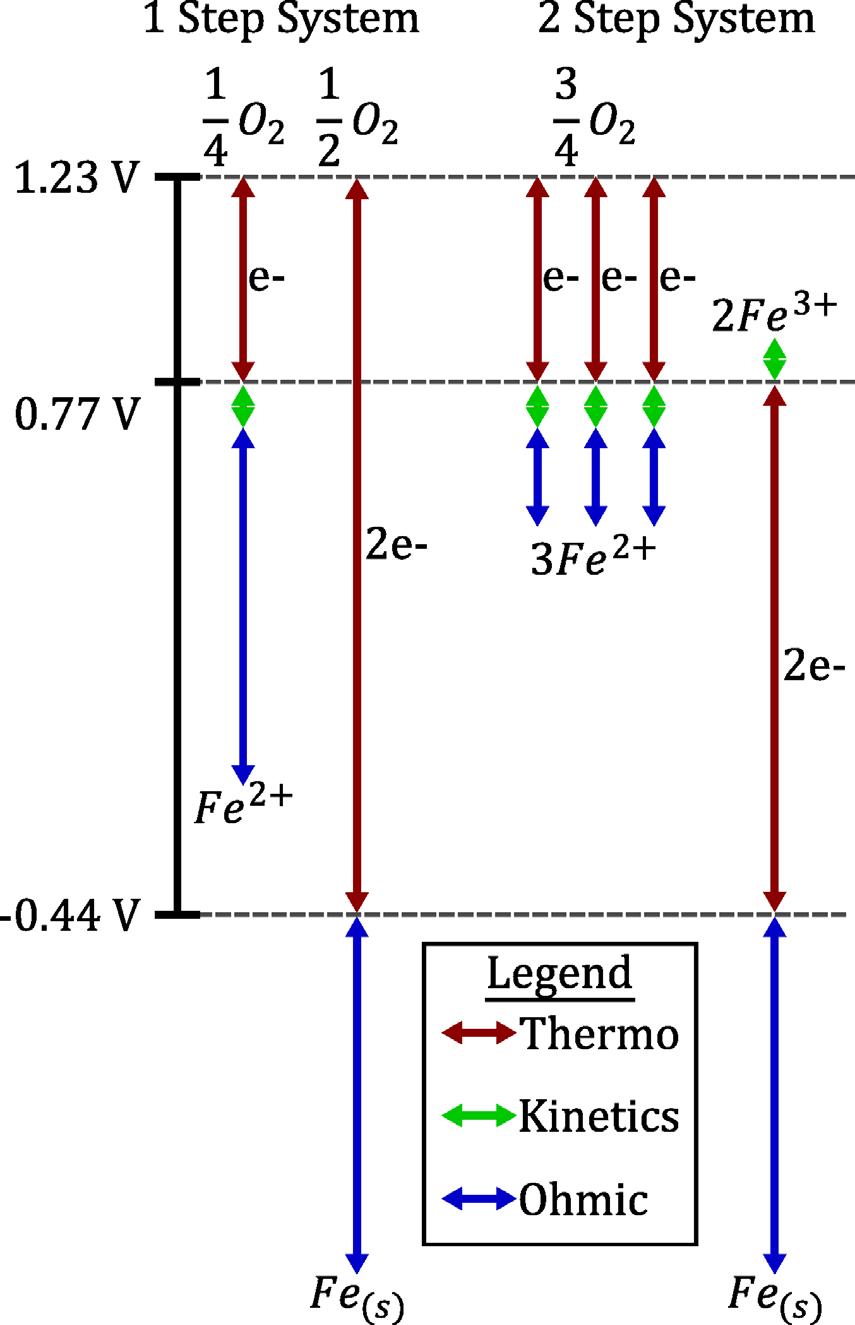

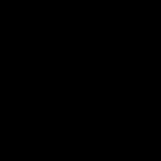

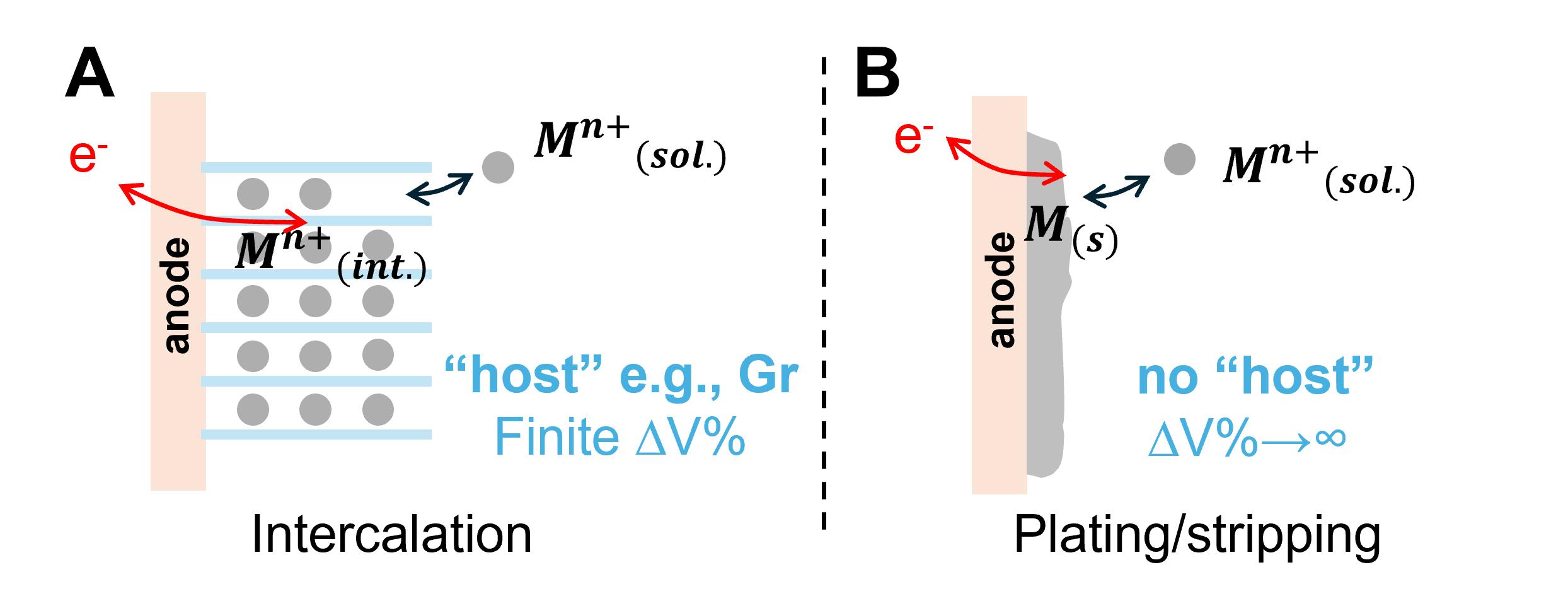

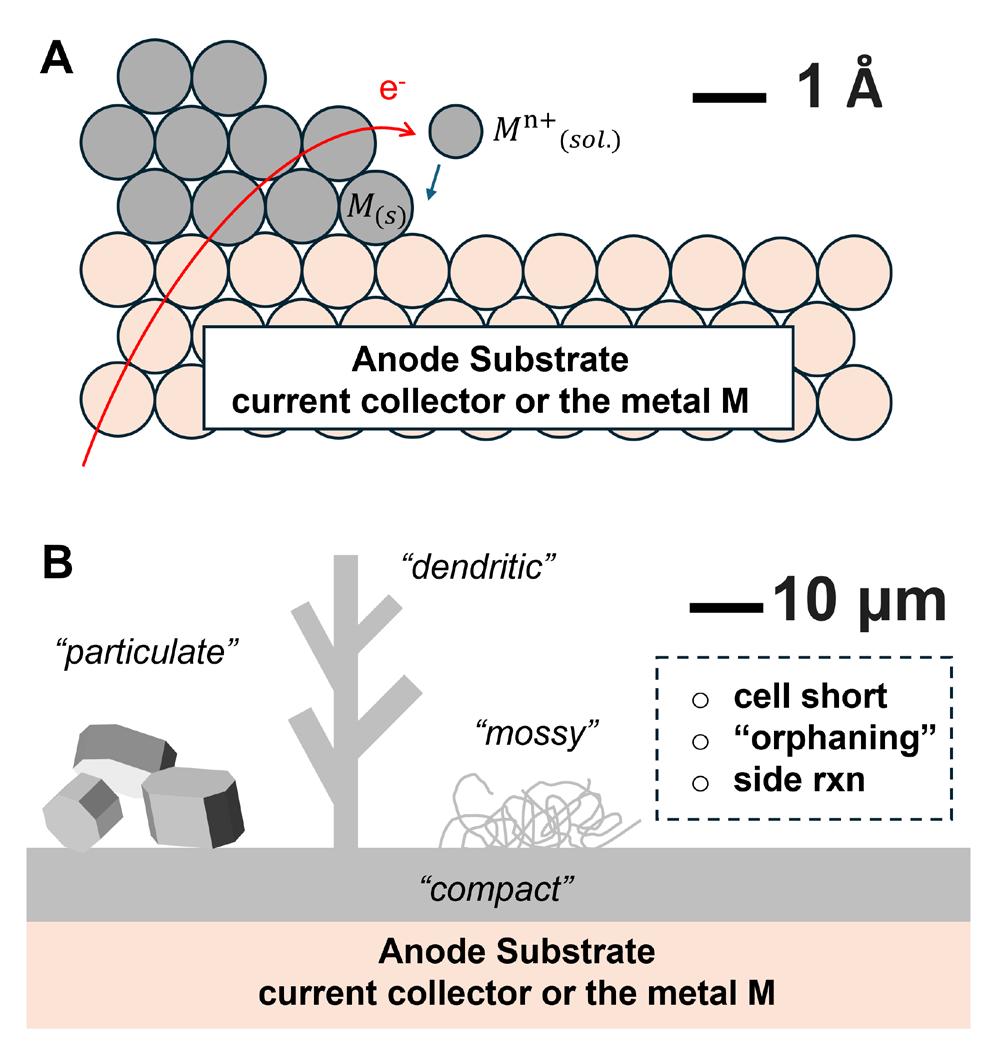

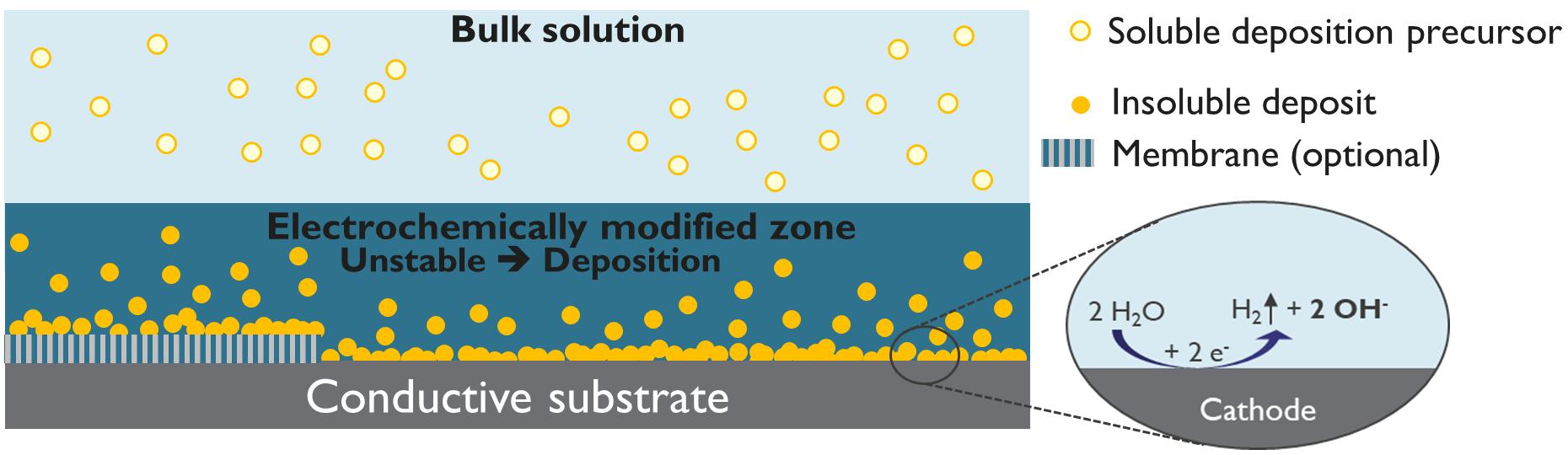

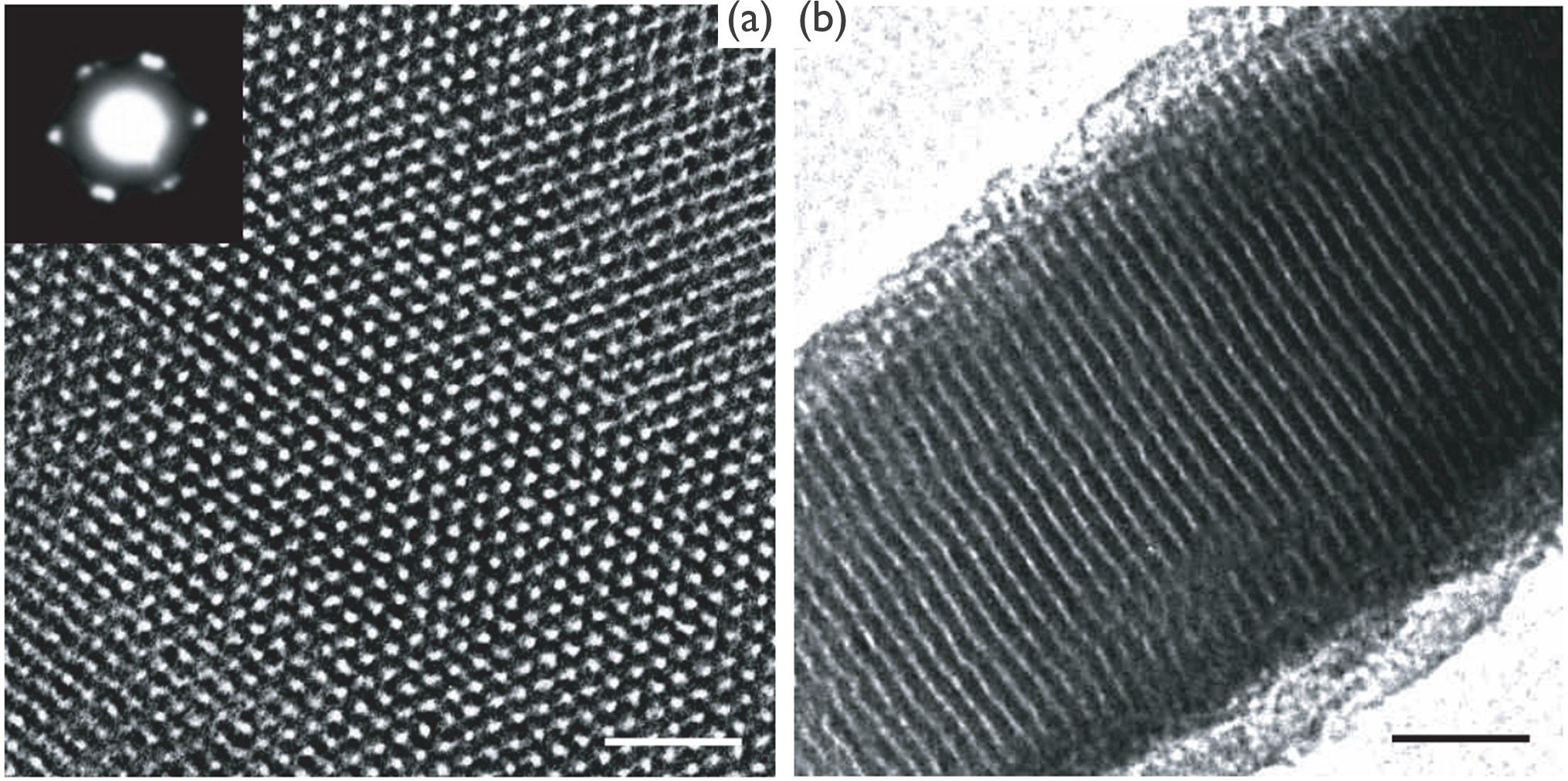

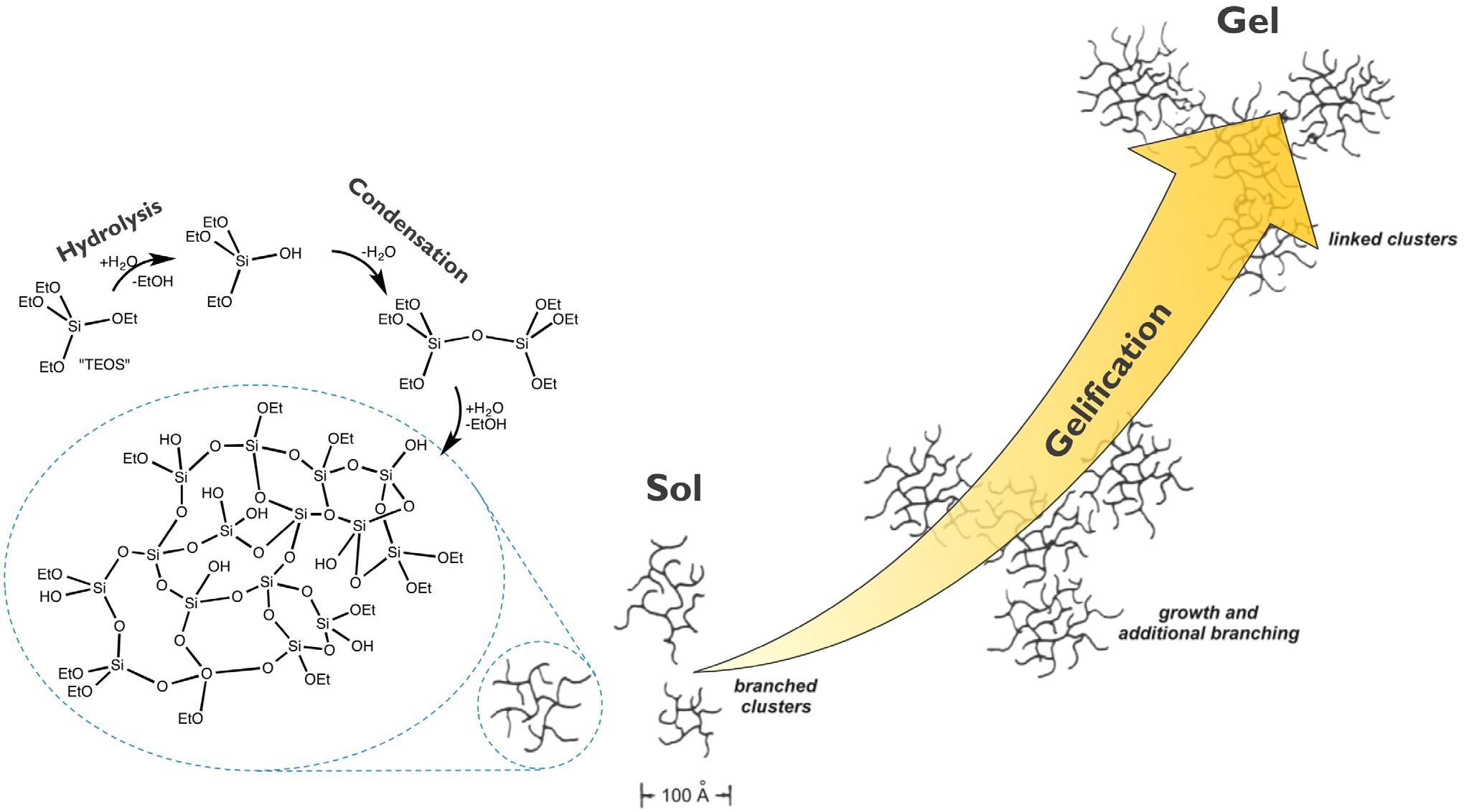

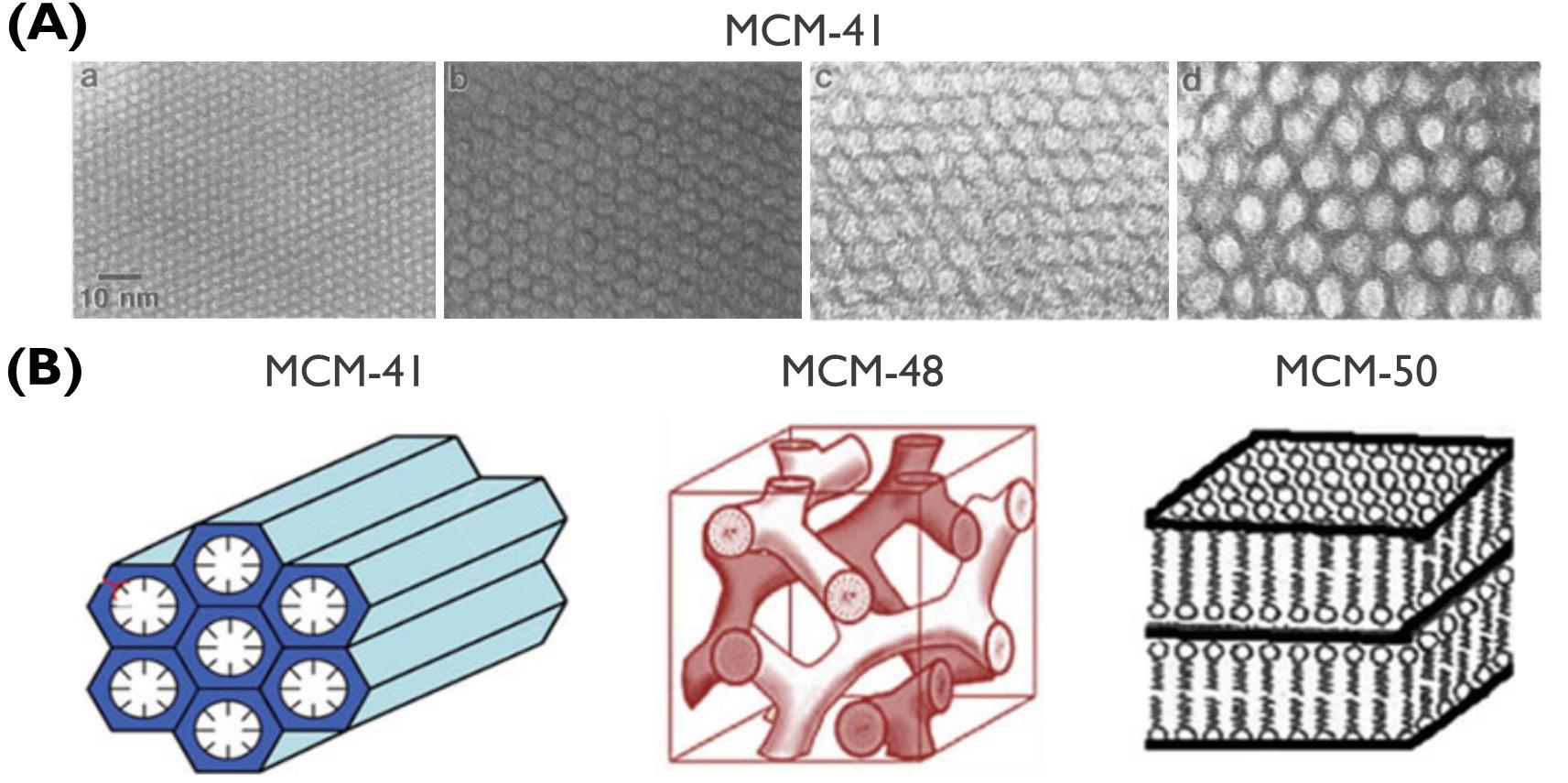

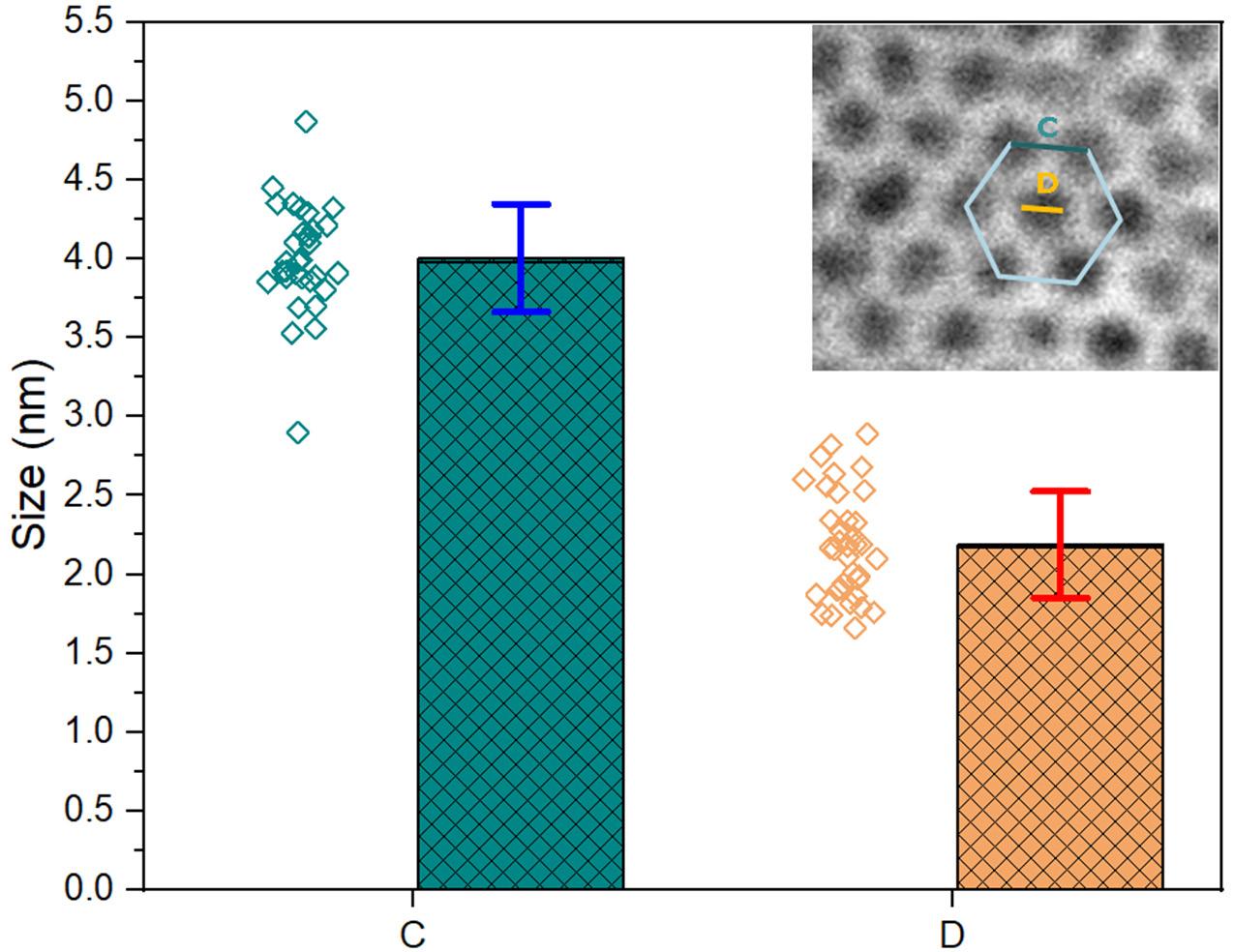

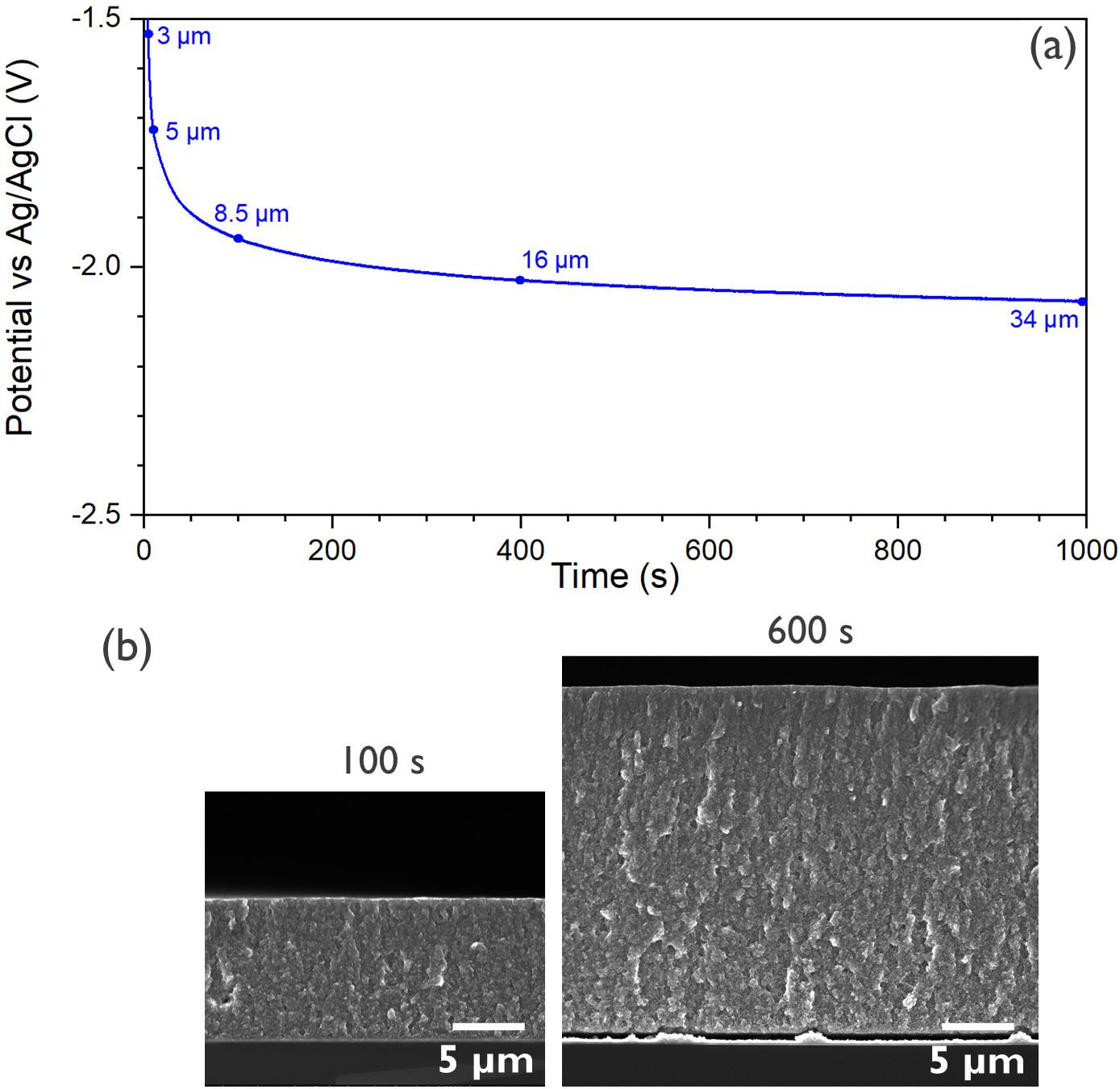

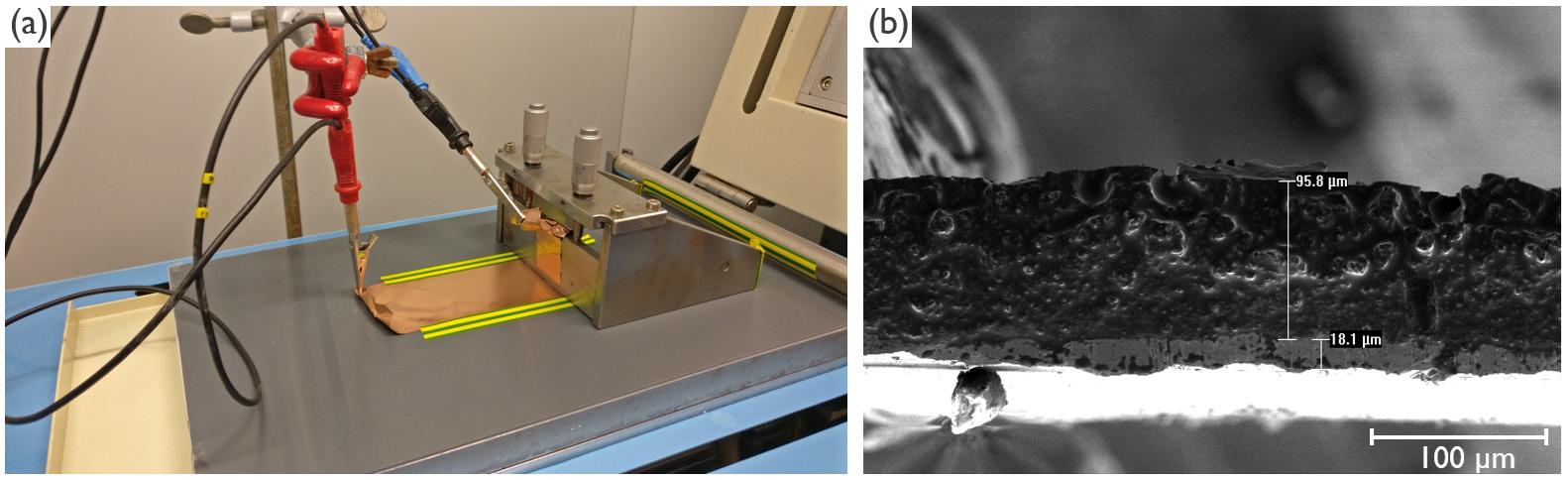

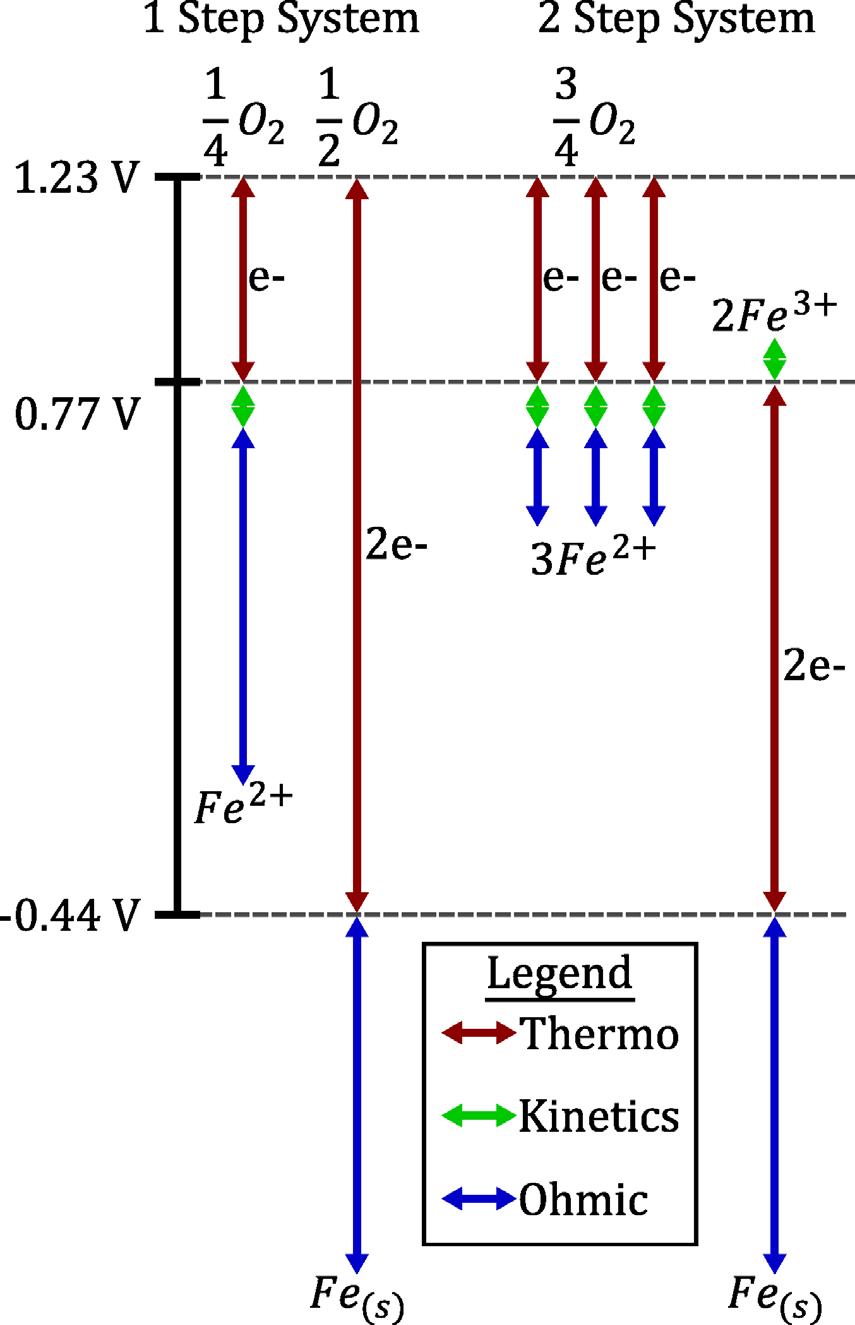

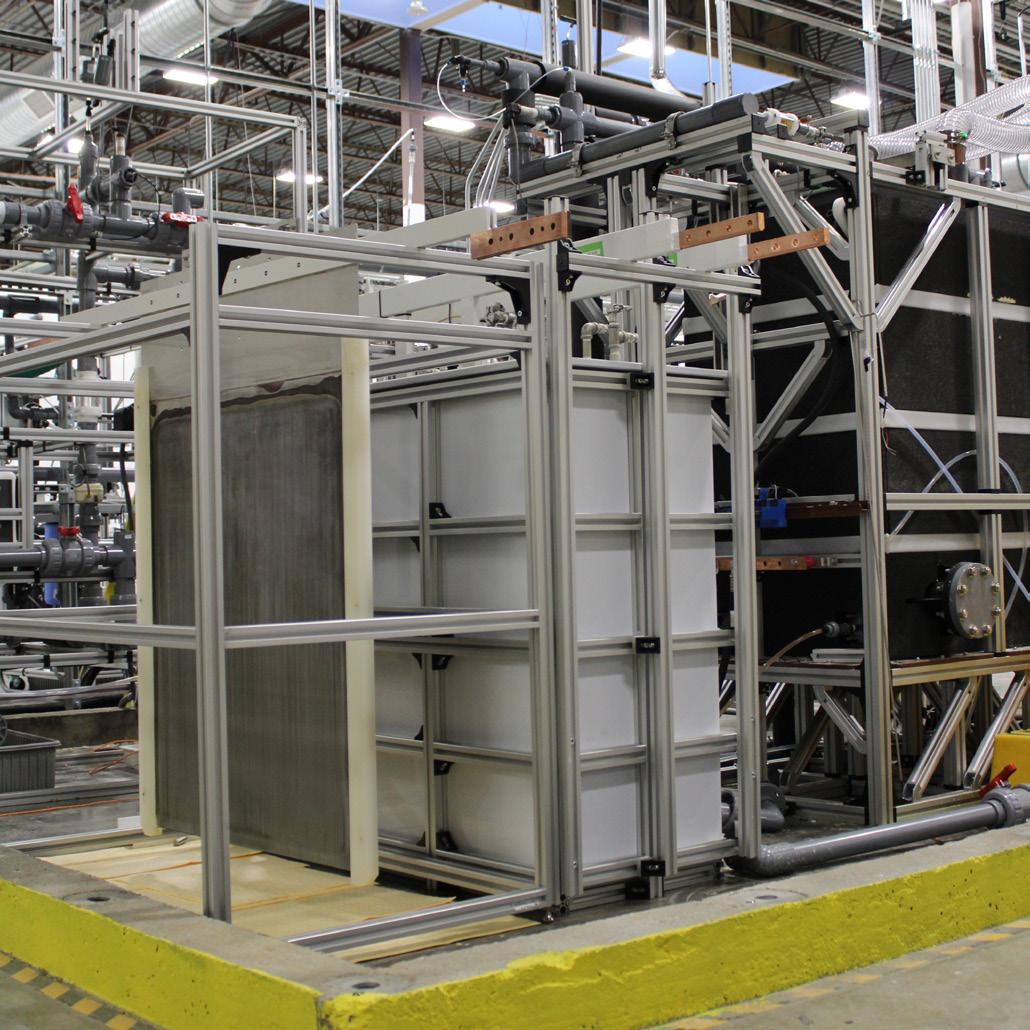

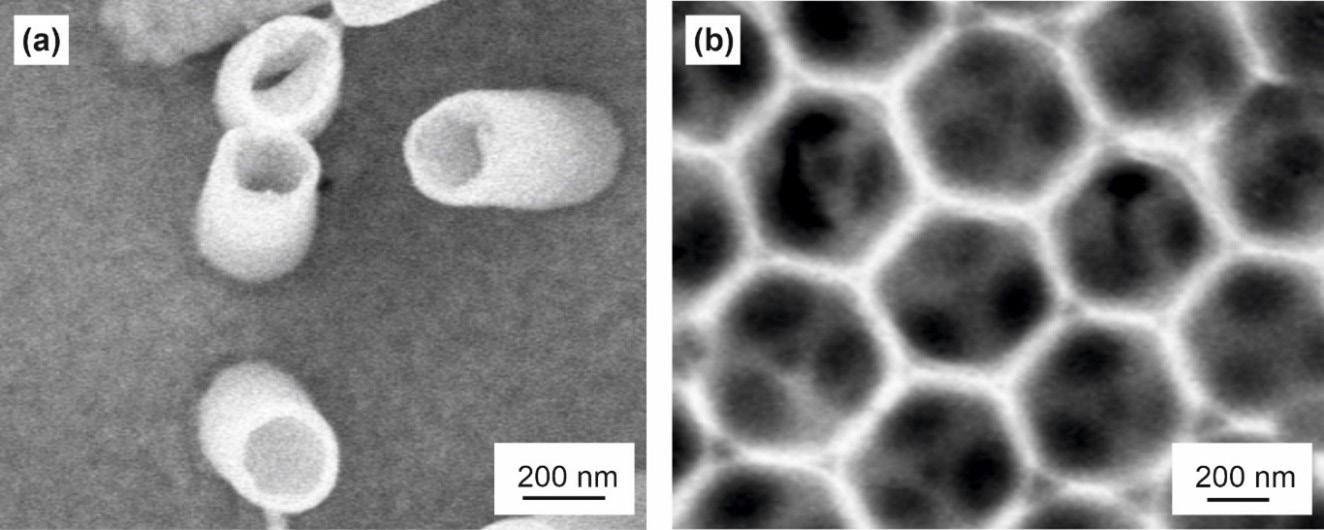

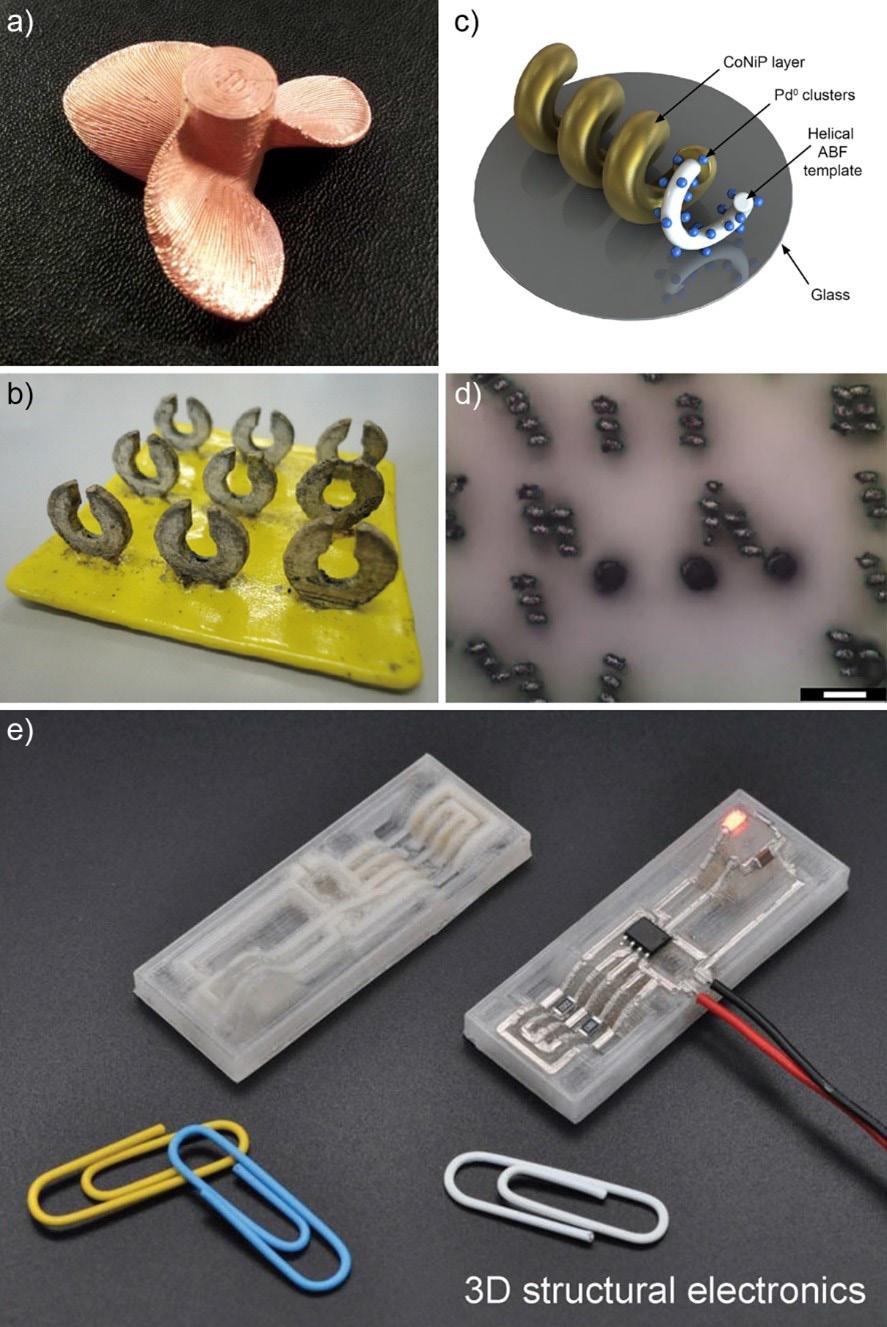

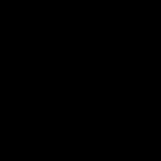

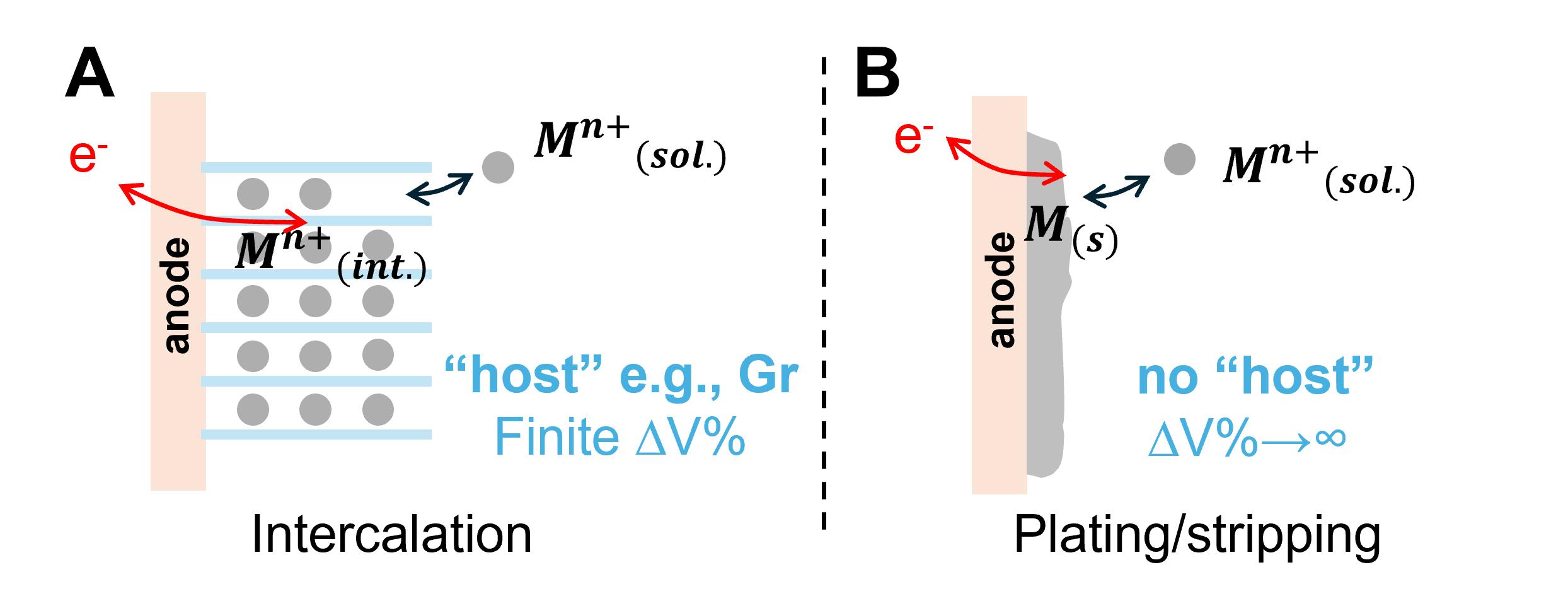

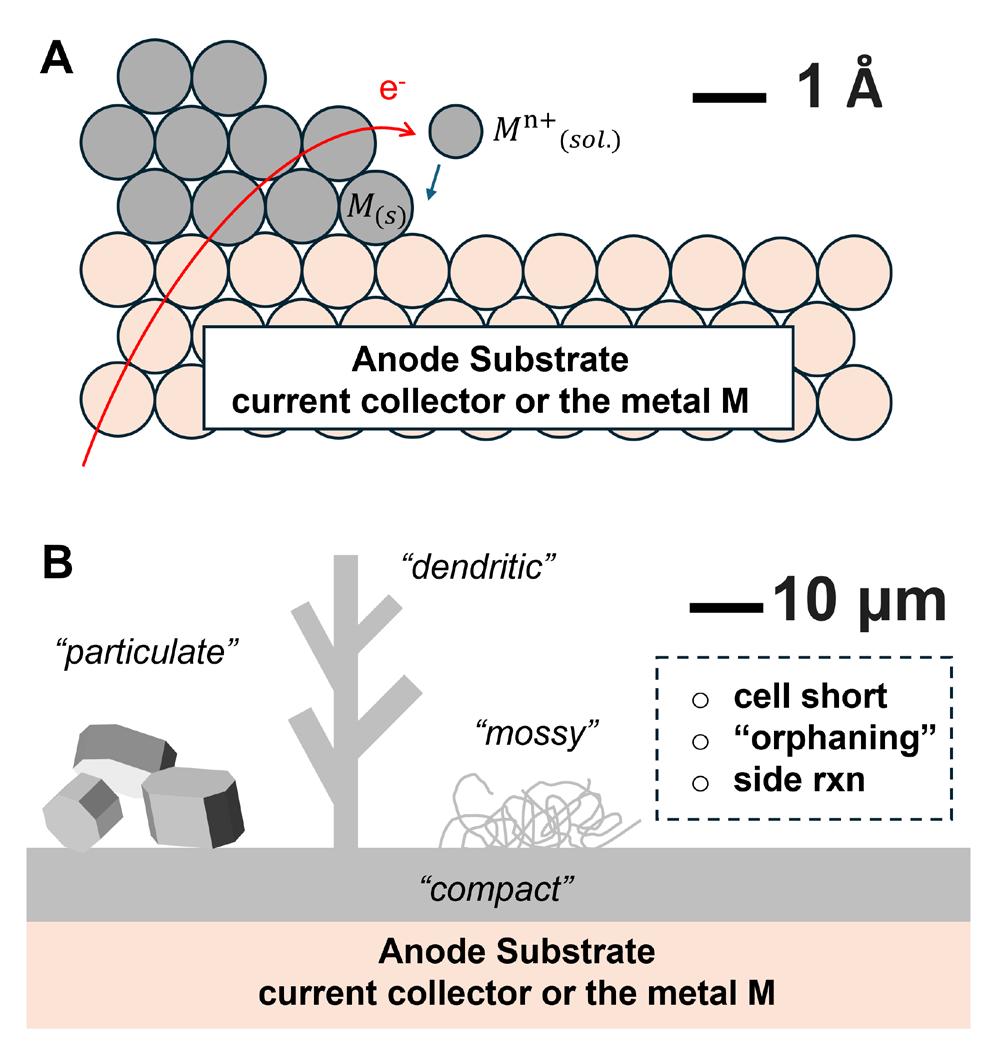

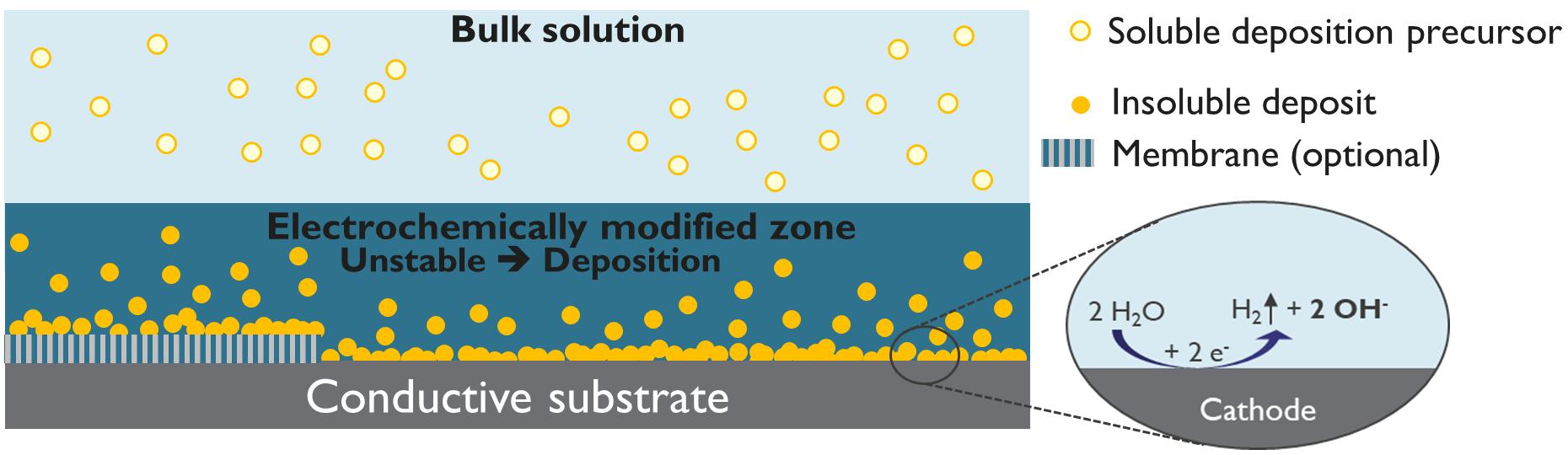

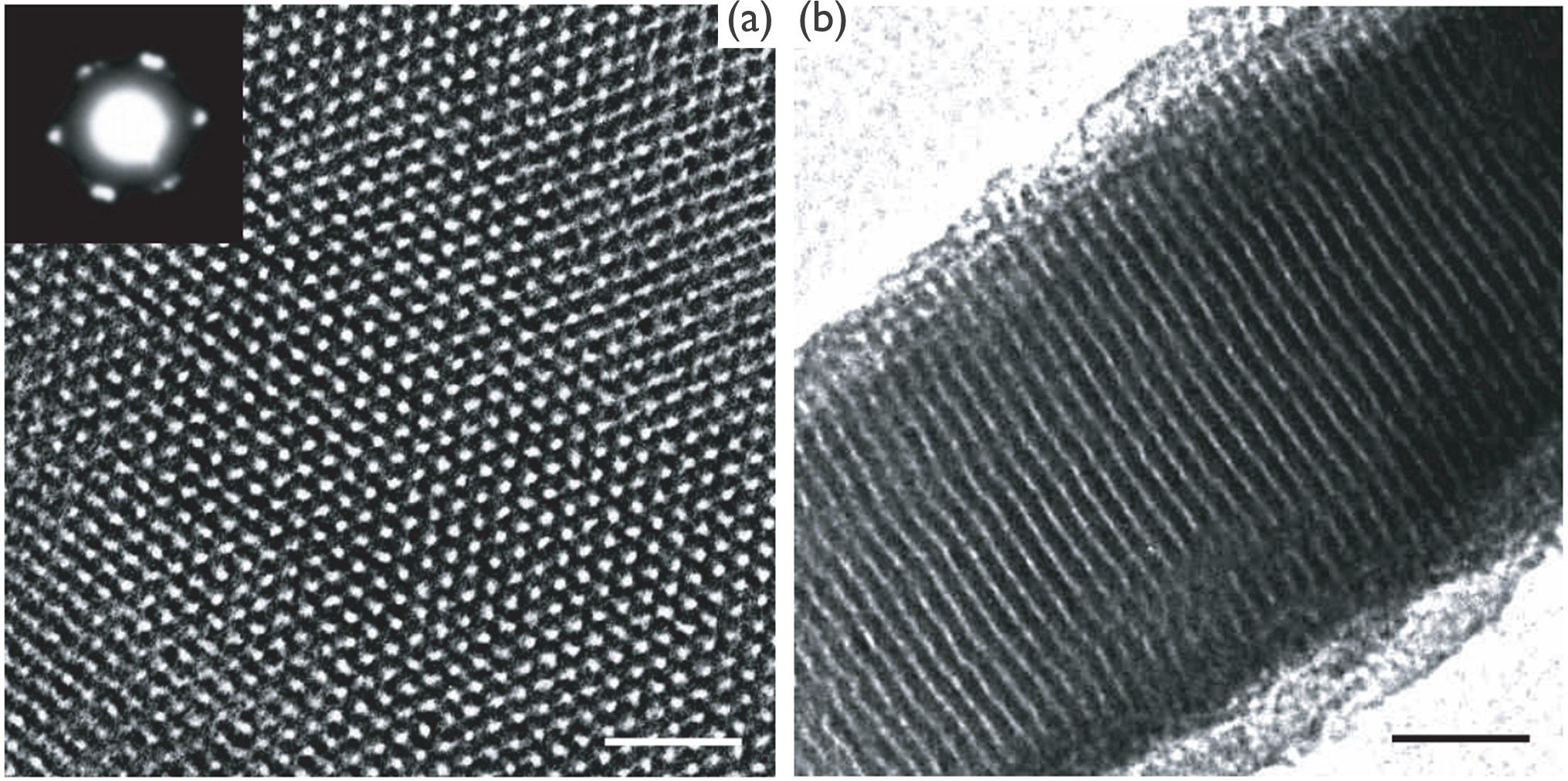

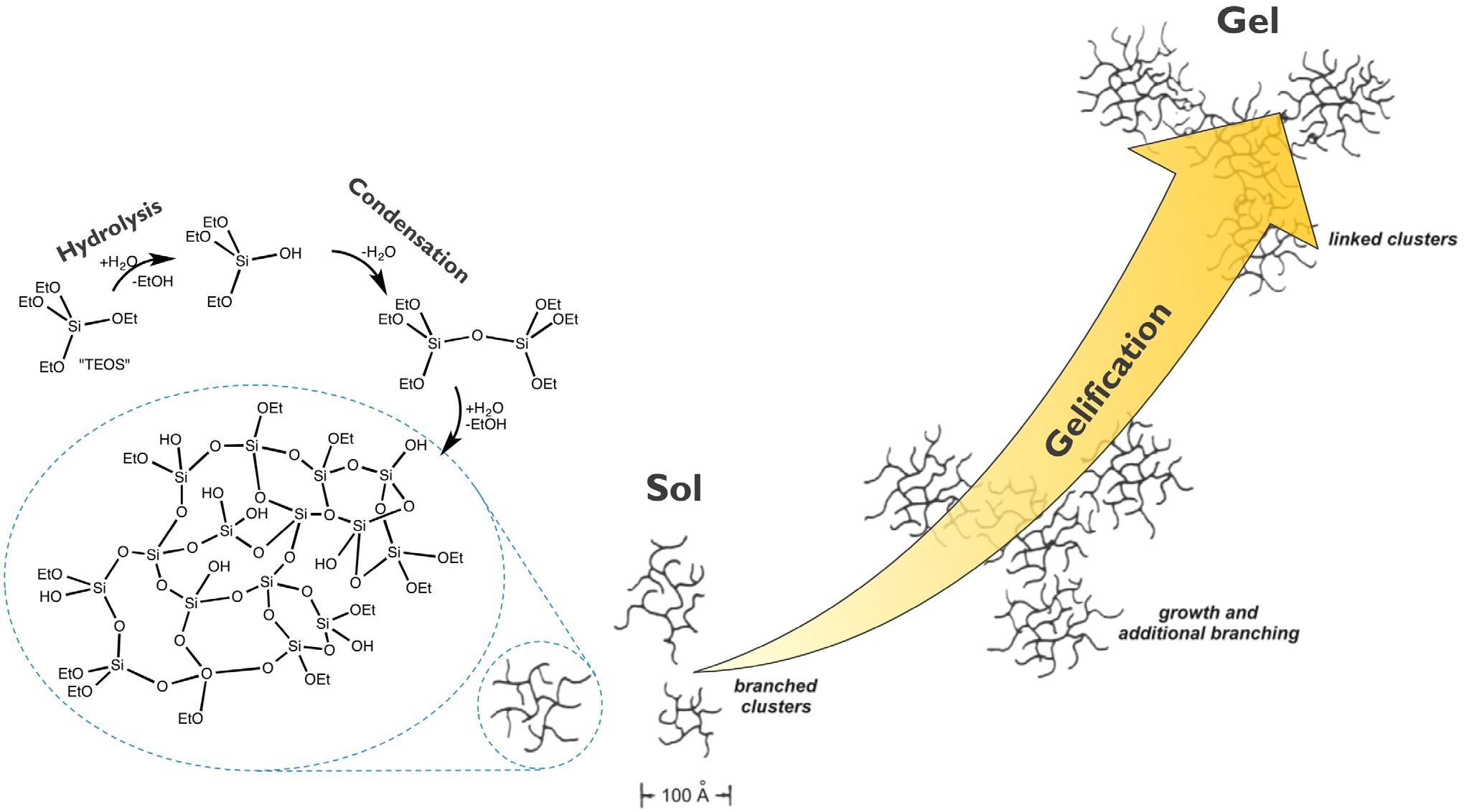

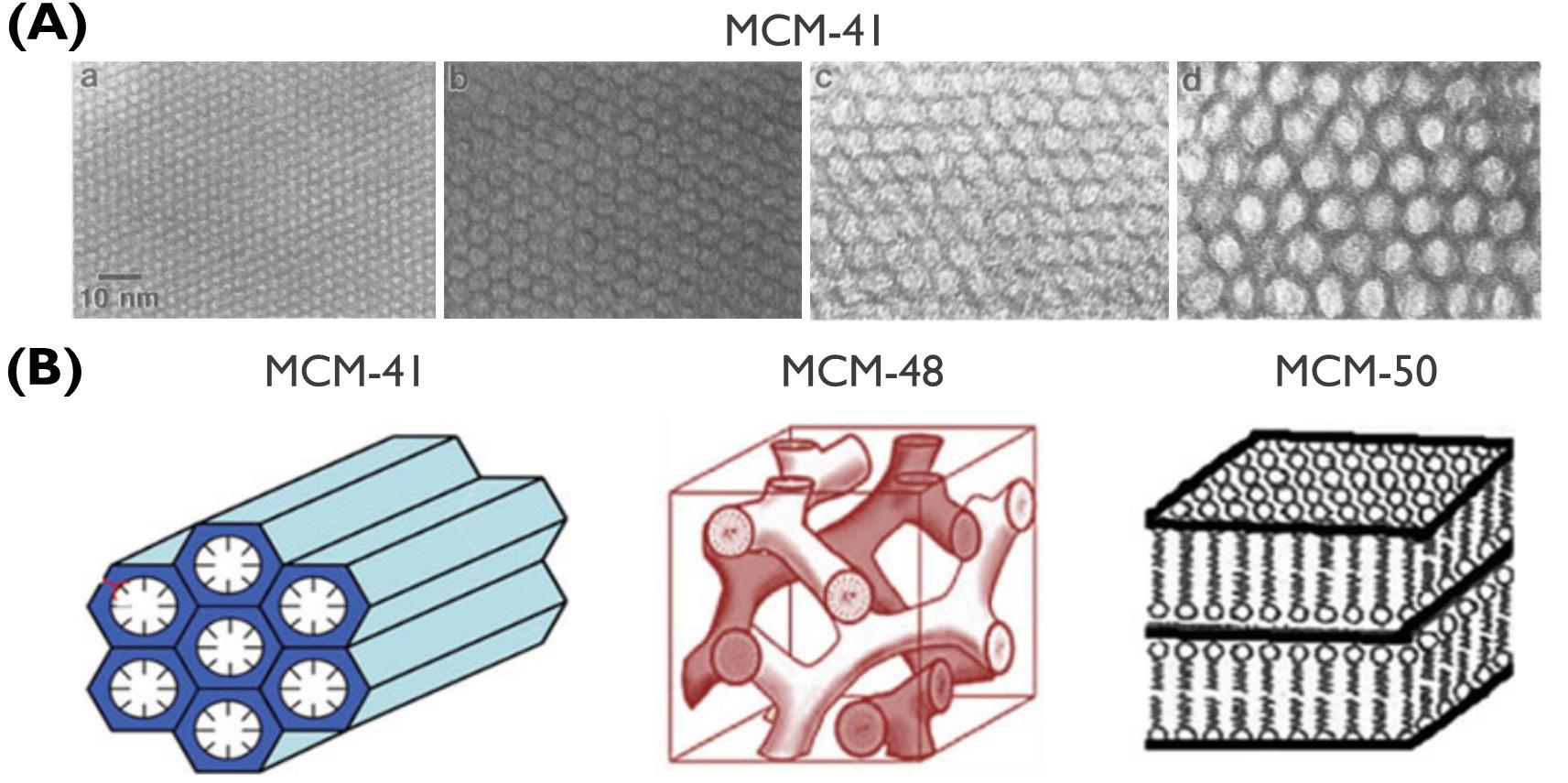

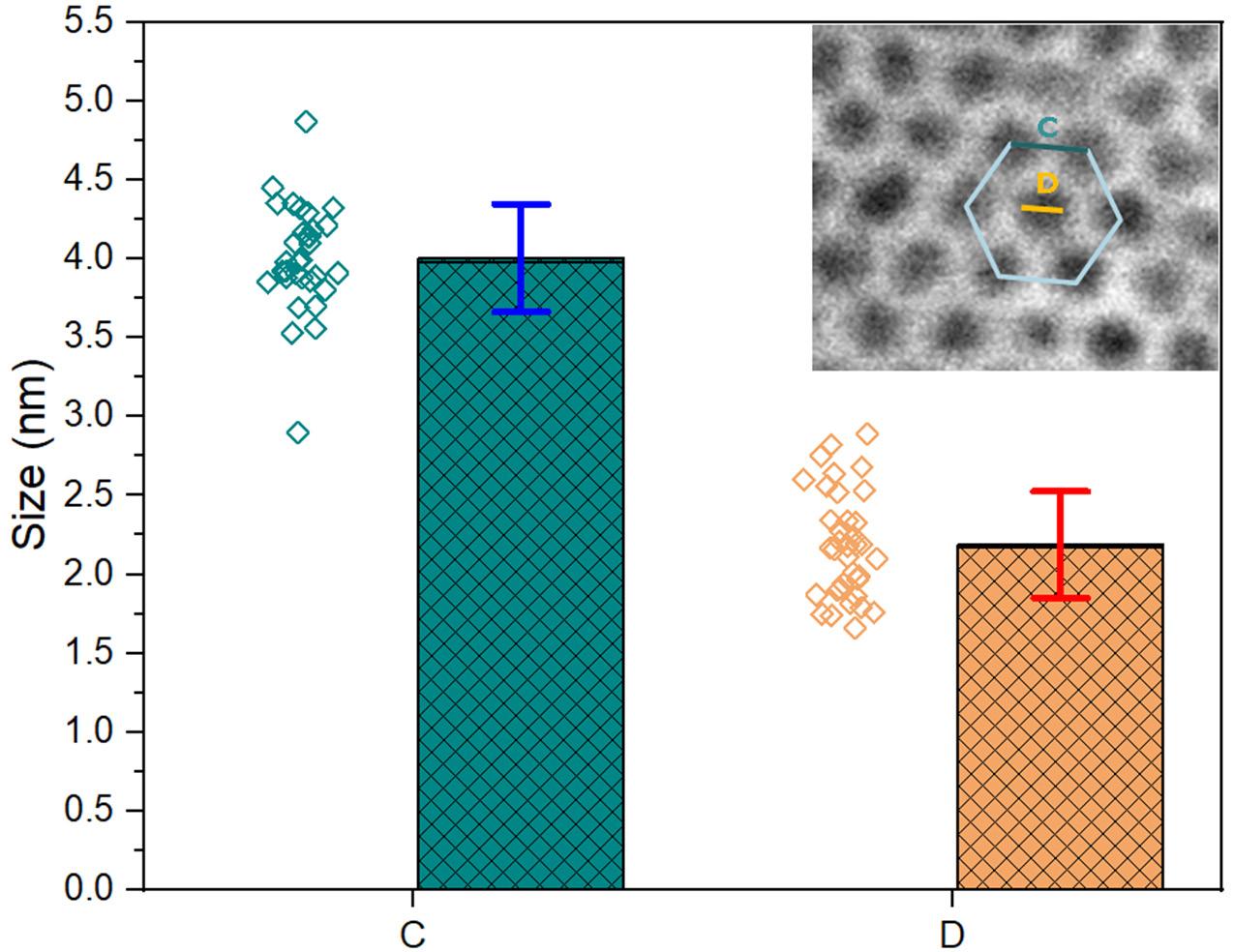

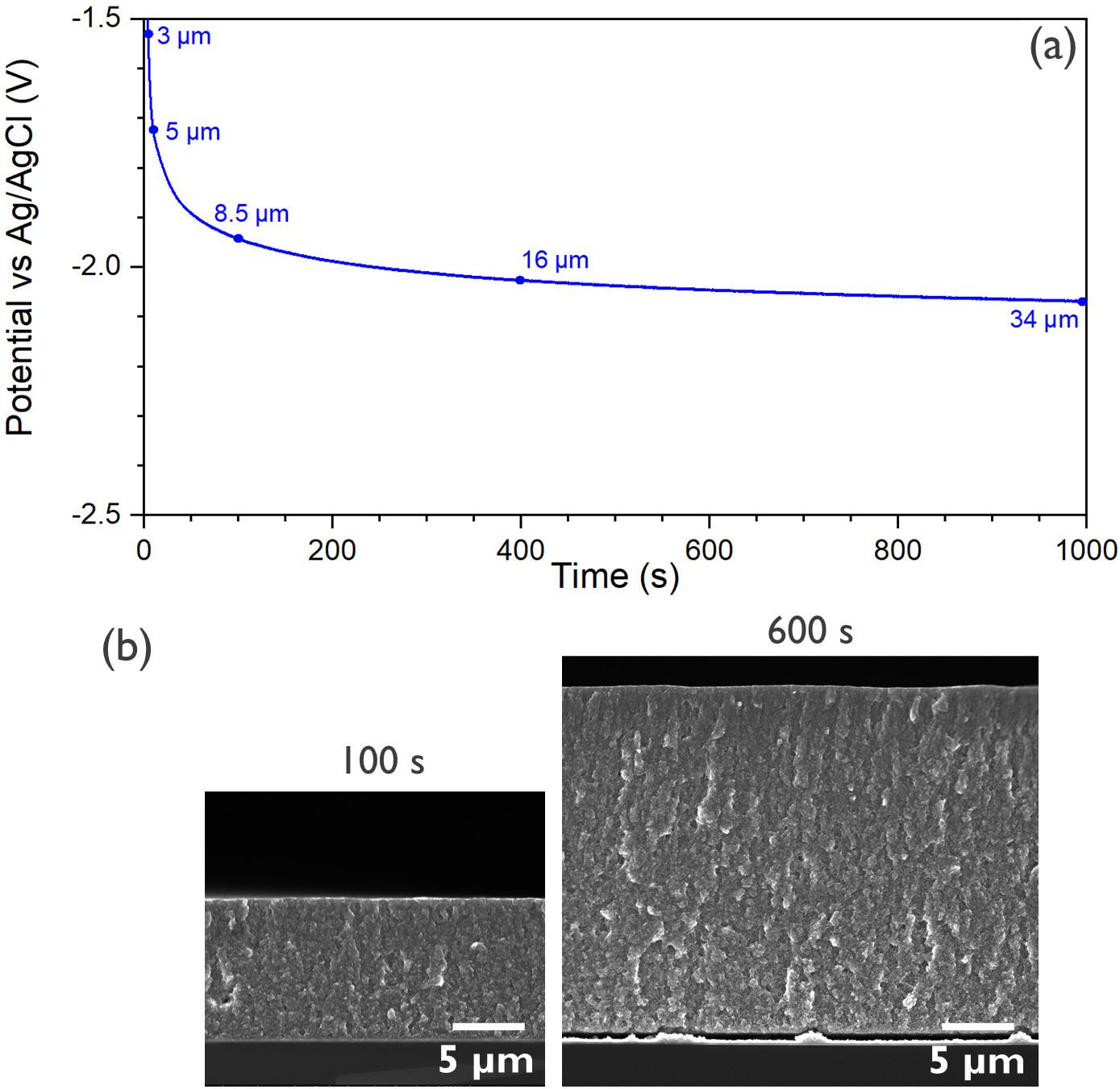

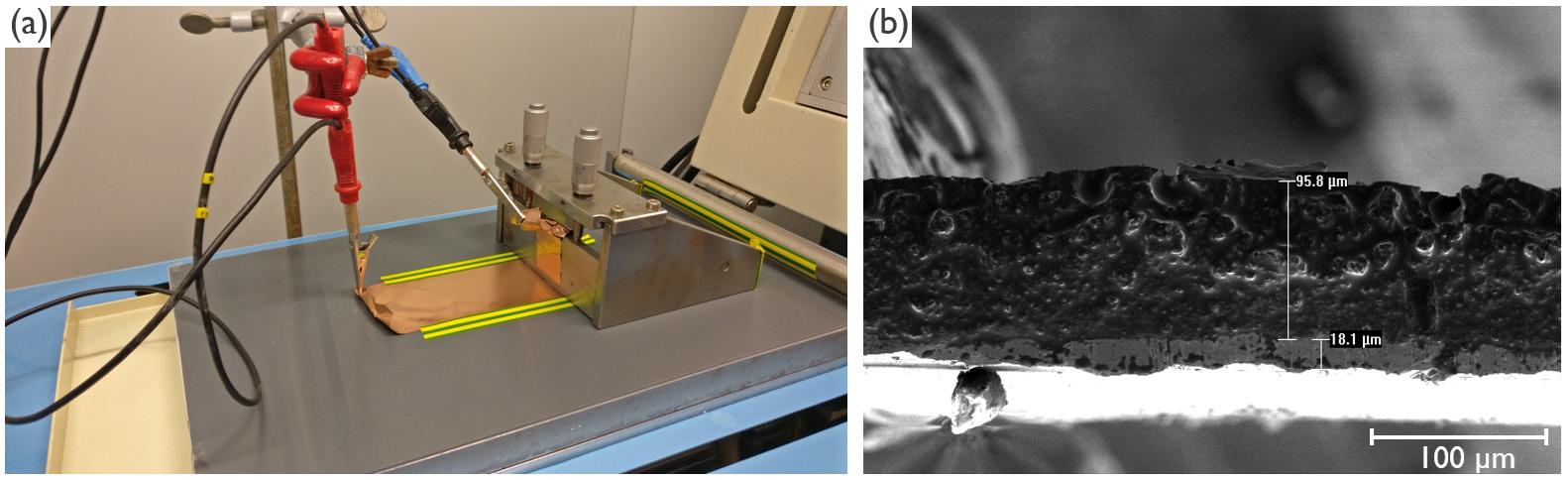

The images in this article were contributed by ECS members touched by Al. More remembrances are available in a collection curated by his former student, Xiaole (Joy) Chen. ©The Electrochemical Society. DOI: 10.1149/2.F03242IF