How Well Do You Know Your Steel?

CONSTRUCTION CIVIL WORKS CIVIL ENGINEERING V9.05 CONCRETE INSTITUTE of AU STRALIA MARCH 2024 PRINT POST APPROVED - 100001889 PROUDLY SUPPORTED BY PROUD MEDIA PARTNER

EXPERT, INDEPENDENT, THIRD PARTY STEEL CERTIFICATION TO AUSTRALIAN AND NEW ZEALAND STANDARDS

About the Cover

With construction steel products being supplied from multiple sources, there are often questions regarding compliance with the material standards, the origins of products and/or traceability through the supply chain. ACRS Cloud gives steel buyers and users instant assurance over product certificates at the touch of a button, in a secure environment, to provide confidence. Turn to Page 12 for the full

contents MAR 2024 Volume 9 Number 5 Registered by Australia Post Publication No. 100001889 ISSN 2204-7247 TERMS AND CONDITIONS This publication is published by Editorial and Publishing Consultants Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright ©2024 - EPC Media Group 4 24 40 4 Industry News 12 Cover Feature: How well do you know your steel? 16 Case Study: TRUECORE® steel 18 Product Focus 24 Formwork Feature 28 Equipment Feature 34 ETIA Blog: Structural Steel and Reinforced Concrete Standards 36 Project Focus: AURA by Aqualand 40 Precast Technology: Revolutionising Precast Construction in Singapore 44 National Precast News 16 Published by: Editorial and Publishing Consultants Pty Ltd ABN 85 007 693 138 PO Box 510, Broadford Victoria 3658 Australia Phone: 1300 EPC GROUP (1300 372 476) Int’l: +61 3 5784 2210 www.epcgroup.com Publisher and Managing Editor Anthony T Schmidt Phone: 1300 EPCGROUP (1300 372 476) Mobile: 0414 788 900 Email: ats@epcgroup.com National Advertising Sales Phone: 1300 EPCGROUP (1300 372 476) Int'l: +61 3 5784 2210 Email: ats@epcgroup.com Business Development Manager Jodie Gaffney - AmAgo Mobile: 0439 749 993 Email: jodie@amago.com.au Advertising Sales - WA Licia Salomone - OKeeffe Media Mobile: 0412 080 600 Email: licia@okm.com.au

story.

NO CONSEQUENCES - NO REGRETS IS IT TIME FOR A ‘ZERO TOLERANCE’ TO GRAFFITI VANDALISM?

Dear Readers,

Considering the amount of time and resources that have been invested in graffiti prevention programs over recent years, I must admit to being more than just a little disappointed that graffiti vandalism is still so rampant throughout Australia.

Before I continue, I would like to clarify that I do understand the difference between graffiti vandalism and ‘street art’. Indeed, many innercity laneways (in Melbourne in particular) are adorned with ‘legally applied’ street art which is quite magnificent.

When I refer to ‘graffiti vandalism’, I am referring to illegally applied graffiti, particularly the mindless application of tags to practically any and/or every available surface – a crass and destructive act of vandalism by any measure.

Despite this, there are still some ‘cultural and social experts’ that will publicly espouse the value of self-expression gained through graffiti or (my personal favourite) the ‘valuable cultural capital’ that our cities could gain when graffiti gangs post photos of illegal graffiti activities and results on underground Internet sites.

Regardless of the fact that I couldn’t disagree more with these types of comments, I believe that the biggest issue is that any type of positive public commentary about graffiti vandalism can appear as ‘tacit approval’ for vandalism in all its forms.

Graffiti continues to be one of the most expensive and time-consuming public maintenance issues facing councils, householders, government authorities and private sector companies today. To suggest that we should somehow turn a ‘blind eye’ to graffiti vandalism is not only totally misguided, I believe it’s also highly irresponsible.

Even though a number of Australian councils have had significant success in reducing the incidence of graffiti (generally through costly, ongoing programs of rapid removal and repair), it’s a sad fact that even for these councils, removing graffiti and repairing graffitirelated damage continues to be an extremely expensive and onerous day-day-today battle.

Unfortunately, while we may have come a long way in some areas of graffiti management, I believe that one of the main reasons that we continue to suffer at the hands of graffiti vandals is that we, as a society, have failed to address some of the core issues surrounding graffiti. In addition to problems caused by easy access to spray paints, large-format permanent markers, and other graffiti ‘tools of choice’, we are yet to attach any real penalties to graffiti vandalism.

As such, I believe that graffiti vandalism continues to be viewed by many of the perpetrators as a simple case of ‘No Consequence - No Regrets’.

Furthermore, the sort of ‘mixed messages’ that are still being sent about graffiti – both

in relation to the cost and seriousness of the problem, and in terms of trying to attach artistic and/or cultural ‘value’ to graffiti – only serve to confuse the issue.

If you’ll excuse the pun, painting graffiti in a favourable light - for whatever reason - only runs a risk of encouraging more graffiti.

This doesn’t mean that we should throw our hands up in despair, believing nothing can be done or, worse still, take an apologist view and start making excuses for graffiti - quite the contrary.

I believe that the best way to address the problem is to remove that prestige. Rather than allowing graffiti vandals to view their individual ‘tags’ as something to be proud of, a ‘zero tolerance’ approach will see their tags become nothing more than a handy method of identifying and prosecuting repeat offenders.

Granted, widespread media campaigns and major policing operations carry a significant cost; however, when one considers the time, cost and resources currently allocated to removing graffiti and repairing the associated damage, the cost benefits of a ‘zero tolerance’ approach are easy to envisage.

Anthony T Schmidt Managing Editor

2 Construction Engineering Australia • March 2024 EDITORS COLUMN

The

INSPIRATION TO BUILD BETTER BUILD BETTER WITH LYSAGHT

National Construction Code of Australia (NCC) sets the standard for safety, health, amenity and sustainability in building and construction. But the risks of using non-compliant

installers, builders and suppliers liable for cost of replacement, rectification and consequential

The LYSAGHT® range of Australian-made steel building products has been developed, tested and manufactured to not only meet our country’s demanding climatic and geographic requirements but also to provide building designers, builders and owners with the confidence that comes from using our guaranteed compliant products. LYSAGHT® and ® product names are registered trademarks of BlueScope Steel Limited and ™ product names are trademarks of BlueScope Steel Limited. © 2024 BlueScope Steel Limited. ABN 16 000 011 058. All rights reserved. LYH2473 – 02/24 Download the educational white paper “Metal Building Products - A Guide to National Construction Code Compliance” and LYSAGHT® Product Compliance Bulletins at products.lysaght.com/compliance BUILD WITH CONFIDENCE

products are real and can leave

damages.

Bentley Systems Issues Call For Nominations For The 2024 Going Digital Awards In Infrastructure

Winners to be selected and announced at the Year in Infrastructure and Going Digital Awards event in Vancouver

Bentley Systems Incorporated, the infrastructure engineering software company, recently announced its call for nominations for the 2024 Going Digital Awards in Infrastructure The awards, which are judged by independent juries of industry experts, recognise infrastructure projects for going digital advancements in infrastructure. The deadline for nominations is April 15, 2024.

Users of Bentley software are invited to enter their projects in the Going Digital Awards in Infrastructure program, no matter which phase the project is in – preconstruction/conceptual, design, construction, or operations. The three finalists chosen for each awards category win a trip to Vancouver to attend The Year in Infrastructure and Going Digital Awards event as guests of Bentley Systems.

As part of the conference, the finalists will present their projects before the judges, industry thought leaders, and members of the media.

The 2024 Going Digital Awards in Infrastructure categories include:

• Bridges and Tunnels

• Construction

• Enterprise Engineering

• Facilities, Campuses, and Cities

• Process and Power Generation

• Rail and Transit

• Roads and Highways

• Structural Engineering

• Subsurface Modelling and Analysis

• Surveying and Monitoring

• Transmission and Distribution

• Water and Wastewater

These projects recognise innovative advancements and measurable impacts in infrastructure delivery and performance using Bentley software, including Bentley Infrastructure Cloud and Bentley’s iTwin Platform for infrastructure digital twins. Projects may also be recognised for advancements

that empower sustainable development goals in terms of climate action, energy transition and efficiency, circularity of land and water resources, and healthy communities.

In addition to the juried awards, Bentley’s founders will honour select projects representing organisations or individuals whose undertakings contribute notably to infrastructure advancement and/or environmental and social development goals. Every project nominated for an award receives recognition across the global infrastructure community. Through the 2024 Going Digital Awards in Infrastructure program, participants:

• Get their infrastructure projects profiled in Bentley’s Infrastructure Yearbook, which is distributed in print and digital formats to media, government, and industry influencers around the world.

• Enhance their competitive edge by demonstrating to existing and potential clients the value that the participants add to projects through their digital innovations.

• Receive coverage from global media and support from the Bentley team in marketing and promoting their respective projects to the media.

For additional information about the 2024 Going Digital Awards in Infrastructure program, or to nominate a project, please visit: https://www.bentley.com/yii/welcome

Winners of the 2023 Going Digital Awards in Infrastructure celebrate their accomplishments. Nominations are open for the 2024 awards. Image courtesy of Bentley Systems. 4 Construction Engineering Australia • March 2024 INDUSTRY NEWS

2024 ETIA Annual Sponsors Contact us: (02) 9899 7447 | registrations@etia.net.au | www.etia.net.au | Connect with us: Over 40 Design and Construction Workshops O erred PROFESSIONAL DEVELOPMENT | SMALL GROUPS | LIVE STREAM | FACE-TO-FACE VIEW OUR COURSES 2024 UPCOMING COURSES 1. Structural Steel Design Workshop 29 + 30 April 2024 F2F BNE 2. Residential Slabs & Footings Design Workshop 2 + 3 May 2024 F2F BNE 3. Forensic Engineering Workshop 7 May 2024 ZOOM 4. Reinforced Concrete Design Workshop: Module Two 8 + 9 May 2024 ZOOM 5. Metallurgy Materials Workshop 14 May 2024 ZOOM 6. Structural Steel Design Workshop 15 + 16 May 2024 F2F SYD 7. Cold-Formed Steel Design Workshop 21 May 2024 ZOOM 8. Earthquake Design Workshop: Module One 22 May 2024 ZOOM 9. Earthquake Design Workshop: Module Two 23 May 2024 ZOOM 10. Pile Foundations Design Geotechnical Workshop 28 + 29 May 2024 ZOOM 11. Precast & Tilt Up Design & Construction Workshop 30 May 2024 ZOOM 12. Wind Design Workshop: Dynamic & High Rise Structures 4 June 2024 ZOOM 13. Repair & Protection Workshop (Concrete, Steel & Masonry Structures) 5 + 6 June 2024 ZOOM 14. Retaining Walls Design Workshop 12 June 2024 ZOOM 15. Slope Stability Design Workshop 13 June 2024 ZOOM 16. Structural Steel Design Workshop 17 + 18 June 2024 F2F MEL 17. Residential Slabs & Footings Design Workshop 20 + 21 June 2024 F2F MEL 18. Building Code of Australia (BCA) for Engineers Course 25 June 2024 ZOOM 19. Residential Slabs & Footings Design Workshop 26 + 27 June 2024 F2F SYD Paul Uno ETIA Director *F2F SYD (Face-to-Face Sydney) * F2F BNE (Face-to-Face Brisbane) * F2F MEL (Face-to-Face Melbourne)

Keeping Asbestos Out Of The Supply Chain Is Everyone’s Responsibility

A leading Australian expert on asbestos management, John Batty, Managing Director of EDP Consultants, part of the RSK Group, has called for community vigilance to stop asbestos at the source. This action will prevent it getting into the supply chain and ending up in mulch at public sites, potentially harming lives. John is also a member of the Asbestos Education Committee of the Australian National Asbestos Awareness Campaign and is a founding member and former president of the Asbestos and Hazardous Materials Consultants’ Association.

John says the community and businesses must be vigilant about how asbestos is being allowed to enter the supply chain through uncontrolled demolition and disposal practices ending up in mulch and potentially other recycled products.

John, who has 18 years’ experience in asbestos and hazardous materials management in Australia, the UK, Europe, and North Africa, points out that collective action can stop it at the source.

“When construction companies, builders, and mum-and-dad renovators demolish old structures, if an asbestos survey isn’t undertaken, there is a risk that the demolition may impact directly on unidentified asbestos-containing materials. This may inadvertently contaminate the building rubble with asbestos being mixed in with bricks, tiles, and timber. This can then lead to asbestos entering the recycling supply chain where items such as timber are being mulched up to be used as part of garden mulch.”

“As asbestos fragments may be small, there is a risk that they bypass the quality control system and end up in garden mulch."

"Even a small amount of asbestos presents a risk as the hazard is being reintroduced into the community,” says John.

“Homeowners, especially, need to be aware that one in three Australian homes contain some form of asbestos, especially those constructed before 1990. Australia had a true love affair with asbestos, with over 3,000 different products found to contain asbestos. That is why it is so important to identify the type and location of any asbestos-containing material within a property before any refurbishment or demolition work is undertaken.”

John also cautions homeowners to be asbestos aware, particularly when undertaking any maintenance on or cleaning asbestos-containing materials.

“EDP was recently called out to resolve an asbestos issue in Sydney where a homeowner engaged a handyperson to pressure wash their corrugated asbestos cement roof. This caused delamination of the cement, causing harmful asbestos fibres to spread throughout the area. It contaminated the house, garden, boundary fence, the neighbour’s house, and parked cars on the street. This posed a serious risk of asbestos exposure to not only the handyperson, but to the property owner, neighbours and public.”

“The neighbour called SafeWork NSW to complain, the property owner was hit with a clean-up notice and the handyperson did a runner. The final clean-up bill was more than $100,000, as all areas had to be cleaned. This included grass, garden beds and even trees having to be removed as asbestos waste,” says John.

John said there is a way forward through this crisis if we all treat asbestos with respect and ensure we follow current regulations to identify, remove and certify the removal of asbestos. This will ensure we keep asbestos out of the mulch supply chain and in a licensed landfill where it belongs.

Builders, homeowners, renovators, and tradesmen should engage a licensed asbestos assessor or competent person to undertake an intrusive and destructive asbestos assessment prior to any works to ensure asbestos is appropriately identified. It should be safely removed by a licensed asbestos removal contractor and be given a final clearance certification to note the area is safe to reoccupy and the remaining structure is safe to demolish.

“Don’t wait until the demolition has started. Asbestos is not a ‘do-it-yourself’ job.” John added.

“Similar to engaging an electrician or plumber, ensure you engage an asbestos professional at the start. That way, we’re limiting the community’s exposure and creating a safer environment for everyone.”

Master Plumbers Association Of NSW Criticises Federal MP's Call To Ban Gas Nationwide In New Developments

The Master Plumbers Association (MPA) of NSW strongly rebukes the recent statement by Wentworth Federal Teal MP Allegra Spender urging the federal Labor Government to implement a gas ban in new developments across Australia.

Nathaniel Smith, CEO of MPA NSW, denounced Spender's call as a “… ridiculous sign of virtue signalling” that threatens the nation's energy security and endangers vulnerable citizens, particularly during colder months of the year. Smith highlighted the essential role of Gas in mitigating power outages, as evidenced by recent incidents such as those in Victoria.

Contrary to Spender's assertions, Smith emphasised that household gas emissions contribute only one to two per cent of total emissions. He underscored the inadequacy of renewables to meet baseload power demands at present, asserting that they “just don't cut the mustard.”

Furthermore, Smith pointed out a glaring oversight in Spender's argument, noting that Jemena's Malabar (in her neighbouring electorate) plant produces 100% renewable gas known as biomethane. He urged Spender to conduct thorough research before making uninformed comments that could mislead the public. He also said, “The banning of Gas is a State Government matter, and recent bans from Councils would stand up in court.”

“In a time when reliable energy sources are crucial for our nation's welfare, misguided proposals like this only hinder progress,” remarked Smith. “We call upon policymakers to base their decisions on sound evidence and consider the broader implications on energy affordability, reliability, and sustainability.”

MPA NSW remains committed to advocating sensible energy policies prioritising Australians' needs while ensuring a sustainable future for future generations.

6 Construction Engineering Australia • March 2024 INDUSTRY NEWS

Framing that delivered an all-round vision within tight timeframes.

When this distinctive circular designed school required completion for the start of the academic year, light gauge steel framing made from TRUECORE® steel delivered.

Prefabricated and then assembled on site, impressively large roof truss and frame modules were craned to height, then safely and e ciently installed into their elevated positions.

The end result is a state-of-the-art learning space designed in the round and produced on time. Visit truecore.com.au to learn more.

TRUECORE®, BlueScope and the BlueScope brand mark are registered trade marks of BlueScope Steel Limited. © BlueScope Steel Limited 2023 ABN 16 000 011 058. All rights reserved. Image courtesy of School Infrastructure NSW and Austruss. LEARN MORE

Finalists Announced For the 38th Annual Dulux Colour Awards

The finalists for the 38th annual Dulux Colour Awards have been announced by this year’s esteemed judging panel. A stunning 83 projects have been chosen from a record 527 entries, as judged by five design industry professionals from Australia and New Zealand.

As one of the region’s most prestigious awards programs, recognising the exceptional and innovative use of colour in the built environment, the Dulux Colour Awards attract an array of extraordinary projects. Up until 2024, awards have been given in seven categories: Commercial Interior – Public and Hospitality; Commercial Interior – Workplace and Retail; Commercial & Multi- Residential Exterior; Residential Interior; Single Residential Exterior; and, Student work for both Australia and New Zealand, with the coveted Australian and New Zealand Grand Prix awards, representing the pinnacle across all categories.

In an exciting expansion of the program, this year, an additional category has been added in recognition of the burgeoning area of Temporary or Installation Design.

“Expanding our program to award innovative colour use in non-permanent projects, such as exhibition spaces, installations and display suites, acknowledges the level of creativity that is being applied in this sector,” says Andrea Lucena-Orr, Dulux Colour and Communications Manager. “In fact, the sophistication of the projects in this category attests to the relevance of its inclusion. They are inspirational.”

Overall, the judges were impressed by the deeply considered, intelligent design pervading this year’s suite of finalists: hospitality venues and retail stores enticing customers through an understanding of colour psychology; primary schools with classrooms distinguished by

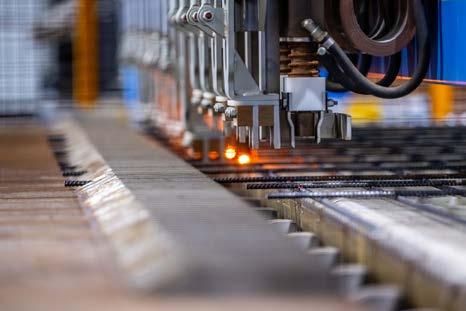

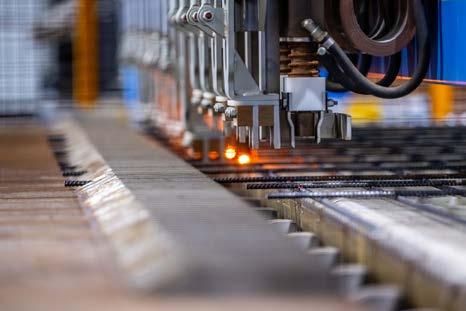

WORLD LEADING REBAR MANUFACTURING EQUIPMENT Supporting and supplying to Australasia's leading reinforcing manufacturers for over 40 years. Backed by MEPGroup Italy, Machinery Indents have the structure, experience and advice to help you with rebar processing equipment • New and Used Machine Sales • Factory Layout Design • Programmed Maintenance • On/Offsite MEP Equipment Training • High Automation and Flexibility • Customer Solutions • Manual Handling Solutions • Technical Assistance • Genuine MEPGroup Spare Parts • Highest Quality Machinery • Manufacturing Process Consultation • Precast - Rebar Manufacturing Equipment MEPGroup Australasian Agent 43 Jesica Road, Campbellfield Victoria, Australia P: +61 3 9357 9769 F: +61 3 9357 0699 E: enquiries@mi-mep.com.au www.mi-mep.com.au 8 Construction Engineering Australia • March 2024 INDUSTRY NEWS

colour to aid learning and navigation; and, human-focused offices with masterful mood-setting palettes.

Having been part of the awards program team for many years, Lucenna-Orr has a unique overview of the shifting colour and design trends.

“This year, biophilia – the affinity of humans with the natural world – is a strong theme, with earthy colours playing a dominant role in interiors,” she says. “Olive greens, warm greys, muted taupes and dusky blues are coming into their own across several categories.”

Another stylistic direction is the bold use of saturated candy-like colours, clashing and contrasting against one another in projects of all types.

“It is an uplifting trend that shows a newfound optimism and confidence to try unexpected combinations for surprising and fun spatial impact,” says Lucena-Orr.

“Architects and designers, as well as their clients, seem to have shaken off the gloom of the lockdown years and are expressing a profound sense of freedom through paint colours that epitomise playfulness and joy.”

The judges have a challenging task ahead but, as five of Australia and New Zealand’s most experienced architects and designers, each adept at using colour assertively in their own work, they have a keen eye for exemplary design, innovation and execution.

The 2024 judging panel comprises Shaun Carter, Founder of Carter Williamson; Monique Woodward, Co-Founder of WOWOWA Architecture; Sarosh Mulla, Director of Pac Studio; Eva-Marie Prineas, Founder of Studio Prineas; and, Nick Travers, Co-Director of Technē Architecture + Interior Design.

The 38th Dulux Colour Awards winners will be announced at an exclusive event at Sydney Opera House Bennelong, during Vivid Sydney on Wednesday 29 May.

For further information on this year’s finalists, judging criteria and terms and conditions, visit:

https://dulux.com.au/colourawards

Dulux Colour Awards 2024 Commercial and Multi-residential Exterior finalist, Macarthur St Amenities Pavilion, Ballarat, by Searle X Waldron Architecture.

Dulux Colour Awards 2024 Commercial and Multi-residential Exterior finalist, Macarthur St Amenities Pavilion, Ballarat, by Searle X Waldron Architecture.

Construction Engineering Australia • March 2024 9 INDUSTRY NEWS

Image: Emma Cross.

INNOVATIVE ‘LOW STRESS’ DESIGN

With its innovative design and patented ‘post/fuse’ system, DOLRE

‘Regular’ barrier delivers MASH TL4-rated protection while limiting the maximum transverse force transmitted to the bridge deck to less than 44 kN/post (22 kN/metre), which equates to only 14% of the ultimate outward transverse design load as per AS5100.2-2017.

What’s more, at around 120 kg/m installed, DOLRE bridge tra c barriers are significantly lighter than many AS5100 ‘Regular’ / MASH TL4-rated barrier alternatives.

SEAMLESS PROTECTION WITH DOLRE TL4 TRANSITIONS

DOLRE transitions have been designed and tested to provide full longitudinal load transfer between the bridge tra c barrier and connecting roadside barriers.

The DOLRE ‘Regular’ barrier, together with the DOLRE transitions and Thrie-Beam barriers create an engineered continuum of MASH TL4 protection – delivering maximum safety for road users onto and across the bridge structure.

CHOICE OF PERFORMANCE LEVELS

WHERE PERFORMANCE AND AESTHETICS MEET

DOLRE’s clean, uncluttered lines and aesthetically pleasing design make it an ideal match for a wide variety of bridge designs and locations. The design allows for rapid installation, as well as rapid repair and reinstatement of the barrier following an impact. DOLRE is also easy to dismantle and remove in times of flood, thereby helping to significantly reduce the risk of damage to valuable bridge assets caused by flood-borne debris.

DOLRE is also available with an extensive range of standard or custom fascia designs and integrated lighting options.

Available in a range of AS5100-2017 performance levels, including DOLRE Low (MASH TL2 | EN1317 N2), DOLRE Regular (MASH TL4 | EN1317 H2) and DOLRE Medium (MASH TL5+ | EN1317 H4b), there is a DOLRE barrier to suit virtually any bridge, culvert or road embankment application.

All DOLRE systems feature three rails - two rails for the initial vehicle impact and one rail to resist rollover – and one post design per system type, suitable for both sides of the bridge.

Ideal for bridge refurbishment and safety upgrade projects, DOLRE’s ground-breaking ‘low stress’ design restricts the outward transverse force transmitted to the bridge deck during a vehicular impact to a fraction of the bridge deck's capacity, thereby minimising the risk of damage to the bridge deck and structure during a vehicular impact.

DOLRE bridge tra c barriers can play a significant role in extending the serviceable life of many existing bridges - delivering AS5100 and AS3845 compliant protection without the need for expensive deck strengthening works or additional reinforcement.

DISCOVER MORE

HOW WELL DO YOU KNOW YOUR STEEL?

CAN

the current construction market, we are seeing an overdue focus on ensuring that compliant products are procured and installed in our building stock. This comes at a time when global markets are providing a wide range of options for supply. As a consequence, methods for demonstrating compliance and giving the end user confidence in the manufacturing process of products are being requested by more builders as they look to mitigate risk.

In

12 Construction Engineering Australia • March 2024 COVER FEATURE

YOU BE SURE YOU’RE GETTING THE STEEL YOU SPECIFIED?

The reinforcing and structural steel markets are not immune to these pressures. With products being supplied from multiple sources, there are often questions regarding compliance with material Standards, the origins of products and/ or traceability through the supply chain.

As the steel supply chain comes under increasing pressure to demonstrate compliance, important questions are raised, including:

• what are the risks of receiving non-compliant material?

• how can we reduce these risks? and

• how do we help to ensure that end-users are getting products that are fit for purpose and meet the relevant Australian and New Zealand Standards?

All products used in building and construction need to comply with the relevant quality and safety standards. For buildings, they fall under the Australian National Construction Code (NCC) or the New Zealand Building Code (depending on jurisdiction), while for infrastructure projects, nominated Standards for compliance are specified. Legislation already exists in a number of states, but increasingly, it is being mandated that all parties along the supply chain of building products need to ensure compliance. In addition, we are also now seeing increasing requests along the materials supply chain for independent compliance monitoring and certification by a trusted third party.

NEW QR CODES

ACRS – EXPERT, INDEPENDENT, THIRD-PARTY STEEL CERTIFICATION

For reinforcing and structural steels, ACRS has a 20-year history of ensuring that both the manufacturers of steels, together with the downstream processors of reinforcing steels, are meeting the requirements of the relevant Australian/New Zealand Standards. This includes mechanical and geometric testing, along with product traceability from source to site.

The ACRS certification process involves an annual on-site assessment of all certificate holders, conducted by experts in steel making. These assessments are further enhanced through witness and independent testing, along with ongoing surveillance of material quality as outlined in the Standards. The ACRS Product certification scheme is independent of manufacturers and holds JAS-ANZ accreditation.

Australian and New Zealand Standards stipulate that all materials, including those being processed downstream, need to be traceable back to the source. They recognise that changes are made to the material and geometric properties of steel during the manufacturing processes.

As a consequence, the Standards require additional testing to be carried out after downstream processes have been completed.

For reinforcing steel, downstream processors include mesh manufacturers and facilities that cut and bend reinforcement to the scheduled lengths and shapes.

For mesh materials there are requirements for geometry, material properties and weld capacities of the joints. For reinforcing bar, the process of straightening and bending may change the mechanical and geometric properties of the product.

Unfortunately, in some cases, a product that was a compliant material from the steel manufacturer is delivered to the end user in a non-compliant state as a result of the downstream processing.

The ACRS scheme monitors all the requirements of the Standards, including testing requirements and traceability, thus providing users of ACRS-certified steels with assurance that the received product is compliant, mitigating risk to the builder.

To ensure that the ACRS-certified product is installed, it is essential that ACRS-certified product is specified up-front, and throughout the procurement process. Importantly, all steel should be checked for compliance when it arrives on site.

In accordance with the relevant Standards, all ACRS-certified products have markings and tags for traceability. Under the ACRS scheme, all tags need to meet the requirements of the relevant Standards and must also include the ACRS Logo and/or certificate number.

The scope and validity of suppliers’ certificates should also be verified in this process.

ACRS certificates all now carry a QR code to circumvent fraudulent certificates. The QR codes may be scanned using the free ACRS Cloud app which is available for download from https://steelcertification.com/cloud

If the QR Code is valid, the app will display the scope of accreditation and other details regarding the certificate in question.

By ensuring that ACRS-certified steel is specified and supplied, the builder/ installer is ensuring the steel products meet the requirements of the relevant Australian and New Zealand Standards, thus minimising the risk of:

3. serious reputational damage.

Specifying and ensuring ACRS-certified products are supplied is as simple as looking for suppliers and processors with the ACRS brand. It is important to remember that any break in the traceability chain may call into question your product's compliance.

1. having to replace product with unknown origins

2. delivering a structure that is not fit for purpose

Construction Engineering Australia • March 2024 13 COVER FEATURE

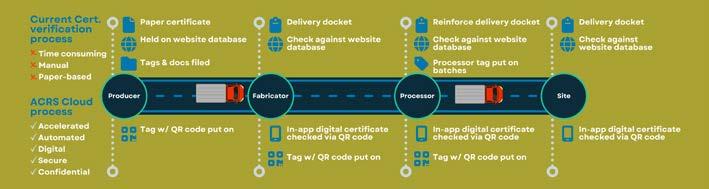

ACRS CLOUD

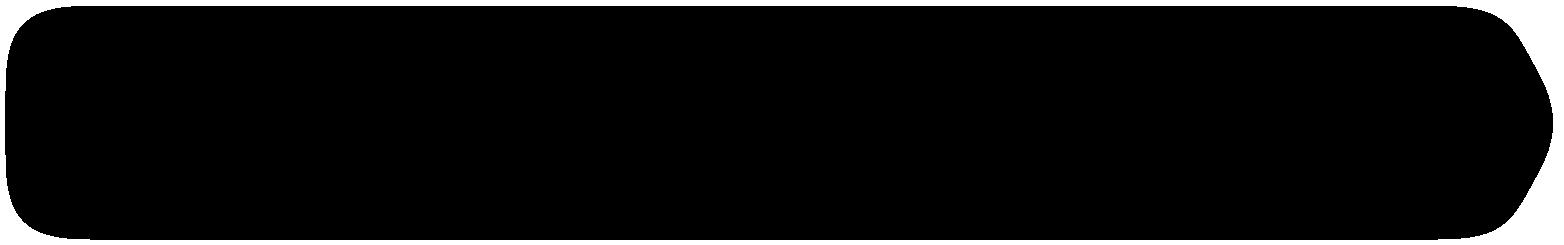

Recognising the industry's move to digital systems and to ensure confidence in the ACRS scheme is maintained, ACRS has launched ACRS Cloud - a digital verifiable conformance scheme. By combining certification and digital product traceability, ACRS will be a trust anchor, providing confidence and traceability to the market.

ACRS Cloud is the first digital certification system of its kind for steel in the Australian and New Zealand construction industries. ACRS Cloud gives steel buyers and users instant assurance over product certificates at the touch of a button - in a secure environment - to provide confidence in products’ conformance to AS/NZS Standards.

Users throughout the supply chain can gain product peace of mind by checking the nature and authenticity of ACRS steel certificates in the new ACRS Cloud app, which is available free on Apple and Android.

The ACRS Cloud system will see batchspecific tags with QR codes put onto steel at steel producers, fabricators, and processors. At each point, these QR codes (and/or those on ACRS certificates) can be scanned on-site to instantly identify the source of a product and its certification details against a ‘single source of truth’, including batch number; bar and tag markings; and verification of product conformance to provide full traceability through the supply chain.

Just like via the ACRS online database, you will be able to search for certificate holders by mill name or country and report any concerns, all in the app.

For certainty over the steel you use, make sure you are specifying ACRS-certified steel, and checking conformance easily in the new ACRS Cloud app. Find out more at: https://steelcertification.com/cloud

The ACRS Cloud app further protects the market from product compliance issues: not just in poor product identification or deliberate misrepresentation, but by making it easier for users to check steel’s provenance at every stage. It also supports best practices for those seeking sustainable steel. Scan the QR Code to download the app today. ASSURANCE IN YOUR HANDS: WHEREVER, WHENEVER 1 2 3 4 DOWNLOAD THE APP SCAN QR CODE on delivery paper/electronic certificate SELECT ACRS ID of certificate in app VIEW CERTIFICATE inc. scope, origin, key dates 14 Construction Engineering Australia • March 2024 COVER FEATURE

How well do you know your steel?

Are you getting the steel you specified?

Does ALL of the steel you’re receiving comply with the right Standards?

With ACRS Certified steels, you can be confident that you are getting the AS/NZS compliant steel you ordered.

By providing an effective, independent, continuous review of both the manufacturer and the fabricator/processor, the ACRS 2-stage product certification scheme, together with the ACRS traceability certification scheme, significantly reduce the risk of non-conforming steels being delivered to your project.

Talk to us TODAY about how ACRS Certification gives you confidence in your steel supply.

ACRS - Independent, Expert Third Party Certification and Verification of Reinforcing, Prestressing and Structural Steels for Compliance with Australian and New Zealand Standards

www.steelcertification.com Ph: (02) 9965 7216 E: info@steelcertification.com ABN: 40 096 692 545

FRAMING MADE FROM TRUECORE® STEEL

ENABLES A STATE-OF-THE-ART, AGED CARE FACILITY TO PROVIDE A TRUE “DOMESTIC” LIVING EXPERIENCE

PROJECT DETAILS:

PROJECT:

BlueCare Sunrise Beach Aged Care Facility, Queensland.

FABRICATOR:

Mitchell Crisp, Principal Ultimate Steel Framing

BUILDER:

Kent Belcher, Project Manager Badge Constructions

ARCHITECT:

Pino Gentile, Principal Architect Thomson Adsett

CLIENT:

Lavinia Dack, Property Group General Manager UnitingCare Queensland (UnitingCare)

PRINCIPLE STEEL PRODUCT:

40,000 lineal metres of LGS made from TRUECORE® steel

PHOTOGRAPHER:

Construction photos by Travis Cooke Badge Constructions, renders by Thomson Adsett.

ADDRESS:

4 Grasstree Court, Sunrise Beach, Queensland

Designed and prefabricated off site, light gauge steel (LGS) framing made from TRUECORE® steel allows a critical aged care facility to be built on schedule and on budget

Located at Sunrise Beach in the Noosa Shire, Phase 1 of the Sunrise Beach Aged Care facility is scheduled to be complete by mid December 2023. In an area where the demand for aged care is growing faster than most other parts of Australia, the first 102 residents will be welcomed into their quality new homes early in 2024.

By utilising LGS made from TRUECORE® steel for the walls, trusses and bracing, the project achieved the following benefits:

PREFABRICATED FOR A FAST BUILD

Designed and prefabricated off site, LGS framing required builder Badge Constructions to work closely with fabricator Ultimate Steel Framing in a more considered manner, right from the start of the project. Items such as safety, PWD rails and TV recess areas were all factored into the framing from the start, helping to reduce mistakes and delays.

LIGHTWEIGHT AND STRONG FILLS THE DESIGN BRIEF

The brief for the Sunrise Beach Aged Care Facility required the provision of a true “domestic” living experience with small clusters of private rooms centered around courtyards or views. With an impressive strength to weight ratio, LGS framing made from TRUECORE® steel supports wide spans that form the backbone of these light-filled villas.

TERMITE PROOF WITHOUT INSECTICIDES

LGS framing made from TRUECORE® steel is termite proof and doesn’t require treatment from insecticides. For client Uniting Care Queensland (UCQ), this was an important consideration for its residents. Additionally, TRUECORE® steel won’t warp, twist or shrink even in Queensland’s tropical environment.

LIGHTWEIGHT AND EASY TO HANDLE

Lightweight and strong, LGS framing made from TRUECORE® steel can be easily handled on site with fewer tradespeople. Consequently, labour was split into smaller groups to work on multiple fronts, further speeding up on-site progress.

16 Construction Engineering Australia • March 2024 CASE STUDY

PROJECT HIGHLIGHTS

Reflecting recommendations set out by the Royal Commission into Aged Care Quality and Safety, each of the private accommodation rooms at Sunrise Beach Aged Care Facility is designed to operate like a small household, offering residents a better lifestyle and superior quality of care.

Pino Gentile, Principal Architect at Thomson Adsett, articulates his brief. "The design of the Sunrise Beach Aged Care Facility responds to ‘Person Centred Care’. Homes are designed to provide residents with an authentic domestic experience and are modeled in small clusters of 8-9 private rooms. Each room is located around a series of light-filled courtyards, or alternatively provides views of the adjacent national park. Residents can easily access common areas and spaces in order to socialise or get food and drink from the house kitchen whenever they want to.”

In a location where the demand for aged care accommodation is continuing to grow faster than most other parts of Australia, the timely provision of quality new homes for residents is critical.

Using LGS framing made from TRUECORE® steel, Builder Badge Constructions was able to significantly reduce construction time, which will be critical to completing Phase 1 of the facility by mid December 2023. In early 2024, 102 residents will be welcomed to their new homes in this next generation aged care facility.

Mitchell Crisp, Principal of fabricator Ultimate Steel Framing said "LGS framing made from TRUECORE® steel has allowed us to work around the limited onsite space. Smaller cranes were used, saving costs and positioning packs in out of the way locations. The ease of handling LGS frames meant labour could be split into smaller groups to work on multiple fronts, again helping accelerate the rapid progress of the job.”

“We are thrilled with the building speed achieved through the adoption of light gauge steel (LGS) framing. Choosing steel has more than paid for itself in construction time savings.”

UnitingCare’s Group General Manager Property, Lavinia Dack

LGS framing made from TRUECORE® steel has the added benefit of staying straight and true. The framing is precision made and remains accurate to measurements. Prefabricated LGS frames made from TRUECORE® steel also have the benefit of having pre-punched service holes, which allows follow-on trades to feed services through the framing for a fast install without the need for additional drilling.

The Sunrise Beach development is one of the largest applications of LGS in the Noosa region, including over 40,000 lineal metres of TRUECORE® steel. Supplied by Australian steel manufacturer BlueScope and fabricated locally by Ultimate Steel Framing, TRUECORE® steel supports UnitingCare’s commitment to use local suppliers.

The content of this case study is based on statements made by the source/s listed above and is a reflection of their views and experience. Same/similar results are not guaranteed for each user and outcomes may vary across projects. TRUECORE®, BlueScope and the BlueScope brand mark are registered trade marks of BlueScope Steel Limited. © 2023 BlueScope Steel Limited ABN 16 000 011 058. All rights reserved.

Construction Engineering Australia • March 2024 17 CASE STUDY

INNOVATION THAT’S MAKING ACCESSIBILITY MORE ACCESSIBLE

The new pre-engineered, adjustable Ezibilt™ system is an efficient solution for creating safe, compliant ramps, stairs and walkways. Compatible with Moddex handrails and balustrades, it’s a revolutionary innovation from Moddex that is already making accessibility more accessible in a wide range of applications, from commercial buildings to public spaces.

Ezibilt is designed for long-lasting performance and durability. Manufactured off-site and installable with simple tools to achieve compliance with council regulations, it is supplied in modules that interconnect, allowing for any number of configurations to take care of all your access requirements on any site.

Features and benefits include:

• Designed for simple assembly – installation doesn’t require skilled staff

• Adjustable and compatible, with the flexibility to fit a wide range of sites

• Delivered as a ready-to-go kit set that can be installed in about two days

• Reduces the need for complex, on-site measuring.

POPS UP IN HOURS - LASTS FOR DECADES

The new Ezibilt™ system takes relatively little time to construct when compared to traditional methods. What’s more, it can be relocated easily, in the same way, with some simple tools — as all the components are pre-engineered to be compatible.

Even though it’s designed to go up in several hours, it has a design life of 50 years.

SAFE, SECURE AND COMPLIANT

The Ezibilt™ system is load-rated to 5 kPa, with two product configurations available for sites of varying heights. It is also designed to comply with the Australian Standards of AS1428.1-2021, which set out a blueprint for mobility, specifically delineating the spatial needs for wheelchair circulation.

The reputation of Moddex has been built on compliance and quality, so you can rest assured that you will have a compliant solution that takes into consideration size and turn angles, clear pathways, visual contrast and cues, gradients, protrusion limits, appropriate components and more. Not only must these structures meet safety requirements, but they must also be durable and compliant with building codes and regulations to ensure a safe and secure space for all users — issues that were top of mind for the Moddex design team.

Additionally, when the handrails and balustrades are added, they can be assembled with little more than a cordless drill and a proprietary Moddex driver bit that secures the tamper-proof Dexx® Locking Screws. These make the system very difficult to vandalise or scavenge.

EASY TO BUILD. EASY TO MAINTAIN. EASY TO SPECIFY.

As with all Moddex solutions, a durable, highquality solution is only the start. You have the support of the entire Moddex end-to-end support system, where everything fits. If you need replacement components, they’re on the shelf, ready to be delivered nation-wide. If you

have a design challenge the product can’t meet, the Moddex team are always ready to help with bespoke engineering solutions.

What’s more, there’s downloadable BIM content, to make configuring and specifying Ezibilt simple, that you can find at https://moddex.com

18 Construction Engineering Australia • March 2024 PRODUCT FOCUS

NCC COMPLIANCE WITH AUSTRALIAN-MADE AND TESTED LYSAGHT® STEEL BUILDING PRODUCTS

The National Construction Code (NCC) plays a crucial role in ensuring the safety, health, and amenity of buildings in Australia. To enhance compliance with the NCC, two key measures - specifying Australian-made steel building products and conducting product testing according to Australian Standards - can prove instrumental. This feature delves into the significance of these measures in maintaining and elevating construction standards across the Australian building industry.

• Specifying Australian-made steel building products: Choosing Australianmade steel building products aligns with the broader goal of supporting the domestic industry. A preference for locally sourced materials not only contributes to the national economy but also holds distinct advantages for compliance with the NCC.

• Quality Assurance: Australian-made steel products are subject to stringent quality control measures. These products consistently meet, and often exceed, industry standards, providing a foundation of structural integrity and reliability.

• Traceability: The transparency embedded in the supply chain of Australianmade products facilitates traceability, a critical factor in satisfying the NCC's stringent requirements, which demand a meticulous understanding of the origins and composition of construction materials.

• Environmental Considerations: Beyond quality, the emphasis on environmentally sustainable practices in locally produced steel aligns seamlessly with the NCC's commitment to fostering sustainable building practices.

• Timely Delivery: Reduced lead times for Australian-made products contribute significantly to timely project completion — an aspect intricately tied to the NCC's stringent timelines and requirements.

PRODUCT TESTING TO AUSTRALIAN STANDARDS

In tandem with the specification of Australian-made steel products, subjecting materials to thorough product testing according to Australian Standards emerges as an indispensable step in ensuring compliance with the NCC. This facet delves into the realm of safety, performance, and the durability of building materials.

• Safety Assurance: Rigorous testing, a hallmark of Australian Standards, provides designers with reliable product performance data to inform their structural design removing ambiguity and reducing the risk of structural failures, thus securing occupant safety - a cornerstone of NCC regulations.

• Durability: Product testing scrutinises the durability of materials, aligning seamlessly with the NCC's emphasis on longevity and resilience in building construction. This aspect not only safeguards investments but also contributes to the sustainability of structures over time.

• Compliance: Meeting the specified Australian Standards inherently ensures compliance with the relevant sections of the NCC. This provides a streamlined and coherent approach to regulatory adherence, reducing complexities in navigating the NCC landscape.

20 Construction Engineering Australia • March 2024 PRODUCT FOCUS

Sleek, modern home with Dominion® walling

NCC COMPLIANCE AND LYSAGHT® PRODUCTS

As a BlueScope company, Lysaght has a long-term commitment to both local manufacturing and adherence to Australian Standards.

Lysaght commenced manufacturing steel building products in Australia over 100 years ago and has grown to be the country’s largest roll-formed products manufacturer. Lysaght locally sources its base products, including COLORBOND® steel and ZINCALUME® steel from BlueScope, in keeping with a commitment to sustainable and responsible sourcing.

BlueScope’s Port Kembla and Western Port manufacturing facilities have both achieved certification to the global ResponsibleSteel™ initiative - the global steel industry's multi-stakeholder sustainability standard and certification program, designed to ensure that customers, stakeholders and consumers can be confident that the steel they use has been sourced and produced responsibly.

Similarly, Lysaght’s commitment to product quality and testing has long been a core component of its success. Lysaght established its in-house product research and testing facility over 50 years ago. At this NATA accredited facility Lysaght is able to conduct rigorous and ongoing development and testing of products to ensure ongoing alignment with Australian Standards and now NCC requirements.

Increasingly regulatory authorities are requiring documentary evidence of compliance. Since 2019, Lysaght has released a series of documents, including supplier declarations and product advisory bulletins detailing how its products comply with the NCC. The company’s website is a valuable reference source for builders, architects, building owners and others with an interest in NCC compliance details.

To enable direct referencing, Lysaght references the NCC legislation in its technical documentation. All LYSAGHT® products are manufactured and tested to the Australian standards referenced in the applicable product documentation. Lysaght can also provide project-specific product testing certification from its own NATA accredited facility if required.

For more information about Lysaght and NCC Compliance, visit: https://lysaght.com

1300 240 337 www.enviroblast.com.au EnviroBlast Australia Mobile Media Blasting - Soda & Garnet • Specialising in Concrete preparation for Carbon Fibre application • Abrasive & Non-Abrasive Blasting • Paint, rust & contaminant removal from many substrates • Line marking removal • Graffiti removal & protection • Removal of sealers & coatings • Creation of non-slip surfaces • Compact machinery for easy access • Low media usage which means less environmental issues with reduced containments and dust • Suitable for confined space blasting size of ad .... 88mm x 135 mm DIRTYSPECIALIST 2", 3" & 4" DIESEL TRASH PUMPS Australian Pump Industries Aussie Pumps 02 8865 3500 aussiepumps.com.au AUSSIE “SITE BOSS” ü Electric start ü Dirty water specialist ü Self priming to 7.6m ü Fast, easy set up ü Flows to 1,600 lpm ü Solids handling CALL NOW!

Construction Engineering Australia • March 2024 21

LYSAGHT® products are tested at Lysaght’s own NATA accredited facility

DYNAMIC INFRASTRUCTURE leverages all available asset condition data, reports and images - regardless of the format or age - to build a detailed chronological ‘health record’ for each bridge asset - providing you with immediate access to all your asset data and empowering you with actionable insights that lead to cost savings and improved maintenance e ciency.

With DYNAMIC INFRASTRUCTURE there is no need to change your current bridge inspection methods or service provider. The system utilises all existing data and reports, regardless of the format or age -including paper-based engineering drawings and plans, photos, paper-based inspection and condition reports, together with digitised data and images - to build a detailed ‘health record’ for each bridge asset.

Using DYNAMIC INFRASTRUCTURE’S AI-enabled technology to identify faults and damage e ectively transforms the entire process from a subjective one that relies on an individual to find and identify all faults on a structure and then make a judgement call on severity, to an objective one where over 99% of faults are identified, categorised, logged and then rated for severity against a global database of over 30,000 bridges and counting.

DYNAMIC INFRASTRUCTURE enables you to identify defects before they escalate into major failures, helping you to better manage risk and prevent unexpected expenses. It can even help you maximize warranty coverage through automated repair tracking - providing you with full visibility from the field to the o ce.

T: 1300 552 878 www.dynamicinfrastructure.com.au

How long would it currently take you to find ALL of the historic inspection, repair and maintenance data for just one of your bridge assets? A couple of hours? A couple of days? Longer?

With DYNAMIC INFRASTRUCTURE you can access ALL of your bridge asset data – including plans and historic inspection data (manual reports) as well as details of faults, damage, repairs and maintenance –within a matter of seconds.

All of the data, for each of your bridge assets, right at your fingertips… in one comprehensive, chronological digital ‘health record’ …and the massive time saving is only one of the benefits!

DISCOVER MORE

By crafting tailor-made solutions like a 21-metre Table Lifting System, Doka has helped boost construction efficiency on the second-highest building in the US city of Detroit.

The Hudson’s Site project, a mixed-use development located in downtown Detroit, Michigan, includes two buildings: a 209-metre high-rise tower and a 70-metre mid-rise building, separated by a through-cut. The tower will house modern offices, event venues, high-tech residences, and a luxurious 5-star hotel. It is expected to be completed in 2024 and will be the second tallest building in Detroit after the Renaissance Center.

To meet the special requirements of the project, which has limited on-site space due to its urban location, Doka developed a system that eliminates the need for traditional crane lifts between level-tolevel transitions. Doka’s engineers came up with a self-climbing Table Lifting System solution, spanning a total of 21-metres, that is exclusively designed to lift slab formwork across six levels of the Hudson’s Site Tower. The hydraulic Table Lifting System not only increases efficiency by strongly improving the speed

of material hoisting, but also helps ensure safety – a paramount aspect in every Doka endeavour.

Additionally, the adaptability of Doka's Framed formwork Frami S Xlife system proved essential in navigating the project's 112 different column cross-sections. Brian Gulick, Superintendent with Barton Malow, commented: “Doka’s personalised Table Lifting System enabled us to operate the construction site without the use of crane lifts between level-to-level transitions, which helped us to optimise construction speed.”

Doka’s cutting-edge BIM Revit model is designed to analyse potential suspension points of the climbing systems of the core and slabs, detecting and preventing possible clashes on site by recoordinating the schedule in advance. Doka ensured early-on that the right solutions were in place for this complex project by collaborating closely with all stakeholders, which enabled the project to stay on track and meet its ambitious schedule.

Doka’s engineers faced further challenges, such as providing the right formwork solutions for the skyscraper’s unequally-shaped core. Doka crafted

NEW 100% RECYCLABLE MANHOLE & STORMWATER PIT FORMWORK

In an Australian first, a local specialist manufacturing company has introduced a new version of manhole formwork made from HDPE plastic as a proven alternative to the heavy steel used on construction sites since the 1920s.

Plastic Formwork Hire has reimagined the production of conventional steel manhole and stormwater pit formwork and introduced a 100% recyclable HDPE plastic version, removing costly management and maintenance issues previously associated with the development of stormwater pits and manholes.

Manufactured from a lightweight and durable High-Density Polyethylene (HDPE) material, the HDPE Formwork is designed to be portable and easy to assemble. It removes the need for heavy transport haulage and machine installation for heavy steel forms, amongst other efficiencies.

Owner and founder Trevor Davis came up with the concept after years of cleaning and repairing steel forms in the sandblasting and industrial painting industry.

“While construction materials and processes have changed dramatically over the years, the use of heavy, steel formwork hasn’t altered since the 1920s.”

“Steel formwork is inherently difficult to manage and maintain, and will cost construction projects

countless man-hours in storage, maintenance, cleaning, installation, and transport,” he said.

“HDPE plastic liners had already been introduced as a requirement for the internal walls of manholes to protect the concrete from sewage gasses. It is strong, flexible, and easy to install, so it made perfect sense to use the material in the manhole forms.”

The HDPE formwork does not rust or degrade, it will not bend out of shape and can be fitted together easily by one person. The lightweight panels are easy to lift and assemble and can be cleaned with a pressure hose or cloth,” Trevor said.

Trevor and his team have spent over two years mastering the designs and piloting the formwork. The products are NATA-certified and have been tested in some of the most rigorous conditions.

“One of the most frequent pieces of feedback we receive is how much lost time has been saved by site workers in installation and cleaning. Foremen cannot believe that heavy haulage transport and lifting equipment are no longer required for starters. It has simplified the process in ways that no one had ever envisaged,” Trevor continued.

Plastic Formwork Hire provides delivery and collection within 25km of a hire depot at no cost and cleaning after use is included in the hire price.

Jim Carruthers from Carruthers Contracting is an

a custom-made formwork solution featuring the large-area formwork Top 50, and the Super Climber SCP, which is recognised as one of the fastest selfclimbing formwork solutions on the US market. A mini crane mounted at the top level of the Super Climber, supported the installation of heavy steel embeds, which significantly reduced the crane’s period of use. This tailored solution achieved an average five-day cycle time instead of the usual seven-day cycle time, resulting in a significant acceleration of the construction while increasing efficiency and safety. What’s more, an integrated concrete placing boom facilitated the concrete pouring of the core, slabs and columns.

A self-climbing Xclimb 60 Protection screen was designed for slab edge protection, as were several screens with integrated storage platforms as an extra feature.

early adopter of the HDPE Formwork and has been using it on sites for almost two years. He said his team loves it because it is extremely easy to set up, disassemble and especially move.

“(The formwork) is a lot easier to use and clean and it only takes a couple of guys to bolt it together and install it. We don’t need machines to lift it in and out,” he said.

“As far as costs go, there are a lot more efficiency and a lot of cost savings when you don't need to pull an excavator off another job to drive over and back just to lift forms.”

The HDPE comes in a range of sizes and form types that can be ordered via an online booking website that offers incentives for advanced bookings.

As part of Plastic Formwork Hire is currently recruiting regional distributors to manage dispatch and local inventory.

Visit www.plasticformworkhire.com.au for more information on bookings and distributor opportunities.

TAILOR-MADE FORMWORK PROPELS HUDSON'S SITE TO NEW HEIGHTS IN DOWNTOWN DETROIT

24 Construction Engineering Australia • March 2024 FORMWORK FEATURE

THE SIGNIFICANCE OF COMPLYING WITH AS/NZS STANDARDS FOR METAL DECKING IN CONSTRUCTION

When it comes to constructing buildings and infrastructure, the use of metal decking has become increasingly popular due to its numerous advantages over traditional materials. Not only does metal decking offer exceptional strength and durability, but it also provides significant cost savings and contributes to faster construction times.

However, to ensure the highest quality and safety standards, it is crucial to comply with relevant industry standards.

In this article, we will delve into the importance of complying with three essential Australian/New Zealand standards: AS/NZS2327, AS/NZS1397 for metallic coated steel products, and the fire rating to AS/NZS1530.

1. AS/NZS2327 – COMPOSITE STRUCTURES FOR BUILDINGS.

AS/NZS2327 is the standard that governs the design and construction of composite steelconcrete structures for buildings. It outlines the requirements and specifications for composite slabs, beams, and columns that incorporate metal decking as a crucial component of the structural system.

Compliance with AS/NZS2327 ensures the following:

a. Structural Integrity: Buildings constructed with composite steel-concrete structures using metal decking will have superior strength and load-bearing capacity, ensuring the safety of occupants and longevity of the structure.

b. Stability and Resilience: Compliant metal decking solutions contribute to the stability and resilience of the building, making it better equipped to withstand external forces such as seismic events and extreme weather conditions.

c. Code Compliance: Following AS/NZS2327 demonstrates adherence to nationally recognized standards and guidelines, which may be a legal requirement and is essential for obtaining necessary permits and approvals from regulatory authorities.

26 Construction Engineering Australia • March 2024 FORMWORK FEATURE

2. AS/NZS1397 – METALLIC COATED STEEL PRODUCTS.

AS/NZS1397 specifies the requirements for continuously hot-dip metalliccoated steel sheet and strip products. These products, commonly used for metal decking, are coated with materials like zinc or zinc-aluminium alloy to enhance corrosion resistance and increase the service life of the decking material.

Compliance with AS/NZS1397 offers the following advantages:

a. Corrosion Resistance: Metal decking manufactured in accordance with this standard will have superior resistance to corrosion, even in harsh environmental conditions, which is critical for ensuring the long-term structural integrity of the building.

b. Quality Assurance: Following the requirements of AS/NZS1397 guarantees that the metal decking meets stringent quality standards and has undergone testing to ensure its suitability for construction purposes.

c. Sustainability: Longer-lasting metal decking reduces the need for frequent replacements, contributing to a more sustainable construction industry by reducing material waste.

3. FIRE RATING TO AS/NZS1530 – METHODS FOR FIRE TESTS ON BUILDING MATERIALS, COMPONENTS, AND STRUCTURES.

AS/NZS1530 outlines methods for determining the fire performance of various building materials, components, and structures, including metal decking. It assesses the reaction to fire, spread of flame, and the ability of the material to resist fire and heat.

Complying with AS/NZS1530 for fire rating provides the following benefits:

a. Fire Safety: Metal decking that meets fire rating standards contributes to the overall fire safety of the building, allowing occupants more time to evacuate in the event of a fire.

b. Building Code Compliance: Many building codes mandate adherence to specific fire rating standards for different building elements. Complying with AS/NZS1530 ensures that the construction is in line with these codes and regulations.

c. Insurance and Liability: Insurance companies often require buildings to meet specific fire safety standards to provide coverage. Compliance with fire rating standards reduces potential liability and insurance risks for building owners and stakeholders.

Complying with AS/NZS2327, AS/NZS1397 for metallic coated steel products, and fire rating to AS/NZS1530 is of paramount importance in the construction industry. These standards collectively ensure the structural integrity, durability, and fire safety of metal decking systems, contributing to the overall safety and reliability of the buildings in which they are used.

NEED FURTHER INFORMATION?

The FTI BlueDeck Composite™ metal decking system has achieved complete compliance, providing users with a sense of confidence and assurance. BlueDeck Composite™’s adherence to the following standards has been confirmed as compliant.

• AS/NZS2327: Comprehensive Composite Action

• AS/NZS1397: Metallic Coated Steel Products

• Fire Rating to AS/NZS1530

For further information on BlueDeck Composite™, you can get in touch with FTI Group at 1300 751 701 or explore their website at ftigroup.com.au

Construction Engineering Australia • March 2024 27 FORMWORK FEATURE

AUSSIE HYDRAULIC TANKER PUMP A WINNER

Australian Pump Industries are pleased to report the huge take up of their high-flow cast iron semi-trash hydraulic drive pump. The 3” self-priming pump, called the Aussie B3XR-A/ST, is close coupled to a powerful 22 cc hydraulic motor that makes for a compact installation and less maintenance.

With a maximum flow of 1,500 litres per minute and a maximum head to 31 metres, the big 3” pump can handle a wide range of applications, including dust suppression, drill rigs, tankers, mine dewatering and moving contaminated water.

Hydraulic drive pumps derive their power from the main engine of the vehicle or equipment on which they are mounted. Thus, operators can get the advantages of virtually unlimited power, delivered through a flexible drive system that doesn’t depend on shaft or separate engines.

The flexibility of the drive system and the compact design means the pump can be placed

in the most appropriate location, with huge operational cost reductions and advantages.

These advantages include a major reduction in maintenance costs and labour with the elimination of a separate petrol or diesel engine to drive the pump.

“This pump really suits applications in the tanker market - delivering a high flow, hydraulic drive pump that will handle dirty water,” said Aussie Pumps Product Manager Dolphie Mascarenhas.

“At a maximum head of 26m the pump will deliver 800lpm flow. That’s impressive for a 3” self-priming semi-trash pump.”

“Not surprisingly, we’re seeing a lot of tanker operators upgrading to the Aussie B3XR-A/ST from their existing pumps, many of which have significant performance issues - particularly when it comes to dealing with the harsh Australian operating conditions and dirty water,” he said.

The 3” pump has excellent self-priming characteristics, with the ability to draw water from pits of depths of 6 metres. It has been designed to pass solids up to 35mm, making it suitable for handling solids-contaminated water.

The new Aussie semi-trash pump is fitted with a silicon carbide mechanical seal with an alumina counterface with nitrile rubber elastomers. It also features a stainless steel wear plate and stainless steel motor shaft.

The pump includes a front opening clean-out port that makes it easy to access the pump’s internals. That’s a huge advantage as this means the unit can be cleared of chokes in situ without having to dismantle pipework.

The hydraulic motor requires 22cm3 per rev at 150 bar pressure, that’s equivalent to 7.5kW.

“We chose Italian hydraulic motors because of their reputation for quality and commitment to aftermarket support,” Dolphie said.

The big pump is also available with a cast 316 grade stainless steel impeller making it suitable for handling more abrasive liquids.

For applications that are really corrosive, Aussie offers a fully cast 316 stainless steel pump. These have been installed in tankers used for transporting whey from dairies in Tasmania and are even in use with the Australian Army.

Like all Aussie Pump products, the units are designed and built to ISO 9001 quality standards. Australian Pump believes that users deserve the best quality and won’t offer any product that is not built to their stringent requirements. These Aussie GMP pumps come with a 3-year warranty against faulty workmanship or material.

Further information including a free catalogue is available from Australian Pump Industries 02 8865 3500 and online at: aussiepumps.com.au

A lot of tanker operators upgrading their old existing pumps to the Aussie B3XR-A/ST. The flexibility of the drive system and the compact design allow the pump to be placed in the most appropriate location, with huge operational cost reductions and advantages. 28 Construction Engineering Australia • March 2024 EQUIPMENT FEATURE

The Aussie 3” B3XR-A/ST semi-trash pump with hydraulic drive is a compact installation, delivering high flows with minimal maintenance required.

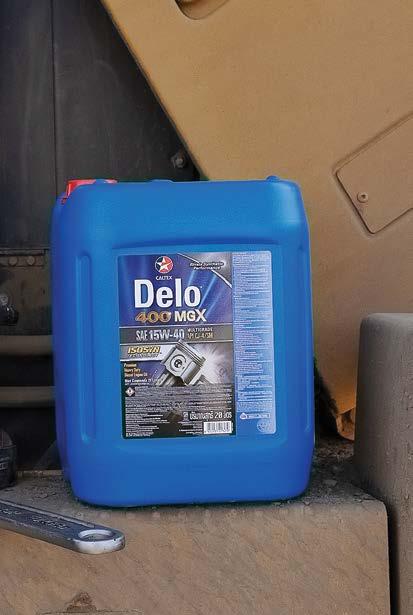

Protecting road work crews from errant vehicles is just as important on suburban streets as it is on major highways and arterial roads. ASSESSED, APPROVED & RECOMMENDED FOR ACCEPTANCE throughout Australia by ASBAP (Austroads Safety Barrier Assessment Panel), the Scorpion II® METRO TMA is not only THE FIRST TL2 TMA to be fully tested and approved to the latest MASH Standards, it is currently THE ONLY TL2 Truck Mounted Attenuator to be successfully TESTED, PASSED & ELIGIBLE to the current MASH Standards. Ideal for use on suburban streets and roads with posted speed limits of up to 70 km/h, Scorpion II® METRO TMA delivers the ideal combination of life-saving MASH TL2-certified impact protection in a compact, easy-to-manoeuvre size. THE EQUIPMENT YOU NEED – THE SERVICE YOU EXPECT A1 Roadlines Pty Ltd | 89 Rushdale Street, Knoxfield, Victoria 3180 | www.a1roadlines.com.au P: 1300 217 623 (A1ROAD) | F: (03) 9765 9499 | E: sales@a1roadlines.com.au Worksite safety on suburban streets… We’ve Got You Covered Scorpion II® METRO Let’s go further™ IN THIS BUSINESS, YOU NEED THE BEST TO SUCCEED When your business is under pressure to deliver you need to maintain your engine at its best. New Caltex Delo® is formulated with our innovative ISOSYN™ Advanced Technology to give you excellent durability, reliability, and efficiency. Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

CALTEX RETURNS WITH FIRST-CLASS BUSINESS SOLUTIONS

Caltex has been a dependable partner for generations across Australia, with the brand ready and committed to support customers, partners and suppliers in a whole new way.

Backed by Chevron – one of the world’s leading energy companies with more than 70 years of history in Australia – Caltex offers its customers high-quality fuels, engine oils, lubricants and more, including the new fully adaptable StarCard fleet management system.

Supporting this, Caltex is currently strengthening its distribution network, ensuring the prompt supply of products, to keep the country moving.

Following Chevron’s acquisition of Puma Energy (Australia) Holdings three years ago, which included a national network of retail locations, they’re now embarking on a rebranding project that will see most Puma Energy sites change to Caltex by the end of the year.

Beyond the retail experience, Caltex offers innovative industry-leading technology, such as the specially formulated fuel system-cleaning ingredient Techron®, which is available in every fuel grade – helping your car’s engine deliver maximised power, better fuel economy, better acceleration, a smother drive, and reliable performance.

On the lubricants side, diesel engines will experience Caltex Delo® ISOSYN Technology, the brand’s high-performance diesel engine oil offering, while Havoline® will be available for petrol engines.

By offering a comprehensive fuel and lubricant offering, Caltex is a one-stop-shop, with solutions available for every kind of application, from construction to mining, agricultural, power generation, transport, and global marine.

TOP-TIER LUBRICANTS AND FUEL THAT KEEP YOU MOVING

Protecting your investment in plant equipment with high-quality lubricants simply makes sense. Caltex Delo® with ISOSYN® Technology, helps protect vital diesel engine parts, provide engine durability and extend service intervals, to help minimise operating costs.

Drawing on over 88 years of expertise, ISOSYN® Technology combines premium base oils with high-performance additives to deliver engine component protection rivalling synthetics.

This high-performance additive formulation helps provide exceptional soot dispersion and prevent deposit build-up, ensuring vehicle performance which can contribute to extended service intervals and minimised downtime.

The road to the modern-day Delo® range is one based on marketplace innovation.

In 1935, Chevron, then known as Standard Oil of California, partnered with Caterpillar Tractor (CAT) to formulate an oil to lubricate the highspeed diesel engines that CAT was planning to build.

This joint venture between the two companies resulted in a multipurpose motor oil known as Delo®, an acronym for Diesel Engine Lubricating Oil. In the 1940s, Delo® was the first brand in the world to develop compound diesel engine oil that could be used in any diesel engine, and in the 1950s, it pioneered the first successful multi-grade engine oil, with innovations over the following decades setting industry benchmarks for long-term engine performance.

Adding further confidence, Chevron has the capabilities to manufacture lubricants by producing its own base oil, maintains 21 individual blending plants, globally (including

joint ventures) and owns Oronite, one of the world’s biggest additive companies.

Delo products are sold in 155 countries, and importantly, Chevron internally controls the three pieces required to manufacture lubricants, by producing its own base oil, it controls Oronite, one of the world’s biggest additive companies, while it also maintains 21 individual blending plants globally, including joint ventures.

Today, Delo® products are sold in 155 countries, and the Caltex Delo® product family includes lubricants, coolants, greases, and construction equipment system consumables such as engine oils, hydraulic system oil, transmission oils, engine antifreeze/coolants, gear drive fluid, grease for bearings and other lubrication points and more.

Similarly, this offering extends to all other fleet vehicles, including trucks, trailers, and passenger vehicles, with the Havoline® brand of oils covering the full spectrum of petrol engines.

Caltex with Techron® is available across all petrol fuel grades and contains an innovative formulation that has been scientifically proven to help clean and protect engines. Techron® not only removes dirt, but also helps prevent deposits from forming on critical parts of your car’s engine. This helps your car’s engine to function at optimum, delivering maximum power to your wheels.

Caltex Diesel with Techron D helps keep fuel injectors clean, protect against corrosion and reduce foaming while filling up.

In diesel engines, the fuel injector nozzle can be as narrow as the width of two human hairs, and with these injectors usually located inside the combustion chamber, they are exposed to extreme heat, and are, therefore, more vulnerable to deposit formation than those experienced in a petrol engine.

30 Construction Engineering Australia • March 2024 EQUIPMENT FEATURE

STARCARD STREAMLINES BUSINESS OPERATIONS

The new Caltex StarCard is a power-packed fuel management card offering a convenient way to increase fleet management efficiency. It provides a wide range of adaptable features to manage fleet and personal expenses and is perfectly suited to the ever-changing requirements of working in the construction industry.