There’s light at the end of the project.

Building it right. Together.

IPEX offers personalized pipe and fittings solutions and support from project ideation to execution. It is the specific knowledge and experience of our people in the field that make all the difference to our customers, with whom we work closely to deliver reliable performance, for today and tomorrow.

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

TECHNICAL ADVISORY BOARD

Archis Ambulkar, OCT Water Quality Academy

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution.

Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales

Second Class Mail

Product Agreement No. 40065446 Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering 220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727 4666 www.esemag.com

FEATURES

6 Back to the future - turning municipal sludge into fuel 8 Nature-wide thinking must replace climate tunnel vision 24 Canada’s Competition Bureau won’t determine whether wet wipes “flushable” claims are misleading 25 Engineers want to create model for optimal wastewater lagoon performance 26 Lake Huron Water Treatment Plant’s high lift pump station upgrade completed 30 More utilities are taking an active role in addressing water scarcity by reducing NRW loss 32 Sludge decanters help cut ship emission control costs 44 New flood map provides engineers with a view of future flood risks 45 New report suggests that the water and wastewater sectors could decarbonize fast 46 Greater Cincinnati completes major CSO improvement project 48 Can thermal hydrolysis of sludge solve problems caused by micro/ nanoplastics? 50 Converting sewage sludge into biofuels via a hydrothermal liquefaction process 53 Increasing FOG recovery rates from a meat processing plant’s wastewater stream 59 Using municipal wastewater ponds for heating and cooling buildings 60 Regina’s new water meters will provide near real-time data

www.esemag.com

61 Manitoba investing millions in wastewater upgrades

Canadian scientists engineer water’s structure to remove industrial contaminants

OPERATORS’ FORUM

12 Conserving valuable fuel and water resources during sewer cleaning

Mentoring meaningful for all winners of National First Nations Water Leadership Award 20 Ontario’s Thames Centre cites importance of transparency over HAA levels in drinking water

Lime dosing solutions for water treatment plants

Optimal systems for oil terminal wastewater treatment

CONSULTANTS’ FORUM

How COVID-19 has changed the consulting engineering business forever

Optimizing the future of engineering – ACEC charts a path forward

Engineering competency must extend beyond purely technical skills 41 Ontario’s changing landscape –how does land use planning affect municipal infrastructure?

DEPARTMENTS

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circur, Chain & Flight, Inclined Plate Settlers, Weir Washing Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

•

Rotary Lobe Pumps & Grinders

• Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – Stations Pump & Stormwater CSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

t e wat e r, Biosolids & Bi o g a s o mple te ra n g e o f ma rke t p ro du c t s. Le t u s sh ow yo u

Back to the future – turning municipal sludge into fuel

According to Statistics Canada, gasoline prices in parts of Canada rose to a record average monthly price of $2.25 per litre in June this year, up from $1.55 the year before. Diesel fuel reached over $2.50 a litre this year, up from $1.46 in 2021.

The main reason for this price jump was the invasion of Ukraine by Russian forces, which in addition to the untold misery, death and destruction unleashed, also created a major energy supply situation.

In 1979, another energy crisis known as the 1979 Oil Shock or Second Oil Crisis, was caused by a drop in oil production in the wake of the Iranian Revolution. Although the global oil supply only decreased by approximately four percent, the oil market’s reaction raised the price of crude oil drastically over the next 12 months, more than doubling it.

In 1980, following the onset of the Iran-Iraq War, oil production in Iran fell drastically. Iraq’s oil production also dropped significantly, triggering economic recessions worldwide. Oil prices did not return to pre-crisis levels until the mid-1980s.

In 1984, while working for Water & Pollution Control Magazine, I wrote an article entitled “Revolutionary experiments turn sludge into fuel”. It had just been announced that researchers from Tubingen University in West Germany had developed a pyrolytic process that converted sewage sludge into oil with an energy value comparable to diesel fuel, char (a substance resembling lignite coal), and non-condensable gases.

If economically and technically viable at full scale, the researchers felt that this process could have important ramifications for areas throughout the world where sludge disposal is a serious problem.

In Canada alone at that time, scientists at the Wastewater Technology Centre estimated that the 350,000 tonnes of sewage sludge generated annually could be converted to 700,000 barrels of oil and 175,000 tonnes of char.

“Revolutionary experiments turn sludge into fuel” was the cover story for the November/ December 1984 edition of Water & Pollution Control Magazine. Credit: Tom and Steve Davey

Additionally, $20 million annually could be saved in incineration costs.

They had evaluated this process using primary and waste activated sludges from Ontario sewage treatment plants in Toronto, Hamilton and Burlington.

Notwithstanding its contributions to rising CO₂ levels and climate change, oil, that one-time geological gift to mankind, is one of the cornerstones of modern civilization. However, what took nature millions of years to create, will be consumed by humanity in a few hundred years as it is a finite resource.

One of the most significant aspects of this fuel-from-sludge technology is that oil could be manufactured in a matter of hours. In the article, I postulated that this process could transform what was formerly a finite fuel situation into a nearly infinite resource.

However, while biofuel is produced from agricultural crops, like corn, vegetable oils or animal fats, and there is growing production of renewable natural gas from WWTPs, it did not seem to me that much progress had been made in creating oil-like fuel from sludge since the early 1980s.

With the energy crunch the world is currently facing, I was pleasantly surprised to read an article by Ibrahim Alper Basar, Huan Liu and Cigdem Eskicioglu from the University of British

Columbia that appears in this issue (See page 50). They describe recent research into using hydrothermal liquefaction (HTL), a biomass processing technology that has recently become prominent in the wastewater treatment field.

This method can convert sludge into biocrude, a free-flowing, viscous, dark brown, hydrocarbon-rich liquid. Biocrude can be processed in oil refineries, like petroleum, to produce diesel and jet fuel.

The authors say that the Pacific Northwest National Laboratory (PNNL) has been the pioneering research institute in the HTL field. It has investigated HTL feedstocks of lignocellulosic biomass, micro-algae, macro-algae, grape pomace, and recently, municipal sludge.

Metro Vancouver is planning a 10 wet tonne per day demonstration HTL facility at its Annacis Island WWTP, using the technology developed by PNNL. It is hoped that findings from this demonstration system will reveal crucial information for the design, operation and incorporation of HTL into existing and future wastewater treatment processes.

The authors say that HTL technology has come a long way in the last decade, but there are critical questions about using municipal sludge as feedstock and integrating HTL into WWTPs, prior to its widespread adoption.

I was 23 years old when I wrote the article “Revolutionary experiments turn sludge into fuel”.

Being almost 62 now, I sincerely hope that it doesn’t take another 39 years before producing municipal sludgebased biofuel becomes viable.

Steve Davey is the editor and publisher of ES&E Magazine. Please email any comments you may have to steve@esemag.com

sequent impacts on biodiversity. Manure also contains antibiotics and heavy metals, which further disturb soil and water biodiversity.

POTENTIAL OPPORTUNITY

Fertilizer prices have increased drastically in 2022, due to shortages caused by natural gas costs. This has drawn political attention to the fact that manure can in theory satisfy 35 – 40% of global needs, much more than it currently fulfils.

In the real world though, manure is so impractical to transport that it becomes practically worthless and rarely travels more than around 5 km, unless directly subsidized by producers or authorities that are more sensitized to pollution management.

For example, manure is worth between $12.50 and $20.00 per 1,000 litres in the U.S., hardly covering the driver’s salary, let alone the investment in storage facilities. If agrochemical companies could capture and commercialize just a fraction of that profitably, the raised circularity of manure nutrients and reduced reliance on chemical and mined products would reduce the industry’s impacts on nature, climate and community health.

With the global fertilizer market estimated to amount to $200 billion annually excluding manure prior to 2022, this segment could see raised interest from investors.

SALMON FEED AND AQUACULTURE

Salmon are carnivorous fish requiring a high-protein diet, which is commonly delivered through fishmeal and fish oil (FMFO) and soy. These ingredients are associated with high biodiversity and climate risks, which FAIRR’s Oceans and Biodiversity Impact report discusses.

Soy is associated with deforestation in some of the most biodiverse areas on the planet. FMFO sourcing is associated with vast quantities of wild fish catch, including overexploited stocks and trawled catch. Fishing has an unparalleled effect on the biodiversity of oceans, with a third of stocks now considered overfished.

The WWF has reported that only 13% of the Earth’s vast network of oceans is still wilderness. The impacts cascade throughout the food chain through marine predators, such as whales and sharks, but also divert key sources of nutrition away from human consumption.

Salmon farming also drives biodiversity loss from the farms’ interface with the environment. For example, the escape of farmed fish poses a threat to native species via competition, predation, mating, and the transmission of parasites and disease.

The waters surrounding salmon farms are also vulnerable to waste from farmed fish and nutrients from uneaten feed. One study has estimated 62% of the nitrogen and 70% of the phosphorus from the feed is released to water. This

can lead to eutrophication events and algal blooms. One such event in Chile resulted in the loss of 3,700 tonnes of salmon, with a financial impact amounting to $15 million.

POTENTIAL OPPORTUNITIES

Potential opportunities may arise from shifting the product mix toward relatively un-innovative solutions, such as vegetarian species. There are also novel ingredients and fully contained, on-land production facilities known as recirculating aquaculture systems (RAS).

Algal oil and insects are seen as possible replacements for the omega-3 and protein contents of fish feed, and benefit from heavy venture capital investment despite slow adoption by large aquaculture companies. Some studies have shown that insect meal is suitable for up to 30% inclusion in feed baskets for aquafeed without compromising on performance.

More waste from the fishing industry could also be reused within feed ingredients, which also has the potential to reduce costs. Some estimate that the annual quantity of these waste co-products used to produce fishmeal and oil amounts to more than 5.7 million tonnes, which is 28.9% of the total. These co-products could produce an additional 10.5 million tonnes if existing resources were fully utilized.

continued overleaf…Join a Diverse and Inclusive Team

Associated Engineering is looking for talented people across Canada. We currently have open positions in Ecology and Hydrogeology, as well as Environmental Professionals and Wildlife Biology. To join a diverse and supportive team, visit ae.ca/careers to apply.

Manure is in theory a good fertilizer, containing nutrients needed for plant health. But many regions currently produce too much of it to be applied on local croplands and it is costly and impractical to transport long distances. Credit: wolfgang jargstorff, stock.adobe.com

In theory, a RAS creates a perfect environment to grow fish to maturity without infection, predation, escape or environmental damage from lost nutrients. However, being capital intensive, it requires high density production to deliver a satisfactory return on invested capital.

Controlling temperature, oxygen and light can reduce fish stress and improve growth. There is also an opportunity for these systems to lower the sector’s carbon footprint by cutting the transportation emissions associated with a product with such a decentralized supply base. Crucially, RAS technology does not need to be near the sea, unlike traditional open-net-pen farming, which requires a coastal environment.

REGENERATIVE AGRICULTURE

Poor practices have already pushed 52% of global agricultural land into a state that is considered as degraded. Fertile soil continues to be lost at a rate of 24 billion tonnes per year. The sector is leading the degradation of lands globally, which is estimated to be between 20% and 40% of the total. The degradation of soils, a key component of healthy ecosystems, happens through the following processes: 1) Erosion at a rate faster than it is reformed by plants. 2) Nutrient and

soil organic matter removal from grazing or harvests being greater than can be replaced. 3) Surface sealing or compaction. 4) Increased salinity, acidity, or pollution, both organic and inorganic.

These issues can all lead to desertification.

Degraded soils are less supportive of plant, insect and animal density and diversity. Less biodiversity means a reduced capacity to capture and store carbon and water. A prolonged period of degradation of dry land can lead to abandonment or desertification. To replace this lost land often means deforestation and thus increased carbon emissions.

Yet, FAIRR identified at least 26 of the largest stock market-listed food-sector companies that mention regenerative agriculture in publicly available filings. Regenerative agriculture is a novel term within corporate language, but it recycles much of the sustainable agriculture practices and principles with a focus on soil health.

The objectives of regenerative agriculture commitments revolve around carbon sequestration by soils, water quality and infiltration improvements, reduced agricultural inputs, improved biodiversity, and improved soil health.

FAIRR extracted the cost of goods sold for 100 of the largest food-sector

companies within our universe, which is mainly capital going into food systems (plus a few things like packaging and some labour).

This figure amounted to nearly $2 trillion in 2021, an amount that is overwhelmingly directed towards practices that are harmful to nature. A redirection of this capital, even partial, could open opportunities for companies within those value chains. It would also create an entirely new ecosystem of products and services to implement, measure and track these practices.

While we are a long way from a full transition from agriculture as we know it to regenerative practices, especially when it comes to meat and dairy production, some companies are raising their ambition. Nestle, notably, targeted 1.2 billion Swiss francs toward this transition in three areas: paying a premium for regenerative agricultural materials, assisting farmer transition, and investing in sustainable crops R&D.

CONCLUSION

For the first time ever, a biodiversity COP will receive considerable attention from business, finance, and hopefully political delegates, showing nature is firmly on the global agenda.

The finance sector for one, is displaying strong support for nature-positive action, as shown by the $23 trillion in support FAIRR gathered for its collaborative engagement on waste and pollution, seeking to put circular fertilizers forward as a serious alternative.

Yet, much remains to be done, with livestock emissions alone representing around 14% of global greenhouse gas emissions and driving most deforestation. So, more ambition will be needed from governments, food companies, investors and consumers to direct considerably more capital toward science-based, nature-positive practices, and transition toward sustainable food systems.

Max Boucher is with the FAIRR investor network. For more information, visit: www.fairr.org

Conserving valuable fuel and water resources during sewer cleaning

By Del WilliamsFor municipalities responsible for keeping sewer lines free from debris and blockages, there is the additional challenge of maintaining these lines during a time of rising fuel prices, as well as water scarcity resulting from increasing population and the drought conditions that many areas face.

To reduce costs and conserve these valuable resources, cleaning crews are being compelled to use more efficient cleaning equipment, tools and techniques to implement water-intensive cleaning that can involve 380 litres per minute. Fuel is also consumed to operate the sewer truck, vacuum system, water pump, operating platform, and pressure/ flow compensation hydraulic system.

Inefficient sewer cleaning tools, as well as poor cleaning techniques can cause crews to make many passes to clear a line. This is a tremendous waste of fuel and water. When crews utilize water inefficiently, additional fuel, time, and labour are required to drive to the nearest fire hydrant to refill the tank.

“For years, sewer crews didn’t pay much attention to water conservation. Today, they must pay attention, or they can’t do their jobs. With sky-high fuel prices and a scarce water supply, municipalities are looking to stretch their resources, including labour, with better tools and training,” says Dan Story of KEG Technologies, a manufacturer of sewer and storm line products.

INCREASING FUEL AND WATER EFFICIENCY

To clean sewer lines more efficiently in the face of these challenges, municipalities should consider using more effective tools and methods. Normally, sewer crews utilize jetting and/or vacuuming systems to remove debris and blockages.

With jetting, a high-pressure water hose with a high-performance nozzle is placed

With the proper tools and techniques, it should be possible 95% of the time to go from manhole to manhole and clean in a single pass.

into the line. Operators release high-pressure water from the sewer jet truck to dislodge debris such as grease, grime, sludge, stones, and other items lodged in the pipe, and flush it into a manhole. As debris is removed, the hose is pushed deeper into the sewer. Jetting typically involves using between 200 – 325 litres of water per minute with a 20 mm – 25 mm hose from the truck. A vacuum may also be used to remove dislodged debris and transfer it to disposal bins.

HIGH EFFICIENCY TOOLS

One of the most effective ways to decrease water and fuel use, while improving cleaning efficiency of sewer vacuum trucks, is by utilizing a high-performance, Tier 3 nozzle. With improved fluid dynamics, these optimize the cleaning process while utilizing less water, revolutions per minute (RPMs) and pressure (PSI). The high-performance nozzles cost more, but reduce fuel and water costs dramatically, and enable faster job completion.

Although nozzles with many configurations are used in the industry, nozzles are classified in three tiers, based on efficiency: Tier 1 (approximately 30% efficient), Tier 2 (50% – 60% efficient), and Tier 3 (75% – 98% efficient).

According to Story, however, a surprising number of municipalities and third-party contractors still do not use Tier 3 nozzles for sewer cleaning, despite the benefits.

What sets the most efficient Tier 3 nozzles apart is the fluid mechanics engineering, which is on par with the aerodynamics of race cars. After exiting the jetter hose, water travels into the body of the nozzle before moving through smooth, curved channels. This design enables the water to maintain its power and speed before entering the nozzle’s replaceable titanium ceramic inserts, which help to straighten the water stream. Next, the water is further funneled to enable an even tighter water pattern to emerge.

The internal workings of the nozzle

(including the way the water gets turned) redirect the energy of the high-pressure water entering the nozzle so it performs as efficiently as possible. This results in what is needed for the task: more thrust and power, using less water.

“If there is turbulence in the water as it exits the nozzle, it dramatically reduces the overall cleaning power,” says Story. “The most effective Tier 3 nozzles create tight water patterns that efficiently clean the pipe wall and produce a powerful water stream to move debris long distances while propelling the nozzle through the lines.”

In the case of KEG’s Tier 3 nozzles, such as the Torpedo and OMG models, the high-performance design of the fluid mechanics leaves little room for power losses and excessive turbulence and so can achieve 98% efficiency. A properly designed Tier 3 nozzle can also be used at lower PSI and RPMs.

“With less efficient Tier 1 or 2 nozzles, operators may run at 2,000 PSI to pro-

vide more power. Because of the superior fluid mechanics of a Tier 3 nozzle, ample power is generated at 1,200 PSI, which saves water and fuel,” says Story.

Story explains that when water hits the nozzle wall of Tier 1 and 2 nozzles, they stop the flow of water and change its direction, which creates considerable turbulence. In contrast, Tier 3 nozzles are designed not to impede or stop the water flow.

“The most efficient Tier 3 nozzles are designed to move water like it is on a curved race track or roller coaster. The water never stops moving so it retains more power,” says Story.

According to Story, a Tier 1, 30-degree drilled nozzle running 275 litres per minute at 2,200 PSI will only exert 13 pounds of force to move debris nine feet away from the nozzle. In contrast, a high-efficiency Tier 3 nozzle running 230 litres per minute at 2,000 PSI will exert 98 pounds of force nine feet away. He adds that efficient Tier 3 nozzles also

allow a lower water pressure to be used from the truck, which saves water.

BETTER CLEANING TECHNIQUES

In addition to water savings, superior cleaning techniques can also dramatically reduce fuel, time and labour. According to Story, the main mistake most operators make is when they do not understand how their cleaning speed affects their performance.

With poor techniques, operators often are forced to make several passes to remove the material, which wastes a tremendous amount of water. “Even after that, I have been in situations where, after a cleaning, the CCTV camera operator radios back to ask if the line was even cleaned,” Story says.

“Most operators want to run up the line in a hurry and clean as they come back because it is how they were taught, but it is impossible to 'dig a hole from the bottom up'. When they shoot past continued overleaf…

all the debris going in, they are trying to bring it all out at once, which is more difficult,” he adds.

Instead, Story advises operators to go slow when cleaning lines. They should pull the nozzle down as they go into a line, observe how dirty it is, and then adjust their cleaning speed accordingly.

“The first 15 metres of a line will tell you how dirty it is and how you should adjust your speed. If you are not getting a lot of debris back, then you can increase your cleaning speed,” says Story.

When the operator reaches a manhole in the line, Story advises dialing down the water pressure to 900 – 1,000 PSI as they return.

“You clean the line, remove all the organic materials going in, and some of the rocks in it will fall out of the flow. By cleaning as you go in, however, you’re able to get the dirt and debris out of the line, so on the return the rocks will move much easier inside the pipe,” he says.

Story points out that operators often

The fluid mechanics of Tier 3 nozzles, such as these 25 mm ones by KEG, minimize power losses and excessive turbulence.

compensate for a lack of power cleaning with Tier 1 or Tier 2 nozzles by increasing the pressure to 2,000 PSI, and the water flow to 190 – 230 litres per minute, or higher, on the way back through the line. With a Tier 3 nozzle, however, a lower

pressure is possible because it provides more cleaning power due to its efficiency in directing water flow without turbulence.

“A Tier 3 nozzle can generate the same amount of cleaning power as a Tier 1 or 2 using 150 litres and 1,200 PSI, saving time, water and fuel. But the trick to that is cleaning as you go in. Chop the debris up and let the flow work like a conveyor belt, carrying the debris out,” says Story. “If you clean correctly, the water is going to carry the debris off and out of the way, so slow the nozzle down and let it do its job. You are not in a race.”

“When you get to the end of the line, just dial your pressure back down and rinse the pipe as you come out. When you come back, the job is done,” says Story. “You don’t have to send it back in a second time.”

“With 150 mm – 375 mm diameter sewer lines, it should be possible 95% of the time to go from manhole to manhole and clean in a single pass,” says Story. “This takes a fraction of the time and resources to make one pass versus making several passes to remove the same material.”

It also eliminates extra trips to a nearby fire hydrant to refill the water tank, which can cost crews an hour or more to put all the equipment back on the truck and set it up again when they return. With a combination of the right tools and techniques, Story estimates that sewer crews can save approximately 9% – 17% in vehicle fuel costs, including travel to refill water tanks.

As municipalities and contractors seek to reduce the use of costly fuel and scarce water, using the most efficient Tier 3 nozzles and cleaning methods will go a long way to stretch their funds and conserve valuable resources. Just as important, adopting industry-proven cleaning techniques will help to protect against future increases in the cost of fuel and water.

Del Williams works with KEG Technologies. For more information, visit: www.kegtechnologies.net

MENTORING MEANINGFUL FOR ALL WINNERS OF NATIONAL FIRST NATIONS WATER LEADERSHIP AWARD

By David NessethFive years in, the National First Nations Water Leadership Award is helping to tell some of the hidden tales of mentorship ongoing in the lives of water operators on Canada’s reserves, and the joy they’re finding in teaching others to carry on the mission towards creating finely-tuned water systems.

Many are passing on their knowledge to those who may soon replace them, as the sun sets on their own careers. Often faced with limited funding and outdated equipment they run alone, the award also illustrates the struggles faced by operators to keep things running smoothly, despite other longstanding water challenges in their communities, such as the many water advisories they have often helped to lift.

For Brian Indian, winner of the 2022 award, mentorship is one of the perks of the job. Indian is one of the only certified Level 3 water treatment operators in his community of about 700 residents near Kenora and the Manitoba border, in Ontario’s Ojibways of Onigaming First Nation. He is using his 17 years of experience to train two successors, who may someday allow him a day off. As it stands now, there’s nobody to fill in.

Despite challenges with Parkinson’s disease, and working with a 16-year-old ozone system with parts he says “no longer exist,” Indian even organizes “Water Awareness” days to educate reserve youth through tours of the local water plant. He hopes they may eventually share the same bright spot of relief and pride that exists in his own work schedule as an operator.

“My favourite part of the day is in the morning, looking at the data and seeing that everything ran the way it is supposed to,” Indian told an award committee operating on behalf of Indigenous Services Canada.

Lorraine Crane, Chief of Slate Falls Nation, was the inaugural winner of the

award in 2018 for her successful lobbying to fund a new water treatment plant for her community. Prior to her accomplishment, the community had an active boil water advisory for 14 years. “We are very excited to finally be able to drink water right from the tap,” Crane said when she accepted the award.

Another former winner of the water operator award, in 2019, is Deon Hassler of the Carry-The-Kettle Nakoda Nation, just east of Regina. He is a decorated military veteran and Circuit Rider technician, who has been enjoying training future operators for years. He is also currently President of the Saskatchewan First Nations Water Association, that works to: “build capacity at the community level for the care and control of water on reserve.”

“I am fortunate to be in a position where I can now share my years of experience and knowledge, to help train, mentor, guide and assist new and future operators and leaders in the ongoing care, maintenance and operation of this critical piece of community infrastructure,” said Hassler, while receiving the award.

As a homage to the water operator award winners, and in the spirit of mentoring, each one has $10,000 in bursaries made available in their name to those

looking to follow in their footsteps.

Earlier this year, the federal government announced up to $500,000 for new projects that target the recruitment and retention of trained and certified wastewater operators for First Nations reserves. While the money cannot go directly towards training costs, it is intended to support operators who work on highrisk systems, or those that require preventative maintenance or enhanced wastewater treatment practices.

A report from the formerly named Indian and Northern Affairs Canada notes that retaining qualified First Nations water operators has been a longstanding issue, as some 25% of them in First Nations communities have left their job over the years, for either the municipal sector or private industry, often for higher pay.

“Increased funding will enable First Nations to better retain qualified water operators in their communities, including through improved salaries, according to First Nations priorities,” Indigenous Services Canada announced during a round of new funding in 2021.

According to Indigenous Services Canada, federal spending on water and wastewater-related operations and maincontinued overleaf…

Some National First Nations Water Leadership Award winners are trying to pass down their knowledge on reserves as part of a mentoring process. Jonathan Riberdy of Zhiibaahaasing First Nation, left, and Deon Hassler of the Carry-The-Kettle Nakoda Nation, are former winners who enjoy teaching. Credit: Indigenous Services CanadaRADAR ULTRASONIC IS THE BETTER

tenance averaged $146 million per year between 2015 and 2018. Last year, the government upped its contribution with an extra $616 million over six years.

Until the shortage of water operators is resolved, those who are still working day in and out on reserves are trying to help the best they can to pass on knowledge.

Winner of the 2020 award, Éric Sioui, a Huron-Wendat chemical engineering technician and water treatment systems technician, has been busy sharing his expertise with other First Nations water operators across Quebec as a coordinator with the Circuit Rider Training Program.

After receiving the award, Sioui spoke about his feeling of connection to other First Nations water operators in Quebec. “From the start, we have worked hard and made tremendous progress on many aspects of our work. As a result, a beautiful relationship of trust has developed over the years. Together, we have shared our knowledge and cultures, passionately and respectfully,” he said.

Sioui even worked to create a Circuit Rider web page to help operators of water supply and wastewater treatment systems.

Yukon University (formerly Yukon College) received university status in the spring of 2020, and recently formed a partnership with the Circuit Rider Training Program to streamline the process. While this program provides on-site training on reserves, as well as troubleshooting and mentorship, it does not deliver the classroom instruction required for all operators in the region to gain and maintain the certifications necessary to operate community water systems.

“Bringing the two programs together at YukonU will allow for greater synergy. We believe this will lead to increased opportunities for collaboration between operators and communities, for promotion of the water and wastewater operator career path, and retention of existing operators,” said Michael Vernon, senior communications coordinator for the university.

Also in 2022, some 14 interns were

recruited from seven northern Ontario First Nations to pursue entry level water operator training or water quality analyst certifications. The hope is that this will kick off their careers in the water field under the new North Shore Tribal Council Water First Internship. It is the fourth iteration of the program.

While significant progress has been made in lifting long-term water quality advisories on First Nations reserves across Canada, Ontario still has 22 ongoing advisories in 19 communities.

Jonathan Riberdy, of Zhiibaahaasing First Nation, has worked hard to reduce those advisories. As the 2021 award winner, he has also trained many young Indigenous water operators across Ontario. He currently serves as his community’s water supervisor, a project manager for Swim Drink Fish Canada, and as a director for the Aboriginal Water and Wastewater Association of Ontario.

“Teaching my knowledge to other operators is most rewarding, knowing that I can share my knowledge,” Riberdy said following his win. “Helping my community is the most important thing, as I didn’t accomplish what I did alone.” Riberdy said that four times a year, Zhiibaahaasing elders and women take the lead in water ceremonies for clean drinking water.

“We take this time to say Miigwech (thank you) to the water for letting us have clean, drinkable, fishable and swimmable water,” he noted. “Having leadership at these ceremonies shows the commitment towards water and gives them an understanding of the water processes.”

All nominees for the 2022 award received a pin designed by an Indigenous company. This year’s nominees were reviewed by an advisory committee formed of First Nations partners and the previous year’s winner.

The nomination process is outlined at the National First Nations Water Leadership Award site.

The nomination period for the 2023 National First Nations Water Leadership Award will run from January 2 to March 31.

David Nesseth is a writer for ES&E Magazine. Email: editor@esemag.com

ONTARIO’S THAMES CENTRE CITES IMPORTANCE OF TRANSPARENCY OVER HAA LEVELS IN DRINKING WATER

By ES&E StaffOfficials with the Municipality of Thames Centre say they are adjusting their day-to-day operations in order to reduce excess levels of haloacetic acids (HAA) found in the drinking water.

Since January 2020, Ontario municipalities have been required to notify local public health units when the HAA concentration exceeds 80 micrograms per litre, or 80 parts per billion. Based on testing done four times a year, the most recent rolling annual average HAA concentration for Thames Centre’s drinking water was 82.6 micrograms per litre.

“We are actively seeking alternatives to reduce the disinfection byproduct precursors in the treatment process at the Water Treatment Facility,” announced Jarrod Craven, director of public works with the Municipality of Thames Centre, in a statement.

Haloacetic acids can form when the chlorine compounds used in the disinfection process react with naturally occurring organic material present in the water. The health benefits associated

with the chlorination of drinking water, officials added, far outweigh the potential risks associated with slightly elevated levels of HAA within the drinking water system.

Dr. Alex Summers, Medical Officer of Health with the Middlesex-London Health Unit, said the slightly elevated HAA levels “do not constitute an immediate health risk,” and alerting the public about the findings is about maintaining transparency.

“Given the many risk factors we are exposed to every day, this situation would not lead to an increase in an individual’s overall risk of developing cancer,” stated Summers.

The threshold levels are set through Ontario’s Drinking Water Quality Standards. When the new reporting level came into effect, the province also suggested the following remedies in addition to reducing disinfection byproduct precursors. These include:

• Reducing the chlorine dose or changing the disinfectant (e.g., to ozone, chlorine dioxide, UV).

• Optimizing the amount of time chlorine is in contact with water to reduce

reaction time but still maintain primary disinfection (CT).

• Reducing water age in the distribution system (e.g., by managing storage levels or using auto-flushers).

According to Health Canada, the haloacetic acids most commonly found in drinking water are monochloroacetic acid (MCA), dichloroacetic acid (DCA), trichloroacetic acid (TCA), monobromoacetic acid (MBA) and dibromoacetic acid (DBA).

The Federal-Provincial-Territorial Committee on Drinking Water also recommends that every effort be made not only to meet the guideline, but to maintain concentrations of HAA as low as reasonably achievable.

In 2019, the Attawapiskat First Nation, in the Kenora district of northwestern Ontario, declared a state of emergency over elevated levels of trihalomethanes and HAA.

For more information, email: editor@esemag.com

Proven. Trusted. Relevant.

“CANECT is a valuable opportunity to network and learn from leading experts in the environmental field, and to bring back best practices to use in the workplace.”

ENVIRONMENTAL MANAGER Gerdau Manitoba

ENVIRONMENTAL MANAGER Gerdau Manitoba

Visit www.CANECT.net for more info

CANECT’s practical professional development courses are designed to help you meet your environmental responsibilities.

Engaging networking opportunities.

Access leading experts for one-on-one compliance problems.

Take home valuable reference and guidance materials.

Connect with technology and service providers.

Receive a Certificate of Attendance featuring Continuing Education Credits (CECs).

Demonstrate your organization’s commitment to environmental due diligence.

Update your knowledge of new regulations.

LIME DOSING SOLUTIONS FOR WATER TREATMENT PLANTS

Operators at one water purification plant had always relied on gravity to feed slaked lime slurry to its softening basins. They decided to give gravity a helping hand by testing a pump to move the slurry more effectively.

Lime slurry is a dense product to transfer, with a high solids content of up to 35%. Due to its abrasive nature, which causes wear on progressive cavity pumps with consequent downtime and operating costs, plant operators opted to use a peristaltic pump for the transfer process. These pumps use alternating compression and relaxation of a reinforced hose to push liquid out of the hose. The resulting vacuum, caused by the repeated cycle, draws more product into the hose.

Peristaltic pumps are accurate and repeatable. The pumped product is totally contained within the hose, eliminating the possibility that any moving parts can clog or corrode. This makes a peristaltic pump a good choice for pumping high solids content slurries such as lime.

For this plant, the largest obstacle when deciding on a suitable pump was the amount of available space. Operators wanted to continually pump approximately 2,350 l/hr, which would normally mean a sizeable pump with a large motor and gearbox. The solution was a Verderflex Dura 35 peristaltic pump, which features a vertical motor and gearbox, dramatically reducing the pump footprint and saving space. The Verderflex Dura 35 is capable of pumping up to 5.5 m3/hr at pressures up to 12 bar. This was more than enough for this installation, which called for pumping at just over 4 bar, 24 hours a day and 7 days a week.

The pump has been running continuously with the same hose for over 8,000 hours. When operators finally need to change the hose, they will find the simple taper fit flange design makes hose changes easy, keeping downtime to a minimum.

Introducing a Verderflex peristaltic pump at this plant has proved to be such a great success that additional Dura 35 pumps have already been installed.

For more information, email: sales@yorkfluid.com

Verderflex peristaltic pumps feature a vertical motor and gearbox, dramatically reducing the pump footprint.

Verderflex peristaltic pumps feature a vertical motor and gearbox, dramatically reducing the pump footprint.

OPTIMAL SYSTEMS FOR OIL TERMINAL WASTEWATER TREATMENT

Aeration systems manufactured by INVENT have been in service reliably and maintenance-free since 2016 in a large industrial park located on an island. An important industrial port is located in the immediate vicinity, and an oil refinery operated there until 1997. An oil port with oil terminal, however, is still in operation, as are the many large storage tanks.

Wastewater treatment and purification are particularly important in this environment. That is why there was no question about building a dedicated wastewater treatment plant at the time the industrial park was being planned. Operators needed high-quality plant and mechanical engineering technology.

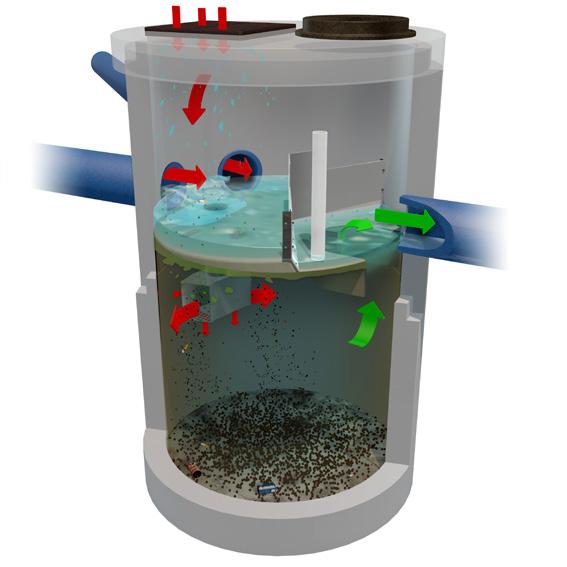

The 10 HYPERDIVE® mixing and aeration systems operate in two round sludge basins to keep the contents in motion. They consist of a robust hyperboloid mixer-body with a cage design, an aeration ring, a submersible drive and a process air hose, specifically designed for heavy-duty use in industrial and municipal wastewater treatment plants. It is a combination of efficient oxygen supply and optimized mixing of the basin content, that ensures that as little sediment as possible is formed on the bottom.

The hyperboloid mixer-body is made of high-quality fibre-reinforced plastic, making it both lightweight and non-corrosive. The cage, with its specially molded stainless steel base construction, provides the required weight, allowing the construction to be placed on stable footing. The base is also coated with epoxy resin.

Only energy-saving and robust motors, gears with reinforced bearings, and seals from reputable manufacturers are used for the moving parts. The supply air hose is connected to a blower station located outside the basin, ensuring the supply of air or oxygen to the mixing and aeration system.

The two rectangular E-FLEX® membrane aeration modules are placed in a smaller, round aeration tank. These maintenance-free systems are made of stainless steel and other wastewater resistant, environmentally friendly, resource-efficient and recyclable materials. They supply fresh air so that the purification bacteria that are “active” in the wastewater receive sufficient oxygen.

The E-FLEX aeration system is designed to inject large volumes of oxygen into the wastewater with the least amount of energy possible. Air bubbles with optimum bubble sizes are generated on the flexible membranes to achieve this task. This technology incorporates fluid mechanical knowledge from INVENT’s research laboratories, as well as know-how in computational fluid dynamics.

The fact that the systems have performed so reliably and

Two of the mixer/aerators placed in the tank.

maintenance-free since 2016 was to be expected, given that even the most heavily stressed components were designed for a service life of at least 100,000 hours.

INVENT is represented in Ontario by Pro Aqua Sales. For more information, email scott@proaquasales.com

CANADA’S COMPETITION BUREAU WON’T DETERMINE WHETHER WET WIPES ‘FLUSHABLE’ CLAIMS ARE MISLEADING

By ES&E Staff

By ES&E Staff

On the heels of a 2019 study on wet wipe flushability by Ryerson University (now called Toronto Metropolitan University), Friends of the Earth Canada (FOE), an eco-action group, along with the Canadian Water and Wastewater Association (CWWA) and the environmental law group Ecojustice, successfully petitioned an inquiry by the Competition Bureau into a problem they alleged was costing some $250 million per year in repairs for Canada’s municipal wastewater systems.

With no decision reached, Canada’s Competition Bureau has closed its investigation into whether wet wipes labeled “flushable” can be safely flushed down the toilet without clogs, Friends of the Earth Canada has revealed.

FOE told The Canadian Press that the Competition Bureau found “a number of competing guidelines” that signaled the end of the inquiry, which came in February, despite no public announcement.

“At this time, enforcement action under the deceptive marketing practices provisions of the Competition Act does not appear to be the most effective way of addressing the issue of what products can be safely disposed of in sewer systems in Canada,” the Competition Bureau wrote to ES&E Magazine in a statement.

“The Bureau’s investigation revealed that there are a number of competing guidelines in Canada and around the world about when a product can be considered to be flushable in municipal sewer systems. Although the Bureau has discontinued its inquiry, it does not endorse the representations made about ‘flushability’, or the tests used to evaluate this feature.

“While the Bureau has discontinued its inquiry at this time, this will not prevent it from investigating other flushability claims should additional information

come to light,” continued the Competition Bureau.

In an article in ES&E Magazine's August 2022 issue, CWWA Executive Director Robert Haller, and Barry Orr, who is with the City of London’s Municipal Enforcement Sewer Use Group, and a flushability researcher with Toronto Municipal University (TMU), said that there were only two guidelines.

One was developed by the International Water Services Flushability Group, an association of wastewater professionals, and the other by INDA, the Association of the Nonwoven Fabrics Industry, whose members are wipes’ producers.

Neither FOE, nor Ecojustice, has yet to issue a public statement on the end of the Competition Bureau’s wet wipes inquiry. However, FOE CEO Beatrice Olivastri told The Canadian Press that the decision was “totally unacceptable.” She indicated to ES&E Magazine that an official statement on the issue will likely be available.

TMU researchers found that toilet paper loses on average 90% of its strength

when wet, allowing it to disperse in toilets, plumbing systems and sewers. In contrast, flushable wipes only lose an average of 29% of their strength in wet conditions.

Canada is currently initiating a flushability standard through the Standards Council of Canada, which is being led by former CWWA Executive Director Duncan Ellison.

Last year, wipes manufacturer Kimberly-Clark Corp. settled a lawsuit with Charleston, South Carolina’s public works commissioners, vowing to improve the “flushability” of its Cottonelle brand flushable wipes, and improve its package labelling.

Early in 2022, the Competition Bureau had a more definitive finding over product label claims, when it fined coffee pod manufacturer Keurig $3 million for exaggerating the recyclability of the pods for Canadian consumers.

For more information, email: editor@esemag.com

Environmental action groups believe that wipes are costing some $250 million per year in repairs for Canada’s municipal wastewater systems. Credit: siam, stock.adobe.comENGINEERS WANT TO CREATE MODEL FOR OPTIMAL WASTEWATER LAGOON PERFORMANCE

By ES&E staffAteam of environmental engineers is using new funding to learn more about how rural, low-tech wastewater lagoons impact nutrients remaining after treatment.

Wastewater lagoons have a large footprint and typically serve smaller communities where land is abundant, but municipal funding is scarce, making them an economical option. Researchers at West Virginia University’s Benjamin M. Statler College of Engineering and Mineral Resources, hope to create a model for optimal lagoon performance under different conditions and with different technologies.

“What’s the sweet spot of removing nutrients while limiting environmental impacts at a reasonable cost?” asks assistant professor Kevin Orner in a media statement.

Orner’s team notes that when treated wastewater containing nutrients like nitrogen and phosphorus enter waterways, it increases algal growth, which in turn uses oxygen when it decomposes. Additionally, said Orner, excess nutrients

Researchers plan to create an interactive map with search filters enabling users to find wastewater lagoons matching certain parameters and pull data demonstrating how well those lagoons remove nutrients in various conditions. Credit: lostinthemidwest, stock.adobe.com

can cause other issues, such as too much nitrate in well water, which could cause infant methemoglobinemia, more commonly known as Blue Baby Syndrome.

“Wastewater enters the lagoon,” Orner explained, “stays for a while and is discharged, typically into a river. Hopefully, over time, solids have settled, maybe the sun has killed pathogens, or some nitrogen leaves the liquid as nitrogen gas. Also, contaminant levels in the wastewa-

ter leaving the lagoon should be less than they were in the wastewater coming in.”

One of the first orders of business, Orner said, will be to determine the number of wastewater lagoons and seek out relevant performance data.

In Canada, there are more than 1,200 lagoon systems, according to Statistics Canada. They are typically more prevalent in Alberta and northern communities. In 2004, the Federation of Canadian Municipalities (FCM) created a best practices guide for wastewater lagoon operation. “A poorly operated lagoon can create objectionable odours and result in the discharge of poorly treated effluent that can adversely affect the aquatic life in the receiving stream,” the FCM guide warns.

Once initial data is organized, Orner’s team plans to create an interactive map with search filters enabling users to find lagoons matching certain parameters and pull data demonstrating how well those lagoons remove nutrients in various conditions.

For more information, email: editor@esemag.com

LAKE HURON WATER TREATMENT PLANT’S HIGH LIFT PUMP STATION UPGRADE COMPLETED

By Bryan OrchardFor half a century residents and commerce across eight municipalities of the greater London area of southwestern Ontario have received their potable water supply from the Lake Huron Water Treatment Plant (WTP) near Grand Bend and the community has been well served over this period. However, in 2017 the Lake Huron Primary Water Supply System (LHPWSS) conducted an audit of pump operations for the pumping station.

The outcome of this study has been the modification of the original five-pump configuration in the pump station and its replacement with a six-pump configuration. This has involved removing three of the original 50-year-old 3,000 hp (2,237 kW) pumps and replacing them with four high lift pumps from KSB.

With the new pumps running on their operational curve, substantial energy savings can be made. As an electrical transmission-connected entity, the LHPWSS was eligible under the Independent Electricity Systems Operator’s (IESO) Industrial Accelerator Program for financial incentives for eligible energy efficiency projects.

The contract was awarded to KSB Canada, who commenced design and consultation work in 2019. Pump manufacturing began in 2020 and the updated pumping station became fully operational in August 2022.

LAKE HURON PRIMARY WATER SUPPLY SYSTEM

Located in southwestern Ontario, London is an interesting city as it gets its water source from both Lake Huron and Lake Erie. The Regional Water Supply Division (RWS) is seconded to the regional water boards and is responsible for two major water supply systems. These are the LHPWSS and the Elgin Area Primary Water Supply System (EAPWSS).

The LHPWSS services the municipal-

ities of London, Lambton Shores, North Middlesex, South Huron, Bluewater, Middlesex Centre, Lucan-Biddulph and Strathroy-Caradoc, from a water treatment plant located north of the village of Grand Bend in South Huron. The plant has a current treatment capacity of 340 million litres per day and serves approximately 420,000 people in the

eight municipalities, including 80% of the City of London.

The pumping station was originally designed for a single pipeline, but later in 1996 and 2014 the RWS partially twinned the 47 km main transmission pipeline to a terminal reservoir. This resulted in the pumps no longer running on their curve.

The high lift pump gallery located on the north side of the station.“After almost 50 years, the existing pumps were becoming inefficient, with the impellers showing signs of pitting. Keeping them operational required a lot of ongoing maintenance because they were running off curve,” reports Billy Haklander, capital program manager for LH&EAPWSS.

PUMP SELECTION

The overriding issues which the suppliers faced were delivering energy savings, ensuring that the pumps could be accommodated in the limited amount of space in the pump hall, and that the floor could withstand the weight of the pumps. In addition, the supplier needed to guarantee a wide operating range with low available NPSH (net positive suction head), covering multiple duty conditions with pumps operating at full speed.

To give the LHPWSS the most flexibility in selecting pumps, four pump suppliers were invited to submit separate bids for the small and large pumps and to identify a credit should the LH&EAP-

WSS decide to source both the small and large pumps from the same supplier.

KSB’s bid offered a creative solution using just a single type for all four pumps, with only the impellers and motors being different in accordance with the size of the pump. The base plates for each pump were the same size. This flexibility enabled the capital cost of its bid to be adjusted to account for fewer spares and

thereby create savings for the customer.

A significant benefit of the proposal made by KSB was that, with the smaller pumps using the same size casings and base plates as the two larger pumps, it is possible to increase the pump size by fitting larger impellers and motors at a future date if necessary. This can be done on-site without any civil works needing to be carried out. Thus, if demand grows for the water supply to be increased, it can be accommodated with the minimum of cost and disruption to the plant.

INSTALLATION CHALLENGES

“One of the constraints that we had to take into consideration when evaluating the bidders’ project was ability to conform to the available space in the existing pump hall,” explains Marcus Henderson, KSB national operations manager. “With this being an existing installation, there was only so much real estate to work with. A key constraint was that the existing pumps were of a

The Lake Huron Water Treatment Plant has a current treatment capacity of 340 million litres per day and serves a population of approximately 420,000 people.

The Lake Huron Water Treatment Plant has a current treatment capacity of 340 million litres per day and serves a population of approximately 420,000 people.

bottom suction configuration. Usually, the installation configuration for horizontal split case pumps is in-line, with the suction and discharge in the same direction. This meant that we had to find a solution to incorporate bottom suction. Some pattern work was needed to incorporate the existing pipework, which enabled us to solve the problem.”

“The eventual scope of the project involved the supply of four bottom suction horizontal split case pumps, vibration monitoring system and flow straighteners (suction conditioning spools) for potable water distribution,” says Henderson. "We were also responsible for torsional and lateral analysis for the pump sets, on-site start-up and commissioning field services.”

The plant’s pumps are rated for 1,158 L/s, and each of the pumps’ discharge piping is equipped with a 500-mm diameter tilting disk check valve, along with a 500-mm diameter metal seated ball valve equipped with a motorized electric actuator. The WTP has two hydro pneumatic tanks, each with a capacity of 580 m3, for transient protection of the 47 km partially twinned 1,200-mm diameter water main distribution system.

RDLO PUMPS

KSB’s RDLO axially split, single stage volute pumps have been developed specifically for handling raw water, clean water, service water and transport fluids with a minimum of flow resistance. The combination of solid bearing brackets, a short and rigid shaft, and pre-loaded bearings, lowers vibra-

pumps are rated for 1,300 L/s or 900 L/sec and each one's discharge piping is equipped with a tilting disk check and throttling valve and isolation ball valve.

tion and extends operating life for the bearings, seals and coupling. Being axially split case pumps simplifies maintenance procedures, enabling ready access to all parts for thorough inspection.

“Two of the pumps are connected up to 3,500 hp motors and the other two to 2,500 hp motors. These are the main pumps

•

•

•

•

RDLOsupplying drinking water to the entire LHPWSS. With many customers located over 50 km away, they consume a great amount of energy. Therefore, improving efficiency by one or two percent results in substantial energy cost savings,” comments Henderson.

INSTALLATION

“Because the pumps were being retrofitted into the original premises, it was necessary to run the plant at half capacity on one transmission side during installation,” explains Haklander. “As there was a spare bay already in the plant, it was possible to utilize this for the installation of the first pump. The procedure involved running pumps one, two and three, while pumps four, five and six were being installed. Once these pumps were tested and we were comfortable with their performance, the procedure switched to running pumps four, five and six, while pumps one, two and three were being installed.”

Historically, the lack of the isolation

valves on the existing pumps required the complete isolation of half of the discharge header board (three pumps) in order to facilitate the repair to one pump. This effectively limited the pump capacity of the plant to half of its rated capacity.

The selection of a combined control/ check valve to replace two valves on each pump discharge meant that each pump would have a dedicated isolation valve for each pump discharge. Isolation valves on each pump discharge would enable the complete isolation of the combination valve and the high lift pump for maintenance and repair purposes.

PUMP EFFICIENCY

A significant element of the project was the issue of the pumps delivering energy savings, which involved factory acceptance testing at KSB’s Halle facility in Germany. Factory testing involved shipping one motor of each size to the factory and coupling them up to the pumps for string testing and recording the overall pump performance. The

motors also underwent type testing under full load in accordance with the IEEE Standard so that they could determine motor efficiency.

“We took the factory overall power and the data from the motor factory to determine pump efficiency. There were strict penalties on performance guarantees on this project, so if we failed to meet the efficiency guarantees given, KSB would be required to pay LHPWSS the difference in energy costs delivered and those which were guaranteed over the performance lifetime,” says Henderson.

It is worth noting that when the pump tests were carried out, they had to be on bare internals. The coatings were only applied after testing, so it was a true test of the raw efficiency of the pumps. The coating can improve efficiency by one to two percent.

Bryan Orchard works with KSB. For more information, email: anna.vezina@ksb.com, or visit: www.ksb.ca

MORE UTILITIES TAKE ACTIVE ROLE IN ADDRESSING WATER SCARCITY BY REDUCING NRW LOSS

By Yolanda Coleman KokayiWater scarcity is not something that most North American water professionals spend a lot of time planning for. However, as we experience more extreme weather, it is becoming common for more parts of Canada to experience water shortages at some point during the year.

Addressing aging infrastructure is an ongoing priority for most water utilities, as they look at ways of reducing non-revenue water (NRW) losses. These can be as high as 30% in some water systems. With more jurisdictions paying attention to water loss, utilities are rising to the challenge of reducing NRW loss.

According to the Global Footprint Network, globally, we are consuming the resources of 1.8 Earths to sustain our current population and demand for resources. If we continue on the same trajectory and factor in population growth, the situation could rapidly become worse. Over half of the world’s major aquifers are being depleted faster than they are being replenished.

REDUCING NRW LOSS BY DOUBLING DOWN ON PRESSURE MANAGEMENT

A lot can be learned from other countries that have already had close calls. Cape Town, South Africa, came very close to “day zero” of water supply in mid-January 2018. While the public faced tremendous restrictions during this time, the city had been working hard to reduce NRW. When a water crisis is imminent, the best chance of avoiding a “day zero” situation is to double down on pressure management.

Cape Town used this strategy by establishing district metered areas (DMAs), installing pressure reducing valves (PRVs), and using Mueller’s advanced pressure management solution. Having the ability to precisely control critical point pressure at the PRVs gave the city the ability to manage water flow more effectively through intelligent, self-learning technology. The end-result was a significant reduction in pipe bursts and leakage, and ultimately decreasing real water loss.

USING AMI TO CONTROL WATER AND REDUCE CONSUMPTION

In many areas, drought extremes have been intensifying. To help cope with this, a lot of utilities have made an impressive investment in advanced metering infrastructure (AMI), which provides up-to-the-minute insight on water usage. If there is a sudden surge, indicating a pipe burst, the utility can shut off the supply and dispatch a repair team, reducing water loss and further damage.

Some municipalities with AMI systems are also sharing data with their customers through mobile apps. By giving residents detailed information about their water usage, custom-

ers can better manage their own consumption and even shut off water if a leak or pipe burst occurs. If a resident is heading away for the weekend and forgot to turn off their sprinklers, they can even shut off their water via the app until they return.

SMART ASSETS HELP UTILITIES MONITOR AND PREPARE FOR SEVERE WEATHER EVENTS

Sensors can be added throughout water distribution networks to collect operational data 24 hours a day. Having this data on a single, centralized water intelligence platform allows utilities to monitor, control, and monetize their water distribution networks.

Smart assets like hydrants, meters and remote pressure monitors provide utilities with the ability to capture pressure, flow, leak and temperature data through state-of-the art sensors installed at virtually any access point along the pipeline.

AUTOMATED FLUSHING REDUCES NRW

Smart assets allow for automation and remote control. This ensures assets are being used under the conditions they were designed for, and also allows utilities to address multiple objectives. For example, recent advancements in automated flushing enable utilities to flush water lines based on temperature and pH rather than a set schedule.

Not only is it a safer approach when water quality is an issue, flushing does not occur when it is not needed. A smart automated flushing unit only flows until the water quality has been restored. This is as opposed to traditional units that run water for a set time period. By only flushing when it’s needed and for the amount of time necessary, utilities can significantly reduce NRW loss.

Digital solutions are being used in the field, giving operators the ability to make efficient repairs with apps that scan QR codes.MOBILE APPS OFFER EFFICIENCIES

IN REPAIR

IoT is helping utilities leapfrog the challenges posed with aging water infrastructure. Digital solutions are being used in the field, giving operators the ability to make efficient repairs with apps that scan quick response codes. This gives crews access to valuable installation information and required resources while in the field. Getting to repairs quicker means utilities can stay on top of repairs and avoid potentially bigger issues. With smart asset management tools, utilities can better plan projects and track outcomes.

SUSTAINABLE MATERIALS LAST LONGER AND PROVIDE ENVIRONMENTAL BENEFITS

Using quality materials is a key factor in sustainability for many reasons. Longer-lasting products result in less breakage and, subsequently, less NRW loss. It also translates into less production time, which takes its own toll on water consumption and use of source material.

New materials, such as lead-free silicon-based copper alloys, are being sourced for their sustainability benefits. Silicon is the second most abundant element in the Earth’s crust, while bismuth (used in copper alloys) is only about twice as abundant as gold and is a byproduct of lead mining. Silicon-based copper alloys not only have a longer-lasting life, but also consistently exhibit zero dezincification.

North American manufacturers are going to great lengths to meet rigorous standards, like those laid out by AWWA and NSF. A simple change in choice of material can impact design life, function and performance.

North American water utilities are fortunate to have many quality manufacturers that are also recognized as leaders in technology with many solutions to choose from, including support services. This means utilities of all sizes have access to experts who are willing to listen, share local knowledge, and help find the right solutions to address individual needs. THE

FUTURE OF WATER IS NOW

All stakeholders need to come

Smart assets like hydrants, meters and remote pressure monitors provide utilities with the ability to capture pressure, flow, leak and temperature data.

together and manage water challenges. Whether you are in a water-scarce part of the world or not, using any of these strategies can help reduce non-revenue water loss and overconsumption.

Yolanda Coleman Kokayi is with Mueller Water Products. For more information,visit: www.muellerwp.com

Sludge decanters help cut ship emission control costs

By Nils Engelke and Peter PolifkaThe shipping industry has historically been allowed many environmental offenses. However, recent regulations require ship operators to clean their exhaust gases in order to sustainably protect the oceans.

Based in Sweden, Stena Line Freight is one of the world’s largest ferry operators. With more than 25,000 annual departures throughout Northern and Western Europe, it boasts more than 37 operating vessels and is one of the largest fleets in the business. It operates, among other water transportation, eight ferries that run daily from Hoek van Holland in the Netherlands to Harwich and Killingholme in England.

According to the German Federal Environmental Agency, approximately 40,000 merchant ships are traversing the world’s oceans, in addition to scores of ferries and giant cruise ships. In international trade alone, shipping holds an undisputed top position at 90%. In terms of environmental protection, however, it is far from the top position with its high emissions.

With stricter guidelines from the International Maritime Organization (IMO), the oceans will be better protected in the future from the stresses of high particulate and sulphur emissions. Beginning in 2020, the sulphur content of the fuel that ships burned on the high seas was required to be reduced to 0.5% from 3.5%, in order to meet those emissions limits. Restrictions for the North and Baltic Seas for sulphur have been limited to 0.1% since 2015.

SCRUBBER SYSTEMS HELP TO CLEAN EMISSIONS

In order to comply with the stricter limits, shipping companies would have to use high-grade marine diesel fuel oil instead of lower-cost heavy fuel oil. However, marine diesel fuel is significantly more expensive. That is why many

ship operators are relying on a more cost-effective and already tried-andtested alternative. Installing wet washers for exhaust gas cleaning in their exhaust systems makes it possible to comply with the required emissions limits.

These scrubbers achieve the required emissions reduction, but they also generate wastewater that must be cleaned before discharge, using a closed loop scrubber. Stena Line also uses scrubber systems to clean their sources of emissions.

During the scrubbers cleaning process, gases in the exhaust system are cleaned using treated seawater, thereby binding exhaust gas particles such as heavy metals, soot and hydrocarbon emissions. Depending on the amount of contamination, the wash water from the gas scrubbing will be removed and sent on to the cleaning stage of a froth flotation system.

Scrubber systems from Wärtsilä, a

company based in Finland, are used on the large ferries of Stena Line. In this system, the contaminated gas scrubbing water is cleaned in a specially developed froth flotation device called a bleed off treatment unit (BOTU). This purified water meets emissions requirements and can be discharged directly into the ocean.

However, this process has a distinct disadvantage. The large-volume, still-liquid froth flotation sludge must be temporarily stored in a tank before it can be disposed of at a port. The amount of sludge remaining to be disposed of is large, and the solids in the tank tend to form deposits. The handling of this material is correspondingly complex and expensive.

OPTIMAL SEPARATION OF SOLIDS AND LIQUIDS WITH A DECANTER CENTRIFUGE

The goal of Stena Line was to signifi-

Approximately 40,000 merchant ships are traversing the world’s oceans, in addition to scores of ferries and giant cruise ships.

Approximately 40,000 merchant ships are traversing the world’s oceans, in addition to scores of ferries and giant cruise ships.

cantly reduce the amount of residual sludge. In order to do this, the solids and liquid in the sludge needed to be further separated. Stena Line independently examined a variety of procedures in the technical development stage.

The solution was to use a decanter. Unlike other separation processes, decanters only require a small amount of space, avoid emissions, and require only minimal operating effort with their continuous, automatic operation.

Stena Line decided to use high-quality decanter centrifuges manufactured in Germany for its larger ships. The company uses Flottweg decanters to treat the resulting sludge from froth flotation and to significantly reduce the volume of the sludge. By dehydrating the solids, this hazardous waste can be temporarily stored in containers on the ship so that it can be disposed of at the nearest port in an environmentally-safe manner.

During the development and optimization phase, a used model, type Z1L decanter built in 1985, was initially installed on Stena Transit vessels.

With the model Z2E-4/4X1, a completely new machine is now available for this application. This optimized design,with slightly larger drum volume, contains all of the improvements of the new Z2 series.

Fed through a centrally-located inlet pipe, sludge passes through to the inlet space of the screw. After gentle pre-acceleration, it goes through the distribution openings in the drum. The drum has a cylindrical/conical shape and rotates at a carefully calibrated speed.

When the full rotational speed is reached, the sludge becomes attached to the drum shell as a cylindrical ring. Therefore, under the influence of centrifugal force, the solids settle on the inner wall of the drum. At the same time, a screw rotates in the interior at a lower differential speed and moves the settled solids toward the conically-narrowed end of the drum, where they are discharged downward.

This relatively dry sludge is collected and disposed of in a port. The clarified liquid flows to the cylindrical end of the drum, where it runs out through openings in the drum cover, clean and depressurized. The drum casting is made from high strength duplex steel and the screw/scroll is made from a stainless-steel casting. This provides optimal protection against corrosion, which is incredibly important for the highly-aggressive residues generated from the exhaust gas scrubbing.

The success of the process is also fast and efficient on the high seas. If the sludge layer after the BOTU process with 2% total solids (TS) by weight percentage still contains a large amount of aqueous material, the decanter drains about 20% – 22% TS by weight percentage. The cleaned aqueous phase is released with the cleaned water from the froth flotation, so that only a very small residual amount of sludge remains. Thanks to the process, it is possible to achieve a reduction from 500 kg/h to 45 kg/h of froth flotation sludge, with a corresponding minimizing of the volume.

The small amount of remaining sludge fits into a small container, which can easily be taken off board. It is usually disposed of in the port of Rotterdam. The decanter is a huge success, not only from an environmental point of view, but also

With the model Z2E-4/4X1, a completely new machine is now available for this application. The decanter is at the end of the cleaning process.

economically. And, the disposal process is significantly optimized since there is no more weekly disposal by truck. The cost savings are therefore significant.

Nils Engelke and Peter Polifka are with Flottweg SE. For more information, visit: www.flottweg.com

HOW COVID-19 HAS CHANGED THE CONSULTING ENGINEERING BUSINESS FOREVER

THE CHALLENGES WE FACED

By Tewfik AtiaWhen COVID-19 hit Canada in March 2020, it sent our industry scrambling. In the first few days and weeks, as everything began to shut down, we struggled to figure out what environmental work would be classified as essential. Also, what could we do to ensure that “business as usual” could be safely conducted without exposing our teams to a potentially