7 minute read

MEAD-ET

Activated carbons for toxin removal

The adsorptive capacity of carbon materials for small molecules is well known. Dr Carol Howell and Dr Susan Sandeman tell us about research within the MEAD-ET and ACROBAT projects using a range of advanced, synthetically derived activated carbons with tailored surface properties and porosity to address a range of pressing healthcare challenges

The surface chemistry of carbon and

its adsorptive capacity makes it well suited to a wide range of applications in adsorption therapy. However, the absence of an appropriate porous structure means that its ability to remove larger molecules, including a number of key biotoxins responsible for infection and inflammation, is limited. Activated carbons have long been used clinically to treat cases of poisoning; now researchers from the MEAD-ET and ACROBAT projects are investigating their capacity to address other major healthcare challenges including sepsis, and also kidney and liver failure. “The MEAD-ET project is looking at the activated carbon nano-structured materials produced by MAST Carbon International. We are aiming to develop them further and optimise their adsorption capacity through knowledge exchange,” says project coordinator Dr Carol Howell. “The Institute of Experimental Pathology, Oncology and Radiobiology (IEPOR) in Ukraine have been working with activated carbon materials for some time and through our collaboration we aim to transfer their technology.”

The overarching aim of the ACROBAT project meanwhile is to progress adsorbent medical device technology for a range of healthcare challenges through exchanging expert knowledge between industrial and academic partners. “The project provides an excellent training ground for participating researchers as they acquire a range of research experience generally unavailable in a single research centre,” says project coordinator Dr Susan Sandeman.

By controlling the porosity of the activated carbon material you can influence what size of molecules will be adsorbed. So if you’re looking to absorb a molecule of a particular size, you can actually tailor the size of the material’s pores so that the toxin will fit within it

Activated carbon

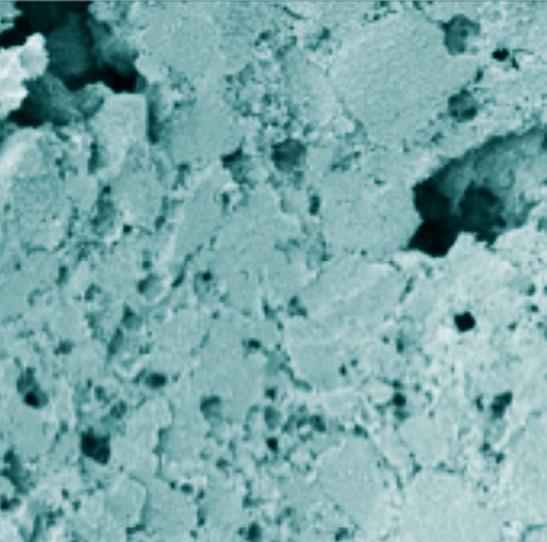

The carbon itself is activated by being heated at temperatures of up to 1000°C in CO2 or steam, a process which generates additional porosity in the material. Depending on the technique used this can

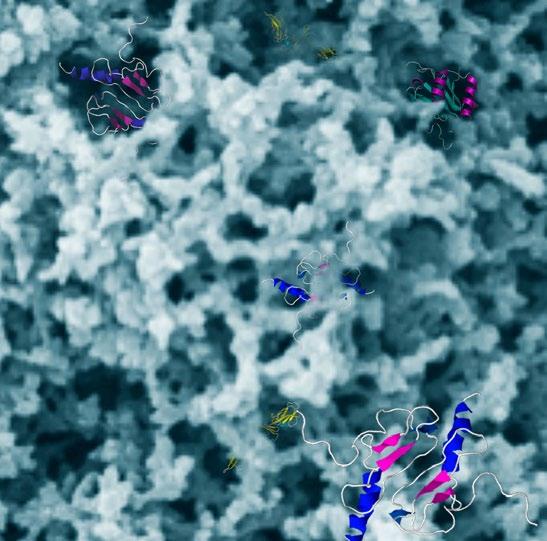

The low magnification image on the left hand side shows the large transport channels into the carbon structure, and the high magnification image on the right demonstrate how toxin molecules can be adsorbed within the nanoporous structure of the activated carbon.

introduce porosity of up to 3,000 metres2 per gram, approximately half the surface area of a football pitch. Dr Howell says this vast surface area is one of the major attributes of the material, and is found not just on the outer surface of the carbon, but is inherent throughout the inner porous structure. “The type of porosity introduced into the material is an important consideration in terms of its ability to adsorb toxins. Micropores are below two nanometres (nm) in size, whereas mesopores range from 2-50 nm in size, while macropores are 50 nm and upwards,” she continues. “We have discovered that by introducing pores in the mesopore and small macropore size range there is a greater adsorption capacity for relatively large toxin molecules that standard carbons fail to remove.”

MEAD-ET

Researchers in MEAD-ET are investigating the capacity of these activated carbon materials to absorb toxins associated with hepatic/renal insufficiency and sepsis. The project is using activated carbon produced from a phenol formaldehyde resin, which Dr Howell says holds some significant advantages over the carbons previously used, which were typically prepared from natural products such as coconut shells. “These carbons are very strong and hard, so they don’t release any microparticles that can lead to particle embolization, a serious clinical side effect of natural activated carbons. This means we can use them without any biocompatible coatings, such as cellulose, so the carbon retains its full adsorption capacity,” she outlines. The material can be used in an extracorporeal device that works via a process called haemoperfusion, where toxic substances are removed from a patient’s blood whilst it is circulated externally through the adsorbent. Dr Howell and her colleagues in the MEAD-ET project are developing these adsorbents for various haemoperfusion applications. “We are introducing more porosity in the activation stage, and then attaching ligands to the surface of the carbon to make them more haemocompatible, so that when the blood comes into contact with the material it doesn’t cause any adverse reactions,” she explains.

By attaching ligands to the surface of the material, researchers also aim to influence the amount and variety of

Full Project Title

Novel medical adsorbents for extracorporeal treatment of life threatening conditions (MEAD-ET) Adsorbent carbons for the removal of biologically active toxins (ACROBAT)

Project Objectives

The main goal of the project is the development of a sorption device for the treatment of renal, hepatic, and multi organ failure (MOF) related to sepsis, used either in combination with dialysis apparatus, or separately, and containing coated or uncoated, new generation, carbon adsorbents which are able to effectively remove protein-bound toxins, bacterial toxins and inflammatory cytokines from patient blood.

Project Partners

School of Pharmacy & Biomolecular Sciences, University of Brighton, UK • The Faculty of Medicine and Pharmacy, Université d’Auvergne Clermont-Ferrand -1, France • R.E.Kavetsky Institute of Experimental Pathology, Oncology and Radiobiology, Ukraine

Contact Details

Project Coordinator, Dr Carol Howell Dr Susan Sandeman T: +44 1273 2015 E: c.a.howell@brighton.ac.uk W: www.brighton.ac.uk/pharmacy/ research/groups/bmmd/acrobat/

Nanoporous activated carbon beads and monolithic columns as effective hemoadsorbents for inflammatory cytokines. Int J Artif Organs 2013; 36(9): 624 - 632

Dr’s Howell and Sandeman

Project Coordinator

Dr’s Howell and Sandeman are principal research fellows within the Biomaterials and Medical Devices research group (BioMED) at the University of Brighton, and have been working in the area of activated carbon adsorbents for the last decade. They have helped to investigate and validate the medical use of a new generation of activated carbon materials with unique structural properties that generate powerful adsorbents capable of adsorbing a range of biological toxin molecules. toxins that are removed. “Activated carbon is a non-specific adsorbent, so it’s able to absorb a wide range of molecules - in that respect you can’t be too specific. But by controlling the porosity of the material you can influence to a certain degree what size molecule will be adsorbed. So if you’re looking to absorb a molecule of a particular size, you can tailor the size of the material’s pores so that the toxin will fit within it,” says Dr Howell.

This approach could remove a wider range of toxins than current methods. While haemodialysis is highly effective at removing small water-soluble molecules and slightly larger molecules, Dr Howell says there are some toxins that it fails to remove. “Because dialysis works with a porous membrane of a certain cut-off, middle molecules (50060,000 Daltons) and protein-bound solutes are often poorly removed by current therapies,” she points out.

There is a mounting body of evidence that these so called uremic molecules are detrimental to patients’ health and can have a severe impact on their quality of life. “Haemoperfusion using these tailored activated carbon adsorbents could be used in line with current dialysis therapy to remove these remaining uremic molecules and have a positive impact on the health of the current 1.9 million haemodialysis patients worldwide,” says Dr Howell. “To date our research has demonstrated that the carbons show good removal for a selection of these uremic molecules including; inflammatory cytokines and protein bound indoles. Another possible use of the device is to treat conditions such as sepsis, where you get systemic inflammation and a cytokine storm. Reducing these excessive levels of cytokines could prove beneficial to the patient by returning their body to normal haemostasis.”

ACROBAT project

The ACROBAT project advances some of the technology developed within MEADET and explores additional adsorbent designs and applications. The project compares different structural conformations and coatings, comparing bead and monolithic devices for assessment in models of liver and kidney failure. The monoliths are essentially extruded carbon tubes with microchannels running in parallel along their entire length, allowing fluid to flow. One of the main benefits of a monolithic system is a reduction in the pressure drop across the system which occurs when using beads. Activated carbon has a broadly acting adsorbent capacity which may be hugely beneficial in some medical applications such as sepsis where restricting excessive biotoxin exposure is essential. The project also addresses more selective removal of specific biotoxins using a model of Anthrax infection. The combined development of methods to attach and orientate bioligands on an adsorbent carbon or polymer composite surface offers an interesting approach to the treatment of such life-threatening infections.