Honda Outdoors is here, bringing together the full range of Honda Outdoor Power Equipment all under one roof. With over 50 Honda Outdoors stores nationwide, there’s one near you. hondaoutdoors.co.nz

DONNA HIRST 027 474 6095 Lower North Island donna.hirst@agrihq.co.nz

OMID RAFYEE 027 474 6091 South Island omid.rafyee@agrihq.co.nz

GRANT MARSHALL 027 887 5568 Real Estate realestate@agrihq.co.nz

ANDREA MANSFIELD 027 602 4925 National Livestock Manager livestock@agrihq.co.nz

DEBBIE BROWN – Directory classifieds@agrihq.co.nz 06 323 0765 Production

LANA KIESELBACH 027 739 4295

Production Manager lana.kieselbach@agrihq.co.nz

Advertising material: adcopy@agrihq.co.nz

“We nearly paid it o completely in the first 12 months because it saved cows’ lives.”

CAMPBELL

2 30 co w s | M at aur a I s l an d , S o u t h l an d Automation

“Because of CowManager, I identified that the cows needed more fibre in their diet, so we added dry silage to their diet and their rumination climbed instantly.

* A c t u a l S i z eCowManager doesn’t allow you to do that. It just keeps telling you the cows.”

The chief executive of DairyNZ says the year ahead will be dynamic and challenging for farmers and the industry.

Globally, our Kiwi dairy farmers are in the enviable position of being among the world’s best producers of milk. This is despite currently facing some confronting challenges, including responding to regulatory change, inflation, weather challenges and staffing on farm.

We are world leaders thanks to decades of expertise on farm and because, frankly, Kiwi farmers are incredibly resilient and hard working. This resilience has led to dairy exports hitting new highs, resulting in our farmers contributing around $50 billion to New Zealand’s economy each year.

Even through some tough times last year, we had some great achievements. The year ahead will continue to be dynamic. Front and centre are the immediate challenges on farm. Profitability is challenged in the face of farm working expense increases of around $1 per kg of milksolids just last season alone.

The milk price has been good for a few years, and dairy’s debt repayment has tracked well – decreasing by $5.2 billion from 2018 to 2022, which is great news.

No one knows with absolute certainty where the milk price will land, but we know our best operators begin thinking about how they will manage a drop and cut the costs before they actually need to.

In the longer term we continue to face the drive to reduce greenhouse gas emissions.

Alongside farm systems support, DairyNZ is researching technologies to support farms to reduce emissions. Off-the-shelf tech needs research in NZ conditions – our free-range system is too different to other countries. So, we turn to innovation – something we know well.

Getting policies right will also ensure our thriving farming sector continues –and, therefore, NZ thrives too.

DairyNZ advocates hard for solutions that achieve the right outcomes. Our

advocacy is always informed by science, whether it’s best-practice animal care in the Dairy Cattle Code of Welfare, water quality or climate change.

To support key issues on the minds of farmers, DairyNZ will continue to roll out targeted initiatives this year.

Our GoDairy campaign will continue, encouraging young Kiwis to consider a dairy career and connecting them to the latest dairy farm vacancies.

This will help contribute to our current workforce needs and attract more people on farm.

We are also prioritising our public audience through our latest campaign, Here for the Long Game. This long-term initiative will look to continue growing trust and pride in dairy, sharing dairy farmers’ long-term commitment to a better future for NZ.

We’re also on a mission to better connect with dairy farmers. As part of that, DairyNZ is broadening the range of support and events we offer, to be relevant to the needs of our farmers.

This support is particularly geared at helping farmers manage the years ahead and the regulatory changes coming through.

I know the past few years have been tough, but I’m proud of everything that farmers and DairyNZ have achieved by working together, and I look forward to continuing this year.

n

n

Who am I?

Dr Tim Mackle is chief executive of DairyNZ

“We are world leaders thanks to decades of expertise on farm and because, frankly, Kiwi farmers are incredibly hard working.”

An emigrant farmer was in the right place to return the favour after a history of generosity from his Taranaki neighbour, who has just turned 100.

Norm Johnson is tough enough to have weathered almost a century of dairy farming, but even he eventually needed help. In a district he has seeded with good neighbourliness, he didn’t have to look far.

EVERY cricketer’s dream is to notch a century – and a Taranaki farmer who was a keen cricketer in his younger days has done just that, except it’s in years, not runs between wickets.

Norm Johnson, who turned 100 in October 2022, has lived on his Auroa, South Taranaki, farm for 93 years. He is now, in his words, “starting the one of the 101”.

The farm – in the person of Johnson’s farm manager, Piet Robbertze – milks 45 Friesian cows through a 16-a-side herringbone cowshed on the 40.5ha (40ha effective) farm. Next season there are 28 heifers coming in, and if a factory agrees to take the farm on once more, they’ll look to milk 100 cows.

Robbertze was born in his grandparents’ house in Rustenburg,

South Africa. When he was four years old his father inherited his grandparent’s 150ha family farm. The property was a general farm where they hand-milked 30 dairy cows and cropped tobacco, chillies and maize, with 25ha under irrigation.

The farm was irrigated from a river via a creek that his grandfather dug by hand all the way to irrigation dams at the cropland.

In Year 6 Robbertze went to high school, where he boarded for four years. His father told him he needed a trade qualification before returning to the farm, so he qualified as a mechanical engineer and then came home.

“When I was 19 years old I was called up for National Service in 1 Parachute Battalion of the South African Defence Force. After training I was sent to the northern border for a year during the Angolan Border War. I had to postpone the last year of my apprenticeship until I’d finished my service,” Robbertze says.

“I was called up for three months annual service for 10 years before going on the Reserve Force, but still subject to immediate call-up. For three months of each year I left the farm and family to serve at the border.”

Robbertze then began managing a 2,000ha grazing farm. After three years he left that farm and leased a 1500ha government grazing farm at Bophuthatswana, near the Botswana border.

• Farm owners: Norm Johnson.

• Farm manager: Piet Robbertze.

• Location: Auroa, Taranaki.

• Farm size: 40.5ha (40ha effective) farm.

• Cows: 45 Friesian cows.

“The area was made up of the same ethnic groups as from where I was brought up, and they also spoke Setswana. When I began primary school my Afrikaans wasn’t too good because I’d mostly spoken Setswana throughout my life,” Robbertze says.

They grew 600ha of maize and sunflowers and milked 112 Holstein

“My daughter had recently visited New Zealand and not only was it a safe country, it had reliable rainfall. I love rain and never complain about it. Where we farmed, we often had three- or four-year droughts.” Piet Robbertze

Friesians to supply the rural area’s township shops with fresh milk.

“We also had 200 Brahman beef animals. We used Brahmans because they can’t be stolen. Once Brahmans know you, they’ll stick to you like a dog and follow you when you talk to them. If you’re a stranger, they’ll run away,” Robbertze says.

“If anyone tried to steal them from our huge 100ha paddocks, the Brahmans

would run home. The moment they started running you knew there was a problem and it was time to check what was happening.”

Robbertze started a butchery in Rustenburg and put his eldest son through butchery school. His son ran the shop and Robbertze’s farm supplied it with meat.

In 2003, growing anxious about their future, the family looked

“My daughter had recently visited New Zealand and not only was it a safe country, it had reliable rainfall. I love rain and never complain about it. Where we farmed, we often had three- or four-year droughts. We had no irrigation, so were completely at the mercy of the weather,” Robbertze says.

The family came to New Zealand in 2005 and Robbertze began working as

a farm manager on an 81ha Auroa farm milking 300 Friesian cows just across the road from Johnson’s farm.

Whenever Robbertze drove past Johnson’s farm with his boss he would be told that “Norm helps a lot of people out. He just does his own thing and lives his own life.”

After a year on that farm Robbertze leased a 90ha farm just around the corner from Johnson.

“One day my tractor broke down so I walked across to Norm’s to see if he could help. He loaned me his International 585 tractor until mine was repaired.

“I got to know him well and often popped in to see him when I’d finished milking. Norm was often still milking his 60-cow herd through his six-bay walkthrough shed at 10pm.”

After two years the farm owner was entitled to review Robbertze’s lease. His third season was his best and his production outstripped anything the farm had previously done. But the lease

was doubled, which he couldn’t afford, so he surrendered it.

“I’d used all of our savings to buy the 150-cow herd and then the milk price dropped from $7.10 to $5. Combined with the lease doubling, I couldn’t make it at all. I sold the herd at a loss, and because I’d surrendered the contract I was penalised $27,000.

“It was then that Stratford’s Central Butchery became available. I worked out a price and made an offer, which was accepted. I went home and said to my wife ‘Where are we going to get the money from?’”

The banks turned them down, and the only person they knew who would help them was Johnson. He loaned Robbertze the money, just as he’d done for so many other people who wanted to buy farms

but had been turned down by the banks. Robbertze gave Johnson his lifestyle block and the butchery as security.

In 2015 Johnson was in hospital for a few days and came home to find that his entire milking herd of 68 cows and three bulls had been stolen. He was left with six calves and 14 heifers. That season he needed to take in heifer grazing until his heifers had calved and were able to be milked.

“When the herd was stolen many of the local farmers wanted to give Norm one or two cows to get him milking again, but he said no,” Robbertze says.

As appreciative as Johnson was for all the generous offers, he wanted to carry on with his own heifers and slowly but surely started from scratch to build up his herd.

The situation precluded him from supplying a milk company, so he needed another outlet for his milk. His solution was to use his milk to raise calves until he managed to build the herd up to a number at which a company would take him on once again.

In 2016 Johnson again found himself in hospital, and because Robbertze knew the farm well, he asked him to look after it.

“I ran the farm for two weeks and then fetched Norm from hospital. Norm got stronger over the next few weeks so I told him that I’d leave it to him now. But he knew that he could fall at any time, and asked me to keep running the farm.”

Robbertze has run the farm since 2016. His son, wife and sister run the butchery. He used to work at the butchery each

“We had 200 Brahman beef animals. If anyone tried to steal them from our huge 100ha paddocks, the Brahmans would run home. The moment they started running you knew there was a problem and it was time to check what was happening.”

Piet Robbertze

day until midday, and then go to the farm to work. He now works at the butchery one day a week.

Robbertze is not sure of the herd’s milk solids totals because there is no daily factory docket, but thinks the best cows would be doing around 500kg milk solids and the lower-producing ones around 350kg MS.

Johnson and Robbertze have been in talks with milk companies in the hope of becoming a factory supplier once again next season.

“I predicted that with 100 cows we’d do 35-40,000kg MS. At the moment we’re milking 45 cows and producing 5000600 litres of milk per day,” Robbertze says.

“We’re a System 2 farm, but if we’re accepted by a milk company and milk 100 cows, we’ll probably jump to System 4.”

Johnson is a firm believer that well-

fed and mineralised cows are the key to good production.

Five tonnes of a mineralised molasses is ordered every two months to feed to the cows through the in-shed system. The cows love the molasses and can’t wait to get into the shed to get to the ad lib troughs where they can eat as much as they like.

Hay and molasses are the only supplements used. Six hectares of hay is harvested which makes about 190 big (15s) square bales.

“The molasses is fortified with minerals and its sugar and protein keeps the cows up, the hay fills them up, and of course they’re grazing in the paddocks. When the bulls are with the herd they eat their molasses from the yard from the troughs at the end of the cowshed.” Robbertze says.

When it begins to get dry in February, Robbertze cuts flax, puts it through the

chaff cutter, mixes it into the molasses and feeds it to the bulls, who absolutely love it.

The shelterbelts and plantations add a diversity of feed for the cattle and Johnson believes it helps mineralise the cows. The farm’s plantations help protect the animals from the sun and South Taranaki’s harsh southerly winds.

“Cattle love karaka leaves and berries. People often say that you can’t have karaka trees near cattle because it’ll kill them, but that’s absolute rubbish. We have plenty of them in the race plantation. When their big, orange berries begin dropping the cows rush down the race to be first to get to them,” Johnson says.

When Robbertze opens the gate to that paddock he shakes the branches and the berries drop to the ground and the cows start a “lolly scramble” to hoover them up.

Johnson says that a ryegrass and clover pasture still takes a lot of beating. In the seven years that Robbertze’s been on the farm they have never ploughed

Easy Draft has been designed and refined over many years to be reliable, easy to use, gentle on animals and has seamless integration with CowManager.

Get in contact and request a free quote today

07 280 5798 www.senztag.co.nz

“Cattle love karaka leaves and berries. People often say that you can’t have karaka trees near cattle because it’ll kill them, but that’s absolute rubbish. When their big, orange berries begin dropping the cows rush down the race to be first to get to them.”

Norm Johnson

the pasture. They use a Groundhog seeder that utilises spikes to reseed pasture without tilling the soil.

During the peak grass growth period the pasture is topped in front of the herd. The paddocks are regularly harrowed to spread the manure and ensure all parts of the pasture receive a similar amount of nutrients to even out the pasture growth.

The 12-week season calving begins around August 7. They never worry about their six week in-calf rate. As Robbertze says, “there’s no rush”. Over the past six years all of the heifer calves have been kept to build up the herd.

“We usually have a 90% or higher incalf rate. This season we only had two empties from 45 cows,” Robbertze says.

“I think part of the reason for our high in-calf rate is that the cows aren’t being put under stress and are well fed and mineralised. I’ve found that by feeding molasses and minerals to the cows they begin bulling much faster.”

The bull calves from the lowest producing cows are steered or sold at weaning. They are weaned at 100kg and sold when 105-110kg.

About 200 calves are raised each season. This season their white-faced autumn calves averaged $700 each and the 100 Friesian bulls raised on Robbertze’s lifestyle block averaged $520 each.

They still have 68 bull calves left and have far too much milk for them, so they sell the excess to a local farmer who is also raising calves. Some mornings the farmer will take away up to 1,400 litres.

“If accepted by a factory we would still raise 150 spring calves, 50 autumn calves, plus the farm’s calves,” Robbertze says.

Robbertze buys colostrum from neighbouring farms to feed the calves. When the farm has excess milk at the end of the calf rearing season, he sells it to other calf rearers.

The bulls go into the herd for mating on October 24, which is Johnson’s birthday, and are taken out on January 30.

“The cows are recorded and we keep five or six bull calves from the bestproducing cows with the best body type

and markings. The best of the bulls are used over the herd when they’re two years old,” Robbertze says.

“It’s exciting seeing the first calves come in and to see if they have the right markings. The aim is to have consistent line of animals, that’s proof that your breeding is working,” Johnson says.

“A dairy cow must have good conformation and be a good all-round animal. Type does come into it, but you want production too. It’s a balance, though, because if the udders are overtaxed they’re inclined to break down.”

Johnson says that cows that are mostly black are more resistant to facial eczema and that black udders are less susceptible to sun and wind chapping. Cows with black teats have long been a sought-after breed trait in his breeding plan.

“The Friesian Association stipulates that a Friesian must have four white feet, four white legs up to the knee and a white tail switch; that’s all that matters. Facial eczema was never a problem in the early days; it’s a fairly recent occurrence and some years are worse than others,” Johnson says.

“I feel that a cow’s black skin is stronger against the sun and facial eczema does seem to start on the white skin. We’ve had no eczema in the seven years I’ve been here,” Robbertze says.

Johnson is an early pioneer of once-aday milking and has been farming this way for about 60 years.

“When I began I couldn’t talk to anybody about it, because milking once a day was unheard of. But I decided to try it anyway,” Johnson says.

“There were plenty of raised eyebrows, but I think most of the comments were said behind my back. I was told that it wouldn’t work, the herd would be rotten with mastitis, and they’d be dry by Christmas. None of that happened. I did it and I’m still here.”

He is a believer in having minimal debt if at all possible. Having low debt levels allowed him to try something different and he says “I could afford it, so I could afford to try it.”

He believes that anyone wanting to try one-a-day should talk to farmers who are successfully practising the regime. He didn’t have that luxury.

“You should milk the cows in the afternoon so they’re not lying all night on an udder full of milk. If it’s a wet and muddy night and the teats are leaking milk, it’s inviting trouble,” Johnson says.

“Milking once a day gives you until 2pm to get your work done. And now with the new herringbone shed, I’m finished milking in an hour and have the rest of the afternoon to finish jobs,” Robbertze says.

“Milking once a day changes your entire attitude. It significantly reduces your farm’s running costs and halves the wear and tear on a lot of the farm plant and machinery. It reduces the wear and tear on your body too.”

Johnson’s father built the original six-bay walk-through cowshed in 1930. Johnson has rebuilt parts of it such as

the milk room, and has removed the dray shed where the dray or tractor was backed in to take the milk cans to the factory.

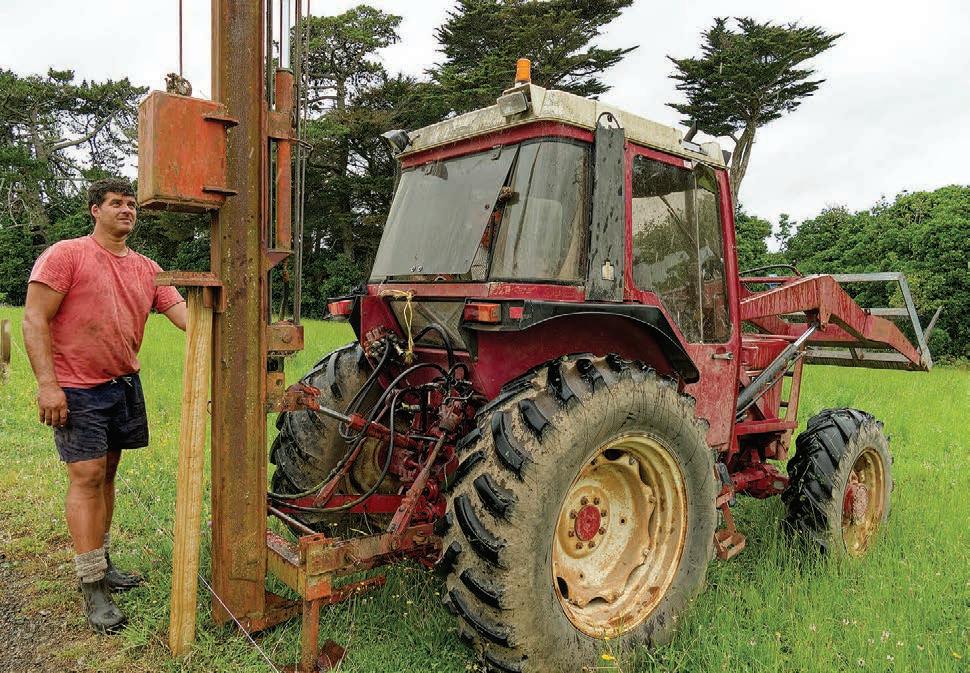

At the end of last season Robbertze rebuilt the old cowshed into a 16-a-side herringbone. He had it completely finished and ready to milk two days before the start of the season.

“We used a little digger that could fit under the roof to dig the pit, and right at the end we struck a rock that we couldn’t remove,” Robbertze says.

It took days and an application of Betonamit, a powder mixed with water and poured into holes bored into the

rock, which then cracked apart. He was able to use their big tractor and chains to lift the blocks out of the hole.

The task of building the new shed at minimal cost was also a lesson in the ability to think outside the square.

“We bought the entire plant from a local farm on Facebook Buy and Sell. The farm had been sold and the purchaser wasn’t carrying on with dairy,” Robbertze says.

“I asked him how much he wanted for it and he said ‘Name a price’. I thought I’d take a chance and offered him $1,000 and he told me to take the lot. A friend and I removed the entire plant in about two hours, put it on the trailer and took it home.”

The next task was sourcing the steel pipes for the rails. Robbertze visited a steel supplier whose quote of $3,000 was far too expensive.

“A farm just outside Hawera advertised a cow shed for sale on Facebook Buy and Sell.

“We only wanted the steelwork and they too asked me to name a price, so

“If you’ve helped to build a home, planted trees and seen things flourish, and have bred cattle the way you want them, it’s you; and you can’t get away from it.”

Norm Johnson

once again I said ‘$1,000’. They told me to take it away. I bought a grinder, and my brother-in-law and I cut it all up in a day and took it to the farm.”

Once the work was completed, Robbertze called a friend who had worked for a dairy plant company to check his handiwork. All of the pipework lined up and the plant ran perfectly.

It now takes Robbertze 35 minutes to milk 45 cows and he’s sure it will only take a little longer to milk 100 cows if the herd size is increased next season.

“I’ve liked farming ever since I was a kid. I think I was born liking it. I enjoy seeing the farm develop and being able to help Norm achieve those goals,” Robbertze says.

“To be a successful farmer you need to keep your wits about you. I do worry about the big corporate farms gobbling up the smaller farms. It’s making it difficult for young farmers to get into a farm,” Johnson says.

“If you’ve helped to build a home, planted trees and seen things flourish, and have bred cattle the way you want them, it’s you; and you can’t get away from it.” n

Robbertze started a butchery in Rustenburg, South Africa, and some time after moving to New Zealand he bought a butchery in Stratford, where he works one day a week.

Each month the Milk Monitor delves into the dairy industry and gives us the low-down on the good, the bad, the ugly and everything in between.

The year 2023 has finally arrived, with wet weather being the dominant feature for many in the North Island over the holiday period.

It’s kept the grass green, while the hot weather in between the showers has helped boost maize and other summer feed crops after many were planted later than usual.

This should have most farms – apart from those affected by flooding damage – looking in pretty good shape as production starts slipping off-peak with the changing seasons.

Another silver lining is that it could extend the lactation on some farms depending on their feed reserves. While it’s been largely unpleasant for those at the beach, there’ll be plenty not minding the warm rain at this time of year, especially those coming off last year’s drought.

It’s just a pity the global dairy market’s gone off the boil, reflected in the results from the two GDT auctions held over the Christmas and New Year period, where it dropped 2.8% and 3.8% respectively.

The latest auction on January 18 saw prices limp back 0.1%.

NZX said of the insipid result: “The diary market simply doesn’t have much direction at the moment. It will take time (and a bit more data) for that direction to become evident.”

Fortunately, it’s not enough of a downward movement to push Fonterra to adjust its forecast.

Looking further out, Westpac senior agri economist Nathan Penny told Farmers Weekly that he expects dairy prices to continue to fall during the first half of 2023, followed by improved global demand and price from the middle of the year as Chinese covid restrictions are eased further.

“Our expectation for a stronger global dairy market from around mid-2023 sets up the 2023-24 season for a bumper milk price,” he said.

Westpac’s opening forecast for 2023-24 is $10/kg. Its current forecast for 2022-23 is $8.75.

Likewise, ANZ agricultural economist Susan Kilsby believes dairy commodity prices have stabilised and that farmers’ returns for milk next season will be similar to this season – around $8.75.

“Farmgate prices are supported by the lower NZD but market uncertainty remains extremely high. Global milk supplies are tight, which will support prices, but demand for dairy products is weakening.

“It is not yet clear whether the reduced availability of dairy products will be sufficient to offset lower demand,” Kilsby said.

From a global perspective, Rabobank says that after record farmgate prices in many exporting regions this year, milk supply growth has emerged at last.

However, as demand falters, farmgate milk prices will follow global commodity market trends lower in 2023, the bank said in its final quarterly update for 2022.

Rabobank senior agriculture analyst Emma Higgins says that fragile growth is on the horizon.

“And with many economies experiencing broad-based food inflation, dairy demand is likely to reduce in the short term before any remarkable improvement.”

Despite these weaker market fundamentals, the bank held its forecast at $9/kg MS, in line with Fonterra’s midpoint forecast it announced in early December.

“But it’s important to note the risks to this forecast are heavily skewed to the downside with any potential upside rally hinging on a supply shock in the northern hemisphere or a meaningful reopening of China in the new post-covid world,” she said.

Higgins expected the global milk supply recession to end, driven by higher production in Europe and the US.

On the input side, it does not look

he expects dairy prices to continue to fall during the first half of 2023, followed by improved global demand and price from the middle of the year as Chinese covid restrictions are eased further.

like there’s any relief in input prices as inflation and the wider impact of the Russia-Ukraine war continues.

While there is some talk offshore of an easing in fertiliser prices as the northern hemisphere emerges from its winter and energy demand eases, that has yet to translate into any meaningful fall in prices here.

Fuel prices have also eased but this could be short-lived as the government subsidy will halve at the end of February and be removed completely in March.

So while there are plenty of challenges to start the new year, they are mostly beyond farmers’ control.

What they can manage is what they do inside the farmgate where the rain and resulting boost in pasture covers is gold from the sky.

Olam Food Ingredients is signing up suppliers for new factory, with plans to trial an almond farming byproduct in their feed mix.

Olam Food Ingredients’ construction of a new dairy factory is on track, with the facility’s roof now attached.

Speaking at Fieldays, OFI New Zealand general manager of milk supply Paul Johnson said it is an exciting milestone with construction on the site at Tokoroa now entering its latter stages.

“We’re on track and scheduled to start July 1,” Johnson said.

“We’re building a team. There’s nine of us at the moment and we’re looking to be 50-60 by July 2023.”

OFI was taking farmers’ names at Fieldays to supply the company.

Johnson said OFI plans to offer farmers a minimum milk price guarantee as well as the opportunity to lock in premiums up front.

“If the milk price is $9/kg MS, for example, that’s great, but if the milk price drops below that floor, we’ll hold it at that floor.”

The offer of premiums will be based on meeting sustainability, animal health and milk quality targets.

“We’re trying to provide confidence, certainty and cashflow,” he said.

The feedback from farmers has been supportive. OFI’s Open Country Dairy investment means the company has been in the New Zealand market for 10 years and has a proven track record.

OFI’s broader business also gives it the opportunity to add value to the dairy product, he said.

“Farmers are pretty confident in our ability to deliver,” he said.

Many of the suppliers who had signed up were from farms who had gone through succession. OFI’s pricing and premiums system resonates with this new generation of farmers, who are often taking on debt and capital when taking over a farm, he said.

The company is also trialling almond hulls and shells as possible animal feed for dairy cattle.

OFI operates large-scale almond orchards in Australia. The trial will see the

almond hulls and shells that are currently a byproduct of almond processing repurposed into a feed source for dairy cows.

“Almond hulls are a proven source of nutrition for dairy cows. As part of our research for the trial we met with

Johnson said the trial will explore ways to efficiently and effectively package and transport the feed and assess if the feed can be manufactured and used in New Zealand at scale.

“Another part of our assessments will be how to blend this feed source in an optimum way with existing feed used in New Zealand dairy farming blends or supplied in bulk on farm.

“We know animal feed is a significant input cost on a dairy farm and believe this trial will make a real difference to our farmers’ bottom lines,” he said.

Australian dairy farmers successfully using almond hulls as a source of fibre in a pasture-based system. That gives us confidence the model will work well here,” Johnson said.

The feed will be supplemented with agolin ruminant (Agolin) which has the potential benefit of reducing methane emissions and increasing the feed conversion rate, which in turn will support milk yields.

Duncan Smith, OFI country head for Australia and New Zealand, said the trial will also bring benefits to OFI’s Australian operation.

“Finding a consistent way to repurpose almond hulls and shells, which are a nutritious byproduct of our almond processing, has been a priority for us as it will contribute to a more efficient and sustainable way of operating on our orchards.”

Access to the trial is open only to OFI dairy farm partners in New Zealand. n

OFINew Zealand general manager of milk supply Paul Johnson says construction of the company’s Tokoroa factory is on schedule for completion in the middle of this year.

“We’re building a team. There’s nine of us at the moment and we’re looking to be 5060 by July 2023.”

Paul Johnson

In a reversal of roles, a British woman works on the farm as a contract milker while her partner looks after their son.

Despite what she thought she knew about farming, a Waikato farmer quickly learnt there are stark contrasts between British and New Zealand dairying. But with a strong work ethic and determination, nearly nine years after arriving she has forged a successful career in dairy farming.

Jen Hodgson is a contract milker on a 350-cow farm at in Waikato Okoroire, South Waikato, alongside her partner Scott Bonk and their young son.

It was the first morning after drying off the herd and even without her alarm Hodgson was wide awake at 4:30am. She lay staring at the ceiling wondering what she was going to do to fill her day. It was a weird feeling not having to get up to milk cows. Coming from England, she was used to having cows calving every week year round and there was certainly no such thing as a dry period.

The bright-eyed 21-year-old wanted to learn more about pasture-based systems and had jumped on a plane 10 days after graduating from Harper Adams University in Newport in the United Kingdom. She landed in Putāruru in October 2014 and had a return ticket booked for the following June – but more than eight years later she’s only managed a move slightly north of Putāruru, near Matamata.

“Despite the adjustment period, I fell

in love with the New Zealand seasonal approach,” she says.

“Back home you have to think about everything at once. Every week there are cows being dried off, calving, calves to feed, but here you can concentrate on each area separately.

“And it just makes sense to be milking the most cows when you’ve got the most amount of grass.”

NZ had popped up on her radar when a guest speaker talked about NZ farming during her second year at university. Plus there was a connection through her mum, who was born here while her grandparents spent five years working on a sheep and beef farm near Te Puke, so she thought it would be worth a trip.

She connected with an outfit called AgriVenture that places employees with employers internationally and they found her the Putāruru placement, but it was more of an experience than she had bargained for.

“It was a massive culture shock coming from home where we farm a System 5 and the farm I went to was a System 1.

“Even though I had been farming my whole life and studied agriculture at uni, I felt like I was starting all over again heading into a seasonal system.

“I couldn’t believe they had more than five cows calve each day and that the cows would be dried off at the same time and the shed would be turned off

• Farm owners: Oakville Farms Ltd

• Contract milker: Jen Hodgson

• Location: Okoroire, South Waikato

• Farm size: 90 hectares

• Herd size: 350 cows

• Production: 2021-2022: 192,388

• Production target: 20222023: 190,000

for a few weeks. It was such a strange experience.”

Hodgson grew up milking with her grandad before and after school back in England. Her family have been farming for five generations and during her childhood her dad and uncle worked two farms together, milking 500 cows between them. They tried to be as pasture based as possible, but because of the climate the cows spent a lot of time indoors.

Calving year-round meant there were always cows calving and a springer and dry mob as well as the milking herd. There was a daily routine year-round and milking was a bit more labour intensive with pre-dipping and wiping teats before putting the cups on.

Hodgson’s younger sister is involved with the home farm and about four years ago she converted it to a deer farm, farming venison.

“They got to a point where they needed to expand to continue to progress the dairy but it’s really tricky as you’re surrounded by other family farms and there aren’t a lot of opportunities to expand.

Jen Hodgson had just got her head around the foreign farming system and the art of staff management when she fell pregnant.

Hodgson milked right up until two hours before her waters broke and while she was in labour, she was writing the plan for the cows on the whiteboard.

Hodgson with son Stan.

“So my sister and the family looked at the other options they had and deer was a good option and the dairy cows are still on my uncle’s farm.”

Despite the foreign feeling when she started farming in NZ, Hodgson quickly came to enjoy the different approach, so much so she asked to extend her original placement and spent 12 months on the Putāruru farm.

She began establishing a social life, tagging along with some of the neighbours to the local Young Farmers Club catch-up every Monday and getting involved with local sports like badminton and netball.

“Once I realised I was staying a bit longer I knew I needed to make friends, so I basically just joined anything anyone was doing.”

After 12 months she knew she still wanted to stay and decided to look for a position on a farm that was operating a more familiar system. She found a role milking 800 cows utilising a System 5 in Walton on the other side of Matamata.

“I’m glad I had the experience of a System 1 farm but I am definitely more into a System 4-5, I like high stocking rates and feeding cows more.”

The Walton farm had three herd homes and she jumped from farm assistant to 2IC and manager fairly quickly.

“That’s another thing I really like about New Zealand dairy farming, there are so many opportunities to move up the ladder and the flip side, and it’s also easier to walk away if you ever wanted to.

“Back home there are challenges with farms that have been in the family for generations and limited opportunities to grow.”

It was also during her time on the Walton farm that she met her partner, Scott Bonk. He was a diesel mechanic in the army based in Palmerston North at the time, and had come to Waikato with a friend for a Young Farmers ball.

“I didn’t think anything was going to come of it but he had already planned to leave the army and just kept driving up on his weekends off till he finished and moved in pretty much,” she laughs.

Bonk grew up in the Bay of Plenty and although he had spent summers on a sheep and beef farm with a family friend he had never milked a cow before. But with Hodgson working every second weekend he quickly realised if he wanted to spend time with her he had to tag along to milking and jobs around the farm.

Here at Alleva Animal Health, we’re constantly evolving and innovating so NZ farmers have reliable products that outperform in the field. We’re proudly NZ owned, operated and offer world-leading parasite control solutions exclusively through vet clinics nationwide.

TURBO® Pour On is designed for NZ’s unruly weather conditions. Its world-first formula can help to achieve cattle weight gains ahead of winter and improve overall condition. Rain or shine, enjoy the ultimate parasite coverage.

She slowly got him doing more and more and he became good at bringing the cows down from the herd homes. She found he was particularly useful with machinery from his mechanic background.

When he moved to Waikato he worked for heavy equipment company Mimico fixing the crushers that do the roading gravel from quarries, and continued helping her over weekends.

After a few seasons in Walton, Hodgson started considering what her next step would be and by word of mouth, she stumbled across a contract milking opportunity with Oakville farms owned by the Van der Heyden family. They had recently purchased another farm in Okoroire and were looking for someone to run it.

“I knew it was a big step and I didn’t even look at the house when I came to see the farm. The people were more

important to me because I wanted to be sure our goals would align,” she says.

The plan was to spring calve 350 cows operating a System 4, which she found attractive but she had reservations about managing people.

“I was really concerned about the idea of employing staff, it just felt weird to consider myself as someone’s boss.”

But she had the backing from the Van der Heydens and she reached out to Primary ITO to see what training was available to help grow her knowledge and confidence. She completed the Agribusiness Diploma, starting with the HR module.

“The study really helped, I wasn’t worried about anything else as I had already done it at the other farm, and milking 350 cows and only calving once a year seemed a breeze but I needed

Available exclusively through veterinary practices nationwide. Visit www.alleva.co.nz for more information.

TURBO® is a registered trademark of Alleva Animal Health Ltd. TURBO® Pour On (A011722) is registered pursuant to the ACVM Act 1997. See www.foodsafety.govt.nz for registration conditions.

“I fell in love with the New Zealand seasonal approach. Back home you have to think about everything at once. Every week there are cows being dried off, calving, calves to feed, but here you can concentrate on each area separately.”

Jen Hodgson

Hodgson heads off to do some feeding out.

that boost to get my head around staff management.”

She began contract milking in 2019 and has appreciated the help and support from the farm owners.

“I mostly work with Pete [van der Heyden] and he is a great boss, I can ask him anything and we talk things through which really helps my confidence.”

She had a farm assistant helping her on the farm and a relief milker for their weekends off or if she had something on. But when that assistant moved on for career progression Hodgson was caught short for a bit. She had another one coming from the US but they were delayed by the border closure.

“I thought it was only going to be

“I was really concerned about the idea of employing staff, it just felt weird to consider myself as someone’s boss.”

Jen Hodgson

closed for a short period so I roped a friend in to help through calving while I waited, but I ended up doing the rest of the season by myself with a relief milker.”

After she lost hope of the border reopening she tried to find another assistant and found more temporary help. But things started to get hard when she got pregnant with their son, Stan.

“I think I had four days off my whole pregnancy,” Hodgson says.

“I milked right up until two hours before my waters broke and while I was in labour I was writing the plan for the cows on the whiteboard as I knew I’d be gone for a few days.”

After Stan was born, Bonk took parental leave from his role with Mimico so Hodgson could stay home for a bit. It was a crash course in farming as, although he had spent weekends helping on the farm, he had never had full responsibilities.

“I was in the deep end, I basically skipped the worker stage and had to learn a lot really quick,” Bonk says.

“I hated milking at the start but it got better as I did it more, especially because I started noticing things about different cows and learnt a bit about them.

“It changed my whole mindset, to stop seeing them as a factory and enjoy them as animals with different personalities.”

Having Bonk step into the farm role helped Hodgson develop her people management skills even further. Until then she had not realised what newbies go through with learning about handling stock and all the bits that go with it.

“I had to learn to look at farming through Scott’s eyes,” she says.

Coming from England, Hodgson was used to milking cows year-round and found the concept of drying off and not milking, foreign. Hodgson in the milking shed.

“I realised a lot of things aren’t obvious and I think that was my biggest obstacle, assuming he would just know, but it was a real eye-opener for me when I had to explain what milk fever was and how to bag a cow, five days after I had Stan.

“There were so many things I took for granted because I grew up on a farm myself; I never really thought about what

others might not know.”

The whole experience has helped her become more aware and a better manager.

“It really has helped me be better at managing people, having that appreciation of knowledge gaps.”

She was still involved with the farm while she was tending to a newborn and kept up with the paperwork and matching cows and calves during calving. She was back in the shed in time for mating for heat detection and as soon as she was strong enough she was back doing most of the daily tasks.

“Mating was like my deadline, I knew I had to be back for morning milkings to detect heats.

“As much as I love Stan, I also love farming and it was my time out when he was really little. I was very thankful to have the option.”

They used the 12 months after Stan was born as a trial, to see if it would work having Scott involved with the farm while still having the option for him to return to his job if he needed to. But they found their different skill sets complement the farming business.

“I’m cows and grass and Scott is

machinery, it works well that we have different interests.

“And I think being able to get through calving and mating with a newborn and still being on speaking terms made us realised we could do anything,” Jen laughs.

Scott has come to love farming now too, he enjoys working outside and appreciates the freedom of running a farming business but it has been an adjustment with the nature of getting tasks done.

“I came from the army where everything was planned and had to be perfect but with farming nothing ever goes to plan,” Scott says.

“You can start the day with your list of tasks and be lucky if you get one completed, but I still reckon even the worst days farming are still better than the mechanic ones.”

He is pleased he made the shift and they are enjoying how it works for family life.

It was the November after Stan was born in 2021 they found their current farm assistant, Jake Humphries and he has slotted into the team well. They really put him to the test after he had only been with them six months when they headed to England to spend a month with Jen’s family but he coped fine and has stuck around since.

“We have a great team, Jake is very capable of doing the day-to-day work and it’s a relief to have a bit of help,” she says.

“And even though we are technically overstaffed it has been a great

opportunity to get ahead on farm maintenance and other bits and pieces because I’ll be off farm again soon when baby number two arrives in April.”

The Okoroire farm is 90 hectares with a 30 aside herringbone shed with the 350 cow herd that was put together when the farm was purchased. They are producing 549kgMS per cow and 2137kgMS per hectare. They recently changed to split calving with 48 cows in the winter milking herd.

“Moving to split calving made sense because we have the feed, we tend to milk as long as we can and dry off by calving date and the withholding period on the dry cow therapy, so they were only dry a couple of weeks before the heifers

would start calving.

“This way, we still have some cows milking which helps the heifers when they come into the shed in the beginning, which is just an added bonus.

“Pete was already familiar with split calving from his other farm and I am very happy to milk year-round so it just works.”

Once the herd has finished calving in early September, she splits the herd based on age and body condition. The younger and skinnier cows go together in a mob so there is less competition and she is able to preferentially feed them. She finds it sets them up better for mating and reduces lameness.

Both herds go onto the feed pad twice every day before milking and the feed varies throughout the season based on the amount of pasture they are able to eat.

She aims for around 21kg of dry matter per cow per day, which starts with pasture and gets topped up with maize and palm kernel, and some bought-in sunflower seed gets added in autumn.

She uses the LIC SPACE programme to monitor pasture production and keeps an eye on what is happening in the paddocks as well. Their feed can be adjusted daily if she feels they need a bit more to reach the 21kg DM goal.

“Pasture is always first and I’m always monitoring the residuals and the herd’s behaviour and if I think they need more I’ll give it to them,” Hodgson says.

“If it’s wet, for example, they might not eat as much in the paddock so I’ll give them a bit more palm kernel, or maize depending on what our FEI is looking like.

“Or if they don’t seem settled I’ll move their break to give them a bit more grass in the evening. I’m always keeping an eye on what’s going on.”

Half of the maize is grown on the farm, with an average yield of 22t per hectare. They have planted 14ha this season and 2ha of that is an early-maturing variety as they expect to be short, so they will need some earlier than usual. Typically they plant as much as they can without impacting their grazing.

The farm is low lying so it holds well through the summer dry periods but unusually wet soil this spring has meant the grass was slow to get started and they have had to top up with additional supplements.

“We usually budget around 1t of palm kernel per cow, but this season we will probably end up using more which is okay because I’d rather the cows were full and happy.”

blanket mated to dairy semen then Jersey bulls are put out for three weeks and all of the calves are sold around four days old.

Around the same time Hodgson started thinking about contract milking and their future in farming, she and Bonk were looking at options to help build some equity. They bought a block of land in Tirau in 2018 and subdivided it and built three houses on it.

“The priority, for now, is family and we know we’ve got it really good where we are. It’s perfect for family time and working for the right people is more important than money.

“If the right sharemilking job came along we would consider it but it would have to be really good.”

In spring, mating is 11 weeks of artificial insemination using nominated semen. The bigger, more Friesian cows go to Jersey straws and the smaller, more Jersey cows get mated to Friesian. They are targeting an efficient, lowmaintenance crossbreed cow. Anything with low breeding worth or undesirable udders gets mated to beef semen, which has been Charolais, and after about six weeks of replacement and beef semen they switch to short gestation.

Typically, the six-week in-calf rate sits around 72% and they keep about 65 replacement calves and sell the rest. They collect calves once a day and feed everything gold colostrum when it gets in the shed and are fed twice a day until they move outside after about six weeks. They run them in two mobs, split by condition, and once they are weaned they head to a support block that Pete’s son Richard has recently purchased 10km away.

All of the beef calves are sold at around 10 days old, mostly to local buyers, but any excess gets sent to the sales. In autumn, the herd is synchronised and

“We wanted our money to do something for us, so property seemed like a good option.

“If we didn’t have that I think we’d be feeling pressure to go sharemilking, which is on the cards someday, but we can’t do a new baby and a new farm in the same season.

Proud of the progress she has made since that first foreign experience drying off a herd, Hodgson is enjoying her farming life in NZ.

At times she wishes she was closer to home but with the border open she has more opportunity to see her family. And she appreciates the opportunities to combine building her own family while keeping her farming passion. n

“As much as I love Stan, I also love farming and it was my time out when he was really little. I was very thankful to have the option.”

Jen Hodgson

A 100-year-old farmer may have stepped back from farming full-time, but he is not letting the grass grow under his feet.

ATARANAKI farmer who late last year celebrated his 100th birthday has slowed down but is still hands-on when it comes to the farm.

Norm Johnson was brought up during the Great Depression and he feels it shaped his view of the world. It showed him that being frugal and never spending money that you don’t have are good qualities for a farmer to possess.

He has lived through the reign of five monarchs, several wars, including World War II, and seen huge changes in the world. He has never married and will never clock up a vast number of air miles points: the sum total of his travel is a visit each to Hawke’s Bay and Auckland. Being brought up through the austere and

sometimes challenging times has taught him to treasure life’s simple pleasures.

“When I was a youngster I travelled by bus and train to visit a friend in Hawke’s Bay. I had cards and envelopes to hand to different people along the way and thought ‘What a load of humbug this is.’ I travelled for many miles and thought that there was no need for it,” Johnson says with a wry laugh.

Having recently celebrated his centenary, Johnson still regularly visits the cowshed – and until two years ago was still milking. Now that’s the job of farm manager Piet Robbertze.

An only child, Johnson was born at Kaponga Hospital. “I was born on the 24th October so Mother was in labour on Labour Day,” Johnson says.

He has lived on the farm for 93 years. The family lived at Kapuni South Taranaki, where his father worked as a factory manager at one of the eight Okaiawa based TL Joll Co-operative Dairy Company factories.

“Dad became the Tempsky Road factory manager as a 20-year-old. He had very little formal education, but had qualified as a boiler maker, milk grader and dairy factory manager,” Johnson says.

He has seen vast changes in New Zealand’s dairy industry. He fondly remembers taking milk cans to the factory with a horse and dray. Now dairy companies use tankers able to carry 28,000 litres of milk.

Taranaki has gone from having many local dairy factories, often one at either

Little communities surrounded them; and there was often a factory general store too. Those factories were the hubs of the community, and those communities provided the pupils for the many country schools.”

end of a road, to one servicing all of Taranaki and further afield.

“When I was young there were factories everywhere. Little communities surrounded them; and there was often a factory general store too. Those factories were the hubs of the community, and those communities provided the pupils for the many country schools.”

The Johnson family were as selfsufficient as possible during the Depression and war years. They grew their own meat and vegetables and kept white leghorn chickens for their eggs.

“Mother had a massive vegetable garden and I delivered the Hawera Star newspaper in the afternoon for 7/6d [seven shillings and sixpence] per week plus a free daily paper.”

His paper run was a 16km bike ride around the district. A keen sportsman, Johnson was a long-distance runner and played high school first XV rugby and first XI cricket. A contributing factor of his fitness must have been the 54km bicycle round trips to Hawera for his matches.

“It was a long way when you had to

cycle to town, play a game of rugby, cycle home again and then deliver the papers. I’ve always had asthma and diabetes and need to have a few sweets in my pocket or risk passing out.

“That once happened during milking. Thank goodness a passer-by checked on me after seeing the cowshed light on at an ungodly hour. They found me unconscious and called an ambulance.”

Johnson’s father bought a 40.5ha farm around 1929 and employed a sharemilker for two years until leaving his managing role to farm fulltime.

Leaving the security of the manager’s job to become a farmer during uncertain times when money was scarce was a big step.

“Dad was dealing with farmers every day and noticed how they’d been able to advance and show a profit, and he felt

that he could do the same,” Johnson says.

“We started off with a mixed six-cow herd and bred up to a 12-cow herd. Dad bought whatever cows he could afford, but took a hankering for Friesians. Being a factory manager, he always said that there was too much fat in high-testing milk, and that lower testing milk was the best for cheese making.”

This was going against the trend as Jerseys were the predominant dairy breed then. Many of the neighbouring farmers shook their heads in disbelief as he transitioned to Friesians.

As soon as he could, Johnson began working on the farm with his parents.

“There was always something to do and I did whatever I was told to do, but never had to milk before school.”

“When I was young there were factories everywhere.

The family bought three pedigree Friesian heifers and a bull from a Greytown breeder and that was the start of their Ratanui Friesian stud. They regularly showed their cattle at the Hawera A&P Show. Johnson hasn’t been registering his cows for some time now though, due to the amount of work it entails.

“Many Friesian cows were heavy milkers but a bit low in test, so we tried our best to improve them. We aimed for a 4% milk fat test.”

By the time Johnson was 10 years old he was taking the milk to the factory in a horse-drawn wagon.

“Later on we used the tractor to go to the Mangawhero Road dairy factory, which was only just across the road from the farm. I built a trailer that was level with the factory loading stage. The trailer had no sides, enabling us to roll the cans straight onto the stage.”

A railway station was situated at the back of the farm. It was 1.5ha in size and cost Johnson’s father the princely sum of £22,000.

“We could then get our super phosphate fertiliser delivered to the station, store the bags in the big goods shed, and use them from there.”

Johnson completed three years at Hawera High School before starting work full-time on the farm at 15 years old. This was near the end of the Depression, and finances were still tight throughout the country.

“One day Dad said to me, “Norm, I’ve got something to put to you. I can’t

afford to pay you wages and pay off the mortgage too. What do you suggest?” Johnson says.

“I said ‘Forget about me, Dad.’ So I continued working for a bit of pocket money so they could still pay off the farm.”

In 1938 and 1939, Johnson did Home Service in the New Zealand Army and became a sergeant and instructor. One of his specialties was the use of explosives and he was very proficient at using gelignite to cut railway lines in half.

“My health wasn’t good but I enjoyed the army. The army in peacetime is a great place and a good place to learn a trade.

“My father said that if I was going to do Home Service then I may as well come home and do it on the farm. He applied to get me released and the magistrate agreed.”

Johnson took over the running of the farm in the 1970s after his father passed away. His father was a smoker, and had severely damaged his lungs to the extent that he often needed oxygen. Johnson had been taking on the extra work as his father became more debilitated, and took over the farm on his passing.

During his father’s last years, Johnson would get bottles of oxygen from the hospital on a frequent basis. One day he visited the hospital and was told that they wouldn’t be supplying him with oxygen anymore.

“I raced home to tell our doctor, who told me to go to the garage and pick up a big oxygen bottle and he’d help me get it

into the house. “Waiting for him seemed like an eternity, so I got to work and managed to carry it inside.

“The doctor asked me who helped carry the bottle in and I replied, ‘No one, my father wanted me, he needed me, and would’ve done the same for me.’

“But Dad was already unconscious and he never recovered. He was in his 70th year.”

After farming for 93 years, Johnson has witnessed huge changes in the industry. One of the biggest has been the summer task of haymaking.

He began farming when horses were still being used for haymaking. It was an era when everyone pitched in to help one another out. This was especially so at haymaking time, when a number of farms would work together to harvest each other’s hay. This made it a very long season.

Very early on Johnson bought an Allis-Chalmers tractor and fitted a hay sweep on the front. He also bought a McCormick-Deering stacker that could hold two sweep loads of hay.

“I attached a hydraulic lift to the tractor to lift the sweep. The stacker didn’t have grabs, so you could drive onto the stacker cradle, and a horse lifted the stacker

“I never married, so instead of spending money on myself I’ve helped others. I loaned people money when they’d found the opportunity they’d been looking for, but the banks had turned them down.”

load of hay up onto the stack.

“We had a big bay Clydesdale with a white blaze on his face and four white feet who could pull the stacker up without being led. He would go back and forth a couple of times to form a track, and continue to follow it for the rest of the day.”

Johnson was a pioneer of once-aday milking but was 60 years ahead of the trend. When he began the milking regime more than 60 years ago, there was no one to ask for advice. He had to forge his own path in farming.

“Everyone told me we’d be dry by Christmas or ruined by mastitis. None of that happened. We were always diligent about disinfecting each teat and it certainly kept trouble away.

“When you milk once a day you’re pleased to see the cows and they’re very pleased to see you, and it’s not as hard on the cows as milking twice a day.”

He knows what it’s like to experience hard financial times, and instead of buying more land he’s helped scores of people into their first farms. Those he’s helped have been incredibly grateful for his assistance and most still keep in touch with him.

“I never married, so instead of spending money on myself I’ve helped others. I loaned people money when they’d found the opportunity they’d been looking for, but the banks had turned them down.”

“I can’t fathom why they were turning these people down, because those that I’ve helped have been no trouble at all. They paid me good interest though, so everybody won.”

Johnson encourages other farmers to help young people get ahead in the industry. He’s enjoyed seeing those he’s helped progress through the industry and has found it an extremely gratifying experience.

He is always happy to pass on some of the wisdom he’s gained in his years of farming.

“You’ve got to try to keep your debt down and try not to buy things until you can afford to pay for them. It’s better to be too careful than too rash because paying interest is just money down the drain. If you look after your farm it grows in value,” Johnson says.

“Farming is like a long distance race, you never give in. It’s not an industry to get into if you think you’re going to make money overnight. Get yourself educated. But life will educate you if you’re observant. If you try as hard as you can, there’s no reason why you can’t succeed.” n

With DeLaval VMS™ you don’t have to change how you farm, just how you milk.

Same Cows. Same Pasture. Still Twice-a-Day. No Milkers.

calculate your farm’s numbers. Different reports will include different information, but the main ones reported are the “key numbers to know” mentioned above.

Once you know your numbers, one of the key things to do is benchmark against other farms.

the same way, but your numbers are not the same as your neighbour’s. So, once you know your numbers, look at your farm system and consider where you can create more efficiencies.

There’s a lot of policy talk at the moment that has many farmers considering what they can do now to adapt for the future.

One of my key pieces of advice is to understand what your key profit and environmental numbers are, to identify improvements in your farm system. It may seem a little overwhelming, but by breaking it down you can easily get to grips with your farm numbers, and what these mean for your business.

What are the key numbers to know?

Some of the environmental key indicators are purchased nitrogen surplus, nitrogen conversion efficiency, emissions per milk solid (GHG/kg MS) and methane, while your profit is analysed through operating profit per hectare.

Where do the numbers come from?

Your metrics and farm numbers are calculated from data you have already collected and submitted to your dairy supply company or consultant to meet regulatory requirements.

Those companies then input your information into programmes or models, such as OverseerFM or the AIM model, to

This can be done through the environmental reports from your dairy company, which contain benchmarks to help understand where your business fits, compared to others.

These benchmarks give an indication of what good looks like so you can see where you need to be, if you aren’t already there.

Find the areas that need the most attention, such as nitrogen fertiliser, imported feed or effluent, and determine what adjustments can be made to become more efficient and adaptable for future.

For example, a significant driver for methane emissions is total feed eaten, so this may be something to consider on your farm.

Any practice that increases feed use efficiency will reduce emissions, without affecting farm profitability.

This would include reducing the amount of feed going to unproductive animals by improving reproductive performance or reducing feed going to maintenance, by increasing per-cow production.

DairyNZ has a range of resources to help, including regional graphs to plot your information on, allowing you to compare your farm at a regional level for operating profit, methane emissions and purchased nitrogen surplus.

DairyBase also allows you to gain a full analysis of your farm numbers, including benchmarking farm profitability.

You might think everyone operates

Our DairyNZ regional teams are always happy to help, so if you have any questions or want support, contact your local team.

DairyNZ is running regional benchmarking events in March and April, so keep an eye on your local DairyNZ events calendar and come along.

More information is available at dairynz.co.nz/knowyournumbers

“Once you know your numbers, one of the key things to do is benchmark against other farms.”Understanding key profit and environmental numbers helps farmers to identify improvements in their farm systems.

Changes to the Essential Freshwater 2020 wetland regulations, which will come into effect in 2023, will help farmers continue to invest in wetland restoration, and provide better wetland restoration, maintenance and water storage options for farmers according to DairyNZ.

“We were concerned about initial government proposals that had regulations applying to constructed wetlands,” says Dr David Burger, DairyNZ general manager for sustainable dairy.

“It made getting consents for constructed wetlands difficult for farmers and could have discouraged them from creating wetlands that would benefit the environment. This has now changed, which is positive for farmers and the environment.

“The changes are timely, as more farmers are looking to reduce their environmental impact, and there’s growing interest in re-establishing and constructing new wetlands,” Burger says.

DairyNZ continues to encourage farmers to invest in wetland restoration due to the environmental benefits. Its water science team works with other science organisations to increase understanding of wetland performance and how farmers can best place new

wetlands in catchments.

Wetlands can significantly reduce nutrient and sediment losses on farms and improve water quality. They also boost biodiversity and can provide a habitat for birds and fish. A constructed wetland about 1% of the catchment size can remove an average of 20-25% of nitrogen and 50% of sediment.

In initial regulations, resource consents were not obtainable for construction of any water storage infrastructure that could adversely impact the extent or values of a wetland.

The new consenting pathway has several conditions, including that the water storage infrastructure needs to provide significant national or regional benefits. These conditions set a high bar for the development of water infrastructure in and around wetland areas and are an improvement on previous regulations, which prevented farmers from creating storage structures if they would adversely impact the extent of or values within a wetland.

“The change addresses concerns raised in DairyNZ’s 2021 government submission on proposed wetland management changes to the Resource Management (National Environmental Standards for Freshwater) Regulations 2020,” Burger says.

DairyNZ also made a joint submission with Fish & Game New Zealand on aligned positions and continues to support farmers wanting to protect and restore existing wetlands.

Tools are available to help farmers manage and improve wetlands on-farm, such as the Constructed Wetland Practitioner Guide – Design and Performance Estimates, which contain information on designing and constructing wetlands.

Interested farmers should contact an environmental consultant to work through the guidance and seek regional council advice about consents and funding opportunities.

“The changes are timely, as more farmers are looking to reduce their environmental impact, and there’s growing interest in re-establishing and constructing new wetlands.”

Dr David Burger

Could mismatched calves be making things a bit hit and miss? Get the success you need with Genemark, LIC’s DNA parentage testing service, to make sure the right animals are in your herd. With whole herd testing, you can confirm you’ve matched the right calves, so you know you are investing in the right animals.

Or stack up your testing options and add an animal’s own DNA information into the mix with the Genomic Evaluation service. This robust analysis provides a more reliable prediction of an animal’s performance so you can try to identify your top performers at a younger age and drive your genetic gain, without chancing your arm.

Talk to your Agri Manager about making sure you’re landing the gains you want with our GeneMark® and Genomic Evaluation services.

There's always room for improvement

There are steps farms can take to ensure their heifer calves reach their full potential – and they start with stock movements on and off farm.

Growing heifers that go on to meet their full potential when they join the herd can be a challenge but there are several things a farmer can do to ensure the heifers are well grown and healthy.

A Smaller Milk and Supply Herds field day held late last year at Andrea and Thomas Annabells Hāwera, South Taranaki, farm was designed to help farmers hit their heifer targets.

The field day featured a number of speakers, including Dallas Nelley, a largeanimal vet at Taranaki Veterinary Centre’s Pātea Clinic, who explored the factors

that go into producing well-grown heifers.

Nelley spoke about heifer health issues of parasites and farm biosecurity.

Parasite burden is by far the most common problem that Nelley sees on farms. In theory, every farmer should undertake faecal egg counts, but he has performed very few in 25 years of vetting.

He emphasised that farmers must at least have a drench plan, and not just drench whenever they feel like it.

“A quarantine drench should be used on any animal that comes onto a farm. The farmer should do it even if the

previous owner has said that they were recently drenched. You need to drench them with something that you know works, so you know it’s been done,” Kelley says.

“You wouldn’t believe how many times I’ve talked to farmers and been told that they’d recently drenched their stock, and it turned out that they’d been drenched six months ago. You must be in control.”

A triple combination oral drench is the ideal quarantine drench, but most farmers tend to use a double pour-on.

“There is now resistance to all of the drench families. You need a thorough

understanding of your system, because eventually it’s going to become an issue for every farmer if they’re not aware of it and know how to manage it.”

“Refugia” refers to a population of parasites in the environment that hasn’t been exposed to anthelmintic drenches. These worms have no drench resistance, and by remaining in the environment (either on the ground or in the animal) they provide a population of worms that are still susceptible to drenches.

“There are many ways of achieving refugia. It can be created by not drenching your best animals, because they don’t need it, due to them having non-resistant worms. Or you can drench them and put them back into the same paddock instead of a new, clean paddock, so they eat the non-resistant worms straight away.”

If you drench stock and put them somewhere clean, the worms that are left (1-2%) and the animal is still carrying, can only breed with the resistant worms. So, you breed the population a great deal faster towards resistance.

“If you drench them and put them somewhere ‘dirty’, or don’t drench some of the animals so some cows have got resistant and non-resistant worms, they’ll breed, and the number of drenchsusceptible larvae will significantly outnumber the drench-resistant population.”

He also highlighted biosecurity as a major animal health issue, saying stock movement is the number one biosecurity risk. Bulls travelling between and onto farms pose one of a farm’s highest biosecurity risks.

“Grazing blocks are very prone to contracting diseases because graziers often receive stock from many farms in many different localities. They also receive bulls. Bulls are often the most disease-ridden animals imaginable, and can carry all manner of diseases,” Nelley says.

He emphasises the need to have a very good relationship with your grazier and to never be afraid to ask them to explain their biosecurity protocols. You must

know your bull buyer well and trust them implicitly.

“Here in Taranaki, for example, bulls come here from all over the country, including the South Island. Many have already done a season on a farm. So, unless you run your own bulls you don’t really know their history.

with the heifers. However, usually the bulls come off the truck and go straight in with them.”

Most farmers are familiar with the disease bovine viral diarrhoea (BVD) and every bull should be tested for it and vaccinated against it.

“We had one case where a farmer lost 35 out of 100 heifer calves because they used a bull that they were told was vaccinated and tested but wasn’t.”

Theileriosis is another disease to be aware of. It’s a disease caused by a species of theileria (a blood-borne parasite) that affects only cattle and is primarily transmitted by ticks. Nelley has tested more positive bulls than negative.

“One farm used cow monitoring boluses and they were constantly getting decreased rumination alerts. It turned out that theileria was going through their herd again. They wouldn’t have known if it wasn’t for the boluses.

“When the bulls are put in with the heifers, they see many animals at once, so you need a good idea of where they’ve come from. Ideally you should wait three to four weeks before putting them in

“I could give you examples of farms that have lost around 40 cows in a year with theileria. It’s not really heard of a lot, yet it’s quite common in south Taranaki.”

When bulls or any other stock arrive on your property you must remember that it’s your property, and you’re in charge.

Ask your grazier to use the same vet that your farm uses, if at all possible. This gives a continuity of care and everyone, including the vet, knows what’s happening at each property.

Farmers can eradicate some diseases that occur on farm, but not drenchresistant worms. Theileria is the same, says Nelley: “Once it’s on your farm it’s there forever.”

Nelley knows of an instance where a farmer bought one BVD-infected cow from a sale and had to put down 35 heifer replacement calves.

“You don’t hear of those cases because very few farmers want to talk about them.

“About 75% of biosecurity issues are caused by stock movement. Of the other 25%, 12.5% is made up of ‘across the fence’ disease infections. It’s not as big a risk as stock movement, but still a considerable biosecurity threat.” n

For tips and ideas, visit farmstrong.co.nz

Largeanimal

vet Dallas Nelley says parasite burden is by far the most common problem he sees among cattle.

“We had one case where a farmer lost 35 out of 100 heifer calves because they used a bull that they were told was vaccinated [against BVD] and tested but wasn’t.”

Dallas Nelley

Tweaks to the Welfarm programme will ease the administrative burden on farmers when completing their Animal Wellbeing Plan.

Asimple solution to help farmers complete the animal wellbeing part of their onfarm assessments is now available thanks to a new relationship between WelFarm and Fonterra.

We have just established an automated link that allows us to notify Fonterra when a farm has completed an Animal Wellbeing Plan with its vet through WelFarm, so there is one less piece of paper that Fonterra suppliers need to gather when preparing for their assessment.

And the plans are stored in the WelFarm portal so when farms do want to refer to them, they can easily log in to find it, which saves sifting through emails or requesting another copy from the vet.

The WelFarm Animal Wellbeing Plan template was developed in 2021 in response to the updated requirements from Fonterra for the Co-operative Difference.

We recognised WelFarm was in a

unique position already connecting vets and dairy farmers through the wider WelFarm programme, so it made sense to include a simple method to help them develop their Animal Wellbeing Plans and leverage their data further.

The WelFarm programme is a framework for proactive herd health and welfare management for a dairy herd. It has a simple reporting method and provides regional and national benchmarking through the web-based platform that gives context to herd data.

The programme supports the relationship between the dairy farm and veterinarian, helping vets provide tailored advice and support.

If a farm is using the wider programme, some of its metrics feed into the Animal Wellbeing Plan directly, which gives vets and farmers more information to discuss as they develop their plans.

The consistent approach to developing plans is valuable for farmers, Fonterra and the wider sector and using the

system gives peace of mind as the template is live and gets updated as Fonterra’s requirements evolve. This saves any back and forth if any updates were missed.

The WelFarm programme is available through a number of vet clinics across New Zealand and more clinics join regularly. We encourage farmers to ask their vet if they are already part of WelFarm or if they would consider joining.