CONSTRUCTION CIVIL WORKS CIVIL ENGINEERING V8.05 CONCRETE INSTITUTE of AU STRALIA MARCH 2023 PRINT POST APPROVED - 100001889 PROUDLY SUPPORTED BY PROUD MEDIA PARTNER EXPERT, INDEPENDENT, THIRD-PARTY STEEL CERTIFICATION TO AUSTRALIAN AND NEW ZEALAND STANDARDS Is your steel compliant with Australian Standards?

SlimDek 210® – Longer spans and lower floor depths

SlimDek 210® is capable of achieving unprecedented unpropped spans during construction of up to 7m and propped spans of over 10m. When combined alongside asymmetric steel beams in Fielders SlimFlor® construction system, floor construction depth can be reduced to as little as 290mm, which represents up to a 35% reduction of in slab thickness compared to traditional concrete construction.

Fielders® and ® product names are registered trademarks of BlueScope Steel Limited and ™ product names are trademarks of BlueScope Steel Limited. © 2023 BlueScope Steel Limited. ABN 16 000 011 058. All rights reserved. FIE0420/02.23 fielders.com.au

You can do it with Fielders.

About the Cover

Recent high-profile incidents involving defects in steel structures have once again highlighted the importance of using construction steels and processes that meet Australian Standards, and the need for appropriate technically based third-party certification. Turn

contents MARCH 2023 Volume 8 Number 5

to Page

for

Published by: Editorial and Publishing Consultants Pty Ltd ABN 85 007 693 138 PO Box 510, Broadford Victoria 3658 Australia Phone: 1300 EPC GROUP (1300 372 476) Int’l: +61 3 5784 2210 www.epcgroup.com Publisher and Managing Editor Anthony T Schmidt Phone: 1300 EPCGROUP (1300 372 476) Mobile: 0414 788 900 Email: ats@epcgroup.com Business Development Manager Lawrence Whiter Mobile: 0418 543 821 Email: lawrencewhiter@bigpond.com National Advertising Sales Phone: 1300 EPCGROUP (1300 372 476) Int'l: +61 3 5784 2210 Email: ats@epcgroup.com Advertising Sales - SA Jodie Gaffney - AmAgo Mobile: 0439 749 993 Email: jodie@amago.com.au Advertising Sales - WA Licia Salomone - OKeeffe Media Mobile: 0412 080 600 Email: licia@okm.com.au Graphic Design Annette Epifanidis Mobile: 0416 087 412 Registered by Australia Post Publication No. 100001889 ISSN 2204-7247 TERMS AND CONDITIONS This publication is published by Editorial and Publishing Consultants Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright ©2023 - EPC Media Group 4 22 38 2 Editorial 4 Industry News 10 Cover Feature: Australian Steel Standards require wider industry adherence 16 ETIA Blog - Innovative new products in the concrete marketplace 18 Product Focus: Fielders KingFlor 22 Equipment Focus 24 Digital Technology 30 Innovative Solutions 38 New Developments 40 Product Brief: Hydralink ENDURO 16

10

the full story.

IT’S NOT ABOUT THE ORIGIN… IT’S ABOUT QUALITY AND CONFORMITY WITH STANDARDS

Dear Readers,

As regular readers of Construction Engineering Australia (CEA) would know, I am passionate about the importance of quality and safety in construction. Indeed, some might even suggest this passion borders on being touch obsessive… fair enough, too!

Unfortunately, there have been a number of incidents in recent months that have once again thrust matters of quality (especially in terms of construction materials) and the importance of conformance with Australian Standards and other relevant regulations and codes, into the spotlight.

Now, before I progress any further with this editorial, there are a number of critical factors that I must point out:

1. Although this editorial refers to two reported incidents, I offer absolutely no suggestion or inference as to the cause or contributing factors that led to the outcomes (including those shown in the image above).

2. I have no connection with any individual or any party involved with either of the two projects mentioned in the editorial. All of my information came from the public domain, including media outlets and press releases from various parties.

3. I understand that as of the time of writing, both of the incidents are still under investigation, and no official findings have been made.

Now, while this may seem a little overcautious, given the ongoing nature of the investigations (not to mention the risk of possible litigation), I want to make it perfectly clear that this editorial is not about these instances directly… it is aimed

squarely at the discussions and arguments that have erupted in the public domain in the wake of these and a number of other incidences around the country.

I also feel that at this stage, it is important to remind readers that CEA has commercial relationships with both Australian and international construction materials suppliers, builders, specifiers, architects and engineers, as well as testing facilities, certification authorities, quality certification organisations, associations and many other organisations involved in every imaginable aspect of construction. Despite that, the commentary in this editorial is not influenced by any of those relationships! THAT SAID…

While there have been a number of incidents, two recent high-profile incidents in particular, namely: the construction of the new stand at Geelong’s GMHBA Stadium, and the partial collapse late last year of a section of steel structure at the multimillion dollar Kew Recreation Centre in suburban Melbourne (pictured above), have sparked furious debate and sometimes heated commentary.

While it seems from the myriad reports and extensive commentary that I have read over the past few weeks that all parties seem to agree on the importance of using construction steels that meet relevant Australian Standards and Construction Codes, these two events in particular, have also been used by some parties and individuals (both within and not at all related to the construction industry) to call for only Australian-sourced construction steels to be used on Australian projects.

Now, notwithstanding the ongoing

investigations, I believe that these kinds of calls for ‘blanket bans’ on imported products serve no good purpose whatsoever. Indeed, I believe they completely miss the point.

Just to be clear, I recognise the importance of supporting and growing Australian manufacturing and Australian businesses in general (we are after all an Australian family-owned business).

However, I also believe that using these types of incidents as the basis of what is, for all intents, a nationalistic ‘closeddoor’ approach to material supply not only contravenes our international trade agreements. It also comes from an unrealistic and uninformed view that ‘…everything that is Australian is good and meets the Standards, while imported materials aren’t and don’t’ – a clearly ridiculous concept on both counts.

Put simply, when it comes to construction materials, it’s NOT ABOUT THE ORIGIN… It’s about QUALITY and CONFORMITY with Standards, Building Codes and other statutory requirements.

Australia has robust Standards and Building Codes, and we need to be sure that all construction materials being used are fit for purpose and conform to all appropriate Standards - regardless of where they are made. After all, we all deserve to have a high level of confidence that our buildings and structures are built well from quality materials.

Anthony T Schmidt Managing Editor

2 Construction Engineering Australia • March 2023 EDITORS COLUMN

2023 ETIA Annual Sponsors Contact us: (02) 9899 7447 | registrations@etia.net.au | www.etia.com.au | Connect with us: Over 40 Design and Construction Workshops O erred PROFESSIONAL DEVELOPMENT | SMALL GROUPS | LIVE STREAM | FACE-TO-FACE 2023 UPCOMING COURSES Paul Uno ETIA Director VIEW OUR COURSES 1. Prestressed Concrete Design Workshop 4 + 5 April 2023 ZOOM 2. Structural Steel Design Workshop 17 + 18 April 2023 F2F BNE 3. Hydraulic Engineering Design Workshop 18 April 2023 F2F BNE 4. On-site Detention Systems Design Workshop 19 April 2023 F2F BNE 5. Process Piping (Pressure) Design Workshop 20 + 21 April 2023 F2F BNE 6. Residential Slabs & Footings Design Workshop 20 + 21 April 2023 F2F BNE 7. Hydraulic Engineering Design Workshop 27 April 2023 ZOOM 8. On-site Detention Systems Design Workshop 28 April 2023 ZOOM 9. Wind Design: Dynamic & High-Rise Structures 2 May 2023 F2F SYD 10. Precast & Tilt Up Design & Construction Workshop 3 May 2023 F2F SYD 11. Detailing in Practice Workshop 4 May 2023 F2F SYD Joanne Bianca Lisa *F2F BNE (Face-to-Face Brisbane) *F2F SYD (Face-to-Face-Sydney)

BETTER, BRIGHTER, GREENER NEW BUILDINGS IN MELBOURNE

The City of Melbourne will take bold action to raise the planning standards for environmentally sustainable design – with stronger energy efficiency standards, green rooftops, vertical gardens and solar panels set to transform Melbourne’s skyline.

The Sustainable Building Design Amendment will introduce stronger planning controls for developments – helping to green city buildings, improve environmental standards, and combat the effects of climate change.

“We’re taking bold action to address climate change – and this is another significant step forward to cut emissions and improve sustainability across our beautiful city,” Melbourne Lord Mayor Sally Capp said.

“Developers can find clarity and confidence in these amendments to know they are contributing to long-term sustainability, while the buildings’ tenants will receive the benefits of cheaper operational costs,” the Lord Mayor said.

Buildings are the biggest polluters in the City of Melbourne, accounting for 66 per cent of all carbon emissions in the city – compared to 25 per cent in other municipalities.

Drawing inspiration from world leaders like Singapore, Vienna and Copenhagen, the new amendment will:

• Improve energy and water efficiency

• Increase the uptake of renewable energy

• Encourage more greenery on roofs and walls

• Boost the number of new trees

• Cut back on waste generation

• Increase electric vehicle infrastructure and bicycle parking

Implementing these measures into the design of new buildings will have a major impact on the city’s emissions – reducing the urban heat island effect, improving energy

efficiency and addressing water shortages and resource recovery.

They will benefit future tenants and property owners, by offering more attractive, environmentally friendly homes, offices and buildings – which are cheaper to operate.

“As Melbourne’s climate gets hotter and we experience more extreme weather events, it’s vital we deliver sustainable buildings and green infrastructure that cools our streets, homes and offices,” Lord Mayor Capp said.

“Whether it’s installing more electric vehicle chargers, boosting renewable energy or increasing greenery – these new measures will benefit everybody who lives, works or visits Melbourne,” she added.

It will also accelerate Council’s commitment to power the city with 100 per cent renewable energy by 2030, and to reach zero net emissions by 2040.

City of Melbourne Sustainable Building portfolio lead Councillor Elizabeth Doidge said that the sustainable building standards are a necessary key to addressing the climate challenge and that she is proud to be part of a Council leading in this space.”

“To meet emissions reduction targets and improve our community health, social and environmental needs, Melbourne must have a plan that addresses our built environment – and this proposed amendment will do just that,” Councillor Dodge said.

“While tackling climate change is a key goal, there are other major benefits to better environmental standards, including lowering power bills and improved indoor comfort and air quality.”

These sentiments were echoed by Deputy Lord Mayor Nicholas Reece, who added: “Melbourne should be a world leader in sustainable design and green urban environments – drawing inspiration from the

incredible success of cities like Singapore.”

“We know buildings contribute 66 per cent of all emissions in our city – that’s why we need to work alongside developers and property owners to combat climate change, which will also reduce energy costs for businesses and homes.”

Speaking about the Sustainable Building Design Amendment, Property Council Victorian Executive Director Cath Evans said that Australian building owners and developers have been at the forefront of sustainable building performance, and great sustainability outcomes are being increasingly sought by tenants, occupiers and residents.

“We encourage building owners and developers of all sizes and sectors to read the detail of this important work and provide their input to this consultation,” Ms Evans said.

The amendment includes policy, as well as mandatory and optional controls, and will apply to particular types of developments.

Council will help developers implement the new standards for greener infrastructure through its award-winning Green Factor Tool – a free online green infrastructure assessment program.

The first of its kind in Australia, the Green Factor Tool allows designers, architects, developers, builders and the community to consider and optimise the inclusion of green infrastructure in building design.

The proposed Sustainable Building Design - Planning Scheme Amendment C376 – is now open for submissions until Monday 17 April 2023.

For more details, to make a submission, or attend an information session, visit the Participate Melbourne website: https://participate.melbourne.vic.gov.au/ amendment-c376

4 Construction Engineering Australia • March 2023 INDUSTRY NEWS

NEW CONSTRUCTION ENGINEERING MICRO-CREDENTIALS TARGET AUSTRALIA’S SKILLS SHORTAGE

Engineers Australia has launched an industry-first suite of micro-credentials on construction engineering skills.

Engineers Australia Chief Engineer Jane MacMaster said the new offering is part of Engineers Australia’s strategy to addressing the acute skills shortage hampering Australia’s ambitious infrastructure agenda.

“Engineering is critical to the health of our nation’s construction industry and addressing the skills shortage through targeted action is one of Engineers Australia’s highest priorities,” Ms MacMaster said.

“Micro-credentials aren’t just a training course. They are highly-targeted tools that develop and certify new skills or certify existing skills, to industry standards of practice.”

The suite of micro-credentials follow on from the benchmarking of skills and competency by Engineers Australia and the Australian Constructors Association,

the Construction Engineering Learning & Development Guide (CELDG), and target the highest priority skill demands in the sector.

The suite focuses on skills outlined in the CELDG for Project Engineers:

• Construction Contract Management: Develops and assesses capability to understand construction contracts including commercial principles, rights, obligations and appropriate use of clauses, and the ability to scope subcontractor procurement.

• Managing Project Costs: Develops and assesses capability to manage and track project budgets and costs as well as communicate budgets and work packages to construction crews.

• Managing Project Schedules: Develops and assesses capability to develop and oversee construction project schedules

including determining the critical path and understanding the commercial impact of change.

• Managing Tenders and Bids: Develops and assesses capability to prepare, evaluate and coordinate construction project tenders, and contribute to tender or bidding processes. They are also relevant for construction professionals, providing recognition for their on-the-job skills development, and Site Engineers looking to progress to the next stage of their career. Engineering Education Australia is the training provider of Engineers Australia, the peak professional body for engineering across the country. We deliver professional development courses and programs, designed specifically for engineers, all around Australia.

Victoria University researchers have developed state-of-the-art technology that will take outdated aspects of Australia’s construction industry into a modern digital age.

Professor Zora Vrcelj (Head of VU’s Built Environment) and Professor Yuan Miao (Head of VU’s Information Technology) and their teams have combined high-tech tools with engineering and architecture to improve safety training in the construction profession – which has one of the highest rates of preventable accidents and deaths of any sector in Australia.

With the help of a construction simulator (COSI) with virtual reality (VR) at VU’s Werribee Campus, the researchers want to reduce workplace injuries and deaths. COSI’s fully-immersive VR experience allows trainees to use high-tech goggles and equipment to enter and explore a detailed simulation of a construction site to learn about safety – a big change from learning it through an instruction booklet or computer modules.

The simulator lets users learn to climb ladders, move equipment, work in a confined space, or walk along narrow scaffolding, without any real risk.

Already city councils, construction giants like Simonds Homes, and even the Victorian Building Authority – the state’s chief industry regulator – have expressed interest. Professor Vrcelj said the project would help modernise the construction industry, which is currently among the least digitised industries in Australia, leading to high rates of worksite injuries, a lack of quality control and inefficiencies.

Andrew Shea, CEO of the Builders Academy Australia, Simonds Group, said training workers via simulated experiences would make a real difference to a worker’s learning and have a “genuine positive impact.”

Research also improves building inspections

The researchers are also helping to modernise the profession of building

surveying. Traditionally, surveyors conduct mandatory inspections of buildings during construction with a clipboard and a checklist, as they assess the framework, electrics, plumbing, and design of a building.

“The surveyor comes, checks that everything is up to code, ticks the boxes, then leaves. But if something changes that affects the build before the next inspection, no one has any idea what’s been done or where the alterations have been made,” said Professor Vrcelj.

Instead, the VU researchers have developed a cloud-based platform where photographs and 360-degree scans of the building are uploaded and can be accessed remotely in real-time from a smartphone or iPad.

This means there are chains of evidence when things go wrong, but more importantly, early opportunities to prevent defects from happening in the first place, she said.

6 Construction Engineering Australia • March 2023 INDUSTRY NEWS

DIGITAL TECHNOLOGIES FOR CONSTRUCTION INDUSTRY WILL IMPROVE SAFETY AND EFFICIENCY

The ABS released the Lending to Households and Businesses data for January 2023 during March, and it paints a gloomy picture for both the construction industry and those looking to build or rent a home according to the HIA (Housing Industry Association).

“ABS data released today is reaching new lows, with lending for new homes recording its weakest month in almost 15 years,” stated HIA Senior Economist, Tom Devitt.

“There were just 4,345 loans issued for the construction or purchase of a new home in January, the weakest month since November 2008, and 8.2 per cent down on the previous month,” added Mr Devitt.

“Owner-occupiers and investors, alike, continue to retreat from the market. Firsthome buyers, especially, were issued fewer loans in January 2023 than in any month in the last six years.

“Even lending for renovations – the part of the sector expected to hold up relatively

well during this downturn – had its weakest month in almost two years.

“The data continues to reflect the weight of interest rate increases which occurred in 2022, and before the RBA increased the rate again in February, with the promise of more rate increases to come.

“There are significant lags evident in this cycle and we are unlikely to see the bottom in this data until the second half of the year, at the earliest.

“The higher cash rate is compounding the adverse impact of the rising cost of materials, labour and land as well as the increased costs of compliance with the building code.

“There remains a large volume of work underway that will be completed in 2023 and this will keep national unemployment exceptionally low until early 2024.

“By continuing to raise rates the RBA risks a longer and deeper slowdown in economic

growth than is necessary,” concluded Mr Devitt.

The number of loans for the construction or purchase of new homes declined in most jurisdictions in January 2023 compared to the previous month, led by South Australia (-37.6 per cent), and followed by New South Wales (-37.2 per cent), Victoria (-32.4 per cent), Queensland (-25.1 per cent), Western Australia (-23.6 per cent) and Tasmania (-1.4 per cent). Increases were seen in the Northern Territory (+47.6 per cent) and the Australian Capital Territory (+24.0 per cent).

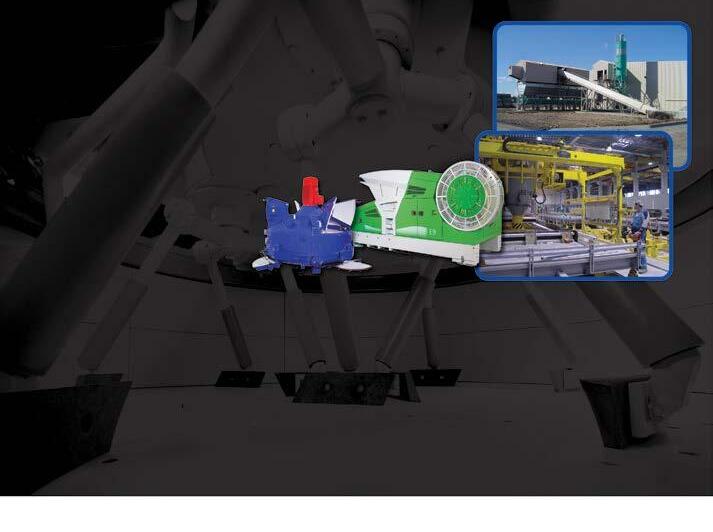

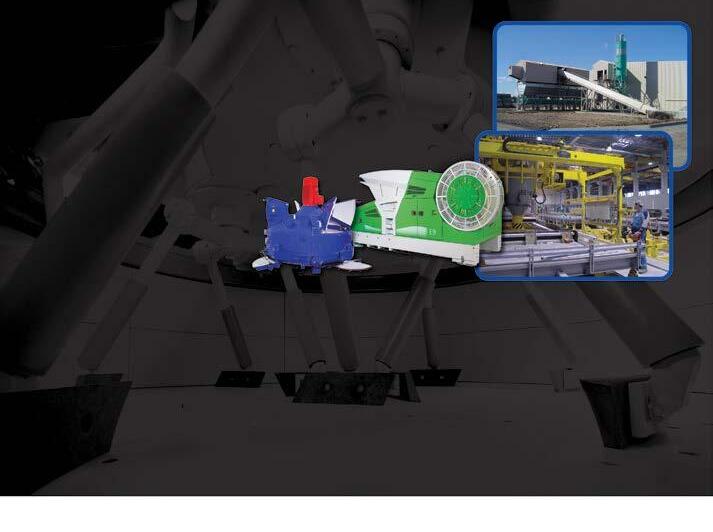

HOUSING DOWNTURN ACCELERATES WORLD LEADING REBAR MANUFACTURING EQUIPMENT Supporting and supplying to Australasia's leading reinforcing manufacturers for over 40 years. Backed by MEPGroup Italy, Machinery Indents have the structure, experience and advice to help you with rebar processing equipment • New and Used Machine Sales • Factory Layout Design • Programmed Maintenance • On/Offsite MEP Equipment Training • High Automation and Flexibility • Customer Solutions • Manual Handling Solutions • Technical Assistance • Genuine MEPGroup Spare Parts • Highest Quality Machinery • Manufacturing Process Consultation • Precast - Rebar Manufacturing Equipment MEPGroup Australasian Agent 43 Jesica Road, Campbellfield Victoria, Australia P: +61 3 9357 9769 F: +61 3 9357 0699 E: enquiries@mi-mep.com.au www.mi-mep.com.au Construction Engineering Australia • March 2023 7 INDUSTRY NEWS

With over 20 years’ experience delivering health and wellbeing programs to Australia’s most at-risk industries of suicide, the OzHelp Foundation (OzHelp) recently announced the launch of Health in Trades (HiT).

On average, around nine Australians die by suicide every day, 75% of which are men, with male construction workers consistently found to die by suicide at a higher rate compared to other male workers.

OzHelp has had a long-standing commitment to delivering health and wellbeing services to Australia’s building and construction industry, and HiT is a hard hat tip to the industry for which the Foundation was born to support.

Backed by over 20 years of experience, in-depth industry knowledge extensive customer and client relationships and voice of lived experience, the HiT program stream was developed to meet the continually evolving needs of the building and construction industry, supporting businesses and their people.

OzHelp’s Partnerships and Engagement Director, Caz Parish, said with the shift in the minimum standards expected of employers in managing psychological risks in the workplace employers are playing an active role in preventing harm and providing genuine care and support to their people.

“Employers are looking beyond mental health advocacy and how as an organisation they can practically prevent psychological harm within the workplace through data-informed decision making and targeted interventions that are tailored to their worker’s needs,” Caz said.

“We have developed evidence-based, scalable and accessible programs that assist employers in creating resilient, psychologically safe workplaces by helping

the building and construction industry has a crucial role to play in achieving this goal,” Ms Wawn said.

individual employees achieve their best possible mental health and wellbeing.”

OzHelp is accredited under the Australian Government National Standards for Mental Health Services and several core initiatives to the HiT program received accreditation under the Suicide Prevention Australia Accreditation Program in late 2022.

Programs such as the Tradie Tune Up (onsite health checks), counselling and wellbeing support services and the Workplace Tune Up program are evaluated against six national suicide prevention standards to ensure they are targeted, outcomes-based, and provide a consistent, high-quality and safe standard of care.

For more information follow Health in Trades on Instagram and Facebook or visit: www.healthintrades.com.au

The peak national body representing the building and construction industry has taken another step in its commitment to a sustainable built environment by joining the Australian Sustainable Built Environment Council (ASBEC).

Master Builders Australia CEO Denita Wawn says the industry is committed to meeting its net zero obligations and is formalising partnerships with key stakeholders to better utilise the network of expertise on critical policy reform areas.

“The transition to a net zero built environment is one of the most significant policy reform areas impacting building and construction and the future direction of the sector.”

“Building a sustainable future requires a collective effort from all stakeholders, and

“Master Builders has committed to supporting this agenda with three essential factors that need to be in place to support this transition such as mitigation of risks in the transition journey, suitable information and education resources developed to support industry transformation, and adequate transition timeframes to enable the sector to effectively transition,” she added.

ASBEC Executive Director Alison Scotland welcomed Master Builders Australia to the collaborative industry network, saying it will add immense value to ASBEC’s work.

“This partnership will enable Master Builders to contribute to and participate in the collective efforts of built environment stakeholders in shaping policy and boosting sector capability that helps deliver more sustainable, decarbonised communities, effective regulation, codes and standards, and that improves Australia’s new and existing building stock,” Ms Scotland said.

Key priorities that Master Builders would like to see more work on include:

• Skilling the sector for energy transformation.

• Retrofitting and improving existing building stock.

• A plan for decarbonisation of building products and product assurance.

• Developing resources that raise awareness about risks from regulatory change, such as moisture management and how to deal with it.

• Addressing conflicts in the National Construction Code (NCC) between existing and new building requirements.

OZHELP’S HEALTH IN TRADES PROGRAM BUILDS ON MENTAL HEALTH AND WELLBEING FOUNDATIONS

SUSTAINABLE BUILT ENVIRONMENT IMPERATIVE FOR THE FUTURE OF THE INDUSTRY

8 Construction Engineering Australia • March 2023 INDUSTRY NEWS

JEBSEN & JESSEN ACQUIRES INDUSTRIAL PRODUCTS BUSINESS FROM KONECRANES

Diversified industrial group Jebsen & Jessen recently announced the acquisition of MHE-Demag’s Industrial Products (IPD) Business, a member of Konecranes Group – a move which will expand the family enterprise’s portfolio and position it to meet the need for engineered mechanical solutions in the rapidly urbanising South East Asia region. The deal is expected to complete in April 2023.

The newly acquired IPD business will be known as “MHE”, retaining the existing MHE branding, and forming the material handling equipment division of Jebsen & Jessen Technology. It will cover manufacturing, engineering, renting, trading, supplying and servicing of MHE’s complete range of industrial and material handling products, such as dock levellers and door systems; mechanical car park systems; building maintenance units; boom lifts and Aerial Work Platforms; warehouse trucks and lift systems, among others. The business spans Australia, Indonesia, Malaysia, the Philippines, Singapore, Thailand and Vietnam.

“We are excited to welcome the 300-people-strong MHE-Demag Industrial Products (IPD) team to the Jebsen & Jessen Group,” said Per Magnusson, Group CEO, Jebsen & Jessen Group.

“The business is already the clear market leader in some segments, and our ambition is to attain market leadership across the portfolio.”

“We are committed to investing in people and the business to achieve our growth ambitions,” Mr Magnusson added. “The acquisition aligns well with our Advance & Build strategy and builds upon our distinctive heritage as a trusted provider of quality industrial products and value-added solutions.”

The IPD business to be acquired by Jebsen & Jessen Group is part of MHE-Demag, a member of the Konecranes Group, which was previously a joint venture between Jebsen & Jessen and Demag. Jebsen & Jessen’s 50% stake in MHE-Demag was acquired by Konecranes in January 2020.

Focusing on its core industrial service and lifting equipment business, Konecranes will, with this deal, be divesting its IPD business to Jebsen & Jessen Group.

Since 1972, the business has provided systems for iconic buildings in the region, such as the Petronas Twin Tower, Merdeka 118 and KL Tower in Malaysia, Marina Bay Sands and Gardens by the Bay in Singapore, BNI 46 in Indonesia, Bitexco Financial Tower in Vietnam and Okada Manila in the Philippines. It also provided the mechanism for the retractable roof of the Singapore Sports Hub – the largest free-spanning dome stadium in the world.

“The divestment of our IPD business back to Jebsen & Jessen will allow Konecranes to fully focus on growth in our core businesses in the region and leverage the earlier acquisition of full ownership in MHE-Demag,” said Marko Tulokas, SVP, Industrial Service & Equipment, Region APAC, Konecranes.

Upon finalisation of the acquisition, approximately 300 highlyskilled Konecranes' employees will join Jebsen & Jessen Group, alongside related assets including all MHE products and solutions. The acquired business will maintain its current commercial presence, and all operations and business will proceed as usual.

size of ad .... 88mm x 135 mm ü 5 year pump warranty 4" TRASH PUMP ... DIRTY WATER SPECIALIST ü Self priming to 7.6m ü Fast, easy set up ü Flows to 1,600 lpm ü 10HP Yanmar diesel 4" DIESEL TRASH PUMPS Australian Pump Industries Aussie Pumps 02 8865 3500 aussiepumps.com.au AUSSIE PRODUCTION SOARS we’reforAustralia 1300 240 337 www.enviroblast.com.au EnviroBlast Australia Mobile Media Blasting - Soda & Garnet • Specialising in Concrete preparation for Carbon Fibre application • Abrasive & Non-Abrasive Blasting • Paint, rust & contaminant removal from many substrates • Line marking removal • Graffiti removal & protection • Removal of sealers & coatings • Creation of non-slip surfaces • Compact machinery for easy access

Low media usage which means less environmental issues with reduced containments and dust

Suitable for confined space blasting

•

•

Construction Engineering Australia • March 2023 9

AUSTRALIAN STEEL STANDARDS REQUIRE WIDER INDUSTRY ADHERENCE

Recent high-profile incidents involving defects in steel structures have once again highlighted the importance of using construction steels and processes that meet Australian Standards, and the need for appropriate technically based third-party certification.

As industry organisations and senior representatives across the industry have stated, there is widespread complacency around the construction sector when it comes to ensuring proper certification of steel products to Australian Standards. These incidents provide a good opportunity to remind ourselves and the construction industry as a whole, that various Standards and a minimum level of compliance need to be met when using steels in construction.

While investigations into the various incidents are ongoing, it is important to note a material may meet the quality requirements and be conforming, but through the fabrication or processing of the products, a non-compliance may have been introduced.

As an example, for welded sections - that are increasingly being utilised in pre-fabricated materials shipped to site from both domestic and international producers - there are three areas of

specification and certification that need to be considered and met.

These include:

1. ensuring the steel materials themselves meet Australian Standards;

2. ensuring that the subsequent fabrication and welding of the steel meets the Standards; and

3. ensuring that the steel products are being used correctly in the structure itself and according to specification –known as erection conformity.

10 Construction Engineering Australia • March 2023 COVER FEATURE

These three areas of certification - all of which form part of AS/NZS 5131:2016

Structural steelwork - Fabrication and erection – it appears that while being specified, at times, are not adhered to. This, not surprisingly, can have significant safety implications.

The steel supply chain, including production, distribution, processing and delivery to site, is complex and variable. Local use, in what is a global supply chain, requires effective management of the supply chain - particularly if construction projects are to be delivered on time, on budget and safely. It is important to remember there are varying levels of capability, compliance and understanding of the Standards in parts of the industry, with quality and conformity tending to be the casualty.

Determining material conformity requires a level of technical expertise, and this validation process should be independent of the product supplier. Likewise, processing/fabrication also requires a level of technical understanding to ensure the procedures as outlined by the Standards are being correctly implemented, and again, this should be validated independently. For steel, it’s not enough to think that just because steel has been ordered to an Australian Standard that the delivered product will

automatically conform with that Standard and be fit for purpose.

Although using construction steel that meets Australian Standards is a requirement, having steel independently certified is not… and that is one reason why Australia continues to see a small but significant percentage of defective steel products.

STEEL ELEMENTS/ PRODUCTS

For steel elements/products, the easiest way to manage and minimise the risk of non-conforming construction material is to specify ACRS certified steel.

ACRS certifies steel reinforcing, steel prestressing, and structural steel manufacturers and suppliers, providing confidence in the conformity and traceability of the products. ACRS certifies the steel mills and processes at the site of manufacture to ensure complying material is an output. For a number of products, ACRS also certifies the processing that follows to ensure ongoing compliance. Verification of production methods at both the steel mill and processor is essential for any materials claiming to be Standardscompliant.

With its unique, two-stage certification scheme, ACRS conducts a review across eight key areas of manufacture and

Construction Engineering Australia • March 2023 11 COVER FEATURE

“Determiningmaterial conformityrequires a level of technical expertise,andthis validationprocessshould beindependentofthe productsupplier.”

decision-making on the conformity of steel products, to one or more of 19 applicable Standards. All ACRSApproved materials are labelled and supplied with the necessary electronic or paper documentation to enable the products to be traced back to the point of manufacture.

STEELWORK FABRICATION AND ERECTION

The material’s subsequent transformation by cutting, bending, or welding can alter the properties of the steel if not done properly. It is vital that producers ensure the steel supplied conforms, and that the subsequent processes follow the procedures outlined in the various Standards to maintain conformity.

The Australian and New Zealand Standard AS/NZS 5131 for Steelwork Fabrication and Erection was developed and published in 2016. The document outlines different requirements in fabrication, with various levels of traceability and conformity depending on the application. For critical structures, there is a level of expertise and testing that is required to assess and assure that

conformity to all aspects of this Standard is maintained.

Consequently, to ensure conformity of products for steel fabrication, the builder/ contractor end-user needs the supply of compliant materials coupled with the use of an appropriate fabricator who has an understanding of the fabrication Standards to ensure the end-product complies. It is critical that traceability and compliance through the complete steel supply chain is obtained, from initial manufacture right through to the finished steel structure.

ACRS certification ensures conformity of materials and traceability of those materials through the supply chain; with schemes such as the ASI’s Steelwork Certification Australia Scheme (SCA) covering the procedural conformance from purchase and supply through the fabrication to the erection of the finished steelwork. Using the two schemes concurrently, specifiers, designers, fabricators and builders can have confidence that the end product delivered to site will meet specification, and that the steel, steelwork fabrication, and erection is compliant with AS/NZS 5131.

Building designers, builders and specifiers need to ensure they are doing everything possible to maximise building resilience. The source of a material is not important. What is critical is the quality - and ensuring that the materials being used throughout construction are fit for purpose and meet the necessary Australian Standards.

CONFIDENCE IN CONFORMITY –REGARDLESS OF ORIGIN

Living in a global community means products in all industries, including the construction industry, are being sourced from all parts of the world.

While it is prudent to seek local content, it needs to be recognized that due to economies of scale and limited opportunities, specialized building components including some steel members are not manufactured in Australia, and thus need to be imported. However, whether it be locally or internationally sourced, the enduser needs to have confidence in the conformity and quality of any material or product used in the construction.

12 Construction Engineering Australia • March 2023 COVER FEATURE

In the case of critical components or where durability and longevity are essential, there is a need for a rigorous third-party independent verification of the products being delivered. Randomly sampling product to ensure conformity, while sometimes necessary, does not ensure ongoing conformance. Only regular auditing on the production floor, coupled with ongoing sampling, provides the assurance of a complying product.

The ACRS third-party certification scheme for steel products provides this confidence to the end-users, through rigorous, independent site audits, which occur on an annual basis, and ongoing quality monitoring. With ACRS certification, end-users can have confidence that certificate holders continue to manufacture the materials to the specified Standards. The ACRS certification scheme also ensures that the traceability requirements as outlined in the Standards are operable, providing the opportunity for the material to be traced back to the source of manufacture.

By nominating ACRS-certified products to be used on projects, specifiers and builders can have confidence that the materials supplied are of the desired quality and conform with the specified Standard, thus reducing the risk of non-compliant elements.

For further information, please email ACRS at: info@steelcertification.com or visit www.steelcertification.com

Construction Engineering Australia • March 2023 13 COVER FEATURE

inspection data - from historical reports, photos and videos, through to current drone imaging and LiDAR data - to provide asset owners and managers with a comprehensive condition report for their assets. Our AI-based predictive analytics utilise your current and historical data to prioritise maintenance requirements and optimise your infrastructure asset management activities. T: 1300 552 878 www.dynamicinfrastructure.com.au WHERE AI MEETS All of your asset data…

ASSET MANAGEMENT

Right at your fingertips

Tested by certified engineers, Dynamic Infrastructure utilises proven, cutting-edge AI technology to provide asset owners and maintenance managers with actionable insights to save money and increase maintenance e ciency.

• Identify defects before they evolve into large-scale failures

• Prevent unplanned expenses & manage risk

• Maximise warranty through automated tracking of repairs

• Gain full field-to-o ce visibility

DISCOVER MORE

Delta +25% since 2018 Corrosion Spall Delta +25% since 2015 Crack Delta +12% since 2017

INNOVATIVE NEW PRODUCTS IN THE CONCRETE MARKETPLACE

by Paul Uno, Director, ETIA

by Paul Uno, Director, ETIA

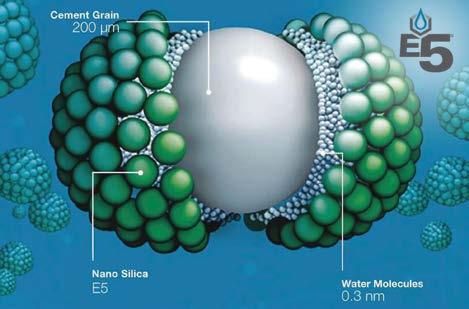

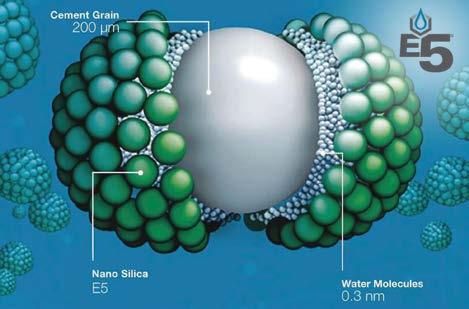

I never cease to be amazed at how industry is always producing new products to improve the status quo of existing materials in the marketplace. The latest two products that have been introduced into the concrete placement area are ‘Biax’ and ‘E5 Internal Cure’.

I am old enough to remember when Waffle pods were first introduced into the Residential Slabs and Footings Code AS2870 in 1988. A firm in South Australia called Koukourou & Partners had been working on this system in the early 1980s and finally created a patent for it in March 1987.

Standard 100 mm flat concrete slabson-ground would deform too much during wet and dry weather periods so Peter Koukourou and his team developed a 3D system using cardboard boxes (from James Hardie), placed under a top slab with ribs in between the boxes. The reason for introducing this waffle pod system into Adelaide was to try to address the problem of expansive soils in that State. Koukourou was also associated with a company called SARTAS which would go on to supply the cardboard pods into the NSW market.

The problem with the cardboard boxes was that when it rained or when the boxes were cut, they would lose their robustness and stability and thus it was difficult to place concrete on and around the weakened pods.

When I commenced working at the Cement and Concrete Association of Australia (CCAA) in 1990, I met two other

entrepreneurs who were trying to introduce the waffle pod system into the industry, by using polystyrene rather than cardboard. The first, Mike Gately, was providing waterstops to the market at the time, but saw an opportunity to expand his business by providing expanded polystyrene (EPS) foam pods into the residential slabs area. He called his system POLYFOAM.

The second, Mike Hird - who owned one of the smaller concrete plants in Sydney (Transit Mix) - also saw the opportunity to replace the Stiffened raft systems with the waffle EPS pods. He also marketed slabs with fibre reinforcement (FIBERSLAB). He was able to get the waffle system accepted into AS2870 by conducting tests on a waffle pod mock-up at the UNSW test laboratory.

Once this system was accepted into AS2870 and builders and concrete placers saw the savings they could make in reduced concrete volumes when compared to the standard raft slab system, it quickly took over the residential slab market in Australia and then New Zealand.

However, over the years, especially with the focus on improving environmental outcomes, a new company has come up with a thinner, domed-shaped “100% recycled reprolene” pod which still provides the 3D advantage of the waffle system in reducing deformation, but with less environmental negatives (i.e., EPS pod fragments blown into waterways and backyards).

Extensive FEM modelling on these biaxial pods has been carried out on the system by European and Australian engineers to substantiate its performance in the area of residential slabs and footings. Quite a number of jobs have used this system on-site, and the system itself has received quite a few awards in recent times. I would recommend engineers reading this article, visit: www.biax.com.au for further information.

On a different note, but still relating to concrete, another innovative product has come into the marketplace called ‘E5 Internal Cure’. As many concrete suppliers, placers and engineering professionals will know, once you place concrete on site, you have to cure it to ensure that you minimize the early-age shrinkage of the concrete. This is to reduce the risk of drying shrinkage cracking as well as any issues with reduced compressive strength and abrasion resistance.

Years ago, the most common curing method involved keeping the concrete wet with a hose, wet hessian or plastic membrane – all very messy and not really efficient or practical in curing the concrete. Then curing compounds were developed to assist in this process, whereby the products would be sprayed on at the end of the pour (i.e., once the slab had reached final set). These compounds included Wax Emulsions, Chlorinated Rubber solutions, Hydrocarbon Resins, Acrylic Emulsions and PVA formulations. Each of these products had advantages and disadvantages (e.g., PVAs did not comply with the Liquid membrane curing Standards AS3799 which requires at least 90% water retention over 72 hours).

Whilst the other curing products listed above did comply with AS3799, many had other disadvantages. For example, waxbased curing applications made it difficult to bond toppings to the surface; chlorinated rubbers had a pungent smell and workers often complained about the odour; and hydrocarbon resins were considered damaging to the environment. The only products that seemed to tick all the boxes at that stage were Acrylic Emulsions, but they still required ‘correct application’ of this spray-on-coating over the entire concrete surface.

16 Construction Engineering Australia • March 2023 ETIA BLOG

Designed and made in Australia from 100% recycled plastic, Biax pods provide an environmentally sustainable alternative to polystyrene waffle pods.

In the last 10 years, researchers overseas (especially in the USA from Purdue University) have found that introducing nano silica into a concrete mix vastly improves its ability to self-cure, whilst also providing some other advantages.

Nano Silica primarily works on the principle of producing more nucleation sites. Since the particles of nano silica (n-SiO2) are so small, they produce more

nuclei upon which better hydration and pozzolanic activity can occur. This reduces drying shrinkage, and crack formation, while also providing better curing within the matrix.

Again I would refer readers to: https://www.mcclay.au/e5-tech or https://intrans.iastate.edu/app/ uploads/2022/04/02-Nelson-Colloidal.pdf

If readers of this article wish to find out more about cement and concrete technology or practice, or wish to be able to design in accordance with AS2870, then they should attend the one (1) and two (2) day ETIA workshops on these topics (some presented via Zoom and others Face-toFace). For further information on these ETIA workshops, visit: www.etia.net.au

This blog is the latest in a series produced for Construction

Engineering Australia by globally respected engineering educator and reinforced concrete specialist, PAUL UNO BE MBdgSc

MIE(Aust) CPEng NER

RPEQ APEC Engineer IntPE(Aus), Director, ETIA (Engineering Training Institute Australia).

Construction Engineering Australia • March 2023 17 ETIA BLOG

E5 is a revolutionary nano silica proven to cure concrete, enhance workability and reduce shrinkage and curling.

Fielders KingFlor® range – a structural decking solution for every project

The Fielders KingFlor® steel decking range provides the designer with the flexibility to tailor a composite flooring solution that best suits project requirements whilst accessing the inherent benefits of steel decking over labour and material intensive ply timber and lost formwork alternatives.

The Fielders KingFlor® range is 100% Australian-made and manufactured using BlueScope’s speciality decking material, DECKFORM® steel. This zinc-coated hightensile steel has been developed by BlueScope specifically for steel decking applications. In addition to DECKFORM® steel’s inherent physical properties, it also benefits from the application of a “blue” low glare coating, or LGC. This unique coating reduces the effects of reflected sun on workers and is required by OH&S workcover guidelines.

Each of the five core profiles in Fielders KingFlor® range has been developed to provide the most optimal flooring solution in the wide range of composite structural building construction types found in Australia.

RF55® is Fielders’ original steel decking product that has become the industry standard that all others are measured against since its introduction. Its traditional flat pan or ‘re-entrant’ profile provides unmatched performance in suspended concrete slabs. RF55® is used in both concrete and steel frame

construction and utilises patented technology to achieve superior spanning capabilities, less deflection and greater composite strength than similar re-entrant profiles.

KF57® is Fielders’ lightest weight formwork solution. KF57® is an easy-to-use steel decking product featuring an enhanced deck profile and deeper pan stiffeners to provide a more effective mechanical interlock for the concrete than comparable product alternatives. Optimal fire performance is one of the key attributes of this popular decking product.

Fielders KF40® is the most economical formwork solution in the range. Suitable for a range of building types, KF40® has been specifically designed to provide a strong and reliable shear bond performance giving strong composite slabs. Featuring an optimum strength-to-weight profile, KF40® combines the performance of a traditional flat pan profile with the unmatched economy and concrete saving of a trapezoidal deck. As the widest decking product available, KF40® can provide improved construction times through higher m2 coverage per installed length. This is the preferred choice when constructing posttensioned slabs.

KingFlor KF70® was the first trapezoidal decking profile introduced in Australia and remains a preferred option for many projects that benefit from lengthy unpropped spans.

It is accepted as the most cost-effective composite steel formwork system for many projects. With a longer spanning capability and a deeper profile than many other formwork systems, the innovative KF70® offers a real alternative and opportunities for significant cost and time savings in construction.

The final product in the KingFlor® range, SlimDek 210® has been specially developed to provide even greater material, structural and construction benefits in suitable projects. SlimDek 210® is, capable of achieving unprecedented unpropped spans during construction of up to 7m and propped spans of over 10m. When combined alongside asymmetric steel beams in Fielders SlimFlor® construction system, floor construction depth can be reduced to as little as 290mm, which represents up to a 35% reduction in slab thickness compared to traditional concrete construction.

The KingFlor® range is supported by a detailed technical design manual, which together with a companion software KingFlor® Designer Suite software, enables designers to quickly assess a multitude of options, to help determine the most economical and effective design solutions.

For more information on the Fielders KingFlor® range visit: https://www.fielders. com.au/products/flooring-solutions

18 Construction Engineering Australia • March 2023 PRODUCT FOCUS

THE EQUIPMENT YOU NEED – THE SERVICE YOU EXPECT A1 Roadlines Pty Ltd | 89 Rushdale Street, Knoxfield, Victoria 3180 | www.a1roadlines.com.au P: 1300 217 623 (A1ROAD) | E: sales@a1roadlines.com.au

INFINITY TESTING

'Infinity

NO RELIANCE ON ROLL-AHEAD DURING AN IMPACT

Rather than relying on some of the impact energy being absorbed by the forward movement of host vehicle on which the TMA is fitted, with ‘Infinity Testing’ the host vehicle is anchored to the ground to prevent any forward movement during an impact.

‘WORST CASE’ SCENARIO TESTING

Compared to standard testing with an unrestrained host vehicle, Infinity Testing is a much tougher testing regimen. It is considered ‘worst-case scenario’ testing which makes it much more difficult to meet the pass criteria for IS values, as all of the Ridedown Acceleration must be provided by the TMA absorbing the energy from the impact.

TMA ABSORBS & DISSIPATES 100% OF THE IMPACT ENERGY

Testing the TMA on a host vehicle which is anchored in place, tests – and for both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMAs – confirms the capacity of the TMA to absorb/dissipate 100% of the impact energywithout the benefit of the host vehicle roll-ahead.

NO UPPER LIMIT FOR HOST VEHICLES

From a practical standpoint, the fact that both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMAs were successfully tested to MASH Standards using the ‘Infinity Testing’ method, means both units are MASH certified with no upper weight limit for the host vehicle.

www.a1roadlines.com.au

Testing’ is without a doubt the harshest method of testing the performance of a Truck Mounted Attenuator (TMA) during an impact.

THE ULTIMATE TEST OF ATTENUATOR PERFORMANCE

HOW IT’S DONE

With ‘Infinity Testing’ the host vehicle is anchored in place during the impacts to assess the TMA's capacity to absorb/ dissipate 100% of the impact energy without the benefit of roll-ahead.

WHAT ABOUT ROLL-AHEAD DISTANCES?

Importantly, to emulate ‘real world’ operating conditions, both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMA have also been successfully tested and MASH certified using standard ‘non-anchored’ host vehicles, with both units posting impressively low roll-ahead distances.

THE EQUIPMENT YOU NEED – THE SERVICE YOU EXPECT A1 Roadlines Pty Ltd | 89 Rushdale Street, Knoxfield, Victoria 3180 P: 1300 217 623 (A1ROAD) | E: sales@a1roadlines.com.au

Scorpion® II TL-3 TMA Crash Test: MASH Test 2-53 Impacting Vehicle Weight: 2266kg Impact Angle: 10.3 Degrees Impact Speed: 103.8km/h Roll-Ahead Distance: 5.1m Scorpion® II METRO® TL-2 TMA Crash Test: MASH Test 2-53 Impacting Vehicle Weight: 2295kg Impact Angle: 9.9 Degrees Impact Speed: 81.6km/h Roll-Ahead Distance: 12.4m

Earthmoving … keeping it clean

One Australian pump and pressure cleaner manufacturer that understands the earthmoving business better than any other is Aussie Pumps. With some of the key executives having had a lifetime of being associated with big equipment, they understand the pressures, the opportunities and most of all, the challenges facing earthmoving contractors and their operators on a daily basis.

One of those challenges is maintenance… and that efficient maintenance depends on the overall condition and cleanliness of machine.

The company, widely regarded as Australia’s leading manufacturer of engine-driven highpressure water blasters up to 500 bar, has designed and built machines tough enough for this industry.

A CLEAN MACHINE MAKES SERVICE EASY

Nobody wants to have to battle through built-up oil and dust caked over an engine or transmission before they can start to do any disassembly or repair. What’s worse, often you can’t even see where the issue is, whether it’s a leaking o-ring or major seal that is the problem. Aussie Pumps has developed pressure cleaners ideally suited to just these types of applications.

The company’s range of heavy-duty steam cleaners and hot wash machines are capable of blasting off greasy, dusty surfaces, making it easy to identify the source of the problem. Indeed, Aussie Pumps recently introduced a new 4,000 psi steam cleaner that is designed specifically for tough jobs in earthmoving.

“We know that earthmovers need to have reliable machines in their wash bays,” said Aussie Pumps Chief Engineer, John Hales.

“The Aussie Admiral 4000 not only provides 130 degrees C steam capability, it also delivers the impact of 4,000 psi to blast off caked-on dirt fast!” he added.

The new 4,000 psi machine is built like a tank and designed for Australian conditions. Mounted on a steel chassis with stainless steel cover, the machine boasts four rubber tyred wheels for stability and manoeuvrability.

The heavy-duty coil comes with a two-year warranty and features a top quality slow-speed triplex pump with brass head and ceramic pistons as standard equipment. The motor, a four pole IP56 1450 rpm unit, is designed for reliable long-life performance. Other major features include an 18-litre diesel fuel tank that provides long running time, especially when the operator runs it at 90 – 100°C.

“We’ve seen operators who want to run these machines at 130°C continuously,” John Hales said. “Apart from using a lot of fuel, that has a tendency to cook internal components like switches, creating potential premature failures.”

The machines all feature a steel bumper for extra protection and a flexible coupling between the motor and the pump for a smoother, cooler drive.

PROTECTION PREVENTS F AILURE AND REDUCES COSTS

The Aussie Admiral 4,000 is also geared to protect the machine and the operator! Each

machine is fitted with a low water cut-out warning light, a low fuel sensor and warning light, and a Timed Total Stop - an automatic shutdown device that turns the machine off a few minutes after the operator closes the gun. The unit also features a Safety Thermostatic to protect the pump, as well as Micro-Leak Detection with a warning light.

“Aussie Pumps knows that for operators working in what is usually a wet environment, it’s easy not to see a leak – especially a small one - under those conditions,” John Hales added. “The Micro-Leak Detection warning light tells you something is wrong, and to stop the machine and fix the leak before continuing!”

THE AUSSIE HEATWAVE –MOBILE STEAM

Need mobile steam? Try Aussie’s Heatwave. This Honda petrol engine-powered machine delivers 4,000 psi at 130 degrees C steam and comes at a bargain price in stainless steel frame for only $10,820!

Best of all for operators, the machines are Class A, and therefore do not require operator certification. Earthmovers and truck operators who want to move dirt fast, where time is everything and every second counts, will appreciate Aussie’s complete range.

Further information is available in Aussie Pumps Blaster Blitz catalogue (see the Hot Water section for a world of heavy-duty cleaning gear designed just for Aussie contractors and operators) which can be downloaded from https://aussiepumps.com.au

Aussie’s 4,000 psi

22 Construction Engineering Australia • March 2023 EQUIPMENT FOCUS

Admiral steam cleaner makes short work of cleaning greasy, oily earthmoving gear.

PRECAST TECHNOLOGY

Highly automated and customized carousel plants

Reinforcement machinery and mesh welding plants

Battery moulds, tilting tables, various mould systems

Slipformer, Extruder, equipment for production on beds

In-house precast production and in-house testing plant

Software for machinery and complete ERP systems

www.progress.group

COMPLETE WORLDWIDE

REDUCE CONSTRUCTION COSTS WITH ONE INTEGRATED SOFTWARE SOLUTION

The Australian construction industry has been hit with challenge after challenge over the last few years, including the COVID-19 pandemic, natural disasters, and labour shortages.

The combination of these challenges has forced costs to soar, rising by 11 per cent in the past 12 months, and it’s showing no signs of slowing. The significant cost inflation in an industry with slim profit margins has seen construction businesses account for almost 25 per cent of all business insolvencies in Australia.

However, there is hope on the horizon. Homegrown technology may be the answer to helping construction businesses see big savings and improve their bottom line. Migrating core business from disparate onpremise solutions to one integrated solution hosted in the cloud known as ‘Software as a Service Enterprise Resource Planning’ (SaaS ERP) has multiple benefits. The Total Cost of Operations (TCO) savings within three years of migrating to SaaS is approximately 14 per cent for large construction firms, three per cent for construction SMEs, and 16 per cent for organisations that own, operate and maintain major infrastructure assets.

A slowdown in the Australian economy over the last few years has led to reduced demand for new construction projects, but that is starting to change, giving suppliers more bargaining power, and driving up the price of materials. These rising costs have had a significant impact on the bottom line for construction companies and it is vital to closely monitor these costs and implement cost-saving measures where possible.

Moving to SaaS has huge cost-saving benefits for the asset and projectintensive industry as a whole sitting at approximately $62 billion over ten years. Implementing enterprise software enables construction businesses to develop more efficient processes with online self-service capabilities and integrated reporting and analytics.

WHAT IS SAAS ERP?

SaaS ERP is a cloud-based solution that transforms the way organisations interact with their staff, customers, and communities with access from any device, anywhere, at any time. For construction, an industry-focused SaaS ERP solution provides a comprehensive platform for project management, financials, supply chain, human resources and payroll, and more. It also helps improve an organisation’s bottom line by reducing costs, improving efficiency and operational productivity, and creating full project visibility enabling better decision making.

One vendor of SaaS is Queensland enterprise software company, TechnologyOne. Their SaaS ERP software solution has supported construction companies, such as BMD, BGC and JWH Group and more, with managing their projects and developments on time and on budget.

Industry General Manager at TechnologyOne, Luke Fleming, weighs in on how SaaS could benefit Australian construction companies.

“Construction businesses and their employees need the right technology and the right tools to deliver for their clients and their communities. I have seen firsthand how the right SaaS ERP solution can help construction companies, developers, suppliers and subcontractors make costeffective decisions in real time by providing a single source of truth and transparency on the information they need.”

MANAGING DATA ACROSS PROJECTS TO MAKE SMART MANAGEMENT DECISIONS

Traditionally, the construction industry has relied heavily on manual paper-based processes and multiple disparate systems to manage different aspects of business, from contracts and invoicing to equipment maintenance and work orders. These

outdated processes can lead to increased costs, lost or damaged assets, and the need for additional staff.

With SaaS ERP, all information is stored in one centralised database providing visibility into the status of projects, resources, and finances and allowing seamless data sharing, enabling a far more accurate level of reporting, leading to direct savings. It also enables non-technical workers to quickly digitise manual processes, which is critical to delivering greater productivity gains.

Regular equipment breakdowns can make it challenging to hit critical milestones on construction projects. With a centralised database of resources, construction companies can track the availability of materials, labour, and equipment, ensuring that projects are completed on time and within budget. It enables companies to easily manage the entire source-to-pay process, inventory management and replenishment as efficiently as possible, improving spending patterns and making strategic sourcing, contract management and stock optimisation decisions to drive savings throughout the supply chain. With full visibility into the status of projects, construction companies can reduce the risk of project delays and help to optimise the use of resources, reducing costs and improving the bottom line.

CUTTING ICT MAINTENANCE AND OWNERSHIP COSTS

On-premise software requires construction companies to purchase and manage onpremise IT Infrastructure. This involves significant capital investment, as well as recurrent costs such as Information and Communications Technology (ICT) consultants and training to be able to customise, manage and continually update the software.

New evidence suggests SaaS has the potential to deliver substantial cost savings

24 Construction Engineering Australia • March 2023 DIGITAL TECHNOLOGY

to organisations. The savings come from reductions in the cost of ICT ownership and maintenance, and productivity improvements associated with the automation and simplification of business processes.

SaaS ERP is hosted by a software provider who takes on the onus of ensuring the software remains updated and functional, meaning no need to invest in hardware or ICT consultants to support it. It also removes pressure from in-house IT staff to keep pace with technological advances and modern cyber security obligations, enabling them to concentrate on other higher-priority matters. This benefit is translating into sizeable gains in the TCO of the software, as well as the hardware and staff resources required to keep it operating. It also means that should a work site get rained out, business can continue as normal with all important systems, automation, and processes safe.

Mitigate the risk of disputes, project delays, and unplanned costs.

The major benefit of SaaS ERP for construction is the ability to access information from anywhere, anytime, on any device, enabling companies to stay connected and informed, even when working on remote sites or on the move. Enabling real-time collaboration between team members, contractors and clients increases productivity and reduces the risk of project delays by improving communication, decision-making, and ultimately improving the bottom line.

“We know the majority of our customers’ employees will be on a construction site during the day with little or no time to sit in front of a computer. That’s why TechnologyOne offers a software solution specifically designed for construction, decreasing the time spent managing paperwork and increasing time spent on the project,” said Mr Fleming.

TechnologyOne’s software provides a secure, configurable portal framework that enables companies to interact with external parties within project environments, as

well as a Subcontractor Portal to securely engage with external parties and provide a single source of truth to view invoices, payments, claims and certifications, insurances, defects RFI’s and more.

SaaS ERP provides a comprehensive solution for managing all aspects of a construction business, from project management and resource management through to financial management. By improving efficiency, reducing costs, and enabling better decision making, it helps construction companies to improve their bottom line and achieve business goals. With its flexible, scalable, and cloudbased architecture, SaaS ERP provides a solution that can grow with a construction company and support its long-term success.

TechnologyOne offers a software solution built for Australian construction that offers more project visibility than a hi-vis vest. For a full solution overview, register for the webinar at: https:// technologyonecorp.com/construction

80 Industrial Drive, Braeside VIC 3195 | info@ascoat.com.au www.ascoat.com.au | Tel: +61 3 9587 7433 From fast, cost-effective concrete sealing solutions, through to

self-levelled, chemical, temperature and

12:37

high-build epoxy,

static-resistant seamless installations, ASCOAT has the solution. Ascoat_Ad03_210x148_PRESS.pdf 1 11/11/22

pm

DIGITAL TECHNOLOGY

So too, the Engineer can use the vast capacity of Finite Element analysis to validate, optimize and adapt data to create the finest design solutions.

Just as Conductors use all the instruments at their disposal to create the finest music... www.if3.com.au

FIVE EASY TIPS FOR QUALITY CONTROL IN CONSTRUCTION MANAGEMENT

Construction project management can be challenging at times. Even if it stays on schedule and within budget, subpar quality control risks upsetting stakeholders and triggering possible legal action when it doesn’t meet standards.

According to research, 12 per cent of construction defects are the result of system and material failures, while 54 per cent of all errors may be linked to human factors like untrained labour or insufficient supervision1

Given the high rates of defects on average construction projects, Regional Lead for PlanRadar Australia, Bart Crowther, explains that quality management can mean different things to different people and urges the construction industry to streamline quality control by reviewing lineof-work processes.

“Quality control is a detailed process evaluation and management system that outlines what acceptable quality assurance looks like, how it can be monitored, and the required adjustments to make sure benchmarks are reached,” said Crowther.

“In the construction sector, quality assurance (QA) is crucial to a company’s expansion, reputation management, and revenue generation.”

WHAT IS QUALITY CONTROL IN CONSTRUCTION?

Construction quality control ensures the finished product adheres to the standards and requirements established by the client, and any industry or government regulations and legislation. That entails finishing the project within the agreed-upon parameters and preventing conflicts throughout the course of the project. Clients, regulatory bodies, environmental standards, and policy directives all determine quality. A construction quality management plan contains a list of all these requirements for QA and outlines methods to achieve them.

Controlling the quality of construction projects is crucial and can result in fewer project issues, rework, and waste caused by errors or poor quality. This can also reduce cost blowouts and missed deadlines, which can jeopardise the reputation of both the project itself and the companies involved.

It’s essential to avoid leaving quality to chance; completed work must be carefully checked by a qualified or accredited person to confirm it meets QA standards. Projects should follow five key steps to achieve quality control:

1. Make a QA checklist - A QA checklist ensures building inspection processes are

thorough and less likely to miss anything. It should be precise and include a punch list for pre-task discussions on how to complete the work.

2. Create a site inspection plan - A site inspection plan should outline what will be inspected and when, as well as what standards must be met.

3. Define build quality expectations clearly and early - All project stakeholders should understand what standards must be met, including what the requirements are, the methodologies in place to achieve these requirements, and the allocated project timeline. Expectations should be clearly communicated to managers, crew, subcontractors, and anyone else involved, including meeting all coding standards, finishing projects without errors, and adhering to client instructions.

4. Follow all on-site safety and compliance requirements - Safety and compliance requirements help protect project workers and organisations, while mitigating instances of subpar work, poor materials, or construction defects and ensure all work is completed to compliance standards. Using a time-tracking tool ensures employees take the required breaks and don’t work excessive overtime.

28 Construction Engineering Australia • March 2023 DIGITAL TECHNOLOGY

5. Review, revise, and rework as needed - Often, QA processes will identify construction defects that need to be corrected. However, it’s important to remember that correcting defects isn’t the last step in the process. Review and debrief with the team to understand how any errors occurred and how to avoid repeating them.

Powering a Sustainable Future

HOW DIGITAL CONSTRUCTION QUALITY MANAGEMENT SOFTWARE CAN HELP YOUR BUSINESS

Manual, paper-based QA processes can be cumbersome and ineffective, resulting in inaccurate reports based on subjective feedback, as well as missed opportunities to improve QA and reduce costs, particularly during construction and inspection phases. The latest building document management software can significantly increase QA efficiency, accuracy, and cost effectiveness.

By using a digital QA platform, like PlanRadar, construction firms can streamline aspects of typical building site operations, including:

• Plan comparison: if the architect’s plan changes, everyone working on the project is immediately informed, instead of waiting for paper blueprints.

• Task management: site managers can assign tasks to specific employees and check if jobs are completed to the required standard. Workers can take pictures or videos of finished tasks for verification.

• Report generation: quickly produce QA report templates so all interested parties can assess development. Reports can also highlight newly discovered quality problems to facilitate corrective action.

• Building inspections: users can ensure that work is finished to their quality standards and note any problems directly on the blueprint.

• Real-time communication: all project participants can ask questions, raise tickets, or submit feedback and reports as soon as they come up.

Using a cloud-based construction management tool can help improve quality control in real-time using data to satisfy all requirements at any stage of the build, from design to planning to construction.

For more information, visit: https://www.planradar.com/au/ 1 http://www.ijesrt.com/issues%20pdf%20file/Archive-2016/July-2016/131.pdf

Did you know you can access the latest issue of Construction Engineering Australia via Informit?

The Informit Engineering Collection is an ever expanding resource covering aspects of municipal engineering – urban management and planning, civil engineering and construction, environmental management, planning issues and traffic management. The database offers an extensive variety of resources including journals, trade publications, reports and conference proceedings.

The Collection guarantees quality through partnerships with peak professional bodies including Engineers Australia and the Institution of Professional Engineers New Zealand, as well as Content Providers including EPC Media Group.

The Informit Engineering Collection delivers hard to find content designed to complete and complement all your construction engineering requirements.

Other key titles published by EPC Media include:

Highway Engineering Australia Waste + Water Management Australia

Request a quote or free trial via www.informit.org/trial-and-quote

Research for your global future

Construction Engineering Australia • March 2023 29

SMART THINKING

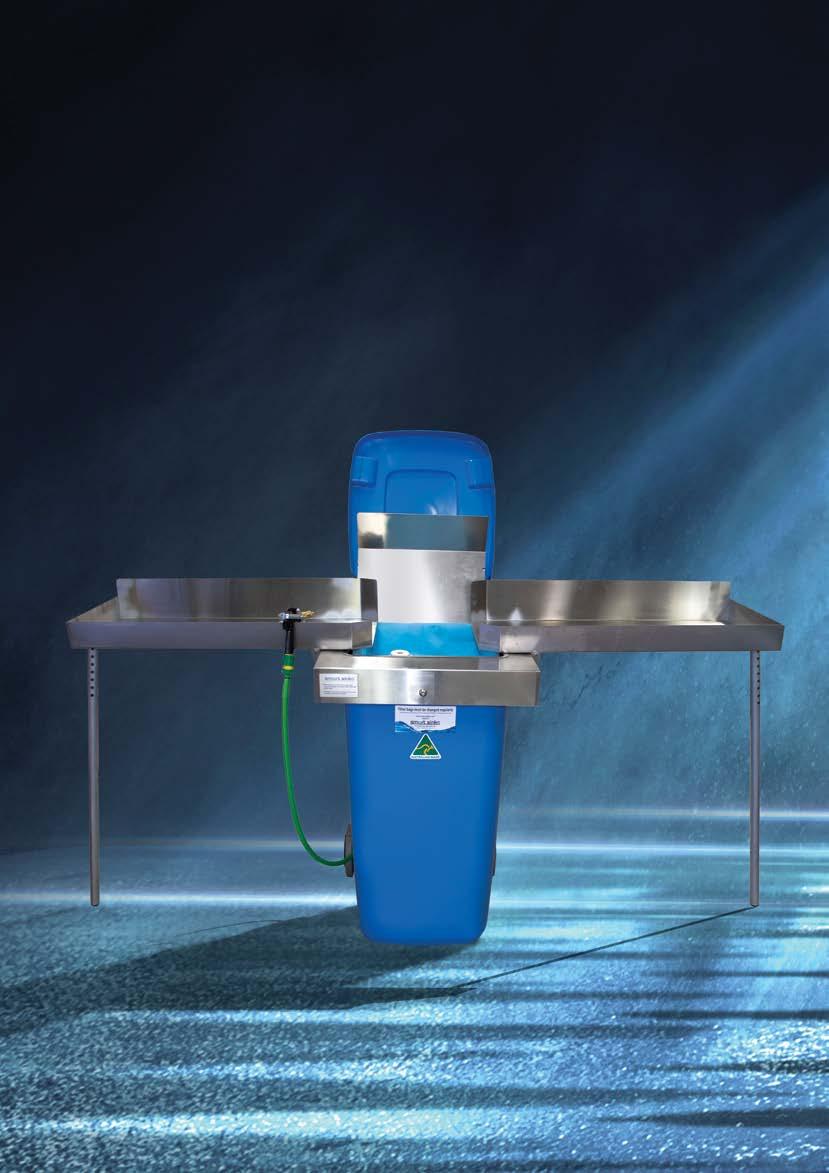

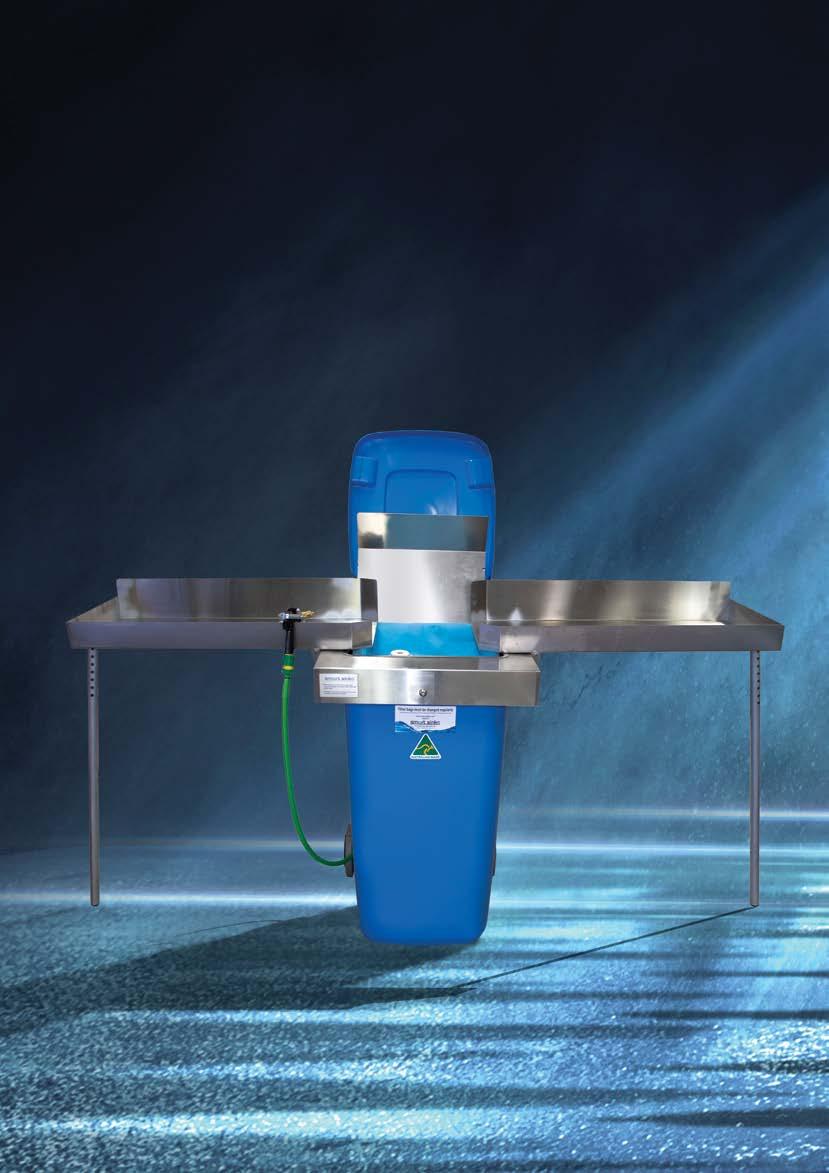

The Smart Aussie mobile tool washing unit that SAVES TIME, SAVES WASTE, SAVES WATER and helps to IMPROVE SAFETY on construction sites large and small

From plaster sediment, to sands, soils and even concrete washout sediments, the award-winning, Australian-designed Smart Sinks™ mobile tool washing station provides a highly-effective, affordable and easy-to-use method of preventing sediments and suspended solids from

being washed into drains or disposed of illegally in gutters, stormwater side entry pits or on open ground.

Now also available in a NEW 100% BATTERY-POWERED VERSION, Smart Sinks™ can help you save up to 2,250 litres of water per week/per plasterer.

What’s more, by eliminating the need to travel to and from a central tool washout facility, Smart Sinks™ also saves you time and money, while also helping to improve safety by reducing movement of personnel around construction sites.

30 Construction Engineering Australia • March 2023 INNOVATIVE

SOLUTIONS

Since its launch in 2015, the Australiadesigned Smart Sinks technology has gained an enviable reputation for its ability to keep waste sediments out of drains.