Combat Guide against E-waste and

Paul Hetrelezis

Repair, Reuse and Recycling

A Combat Guide against E-waste and Throwawayism

● Paul Hetrelezis

● This is an Elektor Publication. Elektor is the media brand of Elektor International Media B.V. PO Box 11, NL-6114-ZG Susteren, The Netherlands Phone: +31 46 4389444

● All rights reserved. No part of this book may be reproduced in any material form, including photocopying, or storing in any medium by electronic means and whether or not transiently or incidentally to some other use of this publication, without the written permission of the copyright holder except in accordance with the provisions of the Copyright Designs and Patents Act 1988 or under the terms of a licence issued by the Copyright Licencing Agency Ltd., 90 Tottenham Court Road, London, England W1P 9HE. Applications for the copyright holder's permission to reproduce any part of the publication should be addressed to the publishers.

● Declaration

The author and publisher have made every effort to ensure the accuracy of the information contained in this book. They do not assume, or hereby disclaim, any liability to any party for any loss or damage caused by errors or omissions in this book, whether such errors or omissions result from negligence, accident, or any other cause.

● ISBN 978-3-89576-648-0 Print

ISBN 978-3-89576-649-7 eBook

● © Copyright 2024 Elektor International Media www.elektor.com

Editor: Jan Buiting, MA.

Cover image: Shutterstock, licence paid.

Prepress Production: D-Vision, Julian van den Berg

Printers: Ipskamp, Enschede, The Netherlands

Elektor is the world's leading source of essential technical information and electronics products for pro engineers, electronics designers, and the companies seeking to engage them. Each day, our international team develops and delivers high-quality content - via a variety of media channels (including magazines, video, digital media, and social media) in several languages - relating to electronics design and DIY electronics. www.elektormagazine.com

6.2.2.1

7.2.1

7.4

7.3.3

7.3.4

Preface

As always, my first thought when considering the proposed contents of this book since my last publication Elektor Books: Retro Audio — A Good Service Guide is this: What’s in it for you, the reader? The main goal of my previous publication was to give you access to a wide range of basic knowledge in an organized way, enabling you to hunt for more specific information online. It was meant to be more of an overview guide than a “fix it all” answer to every audio problem with consumer electronics. After poring over many electronics reference books from a young age, one thing was immediately clear: in the world of electronics, no publication can claim to teach enough to “fix anything”. However, all offer something in terms of new learning in the field, regardless of the amount of material learned. The purpose of this new publication is to serve as a comprehensive reference guide in addition to the various other resources that you may have already obtained and may have read or re-read. Where applicable, the emphasis of all information provided within this book is on economical and resourceful options.

Naturally, electronics servicing on the benchtop is becoming less of a necessity than it used to be, say, half a century ago, in terms of cost, repairability, and ease of access of technicians’ service data. In many ways, our culture has evolved significantly in the modern era. Historically, hacking was rare because consumer products were made and designed to last, possibly to warrant comparatively high retail prices. The term “hacking” was deservedly rare. In today’s consumer market, sentimental bias may be a major factor influencing the restoration of vintage consumer electronics, and is rising in popularity. The signal-to-noise ratio and other basic parameters of vintage consumer devices now being restored will never match those of modern products. However, the less integrated design of the vintage equipment, its higher quality control, ultimate reliability, and ease of use are bonuses rather than trade-offs. Another benefit for you, the electronic hobbyist, is the repairability of these products given the availability of information and parts.

Viewing today’s mass-produced consumer goods, servicing electronic products has decreased dramatically. Most consumer products last just a few years, depending once again on the quality of the purchase. If there is a problem with a product such as an LCD TV, the whole unit is most likely thrown away as electronic waste. At best, a circuit board replacement can be done compared to the component-level replacements of yesteryear. Today, electronics repair is becoming a specialized and designated industry for high-end, vintage, or collectible items. It has also transformed slightly on other socio-economic fronts like our ecology and the associated e-waste. Everything that is built, no matter how small, requires energy. Batteries, circuit boards, lubricants, and other types of e-waste can be turned into plastics that need to be disposed of. Organizations such as Ethics in Electronics have now stepped in to manage the disposal of mass-produced electronics on a global scale.

Most hobbies that involve technical applications of some sort do not require a lot of money to be rewarding and enjoyable. This includes electronics. As a hobbyist, with good organizational skills and most of all passion, you can turn this enjoyable pastime into a

“side hustle” for additional income. In our current economic times, this only adds to the enjoyment. As a reader, you may well benefit in a resourceful way by adopting some or all of the ideas presented in this book. Many simple ideas are presented throughout the book. Components and parts are freely reused where practical from hacked consumer products. Many of these electronic and hardware parts can also find other uses in your workspace without unnecessary waste.

There is so much information available online about virtually everything imaginable. Where do you start getting information for my specific electronic hardware project, such as repair? Much of the content in this book comes from first-hand experience. Supplementing this with your own experience allows you to use the book as a companion reference. Experience is a valuable form of education, especially in practical hobbies such as electronics. In the search for these solutions, online sites such as YouTube, forums, apps on fixes or approaches to repairs are of course readily available and inexhaustible, to say the least. This book condenses all of these approaches and fixes the most common workbench scenarios across a wide range of products that I have encountered over a lifetime. Within this book, I have specifically selected many tables that are most likely to be cross-referenced when needed for your specific electronics repair or hack. Tables are easy to read, rather than trying to fish information out of the written text. This style was also used in my previous publication and reader feedback proved it was worthwhile.

As emphasized earlier, the most valuable and rewarding learning to this day is the application of acquired knowledge through actual time spent on a workbench. Not all the methods, faults, and other facets of some of the products presented in this text may be applicable to your circumstances. However, my goal within the book is to provide a comprehensive range of products that the electronics enthusiast can work on, and then provide as much applicable subject content within those categorized products. See the final chapter of the book for a summary of all the content covered in the book, with real life examples of those I have repaired, recent and past.

For you, the reader, some chapters of the book will be more helpful than others. If there is any tangible gain in terms of assistance in the achievement of results in electronics, then the book has served its purpose. The book may also help you with other practical purposes outside of electronics. Either way, I hope it will be a good companion to other relevant books, soft copy or hard copy, that you already have in your library.

Paul Hetrelezis

Chapter 1 • Workshop Environment, Tools, and Electronics Planning

As a dedicated workspace for electronic enthusiasts, the workshop must provide an environment that is orderly, safe, and comfortable. This type of environment enables optimal work performance, and any serious business with a workshop requires it. A car mechanic business requires an organized environment with the appropriate equipment in order to run effectively. Furthermore, components and parts will inevitably accumulate over time. Such items can be sourced at low cost from disused products. There are straightforward methods of managing them for immediate or future use. The initial outlay for setting up a workshop for electronics is relatively low. Simple techniques for repurposing everyday materials from off-cut hardware items or discarded grocery packaging can reduce this overall cost. A significant proportion of these materials would otherwise end up in landfill, so using them in the workshop is an economical solution. As you gain experience, you will develop new ideas for organizing the workshop, which will further enhance its functionality. The work gear recommended is based on experiences with electronic repairs and hacking. Your own experiences may include or exclude the work gear items listed in this chapter, but the recommendations provided here are typical of the field.

The electronic activity in question, repairs in my history, has inherent potential for significant time-wasting and the emergence of unforeseen issues. These are discussed in the final section of this chapter.

1.1 Organization

There’s a lot to be said for the old saying, “A place for everything and everything in its place.” It’s a great way to keep things organized. Another useful tip is to make a habit of putting everything back where it belongs after use. It’s true that this can be tricky for some people, as with all habits. If you can find a place for each tool or item, it’ll be much easier to stick to the habit of returning them.

In my previous published book, Retro Audio — A Good Service Guide, available from the Elektor Store (www.elektor.com), I made a brief reference in Chapter One of workshop organization. In the following paragraphs of this book, I will provide a more comprehensive and detailed description with a focus on an economical approach.

Workshop organization, or more specifically the level of it, from messy to very orderly, ultimately affects the productivity of the electronics enthusiast. A minimum level of organization needs to be established for practical working efficiency. Even more so, where you have a lot of electronic repairs on the go.

Another matter related to organization is the procurement of a multitude of workspace items. The industry of available retail items is growing rapidly due to consumer demand. A good reason for this demand is that we have so many accessible off-the-shelf cheap items available for every conceivable purpose. It is therefore essential that your workshop is organized to manage the high number of items as you procure more useful items.

Individuals have varying approaches to managing their activities, including the organization of their workspace. The strategies and techniques presented in this chapter may be more beneficial to some than others. I am sharing those that have proven effective for me over the years.

1.1.1 Organizational tips

There are lots of ways to set up a workshop, but at the end of the day it’s down to you. Each electronics workspace would have different volumes of spare components and parts, tools, or test equipment. The idea is to list only the essential setup. On top of that, there’s the time spent in the workshop either repairing or hacking electronics. So, there’s no one way of organizing things. Having said that, there are some practical suggestions that could work across all workspace types if you think about it. Based on my own experiences, I’ve listed some simple but effective steps in my highly cluttered and “busy” workspace. They’re in no particular order.

• Keep commonly used test equipment and gear, tools, and parts within arm’s reach of the product being worked on.

• Infrequently used parts and components should be stored in categorized areas away from the workspace.

• Have containers ready for dead batteries, recycled plastics and papers, and disused aerosols. These can be recycled through a number of vendors and local government councils.

• Store flammable or dangerous chemicals in an area away from the workspace. Also ensure these items are clearly marked to avoid misuse. Refer to storage directions on can or container e.g., keep caps tightly sealed. Refer to Chapter 7 for further recommendations.

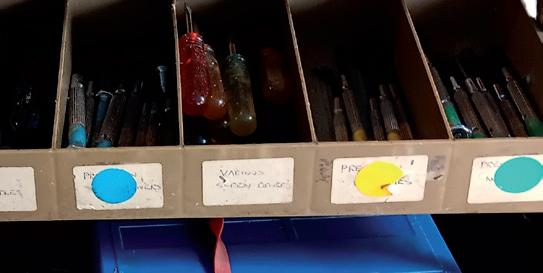

Handy Tip: The colour coding of screwdriver types in a toolbox helps you find the right tool quickly, especially small precision screwdrivers. It’s especially useful if you only need to remember up to four categories — See Figure 1-1.

Figure 1-1: Color coding is another alternative method to numbering. Here, the three primary colors are used with green as a suitable example.

1.1.2 Procurement and storage of items

Over time, a countless number of components, mechanical or hardware parts will accumulate within the workspace of any serious electronics enthusiast. Good organisation is key here. Categorization is one effective approach to good organization as it allows a divide-and-conquer approach to managing not only many components and hardware parts, but tools, jigs, and other accessories. A good example would be you where you have many packets of various watch batteries. You could easily store these batteries in a large container or storage tray. Considering, those batteries have equivalents as governed by the IEC (International Electrotechnical Commission). Each manufacturer of these button batteries will have a code, say, SR626SW which indicates Maxwell. I found a method that’s easier than storing all the batteries in one compartment: sort the packaged batteries by their respective manufacture in small plastic sealed bags. Then when needing an equivalent battery, I can easily reference via an equivalent chart to whatever manufacture could match the battery required.

Disused or broken products can be obtained cheaply through everyday means. The resources for these consume products could be:

• Purchased cheaply from pop-up or opportunity shops.

• Discarded products from friends and relatives (for unviable repair or not used)

• Superseded, damaged or faulty products you acquired through past purchase or as a gift to you.

So, these three sources are a very cheap, if not free way of obtaining perfectly reusable parts and components. A lot, too, can be gained from disassembling and fleshing out those unfixable products. By doing this, you learn how they work and observe features about their design. These learnings apply not only to electronics, but to the hardware design, too. An example of this could be as simple as a white goods product such as a portable heater with an inbuilt tilt switch to avoid a fire hazard. The use of your notebook and pen combined with a cellphone camera is an easy and effective way to note take on repairs and hacking.

When hacking products, there is always something useful you can extract from them, however small, cheap, or common. Typical examples are fasteners, washers, electrical switches, light indicators, and other commonly reused parts. After disassembling any product, you can store salvaged parts in a container. The container is then labelled with the make and model of the product. This allows you to cross-reference any components that you may need in future through online searching. Each hacked product is then manually entered in a spreadsheet. You can then look for a part you need by finding the product with its builtin parts. An example would be an obsolete transistor or IC that could be used to repair an identical product.

In the event of purchasing workshop items, the instructions for use of a new tool are typically provided on the packaging. These can be removed and affixed to the tool casing with adhesive. It is recommended that the printed instructions are covered with a transparent lamination to ensure continued legibility. Check out Chapter 2 for further details.

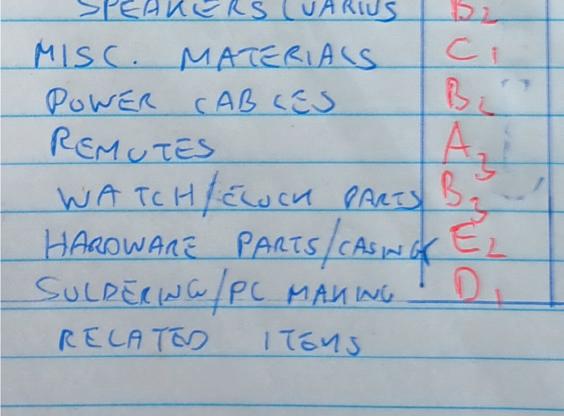

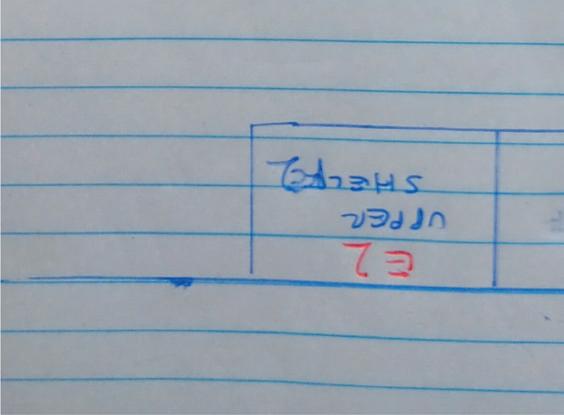

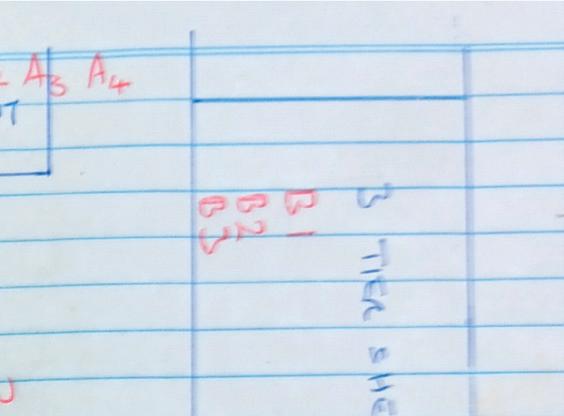

In case you have a large storage of many parts stored on shelves or in cabinet containers, there are ways to manage it. One simple way is to use a sheet of A4 paper marked with a pencil. By mapping the part types through using a plan view on the paper, everything stored gets referenced. This is ideal for larger garages full of equipment and parts — see Figure 1-2.

Figure 1-2: This A4-size parts location plan provides a mental picture for your collective parts and tools. It’s a very simple and useful way of managing workshops with a many different but actually used items.

1.1.3 Other storage tips

If your workspace has lots of items as in Figure 1-3, then visibility is important, so using open, labelled buckets displayed on racks aids toward the quick visual identification.

Figure 1-3: Any storage container having parts should have eligible labels. An example of stick on labels with eligible handwriting have been added to the trays.

Your storage of components and parts shows how organized you are. Electronic repair means you need lots of different parts. Here are some other storage tips.

• Store heavy items at shoulder height on shelves for easy removal and storage.

• Use rubber bands to hold cords and cables. Rubber bands last longer if kept in a dark, sealed container.

• Most enthusiasts have a clear workbench for their electronics.

• Store passive components to the left and active components to the right of your workbench, as one example.

The last point is to use a divide and conquer approach to manage lots of components and parts. Every day, quickly look around the workshop and put everything in its place. If your workshop is messy, you’ll need more time. This may be hard to do at first, but it will get easier. Once you’ve done it for a while, you’ll find it much quicker to put items away. If you can put ten items in their right place each day, that’s around three hundred tools and parts each month! This shows how much you’ve organized your workshop.

If you’re having trouble putting things away, put them in a temporary storage bin. Everything used in the workshop goes in the bin. If you reuse a tool, put it back in the bin. At the end of the day, put everything back where it belongs. This can be anything from a hand tool to wire.