TRENDS | FEATURED PRODUCTS | TRADE FAIRS | INDUSTRY NEWS 115

POOL TILE MARKET WATERPROOFING IN BALCONY CONSTRUCTION PHIL’S TILE WAREHOUSE PROFILE

FULLY ENDORSED BY THE AUSTRALIAN TILE COUNCIL

CONTENTS

INTERNATIONAL MTC

6 The Lumière range by NovaBell represents an equilibrium of technique and a natural aesthetic. International MTC’s partnership with NovaBell means the range is easily accessible in Australia.

POOL TILES

8 Pool specialist company Customed Tiles is going from strength to strength, and Tessellated Tile Factory provides tiles for an award winning pool.

WATERPROOFING

13 Tile Today’s technical specialist Tim Christopher from Consultile Consulting identifies the issues surrounding balcony construction for waterproofers and tilers. In the same feature, the Australian Institute of Waterproofing discusses its central mission.

RETAIL FOCUS

26 As the new owners of Phil’s Tile Warehouse, Scott Christensen and Phoebe King-Christensen are broadening the store’s customer base by targeting architects and designers.

AUSTRALIAN TILE COUNCIL

33 The Australian Tile Council's "Tiles and Tiling Guide" devotes a chapter on tile lippage, lippage control systems and laying patterns.

TILE TODAY DIGITAL

36 In the next phase of its digital development, Tile Today’s new website tiletodaydigital.com.au offers regularly updated content, more e-newsletters and tools for industry professionals that can be used in their day-to-day business.

tiletodaydigital.com.au Find Tile Today on social media @tiletodaymagazine @tiletodaymagazine tile-today-magazine 115

Since the last edition, Tile Today has launched its new website tiletodaydigital.com.au and new e-newsletters (EDMs). Major stories you may have missed include the Cersaie 2022 report by our international correspondent Joe Simpson and contributor Bryan Vadas.

There was also the statistics article on the price increase of ceramic tiles based on data from the Australian Bureau of Statistics. To find out more about Tile Today’s digital development, turn to page 36 in this issue.

In this edition, we look at a new tile range called Lumière from Italian tile manufacturer NovaBell. International MTC makes it available for the Australian market.

We also make a return visit to Andrew Lester from pool specialist Customed Times in Queensland who provides his perspective on the residential pool market. He has also been busy with commercial projects.

Our technical specialist Tim Christopher from Consultile goes over waterproofing issues relating to balconies and we meet with the new owners of Phil’s Tile Warehouse in Noosaville (QLD).

As an industry association, the Australian Institute of Waterproofing is primarily about raising awareness of the crucial role waterproofing plays in construction. Paul Evans explains more in this article.

The Australian Tile Council discusses tile lippage in its latest contribution.

Look out for more content from our EDMs and we hope the holiday season is a safe and enjoyable one.

To be remain informed about the tile industry, just click here to subscribe. https://bit.ly/3dJ5EBc

Until next time, Betty Tanddo

FRONT COVER IMAGE

Vives explores the terrazzo effect with its Luna collection. Luna’s design is inspired by marble pieces set into cement. It evolves around one model in three colours: White, Grey, and Black. Each design boasts two finishes: polished and matte. Both are rectified to visually eliminate the edge of the tiles, generating a continuous surface and increase the sensation space.

Proudly produced and distributed in Australia

ELITE PUBLISHING CO PTY LTD

ABN: 27 006 876 419 PO BOX 800, Templestowe, Victoria, Australia 3106

Ph: + 61 3 9890 0815 Fax: + 61 3 9890 0087 Email: info@elitepublishing.com.au Website: www.tiletodaydigital.com.au www.elitepublishing.com.au

PUBLISHERS

Georgia Glimour Michelle Cammiade

EDITOR

Betty Tanddo betty.tanddo@elitepublishing.com.au

INTERNATIONAL CORRESPONDENT Joe Simpson joe.simpson@elitepublishing.com.au

TECHNICAL SPECIALIST Tim Christopher info@consultile.com.au

GENERAL MANAGER Georgia Gilmour Georgia.Gilmour@elitepublishing.com.au

CIRCULATION

For circulation enquiries please email: info@elitepublishing.com.au

GRAPHIC DESIGN Plum Publishing Pty Ltd dave@plumpublishing.com.au

PRODUCTION

For artwork and production enquiries please email: dave@plumpublishing.com.au

ELITE PUBLISHING CO PTY LTD

PUBLISHERS OF: Flooring Magazine, TileToday Magazine, and Supplier Magazine. Leading the Industry Endorsed by Australian Tile Council www.australiantilecouncil.com.au

ELITE PUBLISHING CO PTY LTD. All rights reserved. No part of this publication maybe reproduced, transmitted or copied in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system, without the express prior written consent of Elite Publishing Co Pty Ltd. Viewpoints, opinions, claims, etc expressed in articles appearing in this publication are those of the authors. The Publishers accept no responsibility for the information supplied or for claims made by companies or their representatives regarding product performance, etc or for any errors, omissions, misplacement, alterations, or any subsequent changes, or for any consequences of reliance on this information or this publication.

Please note: Shade variation is an inherent feature of tile production. The Publisher is not liable for any discrepancy between images published in Tile Today and actual products.

TILE TODAY

FOREWORD TRENDS FEATURED PRODUCTS TRADE FAIRS INDUSTRY NEWS 115 FULLY ENDORSED BY THE AUSTRALIAN TILE COUNCIL POOL TILE MARKET WATERPROOFING IN BALCONY CONSTRUCTION PHIL’S TILE WAREHOUSE PROFILE

The tiles chosen for the award winning Hotel Indigo Adelaide Markets pool were provided by Tessellated Tile Factory. Read more on page 11.

FLORENCE

Florence is a delicate yet modern and fine wall tile collection. Made of 12 original colors with a soft pattern, it is perfect for a modern and cheerful indoor setting.

LUMIÈRE, THE SPIRIT OF PAVING AND HAND-WORKED STONES

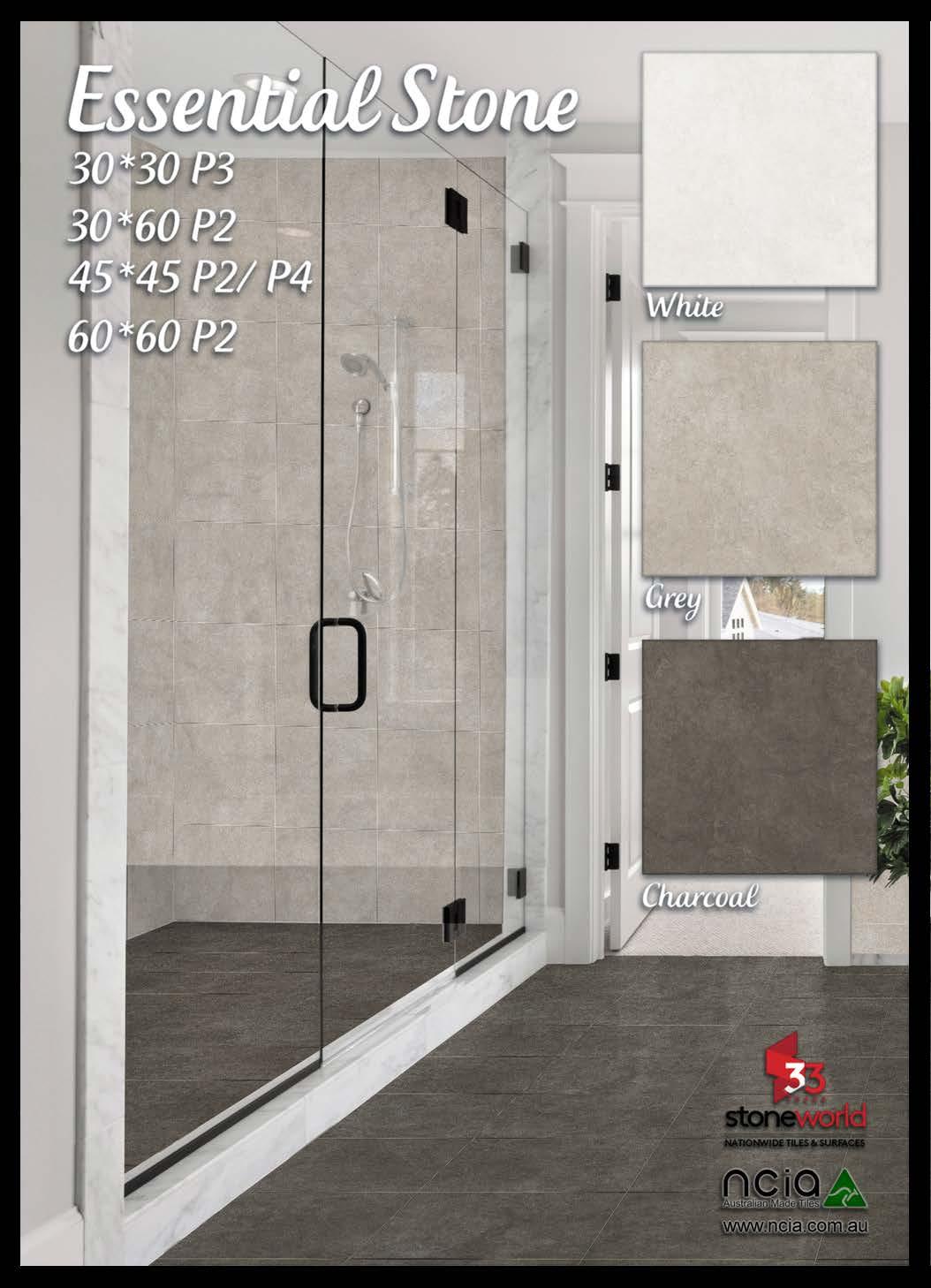

Available from International MTC, the Lumière collection by NovaBell is a surface designed with irregular edges and a pleasantly textured structure. Its ‘unmanufactured’ look is a contemporary take on stone.

Italian tile maker, NovaBell has used an innovative technique to create Lumière. The range is described in the catalogue as: “The sophisticated blend of stones with ancestral charm embodies an unprecedented stone culture and embellishes contemporary rural settings”. Put simply, Lumière represents an equilibrium of technique and a natural aesthetic.

The irregular edges of the ceramic tile range, its hammered structure and time-worn effects reflect a balanced blend of ceramic technique and craftsmanship.

The warm shades, vein patterns and mineral inclusions are maintained throughout the surface. The four colour variants — Talco. Ambra, Sabbia and Cenere — with their meticulous graphic rendering, preserve a natural and realistic effect.

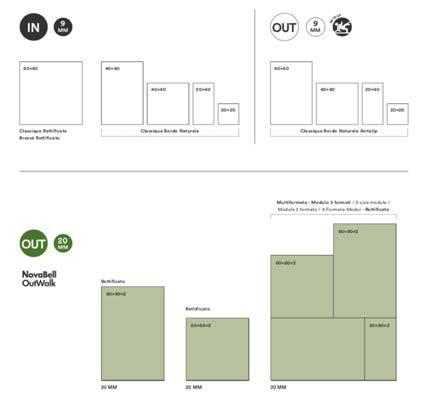

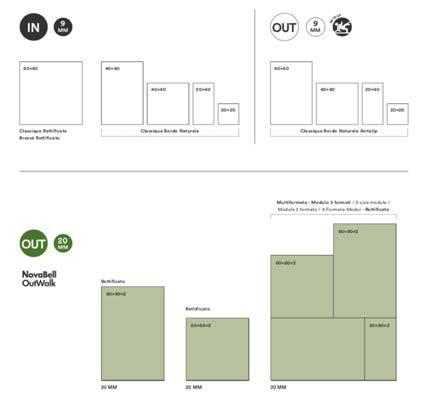

As part of Lumière, Classique and Brossé are two variations that have been imbued with tactile appeal. Classique has a natural, soft feel, while Brossé, with its delicate surface brushing, gives floors a silky touch and sculptural polish.

MODULAR SIZES

Lumière is complemented by modular sizes that enhance the charm of a time-worn look. The

LUMIÈRE IN SABBIA

LUMIÈRE IN CENERE

LUMIÈRE IN AN EXTERNAL SETTING

LUMIÈRE IN SABBIA

LUMIÈRE IN CENERE

LUMIÈRE IN AN EXTERNAL SETTING

“Multiformato” composition includes several different sizes, and offers an additional level of authenticity.

The collection provides an interplay of alternating sizes that can flow in and out of domestic spaces. It has a co-ordinated and consistent look without sacrificing the performance required for outdoor spaces.

From Trani stone to iconic Travertine to the finest limestone, NovaBell has curated a number of details to create Lumière where the structure complements shades that reflect a warm colour palette.

The company also utilises Brossé, a special process that enhances tactile irregularities in a play of contrasts between matt and semi-glossy areas. The surface brushing delivers a deep radiance and a silky, soft feel.

Lumière has been designed with universal beauty in mind. It comes in four colours, seven sizes and five finishes.

ABOUT NOVABELL

NovaBell S.p.A. is a specialist in the field of indoor and outdoor ceramics. It was established in 1988 but its founder, Silvio Bellei — an ex-pilot — already had many years of experience in the field and was considered something of a pioneer in the world of ceramics.

Today, Novabell designs for the future by investing almost 7% of its annual turnover in research, innovation, technology and services.

Although Mr. Bellei died in 2010, his family led by his three daughters are equally passionate about what he created at NovaBell, and they continue to invest in the company, assuring its long-term future.

From traditional-style homes to urban spaces, NovaBell’s

products can customise a living or environment with 100% Made in Italy surfaces. The company believes it is important to optimise the ‘Made in Italy’ label.

It is now present in 90 countries and International MTC represents Novabell in the Australian market.

n

Building a pool tile business, one project at a time

Customed Tiles has carved itself an important niche in the tile industry from its Burleigh Heads base in Queensland. Now it is ready for the next phase in its development.

There has been significant growth since Tile Today last spoke with Andrew Lester from Customed Tiles. Given the current times, there have been some unusual projects as well. One Andrew told Tile Today about involved custom tiles multiple bathrooms in a commercial project in Brisbane — the work for which he ended up doing twice.

It was an elaborate job, according to Andrew which “involved scoring or grooving a dummy grout line running through the tiles at 45 degrees. They were all feature tiles for the bathrooms. It measured a couple of thousand square metres.”

Unfortunately, the original builder for the project went bankrupt. “They've demolished all the bathrooms because the new builder wouldn't guarantee the waterproofing. So we've started doing them all again,” explains Andrew.

As a result, Customed Tiles has been paid twice for the project and as Andrew tells it, “Prices have gone up in between so it’s been expensive.”

The commercial project came about from the work it was doing with a tile store and getting the heads up has been crucial in helping it get the job. “They were supplying the tiles for the job that was being underwritten by CBUS, the superannuation company, and they wanted the work done in Australia, not overseas. We ended up quoting for it for three different tile suppliers,” he said.

Connections

Part of the growth in the last 12 months has come from a relationship that has expanded with a major tile importer based in Queensland. “The company use

One of the hundreds of residential pools that Customed Tiles has worked on

us for their work because of the tile shops they supply, that ask them where they get their work done and then send them our way.

“We are getting regular work from tile stores in Townsville and Rockhampton,” he said.

The importer was already a customer when Andrew took over the business but the machines that were purchased in 2021 allows

them to take on some of the work that was being done overseas.

Its location in Burleigh Heads has also been advantageous for Customed Tiles. “We can do the prices a bit better, and it has been easier for them having it on-call rather than waiting for months to get it from overseas,” said Andrew.

At the same time, there have been issues with quality when the

8 | TILE TODAY #115 | tiletodaydigital.com.au

POOL TILES

work has been sent overseas so being located in Australia means it can deliver more quality control.

In addition to proximity, Andrew believes it is the reputation he has built up that has led to getting more work. He makes it easy for customers to deal with Customed Tiles. “It's basically word of mouth. We try to offer a quick service, and people can just send their tiles here, there's no dramas,” he said.

Machines

The machines purchased from Italian manufacturers Ferrari & Cigarini have made an enormous difference to the business. “I don't think I would have made it through the year without them. The profile machine was probably the main

Ezarri 50mm mosaics

With the larger size of Ezarri’s "Infinite Mosaic", users can create tailormade projects that start with a 50mm piece — four times bigger than its conventional 25mm mosaic tiles.

They come in striking designs and a JointPoint® panelling system for easy installation.

Many of Ezarri’s mosaic tiles are also available in slip-resistant finish to added safety. There is also a variety of special pieces to ensure ideal finishes, corners and edges.

The 50mm mosaics are made from 100% recycled glass as a result of the company’s commitment to the responsible sourcing of primary materials and the environment.

one. Productivity-wise it's roughly twice as fast as my previous machine,” he said.

Andrew acted on the confidence he had in the business and the market when he decided to buy

these machines. His instincts proved that the machines could support the additional work it gained in the past year. “The work just keeps coming. We don't really chase anything at

10

A pool project that is part of Customed Tiles’ portfolio

the moment, and there seems to be more tile shops working with us,” he said.

After investing in these machines, Andrew is looking to buy another machine. “I'm already looking to upgrade again,” he added.

He already has new machinery from Achilli on order to deal with the increased business. One is a mitre saw that cuts the tiles at 45 degrees. The other is a motorised bench saw and both are due to arrive in March. By replacing an older machine, he believes the new one will improve efficiencies.

Pool market

The market for pools seems to be a continuation from 2021, the way Andrew sees it. Last year, he saw the spike in demand coming from two sources: the COVID-19 pandemic and an evolution in attitudes towards pools in Queensland. “It's just out of control. We've never been busier,” he said.

“A lot of people still wanting to stay home, they aren't travelling as much. It's also hard to get a park at the beach! So people are still making their homes their sanctuary, and spending a lot more time at home. There's also a lot of people still working from home, and spending their money at home.”

The migration from the southern states continues to influence the pool market in Queensland, according to Andrew. “There's still a lot of people moving up here from down south — with money to spend,” he said.

Access to labour

Customed Tiles finds itself in a similar situation to many businesses in terms of hiring people to help manage growth. Andrew prefers to take on less experienced people who he can train in the way that is needed for the type of work he does. “Almost everyone that has come through hasn't had much experience,” he said.

“Even someone with some experience and similar skills, there is still a fair bit of training to do. I would like them to do it the way we do it.”

But once he trains new employees, Andrew understands that he also risks losing them too. He accepts that this is part of the situation. “We just lost one and he hasn't been replaced yet. We're just struggling through it and doing as many hours as possible,” he said.

Overall, Andrew’s experience is good news for tile suppliers and retailers in the pool and outdoor category. As he said, “There's still a lot happening in QLD anyway.”

Growth is expected to continue for the near future, and Customed Tiles remains well placed to benefit from it. “We are probably in a good position. There's not a huge amount of competition for us that does the same quality of work,” he said.

The plan also includes potentially getting a larger premises in the next year or two but there is no rush to move, as Andrew integrates the

new machinery and ensures there are many more residential and commercial projects to come. n

10 | TILE TODAY #115 | tiletodaydigital.com.au

The resulting work from the Ferrari & Cigarini machine

Andrew Lester, owner of Customed Tiles

Some of the specialist work done by Customed Tiles

Award winning pool

The tessellated tiles chosen for Hotel Indigo Adelaide Markets pool helped it to win top prizes at the 2022 Swimming Pool and Spa Association (SPASA) Awards for Excellence. The tiles were created and supplied by Tessellated Tile Factory.

The infinity edge pool was built by Hydrilla, innovators in commercial swimming pools and aquatics, and took home gold for best Commercial Pool up to the $500,00 category in South Australia and the national title in the same category.

The tessellated tiles selected for the pool’s internal finish are an homage to the 19th Century cottages that were built in Adelaide, and complements the hotel’s interior décor. Similar design elements are used throughout the hotel in guest rooms and public areas.

Tessellated Tile Factory general manager Laura Bagnato told Tile Today the story behind this complex pool build.

Tile Today TT: How did you get involved in the project?

Laura Bagnato (LB): We were contacted by Loucas Zahos Architects directly with an enquiry to produce a custom design for their hotel project. We workshopped some variations on the design, specifically related to the colours, and provided samples of the patterns for approval by all stakeholders.

TT: Please tell us how you dealt with some of the challenges and processes involved in supplying tiles for a boutique-sized hotel pool in an inner city location?

LB: Installation was a challenge. We didn't have the resources to send a team to Adelaide to complete the installation. (Tessellated Tile Factory is based in Sydney.) So we had to deliver the tiles in a format that allowed for a non-specialised contractor to install. Ordinarily, tessellated tiles are supplied as loose tiles and our specialists install

the tiles piece by piece. This wasn't an option for this project, due to both the scale and location.

Our solution was to supply the entire project as a sheeted product, ie. We manufactured customised templates that held the tiles in place and allowed us to sheet the designs accordingly. This meant the tile contractors just had to install sheets of tiles (similar to the process of laying mosaic pool tiles etc.), a process that was far quicker.

Timing was another challenge. We had to deliver the order in stages in line with the critical construction timeline. This meant liaising with multiple stakeholders and getting sign off and approvals from the architect, client and contractors.

TT: How long did it take?

LB: Production for the whole project was approximately two months.

TT: Tell us about the history of the business.

LB: We are specialists in the supply and installation of tessellated tiles. Our founder, Carmelo Bagnato, has been laying tessellated tiles for over 20 years, completing every stage of the cutting and laying process by hand. In recent years, he has passed on this skill to our team of in-house installers as well as building our Sydney based factory.

Today we are set up to produce hand printed encaustic tiles, the sheeting of custom mosaic designs as well as the manufacturing of our tessellated designs. We continue to develop our production, whilst maintaining this handcrafted quality. We also recently opened a stunning showroom in Sydney's inner west, which has helped us to engage more with our clients and gives them a real sense of everything related to tessellated tiles.

POOL

TILES

A boutique-sized pool, Hotel Indigo Adelaide Markets pool is visually stunning day or night

Located on the level 4 podium, the 11m x 2.5 pool was created with a mixture of cast and pour and shotcrete techniques to provide a robust structure The balance tank sits neatly under the infinity edge on the street-facing side of the pool and gives swimmers an unobstructed view across Adelaide to the eastern suburbs.

EXPLORE. DISCOVER. ENJOY.

Tile Today is the leading publication for Australia’s tile industry.

For tile installers, we provide a mix of indepth technical articles, product guides, the latest trends in design and business, as well as inspiring coverage of Australian and international tile shows and events.

For retailers, we cover all the latest industry news, interview the movers and shakers, and keep you up-to-date on industry statistics and forecasts.

For interior designers, architects and building specifiers, we offer an index to best practice and emerging concerns in the building and construction industries as they relate to tiles.

But what we offer to every reader, is a publication that shares your interest and inspiration

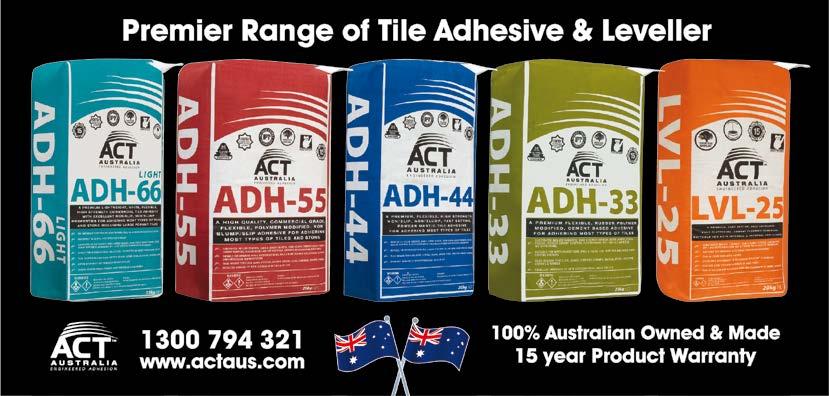

• In-depth technical articles

• Business opportunities

• New tile developments

• Guides to adhesives

• Coverage of anti-slip issues

• Waterproofing best practices

• Trends in interior design

Tile Today is now digital, which means you can read it on your smartphone, tablet and PC. Take it everywhere with you.

Subscribe to Tile Today for FREE.

CLICK TO SUBSCRIBE

WATERPROOFING OF BALCONIES: CHALLENGES TO CONSIDER

It has become generally accepted architectural practice to regard larger buildings as an intricate network of connected systems, all of which are highly interrelated, and need to be seen from the perspective of systems thinking.

Given that, we would have to conclude that many architects and building designers are simply unaware of the actual existence of rain. That's the only explanation for why so many modern buildings still feature design constraints that make functional, long-lasting waterproofing virtually impossible to achieve, resulting in the need for highly expensive, and less than fully effective remedial works.

Tim Christopher from Consultile in this article does us the favour of working through some of the consequences of failed design, outlining the main failure points — many of which will be concealed at first from the waterproofer and tiler.

This article explores the wider construction issues surrounding balcony construction. Rather than a "how to" methodology of waterproofing, the current issues in the construction industry which impact on the waterproofer/tiler are discussed.

The construction of large tower blocks is especially common in New South Wales, and has increased in popularity in other states. Medium density housing has also increased

in most major Australian cities, as they continue to grow larger and more dense.

With Australians still hankering for their small patch of the "outdoors" at home, this has led to an increase in the number of balconies integrated into and attached onto buildings. As a result, the tiling and waterproofing of balconies has become a common feature of the modern building process.

tiletodaydigital.com.au | TILE TODAY #115 13

WATERPROOFING FEATURE 14

Additionally, many new single dwellings have also elevated outdoor entertaining areas as part of their design. Many of these balcony areas function as the roof of the building beneath then, which can be another balcony, or even inhabited space. This means the drainage and control of water and moisture is very important, as it has a direct impact on other building occupants.

In general, taking active steps to prevent rainwater from entering a building is a critical part of balcony design and construction. The design should also take into consideration the ongoing impact of moisture on other building elements which may be affected. The use of a waterproofing system is often chosen as a solution that can achieve these design outcomes.

These waterproofing systems, and specifically the waterproofing membrane used, need to be chosen with consideration for the materials and substrates that form the physical context for their usage. Balconies can be constructed from materials that have specific requirements to successfully waterproof them. A concrete balcony, for example, will have differing requirements to a balcony sheeted with sheet-lap fibre cement board. The waterproofing and tiling of both these types of balconies requires a customised and specific approach.

FAILURE IS COMMON

In my experience, it is common for balcony tiling and waterproofing systems to fail. Water ingress into the building, tile delamination and leeching of various residues for an ongoing period are common. The faults are often a result of a combination of poor or inadequate design including construction methods and waterproofing product selection.

The failure rate of balcony waterproofing and tiling is high, and often the rectification works are also found to be inadequate and suffer from the same design issues where each element is selected in apparent isolation of the other elements. This construction methodology appears to rely on luck as the determining factor of whether a balcony will perform as expected into the future.

Simply put, a construction process which relies on individual trades to select methods and products in isolation of the other building elements is a high-risk construction methodology.

In NSW, there has been an attempt to address these types of issues through the appointment of a Building Commissioner, who has stipulated that design for construction methodology of elements such as balconies and waterproofing is to be established prior to works commencing. Works are to be designed by a suitably

qualified individual such as an engineer or architect.

This appears to be having a positive effect on the construction methodology in NSW. However, there is no guarantee this solution will be adopted to other states. Consequently, there remains a high possibility of inadequate design consideration across the area of balcony construction.

The tiler/waterproofer is often inadequately equipped to, in isolation, assess the requirements of waterproofing a balcony, based on the training and qualifications which are in place for a waterproofer.

CONSTRUCTION DESIGN IMPACTS

There are multiple construction characteristics of a balcony which will impact on the waterproofing system. The following are some issues which the waterproofer may come across.

The use of fibre cement sheetlap boards as a substrate. This is a common light weight construction method. This system introduces elements such as deflection of the substrate due to installation on a framed structure and movement joints where the sheets adjoin one another. The data sheets stipulating the installation requirements of these boards are highly specific, and are often the basis of satisfying the requirements of the waterproofing membrane product warranty used to waterproof the balcony.

The ability for the membrane to adhere to the substrate, the use of floating (unbonded) screeds, the deflection of the balcony, drainage methodology and the installation of movement joints are all subject to specific installation requirements. The joint size used within the tiling system is even referenced in some installation instructions.

Often the installation to the balcony substrate is incorrect before the waterproofer arrives onsite. This creates a situation where the tiler/ waterproofer changes or is forced to compromise the installation design to accommodate the issues which are present.

Movement of concrete construction may require specific details to provide ongoing performance. Many balcony slabs constructed as part of a unit block

14 | TILE TODAY #115 | tiletodaydigital.com.au

WATERPROOFING FEATURE

construction are down to 100mm thickness. There can be deflection in these slabs in certain configurations. It is unlikely this can be successfully assessed visually by a tile/ waterproofing contractor.

Determining the presence and degree of expected deflection may influence the waterproofing and tiling methodology. In extreme cases the deflection of large slabs in a cantilevered configuration may alter the falls and drainage once in use. This is not possible to assess on site during construction, and is an example of critical design characteristics which need to be accommodated and made known to the waterproofing contractor. The transfer of this information does not always occur.

Thin slabs can shrink and crack causing the membrane to fail. It may still be argued the membrane is inadequate in a dispute if it is of incorrect thickness when examined.

Thin slabs have other characteristics that can be detrimental to waterproofing and tiling installations. Shrinkage and deflection can cause cracking, which can telegraph through the waterproofing and tiling installation. When cracking occurs post waterproofing installation, the membrane is put under pressure, which will test its strength.

Some membranes will not tolerate this type of cracking and subsequently leak. Assessing the likelihood of these issues is difficult to determine for a waterproofer/ tiler as there are engineering principles at play which need to be communicated to the relevant trades. This communication often does not occur. Slab cracking can occur through other design inadequacies or errors which also are not possible to assess visually.

Design elements such as set downs at doorways and the configuration of the door assemblies can dictate waterproofing and tiling methodology. It is difficult to achieve falls when the door height restricts the depth of screed levelling layers which may be required to achieve adequate falls to drainage outlets. Some detailing and terminations of waterproofing under existing door assemblies can be difficult or impossible to install in a compliant and functioning way.

The waterproofer is often again

The new Stormtech Wave Grate (Macro Wide style) being used in a balcony

left trying to cobble together a solution to waterproof a balcony, but cannot do this in a way that complies with the relevant standards and waterproofing system manufacturers installation guidelines.

Drainage is an area which can be problematic for the tiler/ waterproofing contractor. The outlet configuration is usually determined and set in place before the tiler/ waterproofer is on site. This can be a situation which presents issues such as drainage outlet diameter, drainage outlet quantity and location.

As an example, I have observed large balconies prior to waterproofing and tiling constructed with a single drainage outlet of 80mm in size which was located at one corner of the balcony which was also installed at the same height as the top of the door entry threshold. A scenario such as this is extremely difficult to waterproof and tile successfully when trying to keep a set down at the doorway, fall to the single waste and achieve adequate drainage rate for water to escape. Another problem that crops up is efflorescence leaching. This needs to be accommodated in the system design if the unsightly problem is to be avoided.

UNDERPERFORMANCE BY CONSTRUCTION

In general, the construction industry is underperforming when it comes

to balcony construction, including waterproofing and tiling. That means it is worth considering the issues at play for the remediation sector. Remediation can be more technically demanding than the original build process. Remediation contractors assume the risk of subsequent waterproofing failure when remediation works are conducted. Simply completing the re-waterproofing and tiling process will often be inadequate to address the original cause of a balcony leaks. The original construction may have multiple causes for the waterproofing failure which may not be addressed by a new membrane and tiling.

Engineering problems of excess building movement and configuration constraints will not necessarily be addressed with the installation of a new waterproofing system. In some instances, liquid applied membranes are not suitable and sheet membranes will be required. Substrate drainage and compatibility are also important factions to consider. The preparation work for the replacement waterproofing membrane may be more demanding than the initial installation process. The remediation work could include major works to address cracks and movement, coring extra drainage outlets and removing existing door assemblies.

Many remedial jobs have to be

www.tiletodaymagazine.com.au | TILE TODAY #113 | 15 16

completed in an occupied strata complex. That means there are multiple access issues, such as heights, loads and noise/dust contaminants. Often a balcony may be 100 to 200m2 in size, which necessitates materials which cannot be transported through the dwelling for installation on the balcony. Scaffold access and cranage may be required to get the material to the work site.

Even after materials are craned up to a balcony, methodology process is complicated on how to install a waterproofing/ tiling system while working amongst the materials for the job. Shuffling two to three tonnes of materials around is problematic, as is loading this type of weight onto one area of many balcony structures. These issues can be overcome but illustrate that remedial work is a far larger and more costly process than a simple (original) waterproofing and tiling job. The costs associated are also worth noting in the instance the rectification work is unsuccessful and requires re-doing.

THE CURE CAN BE WORSE THAN THE CAUSE

General remedial and warranty insurance works can be poorly specified when some causes of failure are viewed in isolation, and then re-specified by individual contractors who do not account

for other building elements and requirements.

For example, a particular sheet waterproofing system installed by a waterproofing contractor on a flat (with no fall) substrate may be durable and long lasting, but can introduce further issues — for example, it cannot be bonded onto with traditional tiling methods. Subsequently the tiling contractor is now required to create fall, accommodate poor or no ability to bond, and yet still consider door heights and set downs.

In the instance where a sand and cement screed is installed it may need to be an "unbonded selfsupporting screed", which can have minimum thickness (e.g. 40mm) required to retain strength. This will accommodate the bonding problem, but creates the risk of leeching from efflorescence which is an additional item to be mitigated. Dealing with efflorescence may necessitate additional membranes or moisture barriers which in turn require detailing correctly as a secondary membrane.

Leeching can be present when drainage is inadequate and levelling layers are continuously wet. The issues present in this scenario become numerous when accommodating drainage points, door heights, secondary membrane termination, screed drying times, product compatibility and costs.

Remedial works undertaken without the full understanding of the entire balcony construction and waterproofing system can themselves be problematic. I have observed remedial builders opt for "bulletproof" waterproofing products to rectify leaks. Subsequently, the builder engineers other problems, such as efflorescence into the installation through insistence on a particular product selection, and a lack of understanding.

Door heights are critical elements. Membranes require correct termination under the assembly. Incorrect termination will fail to prevent water ingress. The door will sometimes require removal to achieve this.

FINAL POINTS

Some final points to consider when taking on balcony works are but not limited to:

- How does the configuration of the balcony align with the Australian Standards Waterproofing membranes for above ground use; (AS4654.2)? If issues such as door heights and membrane terminations are unachievable, there is a considerable risk present for the waterproofer/tiler if there is a leak.

- Balustrade installation through tiles and membranes can void membrane warranty and function when installed incorrectly. The methodology should be determined prior to works proceeding, so that the integrity of the waterproofing membrane can be maintained and guaranteed.

- Drainage. The minimum fall recommended in the Australian Standards Waterproofing membranes for above ground use; (AS4654.2) is 1:100. Or 10mm in 1000mm (one metre). If this is not achievable, pooling and overflow may occur. This must be avoided, however the thickness of a levelling layer required to achieve this fall can be problematic at doorways, as the levelling layer may need to be installed up against, or even above the door assembly. This is a building design issue, not a waterproofing tiling issue. In this instance tilers/ waterproofer have no option to avoid this installation methodology in new building works. The builder should be rectifying this problem, not placing the responsibility on the tiler/ waterproofer to cobble together a

16 | TILE TODAY #113 | tiletodaydigital.com.au

WATERPROOFING FEATURE

solution of configured compromises.

- Waterproofing system installation instructions. This sounds obvious, however many a contractor will omit items such as the correct bond breaking sealant, reinforcing bandages and matting. The Dry Film Thickness of a liquid applied membrane is also critical. Liquid applied membranes are intended to function at the correct thickness. In the event of a leak, no matter what the cause, it is difficult to defend a scenario where a membrane is of incorrect thickness and installation methodology, but the leak is caused by other issues.

WATERPROOFERS/TILERS NEED TO CHECK LIABILITY

In the event of a leak caused by a building design problem, the waterproofer will need to demonstrate a correct installation method to avoid shouldering partial or complete blame for a failure. The simplest protection is to request a specification from a waterproofing manufacturer who will recommend a suitable site-specific system. Many

waterproofing products are suitable for use on balconies according to the label, but may not be suitable for the particular balcony you are installing the waterproofing system onto.

Building design issues must be raised by waterproofer/tilers prior to works commencing. Suitable solutions must be implemented. Attempting to compromise the waterproofing system to accommodate these problems is also assuming an unacceptable risk of failure. It should also be noted that it may be advisable to seek advice from a an appropriate individual such as an engineer to protect the waterproofer from building design failures which cause waterproofing to leak.

Many contractors misunderstand membrane classifications in relation to flexibility such as indicated by the 3 classes of membrane flexibility as listed in the Australian Standard AS4858. Selecting a high flexibility membrane will not accommodate large amounts of substrate cracking of a slab after installation. n

Opening image: The tiling and waterproofing of balconies has become a common feature of the modern building process.

About the author: This article is based on the observations and work conducted by Tim Christopher, principal at Consultile Consulting Australia. Tim is a current member of the Technical Committee on both the Australian Standards AS3958 (Guide to Ceramic Tiling) and Australian Standards AS3740 (Waterproofing).

He also serves as the vice president of TTIAA (Tiles and Tiling Industry Association of Australia), and is a technical advisor for TANZ (Tilers Association of New Zealand).

He can be contacted via email: consultileaus@gmail.com

For more information about Consultile, please go to the website: https://www.consultile.com.au

Excellent additional BARRIER to a waterproofing system

REDUCES construction costs and extra processes

PROTECTS all layers in a tiling system

TO FIND OUT MORE & FOR STOCKISTS

www.efflock.com.au

>500%

ELONGATION

FIBRE REINFORCED INDOOR + OUTDOOR

SikaTile® is more than a system

When distributors and end users share their knowledge and experiences, Sika listens. SikaTile, Sika's breakthrough combination of tile installation components into a single, integrated system, is testament to that responsiveness to the present and future needs of the market. With SikaTile, Sika has both paid attention to the "wish lists" of installers, and built-in future best practice for the industry, while securing the market for retailers as well.

SikaTile is an integrated set of products that function together to provide a complete system, one which installers can rely on to produce installations with great longevity, and which also secure their own health and safety.

The resulting improved confidence in product selection is the key to SikaTile.

SikaTile consists of three products: SikaTile-010 Secure Prime, SikaTile-110 Secure Proof and SikaTile-410 Secure Set. When installed as a system, applicators can be confident in their installations in the three most common situations: indoor dry area, indoor wet area and outdoor wet area.

SikaTile®-010 Secure Prime

The first concern of any installer is how to deal with whatever substrate is supplied for the tile installation. One of the major concerns is how to go about limiting the possibility of efflorescence from occurring. Secure Prime is the industry‘s first dedicated primer with efflorescence inhibiting properties. It does this by using a unique crystalline technology to reduce the porosity of concrete, screeds and renders. It reduces moisture migration by capillary action.

It is sold in liquid, ready-to-use form, in five-litre pails. With average coverage of 13 square

metres per litre, that's enough for 65 square metres. It can be applied with a brush, roller or a low-pressure spray applicator; tools can be cleaned with water before the product sets. It rolls on white, then dries clear. Curing takes place in just 25 to 40 minutes, depending on climatic conditions, the porosity of the substrate and the application technique used.

SikaTile-010 Secure Prime is suitable for use on porous and dense substrates. It can be used both internally and externally, on wall and floor applications. Its many applications include:

- General purpose under tile priming of porous substrates

- General purpose primer for water-based waterproofing membranes

- Primer to prevent efflorescence coming out of substrates, ie. concrete, screeds and renders

- Priming of dense and steel trowelled concrete

Suitable substrates include:

- Concrete

- Cement boards and sheets including Scyon

- Plasterboard

- Glass reinforced concrete

- Cement based screeds and renders

- Cement coated light weight construction boards

- Autoclaved Aerated Concrete (AAC)

SikaTile®-110 Secure Proof

Fibre-reinforced for extra security, Sika-Tile-110 is a premium performance, flexible class III, ready to use, water based polyurethane waterproofing membrane designed for internal and external areas including wet areas, balconies, terraces, and non-UV, exposed above-ground external applications. It can be used on both walls and floors.

tiletodaydigital.com.au | TILE TODAY #115 19

20

The Class III rating of SikaTile-110 Secure Proof means it provides high extensibility, with elongation of up to 500%. It is solvent-free, waterbased, has excellent anti-fracture properties and low VOC. It has a tensile strength of 2.1MPa.

The product comes pre-mixed, in 15-litre pails, which will cover around 10 square metres, and it is grey in colour. It is applied with either a brush or a short-nap roller. Drying time before a second coat can be applied is just one to two hours. The membrane is ready for tiling in six to eight hours after the final coat. Flood testing can be applied 48 hours after the final coat, and the surface can return to service in three days (under ideal circumstances of 23 Celsius and 50% humidity). Ambient air temperature range for application is between five and 35 degrees Celsius.

SikaTile-110 Secure Proof can be used on a wide range of substrates, including:

- Concrete

- GRC (Glass reinforced concrete)

- Cement boards and sheets including Scyon

- Renders and screeds

- Cement coated light weight construction boards

- Plasterboard

- Structural Plywood

- Autoclaved Aerated Concrete (AAC)

SikaTile-110 Secure Proof is a suitable under-tile waterproofing membrane that complies to AS/NZS 4654:2012 and AS 4858:2004.

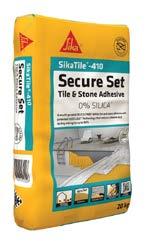

SikaTile®-410 Secure Set

SikaTile-410 Secure Set is a multipurpose premium sand and silica free white tile and stone adhesive. It is perfectly designed for most tile and stone applications, including submerged applications and over under-floor heating systems.

The adhesive is exceptionally smooth and creamy to spread, with high performance non-slump capabilities for large-format tile and stone applications. It is a white adhesive, which means it can be used for light-coloured and translucent stone installations.

It has good early setting properties, so that even under cold conditions tiles can be grouted 24 hours after installation. Light foot traffic is possible after 24 hours, wet area service after three days,

and full traffic some five days after installation. For underwater applications, the adhesive should be applied 21 days before being submerged.

SikaTile-410 Secure Set is sold in standard 20kg bags, which can

20 | TILE TODAY #115 | tiletodaydigital.com.au

Screenshot from Sika YouTube channel: youtu.be/KAfoQ7YZxV4 Sika Tile is an integrated system of three products.

Screenshot from Sika YouTube channel: youtu.be/KAfoQ7YZxV4

Sika Tile-410 Secure Set is a silica-free adhesive

cover around 7 square metres with a 10mm notched trowel. Equipment can be cleaned with water prior to the adhesive setting.

SikaTile-410 Secure Set has an AS ISO 13007 – C2TES1 Classification, and achieves C2TES2 when mixed with 50:50 Davco Davalastic and water. In accordance with those standards, the adhesive has a pot life of two hours, open time of 30 minutes and adjustability time of up to 30 minutes

SikaTile-410 Secure Set is also designed to provide maximum protection to the health and safety of installers using the product. This starts with Sika's patented Dustless® Technology. Where mixing most adhesives results in a moderate dust cloud of adhesive powder — which is inevitably breathed in, contacts skin, and can contact eyes — with Dustless®, airborne particles are reduced by up to 80%. It's not only much safer, but it cuts down on worksite mess, and makes clean-up that much quicker.

The second element of protection is the composition of SikaTile-410 Secure Set. It is a sand-free adhesive, and it does not contain any respirable crystalline silica, making it safer to use than conventional sanded cement-based tile adhesives. Silica (Siliconedioxide, found in both sand and quartz) is the principal cause of the lung disease silicosis.

The adhesive also has low VOC levels of just 7g per litre.

SikaTile-410 Secure Set can be used on a wide range of substrates. These include:

- 7-day old concrete

- Compressed cement boards

- Fibre cement sheet / Ceramic Tile Underlay

- Concrete masonry / rendered brick / blockwork

- Sika approved under tile waterproofing membranes

- Gypsum plasterboard (internal only)

- 24-hour old cement-based screeds and renders

- Autoclaved Aerated Concrete (AAC)

- Sika® approved acoustic underlayments

- Under tile heating systems

- Tile over tile, with suitable Sika primer

SikaTile-410 Secure Set is also suited to a wide range of tile types. These include:

- Large format porcelain, ceramic and stone tiles

- Natural stone including marble, limestone, granite, sandstone, and slate, not suitable for moisture sensitive stone

- Terracotta

- Agglomerates / Terrazzo not sensitive to moisture

- Glass tile and glass mosaic

- Thin brick slips

Innovation and reputation

Through high-touch, personal service, SikaTile offers professionals and end-users trusted solutions and expertise across a full line of innovative tile and stone installation systems.

Sika has led the industry with revolutionary technology, innovative products, and developing high-performance building materials for architects, builders, contractors, and construction professionals worldwide. Sika’s reputation for quality and reliability is illustrated through a comprehensive portfolio of technologies and solutions, and a broad product range that provides superior performance and value. n

tiletodaydigital.com.au | TILE TODAY #115 21

Screenshot from Sika YouTube channel: youtu.be/KAfoQ7YZxV4 Sika Tile-110 Secure Proof is a waterproof membrane.

Screenshot from Sika YouTube channel: youtu.be/8kKhI7QAWVI SikaTile-010 Secure Prime is primer that can help prevent efflorescence

AUSTRALIAN INSTITUTE OF WATERPROOFING: RAISING STANDARDS AND AWARENESS

The Australian Institute of Waterproofing is a nonpartisan, not-for-profit industry association that is the voice of the waterproofing industry. Its primary purpose is to raise awareness of the importance of waterproofing in the construction industry and advocate in raising the standards for waterproofing in Australia.

As the AIW is fond of reminding people in construction (especially tilers), waterproofing is around 1.8 per cent of construction costs (on average), but is responsible for 83 per cent of complaints.

Reminders such as that are really part of the AIW's central mission, which is to raise awareness of the critical importance of waterproofing to the construction industry. It seeks to raise standards in waterproofing practice.

The AIW is a national organisation made up of state chapters. A team of passionate volunteers, who are experts in the industry, form the AIW committee. Paul Evans has been the president for the past six years and involved with the AIW for 11 years.

He is aided by Mal Ferraro as vice president, Karl Wootton as treasurer and David Hepworth as secretary.

Paul has stepped aside recently as his remedial building/ waterproofing business grows rapidly and to encourage some “younger blood” into the mix. The next president is David Previte who is located in NSW which will be the first time the AIW chair has left Victoria, as it hopes for a wider interest nationally.

While the AIW began as a largely Victorian organisation back in 2016, by 2019 it had branches NSW, Queensland and Western Australia. More recently, it has added Tasmania as well. The committee now includes three members from NSW, four from QLD, and one each from WA and TAS. VIC has a further six. There are also members from South Australia and the Northern Territory but no representation on the committee yet.

It's a very active group, promoting better waterproofing practice through meetings,

conferences and training. Some of the events the AIW has been involved in hosting include the "Waterproofing Now and Beyond" events in Parramatta and Newcastle, a meeting about the incoming National Construction Code, and several days of free training in how to properly install water stops (a subject of some importance to most tilers). There is a growing interest in below ground waterproofing with a recent webinar run by the Concrete Institute of Australia. The NSW branch had 108 participants to hear Paul talk on “Waterproofing Basements” and Colin Picton of Fosrock spoke on methods and products they supply.

As Paul explains, the AIW tends to concentrate on methodology, along with the use of materials.

As he says, when it comes to waterproofing: "Everybody wants to know how to do it and what

AIW

22 tiletodaydigital.com.au | TILE TODAY #115 23

they should be looking for." That's not just about training waterproofers themselves, but everyone in construction that relies on waterproofing so that they know what to look for. Paul says:

"The AIW and Master Builders VIC collaborated and created a waterproofing course designed specifically for people who are in the industry but not necessarily waterproofers themselves. It's really what you need to look for in site preparation. We've set up the course to show the key points that construction workers can check in order to make sure a site has been prepared

correctly. Then they can give the okay for the waterproofer to then go and do the next steps with confidence."

One of the aspects of the AIW that really pleases Paul is that it has managed to engage a wide band of professionals who need to know more about waterproofing. "Industry professionals, waterproofers, tilers, architects, designers, manufacturers, suppliers, consultants and engineers. It's right across the board and it's a good matrix of people who were involved and came to get more involved."

In fact, the AIW is very encouraging of anyone who has an interest.

"We don't hold back on who wants to be included. You know, we've got people from overseas that are just interested. So they become affiliate members so they just keep up with our newsletters, as they want to know what's going on in Australia, which is terrific…”

Beyond that kind of broad engagement, however, Paul does have a focus on waterproofing professionals as well. In particular, he is keen to advance the AIW as a place where they can share their experience and

24 | TILE TODAY #115 | tiletodaydigital.com.au

knowledge "among friends", as it were, and have confidence in discussing projects that didn't work out at first, as well as those that did.

"We want them to talk to us to say, okay, here's what's happened. Here's how I got out of it, or here's how I fixed it, or here's what I should do next time. And then we share that with everybody. We aren't trying to bag anybody to say, okay, you should have done this, you should've done that. It's really about education, and we all learn collectively from everybody else's mistakes as well. And also not just from mistakes, but everyone can come up with good, innovative ideas. That's really important. We want that as well."

Paul is quick to clarify it's not about giving direct professional advice, as that carries certain risks with it.

"It's actually just saying, 'This is what I've been through, or one of our committee members has been through'. We share it out and we talk about it. Get to our meetings and say, 'This chap's got this problem, anybody been through something similar to that?' Someone will put up their hand and we get a bit of feedback and then we can impart that to the person.

"Quite often we'll connect up the person asking the question directly with a committee member, and they'll just have a chat on the phone about it, or an email, or whatever. For better or for worse if we think they're doing the wrong thing, we'll tell them.

Say, 'No, look, sorry mate, you've done the wrong thing here, you really need to step up to the plate here and get it sorted'."

While waterproofers may sometimes get it wrong, Paul also reiterates the main (real) reason why waterproofing doesn't work out: the combination of the "need for speed" and cost-savings. A typical scenario is where there has been bad weather, and once it stops raining, the builder expects the waterproofing to be applied immediately — even though the substrate is still moist. And while there may be products, or simply product re-application, that can make it possible, many builders are unwilling to pay for that.

One aspect of handling this better is achieving more cohesion in waterproofing as an acknowledged expertise, Paul says.

"So if you get the cohesion then, you got a chap comes in to do some waterproofing, and the builder says, ‘I've got to get this done right away’. Somebody who's strong will say, 'No, I'm sorry. I can't do that today, I'll come back when it dries out'.

"But then someone else rocks up, and it's 'I'll do it mate, no worries'. So it is chuck the first one out, get the second one in. We've got to stop that from happening. That's about the cohesion of getting everybody like-minded, so they can be strong enough to say, 'No, it's not right. It's not going to happen.' Or, 'We can offer these solutions'."

Membership

The AIW welcomes all construction industry professionals — architects, manufacturers, tilers, and allied trades. Belonging to the AIW will help to raise the standard of waterproofing in the industry and provides members with many direct benefits, such as:

• Access to the latest technical information

• Access to former course and outline training

• The right to use the AIW logo in members' communications with clients and others, which helps to build brand credibility

• Connections with others in the industry to help share and find solutions

Prospective members can contact the AIW on its website at: https://www.waterproof.org.au/

Even if you don't plan on becoming a member, it really is worthwhile going through the AIW's newsletters, past and present. Some of the leading experts in waterproofing offering in-depth articles on topics such as waterproofing around shared tub/shower areas, waterproofing steam rooms (talk about a tough gig!) and how to properly install water stops.

The number of topics is endless when you really get into it. Paul’s philosophy for the AIW and his own remediation business, is to keep it as simple as possible and still achieve a high standard. n

tiletodaydigital.com.au | TILE TODAY #115 25

Renovators’ paradise

As long-time customers of Phil’s Tile Warehouse, Scott Christensen and Phoebe King-Christensen had a reasonable idea of what they were getting into when they bought the business. They have plans to expand the customer base especially with architects and builders.

Located in the centre of Noosaville, Queensland, Phil’s Tile Warehouse occupies a space close to other tile stores, and is situated in an industrial hub, on a main road. Similar to the way large supermarkets and fashion retailers are in the same shopping centre, Phil’s Tile Warehouse benefits from being close to tile store chains and the foot traffic they attract.

As Phoebe explains, “I think it's actually really fortuitous that we're close to bigger retailers because they do a lot of advertising, not just for us, but a lot of advertising that can lure the customer in.

“There's a good selection when it comes to tiles…We are in such close proximity, they might think, ‘We'll just go to see Phil's afterwards’, where they can get a completely different experience. That works for us.”

Phoebe understands this dynamic well as a result of her background in fashion retail, working for brands such as Que and Country Road.

While that serendipitous colocation provides a welcome boost, most importantly there is a vibrant renovation market in Noosaville. According to Phoebe: “In the last couple of years, we've had so many people move to the area from interstate and bought homes they may not necessarily be happy with. So they've been making them their own. There's been a lot of renovators, and people have said to us that after moving into the area, they want to update the home that they've bought, and also extend. That's quite a popular project.

Home extensions provide more opportunities for Phil’s Tile Warehouse. Part of the reason for such a strong renovations and

additions market in Noosaville is the slow release of land by the state government. Phoebe said, “There's not a lot of land that is being released up here. There's probably maybe a couple of new subdivisions opening up, but that’s it. That's why the market was so hot up here, because you've got to fight tooth and nail to get [new land for housing].

“It's not like near Caloundra where you've got the Aura Estate where there are homes upon homes. We just don't have that up here. In Noosaville, you've got to buy an older home and do it up.”

New ownership

Phoebe and Scott took over as store owners in April 2022. In addition to Phoebe’s extensive fashion retail experience, she has also worked in London where she helped set up a

RETAIL FOCUS 26 | TILE TODAY #115 | tiletodaydigital.com.au

design store and cafe. “I did all the purchasing and merchandising, that kind of thing,” she explains.

Both Phoebe and Scott bring ideal experience and skills to the business as an interior designer and builder, respectively. Formerly they sourced tiles for their own projects and their clients at Phil’s Tile Warehouse, before becoming owners.

“We had our own building company up here and we've always worked up this way…We always used to come with our clients to Phil's Tile Warehouse,” said Phoebe.

“I'd always meet our clients here and we'd go through the range. It's always been a tile shop so we've got a nice relationship with the previous owners.

“It was a really good fit when it came around to being on the market…It's got a really good name for itself in this area and in the industry…We've had customers that have been coming here for years.”

INCREASE SALES AND CUT COSTS brought to you by CLEARTILE – MAKES ANY TILE BUSINESS MORE EFFICIENT AND MORE PROFITABLE Key features and benefits: 3 Point of Sale, inventory control and financial accounting for the tile industry. 3 Recalculate sale quantities to whole piece or whole box. 3 Track shades/batches. 3 Convert your m2 quantity into exact number of pieces, boxes and pallets. 3 Easily process a sale from quote to sales order to invoice. 3 Manage your builders selections! 3 Purchasing made easy. 3 Single Touch payroll integration. 3 Analyse your business with advanced reporting. NEW ClearLink add-ons available Call 07 5593 3022 for more information and to arrange a FREE demonstration today! www.clearsoftware.com.au ClearTile – the complete business management software for the tile industry

Large format and decorative tiles 28

In terms of customers, Phoebe describes their main target market as home renovators. “Locals wanting to renovate or doing new builds…Your mums and dads, all sorts of people who just want to get their projects done,” she said.

The store also has a healthy trade customer base who bring their clients in. As Phoebe explains, “People who are working with builders or tilers that are renovating their own homes, or extending or building new, they are coming in and looking at tiles for those projects.”

Phoebe’s professional background as an interior designer means the store can offer genuine design services for customers. “If people come in and want assistance in that area, then I'm here to help. I'm very passionate about design. I help people source particular looks and put things together and help them achieve the overall look that they're going for,” she said.

The flip side of being located close to other tile retailers means Phil’s Tile Warehouse must have compelling reasons why potential customers should visit their store and buy from them. Phoebe believes customer service, a sound knowledge base as well as product range are the main points of difference for the store. “Obviously with the interior design side of things, and Scott being a builder, we have that kind of knowledge to offer. We've also got a staff member who has been in the industry just as long as Phil, the original owner, has been in the industry. He has a huge wealth of knowledge, and is a real asset to our team,” she said.

Providing customers access to a knowledge base in building and interior design has probably given them a slight edge in terms of offering a USP (unique selling proposition). Most home renovators are searching for this type of information and real world experience when undertaking these projects.

But more specifically, it is how this knowledge is expressed and conveyed through customer service that plays a crucial role in winning over new people to the store. Phoebe told Tile Today: “Particularly when people have been to another tile

28 | TILE TODAY #115 | tiletodaydigital.com.au

Scott Christensen and Phoebe King-Christensen took over Phil’s Tile Warehouse in April 2022

Just outside the entrance to Phil’s Tile Warehouse

store before they come to us. They often say that the experience is… chalk and cheese. They might acknowledge the service isn't there so they come to us and we've got probably just as good a range as the other store does, but we've also got the service to go with it. And the friendliness, that's been a really big thing. The interior design aspect [has helped]. I think people really appreciate that next level of service.”

And similar to other tile shops, Phil’s Tile Warehouse will find tiles if customers don’t see them in-store.

Popular categories

Interestingly, Phoebe said there are not many planned promotions mainly because she believes they are able to get a great price when purchasing tile products from their wholesalers and this is passed on to customers, each time.

“We buy quite a lot of stock from our wholesalers. And obviously there are discounted rates associated with this type of purchase, and we pass this on to our customers. So we have stock of tiles that we can get a really good price point…and that would probably be one type of promotion. It's an all-year round promotion,” she said.

“I don't think we need to do [special] promotions, at this stage. We leave that to your larger tile wholesalers and retailers. We do fairly well with just having our prices as it is,” she explains.

The showroom has been partly renovated to feature decorative tiles and this has helped to fuel their popularity at store level.

“We've given them a lot more room to sort of breathe…So we get a lot of people that are interested in decorative tiles, and I think shows like ‘The Block’ and Instagram [help to make them popular]. That's more about decorative tiles in smaller rooms, adding that bit of punch within a budget. They’ve been really popular.

“We've also got the standard 300 by 600mm gloss and matte white tiles that just sell all day, every day. The 600 by 600mm floor and wall tiles are also popular. The majority of people are looking for these tiles for their home…and

we've got a really nice range of that format tile.

“We've also got a central table where there are stone top samples, laminate samples and tap samples for people to come and see to help design their bathroom or kitchen, or the whole house,” said Phoebe.

Regarding colour trends, Phoebe said the showroom is quite greydominated but she is also seeing a lot of warmer tones.

“The warmer base greys or beiges and cream are definitely coming through. This is what the suppliers are showing us as well. When they've got new stock, that tends to be what they're bringing in and a lot more people are asking for that softer or calmer colour palette rather than your cool greys. So we are definitely

seeing a slight change and away from the greys and going more for warmer tones.”

Suppliers

A successful store attributes a lot of its success to its supplier relationships, and Phil’s Tile Warehouse is not different. In fact, some of them have played a key role in re-establishing the store with Phoebe and Scott as the new owners.

“We mainly deal with larger suppliers like DIY Tiles because they've got such a large range. They've been particularly helpful,” said Phoebe.

“The majority of our suppliers are Queensland based. A new one

tiletodaydigital.com.au | TILE TODAY #115 29

31

Decorative tiles on display

EXPLORE. DISCOVER. ENJOY.

Tile Today is the leading publication for Australia’s tile industry.

For tile installers, we provide a mix of indepth technical articles, product guides, the latest trends in design and business, as well as inspiring coverage of Australian and international tile shows and events.

For retailers, we cover all the latest industry news, interview the movers and shakers, and keep you up-to-date on industry statistics and forecasts.

For interior designers, architects and building specifiers, we offer an index to best practice and emerging concerns in the building and construction industries as they relate to tiles.

But what we offer to every reader, is a publication that shares your interest and inspiration

• In-depth technical articles

• Business opportunities

• New tile developments

• Guides to adhesives

• Coverage of anti-slip issues

• Waterproofing best practices

• Trends in interior design

Tile Today is now digital, which means you can read it on your smartphone, tablet and PC. Take it everywhere with you.

Subscribe to Tile Today for FREE.

CLICK TO SUBSCRIBE

that we just started working with is Europe Imports for mosaics. The new Queensland sales rep has been really helpful in helping us establish that brand. Southern Cross Ceramics has also been great as well.”

In addition to tiles, Phoebe mentioned there are adhesives from the major players such as Laticrete, SIKA and Davco. The store stocks trims from DTA. “We've definitely got trade suppliers, and they've been really helpful. We stock Ardex glues, grouts and silicone and the sales rep from there has been really excellent as well,” she said.

E-commerce

At the moment, Phoebe and Scott have decided to prioritise servicing customers in-store and changing some of the ways the stock is displayed over setting up any online sales.

“Right now, we are just updating the website and freshening that up. In-store, we've definitely cleaned up a lot and renovated the back. I don't know if we will ever do online sales. Being such a new business, it's not something we want to focus on just yet. We want to make sure everything's right with the physical aspects of the business,” said Phoebe.

Phoebe believes that companies like Tile Cloud are already providing a great online service with great imagery so she doesn’t think it is the right time to be competing in that area yet.

“We are busy building up the customer base that [previous owners] Phil and Barb created and working on broadening that in the local area,” she explains.

The couple have ambitions to work with a lot more architects and interior designers. That is their next goal, starting with Instagram and the website, making their online presence “a bit fresher and more inviting” as Phoebe puts it.

Once they feel their social media and website have been updated, they plan to establish these new relationships, face-to-face. “We have a few designers and architects that we work with already, but it would be really nice to broaden that network so that's something we're definitely keen to do in the not-too-distant future,” she said.

n

tiletodaydigital.com.au | TILE TODAY #115 31

Stone pavers for outdoor applications

Inside the store

Supporting the tile industry For further information visit australiantilecouncil.com.au Become a member today Australian Tile Council Member benefits: - Industry support from the Australian Tile Council (ATC) - Technical and Industry related information and support - Free access to the Tile and Tiling Guide - Free access to the Tile Reference Manual - Member Benefits programme with exclusive offers - Tiling literature, brochures and notices - Professional recognition as a member of the only recognised national body industry

Tile lippage and smoothing out the edges

The Australian Tile Council’s Tile & Tiling Guide provides a chapter on tile lippage that serves as reminder of the fundamentals for tilers and new information for DIY enthusiasts

The term lipping relates to situations where, for one reason or another, the edge of one tile protrudes above its neighbour.

Lippage is inherent in all installation methods and may also be unavoidable due to the tile tolerances. Lippage may also be unavoidable where tiles larger than 150 x 150 mm are graded to a waste outlet, unless transverse cuts are incorporated.

Australian Standard AS 3958.1 — 2007 recommendations for tile finish and joints are as follows: The lippage between two adjacent tiles should not exceed 2 mm.

In the case of tiles where the surface has been ground flat, the lippage should not exceed 1.5 mm, and for joint widths of 3.0 mm or less the lippage should not exceed 1.0 mm.

In regard to the flatness of the finished surface the standard states. “When measured with a straightedge, the finished surface

of the tiling should be flat and true to within a tolerance of ±4 mm in 2 metres from the required plane.”

Note that in AS 3958 there is no mention of rectified tiles where it is common practice to have narrower grout joints. Therefore it is commonly agreed to treat these tiles similar to ground flat tiles when it comes to allowed lippage. Lipping can be caused by:

• Poor or uneven preparation of the substrate. In many instances, tiles are fixed using thin-bed adhesives and fixing techniques. In this instance the prepared substrate should not deviate by more than 4mm, when a two metre straightedge is placed on the surface. If a gap is larger than 4mm appears, it will be necessary to adopt a thick-bed fixing technique.

• The background may not be clean. All surfaces should be cleaned before adhesive is applied, as particles of grit

trapped under a tile will induce lipping.

• Protruding nails or screws. Ensure that nail or screw heads are flush with the surface of the substrate.

• Excessive curvature of the tile. The Australian Standards allow for a degree of curvature in finished products. This may pose a problem, particularly when a brick-fashion rectangular tiling design is adopted, as curvature will occur in the centre, thus the ends of the adjacent tiles will be lower than the centre. Careful application of adhesive is required to overcome this potential problem, which will be exacerbated if the substrate is not flat. Alternatively, lay tiles in a stackbond pattern rather than brickbond (or at a minimum in a 1/4 / 3/4 pattern).

tiletodaydigital.com.au | TILE TODAY #115 33

ATC

34

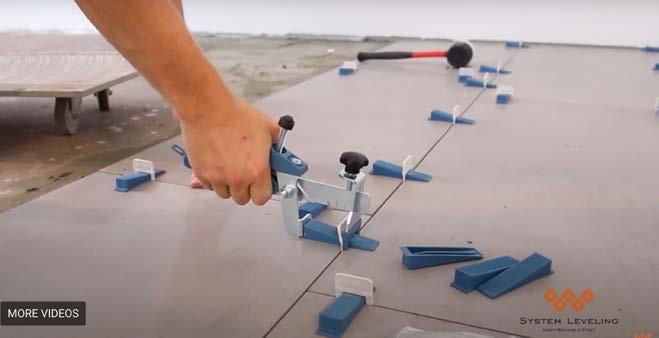

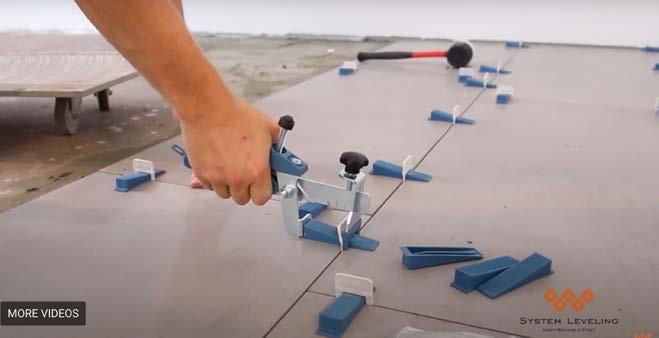

A screen shot from the System Leveling video on its homepage. Click on the image to see more.

General guide

Lipping tiles are unsightly, particularly if they appear throughout the installed tiles. They may also create a trip hazard.

The best way to avoid lipping is to ensure that substrates are flat and are prepared in accordance with the prevailing standards and that they are clean and free of debris before tiling commences. Importantly, the adhesive must be applied evenly using an appropriate notched trowel, using the chosen thin or thick-bed fixing technique.

Slightly uneven backgrounds can be overcome by careful application of adhesive, which should be evenly applied to the substrate and added to the back of the tile in the appropriate place.

Alternatively, the substrate can be screeded to make it flat. A number of suppliers of tiling tools and allied products market lippage control systems which are designed to ensure that the entire floor is completely flat. Spacers are installed which effectively eliminate the possibility of lipping in ceramic and natural stone wall and floor tiles of various thicknesses, including 3 mm.

Perceived or apparent lippage is a condition where the tile installation meets the standards and does not have excessive lippage, but appears to have excessive lippage. This can be caused by natural or manufactured lighting emanating

from an angle that accentuates the lippage by creating a shaded edge. Highly reflective surfaces can compound this condition making it appear to be excessive lippage when it isn't.

Lippage control systems

A number of suppliers of tiling tools and allied products market tile lippage control systems. These systems are designed to not only minimise the possibility of lippage, but also reduce settling from shrinkage in the adhesive where large format tiles are used. However, they should not be used in place of correct surface preparation of a level substrate and back buttering large format tiles. Instead, they should be used as an aid to fine tune the lippage of tiles.

The use of a lippage control system may be unavoidable on large format panels and slabs.

Since these lippage control systems exert force on tiles that have already been fitted, certain precautions should be taken into account when using and removing them to prevent them from having a negative effect on the bonding of the tiles, as the process is carried out while the adhesive is still setting.

Other tips include:

• It is best to use spacers or grid lines for establishing the grout joint width, not the lippage control system straps. To facilitate easier removal and to

avoid damage to the tiles, it is recommended to leave free space around the strap when installing.

• Conduct a test installation of the selected lippage control system to ensure it does not leave marks on the surface of the tiles.

• Make sure the adhesive layer has a suitable regular thickness using the double gluing technique.

• Apply the lippage control system within the open time of the adhesive to prevent weakening the adhesive bond.

• Use the lippage control system between adjacent tiles that have been installed at the same time and not between tiles or rows of tiles installed at different times.

There are various versions available so it is important to refer to the manufacturer's usage instructions on their brand.

Laying patterns

Timber-look ceramic tiles can be as aesthetically pleasing as genuine wooden floors, with added benefits that include greater durability, water resistance and lower maintenance. It is, however, essential to follow the correct installation procedures.