Helping operators deal with heavy lifting tasks safely and efficiently

Toronto’s new wastewater energy project could be the first of many

Using chlorine dioxide to remove manganese in drinking water

PM40065446 APRIL 2024 WWW.ESEMAG.COM @ESEMAG

ipexna.com 1-866-473-9462 EXPLORE OUR SOLUTIONS Pipe, Valves & Fittings Systems to meet all Your Project Needs

Safe, smart and sustainable solutions across the water cycle

From abstraction to treatment, distribution, and management of the wastewater process, ABB supplies an extensive range of reliable measurement & analytical products, services, and solutions meeting customers’ exact requirements. abb.com/measurement

Contact us at instrumentation@ca.abb.com

—

Archis

OCT

Gary Burrows, City of London

Patrick Coleman, Stantec

Bill De Angelis, Metrolinx

Mohammed Elenany, Urban Systems

William Fernandes, City of Toronto

Marie Meunier, John Meunier Inc., Québec

Tony Petrucci, Black & Veatch

FEATURES 6 The evolution of water and wastewater associations 8 US and Canada face 260,000 water main breaks annually, study says 9 Peel Region says wastewater expansion could support up to 47,000 new homes 10 Urban stormwater control measures for nutrients management 14 Town of Casselman, Ontario, starts chlorine dioxide oxidation pilot to solve water’s manganese issue 16 Saskatchewan’s $51M in water, wastewater funding will support 34 major projects 18 Regina water expert pioneers sustainable solution to transform sludge into multi-use ceramsite 22 Ontario's Excess Soil Registry rates jump significantly 24 Ontario continues march towards streamlining EAs, introducing project list approach 26 Edmonton effectively upgrades largediameter self-supported sewer line using grooved system 29 Nutrient management facility soon underway in Red Deer to reduce phosphorus 30 Wetland constructed at Moncton snow disposal facility to protect waterways 32 Toronto’s new wastewater energy project could be first of many 36 Spring marks crucial test for NB biosolids composting facility 38 Perfecting wastewater pretreatment for direct potable reuse 40 The need to handle materials safely and efficiently is omnipresent in the wastewater sector – cover story 44 Consulting engineers need to learn how to help clients navigate the current climate crisis 48 Circuit Riders support water systems and water supply for communities in Northern Manitoba 50 Centrifuge decanter helps WWTP achieve 30% solids sludge cake 52 Lethbridge’s water conservation plan addresses declining reservoirs 53 Downspout disconnection programs can free up sewer capacity and reduce flooding and overflows 60 How to identify excessive sludge accumulation in wastewater lagoons 62 Researchers isolate microalgae strains that capture phosphorus from wastewater for reuse DEPARTMENTS 57 Product Showcase 61 Professional Cards 62 Ad Index CONTENTS April 2024 • Vol. 37 No. 2 • ISSN-0835-605X www.esemag.com @ESEMAG Environmental Science and Engineering Magazine 26 48 4 | April 2024 Editor and Publisher STEVE DAVEY steve@esemag.com Managing Editor PETER DAVEY peter@esemag.com Contributing Editor DAVID NESSETH david@esemag.com Sales Director PENNY DAVEY penny@esemag.com Sales Representative DENISE SIMPSON denise@esemag.com Accounting SANDRA DAVEY sandra@esemag.com Design & Production MIGUEL AGAWIN miguel@esemag.com Circulation BRIAN GILLETT ese@mysubscription.ca Environmental Science & Engineering is a bi‑monthly business publication of Environmental Science & Engineering Publications Inc. An all Canadian publication, ES&E provides authoritative editorial coverage of Canada’s municipal and industrial environmental control systems and drinking water treatment and distribution. Readers include consulting engineers, industrial plant managers and engineers, key municipal, provincial and federal environmental officials, water and wastewater plant operators and contractors. Information contained in ES&E has been compiled from sources believed to be correct. ES&E cannot be responsible for the accuracy of articles or other editorial matter. Articles in this magazine are intended to provide information rather than give legal or other professional advice. Canadian Publications Mail Sales Second Class Mail Product Agreement No. 40065446 Registration No. 7750 Subscription Changes? Please email reader subscription changes to ese@mysubscription.ca, or call 705-502-0024 Advertising Penny Davey Sales Director 416 807 3812, penny@esemag.com Denise Simpson Sales Representative 905 960 4064 denise@esemag.com Environmental Science & Engineering 220 Industrial Pkwy. S., Unit 30 Aurora, Ontario L4G 3V6 Tel: (905)727 4666 www.esemag.com TECHNICAL ADVISORY BOARD

Academy

Ambulkar,

Water Quality

t e wat e r, Biosolids & Bi o g a s

o mple te ra n g e o f ma rke t p ro du c t s. Le t u s sh ow yo u

•

Cleaning, DO Control, AlphaMeter Mixers – Anoxic & Swing Zones, Sludge Holding, Digester; Mechanical, Hydraulic and Gas Bubble

Tank Components – Covers, Fabric Ba es, Troughs, Weirs, Scum Ba es, Skimmers, Decanters, Swivel Joints, Telescoping Valves, Density Current Ba es, Launder Covers, Watertight Doors

Primar y & Secondar y, Circur, Chain & Flight, Inclined Plate Settlers, Weir Washing

Biological – SBR, MBR, RBC, MBBR, MABR, Oxidation Ditch, BioMag, CoMag

Polymer – Liquid and Dr y Systems

Rotary Lobe Pumps & Grinders

• Disinfection – UV, Ozone

• Tertiary Filters – Travelling Bridge, Disk, Membrane

• Sludge Thickening & Dewatering –Disk Thickener, Gravity Thickener, Filter Press, Screw Press, Centrifuge

• Anaerobic Digesters – Sludge Conditioning, In-line Screening, Degritting, Membrane Gas Holders, Liquid Mixing, Nutrient Recover y

• Sludge Drying – Belt, Fluid Bed and Solar

• Septage Receiving – Screens, Dump Stations, Truck Access & ID, data gathering & equipment control

• Sludge Treatment, Transport & Storage – Cake Pumps, Silos, Sliding Frames, Live Bottom Hoppers, Push Floors, Truck Loading, Alkaline Stabilization

• Odour Control – Tank Covers, Chemical & Biological Treatment, Activated Carbon

• – Stations Pump & Stormwater CSO, Tipping Buckets, Bending Weirs, Flushing Gates, Flow Regulating, Vor tex Valves, Storm Screens

• Digester Gas – Gas Holders, Gas Conditioning: chilling; compressing; and removal of moisture, sulphur, carbon dioxide and siloxane, complete Co-Generation facilities

T: (905) 864-9311 F: (905) 864-8469 www.proaquasales.com 7-264 Bronte St. S., Milton, ON L9T 5A3 04 16

The evolution of water and wastewater associations

The first joint annual conference and tradeshow of the Ontario Water Works Association (OWWA) and Water Environment Association of Ontario (WEAO), taking place May 5 – 7 in Niagara Falls, will mark 42 years of involvement in the water and wastewater industry for me.

Many, many years ago, I attended my first OWWA conference and noticed that a significant number of attendees had also been at the WEAO conference. So, I asked, “why in Ontario were there two separate water and wastewater associations?” For the rest of Canada, associations included both water and wastewater members.

Due to this year being the first time that OWWA and WEAO have held their conferences together, I was recently asked this same question at an association meeting. My impromptu answer, based on what I could remember was, “it’s complicated.”

With my curiosity piqued, I re-read parts of a 1985 history book, entitled “Recollections: Water Pollution Control in Ontario”, which was commissioned by the predecessor of WEAO and authored by ES&E Magazine co-founder Tom Davey.

Chapter nine of Recollections covers in detail the evolution of water and wastewater associations. The first one in North America was the American Water Works Association (AWWA). It was founded in 1881 to allow an exchange of information about the management of waterworks.

The first Canadian Section of the AWWA was established in 1920 in Montreal. In 1971, the Canadian Section reorganized and three new AWWA Sections were formed: Atlantic Canada, Ontario, and Western Canada. Waterworks professionals in Quebec had received Section status in 1967. In 1973, the British Columbia Section was inaugurated, which meant there were now five Canadian AWWA Sections.

The Ontario Section of the AWWA restructured in 1995 and officially changed its name to the Ontario Water Works Association – A Section of AWWA.

As described in Recollections, during the early years of AWWA sewage treatment technology was not thought to be as advanced as what was used in the potable water field. The AWWA had held three conferences on sewage treatment, so the idea of forming a sewage treatment section was proposed. However, the proposal was rejected at the 1927 AWWA annual conference.

In 1928, recognizing the need for a wastewater association, some far-sighted individuals founded the Federation of Sewage Works Associations (FSWA). Initially, no annual conventions were held, but the Federation did launch the Sewage Works Journal. Equipment manufacturers promised to advertise in this new journal and other support came from the patent revenues of Dr. Karl Imhoff, the inventor of Imhoff tanks.

The FSWA became the Water Pollution Control Federation (WPCF) in 1960, which in turn was renamed the Water Environment Federation in 1991 to reflect an expanded focus on nonpoint and point sources of pollution.

In 1932, the legendary Dr. Albert Edward Berry called a meeting which resulted in the formation of the Canadian Institute of Sewage and Sanitation (CISS) in 1933. Dr. Berry

later became president of the AWWA and WPCF. In 1962, CISS changed its name to the Canadian Institute of Pollution Control (CIPC), in order to become a vital component in pollution abatement, technology and research.

In 1962, the Association Québécoise des Techniques de l’Eau (now Réseau Environnement) became the first provincial association formed to serve both the water and wastewater sectors.

In 1969, the CIPC briefly formed an Ontario branch, but it dissolved shortly afterwards.

The Pollution Control Association of Ontario (PCAO) was born from the Ontario Branch of the CIPC in 1971. The PCAO became the Water Environment Association of Ontario in 1993.

The Federation of Associations on the Canadian Environment (FACE) was founded in 1971 to create a national body. It was superseded by the Canadian Water and Wastewater Association, which was established in 1986 and continues to represent the common interests of Canada’s municipal water and wastewater systems.

A lot has happened in the water and wastewater sectors during the almost 40 years since Recollections came out. However, I am confident that the visionaries who helped to found the associations we know today would commend the great work done now by staff and volunteers who serve on the boards and committees of water and wastewater associations across Canada.

Having attended OWWA and WEAO annual conferences separately for over 40 years, I am looking forward to this year’s joint event. Let’s hope the clean water and the dirty water crowd feel the same way!

Steve Davey is the editor and publisher of ES&E Magazine. Please email any comments you may have to steve@esemag.com

6 | April 2024 EDITORIAL COMMENT BY STEVE

DAVEY

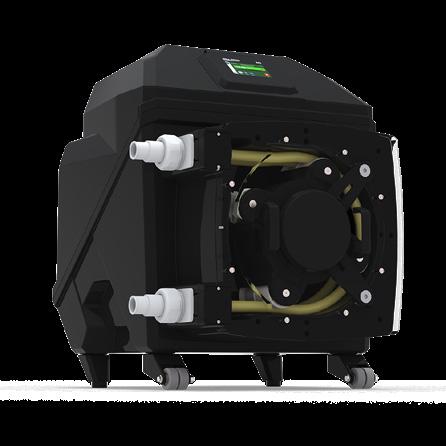

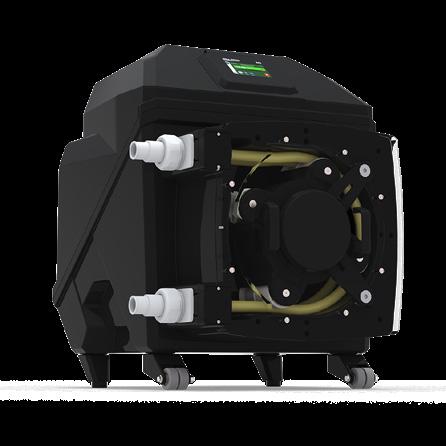

Learn more about the M3, APH20, and CO2 Feed System at www.blue-white.com Fluid Metering Solutions Made Simple. The Tools You Need for Optimum Chemical Treatment of Water & WasteWater FLEXFLO® M3 Peristaltic Metering Pump for Precise Chemical Dosing CO2 FEED SYSTEM for Safe, Effective pH Control APH2O Multi Parameter Online Analyzer Measure Chlorine Levels, pH, Turbidity and Temperature

US and Canada face 260,000 water main breaks annually, study says

By ES&E Staff

Arecent Utah State University (UTU) study created from utility survey data estimates that some 20% of water pipes across the U.S. and Canada are in need of replacement and contribute to some 260,000 water main breaks each year.

Water Main Break Rates in the USA and Canada: A Comprehensive Study was authored by Steven Barfuss, a research professor at USU in the Civil and Environmental Engineering Department, and an associate director at the Utah Water Research Laboratory. Barfuss estimates that the 260,000 annual water main breaks in North America equate to approximately $2.6 billion per year in maintenance and repair costs. The esti-

mate is based on a single water main break repair cost of $10,000.

Both the basic and detailed surveys showed that approximately 70% of utilities have a pipe replacement program. “Small water utilities may find it challenging to renew their water infrastructure in the coming years,” states the study. “They have lower populations with fewer customers per kilometre of pipe, which has the effect of increasing the financial burden of maintaining these systems.”

The average age of failing water mains according to the research was 53 years. The study, which tripled its sample size from its 2018 water main break research, found that four types of pipe materials comprise some 90% of water mains in

the U.S. and Canada. The mains are a combination of 29% PVC, 27% ductile iron, 23% cast iron, and 11% asbestos cement. The remaining materials each represent less than 3%. Additionally, the study found that some 86% of the water mains are 12-inch diameter or smaller.

“Utilities experience widely different break rates for the same pipe material,” the study states. “Indeed, this should not be surprising. Several significant variables affect break rates, including pipe age, soil corrosivity, corrosion prevention methods, installation practices, and climate.

These factors demonstrate why pipe material performance and selection are an important component of optimizing distribution systems.”

PVC pipe has the lowest failure rate among common distribution pipe materials in the study, while cast iron has the highest.

Barfuss also learned that overall water main failures between 2018 and 2023 decreased by 20%, which he correlated with reduced inventory of cast iron and asbestos cement pipe with high failure rates.

The study also notes that portions of Canada have “very corrosive soils” and “extremely cold weather”. These factors, says Barfuss, could potentially explain the higher Canadian break rates for cast iron (38% higher) and ductile iron pipes, the latter of which have a break rate triple that of the U.S. rate. Ductile iron pipe has more than six times the number of failures in highly-corrosive soils compared to low-level corrosive soils, Barfuss found.

Approximately 20% of installed water mains have not been replaced due to lack of funds, the study notes.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine WATER ® C M Y CM MY CY CMY K Waste Water products plus PERIPRO 4.5 x 4.875 Holistic.pdf 1 1/19/2023 3:40:41 PM

ntc.social@netzsch.com

Peel Region says wastewater expansion could support up to 47,000 new homes

By ES&E Staff

Ontario’s Peel Region is investing more than $335 million to expand the wastewater treatment capacity at its G.E. Booth Water Resource Recovery Facility by 40 million litres per day. Peel Region Council estimates that the increased capacity could support between 28,000 and 47,000 additional housing units, depending on the type of development, by 2028.

“Peel Region owns and operates the 2nd largest water and wastewater systems in Ontario and fourth largest in Canada, with world class systems and talent,” announced Peel CAO Gary Kent, in a statement. “This investment in our largest water resource recovery facility is dependent on future flow of development charges and ensures we are using utility dollars in the most sensible way to support effective long-term growth in Peel.”

The G.E. Booth facility originally went into service in 1955 with a capacity of 40 million litres per day. It currently has a rated capacity of 518 million litres per day. In late February, Peel Region Council announced an additional $130 million to “accelerate” the process of expanding it.

Peel officials said the increased capacity can be available sooner by advancing construction through their current capital contractors, ROMAG Contracting Ltd. and CIMA+ Canada Inc.

CIMA+ was retained as the design consultant under a competitive process for the replacement of the original portions of the plant in 2018. In 2019, council endorsed a plan to merge the replacement project with a planned expansion proj-

ect to advance the overall schedule and lower the risk of plant bypasses. This allows the plant to maintain its current capacity while the replacement of the original portion of the plant is completed. The combined project was tendered in 2022, and awarded to ROMAG Contracting Ltd. For

Peel officials said the increased capacity can be available sooner by advancing construction through their current capital contractors, ROMAG Contracting Ltd. and CIMA+ Canada Inc. Credit: Region of Peel

Peel officials said the increased capacity can be available sooner by advancing construction through their current capital contractors, ROMAG Contracting Ltd. and CIMA+ Canada Inc. Credit: Region of Peel

more

email:

information,

editor@esemag.com

April 2024 | 9 www.esemag.com @ESEMAG WASTEWATER ORIVAL ORIVAL Wastewater/Irrigation Pollution / Wet Scrubber ORIVAL WATERFILTERS • Automatic Self-Cleaning • 10-10,000 gpm Units • 10 mic Filtration • Turnkey Systems • ASME Construction • No external power required For Protection of: • Heat Exchangers • Spray Nozzles • Instrumentation • Pump Seals • I.E. & R.O. Units • Air Compressors • The Environment Automatic Self-Cleaning WATER FILTERS ORIVAL ORIVAL Wastewater/Irrigation Pollution / Wet Scrubber ORIVAL WATERFILTERS • Automatic Self-Cleaning • 10-10,000 gpm Units • 10 mic Filtration • Turnkey Systems • ASME Construction • No external power required For Protection of: • Heat Exchangers • Spray Nozzles • Instrumentation • Pump Seals • I.E. & R.O. Units • Air Compressors • The Environment Automatic Self-Cleaning WATER FILTERS 213S.VanBruntSt., Englewood,NJ07631 (800)567-9767 (201) 568-3311 Fax(201)568-1916 www.orival.com filters@orival.com

Urban stormwater control measures for nutrient management

By Julie Stein and Leila Talebi

Nutrients such as total phosphorus, orthophosphate, dissolved phosphorus, total nitrogen, total Kjeldahl nitrogen nitrate, nitrate+nitrite, and ammonia as N are commonly transported in stormwater runoff and are direct contributors to water quality impairments. Excess nutrients from stormwater discharges directly increase aquatic plant growth, harmful algal blooms and anoxia in receiving waterbodies, which adversely impacts fish and aquatic life.

Human activities are a common cause of excessive nutrient loading with specific activities, commonly tied to land use, contributing to high concentrations of nutrients in stormwater runoff. Activities such as urban or residential fertilization, septic systems, yard waste, organic debris, pet waste, trash and food waste, automobile emissions and atmospheric deposition are sources of nutrients discharging to our waterbodies via separate storm sewer outfalls or direct drainage via overland flow.

STORMWATER CONTROL MEASURES FOR NUTRIENT MANAGEMENT

A stormwater control measure (SCM), is an action, either structural or non-structural, implemented to manage stormwater by regulating its flow rate, quantity and/ or pollution levels. Studies over the past several decades have shown that, after source controls through actions like fertilizer bans and street sweeping, structural SCMs or best management practices are effective at removing nutrients in runoff.

Filtration practices such as media filters and high-rate bioretention are most effective for reducing total phosphorus and total nitrogen in stormwater runoff. Detention basins, retention ponds, wetland basins and wetland channels are most efficient at removing dissolved forms of nutrients in stormwater runoff.

Selecting SCMs for nutrient removal can be complicated given the number

of different parameters contributing to nutrient pollution and that specific SCMs are known to export nutrients. Bioretention, grass swales or grass strips, for example, may consist of phosphorus-rich soils or media, or cause ammonification or nitrification of organic nitrogen.

Combined with multiple pollutants of concern for waterbodies, it is important to know which nutrients are impacting a receiving waterbody and review data from the International Best Management Practices (BMP) Database to select SCMs that will address nutrient loads as well as other loadings. This database provides stormwater managers a centralized, online repository for the effectiveness of BMPs, as well as data on urban and agricultural runoff quality. This resource is particularly valuable for selecting SCMs to implement in watersheds that need to address multiple pollutants where competing costs or siting challenges are expected. These challenges can arise as utilities and public works departments try to fit SCMs into tight or constrained urban spaces.

MULTIFACETED APPROACH

A multifaceted approach is of utmost importance in addressing nutrient pollution in stormwater runoff due to the

complexity and scale of the issue. Nutrient pollution, primarily caused by excess nitrogen and phosphorus, poses significant ecological and public health risks. Adopting a multifaceted approach recognizes that nutrient pollution stems from diverse sources such as urban and agricultural runoff, sewage systems and industrial discharges.

By considering the wide range of sources, this approach ensures that strategies and interventions are tailored to address each specific contributor, maximizing the effectiveness of pollution reduction efforts.

Furthermore, a multifaceted approach acknowledges the need for a watershed-scale perspective. Stormwater runoff flows through interconnected watersheds, ultimately impacting downstream water bodies. By implementing strategies at various points along the stormwater pathway, such as source reduction measures, green infrastructure, treatment facilities and non-structural strategies, a multifaceted approach can effectively intercept and treat nutrients before they reach sensitive aquatic ecosystems.

This comprehensive perspective recognizes the interconnectedness of the stormwater system and ensures a holistic approach to tackling nutrient pollution, continued overleaf…

Environmental Science & Engineering Magazine 10 | April 2024 STORMWATER

ultimately leading to improved water quality and healthier environments for both humans and aquatic life.

DETERMINE STORMWATER IMPROVEMENT GOALS FOR WATER QUALITY COMPLIANCE

These goals serve as clear and measurable targets and can be established in collaboration with regulatory bodies or through stakeholder consultation.

CHARACTERIZE EXISTING CONDITIONS AND ESTIMATE EXISTING NUTRIENT LOADS

This requires utilizing available data and employing modelling approaches to accurately assess the nutrient levels. In addition, it is important to consider all stormwater management practices and system assets that are currently in place or implemented at a specified point in time. This comprehensive characterization may require additional resources, such as historical information, environmental data and improved modelling approaches, to ensure accurate estimations.

CALCULATE REQUIRED NUTRIENT LOAD REDUCTIONS

These calculations are essential for developing targeted strategies and measures to achieve the established goals. Based on the existing conditions characterized above, in combination with water quality targets set by total maximum daily loads (TMDLs) or other assessments, the permit, and/or the watershed or stormwater management plan, specific goals can be determined to address impairments caused by stormwater. These goals typically involve specified reductions in stormwater pollutant loads or concentrations, volumes, or peak flows, and serve as benchmarks for effective stormwater management.

CHOOSING EFFECTIVE STRATEGIES AND MANAGEMENT ACTIONS FOR LOAD REDUCTION

This involves evaluating the effectiveness of various management practices, conducting economic assessments and adopting cost-effective approaches. Through the watershed or stormwater management planning process, opportunities for management actions are iden-

tified, including programmatic activities, low-impact development practices and municipal capital improvement projects. These strategies ensure that the selected management approach will lead to the attainment of water quality improvement goals.

MONITOR THE IMPLEMENTED MANAGEMENT APPROACH

This includes conducting ambient monitoring of the water body, tracking nutrient loadings and assessing the effectiveness of specific projects. Monitoring progress is crucial for providing feedback and assessing the effectiveness of the implemented measures.

TRACK AND ASSESS PROGRESS TOWARD GOALS

This assessment can be conducted through various methods, such as citizen observations, monitoring trend analysis and the development of quantifiable measures. It is important to report the results to stakeholders and the public. Developing quantifiable methods for evaluating progress is an area that requires further resources and research.

If progress falls short of expectations, it may be necessary to revisit earlier steps, reassess relationships and strategies, and make necessary adjustments. This assess-

ment process serves multiple purposes. It provides reasonable assurance to stakeholders and regulators, informs future stormwater program enhancements and capital improvement planning, and highlights quantitative results that support adaptive management, implementation tracking, and progress toward meeting stormwater improvement goals and requirements.

URBAN STORMWATER AND CONTROLS FOR NUTRIENT CHALLENGES

Numeric water quality criteria for nutrients in municipal separate storm sewer system (MS4) permits will always point communities toward a watershed or sub-watershed scale approach for SCM implementation. Implementing watershed-wide structural BMPs comes with its fair share of challenges.

Reporting data can be a significant hurdle. Collecting and analyzing data from numerous BMPs across a watershed can be complex and time-consuming. It requires establishing robust monitoring systems and ensuring data consistency and accuracy.

Local pilots, demonstrations and post-construction monitoring or data analysis can help communities determine capital investments. The Interna-

Detention basins, retention ponds, wetland basins and wetland channels are most efficient at removing dissolved forms of nutrients in stormwater runoff.

Environmental Science & Engineering Magazine 12 | April 2024 STORMWATER

tional BMPs Database 2020 Summary Statistics Report spells out BMP-related data needs to provide pollutant removal effectiveness values for nutrients.

Particularly for nutrients, more data is needed relating to green infrastructure and their impact on potential nutrient export, how enhanced engineered media mixes (i.e., iron or biochar) may have positive effects on both nutrients and other pollutants of emerging concern and if nutrient recovery may be useful where soils are nutrient deficient (i.e., for a circular economy, to support agriculture).

Another challenge is the timeline for implementation, which is often identified in permits by regulatory agencies. Implementing SCMs at a watershed scale involves numerous projects and stakeholders, each with their own priorities and schedules. Coordinating and aligning these efforts can be time-intensive and may require overcoming logistical hurdles.

Additionally, securing funding resources for large-scale implementation can pose challenges, especially when considering the diverse range of sites and their site-specific considerations, such as land availability, soil conditions and local regulations.

Furthermore, evolving regulatory criteria present a challenge. Stormwater regulations and permits often undergo updates and revisions to address emerg-

ing concerns and scientific understanding. Keeping up with these changes, including stricter pollutant reduction, monitoring or reporting requirements, and ensuring compliance across a watershed, can be demanding for project planners and implementers. Staying informed and adaptable to evolving regulatory requirements is essential to the successful implementation of watershed-wide stormwater SCMs.

Potential future regulations in stormwater management may involve the adoption of new technologies and practices to improve stormwater quality. Costs of compliance with stormwater regulations can vary depending on many factors. These include the size of the watershed or community, the condition of the stormwater infrastructure, the level of pollution reduction required and the implementation of SCMs. Compliance costs may include infrastructure upgrades, maintenance expenses, monitoring and reporting activities, stakeholder outreach and staff training.

BENEFITS AND OPPORTUNITIES

One of the primary benefits of implementing SCMs at a watershed scale is improved water quality and ecosystem health. By implementing SCMs across a watershed, the overall nutrient and pollutant loads entering water bodies can be significantly reduced. This, in turn, improves water quality, enhances

aquatic habitat, and protects the health of plants, animals and humans who are all dependent on these ecosystems.

Implementing SCMs at a watershed scale often allows for multiple benefit projects. Many SCMs, such as constructed wetlands, permeable pavement and stormwater ponds, provide additional advantages beyond nutrient reduction. They can help manage stormwater volume, reduce erosion, enhance groundwater recharge and create green spaces that improve aesthetics and provide recreational opportunities.

By integrating multiple benefits into a watershed-wide approach, communities can achieve more comprehensive and sustainable stormwater management solutions.

Additionally, a potential future challenge that a watershed-wide approach can help address is climate change resilience. As climate patterns shift, communities may face increased stormwater challenges, such as more frequent and intense rainfall events. Implementing SCMs at a watershed scale can help build resilience and adaptability to these changing conditions by effectively managing stormwater runoff and minimizing its impacts on downstream areas.

Julie Stein and Leila Talebi are with HDR Inc. For more information about HDR’s water program, email negin.salamati@hdrinc.com

Associated Engineering Announcements

Associated Engineering is pleased to announce that Mark Sungaila, M.A.Sc., P.Eng., PMP, has joined our Toronto office as a Senior Project Manager. Mark brings over 37 years of consulting experience on solid waste management projects in the public and private sectors.

Also, Twyla Kowalczyk, M.Sc., P.Eng., IRP, is now Manager of the Water Resources Group in the Infrastructure Division in Calgary. Twyla has helped communities manage flood and climate-related risks and develop emergency response plans.

At Associated, we are passionate about building vibrant, healthy and resilient communities. Together, we can shape a better world.

April 2024 | 13 www.esemag.com @ESEMAG

www.ae.ca

Casselman starts chlorine dioxide oxidation pilot to solve water’s manganese issue

By ES&E Staff

The Ontario South Nation River Town of Casselman is planning to move forward with a chlorine dioxide oxidation pilot project to address rising levels of manganese that are turning tap water a yellowish brown. But local leaders say there will be many hoops of approval to jump through as the province wades through the technology’s unfamiliar waters.

In February, the town council extended its consulting agreement with Bill Dallala, a senior chemical engineer and water treatment expert with Montreal-based Krypton Scien-tek Inc., until summer 2024. Studying Casselman’s manganese challenges in fall of 2023, Dallala recommended that the town discontinue its use of chlorine gas and ammonium sulfate and rely instead on chlorine dioxide as a powerful disinfectant.

“The most powerful advantage of chlorine dioxide is that it’s much faster to oxidize manganese, or iron, and reduce turbidity levels in the water. Also, it does not react with carbon to generate trihalomethanes like chlorine does,” states Dallala’s 2023 report.

Manganese is an essential element for humans that occurs naturally in the environment and is widely distributed in air, water and soil. Health Canada’s maximum acceptable concentration for total manganese in drinking water is 0.12 mg/L. During summer 2023, Casselman’s levels often averaged between 0.35 mg/L. and 0.45 mg/L and even reached 1 mg/L in late July.

Casselman’s water remains safe to drink, despite the discoloration. But Dallala’s report adds that the town, located just southeast of Ottawa, “must also abandon” its chloramination technology and discontinue use of potassium permanganate to resolve the lingering manganese issue, which has

drawn complaints from residents.

He also told Casselman officials that he needs help from engineers to provide detailed drawings. The “time-consuming process”, he said, will be helped through a collaboration with J.L. Richards & Associates Ltd., as well as the Ontario Clean Water Agency, the provincial authority that operates and maintains Casselman’s water and wastewater treatment facility.

“This is a completely new way to treat water in Ontario,” states a public works update by Casselman staff on the water modification project. “Therefore, the Ministry of Environment Conservation and Parks does not have the expertise to provide feedback. The process to get the necessary approvals is long, as every step and action needs to be detailed quite elaborately to get the go ahead.”

Casselman has received a $1 million

federal grant to address manganese in its municipal water system. The municipality has also contributed $266,700.

Casselman Mayor Geneviève Lajoie told residents that she hopes they will notice a positive difference in the colour of the town’s tap water by spring, as the water modification pilot project gets underway. However, Dallala pointed out that testing will be challenged by the fact that manganese levels are often low during the winter and even spring months. It typically presents more aggressively in the summertime, he said.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 14 | April 2024 WATER

During the summer of 2023, Casselman’s manganese levels often averaged between 0.35 mg/L and 0.45 mg/L and even reached 1 mg/L in late July. This created a yellowish-brown hue in the water. Credit: andriymedvediuk, stock.adobe.com

Improve your f ilter per formance

Granular media filtration is a specialized process and each filter configuration is unique. W ith AWI’s site-specific approach to filter optimization you can expect improved filter performance, an operator-friendly treatment process, and the training and technical support to maintain your filters in optimum condition.

AWI’s innovative filter optimization products include the Phoenix Underdrain and Panel Systems. These custom-engineered solutions guarantee uniform backwash water flow distribution, ensuring sustainable filter performance and long service life of your media bed.

Contact one of our knowledgeable filtration specialists to learn how AWI’s approach to filter optimization can help you reach your filter performance goals.

RELIABLE. PROVEN. TRUSTED.

Phoenix Panel System with Air Scour

Filter Assessment & Pilot Studies

Visit us at OWWA Booth #319

Filter Media Design & Supply

Saskatchewan’s $51M in water, wastewater funding will support 34 major projects

By ES&E Staff

Major water and wastewater infrastructure funding totaling more than $51 million was announced recently for Saskatchewan to support 34 projects that range from the addition of reverse osmosis systems, to ultraviolet disinfection, and new sewage pumping stations. The federal and provincial governments are supporting infrastructure upgrades in 17 communities.

Some of the most complex upgrades will take place in the Town of Redvers, which is set for a $6.1-million overhaul and process upgrade for its water treatment plant. The local council said it was “thrilled” with the news of its successful $4.5-million Investing in Canada Infrastructure Program (ICIP) grant, particularly after working on it at most council meetings since 2021.

BCL Engineering will replace the water treatment plant’s current greensand filtration method with biofiltration and reverse osmosis, according to Redvers council. However, officials said they will run a pilot project in the spring to determine what kind of water treatment system will work best.

“Embarking on this project will ensure that Redvers is not only compliant with the Water Security Agency, but also providing the best water to our residents directly to their taps today and in the future. This is an upgrade that was longawaited!” announced Redvers CAO Tricia Pickard.

More than $5 million in funding will also go towards upgrading the water treatment plants in the Northern Village of Green Lake, and the Village of Kincade. In the nearby Town of Lemberg, more than $3 million in upgrades will resolve meeting minimum requirements for bacteriological, turbidity, and chemical parameters.

The Town of Norquay has received funding to replace its existing water storage tank with an equivalent storage tank that is more cost-efficient. Credit: Mona Zubko, Town of Norquay

In terms of wastewater, Saskatchewan will see nearly $3 million in upgrades for the Town of Alameda’s sewage lagoon. A new cell will be dug to increase the town’s capacity and support future growth.

Nearly $5.5 million will also be invested in the Town of Vonda for a two-cell facultative lagoon that will span approximately 6.7 hectares. Its lift station is nearing its life expectancy, and the existing two-cell lagoon is undersized to meet the current and future needs of the community.

Lagoon upgrades are also set for the Town of Watrous and the Town of Whitewood.

In the Town of Cudworth, a new sewage pumping station will be constructed with wet well storage and pumps capable of meeting wastewater flows for 20 years. The project is expected to cost less than $2.5 million.

The Town of Pense and the Village of Pierceland are also set for wastewater upgrades. In Pense, nearly $1 million

will be spent to address ongoing issues with the condition and performance of the existing lift station pumps and process piping.

In Pierceland, more than $1 million will be spent on sewer pumps and piping to be upgraded for maximum efficiency, while creating less head pressure on the pumps. Crews will also upgrade measurement instruments and install an automatic generator to keep up with demands on the lift station when power is out.

Lastly, the Village of Plenty is set to install a new ultraviolet disinfection system, while the Village of Semans will install a reverse osmosis membrane filtration system.

For more information, email: editor@esemag.com

Environmental Science & Engineering Magazine 16 | April 2024 WATER & WASTEWATER

Regina water expert pioneers sustainable solution to transform sludge into multi-use ceramsite

By David Nesseth

When a water treatment expert at the University of Regina (U of R) learned that the nearby Buffalo Pound Water Treatment Plant was spending upwards of $1 million annually to transport and landfill water treatment residual (WTR) stored in on-site lagoons, he set up a meeting with plant management to explore innovative reuse solutions that not only promised substantial cost savings but could significantly diminish the plant’s environmental footprint.

Since 2022, Dr. Jinkai Xue, principal investigator at the U of R’s Cold-Region Water Resource Recovery Laboratory, and an associate professor in the Faculty of Engineering & Applied Science, has been working with his graduate students to explore residual volarization for the some 5,000 m3 of WTR that is produced each year at Buffalo Pound and then hauled to Moose Jaw, where the landfill has reached capacity. “That is expensive—both financially and environmentally,” Xue told ES&E Magazine

WTR, often called sludge, is created primarily from the process of coagulation and flocculation used to separate the suspended solids from the water. Xue says the sludge that eventually accumulates and settles on the bottom of the clarifiers is composed of different minerals, such as aluminum, calcium, magnesium and silicon, which are components of products like bricks, concrete and ceramics.

Xue’s research has since focused on the potential for the sludge to be converted into ceramsite, which forms small, coloured ceramic pebbles that can have environmental, agri-

continued overleaf…

Buffalo Pound Laboratory and Research Manager, Blair Kardash (centre) and U of R students collect sludge from the plant for the research project.

Buffalo Pound Laboratory and Research Manager, Blair Kardash (centre) and U of R students collect sludge from the plant for the research project.

Environmental Science & Engineering Magazine 18 | April 2024 BIOSOLIDS MANAGEMENT

The Vanton AdVantage

The Key to Ending your Pumping Problems

• No Corrosion or Contamination

• No Chemical Absorption or Wicking

• No Tearing, Cracking or Peeling

• No Significant Abrasion

Each Vanton thermoplastic pump features wet-end components that are inert to corrosive chemicals across the full spectrum of pH, will not contaminate ultra-pure liquids, and are also abrasion resistant. Handling flows to 1150 gpm (261 m3/h) heads to 185 ft. (56 m) and temperatures to 275o F (135o C), Vanton pumps are ideal for:

• Chemical Transfer

• Neutralization

• Dosing

• Effluent Control

• Lift Stations

• Odor Control

• Recirculation

• OEM Applications

mkt@vanton.com

PUMP

EQUIPMENT CORPORATION vanton.com e-mail:

•

Sump-Gard® Vertical Centrifugal Pumps Flex-I-Liner® Rotary Peristaltic Pumps Pump/Tank Non-metallic Systems Chem-Gard® Horizontal Centrifugal Pumps Chem Action Inc. 4559 Boul Métropolitain E Saint-Léonard, QC H1R 1Z4 514-593-1515 Vissers Sales Corp. 20-220 Industrial Parkway South Aurora, ON L4G 3V6 905-841-4073

&

908-688-4216

cultural, or gardening applications for soil health. “We want to know what are the fundamental governing mechanisms that make this material good and how we can take advantage of that knowledge to make it better,” says Xue.

The research team discovered that the ceramsite pebbles have surprisingly high mechanical strength and durability that could be promising as a green construction material. With the right manufacturing process, Xue says they may meet the minimum compressive strength defined under Canadian standards for construction purpose.

Xue’s team is also conducting further studies to optimize the properties of the ceramsite. With a high capacity for absorption, the porous ceramsite also has the potential to be used for water pollution reduction. Xue’s tests have shown that putting a small amount of the material into water with high phosphorus concentrations can remove 90% of the phosphorus within 20 minutes, showing promise to address blue-green algae blooms.

“Once it’s been spent for nutrient removal, we can sell it to consumers as landscape mulch. At this stage, it is now saturated with phosphorus, which is a fertilizer that can promote microbial activities and soil health, which is beneficial for the plants. The entire process fits the circular economy strategy very well,” says Xue.

Researchers all over the world have been active in recent years looking for new ways to capitalize on the abundance of WTR. For instance, the University of Córdoba, Spain, recently developed a sustainable way to convert sludge into high-value activated carbon. Others are exploring avenues such as hydrothermal carbonization of the sludge to create an alternative solid fuel comparable to coal.

According to the Buffalo Pound Water Treatment Corporation’s 2022 annual report, the solids content of its sludge is only about 5% when settling out in the lagoon system. Prior to removal, the sludge undergoes a freeze-dry process that increases solids content to ~12% and decreases volume from 30,000 m3 to ~12,500 m3.

“After excavation, with difficulty, the very wet sludge is transported to a dry-

Xue’s research has since focused

the

the Natural Science and Engineering Research Council (NSERC) through the NSERC Alliance program, the Mitacs Accelerate program, and the Canada Foundation for Innovation – John R. Evans Leaders Fund (CFI-JELF) grant.

Whether ceramsite could become a practical and sustainable solution for WTR, and potentially reach commercialization, is a step to be considered further down the road. Xue acknowledges that there could be steep upfront costs when it comes to building a manufacturing facility, but there is no telling who could end up partnering on such a project.

Xue is hopeful that investors, or even various levels of government, could eventually propel the theories explored during the Buffalo Pound research into a practical reality, with the aim of furthering Canada’s circular economy.

For the research team at the Buffalo Pound plant, creating ceramsite from water treatment sludge in combination with other recyclable additives remains the most promising idea to date. Buffalo Pound Laboratory and Research Manager, Blair Kardash, says the high aluminum oxide content and nearly non-detectable levels of harmful metals within the plant’s potable water treatment waste “provided motivation” to find practical purposes for the material rather than hauling it to landfill.

ing bed where it undergoes evaporation, another freeze-dry cycle, followed by further evaporation,” the report states, noting that the solids content increases to ~30% and volume decreases further to ~5,000 m3. The sludge is dry enough to then haul to landfill.

Towards the end of 2023, Xue’s team received new sludge reuse funding of more than $118,000 from the federal government through Prairies Economic Development Canada, which recently introduced a framework to Build a Green Prairie Economy. This research partnership has been supported by

“If the research data at bench and pilot scales confirms this concept works, it then creates a foundation for the Corporation to pursue an environmental assessment,” Kardash told ES&E Magazine. “If the product passes an environmental assessment, the Corporation will look into finding an interested partner such as a third-party, individual investors, or government to pursue full-scale commercialization.”

The plant itself, which is currently immersed in a major expansion process, has come a long way towards building a greener identity. As of 2023, Buffalo Pound began drawing power sourced entirely from green sources, and even has a solar power project in the works.

David Nesseth is with ES&E Magazine. Email: david@esemag.com

Dr. Jinkai Xue is principal investigator at the University of Regina’s Cold-Region Water Resource Recovery Laboratory.

on

potential for the sludge to be converted into ceramsite, which forms small, coloured ceramic pebbles. Photos Courtesy of University of Regina.

Environmental Science & Engineering Magazine 20 | April 2024 BIOSOLIDS MANAGEMENT

Sewage sludge dewatering offers a wide range of potential savings for operators of wastewater treatment plants. The cost of transport and disposal of dewatered solids can amount to as much as 80% of the operating costs of mechanical dewatering. Since dryer solids result in less volume for disposal, the decision to invest in an efficient, reliable and, above all, peakperforming dewatering system is critically important to reducing operating costs.

“The Flottweg centrifuges and the dryer biosolids they produce have saved us about $900,000 annually. Our plant was able to incinerate the dryer sludge without the aid of natural gas, which equated to our high savings. The Flottweg centrifuges also produce cleaner and more consistent centrate.”

S UC CESS I S.. . OP IMI Z ING BIOSOLID S DE E R ING O M AXIMIZE S AVING S S U C C ESS I S.. . OPTIMIZING BIOSOLID S DE WAT E R ING TO M AXIMIZE S AVING S

Greenway Wastewater Treatment Plant, Ontario

Flottweg.com

Ontario’s Excess Soil Registry rates jump

By ES&E Staff

Higher Excess Soil Registry fees for users will be spread out over five years instead of three, following feedback from a consultation period, says Ontario’s Resource Productivity and Recovery Authority (RPRA). But users might be taken aback by some of the increases.

The registry fees cover RPRA’s costs for building, maintaining, and operating the Excess Soil Registry, as well as providing support to registry users. Some of the fees will jump significantly for 2024. For the largest generators of excess soils (volumes greater than 500,000 m3) fees are going up by 400%, jumping from $30,000 to $150,000.

Also, projects that generated less than 2,000 m3 of excess soil did not have to pay registry fees last year. In 2024, however, those same projects will face a flat fee of $90. “The increase in 2024 fees for the Excess Soil Registry is required because substantially fewer filings and less soil volumes are being registered than RPRA had anticipated when the registry was built,” according to the RPRA’s consultation report.

The large fee increases will also impact owners of soil reuse sites. Fees to register for the largest of receivers (over 5,000,000 m3) are going up 250% from the current $12,000 to $42,000.

RPRA added that its 2024 program operating budget has been “reduced substantially” in response to the lower activity, although fee rates still need to increase, both to ensure full recovery of the reduced annual operational budget, and to recover program deficits that

have accumulated from 2021 through 2023, in part because of the low volumes.

Total operational deficits for RPRA at the end of 2023, not including registry capital costs, were estimated to be approximately $3.3 million. RPRA notes in the consultation document that it has “no other means of recovering its costs than through fees to registrants” and it does not receive any government or third-party funding.

RPRA explained that the discrepancy between earlier estimates for filings and current anticipated volumes is likely due to regulatory changes that exempted additional projects and, “potentially, to slow uptake of the program by registrants in its first two years,” according to the consultation report.

Throughout the consultation period, RPRA hosted a webinar to walk through the original proposal, answer questions, and gain feedback from registrants and other interested stakeholders.

Feedback during the RPRA consultation period suggested that the rate increases were too high, particularly given that 2024 project budgets were already approved, and that no new services were being provided to registry users. As a result, RPRA said it would “soften” the fee increase year-over-year and expand the time period to cover its deficit to five years instead of three.

Some of the fees will jump significantly for 2024. For the largest generators of excess soils, fees are going up by 400%, jumping from $30,000 to $150,000. Credit: Siggy Nowak, Pixabay

Environmental Science & Engineering Magazine 22 | April 2024 EXCESS SOILS TOTAL SITE SERVICES & SOLUTIONS Soil and Ground Water Remediation Excavating and Deconstruction UST/AST Decommissioning www.KGSEnvironmentalGroup.ca Toll free: 855-378-3015

LimeGREEN marks a decade of success in rental equipment services

By ES&E Staff

Whether responding with equipment support for a six-alarm chemical distribution centre fire in Toronto, or assisting at the scene of a tractor-trailer pileup and diesel spill on a major highway, LimeGREEN has seen a lot of action over its 10 years in the field.

The Ontario-based specialized equipment rental company’s milestone anniversary highlights a track record of reliability and a reputation for a personal touch from founder Kevin Bailey and his LimeGREEN team, who have also heard a lot of “thank yous” over their first decade in business.

The company's core business includes industrial services, construction dewatering and remediation. “Clients see that everyone has a vested interest. When we get called to a site, we’re part of that team that’s called us there,” Bailey explains.

After he began developing and expanding a Canadian presence for U.S-based BakerCorp in 2005, Bailey was encouraged by those around him to stay in the business and start his own company.

The company came to be called LimeGREEN. The origin of the name is meant to symbolize the cleansing power of citrus and environmental sustainability. Both are elements that have been critical to the company’s success as it has built up an extensive inventory of liquid containment, pumps, and filtration equipment for a wide array of applications that cater to diverse industry requirements.

called upon for emergency response, particularly to help mitigate and contain spills.

“Our team’s commitment and ownership of their tasks resonate with clients,” Bailey emphasizes.

Bailey has been dealing in equipment rentals since his high school days, whether it was washing and servicing light equipment like pumps and saws, or driving equipment to job sites. But it didn’t take long before he began to cut his teeth in sales, marketing, and customer service, as he learned the ropes from mentors like Tony Joosse, Jon Brown, and Tony Brunet at Battlefield Equipment Rentals, and after that, under the wings of Jon Heslin, Tom Bullis, Jim Murray, and Joe Panzarella from BakerCorp.

“I owe a lot to those guys,” says Bailey. “They gave me insight as to what this business could be.”

Of all the mentors Bailey had, he says there’s a little bit of all of them in LimeGREEN as the company celebrates this proud milestone in its journey.

LimeGREEN now offers more than 15 different types of containment equipment through locations in Hamilton, Trenton, Sudbury, Ottawa, and Thunder Bay.

Despite its modest size, LimeGREEN’s word-of-mouth reputation precedes it. With a dedicated team and an ever-evolving inventory of tanks, Bailey ensures swift responses for clients and vendors across Ontario. The company exemplifies readiness and reliability when

Bailey remains humbled by the outpouring of gratitude his company receives from the industries it serves. He’s still amazed how often he’s caught off guard by gratefulness from clients. These moments, he reflects, affirm the significance of his work and fuel his passion for the industry.

“When a customer says thank you through a phone call, email, or text, it suddenly makes everything seem worthwhile,” Bailey says. “That’s why I’m doing this.”

For more information, email kbailey@limegreeninc.com, or visit www.limegreeninc.com

(Top) LimeGREEN founder Kevin Bailey. (Bottom) With a dedicated team and an ever-evolving inventory of tanks, Bailey ensures swift responses for clients and vendors across Ontario.

April 2024 | 23 www.esemag.com @ESEMAG SPONSORED PROFILE:

Ontario continues march towards streamlining EAs, introducing project list approach

By ES&E Staff

Ontario leaders have begun to shift the province to a project list approach for environmental assessments (EAs) as they kick off the spring sitting of the legislature.

The project list approach is part of the Conservative government’s upcoming Get It Done Act, which if passed, will mirror aspects of environmental assessments in Quebec and British Columbia that list types of infrastructure projects that would require the highest level of environmental assessment.

The project list approach is a shift away from the 50-year-old EA focus on project proponents, and a move towards

highlighting the nature of the project and its potential risks to the environment, according to an announcement from the Ministry of Environment, Conservation and Parks.

Ministry officials said a new project list approach would initially include highways, rail, and electricity transmission lines, all of which could be built up to four years faster through a streamlined EA process.

Other projects, however, could undergo streamlined EAs as well, as Ontario begins consultations to include municipal water, shoreline and sewage system projects. Consultations were held in 2020, 2021 and 2023 on the planned changes to move Ontario’s environmental assessment

program to a project list approach.

“Our government is supporting municipal partners by streamlining and simplifying complex environmental assessment processes to get shovels in the ground and finish major projects faster,” announced Ontario Minister of the Environment, Conservation and Parks, Andrea Khanjin. “We’re doing so while protecting strong environmental oversight and ensuring meaningful consultations before projects can move forward.”

In an announcement about streamlining Ontario’s environmental assessment process, officials illustrate the example of the comprehensive EA process for the East-West Tie Transmission Project that runs from Wawa to Lakehead in north-

REGULATIONS www.avensys.com | 888-965-4700 Ideal for Anaerobic Digesters and Biogas Upgrading • Single or Multichannel • Multigas (CH4, CO2, O2, H2S, H • Integrated Sampler Cooling and Conditioning • Continuous or Discontinuous Operation • Hazardous Location Version Available • Built to your requirements Visit us at the Toronto BIOGAS show, BOOTH #38! AwiFlex BIOGAS ANALYZER 800-327-3248 sales@harmsco.com www.harmsco.com Call today to learn about our LT2 Rule and PFAS World’s Largest Selection of NSF Listed Filtration Cartridges: Prefiltration 1-Micron Absolute 3.6 Log Cyst Reduction Activated Carbon High Flow High Purity & more! Unit, Technologies: Cyclonic Separation Upflow Filtration Cartridge Filtration THREE ONE Up to 9,085 lpm per housing Save up to 20% in Energy Costs! Proven, Efficient Solutions to Water Quality Challenges

ern Ontario. What took five years to assess under the former process, could be completed within two years under a streamlined process, officials estimated.

The ministry also noted that expropriation may soon be one of the ways that property can be acquired for a project before the EA process is completed. It is a point that comes as the Conservative government looks to invest nearly $98 billion over the next 10 years to expand public transit and build new roadways such as Highway 413 and the Bradford Bypass.

When it comes to creating a streamlined EA process for certain municipal water projects, provincial officials said it could accelerate project planning by limiting the process to six months instead of 18 months or longer.

“These time changes could be achieved by providing a regulated timeline, whereas under the current process there is no time limit,” the ministry announced. Approving a new large wastewater treatment plant, for instance, could be completed in just six months as opposed to the municipal class EA process that can currently take up to two years or more.

Steven Crombie, director of government and public relations for the Ontario Sewer and Watermain Construction Association, said that modernizing EAs for municipal infrastructure will help reduce the duplication of approvals necessary for the installation of low-risk infrastructure that is a required part of new housing developments.

“Streamlining this approvals process will save time and

resources for individuals, businesses, and government agencies without compromising any environmental outcomes,” Crombie said in a statement. “By simplifying regulations and reducing administrative burdens, Ontario is making it easier for businesses to operate and invest in growth.”

Ministry officials said a new project list approach would initially include highways, rail, and electricity transmission lines, all of which could be built up to four years faster through a streamlined EA process.

Credit: Enrique del Barrio, stock.adobe.com

Ministry officials said a new project list approach would initially include highways, rail, and electricity transmission lines, all of which could be built up to four years faster through a streamlined EA process.

Credit: Enrique del Barrio, stock.adobe.com

For more information, email: editor@esemag.com April 2024 | 25 www.esemag.com @ESEMAG (905) 659-9604 TRAINING RESCUE STANDBY HEALTH & SAFETY CONSULTING VAC TRUCK SERVICES www.terrahx.com YOUR TRUSTED PARTNERS Amicus/Terra HX is an environmental, industrial services and training company. Our team of experts hold decades of knowledge that we use to build our business with emphasis on 3 core values: Trust, Flexibility and Dependability Understanding our Commitment; we say what we do and do what we say. Amicus www.amicus.bz

Edmonton effectively upgrades large - diameter self-supported sewer line using grooved system

By Dave Horton

Wastewater pipelines are often buried underground in urban areas, but Edmonton’s system features a unique design and construction. The 900-millimeter-diameter sanitary sewer line crosses Whitemud Creek on a 232metre length and 30-metre high self-supported pipe, referred to as “Trestle 7.”

In 2020, EPCOR Water Services (EPCOR), the system owner, initiated a project to redesign the entire trestle, but the bridge’s existing architecture made maintenance and repairs impractical and cost-ineffective. EPCOR engaged with Victaulic to meet the project’s demanding timeline and budget constraints. This engagement not only facilitated a swift, cost-effective execution, but also provided additional advantages that enhanced the overall system design.

WHAT LED TO TRESTLE 7’S FULL SYSTEM REDESIGN?

Initially built in 1965 using carbon steel pipe, the appearance of corrosion began to highlight the system’s age and led to a decision to replace the Trestle 7 pipe. When an opening in the pipe required temporary patching, EPCOR’s in-house engineering team accelerated work to evaluate the long-term options. The general contractor, Whitson Contracting Ltd. (Whitson), constructed a massive scaffold deck across the creek to perform repairs, which enabled EPCOR to perform a complete redesign and replacement.

GROOVED SYSTEM TRANSLATES TO SIGNIFICANT TIME-SAVINGS

As a priority project, EPCOR established a one-year completion timeline for the truss design and pipe replace-

ment. To avoid future corrosion issues, a decision was made to replace the original carbon steel with stainless steel pipe. However, this triggered a new set of challenges that put the project’s budget and timeline at risk.

Stainless steel is more expensive to purchase, and its composition makes welding connections significantly more time-intensive than carbon steel. Extending the schedule meant lengthening the amount of time utilizing a wastewater bypass, which inherently increases cost and sewage spill risks.

“Our main concern was finding a way to reduce our time frame while still having reliable joints. That’s when we started looking at Victaulic, and we realized that what we might accomplish in weeks by welding, we would complete in days with a grooved system,” said

Environmental Science & Engineering Magazine 26 | April 2024 WASTEWATER

The Trestle 7 bridge transports Edmonton’s stormwater and wastewater across a 232-metre creek towards the city’s wastewater treatment plant. The redesign project removed the pipeline as a structural support and added walkways for maintenance use.

Abhishek Bhargava, senior manager of pipe strategies at EPCOR.

Installing Trestle 7’s new stainless-steel pipe involved 38 large-diameter joints. EPCOR predicted several problems with utilizing a welded system on a project of this scale and magnitude.

First, performing a single large-diam-

eter weld can take hours, and additional time must be built into the schedule to perform X-rays on each weld to certify joint integrity.

Second, they expected the installation to commence in the winter when freezing temperatures could make welding extremely difficult, elevating the risk of

cracking and poor weld penetration.

Third, the installation took place 30 metres above ground on a scaffold, raising significant safety and environmental (wind, hot-work) concerns. EPCOR approved using Victaulic’s Advanced Groove System (AGS) couplings after

continued overleaf…

(Left) Victaulic AGS couplings provide a fully self-restrained joint, ensuring a secondary restraint device wouldn’t restrict the new walkway space. (Right) A gantry crane was used to place and align 900-mmdiameter stainless steel pipe.

(Left) Victaulic AGS couplings provide a fully self-restrained joint, ensuring a secondary restraint device wouldn’t restrict the new walkway space. (Right) A gantry crane was used to place and align 900-mmdiameter stainless steel pipe.

April 2024 | 27 www.esemag.com @ESEMAG VALVE AUTOMATION RETROFIT EXPERTS WE PROVIDE: New AUMA Intelligent Actuators Custom Designed Adaption and Stems Installation Services Start Up and Long Term Service Single Source Responsibility Toll free: 888-835-3045 Phone: 705-721-8246 Fax: 705-721-5851 121 Commerce Park Drive, Units H-K, Barrie ON L4N 8X1 www.troy-ontor.ca

analyzing the time-saving benefits the mechanical solution offered for the project. The AGS coupling features a two-piece housing design secured using a pair of bolts, facilitating a faster, easier and safer installation.

SELF-RESTRAINED SOLUTION REDUCES MATERIAL COSTS

The sanitary sewer pipe supported the original bridge structure, leading to elevated concerns over the bridge’s longterm structural integrity. In response, EPCOR removed the sanitary sewer pipe as a structural component during the redesign. Its engineers used a series of eight trusses to provide the necessary structural support and added a walkway to the sides of the pipe to ensure operators could safely inspect and perform maintenance on the system.

Separating the pipe from the structure meant additional support was needed to restrain the sanitary sewer system, which was subject to high wind conditions at its altitude. Initially,

EPCOR planned to add expansion joints to provide the necessary dynamic movement, but it wasn’t necessary in the end. Engineers eliminated that cost by utilizing Victaulic AGS couplings.

The AGS system provides a fully self-restrained joint, eliminating the need for a secondary restraint device. This engineered solution reduced material costs and avoided encroaching on the new walkway space that will be critical to maintenance ease in the future.

EASE OF INSTALLATION IN CHALLENGING CONDITIONS

Site conditions on the Trestle 7 project were a significant challenge during the installation process. Whitson and their mechanical sub-contractor (Land Air Contractors) needed to cross 232 metres of pipe over the creek and execute work 30 metres above ground within a strict construction schedule.

The installation also occurred during the frigid winter months and at the peak of the COVID-19 pandemic, further

diminishing the expected ease of installation. The grooved system enabled crews to reduce installation times and material handling for a safer, quicker job.

RETURNING TO NORMAL WITH AN IMPROVED SYSTEM

The Trestle 7 project was successfully completed on schedule, and normal services resumed in November 2021. Bhargava said the new design will make it easier for operators to inspect and maintain the system decades down the line. “The new walkway allows them to safely monitor the movement and performance of the system. If a joint loosens up, they can easily tighten up bolts. If a section needs to be replaced, that can be done without needing to cut and reweld the pipe or build an entire scaffold.”

Dave Horton is with Victaulic. Email: dave.horton@victaulic.com, or visit www.victaulic.com

Barbara A. Robinson, M.A.Sc., P.Eng., founder (2015) and president of Norton Engineering Inc., has 33 years of hands-on sewer experience.

Norton can help your municipality make costeffective I/I decisions:

• Help you calculate the real costs of I/I

• Guide you in finding and fixing I/I quickly

• Implement a “Sewers are NOT Trash Cans” and/or “Mandatory Roof Leader Disconnection” program

• Execute national best practices

• Write or review RFPs, final reports, etc.

• Solve specific sewer problems

• Review and approve new subdivision flow monitoring

• Deliver exclusive Norton workshops to train your engineering & building staff.

• Undertake public education Hire Canada’s

If you want to substantially reduce I/I, count on Norton. Contact us today.

Norton Engineering Inc.

CHEMICAL FEED / SLURRY PUMPS

Simple to operate

Easy to maintain

Long hose life

Newest technology

From stock

YORK

Environmental Science & Engineering Magazine 28 | April 2024 WASTEWATER

We Love Sewers. nortonengineeringinc@gmail.com

national sewer expert.

HOSE PUMPS

PERISTALTIC

FLUID CONTROLS

Free: 877-454-6066

Handling Innovations Since 1960 Authorized Stocking Distributor

www.yorkfluid.com Toll

sales@yorkfluid.com Liquid

WATER - WASTEWATER WATER - WASTEWATER

Nutrient management facility soon underway in Red Deer to reduce phosphorus

By ES&E Staff

Preliminary demolition work was scheduled for this spring for the construction of a new $19-million nutrient management facility (NMF) in Red Deer, Alberta, as local officials aim to extend the life of pipes and pumps impacted by struvite.

The retrofit project at the existing wastewater management facility will separate phosphorus from Red Deer’s biosolid wastewater stream. One bioreactor cell from the original biological nutrient

where crews battled struvite buildup in pipelines and equipment for years following anaerobic digestion.

By converting a minimum of 85% of the available orthophosphate into crystalline form (or leaving no more than 50 ppm remaining in reactor effluent), the phosphorus recycle stream back into the plant was broken, according to the Belgium-based company.

The nutrient management facility project in Red Deer is scheduled to be

we are

a better, more sustainable

Water Reclamation Facility in Arizona, April 2024 | 29 www.esemag.com @ESEMAG BIOSOLIDS

CIMA+,

reshaping Canada’s

cima.ca

At

infrastructure for

world

Wetland constructed at Moncton snow disposal facility to protect waterways

By Leigh Patterson

Runoff from municipal “snow dumps” can be especially problematic, containing gravel, salt and hydrocarbons from oil and gas, among other things. But newly released results from a City of Moncton wetland project constructed by Ducks Unlimited Canada are showing promise as part of the solution.

Adam Campbell, manager of Ducks Unlimited Canada’s provincial operations in Atlantic Canada, spearheaded the wetland’s construction in his former role in environmental services.

“In 2014, we constructed a shallow wetland below the snow disposal facility to filter snowmelt runoff, which is one of the many important things wetlands do,” said Campbell. “Created to mimic a natural wetland, it cleans the water by slowing and capturing sediment, filtering particulate and absorbing excess nutrients.”

The 1.6-hectare wetland is between Moncton’s snow disposal facility just outside the city in Berry Mills and a local watercourse, Jonathan Creek. The small watercourse was exposed to annual meltwater runoff and the wetland was intended to protect it from potential contamination.

Each year, snow is placed by the city on a specially built pad and the meltwater flows from there into the wetland, where it is held and filtered, aided by salt-resistant vegetation. For nearly a decade, city staff have been monitoring the snowmelt surface water collected by the wetland.

In its 2024 report, Historical analysis of water quality monitoring at the Berry Mills snow dump facility, the City of Moncton indicated that initially in 2014 and 2015, water quality was monitored only for the outlet point of the wetland (SW0). However, since 2016, water quality for both inlet (SW1) and outlet (SW0) of the wetland was monitored every year, except for 2019, 2020 and 2022.

Water sampling is usually carried out

each year in the spring (April – May) when snow melting starts from the disposal site. A special sampling program began in September 2018 to monitor water quality in the wetland in snowfree season.

The purpose of the monitoring is to document water quality, including general chemistry, trace metals and total suspended solids in the inlet and outlet of the wetland which receives melt water from the snow disposal site and discharges to downstream spillway.

All parameters were compared with the Atlantic Risk-Based Corrective Action Tier 1 EQS Surface Water Guideline and the Canadian Council of Ministers of the Environment Water Quality Guidelines for the Protection of Aquatic Life. It is understood there are no specific discharge criteria for the meltwater runoff. The city used these guidelines as a reference only.

The city’s report presents historical analysis of some of the water quality parameters such as chloride, pH, total suspended solids, iron, copper, alumi-

num, barium, cadmium, and lead, which have exceeded guideline values in more than one year. Other parameters such as fluoride, manganese, nickel, vanadium, and zinc exceeded guidelines in only one year, mainly at the inlet point. No detailed analysis is presented for these parameters.

Overall, results show a reduction in chloride levels between 66% to 93% when comparing water samples from the inlet and outlet of the wetland. These results suggest that the wetland is functioning well in reducing chloride levels before the meltwater enters the watercourse.

“We’re pleased with the results we’ve seen so far,” said Tim Moerman, director of environmental planning and management at the City of Moncton. “Clearly wetlands and green infrastructure can go a long way towards filtering a lot of the pollutants that get scooped up during snow-removal operations.”

Campbell is also very positive about the results of the project, what they have learned, and the prospects for expanding this practice across the region and country.

Aerial photo of the newly constructed wetland and the snow dump pad above it.

Environmental Science & Engineering Magazine 30 | April 2024 STORMWATER

“We are fortunate to have a wetland policy in the province of New Brunswick that protects wetlands from loss,” noted Campbell. “Naturally occurring wetlands provide us with so many services. They are true natural assets and it is important to appreciate these functions and protect them.”

This isn’t the first time Ducks Unlimited Canada and the City of Moncton have worked together on innovative natural solutions to address urban water quality challenges. In 2015, the city drafted naturalized stormwater management guidelines which set parameters for constructing retention ponds, recognizing that managing stormwater can be done in a way that adds to the quality of

Stormwater Management Systems Inspect Smart GRAF EcoBloc Ontario Distributor 1.866.625.3929 | makeway.ca Canadian Supplier 1.800.665.4499 | barrplastics.com Watch it in action • Suitable for infiltration, detention and retention • Capable of HS-25 • Storage Coefficient of 96% • System is fully inspectable and flushable

A photo of a Moncton naturalized stormwater pond (Fairview Knoll) designed to receive stormwater runoff. Photos courtesy of Ducks Unlimited Canada

Toronto’s new wastewater energy project could be first of many as partners share experience

By David Nesseth

One Toronto project is showing the untapped resource power of the some 175 billion litres of wastewater flowing through North American sewers every day.

By changing the temperature of that wastewater by just 1°C, and temporarily diverting it, cities could generate some 60 billion kilowatt-hours of clean energy annually, replacing traditional cooling towers and natural gas boilers with building climate systems that harness the carbon-free thermal energy of wastewater.

“This is wastewater that flows predictably with predictable flow rates as well as a consistent temperature that is between 10°C and 25°C year-round, and that’s regardless of climate for the most part,” explained Cam Quinn, vice-president, engineering – North America, at Noventa Energy Partners, who presented on the benefits of wastewater energy transfer for a March webinar hosted by ES&E Magazine

The webinar attracted participants from municipalities, institutions and consulting firms across Canada. The session featured speakers from the City of Toronto, Noventa, R.V. Anderson Associates, and IPEX, who sponsored the webinar and is a supplier of the Toronto Western Hospital project, which is nearing completion as one of the largest raw wastewater energy transfer (WET™) projects in the world.

The Toronto Western Hospital project soon hopes to be saving nearly $685,000 per year and reducing 8,400 tonnes of CO2 equivalent annually as it finalizes a switch from fossil fuels to a cutting-edge wastewater energy building climate system.

Toronto’s buildings currently account for nearly 60% of its greenhouse gas (GHG) emissions. Under the city’s TransFormTO plan to displace fossil fuel use in municipal buildings and transition to a low-carbon strategy, Toronto aims to get to net-zero by 2040 or sooner.

“It’s kind of an incredible project actually to decarbonize an entire hospital campus,” said webinar speaker Fernando Carou, who is the director of smart buildings and energy management with Toronto Community Housing.