1 minute read

Bag

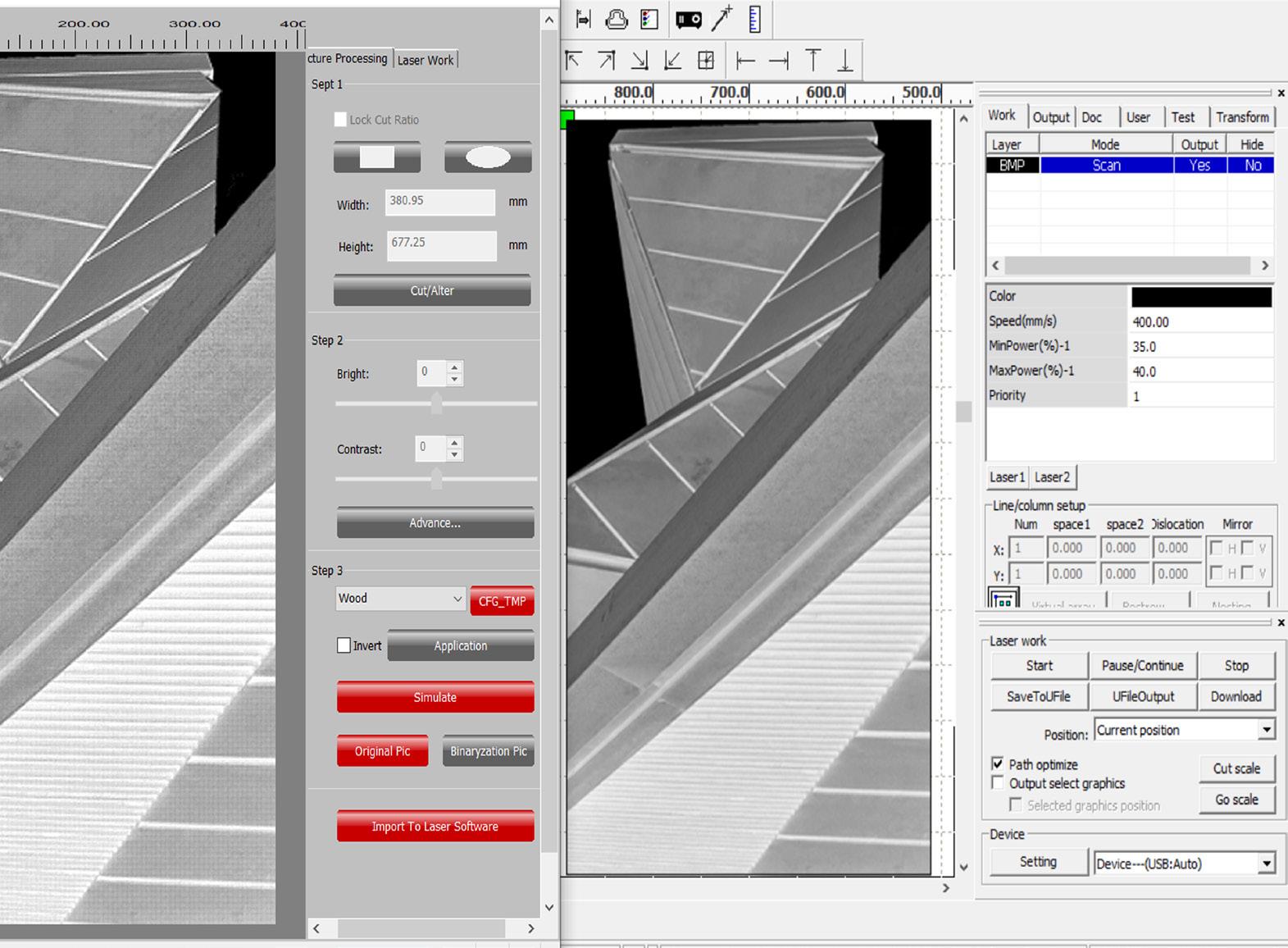

Utilizing as much of the biomaterial surface as possible positions the cut design so there is zero waste. BAG Using the same cutting parameters of the modules and the experience of cutting a lot of modules, I followed all the rules that I had imposed on myself, I decided to cut it first before silk-screening it. Use the entire surface for the base, sides, and reinforcements of the bag.

Advertisement

The next step was to screen print the bag so it is ready to sew.

Due to the detail of the design that I wanted to print, I used a mixture of transparent-based acramine with dark biomass, to be able to use a 77-thread screen and 120-thread for each side, to have a greater definition.

To start the new process, it is best to be organized and put everything as in gastronomy in “Mise en place” order and cleanliness are very important in all processes since that way you are faster and you can focus more on the task at hand in front.

116 BAG Use a double-needle seam, very common in leather goods sewing. For the sides and top add reinforcement to the bag, I have used the modules, which allow you to add a strap and use it as a shoulder bag and have more variety. Here you can appreciate the seams and the printing, with a backlight.