HIGHWAY ENGINEERING AUSTRALIA

JUNE|JULY 2024

V55.4

JUNE|JULY 2024

V55.4

Our integrated vehicle technology suite features advanced telemetry, video, and infotainment systems. It is supported by an automotivegrade cloud platform and cloud connectors that enable predictive analytics, detailed reporting, and effective fault code case management. Connecting manufacturers, dealers, fleets, and drivers seamlessly.

Discover why the world’s leading OEMs and fleets rely on our Australian-designed, turnkey solutions.

directedtechnologies.com.au

On 22 August 2024, Engineers Australia will deliver the Climate Smart Engineering Conference (CSE24), an engaging, one-day conference program focused on our most significant climate challenge – the clean energy transition.

Engineers Australia CEO, Romilly Madew AO, says this is an opportunity to hear from a wide range of experts in climate smart engineering, learn from successful technical solutions and strategies and connect with peers.

“CSE24 brings you the latest insights and engineering innovations – examining everything from the role of digital technology and AI to the challenges of decarbonising transport and upskilling in renewable energy.”

With representatives from Australian Energy Market Operator (AEMO), CSIRO, Energy Networks Australia, GHD, Powerlink Australia and more, the program will discuss:

• The role of digital technologies and AI in making energy systems smarter, more resilient and efficient.

• Opportunities to decarbonise Australia’s heavy industry and transport sector.

• Strategies for navigating the approval process for renewable energy projects.

• Systems-based approaches to building our future energy infrastructure.

Now in its fourth year, CSE24 is dedicated to addressing climate change from the engineering perspective.

With engineers and industry poised to play a major role in Australia’s clean energy transition, this is an opportunity to network, connect and collaborate to build a better and more sustainable world.

• Peter Price, Chief Engineer, Energy Queensland

• Harry Sunarko FIEAust CPEng EngExec NER, Fortescue Future Industries

• Mia Barnard MIEAust CPEng EngExec NER, GHD

• Gillian Cagney, President - Australia & New Zealand (incl PNG & Mongolia), Worley

• Marghanita Johnson, CEO, Australian Aluminium Council

• Dr Jake Whitehead, Chief Scientist, Electric Vehicle Council

To view the program and register, visit engineersaustralia.org.au/cse

CSE24 CLIMATE SMART ENGINEERING CONFERENCE

THURSDAY 22 AUGUST 2024

W HOTEL BRISBANE

To view the program and register, visit: engineersaustralia.org.au/cse

Autoliv, the worldwide leader in automotive safety solutions, continues its journey to a sustainable future by introducing airbag cushions made of 100% recycled polyester which significantly reduce the greenhouse gas (GHG) footprint of airbags.

In collaboration with key supply chain partners, Autoliv has developed yarns, fabrics, and cushions made from 100% recycled polyester for use in airbag production. The completed testing of the new material demonstrates that the airbag cushion provides equal safety functionality to a standard polyester airbag while reducing GHG emissions by approximately 50% at the polymer level.

Using this new recycled material is a crucial step toward Autoliv's commitment to reduce emissions across its product range and will contribute to Autoliv's ambition to achieve net-zero GHG emissions across the supply chain by 2040.

Autoliv's Chief Technology Officer, Jordi Lombarte, states, “We are walking the talk on our climate ambitions at Autoliv, by bringing the first technology to create airbags using 100% recycled polyester fabric. We have successfully proven

the technology and are ready to offer it to our customers worldwide.”

Autoliv continuously develops processes and products in a resource-efficient manner while minimizing environmental impact. The airbag cushion made with 100% recycled polyester is now part of Autoliv's product portfolio, and the new material is available for global customers.

“We are leading the way in developing airbags made from recycled polyester on current airbags. This milestone reflects our commitment to climate action and circularity, and our journey toward a more sustainable future,” continues Jordi Lombarte.

Autoliv, Inc. is the worldwide leader in automotive safety systems. Through its group companies, it develops, manufactures and markets protective systems, such as airbags, seatbelts, and steering wheels for all major automotive manufacturers in the world as well as mobility safety solutions, such as pedestrian protection, connected safety services and safety solutions for riders of powered two wheelers.

For more information go to www.autoliv.com

According to a recently published report, professional drivers in the UK are driving fewer miles prior to a collision, suggesting the need for an increased focus on safety among British fleets. Geotab, a global market leader in connected transportation solutions, found that the total distance per collision driven by truck, van and taxi operators in the UK decreased by almost one-fifth (19.12%) in 2023, from 920,000 miles to 740,000 miles. For a large British company running a fleet of 1,000 heavy goods vehicles (HGVs) each driving 75,000 miles per year, the 2023 data could represent an additional 20 collisions annually.

“Keeping drivers and other road users safe should be a top priority for all fleet decision-makers,” said David Savage, Vice President for the UK and Ireland at Geotab.

“According to a 2022 national study undertaken on behalf of the UK National Highways, just over 20% of all road casualties occur in driving-forwork collisions.”

“As an industry, we have a duty to reduce these numbers – which we can with better safety measures,” Mr Savage added.

In its ‘2024 State of Commercial Transportation’ report, Geotab analysed telematics data from one million commercial vehicles globally. It found the overall trend to be an increase in the number of collisions, with Germany the worst-performing market posting a near one-third (27.3%) reduction in

miles before an accident. Only a few markets bucked this trend, with Spain (+5.66%), Italy (+5.25%) and Brazil (+4%) seeing the most significant rise in miles driven before a collision, suggesting fleet operators in these countries had taken measures to improve vehicle safety.

Improving our approach to safety

Geotab is working with UK companies to enhance the ability to analyse their safety programmes with predictive analytics and benchmarking. Through the Geotab ‘Safety Center’ fleet operators can gain insights into the risk of collisions with predictive collision analytics. The ‘2024 State of Commercial Transportation’ study found that fleets using Geotab’s safety features have shown a 40% reduction in collision rates.

The report also delves into key trends, challenges, and potential within the industry, highlighting the pivotal role of advanced telematics in optimising fleet operations. By leveraging data intelligence and cutting-edge AI models, fleets can enhance safety measures, improve productivity, and reduce costs, amidst rising fuel prices, regulatory shifts, and economic uncertainties.

This report is available for free and can be accessed on the Geotab website: https://www.geotab.com/uk/state-of-commercial-transportation-2023

Dr Mar

Professional Engineer of the Year 2023 2023

Nominations for en. This is your opportunity to help us roud to call ourselves engineers. The ones that inspire and ignite our imaginations.

You can nominate yourself, someone else or the team behind a project.

2 July: Nominations close for project awards.

2 July: Nominations close for people awards.

So too, the Engineer can use the vast capacity of Finite Element analysis to validate, optimize and adapt data to create the finest design solutions.

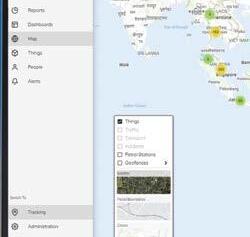

Transport Certification Australia (TCA) has registered MiX by Powerfleet as a service provider for the Road Infrastructure Management (RIM) application of the National Telematics Framework. The registration enables MiX by Powerfleet to support eligible transport operators looking to enrol their vehicles in RIM schemes.

RIM schemes are made available by road authorities as a means for heavy vehicle operators to gain productivity benefits and improved access to road networks. They also enable road managers to gain better insights into the movement of vehicles on their networks through aggregated and deidentified reporting through the Telematics Analytics Platform.

Paddy Goodall, the General Manager of Service Delivery at TCA, congratulated MiX by Powerfleet on their recognition as a RIM service provider.

“RIM service providers create an essential interface between eligible transport operators and the road managers who activate RIM schemes within their jurisdictions,” he said.

“A key element of RIM is the standardised approach to data collection. Standardisation enables data to be collected in an efficient and low-cost manner, enabling Australasian road managers to better understand the footprint of heavy vehicle operations across their road networks,” he added.

MiX by Powerfleet Managing Director Brodie von Berg said acquiring registration from TCA was an “important milestone” for the company and one that was expected to aid operational processes for its current and future customers.

“Fleet operators are faced with complex challenges when it comes to operating safe, efficient, and compliant fleets, and we will continue to build on our ecosystem to support these needs,” he commented.

FleetCard, an Australian fleet management company with over 40 years of experience, is partnering with Chargefox to offer the largest number of electric vehicle charging stations to business fleets through the launch of their new product, FleetCard +Electric.

FleetCard’s collaboration with Chargefox adds an extensive national network of readily available and easily locatable charging stations to FleetCard's fuelling capabilities. Employees driving an electric vehicle can simply tap the FleetCard +Electric to bill the recharge to the company account, just as they would with a regular fuel card – all on one invoice.

This new product extension seamlessly combines FleetCard’s existing fuel card capabilities with an electric offering all on one card, allowing customers more choice when it comes to how they run their company vehicles. This opens the next chapter of fleet management to Australian businesses, supporting them to confidently add electric vehicles to their fleets as

part of a fully comprehensive fleet management service.

Sam Steel, Managing Director of Corpay Australia and New Zealand, FleetCard’s parent company, said that as the industry evolves, FleetCard believes that electric vehicles in fleets are the natural next step to take.

“We’re excited to offer our customers the choice to incorporate EV charging as part of their fleet and fuel card. While the term Fuel Card has meant petrol or diesel until now, electricity is now an important fuel for transport, so it’s natural we added it to the list,” says Mr Steel.

“Our new addition of FleetCard +Electric is helping our customers to make an easy transition to EV, and our partnership with Chargefox gives them access to a vast national network of charging stations, meaning drivers don’t have to stress about on-road charging.”

The addition of electric vehicle charging in combination with FleetCard’s existing petrol and diesel capabilities means Australian businesses

can look after all their on-road expenses through one consolidated invoice, no matter their fleet makeup.

Chargefox CEO, John Sullivan, said the partnership provides an exciting opportunity for business fleets across Australia to take the next step into electric vehicles.

“We’re excited to be partnering with FleetCard on the launch of their new EV offering for business fleets. At Chargefox, we offer the largest and fastest-growing number of EV charging stations, through our hundreds of network partners, taking the stress out of EV adoption and helping individuals and businesses make the switch to electric vehicles.”

This unified offering combines fuel of all types –whether it be petrol, diesel or electric, to make the transition to electric vehicles in company fleets simple and easy.

To incorporate this sustainable approach at every step, FleetCard is also rolling out new sustainable cards across their product portfolio, including FleetCard +Electric. The new cards are developed using SICO-R, a sustainable PVC Film produced with 99% recycled PVC made from industrial waste.

For more information, please visit: https://www.fleetcard.com.au/electric

An Australian first trial to adopt a system of nationally standardised approvals for products to be used in rail and road projects is underway, which could save taxpayers tens of millions of dollars annually. Under the innovative agreement reached between the NSW and Victorian governments, any new product used in rail or road infrastructure projects must meet minimum regulatory, technical and safety standards to obtain type approval.

Currently there is significant inconsistency in approval processes across Australian jurisdictions that has road and rail construction industry bodies and product suppliers calling for change to complex and time consuming approvals. Australasian Railway Association research suggests inefficient processes cost the rail industry alone up to $40 million per year.

Transport for NSW and Victoria’s Department of Transport and Planning have signed a Memorandum of Understanding and started trialling a nationally harmonised process for product type approval, covering a range of road and rail infrastructure products, such as signalling and electrical equipment, and civil products.

Speaking about the agreement, Transport for NSW Secretary Josh Murray, commented: “We are excited that NSW and Victoria are together working to innovate the rail and road infrastructure industries in a way that will promote technological disruption and cost savings in the tens of millions of dollars.”

“Faster and more smoother approvals will assist us as we engage industry to help the government in NSW procure more locally made products to stimulate domestic manufacturing.”

“Standardising processes across state jurisdictions could be a gamechanger. There are significant implications for thousands of items associated with train control systems, active level crossings, electrical substations, track, bridges, traffic lights, road pavements, drainage and pipes,” Mr Murray added. “In NSW alone the existing catalogues of type approved products stretches to 3,000 items listed across 40 different registers.”

The first-of-its-kind cross-border partnership is designed to create efficiencies, reduce costs and remove barriers to new technology being introduced that can perform better, benefitting Australia’s rail and road networks.

These sentiments were echoed by Victoria Department of Transport and Planning Secretary Paul Younis, who said:

“Working with other states to provide greater consistency in standards is a win-win in delivering important road and rail projects with quality and tested components while reducing costs.”

“This trial will help test the benefits and effectiveness of this approach and delivers on our joint commitment to the National Rail Action Plan and delivering nationally harmonised outcomes for public transport,” Mt Younis said.

“We are cooperating closely with industry to support jobs and local content and this trial will help manufacturers comply with the relevant standards in NSW and Victoria,” he said.

Carolyn Walsh, Chair of the National Transport Commission, added:

“I warmly welcome development of the Product Type Approval Framework. It will facilitate the delivery of Ministers’ commitment to drive down

the cost and barriers to investment in safe, reliable and sustainable rail and road services nationally.”

“This work led by the Chief Transport Engineers in NSW and Victoria is breathing real life into the Memorandum of Cooperation signed by Transport Ministers and rail industry representatives last year to advance the interoperability and harmonisation of rail systems across Australia,”

Ms Walsh concluded.

Transport for NSW led a diverse and collaborative working group across government agencies, industry partners and peak industry bodies, which has supported the development of a draft national Product Type Approval (PTA) Framework.

It is expected that the NSW and Victorian trial will be completed by late July 2024, with full acceptance and implementation of the PTA Framework expected by early 2025.

The Chief Transport Engineers of the two states are also collaborating with 49 members across Australia and New Zealand representing organisations including:

• Australasian Railway Association

• Australian Rail Track Corporation

• Austroads

• Crane Industry Council of Australia

• Kiwi Rail

• National Transport Commission

• National Transport Research Organisation (NTRO)

• Queensland Rail

• Rail Industry Safety Standards Board

• Transport and Main Roads, Queensland

• Transport Certification Australia (TCA)

For more information, please visit: https:// www.transport.nsw.gov.au/industry/assetmanagement-branch/product-type-approvalframework

Emirates has begun using Sustainable Aviation Fuel (SAF) as part of its fuel agreement with Neste on flights departing from Singapore Changi Airport, marking its inaugural SAF investment in Asia. Approximately 3.3 million litres of blended SAF have been integrated into the fuelling system of Changi airport over the course of the last few weeks.

Emirates is tracking the delivery of SAF into the fuelling systems, accounting for and assigning its environmental benefits through widely used and accepted industry methodologies. Earlier this year, the airline closely collaborated with Neste for the supply of 2.6 million litres of neat SAF in the fuelling systems of Amsterdam Schiphol airport.

The SAF being provided by Neste is produced from sustainably sourced and 100% renewable waste as well as residue raw materials, including used cooking oil and animal fat waste. SAF used as part of this agreement can be safely used in existing Emirates aircraft and airport fuelling infrastructure, and in neat form reduces lifecycle carbon emissions (CO2) by up to 80% compared to using conventional jet fuel.

Adel Al Redha, Deputy President and Chief Operations Officer, Emirates said: “Emirates’ investment into Neste-produced SAF in Singapore marks a first step forward in our SAF adoption in Asia, a region that is primed to become a leading supplier of SAF, which continues to be in short supply.”

“While the activation of this agreement marks a milestone in our SAF journey in a new region, there’s still a lot of work to do. And as we procure SAF for the short term, we’ve got our sights set on longer-term agreements to help scale up a steady supply of SAF for our operations.”

Alexander Kueper, Vice President Renewable Aviation Business, Neste said: “We are excited Emirates has started using our Neste MY Sustainable Aviation Fuel at Changi Airport as the next step in our cooperation. It makes Emirates the first international visiting carrier using SAF at the airport produced at our Singapore refinery and supplied into the airport via our integrated supply chain.”

“We are looking forward to continuing working together on scaling up the supply of SAF for Emirates’ operations,” Mr Kueper added.

Emirates’ multi-faceted SAF strategy focuses on exploring opportunities to use SAF operationally wherever it is available in its network, share emissions reductions with corporate customers or freight forwarders where feasible, cooperate on longer-term SAF projects with reputable partners and support SAF ventures in the UAE with the potential to supply sustainable aviation fuel at its hub in the future.

Emirates currently operates flights from Amsterdam, London Heathrow, Paris, Lyon and Oslo with SAF. The airline also integrated SAF into the fuelling systems at its Dubai hub late last year. In 2023, Emirates was also the first airline in the world to operate two landmark demonstration flights from Dubai on the Boeing 777 and A380 with 100% SAF in one engine in partnership with Neste and other committed partners, supporting future certification where 100% drop in SAF is approved for commercial airline operations. Currently, SAF is approved for use in all aircraft, but only in blends of up to 50% with conventional jet fuel.

The airline has also committed USD$200 million for research and development (R&D) projects focussed on reducing the impact of fossil fuels in commercial aviation, and last month became an industrial partner of the Aviation Impact Accelerator (AIA), based at the University of Cambridge. Emirates intends to play an active role in sharing its knowledge and data, as well as insights with AIA to support the development of cutting-edge tools and solutions to reduce the long-term impact of commercial aviation.

The airline is a member of the Solent Cluster in the UK, an initiative focused on low carbon investments with the potential to create a Sustainable Aviation Fuel (SAF) plant that can produce up to 200,000 tonnes (200 kt) per year if operational by 2032.

Emirates is also a founding participant of the UAE research consortium AirCRAFT, focused on developing, producing, and scaling sustainable aviation fuel (SAF) technologies for the industry.

4" TRASH PUMP ... DIRTY WATER SPECIALIST ü Self priming to 7.6m ü Fast, easy set up ü Flows to 1,600 lpm ü 10HP Yanmar diesel ü Mine Boss model shown

Mobile Media Blasting - Soda & Garnet

• Specialising in Concrete preparation for Carbon Fibre application

• Abrasive & Non-Abrasive Blasting

• Paint, rust & contaminant removal from many substrates

• Line marking removal

• Graffiti removal & protection

• Removal of sealers & coatings

• Creation of non-slip surfaces

• Compact machinery for easy access

• Low media usage which means less environmental issues with reduced containments and dust

• Suitable for confined space blasting

Available in a range of AS 5100:2017 performance levels, including ‘Low’ (MASH TL2 | EN1317 N2), ‘Regular’ (MASH TL4 | EN1317 H2) and ‘Medium’ (MASH TL5+ | EN1317 H4b), DOLRE traffic barriers have gained an enviable reputation for their lifesaving performance and outstanding versatility along bridges… but they’re not just for bridges!

Indeed, DOLRE low stress barriers, including the purpose-designed TL2 ‘Slimline’ variant, also provide the ideal high-performance traffic safety barrier solution for use along engineered structures including retaining walls and embankments –particularly those with complex site challenges such as poor ground conditions or steep embankments beyond the fence line.

While the use of DOLRE along complex roadside retaining wall and embankment applications is increasingly commonplace across Europe, a recently completed installation in the Sydney harbourside suburb of Rose Bay, marks Australia’s first ‘roadside barrier’ installation of the innovative DOLRE Low Stress Parapet System – and the results are outstanding in more ways than one.

Speaking about the project, Dane Hansen, Engineer with road and bridge safety specialists LB Australia, commented:

“The key benefit of the DOLRE barrier in this type of complex roadside application is that, as in bridge applications, DOLRE’s patented post ‘fuse’ system and innovative post and rail design significantly limits the transverse forces transmitted to the footings during an impact.”

“In fact, even for the MASH TL4 variant, which is designed to cope with an impact by a 13-tonne bus travelling at 70 km/h, the maximum outward transverse force transmitted to the footings is limited to only 44 kN/post (22 kN/metre),” he said.

“What this means in practical terms, is that DOLRE is able to provide life-saving protection for road users in locations where there are challenging ground conditions, without the need for massive footings or extensive slope stabilisation or reinforcing works,” Dane Hansen added.

Located in the harbourside suburb of Rose Bay in Sydney’s inner-east, this latest DOLRE barrier installation stretches from the corner of New South Head Road, some 102 metres along the southern edge of Bayview Hill Road.

Together with the steep grade of the roadway (which is clearly evident in the photos) and the generally poor ground conditions in the vicinity, one of the biggest challenges with the Rose Bay installation is the angle and height of the embankment on the far side of the barrier. Add to that, the high number of vehicles travelling along Bayview Hill Road (especially during school drop-off and pick-up times) and the fact that at the school in question – Sydney’s historic Kambala School – is located on the land at bottom of the steep embankment, and it’s easy to see why safety barrier performance is such a critical consideration for this location.

As well as providing protection for students, staff and visitors to the school, the new DOLRE barrier fence provides critical protection for vehicles turning into and travelling along this extremely steep and extraordinarily busy road.

While the majority of the Rose Bay DOLRE barrier is a standard ‘straight line’ installation, the top section has been constructed at an angle behind the footpath at the corner of Bayview Hill Road and New South Head Road. The angled section was specifically required to protect vehicles turning right into Bayview Hill Road from New South Head Road, which is one of the busiest arterial roads in Sydney’s inner-east. The tight radius of the corner, combined with the steep and variable angles involved, required the design and fabrication of a number of customised DOLRE barrier sections.

“Even though DOLRE is essentially a modular barrier system with standardised posts and barrier rail lengths, for challenging installations such as Rose Bay, we are able to custom-design and fabricate site-specific sections of DOLRE to suit,” Dane Hansen said.

“This was particularly important for Bayview Hill Road, where the variable nature of the incline and the radius of the corner at the top of the hill, together with the location of existing underground services, made it all but impossible to try and ‘smooth out’ the incline with footings alone.”

Designed by infrastructure engineering specialists Turnbull Engineering, the footings for the Bayview Hill Road DOLRE barrier incorporated a series of concrete piles, supporting a reinforced concrete strip footing along the length of the barrier. Preparation of the concrete piles and footings was carried out by specialist contractors in conjunction the team from Waverley Council. The barrier installation work was carried out by a team from DOLRE’s exclusive Australian distributor, LB Australia Pty Ltd.

DOLRE low stress traffic barriers deliver the ideal combination of lifesaving performance and aesthetically pleasing design.

In addition to their proven performance in both bridge and roadside applications, DOLRE low stress traffic barriers feature a modern, aesthetically pleasing design which portrays a sense of safety, strength and reliable protection, while at the same time minimising the overall visual impact on the surrounding environment.

“While the overall aesthetics of roadside infrastructure such as safety barriers is important in any location, for the Rose Bay installation, it was critical,” Dane Hansen said.

“Bayview Hill Road offers outstanding views across Sydney Harbour and some of Australia’s most iconic landmarks, including the Harbour Bridge, Sydney Opera House and Fort Denison/Muddawahnyuh - so it was particularly important to try and minimise the visual impact of the barrier on the surrounding environment.”

“DOLRE’s ‘open’ design made it the ideal barrier solution for the Rose Bay installation,” Dane added. “It delivers the ideal combination of safety, engineering performance and aesthetics, without unnecessarily blockingout the stunning vistas across Sydney Harbour.”

DOLRE Low Stress traffic barriers are also available in a ‘slimline’ variant, which has been specifically designed for locations with a limited installation footprint.

Available in a choice of standard galvanised

finish, or with optional powder-coated posts and rails in a range of colours, DOLRE LOW SLIMLINE delivers AS 5100:2017 performance level ‘Low’ (MASH TL2 | EN 1317 N2) protection

DOLRE Low Stress traffic barriers are available in a variety of colours and architectural finishes, and with a range of optional fascia designs, including pedestrian safety mesh, architectural

and decorative panels, extended height pedestrian protection for rail and motorway crossings, and motorcycle rail protection. DOLRE barriers are also available with fully-

roads with posted speed limits up to 70 kph. DOLRE LOW SLIMLINE is also available with the option of single or double-face pedestrian protection (in a choice of mesh or architectural panels), as well as fully-integrated LED lighting.

integrated LED lighting, with systems ranging from basic white, through to programmable RGB/Colour solutions.

DOLRE’s integrated LED lighting delivers the perfect architectural and safety solution for Italy’s Ciolo Bridge

A

Located in the province of Lecce in Puglia on Italy’s picturesque Adriatic coast, the Ciolo Bridge (Ponte Ciolo) spans some 60 metres between the two rocky outcrops which form the outer edges of Baia del Ciolo (Ciolo Bay) - a rugged rocky bay, leading into a vast rocky canyon dotted by caves. The area is extremely popular with hikers, mountain bike riders, cave climbers, canoeists and sightseers alike, with visitors coming from across Italy and around the world to enjoy the region’s beautiful coastal vistas and recreational activities.

Now, thanks to a recently completed upgrade, the Ciolo Bridge has itself become somewhat of a tourist attraction, with many coming to not only walk or ride across the bridge to enjoy the stunning vistas, but also to photograph the bridge – especially in the evening when it is illuminated.

Constructed in 1967, the Ciolo Bridge is a reinforced concrete ‘Maillart’ arch design with a thin vault and a stiffening deck some 30 metres above sea level. The 9 metre wide deck features a 7 metre road width and two pedestrian pavements, each measuring 1 metre wide. The bridge recently underwent a major refurbishment, involving concrete protection and repair works, pavement resurfacing works, safety upgrade works, and a major cosmetic upgrade including new protective surface coatings and the installation of architectural lighting.

As part of the safety upgrade, some 120 metres of DOLRE Low Stress bridge traffic safety barrier was installed along the kerb between the outer edges of each carriageway and the footpath. As well as providing MASH TL4-rated protection for vehicles crossing the bridge, the Ciolo Bridge installation also provides a significant increase in protection for pedestrians using the bridge.

While DOLRE’s unique performance characteristics – including its ability to provide MASH TL4 | EN1317 H2 protection while limiting the maximum outward transverse force transmitted to the bridge deck to only 44 kN/post (22 kN/metre), and its patented lightweight design (76 kg per linear metre) which helps to minimise static loading on the bridge structure – were key in the engineers’ choice for the Ciolo Bridge upgrade, aesthetics were also another major contributing factor.

In short, while the primary considerations were, understandably, for safety and engineering performance, both the engineers and the designers wanted a safety barrier solution that would not detract from the aesthetics of the bridge or the surrounding natural vistas. DOLRE’s modern, open and streamlined design, together with its optional integrated LED lighting system, made it the perfect choice for the Ciolo Bridge.

Installed along the underside of the centre DOLRE rail, the purpose-designed and manufactured LED light strips provide clear, non-glare lighting for both road users and pedestrians on the bridge. The fully-waterproofed, extra heavy duty LED light strips are securely fastened to the inner surface of the DOLRE rail using

purpose-designed vandal resistant fittings, resulting in no readily visible additional fixtures or fittings, and no protrusions on either the traffic or pedestrian side of the barrier.

The location of the LED light strips along the barrier rail, combined with the lights’ directional focus lens, ensures the light beam is focussed toward the road surface, preventing the lighting from becoming a glare hazard for road users, while also minimising unwanted light pollution.

The integrated DOLRE LED lighting also eliminate the need for additional ‘pole-based’ lighting – further increasing safety through the elimination of large, heavy roadside light poles.

The LED light strips are available in a number of models, including basic white and RGB/Coloured options which can be programmed to provide ‘event specific’ colour options, ranging from different colours or highlight sequences to suit the prevailing road conditions, or to mark cultural events, etc.

Critically, the addition of the LED light strips does not alter the design of the tested barrier, and as such, has no negative impact on the life-saving performance of the DOLRE barrier.

For further information, please contact DOLRE’s exclusive ANZ distributor, LB Australia Pty Ltd, on 1300 522 878, visit the website: www.dolre.com.au or SCAN THE QR CODE.

In the realm of engineering, brilliance isn't just about creating something new; it's about reshaping the world around us. It's about envisioning the future and daring to make it a reality.

For over a century, the Excellence Awards have been the pinnacle of recognition for engineering achievements. They stand as a testament to the relentless pursuit of excellence that defines our community. The progress engineers make pushes the boundaries of what’s truly believed possible, so, it deserves recognition.

Our award categories span the spectrum of engineering disciplines, from adept up-andcomers to seasoned professionals, we recognise the individuals, teams and projects that have achieved real, impactful innovation and make us proud to call ourselves engineers.

Celebrating our greatest achievements and contributions inspires us all to push the boundaries of innovation. Engineers Australia CEO Romilly Madew AO says, "Our Excellence Awards unite the engineering sector in celebrating its most significant accomplishments. It is these individuals and endeavours that break new ground, changing how we see the world, live our lives, work and think creatively."

Beyond receiving due recognition for their contributions to engineering, winners will also enjoy exclusive discounts, profiles and coverage in leading engineering publications and presentation opportunities at key events. You can nominate yourself, someone else or the team behind a project.

Nominations Close Tuesday 2 July

These awards highlight Australia’s top endeavours in engineering and the teams behind them. Specifically, we’ll assess how each nominated project:

• contribution to sustainable and inclusive ethical practices

• capture of Engineers Australia’s purpose to advance society through impactful engineering

• formulates resourceful, innovative and elegant engineering solutions

• support for diversity and inclusion in engineering practice

• pioneering the use of materials or methods.

The national winner of the award will be honoured with the prestigious title of 'Project of the Year 2024.' With the winning project team also receiving recognition across Engineers Australia's extensive network, showcasing the team's accomplishments and facilitating professional networking opportunities.

Learn more about our prestigious project award and how to nominate here: engaus.org/awards

These awards celebrate the people we’ve looked up to and been inspired by this year, no matter what stage of career they’re at. Specifically, we’re looking for engineers who’ve created work that showcases resourcefulness, innovation, and aesthetic appeal. It demonstrates creativity and ingenuity in material or method usage and aligns with Engineers Australia's purpose and strategic vision. Moreover, it promotes the engineering profession and signifies a notable engineering career.

We’ll present six people awards based on the occupational fields within the engineering profession, including an emerging tier specifically designed for early-career professionals, one winner is selected for each category.

• Professional Engineer of the Year

• Engineering Technologist of the Year

• Engineering Associate of the Year

• Emerging Professional Engineer of the Year

• Emerging Engineering Technologist of the Year

• Emerging Engineering Associate of the Year

This is an opportunity to recognise the lifetime achievements of engineers who’ve delivered transformative work, paving the way for future generations. There are three awards in this category.

• PNR Medal

• Honorary Fellows

• The President's Prize

With a diverse mix of awards, in this category we honour significant engineering achievements across industries and career stages. There are 11 awards for outstanding engineers working across various engineering colleges and communities.

• Biomedical College: David Dewhurst Award

• Chemical College: Chemical Engineer Achievement Award

• Civil College: Sir John Holland Civil Engineer of the Year

• Electrical College: MA Sargent Medal

• Engineering Heritage Australia: John Monash Medal

• Environment College: Environmental Engineer Achievement Award

• ITEE College: Neville Thiele Eminence Award

• Mechanical College: AGM Michell Medal

• RISK Society: Risk Engineer Achievement Award

• Structural College: John Connell Gold Medal

• Transport Australia society: Transport Medal

Our first celebration will include the announcement of our national finalists for project and people categories, plus unveil the winners of the achievement awards. These celebrations will be hosted nationwide in September, bringing the engineering community together as we celebrate excellence. The national finalists will then go on to represent their division at the highly anticipated gala in Brisbane on 21 November.

• Project awards nominations close: 31 May

• People awards nominations close: 2 July

• Local winner announcement events: 12–19 September

• National gala dinner in Brisbane: 21 November We invite you to be a part of this prestigious awards program. Complete your nominations by the deadline and stay tuned for announcements regarding tickets to the awards events, which will go on sale in July. Let's raise a glass to the visionaries, the innovators and the champions of engineering excellence.

Visit our website to learn more about the Excellence Awards and submit your nominations. engaus.org/awards

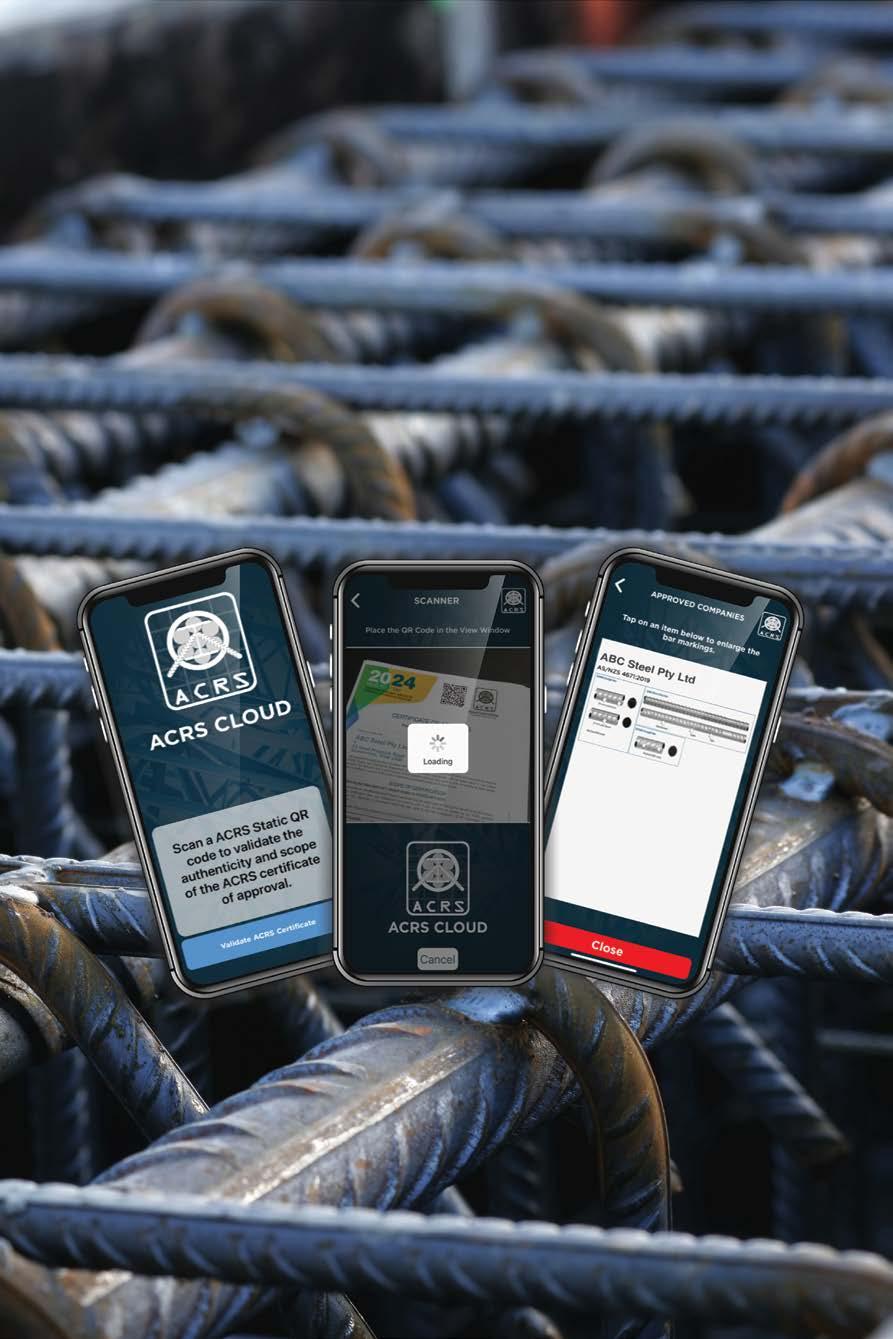

INSTANT VARIFICATION of conformance to AS/NZ Standards.

ü Product Validity & Provenance

ü Bar & Tag Markings

ü Supports Sustainable Steel Use

ACRS Cloud is the first digital certification system of its kind for steel in the Australian and New Zealand construction industries, providing a secure environment for industry to verify product conformance to Australian and New Zealand Standards. It moves ACRS full certification and traceability from source to site to a digital system.

SCAN the QR CODE to DOWNLOAD the app or VISIT: steelcertification.com/cloud

ACRS - Independent, Expert Third Party Certification and Verification of Reinforcing, Prestressing and Structural Steels for Compliance with Australian and New Zealand Standards

DYNAMIC INFRASTRUCTURE leverages all available asset condition data, reports and images - regardless of the format or age - to build a detailed chronological ‘health record’ for each bridge asset - providing you with immediate access to all your asset data and empowering you with actionable insights that lead to cost savings and improved maintenance e ciency.

With DYNAMIC INFRASTRUCTURE there is no need to change your current bridge inspection methods or service provider. The system utilises all existing data and reports, regardless of the format or age -including paper-based engineering drawings and plans, photos, paper-based inspection and condition reports, together with digitised data and images - to build a detailed ‘health record’ for each bridge asset.

Using DYNAMIC INFRASTRUCTURE’S AI-enabled technology to identify faults and damage e ectively transforms the entire process from a subjective one that relies on an individual to find and identify all faults on a structure and then make a judgement call on severity, to an objective one where over 99% of faults are identified, categorised, logged and then rated for severity against a global database of over 30,000 bridges and counting.

DYNAMIC INFRASTRUCTURE enables you to identify defects before they escalate into major failures, helping you to better manage risk and prevent unexpected expenses. It can even help you maximize warranty coverage through automated repair tracking - providing you with full visibility from the field to the o ce.

You’ve been asked to find ALL of the historic inspection, repair and maintenance data for just one of your bridge assets…. How long would it take?

A couple of hours? A couple of days? Longer?

With DYNAMIC INFRASTRUCTURE you can access ALL of your bridge asset data – including plans and historic inspection data (manual reports) as well as details of faults, damage, repairs and maintenance –within a matter of seconds.

All of the data, for each of your bridge assets, right at your fingertips… in one comprehensive, chronological digital ‘health record’ …and the MASSIVE TIME SAVING is only one of the benefits!

DISCOVER MORE

Leading global construction chemicals company MC-Bauchemie expands its presence in Australia

While it’s fair to say that most construction industry professionals across Australia may not be immediately familiar with the name MC-Bauchemie, many of the company’s world-leading products have been specified and used in countless Australian projects, including many major projects, for over two decades. Indeed, over the past 20 years, MC-Bauchemie (or MC as it is generally known) products have gained an enviable reputation for quality, performance and reliability, are widely considered ‘the products of choice’ by an ever-increasing number of engineers, specifiers and contractors – particularly across the tunnelling and infrastructure construction and maintenance sectors.

From injection resins, repair materials and waterproofing membranes for tunnels, through to specialist repair mortars, highdensity surface coatings, and acid and chemical-resistant protection and repair systems for sewers, treatment plants and other heavy industrial facilities, demand for products from MC’s Infrastructure & Industry range has skyrocketed in recent years. So much so, in fact, that products such as MC’s flagship MC-Injekt GL-95 TX injectable acrylate gel waterproofing sealant is now specified and used in the majority of road and rail tunnels up and down Australia’s east coast.

With the ever-increasing demand for its products, MC took the opportunity in 2023 to expand its Australian and New Zealand operations, through the establishment of MC-Bauchemie Australia Pty Ltd. Headed up by Managing Director Jason Bolt, MC Australia aims to expand its business and brand awareness in the Australian market, with products that have been specifically developed to meet the needs of the Australian construction and maintenance industry.

“While MC products have been used with great success for more than 20 years on projects across Australia, including many of the country’s largest ‘flagship’ infrastructure construction and maintenance projects, the fact that MC didn’t have a business presence in Australia meant that we didn’t really have a brand profile outside of those projects,” Jason Bolt commented.

MC has been working in the background for some time in the Australian market, partnering with key, suppliers for unique sustainable solutions. For example, MC has been working with Wagners Concete on Geopolymer concrete for commercial projects in Australia and abroad, including the massive Toowoomba Wellcamp Airport project in Queensland.

“MC products have gained a reputation for quality, sustainable innovation and performance across an array of projects. This has not only resulted in a steady increase in demand for products from our Infrastructure & Industry range, it has also sparked a lot of interest in products from our other business sectors, particularly our Concrete Industry products, including admixtures, curing and release agents, and our concrete cosmetic products,” he added.

While MC products had previously only been available in Australia through its licensed distributor and applicator Building Chemical Supplies (BCS), in late-2023 the then newly formed MC-Bauchemie Australia business reached an agreement with BCS to acquire the assets of its building chemicals trading business - effectively separating the supply and applications businesses.

Jason Bolt explained: “BCS has been a major distributor and applicator of MC products in Australia for nearly twenty years, and the two companies have always enjoyed a strong, cooperative partnership. However, MC has many technologies beyond what was being offered, and with the focus in Australia on sustainability, total cost of construction and innovative construction materials, we believed it was the right time for MC to enter the Australian market directly.”

“By separating the materials supply and application businesses, this acquisition provides both companies with the ideal opportunity to continue working together, while focusing on our individual strengths and further developing our core businesses,” Jason Bolt added.

As part of the acquisition, several BCS sites, including warehouses in the Sydney and Melbourne region, were transferred to MC Australia. MC Australia will also be opening additional offices and warehouse facilities across Australia and New Zealand throughout 2024 and beyond.

The acquisition of the trading business also saw seven BCS employees transfer to MCBauchemie Australia. As well as highlighting the spirit of cooperation and quality of the long-term relationship that exists between the two companies, having the BCS employees join the team at MC Australia means that for BCS customers, the acquisition was as close to ‘seamless’ as possible.

Dan McGown, National Technical Manager – Tunnelling, commented: “From a customer perspective, it also means that there is seamless continuity of both product supply and services, which is critical – particularly on major projects.”

“Customers will have no interruptions in service or material supply, no loss of critical ‘local’ and project-based knowledge, or for that matter, in most instances, no change in people they’re dealing with,” Dan said.

Founded in the German city of Essen in 1961 by Heinrich W. Müller, MC-Bauchemie was established to serve rapidly developing market for ready-mix concrete and precast components – more specifically, the development and production of innovative concrete and mortar admixtures to meet the needs of Germany’s rapidly growing highway and subway infrastructure construction sector.

Not surprisingly, the company’s focus on innovative products, coupled with Dr Müller’s motto “Business is done between people, not companies”, saw a significant growth in demand for its products in a relatively short time. Indeed, by 1962, a little over a year after its establishment, MC was already producing to capacity at its Essen facility, and a new long-term solution to allow expansion was sought.

In 1963, MC-Bauchemie moved to its newly constructed facility in the nearby town of Bottrop, where it is headquartered to this day – albeit on a much larger scale!

From its earliest days, MC-Bauchemie products have been associated with reliability, quality, innovation and, of course - in keeping with the company’s motto “Be sure. Build sure.” – safety in construction. Over the past six decades, this third-generation family owned company has developed from an ambitious business with 25 employees, to a leading international manufacturer of construction chemicals, producing innovative solutions for the treatment,

curing and hardening of concrete, as well as for the protection and maintenance of buildings, tunnels and underground structures.

The group of companies now employs more than 2,500 people, has more than twenty R&D and production facilities across several continents, and a presence in over 40 countries worldwide.

The company’s operations are organised into three key market segments, namely:

• MC for Concrete Industry: incorporating high quality concrete and mortar admixtures, curing and release agents, and concrete cosmetic products;

• MC for Infrastructure & Industry: incorporating protection and repair systems for engineered structures and industrial builds, including repair mortars, surface protection coatings, waterproofing injection and joint sealing systems; and

• MC for Buildings: specialised product systems for the sealing, protection and repair of commercial and residential buildings, including high-efficacy bituminous and bitumen-free waterproofing systems, super-resistant, high-performance coatings for floors, walls and ceilings, together with high performance screed systems, plasters, renders and mortars. The MC for Buildings portfolio also incorporates a separate selection of speciality product systems specifically designed for the restoration and repair of heritage buildings.

Three generations on, this family-owned business maintains its commitment to innovation, safety and sustainability, working with its customers around the globe to find the best solutions to meet the needs of their specific construction challenges.

Importantly, for MC, this commitment is much more than a simple ‘marketing tagline’. In fact, 10 % of MC’s global workforce is in the Research and Development department – a massive commitment by any measure.

“We regard construction as a serious matter,” Jason Bolt said. “We recognise that each product can play a crucial role in ensuring the integrity both of a whole structure and of any repair work done on it.”

Dan McGown added: “Choosing the wrong material or using it incorrectly can lead to damage in building components and in extreme cases, it may even endanger life. That is why we take such care with each and every project, and every product.”

“We combine the expertise of mineralogists, concrete technologists and materials scientists from our in-house laboratories with the knowhow of our construction engineers and specialist advisers assigned to sites around the world. Maintaining short communication paths, these experts work together wherever required in order to find the most appropriate solution to the specific tasks facing planners, contractors and clients,” he said.

As well as expanding the company’s existing Infrastructure & Industry product offering, as part of its Australian expansion, MC will also be introducing its world-renowned Concrete Industry product range to the Australian market for the first time.

With products to enhance a range of performance characteristics in concretes and mortars, including early and final strengths, compaction, resistance to damage, surface quality and ease of placement, the MC Concrete Industry range includes a selection of specialist admixtures for both the ready-mixed and precast concrete sectors. It also includes a range of curing compounds to protect freshly poured concrete during the hydration process, releases agents to optimise the off-form finish of both precast and poured insitu concretes, and concrete cosmetic products to rework, repair and match any damage that may have occurred to precast concrete components either onsite or in transit.

“We’re very excited to be able to provide products from the Concrete Industry range direct

to our Australian customers for the first time,” Jason Bolt said.

“Importantly, while these products have been well and truly proven in countless projects around the world, our team here in Australia are also testing and assessing each admixture formulation to ensure that it performs as specified in Australian conditions and using locally sourced construction materials."

"While it means we can’t simply ‘open up shop and have all our products available from day one’, we believe that this testing and assessment is a critical step when introducing new products to a new market,” he said.

“After all, despite the fact that they’ve been used around world for over six decades, for most customers here in Australia, these admixtures will be completely new to them. Having each of the products tested and assessed under Australian conditions provides our customers with the confidence that when they use our admixtures they will perform exactly as specified and deliver the results they expect,” Jason concluded.

For further information on the full MC-Bacuhemie range, please visit: https://mc-bauchemie.com.au

It’s not only Local Government that’s stuck with the problem of cleaning off the artwork of graffiti artists. Factories, commercial buildings, even retailers in shopping centres can be the targets for this age-old issue. One solution that presents a flexible and chemical free way of removing graffiti safely and efficiently is pure steam!

Leaders in the pressure cleaning industry, Aussie Pumps, recommends using a 4,000 psi steam cleaner like their Heatwave because the steam literally peels paint off walls. This means you can carry out graffiti removal without the need for carcinogenic cleaning chemicals or dangerous caustics.

The steam cleaners can also be used for a myriad of council jobs that include cleaning amenities, sanitising park tables and benches, removing chewing gum, even melting the grease off public BBQs. They also fulfil a useful role cleaning public spaces like car parks or piazzas where spilled food or even oil stains can be removed without the use of cleaning fluids.

The Aussie Heatwave is a Honda petrol-driven 4,000 psi high pressure steam cleaner which delivers steam up to 130°C. The 13HP electric start Honda engine drives a heavy duty triplex pump with solid ceramic pistons and top quality seals for a long trouble free life.

The Heatwave features a 12 volt ignition system and a diesel fired burner. The heating system enables the operator to go from using cold to hot water with the press of a button. The operational temperature of the water delivered can be dialled up from ambient to 130°C.

The unit is built into a compact stainless steel frame with four steel wheels and rubber tyres. This means it can be used as a mobile wash unit in difficult to access locations. Alternatively, it can be hard mounted on a ute, truck or trailer together with a 300 or 400 litre water tank to become a self-contained mobile high pressure cleaning system.

Scan the QR Code or visit aussiepumps.com.au to view the “Aussie Safe Operator” course online.

Aussie invites all users of pressure cleaners, irrespective of brand, to complete the course online at https://aussiepumps.com.au

The use of high pressure accessories can improve cleaning efficiency even further. For example, high pressure reels can either be fitted to the machine or, if it’s part of a mobile cleaning system, bolted to the deck of a vehicle. Using a hose reel to mount extra-long hoses adds operator convenience and reduces hose wear and trip hazards.

When using cold water, a turbo lance for the gun has the effect of multiplying the effectiveness of the pin jet which can halve cleaning times, saving on labour costs. The turbo is a rotating turbine, mounted in the end of the lance, that multiplies the impact of the water jet going through as it spins under pressure.

A flat surface cleaner is ideal for cleaning large flat areas with streak free results. Flat surface cleaners can cut cleaning times by up to 75%, use less water and save on fuel and wear of the machine.

A drain cleaning kit - a portable Mini Reel fitted with 60 metres of sewer hose and drain cleaning nozzles - enables hot water (up to 80°C) under pressure to be used to clear grease traps, blocked drains and even sewer lines.

Australian Pump Industries offer a free Safe Operator online training course. The course is available to Councils, cleaning contractors, graffiti specialists and virtually anybody who professionally uses a pressure cleaner of any brand. The course is informative and makes high pressure pump technology easy to understand. Australian Pump want operators to be safe and

University of Queensland researchers have outlined 5 key steps needed to speed up Australia’s transition to electric vehicles (EVs). The Federal Government recently passed the New Vehicle Efficiency Standard (NVES) requiring car makers to reduce carbon emissions for new vehicles from January 2025.

Dr Kai Li Lim, Dr Dia Adhikari Smith and Associate Professor Archie Chapman said the legislation was an important step toward sustainable transport, incentivising car manufacturers to export their most fuel-efficient vehicles to Australia.

The researchers said 5 further measures would put Australia on the road to an EV future:

1. Improve charging infrastructure

“We advocate for the continued implementation of the National EV Strategy, focusing on EV charging infrastructure to ensure comprehensive coverage across urban, regional and remote areas,” Dr Adhikari Smith said.

“This includes accelerating the building of heavy EV charging infrastructure like fast-charging stations for trucks and buses.”

Dr Lim said public charging infrastructure for passenger EVs needs to be more reliable and built with longevity in mind.

“Chargers also need to be as accessible as possible, including retrofitting existing commercial and residential buildings.”

2. Enable EVs to supply energy back to the grid

“EVs can act as mobile energy storage units, giving owners the opportunity to monetise their vehicles through demand response programs,” Dr Chapman said.

“Light and heavy EVs should be enabled and encouraged to supply energy back to the grid, lowering energy costs for consumers and reducing greenhouse gas emissions.

3. Create local supply chains for EV batteries and parts

“Establishing local battery and part manufacturing and recycling would leverage Australia’s mineral resources,” Dr Adhikari Smith said.

“Local supply chains, including for imports, would stimulate the electrification of commercial vehicles and heavy machineries.”

4. Upskill an EV sector workforce

“There will be high demand for a workforce in all parts of the EV sector, including maintaining vehicles and chargers, building chargers and charging sites and developing software,” Dr Lim said.

“This will require setting up specialised courses to satisfy skill demands and presents opportunity for Australia in the automotive value chain.

“Workers in the internal combustion engine vehicle sector should be supported with transition programs, and ideally be provided with pathways toward EV manufacturing and services.”

5. Replace fuel excise revenue

“A fair road user charge for EVs will eventually be needed to replace the loss of fuel excise revenue in Australia, and to continue recouping road costs equitably,” Dr Lim said.

“This could be a phased approach, with no road charges for EVs initially to encourage adoption before a user pays system is introduced, based on the distance driven.”

The researchers said announcements in the recent Federal Budget including the NVES, investment in integrating EVs with the grid and local battery manufacturing provide hope for accelerating Australia's transition to an EV future.

“We can also expect an influx of EVs into the country thanks in part to policies overseas, so it’s imperative Australia – and our infrastructure – is ready,” Dr Lim said.

“The transition to EVs will require both strategic investment and careful thinking, as charging technology and charging behaviour continue to evolve.”

“This is challenging but vital work that requires a collaborative effort across technology adoption, policy formulation, financial mechanisms and workforce development,” Dr Adhikari Smith said.

“Australia has a unique opportunity to devise a framework to support the uptake of EVs that will benefit consumers, maintain our transport capabilities and reach environmental goals.”

The recommendations formed part of a submission by UQ researchers in response to an inquiry into the transition to EVs by the Federal Parliament House Standing Committee on Climate Change, Energy, Environment and Water in early 2024.

Protecting road work crews from errant vehicles is just as important on suburban streets as it is on major highways and arterial roads.

Ideal for use on suburban streets and roads with posted speed limits of up to 70 km/h, Scorpion II® METRO TMA delivers the ideal combination of life-saving MASH TL2-certified impact protection in a compact, easy-to-manoeuvre size.

ASSESSED, APPROVED & RECOMMENDED FOR ACCEPTANCE throughout Australia by ASBAP (Austroads Safety Barrier Assessment Panel), the Scorpion II® METRO TMA is not only THE FIRST TL2 TMA to be fully tested and approved to the latest MASH Standards, it is currently THE ONLY TL2 Truck Mounted Attenuator to be successfully TESTED, PASSED & ELIGIBLE to the current MASH Standards.

By Jamie Fox, Principal Analyst at Interact Analysis

After years of discussion and development, 2024 is set to be the year that the hydrogen engine market really takes off. In 2024, India will move firmly into pole position due to its drive for energy independence.

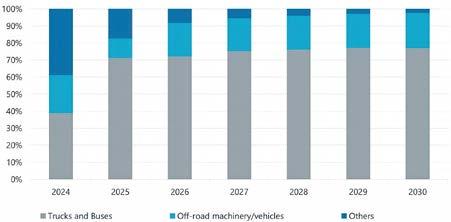

There were no new hydrogen internal combustion engine (H2 ICE) trucks registered in 2023 (excluding test vehicles). We forecast sales of 40 hydrogen engine trucks (new vehicles) in 2024. Most of these sales will be in India, led by Ashok Leyland and followed by Cummins through its partnership with Tata Motors. From there, we see a fast-growing market with hundreds of sales in 2025 and thousands in the following years, reaching a forecast 10,121 in 2030. However, with over 20 million trucks expected to be sold worldwide in 2030, H2 ICE will still only account for 0.05% of the total.

The off-road market, which also stood at zero in 2023 (JCB has already built many H2 ICE vehicles but not sold them for commercial use), is forecast to grow to 23 vehicles in 2024, led by loaders from JCB. Sales of hydrogen ICE telehandlers are also anticipated in the coming years, with the total off-road market projected to reach 2,720 H2 ICE vehicles in 2030. However, once again this figure must be compared with the millions of (mostly diesel) off-road vehicles sold each year.

The order Deutz received from China for gensets, plus the possibility of other orders in this area, will also add to the sales of hydrogen ICE off-road vehicles during the next few years.

Most H2 ICE sales are forecast to be in trucks

Sales, mainly of H2 ICE trucks, off-road machinery/ vehicles and gensets are driven by the need to avoid reliance on foreign energy (in India) and for

environmental reasons – climate change and local pollution (in Europe, the US and elsewhere). In addition, hydrogen engines are somewhat similar to diesel engines, and can be produced by companies with the expertise and production facilities for diesel.

Given these reasons, there will always be national or local governments, or large companies willing to take a chance on a new technology, but early sales don’t necessarily mean that a mass market will follow.

In our experience, conducting modelling and interviews with experts for the last seven years, increasing sales of a new technology from 1%-2% to 5%-10% will only happen when the new technology is less expensive or clearly better in some way than the prevalent technology, or when existing technology is being legislated against in some way.

The path to mass market H2 ICE looks very challenging given that the total cost of ownership of H2 ICE vehicles is more expensive than diesel and BEV vehicles, does not offer greater utility or more advantages vs diesel, and the existing diesel is not currently being phased out (especially in offroad). In addition, the infrastructure for hydrogen is not in place at present.

Diesel will be phased out earlier on-road than off-road, but in most on-road applications BEV will simply beat H2 ICE on cost, and perhaps infrastructure. Long-haul trucking is more of an open question as that is very difficult for BEV which means H2 ICE may be able to compete.

The number one reason why we think H2 ICE will be a niche application is that it will (in total cost of ownership) be too expensive. The high cost of hydrogen as a fuel, even after 2030, is the key problem here.

The second big reason is the lack of infrastructure (at least for now). It may make sense to use hydrogen vehicles near to existing sources of hydrogen – such as industrial facilities, ports and solar and wind farms that are creating hydrogen with spare electricity through electrolysis. In such cases, infrastructure costs and the costs of hydrogen transport may be reduced, allowing hydrogen vehicles to be competitive.

On a positive note, the engineering challenges that H2 ICE engines and vehicles face are being solved. Much progress has been made by companies such as JCB and Cummins on challenges relating to spark plugs, embrittlement and so on. Injector lifetime, given the lack of lubrication, is still very poor but many companies are confident that they will improve it.

So, if the issues around cost and infrastructure could be solved, hydrogen would have a bright future in commercial vehicles.

These findings are from our new H2 ICE report, which has H2 ICE vehicle forecasts to 2040 by region, vehicle/equipment type, and power/size. Direct injection vs port fuel is also shown.

The report compares our forecasts for H2 ICE with those of fuel cell, battery electric, hybrid and non-electrified vehicles (mainly diesel). In addition, the report forecasts the price of hydrogen and has a sample total cost of ownership for Hydrogen ICE and how this compares to other powertrains.

The report also showcases leading suppliers, pros and cons of each supplier, and technical, market and legislative arguments to provide a complete picture of the market.

For more information about the Hydrogen ICE -2024 report, please visit: https://interactanalysis. com/research/hydrogen-ice-market-andtechnology-assessmentfor government and industry to get together and develop a plan for implementation that also includes appropriate data governance. Ultimately, in the case of

government it needs to just do it!” said Adviser and Consultant Chris Koniditsiotis, who was on the panel.

A key feature of day two of the conference program was a panel discussion in which toll road operators, tolling tech providers, and government leaders delved into the key future technology challenges and opportunities in operating and managing motorway tolling systems.

According to the panel, Australia’s ITS industry has been a world leader in building cross-border partnerships across all sectors to deliver harmonised tolling solutions, but that collaboration must now continue into the C-ITS generation of tolling.

The panel also considered global technology innovations, with representatives from tolling technology leaders Kapsch and Q-Free sharing insights into solutions operating in other countries and how we could use that technology to significantly enhance Australia’s tolling ecosystem.

The conference also featured a wealth of fascinating contributions from industry leaders

including Carla Hoorweg, CEO, ANCAP Safety; Matthew Bereni, CEO, Traffic Management Association of Australia; Rita Excell, Head of Transport – ANZ, Amazon Web Services; Pablo Ruiz, Head of Operations – Australia, SICE; Dr Geoff Allan Chief Executive Officer, Austroads and Associate Professor Doug Wilson, Director of Transportation Research Centre, University of Auckland.

In addition to the comprehensive two-day program, a small group of industry leaders convened for an ITS Australia hosted Thought Leadership Dinner on the Tuesday evening before the conference. The guest list, which comprised senior leaders from ITS Australia Platinum and Gold Member organisations was privileged to hear a keynote address from ANCAP CEO Carla Hoorweg, who provided an overview of ANCAP’s program of work and their aspirations to partner with the ITS industry into the future.

The ITS sector will continue many of the important conversations canvassed at Roads, Tolling and Technology at the annual ITS Australia Summit, taking place in Sydney from 13 to 15 August 2024. Under the theme, ‘Safe, Sustainable and Inclusive Transport for Vibrant Communities’, more than 1,000 attendees from Australia and abroad are expected in Sydney to tackle the critical issues and help shape Australia’s transport future.

As Principal Analyst at Interact Analysis, Jamie brings over 15 years’ experience in market intelligence covering components for commercial vehicles including electric vehicles. He holds a BSc in Physics and Astronomy and an MSc in Nanoscale Science and Technology. Jamie is based in Chile.

With its innovative design and patented ‘post/fuse’ system, DOLRE ‘Regular’ barrier delivers MASH TL4-rated protection while limiting the maximum transverse force transmitted to the bridge deck to less than 44 kN/post (22 kN/metre), which equates to only 14% of the ultimate outward transverse design load as per AS 5100.2:2017.

What’s more, at around 80 kg/m installed, DOLRE bridge tra c barriers are significantly lighter than many AS 5100 ‘Regular’ / MASH TL4-rated barrier alternatives.

DOLRE transitions have been designed and tested to provide full longitudinal load transfer between the bridge tra c barrier and connecting roadside barriers.

The DOLRE ‘Regular’ barrier, together with the DOLRE transitions and Thrie-Beam barriers create an engineered continuum of MASH TL4 protection – delivering maximum safety for road users onto and across the bridge structure.

DOLRE’s clean, uncluttered lines and aesthetically pleasing design make it an ideal match for a wide variety of bridge designs and locations. The design allows for rapid installation, as well as rapid repair and reinstatement of the barrier following an impact. DOLRE is also easy to dismantle and remove in times of flood, thereby helping to significantly reduce the risk of damage to valuable bridge assets caused by flood-borne debris.

DOLRE is also available with an extensive range of standard or custom fascia designs and integrated lighting options.

Available in a range of AS 5100:2017 performance levels, including DOLRE Low (MASH TL2 | EN1317 N2), DOLRE Regular (MASH TL4 | EN1317 H2) and DOLRE Medium (MASH TL5+ | EN1317 H4b), there is a DOLRE barrier to suit virtually any bridge, culvert or road embankment application.

All DOLRE systems feature three rails - two rails for the initial vehicle impact and one rail to resist rollover – and one post design per system type, suitable for both sides of the bridge.

Ideal for bridge refurbishment and safety upgrade projects, DOLRE’s ground-breaking ‘low stress’ design restricts the outward transverse force transmitted to the bridge deck during an impact to a fraction of the bridge deck's capacity, thereby minimising the risk of damage to the bridge deck and structure during an impact.

DOLRE bridge tra c barriers can help to extend the serviceable life of many existing bridges - delivering AS 5100 and AS 3845 compliant protection without the need for expensive deck strengthening works or additional reinforcement. DISCOVER MORE

Yunex Traffic has delivered TfL’s ambitious Real Time Optimiser (RTO) programme following a successful, London-wide UTC rollout. This groundbreaking hosted solution is now managing and controlling all of London’s 5,500 traffic signal sites, replacing TfL’s existing system.

Yunex Traffic’s next-generation hosted UTCUX system is now operating right across London. Delivering TfL’s ambitious RTO programme, the huge rollout of this solution effectively replaces TfL’s existing, ageing system. Through the introduction of enhanced user interfaces, together with new functionality, including automatic database updates, bus priority capabilities and the new UTC system future proofs London’s control system and road network.

This new hosted UTC-UX solution was installed over a two-week period, with just five migration days and will enable TfL to deliver reliable and sustainable journeys for all road users, extending to approximately 5,500 junctions and pedestrian crossing sites, supporting over 15,000 SCOOT® links, and making use of over 16,000 SCOOT® Detectors.

“London’s road network plays a vital role in enabling millions of journeys each day and we’re determined to ensure that people can walk, cycle, take the bus and drive as safely and efficiently as possible,” Carl Eddleston, Director of Network

Management and Resilience, TfL commented.

“This world-leading new traffic management system will be a game-changer for us in London. It will use new data sources to better manage our road network, tackle congestion, reduce delay for people choosing healthier travel options and improve air quality,” he said.

An intuitive system that operates directly from a web browser, Yunex Traffic’s hosted UTC-UX solution provides TfL with a range of new features, including at-a-glance system and junction status, and intuitive control features with context sensitive menus. TfL will also benefit from automatic system upgrades, enabling the traffic management team to benefit immediately from new useability and functionality features.

Yunex Traffic’s UTC-UX system also provides TfL with the enabling platform to support the roll out of the company’s FUSION intelligent adaptive control solution, which will revolutionise the city’s traffic signal control, and will replace the SCOOT® system that has been operating across London for more than 30 years. The system will be pivotal in reducing congestion and improving air quality across the city.

Continuously monitoring approaching traffic and developing accurate indicators of congestion and traffic disruption using a wide range of modern data sources, FUSION ensures traffic

management decisions and target outcomes for all road users, not just cars, are policy-driven. So for example, traffic signal timings can be optimized to enable more people and goods to move around the capital’s road network with fewer delays, or to ensure active travel modes and cleaner air outcomes are prioritised.

As a result, road users will benefit from improved journey times, traffic flows and responses to incidents, as well as better data and customer information. In turn, this will lead to reduced congestion and improved air quality, making London and its communities healthier, more sustainable and more attractive places to live, work, play and do business.

Wilke Reints, Managing Director of Yunex Traffic, UK, commented: “We are delighted to be at the heart of this ground-breaking programme, having worked closely with TfL to develop this innovative solution for transport authorities both in the UK and internationally.”

“Building on the UK’s track record of developing modern traffic management and control solutions, RTO provides a robust, reliable system that will meet the needs of the world’s largest cities, helping improve air quality, reduce congestion and make sustainable travel more appealing and accessible to everyone,” Mr Reints added.

This innovative programme was delivered in three distinct phases. Phase One saw Yunex Traffic and TfL’s service delivery team work closely to develop the new, cloud-hosted UTC solution which is now operational as part of TfL’s overall RTO programme. In parallel, Phase Two focused on the development of the new FUSION adaptive control algorithms which, following the successful completion of the UTC-UX implementation, will be deployed across the whole of London over the coming years. Finally, Phase Three now sees Yunex Traffic take responsibility for maintaining the UTC system throughout the rest of the contract term.

An inaugural Careers Expo offers university students the chance to dive into the dynamic intelligent transport sector by spending a day at the prestigious ITS Australia Summit, the nation’s largest annual gathering of ITS professionals.

The final day of the flagship ITS Australia Summit will transform into a bustling Careers Expo, where students from member universities will interact with a broad range of potential employers from government and industry, all actively looking to recruit the next generation of future leaders.

Across the day, students will also enjoy the opportunity to attend an exciting lineup of conference sessions, including two specially curated panel discussions showcasing ITS careers from both the employer and early career professional perspectives.

“As the peak industry body for Australia’s intelligent transport systems sector, ITS Australia is dedicated to fostering the future generation of talent, ensuring the continuous growth and advancement of the thriving ITS industry,” says Susan Harris, CEO of ITS Australia.

“Continuing our commitment, the ITS Australia Careers Expo is the next step in our endeavours, building upon the establishment of the ITS Australia NextGens in 2020, our young Australian transport professionals’ network, and the introduction of our mentorship program in 2021,” Ms Harris said.