Purchasing pollution liability insurance Manitoba takes centre stage for water Creating wastewater system capacity ENVIRONMENTAL GOVERNMENT OFFICES AND ASSOCIATIONS ES&E’S ANNUAL GUIDE TO PM40065446 AUGUST 2023 WWW.ESEMAG.COM @ESEMAG

—

ABB’s new range of modular transmitters for water analysis.

With their modular design, intelligent diagnostics and full approvals, our AWT420 advanced water transmitters offer a flexible, high performance solution for a wide range of industrial applications, from water and wastewater through to chemical and petrochemical. Packed with a host of features including Bluetooth® connectivity, dual PID control and EZ-Link™ sensor connection, water analysis has never been easier. abb.com/wateranalysis

Measurement made easy.

The versatile solution that works the way you want it to work.

Editor and Publisher STEVE DAVEY steve@esemag.com

Managing Editor PETER DAVEY peter@esemag.com

Sales Director PENNY DAVEY penny@esemag.com

Sales Representative DENISE SIMPSON denise@esemag.com

Accounting SANDRA DAVEY sandra@esemag.com

Design & Production MIGUEL AGAWIN miguel@esemag.com

Circulation BRIAN GILLETT ese@mysubscription.ca

TECHNICAL ADVISORY BOARD

Archis Ambulkar, OCT Water Quality Academy

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution. Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors.

Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice.

Canadian Publications Mail Sales

Second Class Mail

Product Agreement No. 40065446

Registration No. 7750

Subscription Changes?

Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024

Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com

Denise Simpson Sales Representative 905 960 4064 denise@esemag.com

Environmental Science & Engineering 220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727 4666 www.esemag.com

FEATURES 6 Looking forward to WEFTEC 2023 in Chicago! 8 Manitoba takes centre stage for water 10 Cruise ships ready for Canada’s mandatory wastewater measures 12 Canadian cities launch hydrant fountain projects during record heat 14 Canadians fare well at AWWA’s 2023 conference and exhibition 18 Harnessing the power of wastewater treatment plant digesters with co‑digestion 22 The use of artificial intelligence in air quality monitoring 26 Students design experiential learning tool kits to educate public about stormwater 28 NASA’s brine processor pushes water reclamation to 98% on ISS 29 Dosing hypochlorite in a new wastewater treatment plant 30 Exploring the vital role of pollution liability insurance for businesses and wastewater treatment plants 33 UBC researchers say rain gardens can capture 90% of toxic tire runoff 35 Overcoming anaerobic digester failures: Shared lessons from municipal and industrial facilities 38 Addressing the issues of legacy gas wells in Ontario 40 Quebec’s new biochar plant set to be largest in North America 41 CEPA amendments aim to strengthen federal management of toxic chemicals 42 Monitoring geologic carbon sequestration sites is needed to protect groundwater quality 46 Creating wastewater system capacity to support housing: Private‑side inflow and infiltration reduction success 49 BC considers bonds to cover high‑risk industrial site project cleanups 59 MABR modules installed as part of Elmira WWTP upgrade 60 What are the pros and cons of arch chamber and modular tank systems? 62 Nutrients and not temperature impact blue green algae blooms DEPARTMENTS 57 Product Showcase 60 Professional Cards 62 Ad Index CONTENTS August 2023 • Vol. 36 No. 4 • ISSN-0835-605X www.esemag.com @ESEMAG Environmental Science and Engineering Magazine 10 30 ES&E ANNUAL GUIDE TO: GOVERNMENT pg. 53 ASSOCIATIONS pg. 50 4 | August 2023

t e wat e r, Biosolids & Bi o g a s

o mple te ra n g e o f ma rke t p ro du c t s. Le t u s sh ow yo u

•

Rotary Lobe Pumps & Grinders

• Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circur, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag Polymer – Liquid and Dr y Systems

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – Stations Pump & Stormwater CSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

T: (905) 864-9311 F: (905) 864-8469 www.proaquasales.com 7-264 Bronte St. S., Milton, ON L9T 5A3 04 16

Looking forward to WEFTEC 2023 in Chicago!

Attending the Water Environment Federation’s annual WEFTEC event has been an important part of my career and professional development. This began in 1987, when during the first Great Canadian Icebreaker reception in Philadelphia, we formally announced the launch of Environmental Science & Engineering Magazine.

Some years later, I was appointed as a Director of the Water Environment Federation (WEF) to represent the Water Environment Association of Ontario (WEAO). At that time, annual Director Meetings were held during WEFTEC events. While attending these, I really began to appreciate what a well-run and important organization WEF was for its 34,000 members and 75 member associations like WEAO.

This year’s Great Canadian Icebreaker is scheduled to be held during WEFTEC 2023 at the Bandit Restaurant and Bar in Chicago on October 1. Visit www.weao.org for more details.

WEFTEC will run from September 30 to October 4 at McCormick Place in Chicago, Illinois.

According to a WEF spokesperson, this year’s opening general session will be a little different than past ones. “Creating a life free of water challenges for all requires us to expand our ideas around who is part of the water community, how we connect with and engage in our communities, how we create and deliver solutions, and to reimagine what we leave behind. This year’s opening general session will combine culture, music, and storytelling to celebrate water, people, and community, and will inspire us to think differently about our work and our world.”

With nearly 150 educational sessions and 17 hands-on workshops, attendees can choose from topics that matter to them, and learn practical skills, techniques, and best practices to apply directly to their job.

Session focuses include municipal design and operations, utility management and leadership, collection

systems, industrial issues, stormwater and watershed management and more. Key workshop topics include:

• Making resource recovery concepts come to life: Operator education through interactive simulation.

• Wastewater microbiology.

• Fate of PFAS through thermal processes at water resource recovery facilities.

• Activated sludge and biological nutrient removal process control: Hands-on in the real world.

• Communicating with public officials and the general public.

• Refinery and petrochemical wastewater treatment: Operations, control, and troubleshooting.

• Aeration control for practitioners: Optimization of aeration, process, and energy.

• Dewatering optimization.

• Inflow and infiltration program management: Strategic approaches for meaningful reduction.

• Design and implementation of membrane bioreactors in water recycling.

• Measuring and reducing water resource recovery facility greenhouse gas emissions.

• Applying resilience and implementing practical applications in a changing climate.

WEFTEC 2023 will also offer 12 Learning Exchanges. These will provide attendees with opportunities to share

their expertise and perspective about trending themes, technologies, and topics in the water sector with small peer groups in a roundtable format.

Additionally, there are 10 technology spotlights scheduled. Formerly called Mobile Sessions, these sessions begin in the exhibition hall and include groups of companies sharing product and service solutions. Often these sessions also tour the exhibition floor to visit selected companies.

During the annual Operations Challenge at WEFTEC, the best wastewater collection and treatment personnel in the industry get to demonstrate their skills and knowledge. In the competition, teams—including several from Canada—will compete to earn the highest score in five different events. Each team includes four members and often a coach as well. Each event is designed to test the diverse skills required for the operation and maintenance of water resource recovery facilities, collection systems, and laboratories. The five events are collections systems, laboratory, process control, maintenance, and safety.

This year, attendance and the number of exhibitors are expected to return to pre-pandemic levels. Hopefully, we will see more fellow Canadians at WEFTEC 2023 than in the past few years. As I first found out in 1987, these events truly reveal the scale and importance of the wastewater sector, especially to young professionals.

Be sure to visit ES&E Magazine’s booth at the Ontario Government Pavilion during WEFTEC to say hi, and pick up our latest issue. (Booth # 6527)

For more information on WEFTEC, visit: www.weftec.org

Steve Davey is the editor and publisher of ES&E Magazine. Please email any comments you may have to steve@esemag.com

6 | August 2023 EDITORIAL COMMENT

The Navy Pier is a fun place to visit while in Chicago, offering great views of both the city and Lake Michigan. Excellent boat tours depart from here. Credit: noelpowell, stock.adobe.com

BY STEVE DAVEY

Learn more about the M3 and Wall Skids at www.blue-white.com Fluid Metering Solutions Made Simple. FLEXFLO® M3 For Simple and Precise Chemical Dosing with No Vapor Lock and No Loss of Prime. Simple Solutions for Precise, Dependable Chemical Dosing CHEM-FEED® WALL SKIDS Short on Floor Space? Here’s the Solution. Ships Fully Assembled.

Manitoba takes centre stage for water

Since Winnipeg was named home of the Canada Water Agency, Manitoba water project announcements have been nonstop.

By David Nesseth

Known for its more than 1,000 lakes, Manitoba has been making headlines with a series of water-related initiatives, including the modernization of its water strategy, access to water network data, and the establishment of new invasive species inspection stations. The government is also ensuring it keeps pace with wastewater infrastructure upgrades and changes to drinking water guidelines for lead.

These initiatives set the stage for the $750-million Canada Water Agency that will be headquartered in Winnipeg. The new agency is tasked with providing policy leadership and a comprehensive approach to freshwater challenges and opportunities.

With the presence of institutions like the Freshwater Institute and the International Institute for Sustainable Development, Winnipeg has long been recog-

nized as a hub for water-related issues, particularly in the Lake Winnipeg basin.

But, apart from news of flooding and algal blooms, the city has recently garnered more positive attention for the provincial investment of $75,000 to enhance the Lake Friendly Initiative that improves water quality in Lake Winnipeg and its watershed. Also, the city of 750,000 just celebrated the unveiling of the refurbished Broadway Centennial Fountain in downtown Winnipeg to serve as a tribute to Shoal Lake 40 First Nation and the source of the city’s drinking water.

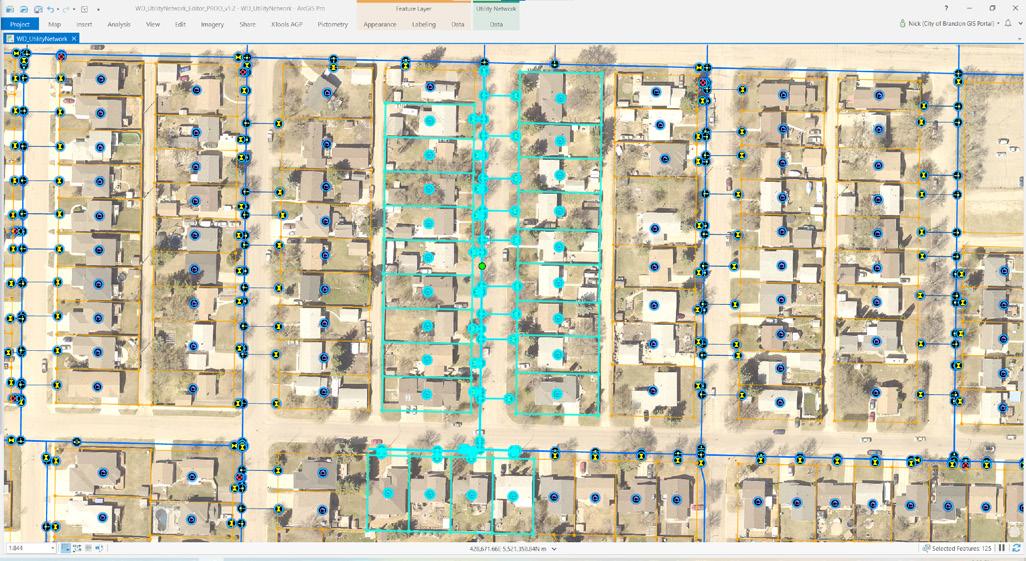

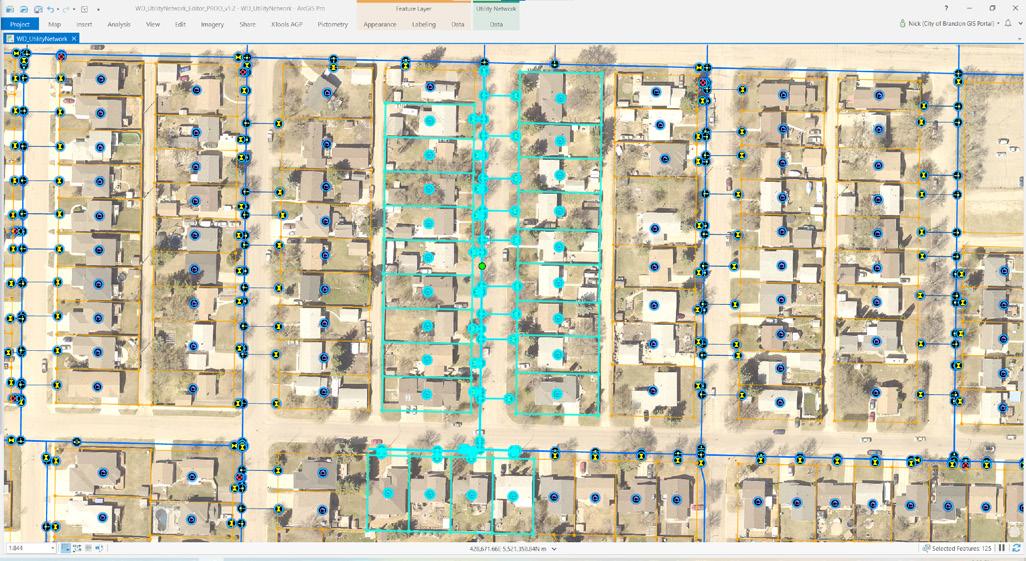

VISUALIZING A WATER NETWORK

However, water-related developments extend beyond Winnipeg. In the City of Brandon, a partnership with Esri Canada has introduced GIS software to manage and share real-time water net-

work information. The implementation of the ArcGIS Utility Network has revolutionized field operations coordination, allowing immediate updates on the status of valves and other equipment. This improved communication enables prompt identification of affected addresses during emergency incidents or planned outages.

The city’s Municipal Assets Manager, Jamie Hart, called the ArcGIS Utility Network a “gamechanger” in terms of coordination. When a field crew closes a valve, for instance, anyone looking at the utility network map in the office or field can immediately see that the valve is closed and when it is opened.

“We’re at the beginning of our journey in this transformation,” Hart said. “The information value we’re able to deliver now across the utility and the city as a whole is exciting.”

GOING GEOTHERMAL

East of Winnipeg, the City of Selkirk is embracing sustainable practices by converting its water treatment plant to use a geothermal heating and cooling system. With completion of the geothermal conversion for both halves of the plant, Selkirk has significantly reduced its corporate greenhouse gas emissions. The geothermal system not only minimizes environmental impacts, but also helps control moisture within the plant, preventing mould production and reducing corrosion.

“Inside the water plant is a very moist environment, which sometimes isn’t a good thing when you’re dealing with pumps and fixtures, so you want to control that moisture,” explains Selkirk’s Director of Operations, Dan McDermid. “The removal of moisture out of the air reduces the potential for mould production and reduces corrosion, so it’s a lot easier on the equipment.”

Selkirk’s wastewater treatment plant, built in 2021, was also converted to a geothermal heating and cooling system. The two plants accounted for 30% of Selkirk’s total corporate GHG emissions prior to the conversions.

Prior to the partial conversion, the water treatment plant emitted 175 tonnes of CO2e in 2018. By comparison, in 2020, the first full year following the

The new Canada Water Agency will be headquartered in Winnipeg (pictured) and tasked with providing policy leadership and a comprehensive approach to freshwater challenges and opportunities. Credit: Thamyris, stock.adobe.com

Environmental Science & Engineering Magazine 8 | August 2023 WATER

conversion of half the plant to geothermal, it produced just 74.7 tonnes.

Selkirk’s Chief Administrative Officer, Duane Nicol, says it’s a community goal to move “towards being the greenest utility we can be.”

WWTP TASK FORCE

While the Canada Water Agency has grabbed recent headlines in Winnipeg, a strong focus remains trained on the delays and rising costs associated with the multi-phase upgrades to the North End Water Pollution Control Centre, the city’s oldest and largest sewage facility. To ensure the project remains a priority, Winnipeg officials formed a task force in collaboration with the province in early spring.

The task force includes experts in wastewater treatment, such as Professor Jan Oleszkiewicz from the University of Manitoba and Michael Paterson from the Experimental Lakes Area. The upgrades, which have soared to $2.2 billion, aim to remove phosphorus and nitrogen from treated wastewater before it is discharged into the Red River.

At the initial task force meeting, the City of Winnipeg’s representatives said they are working to remove as much phosphorus as possible in the short term prior to adding a biological nutrient removal process.

“It was some real moving forward and clearing the air about what we are going to do about wastewater treatment, including phosphorus removal and building capacity for development over the long term,” explained Winnipeg City Councillor Brian Mayes, following the first task force meeting. “Staff were clear that we are committed to our approach and to making progress.”

In late July, Manitoba announced $7.5 million for Winnipeg's southwest sewer interceptor project and $433,000 for risk mitigation infrastructure at the Darcy Sewer Lift station. The work is part of Winnipeg’s long-term combined sewer overflow project to build additional system capacity, and get more wastewater to the South End Sewage Treatment Plant while reducing nutrient loading into freshwater systems.

LEAD TESTING

Another significant development in Manitoba is the government’s commitment to addressing lead contamination in drinking water. Winnipeg schools have faced challenges in meeting new federal guidelines for lead levels. To assist with compliance, the Manitoba government established a $1.6-million grant program to fund testing and mitigation efforts. Most schools have already tested their drinking water, and the results indicate that most are below the new lead standard.

“Safeguarding our children against lead in drinking water is an ongoing effort, but we want to acknowledge the tremendous progress schools have made to address Health Canada’s new lead standard,” Environment and Climate Minister Kevin Klein announced in response to the new grant for testing.

Health Canada revised the national guidelines for lead in drinking water in 2019. The maximum allowable concentration of lead in drinking water dropped from 0.01 mg/L (set in 1992) to 0.005 mg/L.

WATER ACTION PLAN

Recently, Manitoba released its initial water action plan based on the first comprehensive update of its water management strategy in nearly 20 years. The plan includes targeted investments of nearly $1 billion over five years, with a major focus on flooding mitigation around Lake St. Martin. Additionally, it allocates funds for enhanced drinking water safety, resources for the Manitoba Water Services Board, and implementation of the water strategy.

Manitoba’s water management strategy, released in November 2022, is aimed at conserving, protecting, and efficiently utilizing ground and surface water for years to come.

David Nesseth is a writer for ES&E Magazine. Email: editor@esemag.com

With the completion of the geothermal heating and cooling system conversion for both halves of its water treatment plant, the City of Selkirk has significantly reduced its corporate greenhouse gas emissions. Credit: City of Selkirk

August 2023 | 9 www.esemag.com @ESEMAG

Utility Network Screenshot: The implementation of the ArcGIS Utility Network has revolutionized field operations coordination, allowing immediate updates on the status of valves and other equipment in Brandon. Credit: Esri Canada

In Canada’s busiest cruise ship area – the Pacific region – nearly all ships implemented the new measures during the voluntary period, according to Transport Canada reporting records at the ports of Vancouver, Victoria, Nanaimo, and Prince Rupert. Credit: Andreas Prott, stock.adobe.com

Canadian cruise ships ready for mandatory wastewater measures

By ES&E Staff

Canada’s federal government has released mandatory environmental measures for cruise ships that address treatment and discharge practices for greywater and treated sewage. The Ministry of Transport changes, which are effective immediately, follow a one-year period when the environmental measures were voluntary for the $4-billion Canadian cruise industry.

The new measures prohibit the discharge of greywater and treated sewage within three nautical miles from shore, where geographically possible across Canada. Cruise ships must treat sewage to fecal coliform counts equal to or less than 250/100 ml within three nautical miles from shore.

Greywater can consist of drainage from sinks, laundry machines, bathtubs and showers, dishwashers, cleaners, and

cooking oils. Blackwater, or sewage, can contain fecal coliforms, ammonia, chlorine, and a variety of toxic pollutants, such as pharmaceuticals, heavy metals, hydrocarbons, and organochlorides.

The measures also require cruise ships to strengthen the treatment of greywater together with sewage before it is discharged between three and 12 nautical miles from shore south of 60°N. This must be done using an approved treatment device in non-Arctic waters. The measure complements existing regulations for Arctic waters under the Arctic Waters Pollution Prevention Act.

“Cruise ships are an important part of our economy and tourism sector, but they need to operate in a more sustainable manner to protect our waters and our environment,” announced Minister of Transport, Omar Alghabra, in a statement. “The measures introduced are additional tools in our tool box to keep them accountable,” Alghabra added.

In the Pacific region, Canada’s busiest

cruise ship area, nearly all ships implemented the new measures during the voluntary period, according to Transport Canada reporting records at the ports of Vancouver, Victoria, Nanaimo, and Prince Rupert. Cruise ships will be subject to fines for non-compliance with these new mandatory measures, up to a maximum fine of $250,000 under the Canada Shipping Act, 2001.

West Coast Environmental Law in Vancouver has raised concerns over potential loopholes in the new measures. The environmental lawyers’ group says a cruise ship is allowed to dump greywater and sewage within three miles of shore using a marine sanitation device if there are no onshore reception facilities available during the intended voyage.

“For example, in the Great Bear Sea, where Canada’s first marine protected area network is being implemented, there are many narrow passage ways and remote areas where the loopholes in this order may permit cruise ships to dump close to shore,” the law group wrote in a statement. “We also worry that because Canada does not require third party monitors on vessels to observe, it will be very difficult to enforce this order, especially in remote areas.”

The new measures do exceed the current Canadian regulations aligned with international standards from the International Maritime Organization and complement mandatory requirements in place through the Vessel Pollution and Dangerous Chemicals Regulations.

Transport Canada’s measures will also be supported by periodic reporting by the cruise operators to assess levels of compliance. These reports will be made public and the information from them will support a future regulatory approach to controlling discharge of greywater and blackwater in Canadian waters, according to Transport Canada.

These measures are being implemented by an Interim Order, which has the same effect as a regulation, but allows for action to be taken immediately while the process for making the regulations mandatory for the longer term is being implemented.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 10 | August 2023 WASTEWATER

Canadian cities launch hydrant fountain projects during record heat

By ES&E Staff

Lethbridge, Alberta, and Waterloo, Ontario, are joining the City of Ottawa this summer in offering 24/7 hydrant hookups to beat the heat with seasonal drinking water stations.

While Lethbridge’s and Waterloo’s pilot projects are just getting off the ground in locations across the cities, Ottawa’s hydrant fountain program has returned due to popular demand following a successful launch last summer.

The hydrant fountains arrived as temperatures set heat records worldwide. The average worldwide temperature in mid July reached 17.23°C, with records already broken or tied three times. The previous record for average daily temperature was in mid-August 2016.

Lethbridge invested $15,000 in its hydrant fountain pilot. The stations were designed and manufactured by staff at the city’s water treatment plant. “Access to drinking water is important to the general population but also, it’s perhaps most important to the vulnerable members of our community,” explained Lethbridge City Councillor Nick Paladino, who spearheaded the initiative. “I look forward to seeing how the pilot progresses through the summer and how the community uses them.”

In Ottawa, city councillors said the first season of the hydrant fountain program was appreciated by residents, tourists and even pets. In 2023, the city included the option for residents to request new hydrant fountain locations.

The designs of the hydrant fountains vary between the three cities. While the Ottawa and Waterloo hydrant fountains offer a water bottle filling element to the fountain setup, as well as a pet-level drinking component, the Lethbridge fountains are more basic, offering a simple low-level nozzle for refills.

Waterloo officials noted that local fire officials were consulted on the project to ensure that the fountain does not interfere with the normal use of the fire hydrant. “Take a sip, fill your bottle, or offer your pet a drink,” states a poster on the Waterloo fountains.

A City of Cambridge, Ontario councillor recently put forth a motion to bring back public drinking water fountains, after they were removed around 2006 due to the Walkerton E. coli contamination crisis. The councillor said one fountain could cost in the neighbourhood of $15,000, and the idea must consider the cost of potential vandalism. Council also discussed the possibility that the fountains could be designed as art projects.

The concept of bringing back water fountains was also being considered by Hamilton, Ontario.

For more information, email: editor@esemag.com

Lethbridge’s hydrant fountains were designed and manufactured by staff at the city’s water treatment plant. Credit: City of Lethbridge

Environmental Science & Engineering Magazine 12 | August 2023 WATER Visit our website to view our training schedule and browse our online Drinking Water Resource Library. www.wcwc.ca

TRUSTED

Improve your f ilter per formance

Granular media filtration is a specialized process and each filter configuration is unique. With AWI’s site-specific approach to filter optimization you can expect improved filter performance, an operator-friendly treatment process, and the training and technical support to maintain your filters in optimum condition.

AWI’s innovative filter optimization products include the Phoenix Underdrain and Panel Systems. These custom-engineered solutions guarantee uniform backwash water flow distribution, ensuring sustainable filter performance and long service life of your media bed.

Contact one of our knowledgeable filtration specialists to learn how AWI’s approach to filter optimization can help you reach your filter performance goals.

Visit us at WCW Booth # 92 RELIABLE.

.

.

PROVEN

Phoenix Panel System with Air Scour

Filter Assessment & Pilot Studies

Filter Media Design & Supply

Canadians fare well at AWWA’s 2023 conference and exhibition

By ES&E Staff

By ES&E Staff

An estimated 10,000 water professionals from throughout the world gathered for the American Water Works Association’s Annual Conference and Exposition (ACE23) this June in Toronto. The large Canadian contingent earned honours in a range of categories from the Best of the Best Taste Test for tap water, to awards for innovation, recruiting, landmark preservation, and public communications.

Coming off last year’s event in Texas, the AWWA even planned a U.S. vs. Canada hockey matchup, with teams representing the Illinois and Ontario sections of the AWWA. They faced off in the “No Water, No Hockey” match, benefiting AWWA’s philanthropic arm, Water Equation.

“Water is important, even when it’s frozen,” joked AWWA CEO David LaFrance, in a promotional video for the Toronto event, where the AWWA will return in 2029.

The theme of this year’s event was “The Future of Water is 2050”. Autumn Peltier, Anishinaabe Indigenous rights and water advocate from the Wikwemikong First Nation on Manitoulin Island opened ACE23’s general session by providing a land acknowledgment and sharing her personal water story. “The water needs all of you, and we all need water,” she told attendees. “Water is life.”

WATER TASTE TEST

The New Brunswick City of Miramichi won the Best of the Best Water Taste Test at ACE23. The community of nearly 19,000 residents is the largest city in northern New Brunswick. With 4,500 service connections, 175 kilometres of watermains, and one water treatment plant, the area operates three separate water systems sourced from 19 active ground wells.

Receiving the Best Tasting Tap Water award in person were Darren Row, Miramichi’s director of engineering, and Jay Shanahan, the municipality’s director of public works.

INNOVATION

Another prestigious win for Canada came for the Ontario Regional Municipality of York’s Ranin Nseir, recipient of the AWWA Innovation Award, which is designed to “inspire and implement innovative thinking and best practices” within the water industry. Nseir, project manager of inflow and infiltration reduction in York, won the honour for her part on the path towards reducing inflow and infiltration by 40 million litres per day in the York Durham Sewer System by 2031.

HYDRANT HYSTERIA

Canadians also had a strong showing in the annual

Taste Test Winners ACE23: (left to right) Darren Row, Director of Engineering, City of Miramichi; Jay Shanahan, Director of Public Works, City of Miramichi; Dave Gaylinn, Senior Public Affairs Specialist, AWWA. Credit: AWWA, Black Ram Media

Hydrant

The Region of Peel placed first in the women’s Hydrant Hysteria competition. Credit: Elaine Gilliland

Environmental Science & Engineering Magazine 14 | August 2023 WATER

continued overleaf…

VEGA’s commitment to providing the best process measurement solutions means more than just producing precise and reliable instrumentation; it means being there whenever you face a challenging measurement application. That’s why VEGA is proud to now o er direct sales and support to the Atlantic Provinces. SOME

VEGA Instruments, Canada Ltd. +1 833 538 8342 | canadaquotes@vega.com www.vega.com

CAN THE VEGA EXPERIENCE DO FOR YOU? Talk to us today and find out.

WHAT

WOULD

CUSTOMER SERVICE.”

just call it The VEGA Experience.

OFFERING Direct Sales and Support to the Atlantic Provinces

CALL IT “WORLD-CLASS

We

NOW

Hysteria competition in which two-person teams assemble a fire hydrant as quickly as possible. In the women’s competition, the Ontario Region of Peel placed first with a total assembly time of 1 minute and 51 seconds. Peel has more than 27,000 fire hydrants across Brampton, Mississauga and Caledon. Toronto placed third in the women’s competition with a time of 2 minutes and 20 seconds.

PUBLIC COMMUNICATIONS

Metro Vancouver’s public communications team took home top honours for fostering and supporting the development of public outreach programs and integrating public affairs as a core element of utility planning and management. AWWA states that the award is intended to “encourage utilities to incorporate public outreach into their operating plans, as well as to provide examples of successful public outreach programs and best practices.”

RECRUITMENT

Clara Shea, of AWWA’s Atlantic Canada Section, won the Zenno A. Gorder Award for recruiting the most new members. Shea is the executive director of the Atlantic Canada Water and Wastewater Association, based in Dartmouth, Nova Scotia.

WATER LANDMARKS

ACE23 honoured two Ontario cities for their effective preservation of sites at least 50 years old that have had a “direct and significant relationship with water supply, treatment, distribution, or technological development.”

The City of Guelph was recognized for its Waterwork Engine House and Pumping Station built in 1879, while the City of Hamilton was honoured for its first waterworks built in the 1850s.

According to the City of Guelph’s list of Designated Heritage Properties, the stone engine house was “originally only intended for fire protection. But the excavation of the pumping station

changed the purpose of the waterworks when a spring was struck yielding a large supply of uncontaminated water which the Waterworks Commission believed could be used for domestic purposes.”

The Hamilton waterworks was designated a National Historic Site of Canada in 1997 because “it is an early, rare surviving example of a Victorian industrial building complex that is both architecturally and functionally largely intact,” states Parks Canada. It was designed by prominent Canadian engineer Thomas C. Keefer.

ACE is the longest-running water conference in the world, having first convened in 1881. Next year’s event is scheduled for Anaheim, California.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 16 | August 2023 WATER 1 5 2 3 4 Supports OPC connectivity for fast, reliable data transfer Allows for data sharing with third-party OPC clients/servers over WAN or LAN Displays real-time data on a convenient dashboard Monitor your facilities and receive voice, text, and email notification Make configuration changes from anywhere. Features &Benefits egrate real-timedatafrom AlarmAgent.comwith control stemsand other third-party applications.It’sacost-effective olution forindividualand corporateusers, and theperfecttool or OEMs tocreatetheirownHMI/SCADA applications. AlarmAgent.com Server AlarmAgent.info CloudServer HMI/SCADA Applications olu t syst RACO OPCClient RACO OPC Client RACO OPC Client Remotely and Securely Monitor critical Infrastructure. Worry less with AlarmAgent.info® 3230B American Drive Mississauga, ON, L4V 1B3 1-800-811-2811 | info@SPDSales.com www.spdsales.com Official Distributor 905.678.2882 | spdsales.com Improve nutrient removal with continuous online measurements of BOD, COD, ammonium, nitrate, nitrite, UVT, and more. Reliable ISE sensors with individually replaceable electrodes Accurate UV/VIS sensors with built-in ultrasonic cleaning YSI.com/IQSN © 2022 Xylem Inc. IQ SensorNet Process Monitoring CONTROL CONFIDENTLY

Announcing Promotions at Associated

Associated Engineering is pleased to announce the following promotions in our Water teams in Alberta and Saskatchewan.

Based in Calgary, Coenraad specializes in water supply and treatment. He has over 30 years of mechanical engineering experience, encompassing project management, feasibility studies, design leadership, and construction planning. Coenraad succeeds Andy Barr, who has moved into a senior advisory role providing project management, planning, and design support to our water teams in Alberta and across the company.

Working in our Regina office, Nancy provides leadership to our water team, as well as delivering special projects. A Senior Civil Engineer and Project Manager, Nancy has over 28 years of experience in planning, and design and construction of infrastructure projects, most recently, the Westside Irrigation Project Pre-Design. Cory Wihlidal, P.Eng., remains in his role as Manager, Regional Water in Regina, working in collaboration with Nancy.

Jeff is the new Manager of our Water Division in Calgary. He is a Process-Mechanical Engineer with almost 20 years of experience, specializing in computational fluid dynamics, hydraulics, and design of pump stations and water and wastewater treatment plants. Jeff brings expertise in planning, design, construction management, commissioning, project management, and asset management.

Ryan works from our Edmonton office and has over 15 years’ experience specializing in the design of pump stations, water and wastewater treatment facilities. His experience includes planning, modelling, design, construction, and commissioning. Ryan works with Jeff Fetter, P.Eng., Division Manager of our Water Division in Edmonton, including a Regional Water team led by Grant Dixon and a Power and Automation team led by Steve Justus, P.Eng.

Associated’s multi-discipline teams of water specialists, offer expertise from studies and assessments to the design and upgrade of water infrastructure projects. We collaborate with clients to develop sustainable and resilient solutions. Together, we can shape a better world.

Coenraad Pool, M.Eng., P.Eng. Division Manager, Water Calgary

Jeff Ruzicka, P.Eng. Manager, Mechanical Calgary

Coenraad Pool, M.Eng., P.Eng. Division Manager, Water Calgary

Jeff Ruzicka, P.Eng. Manager, Mechanical Calgary

www.ae.ca

Nancy Inglis, P.Eng., PMP Division Manager, Water Regina

Ryan Wirsz, P.Eng. Manager, Urban Water Edmonton

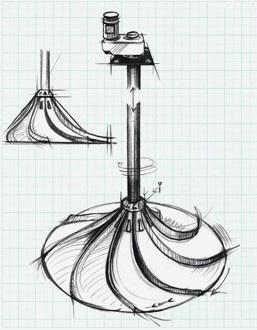

Harnessing the power of wastewater treatment plant digesters with co‑digestion

By Tom Ferencevic

As innovative technologies continue to push the concept of circular economies, enhancing and optimizing existing systems can be just as impactful. Infrastructure already in place for environmental and municipal needs, such as wastewater treatment plants (WWTPs), can be optimized to contribute to cyclical solutions and benefit both the economy and the environment.

Wastewater is a source of biogas, and WWTPs comprise existing infrastructure that could be rapidly put into service using co-digestion to reduce the carbon footprint of municipalities, while also making them more economically resilient.

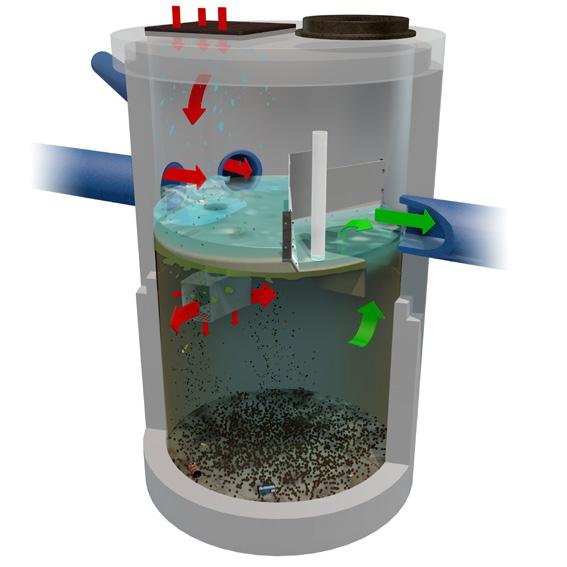

WHAT IS CO‑DIGESTION?

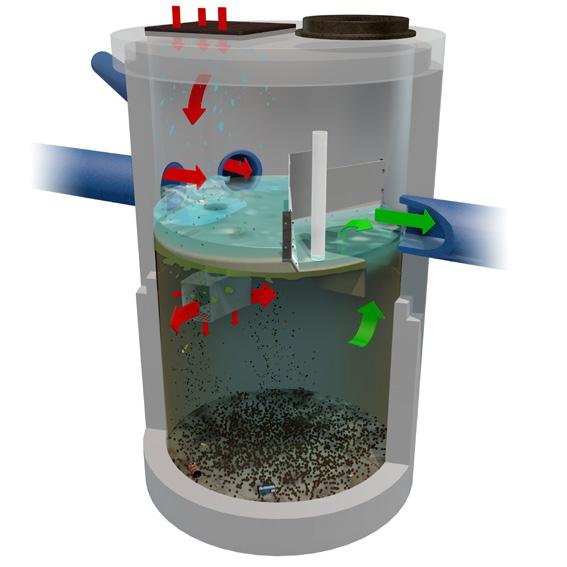

Co-digestion is a process that involves the anaerobic digestion of two or more types of organic waste materials in a single digester tank. The concept involves mixing lower-energy materials with higher-energy materials. Balance is taken into consideration and depends on the biochemical characteristics of the materials to keep the biological system operating optimally.

Lower energy content materials include wastewater sludge and manure. In contrast, food wastes usually have considerably higher energy content. Therefore, they often generate tipping fees to those who are able to accept them and utilize them responsibly.

HOW DOES ANAEROBIC DIGESTION WORK?

The anaerobic digestion process involves breaking down organic matter in the absence of oxygen. During digestion, bacteria break down the organic matter and produce biogas, primarily composed of methane and carbon dioxide. Biogas is a renewable fuel source that can be used to produce heat and electricity.

Several factors can affect the efficiency and effectiveness of the co-digestion process. These include: the temperature and pH of the types of sludges, types and quantities of source separated food waste used, and the organic loading rate of the organic matter in the digester.

Overall, co-digestion is an effective means of increasing biogas production of WWTPs while also providing a means of treating organic waste materials. Existing biogas technology can be an important tool for reducing greenhouse gas emissions, creating a more sustainable future, and making municipal infrastructure profitable and resilient.

UNDERSTANDING BIOGAS AND CLIMATE CHANGE

The environmental and green energy benefits of biogas are

significant. This is in no small part because it is primarily composed of methane (CH4) and carbon dioxide (CO2). Methane is a potent greenhouse gas that is approximately 25 times more effective at trapping heat than carbon dioxide over a 100-year time frame.

When organic waste materials, such as food waste, decompose in landfills, they produce methane, which is released into the atmosphere. By diverting these organic waste materials to anaerobic digesters instead, we can capture the methane and use it as renewable energy, reducing greenhouse gas emissions.

In terms of climate change, biogas has the potential to make a significant impact. The International Energy Agency estimates that the global potential for biogas production could be as high as 12% of current global natural gas production by 2040. If we can reach this level of biogas production, it could make a significant contribution to reducing greenhouse gas emissions and mitigating the impacts of climate change.

WASTEWATER TREATMENT PLANTS: A SOURCE OF BIOGAS

Wastewater treatment plants generate large quantities of sludge. This material is commonly treated in an anaerobic digester where the primary concern is to reduce the occurrence of harmful pathogens and produce a safe and stable product. But it is also a source of renewable energy.

The process of anaerobic digestion of this material produces some biogas which can be used on-site to power the WWTP or sold to the grid as a renewable energy source. Several municipalities convert it to CRNG (compressed renewable natural

Environmental Science & Engineering Magazine 18 | August 2023 ANAEROBIC DIGESTION

Energy produced by various feedstocks.

gas) to run their municipal fleet vehicles.

In addition to sludge, plants can also receive other types of organic waste materials, such as food waste, grease, and fats, which can be added to the anaerobic digester. Combining these different types of organic waste materials in the digester can significantly increase energy production, further enhancing the potential for renewable energy generation.

SUCCESSFUL IMPLEMENTATION OF CO DIGESTION AT A WASTEWATER TREATMENT PLANT

The Moosburg Co-Digestion Plant is a large-scale co-digestion facility located in Moosburg, Austria. The plant is operated by a municipal wastewater treatment company, and it is one of the largest co-digestion facilities in Europe. Fitec’s partners in Germany, Finsterwalder Umwelttechnik, have acted as consultants in the facility’s transition to co-digestion, making them key partners in their success.

organic materials, making biogas from food waste and agricultural waste, along with wastewater sludge from the munic-

ipal WWTP at a ratio of 47:18:35. The feedstock is sourced from a range of

The plant processes a variety of continued overleaf…

www.esemag.com @ESEMAG Proud distributor of these brands: WATER AIR SOIL METEOROLOGY BIODIVERSITY HEALTH & SAFETY LABORATORY GEOMATICS Vaughan Montreal WWW.GENEQ.COM ENVIRONNENT ENVIRONMENT 10700 Secant St, Montreal (Qc) H1J 1S5 910 Rowntree Dairy Rd. Unit #15, Vaughan (ON) L4L 5W5 T (514) 354-2511 F (514) 354-6948 | 1 800 463-4363 info@geneq.com T (365) 527-2508 F (365) 527-2509 | 1 855 527-5808 sales@geneq.com SCIENTIFIC INSTRUMENTS ® ®

(left) Fitec CEO and Environmental Scientist Tom Ferencevic, working on depackaging and separation with the BioSqueeze200.

suppliers, including local farmers, food manufacturers, and supermarkets.

The co-digestion process takes place in several anaerobic digesters that are designed to optimize biogas production. Biogas produced by the digesters is used to generate electricity and heat, which is used to power the plant. Excess production is sold to the grid as a renewable energy source.

This plant has several notable features that contribute to its success. Firstly, it has a high level of automation, with a comprehensive monitoring and controls system that allows operators to optimize the digester operation in real time.

Additionally, the plant has implemented a comprehensive feedstock management system that helps ensure that the feedstock mixture is balanced and optimized for maximum biogas production.

Finally, tipping fees for food waste it receives contribute to the income of the plant. These earnings contribute to the resiliency of the facility, creating a diversified revenue stream while providing a reliable and responsible way to dispose of waste while turning it into renewable energy.

COMMON MYTHS REGARDING CO‑DIGESTION

Concerns can arise when implementing a co-digestion system that operates using both wastewater and municipal food waste. However, with the proper tools and the right collaborative partnership, WWTP operators can take the guesswork out of feeding and understanding the state of the biological system.

This is crucial as the challenges they may face can impact the efficiency and effectiveness of the process, and these challenges must be carefully managed to ensure the proper functioning of the system and optimal energy production capacity.

The following are some of the myths and debunking facts related to co-digestion:

It can be dangerous to mess with the anaerobic digestion of a WWTP. It is not very risky, and it is commonly done all over Europe. In fact, in Europe, municipal WWTPs compete with the private waste sector for organic waste because it is highly profitable to use that waste for co-digestion.

Co-digestion is more trouble than it is worth. This type

of facility requires very little relative investment in additional infrastructure and produces many benefits, several of which are municipal priorities, such as:

• Renewable energy production.

• Reduced waste going to landfills.

• Lessening municipal infrastructure operating costs (this is made possible by using the power generated from the facility for fleet operation).

• Increasing revenue (tipping fees for waste and renewable energy production can be used as additional revenue streams).

It is difficult to maintain optimal operating conditions. While the anaerobic digestion process is sensitive to changes in temperature, pH, and other environmental factors, simple monitoring tools empower operators to easily make necessary adjustments before the system is out of balance.

There is also a certain level of caution that WWTP operators maintain due to the hypercritical nature of maintaining the functionality of this kind of infrastructure. However, there are sound technical solutions available, uncomplicating the process and opening the industry up to more lucrative and robust opportunities.

OVERCOMING CO DIGESTION MYTHS AND CONCERNS

WWTP operators are often resistant to using additional feedstocks in their digesters for fear of disrupting the process. But, working with a knowledgeable service provider like Fitec Environmental Technologies can help to minimize risks. By partnering and focusing on education, operators can be made aware of the signs to look for, and the adjustments needed, to mitigate problems before they become larger-scale issues.

Overall, the successful implementation of a co-digestion system requires careful design, management, and optimization. Addressing the above-listed challenges is paramount, which can only be accomplished by working with a knowledgeable partner, like an anaerobic digestion consultant or service provider. This reduces risks and increases success and an expert partner can help with the following:

• Developing a feedstock management plan and implementing proper storage and handling procedures.

• Deploying automatic monitoring and control systems and optimizing the digester design to maximize operating efficiency.

• Adjusting feedstock ratios to account for variability.

• Conducting regular feedstock analysis, pre-treatment checks, system checks, maintenance and upkeep.

THE ROLE OF CO‑DIGESTION IN A SUSTAINABLE ENERGY FUTURE

Co-digestion of food waste in wastewater treatment plants has been common in Europe for over 20 years, but has only recently received attention from North American municipalities. Co-digestion allows municipalities to increase returns by making better use of existing infrastructure.

Tom Ferencevic is with Fitec Environmental Technologies. For more information, email: hq@fitecbiogas.com or visit: www.fitecbiogas.com

Staff monitoring their anaerobic digestion system; Fitec’s self-cleaning digester at Courthouse Hill Energy.

Environmental Science & Engineering Magazine 20 | August 2023 ANAEROBIC DIGESTION

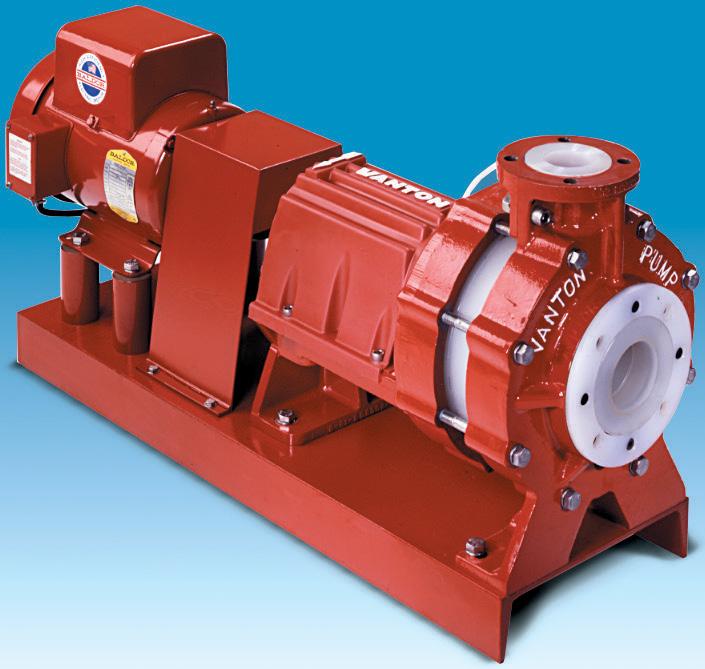

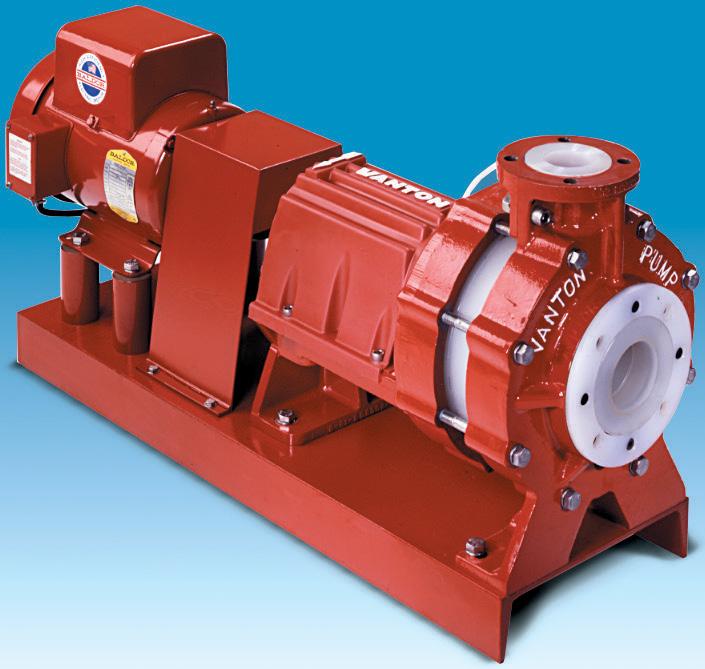

The Key to Ending your Pumping Problems

• No Corrosion or Contamination

• No Chemical Absorption or Wicking

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant. Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for:

The Vanton AdVantage

OEM Applications PUMP & EQUIPMENT CORPORATION vanton.com e-mail: mkt@vanton.com • 908-688-4216 Visit our display at WEFTEC in booth 1841 Sump-Gard® Vertical Centrifugal Pumps Flex-I-Liner® Rotary Peristaltic Pumps Pump/Tank Non-metallic Systems Chem-Gard® Horizontal Centrifugal Pumps Chem Action Inc. 4559 Boul Métropolitain E Saint-Léonard, QC H1R 1Z4 514-593-1515 Vissers Sales Corp. 20-220 Industrial Parkway South Aurora, ON L4G 3V6 905-841-4073

• Chemical Transfer • Neutralization • Dosing • Effluent Control • Lift Stations • Odor Control • Recirculation •

The use of artificial intelligence in air quality monitoring

By John Vogan

Artificial intelligence (AI) is playing an increasing role in air quality monitoring (AQM) strategies in both the private and public sector, especially those involving the acquisition, vetting, management and interpretation of large data sets. Technologies based on AI may offer distinct advantages over traditional approaches.

The need for AI is being driven by the need to cost-effectively gather large amounts of data for a variety of regulatory, carbon management, and health and safety purposes. In addition to greenhouse gas compliance activity, recently passed legislation governing specific contaminant emissions, such as sulphur dioxide (SO) regulations in Ontario, have increased the need for advanced monitoring methods and data analytics. The data needs to be reliable, be available almost instantaneously after collection, and be able to be readily portrayed visually to a variety of stakeholders.

Zach Zehr, an air quality and climate change expert, recently discussed scenarios that could drive the use of such advanced monitoring approaches. His experience over the past 10 years involves air compliance assessments and permitting, dispersion modelling, stack testing, and GHG emissions reporting and offset projects. Zehr explained three possible applications where AI based approaches may have merit.

“In certain instances, large power consumers may want to increase the accuracy and frequency of their carbon emissions monitoring to calculate carbon costs under the federal output-based pricing system regulations. This approach will be driven by the forecast increase in carbon pricing from $65/ tonne currently to $170/tonne by 2030.

“Secondly, implementing such advanced technologies may improve the quality of background data needed for environment assessment approvals governing changes or expansions in land use in Ontario and elsewhere. Ontario legislation now mandates the assessment of climate change on the proposed land use, and the effects of the change/expanded land use on regional projected climate change. A system generating detailed accurate local data would lessen the current reliance

on distant government stations.

“Lastly but significantly, if the devices are reliable and produce high quality results, they could be used as checks, backups, or replacements for current continuous environmental monitoring systems which are used to generate ongoing compliance data.”

Ecosystem Informatics Inc. (ESI) has developed an innovative Air Quality Management System (AQMS) technology based on AI. Dr. Shirook Ali, the founder and chief executive officer of ESI, states that “ESI should be thought of as a software driven technology company. Our AI based algorithms continuously calibrate the air quality parameters we measure, creating a reliable basis for decision making.”

Dr. Ali started the company in 2019, backed by research and development that started in 2016, after recognizing shortcomings in the standard equipment used to monitor airborne contaminant concentrations.

The AI computer algorithms are “trained” using multi-variant data sets (e.g., temperature, pressure, and humidity) generated in a controlled environment over the range of values expected to be encountered by sensors in the field application. The resulting algorithms are then subsequently used to calibrate the field data, ensuring the accuracy of measured sensor readings and identifying and eliminating unreliable outliers.

These algorithms can also be used to forecast future values of the measured parameters. One of ESI’s first steps in technology development was to continuously benchmark the cal-

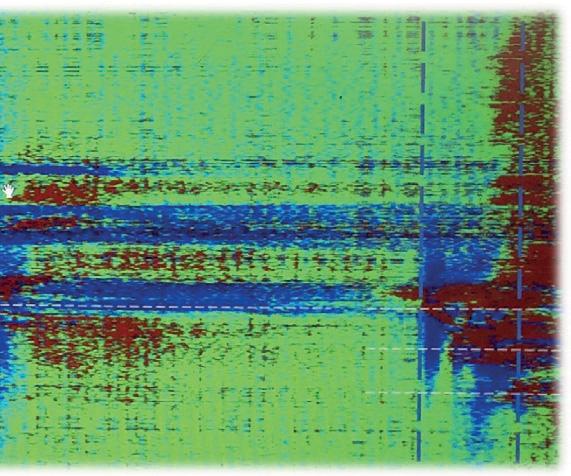

ESI vehicle mounted mobile devices.

Environmental Science & Engineering Magazine 22 | August 2023 AIR QUALITY continued overleaf…

In certain instances, large power consumers may want to increase the accuracy and frequency of their carbon emissions monitoring.

Grow your savings faster with a group TFSA

We know you know a lot, but did you know a group tax-free savings account (TFSA) helps you grow your savings faster than a non-registered savings plan from a retail financial institution? That’s why the Engineers Canada-sponsored Financial Security Program offers a group TFSA to help you save more.

Transfer your non-registered investments into your Engineers Canada group TFSA and watch your savings grow.

See how a $5,000 yearly investment pays off after 20 years

A plan built just for you.

The Engineers Canada-sponsored Financial Security Program is exclusive to engineers and geoscientists, as well as their families, across Canada. Join

Canada Life and design are trademarks of The Canada Life Assurance Company.

1,2 6% annual gross growth rate and mid-year annual lump sum contributions are assumed. Ontario HST is applied. 1 Management Expense Ratio MER (%) based on the average Canadian equity mutual funds from Morningstar. 2 Investment Management Fee IMF (%) based on the JF Canadian Equity fund.

Assumptions:

today canlife.co/Taxfree

ibrated data over a year against publicly available government station measurements, to ensure the accuracy and reliability of outputs from its system.

This use of AI allows ESI’s samplers to avoid the requirement of establishing the controlled environment (e.g., temperature and humidity) otherwise required for stable sensor operation in a field unit. This minimizes power demands for hardware and therefore allows the ESI units to be a fraction of the size (and cost) of conventional equipment.

ESI devices currently weigh about one kilogram and are about the size of a large shoe box in volume. They transmit data directly to the cloud where it is pre-processed for further processing and calibration. Currently, up to five concentration sensors and three meteorological sensors can be installed in a single unit. Samplers can be installed as stationary point monitors, but are particularly suited for use on moving vehicles.

Either through the deployment of several cost-effective ESI samplers at several stations, or by data collection using a single mounted, moving ESI unit, a denser, more granular data set can be generated with ESI’s technology. This means not relying on data from a single conventional AQM installation assumed to represent the same geographic area.

Projects completed using this technology include a carbon emissions monitoring program for the Town of Milton, Ontario, which monitored emissions from transit vehicles using ESI mobile units on a street-by-street level. The data was used as part of a benchmarking study for bus electrification.

An ongoing contaminant monitoring study for the City of Hamilton has involved both fixed stations (for comparison of data to an existing conventional monitoring station) and mobile vehicle monitors. Monitoring has included sulphur dioxide, carbon monoxide, ozone, nitrogen dioxide and most recently particulate matter (PM2.5).

Hotspots within the study area were identified, and trucking routes modi-

UNDERWATER SEARCH AND INSPECTION DRONE

fied to reduce these impacts. ESI sensors were also deployed in 2022 by private sector consultants to monitor particulate emissions during remediation efforts following a forest fire in western Canada.

Minh Le is president of C3 Environmental (C3), a Canadian environmental technology firm that is one of ESI’s key channel partners.

“I am by no means an AI expert” Le said in a recent interview. “But, we do see the data polishing processes in ESI’s system as a major step forward relative to existing technology, where extra hardware is needed to collect the calibration data. This means that the ESI devices should have a smaller footprint, lower power consumption, and lower maintenance needs than existing hardware in the market,” he added.

C3 and ESI envision that many applications will involve subscription-based services, where they assume responsibility for device installation and maintenance, data collection and analysis, and provide the resulting data sets that can be used for a variety of purposes.

Le says that: “We foresee a lot of end users and consultants taking advantage of the data output that can be used in air quality models or portrayed visually in user dashboards and reports.”

Zehr offered the following comments regarding the acceptance of AI-based technologies:

“As one would expect, the keys are robustness and improvements in cost-effectiveness and data reliability, which really need to be demonstrated at a field scale, ideally in ‘head-to-head’ comparisons with common equipment currently on the market. Equipment flexibility and the ability to operate remotely under a variety of climatic conditions are also very important.”

ESI’s technology is commercially available. C3 and ESI are currently pursuing select pilot-scale field demonstrations to further expand the scope of technology application.

(800) 265-0182

2865

info@cdnsafety.com

www.cdnsafety.com

John Vogan is an environmental scientist and writer who prepared this article on behalf of C3 Environmental. For more information, email: minh.le@c3group.com

ESI solar-powered point device.

ESI solar-powered point device.

Environmental Science & Engineering Magazine 24 | August 2023 AIR QUALITY

Search Pro + is revolutionizing underwater search and examinations with state-of-the-art technology. The intelligent underwater 6X drone zoom camera (from SONY-F1.4) integrates both underwater shooting and observational functions in real time, all with a 5-hour battery life, 4-thruster drive, and the ability to dive as deep as 330 feet.

Argentia Rd, Unit 3, Mississauga, ON L5N 8G6

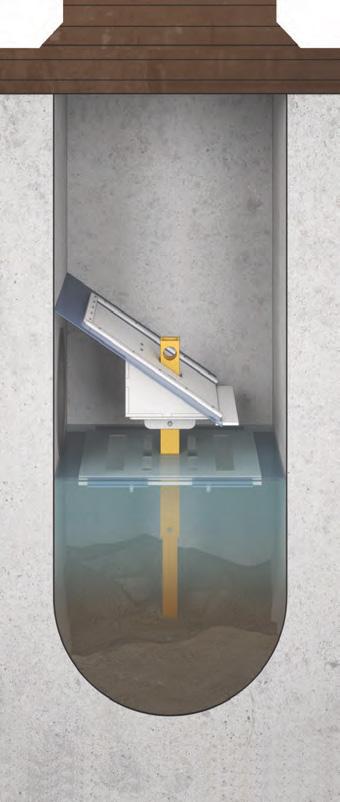

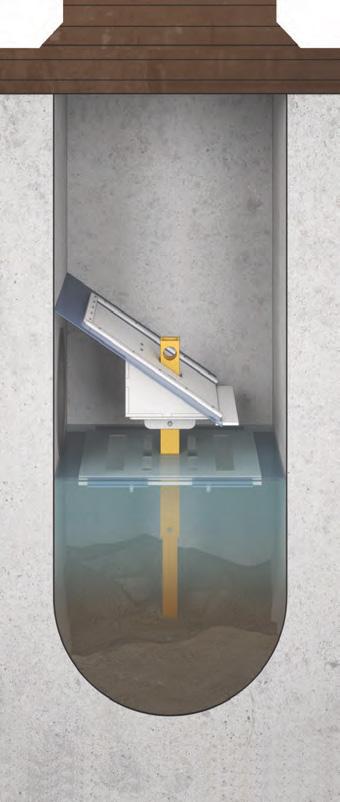

E C OT R A N

I NS TAL L ATI O N

Directional boring and field adjustable risers allow for faster installation and limited disruptions saving time and money

A E STH E TI C S

The materials of construction and EcoTRAN technology allow for lower environmental inter ference and extended product life.

S E RVI C E

You were top of mind with this product’s design. The discharge valve, plug-and-play cord, and basin were engineered to simplif y maintenance.

P

Barnes P r e s s u r e S e w er

a ck aged Sol u tio n

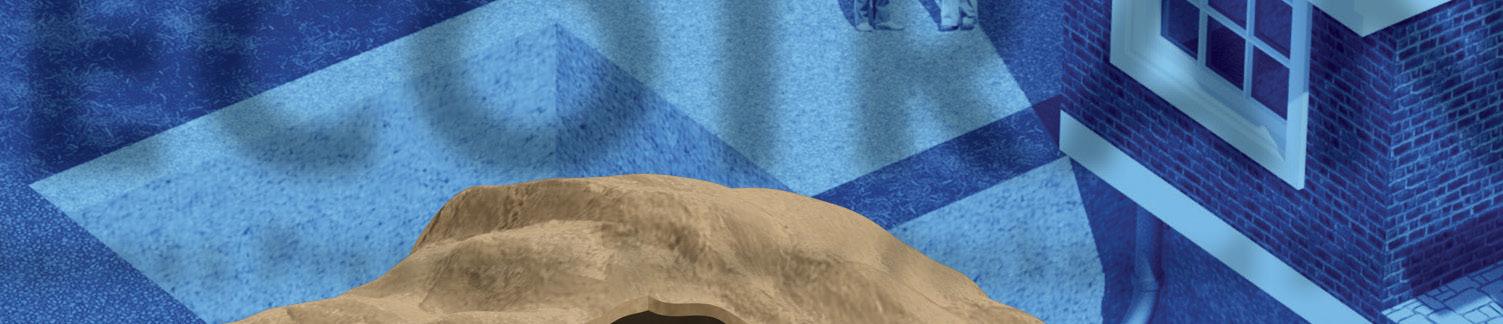

Students design experiential learning tool kits to educate public about stormwater

By Ellen Campbell

The City of London, Ontario, is the 11th largest metropolitan area in Canada with a population of approximately 422,000. It is situated along the Thames River and within the Upper Thames River Conservation Authority area, making it susceptible to flooding during severe weather events.

It is therefore no surprise that it was one of the first cities in Ontario to create a stormwater charge to support the implementation of stormwater infrastructure that protects the city, residents and the environment. The city continues to make rapid improvements to its aging infrastructure to mitigate the impacts of climate change.

Stormwater, its impacts, mechanisms, and mitigation strategies are complex systems that can be difficult for the public to understand. This creates a challenge to justify large capital investments into initiatives to protect public property and environmental health. To help address this knowledge gap, the city partnered with Rain It In, a Canadian non-profit organization that challenges post-secondary students to create climate resilient solutions that focus on intense rainfall and flooding.

In the fall of 2022, a total of 24 Canadian students, in nine different educational programs, were challenged to design experiential learning kits that the city could use to educate the public on stormwater. The grand prize was a $5,000 seed grant from the city to further develop and commercialize the winning prototype. McGill University, University of Toronto Mississauga, University of Victoria and Western University participated in the challenge.

Teams were invited to attend an informational webinar, a mentorship workshop and a skills development workshop. A demonstration video was required by each team to determine which five would be invited to pitch their prototypes live to a judging panel comprised of industry experts.

The mentorship workshop, hosted in

partnership with the Canadian Chapter of the International Water Association’s Young Water Professionals, allowed for networking in a virtual environment. Industry professionals were invited to share their knowledge to inspire the direction of the projects. This opportunity also enlightened students about career paths in the water industry.

The skills development workshop, hosted in partnership with the Canadian Water Resources Association, focused on effective pitch fundamentals. The session was facilitated by Martin Yuill, executive director at Cleantech Commons, who taught the students about pitch types, provided tips, and shared personal experiences that helped prepare the students for the competition, and futures in the profession.

Financial sponsorship from the Sustainability Office at Wilfrid Laurier University allowed Rain It In to award cash prizes to the top three finalists: $500 for first, $300 for second and $200 for third. The real reward, however, was the opportunity to gain hands-on experience solving a real-world challenge, with the support of water professionals.

First place finalist, Emily Lafond, who is currently pursuing a Bachelor of Bioresource Engineering at McGill University, said: “We hope that our target audience

has as much fun using these kits as we did conceptualizing them. Thank you Rain It In for giving us the opportunity to apply creativity, science, and entrepreneurial skills during this fun and flexible competition!”

The winning teams were as follows: First place: McGill University – Team MIST; Second Place: University of Toronto Mississauga – Team Urban Rain; Third Place: Western University – Team Water Benders.

Rain It In would also like to pay special thanks to the judging panel:

• Shawna Chambers, P.Eng., DPA, division manager of stormwater engineering at the City of London

• Aaron Rozentals, P.Eng., division manager of water engineering at the City of London

• Brandon Williamson, land management coordinator at Upper Thames River Conservation Authority

• Erin Mutch, vice principal at Medway High School

“There were so many great and unique ideas. We could tell that everyone put a lot of thought and work into each project,” shared judging panelist Shawna Chambers.

Ellen Campbell is with Rain It In. For more information, visit: www.rainitinsc.com

Team MIST. Top row from left to right: Dylan Gwilliam, Sara Escallon-Sotomayor, Shawna Chambers, Paula Bustard. Bottom row from left to right: Sadie MacDonald, Emily Lafond, Ellen Campbell.

Environmental Science & Engineering Magazine 26 | August 2023 STORMWATER

Rinker Materials is committed to protecting Canada's waterways and providing our customers with peace of mind. That's why we've introduced the industry's most comprehensive and flexible maintenace program with every Stormceptor purchased.

Included in the Program

-Inspection of each unit after installation to ensure proper installation

-Each unit is entered into our database to track for the owner

First Option

-6 Inspections for 5 years

-No cleaning

-First inspection within 6 months of install

Second Option

-Initial inspection and 1 post construction sediment cleaningAdditional 2 inspections that occur annually

Rinker Materials Rely on Rinker! 519-622-7574

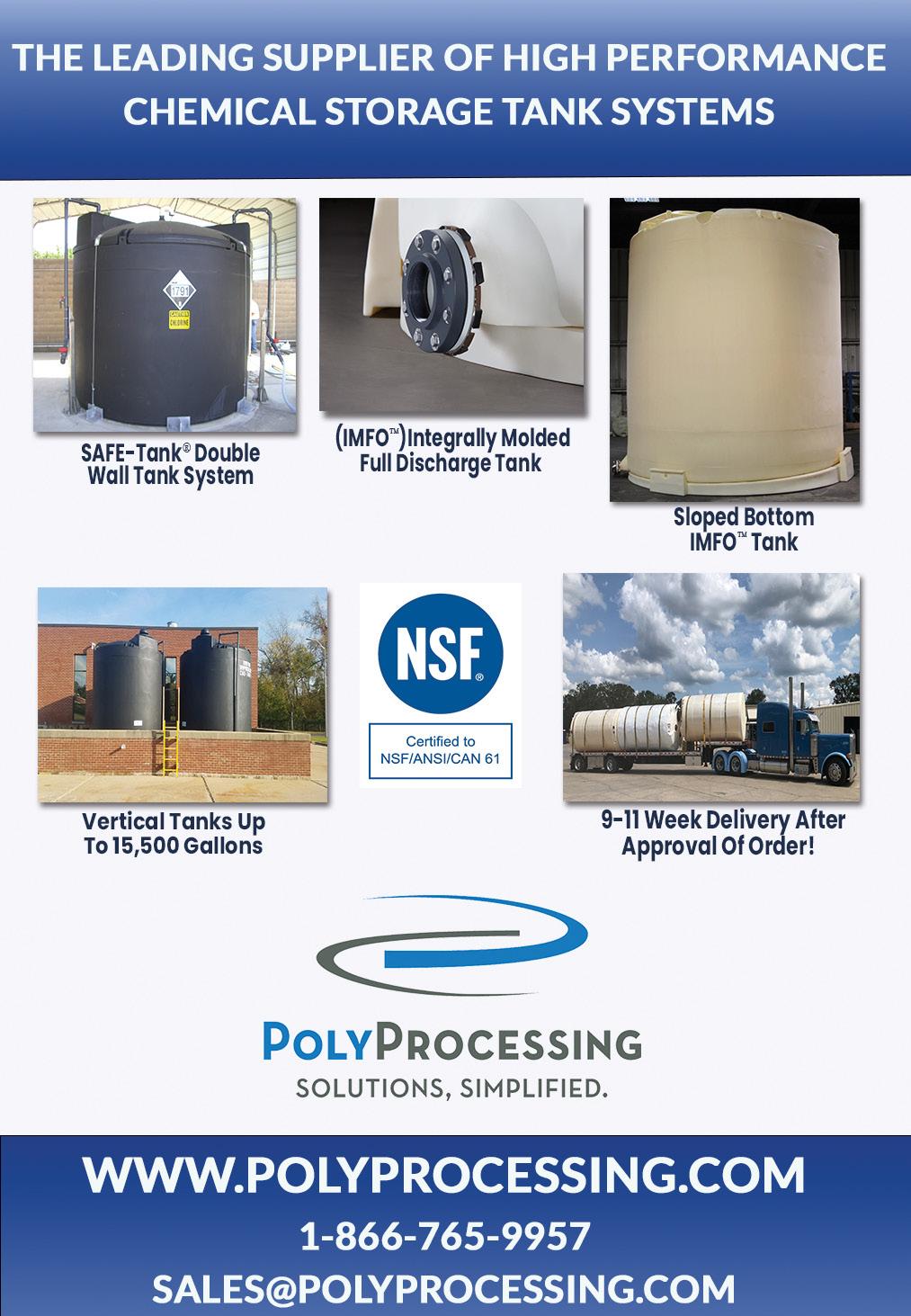

NASA’s brine processor pushes water reclamation to 98% on ISS

By ES&E Staff

New brine processor technology is helping NASA astronauts reach a water reclamation milestone onboard the International Space Station.

Some of the key items on the station include a processor assembly that utilizes vacuum distillation and produces a urine brine that contains some reclaimable water. A brine processor extracts that remaining wastewater and sends it to the water processor assembly, which produces drinkable water and helps NASA achieve its 98% water recovery goal. This is necessary for long-duration space exploration missions.

Prior to the development of the brine processor, NASA had maxed out at 94% water recovery. Now, the brine is sent through a special membrane technology, then blown dry to evaporate the water, creating humid air collected by the station’s water collection systems. The same process is used for astronauts’ breath and perspiration.

“This is a very important step forward in the evolution of life support systems,” explained Christopher Brown, part of the team at Johnson Space Center that manages the space station’s life support system. “Let’s say you collect 40 kg of water on the station. You lose two pounds of that and the other 98% just keeps going around and around. Keeping that running is an awesome achievement.”

The water processor assembly uses a series of specialized filters, then a catalytic reactor that breaks down any trace contaminants that remain. Sensors check the water purity and unacceptable water is reprocessed. The system also adds iodine to the usable water to prevent microbial growth and stores it for crew use. According to NASA, iodine is used for disinfection instead of chlorine because it is less corrosive and much easier to transport to the space station.

Each crew member needs about 3.6 litres of water per day for consumption, food preparation, and hygiene, such as brushing teeth.

Jill Williamson, NASA water subsystems manager, says the water reclamation process is fundamentally like some municipal water distribution systems, “just done in microgravity.”

“The crew is not drinking urine,” Williamson said in a statement from NASA. “They are drinking water that has been reclaimed, filtered, and cleaned such that it is cleaner than what we drink here on Earth. We have a lot of processes in place and a lot of ground testing to provide confidence that we are producing clean, potable water.”

Williamson added that the less water and oxygen taken into space, the “more science that can be added to the launch vehicle.” Efficient regenerative systems, she said, means the crew can focus on the “true intent of their mission”.

For more information, email: editor@esemag.com

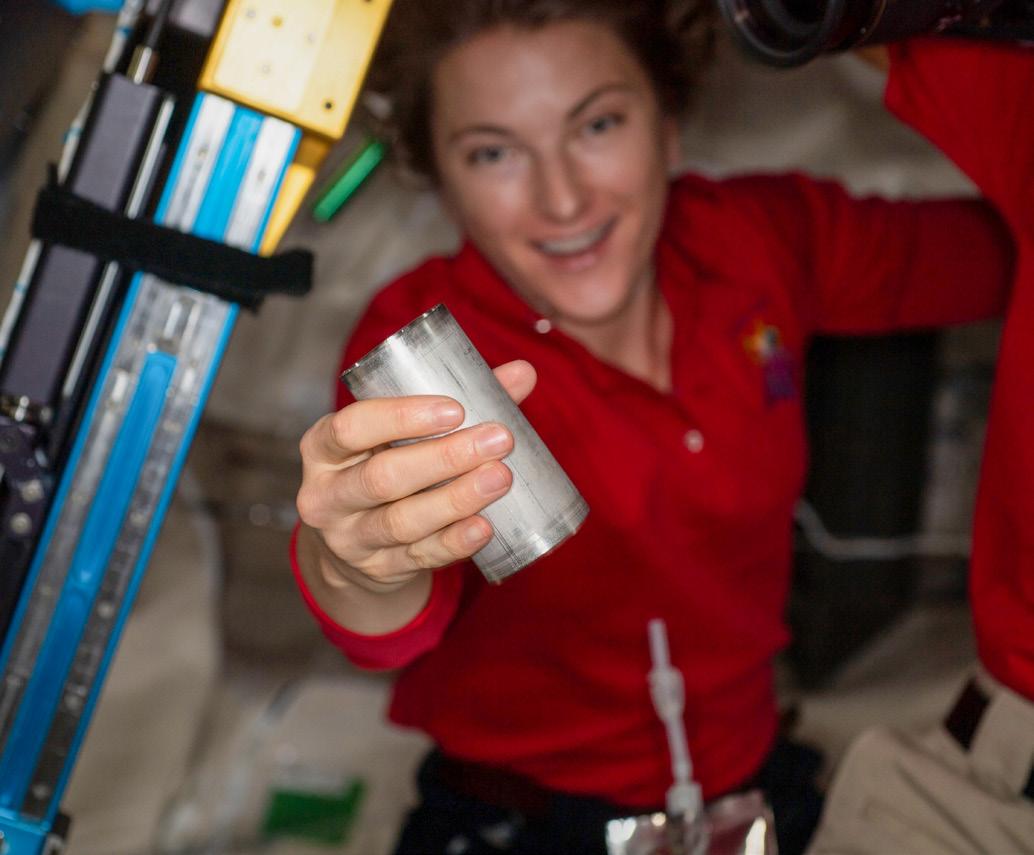

NASA astronaut Kayla Barron replaces a filter in the space station’s Brine Processor Assembly. Credit: NASA

NASA astronaut Kayla Barron replaces a filter in the space station’s Brine Processor Assembly. Credit: NASA

Environmental Science & Engineering Magazine 28 | August 2023 WATER

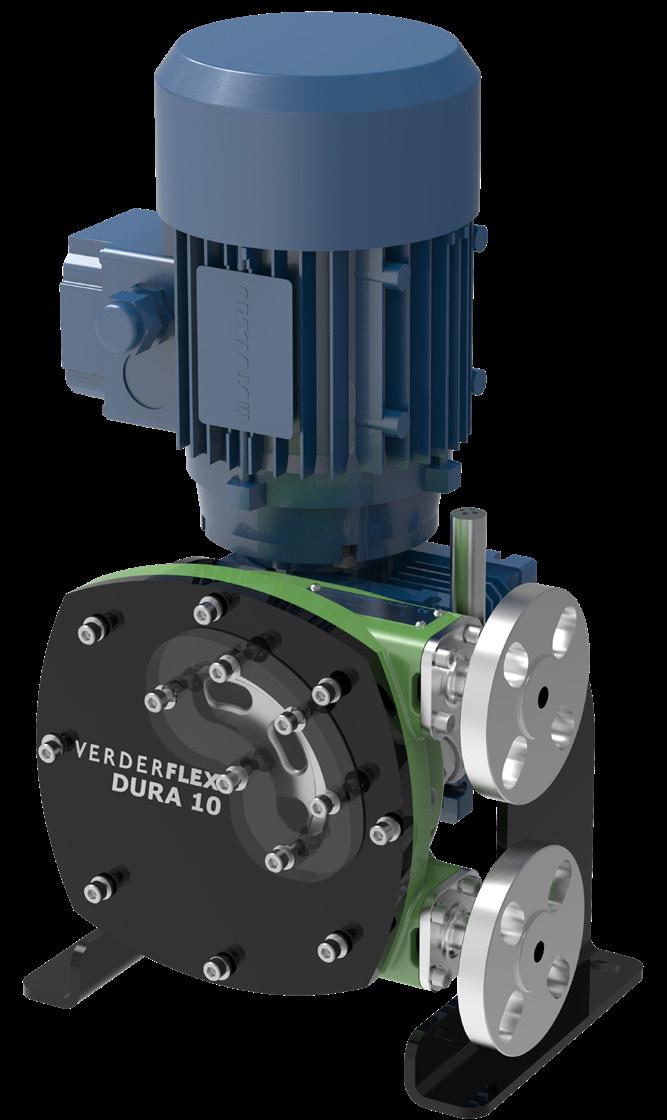

Dosing hypochlorite in a new wastewater treatment plant

By Mike Knapman

Sodium hypochlorite has outstanding disinfection properties, so it is used in wastewater treatment to kill off bacteria before effluent is discharged back into the environment. For drinking water treatment, it is one of the primary methods of disinfection.

Recently, one new wastewater treatment plant required a pump capable of accurately dosing 15% sodium hypochlorite, which is a challenging product to pump. When being pumped, sodium hypochlorite tends to off-gas, causing some pump types to vapour lock.

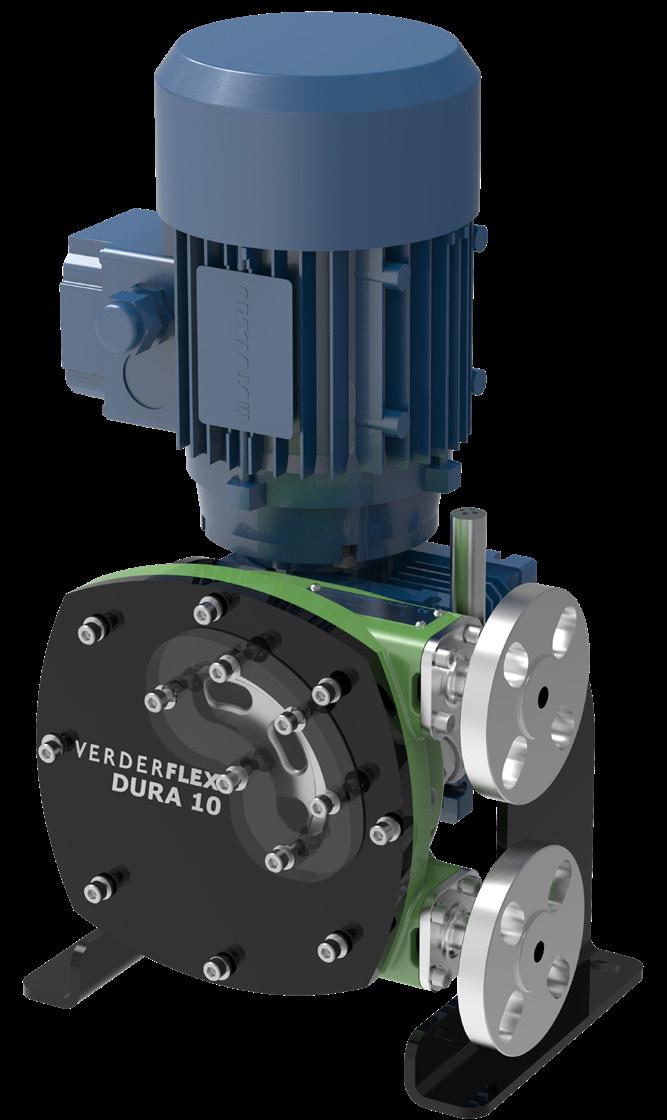

After evaluating several pump choices from several manufacturers, plant owners decided to use ten Verderflex VF10 peristaltic hose pumps for the job. They can handle both gas and liquid, ensuring the liquid stream receives a consistent dose.

The fluid being dosed is kept totally enclosed within the rubber hose. It is then compressed by a rotating shoe, forcing the liquid inside along. Upon restitution of the hose, the resulting vacuum draws in more liquid. This process is known as peristalsis and is what makes the peristaltic pump work well for liquid metering. Variations in hose type allow for low strength and even high strength sodium hypochlorite dosing.

Wastewater plants need to run as cost-efficiently as possible and plant staff were impressed with the long hose life provided by the Verderflex hose and the ease of maintenance when the hose needed to be changed.

“These pumps have certainly been a success for us in this industry,” according to Verderflex.

Because of the pumping process used by peristaltic pumps, the hose is the only part that ever comes onto contact with the fluid being pumped. Not only does

this mean that the pump is hygienic and leak free, it also means that there are no moving parts to become clogged or damaged. The only maintenance required is to change the hose, which is done quickly and efficiently, keeping downtime to an absolute minimum, saving costs and increasing profits.

Plant owners decided to use ten Verderflex peristaltic hose pumps for the job.

Mike Knapman is with York Fluid Controls Ltd. who represent Verderflex peristaltic pumps. Email: sales@yorkfluid.com

Plant owners decided to use ten Verderflex peristaltic hose pumps for the job.

Mike Knapman is with York Fluid Controls Ltd. who represent Verderflex peristaltic pumps. Email: sales@yorkfluid.com

August 2023 | 29 www.esemag.com @ESEMAG WASTEWATER Neubrex Energy Services (US), LLC Onshore US and Canada Operations (713) 899 – 1545 dana.jurick@neubrex.com Continuous high precision, high resolution, state of the art fiber optic measurements across time and space Proven technology with many use cases Talk to Neubrex Energy Services about fiber solutions that meet your project goals Innovation Customer Engagement Low Overhead

Exploring the vital role of pollution liability insurance for businesses and wastewater treatment plants

By Shane McCarthy

By Shane McCarthy

As the world continues to become more conscious of the environment and how individuals and companies pollute, there is an increase in lawsuits and government-issued fines and penalties addressing environmental issues. Consequently, the need to properly transfer a company’s risks is more important than ever to protect its reputation and financial bottom line.

From massive, multi-billion-dollar construction sites to the gas station on the corner, businesses of all sizes and types may have a need for environmental coverage. However, this is an area that continues to be underinsured.

First, we need to review what is considered a pollutant and what could result in a fine, penalty or lawsuit bringing an insurance claim against your company. A pollutant is any material, substance, liquid, product, etc., which is introduced into an environment for other than its intended use or purpose. In other words, something that ends up where it does not belong. Fresh water, cheese, and milk have all been classified as pollutants by insurance carriers under various circumstances.

Unlike most liability exposures that impact a lot of businesses, pollution losses are not a frequency risk, but rather a severity risk. Since almost all businesses can be impacted by environmental liabilities, consideration needs to be given to the benefits of environmental liability insurance as part of a risk transfer strategy, versus self-insurance.

It is important to note that general liability policies typically do not provide meaningful coverage for pollution-related claims. This means that companies without an environmental liability policy could be left to bear the financial burden of these types of incidents on

their own.

Environmental liability policies are designed to protect companies from the financial consequences of environmental incidents such as pollution, contamination, and damage to natural resources. These policies provide coverage for the costs associated with cleaning up contamination, as well as legal defense costs and damages awarded in lawsuits. Today, there are more insurance companies offering environmental liability so there is more competition. This has resulted in lower premiums.

There are several types of environmental policies available, but understanding what they are, and how they respond, is the first step. A properly negotiated and structured policy can help companies respond to incidents more efficiently without worrying about financial strain. Policies include environmental impairment liability (EIL), contractors’ pollution liability (CPL), and transportation pollution liability (TPL). Each type of

policy provides coverage for different risks and exposures.

For example, an EIL policy would be appropriate for wastewater treatment plants that could be susceptible to an economic loss caused by pollution that actually or allegedly originated from their operations. Sometimes referred to as pollution legal liability, this coverage is for those who own, operate, lease, or have any other insurable interest in real property or the operations.

Coverage can be written in a variety of ways, addressing unknown pre-existing pollution conditions or new pollution conditions. Coverage can include first party on-site cleanup, third-party bodily injury and property damage, along with business interruption and extra expense, off-site cleanup costs, legal defense expenses, non-owned disposal sites, transportation and more. EIL can also be offered on multi-year terms, thus providing contract and budget cercontinued overleaf…

Accidents and oversights can happen at any facility, including wastewater treatment plants. However, environmental insurance policies can assist with cleanup costs, defense costs, claim management, and third-party liability. Credit: pxl.store, stock.adobe.com

Environmental Science & Engineering Magazine 30 | August 2023 ENVIRONMENTAL INSURANCE

BEFORE complex. cluttered. THE DICE Up to 50% reduction in mechanical room space required 90% fewer joints = 90% less risk of leakage Simple, consolidated operation AFTER simple. intuitive. #20 – 220 Industrial Parkway S. Aurora, Ontario L4G 3V6 Tel: 1 (905) 841-4073 Fax: 1 (905) 841-4018 www.VissersSales.com THE EVOLUTION OF THE CHEMICAL METERING SYSTEM

tainty for several years at a time.

CPL coverage can be purchased to address two specific exposures. Firstly, contractors that perform environmental remedial service activities (e.g., dayto-day plant operations, asbestos, lead, mould, soil or groundwater remediation, emergency response). Secondly, at nonowned or leased property. CPL protects the insured for pollution conditions they may cause, or if they exacerbate an existing situation whilst performing their covered construction services. The loss must occur away from any premises the insured owns, rents, leases, or occupies. In other words, while they are performing contracting services in the field.

Business auto or trucker’s insurance policies will exclude pollution losses arising from spills or other releases of their cargo. This exposure can be

nesses were evacuated, and several people were hospitalized for inhalation of fumes. Claims against the facility for bodily injury and business interruption, combined with defense costs, exceeded $460,000.

• A liquid wastewater treatment plant utilized sulphuric acid in their process and stored it on-site in a 75,000-litre aboveground storage tank. The storage tank was contained by two-foot-high, chemically sealed masonry walls. Overnight, an area high on the wall of the storage tank ruptured, releasing the sulphuric acid. The leak went beyond the containment walls, releasing approximately 11,000 litres into the soil and into an adjacent stream. Government mandated costs for clean up of on-site soils, the stream and the stream bank exceeded $1 million.

best trained and most attentive staff.

In addition to the actual cost of cleanup, there are three distinct advantages to purchasing an environmental policy:

Defense costs: Environmental liabilities are relatively new and very litigious. Even if you have done nothing wrong you can still get named in a lawsuit and the cost to defend yourself (e.g., legal fees and environmental investigations) can be exorbitant. The environmental insurance policy pays for these expenses.

Claim management: All policies come with specialists to assist you in handling a claim. The policy will provide and pay for experts who will oversee communications, public relations, emergency response, government compliance, financial management, thirdparty claims for bodily injury, property damage and natural resource damage.