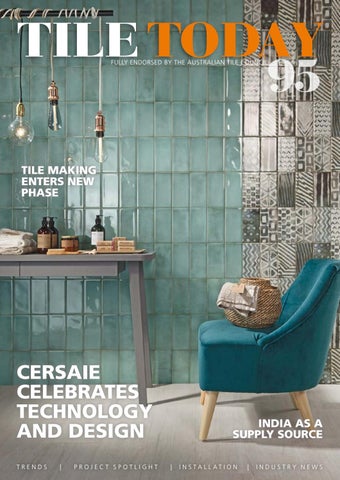

TILE TODAY 95

FULLY ENDORSED BY THE AUSTRALIAN TILE COUNCIL

TILE MAKING ENTERS NEW PHASE

CERSAIE CELEBRATES TECHNOLOGY AND DESIGN TRENDS

|

PROJECT SPOTLIGHT

INDIA AS A SUPPLY SOURCE |

I N S TA L L AT I O N

|

INDUSTRY NEWS

TILE TODAY 95

FULLY ENDORSED BY THE AUSTRALIAN TILE COUNCIL

TILE MAKING ENTERS NEW PHASE

CERSAIE CELEBRATES TECHNOLOGY AND DESIGN TRENDS

|

PROJECT SPOTLIGHT

INDIA AS A SUPPLY SOURCE |

I N S TA L L AT I O N

|

INDUSTRY NEWS