The moor the merrier: putting ocean energy on a sustainable footing

The mooring system accounts for a significant proportion of the overall cost of offshore wind platforms. Researchers in the HYDROMORE project are developing high-fidelity models of ocean waves, which could lead to a shift in the design of mooring systems that will help reduce costs and encourage development in floating wind energy, as Dr David Lande-Sudall explains.

The first offshore windfarms were located in relatively shallow waters, but these platforms can also be built in deeper parts of the oceans, increasing the supply of renewable energy and helping countries reduce their carbon emissions. One factor limiting development however is the cost of the mooring systems, with floating offshore wind platforms still using traditional methods originally designed for the oil and gas industry. “The full-scale devices that have been installed in small clusters of turbines, have all used steel chain moorings,” outlines Dr David LandeSudall, Associate Professor in the Department of Mechanical and Marine Engineering at the Western Norway University of Applied Sciences. This is a fairly conservative approach to design, with a high safety margin, which then leads to higher overall costs. “For deeper water, the length and dimensions of steel chains become excessive, potentially exceeding what is available today and driving up costs through steel consumption,” explains Dr Lande-Sudall.

HYDROMORE

HYDROdynamic Mooring analysis for Ocean Renewable Energy

The HYDROMORE research project is funded by the Research Council of Norway FRINATEK programme, Project No. 324388.

T: +47 55 58 71 47

E: David.Lande-Sudall@hvl.no

W: https://www.hydromore.no/

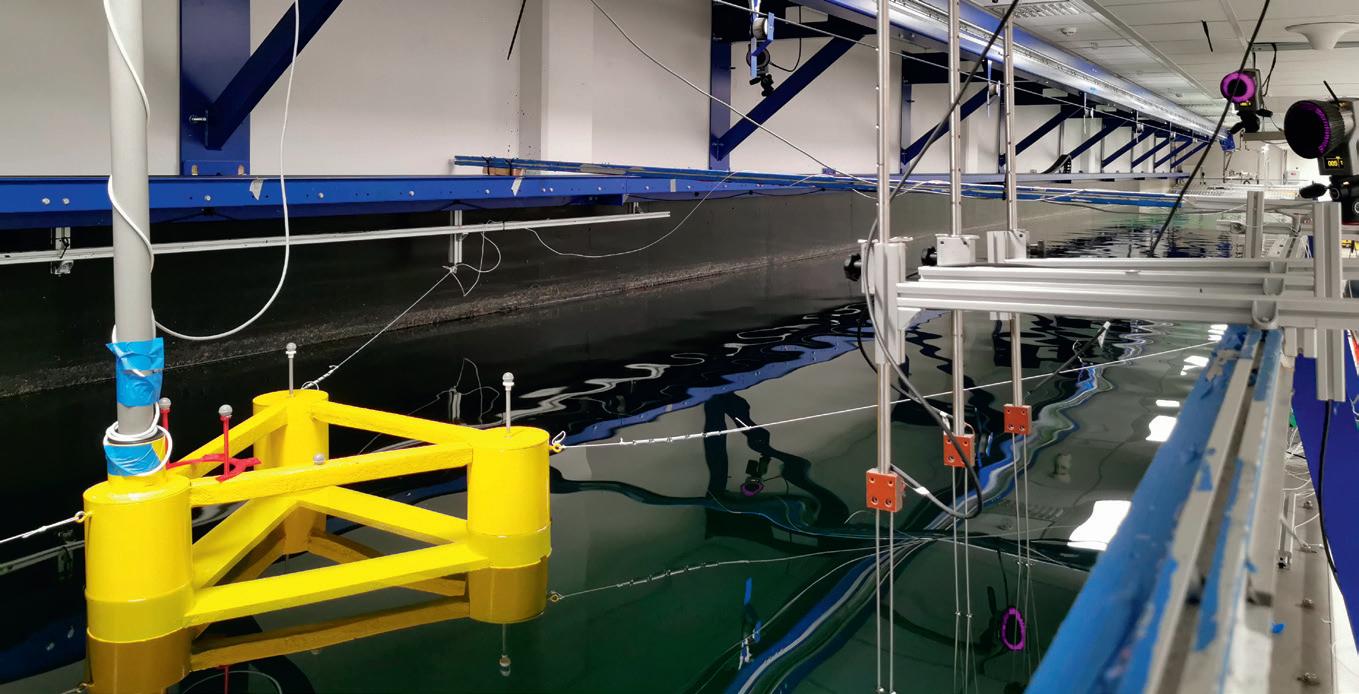

Dr David Lande-Sudall is an Associate Professor in Ocean Engineering at the Western Norway University of Applied Sciences (HVL), Bergen in Norway. His research is focussed on ocean renewable energy and particularly experimental hydrodynamics within HVL’s MarinLab towing tank facility.

1:100 scale model of the 12 MW WINDMOOR semisubmersible wind turbine being tested at the 50 m long, MarinLab towing tank at HVL, Bergen.

HYDROMORE project

As the Principal Investigator of the HYDROMORE project, Dr Lande-Sudall is now working to develop higher fidelity models of the seas, to include more detail. Simplified engineering models work well in some circumstances, for example they might be perfectly adequate in situations where the waves aren’t very steep, but they are less effective in more random, short-crested seas.

“When we have waves from different directions or very steep waves, these models don’t work particularly well. We’re trying to increase the

continues Dr Lande-Sudall. The problem is that very slow varying drift forces act on offshore wind turbine platforms, and a single oscillation can take hundreds of seconds. “That’s a very long time to actually run a CFD model, so we’re trying to create a much shorter time-series that’s representative of different random seastates,” David outlines. “We’re using some characteristics of the motion response of the structure. We can basically design a wave that will force our platform into those types of oscillations, without running hours of random waves to capture a few extreme cases.”

“When we have waves from different directions or very steep waves, these models don’t work particularly well. We’re trying to improve the fidelity, to add more detail.”

fidelity of models, to capture more detail,” says Dr Lande-Sudall. In part of this work David and his team are using fully non-linear potential flow (FNPF) models, which allow them to resolve a wave to the point at which it becomes overtopping. “As long as the wave is intact we can now look at much steeper waves, and get more information on the pressure distribution acting on the floater,” he explains.

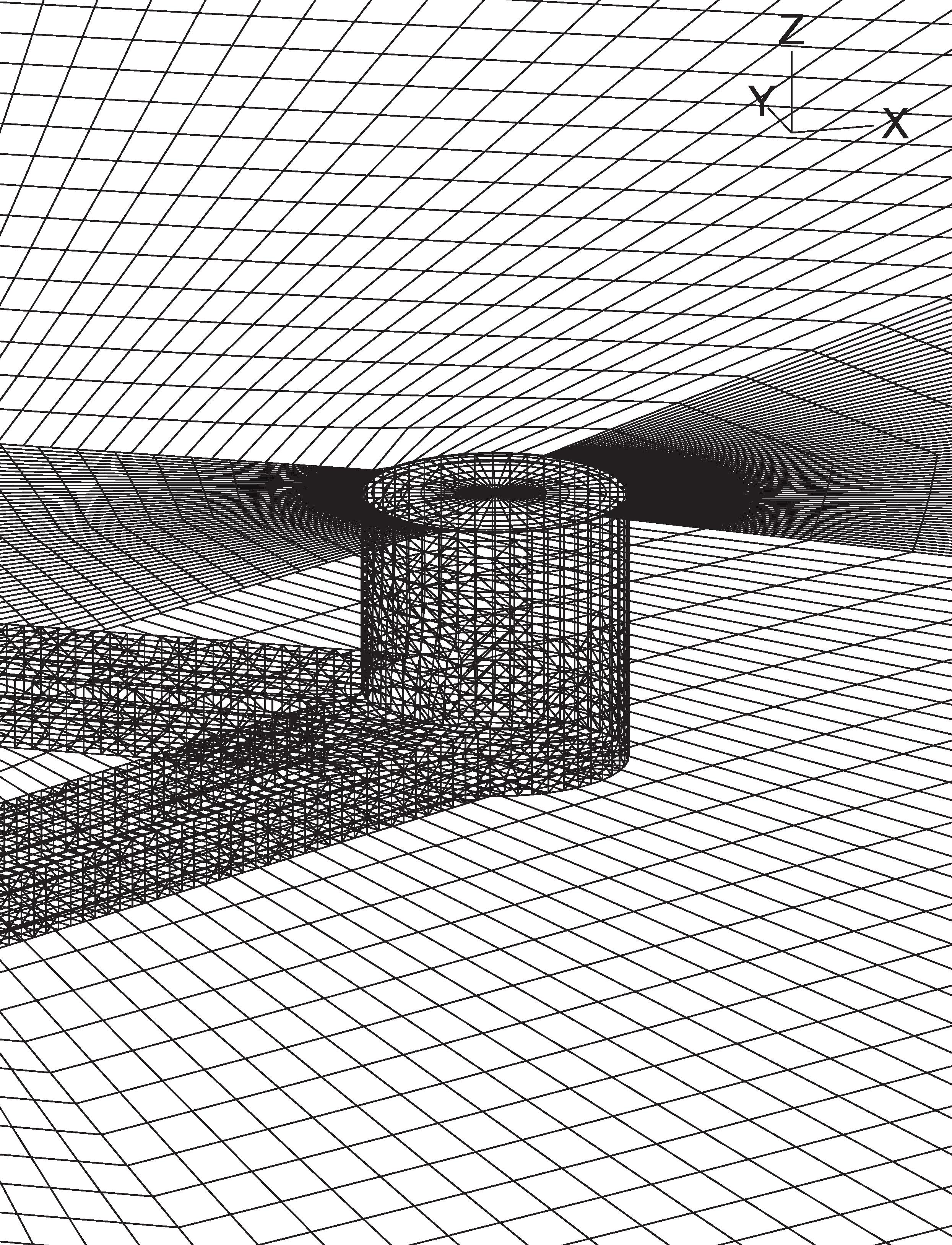

The very high-fidelity, detailed models like computational fluid dynamics (CFD), FNPF and meshless smooth particle hydrodynamics (SPH) are computationally expensive, so researchers aim to use them in an intelligent, targeted manner. The idea is to use the highfidelity models for only a short time-series, for example at the point at which a wave breaks. “That’s when we can couple in the SPH model,”

This work is currently focused on extreme waves and loads, with Dr Lande-Sudall looking at how the platform responds to these forces. Once the models have been experimentally validated, they could then inform the design of mooring systems, potentially leading to a shift towards the use of lighter, more pliant materials. “Can we use lighter, synthetic-type moorings?” asks David. This could help reduce the cost of offshore wind platforms and encourage greater investment in the sector, which is a major motivating factor behind the project’s work. “With simplified models there’s greater uncertainty associated with the maximum loads that you’re predicting a platform will have to withstand,” says Dr LandeSudall. “If we can effectively utilise higherfidelity models, then we can perhaps reduce the conservatism in design.”